Page 1

iXT10A

InstallationManual

MAEN017F,2013-09

English

Page 2

Foreword

InstallationmanualforiXT10A

Foreword

All operator panels are developed to satisfy the demands of human-machine

communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator panel works primarily in an object-oriented way,making it easy to

understand and use. Configuration is carried out on a PC using the iX Developer

configuration tool. The project can then be transferredand stored in the operator

panel itself.

Various types of automation equipment such PLCs, servosor drives can be

connected to the operator panels. In this manual, the term “the controller” refers

to the connected equipment.

This manual explains how to install the operator panel. Please refer to the

iX Developer reference manual for further information.

Order no: MAEN017F

Copyright © 2013-09 Beijer Electronics AB. All rights reserved.

The information in this document is subject to changewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer ElectronicsAB, including all its group companies, reserves the right to change any

information without updating this publication. Beijer Electronics AB, including all its group companies,

assumesnoresponsibilityforanyerrorsthatmayappearinthisdocument. Readtheentireinstallation

manual prior to installing and using this equ ipm ent. Only qualified personnel may install, operate or repair

this equipment. Beijer Electronics AB, including all its group companies, are not responsible for modified,

altered or renovated equipment. Because the equipment has a wide range of applications, users must acquire

the appropriate knowledge to use the equipment properly in their specific applications. Personsresponsible

for the application and the equipment must themselves ensure that each application is in compliancewith

all relevant requirements, standards and legislationinrespecttoconfigurationandsafety. Onlypartsand

accessoriesmanufacturedaccordingto specificationsset by Beijer Electronics AB, including all i ts group

companies, may be used.

BEIJER ELE CTRONICS AB, INCLUDING ALL ITS GROUP

COMPANIES,SHALL NOT BE LIABLE TO ANYONE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTINGFROM THE INSTALLATION, USE OR

REPAIROF THIS EQUIPMENT, WHETHER ARISING IN TORT,

CONTRACT, OR OTHERWISE. BUYER'S SOLE REMEDY SHALL

BE THE REPAIR, REPLACEMENT, OR REFUND OF PURCHASE

PRICE, AND THE CHOICE OF THE APPLICABLE REMEDY SHALL

BE AT THE SOLE DISCRETION OF BEIJER ELECTRONICS AB,

INCLUDING ALL ITS GROUP COMPANIES.

BeijerElectronics, MAEN017F

Page 3

Contents

Contents

1 Safety Precautions ....................................................... 4

1.1 General ...........................................................

1.2 UL and cUL Installation .........................................

1.3 During Installation ..............................................

1.4 During Use .......................................................

1.5 Service and Maintenance . .......................................

1.6 Dismantling and Scrapping .....................................

1.7 Appearance of Air in Touch Screen .............................

2 Installation ............................................................... 8

2.1 Space Requirements .............................................

2.2 Installation Process ..............................................

2.2.1 Connectionsto the Controller ............ ......................

2.2.2 Other ConnectionsandPeripherals ............. ................

3 TechnicalData ........................................................... 12

4 ChemicalResistance .................................................... 14

4.1 MetalCasing .....................................................

4.2 Touch Screen and Overlay .......................................

4.2.1 AutoflexEBA180L ............ ..................................

4.2.2 TouchScreenSurface ............................ ................

4.2.3 AutoflexEBA180L ............ ..................................

5 OperatorPanelDrawings .............................................. 17

5.1 Connectors .......................................................

5.2 Communication Ports ...........................................

5.3 iX T10AOutline .................................................

6 Additional Installation Tips ............................................ 20

6.1 Grounding the Operator Panel .................................

6.2 Ethernet Connection in the Ope

6.3 To Achieve Better EMC Protec

rator Panel ...................

tion .............................

6.4 Ambient Temperature ...........................................

6.5 Safety .............................................................

6.6 Galvanic Isolation ................................................

6.7 Cable and Bus Terminati

on RS485 .............................

11

11

14

15

15

16

16

17

17

19

20

21

23

24

25

26

27

4

4

6

6

6

6

7

8

9

BeijerElectronics, MAEN017F

Page 4

Safety Precautions

1SafetyPrecautions

Both the installer and the owner and/or operator of the operator panel must read

and understand this installation manual.

1.1 General

• Read thesafety precautions carefully.

• Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

• Do not use the operator panel in an environment with high explosive hazards.

• The supplier is not responsible for modified, altered or reconstructed

equipment.

• Use only parts and accessories manufactured according to specificationsof

the supplier.

• Read the installation and operating instructions carefully before installing,

using or repairing the operator panel.

• Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

operator panel. This may cause fire or electrical shock.

• Only qualified personnel may operate the operator panel.

• Storing the operator panel where the temperature is lower/higher than

recommended in this manual can cause the LCD display liquid to

congeal/become isotopic.

• The LCD display liquid contains a powerful irritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open,flushwithplentyofwaterandgetmedicalattention.

• Thefiguresinthismanualservesanillustrativepurpose. Becauseofthemany

variables associatedwith any particular installation, the supplier cannot

assume responsibilityfor actual use based on the figures.

• The supplier neither guarantees that the operator panel is suitable for your

particular application, nor assumes responsibility for your product design,

installation or operation.

• It is recommended to turn on and shut down the operator panel at least once

before installing any components/cards or beforeconnecting the operator

panel to external devices, like for example serial devices.

1.2 ULandcULInstallation

Caution:

ThissectionisonlyvalidforULlabelediX T10Apanels.

• This equipment is suitable for use in Class 2 non-hazardous locations only.

[Combinations of equipment in your system are subject to investigation by

the local authority having jurisdiction at the time of installation].

BeijerElectronics, MAEN017F

4

Page 5

Safety Precautions

• All devices have to be supplied by a Class 2 power supply.

Warning:

Donotdisconnect equipmentunlesspowerhasbeenremovedorthe areais

knowntobenon-hazardous

• ForCanada also AVERTISSEMENT – AVANT DE DECONNECTER

L’EQUIPEMENT, COUPER LE COURANT OUS’ASSURER QUE

L‘EMPLACEMENT EST DESIGNE NON DANGEREUX.

Warning:

OnlyULand cULapprovedexpansionunitsareallowedtobeconnectedto

theportdesignated “EXPANSION”. Atthemomenttherearenosuch units

evaluatedorallowed.

Warning:

Donotreplace expansionunitunlesspowerhasbeen switch

isknowntobenon-hazardous.

edofforthe area

• This product contains a battery; this must only be changed in an area known

to be non-hazardous.

• Replace thebattery with a BR 2032 battery. Use of another type of battery

may present a risk of fire orexplosion.

Warning:

Batterymayexplode ifmistreated. Donotrecharge,disassembleordispose

ofinfire.

• Foruse on a flat surface of a type 4X enclosure indoor use only.

• Use75 degree conductors only

• Use copper conductors only

• To make wiring connections to the power supply connector, follow the table

with cable and torque specifications below:

TerminalBlock No. WireSizeAWG TQLb.In.

X1/X100Phoenixconnectors AWG30–12 5–7

X1/X100Anytekconnectors AWG24–12 3.5

• These de

for the

panel m

vicesareClass2suppliedprogrammablecontrollers(industrialPCs)

use in industrial control equipment and are intended to be (front)

ounted (Type 1 and 4x for indoor use only).

BeijerElectronics, MAEN017F

5

Page 6

Safety Precautions

1.3 DuringInstallation

• The operator panel is designed for stationary installation on a plane surface,

where the following conditions are fulfilled:

– no high explosive risks

– no strong magnetic fields

– no direct sunlight

– no large, sudden temperature changes

• Install the product according to the accompanying installation instructions.

• Ground the product according to the accompanying installation instructions.

• Only qualified personnel may install the operator panel.

• Separate the high voltage, signal and supply cables.

• Make sure that the voltage and polarity of the power source is correct before

connecting the product to the power outlet.

• Peripheralequipment must be appropriate for the application and location.

1.4 DuringUse

• Keep theoperator panel clean.

• Emergency stop and other safety functions may notbe control

operator panel.

• Do not use too much force or sharp objects when touching the

touchscreen etc.

led from the

keys,

1.5 ServiceandMaintenance

• Only qualified personnel should carry out repairs.

• The agreed warranty applies.

• Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

• Clean the display and surrounding front cover with a soft cloth and mild

detergent.

• Replacing thebattery incorrectly may result in explosion. Only use batteries

recommended by the supplier. During the warranty period, the battery needs

to bereplaced by an authorized Beijer Electronics service center.

1.6 DismantlingandScrapping

• The operator panel or parts thereof shall be recycled a ccording to local

regulations.

• The following components contain substances that might be hazardous

to health and the environment: lithium battery,electrolytic capacitor and

display.

BeijerElectronics, MAEN017F

6

Page 7

Safety Precautions

1.7 AppearanceofAirinTouchScreen

• Thelayerstructureofthetouchscreencontainsairandinrarecases

appearance of bubbles can arise. This is purely cosmetic and does not affect

any functio nality of the panel. The appearance can occur under certain

environmental conditions such as temperature, humidity,and atmospheric

pressure.

BeijerElectronics, MAEN017F

7

Page 8

2Installation

2.1 SpaceRequirements

• Maximum installation plate thickness: 8 mm

• Space requirements in millimeters when installing the operator panel:

100

Installation

50

100

280

Note:

Thedimensionsonthedrawingar

10022850

enotproportional.

BeijerElectronics, MAEN017F

8

Page 9

2.2 InstallationProcess

The following is needed:

• A Phillips/slot screwdriver

1.

Unpackand check the delivery. If damageis found, notify the supplier.

Note:

Placetheoperator panelonastablesurface duringinstallation.

Droppingthe panelorlettingitfallmaycause damage.

2.

Usethecutoutdimensionsthatareincludedontheoutlinedrawing,found

in section Operator PanelDrawings and in the Technical Data table, to cut

a correct opening in the cabinet. A separate cut out drawing is available for

download from the Beijer Electronics web site.

3.

Securethe operator panel in position using all the fastening holes and the

provided brackets and screws:

Installation

x 8 0.5 - 1.0 Nm

BeijerElectronics, MAEN017F

9

Page 10

Installation

4.

Connect the cablesin the specified order, according to the drawing and steps

below.

Caution:

• Ensurethattheo perator panelandthe controllersystemhavethesameelectrical

grounding(referencevoltagelevel),otherwiseerrorsincommunicationmay

occur.

• Theoperatorpanelmustbebroughtto ambienttemperaturebeforeitisstarted

up. Ifcondensationforms,ensurethatt he operatorpanelisdrybefore connecting

ittothepoweroutlet.

• Ensurethatthevoltage andpolarityofthepowersourceiscorrect.

• Useonlyshieldedcommunicationcables.

• Separatehighvoltagecablesfromsignalandsupplycables.

B

RS232/

RS422/

RS485

24V DC

C

Power

Controller

24V DC

D

A

Ethernet

– Connect cable A.

– Connect cable B, using an M5 screw and a grounding conductor (as short

as possible) with a cross-section of minimum 2.5 mm

– Connect cable C.

– Connect cable D. The recommended cross-section of the cable is

1.5 mm

5.

Carefully removethe laminated film over the operator panel display, to avoid

2

.

2

.

static electricity that could damage the panel.

Note:

OnlyforiXT10Apanelswithpartnumber630000301:

Whenconnectingtheoperatorpaneltothepoweroutletforthefirsttime,mak e

surenotto interruptpowerforaminimum of48hoursinorder tochargethebattery

completely. Aftert hat,thebatterymay becharged partlyduringashorterperiodof

time.

BeijerElectronics, MAEN017F

10

Page 11

Installation

2.2.1 ConnectionstotheController

Forinformation about the cables to be used when connecting the operator panel to

the controller,please refer to the help file for the driver in question.

2.2.2 OtherConnectionsandPeripherals

Cables, peripheral equipment and accessoriesmust be suitable for the application

and its environment. Forfurther details or recommendations, please refer to the

supplier.

BeijerElectronics, MAEN017F

11

Page 12

3TechnicalData

Parameter iXT10A

Frontpanel,W×H×D 280×228×7mm

Cutoutdimensions,

W×H

Mountingdepth 44mm(144 mmincludingclearance)

Standalonemounting VESA75×75

Frontpanelseal IP65

Rear panelseal IP 20

Touchscreen

material

Touchscreen

operations

Reverse side

material

Framematerial Powder-coatedaluminum

Weight 1.5 kg

Serialportfor

COM1RS232and

COM2RS422/RS485

Serialportfor

COM3RS232and

COM4RS422/RS485

Ethernet 1×10 Base-T/100Base-T(shieldedRJ45)

USB 1×USBHost2.0 , maxoutput current200 mA

Processor 400MHzARM9

Externalstorage

media

Flashmemory

(application

memory)

MemoryRAM 128MB(DDR2)

LED 1× blue/redsoftwareprogrammable

Real time clock Y es(onchip)

(2)

Battery

Power consumption

atratedvoltage

Fuse InternalDCfuse,2.0AT,5×20mm

262×209mm

Note: MaximumscrewlengthforVESAmountingis4mm.

Usageoflongerscrewsmayleadtodamage.

Polyesteronglass,resistive.

Overlay: AutoflexEBA180L

1millionfingertouchoperations

Powder-coated aluminum

9-pinD-subcontact withRS232RTS/CTS,chassis-mounted

femalewithstandardlocking screws4-40 UNC

9-pinD-subcontact withRS232RTS/CTS,chassis-mounted

femalewithstandardlocking screws4-40 UNC

1×SD card(optional). OnlycompatiblewiththestandardSD

formatwithupto2GBstoragecapacity.

128MBSSD(NANDFlash)

LithiumbatterytypeBR2032,soldered

orrechargeablebattery

MS920-SEorsimilar),soldered

9.6W

(1)

.

(2)

(SeikoInstrumentsPart No.

Technical Data

BeijerElectronics, MAEN017F

12

Page 13

Technical Data

Parameter iXT10A

Powersupply +24VDC(18-32VDC)

CE:Thepower supplymustconform withtherequirements

accordingtoIEC60950andIEC61558-2-4.

ULandcUL: Thepowersupplymustconform withthe

requirementsforclassIIpowers upplies.

Display TFT-LCDwithLEDbacklight. 640×480pixels,64kcolors

Activeareaof

display,W× H

Operating

temperature

Storagetemperature -20°C– +70°C

Relativehumidity 5-85% non-condensed

Approvalsand

certifications

(1)

SeesectionChemicalResistanceformo re information.

(2)

iXT10Apanelswithpartnumber630000301usearecharge

versionsuseaBR2032battery.

211.2×158.4mm

-10°C–+60°C

Informationis availableonthewebsite

www.beijerelectronics.com

ablebattery. All other

BeijerElectronics, MAEN017F

13

Page 14

Chemical Resistance

4 ChemicalResistance

4.1 MetalCasing

The frame and casing material is powder-coated aluminum. This powder paint

withstands exposure to the following chemicals without visible change:

Aceticacid10% Phosphoricacid4%

Citricacid10% Phosphoricacid10%

Diesel Seawater

Distilledwater Sodiumchloride2%

Edibleoil Sodiumchloride20%

Fueloil Sulphuricacid20%

Hydrogenperoxide3% Tapwater

The powder paint shows limited resistance to the f

ollowing chemicals at room

temperature:

Butanol Nitricacid3%

Hydrochloricacid5% Nitricacid10%

Isopropylalcohol Phosphoricacid43%

Na-hypochlorite10% Turpentine

Note:

Ifexposure toanyoftheabovechemicalsisdemanded,itis recommended tofirsttest

thechemicalinahiddenspotofthemetalcasing.

Thepowderpaintshowslittleornoresistancetothefollowingchemicalsatroom

temperature:

Aceticacid,conc. Methyl-ethylketone Toluene

Acetone Nitricacid30% Trichlorethylene

Ammonia5% Phenol Xylene

Ammonia,conc. Sodiumhydroxide5% 97octaneunleaded petrol

Ethylacetate Sodiumhydroxide30% 98octaneleadedpetrol

BeijerElectronics, MAEN017F

14

Page 15

Chemical Resistance

4.2 TouchScreenandOverlay

4.2.1 AutoflexEBA180L

Autoflex EBA 180L covers the overlay surrounding the touch screen.

SolventResistance

Autoflex EBA 180L withstands exposure of more than 24 hours duration under

DIN42115Part2tothefollowingchemicalswithoutvisiblechange:

(1)

(1)

Phosphoricacid(<30%)

SBP60/95

(1)

Wisk

(1)

-

Acetonitrile DieselDowney/Lenor

Ajax/Viminsolution Ethanol Potassiumferricyanide

Alkalicarbonate

solution

Ammonia(<40%)

Aceticacid(<50%) Gumption

Arielpowderin

solution

Bleach

Castoroil Methanol Trichloroaceticacid(<50%)

Causticsoda(<40%)

Cuttingoil Paraffinoil Windex

Cyclohexanol Persilpowderin

Diacetonealcohol Petroleumspirit

(1)

(1)

(1)

(1)

Extremelyf

(1)

aintglossing ofthe texturewasnoted.

Glycerine Potassiumhydroxide(<30%)

Glycol PureTurpentine

(1)

Hydrochloricacid(<36%) Sulfuricacid(<10%)

Linseedoil Tomatoketchup

(1)

Nitricacid(<10%) WhiteSpirit

solution

(1)

Autoflex EBA 180L withstands DIN 42 115 Part 2 exposure of up to 1 hour

duration to glacial acetic acid without visible change.

Autoflex EBA 180L is not resistant to high pressure steam at over 100 °C or the

following chemicals:

Concent

Conce

ratedmineralacids

ntratedcausticsolution

BeijerElectronics, MAEN017F

Benzyla

lenechloride

Methy

lcohol

15

Page 16

Chemical Resistance

4.2.2 TouchScreenSurface

The touch screen surface on the operatorpanel withstands exposure to the

following solvents without visible change:

Solvents Time

Acetone 10minutes

Isopropanol 10minutes

Toluene 5 hours

4.2.3 AutoflexEBA180L

It is recommended to use the Autoflex EBA 180Ltouch display protection film,

that can be ordered from Beijer Electronics.

SolventResistance

Autoflex EBA 180L withstands exposure tothesamechemicalsasAutotexF157or

F207 according to section Autoflex EBA 180L.

OutdoorUse

In common with all polyester based films, Autoflex EBA 180L is not suitable for

use in conditions of long-term exposure to direct sunlight.

BeijerElectronics, MAEN017F

16

Page 17

Operator Panel Drawings

5 OperatorPanelDrawings

5.1 Connectors

COM 3/4LANCOM 1/2

1234

Pos. Connector Description

1 Powersupply +24VDC(18-32VDC)

2 COM1/2 CommunicationPorts

3 LAN 1×10/100Base-T(shieldedRJ-45)

4 COM3/4 CommunicationPorts

5.2 CommunicationPorts

Pin

1-

2 RS232RxD - RS232RxD 3 RS232TxD - RS232TxD 4 - RS422Rx+ - RS422Rx+

5 GND GND GND GND

6-

7 RS232RTS - - RS422RTS+

8 RS232CTS - - RS422RTS9 - RS422Rx- - RS422Rx-

Note:

Inordertoutilizetwocommunicationportsonthesamephysicalport,theY-splitcable

CAB109mustbe used.

DrawingforexternalcableCAB109(drawing#Z7100-029E)isavailableonthewebsite:

www.beijerelectronics.com

Serialport,9-pin female Serialport,9-pin female

COM1 COM2 COM3 COM4

RS422Tx+

RS485Tx+/Rx+

RS422Tx-

RS485Tx-/Rx-

-

-

RS422Tx+

RS485Tx+/Rx+

RS422Tx-

RS485Tx-/Rx-

BeijerElectronics, MAEN017F

17

Page 18

Operator Panel Drawings

Note:

OnlyiXT10Apanelswithpartnumber630000301areequippedwithterminated

COM-ports.

BeijerElectronics, MAEN017F

18

Page 19

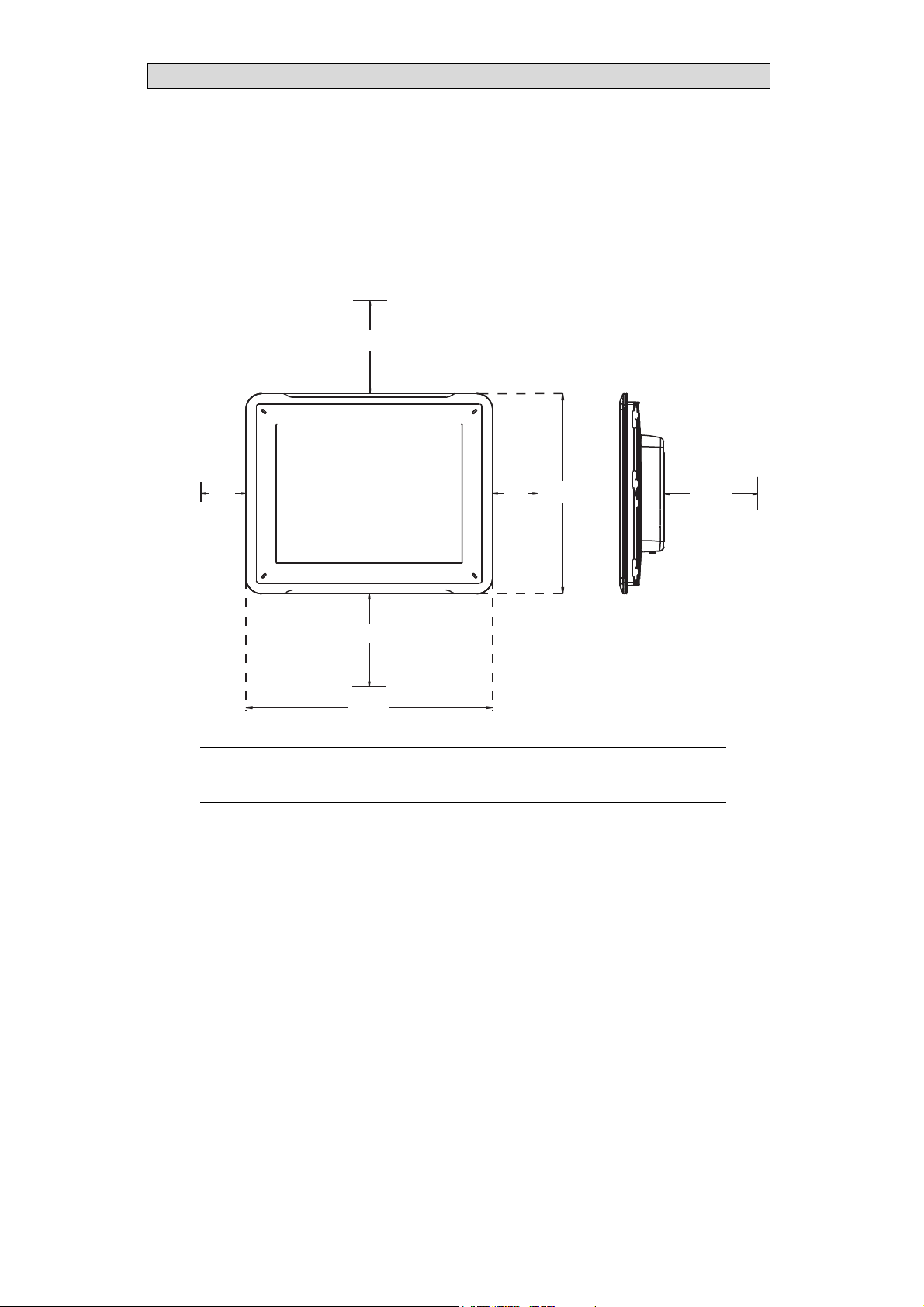

5.3 iXT10AOutline

280

Operator Panel Drawings

COM3 RS232 /

COM4 RS422/RS485

Ethernet

COM1 RS232 /

COM2 RS422/RS485

24 V DC

7

max. 8 mm

44

Expansion port

SD memory

card slot

228

USB host

209 99

262 99

Note:

AStepCADfileis availableon theweb sitewww.beijerelectronics.com

BeijerElectronics, MAEN017F

19

Page 20

Additional Installation Tips

6 AdditionalInstallationTips

When experiencing communication problems infor example noisy environments

or when operating close to temperature limits, the following recommendations

are to be noticed.

6.1 GroundingtheOperatorPanel

Door

Operator panel

1

Ferrite core

6

3

2

5

4

Mounting plate in the cabinet

Power supply

24 V DC

5350

The operatorpanel’s mounting clamps do not provide a secure grounding

connection between the panel and the device cabinet, see 1 in drawing above.

1.

Connect a 2.5 mm

2

wire between the operator panel’s quick-connect plinth

and the panel’schassis, see 2 in drawing above.

2.

Connect a 6 mm

2

or 4 mm2wire or grounding braid between the operator

panel’s chassis and the closest grounding point on the door, see 3 in drawing

above.

3.

Connect a strong but short grounding braid between the door and the device

cabinet,see 4 in drawing above.

4.

Twist the cables onto the 24 V

cross-section of the cable

DC feed, see 5 in drawing above. Minimum

is 2.5 mm

2

.

2 turns around the ferrite core provide 4 times the suppression of 1 turn.

3 turns around the ferrite

core provide 9 times the suppression of 1 turn.

A ferrite core suppresses disturbances to the 24 V feed, see6 in drawing above.

BeijerElectronics, MAEN017F

20

Page 21

Additional Installation Tips

Note:

Thegroundingwiresshouldbeshortandtheconductorshouldhavealargearea.

Along,thin groundingwirehas averyhighimpedance(resistance)athighfrequencies

andwillnot guidedisturbancesto theground.

Multi-wireconductorsare betterthansin glewireconductorswiththesamearea.

Abraided conductor wirewiththesame areaisevenbetter. Thebestisa short,thick

groundingbraid.

6.2 EthernetConnectioninthe OperatorPanel

Industrial Ethernet

RJ45

RJ45

1

RJ45

RJ45

Operator panel

Shielded

0.1 μF

250 V

RJ45

3

4

1-1

2-2

3-3

8-8

Short and

unshielded

5

Operator panel

RJ45

Operator panel

RJ45

Operator panel

RJ45

2

In some industrial units for Ethernet, the RJ45 contact’s shield is connected to the

chassis via a capacitor,see 1 in drawing above.

The o peratorpanel’s Ethernet shield is directly connected to the chassis, see 2 in

drawing above.

1.

Check w hetherthe other Ethernet unit has its shield directly grounded or

grounded via a capacitor.

Note:

Inmanycases,connectingtheshieldedEthernetcablingto thechassisat bothendsis

inappropriate. Humorgroundingloopscanoccur. Unshieldedcabling mayeven result

infewercommunicationerrors.

BeijerElectronics, MAEN017F

21

Page 22

Additional Installation Tips

A g ood solution may be to use a shieldedEthernet cable, but to connect the shield

at one end only.

One option is to break the shield, see 3 in drawing above.

A more elegant method is to expand the shielded Ethernet cabling with a piece of

unshielded Ethernet cable, see 4 in drawing above.

The shield can be grounded via an external 0.1 μF/250 V plastic capacitor, see 5 in

drawing above. This will connect the HF transients to ground.

BeijerElectronics, MAEN017F

22

Page 23

Additional Installation Tips

6.3 ToAchieveBetterEMCProtection

• Initially, use the original cabling from Beijer Electronics primarily.

• Useshielded cables for RS232 communication.

• Usetwisted pair and shielded cabling for RS422 and RS485.

• Usethe cabling intended for the bustype; Ethernet, Profibus, CC-Link,

CAN, DeviceNet etc.

• Install and connect according to applicable specifications for the relevant bus

standard.

• Useshielded cabling for Ethernet, preferably with foil and a braided shield.

• D-sub covers should be shielded, andthe shield should be connected to the

cover 360° where the cable enters.

• Connect the shield at both ends.

Shielded cable

0.1 μF/250 V

Ground plane 1 Ground plane 2

Ground plate Ground plate in another building

Not same potential

With longer distances, there is a risk thatthe ground potential may

In that case, the shield should onlybe connected at one end. A good

is to connect the other end of the shieldto the ground via a

capacitor. Both ends are then connected to theground in

connected to the ground at one end in terms of LF, thus av

0.1 μF/250 V plastic

terms of HF, but only

oiding the 50/60 Hz

be different.

alternative

grounding loops.

Metal cabinet Metal cabinet

Terminal or connector Terminal or connector

Cable clamp

in steel

Short distance

EMC cable gland

Shielded cable

1.

Usean EMC cable gland or regular plastic cable gland, removethe outer jacket

Shielded cable

Plastic cable gland

andconnecttheshieldtotheinstallation plate with a 360° metal cable clamp.

2.

Place the 24 V DC and c ommunications cabling in one cable trunk/cable duct

and 230/380 V AC in another. If the cables need to becrossed, cross them at

90° only. Avoidcombining the cabling for stronger 24 V DC outputs with

the communication cabling.

Ferritecores that are snapped onto the shielded cabling may remove minor

disturbances. Large ferrite pieces that are snapped onto unshielded cabling and

where the wires go 2-4 times around the cores are approximately 5-25 times more

efficient.

BeijerElectronics, MAEN017F

23

Page 24

Additional Installation Tips

6.4 AmbientTemperature

The maximum ambient temperature for the operator panel is provided in the

specifications. The ambient temperature refers to the temperature in the device

cabinet which cools the operator panel’s electronics.

To p

50 °C inside

Operator

panel

30 °C outside

Middle

45 °C inside

Bottom

40 °C inside

Powe r

Powe r

Powe r

Axial fan

120 x 120 mm

Airflow

Inmostcases,theambienttemperaturefortheoperatorpanelissignificantly

higher than the device cabinet’s ambient temperature.

If the cabinet is tall and there are a number of heat-generating devices, the

temperature at the top of the cabinetwill be considerably higher than the

theoretical temperature increase that would be expected. All electronics are

sensitivetoheat. Thelifespanofanelectrolyticcapacitoriscutinhalfwithan

8-10 °Cincrease in temperature. A 15-20 °C temperature increase results in a

quarter of the lifespan etc.

Rittal has a good program for estimating the anticipated average temperature in

the cabinet as well as a large program for controlling the temperature in the device

cabinet.

2

An enamel-coated steel cabinet has a radiantheat value of 5.5 W/m

and degrees

C.

Installing a fan inside the cabinet will even out the temperature, while moving air

provides considerably better cooling than still air.

Install the fan so that it sitsin the cooler area and blows cold air against the operator

panel. If the fan is mounted at the top and sucks warm air upwards, the fan’s

ambient temperature will be higher, resulting in a shorter lifespan.

The operator panel’sloss effect = supply voltage x current. Virtually no power goes

to external users and no loss effects due to inputs.

BeijerElectronics, MAEN017F

24

Page 25

6.5 Safety

Most of the operator panels are fed with 24 V DC.

Power supply

1

2

3

230 V AC to 24 V DC

Power supply

230 V AC to 24 V DC

Power supply

230 V AC to 24 V DC

230 V AC

+24 V

0 V

4

+24 V

0 V

4

Distance?

+24 V

0 V

4

Operator panel

Operator panel

Operator panel

Small controller with expansion unit

COM1

COM100

Ch0

Ch1

Ch100

Ch101

5355

Additional Installation Tips

If a power supply that meets safety standards is used and only feeds the operator

panel, there is no problem. See 1 in drawing above.

However, if a 24 V unit that also feeds other units is used, there is reason to be

cautious, see2 in drawing above. The operator panel does not have insulation

that meets safetyrequirements in the event of a potential short circuit between

230 V AC and 24 V DC. It is assumed that the 24 V feed is secure, for example,

SELV according to EN 60950 (protection against electric shock) and UL 950.

Example:

Hereisan examplethatexplainswhyasecure24V DCfeedcanberuined bymixing

24Vrelaycontactswith 230VACrelaycontactsin asmaller controller. Check thatthe

clearancesandcreepagedistancesbetween24VDCand230 VACfulfillEN60950or

UL950. Ifnot,inputaseparate24Vunitinto theoperatorpanel.

If thereis a substa

230 V AC, it is OK t

ntial distance between the relay contacts for 24 V DC and

ousethesame24Vdevicesforallfeeds. See3indrawing

above.

Connect 0 V on the 24 V feed to the ground, see 4 in drawing above. This offers

three advantages:

• Safety is incr

connection o

• Tr a ns i e n t s

• No risk tha

is notunu

eased. The24Vfeedwillnotbeliveintheeventofafaulty

rshortcircuitbetween0V(24V)and230Vphase.

on the24 V feed are connected to the ground.

t the 24 V feed is at a high level in relationship to the ground. This

sual si nce there is high static electricity.

BeijerElectronics, MAEN017F

25

Page 26

6.6 GalvanicIsolation

r

Additional Installation Tips

+24 V DC

0 V

Filter

DC/DC

galvanic isolation

1.5 m

Internal electronic

VCC

0 V (GND)

RS232RS422/485

USB

DC/AC

USB

Ethernet

CFL

The operator panel has galvanic isolationagainst the 24 V DC feed but no galvanic

isolation between the communication ports for RS232, RS422/485 and USB.

Only the Ethernet connection has galvanic isolation.

Operator panel Modular controller Printe

Power CPU COM COM2

RS422 RS232 USB

* *

**

*

Different ground potential

*

= Internal 0 V (GND) connection

***

*

PCPC

When a PC is connected to the operator panel, the panel’sinternal 0 V (GND) will

be connected to the protective ground via the PC.

A number of USB devices can have theshield connected together with the

protective ground. Here,the operator panel’s0 V (GND) is connected to the

protective ground when, for example, a USB memorystick, keyboard or similar

device is plugged in.

If a number of units are connected that have a 0 V and a ground connection, and

these are connected to various grounding points, there is a substantial risk of

problems. Grounding currents go through communication cables, the rear plate

of thecontroller,and internally in the operator panel, and can cause errors.

Use external units to improve communication and achieve galvanic isolation.

Westermo has good industry-standard insulators that are also insulated from the

24 V DC feed.

Note:

Itisvery importanttomakesurethat the24 Vfeedintheexternalinsulationunitisnot

connectedtooneofthecommunicationoutlets. Ifit doesnot have100% insulation

againstthe24 Vfeed,disturbancesandgroundingcurrentsfromthe0 Vonthe24V

sidewilldisruptcommunication.

Usingthistypeofunitsolves oneproblembutcreatesalargerp roblem! A substandard

installationmayworknow,butproblemsmayarisewhenotherdevicesareconnected.

BeijerElectronics, MAEN017F

26

Page 27

Additional Installation Tips

6.7 CableandBusTerminationRS485

• If maximumtransfer distance and maximum transf er speed is needed,

shielded and twisted pair cable should be used. The mutual capacitance

may notexceed 52.5 pF/m, andthe cable area should be at least 0.25 mm

(AWG 24).

• 0 V,the reference voltage for communication should be included in

the cabling. With two-way communication use two pairs; one pair for

communication and one pair for 0 V.

• The shield mustbe grounded at one end. The other end is usually grounded,

but with longer distances or when there is a difference in the ground potential,

theshieldshouldbeconnectedtothegroundvia0.1μF/250Vplastic

capacitor to prevent ground current in the braided shield. A number of

manufacturers recommend that the shield be grounded at each node. Various

manufacturers have different systems for bus termination.

Depending on the recipients’ design, the bus wires may be on the same level or

require pull-up or pull-down to ensure that no faulty signals are detected when the

bus is in resting mode (all transmittersare disconnected).

2

BeijerElectronics, MAEN017F

27

Page 28

Headoffice

BeijerElectronicsAB

Box426

20124Malmö,Sweden

www.beijerelectronics.com/+4640358600

Loading...

Loading...