Page 1

The #1 Source for Donut and Bakery Equipment www.belshaw.com

OPERATOR’S MANUAL

TECHNICAL SUP

PLEMENT

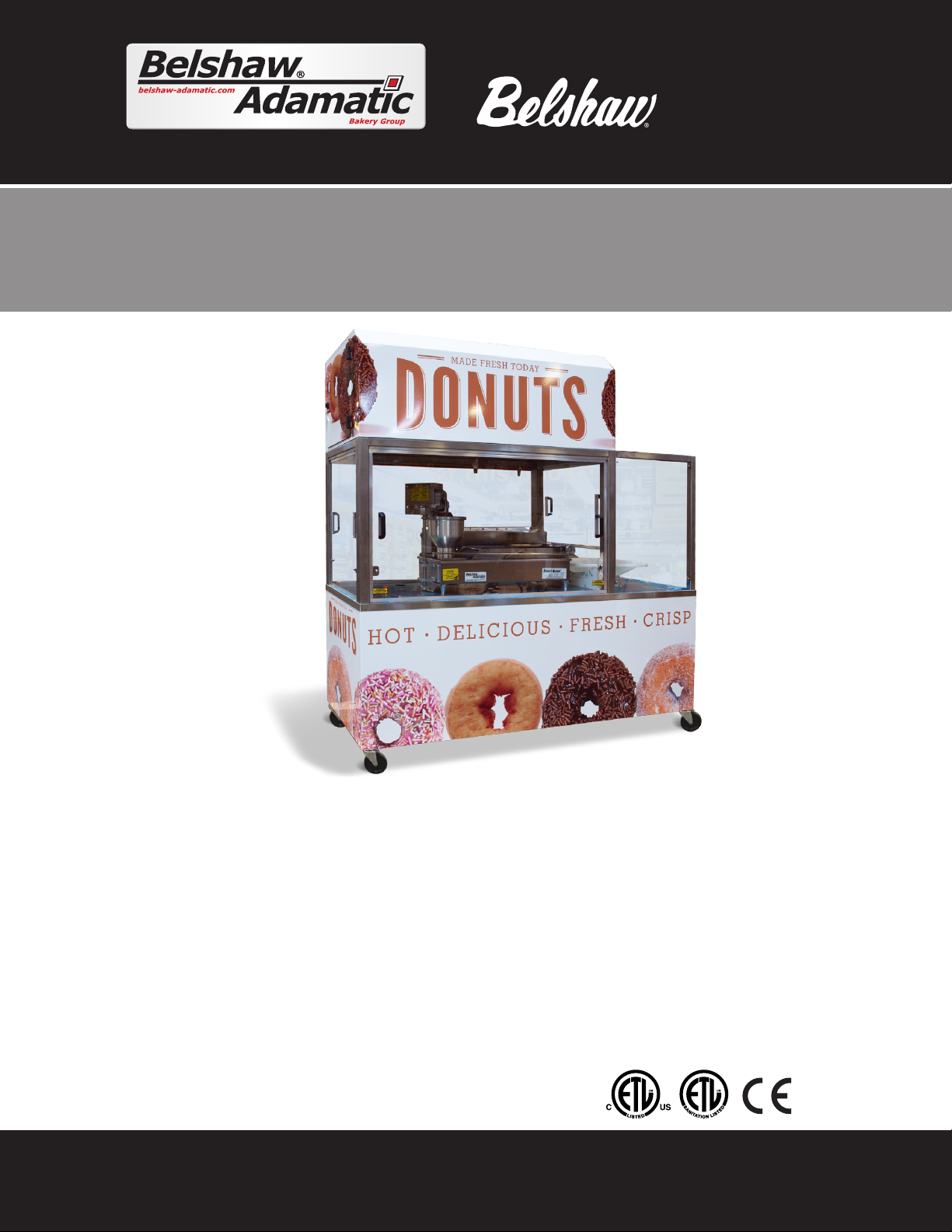

Ventless Donut Center

This manual should only be used with the Item Numbers shown above.

SUPPORT

Insider

USA/Canada 1-800-578-2547

International (+1) 206-322-5474

Email service@belshaw.com

Web www.belshaw.com

Page 2

Belshaw Bros., Inc • 814 44th Street NW, Suite 103 • Auburn, WA 98001 • USA

Tel: 206-322-5474 • Fax: 206-322-5425 • www.belshaw.com

INFORMATION FOR CUSTOMERS

AND APPROVAL AUTHORITIES

INSIDER

DONUT FRYING SYSTEM

COMMERCIAL ELECTRIC COOKING APPLIANCE

WITH INTEGRAL RECIRCULATING SYSTEM

INSTALLATION REQUIREMENTS

• INSIDER SPECIFICATION SHEET

• FIRE SUPPRESSION DESCRIPTION

• INSTALLATION INFORMATION

• STANDARDS & LISTINGS – ETL/UL/NFPA

• ETL/UL LABELS

• PYRO-CHEM DATA SHEET

COMPLETE INSTALLATION PROCEDURES ARE LISTED IN THE

INSIDER INSTALLATION, OPERATORS AND MAINTENANCE MANUAL

Page 3

Page 4

Type INSIDER Ventless Donut Center

The Insider is Belshaw’s distinctive donut frying system

that eliminates the need for a standard exhaust hood.

With its ability to operate indoors, the Insider offers unique

benefits:

The Insider can be easily moved from one place to

•

another. The exhaust hood is built-in and there is no

exterior ductwork.

Customers in high traffic areas can watch the Insider

•

frying donuts automatically. The operator has only to mix

batter, fill the Donut Robot® hopper and bag donuts from

the Roto-Cooler, a rotating tray that collects the donuts

automatically.

The Insider eliminates the purchase and installation cost

•

of standard ventilation and fire suppression hoods.

The Insider is designed to attract the interest of

•

passers-by. With its large window viewing area and

attractive appearance the Insider has great merchandising

potential. Vehicle-style graphic wraps can easily be

applied to top, bottom and side panels.

The Insider addresses fire prevention, air filtration, and

•

sanitation requirements. Cabinet and fryers are tested by

ETL and listed to UL-197, UL-710B, CSA C22.2 and NSF-4

standards.

Models

INSIDER/Mark II • INSIDER/Mark V

VIDEO: https://vimeo.com/belshaw/insider

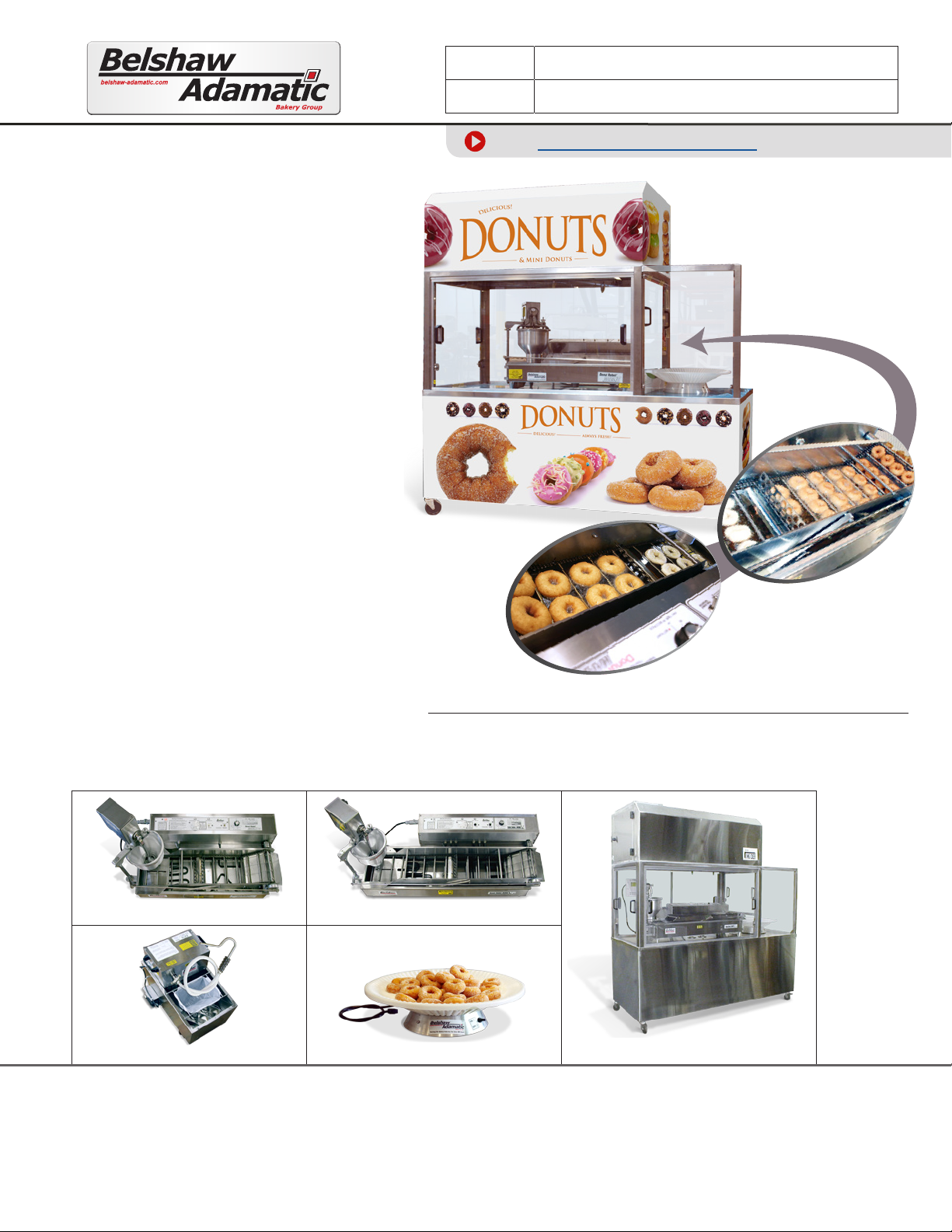

COMPONENTS OF INSIDER DONUT SYSTEM

Insider Clean-Air Cabinet

•

Donut Robot® Fryer, either:

•

- Mark II

- Mark II GP (mini donut model)

- Mark V

- Mark V GP (mini donut model)

EZMelt 18 Melter-Filter.

•

- The EZMelt can be placed inside the cabinet directly

below the fryer. It will quickly empty, filter and refill the

shortening in the fryer.

Roto-Cooler.

•

- Rotating tray that collects donuts after frying.

Donut Robot® Mark II / Mark II GP Donut Robot® Mark V / Mark V GP

Photo shows Insider with Donut Robot® and Roto-Cooler with sample graphic wrap.

Inset shows Mark II and Mark V GP. The Insider accepts either Mark II • Mark II GP • Mark V • Mark V GP

EZ Melt 18 Roto-Cooler Insider / Mark V (without graphic wrap)

90 Years of Quality Donut & Bakery Equipment

BELSHAW ADAMATIC BAKERY GROUP

814 44th St NW, Suite 103

Auburn, WA 98001 USA

PART OF ALI GROUP S.P.A.

CONTACT

800.578.2547 (USA/Canada)

(+1) 206.322.5474 Worldwide

info@belshaw.com

© 2015 Current version available at www.belshaw-adamatic.com

WEB

www.belshaw.com

Page 1 of 2

Page 5

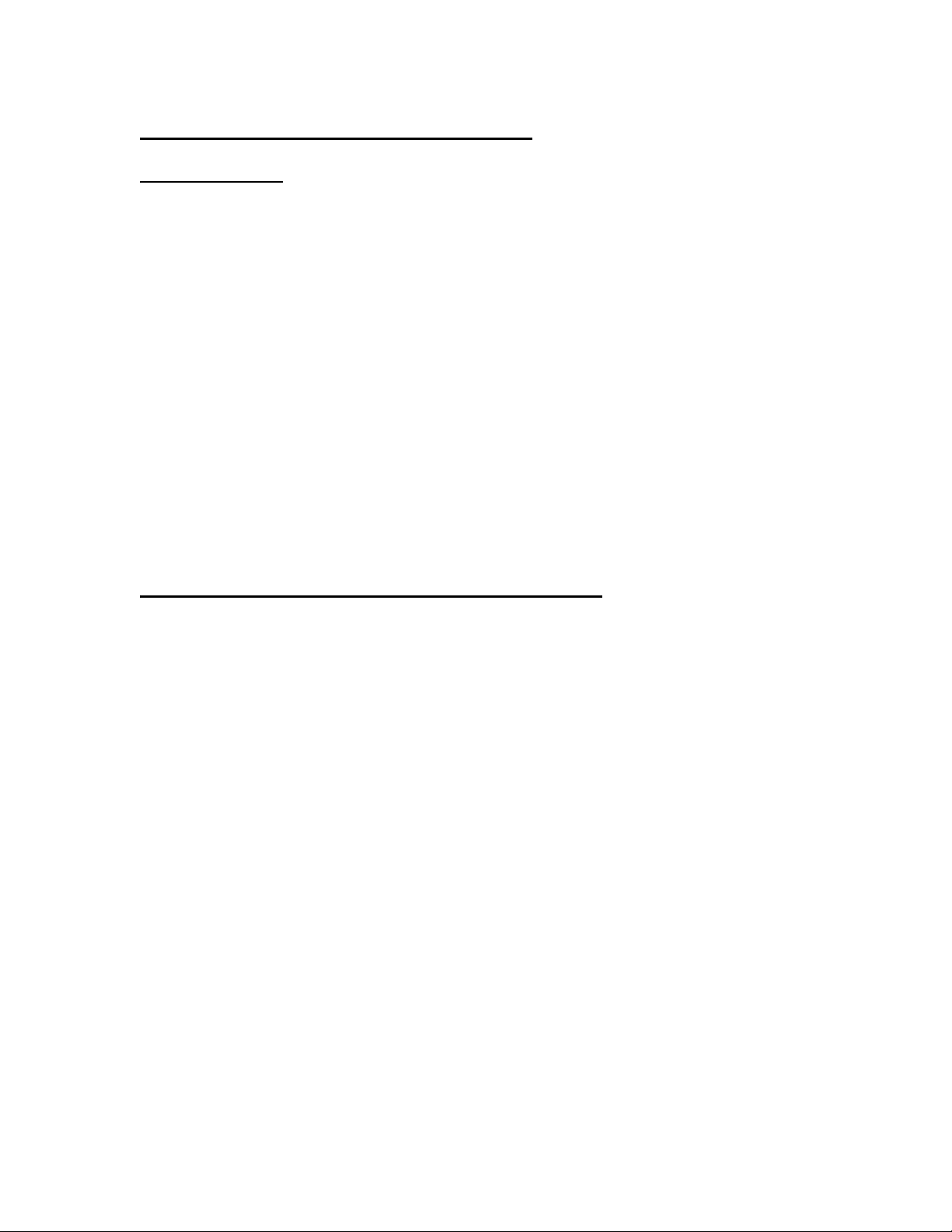

Type INSIDER Ventless Donut Center

Models INSIDER/Mark II • INSIDER/Mark V

84" (213 cm)

Clearance 36" (92 cm)

for operator

DONUT ROBOT

ROTO COOLER

FIRE SUPPRESSION

MANUAL PULL STATION

WET FIRE

SUPPRESSION

CYLINDER

6.5" (16 cm)

FIRE SUPPRESSION

CONTROL BOX

EZMELT 18

MELTER FILTER

POWER

P

OVERALL HEIGHT:

91.5" (232 cm)

35" (89 cm)

PLUG NEMA #14-50 (1-PHASE)

STANDARD FEATURES - INSIDER CABINET

Air recycling system, with fan-assisted grease filter, electronic filter, and odor

•

filters

Interlock system to ensure ventilation is active. Fryer is otherwise shut down or

•

unable to start

Donut Robot® fryer (specify model from list below) and Roto-Cooler

•

Fire suppression system (Pyro-Chem Kitchen Knight II, PLC-240/300).

•

Operates automatically, also manually from a pull station

Stainless steel construction

•

Removable clear polycarbonate viewing windows

•

Heavy Duty 4" casters (feet optional)

•

COMPATIBILITY WITH DONUT ROBOT® FRYERS

Insider is compatible only with Donut Robot® Mark II, Mark II GP, Mark V, or Mark

V GP

For standard size donuts, use Donut Robot® Mark II or Mark V

•

For mini donuts, use Donut Robot® Mark II GP or Mark V GP

•

To make standard size AND mini donuts, use Donut Robot® Mark II or Mark V,

•

along with Mini Donut Hopper/Plunger Kit, Part #MK-1502-1

See Donut Robot Mark II/Mark V spec sheet for specifications

•

Insider is not compatible with Donut Robot® Gas Mark II/Mark II GP

•

DONUT ROBOT® FRYERS – CAPACITY ESTIMATES

Standard Donuts Mini Donuts

Mark II

Mark II GP –

Mark II with Minidonut Kit

Mark V

Mark V GP –

Mark V with Minidonut Kit

Estimates are based on full capacity at frying times of 95 seconds for standard donuts

and 60 seconds for mini donuts.

37 Dozen/hour –

153 Dozen/hour

37 Dozen/hour 109 Dozen/hour

56 Dozen/hour –

226 Dozen/hour

56 Dozen/hour 163 Dozen/hour

AIR DISCHARGE

HOOD/CLEAN AIR ASSEMBLY

STOP/START SWITCH

FILTRATION RECEPTACLE

FRYER RECEPTACLE

12" (30 cm)

POWER CORD 72" (183 cm)

NEMA #6-50P (3-PHASE)

OTHER EQUIPMENT

EZ Melt 18 melter-filter system (purchased separately)

•

ELECTRICAL INFORMATION

Single power connection.

•

208-240V, 50/60hz, 1ph

•

- Insider with Donut Robot® Mark II/Mark II GP: up to 36 Amps

- Insider with Donut Robot

North America models supplied with NEMA#14-50 plug

•

Contact factory for 3-phase and international voltage options

•

INSTALLATION

Installation and usage may require approval by local jurisdictions.

(Customer is responsible for such approval)

Clearance

36" (92 cm) space at rear to allow room for operator, and to

•

allow EZMelt 18 Melter Filter to roll out

36" (92 cm) at left side (viewed from rear) for operator access

•

to the left and rear of the unit

18" (45 cm) overhead clearance for air discharge (nominal)

•

SHIPPING WEIGHT AND DIMENSIONS (estimated)

90" W x 43" D x 89" H (228 x 109 x 226 cm)

•

1400 lbs (636 kg)

•

STANDARDS CERTIFICATION

UL197

UL710B

Certified by ETL to UL-197, UL-710B, NSF-4 and CSA C22.2

•

standards. (ETL Control #68183)

CE models available for European Union and other countries

•

NSF STD 4

CSA C22.2

Nominal clearance

for air discharge

Clearance 36" (92 cm)

for operator

REAR

POWER

31" (79 cm)

®

Mark V/Mark V GP: up to 50 Amps

18" (45 cm)

FRONT

P

90 Years of Quality Donut & Bakery Equipment

BELSHAW ADAMATIC BAKERY GROUP

814 44th St NW, Suite 103

Auburn, WA 98001 USA

PART OF ALI GROUP S.P.A.

CONTACT

800.578.2547 (USA/Canada)

(+1) 206.322.5474 Worldwide

info@belshaw.com

© 2015 Current version available at www.belshaw-adamatic.com

WEB

www.belshaw-adamatic.com

Page 2 of 2

Page 6

Belshaw Bros., Inc • 814 44th Street NW, Suite 103 • Auburn, WA 98001 • USA

Tel: 206-322-5474 • Fax: 206-322-5425 • www.belshaw.com

Insider

The Belshaw’s Insider (Donut Frying System) comprehensively addresses all fire

prevention, clean air, sanitation and electrical requirements and the self-contained

unit meets or exceeds local standards. The Insider houses Donut Robot® Mark II or

Mark V Fryers; and is UL197 Listed under ETL #68183.

• Tested to UL197 standards for Commercial Electric Cooking Appliances with

Recirculating Systems and Listed under ETL #68183.

• Intended for installation and use to NFPA-96 Standard For Ventilation Control and Fire

Protection of Commercial Cooking Operations.

Fire Prevention/ Suppression System

The Insider uses the Pyro-Chem Restaurant Fire Suppression System. It is a pre-engineered

type as defined by NFPA-17A Standard for Wet Chemical Extinguishing Systems and is

designed to provide fire protection for restaurant cooking appliances, hoods, and ducts.

The Pyro-Chem System (PLC-240/300 KITCHEN KNIGHT II) utilizes a wet chemical agent

specifically designed to suppress restaurant-cooking fires. The system provides automatic

actuation and can be manually actuated through a remote mechanical pull station. Upon

actuation, the system discharges a pre-determined amount of agent to the duct, plenum, and

cooking appliances. The agent acts to suppress fires in 3 ways:

• Both the agent itself and the resulting steam formation interrupt the chemical chain

reaction causing combustion.

• The agent cools the fire bringing it below auto-ignition temperature.

• The agent reacts with hot grease forming a soap-like layer (saponification) that helps

prevent the escape of combustible vapors, thus preventing re-ignition.

The Pyro-Chem Restaurant Fire Suppression System has been tested to the UL Standard for

Fire Extinguishing Systems For Protection of Restaurant Cooking Areas, UL300 and PyroChem listed by Underwriters Laboratories, Inc. under ULC/ORD-C1254.6-1995 listing meets

Underwriters Laboratories of Canada’s standards.

Page 7

Clean Air- Ozone and Emissions

The Insider meets the emission requirements of 5.0mg/m3 as measured at the exhaust outlet

of the system per the requirements of the U.S. Environmental Protection Agency (EPA) Test

Method 202, Determination of Condensable Particulate Emissions from Stationary Sources,

which is referenced in NFPA-96 (Test results 1.81 mg/m3) UL File E213302.

Underwriters Laboratories also tested it at well below the maximum ozone levels permitted of

0.1ppm time-weighted average with a maximum peak concentration of 0.3ppm (Test results

less than 0.015 ppm).

Sanitation

The Insider is built in accordance with NSF International Standard No. 4, for commercial

cooking and hot food storage equipment and conforms to ANSI/NSF STD 4 (ETL Listing

#68183).

The fryer portion, Donut Robot Mark II, Mark V, or the Mark IX, is separately ETL

Classified in accordance with NSF International Standard No. 4. One of the above models is

used in each Insider:

Materials employed have been found to be able to withstand normal wear, penetration of

vermin, corrosive action of foods, cleaning products, and other elements in the end use

environment. The materials do not impart an odor, color, taste, or toxic material to food

products.

Electrical

The Insider and the Mark Donut Robots are also listed as Commercial Cooking Appliances,

in accordance with UL 197, and they are in compliance with electrical code ANSI/NFPA 70

the Standard for Commercial Electric Cooking Appliances and conforms to ANSI/UL STD

197 Certified to CAN/CSA C22.2 STD No. 109 (ETL Listing #68183).

Ventilation and Recirculating Systems

The Insider is tested by ETL to conform to UL710B standard for recirculation systems, as

detailed below.

1.1 These requirements cover the following recirculating systems rated 600 volts or

less and intended for indoor use:

a) Non-integral recirculating systems for installation in commercial

establishments for the preparation of food;

Page 8

b) Electric commercial cooking appliances provided with integral recirculating

systems intended for installation in commercial establishments for the preparation

of food; and

c) Vending machines provided with integral recirculating systems.

1.2 These devices incorporate an air filtering system enclosed in a hooded or

otherwise contained area intended to capture air from the cooking process area. The

hood assembly typically includes a fan, collection hood, or equivalent design and an

air filtering system (consisting of a grease filter with or without other filtering

means). In addition, except as noted in the Exceptions to 37.1 and 38.1, the hood

assembly includes a fire actuated damper, and a fire extinguishing system.

1.3 Recirculating systems covered by these requirements are intended for installation

in accordance with:

a) The Standard for Ventilation Control and Fire Protection of Commercial

Cooking Operations, NFPA 96;

b) The National Electrical Code, ANSI/NFPA 70; and

c) Other codes such as the International Mechanical Code (IMC), and the

Uniform Mechanical Code (UMC).

1.4 Integral recirculating systems shall comply with the requirements for the cooking

appliance as noted below, except as modified or superseded by the requirements in

this Standard.

a) Commercial electric cooking appliances shall comply with the requirements in

the Standard for Commercial Electric Cooking Appliances, UL 197.

b) Vending machines shall comply with the requirements in the Standard for

Vending Machines, UL 751.

International Mechanical Code (IMC)

507.1 General.

Commercial kitchen exhaust hoods shall comply with the requirements of this

section. Hoods shall be Type I or II and shall be designed to capture and confine

cooking vapors and residues. Commercial kitchen exhaust hood systems shall operate

during the cooking operation.

Exceptions:

Page 9

1. Factory-built commercial exhaust hoods that are listed and labeled in

IFICATION

OCCUPANT

PEOPLE

CFM/PERSON

BREATHING

EXHAUST

AIRFLOW

Food and beverage

service

Bars, cocktail

lounges

Cafeteria, fast food

100

7.5

0.18

—

Dining rooms

70

7.5

0.18

—

Kitchens (cooking)b

—

—

—

0.7

accordance with UL 710, and installed in accordance with Section 304.1 shall not

be required to comply with Sections 507.4, 507.5, 507.7, 507.11, 507.12, 507.13,

507.14, and 507.15.

2. Factory-built commercial cooking recirculating systems that are listed and

labeled in accordance with UL 710B, and installed in accordance with Section

304.1 shall not be required to comply with Sections 507.4, 507.5, 507.7, 507.11,

507.12, 507.13, 507.14, and 507.15. Spaces in which such systems are located

shall be considered to be kitchens and shall be ventilated in accordance with

Table 403.3. For the purpose of determining the floor area required to be

ventilated, each individual appliance shall be considered as occupying not less

than 100 square feet (9.3 m2).

3. Net exhaust volumes for hoods shall be permitted to be reduced during partload cooking conditions, where engineered or listed multispeed or variable-speed

controls automatically operate the exhaust system to maintain capture and

removal of cooking effluents as required by this section. Reduced volumes shall

not be below that required to maintain capture and removal of effluents from the

idle cooking appliances that are operating in a standby mode.

TABLE 403.3 MINIMUM VENTILATION RATES

OCCUPANCY

CLASS

AREA

OUTDOOR

AIRFLOW

RATE IN

ZONE,

Ra CFM/FT2a

DENSITY

#/1000 FT2a

OUTDOOR

AIRFLOW

RATE IN

BREATHING

ZONE,

Rp

100 7.5 0.18 —

RATE

CFM/FT

2a

Page 10

Insider Installation Requirements

INSTALLATION must be done by certified personnel acceptable to the authority

having jurisdiction and they shall inspect and test the Insider. A test of the safety

interlocks, control head and manual pull station may be performed and a trip test and

dry pressure test may also be required at installation.

The charging and setup of the Pyro-Chem PLC-240/300 Fire Suppression System must

be done by certified personnel and the use and maintenance of the Insider is to be in

accordance with NFPA-96.

The manufacturer’s instructions for “System Checkout after Installation” is on page 17

of the Insider Installation, Operators and Maintenance Manual.

After testing, the Fire Suppression System will need to be activated by screwing the

carbon dioxide pilot cartridge into the actuator, removing the control head safety pull pin,

replacing the control head cover and removing the Fire Damper Safety Pin.

A signed and dated log of installation and maintenance must be kept on premises for use

by authority having jurisdiction.

ETL/UL/NFPA - Standards And Listings

• UL197SB/UL710B (KNKG7) - Standard for Commercial Electrical Cooking

Appliances with Integral Recirculating Systems and Listed under ETL #68183,

Conforms to ANSI/UL STD 197, certified to CAN/CSA C22.2 STD No. 109

• NSF 4 –Commercial Cooking, Rethermalization and Powered Hot Food Holding

and Transport Equipment and Listed under ETL #68183, conforms to

ANSI/NSF4-2002e.

• NFPA-96 - used in accordance with Standard For Ventilation Control and Fire

Protection of Commercial Cooking Operations.

• NFPA-17A - the Insider uses the pre-engineered Pyro-Chem Restaurant Fire

Suppression System (PLC-240/300 Kitchen Knight II).

• UL300 - Standard For Fire Extinguishing Systems For Protection of Restaurant

Cooking Areas and Pyro-Chem Listed under ULC/ORD-C1254.6-1995.

• ANSI/NFPA 70 - Electrical Code – used in accordance with Standard for

Commercial Electric Cooking Appliances.

Page 11

LOCAL PERMITS and approval by the Fire Marshal may be required. The Insider is a

UL Listed portable plug in appliance (single) and is not a fixture. It is a portable

appliance for use in noncombustible surroundings.

MODIFICATIONS AND CHANGES will invalidate the ETL Listing of this appliance.

The Insider has been fire tested by UL/ETL, as a stand-alone appliance, and is not subject

to change. The ETL Listing does not allow it to be hardwired or permanently attached to

the building structure. The Remote Manual Pull Station must remain on the Insider as

UL/ETL Listed and Tested. The Fire Suppression System shuts down all electrical

circuits during a fire. An auxiliary circuit or permanent connection to the building alarm

system is not a part of this ETL Listing.

ETL/UL Certification Labels

Page 12

Pyro-Chem Data Sheet

Page 13

Page 14

Insider

With Air Filtration Hood and Fire

Extinguishing System

Operator's Manual

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 15

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

shipping, file a freight claim with the shipping

company immediately.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

021208

MN-1852EN

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 16

Contents

1 Operation 1

Startup/Run 1

Shutdown 1

In Case of Fire 2

2 Cleaning 3

Cleaning 3

Hand Washing Instructions 4

Automatic Dishwasher Instructions 4

Cleaning Windows & Sliding Doors 5

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider OM MN-1852EN iii

Page 17

Preface

The Insider is designed to hold and power the

Belshaw Mark II, V, or IX Fryer and is provided

with an air filtration and fire extinguishing

system. It is not designed for any other purpose.

The operator must work safely at all times, read

included manuals, and follow all instructions and

warnings. A thorough understanding of how to

install, maintain, and safely operate the Insider

will prevent production delays and injuries.

To use the Insider safely, heed the following

warnings and all other warnings that appear in

this manual:

WARNING

THE CHARGING & SETUP OF THE PYRO-

CHEM PLC-240/300 FIRE SUPPRESSION

SYSTEM MUST BE DONE BY CERTIFIED

PERSONNEL ON A REGULAR BASIS

AND THE USE AND MAINTAINENCE OF

THE INSIDER IS TO BE IN ACCORDANCE

WITH NFPA-96.

• Be careful never to get shortening, water,

or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

• To prevent unintentional startup and

possible fire, unplug the machine if there

is a local power outage. When the

power is restored, it is safe to plug the

machine in again.

• To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

• Make sure that all electrical cords are

routed so that no one will trip over them.

• The Insider is “Intended for use in

noncombustible surroundings only.”

• To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1852EN Insider OM

Page 18

1 Operation

Startup/Run

1. Make sure all filters are properly installed

and all doors are closed.

2. Check the fire suppression cylinder gauge

for the proper range of pressure and the red

control box indicator for the set mode.

CAUTION

Do not operate the Insider if gauge

pressure is low or set mode is not

displayed. The fire suppression system

will not operate.

3. Plug the Mark II, V, or IX Fryer power cord

into the receptacle labeled “Fryer” on the

electrical box. The large hole in the counter

top is for the power cord of the fryer.

CAUTION

Do not operate the Insider with

polycarbonate windows or doors

removed or open. Fire suppression

system will cause hot shortening to

splatter causing serious injury and

burns.

4. Turn on the fryer, Insider and auxiliary

circuit breakers.

II, V, or IX Fryer manual for information on

fryer and cutter operation).

8. After charging and setup by certified

personnel, the fire suppression system is

always operational.

9. Note: If manual operation of the fire

suppression system is required, the system

can be actuated by pulling the handle

straight out. The manual actuator is located

to the right of the red fire suppression

cylinder.

Shutdown

1. Pushing the "Stop" button shuts off all

power to the unit, including fryer.

2. Opening the hood doors, removing a filter or

operation of the fire suppression system will

shutdown the Insider.

3. The unit will not restart if the fire

suppression system has been operated.

Recharging and setup by certified personnel

will be required.

4. After shutdown disconnect power and let

shortening cool to 100° F/38° C before

disassembling or cleaning fryer. Refer to

Mark II, V, or IX manual for instructions.

WARNING

5. Plug the Insider main power plug into the

customer supplied power receptacle.

6. Push the green "Start" button to energize the

unit. Hold the “Start” button in for a few

seconds while the proper airflow is attained.

7. The system must be on to provide power to

the air filtration system, overhead lights,

auxiliary outlet, fryer and cutter. (See Mark

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider OM MN-1852EN 1

Electrical Shock Hazard. Have power off

and disconnected at source before doing

any cleaning or maintenance.

Page 19

In Case of Fire

Fires can potentially start in the fryer, the hood,

or the duct. In case of fire, it is important that

you fully understand the operation of your fire

suppression system.

1. Evacuate all personnel and customers from

the fire area.

2. If your fire suppression system has not

already automatically activated, you may

activate it manually by pulling the handle on

the silver manual pull station, located at the

back of the Insider to the right of the red fire

suppression cylinder.

3. Call the Fire Department.

4. Personnel trained in the proper operation of

hand portable extinguishers may stand by if

means of easy exit are available.

When the fire has been extinguished, call your

local authorized Pyro-Chem distributor to

recharge the system, after determining the cause

of fire. Under no circumstances should cooking

operations be attempted before qualified

personnel re-instate the integrity of your fire

suppression system.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1852EN Insider OM

Page 20

2 Cleaning

Cleaning

WARNING

Thoroughly clean and dry floor if

shortening, water, or other materials are

spilled. If spillage is not cleaned and

dried there will be danger of serious

injury or loss of life.

WARNING

Do not use flammable solvents or other

flammable cleaning aids for cleaning.

WARNING

Do not apply cleaning chemicals on

fusible links or other detection devices of

the automatic fire suppression system.

Hood, cabinet, counter top, fans, ducts, and other

surfaces should be cleaned to bare metal at

frequent intervals or a minimum of every 3

months, before they become heavily

contaminated with grease or oily sludge. They

should be inspected at least once every month.

If a vent cleaning service is used, a certificate

showing date of inspection or cleaning should be

maintained on the premises.

A certified person acceptable to the authority

having jurisdiction shall inspect the entire

system.

IMPORTANT

A signed and dated log of maintenance

must be kept on premises for use by

authority having jurisdiction.

WARNING

Handle the air cleaner cell carefully to

avoid damage.

The pre-filter, and grease filter should be

cleaned daily. The air cleaner cell should be

washed weekly. The doors on the hood

provide access to the air cleaner cell and prefilter (see Illustration A).

Replacement filters

Qty. Part No. Description

1 H200-002 Primary Grease Filter

1 I-0123 Pre-Filter

1 IN-0526 Air Cleaner Cell

1 I-0181 Air Baffle

2 I-0068 Carbon Filter

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider OM MN-1852EN 3

Page 21

Illustration A

Note: See section 3, on page 20 for air

cleaner cell maintenance and washing

instructions.

until the water draining from the cell, prefilter and grease filter no longer feels

slippery.

Automatic Dishwasher

Instructions

1. Put the air cleaner cell on the lower rack of

the dishwasher with the airflow arrow

pointing up. It maybe necessary to remove

the upper rack. Don't block water flow to

the upper arm, if provided on your

dishwasher.

2. If you are washing the pre-filter and grease

filter with the cell, place them where they

won't block the water from the electronic

cell.

Hand Washing Instructions

Note: Always wash the air cleaner cell first,

then the pre-filters. This will help keep heavy

lint on the pre-filter from getting caught in the

cells.

Wash the cell and filters as follows:

1. Use a container large enough to hold the air

cleaner cell, such as a laundry tub or trash

container.

2. Dissolve about 3/4 cup of automatic

dishwasher detergent in enough hot water to

cover the cell. If the detergent doesn't

dissolve readily, or forms a scum on the

water, try another brand, or use softened

water.

3. After the detergent has completely

dissolved, place the cell in the container and

let soak for 15-20 minutes. Agitate up and

down a few times, and remove.

4. Next, wash the pre-filter and grease filter the

same way. Empty and rinse the wash

container.

5. Rinse the cell, pre-filters and grease filter

with a hard spray of very hot water, rinse the

tub clean, and then fill the tub with clean hot

water and soak for 5 to 15 minutes. Rinse

3. Using the detergent that works best for

normal dishwashing, allow the dishwasher to

run through the complete wash and rinse

cycle. Do not use the dry cycle. To avoid

burns, wear protective gloves when

removing the cell, or let it cool first.

Remember that water maybe trapped in the

tubes supporting the collector plates. Tip the

cell so these tubes can drain.

4. Inspect the dishwasher. You may wish to

rerun the wash and/ or rinse cycle with the

dishwasher empty if you see dirt or residue

from washing the cell. If dirt or residue

seems excessive, wash the cell more often or

try a different detergent.

WARNING

Allow the cell to cool or wear protective

gloves to avoid burns. Hot water may

accumulate in the tubes supporting the

collector plates. Tip the cells so these

tubes will drain.

5. Wipe the ionizer wires and red contact board

with a clean cloth.

6. Reinstall the filters and air cleaner cell.

Note: A snapping sound may be heard when the

cell is reinstalled after washing. This is caused

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1852EN Insider

Page 22

by arcing do to water remaining in the cell. This

will cause no harm and the sound will quit when

the cell has dried

Cleaning Windows &

Sliding Doors

1. Use a mild liquid dishwashing soap and a

soft cloth or sponge.

2. Dry with soft cloth.

WARNING

Polycarbonate will mark easily, be very

careful while handling. DO NOT use any

solvents or cleaning chemicals

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider OM MN-1852EN 5

Page 23

Page 24

Insider

With Air Filtration Hood and Fire

Extinguishing System

Technical Supplement

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 25

Page 26

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

To unpack the Insider and transport it to the

workstation:

1. Use a forklift or a pallet jack to move the

shipping crate to the workstation.

2. Remove the machine from the shipping

crate, being careful not to lose or damage

any of the parts.

3. Remove all packing materials from the

machine.

shipping, file a freight claim with the shipping

company immediately.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

021208

MN-1853EN

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 27

Page 28

Contents

1 Installation 1

Unpacking the Insider 1

Initial Cleaning 1

Replacement Air 1

Required Placement 1

Insider Assembly 2

Fire Suppression System 4

Fire Damper System 4

Arming the Fire Damper 5

2 Maintenance 6

“Quick Check” Inspections 6

Use and Maintenance 6

Fire Suppression System 6

Fire Damper System 13

Carbon Filters 14

Electronic Air Cleaner 14

3 Troubleshooting 15

Troubleshooting 15

1 Insider will not run 16

2 Insider will not stay running 16

3 Electronic Air Cleaner – Troublechart 18

4 Electronic Air Cleaner Symptoms and Corrections 18

5 Electronic Air Cleaner Electrical Problems 19

4 Pyro Chem 23

In Case of Fire 24

5 Appendix 26

Pyro Chem (Kitchen Knight) Owners Manual Insert

Parts List Drawing Insert Page Insert

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN iii

Page 29

Preface

The Insider is designed to hold and power the

Belshaw Mark II, V, or IX Fryer and is provided

with an air filtration and fire extinguishing

system. It is not designed for any other purpose.

The operator must work safely at all times, read

included manuals, and follow all instructions and

warnings. A thorough understanding of how to

install, maintain, and safely operate the Insider

will prevent production delays and injuries.

To use the Insider safely, heed the following

warnings and all other warnings that appear in

this manual:

WARNING

THE CHARGING & SETUP OF THE PYRO-

CHEM PLC-240/300 FIRE SUPPRESSION

SYSTEM MUST BE DONE BY CERTIFIED

PERSONNEL ON A REGULAR BASIS

AND THE USE AND MAINTAINENCE OF

THE INSIDER IS TO BE IN ACCORDANCE

WITH NFPA-96.

• Be careful never to get shortening, water,

or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

• To prevent unintentional startup and

possible fire, unplug the machine if there

is a local power outage. When the

power is restored, it is safe to plug the

machine in again.

• To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

• Make sure that all electrical cords are

routed so that no one will trip over them.

• The Insider is “Intended for use in

noncombustible surroundings only.”

• To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1853EN Insider TS

Page 30

1 Installation

Unpacking the Insider

Use a forklift to transport the shipping crate to

the workstation.

• Break down the shipping crate.

• Remove the packing materials from the

Insider, including foam, tape, brown paper,

plastic, and white protective coating. Do not

remove the plastic from the Plexiglas doors at

this time.

• Inspect the machine to see that no parts are

bent, scratched, or otherwise damaged. If any

damage has occurred in shipping, file a

freight claim with the shipping company

immediately.

• Mail the attached warranty registration form

within ten days of installation.

• Keep this manual for future reference. Put it

where you know you can find it.

NOTICE

”IN CASE OF FIRE”

Instructions for manually operating the

fire suppression system are posted

conspicuously on the insider hood and

should be reviewed periodically with

employees by the management. Only

persons properly trained and qualified to

install the specific system being provided

must make installation and charging of

systems. The installer must certify to the

authority having jurisdiction that the

installation is in complete agreement with

the terms of the listing and the

manufacture instructions and/or

approved design.

WARNING

Initial Cleaning

Remove all the packing materials. Wipe the

Insider with a soft, damp cloth. Dry these areas

completely.

WARNING

To avoid electrocution or other injury,

turn off the machine’s main power before

attempting any cleaning, disassembly,

adjustment, or repair.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 1

Always dry floor after washing equipment

Replacement Air

Replacement air quantity must be adequate to

prevent negative pressures in the commercial

cooking area(s) from exceeding 0.02-inch water

column (4.98 Pa).

Required Placement

When the Mark II, V, or IX Fryer is installed in

the insider cabinet. It must be located on the

lineup pins to provide the proper placement.

Page 31

WARNING

The Insider is “intended for use in

noncombustible surroundings only.”

WARNING

Electrical shock hazard. Have power off

and disconnected at source before

making connections.

Insider Assembly

WARNING

DO NOT connect the insider to power

until all assembly has been completed

and the fire suppression system has

been set up and checked by certified

personnel.

Note: Some of the following items may be

shipped installed. See illustrations A & B for

Insider assembly.

1. Unpack and setup the Mark II, V, or IX

Fryer per instructions in the operator’s

manual.

2. Install the Insider cabinet legs to the

threaded holes in the bottom four corners of

the frame. Level the cabinet by screwing the

four legs all the way in and then unscrewing

individual legs as required to level the

counter top.

3. Lift the Mark II, V, or IX Fryer assembly on

the cabinet top and place over the locating

pins. This properly locates the fryer under

the fire suppression nozzles.

4. Remove the protective paper and the vinyl

from the sheet metal, windows and doors.

5. Install the lower back door track by

dropping it over the two locking tabs in the

lower door opening.

6. Install the poly-carbonate windows by

inserting them in the upper channel and

sliding them over the two locking pins.

7. The two back sliding doors are installed by

lifting them into the door runners.

8. Install the grease trap under the hood and

install the primary grease filter by turning

sideways and up through the large opening

under the hood. Locate the filter between

the angle guides and against the interlock

switch.

9. Install the cell support assembly into the

hood compartment located by the back door

hinge side. Slide it straight in between the

two baffles and then drop straight down to

the hood bottom. It will not fit if installed at

an angle. The grease tray slides into the cell

support.

10. The air cleaner cell will slide into the hood

on top of the cell support. Slide the cell

straight into the opening so as not to damage

the cell top contact tab.

CAUTION

2a. The optional casters can be used in place of

the legs and are installed in the threaded

holes in the bottom four corners of the

frame. Install a flat washer between the

caster and frame. Use the 7/16” hex nut

beneath the lower wheel raceway to install.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1853EN Insider TS

Installing the air cleaner cell at an angle

may damage the cells electrical contact.

DO NOT force the cell into place.

Page 32

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 3

Page 33

11. Slide the aluminum mesh pre-filter all the

way into the groove on the left side of the

cell, then push the cell all the way back

against the angle stop and lock into place

with the slidebolt. The slidebolt will hold

the pre-filter in place and hold the cell and

pre-filter against the inside interlock

switches. Make sure the slidebolt is engaged

through the small locating hole in the left

side compartment.

12. Slide the air-circulating baffle all the way

into the cell’s right side groove.

13. Install the damper sleeve assembly by

dropping it into the large hole on the top of

the hood. Install with the fuse link pivot

assembly towards the hinge side.

CAUTION

Installing damper the wrong way will

damage the interlock switch.

14. Place two carbon filters into the filter slide

tray and install through the end door on top

of the support guides. The tray must be

centered in the door opening, before opening

the door.

CAUTION

Failure to center the tray may result in

damage to tray and door.

WARNING

The Insider will not run with only one

carbon filter. All the filters and door

interlocks must be made before the

Insider will start.

16. The system is now ready for the certified

fire suppression service personnel to finish

the installation procedure, including arming

the fire damper.

Fire Suppression System

WARNING

THE CHARGING & SETUP OF THE PYRO-

CHEM PLC-240/300 FIRE SUPPRESSION

SYSTEM MUST BE DONE BY CERTIFIED

PERSONNEL ON A REGULAR BASIS

AND THE USE AND MAINTAINENCE OF

THE INSIDER IS TO BE IN ACCORDANCE

WITH NFPA-96.

Note: The fusible links used in the INSIDER are

212º F fusible links.

THE FIRE SUPPRESSION SYSTEM IS

SHIPPED INACTIVE. The system must be

armed before using. Removing the red control

head internal safety pin and installing the CO2

cartridge is required to arm the fire suppression

system.

15. Make sure the top carbon filter is in place

and pushing against the inside interlock

switch. There is a 1” diameter disc that

pushes against the top filter. The disc and

switch are adjustable if required to make the

interlock function. Shutting the door pushes

the top filter against the interlock switch.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1853EN Insider TS

A customer provided hand portable fire

extinguisher is required on the premises

Fire Damper System

FD-1300 Dynamic rated multi-blade fire damper

UL-555 1-1/2hr, File No. R11172.

The unit must be armed before using the insider.

Note: the fusible link used in the damper is

212ºF.

WARNING

per NFPA 96 7-10.

Page 34

Arming the Fire Damper

The damper is not functional until the safety pin

is removed. A streamer is attached to the safety

pin for identification. Remove the safety pin to

arm the damper release mechanism as shown in

Illustration C.

Fusible Link

To avoid causing death or serious bodily

harm to building occupants, follow this

step carefully. Removing the safety pin

allows the damper blades to close

completely to preserve the integrity of

DANGER

the fire barrier.

Safety Pin

Illustration C

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 5

Page 35

2 Maintenance

“Quick Check” Inspections

Inspection shall be conducted on a monthly

basis by the owner, in accordance with the

manufacturer’s installation and maintenance

manual. As a minimum, the “quick check” or

inspection shall include verification of the

following:

The fire suppression system is in its proper

location.

The manual actuators are unobstructed.

The maintenance tag or certification is in place.

No obvious physical damage or condition exists

that might prevent operation.

The pressure gauge is in operable range.

The nozzle blowoff caps are intact and

undamaged.

The hood, duct, and protected cooking

appliances have not been replaced, modified, or

relocated.

If any deficiencies are found, appropriate

corrective action shall be taken immediately.

Personnel making inspections shall keep records

for those fire suppression system that was found

to require corrective actions.

At least monthly, the date the inspection is

performed and the initials of the person

performing the inspection shall be recorded.

daily. The carbon filters should be replaced a

minimum of every six (6) months.

The air cleaner cell shall be cleaned a minimum

of once per week following manufacturers

cleaning instructions.

The entire hood plenum and the blower section

shall be cleaned a minimum of once every three

(3) months.

Inspection and testing of the total operation and

all safety interlocks in accordance with the

manufacturers instructions shall be performed by

qualified service personnel a minimum of once

every six (6) months or more frequently if

required.

A signed and dated log of maintenance as

performed in accordance with above shall be

available on the premises for use by the authority

having jurisdiction.

Fire Suppression System

WARNING

THE CHARGING & SETUP OF THE PYRO-

CHEM PLC-240/300 FIRE SUPPRESSION

SYSTEM MUST BE DONE BY CERTIFIED

PERSONNEL ON A REGULAR BASIS

AND THE USE AND MAINTAINENCE OF

THE INSIDER IS TO BE IN ACCORDANCE

WITH NFPA-96.

The records shall be retained for the period

between the semiannual maintenance

inspections.

Use and Maintenance

All filters shall be cleaned or replaced in

accordance with the manufacturer’s instructions.

The grease filter and pre-filter should be cleaned

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

6 MN-1853EN Insider TS

Fusible links and nozzle caps must be replaced at

least annually or more frequently if necessary to

ensure proper operation of the system. Fusible

links and all other detection devices must be

serviced or replaced in accordance with the

manufacturer’s recommendations.

Page 36

For maintenance requirements read, the Pyro

Chem fire suppression system inserts that are

included in this manual.

Note: See section 1, page 3, Illustration A & B

for component locations.

a) Daily Maintenance

1. Visually inspecting the red fire suppression

control head assembly, for set mode display

and pressure gauge to make sure the system

pressure is within proper range.

2. Visually inspecting the system detection

lines to make sure that the fusible links are

operational.

3. Inspecting all nozzles, keeping them free

from grease and assuring that all blow-off

covers are in place.

4. Determining that easy access to the manual

pull station can be made for manual

activation.

5. Assuring that good housekeeping practices

have been maintained to eliminate potential

fire hazards.

6. Visually inspect the fire damper and fusible

link for damage and operational readiness.

At this time, it is also good practice to visually

inspect all premises hand portable fire

extinguishers to verify good working condition.

b) Regular System Maintenance

To ensure the proper operation of the system,

regular inspection and maintenance must be

performed by certified personnel and on a semi-

annual basis, and after every periodic hood and

duct cleaning (whichever occurs more

frequently).

The authorized distributor must be consulted

after the system is discharged.

For six (6) month maintenance, annual

maintenance and hydrostatic testing see the PyroChem insert “System Maintenance”.

Storage

Recharging supplies of wet chemical shall be

stored in the original closed shipping container

supplied by the manufacturer. These containers

shall not be opened until the system is recharged.

Wet chemical supplies shall be maintained

within the manufacturers recommended storage

temperature range.

Maintenance

A trained person who has undergone the

instructions and certification necessary to

perform the maintenance and recharge service

reliably and has the applicable manufacturers

installation and maintenance manual and service

bulletins shall service the wet chemical fire

extinguishing system six (6) months apart as

outlined below.

At least semiannually, maintenance shall be

conducted in accordance with the manufacturers

installation and maintenance manual. As a

minimum, such maintenance shall include the

following:

1. An examination of all detectors, the

expellant gas container, releasing devices,

piping, hose assemblies, nozzles, interlocks,

the fire suppression cylinder and gauge

pressure, and all auxiliary equipment.

2. Verification that the agent distribution

piping is not obstructed.

3. Where semiannual maintenance of any wet

fire suppression cylinder or system

components reveals conditions such as, but

not limited to, corrosion or pitting, structural

damage or fire damage; or repairs by

soldering, welding, or brazing; the affected

part(s) shall be replaced or hydrostatically

tested in accordance with the

recommendations of the manufacturer. The

hydrostatic testing of wet chemical

containers shall follow the applicable

procedures as outlined below.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 7

4. The wet fire suppression systems shall be

tested, which shall include the operation of

the control head interlock mechanism and

Page 37

switch, and releasing devices, including

manual pull station and other associated

equipment. A discharge of the wet chemical

normally is not part of this test.

5. Where the maintenance of the system

reveals defective parts that could cause an

impairment of failure of proper operation of

the system, the affected parts shall be

replaced or repaired in accordance with the

manufacturer’s recommendations.

6. The maintenance report, with

recommendations, if any, shall be filed with

the owner or with the designated party

responsible for the system.

7. Each wet chemical system shall have a tag

or label securely attached, indicating the

month and year the maintenance is

performed and identifying the person

performing the service. Only the current tag

or label shall remain in place.

Fixed temperature-sensing elements of the

fusible metal alloy type shall be replaced at least

annually from the date of installation. They shall

be destroyed or removed.

The year of manufacture and the date of

installation of the fixed temperature-sensing

element shall be marked on the system inspection

tag. The tag shall be signed or initialed by the

installer.

Recharging

All extinguishing systems shall be recharged

after use or as indicated by an inspection or

maintenance procedure.

Systems shall be recharged in accordance with

the manufacturer’s installation and maintenance

manual.

Hydrostatic Testing

The following parts of wet chemical

extinguishing systems shall be subjected to a

hydrostatic pressure test at intervals not

exceeding 12 years:

1. Wet fire suppression cylinder

2. Auxiliary pressure container

Exceptions:

1. Auxiliary pressure containers not exceeding

2-in. (0.05-m) outside diameter and less than

2 ft (0.6-m) in length.

2. Auxiliary pressure containers bearing the

DOT “:3E” marking.

Wet fire suppression cylinder and auxiliary

pressure container, shall be subjected to a

hydrostatic test pressure equal to the marked

factory test pressure or the test pressure specified

by the manufacturer. No leakage or rupture shall

be permitted. The test procedure shall be in

accordance with the manufactures’ detailed

written hydrostatic test instructions.

Exception:

Containers bearing DOT or TC markings shall be

tested or replaced in accordance with the

appropriate DOT or TC requirements.

Wet chemicals removed from the containers

prior to hydrostatic testing shall be discarded.

To protect the hazard during hydrostatic testing,

if there is no connected reserve, alternate

protection acceptable to the authority having

jurisdiction shall be provided.

c) Pipe and Nozzle Installation

All pipe ends shall be thoroughly reamed after

cutting and all oil and foreign matter removed

from the pipe. It is recommended that the

following procedures be followed:

1. Disconnect and remove discharge piping

from the inside.

2. Make certain that all threaded ends and pipe

are clean and the pipe is free of foreign

matter and oil.

3. Apply Teflon tape on threaded ends. Start at

the second mail thread, wrapping the tape

clockwise around the threads, away from the

pipe opening.

4. Do not over tighten, but be sure the pipe is

snug. Do not back-off sections of pipe to

make them fit better.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

8 MN-1853EN Insider TS

Page 38

CAUTION

Do not apply Teflon tape to cover or

overlap the pipe opening, as the pipe and

nozzles could become blocked and

prevent the proper flow of agent. Do not

use thread sealant or pipe joint

compound.

All piping shall be securely fastened to pipe

hangers. A union is installed in the discharge

piping close to the cylinder valve, to permit

disconnection and removal for inspection and

service. Dry air or nitrogen should be blown

through the discharge piping to remove chips and

other debris prior to installation of nozzles.

Nozzles shall be installed in accordance with the

limitations described in this manual. Blowoff

caps are provided for each nozzle. These will

prevent dirt and grease from clogging the nozzle.

d) Fusible Link Detector

Installation

After mounting the cylinder and control head, the

fusible link line can be installed. The first step

to installing the fusible link line is to install the

detector bracket(s). These brackets must be

installed in the plenum area of the ventilation

hood over all protected Mark II, V, or IX Fryer

and in each duct.

Note: Only FL-212 Fusible Links can be used.

Connect the fusible link brackets together using

1/2” conduit and the conduit connectors supplied

in the detector kit (Model FLK-1/1A). A PyroChem corner pulley must be used whenever a

change in conduit direction is necessary. The

conduit is connected to the control head through

a knockout in the upper left-side corner.

In general, fusible links centered in the detector

brackets are connected in series using 1/16”

diameter stainless steel cable. The spring plate in

the control head maintains tension on this series

of fusible links.

Fusible links are always used in conjunction with

the Model NMCH Mechanical Control Head.

Illustration E

Terminal Link Installation

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 9

Page 39

If the tension is released for any reason (i.e., a

fusible link separates), the control head will

operate and actuate the system. Maximum

limitations for the fusible link detection line are

as follows:

Fusible links can be installed with or without

fusible link hangers.

1. Fusible Link Installation Without

Hangers

Begin installing links at the terminal bracket.

The link is connected to the far side of the

terminal bracket using an “S” hook. The “S”

hook must be crimped closed after the link is

installed. A tight loop is then made in the cable

and secured by the crimp provided. This loop is

connected to the other side of the terminal link

(see Illustration E) and the cable fed through the

conduit to the next bracket.

After the last link in the series is connected, the

cable should be fed through the conduit back to

the control head. Thread the cable through the

hole in the fusible link ratchet wheel. The line

must then be crimped, and the crimp positioned

inside the center of the ratchet wheel.

NOTE

Illustration F

Fusible Line Link Termination

2. Fusible Link Installation Using Model

FLH-1 Fusible Link Hangers

Beginning at the control head feed the stainless

steel cable through the conduit and brackets to

the terminal bracket in one continuous length.

Allow approximately two and one half (2.5)

inches of slack at each bracket for the installation

of he Fusible Link Hangers. At the terminal link,

a tight loop is made in the cable and secured by

the crimp provided. The cable is attached to the

far side of the terminal bracket using an “S”

hook. The “S” hook must be crimped closed

after the cable is installed. See Illustration G.

Crimps must always be used in

conjunction with two (2) cable lengths.

Loops are the accepted method of

connecting the cable to mechanical

components. The crimp must never be

used on a single cable.

The fusible link line can now be put into a set

position by applying tension to the fusible link

line. This is accomplished by using 3/4” socket

on the fusible link line ratchet wheel. The

ratchet wheel will be ratcheted in a clockwise

direction until the spring plate makes contact

with the top of the control head box. The fusible

link line is now in a set position.

See Illustration F

Illustration G

Terminal Bracket Connection

Begin installing the Fusible Link Hangers at the

terminal bracket and work toward the control

head. Loop the cable through the oval opening

in the hanger and hook the fusible link on the

loop. See Illustration H

Note: Only FL-212 Fusible Links can be used.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

10 MN-1853EN Insider TS

Page 40

Illustration H

Fusible Link Connection

Hook the bottom of the link onto the bottom leg

of the hanger. See Illustration I

NOTE

Crimps must always be used in

conjunction with two (2) cable lengths.

Loops are the accepted method of

connecting the cable to mechanical

components. The crimp must never be

used on a single cable.

The fusible link line can now be put into a set

position by applying tension to the fusible link

line. This is accomplished by using a ¾” socket

on the fusible link line ratchet wheel. The

ratchet wheel will be ratcheted in a clockwise

direction until the spring plate makes contact

with the top of the control head box. The fusible

link line is now in a set position. See Illustration

F. Check to ensure that the fusible link hanger(s)

remain centered in the bracket after the fusible

link line is set. See Illustration J.

Illustration I

Fusible Link/Hanger Connection

Center the hanger/link in the fusible link bracket

by sliding it along the link line. This is easily

accomplished before any tension is applied to the

link line. Repeat this procedure for all fusible

links.

After the last hanger/link in the series is

connected, the cable should be fed through the

hole in the fusible link ratchet wheel. The line

must then be crimped, and the crimp positioned

inside the center of the ratchet wheel.

Illustration J

Fusible Link/Hanger In Set Position

e) Setting the Control Head

Model NMCH Mechanical Control Head

Once the fusible link line is set, the control head

can be placed in the set position. To set the

control head, the slide plate is moved from right

to left, ensuring the bolt extending from the cam

arm is in the slot provided in the slide plate.

Continue moving the slide plate to the left until

the latching arm is in the locked position. Insert

the pull pin into the hole in the slide plate above

the latching arm. This will lock the control head

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 11

Page 41

in the set position, eliminating accidental

actuation during the rest of the installation

procedure. See Illustration K

Illustration K

Miniature Switch Installation

f) Remote Pull Station

Installation

The model RPS-M Remote Mechanical Pull

Station is used for remote mechanical actuation

of all system releasing devices. It is to be located

near an exit in the path of egress from the hazard

area no more than five feet above the floor.

NOTE

A Model RPS-M Remote Mechanical Pull

Station must be used for manual

activation of a Model EN-MCU or a Model

NMCH releasing device.

The Pull Station can be surface mounted or flush

mounted. For flush mounting a RACO #232, 4”

deep electrical box or equivalent must be used

(dealer supplied). It is connected to the releasing

device using 3/64” or 1/16” diameter stainless

steel cable. The cable enters the pull station box

through the center hole in the bottom, top, either

side, or the center back hole. The cable enters

the control head through the top center knockout.

The cable must be enclosed in 1/2” conduit with

a Pyro-Chem corner pulley at each change in

conduit direction.

After mounting the pull station box and conduit,

feed the stainless steel cable from the releasing

device, through the conduit, and into the pull

station box. Feed the cable through the bushing

and through the hole provided in the pull handle.

Loop the cable through the pull handle an secure

it with the crimp provided. See Illustration L.

Illustration L

Model RPS-M Remote Pull Station Installation.

g) System Checkout After

Installation

Model NMCH Mechanical Control Head

Before putting the system into service, all

components must be checked for proper

operation. During this checkout, assure that the

carbon dioxide pilot cartridge is not installed in

the control head actuator. Remove the pull pin

from the hole in the slide plate.

To check satisfactory operation of the control

head, cut the terminal link or the “S” hook

holding the link. This will relieve all tension on

the fusible link line and operate the control head.

The slide plate will have moved fully to the right.

Any auxiliary equipment connected to the dry

contacts of the Miniature Switch in the control

head will have operated.

If any of these events fail to occur, the problem

must be investigated and repaired.

Repair the terminal link and put the fusible link

line back into the set position. This is

accomplished by using a 5/8” socket on the

fusible link line ratchet wheel. The ratchet wheel

will be ratcheted in a clockwise direction until

the spring plate makes contact with the top of the

control head box.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

12 MN-1853EN Insider TS

Page 42

Once the fusible link line is set, the control head

can be placed in the set position. M To set the

control head, the slide plate is moved from right

to left, ensuring the bolt extending from the cam

arm is in the slot provided in the slide plate.

Continue moving the slide plate to the left until

the latching arm is in the locked position.

Once the control head is set, pull the pull handle

on the remote pull station to assure that the

control head operates. If the control head

operates normally, the control head can be reset

as described above.

CAUTION

Before screwing the carbon dioxide pilot

cartridge into the actuator, ensure that

the actuator has a Teflon O-ring installed.

Using a felt-tipped marker, write the date of

installation in the gray area of the carbon dioxide

pilot cartridge. Screw the cartridge into the

control head actuator until hand-tight. Never use

a wrench to tighten the cartridge into the

actuator.

Remove the pull pin from the hole in the slide

plate and install the control head cover.

Fire Damper System

Visually inspect the damper or damage and

verify that the fusible link is in place between the

two couplers as shown in Illustration M.

Illustration M

Fusible Link Location

If the fusible link is not present or there are any

signs of damage during the inspection:

DANGER

To avoid causing death or serious bodily

harm to building occupants, make sure

all damper corners are square and the

damper has not been damaged. Do not

install any damper which is deformed or

damaged.

Note: Maintain the UL approval by ordering a

replacement fusible link from Johnson

Controls before continuing.

DANGER

To avoid causing death or serious bodily

harm to building occupants, never install

a fire damper without the proper UL

approved fusible link in place.

Use the following fusible link:

For code FOVHN (212° F) use replacement

fusible link DMPR-RF002.

After you receive the new fusible link:

1. Place the fusible link on the coupler from

the bracket shown in Figure 3-9. Use long

needle-nose pliers to hold fusible link in

position.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 13

Page 43

2. Attach a pipe wrench to a convenient

location on the jackshaft or use a 1/2” openend wrench on the end of the drive shaft.

3. Rotate the jackshaft in a clockwise direction

until the other coupler post is in position and

install the fusible link onto the post.

4. Slowly reduce pressure on the pipe wrench

until slack is taken up by the fusible link.

WARNING

The damper must be armed. It is shipped

with the safety pin installed.

CAUTION

Do not put hands or fingers into the fire

damper. It is spring-loaded and bodily

harm could result.

Carbon Filters

The carbon filters are 1-3/4 inches by 11-1/2

inches by 19-1/2 inches. The INSIDER requires

the use of two (2) filters. The carbon filters

should be replaced every six (6) months.

The washing frequency best suited for you unit

can be determined by examining the dirt

collected components at three (3) week intervals.

As the dirt begins to collect, you will notice a

light film, then a very definite collection will be

evident at a later examination. When there is a

noticeable build-up of dirt, it is time to wash.

In most areas the collecting cell should be

washed about every twelve (12) weeks.

Note: Dirt build-up on the ionizing-collecting

cell should not be confused with dirt

stains. Dirt stains are normal and do not

affect efficiency.

Steps for Washing:

1. Switch control switch “OFF”.

2. Remove pre-filter and cell.

3. Place components in automatic dishwasher,

stationary tub, shower stall or over floor

drain. Use hot soapy water and rinse

thoroughly. As an aid to drying, rinse with

clear, hot water. Allow components to dry

thoroughly.

Note: Ionized wires are easily broken. Handle

the cells with care.

4. Replace pre-filter and cell.

5. Close cell access door.

Electronic Air Cleaner

Maintenance and Washing

When to Wash:

Periodically the dirt collected by your unit must

be removed. The frequency of washing will

depend on the amount of dirt present in the air in

you locality.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

14 MN-1853EN Insider TS

6. Switch control switch to “ON”.0

If arcing noise occurs due to wet cells, turn

switch off and allow more drying time.

If there are any problems, refer to the service

checklist.

Page 44

Troubleshooting

For factory service, return your machine, freight

Troubleshooting

This section is designed as an aid in

troubleshooting, not as a substitute for a qualified

technician. Feel free to call Belshaw Bros. at

(206) 322-5474. One of our customer support

representatives will be happy to help you. When

you call, please specify the following:

• The model name of the machine

• The serial number of the machine

• The voltage, phase, and the hertz

(cycles) of the machine.

prepaid, with your instructions for service, your

phone number, and the name of the person for us

to contact when we have made a cost estimate.

In most cases, the machine can be shipped back,

freight collect, within five (5) days.

Ship machines in need of service to:

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Following is a troubleshooting chart to help you

identify and solve some basic problems.

CAUTION

If you perform repairs yourself or have

them performed by anyone other than

Belshaw Bros. or a service technician

authorized by Belshaw Bros., you do so

at your own risk.

WARNING

Disconnect the machine from the power

source before disassembling, repairing,

or wiring.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 15

Page 45

1 INSIDER WILL NOT RUN

Possible Cause What To Do

The power cord is not plugged in, or the

outlet has no power.

Connect the machine to a good power

source.

The power cord is defective Replace the power cord.

The circuit breaker has been tripped Reset it by lifting cover on electrical

enclosure and turn Insider breaker to

“OFF” and then to “ON”.

There is a loose connection See if circuit breaker has been tripped.

Test circuits and repair it.

WARNING

To avoid electrical shock injuries, before

doing any of the following, unplug the

machine.

2 INSIDER WILL NOT STAY RUNNING

Possible Cause What To Do

Fuse has blown out Check fuses located inside electrical

enclosure and replace. If condition

continues look for electrical short.

Fire suppression system has fired Call the Pyro-Chem certified personnel

to reset & change the system. The

interlock switch in the control head will

prevent the Insider from running.

Hood doors are not closed or making

contact with interlock switches

Grease baffle filter not installed or

properly seated on interlock switch.

Pre-filter not installed or locked in place Install filter and lock into place with slide

Electronic Air Cleaner (air cleaner cell)

not installed or locked in place.

Close the doors and latch tight or adjust

interlock switch position.

Install filter or adjust interlock switch at

the bottom of filter opening.

bolts.

Install cell and lock into place with slide

bolt. Push the cell all the way back

against rear stop and engage slide bolt

into hole in sheet metal baffle.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

16 MN-1853EN Insider TS

Page 46

2 INSIDER WILL NOT STAY RUNNING - continued

Possible Cause What To Do

Carbon Filter not installed or contacting

interlock disc.

Install two (2) carbon filters in the slide

tray. Make sure that they contact the

interlock disc behind the filters. The

door pushed the filters back against the

disc when it is latched. The disc can be

adjusted in or out by turning the disc. If

the disc is too loose put Loctite on the

threads. The interlock switch can be

adjusted from inside the electrical

enclosure.

Air pressure differential switch not

adjusted properly or obstruction in

filters/air flow.

1. Hold the “Start button” in for a few

seconds to attain proper air flow.

2. Check, clean or replace filters.

3. Check to see if reed switch is stuck.

Tap on switch housing.

4. Check differential adjustment screw

located under pressure switch cover,

inside upper electrical enclosure.

Approximate setting is 2-1/2 turns

clockwise with N.O. contacts.

Cell relay interlock is not latching in. 1. Hold the “Start button” in for a few

seconds to allow for latching time.

2. Check fuse labeled filter and replace.

3. Check for loose connections and

power to relay.

4. Replace relay.

The fire damper is closed The damper fusible-link has activated

the damper. Replace the fusible-link

and reset the damper. Temperatures

over 212° F will release the damper.

Also old or damaged fuse-links may

allow damper to close.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider TS MN-1853EN 17

Page 47

3 ELECTRONIC AIR CLEANER – TROUBLECHART

Condition

or

Trouble

Description

Probable

Location

Possible

Cause

Symptom

Power On/Off

Light (Amber) out

Cracking Noise Objectionable