Page 1

Shortening Filter

EZ18/24/34

Operator’s Manual

and

Technical Supplement

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Tel: (206) 322-5474

Fax: (206) 322-5425

Toll Free (US): 1-800-578-2547

E-mail: service@belshaw.com

www.belshaw.com

Page 2

EZ Melt Fill & Filter

EZ18, EZ24 & EZ34

Operator’s Manual

Belshaw Bros., Inc.

814 44

Tth

Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

Email: service@belshaw.com • http://www.belshaw.com

Page 3

Page 4

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

shipping, file a freight claim with the shipping

company immediately.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

091609

MN-1317EN

Belshaw Bros., Inc.

Tth

814 44

ST NW Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

Email: service@belshaw.com • http://www.belshaw.com

Page 5

Page 6

Contents

1 Operation 1

Melting and Filling 5

Filtering 7

2 Cleaning 10

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 OM MN-1317EN iii

Page 7

Preface

The EZ Melt, Fill and Filter models EZ18, EZ24,

and EZ34 are designed to be used with Belshaw

fryers. It performs four functions:

• It melts shortening

• It holds shortening

• It supplies shortening to the fryer kettle

• It filters used shortening for re-use

It is not designed to perform any other functions.

The EZ Melt, Fill and Filter uses electrical

elements to melt shortening.

The EZ Melt moves around on casters. It is

meant to be used on the floor. The operator of

the EZ Melt is expected to behave safely and to

read this manual and follow its instructions and

warnings.

Study the instructions and warnings in this

manual carefully. A thorough understanding of

how to install, maintain, and safely operate the

EZ Melt, Fill and Filter will prevent production

delays and injuries.

To use the EZ Melt safely, heed the following

warnings and all other warnings that appear in

this manual:

• Make sure all hose connections are tight.

If you do not, you may be sprayed with

hot shortening. This could result in

serious burns.

• Make sure no water gets into the

shortening. Water causes hot shortening

to spatter, which could cause serious

burns.

• Make sure the EZ Melt kettle has enough

room in it before draining shortening

from the fryer. If you do not, shortening

may overflow the kettle and get on the

floor, possibly causing slips, falls, injury,

burns, or even death.

• Hot shortening can cause serious burns.

Make sure that proper protective gear

(face shield, gloves and apron) are worn

before filtering, disassembly and

cleaning.

• Make sure the nozzle of the supply hose

is securely mounted on the side of the

fryer before turning on the pump. If you

do not, hot shortening could spray you,

resulting in serious burns. Also,

shortening could get on the floor,

possibly causing slips, falls, injury,

burns, or even death.

• Make sure that the system and the

shortening are cool before attempting

any adjustments or repairs. If you do

not, you may be burned.

• Be careful never to get shortening,

water, or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. If you do not,

someone could slip or fall, be burned or

injured, or even die.

• To avoid damaging the EZ Melt, never

use force to assemble, disassemble,

operate, clean, or maintain it.

• To avoid electrocution, make sure that

the power cord is not frayed or cracked

and that it does not pass through any

water or shortening.

• Make sure that the power cord is routed

so that no one will trip over it.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1317EN EZ18, EZ24, EZ34 OM

Page 8

1 Operation

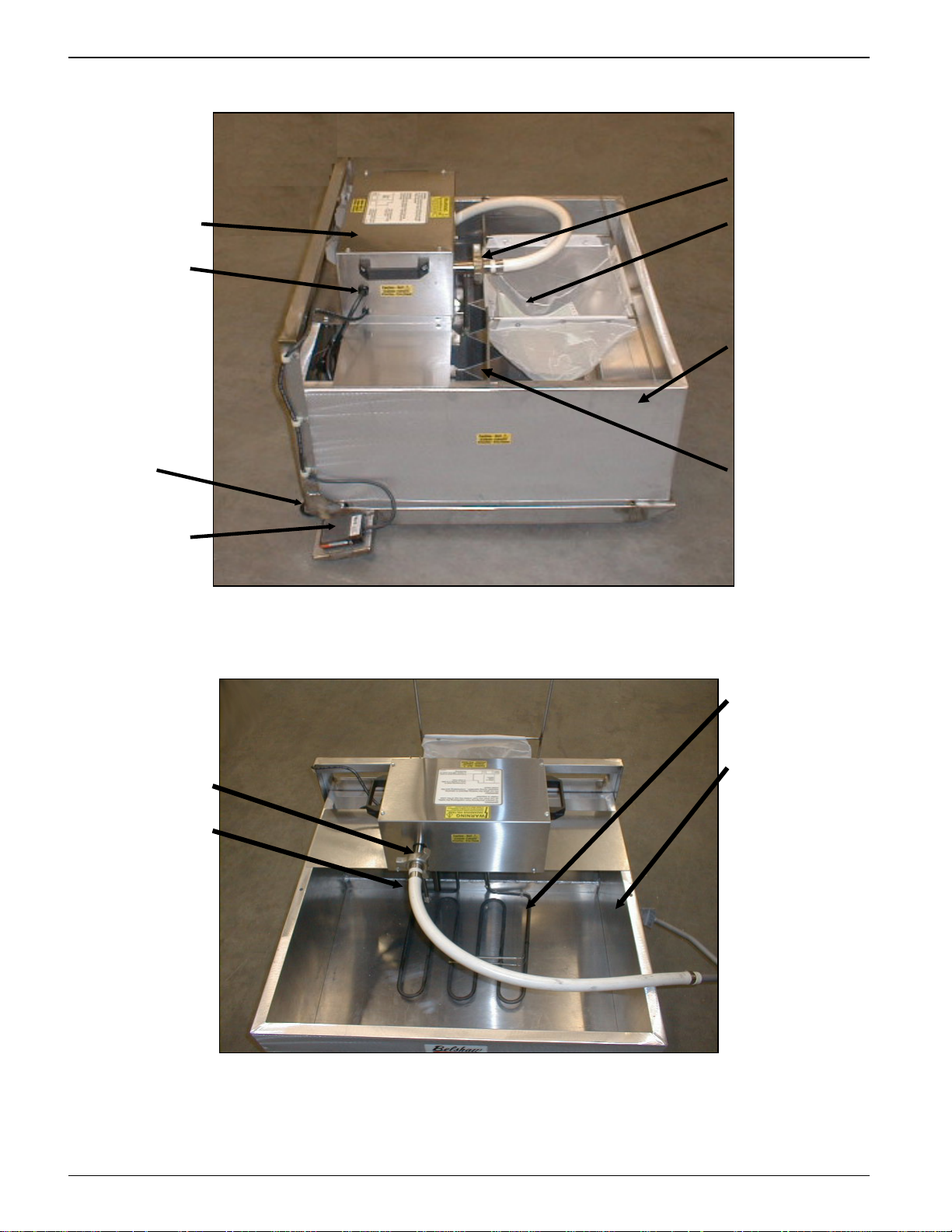

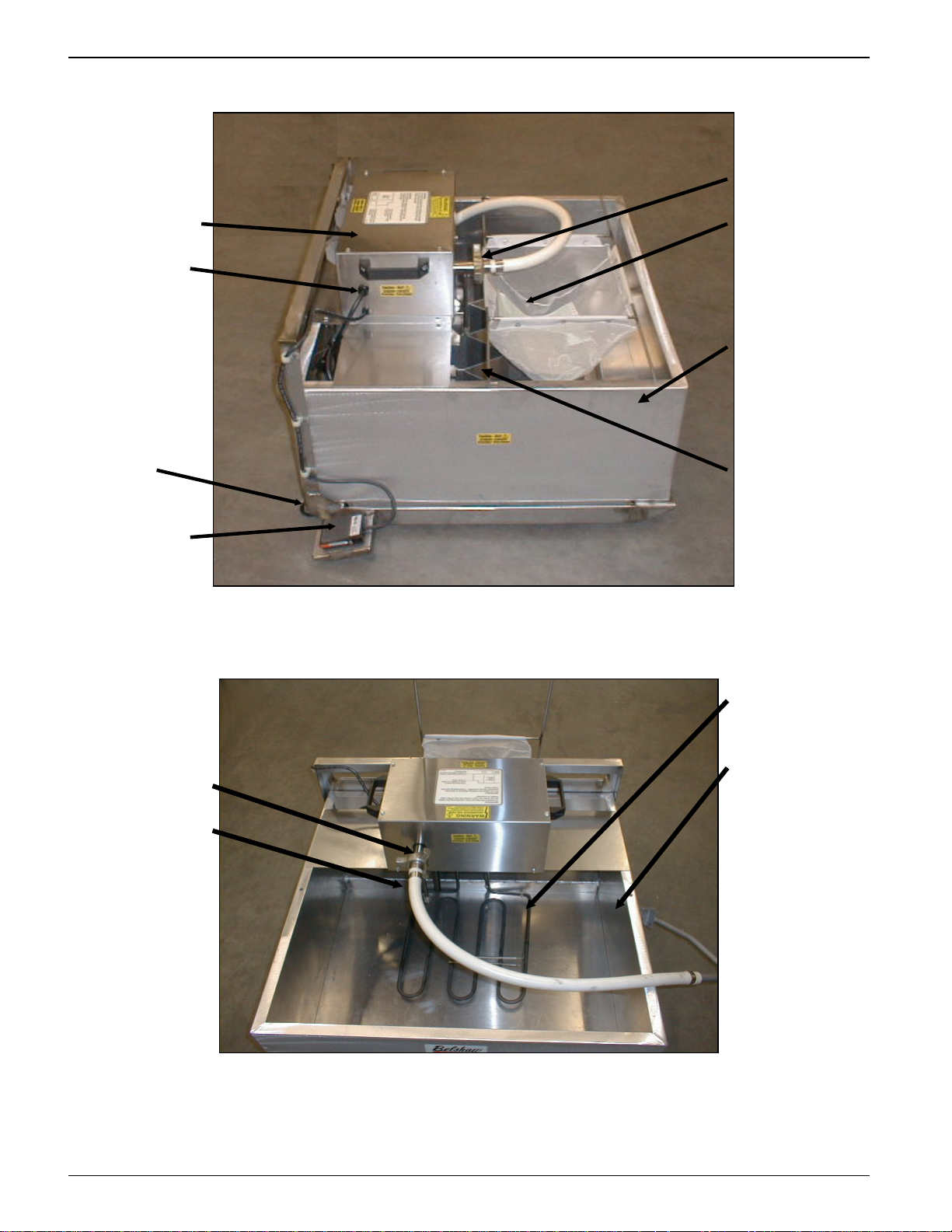

To help familiarize you with the major parts of

your EZ Melt model EZ18, EZ24, or EZ34, please study the

photographs below.

handle heater head filter assembly kettle

casters

foot pedal

Figure 1-1. Front View.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 OM MN-1317EN 1

Page 9

hose connector

heater head

power cord

frame with

casters

foot pedal

filter assembly

kettle

cube melter

Figure 1-2. Side View.

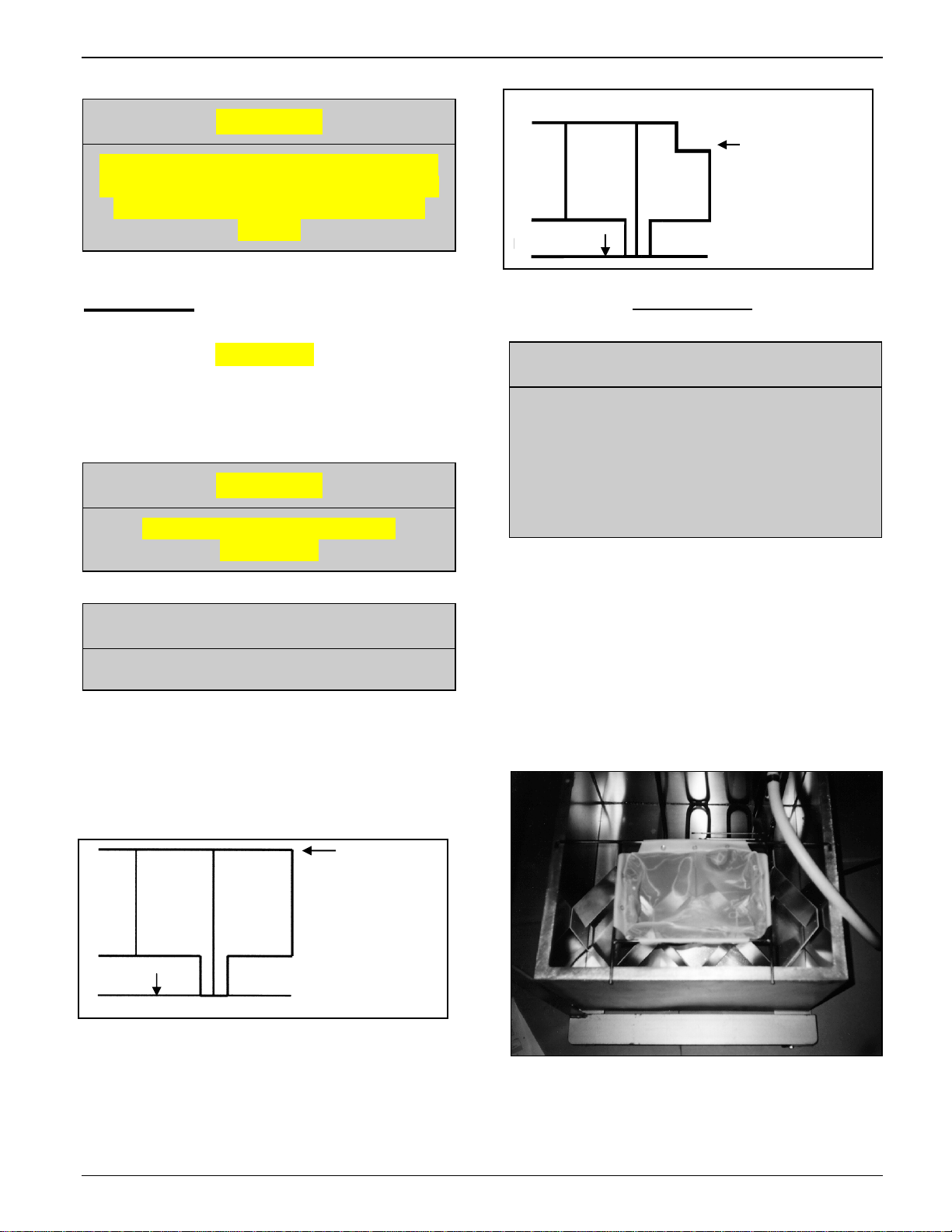

hose connector

supply hose

heating

element

kettle

Figure 1-3. Top View, Heater Head.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1317EN EZ18, EZ24, EZ34 OM

Page 10

Reset

button

Pump switch with

pilot light

Heat

switch

with pilot

light

Figure 1-4. Heater head

Bleeder

Pickup tube

Heating

element

kettle

Figure 1-5. Elements and kettle.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 OM MN-1317EN 3

Page 11

Thoroughly clean your EZ Melt before using it.

Refer to Section 2, “Cleaning,” for cleaning

instructions.

WARNING

Moisture causes hot shortening to spatter,

which may cause serious injury. Thoroughly

dry the kettle and any other parts you wash.

WARNING

To avoid electrocuting yourself or damaging

the EZ Melt, never allow water, steam,

cleaning solution, or other liquid to enter the

heater head.

Make sure that the power requirements of the EZ

Melt, shown on the data plate, match your power

source.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1317EN EZ18, EZ24, EZ34 OM

Page 12

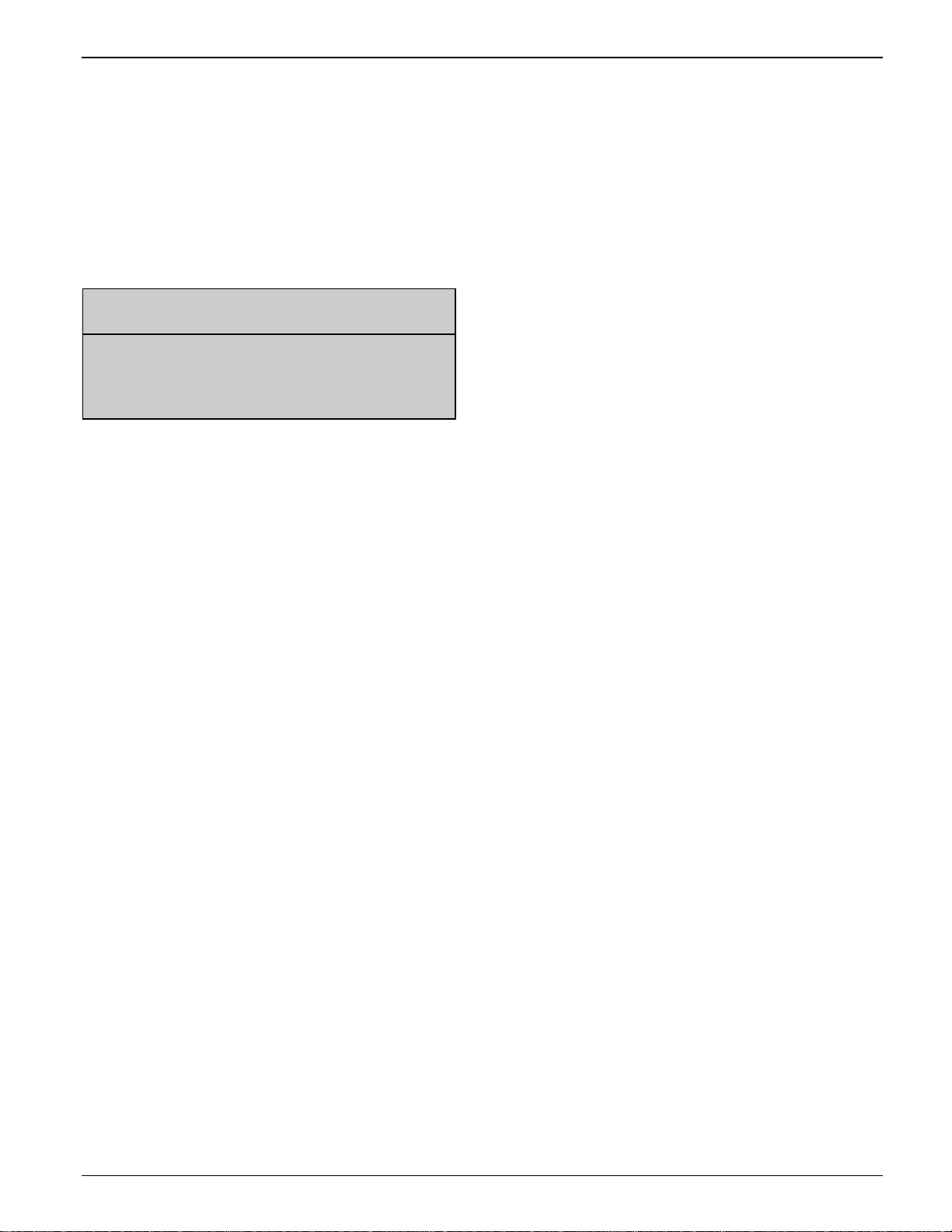

Melting and Filling

1. Completely cover the heating element with

shortening. There are two ways to do this:

• Pre-melt some shortening in a pan on the

stove and pour it into the kettle to cover

the element.

• Pack solid shortening tightly around the

heating element and bulbs. Do not leave

any air spaces. Cover the heating element

at least 2”/5 cm. (See Figure 1-6)

WARNING

Air spaces can cause the shortening to

overheat and catch on fire.

Figure 1-7. Cube Melter

2. Install the cube melter in the kettle, opposite

the heater head. Push the cube melter through

the shortening so its legs rest on the bottom

of the kettle. (See Figures 1-7 & 1-8.)

Figure 1-6. Packing Solid Shortening in the

Kettle.

Figure 1-8. Installing the Cube Melter.

3. Position the EZ Melt near the fryer.

4. Install the supply hose. Follow these steps:

a. Attach the hose to the pump outlet by

hand-tightening the hose connector.

b. Mount the nozzle of the hose on the edge

of the fryer kettle with the opening

inside the kettle.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 OM MN-1317EN 5

Page 13

5. Make sure that the HEAT and PUMP

switches are in the OFF position. Connect

the EZ Melt to the power source.

To avoid damaging the heating element, make

sure it is completely covered with shortening

before you turn the heater on.

6. Turn the machine on using the HEAT

switch. When the heat is on, the heating

element melts shortening at 200°F/93°C.

The heat must also be on to operate the

pump.

7. Turn the pump on using the PUMP switch.

8. When you want to supply shortening to the

fryer, press the foot pedal.

WARNING

To avoid burning yourself, never touch the

nozzle while the machine is in use.

SIDE OF

CUBE

MELTER

BOTTOM OF

KETTLE

IF SHORTENING

LEVEL IS HERE

OR BELOW ADD

ONE CUBE OF

SHORTENING.

Figure 1-9A. (EZ34 ONLY) When to Add a

Cube of Shortening.

To add a cube of shortening, follow these steps:

1. Position the filter assembly so you can

add shortening. The edge of the kettle

has one or two sets of holes in it. Use

the set of holes that is nearer to the

heater head. When two of the filter

frame’s pins rest in these holes, the filter

assembly hangs vertically. (See Figure

1-10.)

9. When the fryer has enough shortening in it,

release the foot pedal.

10. As needed, add shortening to the kettle, one

cube at a time. Always add a cube if the

shortening level drops to the tops of the legs

of the cube melter. (See Figure 1-9 & 1-9A.)

SIDE OF

CUBE

MELTER

BOTTOM OF

KETTLE

IF

SHORTENING

LEVEL IS

HERE OR

BELOW ADD

ONE CUBE OF

SHORTENING

Figure 1-9. When to Add a Cube of

Shortening.

Figure 1-10. Positioning the Filter Frame for

Melting.

b. Place a solid cube of shortening on the

cube melter. Let one cube melt and be

pumped out before adding another cube.

Do not overload the EZ Melt.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

6 MN-1317EN EZ18, EZ24, EZ34 OM

Page 14

WARNING

Be careful with hot shortening. Always wear

proper protective gear (face shield, apron and

gloves) when filtering, disassembling and

cleaning

Filtering

1. Turn the fryer off. Allow the shortening

to cool to 250°F/121°C. Because hot

shortening is dangerous, FILTER

SHORTENING AT THE LOWEST

TEMPERATURE THAT WORKS. Hot

shortening may also trip the pump motor.

WARNING

Maximum filtering temperature is

325°F/163°C

WARNING

Hot shortening may cause serious injury.

2. Turn the EZ Melt off. Make sure that both

the HEAT and PUMP switches are in the

OFF position.

Side of

cube

melter.

If

shortening

level is here

or below

drain fryer.

Bottom of

kettle.

Figure 1-11A. (EZ-34 ONLY) When to Drain

the Fryer.

WARNING

When you begin to drain the fryer, the

shortening in the EZ Melt must be shallow

enough for the top of the cube melter to be

exposed. If the shortening is deeper it might

overflow when you drain the fryer, thus

causing burns or other serious injury.

4. Position the shortening filter assembly on

the EZ Melt kettle. The edge of the kettle

has one or two sets of holes in it. Use the

set of holes that is farther from the heater

head. When two of the filter frame’s pins

rest in these holes, the filter assembly rests

horizontally on the end of the kettle. (See

Figure 1-12.)

3. Make sure that the top of the cube melter is

exposed.

If

Side of

Cube

Melter.

shortening

level is

here or

below

Bottom of

kettle.

drain fryer.

Figure 1-11. When to Drain the Fryer.

Figure 1-12. Positioning the Filter Assembly

for Filtering.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 OM MN-1317EN 7

Page 15

5. Disconnect the supply hose from the hose

connector. Hold the two ends of the hose up

so shortening does not drip out. Hang hose

vertically over a pan so the shortening will

drip into the pan.

6. Attach the rinsing hose securely to the hose

connector. (See Figure 1-13.)

WARNING

To avoid burning yourself, never hold or

touch the metal portion of the nozzle while

the machine is in use. Wear protective

gloves.

WARNING

Thoroughly clean and dry the floor if

shortening, water, or other materials are

spilled. Materials spilled on the floor may

cause serious injury and loss of life.

11. After you have rinsed all the loose particles

out of the fryer kettle, release the foot pedal.

12. After the shortening has drained out of the

fryer kettle and through the EZ Melt filter,

close the drain valve.

Figure 1-13. Rinsing Hose.

7. Position the EZ Melt so the filter is directly

under the drain in the fryer kettle.

8. Reach under the table and slowly open the

fryer’s drain valve.

9. Move the HEAT and PUMP switches of the

EZ Melt to the ON position.

10. Hold the insulated handle of the hose.

Direct the nozzle into the fryer kettle. Press

the foot pedal and rinse the kettle with

shortening. Do not let shortening splash out

of the kettle!

13. Turn the EZ Melt off. Make sure that both

the HEAT and PUMP switches are in the

OFF position.

14. Disconnect the rinsing hose assembly. Hold

the two ends of the hose up so shortening

does not drip out. Hang the hose vertically

over a pan so shortening will drip into the

pan.

15. Bring the supply hose back to the EZ Melt,

holding the two ends of the hose up so

shortening does not drip out.

16. Securely attach the supply hose to the hose

connector. Make sure the outlet nozzle is

securely mounted to the fryer, with the

opening inside the kettle.

17. Move the HEAT and PUMP switches to the

ON position. Press the foot pedal to supply

filtered shortening to the fryer.

18. Before you filter shortening again, empty the

EZ Melt filter. Follow these steps:

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

8 MN-1317EN EZ18, EZ24, EZ34 OM

Page 16

a. Allow the filter assembly to cool to the

touch.

b. Lift off the filter assembly, holding it by

the frame.

c. Invert the filter assembly over a sink or

garbage can and shake the sediment off

of it. DO NOT rinse the filter.

WARNING

Rinsing the filter could cause water to drop

into the kettle. Hot shortening could spatter

and cause serious injury.

d. Put the filter assembly back on the EZ

Melt.

To order replacement filters for your EZ Melt,

call Belshaw.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 OM MN-1317EN 9

Page 17

2 Cleaning

8. Clean the EZ Melt filter. Follow these

WARNING

steps:

Be careful with hot shortening. Always wear

proper protective gear (face shield, apron and

gloves) when filtering, disassembling and

cleaning

Clean the EZ Melt after every use. Follow these

steps:

1. Turn on the heat and the pump.

2. Press the foot pedal to pump shortening out

of the EZ Melt and into a metal container or

fryer kettle.

3. When you cannot pump any more

shortening out of the EZ Melt, release the

foot pedal. Turn off the heat and the pump.

4. Disconnect the EZ Melt from the power

source.

5. Disconnect the filter hose assembly while

still hot and drain any remaining shortening

back into the filter kettle to prevent

shortening from hardening in the hose.

6. Store the hose hanging vertically with the

lower end of the hose in a metal container to

catch any shortening that may drip.

7. Allow the shortening in the EZ Melt kettle

to cool to 115°F/46°C.

a. Allow the filter assembly to cool to the

touch.

b. Lift off the filter assembly, holding it by

the frame.

c. Invert the filter assembly over a sink or

garbage can and shake the sediment off

of it.

d. Unsnap the filter to remove it from the

filter frame.

e. Rinse the remaining shortening and

crumbs off of the filter.

WARNING

Thoroughly clean and dry the floor if

shortening, water, or other materials are

spilled. Materials spilled on the floor may

cause serious injury and loss of life.

9. Remove the cube melter.

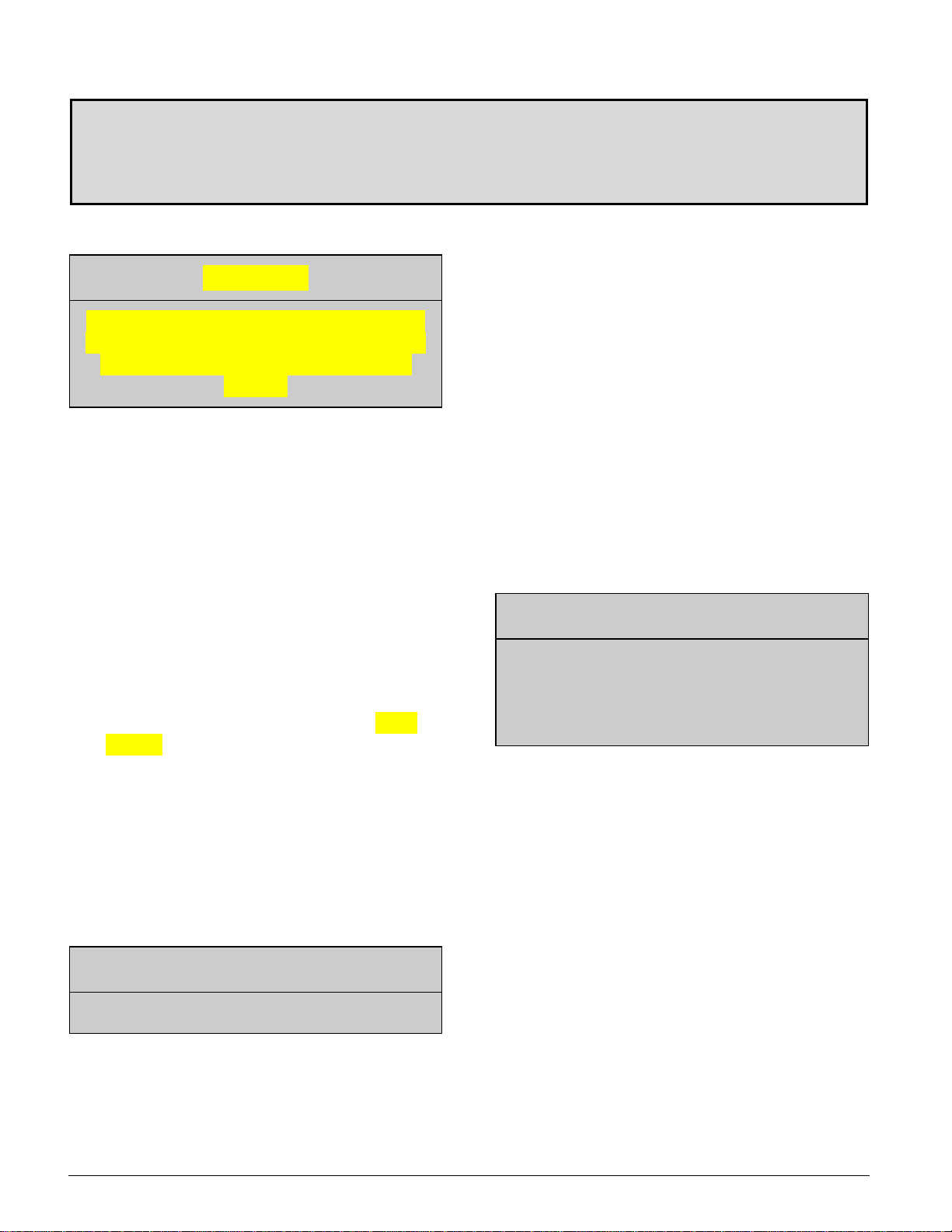

10. Loosen the two fasteners at the back of the

heater head, lift it off the kettle and place it

in a clean safe place. The foot valve and

cord will unsnap from the frame. See Figure

2-1.

WARNING

Hot shortening can cause serious injury.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

10 MN-1317EN EZ18, EZ24, EZ34 OM

Page 18

15. Dry all the parts completely. The kettle and

all other parts must be completely dry before

you use the EZ Melt again.

WARNING

Failure to dry the kettle and all parts of the EZ

Melt completely may cause shortening to

spatter or erupt. Shortening will overflow the

EZ Melt and may result in fire, injury, or

death.

16. Re-assemble the EZ Melt.

Figure 2-1. Removing the Heater Head.

(Place heater head as shown above so no

damage is done to the element.)

WARNING

Do not touch the heating element! It is very

hot and will burn you.

11. Remove the kettle from the frame. You

must remove it from the rear.

12. Pour any shortening remaining in the kettle

into a metal container. If it is too heavy or

awkward for you to lift by yourself, get

someone to help you.

WARNING

Thoroughly clean and dry the floor if

shortening, water, or other materials are

spilled. Materials spilled on the floor may

cause serious injury and loss of life.

13. Scrape out any residue and discard it.

14. Wash the kettle, the cube melter, and the

filter frame with warm, soapy water.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 OM MN-1317EN 11

Page 19

EZ Melt Fill & Filter

EZ18, EZ24 & EZ34

Technical Supplement

Belshaw Bros., Inc.

814 44

Tth

Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

Email: service@belshaw.com • http://www.belshaw.com

Page 20

Page 21

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

shipping, file a freight claim with the shipping

company immediately.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

021810

MN-1318EN

Belshaw Bros., Inc.

Tth

814 44

Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

Email: service@belshaw.com • http://www.belshaw.com

Page 22

Page 23

Contents

1 Installation 1

2 Troubleshooting 5

3 Appendix 7

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 TS MN-1318EN iii

Page 24

Preface

The EZ Melt, Fill and Filter models EZ18, EZ24,

and EZ34 are designed to be used with Belshaw

fryers. It performs four functions:

• It melts shortening

• It holds shortening

• It supplies shortening to the fryer kettle

• It filters used shortening for re-use

It is not designed to perform any other functions.

The EZ Melt, Fill and Filter uses electrical

elements to melt shortening.

The EZ Melt moves around on casters. It is

meant to be used on the floor. The operator of

the EZ Melt is expected to behave safely and to

read this manual and follow its instructions and

warnings.

Study the instructions and warnings in this

manual carefully. A thorough understanding of

how to install, maintain, and safely operate the

EZ Melt, Fill and Filter will prevent production

delays and injuries.

To use the EZ Melt safely, heed the following

warnings and all other warnings that appear in

this manual:

• Make sure all hose connections are tight.

If you do not, you may be sprayed with

hot shortening. This could result in

serious burns.

• Make sure no water gets into the

shortening. Water causes hot shortening

to spatter, which could cause serious

burns.

• Make sure the EZ Melt kettle has enough

room in it before draining shortening

from the fryer. If you do not, shortening

may overflow the kettle and get on the

floor, possibly causing slips, falls, injury,

burns, or even death.

• Hot shortening can cause serious burns.

Make sure that proper protective gear

(face shield, gloves and apron) are worn

before filtering, disassembly and

cleaning.

• Make sure the nozzle of the supply hose

is securely mounted on the side of the

fryer before turning on the pump. If you

do not, hot shortening could spray you,

resulting in serious burns. Also,

shortening could get on the floor,

possibly causing slips, falls, injury,

burns, or even death.

• Make sure that the system and the

shortening are cool before attempting

any adjustments or repairs. If you do

not, you may be burned.

• Be careful never to get shortening,

water, or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. If you do not,

someone could slip or fall, be burned or

injured, or even die.

• To avoid damaging the EZ Melt, never

use force to assemble, disassemble,

operate, clean, or maintain it.

• To avoid electrocution, make sure that

the power cord is not frayed or cracked

and that it does not pass through any

water or shortening.

• Make sure that the power cord is routed

so that no one will trip over it.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1318EN EZ18, EZ24, EZ34 TS

Page 25

1 Installation

To help familiarize you with the major parts of

your EZ Melt model EZ18, EZ24, or EZ34, please study the

photographs below.

handle heater head filter assembly kettle

casters

foot pedal

Figure 1-1. Front View.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 TS MN-1318EN 1

Page 26

hose connector

heater head

power cord

frame with

casters

foot pedal

filter assembly

kettle

cube melter

Figure 1-2. Side View.

hose connector

supply hose

heating

element

kettle

Figure 1-3. Top View, Heater Head.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1318EN EZ18, EZ24, EZ34 TS

Page 27

Reset

button

Pump switch with

pilot light

Heat

switch

with pilot

light

Figure 1-4. Heater head

Bleeder

Pickup tube

Heating

element

kettle

Figure 1-5. Elements and kettle.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 TS MN-1318EN 3

Page 28

Thoroughly clean your EZ Melt before using it.

Refer to Section 2 in the Operator's Manual,

“Cleaning,” for cleaning instructions.

WARNING

Moisture causes hot shortening to spatter,

which may cause serious injury. Thoroughly

dry the kettle and any other parts you wash.

WARNING

To avoid electrocuting yourself or damaging

the EZ Melt, never allow water, steam,

cleaning solution, or other liquid to enter the

heater head.

Make sure that the power requirements of the EZ

Melt, shown on the data plate, match your power

source.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1318EN EZ18, EZ24, EZ34 TS

Page 29

2 Troubleshooting

This section is designed as an aid in troubleshooting, not as a substitute for a qualified

technician. You may encounter a problem with

your EZ Melt that is not covered in this section,

or you may try the remedies suggested here and

find that they do not correct the problem. In

either case, feel free to call Belshaw Bros. at

(206)322-5474. One of our customer support

representatives will be happy to help you. When

you call, please specify the following:

• The model number of the machine.

• The serial number of the machine.

• The voltage, phase, and hertz (cycle) of

the machine.

CAUTION

If you perform repairs yourself or have them

performed by anyone other than Belshaw

Bros. or a service technician authorized by

Belshaw Bros., you do so at your own risk.

For factory service, call us for a return goods

authorization. Then send your machine to us,

freight prepaid, with your instructions for

service, your phone number, and the name of the

person for us to contact when we have made a

cost estimate. In most cases, the machine can be

shipped back, freight collect, within five days.

To avoid down time, call us to see whether we

have a machine we can loan to you while your

machine is being serviced.

Ship machines in need of servicing to:

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Following is a troubleshooting chart to help you

identify and solve some basic problems.

WARNING

Disconnect the machine from the power

source before disassembling, repairing, or

wiring.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 TS MN-1318EN 5

Page 30

THE SHORTENING DOES NOT FLOW FREELY THROUGH THE FILTER

SYSTEM

Possible Causes What To Do

The hose is crimped. Straighten the hose.

Solid shortening is building up inside the hose and

pump

To avoid being burned, before doing any of the

The hose is clogged with shortening. Soak the hose in warm or hot water to help release

The drain tube is clogged with solid shortening. Remove the drain tube and soak it in warm or hot

The pickup tube is clogged with residue. Remove the pickup tube and clean it.

Filter shortening at a higher temperature.

WARNING

following, turn off the EZ Melt and allow the

shortening to cool.

the clogged shortening. Hang it up and let it dry

before you use it again.

water to help release the clogged shortening.

THE PUMP MOTOR WILL NOT RUN

Possible Causes What To Do

The connection of the power cord to the power

source is faulty.

The circuit breaker has been tripped. Press the reset button.

The power switch is defective. Repair or replace the power switch.

The motor is defective. Repair or replace the motor.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

6 MN-1318EN EZ18, EZ24, EZ34 TS

Make sure the power cord is fully plugged in to a

proper power source.

If the problem persists, consult your Belshaw

dealer, or call Belshaw.

WARNING

Before doing the following, turn off the

machine, allow it to cool, and disconnect it

from the power source.

Page 31

3 Appendix

See Parts List Drawing Insert Page.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

EZ18, EZ24, EZ34 TS MN-1318EN 7

Loading...

Loading...