Bell OH-58A, OH-58 C Technical Manual

TECHNICAL MANUAL

OPERATORS, AVIATION UNIT,

AND AVIATION

INTERMEDIATE MAINTENANCE

CHAPTER 1. GENERAL INFORMATION

CHAPTER 2. ASSESSING BATTLEFIELD DAMAGE

CHAPTER 3. GENERAL REPAIR

CHAPTER 4. AIRFRAME

TM 55-1520-228-BD

FOR

HELlCOPTER,

OBSERVATION

OH-58A & OH-58C

ITEM NSN

INSIDE FRONT COVER

This publication supersedes

TM 55-1520-228-BD dated

17 August 1990.

CHAPTER 5. ALIGHTING GEAR

CHAPTER 6. POWER PLANT

CHAPTER 7. ROTORS

CHAPTER 8. DRIVE TRAIN SYSTEM

CHAPTER 9. HYDRAULIC SYSTEM

CHAPTER 10: INSTRUMENT SYSTEMS

CHAPTER 11. ELECTRICAL SYSTEM

CHAPTER 12. FUEL SYSTEM

CHAPTER 13. FLIGHT CONTROLS

CHAPTER 14. UTILITY SYSTEM

CHAPTER 15. ENVIRONMENTAL CONTROL SYSTEM

CHAPTER 16. MISSION EQUIPMENT

CHAPTER 17. EMERGENCY EQUIPMENT

APPENDIX A . REFERENCES

APPENDIX B. SPECIAL OR FABRICATED TOOLS

APPENDIX C. EXPENDABLE/DURABLE SUPPLIES

& MATERIALS

APPENDIX D. SUBSTITUTE MATERIALS/PARTS

APPENDIX E. BDAR TRAINING PROCEDURES

APPENDIX F. AVIONICS CONFIGURATIONS

HEADQUARTERS, DEPARTMENT OF THE ARMY

4 January 1991

TM 55-1520-228-BD

AND SHALL BE REPAIRED BY STANDARD MAINTENANCE PROCEDURES

AS SOON AS PRACTICABLE AFTER THE MISSION IS COMPLETED.

BDAR FIXES SHALL BE USED ONLY IN COMBAT

AT THE DISCRETION OF THE COMMANDER

BDAR TECHNIQUES

OH-58A

OH-58C

Helicopter, Observation

Helicopter, Observation

IN THIS

MANUAL PERTAIN to the following helicopters:

NSN 1520-00-169-7137

NSN 1520-01-020-4216

TM 55-1520-228-BD

WARNING DATA

Personnel performing operations, procedures, and practices which are included or

implied in this technical manual shall observe the general following warnings.

Disregard of these warnings can cause serious injury or death.

WARNINGS

FLIGHT SAFETY

The standards contained herein allow aircraft to be flown with battle damage

substantially in excess of peacetime limits. Under no circumstances shall this

manual be used entirely or in part for peacetime maintenance of the aircraft.

Assessment of aircraft battle damage requires extreme care and diligence and strict

adherence to the instructions and standards contained in this manual. If at any

stage of damage assessment the assessor believes that oversights or errors have

been made, the assessment shall be stopped at that point and repeated from the

beginning.

Under no circumstances shall the requirements of this manual be waived

or circumvented without the express approval of the commander or his designated

representative.

EXPLOSIVES

Battle damaged areas should be inspected for unexploded ordnance before attempting

repairs. Disposal of unexploded ordnance should be accomplished by qualified

personnel.

ARMAMENT

Loaded weapons or weapons being loaded or unloaded shall be pointed in a direction

which offers the least exposure to personnel or property in the event of accidental

firing.

Personnel shall remain clear of hazardous area.

CLEANING SOLVENTS

Cleaning solvents may be flammable and toxic. Use only in well-ventilated areas.

Avoid inhalation of vapor and skin contact. Do not use solvents near open flame or

in areas where very high temperatures prevail. Solvent flash point must not be less

than 100°F.

COMPRESSED AIR

Compressed air can blow dust into eyes. Wear eye protection. Do not exceed 30 psig

air pressure.

ELECTROLYTE

Battery Electrolyte (Potassium Hydroxide) is corrosive. Wear rubber gloves, apron,

and face shield when handling leaking batteries. If potassium hydroxide is spilled

on clothing or other material, wash immediately with clean water. If spilled on

personnel, immediately start flushing the affected area with clean water. Continue

washing until medical assistance arrives.

a

TM 55-1520-228-BD

HIGH VOLTAGE

is used in this equipment.

DEATH ON CONTACT

may result if personnel fail to observe safety precautions.

Never work on electronic equipment unless there is another person nearby who is

familiar with the operation and hazards of the equipment and who is competent in

administering first aid. When the technician is aided by operators, he must warn

them about dangerous areas.

Whenever the nature of the operation permits, keep one hand away from the equipment

as to reduce the hazard of current flowing through vital organs of the body.

Do not be mislead by the term “low voltage.” Potentials as low as 50 volts may

cause death under adverse conditions. For Artificial Respiration, refer to FM 21-11.

b

TM 55-1520-228-BD

EXTERNAL STORES

Prior to any helicopter maintenance functions that require external stores be

removed, JETTISON cartridge shall be removed. To prevent injury to personnel

and damage to equipment, remove jettison cartridges from stores ejection device

prior to placing helicopter in a hangar.

All ground safety pins must be removed before flight.

Failure to do so will prevent

emergency jettison of stores.

FIRE EXTINGUISHER

Exposure to high concentrations of monobromotrifluoromethane (CF

agent or decomposition products should be avoided.

The liquid should not be allowed

3BR) extinguishing

to come into contact with the skin, as it may cause frost bite or low temperature

burns.

FUELING AND FUEL REPAIRS

When refueling helicopter,

the refueling vehicle must be parked a minimum of 20 feet

from the helicopter. Before starting the fueling operation, always insert fueling

nozzle grounding cable of fuel truck into GROUND HERE receptacle.

10-68. When defueling,

power from the helicopter.

turn off all electrical switches and disconnect external

The helicopter must be electrically grounded prior to

Refer to FM

defueling.

Fuel line and tank repairs often involve handling of highly flammable material.

Mishandling can result in serious injury or death.

GROUNDING HELICOPTER

The helicopter should be electrically grounded when parked to dissipate static

electricity.

Turn off all power switches before making electrical connections or

disconnections.

HIGH PRESSURE

Extremely high pressure can occur during and after operation of certain equipment.

If this pressure is not relieved before working on this equipment, serious injury or

death may occur.

Be sure to open all drains and vents before beginning disassembly.

HYDRAULIC FLUID

Prolonged contact with liquid or mist can irritate eyes and skin. Wear rubber

gloves when handling liquid. After contact with skin, inmmediately wash contacted

area with soap and water. If liquid contacts eyes,

flush immediately with clear

water. If liquid is swallowed, do not induce vomiting, get immediate medical atten-

tion. If prolonged exposure with mist is likely, wear an appropriate respirator.

When fluid is decomposed by heating, toxic gases are released.

c

TM 55-1520-228-BD

LIFTING

Lifting or moving heavy equipment incorrectly can cause serious injury. Do not try

to lift or move more than 50 pounds by yourself. Bend legs while lifting. D

support heavy weight with your back.

tions.

Use guide ropes to move hanging assemblies.

Always use assistants during lifting opera-

Lack of attention or being in

an improper position during lifting operations can result in serious injury.

close attention to movements of assemblies being lifted.

Do not stand under lifted

O

not

Pay

assembly or in a position where you could be pinned against another object. Watch

your footing.

NOISE

Sound pressure levels in and around this aircraft during operating conditions exceed

the Surgeon General’s hearing conservation criteria, as defined in TB MED 501.

Hearing protection devices such as aviator helmet or ear plugs are required to be

worn.

RADIOACTIVE MATERIALS

Self-luminous dials and ignition units may contain radioactive materials. If such

an instrument or unit is broken or becomes unsealed, avoid personal contact. Use

forceps or gloves made of rubber or polyethylene to pick up contaminated material.

Place materials and gloves in a plastic bag.

Seal bag and dispose of it as radio-

active waste in accordance with AR 708-1 and TM 3-261 (Refer to TB 43-0108). Repair

shall conform to requirements in AR 385-11.

SANDING DUST

Sanding on reinforced laminated glass produces fine dust that may cause skin

and lung irritations.

Observe necessary protective measures.

STARTING HELICOPTER

Starting and operation of the helicopter will be performed only by authorized

personnel.

TOXIC POISONS

Turbine fuels, lubricating oils,

and readily absorbed through the skin.

than necessary.

Wear protective equipment.

and adhesives contain additives which are poisonous

Do not allow them to remain on skin longer

d

TM 55-1520-228-BD

C 1

CHANGE HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 1 WASHINGTON, D.C., 1 September 2005

TECHNICAL MANUAL

OPERATORS, AVIATION UNIT, AND AVIATION INTERMEDIATE

MAINTENANCE

BATTLEFIELD DAMAGE ASSESSMENT AND REPAIR

FOR HELICOPTER, OBSERVATION OH-58A & OH-58C

DISTRIBUTION STATEMENT A:

TM 55-1520-228-BD, dated 4 January 1991, is changed as follows:

1. Remove and insert pages as indicated below. New or changed text material is indicated by a vertical

bar in the margin. An illustration change is indicated by a miniature pointing hand.

Remove Pages Insert Pages

------------- A/(B blank)

i and ii i and ii

1-5 and 1-6 1-5 and 1-6

Approved for public release; distribution is unlimited.

2. Retain this sheet in front of manual for reference purposes.

By Order of the Secretary of the Army:

Official:

SANDRA R. RILEY

Administrative Assistant to the

Secretary of the Army

0518801

PETER J. SCHOOMAKER

General, United States Army

Chief of Staff

DISTRIBUTION:

To be distributed in accordance with Initial Distribution Number (IDN) 311704, requirements for

TM 55-1520-228-BD.

TM 55-1520-228-BD

LIST OF EFFECTIVE PAGES

Insert latest changed pages. Dispose of superseded pages in accordance with regulations.

NOTE: On a changed page, the portion of the text affected by the latest change is indicated by a vertical

line, or other change symbol, in the outer margin of the page. Changes to illustrations are indicated by

miniature pointing hands. Changes to wiring diagrams are indicated by shaded areas.

Dates of issue for original and changed pages are:

Original………… 4 January 1991 Change 1……… 1 September 2005

TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 762. CONSISTING OF THE FOLLOWING:

Page

No. No. No. No.

Cover.....................................................0

A through d............................................0

i..............................................................1

ii through ix............................................0

x blank...................................................0

1-1 through 1-5......................................0

1-6.........................................................1

1-7 through 1-11....................................0

1-12 blank..............................................0

2-1 through 2-9......................................0

2-10 blank..............................................0

3-1.........................................................0

3-2 blank................................................0

4-1 through 4-70....................................0

5-1 through 5-6......................................0

6-1 through 6-12....................................0

7-1 through 7-8......................................0

8-1 through 8-12....................................0

9-1 through 9-17....................................0

9-18 blank ............................................0

10-1.......................................................0

10-2 blank..............................................0

11-1 through 11-49................................0

11-50 blank ...........................................0

12-1 through 12-9..................................0

12-10 blank ...........................................0

13-1 through 13-14................................0

14-1 and 14-2........................................0

15-1 through 15-11................................0

15-12 blank ...........................................0

16-1.......................................................0

16-2 blank..............................................0

17-1.......................................................0

17-2 blank..............................................0

A-1.........................................................0

A-2 blank...............................................0

B-1 and B-2...........................................0

C-1 through C-4 ....................................0

*Zero in this column indicates an original page.

*Cha

nge

Page *Change

D-1 through D-11..................................0

D-12 blank.............................................0

E-1 and E-2...........................................0

F-1 through F-22...................................0

Index-1 through index-5........................0

Index-6 blank ........................................0

Glos-1 through Glos-8 ..........................0

Change 1 A/(B blank)

TM 55-1520-228-BD

Technical Manual

HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 55-1520-228-BD

WASHINGTON, D.C., 4 January 1991

TECHNICAL MANUAL

OPERATORS, AVIATION UNIT, AND AVIATION INTERMEDIATE MAINTENANCE

BATTLEFIELD DAMAGE ASSESSMENT AND REPAIR

FOR HELICOPTER, OBSERVATION OH-58A & OH-58C

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes, or if you know of a way to improve these procedures, please let us

know. Mail your letter or DA Form 2028 (Recommended Changes to Publications and Blank Forms) located in the back of this

manual, directly to: Commander, U.S. Army Aviation and Missile Command, ATTN: AMSAM-MMC-MA-NP, Redstone Arsenal,

AL 35898-5000. A reply will be furnished to you. You may also provide DA Form 2028 information to AMCOM via e-mail, fax, or

the World Wide Web. Our fax number is: DSN 788-6546 or Commercial 256-842-6546. Our e-mail address is

2028@redstone.army.mil. Instructions for sending an electronic 2028 may be found at the back of this manual immediately

preceding the hard copy 2028. For the World Wide Web use: https://amcom2028.redstone.army.mil.

Distribution Statement: Approved for public release; distribution is unlimited.

TABLE OF CONTENTS

Page

HOW TO USE THIS MANUAL

viii

CHAPTER 1 Section I.

Section II.

Section III. Tasks and Responsibilities . . . . . . . . . . . . . . . . .

CHAPTER 2 -

Section I.

Section II. General Fault Assessment Table . . . . . . . . . . . . . . .

CHAPTER 3 - GENERAL REPAIRS . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION

Introduction . . . . . . . . . . . . . . . . . . . . . . . .

Standards and Practices. . . . . . . . . . . . . . . . . . .

ASSESSING BATTLEFIELD DAMAGE

Introduction. . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-3

1-5

2-1

2-3

3-1

CHAPTER 4 - AIRFRAME

Section I.

Introduction. . . . . . . . . . . . . . . . . . . . . . . .

Section II. Expedient Structural Repairs . . . . . . . . . . . . . . . .

4-1

4-49

CHAPTER 5 - ALIGHTING GEAR

Section I.

Introduction. . . . . . . . . . . . . . . . . . . . . . . .

Section II. Skid Tube. . . . . . . . . . . . . . . . . . . . . . . . . .

Section III. Skid Damage. . . . . . . . . . . . . . . . . . . . . . . . .

5-1

5-1

5-4

CHAPTER 6 - POWER PLANT INSTALLATION

Section I.

Section II.

Introduction. . . . . . . . . . . . . . . . . . . . . . . .

Component Expedient Fixes. . . . . . . . . . . . . . . . . .

Change 1 i

6-1

6-1

TM 55-1520-228-BD

CHAPTER 7 - ROTORS

TABLE OF CONTENTS (Cont)

Page

Section I. Introduction. . . . . . . . . . . . . . . . . . .

Section II. Repairs . . . . . . . . . . . . . . . . .

CHAPTER 8 - DRIVE TRAIN SYSTEM

Section I. Introduction. . . . . . . . . . . . . . . . . . . . .

Section II. Repair. . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 9 - HYDRAULIC

Section I. Introduction. . . . . . . . . . . . . . . . . . . . .

Section II. Lines and Hoses. . . . . . . . . . . . . . . . . . .

Section III. Seals, Packings, and Gaskets

CHAPTER 10 - INSTRUMENTS

Section I. Introduction. . . . . . . . . . . . . . . . . . . . .

Section II. Instrument Replacement

CHAPTER 11 - ELECTRICAL AND AVIONICS SYSTEM

Section I. Introduction. . . . . . . . . . . . . . . . . . . . .

Section II. Electrical and Avionics Wiring Damage. . . . . . . .

CHAPTER 12 - FUEL SYSTEMS

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

7-1

7-1

8-1

8-1

9-1

9-1

9-14

10-1

10-6

11-1

11-6

Section I. Introduction. . . . . . . . . . . . . . . . . . . . .

Section II. Lines and Hoses. . . . . . . . . . . . . . . . . . .

Section III. Fuel Cell Damage.

CHAPTER 13 - FLIGHT CONTROLS SYSTEM

Section I. Introduction. . . . . . . . . . . . . . . . . . . . .

Section II. Flight Control Tubes. . . . . . . . . . . . . . . . .

CHAPTER 14 - UTILITY SYSTEMS

Section I. Introduction. . . . . . . . . . . . . . . . . . . .

Section II. De-Ice Valve or Control. . . . . . . . . . . . . . .

CHAPTER 15 - ENVIRONMENTAL CONTROL SYSTEM

Section I. Introduction, . . . . . . . . . . . . . . . . . . . .

Section II. Rigid Plastic Ventilation Duct . . . . . . . . . . .

Section III. Bleed Air Line Damage. . . . . . . . . . . . . . .

ii

. . . . . . . . . . . . . . .

12-1

12-1

12-4

13-1

13-1

14-1

14-1

15-1

15-1

15-9

TABLE OF CONTENTS (Cont)

TM 55-1520-228-BD

Page

CHAPTER 16 CHAPTER 17 CHAPTER 18 -

HOIST AND WINCHES. . . . . . . . . . . . . . . . . . . . . .

AUXILIARY POWER PLANT . . . . . . . . . . . . . . . . . . . .

MISSION EQUIPMENT . . . . . . . . . . . . . . . . . . . . . .

Section I.

Section II.

CHAPTER 19 APPENDIX A -

APPENDIX B APPENDIX C APPENDIX D APPENDIX E APPENDIX F -

EMERGENCY EQUIPMENT. . . . . . . . . . . . . . . . . . . .

REFERENCES . . . . . . . .

SPECIAL OR FABRICATED TOOLS . . . . . . . . . . . . . .

EXPENDABLE/DURABLE SUPPLIES AND MATERIALS . . . . . . . . . . C-1

SUBSTITUTE MATERIALS/PARTS. . . . . . . . . . . . . . . . . . D-1

BDAR TRAINING PROCEDURES. . . . . . . . . . . . . . . . .

AVIONICS CONFIGURATION. . . . . . . . . . . . . . . . . . . .

GLOSSARY . .

INDEX . . .

Figure

16-1

17-1

Introduction. . . . . . . . . . . . . . . . . . . . . . . .

Gun and Mount Assembly . . . . . . . . . . . . . . . . . . .

.

.

. . . . . . . . . . . . . . . . . . A-1

.

. . . . . . . . B-1

18-1

18-1

19-1

.

. E-1

F-1

✎ . . . . ✎ .. . .... ... . . . . . ...

. . . . . . . . .... . ... ... ..

GLOS-1

INDEX-1

LIST OF ILLUSTRATIONS

Title

Page

1-1

1-2

1-3

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

4-12

4-13

4-14

4-15

4-16

4-17

4-18

4-19

4-20

4-21

4-22

DA Form 2408-13. . . . . . . . . . . . . . . . . . . . . . .

DA Form 2408-18. . . . . . . . . . . . . . . . . . . . . . .

Damage Assessment Markings (Sheet 1 of 3). . . . . . . . .

Aircraft Sections. . . . . . . . . . . . . . . . . . . . . .

DA Form 2404. . . . . . . . . . . . . . . . . . . . . . . .

Evaluating Damage to Angles, Channels, and Z-Angles. . . . .

Damaged Cross Section. . . . . . . . . . . . . . . . . . . .

Measuring Skin Panel Damage. . . . . . . . . . . . . . . . .

Measuring Damage in Webs and Panels. . . . . . . . . . . . .

Measuring Damage in Honeycomb Sandwich Panels. . . . . . . .

OH-58 Helicopter. . . . . . . . . . . . . . . . . . . . . .

Airframe Reference Lines. . . . . . . . . . . . . . . . . .

Cockpit. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuselage Pylon Support Structure (Sheet 1 of 5). . . . . . .

Upper and Lower Shell Structure. . . . . . . . . . . . . . .

Aft Fuselage Structure.. . . . . . . . . . . . . . . . . .

Tail Boom . . . . . . . . . . . . . . . . . . . . . . . . .

Cowling and Firewalls . . . . . . . . . . . . . . . . . . . .

Typical Former Repair (Sheet 1 of 2) . . . . . . . . . . . .

Cutout in Damage Skin. . . . . . . . . . . . . . . . . . . .

Patch Plate. . . . . . . . . . . . . . . . . . . . . . . . .

Typical Patch Plate Repair . . . . . . . . . . . . . . . . .

Expedient Cap/Longeron Repair. . . . . . . . . . . . . . . .

Repair of Damage Bulkhead Flange . . . . . . . . . . . . . .

Typical Combination Repair (Sheet 1 of 2). . . . . . . . . .

1-7

1-8

1-9

4-3

4-6

4-8

4-9

4-10

4-11

4-13

4-17

4-18

4-19

4-20

4-25

4-26

4-27

4-28

4-52

4-54

4-55

4-56

4-58

4-60

4-61

iii

TM 55-1520-228-BO

LIST OF ILLUSTRATIONS (Cont)

Figure

4-23

4-24

4-25

4-26

4-27

4-28

4-29

4-30

5-1

5-2

5-3

5-4

5-5

6-1

6-2

6-3

6-4

6-5

6-6

6-7

6-8

7-1

7-2

7-3

7-4

7-5

8-1

8-2

8-3

9-1

9-2

9-3

9-4

9-5

9-6

9-7

9-8

,9-9

9-10

9-11

9-12

Title

Damaged Honeycomb Core Panel, Small Damage to One Skin

and Core... . . . . . . . . . . . . . . . . . . . . . . .

Damaged Honeycomb Core Panel, 2-8 Inch Damage - One Skin

and Core. . . . . . . . . . . . . . . . . . . . . . . . .

Repaired Honeycomb Core Panel, 2-8 Inch Damage - One Skin

and Core. . . . . . . . . . . . . . . . . . . . . . . . . .

Damaged Repair,

Patch Plates, One Side Accessible Repair . . . . . . . . . .

Repair of Honeycomb Core Panel,

Skins and Core. . . . . . . . . . . . . . . . . . . . . . .

Fracture Lacing with Safety Wire . . . . . . . . . . . . . .

Tail Boom Skin Damage. . . . . . . . . . . . . . . . . . . .

Landing Gear and Support Installation. . . . . . . . . . . .

Skid Tube Damage Zones. . . . . . . . . . . . . . . . . . .

Skid Repair. . . . . . . . . . . . . . . . . . . . . . . . .

Clamp Repair. . . . . . . . . . . . . . . . . . . . . . . .

Fabricated Clamp. . . . . . . . . . . . . . . . . . . . . .

T63 Series Engine. . . . . . . . . . . . . . . . . . . . . .

Blocking Plate Installation. . . . . . . . . . . . . . . . .

Double-Check Valve System, Possible Alternatives . . . . . .

Wood Plug. . . . . . . . . . . . . . . . . . . . . . . . . .

Sealant for Small Holes... . . . . . . . . . . . . . . . .

Repair Using Screw, Washer and Gasket. . . . . . . . . . . .

Hose Assembly, Sealant, Nut, and Bolt. . . . . . . . . . . .

Sheet Metal with Sealant and/or Cherry Rivets. . . . . . . .

Main Rotor System. . . . . . . . . . . . . . . . . . . . . .

Tail Rotor System. . . . . . . . . . . . . . . . . . . . . .

Rotor Blades, Damage Sensitive Areas . . . . . . . . . . . .

Rotor Blade Repair,

Repair Areas

Drive Train System (Sheet 1 of 4). . . . . . . . . . . . .

External Components - Transmission Oil System. . . . . . . .

Flex Duct Repair (Sheet 1 of 2) . . . . . . . . . . . . . . .

Hydraulic System. . . . . . . . . . . . . . . . . . . . . .

Hydraulic System Schematic . . . . . . . . . . . . . . . . .

Two-Part Fitting. . . . . . . . . . . . . . . . . . . . . .

Four-Part Fitting. . . . . . . . . . . . . . . . . . . . . .

Using Tube Cutter. . . . . . . . . . . . . . . . . . . . . .

Properly Burred Tubing . . . . . . . . . . . . . . . . . . .

Damaged Tube Section-Straight Tube . . . . . . . . . . . . .

Splice Repair Assembly . . . . . . . . . . . . . . . . . . .

Repair Fitting and Tube Installation . . . . . . . . . . . .

Damaged Tube Section-Complex Bends . . . . . . . . . . . . .

Splice Adapter Assembly Installation . . . . . . . . . . . .

Installation of Socket and Sleeve. . . . . . . . . . . . . .

Accessible One Side Only . . . . . . . . . .

Damage Over 8 Inches - Both

Application of Tape. . . . . . . . . . .

- Main Rotor B1ades . . . . . . . . . . . . . .

Page

4-64

4-64

4-64

4-66

4-66

4-67

4-69

4-70

5-2

5-2

5-5

5-5

5-6

6-2

6-5

6-7

6-8

6-9

6-9

6-10

6-12

7-2

7-3

7-5

7-7

7-8

8-2

8-8

8-9

9-2

9-3

9-4

9-5

9-5

9-7

9-7

9-8

9-8

9-10

9-10

9-12

iv

LIST OF ILLUSTRATIONS (Cont)

TM 55-1520-228-BD

Figure

9-13

9-14

11-1

11-2

11-3

11-4

11-5

11-6

11-7

11-8

11-9

11-10

11-11

11-12

11-13

11-14

11-15

11-16

11-17

11-18

11-19

11-20

11-21

11-22

11-23

11-24

11-25

11-26

11-27

11-28

11-29

11-30

11-31

11-32

11-33

11-34

11-35

11-36

11-37

11-38

11-39

11-40

11-41

11-42

11-43

11-44

11-45

Title

Assembly of MS Fitting . . . . . . . . . . . . . . . . . . .

Union Connection. . . . . . . . . . . . . . . . . . . . . .

Circuit Identification . . . . . . . . . . . . . . . . . . .

Crimp Splice. . . . . . . . . . . . . . . . . . . . . . . .

Splicing with Terminal Lug Barrel. . . . . . . . . . . . . .

Twist Wire Splice . . . . . . . . . . . . . . . . . . . . .

Replacement Section; Twist Wire Splice . . . . . . . . . . .

Metal Casing Splice Splice. . . . . . . . . . . . . . . . .

Bolted Terminal Lug Repair of Large Wires. . . . . . . . . .

Replacement Section; Terminal Lug Repair . . . . . . . . . .

Ram Wire Repair . . . . . . . . . . . . . . . . . . . . . .

Heat-Shrinkable Tape . . . . . . . . . . . . . . . . . . . .

Insulation Repair with Sleeving. . . . . . . . . . . . . . .

Shielded Cable Repair Preparation. . . . . . . . . . . . . .

Shielded Cable Splice Preparation. . . . . . . . . . . . . .

Shielded Cable Spliced . . . . . . . . . . . . . . . . . . .

Shielded Cable Repair... . . . . . . . . . . . . . . . . .

Pigtail Method Repair . . . . . . . . . . . . . . . . . . .

Substitute Shielded Braid Repair . . . . . . . . . . . . . .

Shield Terminator Repair Preparation . . . . . . . . . . . .

Shield Terminator Repair.. . . . . . . . . . . . . . . . .

Nickel-Plated Shield Terminator Preparation. . . . . . . . .

Nickel-Plated Shield Terminator Repair . . . . . . . . . . .

Terminal Lug Repair. . . . . . . . . . . . . . . . . . . . .

Self-Clinching Cable Strap . . . . . . . . . . . . . . . . .

Self-Clinching Cable Strap and Tool. . . . . . . . . . . . .

Tie Tape Repair Procedure. . . . . . . . . . . . . . . . . .

Coax Splice Preparation.. . . . . . . . . . . . . . . . . .

Coax Splice Inner Sleeve. . . . . . . . . . . . . . . . . .

Coax Splice Shield Sleeve. . . . . . . . . . . . . . . . . .

Coax Splice with Tubing Sleeve . . . . . . . . . . . . . . .

Coax Splice with Cable Braid over Barrier Sleeves. . . . . .

Coax Repair with Cable Braid over Barrier Sleeve . . . . . .

Component Bypass. . . . . . . . . . . . . . . . . . . . . .

Connector Pin and Socket.. . . . . . . . . . . . . . . . .

Damaged Connector and Pigtail. . . . . . . . . . . . . . . .

Circuit Breakers, . . . . . . . . . . . . . . . . . . . . .

Typical Circuit Breaker Connection . . . . . . . . . . . . .

Construction of Fuse Link. . . . . . . . . . . . . . . . . .

Splicing Bus Bars. . . . . . . . . . . . . . . . . . . . . .

Lengthening Bus Bars... . . . . . . . . . . . . . . . . .

Battery, Storage BB-476/A, Cell Layout . . . . . . . . . . .

Block Diagram Power Relay, Check and Test. . . . . . . . . .

Location of Power Relays. . . . . . . . . . . . . . . . . .

Block Diagram,

Jumper Wire Fabrication.. . . . . . . . . . . . . . . . . .

Frequency vs. Wave length. . . . . . . . . . . . . . . . .

Typical Power Relays. . . . . . . . . . . . .

Page

9-12

9-13

11-2

11-8

11-10

11-11

11-12

11-12

11-14

11-14

11-14

11-16

11-16

11-17

11-18

11-19

11-20

11-22

11-23

11-24

ll-25

11-25

11-25

11-26

11-28

11-28

11-29

11-29

11-31

11-31

11-31

11-32

11-32

11-33

11-33

11-34

11-36

11-36

11-37

11-39

11-39

11-40

11-41

11-43

11-44

11-44

11-46

v

TM 55-1520-228-BD

LIST OF ILLUSTRATIONS (Cont)

Figure

11-46

11-47

12-1

12-2

12-3

12-4

12-5

13-1

13-2

13-3

13-4

13-5

13-6

13-7

13-8

13-9

13-10

13-11

14-1

15-1

15-2

15-3

15-4

15-5

15-6

15-7

F-1

F-2

F-3

F-4

F-5

F-6

F-7

F-8

F-9

F-10

Title

Preparation of Coax . . . . . . . . . . . . . . . . . . . .

Installation of Field Expedient Antenna. . . . . . . . . . .

0H-58 Fuel System. . . . . . . . . . . . . . . . . . . . . .

Emergency Mechanical Clamp Repair . . . . . . . . . . . . .

Mixing Instruction for Sealant Cartridges. . . . . . . . . .

Rubber Repair Plug Assembly. . . . . . . . . . . . . . . . .

Plug Modification for Three Plain Repair . . . . . . . , . .

OH-58 Flight Controls Schematic. . . . . . . . . . . . . . .

Collective Flight Control. . . . . . . . . . . . . . . . . .

Cyclic Flight Control . . . . . . . . . . . . . . . . . . . .

Flight Control Actuators. . . . . . . . . . . . . . . . . .

Anti-Torque Controls (Sheet 1 of 2). . . . . . . . . . . . .

Control Tube Dimensions. . . . . . . . . . . . . . . . . . .

Suggested Repair for Control Rods or Tubes . . . . . . . . .

Control Rod with Bearing and Clevis Assemblies . . . . . . .

Flattened End of Fabricated Flight Control . . . . . . . . .

Corner Rounding on Fabricated Flight Control . . . . . . . .

Bearing Assembly Connection of Fabricated Flight Control . .

Engine De-Ice System. . . . . . . . . . . . . . . . . . . .

Bleed Air Heating and Ventilating System A & C . . . . . . .

Heating and Ventilating System (Bleed Air) A Model . . . . .

Heating and Ventilating System (Bleed Air) C Model . . . . .

Combustion Heater. . . . . . . . . . . . . . . . . . . . . .

Shroud Heater System Schematic . . . . . . . . . . . . . . .

Bleed Air Line Installation. . . . . . . . . . . . . . . . .

Bleed Line Patch Repair. . . . . . . . . . . . . . . . . . .

Intercom System (Sheet 1 of 2).. . . . . . . . . . . . . .

UHF/AM Communications System (Sheet 1 of 2). . . . . . . . .

VHF/AM Communications System and Connecting Cables . . . . .

VHF/FM Communication System. . . . . . . . . . . . . . . . .

Gyromagnetic Compass Set AN/ASN-43 and Connecting Cable

(Sheet 1 of 2) . . . . . . . . . . . . . . . . . . . . . . .

Direction Finder Set AN/ARN-89 (Sheet 1 of 2). . . . . . . .

Radio Receiving Set AN/ARN-123(V)1 . . . . . . . . . . . . .

Radar Altimeter System AN/APN-209. . . . . . . . . . . . . .

Transponder (IFF) System AN/APX-72, AN/APX-100 . . . . . . .

Radar Warning System AN/APR-39 . . . . . . . . . . . . . . .

Page

11-47

11-49

12-2

12-5

12-7

12-9

12-9

13-2

13-5

13-6

13-7

13-8

13-10

13-10

13-12

13-13

13-13

13-13

14-2

15-2

15-3

15-4

15-5

15-6

15-10

15-11

F-2

F-4

F-6

F-8

F-10

F-12

F-14

F-16

F-18

F-21

Table No.

2-1

2-2

4-1

4-2

4-3

4-4

4-5

vi

LIST OF TABLES

Title

General Decision Logic . . . . . . . . . . . . . . . . . . .

General Assessment Table . . . . . . . . . . . . . . . . . .

Aircraft Structure Damage Assessment Procedures. . . . . . .

Damage Limits Forward Fuselage - Condition I . . . . . . . .

Damage Limits Aft Fuselage - Condition I . . . . . . . . . .

Damage Limits Tail Boom and Landing Gear - Condition I . . .

Damage Limits Forward Fuselage - Condition II. . . . . . . .

Page

2-2

2-3

4-2

4-31

4-36

4-39

4-39

LIST OF TABLES (Cont)

TM 55-1520-228-BD

Table No.

4-6

4-7

4-8

5-1

6-1

7-1

8-1

9-1

9-2

11-1

11-2

11-3

11-4

11-5

11-6

11-7

12-1

13-1

13-2

13-3

15-1

D-1

D-2

D-3

D-4

D-5

D-6

D-7

F-1

F-2

F-3

F-4

F-5

F-6

F-7

F-8

F-9

F-10

F-11

Title

Damage Limits Aft Fuselage - Condition II. . . . . . . . . .

Damage Limits Tail Boom and Landing Gear - Condition II. . .

Metal Substitution Chart. . . . . . . . . . . . . . . . . .

Assessment Procedure Logic . . . . . . . . . . . . . . . . .

Engine BDAR Assessment Logic . . . . . . . . . . . . . . . .

Assessment Procedures. . . . . . . . . . . . . . . . . . . .

Drive Train System BDAR Assessment Procedures. . . . . . . .

Assessment Logic. . . . . . . . . . . . . . . . . . . . . .

Seals Reference and Temperature Guides Chart . . . . . . . .

Electrical and Avionics Assessment Logic . . . . . . . . . .

Function and Designation Letters . . . . . . . . . . . . . .

Unshielded Crimp Splice Application. . . . . . . . . . . . .

Wire Repair Segments. . . . . . . . . . . . . . . . . . . .

Shielded Cable Repair . . . . . . . . . . . . . . . . . . .

Terminal Lugs. . . . . . . . . . . . . . . . . . . . . . . .

Fuse Link Strands. . . . . . . . . . . . . . . . . . . . . .

Fuel System Assessment Procedures. . . . . . . . . . . . . .

Flight Control System Assessment Procedures. . . . . . . . .

Nominal Tube Splice Sizes. . . . . . . . . . . . . . . . . .

Bolt/Drill Sizes for Control Tube Repairs. . . . . . . . . .

Assessment Procedures. . . . . . . . . . . . . . . . . . . .

Essential Spare Parts. . . . . . . . . . . . . . . . . . . .

Spare and Repair Parts . . . . . . . . . . . . . . . . . . .

Weapons. . . . . . . . . . . . . . . . . . . . . . . . . . .

Substitute Fuels for JP-4 Fuel . . . . . . . . . . . . . . .

Fuels for the OH-58 Helicopter . . . . . . . . . . . . . . .

Substitute Commercial Fuels . . . . . . . . . . . . . . . .

Alternate and Expedient Fuel Blends. . . . . . . . . . . . .

Wire Table, Intercom System. . . . . . . . . . . . . . . . .

Wiring Table, UHF/AM Communication System. . . . . . . . . .

Wiring Table,

Wiring Table, VHF/FM Communication System. . . . . . . . . .

Wiring Table, Gyromagnetic Compass Set . . . . . . . . . . .

Wiring Table, ADF AN/APN-89

Radio Receiving Set AN/ARN-123(V)1, OH-58C . . . . . . . . . .

Wiring Table, Radar Altimeter AN/APN-209, OH-58C . . . . . .

Wiring Table, IFF, APX-72, OH-58A . . . . . . . . . . . . .

Wiring Table,

Wiring Table, AN/APR-39 . . . . . . . . . . . . . . . . . . .

VHF/AM Communication System. . . . . . . . . .

IFF, APX-1OO, OH-58C . . . . . . . . . . . . .

Page

4-44

4-47

4-50

5-3

6-3

7-4

8-6

9-4

9-18

11-2

11-3

11-7

11-16

11-18

11-27

11-37

12-3

13-3

13-11

13-11

15-7

D-2

D-3

D-5

D-7

D-8

D-9

D-10

F-3

F-5

F-7

F-9

F-11

F-13

F-15

F-17

F-19

F-20

F-22

vii

TM 55-1520-228-BD

HOW TO USE THIS MANUAL

This manual is developed to assist the soldier in a battlefield environment to make

assessment and repair of damage to the OH-58 helicopter which cannot, due to asset

availability or environmental factors,

Within this technical manual,

requirement.

The word should is used to indicate a nonmandatory but preferred

the word shall is used to indicate a mandatory

method of accomplishment. The word may

be repaired in the normal prescribed manner.

is used to indicate an acceptable method of

accomplishment.

Organization of the Manual.

1.

This manual contains a general information chapter

(chapter 1), a general assessment chapter (chapter 2), and specific repair chapters

(chapters 4 thru 19).

Chapter 3 is not used.

It also contains five appendices.

References (Appendix A), special or fabricated tools (Appendix B),

expendable/durable supplies and materials list (Appendix C), substitute materials

and parts (Appendix D), and BDAR fixes authorized for training (Appendix E).

Chapter 2 is used to assess the helicopter in general and references specific

2.

chapters for detailed repair procedures of the major functional groups.

The major

functional groups correspond with the functional groups of the -23 series manuals

that are employed in routine repairs to the helicopter.

Chapter 3 is not used in this manual.

3.

It would normally contain repairs for

equipment which does not fall under one of the standard helicopter functional groups.

4.

Each functional group chapter is organized as follows:

a. Section I

(1) Scope.

(2) Assessment procedures.

- Introduction.

Purpose of the chapter.

General assessment information for the repairs

covered therein.

(3) Repair procedure index.

Section II

b.

- Repair Item.

covered in that functional group.

A subsection is included for each repair item

It contains the following:

(1) General.

About the nature and cause of damage and repair.

(2) Item and trouble statement with:

(a) Limits given.

(b) Personnel and time required to effect repairs.

(c) Materials and tools needed.

(d) Procedural steps to accomplish the repair.

(3) If more than one method of repair can be used, the various options will

be included next.

NOTE

The first option is the preferred choice, the second option

is the next preferred, etc.

Selection of the option should

be the most preferred method possible under the circumstances

and with the available materials and manpower.

viii

HOW TO USE THIS MANUAL (Cont)

5.

Finding Repairs in this Manual.

TM 55-1520-228-BD

a. When the damage is obvious and known,

which the damaged item is a part.

Turn to the repair procedure index, section I,

find the functional group chapter of

subparagraph c of each chapter to locate the item being repaired. Then turn to the

repair section and review each option to ascertain the appropriate fix.

entire section for the option,

then effect the repairs following the procedures

Read the

given.

b.

When the damage is hidden and/or unknown,

follow the overall assessment proce-

dures provided in chapter 2, and follow the procedures and directions provided.

6.

Preparation.

a. Each mechanic/technician shall have read chapters 1 and 2 and become familiar

with the repairs and layout of the manual prior to attempting to accomplish BDAR

repairs.

b.

All warnings,

cautions, and safety precautions shall be followed, inasmuch as

possible, at all times during BDAR procedures so as not to further damage and/or

jeopardize either personnel or the equipment during or subsequent to the BDAR

action.

Ensure all documentation is completed as directed in this manual and by

local command.

7.

Expendable/Durable Supplies and Materials.

a. Each fix or repair option contains a short listing of materials and tools considered basic to the repair. It is important to note that the expendable materials

listed usually cover a wide range for any one item.

Example:

MATERIALS/TOOLS REQUIRED:

●

Drill with Bit

●

Sheet Metal (items 131-142, Appx C)

●

Rivets (items 98-115, Appx C)

In this example, sheet metal covers the range of items 131 thru 142 in Appendix C.

This means that, depending on the circumstances and location of the fix, any one of

these metals could be used.

Likewise any one of the rivets, items 98 thru 115, may

be used to attach the patch plate depending on the application.

b.

One of the key points concerning successful BDAR repairs is flexibility. The

users of this manual should strive to use the items on hand, provided a safe repair

is made.

The stringent requirements of normal maintenance may be lifted.

ix/(x-Blank)

TM 55-1520-228-BD

CHAPTER 1

GENERAL INFORMATION

BDAR FIXES SHALL BE USED ONLY IN COMBAT OR FOR TRAINING

AT THE DISCRETION OF THE COMMANDER.

(AUTHORIZED TRAINING FIXES ARE LISTED IN APPENDIX E.)

IN EITHER CASE, DAMAGES SHALL BE REPAIRED BY STANDARD

PROCEDURES AS SOON AS PRACTICABLE.

Section I. INTRODUCTION

1-1.

PURPOSE.

Damage Assessment and Repair (BDAR) is

to quickly return the disabled heli-

copter to the operational commander by

expediently fixing, bypassing, or jury-

rigging components to restore the mini-

mum essential systems required for the

support of the specific combat mission

for self-recovery. These repairs will

be temporary and may not restore full

performance capability. Standard repair

will be completed as soon as practical.

1-2.

cribes BDAR procedures applicable to

OH-58 helicopter series, and these

procedures are to be used by crew,

operators, aviation unit maintenance

(AVUM) teams, and aviation intermediate

maintenance (AVIM) support teams.

OH-58 helicopter are included in other

technical manuals which are referenced

in Appendix A of this TM. Details of

these procedures are not duplicated in

whole in this TM.

more than one page in length, the

repairs may only be referenced in

appropriate chapter.

damage and failure modes cannot be predicted, nor are all effective field

expedient repairs known.

vides guidelines for assessing and

repairing battlefield failures of OH-58

helicopters and is not intended to

SCOPE.

a.

This technical manual (TM) des-

b.

Standard repair techniques for the

c.

All possible types of combat

The purpose of Battle

If the repairs are

This TM pro-

be a complete catalog of all possible

emergency repairs. The repairs described

here will serve as guidelines and will

stimulate the experienced mechanic/

operator to devise repairs as needed to

rapidly return equipment to operation in

a combat situation.

d.

of equipment by its spare, even under

battlefield conditions, is not a BDAR

fix and may not be covered is in this

TM.

formed in preference to a BDAR fix when

time and spares are available.

1-3. APPLICATION.

a. The procedures in this manual are

designed for battlefield environments

and should be used in situations where

standard maintenance procedures are

impractical. These procedures are not

meant to replace standard maintenance

practices, but rather to supplement them

strictly in a battlefield environment.

Standard maintenance procedures will

provide the most effective means of

returning damaged equipment to ready

status provided that adequate time,

replacement parts, necessary tools, and

trained/qualified repair persons are

available. BDAR procedures are only

authorized for use in an emergency

situation in a battlefield environment,

and only at the direction of the commander. They are not to be continued

after the equipment is out of the battle

environment.

The direct replacement of a piece

A standard procedure should be per-

1-1

TM 55-1520-228-BD

GENERAL INFORMATION

BDAR techniques are not limited to

b.

simple restoration of minimum functional

combat capability.

capability can be restored expediently

with a limited expenditure of time and

assets, it will be accomplished.

c. Some of the special techniques in

this manual,

shortened life or in further damage to

major components of the helicopter.

commander must decide whether the risk

of having one less helicopter available

for combat outweighs the risk of

applying the potentially destructive

expedient repair technique.

nique gives appropriate warnings,

cautions, and lists systems limitations

caused by this action.

1-4.

such as combat damage, random failures,

operator errors, accidents, and wear-out

failures which occur on the battlefield

and which prevent the helicopter from

accomplishing its mission.

action that returns a damaged part or

assembly to a full or an acceptably

degraded operating condition, including:

installation.

from other equipment that can be

modified to fit or interchange with

components on the damaged equipment.

a noncritical function elsewhere on

the same equipment for the purpose of

restoring a critical function.

DEFINITIONS.

a. Battlefield Damage.

b. Repair

(1) Short cuts in parts removal or

(2) Installation of components

(3) Repair using parts that serve

if applied, may result in

or Fix. Any expedient

If full functional

The

Each tech-

Any incident

or readily available materials.

c. Damage Assessment. A procedure to

rapidly determine what is damaged,

whether it is repairable, what assets

are required to make the repair, who can

do the repair (e.g., crew, maintenance

team or maintenance support team), and

where the repair should be made.

assessment procedure includes the

following steps:

deferred, or if it must be done.

components.

must be fixed.

ponents, materials, and tools are

available.

skill required.

hours) required to make the repair.

fixes.

performed.

tion is necessary and to what location.

(6) Fabrication of parts from kits

(7) Jury-rigging.

(8) Use of substitute materials.

The

(1) Determine if the repair can be

(2) Isolate the damaged areas and

(3) Determine which components

(4) Prescribe fixes.

(5) Determine if parts or com-

(6) Estimate the manpower and

(7) Estimate the total time (clock

(8) Establish the priority of the

(9) Decide where the fix shall be

(10) Decide if recovery or evacua-

(4) Bypassing of noncritical com-

ponents in order to restore basic func-

tional capability.

(5) Expeditious cannibalization

procedures.

1-2

d.

helicopter can perform all its combat

missions. To be FMC, the helicopter must

be complete and fully operable with no

faults listed in the aircraft inspection

and maintenance record as prescribed in

DA PAM 738-751.

Fully Mission Capable (FMC). The

TM 55-1520-228-BD

GENERAL INFORMATION

e. Combat Capable.

the minimum functional combat capability

requirements.

(See paragraph 1-8. )

Equipment meets

j.

battle damaged helicopter to retrieve

itself (fly out) from a battlefield

environment.

f.

Combat Emergency Capable. The

equipment meets the needs for specific

tactical missions; however, all systems

are not functional.

Also, additional

damage due to the nature of an expedient

repair may occur to the equipment if it

is used.

The commander must decide if

these limitations are acceptable for

that specific emergency situation.

g.

Cannibalization or Controlled

Exchange.

Throughout this manual, can-

nibalization and controlled exchange are

flying with degraded flight status and

with restrictions and limitations placed

on performance characteristics such as

limitations placed on weight, airspeed,

engine torque, and other characteristics.

In BDAR repairs,

mended should be followed.

flight procedure in TM 55-1520-228-10

should further be consulted.

k.

point operated by AVIM unit for the

collection of equipment for repair.

used interchangeably meaning the removal

of an item of materiel from one piece of

equipment for immediate use in another.

Generally the rules for cannibaliza-

tion/controlled exchange provided in

TM 55-1500-328-25,

as modified by local

1.

team of AVIM mechanics and technical

specialists who are trained in assessing

battlefield damage and field repair

procedures.

authority, will prevail.

m.

h.

Evacuation,

port function which involves the move-

A combat service sup-

ment of recovered helicopters from a

main supply route,

maintenance collection point, or maintenance activity to

higher categories of maintenance. The

materiel may be returned to the user, to

the supply system for reissue, or to

property disposal activities.

crew chief or AVUM mechanics/technicians

who are trained in assessing battlefield

damage and field repair procedures.

1-5. QUALITY DEFICIENCY REPORT/EQUIP-

MENT IMPROVEMENT RECOMMENDATION

(QDR/EIR). If your helicopter and its

equipment need improvement, let us

know:

are the only one who can tell us what

i.

Recovery.

bile, inoperative,

The retrieval of immo-

or abandoned OH-58

helicopter from the battlefield or

immediate vicinity, and its movement

to a maintenance collection point, the

main supply route, or a maintenance

activity for disposition, repair, or

evacuation.

you don’t like about your equipment.

Let us know why you don’t like the

design. Put it on an SF 368 (Quality

Deficiency Report). Mail it to

Commander, U.S. Army Aviation Systems

Command, ATTN:

Goodfellow Boulevard, St. Louis, MO

63120-1798. We’ll send you a reply.

Self-Recovery.

The ability of a

It usually will involve

the limitations recom-

Emergency

Maintenance Collection Point. A

Maintenance Support Team (MST).

Maintenance Team (MT).

Helicopter

A

Send us an EIR. YOU, the user,

AMSAV-QF, 4300

Section II. STANDARDS AND PRACTICES

1-6.

BDAR CHARACTERISTICS. BDAR capa-

bility requires simplicity, speed, and

effectiveness. Some BDAR procedures

include repair techniques that violate

standard peacetime maintenance practices.

In a combat emergency situation, greater

risks are sometimes necessary and

acceptable.

1-3

TM 55-1520-228-BD

GENERAL INFORMATION

1-7.

combat conditions, BDAR may be performed

on helicopters which are in flight or

which are under power while on the

ground.

may require waiving of safety precautions,

the cautions to protect personnel life

should not be overlooked.

precautions may be waived at the discre-

tion of the commander.

be required in a chemically toxic environment or under other adverse battlefield

conditions with severe limitations in

personnel, facilities, equipment, and

materials. Performance of repair tasks

may be necessary while wearing protective

gear.

described in FM 3-5.

1-8

manual covers expedient repairs for the

OH-58 helicopter and its components. It

is entirely possible that in a combat

situation, the helicopter having undergone one or more repairs may suffer

degradation of its normal operating

characteristics (e.g., reduced speed,

reduced load capability, reduced range,

etc.), and still be able to carry out

all or parts of an assigned mission.

The minimum functional combat capability

(MFCC) criteria for the OH-58 is as

follows:

Completion. Helicopter’s flight characteristics degraded to a minimum of

combat capable (CC).

main and tail rotor to accommodate lift

capability for helicopter crew and cargo.

tail the intended length of flight.

WAIVER OF PRECAUTIONS. Under

While some of these BDAR actions

Other similar

BDAR fixes may

Decontamination procedures are

OPERATING CHARACTERISTICS. This

a.

Flight Capability for Mission

(1) Sufficient power delivered to

(2) No fuel leaks which will cur-

intercom communications within aircraft

and at least two tactical receivertransmitter (R-T) units operating at

full capability.

Self-Recovery Capability (SRC).

main and tail rotor at acceptable

limits.

members. Unload unnecessary weight.

function level acceptable for flight.

required to meet mission needs.

2 hours.

to minimize flight duration.

procedures.

Chapter 9.

(4) Communications. Must have

Criteria may be waived for

recovery or if the tactical

situation demands otherwise.

b.

Flight Capability for

(1) Must have power delivered to

(2) Maximum engine torque:

(3) Lift capability for crew

(4) Flight controls at minimum

(5) Instruments/avionics as

(6) Maximum airspeed of 50 kts.

(7) Maximum flight duration of

(8) Be prepared for emergency

NOTE

80% at 0 kts

64% at 16 kts

53% at 32 kts

50% at 50 kts

Consideration will be given

See TM 55-1520-228-10,

(3) No degradation of any component/system which will end in failure

and curtailment of intended mission.

1-4

TM 55-1520-228-BD

GENERAL INFORMATION

WARNING

outside authorized standard repairs, and

may degrade the inherent safety of the

Careful consideration shall be given

to the operation of the Identify

Friend or FOE (IFF), Mode 4,

avionics system.

Failure of the

IFF or failure to properly communi-

helicopter.

not intended to supplement, replace stan-

dard maintenance practices during peace-

time, nor should they be employed indis-

criminately to facilitate training.

cate with area air defense command

prior to liftoff could result in an

attack from friendly forces due to

mistaken identity.

b.

which can be appropriately accomplished

in order to provide training, are listed

in Appendix E and are highlighted in each

1-9.

TRAINING.

repair chapters repair procedure index.

The trainable repair in the index will be

a. BDAR by its nature involves fixes,

blocked

bypasses, and/or jury-rigging, which is

Section III.

TASKS AND RESPONSIBILITIES

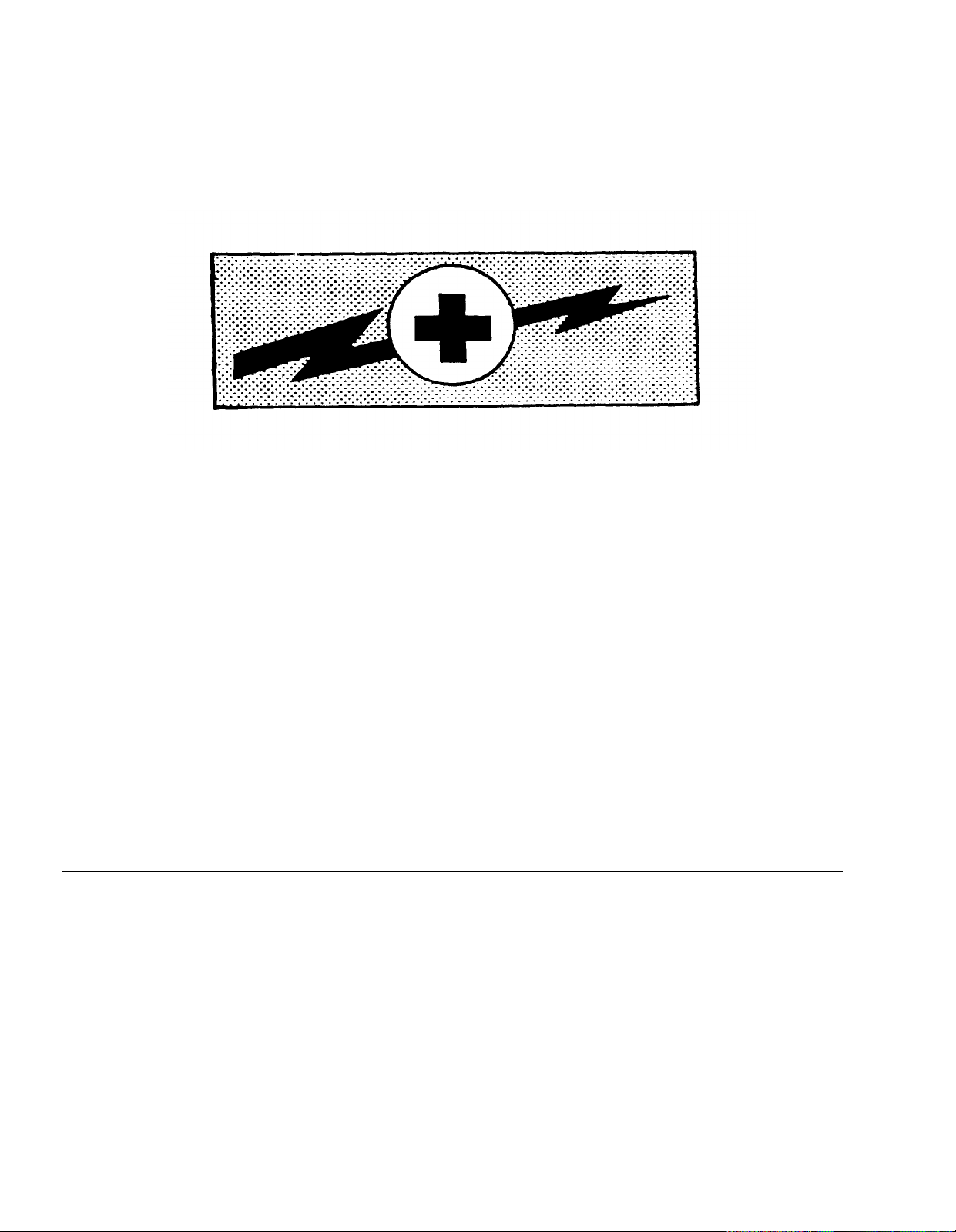

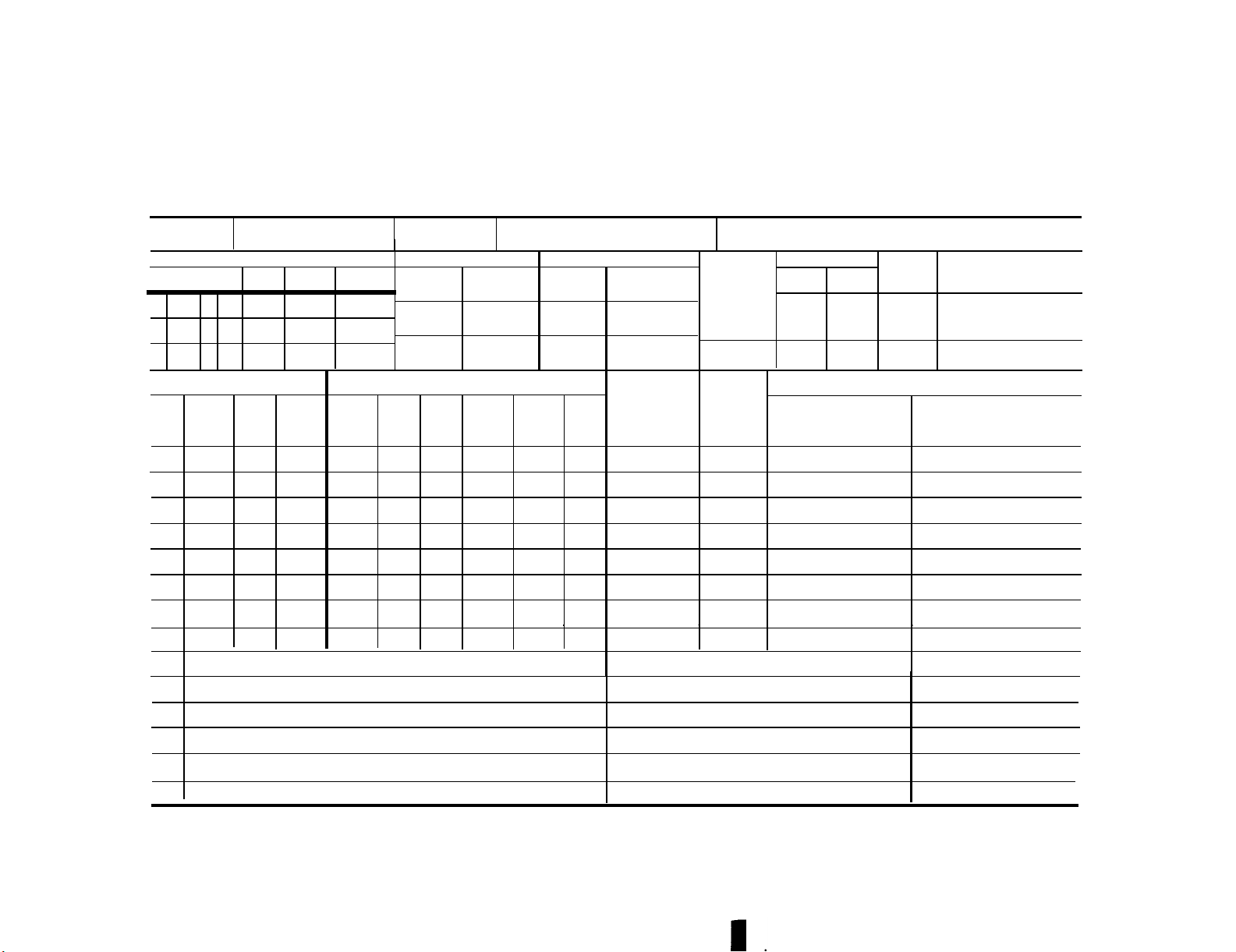

1-10. TAGGING/IDENTIFYING BDAR REPAIRS.

inside a red circle indicates a limiting

a. All damage will be identified on

aircraft inspection and maintenance

record, DA Form 2408-13 and DA Form

2408-18, as per DA PAM 738-751. See

defect.

specific limits as directed by higher

authority, or as directed locally until

corrective action is taken.

Figures 1-1, 1-2.

Recording of BDAR repairs and the

b.

use of status symbols, as defined in DA

PAM 738-751, will be completed as soon

as practical to indicate any limita-

tions and restrictions or required stan-

dard repairs.

inspection,

ponent replacement, maintenance opera-

tional check, or test flight is needed.

The symbol is also used to indicate that

a normal modification work order (MWO)

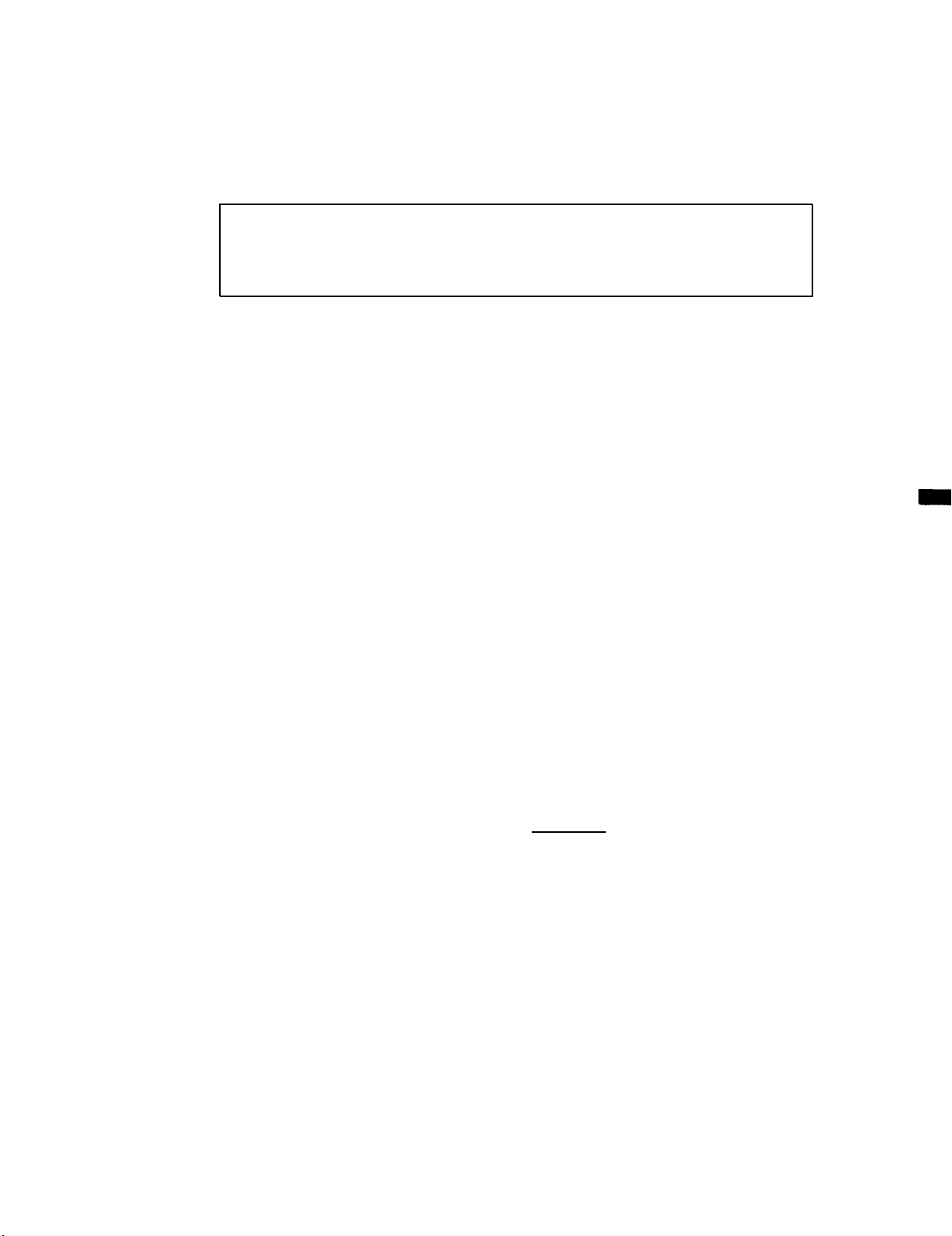

c. In addition to recording all

is overdue.

damage, the area damaged will be marked

on aircraft or component part using

damage assessment markings as shown in

Figure 1-3.

the condition of the equipment is

unknown. A potentially dangerous condition may exist.

d.

Status Symbols. Status symbols

corrected as soon as possible.

used in aircraft logbooks to record

defects are defined below.

indicates a defect exists that is not

(1) Red “X.”

A red “X” shows that

serious enough to ground the aircraft.

a defect exists and the aircraft is

unsafe for flight.

Therefore, BDAR actions are

Repairs described in this manual,

in.

(2) Circled red “X.” A red “X”

The aircraft may be flown under

(3) Red horizontal dash (-).

(a) This symbol indicates an

special inspection, com-

(b) This symbol also shows that

The condition will be

(4) Red diagonal (/). This symbol

1-5

TM 55-1520-228-BD

GENERAL INFORMATION

e. Maintenance of Forms. Instructions for the maintenance of forms,

records, and reports are listed in DA

PAM 738-751 and TB 55-1500-307-24. When

requires an inspection at intervals,

list the required inspection on DA Form

2408-18.

battle damage assessment and repair

(BDAR) becomes necessary, the procedures

in DA PAM 738-751 will apply. Refer to

in block 5.

Figures 1-1 and 1-2 for examples.

(1) In block 17 of DA Form

block 6.

2408-13, list the fault.

(2) In block 16 of DA Form

inspection in block 7.

2408-13, enter the status symbol.

1-11. REPORTS. All written reports

(3) In block 18 of DA Form 2408-13,

enter the corrective action taken.

required for BDAR fixes are found in DA

PAM 738-751.

longer fly, the aircraft commander

(4) The individual completing the

repair will sign the form in block 19

opposite the first line of the action

taken, and will place his last name ini-

tial over the status symbol in block 16.

should immediately initiate an out-ofaction report to his superior.

munications capability is damaged, the

aircraft commander should approach the

nearest friendly radio and make his

report if possible. The report should

f.

Temporary Repair. If the repair

include these essentials:

is temporary, take the following addi-

tional action:

a. Aircraft damage (out-of-action or

function partially impaired).

(1) In block 18 of DA Form 2408-13,

enter the corrective action and a state-

b.

ment that the repair is temporary. Then

make an entry in DA Form 2408-14, block

The entry will be a duplicate of the

b.

entry in block 17 of DA Form 2408-13 to

c. Defense status.

d.

include a statement that a temporary

repair has been made.

e. Personnel report.

(3) If the temporary repair

(a) Enter item to be inspected

(b) List the applicable TM in

(c) State the frequency of the

If the helicopter can no

If com-

Location of aircraft.

Mobility.

NOTE

Faults with status symbol of red "x", or

circle red "x" will not be entered on

DA form 2408-14.

(2) If the temporary repair limits

f.

action.

g.

time.

the capability of the aircraft, the

following entry will be made on DA Form

2408-13:

(a) Place a circled red “X” in

block 16.

(b) State the limitation in

block 17.

1-6 Change 1

Current and anticipated hostile

Anticipated BDAR fixes and repair

TM 55-1520-228-BD

GENERAL INFORMATION

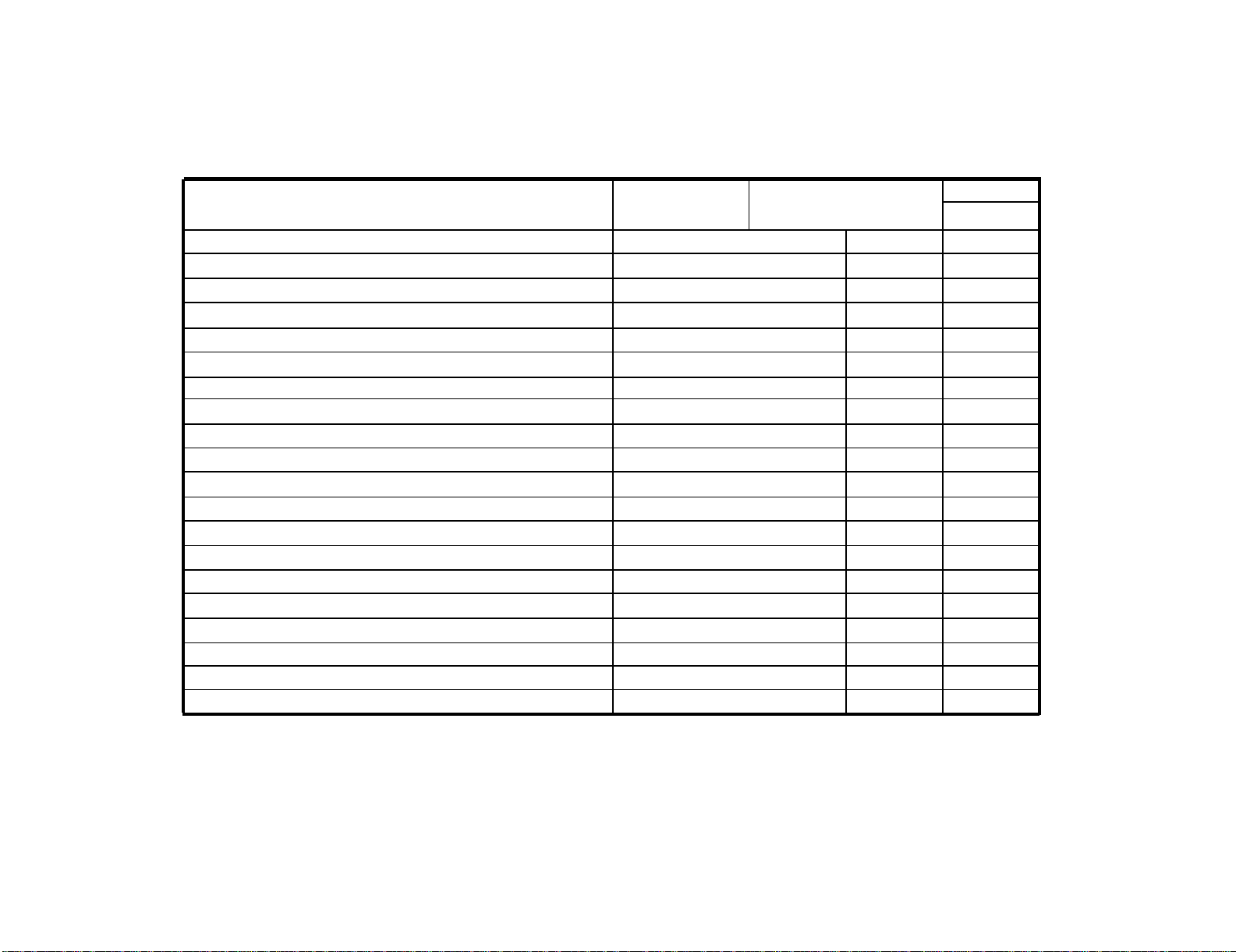

1. DATE 2 MODEL

7

1

2

3

11

SERV-

ICE

NO.

TOTAL

16

STATUS

AIRCRAFT

1

2

3

4

5

6

7

17

STATUS TODAY

ELEC-

TRONIC

4

5

6 TIME

FUEL (Gals or Lbs)

GRADE

ADDED

ARMA-

MENT

TOTAL

IN

TANKS

OTHER

12

ADDED

GRADE

FAULTS AND/OR REMARKS

N0.

ENG

3. SERIAL NO.

8

AIRCRAFT TIME

TIME TO

DATE

TIME TO-

DAY

TOTAL

OIL ( Quarts)

TOTAL

1

IN

TANKS

4 NAME OF CREW CHIEF/MECHANIC 5 STATlON

9

NEXT INSPECTION DUE

INTMED

NO.

P.E. NO.

OTHER

14

ADDED

N0. 2

ENG

TOTAL

IN

TANKS

APU

13

0XYGEN

(PSI)

18.

I

ENGINE

PREVIOUS

TODAY

TOTAL

ANTl-

ICING

FLUID

(Gals)

ACTION TAKEN

15

HOT STARTS

N0.1

NO. 2

ENGINE

BY

6 PAGE NO.

LANDINGS

b

SERVICED

19

6a NO. OF PAGES

OTHER

c

STATION

SIGNATURE

I

DA FORM 2408-13, 1 DEC 66

REPLACES EDITION OF 1 JAN 64, WHICH WILL BE USED

Figure 1-1. DA Form 2408-13

I

I

AIRCRAFT INSPECTION AND MAINTENANCE RECORD

For use of this form see DA PAM 738-751, the proponent army is DCSLOG

1

1-7

TM 55-1520-228-BD

GENERAL INFORMATION

1. NOMEN CLATURE

5.

ITEM TO BE INSPECTED

2. MODEL 3. SERlAL NUMBER 4. PAGE NO.

NO. OF PAGES

6.

REEFERENCE

7.

FREQUENCY

8.

NEXT DUE

●

DA FORM 2404.18. 1 JAN 64

1-8

Figure 1-2. DA Form 2408-18

EQUIPMENT INSPECTION LIST

For use

of this form, see TM 38-750;

the proponent agency is DCSLOG.

TM 55-1520-228-BD

GENERAL INFORMATION

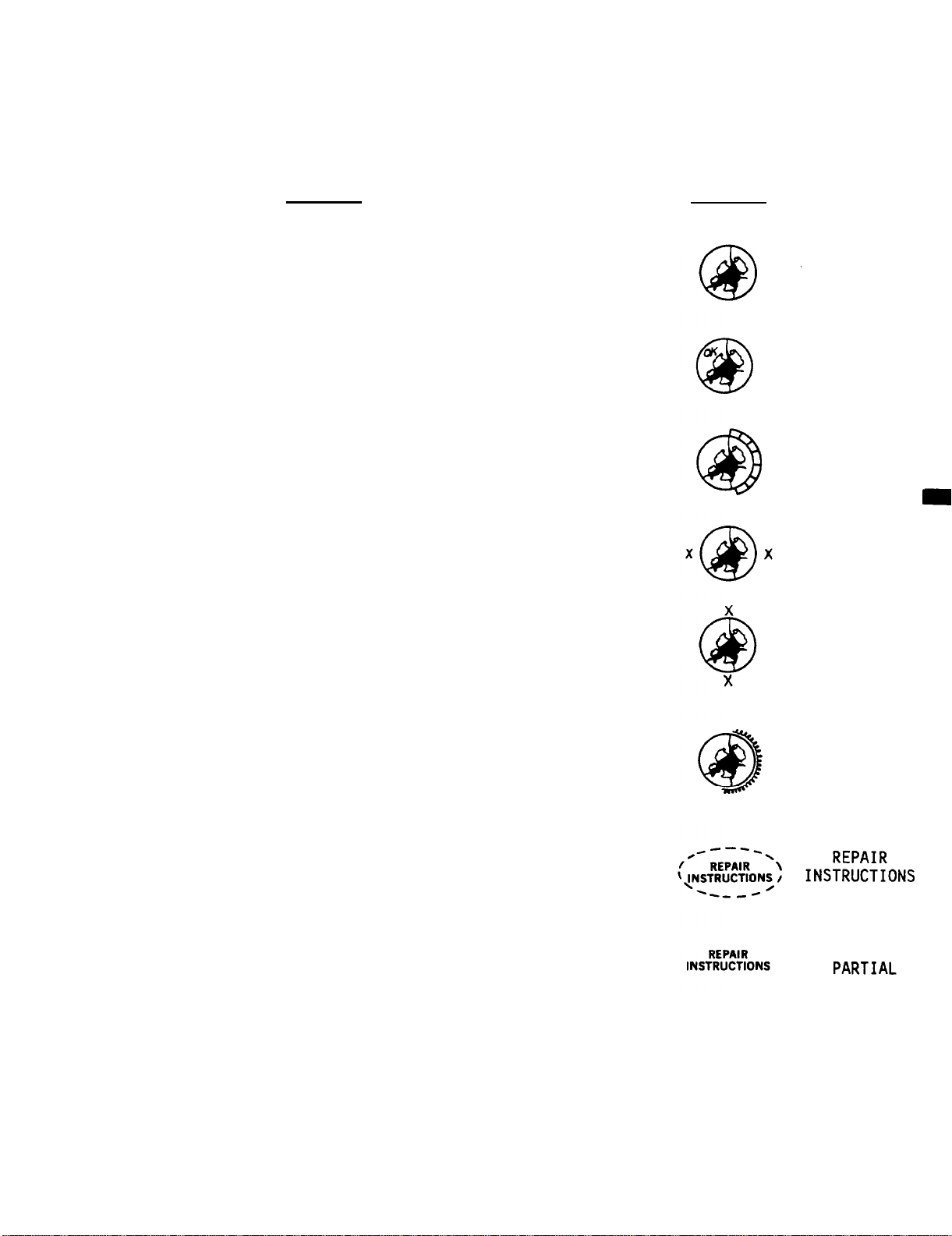

MEANINGS

TO INDICATE DAMAGE HAS BEEN ASSESSED AND EVALUATED:

Draw a circle around the damage.

TO INDICATE NO BDAR REPAIR REQUIRED:

Write “OK” inside the circle.

TO INDICATE STRUCTURAL REPAIRS ARE REQUIRED:

Draw a second line about 1/4 to 1/2

way around the initial circle then

draw slashes or crosshatch between

the two circular lines.

STRINGER REPAIR:

left and right of the circle.

FRAME REPAIR: Place an X above and

below the circle.

Place an X to the

MARKINGS

TO INDICATE DAMAGE TO SYSTEMS REQUIRING REPAIRS:

Draw a series of “curly cue” lines about

1/4 to 1/2 way around the initial circle.

TO INDICATE REPAIR INSTRUCTIONS:

For internal damage - draw a dashed

circle around the repair instructions.

For external damage - write repair

instructions but do NOT enclose

with a circle.

Figure 1-3.

Damage Assessment Markings (Sheet 1 of 3)

1-9

TM 55-1520-228-BD

GENERAL INFORMATION

WRITTEN INSTRUCTIONS

See me -

print name &

rank. (Signature)

Names of parts to

be repaired, (item,

skin, stringer.

Full

Partial

See assessor or whoever has signed written instructions

for additional information.

Where compound damage occurs, the names or abbreviations

of specific items can be written adjacent to the damage

to clarify repair instructions.

A full strength repair is required.

Partial strength repair required in accordance with

MEANING

specific aircraft BDAR manual.

OK

No repairs required - damage is within acceptable limits

for battle conditions.

?

Continual assessment or reinspection is required after

each sortie.

Instruction markings for system are in two parts:

(1) Repair instruction markings and meanings are shown on this sheet and are

used to indicate repair actions required.

(2) System Identification - When known,

identify the system using markings

shown on sheet 3 of this figure.

MARKINGS MEANING

Fix

Repair the damaged system in accordance with approved

standard BDAR techniques for type of system, item,

high pressure, low pressure, etc.

Cap

Repl

OK

Tag

Terminate or block the system to prevent leakage.

Replace damaged part -

repairs not acceptable.

No repairs required.

Repair instructions are written on tags tied to indivi-

dual damaged lines/components.

1-10

Figure 1-3.

Damage Assessment Markings (Sheet 2 of 3)

Loading...

Loading...