Page 1

Proofing / Holding Cabinet

Model Nbr: BAP85-8.

BAP85-12.

Installation and Operation Manual

233229 - 1

Page 2

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in

writing by the manufacturer.

In line with policy to continually develop and improve its products, Belshaw Adamatic, reserves the right to change the specifications

and design without prior notice.

© Copyright Belshaw Adamatic. April 2009

Page 3

US/Canada/Mexico Limited Warranty and Return Policy

Belshaw Adamatic Bakery Group warrants parts of its manufacture and assembly of equipment to be free

from defects in workmanship and material which would result in product failure under normal use and

service. Belshaw Adamatic Bakery Group’s entire liability under this Warranty is limited to either repairing

or replacing at its factory or; on user’s premises, at Belshaw Adamatic Bakery Group’s option, any

equipment or parts thereof, which shall be determined by Belshaw Adamatic Bakery Group to be defective.

If necessary to return parts to the factory they must be shipped transportation charges prepaid. This

shall be purchaser’s sole and exclusive remedy.

Belshaw Adamatic Bakery Group reserves the right to make changes in design, or add any improvement, at

any time without incurring any obligations to install the same, on equipment previously sold.

This warranty is expressly in lieu of any and all other warranties express or implied, including:

implied warranties of merchantability and fitness for any particular purpose, and all other

obligations or liabilities what so ever on Belshaw Adamatic Bakery Group’s part. All statutory

or implied warranties, other than title, are expressly nullified and excluded.

Belshaw Adamatic Bakery Group neither assumes nor authorizes any person to assume for it

any obligation or liability in connection with the sale of its products or parts thereof.

Possession, use/or operation of equipment, or parts sold hereunder for any other than their designed

purpose, or use of equipment which is in poor repair, modified, improperly operated, or neglected is done

at the owner’s risk. Belshaw Adamatic Bakery Group hereby disclaims any liability for these actions and

shall not be liable for defects in or for any damages or loss to the property sold which is attributable to

such actions.

Under no circumstances shall Belshaw Adamatic Bakery Group be liable for any indirect,

special, incidental, or consequential damages arising out of, or from the use of Belshaw

Adamatic Bakery Group’s product by buyer, it assignees, employees, agents or customers.

Belshaw Adamatic Bakery Group makes no express warranties except those contained in this Warranty

concerning the product sold hereunder. No modification or alteration of this Warranty shall be made

except by Belshaw Adamatic Bakery Group in writing.

Warranty Period / Guidelines

This limited warranty shall extend for a period of one year from date of shipment and to the original owner

only. It covers parts (manufactured by Belshaw Adamatic Bakery Group) and labor. This warranty covers

only items sold within the United States, Canada and Mexico. A pre-authorization must be obtained from

Belshaw Adamatic Bakery Group before any warranty work is carried out, failure to do so may void the

warranty of the product.

Belshaw Adamatic Bakery Group www.belshaw-adamatic.com Phone (206) 322-5474 Fax: (206) 322-5425

Revised 03/10/2007 US / Canada / Mexico Limited Warranty Page 1 of 2

Page 4

Limited Warranty

With respect to parts not manufactured by Belshaw Adamatic Bakery Group, warranty coverage shall be

limited to the original part manufacturer’s warranty, or the Belshaw Adamatic Bakery Group limited

warranty, whichever is the lesser coverage period. In no case will the warranty be in excess of 18 months

after date of shipment of the equipment.

Replacement parts provided under the terms of this warranty are warranted for the remainder of the

original warranty period applicable to the product.

Exclusions:

This warranty excludes from its coverage and does not apply to: (a) solenoid and relay coils; (b) lamps;

(c) “O” rings; (d) belts; and (e) impellers. These items are excluded because (1) failure is usually due to

causes beyond our control; (2) it is not practical to accurately determine the failure cause; and (3) the

normal life of the parts is shorter than our warranty period.

Procedure for Return:

To speed up your credits for returned equipment, we have a return goods policy and procedure. Our

procedure starts with a phone call to (206) 322-5474 or Service Department for a return authorization.

When contacting Service Dept. you should be ready to give:

• Customer name, address, phone number and individual’s name, Invoice number and date, Model

number and serial number, reason for return (i.e. credit, exchange, warranty, or repair), description of

item, and problem.

When we get this information we will issue you a Return of Goods Authorization Number (RGA). This

number must be marked clearly on the outside of the package. If the package is not clearly marked with

the RGA#, then the package will be returned unopened to the sender. The RGA# will be open for 30 days,

if returnable goods have not been received within the 30 days, then RGA# will be voided.

Return goods must be:

• Returned freight prepaid, packaged securely and carefully so that in-transit damage cannot occur.

• Marked so the package contains the RGA# in the first line of the address line, “Attn: RGA#” (the

number being the number given you by the Belshaw Adamatic Bakery Group service department.)

Please note the following:

• If the returned goods were sent to you due to our mistake, then we will pay all freight charges via our

choice of carrier.

• If the returned goods failed while in service and are still covered by warranty, they need to be

returned freight prepaid by you. We will then replace the goods at no charge.

• When returning parts for re-stock: our minimum re-stocking charge is 20% of original invoice amount

or $20 (whichever is greater), providing the equipment is in new, never-been-used condition.

Restocking charges may be increased above the minimum, depending on how much rework the

returned goods need. Final determination will be made after factory inspection of goods.

• No RGA# will be issued if the item in question was invoiced anytime prior to 180 days of the request.

Following these guidelines will help expedite the processing of your return.

Belshaw Adamatic Bakery Group www.belshaw-adamatic.com Phone (206) 322-5474 Fax: (206) 322-5425

Revised 03/10/2007 US / Canada / Mexico Limited Warranty Page 2 of 2

Page 5

Contents

BAP85 Proofer / Holding Cabinet

Introduction........................................................................................................2

Specifications ....................................................................................................3

BAP858 Proofer

BAP8512 Proofer

BAP858 Proofer / BACO35E Oven

BAP8512 Proofer / BACO35E Oven

Installation.......................................................................................................... 7

Before Connection to Power Supply

Location

Electrical Connection

Water Connection

Rack Width

Stacking with Convection Oven

Operation............................................................................................................ 9

Description of Controls

Condensation Channel

Operating in PROOF Mode

Bake-Off

Problem Solving

Hints

Operating in HOLD Mode

Cleaning............................................................................................................ 13

Fault Finding .................................................................................................... 14

Wiring Schematic............................................................................................. 15

BAP85 Proofer / Holding Cabinet Circuit Schematic

BAP85 Proofer / Holding Cabinet Wiring Diagram

Replacement Parts List ...................................................................................17

Date Purchased................................................................. Serial No ..........................................................

Dealer............................................................................................................................................................

Service Agent ................................................................................................................................................

Page 6

Introduction

We are confident that you will be delighted with your BAP85 PROOFER / HOLDING CABINET, and it will

become a most valued appliance in your commercial kitchen.

A new Proofer / Holding Cabinet can seem very complex and confusing at first glance. To ensure you

receive the utmost benefit from your new Proofer / Holding Cabinet, there are two important things you can

do.

Firstly

Please read the instruction book carefully and follow the directions given. The time taken will be well spent.

Secondly

If you are unsure of any aspect of the installation, instructions or performance of your proofer, contact your

Belshaw Adamatic dealer promptly. In many cases a phone call could answer your question.

2

Page 7

Specifications

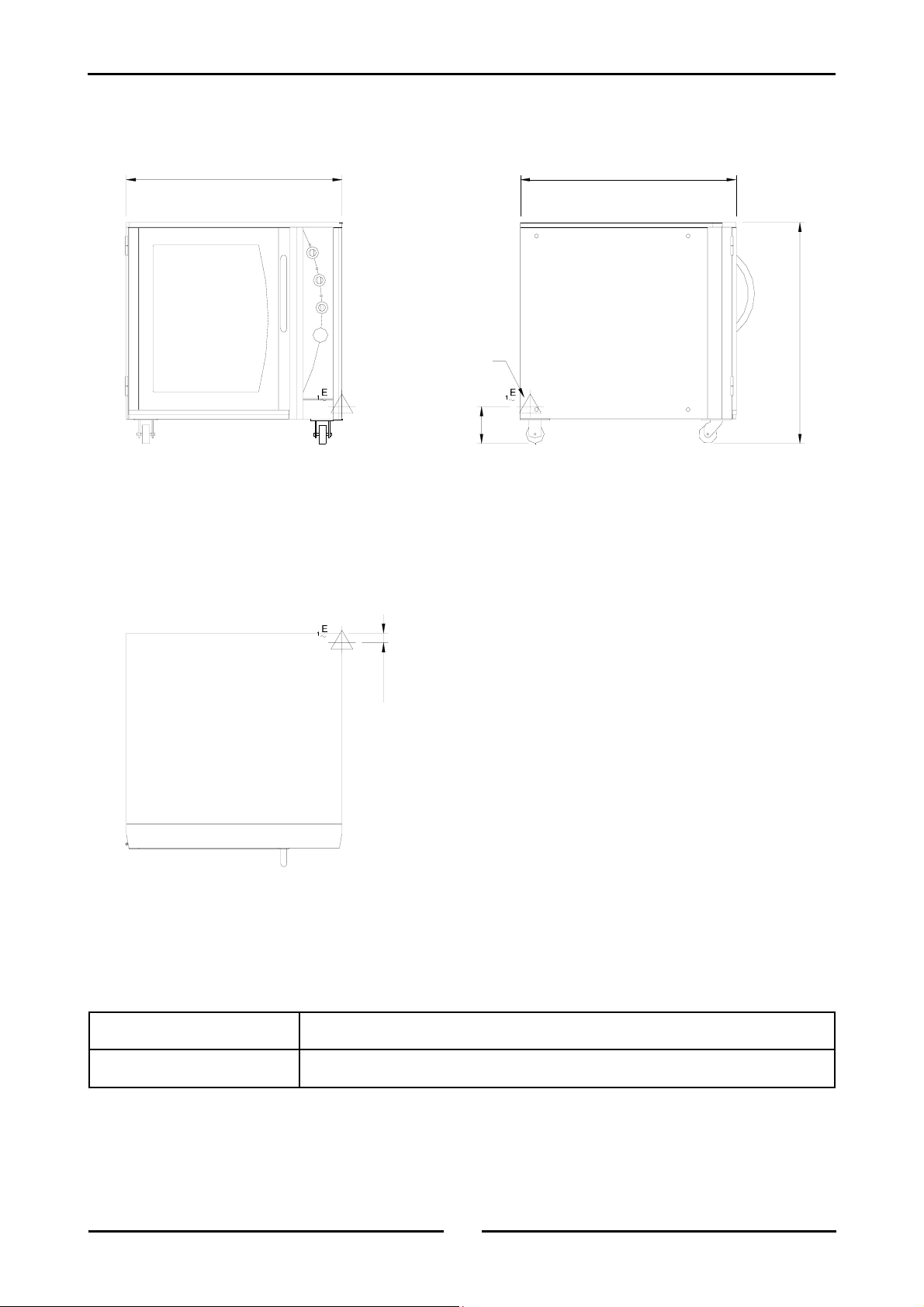

BAP858 Proofer

Front

34 3/4"34 3/4"

ELECTRICAL ENTRY

6"

Side

35 1/2"

1 5/8"

Plan

Electrical Connection 110-120 Volts A.C, 60 Hz, 1P+N+E, 1.65 kW, 14.5 A.

Cold Water Connection

¾” B.S.P. or ½” ID hose (550kPa / 80psi maximum pressure).

3

Page 8

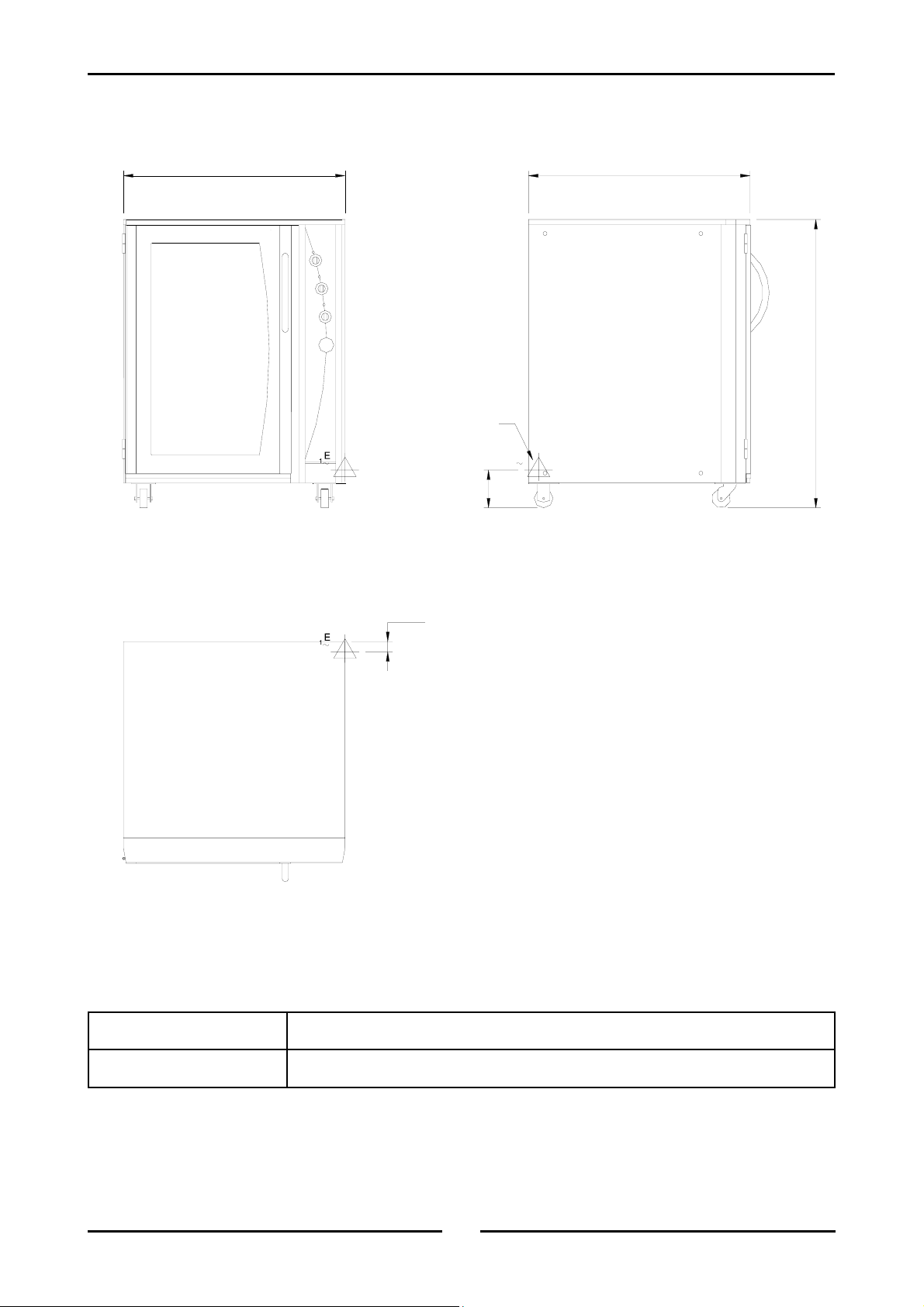

Specifications

BAP8512 Proofer

34 3/4"

Front

34 3/4"

45 1/8"

ELECTRICAL ENTRY

E

1

6"

Side

1 5/8"

Plan

Electrical Connection 110-120 Volts A.C, 60 Hz, 1P+N+E, 1.65 kW, 14.5 A.

Cold Water Connection

¾” B.S.P. or ½” ID hose (550kPa / 80psi maximum pressure).

4

Page 9

Specifications

BAP858 Proofer / BACO35E Oven

34 3/4"

E

ELECTRICAL ENTRY

WATER ENTRY

34 3/4"

31 1/2"

4"

39 5/8"

E

69"

35 1/2"

Front

Plan

6"

ELECTRICAL ENTRY

1 5/8"

Side

5

Page 10

Specifications

BAP8512 Proofer / BACO35E Oven

34 3/4"

E

ELECTRICAL ENTRY

WATER ENTRY

34 3/4" (26")

31 1/2"

EE

4"

3

78 5/8"

Front

ELECTRICAL ENTRY

1 5/8"

49 1/4"

6"

Side

45 1/8"

Plan

6

Page 11

Installation

Installation Requirements

It is most important that this proofer / holding cabinet is installed correctly and that

operation is correct before use.

Installation shall comply with local electrical, health and safety requirements.

Before Connection to Power Supply

• Remove all packing.

• Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

• Remove protective plastic coating from the side panels.

• Check that the available power supply is correct to that shown on the rating plate located on the

right-hand side panel.

Model Electrical Rating

BAP858110-1

BAP8512110-1

Location

110-120 Volts A.C, 60 Hz, 1P+N+E, 1.65 kW, 14.5 A.

• To ensure correct ventilation for the motor and controls the following minimum installation

clearances are to be adhered to:

Rear 0” / 0 mm.

Left-hand side 0” / 0 mm.

Right-hand side 1” / 25 mm.

Electrical Connection

WARNING:

THIS APPLIANCE MUST BE EARTHED / GROUNDED.

• BAP85 Proofers are supplied fitted with cords. Ensure the unit is fitted with correct cord and plug.

• To access the electrical connection terminal block, grounding lug and strain relief, remove the

right hand side panel.

Water Connection

• A cold water supply should be fitted to the water inlet (¾” BSP connection) which is located near

the rear of the right hand side of the unit.

• Alternately, a connection elbow and sealing washer is supplied with this unit for direct connection

of a ½” ID hose, and is recommended for easy installation and service.

• Connect water supply - Max inlet pressure 80psi / 550kPa.

• Turn on water supply to check for leaks.

Rack Width

• The BAP85 Proofer / Holding Cabinet has been designed to

accept either 18” or 16” wide trays.

• The Proofer comes factory set for 18” trays, to change to 16”

trays:

a. Remove the RH side rack (lift and extract).

b. Undo the thumb screws (A) holding the RH rack supports (B)

and turn RH rack supports around, then re-secure with thumb

screw.

7

A

For 18” trays

A

B

B

B

For 16” trays

B

A

A

Page 12

Installation

Stacking with Convection Oven

• The BAP85 Proofer / Holding Cabinet is supplied standard with a top lid for stand alone use.

• Optionally, the BAP85 Proofer / Holding Cabinet can be combined underneath a BACO35E

Convection Oven as a complete unit. For this a stacking kit is required (Part Number 233220).

• For installation of the stacking kit, refer to the instructions provided with the kit. These instructions

also include the procedure for mounting the BACO35E Convection Oven on top of the BAP85

Proofer / Holding Cabinet and stacking kit.

8

Page 13

Operation Guide

Operation

Description

Function

O Unit is ‘Off’.

PROOF Unit is in proofing mode (indicator illuminates).

HOLD Unit is in holding mode (indicator illuminates).

Thermostat

Temperature range 32 - 175°F.

Indicator illuminates when the elements are cycling ‘On’

to maintain set temperature.

(Controls the cabinet air temperature).

Humidity Control

of

Controls

LO - Setting for butter based pastries (croissants, Danish

pastries etc.).

MED / HI - Setting for yeast based breads and doughs.

Indicator illuminates when elements are cycling ‘On’ to

maintain set temperature.

(Controls the cabinet humidity in PROOF Mode only).

Thermometer

Dual Fahrenheit and Centigrade scale.

Indicates cabinet temperature.

9

Page 14

Operation

Condensation Channel

There is a condensation channel below the proofer door for the purpose of collecting door condensation run-off.

A diameter 12.7mm (½”) drain outlet is provided in the centre of this channel and is factory fitted with a

drain bung. The drain facility can be used in three ways:

• Remove the bung when emptying is required and drain into collection vessel. Refit the bung until

next drainage.

• Place a suitable collection vessel or pan on the floor below the drain outlet and remove bung

permanently for continual draining. Empty collection vessel or pan as required.

• Remove the bung and connect a 12.7mm (½”) I.D. hose or similar to drain outlet and route hose

to permanent drainage.

Operating in PROOF Mode

Ensure that power is supplied to the unit and the water trough is filled

It is recommended that the proofer operates empty before loading with product

- Warm days up to 10 minutes - Cool days up to 30 minutes

1. Ensure water tank is filled with water.

Check the water tank is full and that the heating element is well covered.

2. Set function to PROOF.

Indicator light will illuminate when the switch is in the “PROOF” position.

3. Set thermostat to desired proofing temperature.

Indicator light will illuminate when the elements are cycling on to maintain set temperature.

75-85°F Butter based pastries.

95-105°F Yeast based breads and doughs.

4. Set humidity to desired level.

Indicator light will illuminate whenever elements are cycling on to maintain set humidity.

As a guide;

Set humidity to between ‘LO’ and MED’ marks on control panel as a general rule.

Humidity is required only to avoid product dry skinning on surface. Do not set humidity

Avoid excess humidity levels as this will also create excess condensation in the cabinet

NOTE: Butter based product require much less humidity than breads.

Increase or decrease as found necessary for specific product types.

such that product becomes sticky and wet on surface. A silky to touch surface on the

product is a general recommendation for correct humidity levels.

interior.

10

Page 15

Operation

Bake-Off

This proofer has been designed for use together with a refrigerator and oven to take frozen uncooked yeast

or butter based products to finished cooked products.

1. Prepare the product.

Arrange frozen products onto baking trays.

2. Thaw.

Refrigerate at 40°F overnight. Do not leave standing at room temperature or product may dry out.

3. Proof.

Place thawed products directly from the refrigerator into the pre-heated proofer. Proof for 30-60

minutes dependant on product and food proofing recommendations.

4. Bake.

Place proofed product directly from the proofer into the pre-heated oven. We recommend the

Belshaw Adamatic BACO35E Convection Oven.

Problem Solving

Product collapses

When using frozen dough which collapses or shrinks in the oven after proofing, this is caused by too

much proofing. Reduce the proofing time for the next batch.

Dry product

The dough piece in the proofer should never be dry to the touch. A moist, firm and silky membrane

should cover the dough piece during proofing.

Wet product

The dough piece in the proofer should not be wet to touch whilst proofing and should not adhere to

fingers. Water should not condense on the trays. If it does there is either too much moisture or too

little heat in the proofer.

If there are any problems with your dough the most likely causes are as follows:

• Too much heat and too little moisture.

• Not enough heat and too much moisture.

• Proofing time too long or too short.

• Incorrect oven temperature.

• Incorrect maturity adjustment in the formulation of the dough for the flour.

• Incorrect thawing procedure, or handling of the dough after thawing.

11

Page 16

Operation

Hints

Heat

It is better to operate the proofer at a lower temperature with adequate moisture rather than at a

hotter temperature with too little moisture.

Yeast

Yeast activity starts very slowly at about 41°F (5°C) and increase in speed or gas production as the

temperature rises. When a temperature of approximately 140°F (60°C) is reached, the yeast is killed

and baking of the aerated product starts. Thus different rates of proofing occur as the

temperature changes.

Flour

The amount of proofing required is determined by the quality of the GLUTEN in the flour. Gluten is a

rubber like product and can perish if stretched too far by too much proofing. Collapsing of the

product or shrinkage will occur.

Proof

You must recognise the proof of the product by the appearance of the dough rather than the size.

Operating in HOLD Mode

Ensure that power is supplied to the unit and the water trough is filled

It is recommended that the cabinet operates empty before loading with product

- Warm days up to 10 minutes - Cool days up to 30 minutes

1. Set function to HOLD

Indicator light will illuminate when the switch is in the “HOLD” position.

2. Set thermostat to desired holding temperature

Indicator light will illuminate when the elements are cycling on to maintain set temperature.

3. Humidity

The humidity is not used in HOLD mode. The setting on this dial will have no effect as the wet

element is disabled.

4. Thermometer

The thermometer gives an accurate reading of the cabinet temperature to ensure that the

product being held is at the correct temperature.

12

Page 17

Cleaning

Cleaning Guidelines

C

Always turn off the electrical supply at the mains supply before cleaning.

This appliance is not water proof.

Do not

use water jet spray to clean interior or exterior of this appliance.

AUTION

Cabinet

Clean with a good quality stainless steel cleaning compound. Harsh abrasive cleaners may damage

the surface.

Side Racks

To remove, take hold of the centre rung and lift upwards to disengage the rack key-holes from the

hanger studs. To replace, hold horizontally, engage keyholes onto studs and push down.

:

Door

Wash with warm water and detergent solution using a soft sponge in straight lines up and down the

door. Rinse with clean, warm water and dry off.

Water Tank

Remove the RH side rack and remove tank by lifting off its hanger studs. Clean with warm soapy

water. Rinse thoroughly and refit.

Water Tank Element

• When the element becomes limed / scaled remove the water trough and clean.

• Replace water trough and half fill with white vinegar or acetic acid, then fill to the normal level with

water.

• Switch the unit on, turn the humidity to ‘HI’ and operate for approximately 30 minutes.

• Remove trough and clean the element with a damp cloth when cooled.

• Rinse out the trough and refit to unit.

• This procedure is recommended to be carried out once a week.

• Frequency of cleaning the element may be increased or decreased depending on the lime depositing on

the element.

13

Page 18

Fault Finding

This section provides an easy reference guide to the more common problems that may occur during the

operation of your equipment. The fault finding guide in this section is intended to help you correct, or at

least accurately diagnose problems with your equipment.

Although this section covers the most common problems reported, you may encounter a problem not

covered in this section. In such instances, please contact your local authorised service agent who will

make every effort to help you identify and resolve the problem. Please note that the service agent will

require the following information:-

• Model code and Serial Number of the appliance. (both can be found on the Rating

Plate located on the appliance.

Fault Possible Cause Remedy

The proofer does not operate /

start.

No humidity. Unit is in HOLD Mode.

Slow recovery. Overloading of cabinet.

Door does not close. Tray in way of door. Correctly position tray in rack.

The mains isolating switch on the

wall, circuit breaker or fuses are

‘Off’ at the power board.

The power switch on the cabinet

is ‘Off’.

No water in trough.

Door opened unnecessarily.

Turn ‘On’.

Rotate switch. Indicator will

illuminate.

Switch unit to PROOF Mode.

(Humidity is only generated in

PROOF Mode).

Fill with water.

Reduce batch size.

Do not open unnecessarily.

14

Page 19

Wiring Schematic

BAP85 Proofer / Holding Cabinet - Circuit Schematic

15

Page 20

Wiring Schematic

BAP85 Proofer / Holding Cabinet - Wiring Diagram

800W 110V

DRY

ELEMENT

14

800W 240V

HOLD

ELEMENT

WET

ELEMENT

25

16

EARTH

POWER SUPPLY CORD

17

FAN MOTOR

15

8

15

13

10

EN

L

3

23

1

MAINS

11

LIGHT

7

26

DRY

PILOT

8

20

12

(0-85°C)

THERMOSTAT

POWER

INDICATOR

4

25

5

6

2

2

1 P1

P33

P44

P2

2

SWITCH

FUNCTION

2

1

12

18 19

PILOT

LIGHT

4

9

WET

(50-80°C)

THERMOSTAT

12

EARTH

6

20

26

BLOCK

TERMINAL

7

8

64

5

3

2

1

RELAY

22

21

24

24

16

WATER

23

SOLENOID

FLOAT SWITCH

Page 21

Replacement Parts List

Replacement Parts List

IMPORTANT:

Only genuine authorized replacement parts should be used for the servicing and

repair of this appliance. The instructions supplied with the parts should be followed

when replacing components.

For further information and servicing instructions, contact your nearest authorized

service branch (contact details are as shown on the reverse of the front cover of this

manual).

When ordering replacement parts, please quote the part number and the description as listed below. If the

part required is not listed below, request the part by description and quote model number and serial

number which is shown on the rating plate.

Main Assembly Parts List - BAP85

Pos Part No. Description

021438 SUPPORT PLATE (Stacked Unit).

1

2 020972 STACKING BACK (Stacked Unit).

3 020794 BASE COVER SHEET (Stacked Unit).

4 020968 STACKING SIDE (Stacked Unit).

5 021137 STACKING FRONT (Stacked Unit).

6 021439 TOP COVER (Stand Alone Unit).

7 022254 RELAY MOUNTING BRACKET

(Auto Fill Only).

8 020895 CABLE GUIDE BRACKET.

019239 SNAP BUSH Ø19mm (Not Shown).

022455 CABLE GLAND GN16 (Not Shown).

9 020791 BACK PANEL (8 Tray Models).

021430 BACK PANEL (12 Tray Models).

10 020781 CHASSIS HORIZONTAL.

11 020782 CHASSIS VERTICAL REAR

(8 Tray Models).

021428 CHASSIS VERTICAL REAR

(12 Tray Models).

020238 DOME PLUG Ø19mm (Not Shown).

12 020785 PANEL MOUNTING BRACKET.

13 021657 LINER SUPPORT.

14 021673 LINER SIDE SUPPORT.

15 020899 BLANKING PLATE.

16 021668 CASTOR 3" RIGID.

17 020787 SIDE PANEL LH (8 Tray Models).

021431 SIDE PANEL LH (12 Tray Models).

18 021665 FRONT UPRIGHT LH

(8 Tray Models).

021424 FRONT UPRIGHT LH

(12 Tray Models).

19 021664 CASTOR 3" SWIVEL BRAKE.

20 022848 LINER ASSEMBLY (8 Tray Models).

022849 LINER ASSEMBLY (12 Tray Models).

022293 DRAIN PLUG (Not Shown).

21 020792 SERVICE ENTRY PANEL

(8 Tray Models).

021433 SERVICE ENTRY PANEL

(12 Tray Models).

019213 SNAP BUSH Ø31.5 (Not Shown).

22 004773 TOP CAP WA ENAMELLED.

23 021672 CAP RETAINING PLATE.

24 021656 CHASSIS TOP STIFFENER.

25 021659 RH UPRIGHT MTG BRACKET.

Pos Part No. Description

26 022303 COVER SUPPORT (Optional Extra

for Stand Alone Unit).

27 021661 SIDE PANEL RH (8 Tray Models).

021432 SIDE PANEL RH (12 Tray Models).

28 021645 CHASSIS VERTICAL FRONT

(8 Tray Models).

021429 CHASSIS VERTICAL FRONT

(12 Tray Models).

29 024355 FRONT HORIZONTAL BRACE.

30 013586 TERMINAL BLOCK.

31 025711 TERMINAL BLOCK MTG BRACKET.

32 020786 CHASSIS HORIZONTAL SIDE.

020238 DOME PLUG Ø19mm (Not Shown).

33 022055 SIDE INSULATION PANEL

(8 Tray Models).

022770 SIDE INSULATION PANEL

(12 Tray Models).

34 025387 FAN MOTOR 110V.

35 021809 MAGNET MOUNTING BRACKET.

36 021692 KEEPER BRACKET PLATED.

37 021667 MAGNET.

38 020834 CONTROL PANEL MTG BRACKET.

39 ---------- CONTROL PANEL (Refer Page 21).

40 021649 FRONT UPRIGHT RH

(8 Tray Models).

021425 FRONT UPRIGHT RH

(12 Tray Models).

41 014725 HANGER STUD.

42 021679 RACK MOUNTING BRACKET.

021698 SECURING SCREW (Not Illustrated).

43 021691 HANGER STUD.

44 021800 WATER TANK WA.

45 012272 CAPILLARY PLATE.

46 021642 BAFFLE (8 Tray Models).

021654 BAFFLE (12 Tray Models).

47 021643 BAFFLE MOUNTING CHANNEL

(8 Tray Models).

021653 BAFFLE MOUNTING CHANNEL

(12 Tray Models).

48 022042 FAN.

49 021693 DRY ELEMENT 110V.

015292 SEALING WASHER.

50 022774 DRY ELEMENT 110V 600W.

015292 SEALING WASHER.

17

Page 22

Replacement Parts List

Main Assembly - BAP85

56

58

57

55

495150

47 48

45

46

43

44

4139

40 42

545253

37

3635 38

272928

26

252423

5

4

2221

31

30

29

33

32

348783

82

81

787779

80

75

76

72

74

73

60

59

66 6465 6263 61 36 37

67

69 68

40

70

71

85

84

19 8820

18

17

697

3

2

1

8

10

12

13

11

14

16

15

86

18

Page 23

Main Assembly Parts List - BAP85 (Cont’d)

Replacement Parts List

19

Page 24

Replacement Parts List

Main Assembly Parts List - BAP85 (Cont’d)

Pos Part No. Description

51 022775 HEAT DEFLECTOR.

52 015596 CAPILLARY BUNG.

53 021695 WET ELEMENT 110V.

015292 SEALING WASHER.

54 012271 CAPILLARY BRACKET.

56 022776 CAPILLARY BRACKET.

57 022757 SEAL STRIP RH (8 Tray Models).

022765 SEAL STRIP RH (12 Tray Models).

58 022758 DOOR CATCH PLATE.

59 022754 TRIM RH (8 Tray Models).

022763 TRIM RH (12 Tray Models).

60 021468 HANDLE.

61 022768 DOOR ASSEMBLY (8 Tray Models).

021410 DOOR GLASS (Part of Door

Assembly) (8 Tray Models).

022769 DOOR ASSEMBLY (12 Tray Models).

021411 DOOR GLASS (Part of Door

Assembly) (12 Tray Models).

62 022755 SEAL STRIP TOP.

63 022756 SEAL STRIP LH (8 Tray Models).

022764 SEAL STRIP LH (12 Tray Models).

64 022989 DOOR SEAL (8 Tray Models).

022990 DOOR SEAL (12 Tray Models).

65 021663 DOOR HINGE - DRILLED.

66 022069 DOOR HINGE SHIM.

67 021810 WATER TROUGH WA.

69 021416 RACK WA (8 Tray Models).

021417 RACK WA (12 Tray Models).

70 021414 CONTROL PANEL BRACKET.

71 021650 CONTROL PANEL TRIM LH

(8 Tray Models).

021427 CONTROL PANEL TRIM LH

(12 Tray Models).

72 020991 SOLENOID MOUNTING BRACKET.

73 022250 FLOAT SWITCH.

74 022097 SENSOR BRACKET.

75 022252 FLOAT SWITCH SLEEVE.

76 022253 BETAFLEX ADAPTOR.

77 022251 ½" x ¼" REDUCING UNION.

78 022101 WATER TUBE.

79 013836 ELBOW ¼” x ⅛” MALE.

80 022998 REDUCING SOCKET ⅜” x ⅛”.

021535 RELAY-LY1F-140v.

82 021617 WATER SOLENNOID-110v.

021526 WATER INLET ELBOW

(Not Illustrated).

021527 WASHER (Not Illustrated).

83 022108 LINER BLANKING PLATE

(Not Auto Fill).

84 022256 DRAIN PAN.

85 022107 WATER PAN STOP.

86 022106 WATER PAN SUPPORT CHANNEL.

87 024031 LINER STIFFENER.

88 024353 HINGE STIFFENER (8 Tray Models).

024354 HINGE STIFFENER (12 Tray Models).

20

Page 25

Control Panel Assembly - BAP85

Replacement Parts List

3

Pos Part No. Description

1 233243 CONTROL PANEL ºF (8 TRAY MODELS).

233244 CONTROL PANEL ºF (12 TRAY MODELS).

2 023857 INDICATOR LIGHT 110V.

3 020823 KNOB BLANK SELECTOR / TEMPERATURE.

4 021472 KNOB BLANK HUMIDITY.

5 022788 THERMOMETER (30-240ºF, DUAL SCALE, ºF AND ºC).

6 022789 SELECTOR SWITCH.

7 022787 THERMOSTAT AIR.

8 015485 THERMOSTAT HUMIDITY.

21

Page 26

Loading...

Loading...