Page 1

Installation, Operation and Maintenance Manual

IM 959

Group: Aftermarket Products

Enclosed Variable Frequency Drive

Installation and Operation Manual

Part Number: IM 959

Date: September 2008

Supersedes: New

For McQuay enclosed variable frequency drive products

incorporating MD-2 variable frequency drives

460-480 Volt, 1-100 HP

200-240 Volt, 1-40 HP

Page 2

Table of Contents

Introduction................................................................................................................................................................................. 4

Safety Symbols, Words and Labels........................................................................................................................................ 4

Hazardous Identification Information................................................................................................................................ 4

Before You Begin................................................................................................................................................................... 5

Specifications .............................................................................................................................................................................. 6

Receiving and Preliminary Inspection ........................................................................................................................................ 9

Storing and Shipping.............................................................................................................................................................. 9

Lifting and Handling ............................................................................................................................................................ 10

Dimensions and Weights........................................................................................................................................................... 11

Accessories and Options ........................................................................................................................................................... 12

NEMA Enclosure Type ................................................................................................................................................... 13

Disconnect Type.............................................................................................................................................................. 13

Phase Failure Monitoring ................................................................................................................................................ 13

Panel Door Security......................................................................................................................................................... 14

Wiring to Terminal Blocks .............................................................................................................................................. 14

Electrical Bypass ............................................................................................................................................................. 14

Auxiliary Contacts........................................................................................................................................................... 14

Hand/Off/Automatic Selector Switch.............................................................................................................................. 14

Local/ Remote Selector Switch........................................................................................................................................ 14

Communication Protocol................................................................................................................................................. 14

Forced Air Ventilation..................................................................................................................................................... 15

Interior Heater.................................................................................................................................................................. 15

Pressure Transmitter........................................................................................................................................................ 15

Remote Keypad ............................................................................................................................................................... 15

Spare Filters..................................................................................................................................................................... 15

Spare Fuses...................................................................................................................................................................... 15

Transient Arrestor............................................................................................................................................................ 16

Mounting the Drive Controller.................................................................................................................................................. 17

Clearances ............................................................................................................................................................................ 17

Mounting Methods ............................................................................................................................................................... 18

Bus Voltage Measurement Procedure .................................................................................................................................. 19

Wiring ....................................................................................................................................................................................... 20

Wiring Recommendations.................................................................................................................................................... 20

Branch Circuit Protection ................................................................................................................................................ 20

Grounding........................................................................................................................................................................ 21

Power Wiring................................................................................................................................................................... 22

Power Terminals.............................................................................................................................................................. 25

Control Terminals............................................................................................................................................................ 26

Integrated Display Terminal...................................................................................................................................................... 30

Programming the Drive Controller....................................................................................................................................... 31

Mode Access.................................................................................................................................................................... 31

Parameter Groups ............................................................................................................................................................ 32

Access to Menus and Parameters ......................................................................................................................................... 33

AUF Quick Menu................................................................................................................................................................. 35

Complete List of Parameters and Definitions ........................................................................................................................... 37

Logic Input Functions .......................................................................................................................................................... 42

Relay Output Functions........................................................................................................................................................ 46

Analog Inputs ....................................................................................................................................................................... 49

Analog Outputs..................................................................................................................................................................... 50

PID Control .......................................................................................................................................................................... 52

PID Setpoint .................................................................................................................................................................... 53

PID Tuning ...................................................................................................................................................................... 54

Floating Point Control ..................................................................................................................................................... 56

Wiring Diagram ........................................................................................................................................................................ 57

Troubleshooting ........................................................................................................................................................................ 58

Drive Controller Fault Conditions........................................................................................................................................ 58

2 IM 959

Page 3

Pre-alarm Displays ............................................................................................................................................................... 63

Drive Controller Alarm Conditions...................................................................................................................................... 64

Resetting the Drive Controller after a Fault Condition is Detected...................................................................................... 66

Parts........................................................................................................................................................................................... 67

Parts List............................................................................................................................................................................... 67

Product Support......................................................................................................................................................................... 70

IM 959 3

Page 4

Introduction

McQuay enclosed variable frequency drives (VFDs) can be added to most motor and pump applications to reduce energy

costs during low demand periods of a heating, ventilating, and air conditioning (HVAC) system. McQuay VFDs are

designed and tested for use with a variety of HVAC system components including:

• Rooftop units

• Air handling units

• Chilled water pumps

• Heating water pumps

• Cooling tower fans

• Condenser water pumps

This manual contains information regarding the installation and startup of a McQuay enclosed variable frequency drive

product. The information in this manual pertains to the following enclosed drive products.

• 1-100 horsepower, 400-480 volt Enclosed Variable Frequency Drives

• 1-40 horsepower, 200-240 volt Enclosed Variable Frequency Drives

Safety Symbols, Words and Labels

The following symbols and labels are used throughout this manual to indicate immediate or potential hazards. It is the owner

and installer’s responsibility to read and comply with all safety information and instructions accompanying these symbols.

Failure to heed safety information increases the risk of property damage and/or product damage, serious personal injury or

death. Improper installation, operation and maintenance can void the warranty.

Hazardous Identification Information

!

DANGER

Dangers indicate a hazardous situation which will

result in death or serious injury if not avoided.

!

WARNING

Warnings indicate potentially hazardous situations

which can result in property damage, severe

personal injury, or death if not avoided.

!

CAUTION

Cautions indicate potentially hazardous situations,

which can result in personal injury or equipment

damage if not avoided.

4 IM 959

Page 5

Before You Begin

Read and understand these instructions before performing any procedure on this drive controller.

!

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Read and understand this manual before installing or operating the McQuay Enclosed Variable

Frequency Drive controller. Installation, adjustment, repair and maintenance must be performed by

qualified personnel.

• The user is responsible for compliance with all international and national electrical code requirements

with respect to grounding of all equipment.

• Many parts of this drive controller, including the printed circuit boards, operate at line voltage. DO

NOT TOUCH. Use only electrically insulated tools.

• DO NO TOUCH unshielded components or terminal strip screw connections with voltage present.

• DO NOT short across terminals PA/+ and PC/- or across the DC bus capacitors.

• Before servicing the drive controller:

− Disconnect all power, including external power control that may be present.

− Place a “Do Not Turn On” label on all power disconnects.

− Lock all power disconnects in the open position.

− WAIT 15 MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage

measurement procedure on page

LED is not an indicator of the absence of DC bus voltage.

• Install and close all covers before applying power or starting and stopping the drive controller.

Failure to follow these instructions will result in death or serious injury.

19 to verify that the DC voltage is less than 45 volts. The drive

IM 959 5

Page 6

Specifications

®

Table 1: McQuay Enclosed Drive Specifications

Input voltage

Displacement power factor

Input frequency

Output voltage

Galvanic isolation

frequency range of the power converter

Current limit

switching frequency

Speed reference

Frequency resolution in analog reference

Speed accuracy

20-100% of motor rated torque

Efficiency

Reference sample time

Acceleration and decelerations ramps

Motor protection

Keypad display

Storage temperature

Operating temperature

Humidity

Altitude

Enclosure

Codes and standards

208 Vac +/- 10%, 230 Vac +/- 10%, 460 Vac +/- 10%

Approximately 0.96

50/60 Hz +/- 5%

Three-phase output, maximum voltage equal to input voltage

Galvanic isolation between power and control (inputs, outputs, and power supplies)

0.5 to 200 Hz (factory setting of 60 Hz maximum)

110% of nominal drive full load amperage (FLA) for 60 seconds

Selectable from 6 to 16 kHz

factory setting: 6 kHz

1

VIA

: 4 to 20 mA, Impedance = 242 ohm or

0 to 10 Vdc, Impedance = 30 kohm

0 to 20 mA (reassignable, X-Y range with keypad display)

VIB: 0 to +10 Vdc, Impedance = 30 kohm

030048 Hz (11bits)

+/- 10% of nominal slip without speed feedback

Typically greater than 95%

2 ms

0.1 to 3,200 seconds (adjustable in 0.1 sec. increments)

Class 10 overload protection when any bypass option is installed and internal

electronic thermal protection on drive controller

Self-diagnostics with fault messages

-13 to +158 oF (-25 to + 70 oC) with vent cover on the VFD removed and without

derating

NEMA 1, non-ventilated, no direct sunlight: +14

NEMA 1, ventilated, no direct sunlight: +14

NEMA 12: +14

NEMA 3R: +14

o

to +122oF (-10o to +50oC)

o

to +122oF (-10oto +50oC), 0oF (-17.8oC) with heater option

o

to +104oF (-10o to +40oC)

o

to +122oF (-10o to +50oC)

95% with no condensation or dripping water, conforming to IEC 60068-2-3

3,300 ft. (1000 m) maximum without derating; derate the current by 1% for each

additional 330 ft. (100 m) up to 10,000 ft. (3000 m)

UL Type 1, UL Type 12, or UL Type 3R

UL Listed per UL508A. Conforms to applicable NEMA ICS, NFPA, and IEC

standards.

1

Not available with the following communication card options: BACnet®, LonWorks

Metasys® N2, ApogeeTM P1

Factory set for voltage control.

6 IM 959

Page 7

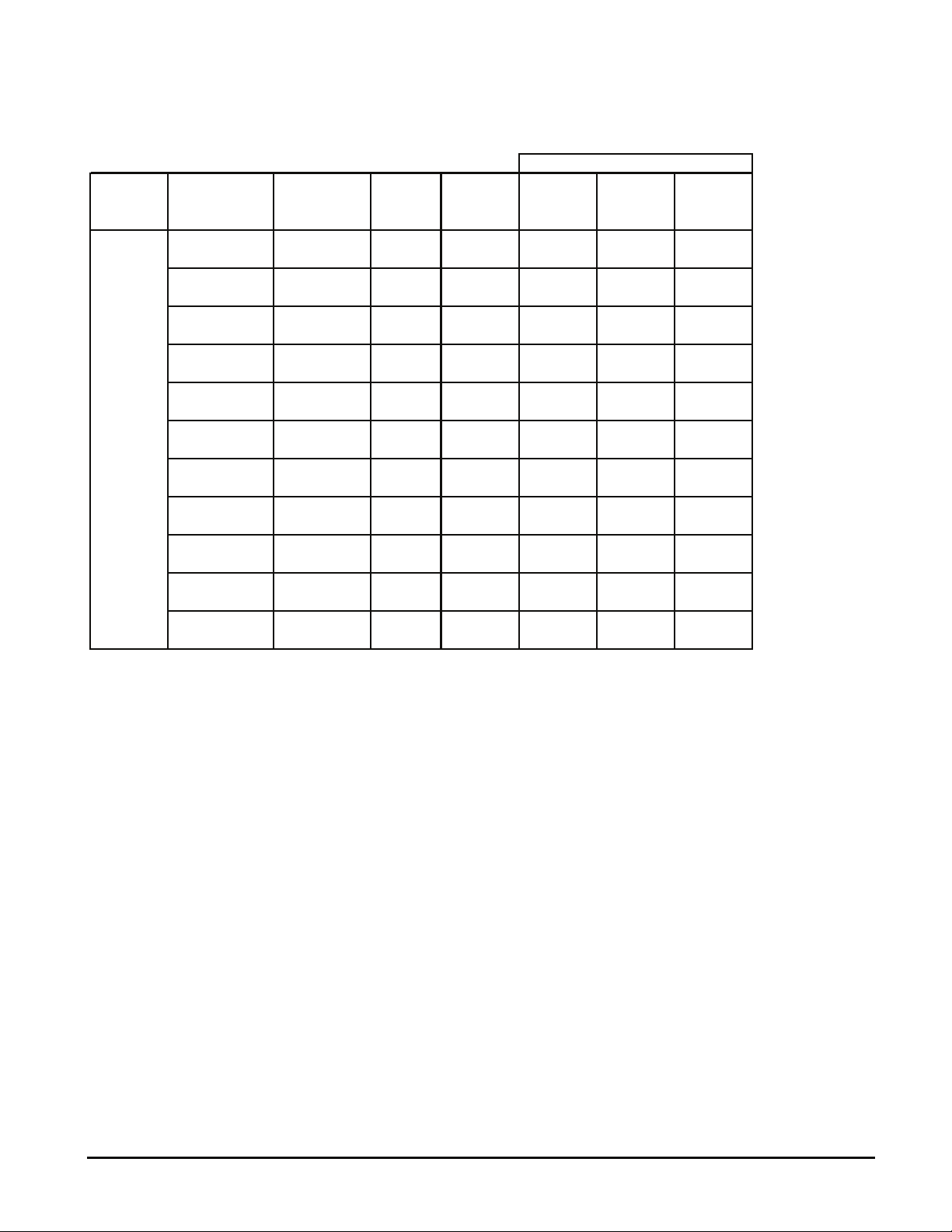

Table 2 and Table 3 list specifications of each enclosed drive controller according to voltage, horsepower, and ampere rating.

(A)

(kg)

-

)

(

)

(

)

(

)

-

-

)

(

)

(

)

(

)

-

)

(

)

(

)

(

)

-

-

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

(

)

(

)

(

)

Mounting dimensions and maximum weight dimensions are illustrated in Table 4 on page

11.

Table 2: 200-240V Enclosed Drive Controller Specifications

Nominal Dimensions in. (mm)

Nominal

Voltage

230

Horsepower

(kW)

1 (0.75) 4.6

2 (1.5) 7.5

3 (2.2) 10.6

5 (4) 17.5

7.5 (5.5) 24.2

10 (7.5) 32

15 (11) 46.2

20 (15) 61

25 (18.5) 74.8

30 (22) 88

40 (30) 117

Maximum

Continuous

Current

Average

Weight

lbs.

70-80 (32

36

70-80 (32

36)

70-80 (32

36

70-80 (32

36

70-80 (32

36)

70-80 (32

36

115-135

52-61

115-135

(52-61)

115-135

52-61

250-280

(113-

250-280

113-

Frame

Size

1

1

1

1

1

1

2

2

2

4

4

Width Height Depth

11.40

289.56

11.40

(289.56)

11.40

289.56

11.40

289.56

11.40

(289.56)

11.40

289.56

13.25

336.35

13.25

(336.35)

13.25

336.35

16.50

(368.30)

16.50

368.30

43.50

1104.9

43.50

(1104.9)

43.50

1104.9

43.50

1104.9

43.50

(1104.9)

43.50

1104.9

50.00

1270.00

50.00

(1270.00)

50.00

1270.00

71.00

(1803.40)

71.00

1803.40

10.25

260.35

10.25

(260.35)

10.25

260.35

10.25

260.35

10.25

(260.35)

10.25

260.35

12.10

307.34

12.10

(307.34)

12.10

307.34

15.35

(389.89)

15.35

389.89

* Exact weight of each drive controller varies and depends on the options selected at time of purchase.

IM 959 7

Page 8

Table 3: 400-480 Enclosed Drive Controller Specifications

-

-

-

-

-

-

-

Nominal Dimensions in. (mm)

Nominal

Voltage

480

Horsepower

(kW)

1 (0.75) 2.2

2 (1.5) 3.7

3 (2.2) 5.1

5 (4) 9.1

7.5 (5.5) 12

10 (7.5) 16

15 (11) 22.5

20 (15) 30.5

25 (18.5) 37

30 (22) 43.5

40 (30) 58.5

50 (37) 79

60 (45) 94

75 (55) 116

100 (74.6) 160

Maximum

Continuous

Current (A)

Average

Weight

lbs. (kg)

70-80 (32

36)

70-80 (32

36)

70-80 (32

36)

70-80 (32

36)

70-80 (32

36)

70-80 (32

36)

70-80 (32

36)

115-135

(52-61)

115-135

(52-61)

180-200

(82-91)

180-200

(82-91)

180-200

(82-91)

180-200

(82-91)

250-280

(113-

127)

250-280

(113-

127)

Frame

Size

1

1

1

1

1

1

1

2

2

3

3

3

3

4

4

Width Height Depth

11.40

(289.56)

11.40

(289.56)

11.40

(289.56)

11.40

(289.56)

11.40

(289.56)

11.40

(289.56)

11.40

(289.56)

13.25

(336.35)

13.25

(336.35)

13.25

(336.55)

13.25

(336.55)

13.25

(336.55)

13.25

(336.55)

16.50

(368.30)

16.50

(368.30)

43.50

(1104.90)

43.50

(1104.90)

43.50

(1104.90)

43.50

(1104.90)

43.50

(1104.90)

43.50

(1104.90)

43.50

(1104.90)

50.00

(1270.00)

50.00

(1270.00)

61.50

(1562.10)

61.50

(1562.10)

61.50

(1562.10)

61.50

(1562.10)

71.00

(1803.40)

71.00

(1803.40)

10.25

(260.35)

10.25

(260.35)

10.25

(260.35)

10.25

(260.35)

10.25

(260.35)

10.25

(260.35)

10.25

(260.35)

12.10

(307.34)

12.10

(307.34)

12.10

(307.34)

12.10

(307.34)

12.10

(307.34)

12.10

(307.34)

15.35

(389.89)

15.35

(389.89)

* Exact weights of each drive controller vary and depend on the options selected at time of purchase.

8 IM 959

Page 9

Receiving and Preliminary Inspection

!

WARNING

DAMAGED PACKAGING

If the packaged appears damaged, it can be dangerous to open it or handle it. Handle with care.

Failure to follow this instruction can result in death, serious injury, or equipment damage.

!

WARNING

DAMAGED EQUIPMENT

Do not operator or install any drive controller that appears damaged.

Failure to follow this instruction can result in death, serious injury, or equipment damage.

Before installing the McQuay enclosed VFD controller, read this manual and follow all precautions.

Before removing the drive controller from its packaging, verify that the carton was not damaged in shipping. Carton damage

usually indicates improper handling and the potential for device damage. If any damage is found, notify the carrier and your

McQuay Parts Distributor.

Storing and Shipping

If the drive controller is not being immediately installed, store it in a clean, dry area where the ambient temperature is

between -13 and +158

shipping carton and packing material to protect it.

o

F (-25 and +70 oC). If the drive controller must be shipped to another location, use the original

IM 959 9

Page 10

Lifting and Handling

!

WARNING

HANDLING AND LIFTING HAZARD

Keep the area below any equipment being lifted clear of all personnel and property. Use the lifting method illustrated

in Figure 1 on page

Failure to follow this instruction can result in death, serious injury, or equipment damage.

RISK OF TOPPLING

• Keep the drive controller on the pallet until ready to install.

• Never place the drive controller in an upright position without proper support, such as a hoist, braces, or other

mounting support.

Failure to follow this instruction can result in death, serious injury, or equipment damage.

• A hoist must be used for handling and lifting all McQuay drive controllers.

• After removing the drive controller from its packaging, inspect it for damage. If any damage is found, notify the

carrier and your McQuay Parts Distributor.

• Verify that the drive controller nameplate and label conform to the packing slip and corresponding purchase order.

10.

!

WARNING

Figure 1: Lifting and Hoisting the Drive Controller

10 IM 959

Page 11

Dimensions and Weights

Figure 2: Enclosed Drive Dimensions

Table 4: Enclosed Drive Dimensions and Weights Frame size is determined by voltage and horsepower and is

shown in Tables 2 and 3, of pages 7 and 8 respectively.

FRAME

SIZE

1

2

3

4

DIMENSIONS, in. (mm)

A B C D E G H

11.40

(289.56)

13.25

(336.35)

13.25

(336.55)

16.50

(368.30)

12.64

(321.05)

14.49

(368.05)

14.49

(368.05)

17.74

(450.60)

10.25

(260.35)

12.10

(307.34)

12.10

(307.34)

15.35

(389.89)

0.39

(9.91)

0.39

(9.91)

0.39

(9.91)

0.39

(9.91)

13.58

(344.93)

15.43

(391.92)

15.43

(391.92)

18.68

(474.47)

41.28

(1048.51)

47.78

(1213.61)

59.28

(1505.71)

68.78

(1747.01)

43.50

(1104.90)

50.00

(1270.00)

61.50

(1562.10)

71.00

(1803.40)

AVERAGE

WEIGHT

lbs. (kg)

70-80

(32-36)

115-135

(52-61)

180-200

(82-91)

250-280

(113-127)

IM 959 11

MAXIMUM

WEIGHT,

lbs. (kg)

100 (45)

150 (68)

220 (100)

300 (136)

Page 12

Accessories and Options

This section defines all available options that can be selected with a McQuay enclosed VFD. Figure 3 illustrates a twodimensional layout of the entire VFD enclosure and shows individual component locations. Refer to Figure 22 on page

for a typical wiring schematic for each or all of the components shown on the two-dimensional layout.

Figure 3: Enclosed Drive Controller Dimensional Layout and Internal Components

57

12 IM 959

Page 13

NEMA Enclosure Type

The National Electrical Manufacturing Association (NEMA) sets electrical manufacturing standards for the United States.

NEMA establishes specific design criteria for which industrial electrical panels and enclosures should be designed and built.

NEMA establishes ratings and definitions for each type of industrial panel. The following definitions are referenced in

accordance with NEMA Standard 250-2003 (NEMA Enclosures section, November 2005). These NEMA types apply to the

McQuay Enclosed Variable Frequency Drive product.

• NEMA Type 1 - Enclosures are intended for indoor use, primarily to provide a degree of protection against the

contact with the enclosed equipment. The McQuay enclosed drive controller temperature limit for this NEMA type

without forced air ventilation is +14

installed is +14

o

to +122oF (-17.8o to +50oC).

• NEMA Type 12 - Enclosures are intended for indoor use, primarily to provide a degree of protection against

circulating dust, falling dirt, and non-corrosive liquids. The McQuay enclosed drive controller temperature limit for

this NEMA type is +14

o

to +122oF (-10o to +50oC).

• NEMA Type 3R (non-filtered) - Enclosures are intended for outdoor use, primarily to provide a degree of protection

against rain, sleet, and damage from external ice formation. The McQuay enclosed drive controller temperature

limit for this NEMA type is +14

when the heater option is present.

o

to +104oF (-10o to +40oC). The temperature range with forced air ventilation

o

to +122oF (-10o to +50oC). The drive controller is rated down to 0°F (-17.8°C)

• NEMA Type 3R (filtered) -

Enclosures are intended for outdoor use, primarily to provide a degree of protection

against rain, sleet, and damage from external ice formation, as well as a degree of protection against circulating dust,

falling dirt, and non-corrosive liquids.. The McQuay enclosed drive controller temperature limit for this NEMA type

o

to +122oF (-10o to +50oC). The controller is rated down to 0°F (-10°C) when the heater option is installed.

is +14

Disconnect Type

The National Electric Code (NEC) requires a unit disconnect on electrical motor circuits. A unit disconnect is a selectable

option on McQuay enclosed drive products. A disconnect allows power to be isolated from the enclosed drive controller for

serviceability and safety. Refer to DS1 of Figure 3 on page

12 for the disconnect location inside the enclosure. The

following types of disconnects are selectable with McQuay enclosed drive controllers.

• None – If a disconnect is located upstream of the motor power circuit, then a unit disconnect may not have been

installed inside the drive controller enclosure. Power may have to be shut down upstream within the power circuit

before installation and startup of the drive controller can be carried out in this situation.

• Non-Fusible Disconnect – This type of disconnect is manually operated and allows incoming power to be isolated

from the drive controller. This type of disconnect adds no circuit protection to the unit.

• Fusible Disconnect – This type of disconnect is manually operated and allows incoming power to be isolated from

the drive controller. This type of disconnect adds a certain level of circuit protection by incorporating a J type fuse.

• Circuit Breaker Disconnect – This type of disconnect is manually operated and allows incoming power to be isolated

from the drive controller. This type of disconnect adds a certain level of circuit protection by incorporating a circuit

breaker that can be manually reset.

Phase Failure Monitoring

A phase failure monitor is a selectable option on McQuay enclosed drive controllers. Refer to PVM1 of Figure 3 on page 12

for the location of the phase failure monitor inside the enclosure. The phase failure monitor is a device that protects the

motor from the following system failures:

• Single phasing (loss of any phase)

• Low voltage

• High voltage

• Voltage imbalance

• Phase reversal

• Rapid cycling

IM 959 13

Page 14

Panel Door Security

Panel door security is a selectable option on McQuay enclosed drive controllers that allows the enclosure to be locked by way

of a paddle lockable device. This keeps unauthorized personnel from entering the enclosure or tampering with the drive

controller and internal components.

Wiring to Terminal Blocks

This option terminates all enclosed drive control wiring (I/O) to a common terminal block. Refer to Figure 10 on page 28 for

terminal designations. Figure 3 on page

12 shows the location of the terminal block (TB2) inside the enclosure.

Electrical Bypass

Electrical bypass is an available option on enclosed drive controllers. A bypass allows the variable frequency drive to be

eliminated from the power circuit. When the drive controller is put in the bypass mode, an independent circuit is enabled that

does not include (bypasses) the VFD. The unit operates at full speed with an across-the-line start when bypass mode is

selected. Variable speed control by way of the VFD is lost when the controller is in the bypass mode.

There are two types of electrical bypass options on McQuay enclosed drive controllers. A two-contactor bypass does not

isolate the VFD from main line voltage power. If the VFD fails and the bypass mode is enabled, the drive controller cannot

be serviced until the unit is completely shut down. A three-contactor bypass isolates the bypass circuit from the inverter

circuit. This means that the VFD can be serviced while running in the three-contactor bypass mode. M10B of Figure 3 on

12 represents the two contactor bypass option. M10C is the three contactor bypass and shown as a selectable option

page

within Figure 3.

Auxiliary Contacts

Each contactor on the enclosed drive controller is equipped with one normally open and one normally closed contact. If this

option is selected, an additional normally open and normally closed contact is added to each contactor within the McQuay

enclosed drive controller. When this option is selected with a two-contactor bypass, then four normally open and four

normally closed contacts are equipped on the unit. If a three-contactor bypass is present within the unit, and the auxiliary

contacts option is selected, then six (6) normally open and six (6) normally closed contacts will be present within the

enclosed drive controller.

Hand/Off/Automatic Selector Switch

S1 shown within Figure 3 on page 12 represents the Hand/Off/Automatic (HOA) switch. This option is a three-position

selector switch located on the outside of the enclosure. When this option is selected, the drive controller can be switched

between three different modes: Hand, Off, or Auto mode. The Hand mode allows the drive speed to be controlled via the

display keypad. The Off mode stops power to the VFD. The Automatic mode allows the system to control motor speed.

Local/ Remote Selector Switch

S2 represents the local/remote selector switch within Figure 3 on page 12. This option is a two-position selector switch

located on the outside of the enclosure. This option allows the drive controller to be selected between two modes - Local or

Remote mode. Local mode allows the drive speed to be controlled via the display keypad or system controls. Remote mode

allows the drive to be controlled by the building automation system (BAS) controls.

Communication Protocol

Modbus® is the standard communication protocol within the McQuay enclosed drive controller. Other communication

options are available. Separate installation and operation instructions are included with the enclosed drive controller when a

communication option other than Modbus is selected. The following communication protocols are available for the McQuay

enclosed drive controller:

• Modbus (Standard)

• Metasys® N2

• BACnet®

ONWORKS®

• L

14 IM 959

Page 15

• Apogee P2™

Forced Air Ventilation

McQuay enclosed drive controllers may have thermostatically controlled forced air ventilation installed as an option. When

this option is selected, the ventilation fan (located at the top of the enclosure as shown in Figure 3 on page 12) will cycle on

o

F (29.4oC), and will shut off at 67oF (19.4oC). This option comes standard on NEMA 12 and 3R enclosures.

at 85

Thermostatically controlled forced air ventilation is a selectable option on NEMA 1 enclosure types. The upper temperature

limits for this selectable option are listed below.

• NEMA 1, non-ventilated: +104

• NEMA 1, ventilated: +122

• NEMA 12: +122

• NEMA 3R: +122

o

F (+50oC)

o

F (+50oC)

o

F (+40oC)

o

F (+50oC)

Interior Heater

McQuay enclosed drive controllers are selectable with an enclosed heater where weather conditions require it. The heater

will cycle on at 40

is positioned on the inside of the enclosure, along the side of the VFD (see Figure 3 on page 12 for details). When this option

is selected on Frame 4 enclosed drive controllers, two heaters are installed inside the enclosure. All other frame sizes ship

with one heater installed. The temperature limits with or without a heater installed are listed below.

• Enclosures with a heater installed: 0

• Enclosures without a heater installed: +14

o

F (4.4oC), and shut off at 50oF (10oC) when this option is installed inside the drive enclosure. The heater

o

F (-17.8oC)

o

F (-10oC)

Pressure Transmitter

This option is selectable when the drive controller will be installed in a fan application, where VFD speed will be controlled

by a pressure transmitter. The pressure transmitter can either be selected to mount on the inside of the enclosure (NEMA 1)

or outside of the enclosure (NEMA 4X). The pressure transducer is represented as SPS1 on the two dimensional layout of

Figure 3 on page

12.

The transducer is powered by 24 VDC via the P24 terminal of the MD-2 VFD. It transmits a 4-20 mA signal to the VIB

analog input terminal at the MD-2 VFD. The 4-20 mA signal is converted to a 2-10 VDC signal via a 499 ohm resistor

installed between the VIB and CC terminals of the VFD (refer to SPS1 of Figure 22 on page

57 for details).

Remote Keypad

The remote keypad is an available option on McQuay enclosed drive controllers. The remote keypad comes with a 9.8-foot

(3 m) cable that allows the user display and keypad to be accessed from a remote location. The remote keypad option is

available in a NEMA 1 or NEMA 3R rating. The NEMA 1 option is shipped loose, inside the enclosure for field mounting in

an indoor application. The NEMA 3R option is shipped loose, inside the VFD enclosure for field mounting in an outdoor

application.

Spare Filters

When this option is selected, the enclosed drive controller will ship with extra filters on NEMA 12 and NEMA 3R (filtered)

enclosure types. In these types of enclosure types, one filter is mounted inside the bottom of the enclosure at the outside air

intake louver. A second filter is mounted inside the top of the enclosure at the exhaust air louver. When spare filters are

ordered, an additional five (5) filters are shipped with the unit.

Spare Fuses

When this option is selected, the enclosed drive controller will ship with extra fuses when a fused disconnect or control

power transformer is installed in the unit. There are three large, fast acting, J type fuses when a fused disconnect is selected.

There are also three fuses installed on the control power transformer (CPT) when 115 VAC power is installed inside the drive

controller enclosure. When spare fuses are ordered, an additional quantity of three fuses for a fused disconnect, and three

fuses for the CPT are shipped with the unit.

IM 959 15

Page 16

Transient Arrestor

The transient arrestor is a selectable option on McQuay enclosed drive controllers. This option adds a certain level of circuit

protection to the drive controller. The transient arrestor acts like a filter to stop sudden over-voltage transient conditions that

may exist in the power circuit. The large transients can be caused internally by the distribution network, or externally from

events such as lightning or motor arcing. The transient arrestor is shown as TA1 on the two-dimensional layout of Figure 3

on page 12.

16 IM 959

Page 17

Mounting the Drive Controller

Clearances

When mounting a McQuay drive controller:

• Install the drive controller vertically, +/- 10

• Do not place the drive controller close to heat sources.

• Leave sufficient free space around the drive controller to ensure that air can circulate from the bottom to the top of

the unit.

• Leave enough free space in front of the drive controller enclosure door so that it opens at least 90

• Clearances must be in accordance with local AHJ requirements.

The enclosed drive controller has certain clearance requirements. Refer to Figure 4

mounting. The top of the enclosure should have a clearance of no less than six (6) inches (not including the shroud on

NEMA 3R enclosures). The bottom of the enclosure should also have a clearance minimum of six inches. There is no side

minimum clearance limit for mounting the drive controller. However, the drive controller should be mounted in a way that

still allows adequate clearance room for the enclosure door to open.

Figure 4: Minimum Clearance Requirements for Mounting the Enclosures

o

.

6 inch minimum

o

.

below for necessary clearances when

No

Limit

6 inch minimum

No

Limit

IM 959 17

Page 18

Mounting Methods

• Mount the drive in an upright position.

• Mount the drive controller against a back panel or mounting support capable of supporting the maximum controller

weights shown in Table 5.

• Use mounting hardware capable of supporting the drive controller weight. Again, refer to Table 5 for maximum

weight requirements.

Table 5: Maximum Weights for Enclosed Drives.

VOLTAGE HORSEPOWER

1–10 1 100 (45)

208-230

460

Install the drive controller using the mounting feet provided on the outside of the enclosure. Refer to dimensional references

B and G of Table 4 on page

question.

15-25 2 150 (68)

30-40 4 300 (136)

1 - 15 1 100 (45)

20 - 25 2 150 (68)

30 - 60 3 220 (100)

75 - 100 4 300 (136)

11 for the mounting dimensions between each mounting foot depending on the frame size in

FRAME

SIZE

MAXIMUM WEIGHT,

lbs (kg)

18 IM 959

Page 19

Bus Voltage Measurement Procedure

Before working on the drive controller, remove all power and wait 15 minutes to allow the DC bus to discharge. Then

measure the DC bus voltage between the PA/+ and PC/- terminals.

!

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH. DISCONNECT ALL POWER.

Read and understand the precautions in the “Before You Begin” section on page

Failure to follow this instruction can result in death or serious injury.

The DC bus voltage can exceed 1,000 VDC. Use a properly rated voltage-sensing device when performing this procedure.

To measure the DC bus voltage:

1. Disconnect all power.

2. Wait 15 minutes to allow the DC bus to discharge.

3. Measure the voltage of the DC bus between the PA/+ and PC/- terminals to ensure that the voltage is less than 45

VDC.

4. If the DC bus capacitors do not discharge completely, contact your local McQuay Parts Distributor. Do not repair or

operate the drive controller.

4 before performing this procedure.

Figure 5: Capacitor Charging LED

IM 959 19

Page 20

Wiring

Wiring Recommendations

Good wiring practice requires the separation of control wiring from all power (line) wiring. In addition, power wiring to the

motor must have the maximum possible separation from all other power wiring, whether from the same drive controller or

other drive controllers. Do not run power and control wiring, or multiple power wiring, in the same conduit. This

separation reduces the possibility of coupling electrical transients from power circuits into control circuits or from motor

power wiring into other power circuits.

!

DANGER

IMPROPER WIRING PRACTICES

• Follow the wiring practices described in this document in addition to those already required by the

National Electrical Code and local electrical codes.

• Do not apply input line voltage to the output terminals (U/T1, V/T2, W/T3).

• Check the power connections before energizing the drive controller.

• If replacing another drive controller, verify that all wiring connections to the McQuay enclosed drive

controller comply with all wiring instructions in this manual.

Failure to follow these instructions will result in death, serious injury, or equipment damage.

Follow the practices listed below when wiring McQuay drive controllers:

• Verify that the voltage and frequency of the input supply line and the voltage, frequency, and current of the motor

match the rating on the drive controller nameplate.

• Use metallic conduit for all drive controller wiring. Do not run control and power wiring in the same conduit.

• Separate the metallic conduits carrying power wiring or low-level control wiring by at least 3 in. (76 mm).

• Separate the non-metallic conduits or cable trays carrying power wiring form the metallic conduit carrying control

wiring by at least 12 inches (305 mm).

• Whenever power and control wiring cross, the metallic conduits and non-metallic conduits or trays must cross at

right angles.

• Equip all inductive circuits near the drive controller (such as relays, contactors, and solenoid valves) with noise

suppressors.

• Cable lengths greater than 100 feet (30.5 m) can affect the drive controller and motor performance. For cables

longer than 100 feet, an output filter may be necessary.

Branch Circuit Protection

Refer to NEC Article 430 for sizing of branch circuit conductors. Ensure that all branch circuit components and equipment

(such as transformers, feeder cables, disconnect devices and protective devices) are rated for the input current of the drive

controller, or for the rated output current, whichever value is larger. Rated input and output current values are shown on the

drive controller nameplate.

NOTE: Ensure that the branch circuit feeder protection rating is not less than the rated output current of the drive controller.

20 IM 959

Page 21

!

DANGER

INADEQUATE OVERCURRENT PROTECTION

• Over current protective devices must be properly coordinated.

• The National Electrical Code and the Canadian Electricity Code require branch circuit protection. Use

the fuses recommended on the drive controller nameplate to achieve published fault-withstand current

ratings.

• Do not connect the drive controller to a power feeder whose short circuit capacity exceeds the drive

controller short circuit current rating listed on the drive controller nameplate.

Failure to follow these instructions will result in death, serious injury, or equipment damage.

Grounding

Grounding of the drive controller should be done using the ground lug located at the bottom, on the inside of the enclosure.

The ground lug has a tag designation and is labeled GLG1

.

Figure 6: Ground Lug Location on McQuay Enclosed Drive Controllers

Ground Lug

(GLG1)

!

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Ground the equipment using the provided ground connecting point as shown in Figure 8 on page

22. The drive controller panel must be properly grounded before power is applied.

Failure to follow these instructions will result in death, serious injury, or equipment damage.

IM 959 21

Page 22

Ground multiple drive controllers as shown in Figure 7 below. Do not loop the ground cables or connect them in series.

Figure 7: Grounding Multiple Controllers

Power Wiring

The drive controller enclosure does not come equipped with standard knockouts installed. Field-drilled power and control

wiring openings will have to be cut into the enclosure. Power and control wiring can be brought into the drive controller

through the bottom, the right side, or the left side of the enclosure. It is up to the installer to size, place, and cut the power

and control wiring holes correctly for their specific application, and according to the necessary conductor sizes shown in

Table 6 or Table 7 depending on power termination locations. Wire size must be selected in accordance with NEC table

310.16 for copper conductors at a temperature rating of 165

o

F (75oC) and/or local codes.

Figure 8: Typical Knockout Locations for Control and Power Wiring of the Drive Controller

Typical knockout locations

22 IM 959

Page 23

Maximum conductor sizes for the McQuay MD-2 variable frequency drives are shown in Table 6 below. All other conductor

wire sizing for components inside the enclosure should be selected according to Table 7 on page

24.

Table 6: Maximum Conductor Sizes for Power Terminals on the MD-2 VFD only.

Voltage HP

1 1 6 10 1.3 11.5

2 1 6 10 1.3 11.5

3 1 6 10 1.3 11.5

4 1 6 10 1.3 11.5

200

To

240

400

To

480

5 1 6 10 1.3 11.5

7.5 1 16 6 2.5 22

10 1 16 6 2.5 22

15 2 25 3 4.5 40

20 2 25 3 4.5 40

25 2 25 3 4.5 40

30 4 50 1/0 24 212

40 4 150 300 mcm 41 363

1 1 6 10 1.3 11.5

2 1 6 10 1.3 11.5

3 1 6 10 1.3 11.5

4 1 6 10 1.3 11.5

5 1 6 10 1.3 11.5

7.5 1 6 10 1.3 11.5

10 1 6 6 2.5 22

15 1 16 6 2.5 22

20 2 25 3 4.5 40

25 2 25 3 4.5 40

30 3 50 1/0 24 212

40 3 50 1/0 24 212

50 3 50 1/0 24 212

60 3 50 1/0 24 212

75 4 150 300 mcm 41 363

100 4 150 300 mcm 41 363

Frame

Size

Power Terminals (Input,

Output, and Ground

Wires)

mm2 AWG N-m lb-in

Maximum Tightening

Torques

IM 959 23

Page 24

McQuay enclosed drive controllers are available with a variety of options. Wire termination locations for input power,

output power, and ground wiring will vary depending on the options installed within the unit. Wire conductor sizes should be

chosen according to Table 7

below when terminating power at components other than the variable frequency drive (i.e.

disconnects, overload relays, power blocks, etc.).

Table 7: Recommended conductor sizes for specified voltage and horsepower ranges on McQuay enclosed drives,

according to NEC Table 310.16 at 75

Voltage HP Full Load Amps

208

230

460

o

C temperature rating for copper conductors.

Recommended Wire Size

1

1.5

2

3

5

7.5

10

15

20

25

30

40

1

1.5

2

3

5

7.5

10

15

20

25

30

40

1

1.5

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

4.6

6.6

7.5

10.6

16.7

24.2

30.8

46.2

59.4

74.8

88.0

114.0

4.2

6.0

6.8

9.6

15.2

22.0

28.0

42.0

54.0

68.0

80.0

104.0

2.1

3.0

3.4

4.8

7.6

11.0

14.0

21.0

27.0

34.0

40.0

52.0

65.0

77.0

96.0

124.0

(AWG)

14

14

14

14

12

10

8

6

4

3

2

1/0

14

14

14

14

14

10

10

6

4

4

3

1

14

14

14

14

14

14

14

10

10

8

8

6

4

3

1

2/0

24 IM 959

Page 25

Power Terminals

Incoming power should be terminated at the main unit disconnect (DS1), or the power distribution block (PB1) if a

disconnect was not installed in the unit. Phases shall be kept consistent to insure proper motor rotation and power

distribution to the motor control circuit. Identify each phase leg (L1, L2, and L3) and match it up to the proper label shown

on the inside of the unit enclosure back panel. See Figure 9 for details.

Outgoing power to the motor should be terminated at the overload relay (OL10), connected to the inverter contactor (M10).

If the drive is not ordered with a bypass, output power shall be terminated at the T1, T2, and T3 terminals of the inverter. All

phases should be kept consistent to keep motor rotation correct (T1, T2, and T3). See Figure 9

below for details.

Figure 9: Input and Output Power Wiring Termination Locations

IM 959 25

Page 26

Control Terminals

The McQuay enclosed drive is equipped with multiple control terminals capable of a wide range of control schemes. The

drive controller is quipped with the following control terminals:

• 1 External power supply input (PLC)

• 1 Internal power supply (P24)

• 2 Common terminals (CC)

• 5 Configurable relay outputs (FLA, FLB, FLC, RY, RC)

• 3 Configurable logic inputs (F, R, RES)

• 1 Configurable analog output (FM)

• 1 Configurable analog/logic input (VIA)

• 1 Configurable analog input (VIB)

• 1 Internal supply (PP)

Table 8 defines each terminal in detail. Refer to the Programming section on page

control terminals for various applications.

31 for more detail on utilizing these

Table 8: Terminal Designations and Their Function

26 IM 959

Page 27

Table 8: Continued

The drive controller has two different control wiring terminal locations depending on the options that were selected with the

unit. Figure 10 on page

applies if this option was selected and installed on the drive controller at the time of purchase. If the drive controller was not

selected with the TB 2 terminal block option, then all control wiring will be terminated at the McQuay MD-2 variable

frequency drive. Figure 11 on page

28 shows the McQuay MD-2 wiring terminations located at the TB 2 terminal block. This figure

29 illustrates these control terminal designations.

IM 959 27

Page 28

Figure 10: Control Terminal Locations of the Drive Controller, when the terminal block option is selected (TB2).

Terminal Block 2 (TB 2)

Terminal Block 1 (TB 1)

28 IM 959

Page 29

Figure 11: Terminal Locations of Main Control Terminal Board of the MD-2 VFD Controller.

IM 959 29

Page 30

Integrated Display Terminal

The LEDs and keys on the integrated display terminal are illustrated in Figure 12 below.

Figure 12: Description of Display Terminal

Table 9: Display Terminal Features

30 IM 959

Page 31

Programming the Drive Controller

This section describes how to access drive controller modes and parameters, and how to configure the drive controller for the

most common applications.

Refer to the Complete List of Parameters and Definitions section starting on page

used in most HVAC applications.

Mode Access

The McQuay drive controller has three modes of operation described in Table 10.

Table 10: Mode Descriptions

Figure 13 illustrates how to access the modes with the MODE key on the keypad display.

Figure 13: Mode Access

37 for a list of drive controller parameters

IM 959 31

Page 32

Parameter Groups

Table 11 describes the drive controller parameter groups. For a complete list of parameters that are generally used for most

HVAC applications, refer to Table 13 on page 35.

For more information on configuring the other basic parameters and the extended parameters, refer to the Commonly Used

Parameters and Definitions section on page 34 of this manual.

Table 11: McQuay Drive Parameter Groups

32 IM 959

Page 33

Access to Menus and Parameters

Figure 14 illustrates how to access menus on the drive display keypad.

Figure 14: Menu Access

IM 959 33

Page 34

Figure 15 illustrates how to access parameters on the drive display keypad.

Figure 15: Access to Parameters

34 IM 959

Page 35

AUF Quick Menu

The drive has a quick menu for easy access to the most commonly used basic and extended parameters.

Figure 16: Quick Menu Parameters

IM 959 35

Page 36

Table 12 describes the parameters that can be accessed from the AUF Quick menu. With the exception of ACC and DEC,

the parameters cannot be modified while the drive controller is running.

Table 12: AUF Quick Menu Parameters

36 IM 959

Page 37

Complete List of Parameters and Definitions

The most commonly used parameters in most HVAC applications are listed in Table 13. The drive has other programmable

parameters that are not listed here. A complete list of parameters and more information about the drive controller is available

in the Schneider Electric Instruction Bulletin #30072-451-63.

Table 13: Complete List of Programming Parameters for Most HVAC Applications

Parameter

Title

AU1 0000

CnOd 0003

FnOd 0004

FnSL 0005

Fn 0006

tyP 0007

IM 959 37

Communication

Address

Function

Automatic

Acceleration/

Deceleration

Command

mode

selection

Frequency

setting mode

selection 1

Meter

selection

Meter

adjustment

Default

setting

Default

Value

0 0 2

0 0 2

2 1 5

0 0 19

145 1 1280 1-1280 steps

2 0 9

Lowest

Value

Highest

Value

Description Notes

0: Disabled (manual)

1: Automatic

2: Automatic (only at

acceleration)

0 : Terminal Board

1: Operation Panel

2: Serial

Communication

1: VIA

2: VIB

3: Operation panel

4: Communication

5: UP/DOWN frequency

0: Output frequency

1: Output current

2: Set frequency

3: DC voltage

4: Output voltage

command value

5: Input power

6: Output power

7: Torque

8: Torque current

9: Motor cumulative

load factor

10: Inverter cumulative

load factor

12: Frequency setting

value (after PID)

13: VIA Input value

14: VIB Input value

15: Fixed output 1

(Output current: 100%)

16: Fixed output 2

(Output current: 50%)

17: Fixed output 3

(Supposition output at

fsl = 17)

18: Serial

communication data

(FA51 = 1000)

19: For adjustments (c

set value is displayed.)

0: - (invalid)

1: 50Hz default setting

2: 60Hz default setting

3: Standard Default

setting (Initialization)

4: Trip record clear

5: Cumulative operation

time clear

6: Initialization of type

information

7: Save user-defined

parameters

8: Call user-defined

parameters

9: Cumulative fan

operation time record

clear

This parameter allows the drive to

automatically adjust acceleration

(ACC) and deceleration (dEC) time in

line with load size. It can be disabled

by setting this parameter to 0.

These parameters are used to specify

which input device takes priority in

entering an operation stop command

or a frequency setting command

(internal potentiometer, VIA, VIB,

operation panel, serial communication

device, external contact up/down).

These parameters are used to specify

which input device takes priority in

entering a frequency setting command

during operation panel, terminal

board, or serial communication

control.

The signal output from the FM

terminal is an analog voltage signal.

This parameter allows you to output a

signal based on any of the 19 options

listed here. For the meter, use either

a full-scale 0-1mAdc ammeter or fullscale 0-7.5Vdc (or 10Vdc-1mA)

voltmeter.

Switching to 0-20mAdc (4-20mAdc)

output current can be made by tuning

the FM (SW2) slide switch to the I

position. When switching to 4-20mAdc

current input, make adjustments using

F691 (analog output gradient) and

F692 (analog output bias).

Adjusts the analog output signal that

is sent out through terminal FM of the

drive. See the Analog Output Section

on page 46 Of this manual for more

details.

Setting this parameter to 3 changes all

parameters back to factory default

values.

Note that Fn, FnsL, F109, F470 –

F473, F669and F880 will not be reset

to their factory default settings.

Page 38

Table 13: Complete List of Programming Parameters for Most HVAC Applications, Continued

Parameter

Title

ACC 0009

DEC 0010

FH 0011

UL 0012

LL 0013

uL 0014

uLu 0409

Pt 0015

ub 0016

*tHr 0600

Communication

Address

Function

Acceleration

time 1

Deceleration

time 1

Maximum

frequency

Upper limit

frequency

Lower limit

frequency

Base

frequency 1

Base

frequency

voltage 1

V/F control

mode

selection 1

Torque boost

1

Motor

electronic-

thermal

protection

level 1

Default

Value

Varies 0 3200 0.0-3200 seconds

Varies 0 3200 0.0-3200 seconds

60 30 200 30.0-200.0 hertz

60 0.5 200 0.5-200.0 hertz

0 0 50 0.0-50.0 hertz

60 25 200 25.0-200.0 hertz

460

208

230

1 0 6

Varies 0 30

Varies 0

Lowest

Value

50

Highest

Value

660

330

drive

rating

Description Notes

Sets the time for the drive to accelerate

from 0 (Hz) frequency to maximum

frequency set by parameter FH.

Sets the time it takes for the drive to

decelerate from maximum frequency set

by parameter FH to 0 (Hz) frequency.

Programs the maximum frequency that

other drive parameters are allowed to

operate in. This parameter is used as the

reference for the acceleration /

deceleration time.

Programs the maximum frequency that the

drive is allowed to operate in. This

parameter's maximum value is limited to

the setting of FH.

Programs the lower limit frequency that

the drive is allowed to operate.

Sets the drive base frequency. This

parameter sets the constant torque control

50-330 volts (200-

240V class)

50-660 volts (400-

480V class)

0: V/f constant

1: Variable torque

2: Automatic

torque boost

control

3: Vector control

4: Energy Saving

5: (Do not select)

6: PM motor

control

0.0-30.0 adjustable

range

0-drive rating

(amperes)

area.

Sets the base frequency voltage of the

drive. This parameter sets the constant

torque control area.

0: This parameter applies to loads that

require the same torque at low speed as at

rated speeds.

1: Select this option when applying the

drive to variable torque loads like

centrifugal fans and pumps

2: This option detects load currents in all

speed ranges and automatically adjusts

voltage output (torque boost) from the

drive.

3: Using this selection with a standard

motor will provide the highest torque at low

speed ranges.

4: This options saves energy in all speed

areas by detecting load current and

flowing the optimal current to fit the load.

6: This feature can be used with

permanent magnet motors (not induction

motors), and can be operated in sensorless operation mode.

This parameter has the ability to increase

the starting torque of the system, however

increasing the torque boost to high can

cause over current trips at startup. This

parameter is generally not changed from

default for HVAC applications.

Ampere ratings for each drive vary by

model. Refer to the drive specifications

section of this manual for information on

drive voltage and ampere ratings.

38 IM 959

Page 39

Table 13: Complete List of Programming Parameters for Most HVAC Applications, Continued

Parameter

Title

OLM 0017

F108 0108

F109 0109

F111 0111

F112 0112

F113 0113

F118 0118

F130 0130

F132 0132

F137 0137

F139 0139

F201 0201

Communication

Address

Function

Electric-

thermal

protection

characteristic

selection

Always-active

function

selection

Analog/conta

ct input

function

selection

(VIA/VIB)

Input terminal

selection1 (F)

Input terminal

selection 2

(R)

Input terminal

selection 3

(RES)

Input terminal

selection 8

(VIA)

Output

terminal

selection 1A

(RY-RC)

Output

terminal

selection 3

(FL)

Output

terminal

selection 1B

(RY-RC)

Output

terminal logic

selection (RY-

RC/OUT-NO)

VIA input

point 1 setting

Default

Value

0 0 7

0 0 71 57 types of settings

0 0 2

2 0 71 57 types of settings

1 0 71 57 types of settings

48 0 71 57 types of settings

7 0 71 57 types of settings

4 0 255

11 0 255

255 0 255

0 0 1

0 0 100 0-100%

Lowest

Value

Highest

Value

Description Notes

0: Standard motor,

overload protection,

non overload stall

1: Standard motor,

overload protection,

overload stall

2: Standard motor,

non overload

protection, non

overload stall

3: Standard motor,

non overload

protection overload

stall

4: Special motor,

overload protection,

non overload stall

5: Special motor,

overload protection,

overload stall

6: Special motor,

non overload

protection, non

overload stall

7: Special motor,

non overload

protection, overload

stall

0: VIA - analog

input

1: VIA - contact

input (sink)

2: VIA - contact

input (source)

59 functions

available

59 functions

available

59 functions

available

0: F130 (primary)

and F137

(secondary)

1: F130 (primary)

or F137

(secondary)

This parameter allows selection of the

appropriate electronic thermal protection

characteristics according to the particular

rating and characteristics of the motor.

See Table 14 on page

options when setting this parameter.

The parameter allows you to choose

between signal input and contact input for

the VIA terminal. When using VIA

terminal as a contact input, slide switch 3

(SW3) to V on the terminal board. A

resistor of 4.7k ohm - 1/2 W should be

used across P24 and VIA when using a

contact input in the sink mode.

See Table 14 on page

of options for setting this parameter.

See Table 14 on page

of options for setting this parameter.

See Table 14 on page

of options for setting this parameter.

See Table 14 on page

of options for setting this parameter.

See Table 15 on page

available functions for setting this

parameter.

See Table 15 on page

available functions for setting this

parameter.

See Table 15 on page

available functions for setting this

parameter.

The RY-RC relay can be configured to

energize when either:

• Both the primary AND secondary

• Or only one OR the other is met (true)

Sets the low limit analog signal input at

VIA according to the frequency that is

programmed through parameter F203.

Refer to the Analog Inputs Section on

page

42, for available

42 for the 57 types

42 for the 57 types

42 for the 57 types

42 for the 57 types

46 for all 59

46 for all 59

46 for all 59

conditions are met (true) (F139=0),

(F139=1).

49 for details.

IM 959 39

Page 40

Table 13: Complete List of Programming Parameters for Most HVAC Applications, Continued

Parameter

Title

F202 0202

F203 0203

F204 0204

F210 0210

F211 0211

F212 0212

F213 0213

F268 0268

F294 0294

F300 0300

F303 0303

F359 0359

F360 0360 PID control 0 0 2

F362 0362

Communication

Address

Function

VIA input

point 1

frequency

VIA input

point 2 setting

VIA input

point 2

frequency

VIB input

point 1 setting

VIB input

point 1

frequency

VIB input

point 2 setting

VIB input

point 2

frequency

Initial value of

UP/DOWN

frequency

Forced-fire

speed setting

frequency

PWM carrier

frequency

Retry

selection

(number of

times)

PID control

waiting time

Proportional

gain

Default

Value

0 0 200 0-200 hertz

100 0 100 0-100%

60 0 200 0-200 hertz

0 0 100 0-100%

0 0 200 0-200 hertz

100 0 100 0-100%

60 0 200 0-200 hertz

0 0 50 0-50 hertz

50 0 50 0-50 hertz

6 6 16 6-16 KHZ

3 0 10

0 0 2400 0-2400 seconds

0.3 0.01 100 0.01-100 unitless

Lowest

Value

Highest

Value

Description Notes

0: Disabled

1-10 Times

0: Disabled

1: Enabled

(Feedback: VIA)

2: Enabled

(Feedback: VIB)

Sets the frequency that the low limit

analog signal input will correspond to

through the VIA terminal. Refer to the

Analog Inputs Section on page

details.

Sets the high limit analog signal input at

VIA according to the frequency that is

programmed through parameter 204.

Refer to the Analog Inputs Section on

page

Sets the frequency that the high limit

analog signal input will correspond to

through the VIA terminal. Refer to the

Analog Inputs Section on page

details.

Sets the low limit analog signal input at

VIB according to the frequency that is

programmed through parameter 203.

Refer to the Analog Inputs Section on

page

Sets the frequency that the low limit

analog signal input will correspond to

through the VIB terminal. Refer to the

Analog Inputs Section on page

details.

Sets the high limit analog signal input at

VIB according to the frequency that is

programmed through parameter 204.

Refer to the Analog Inputs Section on

page

Sets the frequency that the high limit

analog signal input will correspond to

through the VIB terminal. Refer to the

Analog Inputs Section on page

details.

This parameter is used to set an output

frequency by means of a signal from an

external device. This parameter is used

during floating point control when Fnod is

set to 5. See page

This parameter is used to set a speed

reference frequency during an

emergency. It's used when an input

function is set to 54 (FORCE) or 53

(FIRE).

This parameter allows the pulse width

modulation (PWM) carrier frequency to be

increased or decreased. Increasing this

parameter increases the control resolution

of the drive, but de-rates the ambient

temperature rating. Decreasing this

parameter decreases control resolution,

but increases the ambient temperature

rating of the drive.

This parameter resets the inverter

automatically when the inverter gives an

alarm. During the retry mode, the motor

speed search function operates

automatically as required and thus allows

smooth motor restarting.

This parameter sets the amount of time (in

seconds) that the drive will not enter the

PID control mode upon startup of the

drive. During this time period the drive will

accelerate to its speed reference input.

See PID control section on page

details.

This parameter enables feedback control

through either the VIA or VIB input

terminals. See PID control section on

page

signal of 4-20 mA or 0-10 VDC can be

used, or a scaling of these inputs can be

done through parameters F202 - F213.

This parameter adjusts the proportional

gain level during PID control. See PID

control section on page

49 for

49 for details.

49 for

49 for details.

49 for

49 for details.

49 for

56 for details

52 for

52 for details. A default analog input

52 for details.

40 IM 959

Page 41

Table 13: Complete List of Programming Parameters for Most HVAC Applications, Continued

Parameter

Title

F363 0363 Integral gain 0.2 0.01 100 0.01-100 unitless

F366 0366 Differential gain 0 0 2.55 0-2.55 unitless

F415 0415

F417 0417

F605 0605

F608 0608

F650 0650

F701 0701

F800 0800

F801 0801 Parity 1 0 2

F802 0802 Inverter number 1 0 247

F803 0803

F880 0880 Free notes 121 0 65,535 0-65,535 (unitless)

Communicatio

n Address

Function

Motor rated

current

Motor rated

speed

Output phase

failure detection

mode selection

Input phase

failure detection

mode selection

Forced/Fire-

speed control

selection

Current/voltage

display mode

Modbus or TSB

baud rate

Communication

error trip time

Default

Value

Varies 0.1 200 0.1-200 amperes

1430 100 15,000 100-15,000 RPM

3 0 5

1 0 1

0 0 1

1 0 1

1 0 1

3 0 100

Lowest

Value

Highest

Value

Description Notes

This parameter adjusts the integral gain level

during PID control. See PID control section on

page

This parameter adjusts the differential gain level

during PID control. See PID control section on

page

This parameter should be set to the rated

current of the motor. This is usually listed as the

FLA (full load amps) on the motor nameplate or

the motor test report.

This parameter should be set to the motor's

0: Disabled1: At

start-up (only one

time after power is

turned on)2: At start-

up (each time)3:

During operation4:

At start-up + during

operation5:

Detection of cutoff on

output

0: Disabled

1: Enabled

0: Disabled

1: Enabled

0: %

1: A (ampere)/ V

(volt)

0: 9600bps

1: 19200bps

0: NONE (No parity)

1: EVEN (Even

parity)

2: ODD (Odd parity)

1-247 address

number

0: Disabled

1-100 Seconds

rated rotational speed in RPM.

This parameter detects drive output phase

failure. If the phase failure status persists for

one second or more, the tripping function and

the FL relay will be activated. At the same time,

fault EPHO will be shown on the drive display.

This parameter detects drive input phase failure.

If the abnormal voltage status of the main circuit

capacitor persists for a few minutes or more, the

tripping function and the FL relay will be

activated. Therefore, input phase failures

cannot always be detected. A fault of EPH1 will

be shown on the drive display.

This parameter enables or disables the drive to

enter an emergency state through an input

terminal function assigned to type 52 (FORCE)

or type 53 (FIRE) functions. The frequency

setting when the drive enters this state is set by

parameter F294. For details see page

This parameter is used to switch between a

percentage or volt/ ampere read out on the

keypad display for certain parameters.

This parameter allows the baud rate to be

established through a data communication

network for exchanging data between a host

computer or controller and the drive by

connecting an internal RS485 communication

function or optional USB communication

conversion unit.

The data transfer speed, parity type, drive

controller number, and communication error trip

time can be set/edited by the operation panel or

communication function.

This parameter is used to set the communication

address for the drive when used with a

communication protocol.