Belshaw MARK V Operator’s Manual

|

|

|

|

|

|

|

|

|

The #1 Source for Donut and Bakery Equipment |

www.belshaw.com |

|

|

|||

|

|

|

|

TOEPCECHRHNANTI COI CARLA’ SSLUMSPAUPNLPUEPAMLEENMTE N T

O P E R A T O R ’ S M A N U A L

PT AE CR HT SN IACNADL ESLUEPCPTLREIMCEANL TD I A G R A M S

S U P P L É M E N T T E C H N I Q U E

Donut Robot®

Mark II, Mark II GP,

Mark V, Mark V GP

Automated Donut Fryer

CE DECLARATION OF CONFORMITY ENCLOSED

SUPPORT |

International (+1) 206-322-5474 |

Web www.belshaw.com |

|

USA/Canada 1-800-578-2547 |

Email service@belshaw.com |

|

|

|

Donut Robot

Mark II, Mark II GP Mark V & Mark V GP

Operator’s Manual

Belshaw Adamatic Bakery Group

814 44th Street Northwest, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • E-mail: service@belshaw.com www.belshaw-adamatic.com

EQUIPMENT RECORD

Please provide the information below when you correspond with Belshaw about your machine. Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ____________________________________________________________________

Serial number

IN CASE OF DAMAGE TO EQUIPMENT

In case of damage to the equipment upon delivery, follow these steps immediately.

1.Inform the freight carrier. The phone number will be on the shipping receipt or label.

2.Take photographs of the equipment, both inside and outside the box or crate.

3.Do not throw away any packaging.

4.Report the damage to the distributor (or other party) from whom you bought the equipment.

5.Email your photos to the distributor (or other party) AND to Belshaw Customer Service at service@belshaw.com. Include a Belshaw Order Number in your communications. Your Order Number will begin with “CO…, followed by 6 digits) and should be marked on the box or crate.

IN CASE OF MISSING ITEMS

1.If possible, note the missing items on the delivery receipt of the freight carrier.

2.Take photographs of the entire shipment.

3.Follow steps 2 – 5 above.

012916 MN-1012EN

Belshaw Adamatic Bakery Group

814 44th Street Northwest, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw-adamatic.com

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

2 |

MN-1012EN |

Donut Robot Mark II / Mark V OM |

Contents

1 |

Introduction |

4 |

|

Major |

components of the Donut Robot® Mark II and Mark V |

5 |

|

2 |

Operation |

6 |

|

Operating Controls |

6 |

|

|

Inserting Shortening |

7 |

|

|

Heating Shortening |

7 |

|

|

Making Cake Donuts |

8 |

|

|

Making Yeast-Raised Donuts |

9 |

|

|

3 |

Cleaning |

10 |

|

Cleaning |

the Hopper and the Plunger |

10 |

|

Cleaning the Conveyor and the Kettle |

11 |

||

4 |

Maintenance |

14 |

|

Taking |

Care of the Plunger, Hopper, and Cylinder |

14 |

|

Lubrication |

14 |

||

5 |

Accessories |

15 |

|

FT-42 |

Feed Table |

15 |

|

Roto Cooler |

17 |

||

Filter Flo Siphon |

18 |

||

Shortening Reserve Tank |

20 |

||

5 |

Donut-Making Helps |

21 |

|

Tips on Making Quality Cake Donuts |

21 |

|

|

Calculating Correct Water Temperature |

22 |

||

Ratios of Plunger Sizes to Donut Weights |

22 |

||

Temperature Conversion |

22 |

||

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

Donut Robot Mark II / Mark V OM |

MN-1012EN |

3 |

1 |

Introduction |

|

|

The Donut Robot® Mark II and Mark V are designed to automatically deposit and fry cake donut products, and to fry yeast-raised donut products. It is not designed to deposit or fry any other products.

The Donut Robot is designed to be used on a flat, stationary table or countertop, with the operator standing opposite the heater head of the machine. The operator must work safely at all times and read this manual and follow its instructions and warnings.

The Donut Robot® produces only 71.5 dB(A) of equivalent A-weighted sound pressure at workstations. This has been determined during a dry run of the machine, using a Bruel & Kjaer sound level meter, type 2236.

Study the instructions and warnings in this manual carefully. A thorough understanding of how to install, maintain, and safely operate the Donut Robot® will prevent production delays and injuries.

To use the Donut Robot® safely, heed the following warnings and all other warnings that appear in this manual:

•Make sure the machine is secured to the work surface. Doing so will prevent the machine from moving or falling, which could cause serious injury.

•Never let water and hot shortening come in contact with each other. Moisture causes hot shortening to spatter, which may cause serious burns.

•Do not overfill the kettle with shortening. If shortening overflows the

kettle, it could cause serious burns or could cause someone to slip on the floor and be seriously injured.

•Hot shortening can cause serious burns. Make sure that the system and the shortening are cool before attempting any adjustment, repair, disassembly, or cleaning.

•To avoid electrocution or other injury, unplug the machine before attempting any adjustment, repair, disassembly, or cleaning.

•To avoid damaging the machine, never use force to assemble, disassemble, operate, clean, or maintain it.

•Be careful never to get shortening, water, or other materials on the floor. If anything does get spilled on the floor, clean the area immediately. Materials on the floor can cause people to slip or fall, resulting in serious injury or loss of life.

•To prevent unintentional startup and possible fire, unplug the machine if there is a local power outage. When the power is restored, it is safe to plug the machine in again.

•To avoid electrocution, make sure that all electrical cords are not frayed or cracked and that they do not pass through any water or shortening.

•Make sure that all electrical cords are routed so that no one will trip over them.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

4 |

MN-1012EN |

Donut Robot Mark II / Mark V OM |

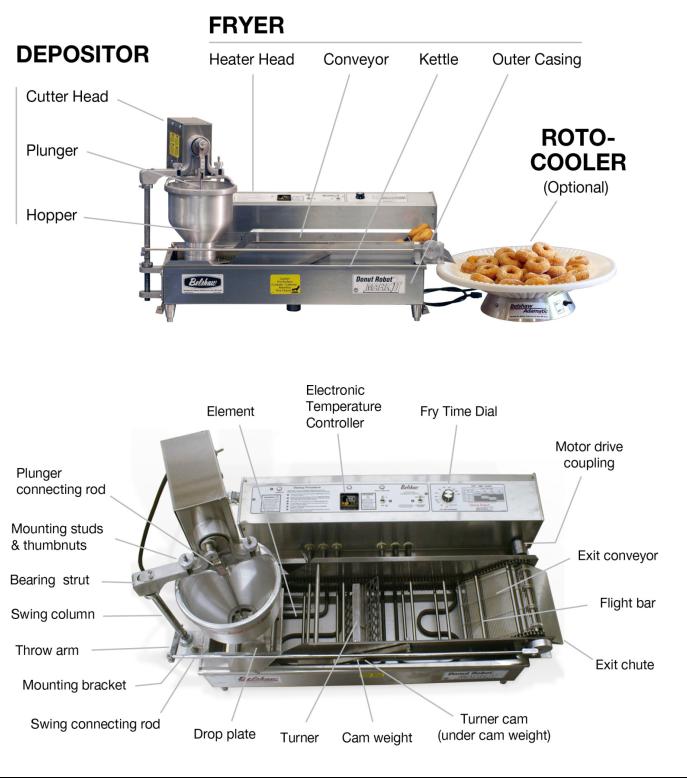

Major components of the Donut Robot® Mark II and Mark V

The photos below show the major visible components in a Donut Robot Mark II. The Donut Robot Mark V is 50% longer. All components apply to Mark II and Mark V, both standard and GP models.

Figure 1.1. Donut Robot Mark II. (components apply also to Donut Robot Mark V)

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

Donut Robot Mark II / Mark V OM |

MN-1012EN |

5 |

2 |

Operation |

|

|

|

|

|

|

|

|

|

|

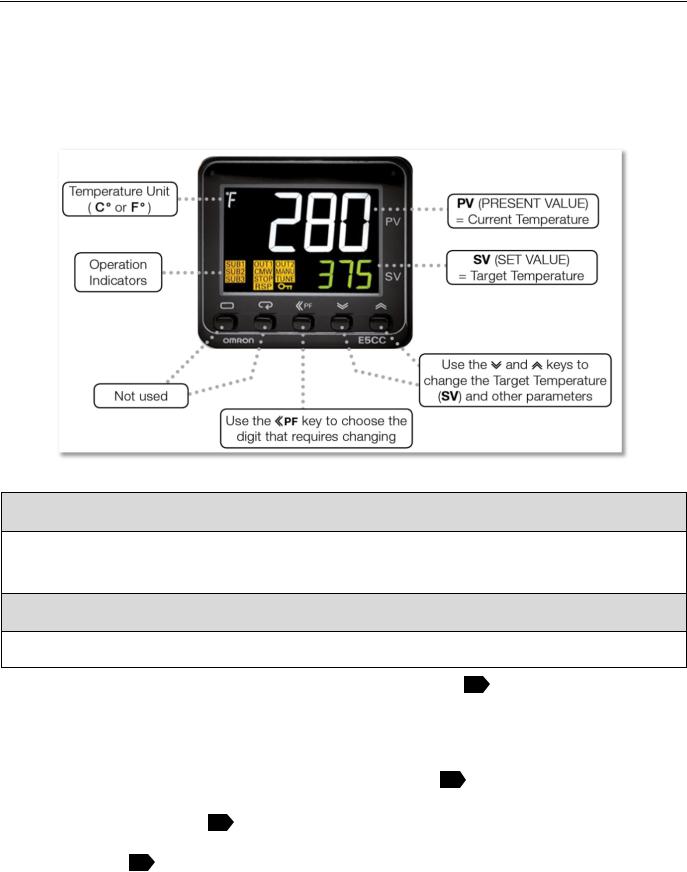

Figure 1.2, Temperature controller

IMPORTANT

To unpack and install your Donut Robot®, follow the installation instructions in the Technical Supplement to this manual.

CAUTION

Read this section completely before operating the machine!

Operating Controls

1.Ensure that the Donut Robot has been connected to correct power source.

2.Ensure the fryer is filled with shortening. If there is no shortening in the fryer, see the section below, “Inserting Shortening”.

3.Turn on the main circuit breaker on the

back of the heater head ( 1 POWER LIGHT will turn on).

4.Turn on the 2 FRYER HEAT switch (the temperature controller will turn on).

5.Set the 2 TEMPERATURE CONTROL to the target frying temperature (See Figure 1.2)

(TEMPERATURE CONTROL light will turn on when fryer is heating).

6.Set 3 FRYER CONVEYOR switch to

AUTO (the conveyor will start automatically when the target temperature is reached).

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

6 |

MN-1012EN |

Donut Robot Mark II / Mark V OM |

NOTE

The 3 FRYER CONVEYOR switch can also be turned to ON (The conveyor will run immediately, make sure the shortening is completely melted before using ON position).

7. Turn the 4 FRY TIME dial to adjust the fry time to the desired speed. As the fry time goes down the speed of the conveyor increases.

8.Set the 5 Feed table/Cake Donut depositor switch to FEED TABLE for yeast-raised donuts or CAKE DONUT DEPOSITOR for cake donuts or mini donuts.

c.Put solid shortening into the kettle, packing it tightly around the elements and bulbs without air spaces.

WARNING

Air spaces can cause the shortening to overheat and catch on fire. Pack the shortening tightly without air spaces.

WARNING

Shortening expands as it increases in temperature. Do not fill shortening all the way up to the flight bars or chains, if it is cold. The shortening level will rise by up to 1 inch (25 mm) when it is fully heated.

9. Connect the 6 Cake Donut Depositor or Feed Table to the electrical connector socket located at the left end of the control panel.

Inserting Shortening

WARNING

Hot shortening is much hotter than boiling water! It will cause severe burns if it touches your skin. Never touch hot shortening. Always exercise extreme caution with hot shortening. Use oven gloves when working near hot shortening.

1.When the shortening reaches the correct frying temperature, it should reach the top of the flight bars or chains.

2.If your fryer has a drain, close the drain valve.

3.Put shortening in the kettle using one of these methods:

a.Pre-melt shortening in a pan on the stove and carefully pour it into the kettle.

b.Use the optional EZ Melt to melt shortening and transfer it to the kettle. See your EZ Melt manual.

Heating Shortening

1. Turn on the 2 FRYER HEAT switch (the temperature controller will turn on).

a.If you are heating solid shortening using method 2c above, turn the heat switch on and off every 10 seconds, until the solid shortening has melted and no air pockets remain.

IMPORTANT

If you are heating solid shortening, turn the heat switch on and off every 10 seconds, until shortening has melted around the elements and no air pockets remain.

2.Wait for the shortening to reach the desired temperature. When it does, the Temperature Control light on the front of the heater head will turn off and the conveyor will start. DO NOT run the conveyor until all the shortening has melted.

3.If you are using the optional Shortening Reserve Tank, fill it with shortening. Then position it on the conveyor side panels either ahead of or behind the turner, but not above it. The heat of the fryer will melt the shortening in the tank.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

Donut Robot Mark II / Mark V OM |

MN-1012EN |

7 |

NOTE

If the Power light is on but the Temperature Controller fails to turn on, the high temperature limit control could be tripped. Push the red reset button on the back bottom of the heater head.

Making Cake Donuts

1.If not already in place, install the swing column, install the depositor’s cutter head, and install the hopper and the plunger.

2.Swing the hopper away from the fryer so it is not directly above the fryer.

a.It may be necessary to disengage the swing connecting rod from the swing column throw arm.

3.Adjust the size selector dial on the depositor’s crankshaft assembly. This dial regulates the donut weight. The higher the setting, the larger the donuts will be. Adjust the dial setting as follows:

a.Unscrew the dial lock nut 1/2 turn.

b.Turn the dial to the desired position, as indicated by the marks on the crank plate.

c.Tighten the dial in place with the lock nut. Tighten it using your fingers only.

4.Put batter into the hopper. ‘PRIME’ the hopper to expel any air that may be trapped in the bottom of hopper. To prime the hopper:

a.Hold a mixing bowl or other receptacle under the depositor hopper.

b.Hold DOWN the switch on the depositor until it has dropped two or three donuts into the bowl.

NOTE

Holding down the prime switch causes the depositor to run continuously without the normal delay between cuts.

c.Put the batter in the bowl back into the hopper.

5.Return the hopper into position over the fryer and reconnect the swing connecting rod to the swing column throw arm.

6. Turn the 4 FRY TIME dial to adjust the fry time to the desired speed.

7.For 2 donuts (or 4 mini donuts) per row, set

the 5 Feed table/Cake Donut depositor switch to CAKE DONUT DEPOSITOR. For 1 donut (or 2 mini donuts) per row, set the switch to FEED TABLE.

8.Turn on the cake donut depositor by pushing UP the switch on the depositor.

9.Set 3 FRYER CONVEYOR switch to AUTO.

NOTE

If the conveyor becomes jammed, a warning buzzer will sound about a minute later and stop when the conveyor is turned off. The conveyor drive motor is impedanceprotected so it will not burn out due to jamming.

WARNING

If the conveyor becomes jammed:

1.Turn off the conveyor drive and the heater.

2.Allow the system to cool down.

HOT SHORTENING IS DANGEROUS.

3.Determine the cause of the jamming.

4.Clear it.

5.Restart the system.

1.Continue adding shortening to the kettle to maintain the proper shortening level (level chain).

2.Continue adding batter to the hopper as needed.

a.You can add batter to the hopper without priming it again as long as it does not become empty.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

8 |

MN-1012EN |

Donut Robot Mark II / Mark V OM |

b.If the hopper does become empty, you must prime it again.

c.When you fill the hopper for the last time, you will want to use all of the batter in the hopper. To do so, push the dough to the bottom of the hopper using a rubber scraper or spatula.

WARNING

10.Turn on the Feed Table switch to activate the Feed Table.

11.Load proof cloths with donuts onto the Feed Table as needed.

To avoid injury, never put your hand in or under the hopper while the machine is on.

If the conveyor becomes jammed:

1.Turn off the conveyor drive and the heater.

2.Allow the system to cool down. HOT SHORTENING IS DANGEROUS.

3.Determine the cause of the jamming.

4.Clear it.

5.Restart the system.

Making Yeast-Raised Donuts

To make yeast-raised donuts, remove both the depositor, and the swing column that supports it. They will not be used for yeast raised donuts.

1.Unplug the depositor power cord of your Donut Robot.

2.Release the plunger from the depositor.

3.Unscrew and lift off the hopper.

4.Lift off the depositor and swing column.

5.Install your Feed Table and plug into the fryer.

6.Refer to Section 5 of this manual for instructions how to use the Feed Table.

7.Ensure there is sufficient shortening in the fryer. The shortening should come up to the level of the chains.

8. Turn the 4 FRY TIME dial to adjust the fry time to the desired speed.

9.Set 3 FRYER CONVEYOR switch to AUTO.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

Donut Robot Mark II / Mark V OM |

MN-1012EN |

9 |

3 |

Cleaning |

|

|

WARNING

Thoroughly clean and dry the floor if shortening, water, or other materials are spilled. Materials spilled on the floor can cause serious injury or loss of life.

WARNING

To avoid electric shock or damage to the machine, never allow water, steam, shortening, cleaning solution, or any other liquid to enter the heater head or the depositor.

Cleaning the Hopper and the Plunger

You must clean the hopper and the plunger daily, or after each use. Follow these general guidelines:

•Use household dishwashing detergent. Do not use strong alkali cleaners such as lye, soda ash, or trisodium phosphate, as these discolor and corrode aluminum.

•Wash, dry, and lubricate parts thoroughly to prevent rusting.

•When washing parts by hand, wash each part separately; do not put any other utensil or dish in the sink with the part being washed.

Cleaning method

1.Unplug the depositor power cord.

2.Remove the plunger and the hopper.

a.Pull the plunger connecting rod up and away from the plunger to release the top of the plunger.

b.Lift out the plunger and set aside

c.Loosen the two mounting studs holding the top of the hopper

d.Remove the hopper

3.Wash the hopper and the plunger thoroughly in hot water and mild detergent.

4.Rinse the hopper and the plunger separately in clear, hot water.

5.Dry each part completely.

6.Dip the plunger and the hopper cylinder in vegetable oil or shortening to prevent rust and sticking.

7.Wipe the depositor assembly with a soft cloth dampened with hot water and an appropriate cleaner. Wipe it with another damp cloth to remove the cleaner. Wipe it dry.

CAUTION

Never immerse the depositor’s cutter head in water. This may cause an electric shock and/or damage to the machine.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

10 |

MN-1012EN |

Donut Robot Mark II / Mark V OM |

Cleaning the Conveyor and the Kettle

The conveyor and fryer kettle should be well cleaned once per week for normal usage.

After cleaning, dry the conveyor, then return the conveyor to the fryer and cover with shortening. If left open to the air overnight, water trapped in the chain may cause staining.

Step 1: Drain the shortening

WARNING

To avoid being burned or electrocuted, disconnect the machine from the power source before cleaning the fryer.

1.Disconnect the machine from the power source.

2.Unplug the depositor power cord.

3.Let the shortening cool to 100°F/38°C.

4.Lift the depositor off the swing column, and set to one side.

5.Lift off the swing connecting rod that extends to the base of the column supporting the depositor.

6.Drain the shortening, using the drain valve under the fryer (if installed) or Filter-Flo Siphon.

a.If the fryer has a drain valve and an EZMelt filtration system, open the drain valve and empty the fryer kettle.

b.If you have a Filter Flo Siphon,use this to transfer the shortening into a large metal bucket. (See the instructions in Appendix A)

conveyor and keep running for 15-20 minutes.

3.Scrub the soiled parts of the kettle and conveyor while the solution is under heat. Use oven gloves for protection.

4.Turn off the heater and disconnect the machine from the power source.

5.Clean the control panel with a damp cloth only. DO NOT clean the control panel while power is connected.DO NOT allow cleaning solution or water onto the control panel.

Step 3: Drain the cleaning solution

1.Allow the cleaning solution to cool to 100°F/38°C.

2.Drain the cleaning solution from the kettle using one of these methods. (These are the same methods already used to drain shortening.)

a.If the fryer has a drain valve, drain the water into a large bucket. DO NOT drain the cleaning solution into the EZMelt.

b.If you have a Filter Flo Siphon, remove its filter assembly. Then use the Filter Flo to siphon the cleaning solution into one or more large buckets. (For Filter Flo instructions, see Appendix A.)

3.Pour out the solution down a drain.

WARNING

Clean and dry and floor spills immediately. Liquid on the floor can cause serious injury or loss of life.

Step 2: Wash the kettle and conveyor

1.Pour hot water into the kettle, up to the level of the chains. Add about 2 oz/59 ml of trisodium phosphate (TSP) or other appropriate cleaner.

2.Connect the machine to the power source. Using the temperature controller, heat the solution to 200°F/93°C. Turn on the

Step 4: Rinse with water

1.Pour clean water into the kettle, up to the normal level of the shortening.

2.Connect the machine to the power source. Heat the water to 200°F/93°C.

3.Run the conveyor for 5-10 minutes.

4.Turn off the heater and disconnect the machine from the power source. Allow the water to cool to 100°F/38°C.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

Donut Robot Mark II / Mark V OM |

MN-1012EN |

11 |

5.Drain the rinse water from the kettle using the same method as Step 4

Step 5: Remove the conveyor

1.Ensure that the conveyor is cool to the touch. If possible, ask another person to help you lift it. Use oven gloves.

2.Obtain two clean pieces of wood, at least 1” x 1” x 15” (2.5 cm x 2.5 cm x 38 cm).

3.Remove the conveyor from the fryer as explained below:

a.Lift the infeed side of the conveyor UP by 2” (5 cm), to rise above the locator pins on the infeed side.

b.Lift the front of the conveyor (the side closest to you) UP by 4” (10 cm)

c.Pull the entire conveyor toward you, and away from the control panel .

d.The conveyor should now be free from the rest of the fryer

4.Place the conveyor on a clean surface, using the two wood pieces to lift the bottom clear of the surface.

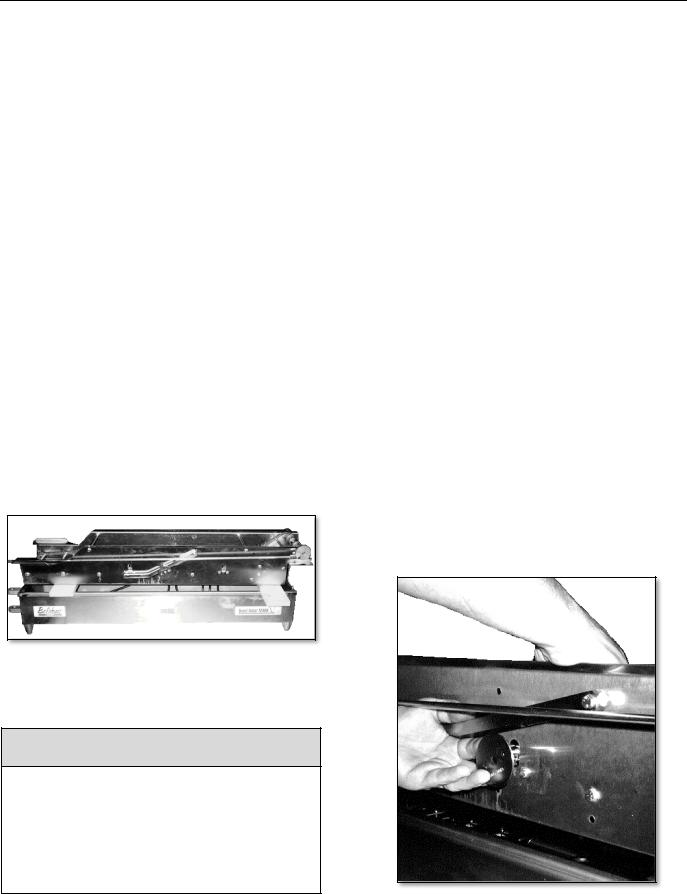

5.OR, rest the conveyor on top of the fryer kettle, using the two pieces of wood as shown in Figure 2 below.

Figure 2: Rest the conveyor on the fryer.

Step 6: Dry all parts

WARNING

All parts must be dried thoroughly. Failure to dry the kettle, conveyor, and all parts of the Donut Robot completely will cause Shortening to spatter or overflow the fryer and may result in fire, injury, or death.

Thoroughly dry all parts, including the conveyor, the heating element(s), the inside of the kettle, and the drain.

1.There should be no water drops anywhere on the Donut Robot.

2.If your kettle has the optional drain assembly, make sure no water is in the drain or drain tube.

3.After cleaning, return the conveyor to the fryer and cover with shortening. Water trapped in the chain may cause staining.

Step 7: Cleaning the turner, heating element, and kettle

1.If the turner requires extra cleaning, remove and clean it as follows.

2.Set the conveyor on a clean surface.

a.Use the same pieces of wood as in Step 6 to raise the conveyor 1” (25 mm) from the surface. This will enable the turner to turn freely.

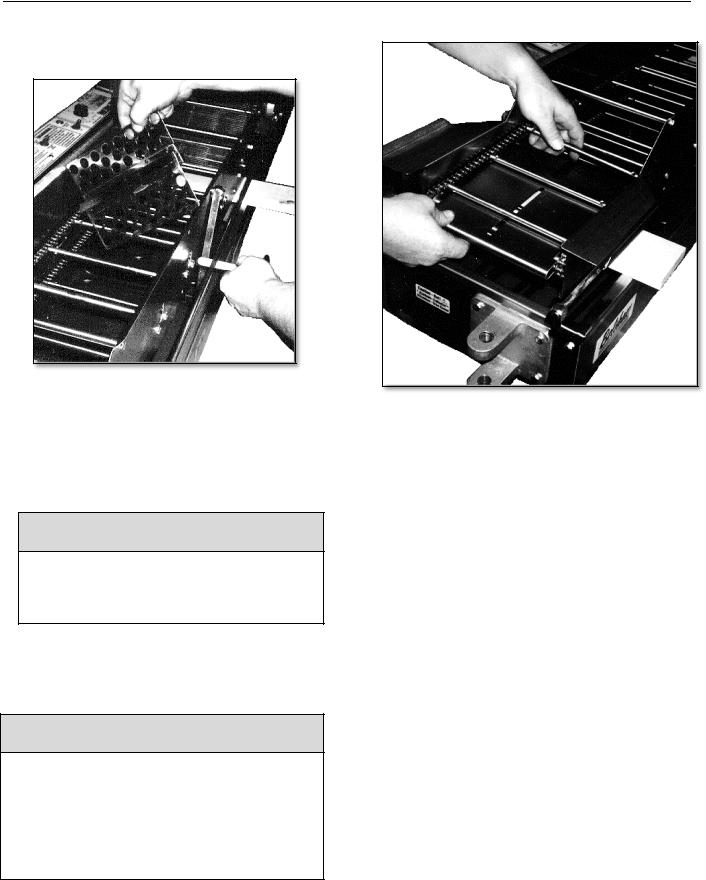

3.Move the flight bars of the conveyor until the turner is in the middle of a flight pocket. Do this by turning the round motor coupling on the outfeed end of the conveyor.

4.Swing the turner cam weight up out of position. (See Figure 3).

5.Holding the turner in one hand, lift up and pull out the turner cam with the other hand.

Figure 3 Removing the Turner Cam

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

12 |

MN-1012EN |

Donut Robot Mark II / Mark V OM |

6. Lift out the turner. See Figure 4.

Figure 4 Removing the Turner

7. Wash the turner cam and turner using mild detergent and warm water.

12.Rinse the turner cam and turner in clear water.

13.Dry thoroughly.

WARNING

All parts must be dried thoroughly. Moisture causes hot shortening to spatter, which may cause serious injury.

14.To clean the drop plate, remove it by lifting its forward end and sliding it toward the rear of the conveyor. (See Figure 5) Wipe the drop plate with a damp cloth.

CAUTION

If the drop plate is scratched, donuts will stick to it. To prevent this from happening, always wipe the drop plate in the direction of the grain in the metal, which runs parallel to the length of the conveyor, and never use abrasive cleaners.

Figure 5 Removing the Drop Plate

15.Brush off any carbon that has accumulated on the Donut Robot’s heating element. Accumulated carbon can cause corrosion and ineffective heating.

16.Tilt the heater head assembly back, raising the heating element out of the kettle.

17.Lift the kettle out of the fryer case.

18.Clean all parts of the kettle if needed, inside and out.

19.Ensure all parts are dry

20.Replace the kettle and lower the heater head.

21.Put the drop plate, turner cam, and turner back on the conveyor.

22.Replace the conveyor

a.When you replace the conveyor, line up the notch in the drive coupling with the large bolt in the motor drive (at the right end of the heater head).

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

Donut Robot Mark II / Mark V OM |

MN-1012EN |

13 |

4 |

Maintenance |

|

|

WARNING

To avoid being burned, electrocuted, or otherwise injured, always unplug the machine and allow it to cool down before making adjustments, clearing obstructions, lubricating, cleaning, or disassembling.

Taking Care of the Plunger, Hopper, and Cylinder

The plunger, hopper, and cylinder of your Donut Robot are precision instruments. With proper care, they will perform well for years. Follow these guidelines:

*Clean these parts only in the manner explained in this manual.

*Handle these parts with care. Avoid dropping them on hard surfaces.

*Do not force the machine if it becomes jammed. To avoid damaging the plunger, disassemble the machine and remove any obstructions.

Lubrication

Daily

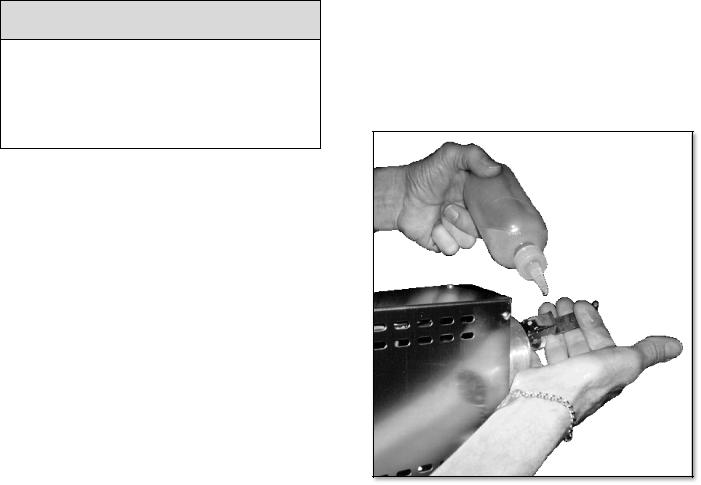

Before using the machine each day, apply Food Grade mineral oil to the plunger connecting rod. The oil should penetrate the ball lock and the spring socket. See Figure 6.

Figure 6 Lubricating the Connecting Rod.

Weekly

Apply a few drops of Food Grade mineral oil to the swing column where it contacts the swing column bracket.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

14 |

MN-1012EN |

Donut Robot Mark II / Mark V OM |

5 |

Accessories |

|

|

This section contains information about accessories which can be used with your Donut Robot :

•Feed Table

•Roto Cooler

•Filter Flo Siphon

•Shortening Reserve Tank

FT-42 Feed Table

Figure 7 FT-42 Feed Table with Feed Table cloth.

The FT-42 Feed Table is designed to supply proofed yeast-raised donuts to the Donut Robot. It produces less than 70 dB(A) of equivalent A- weighted sound pressure at work stations. This has been determined while running the machine, using a Bruel & Kjaer sound level meter, type 2236. The Feed Table is meant to be used on a flat, stationary table or countertop, positioned end-to-end with the Donut Robot. The operator is expected to read and follow these instructions.

Installation

1.Unplug the depositor power cord of your Donut Robot.

2.Release the plunger from the depositor.

3.Unscrew and lift off the hopper assembly.

4.Lift off the depositor and swing column.

5.Lift the outfeed end of the Feed Table and set the brace under the trip shelf over the edge of the kettle.

WARNING

To avoid injury, make sure that the Feed Table is turned off before proceeding.

6.Plug the Feed Table power cord into the outlet on the end of the heater head.

7.Set the switch on the control panel to “Feed Table”.

Belshaw Adamatic Bakery Group • www.belshaw-adamatic.com • 206-322-5474 •service@belshaw.com

Donut Robot Mark II / Mark V OM |

MN-1012EN |

15 |

Loading...

Loading...