Belshaw BX4E Service Manual

OPERATING AND MAINTENANCE

MANUAL

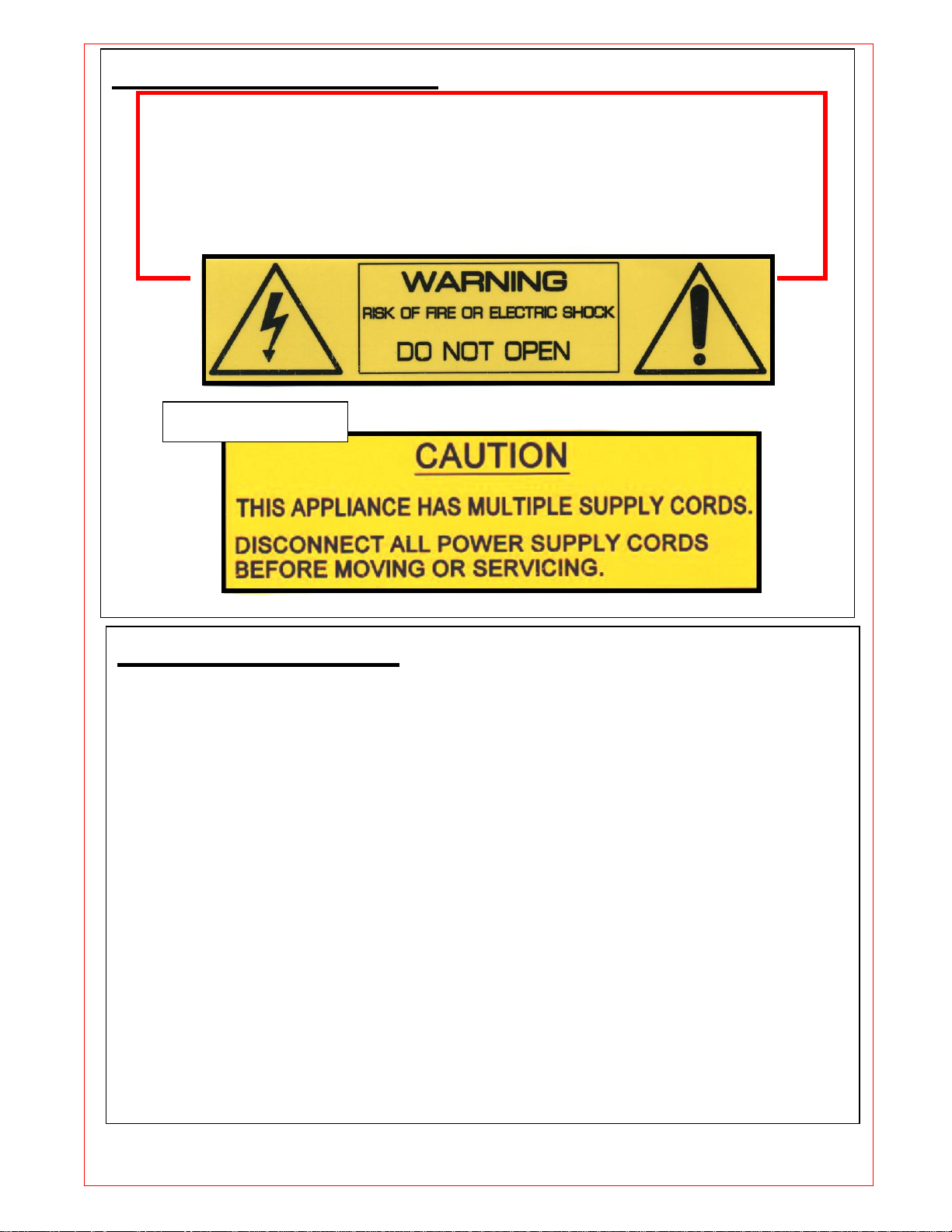

CAUTION

Enter Serial No. here

In

the event of an enquiry please quote this serial number.

BX ECOTOUCH Convection Oven

THIS APPLIANCE HAS MULTIPLE SUPPLY CORDS.

CONNECT ALL SUPPLY CORDS BEFORE MOVING OR CLEANING/SERVICING

DIS

2

LABELS ON THE OVEN

REPAIR SHOULD BE DONE BY AUTHORISED PERSONNEL ONLY

CAUTION LABEL

IMPORTANT NOTES

OVEN IS TO BE SEALED TO STAND, COUNTER OR SECOND

OVEN USING A NSF APPROVED SEALANT. APPLY A SMALL

CONTINUOUS BEAD AROUND THE PERIMETER OF THE UNIT.

FAILURE TO FOLLOW THE CLEANING AND MAINTENANCE

INSTRUCTIONS DETAILED IN THIS OWNER MANUAL COULD

WARNING LABEL, TO REDUCE RISK OF FIRE

OR ELECTRIC SHOCK

DO NOT REMOVE COVER (OR BACK)

NO USER SERVICEABLE PARTS INSIDE

AFFECT THE WARRANTY OF THIS OVEN.

“NSF REQUIRES THAT THIS EQUIPMENT IS TO

BE INSTALLED WITH ADEQUATE BACKFLOW PROTECTION

TO COMPLY WITH APPLICABLE FEDERAL, STATE AND

LOCAL CODES.”

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

3

14

CONTENTS

PAGE

PART 1.0 Introduction.

4

PART 2.0 Dimensions.

5

PART 3.0 Specifications.

6

PART 4.0 Safety.

7

PART 5.0 Installation.

8

PART 6.0 Isolation.

10

PART 7.0 Daily Cleaning.

11

PART 8.0 Weekly Cleaning.

12

PART 9.0 TOUCH SCREEN OPERATION

Basic operation

9-1.0 “PROGRAMMES” menu

16

9-2.0 Cleaning cycle

19

9-3.0 Settings

20

Time and date

21

General settings

22

High level settings

24

Pass codes

26

9-4.0 Using the USB port

27

PART 10.0 Maintenance

29

PART 11.0 Light bulb Replacement.

29

Frequently asked questions

30

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

4

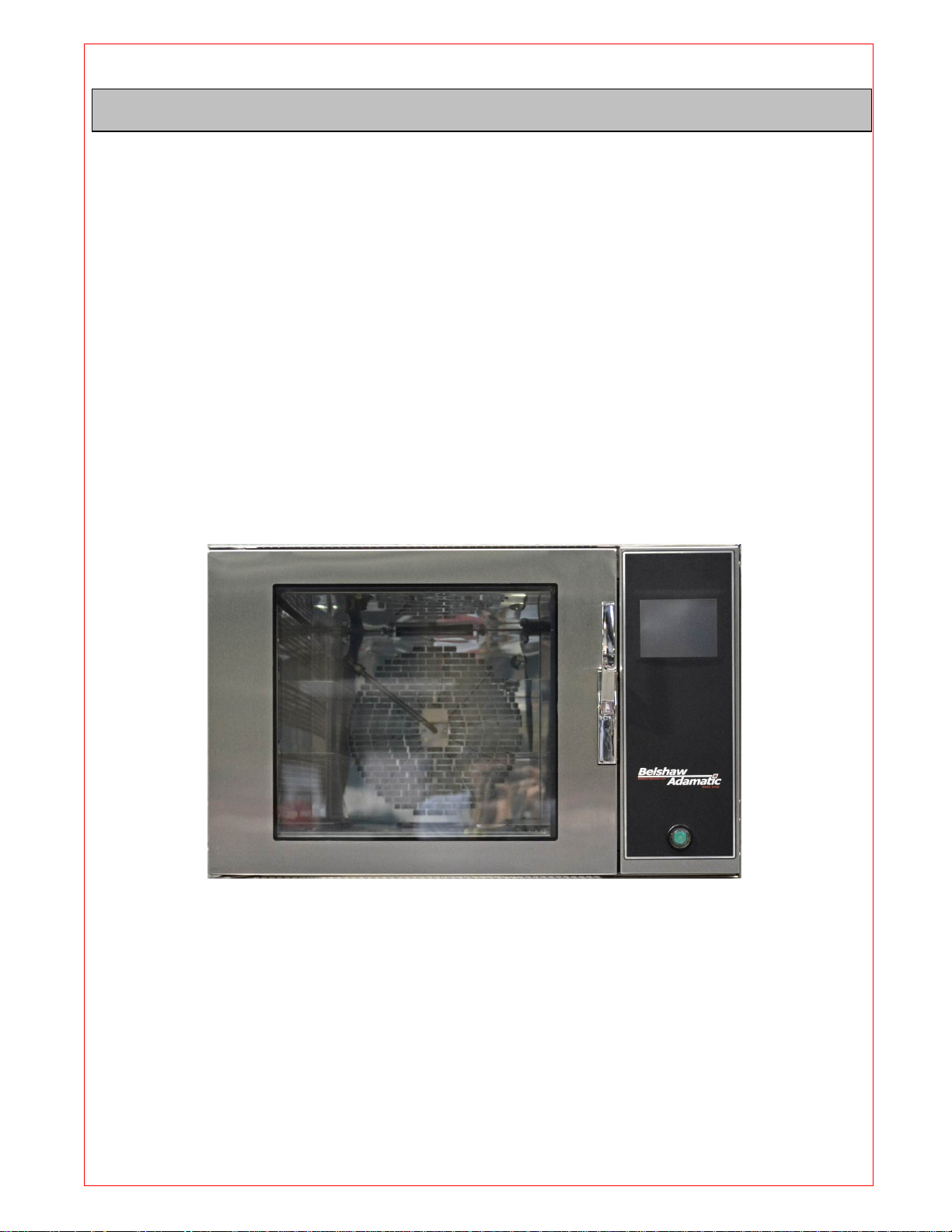

1.0 INTRODUCTION

The BX EcoTouch oven is a computerised, compact, electric convection oven with

steam capability and a capacity of three 26” x 18” trays.

The oven is constructed of stainless steel and features the state of the art Eco-Touch

controller with color display and 240 programmable recipes each with up to six steps in

which the bake time, temperature, steam time, fan and vent can be controlled.

Designed to be stackable, without the requirement for a separate support.

The high-speed fan and ring element provides efficient air circulation and an even bake

across a range of products

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

5

2.0 DIMENSIONS

EACH OVEN:

Height: 20.75"

Depth, door closed: 46"

Width: 34"

2" (50mm) clearance is required at the back and sides of the oven to allow

adequate circulation of air for cooling.

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

Net weight (1 oven) 370 lbs

Net weight (Short stand) 145 lbs

Net weight (Tall stand) 206 lbs

6

3.0 SPECIFICATIONS

“NSF REQUIRES THAT THIS EQUIPMENT IS TO BE

INSTALLED WITH

Electric: 208V/220V Three phase Power/120V single phase control

60Hz. 24Amps per phase

Loading: 7kW Ring element

Total Power: 7.5 kW.

0r

Electric: 240V Three phase Power/120V single phase control

60Hz. 24Amps per phase.

Loading: 8kW Ring element

Total Power: 8.5 kW.

POWER Cable: 6 feet of cable with NEMA L15-30P plug supplied.

CONTROL Cable: 6 feet of cable with NEMA 5-15P plug supplied.

Fan Drive: Direct to motor

Tray Size: 26” x 18”

Tray Capacity: 3.

Damper: Butterfly type.

Noise Level: Less than 85dB.

Water Supply: 20 PSI Cold water.

For proper operation of the steam system it is recommended that the water

supply follows the following specifications:

Hardness 0-4 grains per gallon

PH range 7.0 to 8.5

Chloride concentration 0 –30 ppm

Calcium 0 – 4 ppm

Magnesium 0 – 4 ppm

Alkalinity 0 – 20 ppm

Consult your water treatment company for proper water filtration system

information.

ADEQUATE BACKFLOW PROTECTION TO COMPLY WITH APPLICABLE

FEDERAL, STATE AND LOCAL CODES.”

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

7

CAUTION

ATTENTION

4.0 SAFETY

To safely use this convection oven, read this owner manual completely and follow

the warnings below, as well as all other warnings in this manual.

• The oven is designed for the baking of bread, confectionery and savory products.

Do not use it for baking other items without first consulting Belshaw/Adamatic.

• All repairs and maintenance of electrical units must only be carried out by an

authorized Belshaw/Adamatic service technician.

• Electrical access panels must not be opened unless the oven power cords are

unplugged. (There are two).

• All connections to the oven must be made in accordance with National, State,

and local codes and regulations.

• While the oven is in operation, and for some time after use, DO NOT TOUCH the

oven window and surrounding area as these surfaces may be hot.

• The oven must be operated as described in this manual.

• Use only original manufacturer spare parts on the oven.

• The construction of the oven must not be changed or altered.

• The owner of the oven is legally obligated to instruct staff using the oven in its

operation and in these safety regulations. The instructions must be readily

accessible for the operator.

THIS APPLIANCE HAS MULTIPLE SUPPLY CORDS.

DISCONNECT ALL SUPPLY CORDS BEFORE MOVING OR CLEANING/SERVICING

DO NOT BLOCK THE DAMPER VENT ON THE TOP OF THE OVEN

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

8

5.0 INSTALLATION

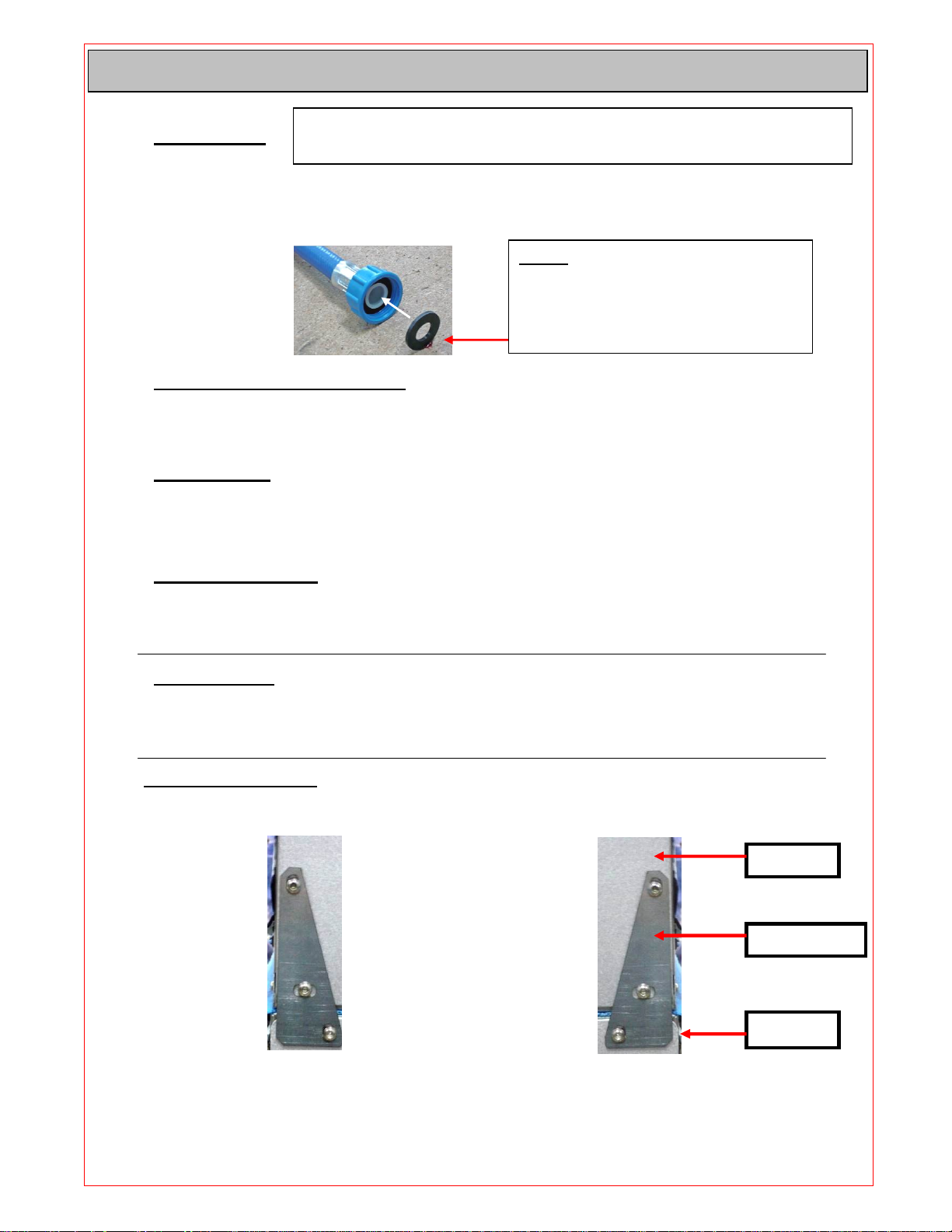

NOTE

OVEN

“NSF REQUIRES THAT THIS EQUIPMENT IS TO BE

INSTALLED WITH ADEQUATE

LOCAL CODES.”

BRACKET

Water Supply;

It is the customer’s responsibility to provide an appropriate water treatment system

that will supply water that meets the water specification listed on page 6.

The supply must be provided with a shut-off valve, pressure reduction valve and

pressure gauge.

• AMBIENT TEMPERATURES : -

Maintain ambient temperatures below 115° F (40° C) around the oven.

• CLEARANCE:

Provide 2” (50mm) clearance at the back and sides of this oven and 10” clearance at the

top to allow adequate air circulation.

• INITIAL CLEANING:

Before using the oven for the first time, Carefully wipe the interior and exterior of the oven

thoroughly with a clean cloth soaked in warm soapy water.

• BEFORE USE:

Fix top sealing ring M189-01-02000 over top pipe with NSF approved silicone sealant.

(as seen on the next page in the illustration for stacking ovens)

• IF A STAND IS USED under the oven, it must be sealed to the oven using a

continuous bead of NSF approved sealant around the perimeter and attached by two

brackets M189-05-00900 (one each side) at the rear.

BACKFLOW PROTECTION TO COMPLY WITH APPLICABLE FEDERAL, STATE AND

A RUBBER WASHER SHOULD BE

FITTED TO ENSURE A FULL SEAL

WITH WATER SUPPLY.

(Part Number A900-05-261)

CLAMPING BRACKET

M189-05-00900

LEFT SIDE

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

BASE

CLAMPING BRACKET

M189-05-00900

RIGHT SIDE

9

•

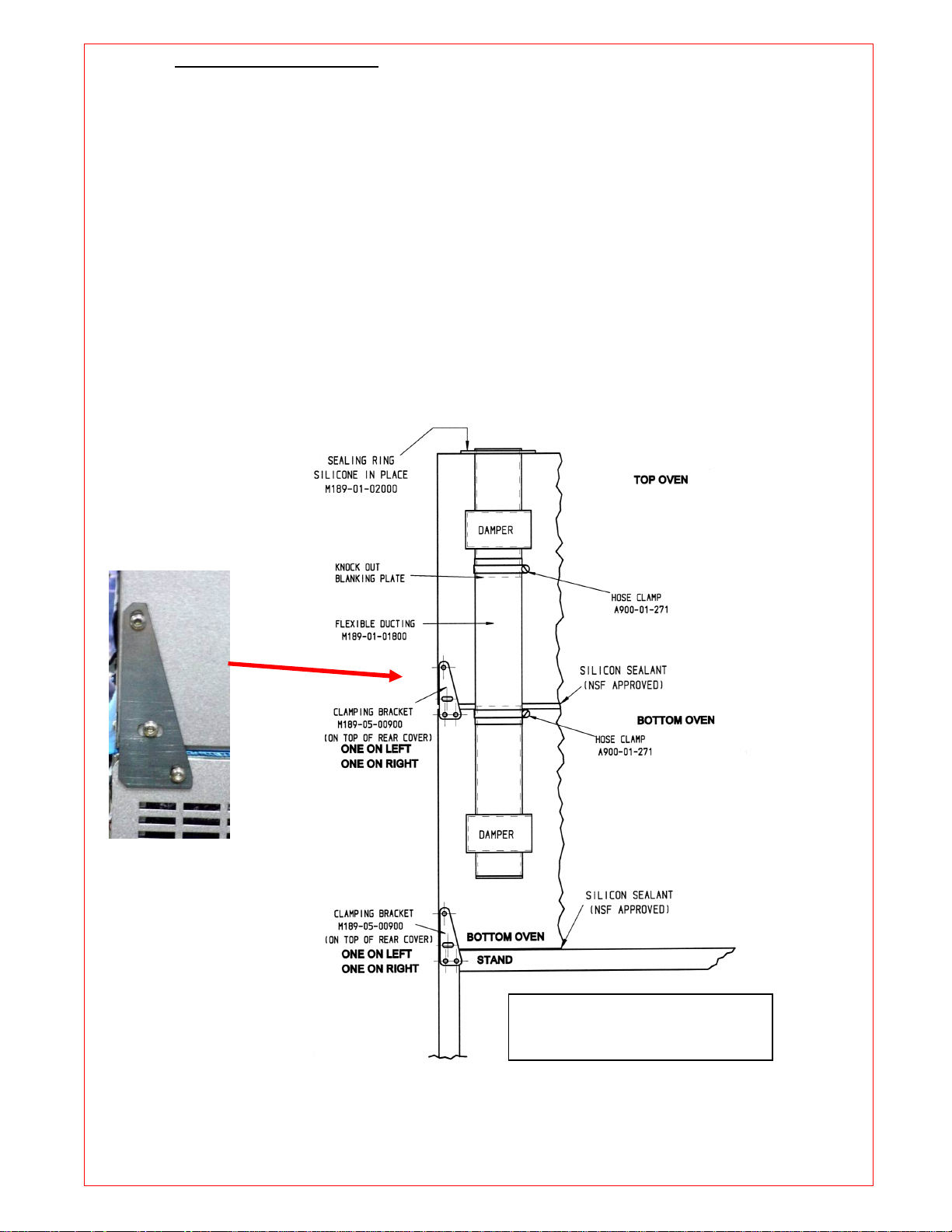

STACKING TWO OVENS

REAR VIEW OF

TWO

1. After applying a small continuous bead of NSF approved sealant around the perimeter of

the lower unit, position ovens one on top of the other

2. Remove both ovens rear covers.

3. Remove blanking plate (fixed with silicone sealant) from damper tube of upper oven.

4. Fit end of flexible ducting over top damper tube and attach to lower oven damper tube. Use

silicone sealant and worm drive clips to fasten in position.

5. Replace both ovens rear covers and fix ovens together using clamping bracket M189-05-

00900. (One each side at the rear.)

6. If a stand is used under the ovens, it must be sealed to the oven using a continuous bead

of NSF approved sealant around the perimeter and attached by two brackets M189-0500900 (one each side) at the rear.

7. Fix top sealing ring M189-01-02000 over top pipe with NSF approved silicone sealant.

RIGHT HAND OVENS

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

10

6.0 ISOLATION

T

o stop the oven in an emergency,

Unplug the oven from the outlets.

(THERE ARE TWO CABLES)

FG 189 ECO-TOUCH 26 x18 UL 3 TRAY Belshaw Adaamatic t full 03-12 RAC

Loading...

Loading...