Page 1

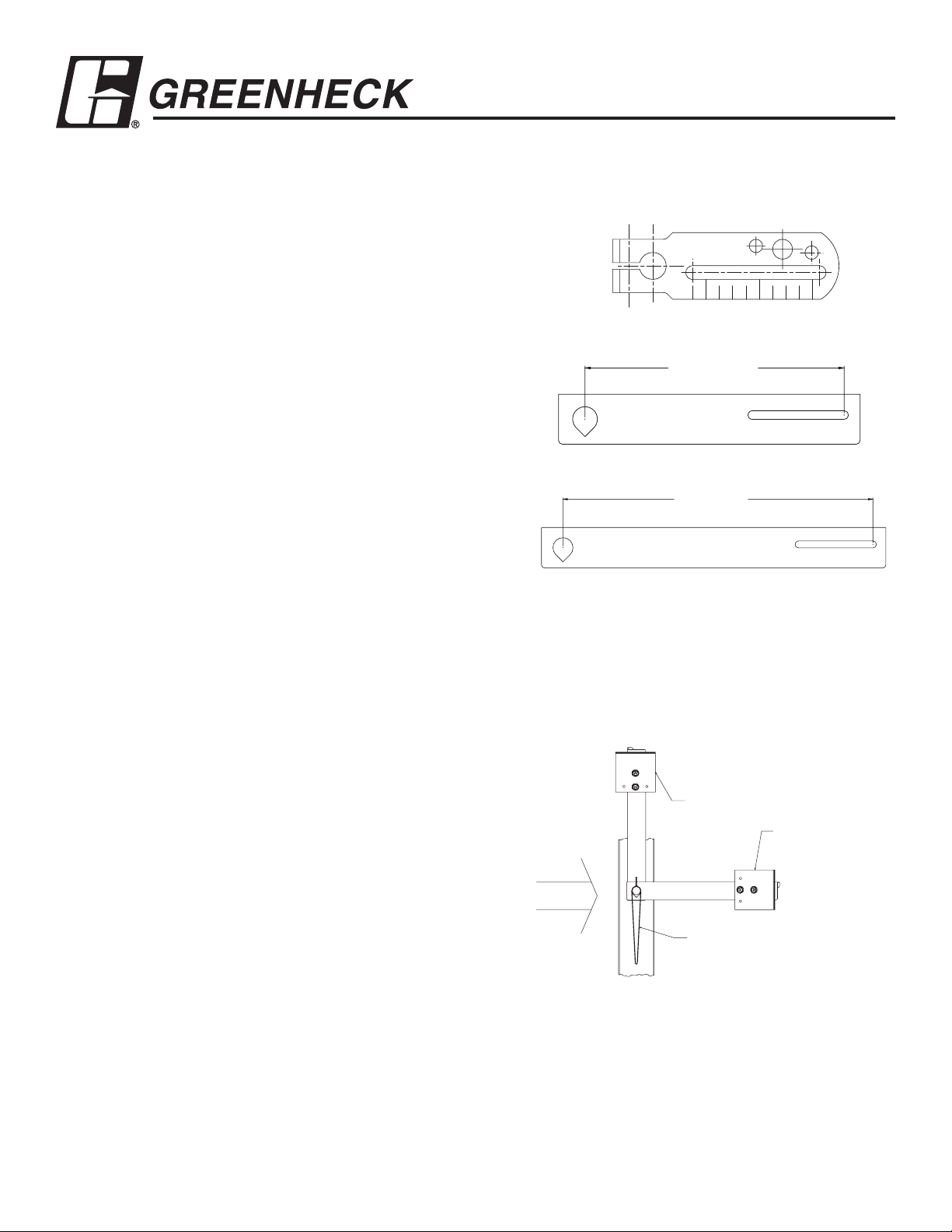

Part number 469134

21 3

12 1/2 in. (318mm)

8 1/2 in. (216mm)

FLOW

DAMPER BLADE

COUNTERBALANCE

PRESSURE SET

HPR series

Instructions for Adjustment on Pressure Relief Dampers

The following instructions should be followed when attempting

to modify HPR series pressure relief dampers for different

damper orientations or start-to-open pressures. Dampers

shipped are set for the specified start open pressure and flow

direction.

Pressure relief dampers designed for horizontal flow (vertical

mounting) are equipped with two sets of arms (Figure 2A).

The first set is in the direction opposite the blades and offset,

or balance, the weight of the blades. The second set of arms

is always positioned horizontally when the damper is closed

(approximately vertical with blades open) and hold the blades

closed until the start-open pressure is reached. Pressure relief

dampers with vertical up flow/relief (figure 2B) and vertical down

flow (figure 2C) only have one set of arms, as the weight of the

edge pivoted blades is either added or subtracted from the

weight necessary to hold blades closed.

Damper will respond to a positive differential pressure in the

direction of blade opening,

Small crankarm

Medium crankarm

Three (3) different crankarms may be used, depending on

damper size and magnitude of start open pressure. See figure 1.

The blades of this type damper exhibit a gradual “lift off” as

start-open pressure is reached. The operating point is not

sharply defined, as when a door suddenly opens. There is a wide

flow range where pressure is approximately constant.

Counterweight Set Procedure (Horizontal flow

only)

The counterbalance weights on a vertically mounted damper

(horizontal flow), must be adjusted first, if the airflow direction

is changed. This is covered by a separate procedure. Basically,

the damper is adjusted for easy operation (blade weight is just

counterbalanced) before the pressure set arms and weights are

added.

Pressure Setting Procedure

Position damper in the proper orientation and flow direction.

If a specific relief pressure is required, install a U-tube

manometer or other pressure measuring device in the duct work

to monitor the static pressure.

Large crankarm

Figure 1

Figure 2A Horizontal Flow

If damper flow direction must be changed in the field, loosen

fastener in pressure set crankarm and rotate arms to correct

position. See figures 2A, 2B and 2C for correct pressure set arm

orientation with damper blades closed.

Page 2

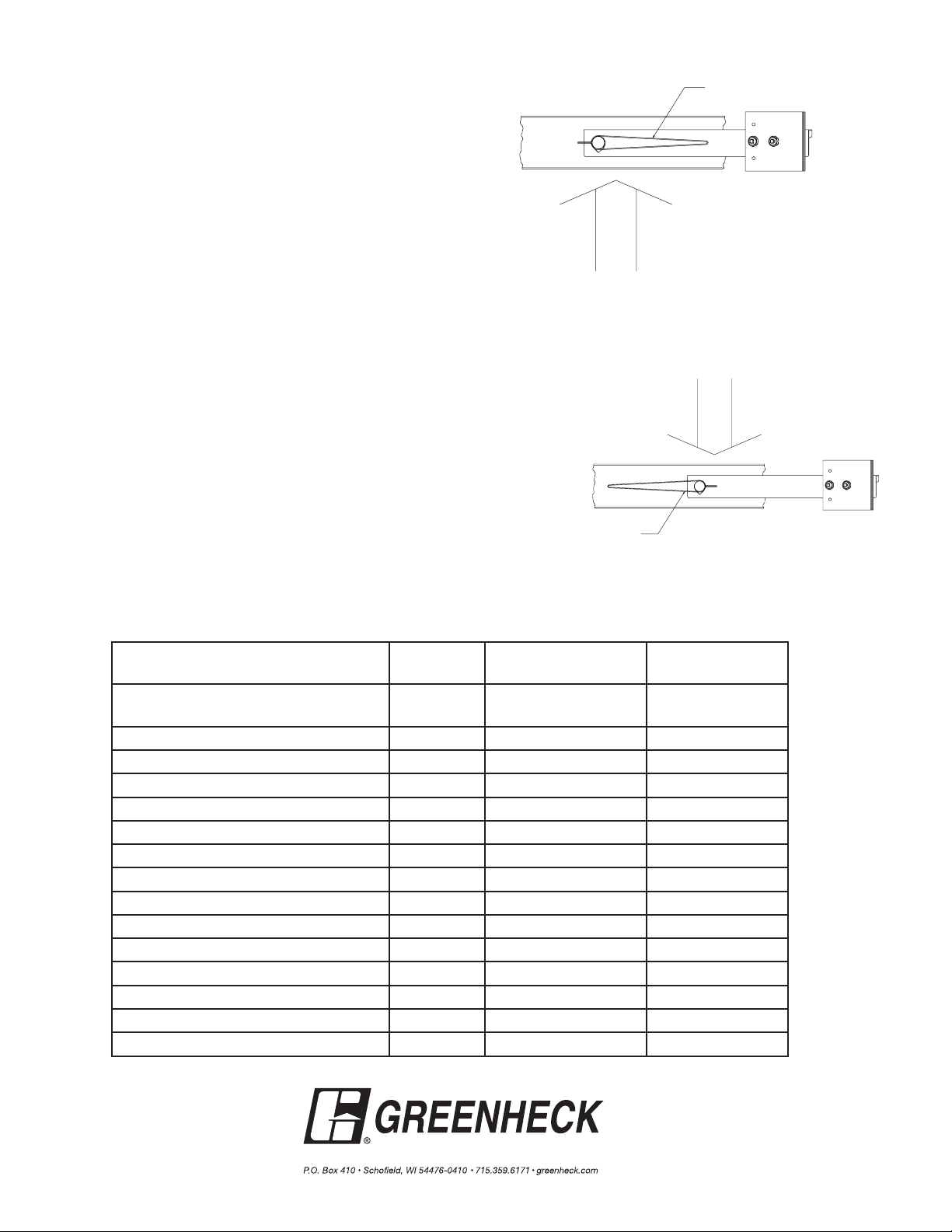

FLOW

DAMPER BLADE

Pressure Setting Procedure cont....

FLOW

DAMPER BLADE

Start-open pressure is adjusted by either changing weight

center distance from axle center line, or by increasing

or decreasing the quantity of plates mounted to arms.

In extreme cases, the arm length and quantity must be

changed. See table at the end of procedure for replacement

parts.

Adjust weight center distance first. Loosen fasteners

holding weight plates to arm and move inward or outward in

arm slot as required. Moving plates toward axle will reduce

start-open pressure; increasing the center distance will

increase the pressure at which blades start to open. If a

greater range of pressure set adjustment is required, add or

remove plates from arms as required to obtain the required

start-open pressure.

Check all fasteners for tightness.

Figure 2B Vertical Up Flow

Table of Components

Components Applicable

Axle adapter, 3/8” sq. to ¾” OD, 3”

long

Axle adapter, short, ¾” OD HPR-120 370120 416343

¾” crankarm All 653630 687738

3/8”-16 x 2 crankarm bolt All 415882 415924

3/8”-16 hex nut for crankarm All 415457 416168

Short counterweight arm (8½”) All 647344 689404

Long counterweight arm (12½”) All 657343 683951

3/8”-16 set screw for short/long arm All 415050 415763

3/8”-16 weld nut for short/long arm All 415127 415928

Counterweight plate, 1¼” x 3½” All 653144 687637

Counterweight plate, 2½” x 3½” All 653143 687636

Counterweight plate, 3½” x 3½” All 653142 687635

Bolt, ¼” - 20 x 1¼” All 415973 NA

Bolt, ¼” - 20 x 1½” All 415517 416103

Nut, ¼” - 20 All 415455 415575

Figure 2C Vertical Down Flow

Galvanized Part

Model

HPR-120 458959 NA

Number

Stainless Steel

Part Number

Copyright © 2006 Greenheck Corporation

469134 Adj. on Pressure Relief Dampers

Rev. 1 May 2006

Loading...

Loading...