Page 1

The #1 Source for Donut and Bakery Equipment www.belshaw.com

OPERATOR’S MANUAL

TECHNICAL SUPPLEMENT

PARTS AND ELECTRICAL DIAGRAMS

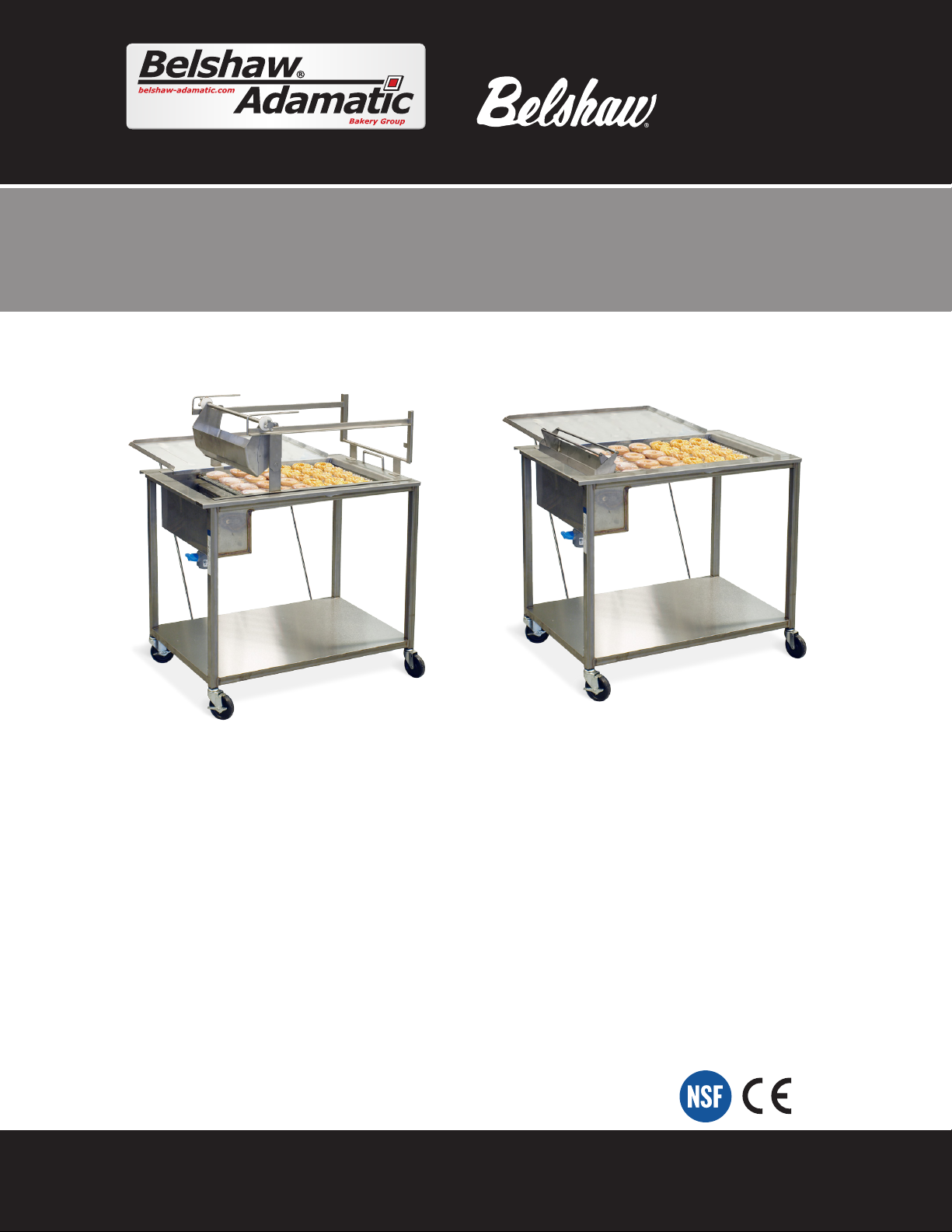

Donut Glazers

HG18EZ • HG18C

SUPPORT

USA/Canada 1-800-578-2547

International (+1) 206-322-5474

Email service@belshaw.com

Web www.belshaw.com

Page 2

Donut Glazer

HG18EZ

Owner’s Manual

Belshaw-Adamatic Bakery Group

814 44

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

Email: service@belshaw.com

TH

ST NW, Suite 103

●

HG18C

http://www.belshaw.com

Page 3

2

BELSHAW-ADAMATIC FREIGHT

DAMAGE POLICY

Belshaw-Adamatic has made every

effort to insure that your equipment

arrives in excellent condition. For

your protection, please inspect your

shipment for any signs of damage that

may have occurred during transport.

Please note any damage that is found

during inspection and file a freight

claim with the shipping company

immediately. Acceptance of damaged

equipment may become the

responsibility of the acceptor.

Keep This Manual For Future

IMPORTANT

Reference.

EQUIPMENT RECORD

Please provide the information below when you correspond with us

about your machine.

Purchased by _____________________________________________________

Installed by ______________________________________________________

Date of installation _________________ Model number _________________

Serial number ____________________________________________________

030116

MN-1755EN

Belshaw-Adamatic Bakery Group

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

Email: service@belshaw.com http://www.belshaw.com

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 4

3

Contents

ABOUT THE HG18EZ AND HG18C GLAZERS ........................................................................................................ 4

1 ASSEMBLY – HG18EZ GLAZER ................................................................................................................... 5

I

NITIAL CLEANING AND SANITATION .................................................................................................................................. 5

A

SSEMBLING THE GLAZER ............................................................................................................................................... 5

2 ASSEMBLY – HG18C GLAZER ..................................................................................................................... 7

NITIAL CLEANING AND SANITATION .................................................................................................................................. 7

I

A

SSEMBLING THE GLAZER ............................................................................................................................................... 7

3 ASSEMBLY – KETTLE COVER AND DRAIN TRAY .......................................................................................... 8

I

NSTALLING THE KETTLE COVER ........................................................................................................................................ 8

I

NSTALLING THE DRAIN TRAY (OPTIONAL) ........................................................................................................................... 9

3 OPERATION – HG18EZ GLAZER ................................................................................................................11

G

ENERAL USE OF THE GLAZER ........................................................................................................................................ 11

O

PERATING THE GLAZER ............................................................................................................................................... 11

4 OPERATION – HG18C GLAZER ..................................................................................................................13

ENERAL USE OF THE GLAZER ........................................................................................................................................ 13

G

O

PERATING THE GLAZER ............................................................................................................................................... 13

5 CLEANING ...............................................................................................................................................14

C

LEANING THE GLAZER ................................................................................................................................................. 14

6 MAINTENANCE .......................................................................................................................................15

5 PARTS .....................................................................................................................................................16

P

ARTS LIST, HG18EZ GLAZER ........................................................................................................................................ 16

P

ARTS LIST, HG18C GLAZER ......................................................................................................................................... 19

P

ARTS LIST, DRAIN TRAY FOR HG18EZ AND HG18C ......................................................................................................... 22

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 5

4

About the HG18EZ and HG18C Glazers

The HG18EZ and HG18C Glazers are

designed to glaze donuts on the top

and sides with an even distribution of

glaze.

• The HG18EZ Glazer uses the

EZLift rail system. The glaze

applicator slides on a frame

above the glazer.

• The HG18C Glazer has no

frame. The glaze applicator is

held directly by the operator.

The HG18EZ and HG18C Glazers are

designed to be used on a level floor.

The HG18EZ and HG18C Glazers

produce 0.0 dB(A) of equivalent Aweighted sound pressure at

workstations. This has been

determined because there is no

machine-driven operation. Operation

of HG18EZ and HG18C Glazers is by

a human operator.

Thorough understanding of how to

safely operate, clean, and maintain the

The HG18EZ and HG18C Glazers will

prevent production delays and injuries.

The operator must work safely at all

times, read and follow the instructions

in this manual, and heed all warnings,

including the following:

DO NOT OVERFILL the Glaze

Kettle. If glaze overflows the

Kettle, it could cause someone to

slip on the floor and be seriously

injured.

BE CAREFUL never to get glaze,

water, or other materials on the

floor. If anything does get spilled

on the floor, clean the area

immediately. Materials on the floor

can cause people to slip or fall,

resulting in serious injury or loss of

life.

TO AVOID damaging the glazer,

never use force to assemble,

disassemble, operate, clean, or

maintain it.

TO PREVENT damage to the

Kettle, never scrape it with a

metal object. Use only a plastic or

rubber bowl scraper.

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 6

5

1 Assembly – HG18EZ Glazer

Initial Cleaning and Sanitation

1. REMOVE the HG18EZ Glazer

from box and discard all packing

materials.

2. WASH, RINSE AND SANITIZE all

the parts of the HG18EZ Glazer

before use. (See Cleaning,

Section 3.)

Assembling the Glazer

1. PLACE the Lower Shelf (8) onto

the bottom of the Frame (5).

2. INSERT the Glazer Kettle (10)

onto the Frame (5). (See Figure

1.)

3. PLACE the Screen Support (9)

onto the Kettle (10).

4. INSERT the Drain Valve (6)

onto the drain under the Glaze

Kettle. (10).

Notes:

5. Cover (2) is optional

6. Sloping Kettle: Your glazer may

have a sloping Kettle (12),

rather than box shaped

Figure 1, Glazer Assembly

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 7

6

7. ASSEMBLE the Upper Frame

(7) onto the Screen Support

(9) by inserting the pin on the

Upper Frame into the top of the

slot on the Screen Support and

sliding it down. (See Figure 2.)

8. ASSEMBLE the Glaze

Applicator onto the top of the

Upper Frame, aligning the

rollers with the tracks (See

Figure 3.)

Figure 2, Screen Support Slot

Figure 3, Upper Frame Assembly

Note: The optional Glaze Kettle

Cover (2) can be installed onto the

kettle after the Upper Frame and

Screen Support are removed. (See

Figure 1.)

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 8

7

2 Assembly – HG18C Glazer

Initial Cleaning and Sanitation

1. REMOVE the HG18C Glazer

from box and discard all packing

materials.

2. WASH, RINSE AND SANITIZE all

the parts of the HG18C Glazer

before use. (See Cleaning,

Section 3.)

Assembling the Glazer

1. PLACE the Lower Shelf (6) onto

the bottom of the Frame (9).

2. INSERT the Glazer Kettle (12)

onto the top of the Frame (9).

3. PLACE the Screen Support (10)

onto the Kettle (12).

4. INSERT the Drain Valve (11)

onto the drain under the Glaze

Kettle (12).

Notes:

• Cover (3) is optional

• Sloping Kettle: Your glazer

may have a sloping Kettle

(12), rather than box shaped

Figure 4, HG18C Glazer Assembly

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 9

8

3 Assembly – Kettle Cover and Drain Tray (optional)

The Drain Tray is optional with HG18EZ and HG18C glazers.

Installing the Kettle Cover (optional)

1. Find the four Cover Support

Brackets (Figure 5).

Figure 5, Kettle Cover support

brackets

2. Place the Lower Support

Brackets on the lower bar of the

frame (Figure 6). The Lower

Support Brackets are smaller

than the Upper Support

Brackets. Lift the bottom shelf if

necessary.

Figure 6,

Kettle Cover support brackets

3. Place the Upper Support

Brackets on the upper bar of the

frame (Figure 7). Lift the kettle

up if necessary.

Figure 7, Upper support brackets

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 10

9

4. Install the Kettle Cover on the

side of the Glazer (Figure 8).

Figure 8, Kettle Cover installed on

side of glazer

5. Or, place the cover over the top

of the Glazer Kettle (Figure 9).

Installing the drain tray (optional)

1. Find the Drain Tray support

brackets (Figure 10)

Figure 10, Drain Tray support

brackets

2. Place the Drain Tray support

brackets on the lower bar of the

frame (Figure 11)

Figure 9, Glazer with cover on

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Figure 11, Drain Tray support

brackets

Page 11

10

4. Make sure that the Drain Tray

Support Rod is inserted into the

Mounting Brackets under the

Drain Tray (Figure 12)

Figure 12, Brackets under Drain Tray

Install the Drain Tray (Figure 13)

Figure 13, Installing the Drain Tray

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 12

11

3 Operation – HG18EZ Glazer

General Use of the Glazer

To use the HG18EZ Glazer, SET a

screen of donuts onto the Screen

Support, then PASS the Glaze

Applicator over the donuts by the

frame-supported applicator on the

HG18EZ Glazer.

The Glaze Applicator is designed to

give uniform glaze coverage to donuts.

Any excess glaze will drain back into

the reservoir.

Operating the Glazer

1. After the HG18EZ Glazer has

been cleaned, sanitized and

assembled, POUR glaze into the

glaze reservoir section of the

Kettle (Kettle will hold

approximately 30 pounds of

glaze).

2. TILT the Upper Frame assembly

up, placing the Glaze

Applicator into the Glaze

Reservoir (See Figure 14.)

Figure 14, Filling Position

3. Allow the Applicator to FILL

with glaze.

4. PLACE a screen of donuts on top

of the Screen Support, locating

it on the pins.

5. SPREAD the Glaze Applicator

handles apart to close the

bottom of the applicator.

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 13

12

7. TILT the Upper Frame assembly

down lifting the Glaze

Applicator out of the Kettle

(See Figure 15)

Figure 15, Tilt Upper Frame Down

8. ROLL the Glaze Applicator over

the donuts and return it to the

reservoir end to the Kettle. (See

Figure 16.)

9. TILT the Upper Frame assembly

up again, placing the Glaze

Applicator back into the

reservoir.

10. REMOVE the screen of donuts

and place a new screen on the

Screen Support.

11. REPEAT steps 2 through 10

IMPORTANT

Casters with brakes can be locked

during operation to keep glazer

stationary. DO NOT forget to

unlock brakes on wheels after

operation, as most bakery floors

are very hard on rubber wheels.

Figure 16, Glazing Position

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 14

13

4 Operation – HG18C Glazer

General Use of the Glazer

To use the HG18C Glazer, PLACE a

screen of donuts onto the Screen

Support, then PASS the Glaze

Applicator over the donuts by hand.

The Glaze Applicator is designed to

give uniform glaze coverage to donuts.

Any excess glaze will drain back into

the reservoir.

Operating the Glazer

1. After the HG18C Glazer has

been cleaned, sanitized and

assembled, POUR glaze into the

glaze reservoir section of the

Kettle (Kettle will hold

approximately 30 pounds of

glaze).

6. SPREAD the Glaze Applicator

handles apart to close the

bottom of the applicator.

7. MOVE the Glaze Applicator

over the donuts about 3 inches

(75 mm) above them

8. Return the Glaze Applicator to

the reservoir end of the Kettle.

9. REMOVE the screen of donuts

and place a new screen on the

Screen Support.

10. REPEAT steps 2 through 9.

2. PLACE a screen of donuts on top

of the Screen Support, locating

it on the pins.

3. SQUEEZE the Glaze Applicator

handles together to open the

bottom and allow glaze enter.

4. LOWER the Glaze Applicator by

hand into the Glaze Reservoir.

5. Allow the Applicator to FILL

with glaze.

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 15

14

5 Cleaning

Cleaning the Glazer

For your safety, observe the following

warnings throughout the entire

cleaning process.

Once a day, clean as explained below:

1. DRAIN/DISCARD unused glaze.

2. REMOVE the following parts from

the HG18EZ/HG18C Glazer:

Glaze Applicator

Upper Frame (HG18EZ only)

Screen Support

Kettle

3. WASH each of the above parts

with mild soap and hot water

then RINSE and SANITIZE.

IMPORTANT

Casters with brakes can be locked

during operation to keep glazer

stationary. DO NOT forget to unlock

brakes on wheels after operation, as

most bakery floors are very hard on

rubber wheels.

WARNING

Thoroughly clean and dry the floor

if glaze, water, and/or other

materials are spilled. Materials

spilled on the floor can cause

serious injury or loss of life.

4. WIPE down the Frame with

damp cloth with mild soap and

hot water and SANITIZE.

5. REASSEMBLE in reverse order.

(See Assembly, Sections 1 and

2.)

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 16

15

6 Maintenance

In order to ensure the intended and

safe operation of the HG18C or

HG18EZ Glazer, follow all procedures

and instructions listed in the manual.

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 17

16

Glazer

QTY

Part Number

Description

1 4 FT6-0120

Caster Socket, 18 Ga. 125, RT-Poly

2

REF

HG18-0020

Cover, Kettle

3 2 HG18-0031-4

Swivel Caster, 4”

4 2 HG18-0031B-4

Swivel Caster w/Brake, 4”

5 1 HG18-8001

Frame

6 1 HG18-9001

Low-Pressure CPVC Ball Valve

7 1 HG18EZ-0535

Frame, Upper

8 2 HG18EZ-7036

Shelf, Flat

9 2 HG18EZ-8018

Support, Screen

10 1 HG18EZ-8019

WLDT, Kettle, 2-Piece

11 4 905-0054-1.25

Plastic End Cap 1-1/4 SQ BLK

Applicator

QTY

Part Number

Description

1 2 HG18-0003

Hinge Stud

2 1 HG18EZ-0033

Main Shaft

3 2 HG18EZ-0057

Glazer Roller

4 2 HG18EZ-0527

Clamping Knob, ½-13 Thread

5 1 HG18EZ-6006

Handle; Adj. Flow Applicator, Outer Shell

6 1 HG18EZ-7030

Glaze Applicator, Adj. Flow, Side Outer Shell

7 1 HG18EZ-7031

Glaze Applicator, Adj. Flow, Side Inner Shell

8 2 903-0979

SST. ¼-20 x 0.75 Hex Head Machine Screw

9 2 903-7531SS

SST. ¼ Flat Washer, Regular

5 Parts

Parts list, HG18EZ Glazer

ITEM

(See Figure 16, Parts List, HG18EZ Glazer Body)

ITEM

(See Figure 17, Parts List, HG18EZ Glaze Applicator)

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 18

17

Figure 16, Parts List, HG18EZ Glazer Body

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 19

18

Figure 17, Parts List, HG18EZ Glaze Applicator

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 20

19

Glazer

QTY

Part Number

Description

1 4 FT6-0120

Caster Socket, 18 Ga. 125, RT-Poly

2

REF

HG18-0020

Cover, Kettle

3 2 HG18-0031-4

Swivel Caster, 4”

4 2 HG18-0031B-4

Swivel Caster w/Brake, 4”

5 1 HG18-8001

Frame

6 1 HG18-9001

Low-Pressure CPVC Ball Valve

8 2 HG18EZ-7036

Shelf, Flat

9 2 HG18EZ-8002

Support, Screen

10 1 HG18EZ-8019

WLDT, Kettle, 2-Piece

11 4 905-0054-1.25

Plastic End Cap 1-1/4 SQ BLK

Applicator

QTY

Part Number

Description

1 1 HG18-0088

Handle; Glaze applicator inner shell

2 1 HG18-0087

Handle; Glaze applicator outer shell

3 1 HG18-0086

Glaze applicator side – inner shell

4 2 HG18-0085

Glaze applicator side – outer shell

5 2 HG18-0003

Hinge Stud

6 4 903-7531SS

SST. ¼ Flat Washer, Regular

7 4 903-0979

SST. ¼-20 x 0.75 Hex Head Machine Screw

Parts list, HG18C Glazer

ITEM

(See Figure 18, HG18C Glazer Body)

ITEM

(See Figure 19, HG18C Glaze Applicator)

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 21

20

Figure 18, Parts List, HG18C Glazer Body

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 22

21

Figure 19, Parts List, HG18C Glaze Applicator

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Page 23

22

Drain Tray

QTY

Part Number

Description

1 2 HG18-0042

Drain Tray Support Bracket

2 1 HG18EZ-6002

Drain Tray Support Rod

3 1 HG18EZ-8004

Drain Tray

Parts list, Drain Tray for HG18EZ and HG18C

(Drain Tray is optional)

ITEM

Belshaw-Adamatic Bakery Group HG18EZ/HG18C Glazer OM, MN-1755EN

CALL 800-578-2547 or EMAIL service@belshaw.com for SUPPORT

Figure 20, HG18EZ/HG18C Drain Tray

Loading...

Loading...