Page 1

iXPanelTA100

Service&MaintenanceManual

MAEN013A,2010-12

English

Page 2

Service&MaintenancemanualforiXPanelTA100

Foreword

This manual contains detailedinformation about iX Panel TA100, including

descriptions of variousactions that can be carried out inorder to maintain or

update the operator panelhardware and software.

The manual contains descriptionsof basic maintenance and replacement of

common parts in iX Panel TA100.

The manual assumes thatthe most recent versions of the system program

(firmware) and iXDeveloper are used.

The followingother manuals are available for iXPanel TA100:

iX PanelTA100installation manual (MAEN010x) for in formation regarding

installation.

iX Developer reference manual (MAEN831x) for a descriptionof the

configuration tool.

iX Developer user’s guide (MAEN832x) for function-based descriptions.

Foreword

Order no: MAEN013A

Copyright © 2010-12 Beijer Electronics AB. All rights reserved.

The information inthis document is subject tochangewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer Electronics AB reserves the rightto change any information without updating th is

publication. Beijer Electronics AB assumes no responsibility for any errors that mayappear inthis document.

Read the entireinstallation manual prior to installing and usingthis equipment. Only qualified personnel

may install, operate or repair this equipment. Beijer ElectronicsAB is not responsible for modified, altered

or renovated equipment. Because the equipment hasa widerangeofapplications,usersmustacquirethe

appropriate know l edge to use the equipment properly in their specific applications. Persons responsible

for the application and the equipment must themselves ensure that each application is in compliance with

all relevant requirements, standards and legislationinrespecttoconfigurationandsafety. Onlypartsand

accessories manufactured according to specifications set by Beijer ElectronicsAB may be used.

BEIJER ELECTRONICSAB SHALL NOT BE LIABLE TO ANYONE

FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGESRESULTING FROMTHE

INSTALLATION, USE OR REPAIR OF THIS EQUIPMENT, WHETHER

ARISING IN TORT, CONTRACT, OR OTHERWISE. BUYER'S SOLE

REMEDYSHALL BE THE REPAIR, REPLACEMENT, OR REFUND

OF PURCHASE PRICE, ANDTHE CHOICE OF THE APPLICABLE

REMEDYSHALLBEATTHESOLEDISCRETIONOFBEIJER

ELECTRONICSAB .

BeijerElectronics, MAEN013A

Page 3

Contents

Contents

1 Safety Precautions ....................................................... 5

1.1 General ...........................................................

1.2 During Installation ..............................................

1.3 During Use .......................................................

1.4 Service and Maintenance ........................................

1.5 Dismantling and Scrapping .....................................

2 Introduction ............................................................. 7

2.1 iX PanelTA100 ..................................................

2.2 Maintenance .....................................................

2.3 Service andRepairs ..............................................

2.4 Dismantling and Scrapping .....................................

2.5 Contact andSupport ............................................

3 Installation ............................................................... 10

3.1 Space Requirements .............................................

3.2 InstallationProcess ..............................................

3.2.1 Connections tothe Controller ........................ ..........

3.2.2 Other Connections andPeripherals ......................... ....

4 TechnicalData ........................................................... 14

5 ChemicalResistance .................................................... 15

5.1 Metal Casing .....................................................

5.2 Touch Screen and Overlay .. .....................................

5.2.1 AutotexF157/207 ....... ........................................

5.2.2 TouchScreenSurface ....... .....................................

5.2.3 AutoflexEB ........ ..............................................

6 Hardware Tests .......................................................... 18

7 Hardware Replacement ................................................. 19

7.1 Mode Switches ...................................................

7.2 Cables .............................................................

7.3 Replacing the Rear Cover ........................................

7.4 Replacing the Display/Disp

7.4.1 Self TestoftheDisplay ... ........................................

7.4.2 CalibratingtheTouch Screen ....................................

layCable ..........................

7.5 ReplacingtheCompleteFront ..................................

7.6 Replacing the Backlight .. .......................................

7.7 Available SpareParts for iX Panel TA100 .......................

8 Service Menu ............................................................ 27

8.1 Service Menu in an Empty Panel ...............................

8.2 Service Menu in a Panel with Project ...........................

8.3 Service Menu Options ...........................................

8.3.1 IPSettings ..................... ..................................

8.3.2 Date/Time ........................... ............................

8.3.3 EraseProject ................ .....................................

8.3.4 TouchCalibrate ...... ...........................................

9 Hardware Self Test ...................................................... 29

9.1 Self Test Items ....................................................

10

10

13

13

15

16

16

17

17

19

20

21

22

23

23

24

25

26

27

27

27

27

28

28

28

30

5

5

6

6

6

7

8

8

8

9

BeijerElectronics, MAEN013A

Page 4

Contents

10 AdditionalInstallation Tips . ........................................... 31

10.1 Grounding the OperatorPanel .................................

10.2 Ethernet Connection in the Panel ..............................

10.3 To Achieve Better EMC Protection .............................

10.4 Ambient Temperature ...........................................

10.5 Safety .............................................................

10.6 GalvanicIsolation ................................................

10.7 Cable and Bus Termination RS485 .............................

31

32

33

34

35

36

37

11 Fault Tracing ............................................................. 38

12 Software .................................................................. 40

12.1 General Information aboutSoftware ...........................

12.1.1 Software Products ....... ........................................

12.2 Update Software .................................................

12.2.1 iXDeveloper ................................................. ....

12.2.2 Remote AccessViewer ............ ...............................

12.2.3 System Program ..................... ............................

40

40

41

41

41

41

13 Environmental Aspects ................................................. 43

13.1 General Environmental Aspects ................................

13.2 Environmental Impactofthe OperatorPanels .................

13.2.1 Mechanical Components .................. ......................

13.2.2 Electronics ............ ...........................................

13.3 Recycling .........................................................

13.4 Environmental Impact Report ..................................

43

43

43

43

44

44

BeijerElectronics, MAEN013A

Page 5

Safety Precautions

1SafetyPrecautions

Both the installer andthe owner and/or operator of the operatorpanel must read

and understand thisinstallation manual.

1.1 General

• Read the safety precautionscarefully.

• Check the delivery for transportation damage. If damage is found, notif y the

supplier as soon as possible.

• Do not use the operator panel in an environment with high explosive hazards.

• The supplier is not responsible for modified, altered or reconstructed

equipment.

• Use only parts and accessories manufactured accordingto specifications of

the supplier.

• Read the installationand operating instructions carefully before installing,

using or repairingthe operator panel.

• Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

operator panel. This may cause fire or electrical shock.

• Only qualified personnel may operate the operator panel.

• Storing theoperator panel wherethe temperature is lower/higher than

recommended in this manualcan cause the LCD display liquid to

congeal/become isotopic.

• The LCD display liquid contains a powerful irritant. In caseof skin contact,

wash immediately with plenty of water. In case of eyecontact, hold the eye

open,flushwithplentyofwaterandgetmedicalattention.

• Thefiguresinthismanualservesanillustrativepurpose. Becauseofthemany

variables associated with anyparticular installation, the suppliercannot

assume responsibility for actual use based onthe figures.

• The supplier neither guarantees thatthe operator panel is suitable for your

particular application, nor assumes responsibility for your productdesign,

installation or operation.

1.2 DuringInstallation

• The operator panelis designed for stationary installation on a plane surface,

where thefollowing conditions arefulfilled:

– no high explosive risks

– no strong magnetic fields

– no direct sunlight

– no large, sudden temperature changes

• Install the product according to the accompanying installation instructions.

• Ground theproduct according to the accompanying installation instructions.

• Only qualified personnel may install the operator panel.

• Separate the high voltage,signal and supply cables.

• Make surethat the voltage and polarity of thepower source is correct before

connecting the product to the power outlet.

• Peripheralequipment must be appropriate for theapplication and location.

BeijerElectronics, MAEN013A

5

Page 6

Safety Precautions

1.3 DuringUse

• Keep the operator panel clean.

• Emergency stop and othersafety functions may not be controlled from the

operator panel.

• Do not usetoo much force or sharp objects when touching the keys,touch

screenetc.

1.4 ServiceandMaintenance

• Only qualified personnel should carry out repairs.

• The agreed warranty applies.

• Before carrying out any cleaningor maintenance operations, disconnect the

equipment from theelectrical supply.

• Clean the display andsurrounding front cover with a soft cloth andmild

detergent.

• Replacing the battery incorrectly may resultin explosion. Only use batteries

recommended by the supplier.

1.5 DismantlingandScrapping

• The operator panelor parts thereof shall be recycledacc

regulations.

• The followingcomponents contain substances t

to health andthe environment: lithium batter

display.

hat might be hazardous

y, electrolytic capacitor and

ording to local

BeijerElectronics, MAEN013A

6

Page 7

Introduction

2Introduction

This manual describes howto maintain the iX PanelTA100.

The functions availablein iX Developer depend onwhich operator panel model is

used.

2.1 iXPanelTA100

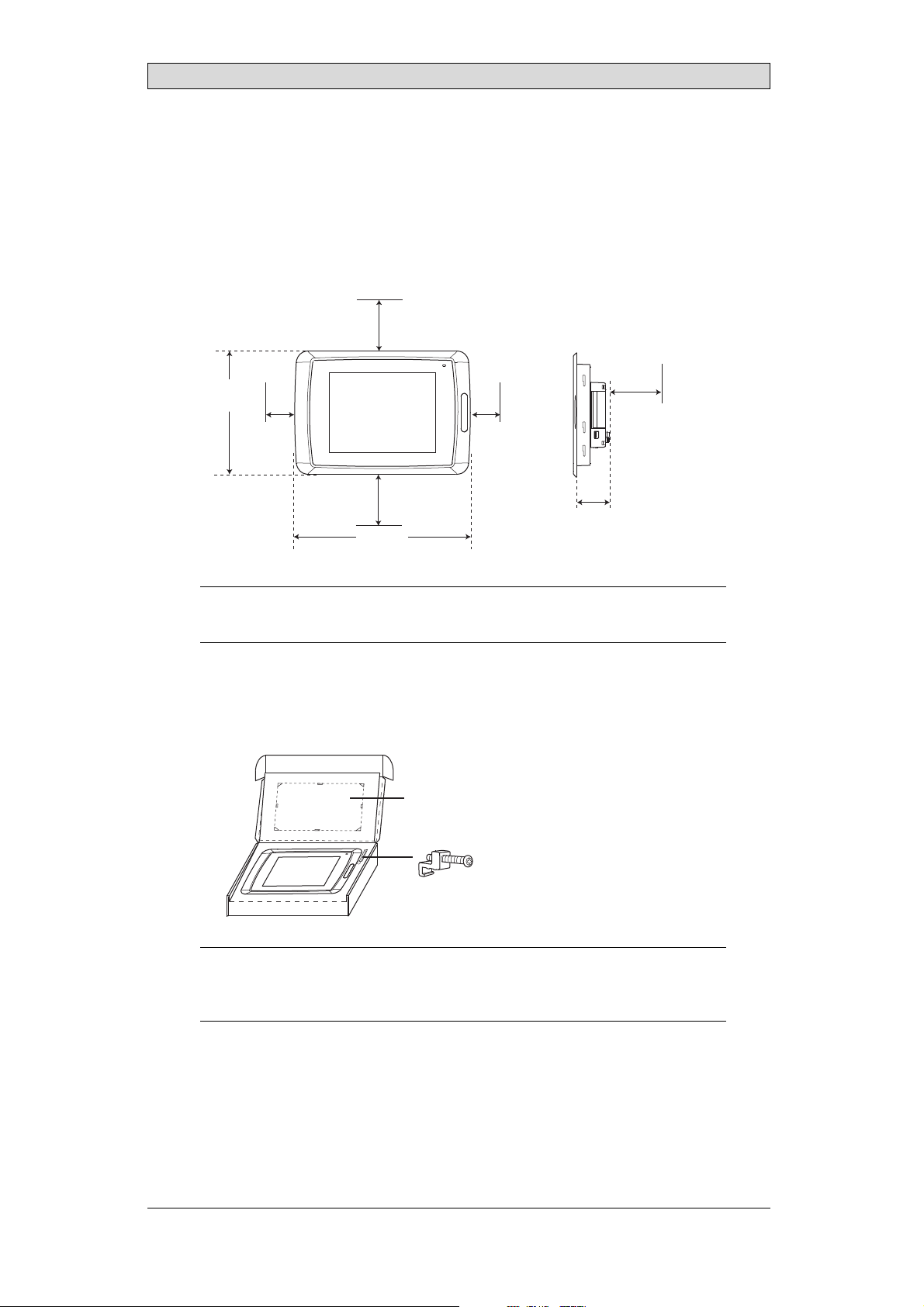

The followingdrawings are available foriX Panel TA100:

• Outline drawing

• Panelcut-out

BeijerElectronics, MAEN013A

7

Page 8

Introduction

2.2 Maintenance

Carefully read the instr uctions before beginning maintenance on theoperator

panel.

• Only qualified personnel should carry out maintenance.

• The agreed warranty and license agreements apply.

• Any damage tothe operator panel caused by personnel invalidates the

warranty.

• Before carrying out any cleaningor maintenance operations, disconnect the

operator panel fromthe power supply.

• Clean the display andsurrounding front cover with a soft cloth andmild

detergent. Recommended cleaning fluids for the display are water and IPA

(Isopropyl Alcohol orHexane).

• Replacing the battery incorrectly may resultin explosion. Only use batteries

recommended by the supplier.

• A 6-month warrantyon all service parts is provided.

Maintenance personnel are permitted to carry out the following actions:

• Replacing the Rear Cover

• Replacing the Display/Display Cable

• Replacing the Complete Front

• Replacing the Backlight

2.3 ServiceandRepairs

• Only accredited companies are permitted to perform service and repairs.

• Ifanon-accreditedcompanyconductsanykindofserviceorrepair,theagreed

warranty will be i nvalidated.

• If training is required,contact the supplier.

• All maintenance should be performed in a 15-30 °C temperature range.

• Any damage tothe operator panel caused by personnel invalidates the

warranty.

• Contracts with customers supersede the information in thisdocument.

2.4 DismantlingandScrapping

• The operator panel, or parts thereof, should berecycled according to local

regulations.

• The followingcomponents contain substances that mightbe hazardous to

health and theenvironment: lithium battery, electrolytic capacitor, display.

BeijerElectronics, MAEN013A

8

Page 9

Introduction

2.5 ContactandSupport

If you wantto report a fault or have aquestio n about the operator panels, please

contact your localsupplier or fill out the form onthe web site.

1.

Enter the web site www.beijerelectronics.com and selectSupport.

2.

Select Contact inthe menu. Make sure to provideinformation about type

number, serial number, environmentand an installation description.

The form will besent to the manufacturer’s help desk and they will answer your

question or registeryour improvement/fault.

To ensure quick resolution, provideas many details as possible in your report.

Include the date and time when the problem occurred, a description of what you

were trying to do, the detailed steps you took that led up to the problem, and

details about any error messagesreceived.

BeijerElectronics, MAEN013A

9

Page 10

3Installation

3.1 SpaceRequirements

• Installation plate thickness: 1.5 - 9.0mm (0.06 - 0.35 inch)

• Space requirementswhen installing the operator panel:

100 mm

(4.0 inch)

228 mm

(8.98 inch)

50 mm

(2.0 inch)

100 mm

(4.0 inch)

302 mm

(11.89 inch)

50 mm

(2.0 inch)

58 mm

(2.28 inch)

Installation

100 mm

(4.0 inch)

Caution:

Theopenings ontheenclosureareforairconvection. Donotcovertheseopenings.

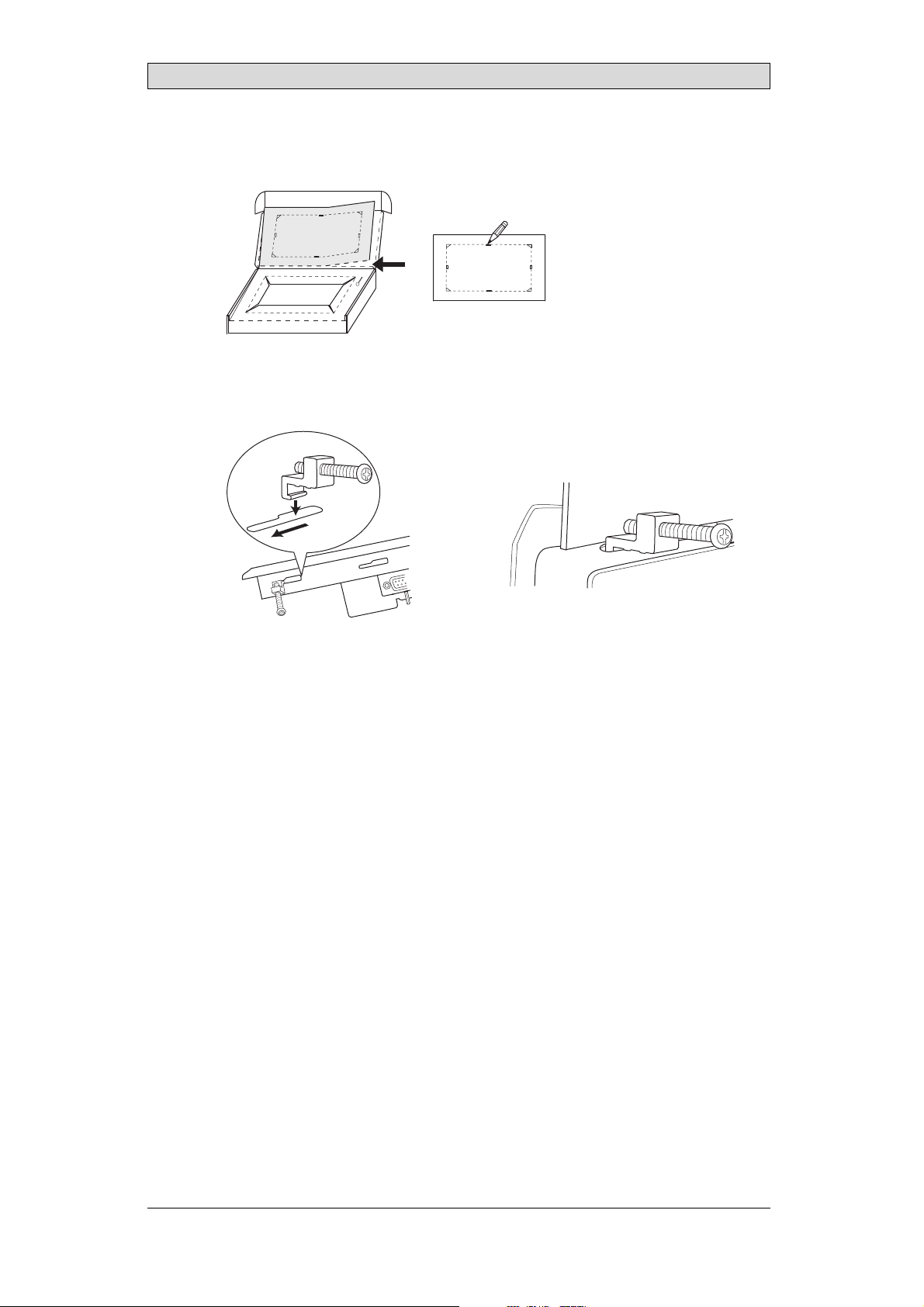

3.2 InstallationProcess

1.

Unpackand check the delivery. If damage is found, notify the supplier.

Panel cut out 264.5 x 206.0 mm

(10.41 x 8.11 inch)

x 13

Note:

Placethe operatorpanelonastablesurfaceduring installation.

Droppingitorlettingitfallmaycause damage.

BeijerElectronics, MAEN013A

10

Page 11

2.

Place thepanel cut out where theoperator panel is to besituated, draw along

the outer sides of theholes and cut according to themarkings.

3.

Secure the operator panel in position, using all the fastening holes and the

provided brackets and screws:

x 13

Installation

0.5 - 1.0 Nm

BeijerElectronics, MAEN013A

11

Page 12

Installation

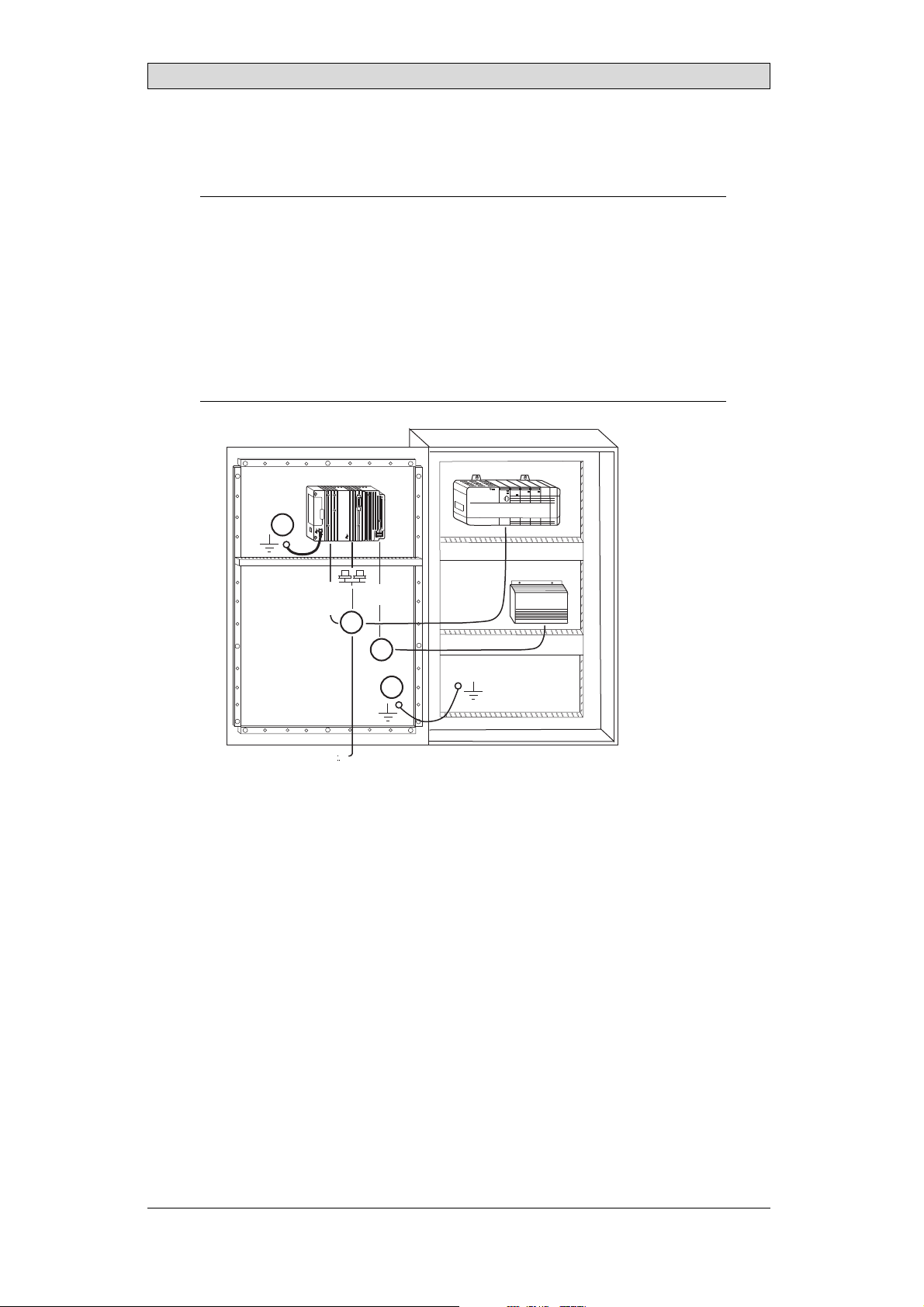

4.

Connect the cables in the specified order, accordingto the drawing and steps

below.

Caution:

• Ensurethattheoperatorpanelandthecontrollersystemhavethesame electrical

grounding(referencevoltagelevel),otherwiseerrors incommunicationmay

occur.

• Theoperatorpanelmustbebroughttoambient temperaturebeforeitisstarted

up. Ifcondensation forms,ensurethattheoperatorpanelisdrybeforeconnecting

itto thepoweroutlet.

• Ensurethatthevoltageandpolarity ofthepowersourceiscorrect.

• Useonly shieldedcommunicationcables.

• Separatehighvoltagecablesfromsignalandsupplycables.

Power

CF CARD

B

1

Controller

RS422/RS485

RS232

24V DC

24V DC

C

D

A

Ethernet

– Connect cable A.

– Connect cable B, using an M5 screw and a grounding conductor (as short

as possible) with a cross-section of minimum 2.5 mm

– Connect cable C.

– Connect cable D.

5.

Carefully removethe laminated film over the operator panel display, to avoid

2

.

static electricity that could damage the panel.

BeijerElectronics, MAEN013A

12

Page 13

Installation

3.2.1 ConnectionstotheController

Forinformation about the cables to be usedwhen connecting the operator panel to

the controller,please refer to the help file forthe driver in question.

3.2.2 OtherConnectionsandPeripherals

Cables, peripheral equipment and accessories must besuitable for the application

and its environment. Forfurther details or recommendations, pleaserefer to the

supplier.

BeijerElectronics, MAEN013A

13

Page 14

Technical Data

4TechnicalData

Parameter iX Panel TA100

Frontpanel,WxHxD 302x228x6mm

Mountingdepth 58mm (158mmincludingclearance)

Frontpanel seal IP66

Rear panel seal IP 20

Keyboard

material/Front

panel

Reverseside

material

Weight 2.1 kg

Serialport

RS422/RS485

SerialportRS232C 9-pinD-subcontact,malewithstandardlocking screws4-40

Ethernet 2x shieldedRJ45

USB HosttypeA(USB 2.0),m ax outputcurrent500m A

Memoryslots 1x SDcard

Realtimeclock ±30PPM +errorbecauseofambienttemperature. Total

Power consumption

atrated voltage

Display TFT-LCD.800x600pixels,64Kcolors.

Activeareaof

display,WxH

Fuse InternalDCfuse,3.15AT, 5x20mm

Powersupply +24VDC (20-30VDC).Powersupplyconnector.

Ambient

temperature

Storagetemperature -20°to+70°C

Relativehumidity 5- 85%non-condensed

Approvalsand

certifications

Touch screen: Polyesteronglass,1millionfinger touch

operations. Overlay: AutotexF157orF207*.

Powder-coatedaluminum

25-pinD-sub contact,chassis-mountedfemalewith

standardlo cking screws4-40UNC

UNC

maximumerror: 77seconds/monthat25°C.

Temperature coefficient: -0.034±0.006ppm/°C

Rechargeablebattery.

Normal: 0.5A

Maximum: 1.0A

CCFLbacklight lifetimeat theambienttemperatureof

+25°C:>50,000h.

211.2x 158.4mm

CE:The powersupplymustconformwiththerequirements

accordingtoIEC60950andIEC 61558-2-4.

ULand cUL:Thepowersupplymustconformwith the

requirementsforclassIIpowersupplies.

Verticalinstallation: 0°to+50°C

Horizontalinstallation: 0°to +40°C

Informationisavailableon thewebsite

www.beijerelectronics.com

2

*SeesectionChemicalResistanceformore information.

BeijerElectronics, MAEN013A

14

Page 15

Chemical Resistance

5 ChemicalResistance

5.1 MetalCasing

The frame and casing material is powder-coated aluminum. This powder paint

withstands exposure to the following chemicals without visible change:

Aceticacid 10% Phosphoricacid4%

Citricacid10% Phosphoricacid10%

Diesel Seawater

Distilledw ater Sodiumchloride2%

Edibleoil Sodiumchloride20%

Fueloil Sulphuricacid 20%

Hydrogenperoxide3% Tap water

The powderpaint shows limited resistance to the f

ollowing chemicals atroom

temperature:

Butanol Nitricacid3%

Hydrochloricacid5% Nitricacid10%

Isopropylalcohol Phosphoricacid43%

Na-hypochlorite10% Turpentine

Note:

Ifexposureto anyofthe abovechemicalsisdemanded,itisrecommendedtofirsttest

thechemical onan“invisible”spotofthemetalcasing.

Thepowderpaintshowslittleornoresistancetothefollowingchemicalsatroom

temperature:

Aceticacid, conc. Methyl-ethylketone Toluene

Acetone Nitricacid 30% Trichlorethylene

Ammonia5% Phenol Xylene

Ammonia,conc. Sodiumhydroxide5% 97octanunleadedpetrol

Ethylacetate Sodiumhydroxide30% 98octanle ad edpetrol

BeijerElectronics, MAEN013A

15

Page 16

Chemical Resistance

5.2 TouchScreenandOverlay

5.2.1 AutotexF157/207

Autotex F157 or F207 covers the overlay surrounding the touch screen.

SolventResistance

Autotex F157/F207 withstands exposure of more than 24hours duration under

DIN42115Part2tothefollowingchemicalswithoutvisiblechange:

Acetonitrile DieselDowney/Lenor

Ajax/ Vimin solution EthanolPotassiumferricyanide

Alkalicarbonatesolution1Glycerine Potassiumhydroxide

Ammonia(<40%)

Aceticacid (<50%) Gumption

Arielpowderinsolution

1

Bleach

Castoroil Methanol Trichloroaceticacid

Causticsoda(<40%)

Cuttingoil Paraffinoil Windex

Cyclohexanol Persilpowderinsolution1Wisk

Diacetonealcohol Petroleumspirit

1

Extremelyfaintglossingofthe texturewasnoted.

1

1

Glycol PureTurpentine

1

1

Hydrochloricacid(<36%) Sulfuricacid(<10%)

Linseedoil Toma to ketchup

Nitricacid (<10%) WhiteSpirit

1

Phosphoricacid(<30%)

(<30%)

SBP60/95

(<50%)

1

-

1

1

Autotex withstands DIN 42 115Part 2 exposure of up to 1 hour duration to glacial

acetic acid withoutvisible change.

Autotex is no

t resistant tohigh pressure steam at over 100°C or the following

chemicals:

Concentratedmineralacids Benzylalcohol

Concentratedcaustic solution Methylenechloride

OutdoorUse

In common withall polyester based films AutotexF157/F207 is not suitable for

use in conditions of long term exposure to directsunlight.

BeijerElectronics, MAEN013A

16

Page 17

Chemical Resistance

5.2.2 TouchScreenSurface

Thetouchscreensurfaceonthepanelwithstandsexposuretothefollowing

solvents without visible change:

Solvents Time

Acetone 10minutes

Isopropanol 10minutes

Toluene 5 hours

5.2.3 AutoflexEB

It isrecommended to use the Autoflex EB touchdisplay protection film, that can

be ordered from Beijer Electronics.

SolventResistance

Autoflex EB withstands exposure to the same chemicals asAutotex F157 or F207

according to section AutotexF157/207.

OutdoorUse

In common withall polyester based films Autotex EB is not suitable for use in

conditions of long term exposure to direct sunlight.

BeijerElectronics, MAEN013A

17

Page 18

Hardware Tests

6 HardwareTests

Before the operator panels are approved for market introduction, theyare tested

by independent authorities. The iX Panelsare examined by several authorities

before being approvedfor market introduction. A ll operator panels are designed

to fulfill standards such as CE. The quality policy and environmental policy place

demands on all suppliersand subcontractors.

The manufacturer performs extensive hardware testing before an operator panel

is approved. Some tests are performed byexternal testing companies, such as

the SwedishNational Testing and Research Institute. All operator p anels are

submitted to testingbefore leaving the manufacturer.

BeijerElectronics, MAEN013A

18

Page 19

Hardware Replacement

7 HardwareReplacement

This section containsinstructions on how to replace operatorpanel hardware.

Only components included in the latest bill of material and spareparts list are

allowed. See Available Spare Parts for iX Panel TA100.

7.1 ModeSwitches

The iX Panel TA100 has four modeswitches (DIP switches) located on the rear

side of the operator panel.

1 2 3 4

MODE

ON DIP

10/100

EXPANSION

RS232

COM 2

24V DC

1

1 2 3 4

MODE

ON DIP

CF CARD

BUSY

COM 1

RS422

RS485

Warning:

Themodes belowaretobeusedwithcaution.

Themodeswitcheshavethefollowingfunctions: 1=ON,0=OFF

Each letter in “MODE” has a corresponding mode switch.

MODE Description

0000 “Runmode” -bootsCE,normaloperation.

0010 Notused.

0100 Notused.

1000 ServiceMenumode,theservicemenuforthesystemprogramis

shown. Allowsthe usertosetIPconfiguration,erasethe project,

calibratethe touchscreenetc. SeesectionServiceMenufordetails.

1100 Notused(runmode).

1110 Selftest.

xxx1 Not used.

To change mode switches, follow the steps below:

1.

Disconnect power from the operator panel.

2.

Set the mode switches using a ballpoint pen.

3.

BeijerElectronics, MAEN013A

nnect power to the operator panel.

Reco

19

Page 20

Hardware Replacement

7.2 Cables

Mostoftheoperatorpanelsusethesametypeofflexcableconnectors.

connector flanges

Flex cable connector

To release the flex cables fromthe connector, gently push the two flangeson the

cable connector towards theflex cable.

Note:

Theconnectorsmustbeunlockedonbothsidesbeforeremovingthecable,otherwise

theflexcablemaybedamaged.

BeijerElectronics, MAEN013A

20

Page 21

Hardware Replacement

7.3 ReplacingtheRearCover

The followingis needed:

• Anewrearcover,seeAvailable Spare Parts for iX Panel TA100

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Follow the stepsbelow to replacethe rear cover:

1.

Poweroff the operator panel.

2.

Remove the rear cover of the operator panel by loosening the 4torx screws.

4 x torx screws

3.

Re-assemble withthe new rear coverin reverse order.

BeijerElectronics, MAEN013A

21

Page 22

Hardware Replacement

7.4 ReplacingtheDisplay/Display Cable

The followingis needed:

• A new display/display cable, see Available Spare Parts for iX Panel TA100

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Followthe steps belowto replace the display/displaycable:

1.

Poweroff the operator panel.

2.

Followthe instructions under Replacing the Rear Cover to remove the rear

cover.

3.

Disconnect the two flex cables the flex cable and the LED cable fromthe

power cardand remove the two plastic nuts that hold thepower card in place.

LED cable

plastic nut

flex cable

plastic nut

4.

Lift the powercard and gently remove thebacklight cables and the display

cablefromtherearsideofthepowercard.

display cable

backlight cables

BeijerElectronics, MAEN013A

22

Page 23

Hardware Replacement

5.

Remove themounting plate (9 torx screws). Gently lift the mounting plate

with the display and power card.

9 x torx screws

6.

Flip the mounting plate and unscrew th e 4 torx screws.

4 x torx screws

7.

Re-assemble the panel in reverse order.

7.4.1 SelfTestoftheDisplay

To perform a self test of the display, followthe steps below:

1.

Start theoperator panel in a self test mode(see table in the Mode Switches section).

2.

Go to the display test, by running or ski

the display works.

3.

If the screendoes not work, try fault tracing, see the Fault Tracing section.

pping thepreceding tests. Verify that

7.4.2 CalibratingtheTouchScreen

Followthe steps below to calib

1.

Set the MODE switches to thecorrect positions in order to enterthe Service

Menu mode (see table in the Mode Switches section).

2.

Switchon the power and follow the instructions.

3.

Poweroff the operating panel.

4.

Reset all MODE switches to theOFF position.

rate the touch screen:

BeijerElectronics, MAEN013A

23

Page 24

Hardware Replacement

7.5 ReplacingtheCompleteFront

The followingis needed:

• Anewfront,seeAvailable Spare Parts for iX Panel TA100

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Followthe steps belowto replace the completefront of the iX Panel TA100:

1.

Poweroff the operator panel.

2.

Followthe steps 1-3 and 5 in the Replacingthe Display/Display Cable instructions, but in step3, only disconnect the flex cables and the LED cable (do not

remove the power card).

3.

Attach the new front.

4.

Re-assemble the unit.

BeijerElectronics, MAEN013A

24

Page 25

Hardware Replacement

7.6 ReplacingtheBacklight

Note:

Alllamps inthedisplaymustbereplacedat thesametime.

The followingis needed:

• A new backlight, seeAvailable SpareParts for iX Panel TA100

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Followthe steps below to replace the battery of the iXPanel TA100:

1.

First,follow the steps1–5 in section Replacing the Rear Cover.

2.

Gently move the backlight diagonally in direction from the display center to

release the snap-in closure that keeps the backlight in place.

3.

Remove the backlight from the display.

backlight

backlight snap lock

4.

Insert the new backlight. Be careful not to pull the cables of the new backlight

when inserting it, since pulling the cables will damage the backlight.

5.

Re-assemble the complete operator panel.

connectors

BeijerElectronics, MAEN013A

25

Page 26

Hardware Replacement

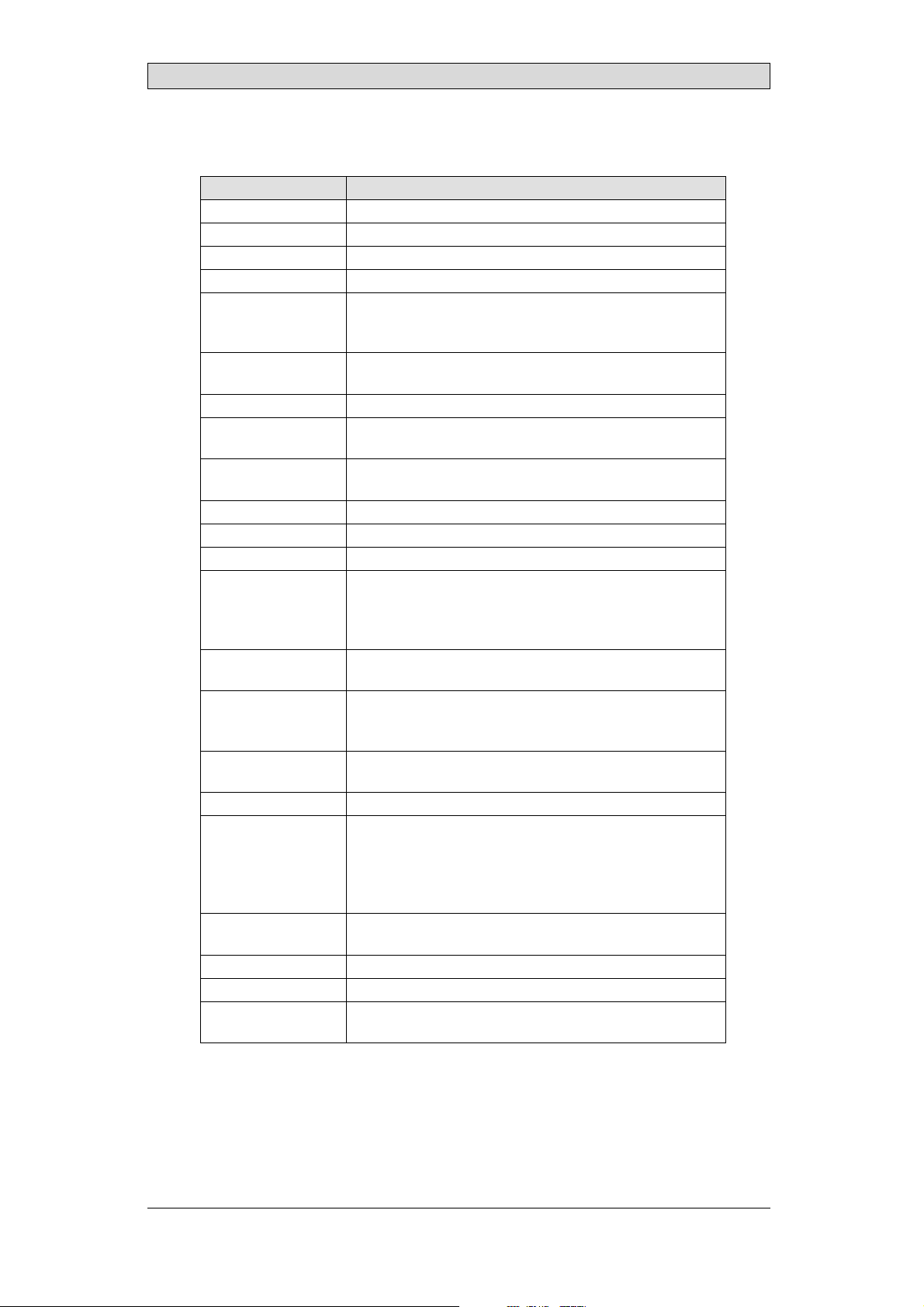

7.7 AvailableSparePartsforiXPanel TA100

Ordernumber Description

601009276 COMPLETEFRONT

Includingfrontcover,touchoverlay, gasketsandlabels

601009027 DISPLAY

Includingframeandcable

601009050 BACKLIGHT

601009028 DISPLAYCABLE

321099040 POWERCONNECTOR

601009011 REARCOVER

601009003 CFCOVER

601009001 MOUNTINGBRACKETS

601009039 TOUCHPROTECTIONSHEET

601009295 FRONTLABEL

601009135 COMPLETEBOX

601009008 TESTPLUGETHERNET

EthernetRJ45testconnector

601009006 TESTPLUGRS232

RS232test connector

601009007 TESTPLUGRS422/485

RS422/485testconnector

601009069 TESTPLUGUSBH

USBHosttestconnector

BeijerElectronics, MAEN013A

26

Page 27

Service Menu

8ServiceMenu

The service menu for theoperator panel can be accessed beforea project is

downloaded, or by setting th e mode switches in mode 1000. The location of the

mode switches is des cribed in the Mode Switches section.

8.1 ServiceMenuinanEmptyPanel

When no project isloaded in the panel memory,the panel will boot, displaying the

Welcome screen. Press anywhere on the panel display to enter the service menu.

8.2 ServiceMenuinaPanelwith Project

When a project is loaded in the panel memory, the panel willautomatically start to

execute theproject. To display the service menu atboot-up:

1.

Disconnect the powersupply from the panel.

2.

Set the mode switches in mode 1000 (Service Menu mode).

3.

Connect the powersupply.

When the panelboots up it will suggest to go into the Touch Calibrate mode.

This ensures that it willbe possible to recover froma bad calibration.

4.

Pressanywhere on the panel display to interrupt the timer and to enter the

service menu.

5.

Make desiredsettings in the service menu.

6.

Disconnect the powersupply from the panel.

7.

Set themode switches in mode0000 (Run mode).

8.

Reconnect thepower supply.

8.3 ServiceMenuOptions

The followingoptions are available in the ServiceMenu:

8.3.1 IPSettings

The panel hastwo built-in Ethernet ports, according to the drawing below. For

each port, selectto obtain an IP address automatically via DHCP, or specify an

IP address for the first Ethernet port.

Port 1

The port that is currently connected is recognized by a *.

BeijerElectronics, MAEN013A

Port 2

27

Page 28

Service Menu

8.3.2 Date/Time

Use the Date/Time Settingsdialog to set the time zone, date and timefor the

panel.

8.3.3 EraseProject

The erase functionwill detect if the projectis located in the panelmemory or ona

memory card. Pressing Erase Project will completely removethe project and all its

components from the panelmemory/the memory card.

8.3.4 TouchCalibrate

SelectTo uc h Ca li br at e if the touch screen needs tobe calibrated. Followthe

instructions on the screento perform a calibration.

BeijerElectronics, MAEN013A

28

Page 29

Hardware Self Test

9 HardwareSelfTest

The self testprogram can be used to test aspectsof operator panel functionality

and thecommunication ports. To run the testyou will need:

• Test plugs, including two Ethernet test plugs; see Te st pl u g d ra wi ng .

• 24 V DC, min. 3 A.

• SD card

Followthe steps below to run the self test program on the operator panel:

1.

Poweroff the operator panel.

2.

Go to the self test. Set the mode switches tothe self test positions, s ee the table

in the Mode Switches section.

3.

Power on the operator paneland follow the instructions at the bottom of the

display.

4.

When using thetest plugs, make sure the +5V DC LED on the RS422 test

plug and theLED of the RS232 test plug areon.

5.

When the selftest is finished, power off theoperator panel and set all mode

switches tothe OFF position.

If an error occurs during the self test, try to fault trace. See Fault Traci

ng.

BeijerElectronics, MAEN013A

29

Page 30

Hardware Self Test

9.1 SelfTestItems

The following tests, of whichsome may be dismissed, are performed:

Maybe

Test item

RS422(short-circuit) No 25pinD-sub plug(male);

RS232(short-circuit) No 9pinD-subplug(female);

EEPROM No CoreTemperature No BoardTemperature No Touch Yes Buzzer Yes Power LED Yes Backlight Yes Display Yes SDCard Yes SDcardmustbe

BurnIn

(loopwith

6repeating

tests)

CoreTemperature BoardTemperature Ethernet1 RJ 45 plug

Ethernet2 RJ 45 plug

RS422 25pinDSUB plug(male)

RS232

dismissed Plug

maynot beconnected

mayno t bepluggedin

connected

Yes

9pinDSUBplug(female)

BeijerElectronics, MAEN013A

30

Page 31

Additional InstallationTips

10 AdditionalInstallationTips

When experiencing communication problems in for example noisy environments

or when operating closeto temperature limits, the following recommendations

are to benoticed.

10.1 GroundingtheOperatorPanel

Door

Operator panel

1

Ferrite core

3

2

5

6

4

Mounting plate in the cabinet

Power supply

24 V DC

5350

The operator panel’s mounting clamps do not provide a securegrounding

connection between the panel and the device cabinet, see1 in drawing above.

1.

Connect a 2.5 mm

and the panel chassis, see2 in drawi

2.

Connect a 6 or 4mm

2

wire betweenthe ope

rator panel’s quick-connect plinth

ng above.

2

wire or groundingbraid between the panel’s chassis and

the closest grounding pointon the door,see 3 in drawing above.

3.

Connect a strong but short grounding braid between the door and thedevice

cabinet,see 4 in drawing above.

4.

Twist the cables onto the24 V DC feed, see 5in drawing above.

2 turns aroundthe ferrite core provide 4 times the suppression of 1 turn.

3 turns aroundthe ferrite core provide 9 times the suppression of 1 turn.

A ferrite core suppresses disturbances to the 24 Vfeed, see 6 in drawing above.

Note:

Thegroundingwiresshouldbeshortandtheconductor shouldhavealargearea.

Along, thingroundingwirehasaveryhighimpedance(resistance)athighfrequencies

andwill notguidedisturbancestotheground.

Multi-wireconductors arebetterthansinglewireconductorswiththesamearea.

Abraidedconductorwirewith thesameareaisevenbetter. Thebestisashort,thick

groundingbraid.

BeijerElectronics, MAEN013A

31

Page 32

Additional InstallationTips

10.2 EthernetConnectioninthePanel

Industrial Ethernet

RJ45

RJ45

RJ45

RJ45

Operator panel

RJ45

1

2

Operator panel

RJ45

Operator panel

RJ45

Operator panel

RJ45

5351

Shielded

0.1 uF

250 V

3

4

1-1

2-2

3-3

8-8

Short and

unshielded

5

In some industrialunits for Ethernet, the RJ45 contact’s shield is connected to the

chassis via a capacitor, see 1 in drawing above.

The operator panel’s Ethernet shield is directly

connected to the chassis, see 2 in

drawing above.

1.

Check whether the other Ethernetunit has its shield directly grounded or

grounded via a capacitor.

Note:

Inmanycases,connecting theshieldedEthernetcablingtothechassisatbothendsis

inappropriate. Humo r groundingloopscanoccur. Unshieldedcablingmayevenresult

infewercommunicationerrors.

A good solution may beto use a shielded Ethernet cable, but toconnect the shield

at one end only.

One option is to break the shield, see 3 in drawing above.

A more elegantmethod is to expand the shielded Ethernet cabling witha piece of

unshielded Ethernetcable, see 4 in drawing above.

You can ground the shield via an external 0.1uF/250 V plastic capacitor,see 5 in

drawing above. This will connect theHF transients to the ground.

BeijerElectronics, MAEN013A

32

Page 33

Additional InstallationTips

10.3 ToAchieveBetterEMCProtection

• Initially,use the original cabling from BeijerElectronics primarily.

• Use shielded cables for RS232 communication.

• Use twisted pair andshielded cabling for RS422 and RS485.

• Use the cabling intended for the bus ty pe; Ethernet, Profibus, CC-Link,

CAN, Device Netetc.

• Install and connect according to applicable specifications for the relevant bus

standard.

• Use shielded cabling forEthernet, preferably with foil+ braided shield.

• D-sub covers should be shielded, andthe shield should be connected to the

cover 360° where the cable comes in.

• Connect the shield at both ends.

Shielded cable

0.1 uF/250 V

Ground plane 1 Ground plane 2

Ground plate Ground plate

Not same potential

in another building

5352

With longer distances, there is a risk that the ground potential may be d ifferent.

In that case,the shield should only be connected at one e nd. A good alternative

is to connect the other end of the shield to the ground via a 0.1 uF/250V plastic

capacitor. Both endsare then connected to the ground in terms of HF, but only

connected to the ground at one end in terms ofLF, thus avoiding the 50 Hz

grounding loops.

Metal cabinet Metal cabinet

Terminal or connector Terminal or connector

Cable clamp

in steel

Short distance

EMC cable gland Plastic cable gland

Shielded cable Shielded cable

1.

Usean EMC cable gland or regular plastic cable gland,remove the outer jacket

5353

and connect theshield to the installation plate with a 360 ° metal cable clamp.

2.

Place the 24V DC and communications cabling in one cable trunk/cable duct

and 230/380 V AC in another. If the cables need to be crossed, cross them at

90 ° only. Avoidcombining the cabling for stronger 24 V DCoutputs with

the communication cabling.

Ferritecores that are snappedonto the shielded cabling mayremove minor

disturbances. Large ferrite pieces that aresnapped onto unshielded cablingand

where the wiresgo 2-4 times around the coresare approximately 5-25 times more

efficient.

BeijerElectronics, MAEN013A

33

Page 34

Additional InstallationTips

10.4 AmbientTemperature

The maximum ambient temperature for the operator panel is provided in the

specifications. The ambient temperature refers to the temperature in the device

cabinet which cools the panel’s electronics.

Top

50 °C inside

Operator

panel

30 °C outside

Middle

45 °C inside

Bottom

40 °C inside

Power

Power

Power

Axial fan

120 x 120 mm

Airflow

5354

Inmostcases,theambienttemperaturefortheoperatorpanelissignificantly

higher than thedevice cabinet’s ambient temperature.

If the cabinetis tall and there area number of hea

temperature at thetop of the cabinet will be con

theoretical temperature increasethat would

sensitivetoheat. Thelifespanofanelectro

° increase in temperature. A 15-20 ° tempera

t-generating devices,the

siderably higher than th e

be expected. All electronics are

lytic capacitor iscut in half with an 8-10

ture increase results in a quarter of the

lifespan etc.

Rittal has a good program for estimating the anticipated averagetemperature in

the cabinet as well as a large program for controlling thetemperature in the device

cabinet.

An enamel-coated steelcabinet has

a radiant heat value of 5.5 W/m

2

and degrees

C.

Installing a faninside the cabinet will even out thetemperature, while moving air

provides considerably better cooling than still air. A suitable fan is a120 x 120 mm

axial fan, availablein 24 V DC, 115 and 230 V AC.

Installthefansothatitsit

operator panel. If the fan i

ambient temperaturewill

s in thecooler area and will blow cold air against the

s mounted at the top and sucks air upwards, the fan’s

be higher = shorter lifespan.

Agoodfanwithaball-bearingmountinghasanexpectedlifespanofatleast

40,000 hours (nota guaranteed lifespan) at 40 °C.This corresponds to at least 4

years of continuoususe. If a thermostatis installed, the fan only needs tocome

on when needed.

Large graphic termi

lighting is off. Th

nals draw only one fifth of the current when the background

e loss effect dropsfrom e.g. 25 Wto only 5 W.

The operator panel’s loss effect = supply voltagex current. Virtuallyno power goes

to external users andno loss effects due to inputs.

BeijerElectronics, MAEN013A

34

Page 35

10.5 Safety

Most of the operator panels are fed with 24 V DC.

Power supply

1

2

3

230 V AC to 24 V DC

Power supply

230 V AC to 24 V DC

Power supply

230 V AC to 24 V DC

230 V AC

+24 V

0 V

4

+24 V

0 V

4

Distance?

+24 V

0 V

4

Operator panel

Operator panel

Operator panel

Small controller with expansion unit

COM1

COM100

Ch0

Ch1

Ch100

Ch101

5355

Additional InstallationTips

Ifyouuseapowersupplythatmeetssafetystandardsandonlyfeedstheoperator

panel, there is no problem. See 1 in drawing above.

However,ifyouhavea24Vunitthatalsofeedsotherunits,thereisreasontobe

cautious, see 2 indrawing above. The operator panel doesnot have insulation that

meets safety requirementsin the event of a potential short circuit between 230V

AC and 24V DC. It is assumed that the 24V feed is secure, for example, SELV

according to EN 60950 (protection against electric shock) and UL 950.

Example:

Hereis anexamplethatexplainswhyasecure24V DCfeedcanberuinedbymixing 24

Vrelaycontactswith230VACrelaycontactsinasmallercontroller. Checkthatthe

“clearancesand creepagedistancesbetween24VDCand230VACfulfillEN60950orUL

950”. Ifnot, inputaseparate24V unitintotheoperatorpanel.

If there is asubstant

AC, it is OK to use the

ial distance between therelay contacts for 24 V DC and230 V

same 24 V devices for all feeds. See 3 in drawing above.

Connect 0 V onthe 24 V feed to the ground, see4 in drawing above. This offers

three advantages:

• Safety is increa

connection or s

• Tr a n si e n t s o n

• No risk that th

is not unusua

sed. The24Vfeedwillnotbeliveintheeventofafaulty

hortcircuitbetween0V(24V)and230Vphase.

the 24 V feed are connected to the ground.

e 24 V feedis at a high level in relationship to theground. This

l since there is high static electricity.

BeijerElectronics, MAEN013A

35

Page 36

10.6 GalvanicIsolation

r

Additional InstallationTips

+24 V DC

DC/DC

galvanic isolation

Filter

0 V

1.5 m

Internal electronic

VCC

0 V (GND)

RS232RS422/485

USB

USB

DC/AC

Ethernet

CFL

5356

The operator panelhas galvanic isolation against the 24 V DCfeed but no galvanic

isolation between the communication ports forRS232, RS422/485 and USB.

Only the Ethernetconnection has galvanic isolation.

Operator panel Modular controller Printe

RS422 RS232 USB

**

* *

Not same ground potential

* = Internal 0 V (GND) connection

When a PC is connected to the panel, the panel’s internal 0 V (G

*

Power CPU COM COM2

***

*

PCPC

5357

ND) will be

connected to the protective groundvia the PC.

A number of USBdevices can have the shield connected together with the

protective ground. Here, the panel’s 0 V (GND) is connected to the protective

ground when, for example, a USB memory stick, keyboard or similar device is

plugged in.

If a number of units are connected that have a 0 V a

these are connected to various grounding poin

problems. Grounding currents go through com

of the controller, and internally inth

e operator panel, and can cause errors.

nd a ground c onnection, and

ts, there isa substantial risk of

munication cables, the rearplate

Use e xternal units to improvecommunication and achieve galvanic isolation.

Westermo has good industry-standard insulators that arealso insulated from the

24 V DC feed.

Note:

Itis veryimportanttomakesurethatthe 24Vfeedinthe externalinsulationunitisnot

connectedtooneofthe communicationoutlets. Ifitdoesnothave100% insulation

againstthe24Vfeed,disturbancesandgroundingcurrentsfromthe0Vonthe24V

sidewill disruptcommunication.

Usingthis typeofunitsolvesoneproblembutcreatesalargerproblem! Asubstandard

installationmayworknow,b ut problemsmayarisewhenotherdevicesareconnected.

BeijerElectronics, MAEN013A

36

Page 37

Additional InstallationTips

10.7 CableandBusTe rminationRS485

• Use sh ielded and twisted p air cable. The pair capacitance may notexceed 52.5

2

pF/m and areaat least 0.25 mm

(AWG 24), if you want touse the maximum

transfer distance and maximumtransfer speed.

• 0 V, the reference voltagefor communication should be included in

the cabling. With two-way communication use two pairs; one pair for

communication and one pairfor 0 V.

• The shield must be grounded at one end. The other end is usuallyground ed,

but with longer distances or whenthere is a difference in theground potential,

theshieldshouldbeconnectedtothegroundvia0.1uF/250Vplastic

capacitor to prevent ground currentin the braided shield. A number of

manufacturers recommendthat the shield be grounded at each node. Various

manufacturers have differentsystems for bus termination. The RS485

standard does notdescribe how the “FailSafe” function would becarried out,

justthatthesystemshouldbeabletohandletheerror.

Depending on therecipients’ design, the bus wires may be on the samelevel or

require pull-upor pull-down to ensure that nofaulty signals are detected when the

bus is in resting mode (all transmitters are disconnected).

Inside operator panel

+5 V

0 V

1 23

1 K

120 ohm 120 ohm

1 K

+5 V

(120 ohm)

14

1 K

2

15

6

19

1 K

7

8

0 V

0 V

4

55

17

50

Operator

panel

RS422

1 2 3 4 5 6 7 8

CAB8CAB8 Bus

2

15

3

16

17

4

14

+5 V

VCC

8

0 V

7

0 V

VCC

1 K

120 ohm

1 K

RS485

1

2

3

4

5

6

7

8

Bus termination

Shield

0 V

0 V

5358

Some (older) operator panel s had pull-up and pull-down resistance except for

the actual bus termination at120 ohm, similar to Westermoand Profibus. See 1

in drawing above.

Newer panelshave another type of recipient, so-called built-in “Fail Safe”,where

simple bus termination resistance is sufficient. See 2 in drawing above.

If other nodes onthe RS485 network require pull-up andpull-down and the

operator panel is at one end of the loop, one of thefollowing procedures can be

carried out:

• Connect two 1k/0.25 W resistorsin the 25-pole D-sub contact. See 3 in

drawing above. Set jumperpins 6-19.

• Use CAB8. It offers the option of bus termination with pull-up/-down. It

isalsoeasytoconnectthebuscableviathescrewterminalblock. See4in

drawing above.

BeijerElectronics, MAEN013A

37

Page 38

Fault T racing

11 FaultTracing

This section includesdifferent fault scenarios and steps to follow to trace the fault.

TheiXPanelTA100isnotworkingproperly,andthe

powerLEDis off

1.

Isthepowervoltagecorrect?

2.

Does the powersupply deliver enough current?

3.

Check the fuse.

4.

Check the power card.

5.

Is thepower card correctly mounted?

TheiXPanelTA100isnotcommunicatingwiththe

controller

1.

Check the communication cable between the units.

2.

Check that the operator panelhas a controller driver downloaded.

3.

Checkthatthecorrectcontrollerdriverisused.

4.

Check the communicationports on the CPU board.

TheiXPanelTA100isworkingbutthebacklightisoff

1.

Check the backlight dimming.

2.

Check that the backlight is connected to the power card.

3.

Replace the backlight according to the Replacing th

4.

Check the DC/AC onthe power card.

eBacklightsection.

TheiXPanelTA100isnotworking,thebacklightisoff

butthepowerLEDison

1.

Check the backlight dimming.

2.

Check the CPUboard for burned components.

3.

Download new firmwareto the operato

rpanel.

TheiXPanelTA100doesnotincludethelatestimage

1.

Check the versions i ncluded with the operator panel.

2.

Make sure to save a copy of the project to the PC.

3.

Download anupdated image wi

in the System Programsectio

th the Image Loaderand follow the directions

n.

BeijerElectronics, MAEN013A

38

Page 39

Thetouchscreenismalfunctioningorisnot

respondingatall

1.

Re-calibrate the touch screenaccording to the Calibrating the Touch Screen sec-

tion.

2.

Check that the flex cableis correctly fitted.

3.

Replace the display of the operator panel according to the

Replacing the Display/Display Cable section.

4.

Check the touch interface on the powercard.

Linesindisplayhavewrongcolororthedisplay

pictureisshifted

1.

Check if the display has a wide vertical or horizontal area across the

display. It should be at least2-3 cm wide with a grey or black c o lor. See

Replacing the Display/Display Cable for instructions on howto correct this.

2.

Make sure the display cable is correctlyfitted.

3.

Make surethe display cable is not folded ordamaged in any way. Replace the

display cableaccording to the Replacingthe Display/Display Cable section.

Fault T racing

BeijerElectronics, MAEN013A

39

Page 40

Software

12 Software

This chapter describes how to maintain and update the software inthe iX Panels.

The chapter includes a general description of the operator panel softwareand

instructions about how to upgrade thesoftware and load projects and system

programs.

12.1 GeneralInformationabout Software

The software requiredto run and maintain the operator panels is found on the

software USB stick. It isalso available through your local distributor.

The software istested by the manufacturer’s own testing department before

market introduction is approved. The test procedure is closely integrated with the

development process. The test group works in close concert with the developers

andisISEBCertifiedforSoftwareTesting.

12.1.1 SoftwareProducts

The followingsoftware products are used:

• iX Developer

iX Developer is u sed for creating application projects for iX Panels and their

accessories.

• Remote AccessViewer

Remote AccessViewer is a program for remote ac

It ispossible to access, reflect and control t

client programRemote Access Viewer (freew

server (Remote Accessfunction) in th

• System Program

The iX Panel TA100 is delivered with an image (operating system) pre-stored in

the operator panel memory.

eiXPanels.

cess and control of the iX Panels.

he iX Panels from a PC using the VNC

are) together with thebuilt-in VNC

BeijerElectronics, MAEN013A

40

Page 41

12.2 UpdateSoftware

When an update is available, an e-mail is sent to the distributors. The software is

also available onthe manufacturer’s web site.

Theupdateshouldbeinstalledbyqualifiedpersonnel.

12.2.1 iXDeveloper

iX Developer is not a freeware product.

A demo versioncan be downloaded from www.beijerelectronics.com.

To update iX Developer, an accredited iX Panels dealer must be contacted.

12.2.2 RemoteAccessViewer

This software isincluded on the iX Developer USB stick.

To update the Remote Access Viewer, go towww.beijerelectronics.com and select

Support/Downloads inthemenu. BrowsethesoftwarefoldertolocateRemote

Access Viewer. Runthe .exe file and followthe instructions.

Software

12.2.3 SystemProgram

An upgrade of thecomplete software package is sometimes needed to take

advantage of new functionality.

The upgrade is done by running the Image Loader execu

IML_TA70–150_bxxx.exe. The Image Loader applica

through the upgrade.

Two upgrade options are available:

• Upgradingthe System Program Usinga USB Memory S

• Upgradingthe System Program via Ethernet

Whentheupgradeisfinished,theoperatorpanelwillreceivethedefaultIPaddress

192.168.1.1. Followthe instructions on the screen after startup to change t he IP

address.

Note:

TheImageLoadersoftware isonlyintendedforcustomersandpartnersthathave an

operatorpanel. Nootherdistributionisallowed.

Note:

Whenupgradinganoperatorpanel,itisimportanttoensurethatpoweris not

interruptedduring theupgrade.

table file,

tion will help andguide you

tick

BeijerElectronics, MAEN013A

41

Page 42

Requirements

Upgrading of the operator panel system program requiresthe following:

• APC

• An Ethernet connection between the PC andthe operator panel or an empty

USB memory stick.

• The Image Loader executable file from the web site

UpgradingtheSystemProgramUsingaUSBMemory

Stick

When upgrading the system program using a memory stick, you can select to

delete or to keepthe project in the operator panel.

Followthe steps below:

1.

Connect an empty USB memory stick to your PC.

2.

Double-click on the e xecutable Image Loader file.

3.

Select the driveof the desired USB stick and click Create.

The files arecopied to the USB stick.

4.

Connect the USB memory stick to the operator panel.

5.

Cyclethepowertoinitiatetheupgrade.

Software

UpgradingtheSystemProgramviaEthernet

When upgrading the system programvia Ethernet, the project in the operator

panel is retained.

Followthe steps below:

1.

Make sure that your PC and the operator panel are connectedvia Ethernet.

2.

Double-click on the e xecutable Image Loader file.

3.

Enter the IP addressof the operator panel.

4.

Click Update, and followthe instructions.

The files aretransferred to the operator panel. The panel will reboot

automatically when the transfer is finished.

BeijerElectronics, MAEN013A

42

Page 43

Environmental Aspects

13 EnvironmentalAspects

This chapter includes information about theenviron mental impact of iX Panels.

More information can be found on the manufacturer’s web site.

13.1 GeneralEnvironmentalAspects

The manufacturer’s activities meet internal requirementsas well as those of the

SS-EN ISO 9001:2000and SS-EN ISO 14001:2004 internationalstandards.

13.2 EnvironmentalImpactofthe OperatorPanels

13.2.1 MechanicalComponents

The aluminum and stainlesssteel used in the mechanical components are judged

to be non-environmentally hazardous. The expanded rubber packing for thefront

and the expanded polyethylenepacking for the display contain an adhesive that is

not classified as environmentally hazardous.

Screws may haveundergone the followingsurface treatments: Bright

nickel-plating or bright zinc-plating. Themembranekeyboardismadeof

polyester with silver wiring. On some models the keyboardcontains LEDs.

Display framesand CF covers are made of halogen-free plastic, PC/ABS.

13.2.2 Electronics

CircuitBoard

Note:

AlloperatorpanelsareRoHScompliant.

The electronics are complex and almost all elements of the periodic table are

represented.

Display

There is a separate circuit board for the display. The liquid crystals in thedisplay

are cyclohexanecompounds. The fluorescenttube contains mercury and lead

solder.

Batteries

The operator

classified a

(1997:645

panel contains a buttoncell lithium battery. The battery is not

s environmentally hazardousby the Swedish Battery Ordinance

).

BeijerElectronics, MAEN013A

43

Page 44

Environmental Aspects

13.3 Recycling

The operator panelsconsist largely of aluminum. It is a greatadvantage in terms of

both resources and the environment if it can be recycled. Make sure that operator

panels taken out ofservice are sent tofacilities for electronic scrap.

The manufacturer’s electronic waste is recycled by Stena Technoworld AB.

Aluminum front/rearcasings and othercovers can be removed and recycled.

Plastic display frames and CF covers must be recycledas hard plastic. The circuit

board containsmany valuable metals and should thereforebe recycled.

Remove the lithium battery. Electrolytic capacitors and displays are currently not

classified as hazardouswaste, but may be harmful tohealth and the environment.

The electrolytic capacitors should behandled as per Handbook 2001:7 (NFS)

and displays asper NFS 2001:8.

Thefluorescenttubemustbehandledashazardouswaste.

The packagingis made from wood fiberand shouldberecycled. Thelargeprinted

label on the front,however, must first be removed as it ismade of PVC vinyl. The

label and theplastic bag for the brackets are recycled as softplastic.

The manufacturer is a member of the REPAregister. The protective film on the

front is recycledas soft plastic. When the operator panel is no longer useful it

can be returnedto the manufacturer for environmentally responsible recycling.

Contact the company for further information.

13.4 EnvironmentalImpactReport

An operator panel impacts the environment through itsfunction, i.e., controlling

industrial equipment. The energy and the scrapped parts that canbe saved with

efficient management meanthat the operator panel contributes to reduced

environmental impact.

Listed below are examples of how you canreduce environmental impact during

operator panel use.

• Switch the system off when not in use.

• Use green electricity.

• Use energy-saving options, e.g.,turn off the backlight to both save energyand

reduce wearon the fluorescent tube.

• If possible, reduce the backlight brightness to reduce energy consumption

and increase fl uorescent tube service life.

Supplythe operator panel with 2

effect increases. Ensure that

recycled in an environmentall

4 V DC. Ifthe input voltage is lower, the loss

the operator panel, battery, and packaging are

y responsible manner.

BeijerElectronics, MAEN013A

44

Page 45

Headoffice

BeijerElectronicsAB

Box4 26

20124Malmö,Sweden

www.beijerelectronics.com/+4640358600

Loading...

Loading...