Belshaw TG50 Specifications

belshaw-adamatic.com

Thermoglaze TG-50

Frozen Donut Processing

Belshaw’s Thermoglaze system provides the

method for thawing, heating and glazing

pre-fried, frozen donuts and baked goods that

bakers have been looking for.

The Thermoglaze system successfully

addresses a common complaint with frozen

donuts — stale taste and poor shelf-life after

thawing. Frozen donuts that are reconstituted

using the Thermoglaze system have greater

moisture content and longer shelf-life than

those thawed in air. In fact, donuts produced

on the Thermoglaze system often surpass the

quality of fresh made donuts.

The Thermoglaze TG-50 System consists of two

components — the Thermolizer, for thawing

frozen baked goods, and the Thermoglaze, for

heating and glazing. Donuts (or other baked

goods) can be held in the Thermolizer for

up to ve hours, allowing you to supply hot,

fresh-tasting donuts to your customers with

little wait — or fuss.

The Thermoglaze system does not require a

ventilation hood, does not utilize shortening,

and improves glaze yield — reducing both

set-up costs and operating costs.

TG-50 operates using standard size 17" x

25" (43 x 64 cm) glazing screens, Belshaw

Part No. SL-0004 (minimum 36 screens are

recommended).

Capacity of the TG-50 is approximately 600

donuts/hour. Actual production will vary with

time and temperature settings chosen.

Providers of quality bakery equipment for more than 80 years

1-800-578-2547 ▪ info@belshaw-adamatic.com ▪ www.belshaw-adamatic.com

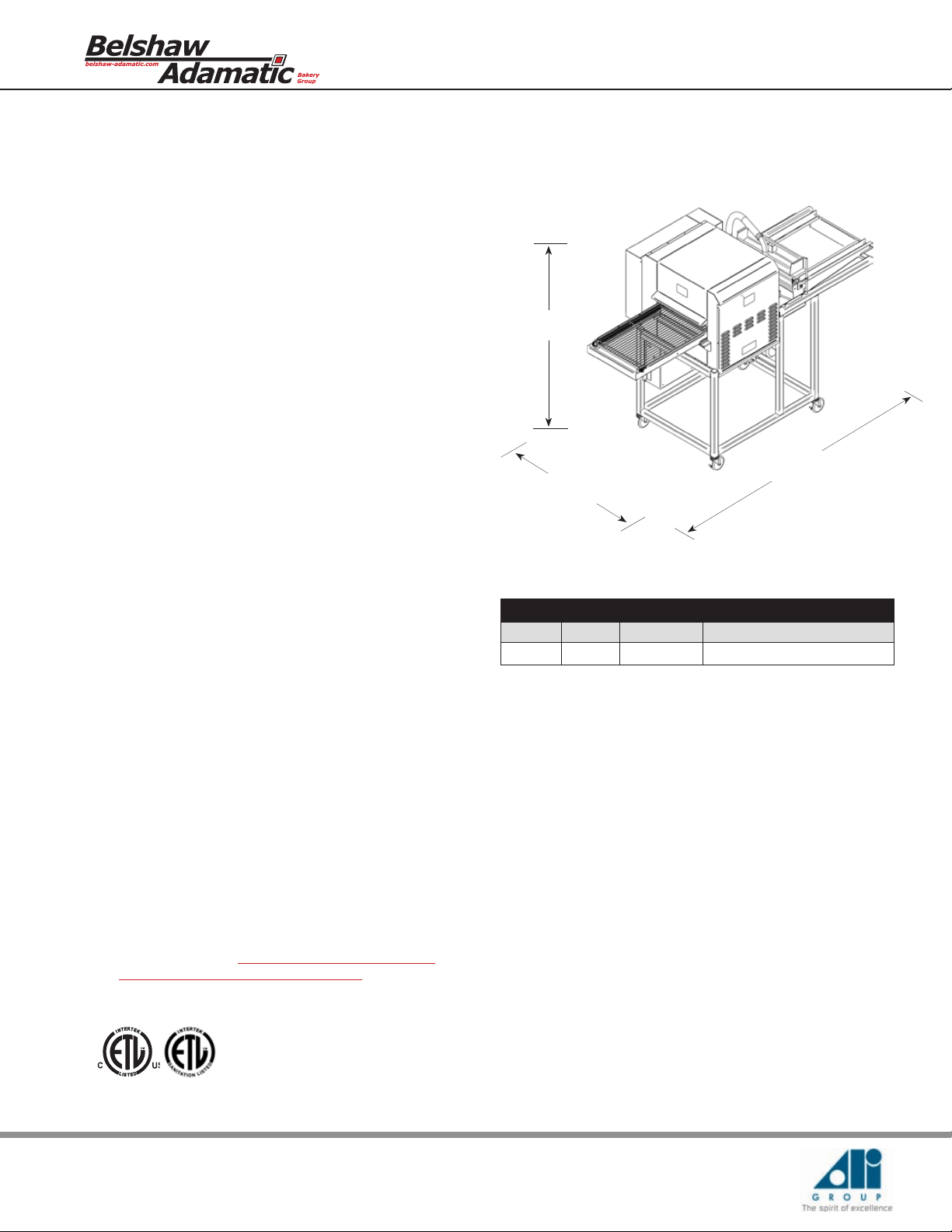

Above: TG-50 #22306 (front view)

17 Shelf Thermolizer (TZ-17) TG-50 (rear view) TG-50 glazer in operation

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2010 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Thermoglaze TG-50

Thermoglaze TG-50 Standard Features

Simple 2-switch operation (Oven and Glazer) ▪

Capacity 600 donuts/hour ▪

No ventilation hood or re suppression system ▪

required. (Verify with local authorities)

Heavy duty glaze pump ▪

Speed and temperature adjustable inside control box ▪

Quiet operation ▪

Glaze pump can be switched on/off as required ▪

All stainless steel construction ▪

Easy to clean oven interior ▪

2 Teon handles supplied for picking up screens ▪

Spare gaskets kit ▪

Mobile on 4" (25mm) casters ▪

Requires glazing screens 17" x 25" (holding 24 donuts ▪

each)

Lock-out feature to prevent machine starting while ▪

cleaning is in progress

48 to 96 screens are recommended depending on the ▪

amount produced

ETL Certied, conforms to UL-197, CSA C22.2, and ▪

NSF-4

TG-50 Dimensions

Overall width: 84" (213 cm) ▪

Overall depth: 34" (86 cm) ▪

Overall height: 54" (137cm) ▪

TG-50 Electrical data

Voltage 208V/60hz/1ph, 33A, 6.7 KW ▪

Plug: NEMA #6-50p ▪

Cord: 72" (1.8m) ▪

TG-50 Diagram

Overall Height:

54” (137 cm)

Overall Width:

Overall Depth:

34” (86 cm)

84” (213 cm)

Model Selection

MODEL SELECTION

Model Item# Voltage Description

TG-50 22306 208V/60/1 Standard model

Options

None ▪

Glazing Screens

17" x 25" glazing screens (Item #SL200-0004). 48-96 ▪

screens are recommended, depending on the number

of donuts produced

Accessory: Thermolizer TZ-17

The optional Thermolizer TZ-17 is an independent ▪

17-shelf cabinet used for thawing and holding donuts

up to 5 hours without losing moisture. Donuts thawed

in the Thermolizer can be warmed and glazed by the

TG-50 in less than 5 minutes.

TZ-17 spec sheet: -

http://www.belshaw-adamatic.

com/products/thermoglaze/tz-17.html

Certication

ETL certied to UL-197, CSA C22.2 and NSF-4

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2010 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Loading...

Loading...