Page 1

iXT10AInstallationGuide

1SafetyPrecautions

Both theinstaller and the owner and/oroperator of theoperator panel mustread

and understandthis installation manual.

1.1 General

Read the safetyprecautions carefully.

•

Check thedelivery for transportationdamage. If damage isfound, notify the

•

supplier as soon as possible.

Do not use the operator panel in an environment with high explosive hazards.

•

The supplier is not responsible for modified, altered or reconstructed

•

equipment.

Use only parts and accessories manufactured according to specifications of

•

the supplier.

Read the installation and operating instructions carefully before installing,

•

using or repairing the operator p anel.

Never allow fluids, metal filings or wiring debris to enter any openings in the

•

operator panel. Thismaycause fire or electrical shock.

Only qualified personnel may operate the operator panel.

•

Storingthe operator panel where the temperature is lower/higherthan

•

recommended in this manual can cause the LCD display liquid to

congeal/become isotopic.

The LCD display liquid contains a powerful irritant. Incaseof skin contact,

•

wash immediately with plenty of water. In case of eye contact, hold the eye

open, flush with plenty of water and get medical attention.

Thefiguresinthismanualservesanillustrativepurpose. Becauseofthemany

•

variables associated with any particular installation, the supplier cannot

assume responsibility for actual use based on the figures.

The supplier neither guarantees that the operator panel is suitablefor your

•

particular application, nor assumes responsibility for your product design,

installation or operation.

It is recommended to turn on and shut down the operator panel at least once

•

before installing any components/cards or before connecting the operator

panel to external devices, like for example serial devices.

1.2 ULandcULInstallation

Caution:

ThissectionisonlyvalidforULlabelediX T10A panels.

This equipment is suitable for use in Class 2 non-hazardous locations only.

•

[Combinations of equipment in your system are subject to investigation by

the local authority having jurisdiction at the time of installation].

All devices have to be supplied by a Class 2 powersupply.

•

Warning:

Donotdisconnectequipment unless powerhasbeenremoved or

theareaisknown to benon-hazardous

ForCanada also AVERTISSEMENT – AVANT DE DECONNECTER

•

L’EQUIPEMENT, COUPER LE COURANT OUS’ASSURER QUE

L‘EMPLACEMENT EST DESIGNE NON DANGEREUX.

Warning:

OnlyULandcULapprovedexpansionunitsareallowedto be

connectedtotheport designated“EXPANSION”. At the moment

therearenosuch units evaluatedorallowed.

Warning:

Donotreplaceexpansion unit unlesspowerhasbeenswitched off

ortheareaisknown tobenon-hazardous.

This product contains a battery;this must only be changed i n an area known

•

to be non-hazardous.

Replace the battery with a BR 2032 battery. Use of another type of battery

•

may presenta risk of fire or explosion.

Warning:

Batterymayexplodeifmistreated. Donotrecharge, disassemble

ordisposeofin fire.

Foruse on a flat surface o f a type 4X enclosure indoor use only.

•

Use75degreeconductorsonly

•

Usecopper conductors only

•

Tomake wiring connections to the power supply connector,followthetable

•

with cable and torque specifications below:

TerminalBlockNo. WireSizeAWG TQLb.In.

X1/X100Phoenixconnectors

X1/X100Anytekconnectors

These devices are Class 2 supplied programmable controllers (industrial PCs)

•

AWG 30–12

AWG24–12 3.5

5–7

for the use in industrial control equipment and are intended to be (front) panel

mounted (Type1 and 4x for indoor use only).

1.3 DuringInstallation

The operator panel is designed for stationary installation on a plane surface,

•

where the following conditions are fulfilled:

– no high explosive risks

– no strong magnetic fields

– no direct sunlight

– no large, sudden temperature changes

Install the product according to the accompanying installation instructions.

•

Groundthe product according to the accompanying installation instructions.

•

Only qualified personnel may install the operator panel.

•

Separate the high voltage, signal and supply cables.

•

Make sure that the voltage and polarity of the power source is correct before

•

connecting the product to the power outlet.

Peripheralequipmentmust be appropriate for the application and location.

•

1.4 DuringUse

Keep the operator panel clean.

•

Emergency stop and other safety functions may not be controlled from the

•

operator panel.

Do not use too much force or sharp objects when touching the keys,

•

touchscreen etc.

1.5 Serviceand Maintenance

Only qualified personnel should carr y out repairs.

•

The agreed warranty applies.

•

Before carrying out any cleaning or maintenance operations, disconnect the

•

equipment from the electrical supply.

Clean the display and surrounding front cover with a soft cloth and mild

•

detergent.

Replacing the battery incorrectly may result in explosion. Only use batteries

•

recommended by the supplier. During the warranty period, the battery needs

to be replaced by an authorized Beijer Electronics service center.

1.6 Dismantlingand Scrapping

The operator panel or parts thereof shall be recycled according to local

•

regulations.

The following components contain substances that might be hazardous

•

to health and the environment: lithium battery,electrolyticcapacitor and

display.

1.7 Appearanceof Airin TouchScreen

Thelayerstructureofthetouchscreencontainsairandinrarecases

•

appearance of bubbles can arise. This is purely cosmetic and does not affect

any functionality of th e panel. Theappearance can occur under certain

environmental conditions such as temperature,humidity,and atmospheric

pressure.

2Installation

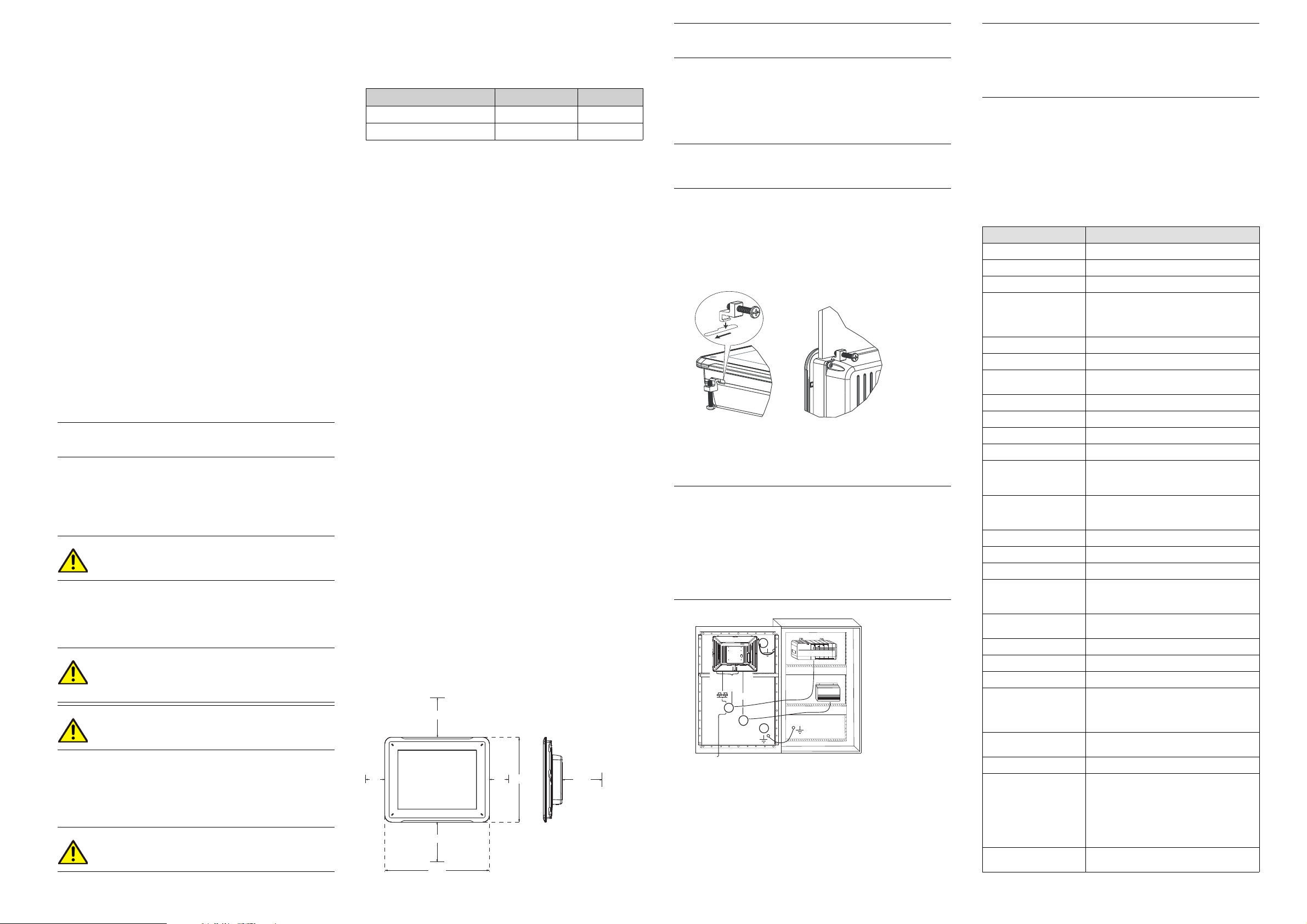

2.1 SpaceRequirements

Maximum installation plate thickness: 8 mm

•

Space requirements in millimeters when installing the operator panel:

•

100

50

100

280

10022850

Note:

Thedimensionson the drawingarenot proportional.

2.2 Installation Process

The following is needed:

A Phillips/slot screwdriver

•

1.

Unpackand check the delivery. If damage is found, notify the supplier.

Note:

Placetheoperatorpanel on astablesurfaceduring installation.

Droppingthepanelorlettingitfallmaycausedamage.

2.

Use the cut out dimensions that are included on the outline drawing, found

in section Operator Panel Drawings and in the Technical Data table, to cut a

correct opening in the cabinet. A separate cut out drawing is available for

download from the Beijer Electronics web site.

3.

Secure the operator panel in position using all the fastening holes and the

provided brackets and screws:

x 8 0.5 - 1.0 Nm

4.

Connect the cables in the specified order,accordingto the drawing and steps

below.

Caution:

Ensurethattheoperatorpanelandthecontrollersystemhavethesame

•

electricalgrounding(referencevoltage level), otherwise errors in

communicationmayoccur.

Theoperatorpanelmustbebroughttoambienttemperaturebefore it

•

isstartedup. Ifcondensationforms, ensurethattheoperatorpanel is

drybeforeconnecting it to the power outlet.

Ensurethatthevoltageandpolarityofthepowersourceiscorrect.

•

Useonlyshieldedcommunicationcables.

•

Separatehighvoltage cablesfromsignalandsupply cables.

•

B

RS232/

RS422/

RS485

24V DC

C

D

A

Ethernet

– Connect cable A.

– Connect cable B, using an M5 screw and a grounding conductor (as

short as possible) with a cross-section of minimum 2.5 mm

– Connect cable C.

– Connect cable D. The recommended cross-section of the cable is

5.

Carefully removethe laminated film over the operator panel display, to avoid

1.5 mm

2

.

static electricity that coulddamage the panel.

Power

Controller

24V DC

Note:

OnlyforiXT10A panelswithpartnumber630000301:

Whenconnectingtheoperator panel to thepoweroutletforthe firsttime,

makesurenottointerrupt powerforaminimumof 48 hoursinordertocharge

thebatterycompletely. Afterthat,the batterymaybechargedpartly during

ashorterperiodoftime.

2.2.1 Connectionstothe Controller

Forinformation about the cables to be used when connecting the operator panel to

the controller,pleaserefer to the help file for the driver in question.

2.2.2 OtherConnectionsand Peripherals

Cables, peripheral equipment and accessories must be suitable for the application

and its environment. Forfurther details or recommendations, please refer to the

supplier.

3TechnicalData

Parameter

Frontpanel,W×H×D

Cutoutdimensions,W × H

Mountingdepth 44mm(144 mm includingclearance)

Standalonemounting

Frontpanelseal

Rearpanel seal

Touchscreenmaterial Polyesteronglass,resistive.

Touchscreenoperations 1million fingertouchoperations

Reversesidematerial Powder-coatedaluminum

Framematerial Powder-coated aluminum

Weight 1.5kg

Serialportfor

COM1RS232and

COM2RS422/RS485

Serialportfor

COM3RS232and

COM4RS422/RS485

Ethernet 1×10Base-T/100Base-T (shielded RJ 45)

USB 1×USBHost2.0, max outputcurrent200mA

Processor

Externalstoragemedia 1×SDcard(optional). Only compatible

Flashmemory

(applicationmemory)

MemoryRAM 128MB(DDR2)

LED

Realtime clock Yes(onchip)

(2)

Battery

Powerconsumptionat

ratedvoltage

Fuse

Powersupply

2

.

Display TFT-LCDwithLED backlight. 640×480pixels,

280×228×7mm

262×209mm

VESA75×75

Note: Maximumscrewlengthfor VESA

mountingis4mm. Usageoflongerscrews

mayleadtodamage.

IP65

IP20

Overlay: Autoflex EBA 180L

9-pinD-subcontactwithRS232RTS/CTS,

chassis-mountedfemalewithstandard

lockingscrews4-40UNC

9-pinD-subcontactwithRS232RTS/CTS,

chassis-mountedfemalewithstandard

lockingscrews4-40UNC

400MHzARM9

withthestandard SDformatwithup to 2GB

storagecapacity.

128MBSSD(NANDFlash)

1×blue/redsoftwareprogrammable

LithiumbatterytypeBR2032,soldered

orrechargeablebattery

InstrumentsPartNo. MS920-SEor similar),

soldered

9.6W

InternalDCfuse,2.0AT,5×20mm

+24VDC(18-32 V DC)

CE:Thepowersupply must conformwiththe

requirementsaccordingtoIEC60950and

IEC61558-2-4.

ULandcUL:Thepower supply must conform

withtherequirementsforclass II power

supplies.

64kcolors

iXT10A

(2)

(1)

.

(Seiko

Page 2

Parameter

Activeareaofdisplay,

211.2×158.4mm

iXT10A

W×H

Operatingtemperature -10°C–+60 °C

Storagetemperature -20 °C –+70°C

Relativehumidity 5-85%non-condensed

Approvalsand

certifications

(1)

SeesectionChemicalResistanceformoreinformation.

(2)

iXT10Apanels with partnumber630000301 usearechargeable battery. All

Informationisavailableonthewebsite

www.beijerelectronics.com

otherversionsuseaBR 2032 battery.

4 ChemicalResistance

4.1 MetalCasing

The frame and casing material is powder-coated aluminum. Thispowder paint

withstands exposure to the following chemicals without visible change:

Aceticacid10% Phosphoric a cid 4%

Citricacid 10% Phosphoricacid10%

(1)

Seawater

Tap water

Turpentine

Phosphoricacid(<30%)

(<30%)

PureTurpentine

SBP60/95

(1)

Diesel

Distilledwater Sodiumchloride2%

Edibleoil Sodiumchloride20%

Fueloil Sulphuricacid20%

Hydrogenperoxide3%

The powder paint shows limited resistance to the following chemicals at room

temperature:

Butanol Nitricacid3%

Hydrochloricacid 5% Nitricacid 10%

Isopropylalcohol Phosphoricacid43%

Na-hypochlorite10%

Note:

Ifexposuretoanyofthe above chemicalsisdemanded,itisrecommended to

firsttestthechemicalinahiddenspotofthemetalcasing.

The powder paint shows little or no resistance to the following chemicals at room

temperature:

Aceticacid,conc. Methyl-ethylketone Toluene

Acetone

Ammonia5%

Ammonia,conc.

Nitricacid30% Trichlorethylene

Phenol Xylene

Sodiumhydroxide5% 97octane unleaded petrol

Ethylacetate Sodiumhydroxide30% 98octaneleadedpetrol

4.2 Touch Screenand Overlay

4.2.1 AutoflexEBA180L

Autoflex EBA 180L covers the overlay surrounding the touch screen.

SolventResistance

Autoflex EBA 180L withstands exposure of more than 24 hours duration under

DIN 42 115 Part 2 to the following chemicals without visible change:

Acetonitrile DieselDowney/

Ajax/Vimin

(1)

Lenor

Ethanol Potassiumferricyanide

solution

Alkalicarbonate

(1)

solution

Ammonia(<40%)

Aceticacid(<50%)

Glycerine Potassiumhydroxide

(1)

Glycol

Gumption

Arielpowderin

(1)

solution

(1)

Bleach

Hydrochloricacid

Sulfuricacid(<10%)

(<36%)

Linseedoil Tomatoketchup

Castoroil Methanol Trichloroaceticacid

(<50%)

Causticsoda

(1)

(<40%)

Cuttingoil Paraffinoil Windex

Cyclohexanol Persilpowderin

Diacetonealcohol Petroleumspirit

(1)

Extremelyfaintglossingofthetexture was noted.

Nitricacid(<10%) White Spirit

(1)

solution

(1)

Wisk

(1)

-

Autoflex EBA 180L withstands DIN 42 115 Part2exposure of up to 1 hour

duration to glacial acetic acid without visible change.

Autoflex EBA 180L is not resistant to high pressure steam at over 100 °C or the

following chemicals:

Concentratedmineralacids Benzylalcohol

Concentratedcausticsolution Methylenechloride

4.2.2 Touch ScreenSurface

The touch screen surface on the operator panel withstands exposure to the following

solvents without visible change:

Solvents

Time

Acetone 10minutes

Isopropanol

10minutes

Toluene 5hours

4.2.3 AutoflexEBA180L

It is recommended to use the AutoflexEBA 180Ltouch display protection film, that

can be ordered from Beijer Electronics.

SolventResistance

Autoflex EBA 180L withstands exposure to the same chemicals as Autotex F157 or

F207 according to section Autoflex EBA 180L.

OutdoorUse

In common with all polyester based films, Autoflex EBA 180L is not suitable for use

in conditions of long-term exposure to direct sunlight.

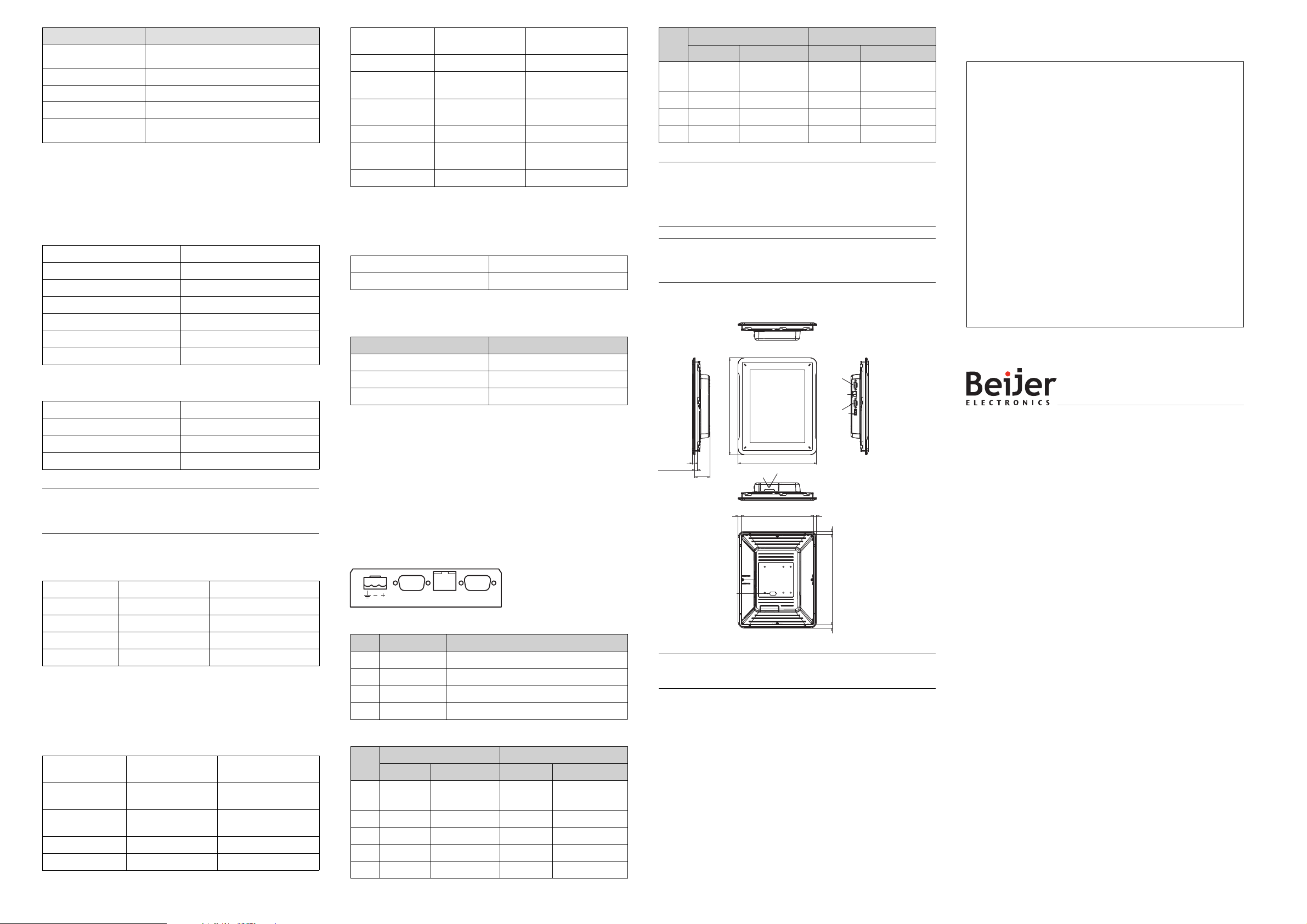

5 OperatorPanelDrawings

5.1 Connectors

COM 3/4LANCOM 1/2

1234

Pos. Connector Description

1

Powersupply

2 COM 1/2 Communication Ports

3LAN

4

COM3/4 CommunicationPorts

5.2 CommunicationPorts

Pin

Serialport,9-pinfemale Serialport,9-pinfemale

COM1 COM2 COM3 COM4

1

-

2RS232RxD

3 RS232TxD

4

5

-

GND GND GND GND

+24VDC(18-32V DC)

1×10/100Base-T (shieldedRJ-45)

RS422Tx+

RS485Tx+/Rx+

-

-

RS422Rx+

-

RS232RxD

RS232TxD

-

RS422Tx+

RS485Tx+/Rx+

-

-

RS422Rx+

Pin

Serialport,9-pin female Serialport,9-pin female

COM1 COM2 COM3 COM4

6

7

-

RS232RTS

8RS232CTS

9

-

RS422Tx-

RS485Tx-/Rx-

-

--

--

RS422Rx-

-

RS422Tx-

RS485Tx-/Rx-

RS422RTS+

RS422RTS-

RS422Rx-

Note:

Inordertoutilizetwocommunicationportsonthesamephysicalport,the

Y-splitcableCAB109mustbeused.

DrawingforexternalcableCAB109(drawing#Z7100-029E) is availableonth

website: www.beijerelectronics.com

Note:

OnlyiXT10Apanelswithpartnumber630000301areequippedwith

terminatedCOM-ports.

5.3 iXT10AOutline

COM3 RS232 /

COM4 RS422/RS485

Ethernet

280

max. 8 mm

7

44

Expansion port

SD memory

card slot

228

USB host

209 99

Note:

AStepCADfileisavailable ontheweb sitewww.beijerelectronics.com

COM1 RS232 /

COM2 RS422/RS485

24 V DC

262 99

Order no: MAEN017F

Copyright © 2013-09 Beijer Electronics. Allrightsreserved.

The information in this document is subject to change without notice and is

providedas available at the time of printing. BeijerElectronics AB, including

all its group companies, reserves the right to change any information without

updating this publication. Beijer Electronics AB, including a ll its group

companies, assumes no responsibility for any errors that may appear in this

document. Readthe entire installation manual prior to installing and using

this equipment. Onlyqualifiedpersonnel may install, operate or repair this

equipment. BeijerElectronics AB, including all its group companies, are

not responsible for modified, altered or renovated equipment. Because the

equipment has a wide range of applications, users must acquire the appropriate

knowledge to use the equipmentproperly in their specific applications. Persons

responsible for the application and the equipment must themselves ensure that

each application is in compliance with all relevant requirements, standards and

e

legislation in respect to configuration and safety. Only parts and accessories

manufactured according to specifications set by Beijer Electronics AB, including

all its group companies, may be used.

BEIJER ELECTRONICS AB, INCLUDING ALL ITS GROUP

COMPANIES,SHALL NOT BE LIABLE TO ANYONE FOR ANY

DIRECT,INDIRECT,SPECIAL, INCIDENTALORCONSEQUENTIAL

DAMAGES RESULTING FROM THE INSTALLATION, USE OR REPAIR

OF THIS EQUIPMENT,WHETHER ARISING IN TORT, CONTRACT,

OR OTHERWISE. BUYER'S SOLE REMEDY SHALL BE THE REPAIR,

REPLACEMENT, OR REFUND OF PURCHASE PRICE, AND THE

CHOICE OF THE APPLICABLE REMEDY SHALL BE ATTHE SOLE

DISCRETION OF BEIJER ELECTRONICS AB, INCLUDING ALL ITS

GROUPCOMPANIES.

Headoffice

BeijerElectronicsAB

Box426

20124Malmö,Sweden

www.beijerelectronics.com/+4640358600

Loading...

Loading...