Page 1

belshaw-adamatic.com

Serving the donut and bakery industry for over 85 years

1-800-578-2547 ▪ info@belshaw-adamatic.com ▪ www.belshaw-adamatic.com

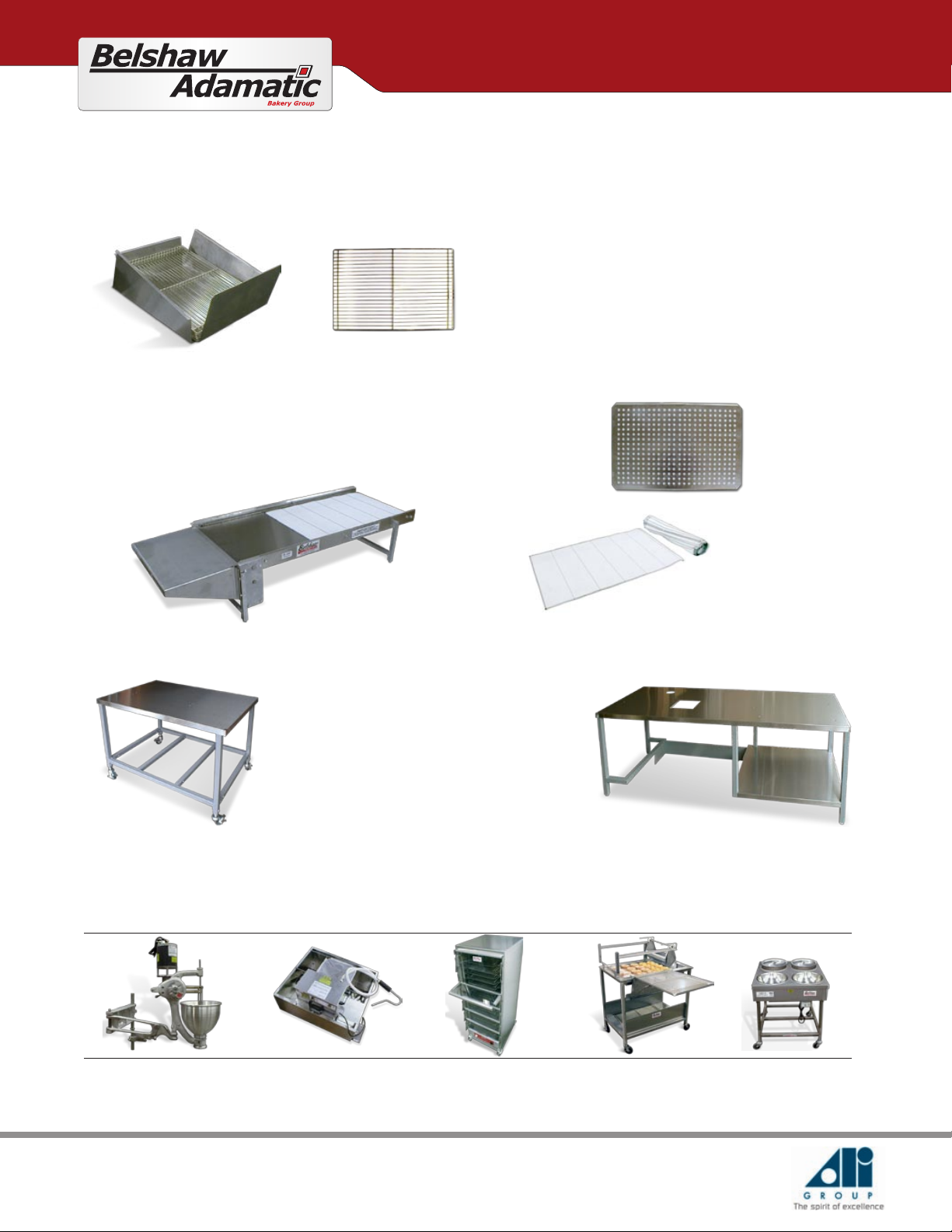

Accessories for Donut Robot® Mark VI System

Collecting and cooling donuts for transfer direct to icer or glazer

Mark VI systems feature the RL-18 Rack

Loader pictured. It smoothly gathers donuts

(or other similar products) fresh from the

fryer onto Glazing Screens so that the they

can be transferred direct to the glazer in

batches of 24. The screens can also be placed

direct on Belshaw’s HI18 high-production icer,

saving time and eliminating almost all product

Glazing ScreenRL-18 Rack Loader

Inserting yeast-raised donuts into the fryer

The FT-6 Feed Table accepts raised donuts from a proof box such as Belshaw’s

EP18/24. The donuts are laid on a Proofing Cloth and Proofing Tray to rise, then

transferred onto the FT-6. The Feed Table advances in time with the fryer and drops

the donuts into the fryer. The process allows the donut maker to move about rather

than standing in front of the fryer.

handling.

Proong Tray

Proong ClothsFT-6 Feed Table with extension

Mounting and storage tables for Mark VI

The FT-6 Mounting Table (left) secures the

FT-6 Feed Table while allowing it to slide back

while cake donut production is in progress. It is

movable on heavy duty height-adjustable casters.

The Mark VI Table supports and locks down the

fryer, has holes for the fryer drain and EZ Melt

rell tube, and is height adjustable. It houses the

EZ Melt 34 shortening lter below the fryer. Both

tables make efcient use of space with storage

available for shortening blocks, glazing screens,

Mark VI TableFT-6 Table

proong cloths and proong trays.

Other companion equipment for a Mark VI donut system

Depositing Cake Donuts Filtering Proong Glazing Icing

Type B or Type F Depositor

(see page 74)

EZ Melt 34 Melter-Filter

(see page 78)

EP18/24 Donut Proofer

(see page 80)

HG18/HG18EZ Glazers

(see page 82)

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2009 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

H+I Icers

(see page 84)

Page 2

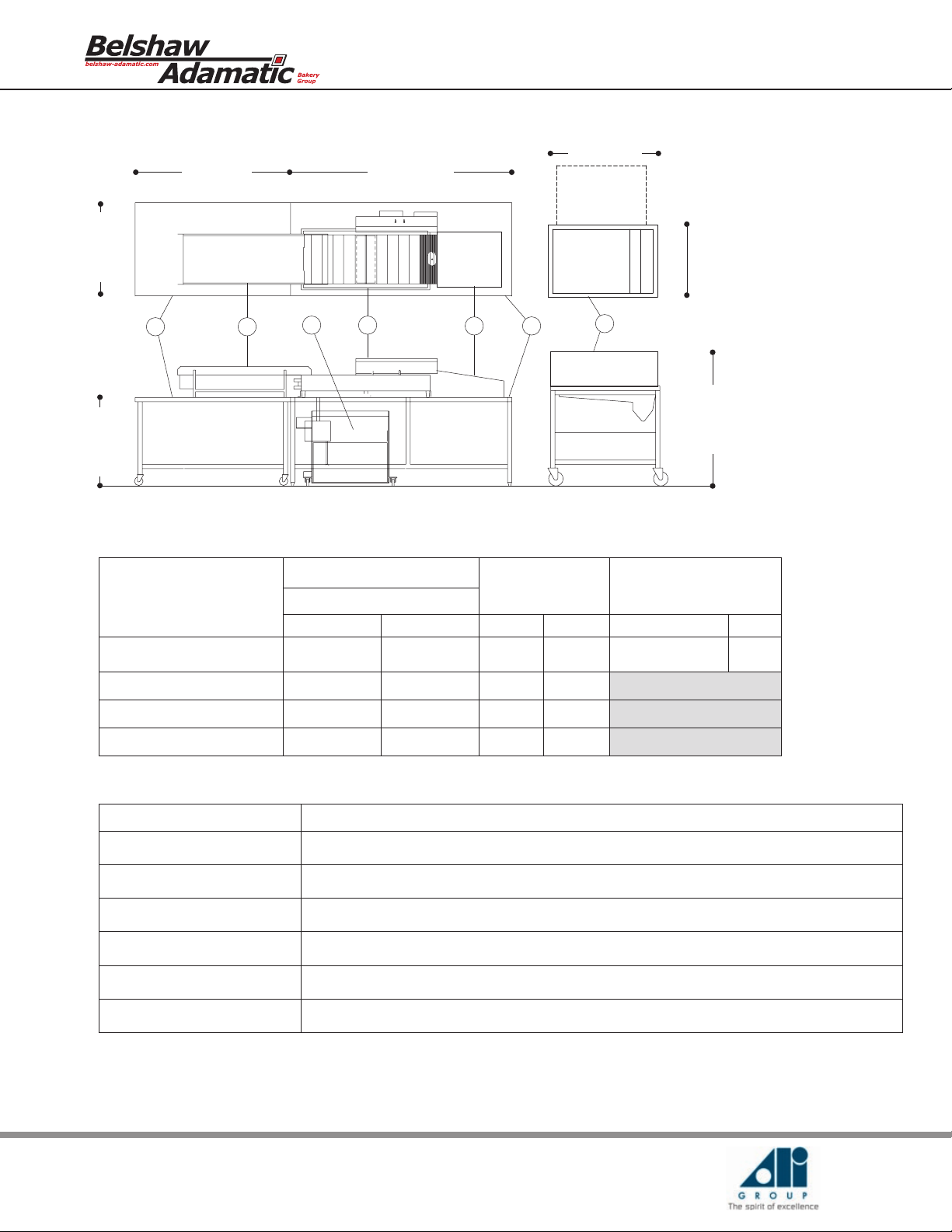

Mark VI System Sample Layout

30” (762 mm) 67” (1702 mm)

Accessories for

42” (1067 mm)

Donut Robot

®

Mark VI

32” (813 mm)

7

31” (787 mm)

34

5

1

6

2

Mark VI Accessories - Dimensions And Power

OVERALL DIMENSIONS

MODEL

FT-6 FEED TABLE 44 x 18 x 11 112 x 46 x 28 62 28

RACK LOADER (RL18) 21 x 29 x 10 53 x 74 x 25 25 11.5 N/A

MARK VI MOUNTING TABLE 77 x 32 x 31 196 x 81 x 79 275 125 N/A

Width x Depth x Height

in. cm. lbs. kg. V W

APPROX SHIPPING

WEIGHT

ELECTRICAL DATA

110V, 50/60Hz,1ph

(connected to fryer)

26” (660 mm)

1 Mark VI Fryer

2 Mark VI Table

3 FT VI Feed Table

4 Table for FT VI

34” (864 mm)

5 EZMelt 34 Melter-Filter

6 RL-18 Rack Loader

7 HG18-EZ Glazer

600

FT-6 MOUNTING TABLE 54 x 32 x 31 137 x 81 x 79 162 74 N/A

Mark VI Accessories - Other Specications

MODEL CONSTRUCTION

FT-6 FEED TABLE

RACK LOADER (RL-18) Loader is stainless steel. Glazing screens (available separately) are nickel plated steel.

MARK VI MOUNTING TABLE Frame is painted steel. Shelves are stainless steel. Casters are stainless steel.

FT-6 MOUNTING TABLE Frame is painted steel. Shelves and adjustable feet are stainless steel.

PROOFING CLOTHS with rods Proong cloths are polypropylene. Rods (1 per cloth) are mild steel.

PROOFING TRAYS Proong trays are aluminum with 1/2” (13mm) perforations.

Chains and hooks are stainless steel. Other parts are stainless steel, nickel plated steel, and cast aluminum

alloy. Extension (11”/28cm) is stainless steel.

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2009 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Loading...

Loading...