Page 1

The #1 Source for Donut and Bakery Equipment www.belshaw.com

OP

ERATOR’S MANUAL

TECHNICAL SUPPLEMENT

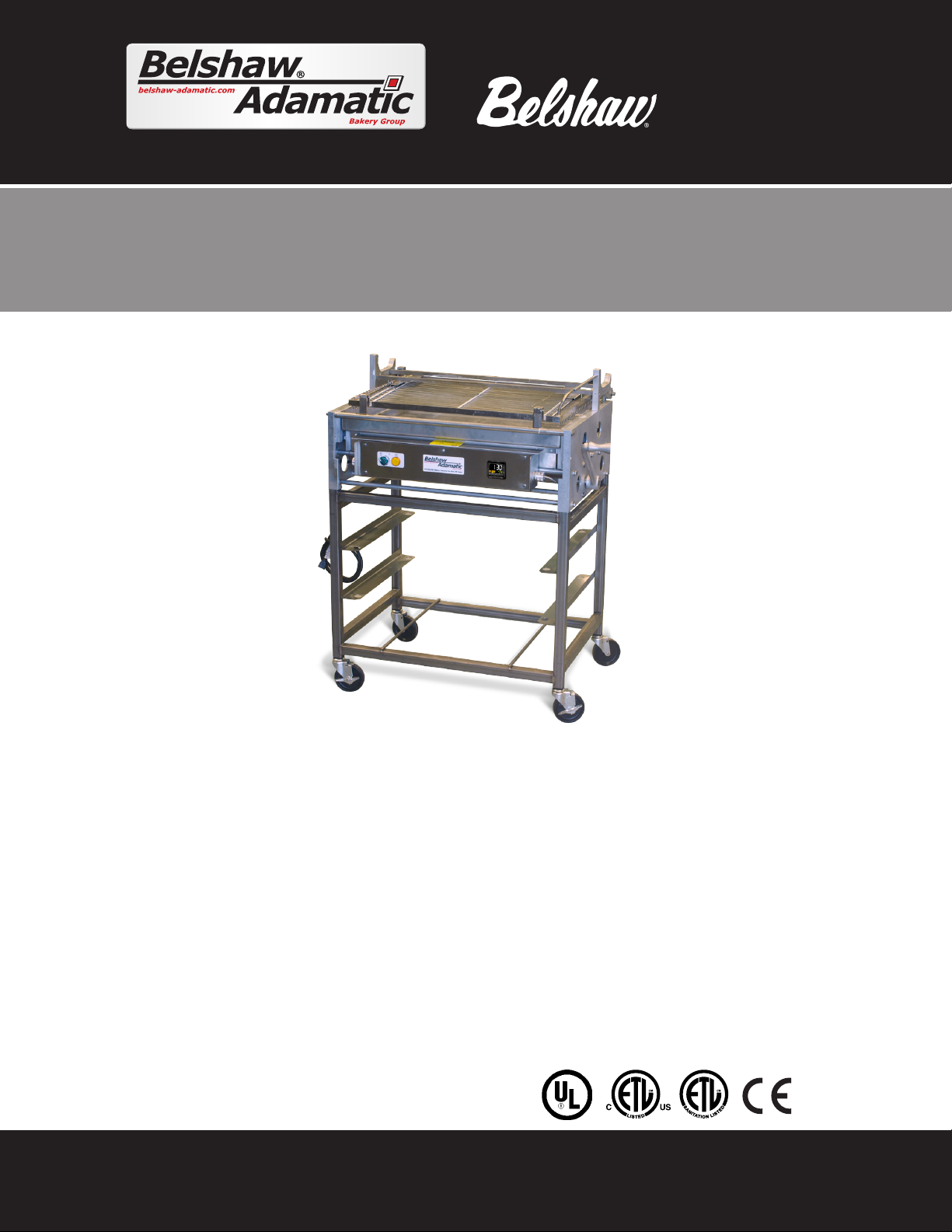

Donut Icer

HI18F - HI24F

This manual should only be used with the Item Numbers shown above.

USA/Canada 1-800-578-2547

SUPPORT

International (+1) 206-322-5474

Email service@belshaw.com

Web www.belshaw.com

Page 2

Econo-Icer HI18/HI24

Operator's Manual

Belshaw Bros., Inc.

814 44TH ST NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

Email: service@belshaw.com http://www.belshaw.com

Page 3

Page 4

Page 5

BELSHAW FREIGHT DAMAGE

POLICY

Belshaw has made every effort to

insure that your equipment arrives in

excellent condition. For your

protection, please inspect your

shipment for any signs of damage that

may have occurred during transport.

Please note any damage that is found

during inspection and file a freight

claim with the shipping company

immediately. Acceptance of damaged

equipment may become the

responsibility of the acceptor.

IMPORTANT

Keep This Manual For Future

Reference

.

EQUIPMENT RECORD

Please provide the information below when you correspond with us

about your machine.

Purchased by ____________________________________________________

Installed by ______________________________________________________

Date of installation __________________ Model number _________________

Serial number ____________________________________________________

042615

MN-1747EN

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

Email: service@belshaw.com http://www.belshaw.com

Page 6

Contents

PREFACE......................................................................................................................................................................................2

1 OPERATION........................................................................................................................................................................4

OPERATION..................................................................................................................................................................................................4

2 INSTALLINGHI18/HI24DIGITALTEMPERATURERETROFITKIT.................................................................7

PARTSNEEDED...........................................................................................................................................................................................7

INSTALLATIONINSTRUCTIONS..................................................................................................................................................................7

3 CLEANING.........................................................................................................................................................................11

4 MAINTENANCE................................................................................................................................................................12

LUBRICATION............................................................................................................................................................................................12

FIGURE1,INSTALLINGNEWCONTROLPANEL....................................................................................................................................................................9

FIGURE2,ELEMENTCONNECTIONSONRELAY....................................................................................................................................................................9

FIGURE3,THERMOCOUPLEROUTING1................................................................................................................................................................................9

FIGURE4,THERMOCOUPLEROUTING2................................................................................................................................................................................9

FIGURE5,INSTALLATIONOFTHERMOCOUPLEBRACKET..................................................................................................................................................9

FIGURE6,INSTALLATIONOFTHERMOCOUPLE....................................................................................................................................................................9

FIGURE7,INSTALLATIONOFTHERMOCOUPLE..................................................................................................................................................................10

FIGURE8,INSTALLATIONOFTHERMOCOUPLE..................................................................................................................................................................10

FIGURE9,CONTROLS..............................................................................................................................................................................................................10

FIGURE10,TEMPERATURECONTROLLER..........................................................................................................................................................................10

iii

Page 7

Preface

The HI18/HI24 Econo-Icer is

designed for quickly and easily icing

donuts and a variety of baking

products.

The HI18/HI24 Econo-Icer is meant

to be used on a flat, stationary

surface, with the operator standing on

the handled side. The operator must

work safely at all times and follow the

instructions and warnings in this

manual.

The HI18/HI24 Econo-Icer uses

electrical elements to heat frosting in

its kettle. The machine is available

with the following electrical

configurations:

120 volts, 1 phase, 60 hertz

220 volts, 1 phase, 60 hertz

avoid electrocution or

other injury.

NEVER USE force to

assemble, disassemble,

operate, clean, or maintain

the machine.

To prevent unintentional

startup and possible fire,

UNPLUG the machine if

there is a local power

outage. When the power is

restored, it is safe to plug

the machine in again.

MAKE SURE that all

electrical cords are routed

so that no one will trip

over them.

The HI18/HI24 Econo-Icer

produces less than 70 dB(A) of

equivalent continuous A-weighted

sound pressure at work stations. This

has been determined during a run of

the machine with shortening in the

kettle, using a Bruel & Kjaer sound

level meter, type 2236.

To use the HI18/HI24 Econo-Icer

safely, heed the following warnings:

UNPLUG the machine

before attempting any

adjustment, repair,

disassembly, or cleaning to

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

To avoid electrocution,

MAKE SURE that no

electrical cords are frayed

or cracked and that they

do not pass through any

water or icing.

NEVER TOUCH the icing

pan once the machine is

on. The pan gets very hot,

which may cause serious

burns.

DO NOT OVERFILL the

icing pan with icing. If

shortening overflows the

2

Page 8

icing pan, it could cause

serious burns or could

cause someone to slip on

the floor and be seriously

injured.

MAKE SURE that the

machine and the icing are

cool before attempting any

adjustment, repair,

disassembly, or cleaning.

Hot icing can cause serious

burns.

BE CAREFUL never to get

icing, water, or other

materials on the floor. If

anything does get spilled

on the floor, mop it up

immediately. Materials on

the floor can cause people

to slip or fall, resulting in

serious injury or loss of

life.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

3

Page 9

1 Operation

Operation

1. FILL Icing Pan with icing

approximately 1/2” from the top of

the pan.

2. TURN ON Heater.

3. ALLOW icing to heat for 45 minutes

to reach desired icing temperature.

The Heating Indicator Light will

turn off, and the Temperature

Controller will display the icing

temperature.

NOTE: Periodic stirring of the icing is

necessary to ensure constant, even

heating of the icing.

4. ROTATE Wire / Frame over icing.

5. SLIDE the rack of donuts into the

Rack Holder.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

4

Page 10

6. ROTATE the Wire / Frame over

the rack of donuts to be iced.

7. FIRMLY GRIP the two (2) handles

and rotate the Wire / Frame and

rack of donuts to be iced.

8. RETURN the empty donut rack to

the original position.

10. LOWER the Icing Pan.

11. ROTATE the empty donut rack over

the iced donuts.

9. PUSH DOWN on the Icing Lift

Handle to raise the Icing Pan

until it reaches desired height.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

12. FIRMLY GRIP the two (2) handles

and rotate the Wire / Frame and

donut rack to the original position.

5

Page 11

13. ROTATE the Wire / Frame over

the icing, remove iced donuts, and

repeat steps 1-13.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

6

Page 12

2 Installing HI18/HI24 Digital

Temperature Retrofit Kit

Parts Needed

1. Heater Control Box Assembly

(HI24-1017) + Hardware:

4X .” Bolts

8X .” Washers

2X 6” High Temperature Wire

Sleeves

2. 6X Wire Ties (990-0150)

3. Thermocouple Mounting Bracket

(HI24-7008)

4. Heating Element Mounting

Hardware:

4X #10 Washers

2X #10 Nuts

Heating Panel (4X Bolts).

Remove wires from Heating

Element.

Remove old Heating Control

Box Front Cover (4X Bolts).

Remove 4X bolts connecting

the old Heating Control Box to

Heating Panel.

Remove old Heating Control

Box, including wire for

connecting to Heating

Elements, and Wire Sleeves.

3. ATTACH Retrofit Heating

Control Box:

Remove 5X bolts securing the

Front Cover of the new

Heating Control Box Assembly

and remove the cover.

Installation Instructions

1. UNPLUG HI Unit from power

source.

2. REMOVE existing Heater

Control Box:

Remove Icing Pan.

Remove Top Cover from

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Place Wire Sleeves on 12 GA

white wires sticking out of the

backside of the new Heater

Control Box. (See Figure 1.)

Insert the wires and sleeves

through heating box holes.

(See Figure 1.)

Ensure sleeves are located as

shown below. (See Figure 1.)

NOTE: Grommets located in

7

Page 13

the new Heating Control Box

pop off easily. Use care

when moving wire through

grommets.

Remove Front Cover of the

new Heating Control Box

Assembly.

Remove 4X nuts and 4X

washers from long bolts on

back of new Heater Control

Box.

Install the new Heating

Control Panel onto the

Heating Box using

corresponding holes and

hardware provided in this kit.

Replace Heating Control Box

Front Cover (5X Bolts),

making sure not to pinch any

wires under the cover. DO

NOT over-tighten Front

Cover bolts. Doing so could

lead to gasket leakage.

4. Reinstall the Top Cover of

Heating Panel (5X Bolts).

Icing Pan. (See Figure 6, 7, and

8.)

9. PLUG in unit and verify all

functions work properly.

Rotate Green ON/OFF Switch

(located furthest to the left of

the unit) to the ON position.

The green light in the switch

should illuminate. (See Figure

9.)

Omron Controller (far right)

should power up and display

Current Temperature (PV,

large number) and Set Point

temperature (SV, small

number). (See Figure 10.)

To test digital temperature

controller, wrap hand around

Thermocouple, and ensure

the indicated temperature

(PV, displayed in large text)

rises.

The Set Point (SV) can be

changed by pushing the D or

U arrows. (See Figure 10.)

5. Replace Icing Pan.

6. Route Female Thermocouple wire

under the unit. (See Figures 3

and 4.)

Attach shielded thermocouple

wire to Frame using supplied

wire ties. (See Figure 4.)

7. Place Thermocouple into

indicated alignment hole on

Thermocouple Bracket. (See

Figure 5.)

8. PLACE Thermocouple Bracket on

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Heat Cycle light should turn

on after approximately 5

seconds.

8

Page 14

Figure 1, Installing New Control Panel

Figure 2, Element Connections on Relay

Figure 4, Thermocouple Routing 2

Figure 5, Installation of Thermocouple

Bracket

Figure 3, Thermocouple Routing 1

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Figure 6, Installation of Thermocouple

9

Page 15

Figure 7, Installation of Thermocouple

Figure 9, Controls

Figure 8, Installation of Thermocouple

Figure 10, Temperature Controller

TROUBLESHOOTING

Potential Issue

Error or Alarm present on Digital Temperature

Control

Thermocouple becomes disconnected, Digital

Temperature Control is flashing S.ERR

Device on, indicated temperature not rising Ensure Thermocouple is connected,

What To Do

Ensure Thermocouple is connected and

functioning properly

Cycle power (Green Power Switch, or

unplug unit for 10 seconds, and plug

back in)

Reconnect Thermocouple. S.ERR on

temperature controller will disappear

after a brief moment.

Cycle power if necessary to clear

controller error/alarm warning

located in the Thermocouple Bracket

and connected to the Icing Pan

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

10

Page 16

3 Cleaning

Once a day, clean the HI18/HI24

Econo-Icer as explained below:

1. REMOVE any debris from the

work area before disassembling

the HI18/HI24 Econo-Icer.

2. UNPLUG and REMOVE

Thermocouple and Bracket

from Icing Pan.

3. To avoid being burned, WAIT for

Icing Pan to cool before

removing; REMOVE Icing Pan.

4. UNPLUG AND REMOVE heating

panel assembly from unit.

5. CLEAN the HI18/HI24 Econo-

Icer with warm water and mild

cleaner.

6. LIFT the Tray Holder over to

the right side rest position, wash

with warm soapy water, rinse,

and wipe dry.

7. REMOVE Retainer Knob (HI240041, see parts list) that holds

the Wire / Frame in place and

lift out the Wire / Frame. Place

Wire / Frame in automatic

dishwasher. Use caution so that

the wires do not get damaged.

8. RETURN the Tray Holder to the

left side rest position.

For your safety, observe the following

warnings throughout the entire

cleaning process.

Thoroughly clean and dry

the floor if icing, water, or

other materials are spilled.

Materials spilled on the floor

can cause serious injury or

loss of life.

To avoid the possibility of

shock, unplug the unit

before cleaning.

To avoid damage to the

Wire / Frame, use caution

when removing and

transporting.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

11

Page 17

4 Maintenance

Lubrication

1. USE several drops of Lubriplate

FMO-900-AW gear oil on the Lift

Handle Axle, located under the

heating panel assembly.

LUBRICATE EVERY TWO WEEKS.

2. USE Lubriplate FMO-900-AW

gear oil to lubricate the

tray Holder and Wire

Holder Pivot Pins.

LUBRICATE EVERY WEEK.

WARNING

To avoid serious burns or other injury,

always disconnect the machine from the

power source before lubricating.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 OM, MN-1747EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

12

Page 18

Econo-Icer HI18/HI24

Technical Supplement

Belshaw-Adamatic Bakery Group

TH

814 44

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

Email: service@belshaw.com http://www.belshaw.com

ST NW, Suite 103

Page 19

BELSHAW FREIGHT DAMAGE

POLICY

Belshaw has made every effort to

insure that your equipment arrives in

excellent condition. For your

protection, please inspect your

shipment for any signs of damage that

may have occurred during transport.

Please note any damage that is found

during inspection and file a freight

claim with the shipping company

immediately. Acceptance of damaged

equipment may become the

responsibility of the acceptor.

EQUIPMENT RECORD

IMPORTANT

Keep This Manual For Future Reference.

Please provide the information below when you correspond with us

about your machine.

Purchased by ____________________________________________________

Installed by ______________________________________________________

Date of installation __________________ Model number _________________

Serial number ____________________________________________________

042615

MN-1748EN

Belshaw-Adamatic Bakery Group

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

Email: service@belshaw.com http://www.belshaw.com

Page 20

Contents

PREFACE......................................................................................................................................................................................2

1 MAINTENANCE...................................................................................................................................................................4

WIRETENSIONINGANDREPLACEMENT.................................................................................................................................................4

2 PROGRAMMINGTEMPERATURECONTROLLER....................................................................................................6

UNLOCKINGTHECONTROLLER.................................................................................................................................................................6

CHANGINGOPERATORSETPOINTS.........................................................................................................................................................7

CHANGINGOPERATORLEVELPARAMETERS.........................................................................................................................................8

CHANGINGINITIALLEVELPARAMETERS................................................................................................................................................8

CHANGINGADVANCEDLEVELPARAMETERS.........................................................................................................................................9

LOCKINGTHECONTROLLER...................................................................................................................................................................10

SETTINGTHECONTROLLERTODEFAULTSETTINGS.........................................................................................................................10

3 TROUBLESHOOTING.....................................................................................................................................................12

TROUBLESHOOTINGSPECIFICS..............................................................................................................................................................13

iii

Page 21

Preface

To transport the HI18/HI24 EconoIcer to the workstation and unpack it,

follow the steps listed below:

1. Use a fork lift or pallet jack to

transport the shipping crate to

workstation.

2. Break down the shipping crate.

3. Remove all packing materials,

including foam, tape, brown

paper, plastic, and white

protective coating.

The HI18/HI24 Econo-Icer is

designed for quickly and easily icing

donuts and a variety of baking

products.

The HI18/HI24 Econo-Icer is meant

to be used on a flat, stationary

surface, with the operator standing on

the handled side. The operator must

work safely at all times and follow the

instructions and warnings in this

manual.

The HI18/HI24 Econo-Icer uses

electrical elements to heat frosting in

its kettle. The machine is available

with the following electrical

configurations:

220 volts, 1 phase, 50 hertz

240 volts, 1 phase, 50 hertz

The HI18/HI24 Econo-Icer

produces less than 70 dB(A) of

equivalent continuous A-weighted

sound pressure at work stations. This

has been determined during a run of

the machine with shortening in the

kettle, using a Bruel & Kjaer sound

level meter, type 2236.

To use the HI18/HI24 Econo-Icer

safely, heed the following warnings:

UNPLUG the machine

before attempting any

adjustment, repair,

disassembly, or cleaning to

avoid electrocution or

other injury.

NEVER USE force to

assemble, disassemble,

operate, clean, or maintain

the machine.

To prevent unintentional

startup and possible fire,

UNPLUG the machine if

there is a local power

outage. When the power is

restored, it is safe to plug

the machine in again.

MAKE SURE that all

electrical cords are routed

so that no one will trip

over them.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

2

Page 22

To avoid electrocution,

MAKE SURE that all

electrical cords are not

frayed or cracked and that

they do not pass through

any water or icing.

NEVER TOUCH the icing

pan once the machine is

on. The pan gets very hot,

which may cause serious

burns.

DO NOT OVERFILL the

icing pan with icing. If

shortening overflows the

icing pan, it could cause

serious burns or could

cause someone to slip on

the floor and be seriously

injured.

MAKE SURE that the

machine and the icing are

cool before attempting any

adjustment, repair,

disassembly, or cleaning.

Hot icing can cause serious

burns.

BE CAREFUL never to get

icing, water, or other

materials on the floor. If

anything does get spilled

on the floor, mop it up

immediately. Materials on

the floor can cause people

to slip or fall, resulting in

serious injury or loss of

life.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

3

Page 23

1 Maintenance

Wire Tensioning and

Replacement.

The following tools are required for

wire tensioning and replacement:

5/16” Open-End Wrench

Wire Cutter

IMPORTANT

Do not use a box wrench to tighten.

This will cause too much torque, and

frame may bend and bow.

1. PLACE looped end of wire over

the Wire Retainer Pin (HI18-

0004) placing it in the groove.

2. THREAD other end of wire

through the hole in the Wire

Adjusting Pin (HI24-0020) and

BEND the end pointing up as

shown.

3. With the 5/16” open-end

wrench, LOOSEN the #10-

32X1” machine screw.

4. With the 5/16” open-end

wrench, TURN the Wiring

Adjusting Pin to tighten the

wire. Be sure the wire winds in

the groove of the pin. (This will

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

4

Page 24

also tighten the loop around the

Wire Retainer Pin.)

5. TIGHTEN the wire until taut,

removing all slack. Do Not Over

Tighten! Over Tightening Will

Cause The Frame To Bend

And Bow.

6. TIGHTEN the #10-32 machine

screw to hold pin in place.

7. TRIM excess tail of the end of

wire with wire cutters.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

5

Page 25

2 Programming Temperature

Controller

The TJ-0184D-1 or 2 Controller

comes per-programmed and protected

so the operator cannot change the

setup parameters. To change any

settings, you must first unlock the

Controller.

Note: Only the settings that are

changed from the factory settings are

listed in this section.

Unlocking the Controller

To unlock the controller:

1. PRESS the + keys for more

than 3 seconds.

2. PRESS the key to move to the

next parameter.

3. PRESS the or to change the

parameter and from 2

to 0.

4. PRESS the + keys for more

than 1 second to return to

operator screen.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

6

Page 26

2

2

PARAMETER FACTORY

DEFAULT

PRESENT

SETTING

UNIT FRONT

SETTING

Protection Parameters

Operation/Adjustment

Protect

Initial

Setting/Communications

Protect

0

1

Changing Operator Set

Points

.

.

To change operator set points: (Must

be unlocked to change Alarm Value 1.)

EXPLANATION OF

PANEL

PRESENT

SETTING

2:Display and change

of only "PV" and

"PV/SP" parameters

are allowed. [2]

2:Prohibited. [2]

1. PRESS the key to move to the

next parameter.

2. PRESS the or key to

change the parameter.

3. PRESS the key to return to

operator screen.

PARAMETER FACTORY

DEFAULT

SETTING

Operator Set Points

Set Point 0.0 125.0/50.0 °F/°C . .

Alarm Value 1 0.0 10.0/5.0 °F/°C

PRESENT

SETTING

UNIT FRONT

PANEL

EXPLANATION OF

PRESENT

SETTING

.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

7

Page 27

Changing Operator Level

Parameters

To change operator level parameters:

(Must be unlocked.)

1. PRESS the key for less than 1

second.

2. PRESS the key to move to the

next parameter.

3. PRESS the or key to

change the parameter.

4. PRESS the key to return to

operator screen.

PARAMETER FACTORY

DEFAULT

SETTING

PRESENT

SETTING

UNIT FRONT

PANEL

EXPLANATION OF

PRESENT

SETTING

Operator Level

Parameters

Process Value Input Shift 0.0

Hysteresis (Heating) 1.0

Changing Initial Level

Parameters

To change initial level parameters:

(Must be unlocked.)

1. PRESS the key for more

than 1 second to adjust intial

parameters.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

0.0 °F/°C

0.5 °F/°C

2. PRESS the key to move to

the next parameter.

3. PRESS the or key to

change the parameter.

4. PRESS the key for more

than 1 second return to

operator screen.

8

This is the offset

setting for

calibration.

.

Page 28

8

1

0

0

0

PARAMETER FACTORY

DEFAULT

PRESENT

SETTING

UNIT FRONT

SETTING

Initial Level Parameters

Input Type 5

Temperature Unit 0

SP Upper Limit 130.0 150.0/65.0 °F/°C

SP Lower Limit -20.0

Alarm 2 Type 2

Alarm 3 Type 2

Alarm 4 Type 2

.

.

0.0 °F/°C

.

.

.

PANEL

EXPLANATION OF

PRESENT

SETTING

8:Thermocouple [J]

(-20.0 to 400.0°C or

0.0 to 750.0°F) [8]

°F [F]

.

.

0:Alarm function OFF

[0]

0:Alarm function OFF

[0]

0:Alarm function OFF

[0]

Changing Advanced Level

Parameters

To change advanced level parameters:

(Must be unlocked.)

1. UNLOCK the controller.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

2. PRESS the key for more

than 1 second to adjust intial

parameters.

3. PRESS the key until you

get to parameter .

4. PRESS the or key to

change parameter to -

169.

9

Page 29

1

1

0

PARAMETER FACTORY

DEFAULT

SETTING

Advanced Level

Parameters

Alarm 1 Latch 0

PV/SP No. 1 Display

Selection

PV Decimal Point Display 1

4

Locking the Controller

After programming: To lock the

controller:

1. PRESS the + keys for

more than 3 seconds.

2. PRESS the key to move to

the next parameter.

PRESENT

SETTING

UNIT FRONT

PANEL

EXPLANATION OF

PRESENT

SETTING

.

.

.

Enabled [oN]

1:"PV/SP/No display"

[1]

OFF [ ]

Setting the Controller to

Default Settings

To set the controller back to factory

default settings: (Must be unlocked.)

1. PRESS the key for more than

1 second to adjust intial

parameters.

3. PRESS the or key to

change the parameter

and from 0 to 2.

4. PRESS the + keys for

more than 1 second to return

to operator screen.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

2. PRESS the key until you get

to parameter .

3. PRESS the or key to

change parameter to -

169.

4. CHANGE parameter from

to .

5. PRESS the key for more than

1 second to return to initial

screen.

6. PRESS the key for more than

1 second to return to operator

screen.

10

Page 30

3 Troubleshooting

If you have a problem with your

HI18/HI24 Econo-Icer that you

cannot solve, call your dealer or

another qualified technician.

If your dealer cannot help you, please

call Belshaw-Adamatic at 800-578-

2547. When you call, please specify

the following:

The MODEL NAME of the

machine.

The SERIAL NUMBER of the

machine.

The VOLTAGE, PHASE, and

CYCLE of the machine.

CAUTION

IF YOU PERFORM REPAIRS YOURSELF,

OR HAVE THEM PERFORMED BY

ANYONE OTHER THAN A SERVICE

TECHNICIAN AUTHORIZED BY

BELSHAW-ADAMATIC, YOU DO SO AT

YOUR OWN RISK.

DISCONNECT THE MACHINE FROM

THE POWER SOURCE BEFORE

DISASSEMBLING, REPAIRING, OR

WIRING.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

12

Page 31

Troubleshooting Specifics

NO HEAT AND ON/OFF SWITCH DOES NOT LIGHT UP

Possible Causes What To Do

Unit not plugged in or wall electrical breaker is

tripped.

Plug unit in and/or check electrical outlet.

ON/OFF SWITCH ON AND LIT UP, HEATING LIGHT NOT ON

Possible Causes What To Do

Loose wire. Check wires.

NO HEAT, ON/OFF SWITCH ON AND LIT UP, HEATING LIGHT ON

Possible Causes What To Do

Heating element failure. Check heating element of open circuit; replace

if defective.

Relay failure. Check if relay turns on; replace if defective.

UNEVEN ICING TEMPERATURE.

Possible Causes What To Do

Icing needs stirring. Stir icing.

WIRES ARE NOT EVENLY TAUT

Possible Causes What To Do

Wires are not evenly adjusted. Tighten loose wires.

NO HEAT, ON/OFF SWITCH ON AND LIT UP, HEATING LIGHT NOT ON

Possible Causes What To Do

Loose wire. Check wires.

High limit tripped. Wait 10 minutes and recheck.

Temperature controller set too low. Adjust set point higher.

Thermocouple not plugged in. Plug thermocouple into connector.

Belshaw-Adamatic Bakery Group Econo-Icer HI18/HI24 TS, MN-1748EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

13

Page 32

Belshaw Adamatic Bakery Group

Limited Warranty / Retur n P olicy

Subject to the terms and limitations set forth in this limited war r ant y (“Limited Warranty”), Belshaw Adamatic

Bakery Group (also referred to as “the Manufacturer”) warrants to the original purchaser (“Purchaser”) of

Manufacturer’s equip me nt and par t s ( “Pr oducts”), Belshaw Adamatic Bakery Group’s m anufacture and

assembly of Products to be free from defects in wor km anship and material which would result in product

failure under normal use and ser vice. Belshaw Adamatic Bakery Group’s entire liabi lity under this Limited

Warranty is limited to either repairing or replacing at Manufacturer’s factory or on Purchaser’s premises, at

Belshaw Adamatic Ba kery Group’s option, any Products purchased by Pur chaser which shall be determined

by the Manufacturer to be defectiv e. If necessary to return Products to Manufacturer’s factory, Products

must be shipped by Purchaser with transportation charges prepaid by Purchaser.

Belshaw Adamatic Ba kery Group reserves the right to make changes in design or add any improvement to

its Products at any time without incurring any obligati ons t o install the same on Products previously sold.

Possession, use or oper at ion of Products sold hereunder f or any other than their designed purpose, or use

of Products which are in poor repair, modified, improperly operat ed, or neglected, is done at the Purchaser’s

risk. Belshaw Adamatic Bakery Group hereby discl aims any liability for these actions and shall not be liable

for defects in or for any damages or l os s t o any property which is attributable to such actions .

Under no circumstance s shall Belshaw Adamatic Bakery Group be l i abl e for any indirect, special,

incidental, or c onsequential damages arising out of, or from the use of its Products by Purchaser, its

assignees, employees, agents or customers.

THIS LIMITED WARRANTY SHALL BE PURCHASER’S SOLE AND EXCLUSIVE REME DY WITH

RESPECT TO DEFECTIVE PRODUCTS.

Warranty Period

This Limited Warranty covers Pr oducts manufactured by Belshaw Adamatic B akery Group and sold by

Belshaw Adamatic Ba kery Group or its authorized distributor (“Distributor”) or authorized dealer (“Dealer”),

and this Limited Warranty shall extend for a period o f one (1) year from date of shipment to Purchaser, and

to the original Purchaser only.

Limited Warranty

With respect to products not manufactured by Belshaw Adamatic Bakery Group, warranty coverage shal l be

limited to the warranty of the original manufacturer of the product, or the Bel shaw Adamatic Bakery Group

Limited Warranty, w hichever is the lesser coverage period.

Replacement Products provided under the terms of this Limited Warranty are warr ant ed f or t he r em ainder of

the original warranty period applicable to the Product.

Exclusions

This Limited Warranty excludes from its coverage and does not apply to: ( a) solenoid and relay coils; ( b)

lamps; (c) “O” rings; (d) belt s; and ( e) i m pellers. This Limited Warranty also excludes the cost of labor for

removing and replacing Products subject to a warranty claim, other t han the labor incurred directly by the

Manufacturer when, in Bel shaw Adamatic Bakery Group ’s opinion, a repair of the Product by the

Manufacturer is justified.

Belshaw Bros., Inc. doing business as Belshaw Adamatic Bakery Group

www.belshaw-adamatic.com, www.belshaw.com Phone (+1) 206-322-5474

Revised 08/31/15 Limited Warranty Page 1 of 2

Page 33

Warranty Claims

In case of warranty claims relat in g t o your Product, you must follow the instructions b elow.

Report Claims to Your Authorized Distributor or Dealer or to Belshaw Adamatic Bakery Group

As soon as you discover a pr oblem, contact the Distributor or Dealer from whom you purchased t he Product

or Belshaw Adamatic Ba ker y Group. Your Distributor or Dealer will notify Belshaw Adamatic Bakery Group

for you. Only Belshaw A damat ic Customer Service can approve or authorize warranty claims.

You must state the following:

1. Your name, company name, and telephone nu m ber

2. The location, phone number, and contact nam e w here the Product is located

3. The invoice number and date of purchase of the Product

4. The Model and Serial Number of the Product, as w r it t en on t he dat a tag attached to the Product

5. A description of the prob lem and how it occurred

Shipping Damage and Missing Items

Damage to the Packagi ng or Crate. On delivery , promptly check all p ackages thoroughly for any sign of

damage. In cases of visib le damage, always note the dam age on the Delivery Receipt. Failure to note

damage is taken by the Freig ht Carr ier to mean that the package is in good condition at time of receipt, and

can result in denial of a Freight Cl ai m. Take photographs that clearly show the damage.

Damage to Products. If you find any damaged Product inside the shipment, photograph the damage both

inside and outside of the pac kag e. Do not throw the packaging away. Photos of the package and contents

are needed to show the condition of the Product at the ti me it w as r eceived.

Missing Items. As soon as you believe any items to be missing from a shipment, promptly report this to t he

Distributor or Dealer from whom the Product was purchased or to Belshaw Adamatic Bakery Group. If

possible, photograph t he ent ire contents of the delivery and email this to your Distributor or Dealer, or to

Belshaw Adamatic Customer Service at service@belshaw.com

.

Returning Products to Belsha w Adamatic Bakery Group

Under the terms of the Limited Warra nt y, you may be asked to return to Belshaw Adamatic Bakery Group

any Product that is the subject of a warranty claim. These Products must be clearly labeled with a Return

Goods Authorization Number (“RGA Number”) giv en to you by your Distributor or Dealer, or by Belshaw

Adamatic Customer Service. Products received without an RGA Number will not be proce s sed. All

Products must be shipped freight pr epaid by the Purchaser to Belshaw Adamatic Bakery Group at the

address below.

Contacting Belshaw Adamatic Bakery Group

At any time, you can contact Belshaw Adamatic Bakery G r oup cus t omer service for assistan c e

Belshaw Adamatic Ba kery Group Customer Service

814 44th St. NW, Suite 103,

Auburn WA 98001, USA

Phone: 800-578-2547 ( US A/ Canada) or (+1)206-322-5474 (Worldwide)

Email: service@belshaw.com

Office Hours: Monday – Friday, 6am to 4pm, USA Pacific Time

Belshaw Bros., Inc. doing business as Belshaw Adamatic Bakery Group

www.belshaw-adamatic.com, www.belshaw.com Phone (+1) 206-322-5474

Revised 08/31/15 Limited Warranty Page 2 of 2

Page 34

The #1 Source for Donut and Bakery Equipment

www.belshaw.com

BELSHAW ADAMATIC BAKERY GROUP

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

1-800-578-2547 (USA/Canada)

(+1) 206-322-5474 (Worldwide)

service@belshaw.com

an Ali Group Company

The Spirit of Excellence

Loading...

Loading...