Page 1

1 MODBUS Programmable I/O NA-9379 FnIO S-Series

2014 CREVIS Co.,Ltd

NA-9379

User Manual

MODBUS Programmable I/O

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Version 1.03

Page 2

2 MODBUS Programmable I/O NA-9379 FnIO S-Series

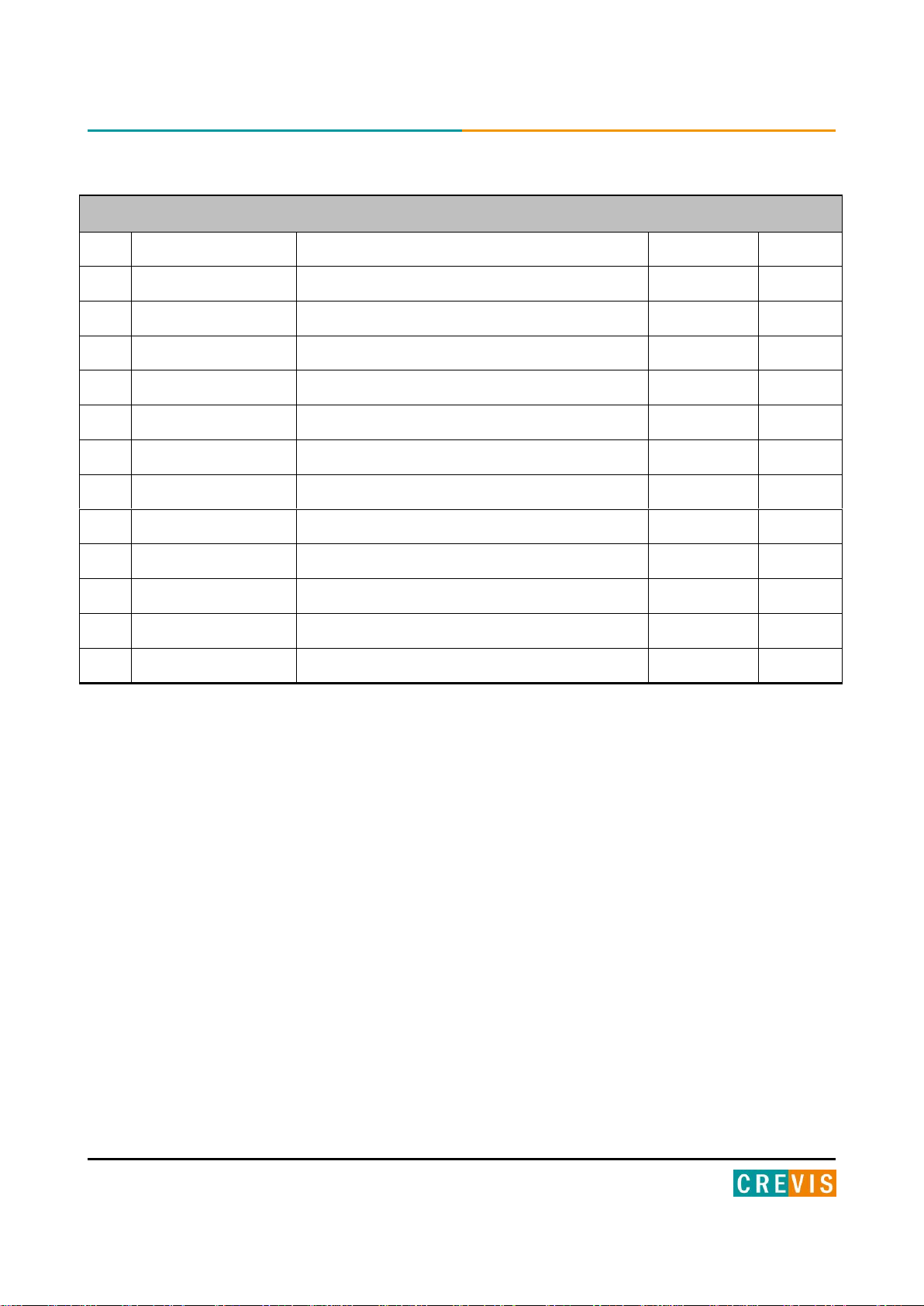

DOCUMENT CHANGE SUMMARY

REV

PAGE

REMARKS

DATE

EDITOR

1.0

New Document

Draft

2013/04/05

JE Kang

1.01

Reorganize

Draft

2014/03/25

YMKIM

1.02 Modify the Pin Description

2014/05/08

YMKIM

1.03

Reorganize2

Draft

2014/05/29

YMKIM

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 3

3 MODBUS Programmable I/O NA-9379 FnIO S-Series

CONTENTS

1. Important Notes ......................................................................................................................................................... 7

1.1. Safety Instruction ...................................................................................................................................... 8

1.1.1. Symbols ......................................................................................................................................................... 8

1.1.2. Safety Notes ................................................................................................................................................ 8

1.1.3. Certification (TBD) ..................................................................................................................................... 8

2. S-Series System ........................................................................................................................................................... 9

2.1. Electrical Interface ..................................................................................................................................... 9

2.2. I/O Process Image Map ....................................................................................................................... 10

3. Specification ................................................................................................................................................................ 11

3.1. General Specification ............................................................................................................................. 11

3.2. Interface Specification........................................................................................................................... 12

4. Module Description ................................................................................................................................................. 13

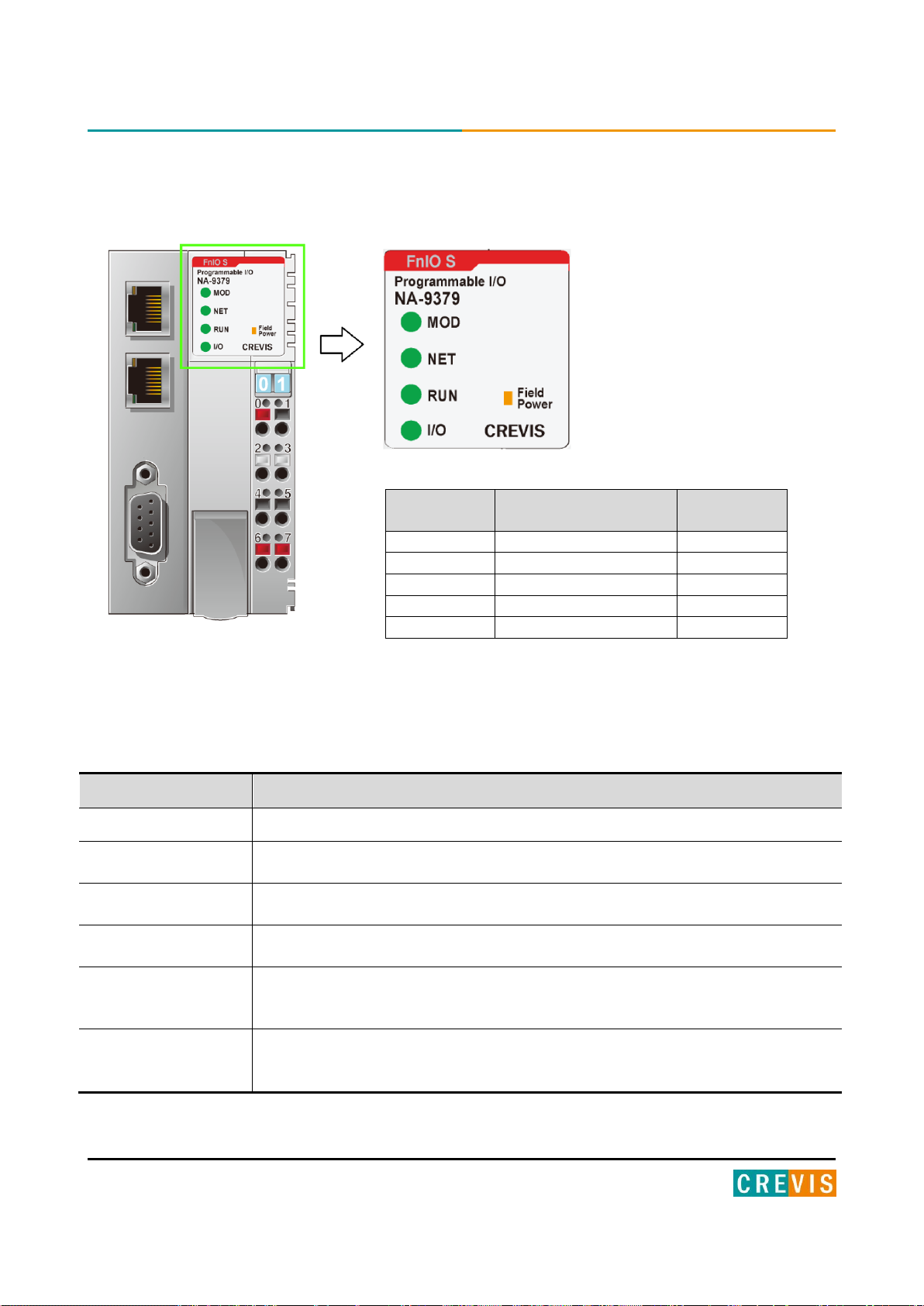

4.1. NA-9379 (MODBUS Programmable I/O) ...................................................................................... 13

4.2. LED Indicator ............................................................................................................................................. 14

3.2.1. Indicator Status and Flash Rates ...................................................................................................... 14

3.2.2. Module Status LED (MOD) ................................................................................................................. 15

3.2.3. Network Status LED (NET) .................................................................................................................. 15

3.2.4. PLC Run/Stop Status LED (RUN) ...................................................................................................... 15

3.2.5. Extension Module Status LED (I/O) ................................................................................................ 16

3.2.6. Field Power Status LED ........................................................................................................................ 16

3.3. RJ-45 Socket , RS232/485 Port ......................................................................................................... 17

3.4. Toggle Switch , Push Button ............................................................................................................. 17

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 4

4 MODBUS Programmable I/O NA-9379 FnIO S-Series

3.5. RTB Terminal Block ................................................................................................................................ 18

3.6. Pin Description ......................................................................................................................................... 18

3.7. Dimension .................................................................................................................................................. 19

4. Mechanical Setup ..................................................................................................................................................... 20

4.3. Inserting and Removing the Module. ............................................................................................ 20

4.4. Removable Terminal Block (RTB) ..................................................................................................... 21

4.5. Method of Wiring. .................................................................................................................................. 21

5. Various Functions of PIO (With IO Guide Pro) ........................................................................................... 22

5.1. Connect IO Guide Pro (MODBUS Serial) ...................................................................................... 22

5.2. Confirmation of Network Information. ......................................................................................... 25

5.3. BootP/DHCP Setting .............................................................................................................................. 27

5.4. Setup IP Address ..................................................................................................................................... 29

5.5. Serial Communication Settings......................................................................................................... 32

5.6. Memory Reset .......................................................................................................................................... 34

5.7. RTC(Real Time Clock) Function ......................................................................................................... 35

6. Programing the PIO (CoDeSys) .......................................................................................................................... 36

6.1. Download and Install the CoDeSys ................................................................................................ 36

6.2. The Basic Configuration CoDeSys ................................................................................................... 37

6.2.1. Installation of XML ................................................................................................................................. 37

6.2.2. Created Project ........................................................................................................................................ 41

6.2.3. CoDeSys User Interface ........................................................................................................................ 42

6.2.4. Setup I/O .................................................................................................................................................... 43

6.3. MODBUS TCP Setting ........................................................................................................................... 46

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 5

5 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.4. Network Variable .................................................................................................................................... 50

6.5. Download and Monitoring ................................................................................................................. 53

7. Upgrade Firmware ................................................................................................................................................... 54

7.1. Using IAP over Ethernet....................................................................................................................... 54

8. Trouble Shooting ...................................................................................................................................................... 56

8.1. How to diagnose by LED indicator ................................................................................................. 56

8.2. How to diagnose when device couldn’t communicate network ....................................... 57

APPENDIX A - MODBUS INTERFACE ........................................................................................................................ 58

A.1 MODBUS Interface Register / Bit Map .......................................................................................... 58

A.2 MODBUS Transmission Mode ........................................................................................................... 59

A.2.1. RTU Transmission Mode ..................................................................................................................... 59

A.2.2. ASCII Transmission Mode ................................................................................................................... 59

A.3 Supported MODBUS Function Codes ............................................................................................ 59

A.3.1. 1 (0x01) Read Coils ................................................................................................................................ 60

A.3.2. 2 (0x02) Read Discrete Inputs .......................................................................................................... 61

A.3.3. 3 (0x03) Read Holding Registers ..................................................................................................... 62

A.3.4. 4 (0x04) Read Input Registers .......................................................................................................... 63

A.3.5. 5 (0x05) Write Single Coil ................................................................................................................... 64

A.3.6. 6 (0x06) Write Single Register .......................................................................................................... 65

A.3.7. 8 (0x08) Diagnostics .............................................................................................................................. 66

A.3.8. 15 (0x0F) Write Multiple Coils .......................................................................................................... 69

A.3.9. 16 (0x10) Write Multiple Registers ................................................................................................. 70

A.3.10. 23 (0x17) Read/Write Multiple Registers .................................................................................... 71

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 6

6 MODBUS Programmable I/O NA-9379 FnIO S-Series

A.4 MODBUS Special Register Map........................................................................................................ 72

A.4.1. Adapter Register Mapping ................................................................................................................. 72

A.4.2. Adapter Identification Special Register (0x1000, 4096) ........................................................ 72

A.4.3. Adapter Watchdog Time, other Time Special Register (0x1020, 4128) ......................... 73

A.4.4. Adapter Information Special Register (0x1100, 4352) ........................................................... 74

A.4.5. Adapter Setting Special Register (0x1600, 5632) ..................................................................... 75

A.4.6. Expansion Slot Information Special Register (0x2000, 8192) ............................................. 76

A.5 Example ....................................................................................................................................................... 78

A.5.1. Example of Input Process Image(Input Register) Map .......................................................... 78

A.5.2. Example of Output Process Image(Output Register) Map .................................................. 80

A.6 Error Response ......................................................................................................................................... 82

A.7 MODBUS Reference ............................................................................................................................... 83

APPENDIX B - Product List ........................................................................................................................................... 84

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 7

7 MODBUS Programmable I/O NA-9379 FnIO S-Series

Warning!

Caution!

1. Important Notes

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls describes some important

differences between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will CREVIS be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables

and requirements associated with any particular installation, CREVIS cannot assume responsibility or liability for actual

use based on the examples and diagrams.

If you don’t follow the directions, it could cause a personal injury, damage to the equipment or explosion

• Do not assemble the products and wire with power applied to the system. Else it may cause an electric arc, which

can result into unexpected and potentially dangerous action by field devices. Arching is explosion risk in

hazardous locations. Be sure that the area is non-hazardous or remove system power appropriately before

assembling or wiring the modules.

• Do not touch any terminal blocks or IO modules when system is running. Else it may cause the unit to an electric

shock or malfunction.

• Keep away from the strange metallic materials not related to the unit and wiring works should be controlled by the

electric expert engineer. Else it may cause the unit to a fire, electric shock or malfunction.

If you disobey the instructions, there may be possibility of personal injury, damage to equipment or

explosion. Please follow below Instructions.

• Check the rated voltage and terminal array before wiring. Avoid the circumstances over 55℃ of temperature.

Avoid placing it directly in the sunlight.

• Avoid the place under circumstances over 85% of humidity.

• Do not place Modules near by the inflammable material. Else it may cause a fire.

• Do not permit any vibration approaching it directly.

• Go through module specification carefully, ensure inputs, output connections are made with the specifications. Use

standard cables for wiring.

• Use Product under pollution degree 2 environment.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 8

8 MODBUS Programmable I/O NA-9379 FnIO S-Series

1.1. Safety Instruction

1.1.1. Symbols

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death property damage or

economic loss.

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal

injury, property damage, or economic loss.

Attentions help you to identity a hazard, avoid a hazard, and recognize the consequences.

1.1.2. Safety Notes

The modules are equipped with electronic components that may be destroyed by electrostatic

discharge. When handling the modules, ensure that the environment (persons, workplace and

packing) is well grounded. Avoid touching conductive components.

1.1.3. Certification (TBD)

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 9

9 MODBUS Programmable I/O NA-9379 FnIO S-Series

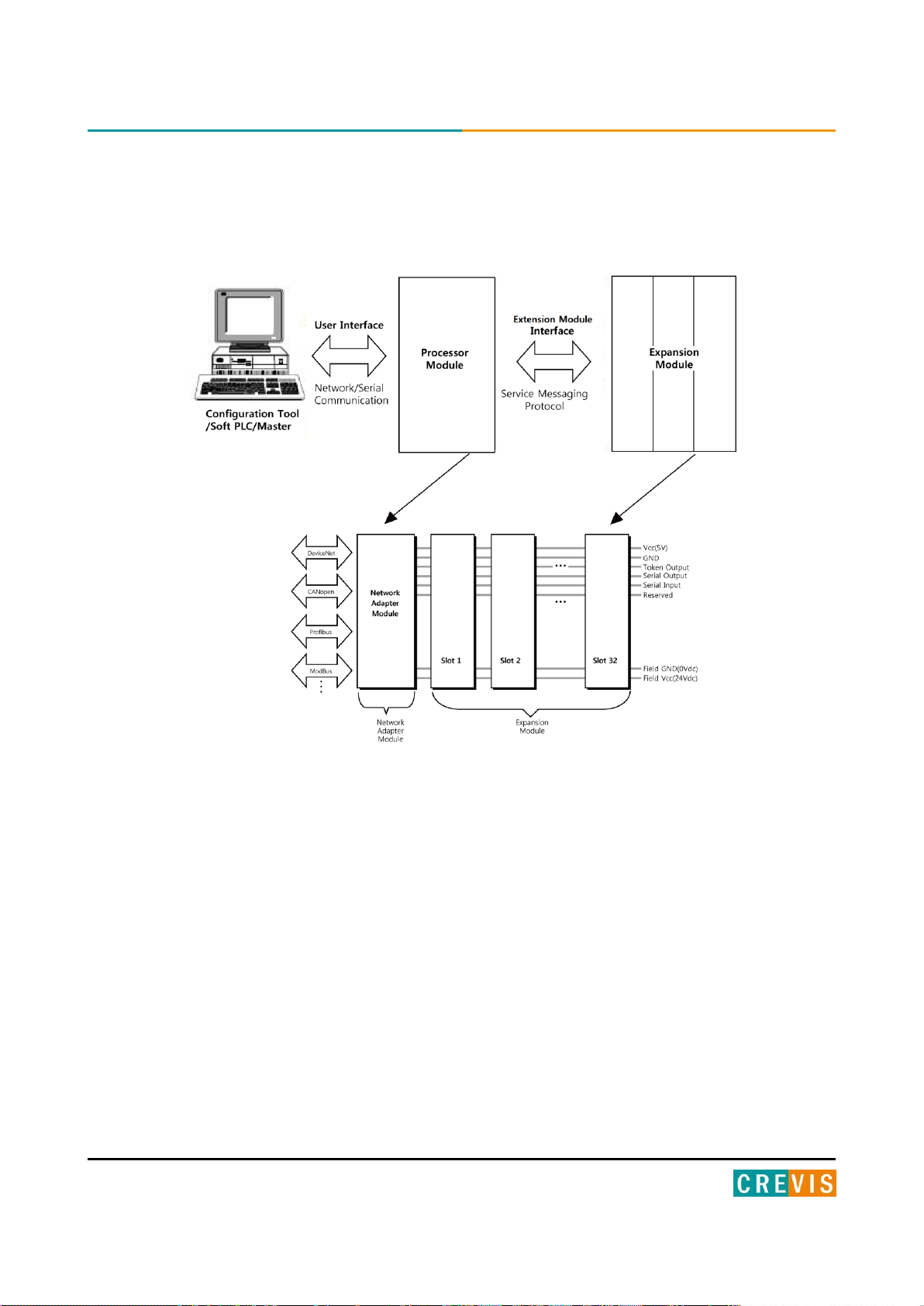

2. S-Series System

2.1. Electrical Interface

• Network Adapter Module

The Network Adapter Module forms the link between the field bus and the field devices with the Expansion Modules.

The connection to different field bus systems can be established by each of the corresponding Network Adapter

Module, e.g. for SyncNet, PROFIBUS, CANopen, DeviceNet, Ethernet/IP, CC-Link, MODBUS/Serial,

MODBUS/TCP etc.

• Expansion Module

The Expansion Modules are supported a variety of input and output field devices. There are digital and analog

input/output modules and special function modules.

• Two types of Message

Service Messaging / I/O Messaging

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 10

10 MODBUS Programmable I/O NA-9379 FnIO S-Series

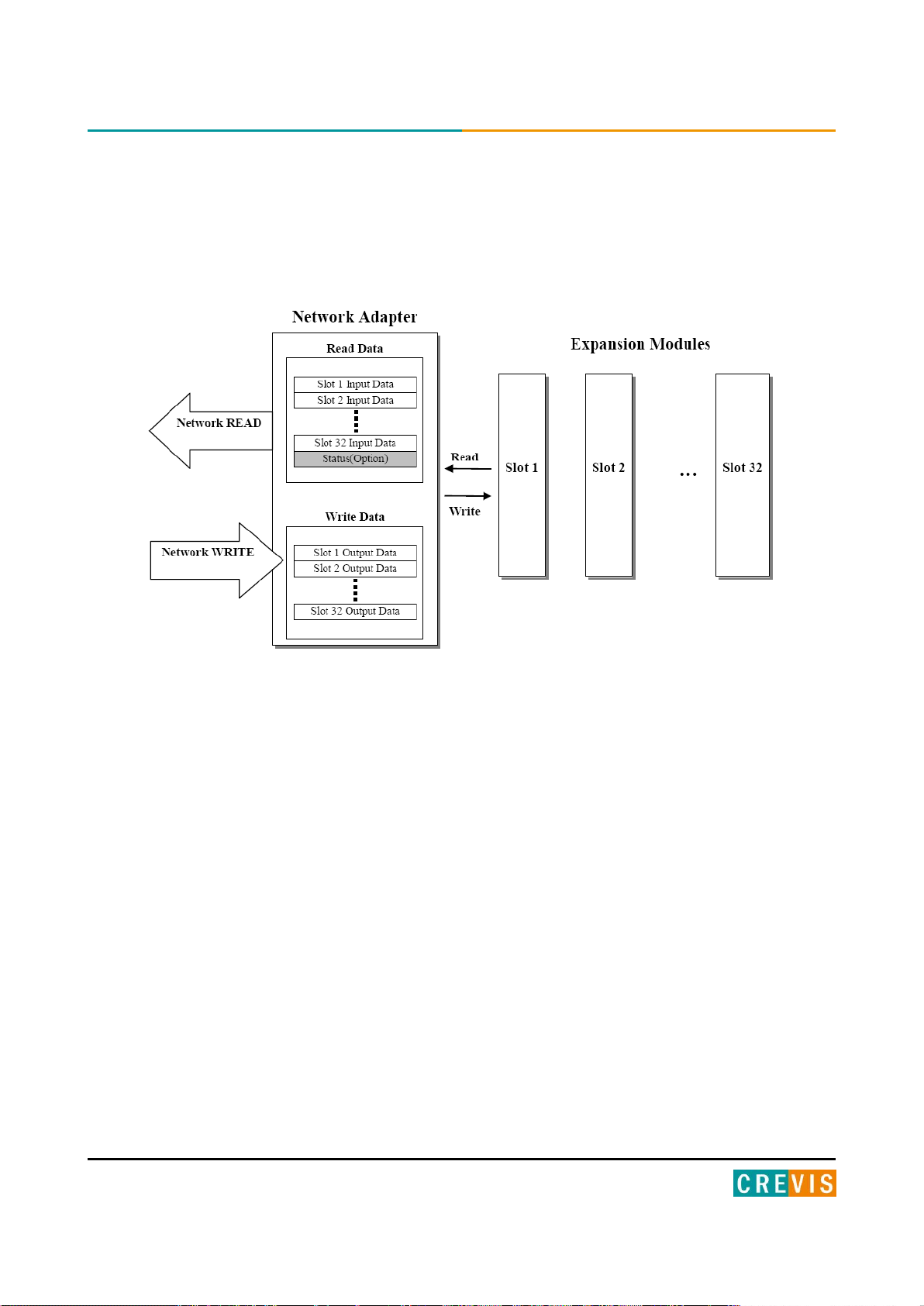

2.2. I/O Process Image Map

An expansion module may have 3 types of data as I/O data, configuration parameter and memory register.

The data exchange between network adapter and expansion modules is done via an I/O process image data by

internal-protocol. The following figure shows the data flow of process image between network adapter and

expansion modules.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 11

11 MODBUS Programmable I/O NA-9379 FnIO S-Series

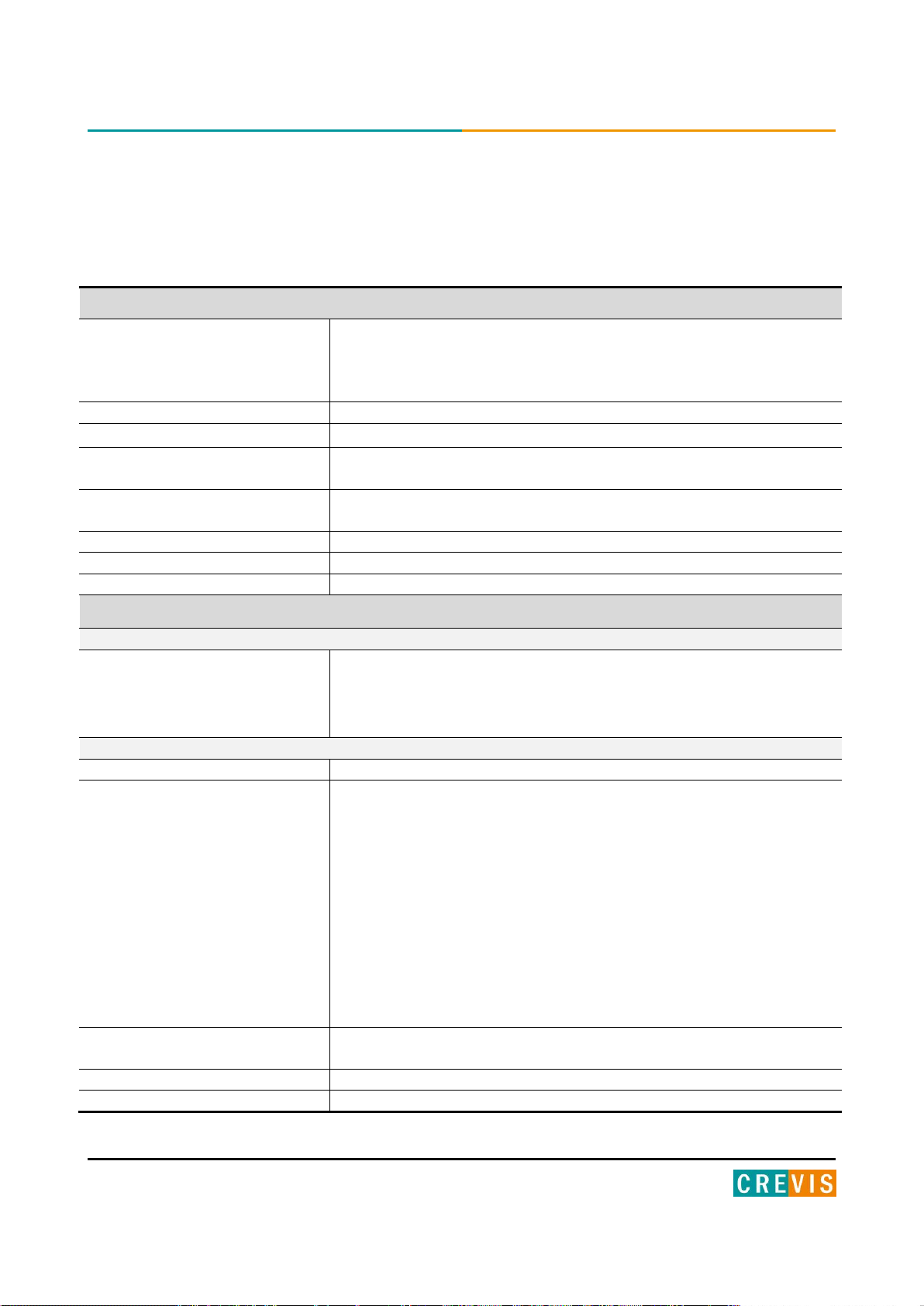

General Specification

System Power

Supply voltage : 24Vdc nominal

Supply voltage range : 11~28.8Vdc

Protection : Output current limit (Min. 1.5A)

Reverse polarity protection

Power Dissipation

110mA typical @ 24Vdc

Current for I/O Module

1.5A @5Vdc

Isolation

System power to internal logic : Non-isolation

System power I/O driver : Isolation

Field Power

Supply voltage : 24Vdc nominal

Supply voltage range : 11~28Vdc

Max. Current Field Power Contact

DC 10A Max.

Weight

172g

Module Size

54mm x 99mm x 70mm

Environment Condition

Environmental Specifications

Operating Temperature

Storage Temperature

Relative Humidity

Mounting

-20℃~60℃

-40℃~85℃

5% ~ 90% non-condensing

DIN rail

General Specifications

Shock Operating

IEC 60068-2-6

Vibration/shock resistance

Based on IEC 60068-2-6

Sine Vibration

- 10 ~ 25 Hz : 0.5mm

- 50 ~ 150 Hz : 5g

- 150 ~ 1000 Hz : 2g

- Sweep Rate : 1 Oct/min, 50 cycles

Sine Vibration

- 10 ~ 25 Hz : 0.03 g²/Hz

- 25 ~ 50 Hz : 0.05 g²/Hz

- 50 ~ 150 Hz : 0.15 g²/Hz

- 150 ~ 1000 Hz : 0.01 g²/Hz

- Test time : 5hrs for each test

EMC resistance burst/ESD

EN 61000-6-2 : 2005

EN 61000-6-4/ALL : 2011

Installation Pos. / Protect. Class

Variable/IP20

Product Certifications

TBD

3. Specification

3.1. General Specification

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 12

12 MODBUS Programmable I/O NA-9379 FnIO S-Series

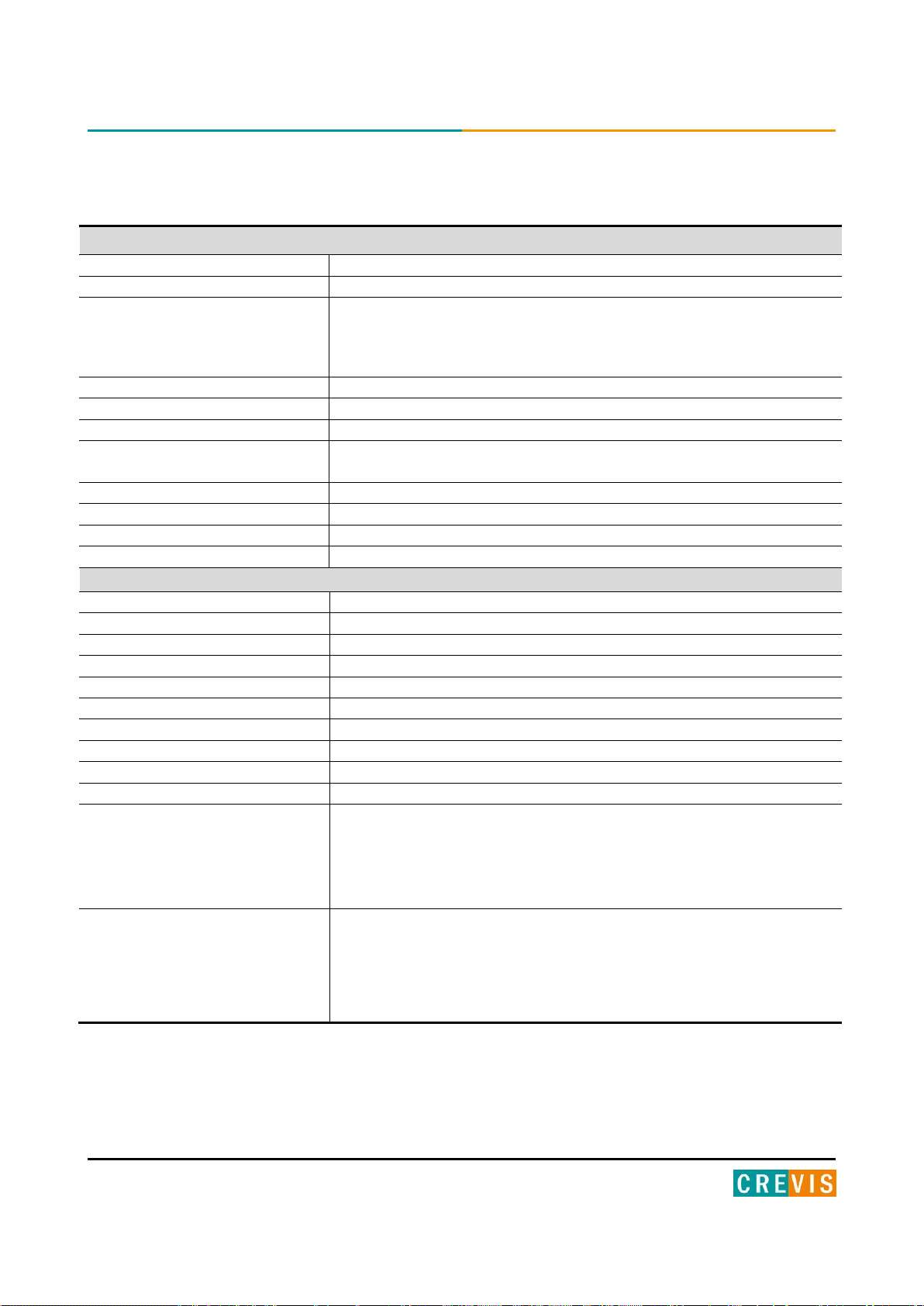

Programmable Specification

Programming

CoDeSys V3.5 SP3 Patch 1

Program Memory

512 Kbytes

Data Memory

512 Kbytes

%IW0~%IW639 (640 word Input and Internal memory)

%QW0~%QW639 (640 word Output and Internal memory)

%MW0~%MW639 (640 word Internal memory)

Non-Volatile Memory

32 Kbytes (Retain : 16Kbytes, Flag : 16Kbytes

Run-Time system

Multiple PLC Task

Program Languages

IEC 61131-3 (LD, IL, ST, FBD, SFC)

RTC

Retain Time : 6 days

Accuracy : <2min/month

Max. Task

2

Max. Cycle Task

2

Max. Status Task

1

Process Time

3us (100Instruction)

Interface Specification

Adapter Type

Master & Slave Node (MODBUS TCP)

Max. Expansion Module

32 slots

Max. Input Size

126 Words (252 Byte)

Max. Output Size

126 Words (252 Byte)

Max. Nodes

Limited by Ethernet Specification

Baudrate

10/100Mps, Auto-negotiation, Full Duplex

Interface Connector

RJ-45 socket * 2pcs

Protocol

MODBUS TCP, DHCP, BOOTP, SNMP

Max. Socket

18 (UDP : 6, TCP : 12, TCP_LISTEN : 6)

Other Serial Port

RS232/485 for MODBUS RTU, Touch Pannel or IOGuide

Serial Configuration (RS232/485)

Node : 1(default)

Baudrate : 38400(default)

Data bit : 8(default)

Parity bit : No parity(default)

Stop bit : 1(default)

Indicator

4 LEDs (NET LED is Not used)

1 Green/Red, Module Status (MOD)

1 Green/Red, Run Status (RUN)

1 Green/Red, Extension Module Status (I/O)

1 Green, Field Power Status

3.2. Interface Specification

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 13

13 MODBUS Programmable I/O NA-9379 FnIO S-Series

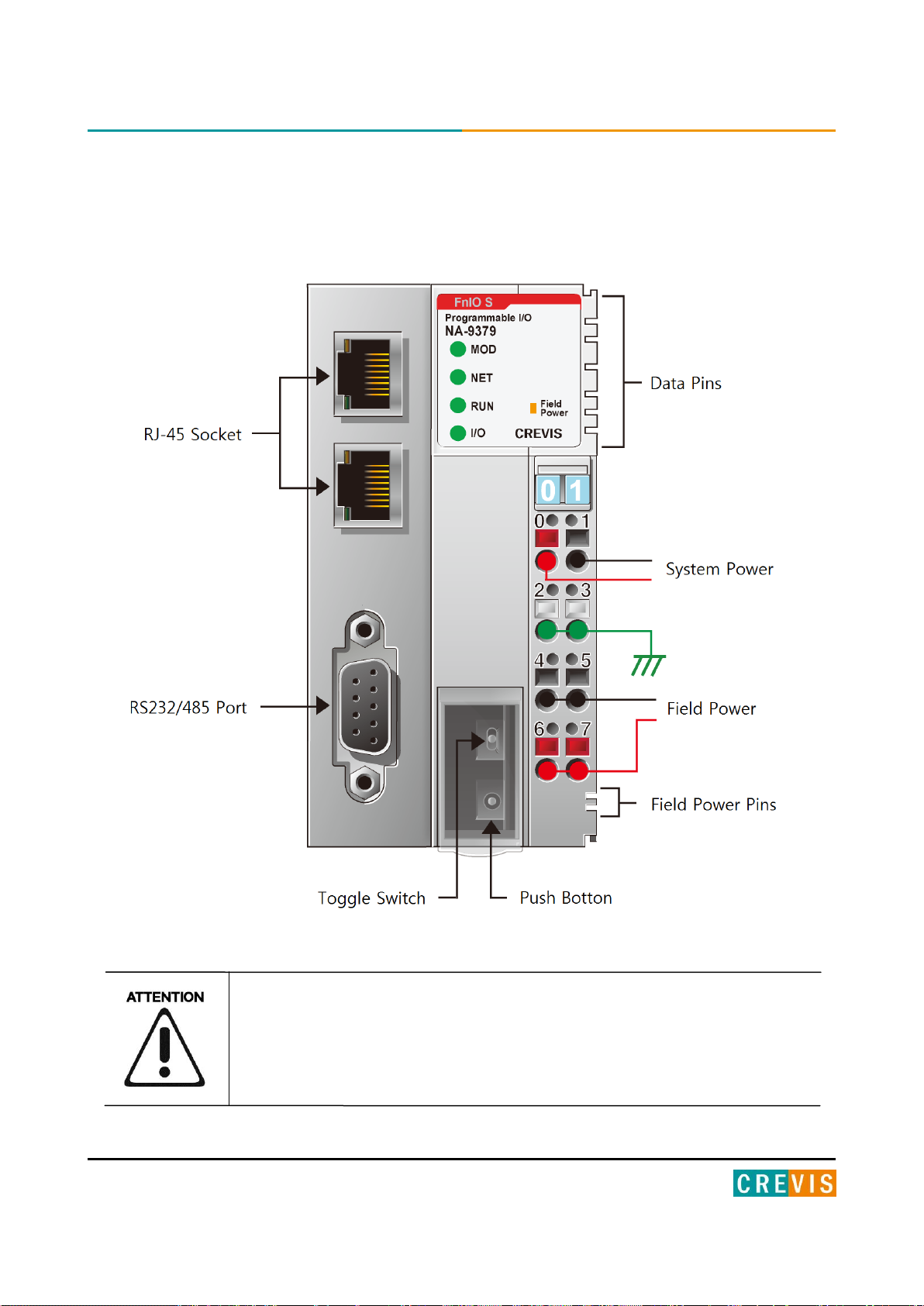

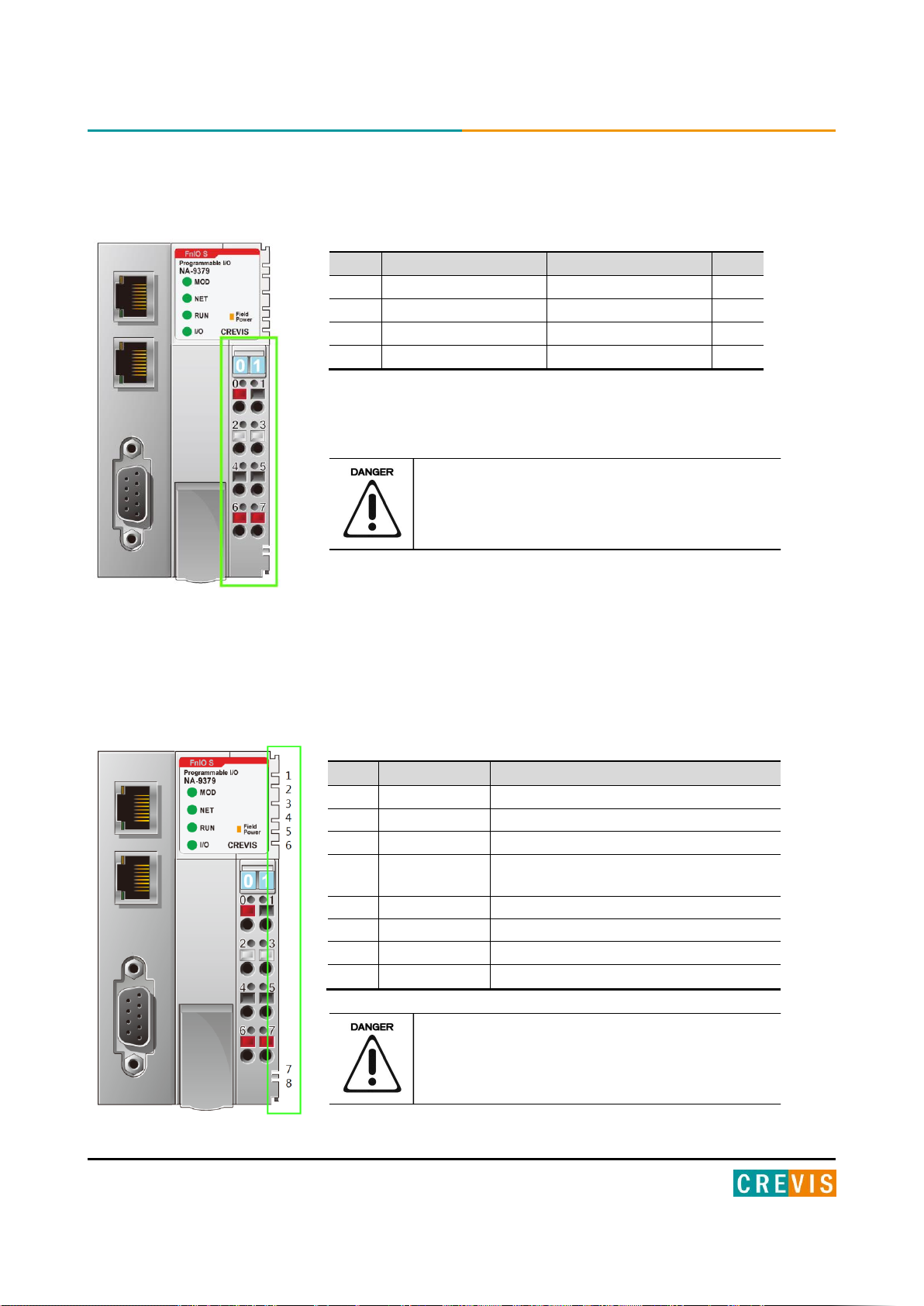

4. Module Description

4.1. NA-9379 (MODBUS Programmable I/O)

The modules are not hot swappable and should be not removed in power on condition.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 14

14 MODBUS Programmable I/O NA-9379 FnIO S-Series

LED is:

Constantly on

LED Off

Constantly off

LED Flickering

Equal on and off times with a frequency of approximately 10 Hz: on for approximately

50ms and off for approximately 50ms.

LED Blinking

Equal on and off times with a frequency of approximately 2, 5Hz: on for approximately

200ms followed by off for approximately 200ms.

LED Single flash

One short flash (approximately 200ms) followed by a long off phase (approximately

1000ms)

LED Double flash

A sequence of two short flashes (approximately 200ms), separated by an off phase

(approximately 200ms). The sequence is finished by a long off phase (approximately

1000ms).

LED Triple flash

A sequence of three short flashes (approximately 200ms), separated by an off phase

(approximately 200ms). The sequence is finished by a long off phase (approximately

1000ms).

LED No.

LED Function /

Description

LED Color

MOD

Module Status

Green/Red

NET

Not Used

-

RUN

Error Status

Green/Red

I/O

Extension module Status

Green/Red

Field Power

Field Power Enable

Green

4.2. LED Indicator

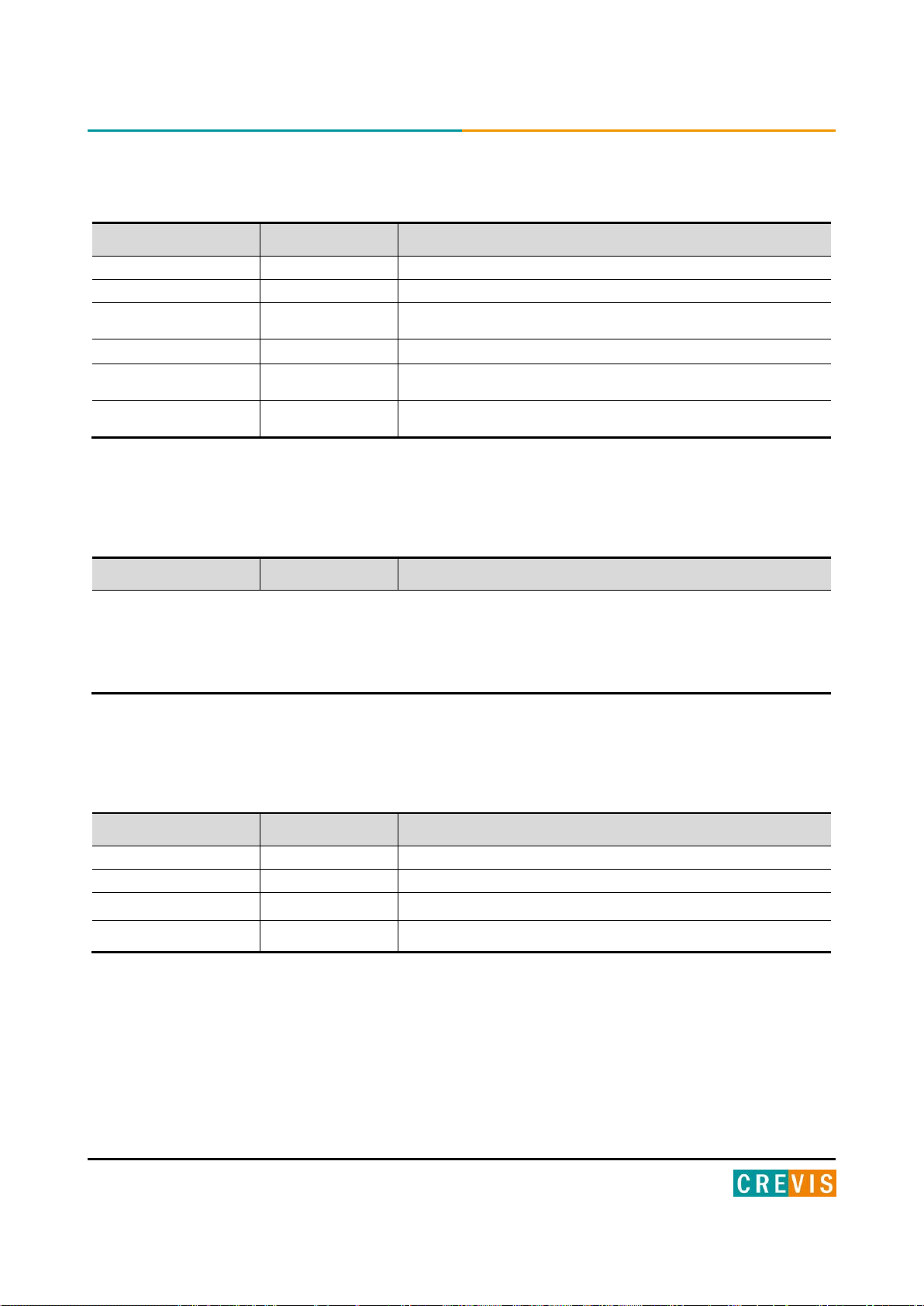

3.2.1. Indicator Status and Flash Rates

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 15

15 MODBUS Programmable I/O NA-9379 FnIO S-Series

State

LED is :

To indicate :

No Power

Off

No power is supplied to the unit.

Device Operational

Green

The unit is operating in normal condition.

Device in Standby

Blinking Green

The EEPROM parameter is not initialized yet.

Serial Number is zero value (0x00000000)

IAP Mode

Flashing Green

IAP Mode : Available for firmware download using FireFox.

Minor Fault

Blinking Red

The unit has occurred recoverable fault in self-testing.

- EEPROM checksum fault

Unrecoverable Fault

Red

The unit has occurred unrecoverable fault in self-testing.

- Firmware fault

State

LED is :

To indicate :

Not Used

State

LED is :

To indicate :

Not Programmed

OFF

Not Power is supplied or the unit or Not programmed

Run

ON

PLC Run

Stop

Blinking Green

PLC Stop

Error

Blinking Red

Failure of Module Configuration

3.2.2. Module Status LED (MOD)

3.2.3. Network Status LED (NET)

3.2.4. PLC Run/Stop Status LED (RUN)

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 16

16 MODBUS Programmable I/O NA-9379 FnIO S-Series

State

LED is :

To indicate :

Not Powered

No Expansion Module

Off

Device has no expansion module or may not be powered

On-line,

Do not Exchanging I/O

Flashing Green

Extension module is normal but does not exchanging I/O data

(Passed the expansion module configuration).

Connection,

Run Exchanging IO

Green

Exchanging I/O data

Connection fault

during exchanging IO

Red

One or more expansion module occurred in fault state.

- Changed expansion module configuration.

- expansion module communication failure.

Expansion

Configuration Failed

Flashing Red

Failed to initialize expansion module

- Detected invalid expansion module ID.

- Overflowed Input / Output Size

- Too many expansion module

- Initial protocol failure

- Mismatch vendor code between adapter and expansion module.

State

LED is :

To indicate :

Not Supplied Field Power

Off

Not supplied 24V dc field power, 5Vdc System Power.

Supplied Field Power

Green

Supplied 24V dc field power, 5Vdc System Power.

3.2.5. Extension Module Status LED (I/O)

3.2.6. Field Power Status LED

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 17

17 MODBUS Programmable I/O NA-9379 FnIO S-Series

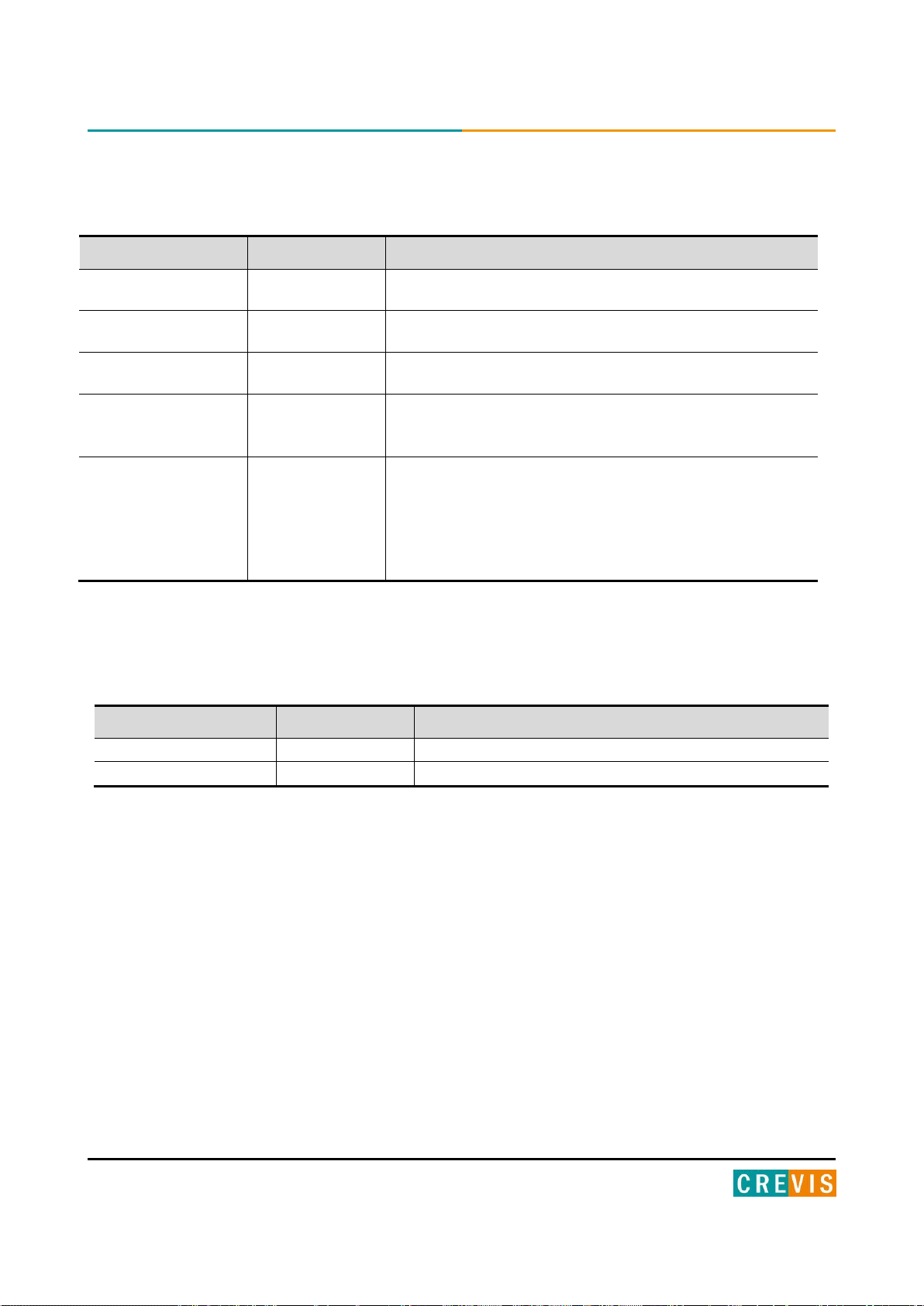

RJ-45

Signal Name

Description

1

TD+

Transmit + 2 TD-

Transmit - 3 RD+

Receive + 4 - 5

-

6

RD-

Receive -

7

- 8

-

Case

Shield

RS 232/485

Signal Name

Description

1

-

2

RXD

RS232 RXD

3

TXD

RS232 TXD

4

-

5

GND

RS232 GND

6

D+

RS 485 D+ 7 - 8

D-

RS485 D- 9 -

Toggle Switch Status

Module is

Description

UP

RUN

PLC Run

DOWN

STOP

PLC Stop

(Fault Action is performed)

Push Button

Module is

Description

Press and release.

Reset

Reset the PLC and then stop.

Hold down and reset

the power.

IAP mode

Available for firmware download

using FireFox

3.3. RJ-45 Socket , RS232/485 Port

3.4. Toggle Switch , Push Button

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 18

18 MODBUS Programmable I/O NA-9379 FnIO S-Series

Pin

Signal Description

Signal Description

Pin

0

System Power 24V

System Power 0V

1

2

F.G

F.G

3 4 Field Power 0V

Field Power 0V

5

6

Field Power 24V

Field Power 24V

7

No.

Name

Description

1

System Vcc

System supply voltage (5V dc).

2

System GND

System Ground.

3

Token Output

Token output port of Processor module.

4

Serial Output

Transmitter output port of Processor

module.

5

Serial Input

Receiver input port of Processor module.

6

Reserved

Reserved for bypass Token.

7

Field GND

Field Ground.

8

Field Vcc

Field supply voltage (24Vdc).

3.5. RTB Terminal Block

- System Power: The power for starting up CPU.

- Field Power: The power for input and output line.

Do not use an incorrect voltage/frequency!

The use of an incorrect supply voltage or frequency

can cause severe damage to the component.

3.6. Pin Description

Communication between the Network adapter and the expansion module as well as system / field power supply of the

bus modules is carried out via the internal bus. It is comprised of 6 data pin and 2 field power pin.

Do not touch data and field power pins in order to

avoid soiling and damage by ESD noise.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 19

19 MODBUS Programmable I/O NA-9379 FnIO S-Series

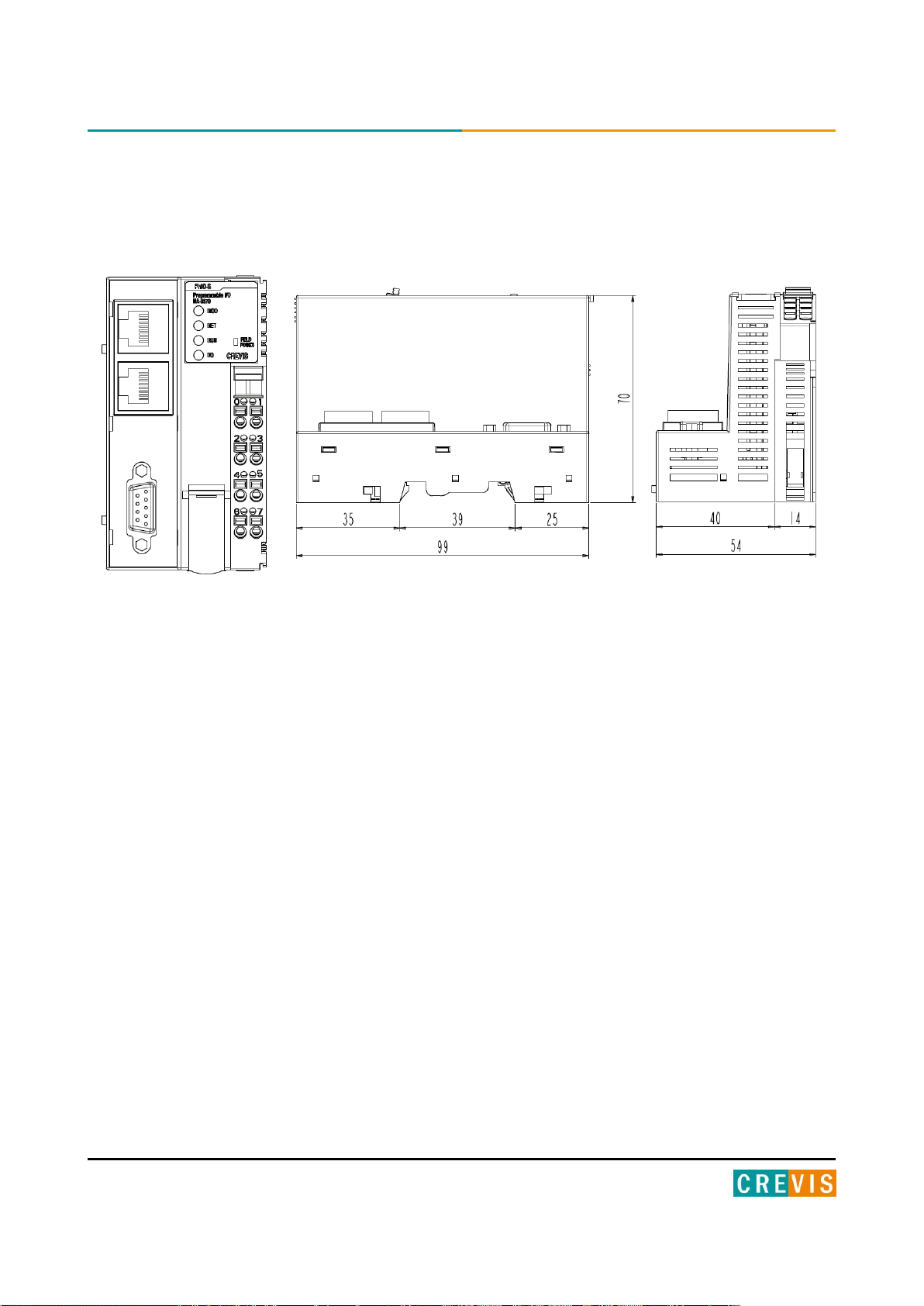

3.7. Dimension

(mm)

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 20

20 MODBUS Programmable I/O NA-9379 FnIO S-Series

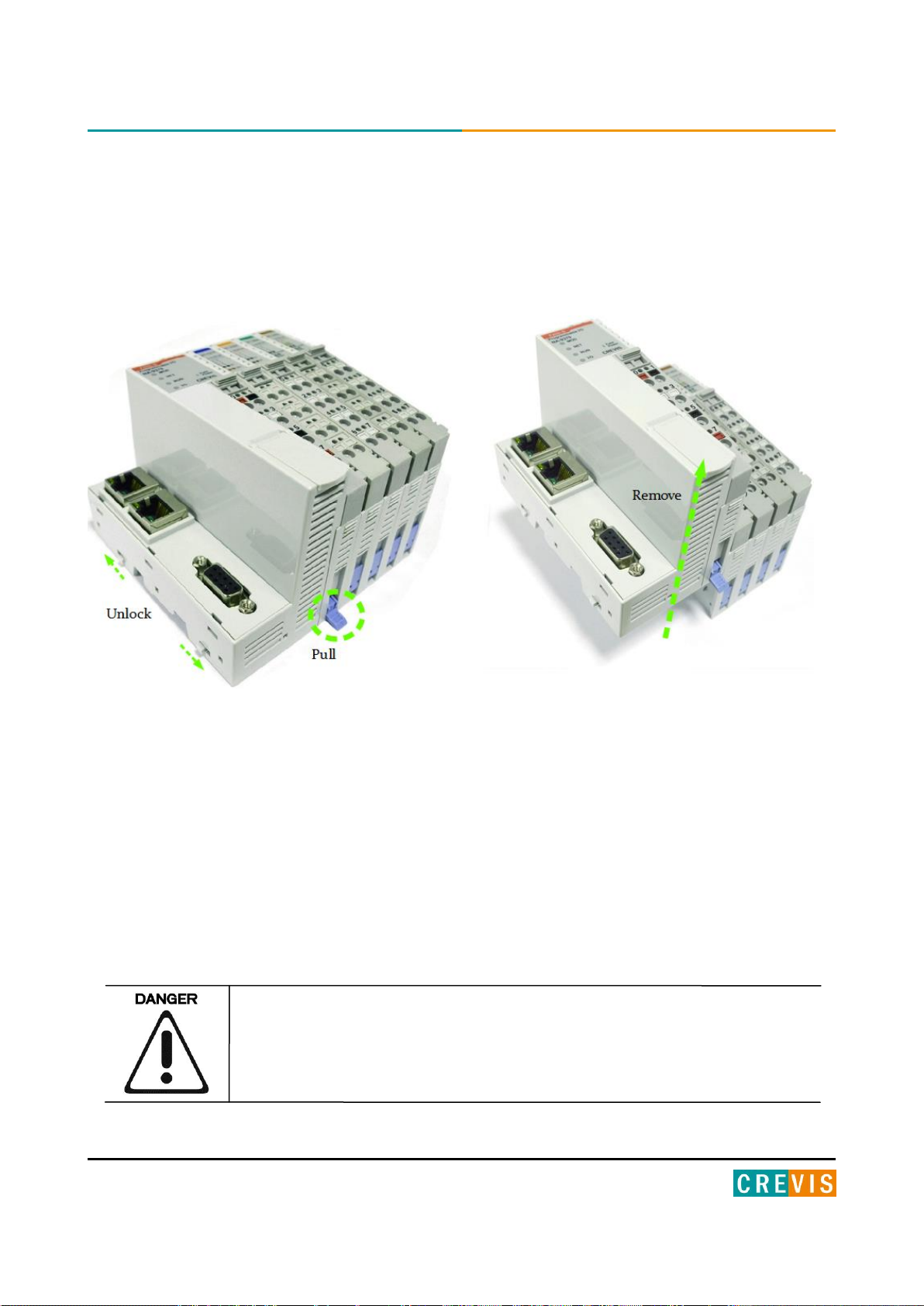

4. Mechanical Setup

4.3. Inserting and Removing the Module.

As above figure in order to safeguard the FnIO module from jamming, it should be fixed onto the DIN rail with locking

level. To do so, fold on the upper of the locking lever.

To pull out the FnIO module, unfold the locking lever as below figure.

Before work is done on the components, the voltage supply must be turned off.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 21

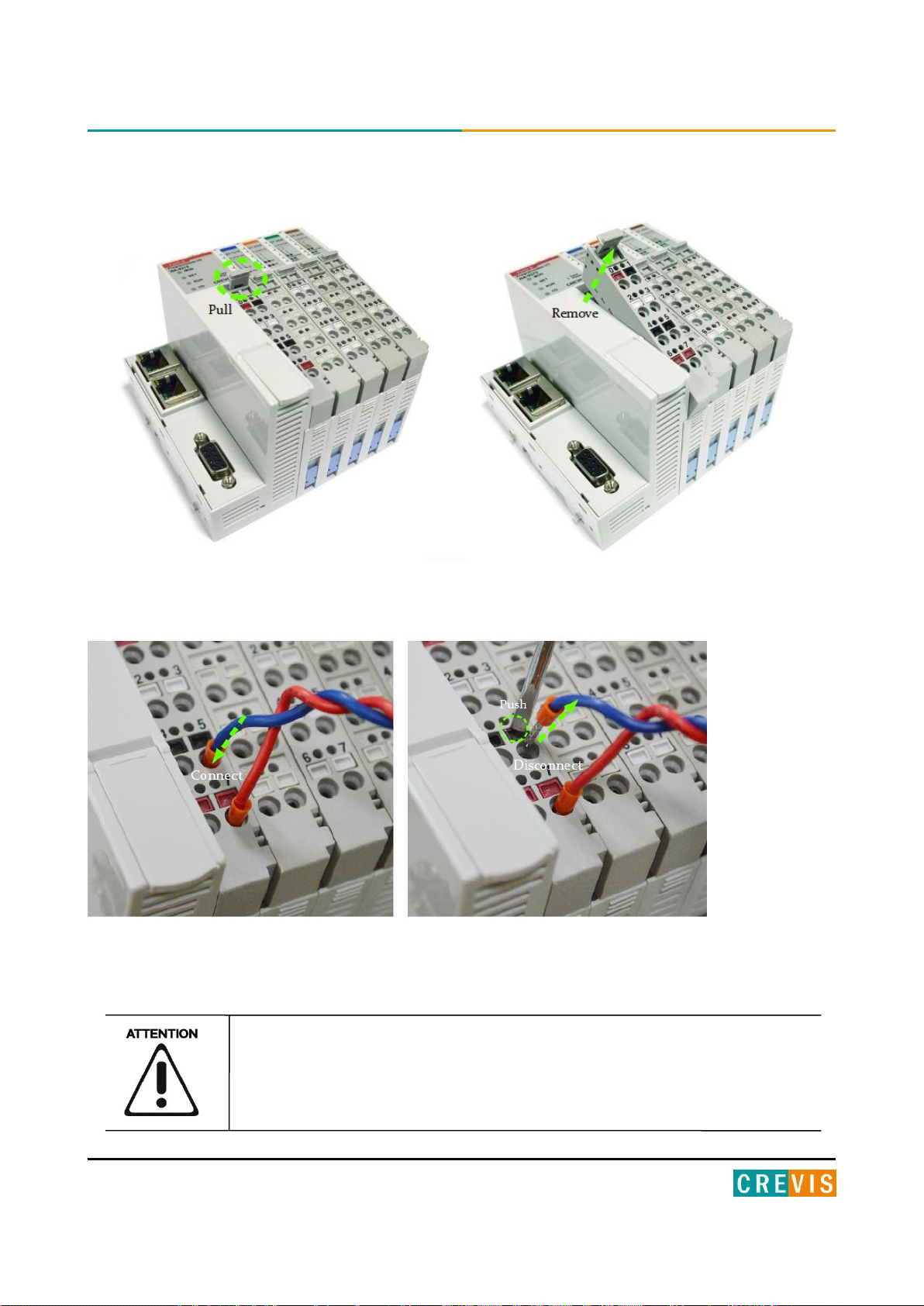

21 MODBUS Programmable I/O NA-9379 FnIO S-Series

4.4. Removable Terminal Block (RTB)

4.5. Method of Wiring.

Connecting or removing the cable by pushing the terminal button for the relevant points.

The use of an incorrect supply voltage or frequency can cause severe damage to the

component.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 22

22 MODBUS Programmable I/O NA-9379 FnIO S-Series

5. Various Functions of PIO (With IO Guide Pro)

Crevis IO Guide Pro is compatible with the PIO(NA-9379).

The basic parameter set-up and configuration for the PIO is available via the IO Guide Pro.

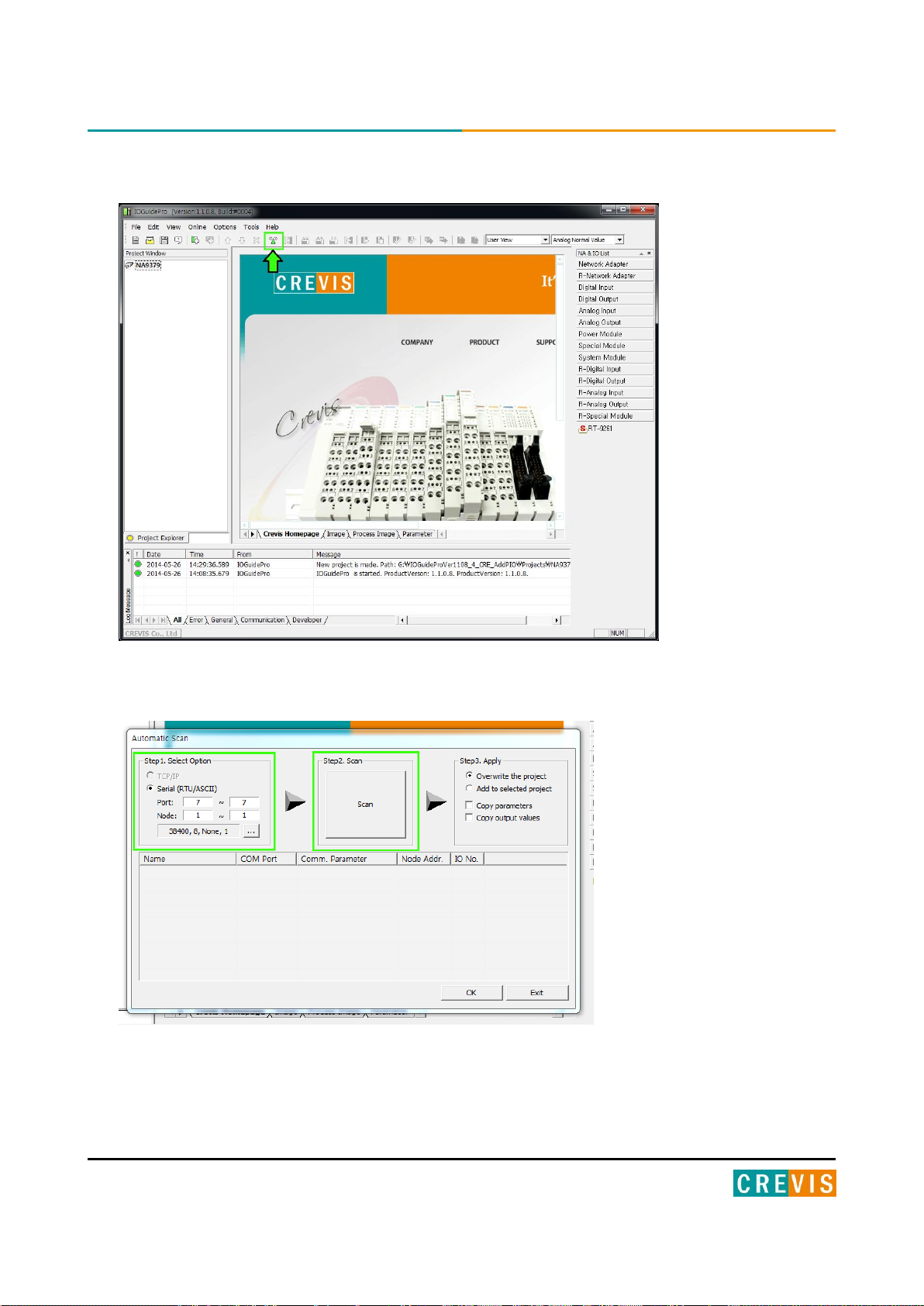

5.1. Connect IO Guide Pro (MODBUS Serial)

(1) Installation program-IO Guide Pro that provides CREVIS(www.crevis.co.kr).

(2) Open the IO Guide and Click on the ‘New project’ Icon.

(2) Write the ‘Project Name’ and Select of bus type Specify the local and Click on the ‘OK’ button.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 23

23 MODBUS Programmable I/O NA-9379 FnIO S-Series

(1) After creating a project and click the ‘Automatic scan’ Icon.

(4) Write the value(Port, node, Baudrate) click the ‘Automatic scan’ button.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 24

24 MODBUS Programmable I/O NA-9379 FnIO S-Series

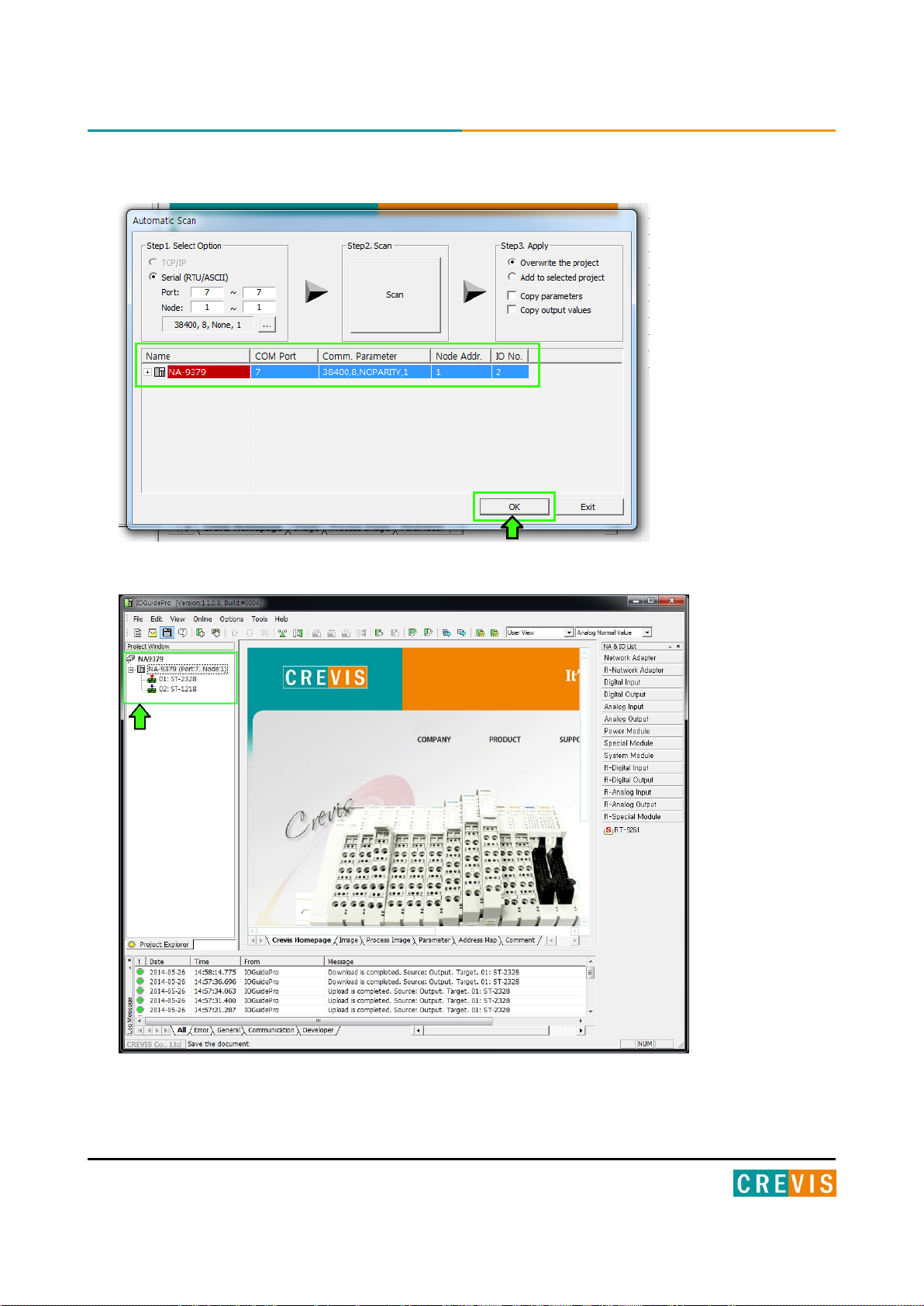

(1) After the scan completes, click the ‘OK’ button.

(1) It is ready to use the IO Guide Pro.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 25

25 MODBUS Programmable I/O NA-9379 FnIO S-Series

5.2. Confirmation of Network Information.

You can see by checking the IP Address , Subnet Mask, Gate Way, Mac Address of NA-9379 .

* IP Address : Also known as an "IP number" or simply an "IP," this is a code made up of numbers separated by

three dots that identifies a particular computer on the Internet. Every computer, whether it be a Web server or the

computer you're using right now, requires an IP address to connect to the Internet. IP addresses consist of four sets

of numbers from 0 to 255, separated by three dots.

* Subnet Mask : A subnet mask is a number that defines a range of IP addresses that can be used in a network. (It

is not something you wear on your head to keep subnets out.) Subnet masks are used to designate sub networks, or

subnets, which are typically local networks LANs that are connected to the Internet. Systems within the same

subnet can communicate directly with each other, while systems on different subnets must communicate through a

router.

* Gate Way : A gateway is either hardware or software that acts as a bridge between two networks so that data can

be transferred between a number of computers.

* Mac Address : A MAC address is a hardware identification number that uniquely identifies each device on a

network. The MAC address is manufactured into every network card, such as an Ethernet card or Wi-Fi card, and

therefore cannot be changed.

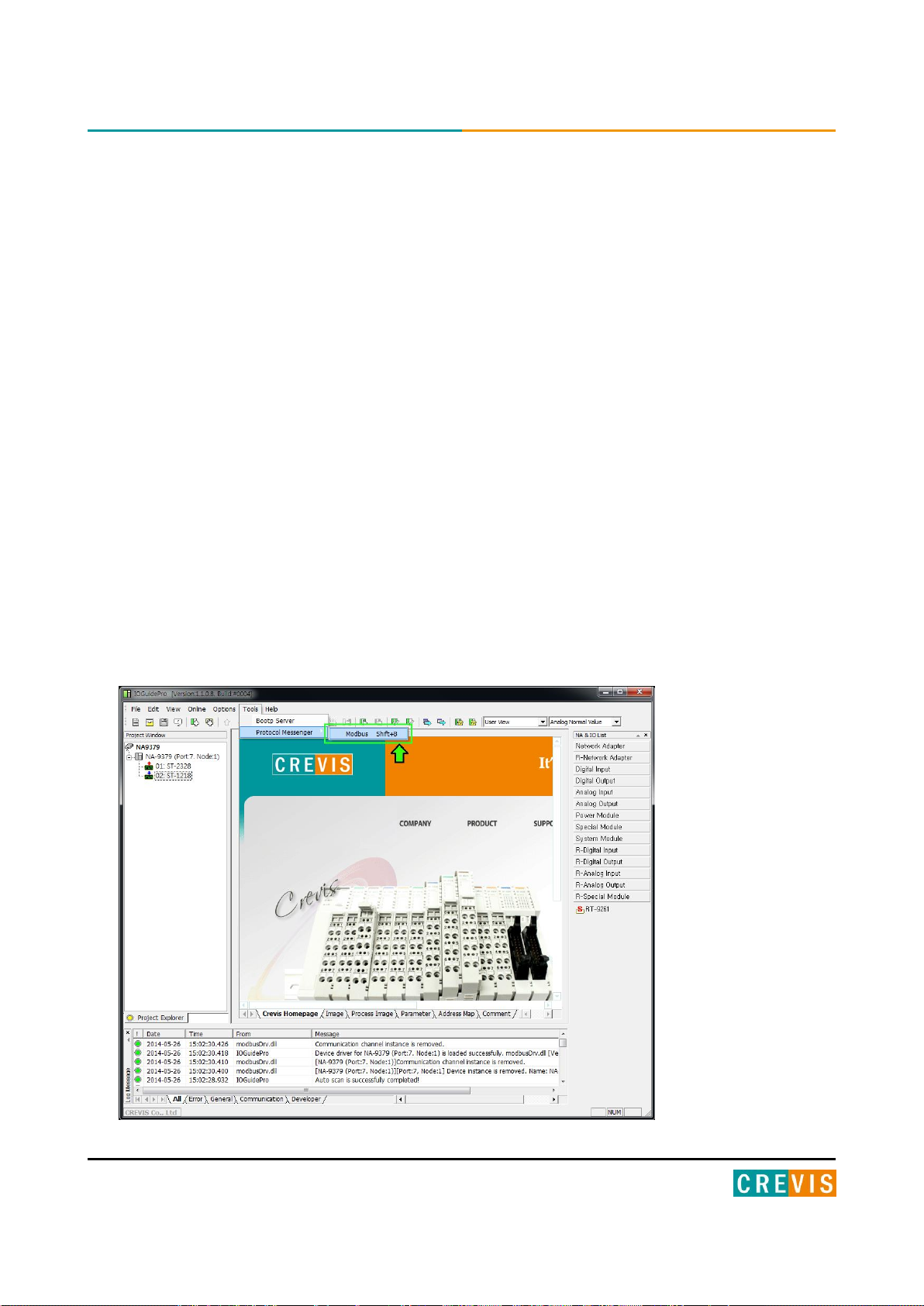

(1) Run ‘[Crevis] -> [IOGuidePro] -> [Protocol Messenger] -> [Modbus]’

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 26

26 MODBUS Programmable I/O NA-9379 FnIO S-Series

(2) Write the value of each.

*Protocol : Modbus RTU

*ComPort : User Port / Baudrate : 38400(default)

*Address(Hex) : 1600 (IP Address Register)

:1602 (IP Subnet Mask Register)

:1604 (Gate way Register)

:1610 (Mac Address Register)

*Function(Dec) : 03, Read Holding Registers

(3) After clicking the ‘send’ button and confirm the necessary information.

If you choose to 'ByteDec', More easy to see.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 27

27 MODBUS Programmable I/O NA-9379 FnIO S-Series

5.3. BootP/DHCP Setting

You can selected to ‘IP Setting method’.

* BOOTP: short for Bootstrap Protocol, is a UDP network protocol used by a network client to obtain its IP

address automatically. This is usually done in the bootstrap process of computers or operating systems running on

them. The BOOTP servers assign the IP address from a pool of addresses to each client.

* DHCP: set of rules used by communications devices such as a computer, router or network adapter to allow the

device to request and obtain an IP address from a server which has a list of addresses available for assignment.

(1) Run ‘[Crevis] -> [IOGuidePro] -> [Protocol Messenger] -> [Modbus]’

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 28

28 MODBUS Programmable I/O NA-9379 FnIO S-Series

(2) Write the value of each.

*Protocol : Modbus RTU

*ComPort : User Port / Baudrate : 38400(default)

*Address(Hex) : 160B (IP Setting Method Register)

*Function(Dec) : 16, Write Multiple registers

(3) Write the register value and click the ‘Send’ button.

*Not Use : 0000 / *BootP Setting : 8000 / *DHCP Setting : 8001

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 29

29 MODBUS Programmable I/O NA-9379 FnIO S-Series

5.4. Setup IP Address

You can assign the IP Address manually via the setting of Bootp server.

Default IP Address is 192.168.100.100

(1) Run ‘[Crevis] [IOGuidePro] [Bootp Server]’

NA9379 is a model that supports DHCP and Bootp.

If you have a DHCP server on the same communications,

IP settings from Bootp is impossible.

In this case, set the IP from the DHCP server.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 30

30 MODBUS Programmable I/O NA-9379 FnIO S-Series

(2) Power on the NA9379, and Click the ‘Start Bootp’ button.

(3) Double Click ‘MAC address of NA9379’

Turn on the power of NA-9379, and Retry 2imes for 4 seconds.

IP settings will be within that time.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 31

31 MODBUS Programmable I/O NA-9379 FnIO S-Series

(4) Set the IP, and click ‘OK’.

(5) Finish

Subnet Mask and Gateway is

assigned automatically by the value that is set in the computer.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 32

32 MODBUS Programmable I/O NA-9379 FnIO S-Series

0x160A

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

- 1 nibble : Data bit(0 : 8bit(default), 1 : 9bit)

- 2 nibble : Stop bit(0 : 1bit(default), 1 : 2bit)

- 3 nibble : Parity bit(0 : none(default), 1: even, 2 : odd)

- 4 nibble : Reserve

0x1607

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

0x1609

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

1 : 2400 2 : 4800 3 : 9600 4 : 19200

5 : 38400 (default) 6 : 57600 7 : 115200

5.5. Serial Communication Settings

Setting according to the each communication state is possible Because NA-9379 is available the

RS232 and RS485 Serial Communications.

• Station Setting

The following illustration is an area of Register 0x160A address that can be used to set the code of Serial

communication. High 1byte is the area of rs232, and Low 1byte is the area of rs485.

It is possible to set a maximum of 247 for each area. (default : 1)

MSB LSB

RS232C Modbus station RS485 Modbus station

• RS232/ RS485 Communication setting

The options for the communication can be selected.

RS232 can be selected from the register address, “0x1606”.

RS485 can be selected from the register address, “0x1608”.

MSB LSB

Data bit Stop bit Parity bit Reserve

MSB LSB

Data bit Stop bit Parity bit Reserve

RS485

• Baudrate setting

The baudrate from 1200bps to 115200bps is supported.

RS232 can be selected from the register address, “0x1606”.

RS485 can be selected from the register address, “0x1608”.

RS232

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 33

33 MODBUS Programmable I/O NA-9379 FnIO S-Series

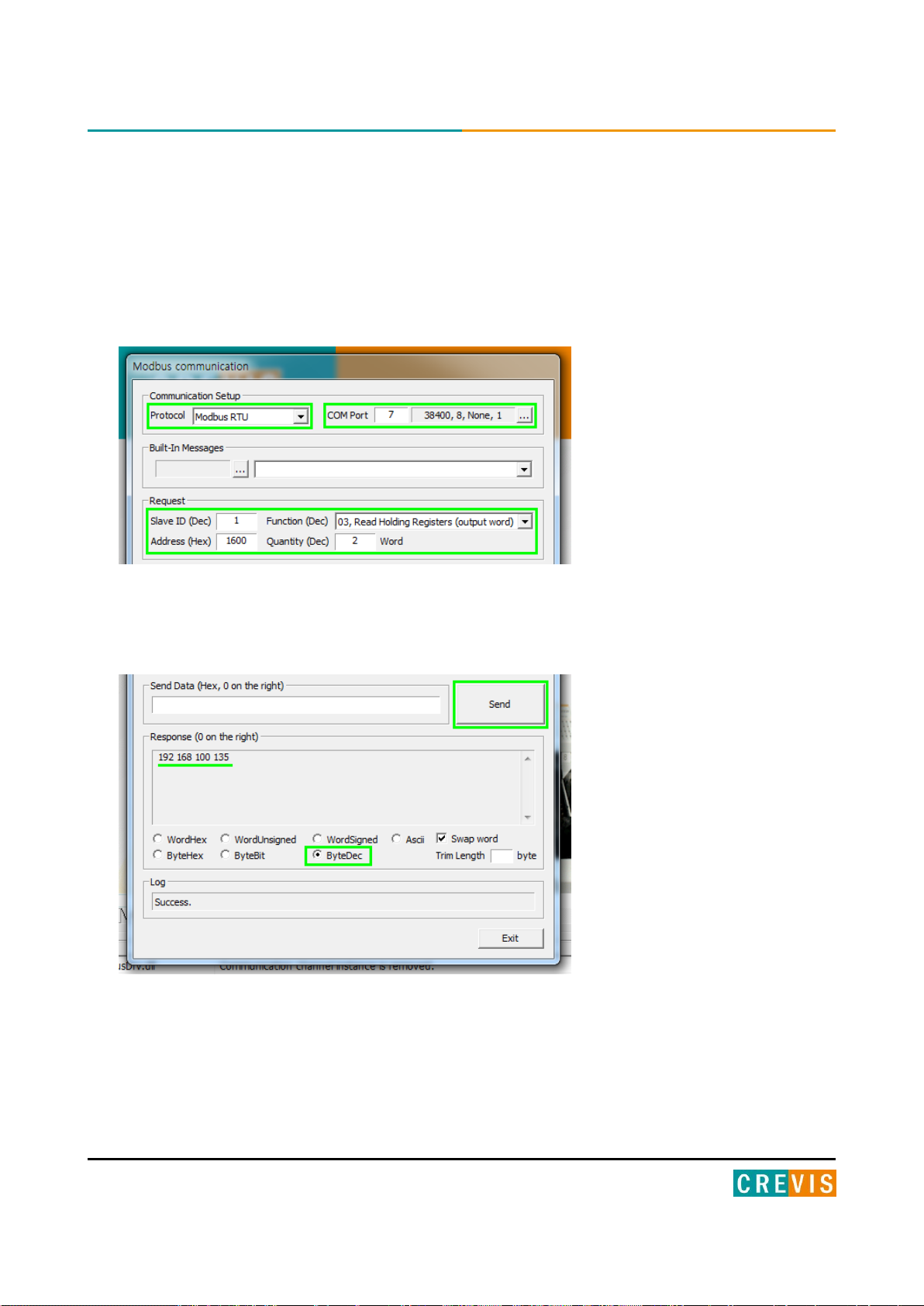

(1) Run ‘[Crevis] -> [IOGuidePro] -> [Protocol Messenger] -> [Modbus]’

(2) Write the value of each.

*Protocol : Modbus RTU

*ComPort : User Port / Baudrate : 38400(default)

*Address(Hex) : 1606 (RS232 Baudrate Register)

:1607 (RS232 Use bit Setting Register)

:1608 (RS485 Baudrate Register)

:1609 (RS485 Use bit Setting Register)

*Function(Dec) : When the value is write - 16, Write Multiple registers

When the value is read - 03, Read Holding Registers

(3) confirm the necessary information.

*When the value is write *When the value is read

write the desired value and click the Send button. Click the Send button and confirm the value.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 34

34 MODBUS Programmable I/O NA-9379 FnIO S-Series

5.6. Memory Reset

data field 0x55AA makes the remote device to restart with factory default setup of EEPROM.

*All expansion slot configuration parameters are cleared.

(1) Run ‘[Crevis] -> [IOGuidePro] -> [Protocol Messenger] -> [Modbus]’

(2) Write the value of each.

*Protocol : Modbus RTU

*ComPort : User Port / Baudrate : 38400(default)

*Address(Hex) : 0001 (Factory default setup)

*Function(Dec) : When the value is write – 08, Diagnostics

(3) Write the register value and click the ‘Send’ button.

*Value : 0x55AA

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 35

35 MODBUS Programmable I/O NA-9379 FnIO S-Series

5.7. RTC(Real Time Clock) Function

A real-time clock (RTC) is a computer clock (most often in the form of an integrated circuit) that keeps

track of the current time. RTC information of NA-9379 is stored in address 0x1620 in the Register,

also can be read.

(1) Run ‘[Crevis] -> [IOGuidePro] -> [Protocol Messenger] -> [Modbus]’

(2) Write the value of each.

*Protocol : Modbus RTU

*ComPort : User Port / Baudrate : 38400(default)

*Address(Hex) : 1620 (RTC Register)

*Function(Dec) : When the value is write - 16, Write Multiple registers

When the value is read - 03, Read Holding Registers

(3) confirm the necessary information.

*When the value is write *When the value is read

write the desired value and click the Send button. Click the Send button and confirm the value.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 36

36 MODBUS Programmable I/O NA-9379 FnIO S-Series

6. Programing the PIO (CoDeSys)

6.1. Download and Install the CoDeSys

Please use the CoDeSys version V3.5.3.1 (V3.5 SP3 Patch 1)

Except for the above version, any versions including the latest version

will not be allowed for PIO(NA-9379).

Unzip the downloaded file, and Installation ‘Setup_CoDeSysV35SP3Patch1.exe’

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 37

37 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.2. The Basic Configuration CoDeSys

6.2.1. Installation of XML

(1) Run the CoDeSys program

(2) [Tools] [Options], Click ‘Predefined feature sets…’

(3) Standard Professional, Click ‘OK’

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 38

38 MODBUS Programmable I/O NA-9379 FnIO S-Series

(4) Click ‘OK’

(5) [Tools] [Device Repository], Click ‘PLCs’ and select PIO Description (download to CREVIS

website), Install…

(ProgrammableIO_NA9379.devdesc.xml)

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 39

39 MODBUS Programmable I/O NA-9379 FnIO S-Series

*Please check whether they are installed correctly or not.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 40

40 MODBUS Programmable I/O NA-9379 FnIO S-Series

(6) [Tools] [Device Repository], Click ‘Miscellaneous’ and install the slot description and I/O

Description (download to CREVIS website).

(ST-xxxx.devdesc.xml)

*Please check whether they are installed correctly or not.

(CVSRACK.devdesc.xml)

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 41

41 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.2.2. Created Project

(1) Run the CoDeSys program.

(2) [File] [New Project], select ‘Standard project’. Write the Project Name and Location.

Click ‘OK’

(3) Select Device : NA9379, select the Programming Language.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 42

42 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.2.3. CoDeSys User Interface

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 43

43 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.2.4. Setup I/O

(1) Additional Device

Click on the model you want to use, and click ‘Plug Device’.

For the normal operation, you must select the module image in order through the CoDeSys

like the user configuration.

Auto Scan is not supported.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 44

44 MODBUS Programmable I/O NA-9379 FnIO S-Series

(2) Setting Device Parameter and IO Mapping

Click IO Right click Click ‘Edit object’.

• Parameter setting

Click ‘Digital IOs Configuration’

* The setting unit of the parameter is bytes.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 45

45 MODBUS Programmable I/O NA-9379 FnIO S-Series

• IO Mapping

Click ‘Digital IOs I/O Mapping’

If there are no set values in the red square, you can program the variable area set by the address.

If you use the variable set by the POU or GVL, you can use the variable area after deleting the variable in the

address.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 46

46 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.3. MODBUS TCP Setting

(1) Add Device

Click Device(NA9379) right click Click ‘Add Device…’.

(2) Add Ethernet Adapter

Click ‘Fieldbus’ ‘Ethernet Adapter’ ‘Ethernet’ and ‘Add Device’ Click.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 47

47 MODBUS Programmable I/O NA-9379 FnIO S-Series

(3) Add Device after Selecting Ethernet and Add MODBUS TCP Master

Click Ethernet (Ethernet) right click Click ‘Add Device’

Click ‘Fieldbuses’ ‘Modbus TCP Master’ ‘Modbus TCP Master’ and ‘Add Device’ Click.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 48

48 MODBUS Programmable I/O NA-9379 FnIO S-Series

(4) Add Device after adding MODBUS TCP Master and Add Modbus TCP Slave

Click Modbus_TCP_Master right click Click ‘Add Device’

Click ‘Fieldbuses’ ‘Modbus’ ‘Modbus TCP Slave’ ‘Modbus TCP Slave’ and ‘Add Device’ Click.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 49

49 MODBUS Programmable I/O NA-9379 FnIO S-Series

(5) Configuration the ModbusTCP Slave

Click ‘Modbus_TCP_Slave’(Modbus TCP Slave)

Write Slave IP Address (NA-9379)

Click ‘Modbus Slave Channel’

Add a channel of NA-9379 and Modify Cycle Time

* Default Cycle Time(ms) : 100ms.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 50

50 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.4. Network Variable

(1) Click ‘Application’ Right click and click ‘Add Object’ Click ‘Network Variable List (Sender)’.

* You have to add one more devices in the devices tree.

(2) Define the network properties of the sender GVL

* You have to select UDP as network type.

* List identifier and Node ID is the same concept.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 51

51 MODBUS Programmable I/O NA-9379 FnIO S-Series

(3) Add a Global Network Variable List in the Receiver

* You find a selection list of all GVLs with network properties currently available in the project.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 52

52 MODBUS Programmable I/O NA-9379 FnIO S-Series

(4) Created by Global Variables.

(5) It is possible to create a program using a global variable.

- in prog_sender in the sender application enter the following use of variable iglobvar.

- in prog_Receiver in the receiver application also use variable iglobvar.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 53

53 MODBUS Programmable I/O NA-9379 FnIO S-Series

6.5. Download and Monitoring

(1) Scan network

[Device] [Communication Settings], click ‘Scan network’.

After completing the search, double click the Gateway icon to make it activated.

(2) Login

[Online] [Login] Download to Application Entry into Monitoring Mode [Debug] [RUN]

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 54

54 MODBUS Programmable I/O NA-9379 FnIO S-Series

7. Upgrade Firmware

7.1. Using IAP over Ethernet

Using Firefox, can download the firmware.

(1) Apply a power with pushing a reset button.

(2) Execute Firefox

(3) Connect to 192.168.100.10 and login (User ID :1 / Password : 1)

(4) Search the file to download using a search button.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 55

55 MODBUS Programmable I/O NA-9379 FnIO S-Series

(5) Click a Upload Button.

(6) If it finish, you can see a below message (File Upload Done!)

And click a ‘reset mcu’ button.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 56

56 MODBUS Programmable I/O NA-9379 FnIO S-Series

LED Status

Cause

Action

All LED turns off

- No power

- Check main power Cable

- System power is not supplied.

- Contact Sales team and send module

for repair.

MOD LED flashes green

- Failure of initialization EEPROM

parameter.

- Contact Sales team and send module

for repair.

MOD LED flashes red

- Excess of expansion slot

- Excess of IO size

- Wrong IO composition

- Occurrence of EEPROM checksum

error

- Use expansion slot up to 32.

- Compose that IO total size is not

excess.

- Check composition I/O Module

MOD LED is red

- Wrong address ID

- Occurrence critical error in firmware

- Contact Sales team and send module

for repair.

I/O LED turns off

- Failure of realization expansion Module

- None expansion Module

- Check connector status both NA

series and expansion module.

I/O LED flashes red

-Failure of configuration baud rate

- Check communication cable with

Master

- Check power for master.

-Failure of initialization I/O

- Use expansion slot up to 32.

- Compose that IO total size is not

excess.

NA series notice unidentified

expansion module ID. Check status of

expansion module.

I/O LED is red

-Failure of exchanging I/O data

Check status of expansion IO

connection.

RUN LED flashed red

-Failure of Module Configuration

Check the module hardware and

software configurations are the same.

8. Trouble Shooting

8.1. How to diagnose by LED indicator

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 57

57 MODBUS Programmable I/O NA-9379 FnIO S-Series

8.2. How to diagnose when device couldn’t communicate network

Inspection of wrong or omission cable connection.

- Check status of cable connection for each node.

- Check that all color matches between connector and cable.

- Check wire omission.

Terminator resistor

- If terminator resistor is not installed, install terminator resistor

- Check location of terminator resistor

Configuration of Node address

- Check duplication node address.

Configuration of Master

- Check configuration of master

- Check whether to do download or don’t

- Check composition is right

Configuration of communication baudrate

I/O size

Configuration of each node

Ground and environment

- Check ground is contacted

- Check environment factor (temperature, humidity, etc.) is in less than regular limit

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 58

58 MODBUS Programmable I/O NA-9379 FnIO S-Series

Start Address

Read/Write

Description

Func. Code

0x0000 ~

Read

Process input image registers (Real Input Register)

4, 23

0x0800 ~

Read/Write

Process output image registers (Real Output Register)

3, 16, 23

0x1000 ~

Read

Adapter Identification special registers.

3, 4, 23

0x1020 ~

Read/Write

Adapter Watchdog, other time special register.

3, 4, 6, 16,

23

0x1100 ~

Read/Write

Adapter Information special registers.

3, 4, 6, 16,

23

0x2000 ~

Read/Write

Expansion Slot Information special registers.

3, 4, 6, 16,

23

Start Address

Read/Write

Description

Func. Code

0x0000 ~

Read

Process input image bits

All input registers area is addressable by bit address.

Size of input image bit is size of input image register * 16.

2

0x0800 ~

Read/Write

Process output image bits

All output registers area is addressable by bit address.

Size of output image bit is size of output image register * 16.

1, 5, 15

APPENDIX A - MODBUS INTERFACE

A.1 MODBUS Interface Register / Bit Map

• Register Map

• Bit Map

* The special register map must be accessed by read/write of every each address (one address).

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 59

59 MODBUS Programmable I/O NA-9379 FnIO S-Series

Start

Address

Function

Data

CRC Check

End

≥ 3.5 chars

1 char

1 char

Up to 252 chars

2 chars

≥ 3.5 chars

Start

Address

Function

Data

CRC Check

End

1 char

2 chars

2 chars

Up to 252 chars

2 chars

2 chars CR,LF

Function Code

Function

Description

Unicast / Broadcast

1 (0x01)

Read Coils

Read output bit

Unicast

2 (0x02)

Read Discrete Inputs

Read input bit

Unicast

3 (0x03)

Read Holding Registers

Read output word

Unicast

4 (0x04)

Read Input Registers

Read input word

Unicast

5 (0x05)

Write Single Coil

Write one bit output

Unicast / Broadcast

6 (0x06)

Write Single Register

Write one word output

Unicast / Broadcast

8 (0x08)

Diagnostics (Serial Line only)

Read diagnostic register

Unicast

15 (0x0F)

Write Multiple Coils

Write a number of output bits

Unicast / Broadcast

16 (0x10)

Write Multiple registers

Write a number of output words

Unicast / Broadcast

23 (0x17)

Read / Write Multiple register

Read a number of input words /

Write a number of output words

Unicast

A.2 MODBUS Transmission Mode

Two different serial transmission modes are defined: The RTU mode and the ASCII mode. It defines the bit

contents of message fields transmitted serially on the line. It determines how information is packed into the

message fields and decoded.

A.2.1. RTU Transmission Mode

When devices communicate on a MODBUS serial line using the RTU (Remote Terminal Unit) mode, each 8–bit

byte in a message contains two 4–bit hexadecimal characters. The main advantage of this mode is that its greater

character density allows better data throughput than ASCII mode for the same baudrate. Each message must be

transmitted in a continuous stream of characters.

A.2.2. ASCII Transmission Mode

When devices are setup to communicate on a MODBUS serial line using ASCII (American Standard Code for

Information Interchange) mode, each 8–bit byte in a message is sent as two ASCII characters. This mode is used

when the physical communication link or the capabilities of the device does not allow the conformance with RTU

mode requirement regarding timers management.

A.3 Supported MODBUS Function Codes

- Refer to MODBUS APPLICATION PROTOCOL SPECIFICATION V1.1a

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 60

60 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x01

0x01

“01”

0x30, 0x31

Starting Address Hi

0x10

0x10

“10”

0x31, 0x30

Starting Address Lo

0x00

0x00

“00”

0x30, 0x30

Quantity of Outputs Hi

0x00

0x00

“00”

0x30, 0x30

Quantity of Outputs Lo

0x0A

0x0A

“0A”

0x30, 0x41

Error Check (CRC/LRC)

-

0xB8, 0xAB

“DE”

0x44, 0x45

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x01

0x01

“01”

0x30, 0x31

Byte Count

0x02

0x02

“02”

0x30, 0x32

Output Status

0x55

0x55

“55”

0x35, 0x35

Output Status

0x02

0x02

“02”

0x30, 0x32

Error Check (CRC/LRC)

-

0x8F, 0x6D

“9F”

0x39, 0x46

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

A.3.1. 1 (0x01) Read Coils

This function code is used to read from 1 to 2000 contiguous status of coils in a remote device. The Request PDU

specifies the starting address, i.e. the address of the first coil specified, and the number of coils. In the PDU Coils

are addressed starting at zero. Therefore coils numbered 1-16 are addressed as 0-15. The coils in the response

message are packed as one coil per bit of the data field. Status is indicated as 1= ON and 0= OFF.

• Request

• Response

* In case of address 0x1015~0x1000 output bit value: 00000010_01010101.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 61

61 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x02

0x02

“02”

0x30, 0x32

Starting Address Hi

0x00

0x00

“00”

0x30, 0x30

Starting Address Lo

0x00

0x00

“00”

0x30, 0x30

Quantity of Inputs Hi

0x00

0x00

“00”

0x30, 0x30

Quantity of Inputs Lo

0x0A

0x0A

“0A”

0x30, 0x41

Error Check (CRC/LRC)

-

0xF8, 0x6B

“ED”

0x45, 0x44

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x02

0x02

“02”

0x30, 0x32

Byte Count

0x02

0x02

“02”

0x30, 0x32

Input Status

0x80

0x80

“80”

0x38, 0x30

Input Status

0x00

0x00

“00”

0x30, 0x30

Error Check (CRC/LRC)

-

0x50, 0x78

“75”

0x37, 0x35

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

A.3.2. 2 (0x02) Read Discrete Inputs

This function code is used to read from 1 to 2000 contiguous status of discrete inputs in a remote device. The

Request PDU specifies the starting address, i.e. the address of the first input specified, and the number of inputs. In

the PDU Discrete Inputs are addressed starting at zero. Therefore Discrete inputs numbered 1-16 are addressed as

0-15. The discrete inputs in the response message are packed as one input per bit of the data field.

Status is indicated as 1= ON; 0= OFF.

• Request

• Response

- In case of address 0x0015~0x0000 output bit value: 00000000_10000000.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 62

62 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x03

0x03

“03”

0x30, 0x33

Starting Address Hi

0x08

0x08

“08”

0x30, 0x38

Starting Address Lo

0x00

0x00

“00”

0x30, 0x30

Quantity of Register Hi

0x00

0x00

“00”

0x30, 0x30

Quantity of Register Lo

0x02

0x02

“02”

0x30, 0x32

Error Check (CRC/LRC)

-

0xC6, 0x0D

“EC”

0x45, 0x43

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x03

0x03

“03”

0x30, 0x33

Byte Count

0x04

0x04

“04”

0x30, 0x34

Output Register #0 Hi

0x11

0x11

“11”

0x31, 0x31

Output Register #0 Lo

0x22

0x22

“22”

0x32, 0x32

Output Register #1 Hi

0x33

0x33

“33”

0x33, 0x33

Output Register #1 Lo

0x44

0x44

“44”

0x34, 0x34

Error Check (CRC/LRC)

-

0x2D, 0xC6

“38”

0x33, 0x38

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

A.3.3. 3 (0x03) Read Holding Registers

This function code is used to read the contents of a contiguous block of holding registers in a remote device. The

Request PDU specifies the starting register address and the number of registers.

The register data in the response message are packed as two bytes per register, with the binary contents right

justified within each byte. For each register, the first byte contains the high order bits and the second contains the

low order bits.

• Request

• Response

- In case of address 0x0800, 0x0801 output register value: 0x1122, 0x3344.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 63

63 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x04

0x04

“04”

0x30, 0x34

Starting Address Hi

0x00

0x00

“00”

0x30, 0x30

Starting Address Lo

0x00

0x00

“00”

0x30, 0x30

Quantity of Register Hi

0x00

0x00

“00”

0x30, 0x30

Quantity of Register Lo

0x02

0x02

“02”

0x30, 0x32

Error Check (CRC/LRC)

-

0x71, 0xAD

“F3”

0x46, 0x33

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x04

0x04

“04”

0x30, 0x34

Byte Count

0x04

0x04

“04”

0x30, 0x34

Input Register #0 Hi

0x00

0x00

“00”

0x30, 0x30

Input Register #0 Lo

0x80

0x80

“80”

0x38, 0x30

Input Register #1 Hi

0x00

0x00

“00”

0x30, 0x30

Input Register #1 Lo

0x00

0x00

“00”

0x30, 0x30

Error Check (CRC/LRC)

-

0x9C, 0x6C

“71”

0x37, 0x31

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

A.3.4. 4 (0x04) Read Input Registers

This function code is used to read from 1 to approx. 125 contiguous input registers in a remote device. The

Request PDU specifies the starting register address and the number of registers. The register data in the response

message are packed as two bytes per register, with the binary contents right justified within each byte. For each

register, the first byte contains the high order bits and the second contains the low order bits.

• Request

• Response

- In case of address 0x0000, 0x0001 input register value: 0x0080, 0x0000.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 64

64 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x05

0x05

“05”

0x30, 0x35

Starting Address Hi

0x10

0x10

“10”

0x31, 0x30

Starting Address Lo

0x01

0x01

“01”

0x30, 0x31

Quantity of Outputs Hi

0xFF

0xFF

“FF”

0x46, 0x46

Quantity of Outputs Lo

0x00

0x00

“00”

0x30, 0x30

Error Check (CRC/LRC)

-

0xD9, 0x5C

“E4”

0x45, 0x34

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x05

0x05

“05”

0x30, 0x35

Output Address Hi

0x10

0x10

“10”

0x31, 0x30

Output Address Lo

0x01

0x01

“01”

0x30, 0x31

Output Value Hi

0xFF

0xFF

“FF”

0x46, 0x46

Output Value Lo

0x00

0x00

“00”

0x30, 0x30

Error Check (CRC/LRC)

-

0xD9, 0x5C

“E4”

0x45, 0x34

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

A.3.5. 5 (0x05) Write Single Coil

This function code is used to write a single output to either ON or OFF in a remote device. The requested ON/OFF

state is specified by a constant in the request data field. A value of FF 00 hex requests the output to be ON. A value

of 00 00 requests it to be OFF. All other values are illegal and will not affect the output.

• Request

• Response

- Output bit of address 0x1001 turns ON.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 65

65 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x06

0x06

“06”

0x30, 0x36

Starting Address Hi

0x08

0x08

“08”

0x30, 0x38

Starting Address Lo

0x00

0x00

“00”

0x30, 0x30

Quantity of Outputs Hi

0x11

0x11

“11”

0x31, 0x31

Quantity of Outputs Lo

0x22

0x22

“22”

0x32, 0x32

Error Check (CRC/LRC)

-

0x07, 0x85

“B8”

0x42, 0x38

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x06

0x06

“06”

0x30, 0x36

Output Address Hi

0x08

0x08

“08”

0x31, 0x38

Output Address Lo

0x00

0x00

“00”

0x30, 0x30

Output Value Hi

0x11

0x11

“11”

0x31, 0x31

Output Value Lo

0x22

0x22

“22”

0x32, 0x32

Error Check (CRC/LRC)

-

0x07, 0x85

“B8”

0x42, 0x38

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

A.3.6. 6 (0x06) Write Single Register

This function code is used to write a single holding register in a remote device. Therefore register numbered 1 is

addressed as 0. The normal response is an echo of the request, returned after the register contents have been

written.

• Request

• Response

- In case of address 0x0800 outputs register value: 0x0000 changes to 0x1122.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 66

66 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x08

0x08

“08”

0x30, 0x38

Sub-Function Hi

0x00

0x00

“00”

0x30, 0x30

Sub-Function Lo

0x00

0x00

“00”

0x30, 0x30

Data Hi

0x11

0x11

“11”

0x31, 0x31

Data Lo

0x22

0x22

“22”

0x32, 0x32

Error Check (CRC/LRC)

-

0x6C, 0x24

“BE”

0x42, 0x45

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x08

0x08

“08”

0x30, 0x38

Sub-Function Hi

0x00

0x00

“00”

0x30, 0x30

Sub-Function Lo

0x00

0x00

“00”

0x30, 0x30

Data Hi

0x11

0x11

“11”

0x31, 0x31

Data Lo

0x22

0x22

“22”

0x32, 0x32

Error Check (CRC/LRC)

-

0x6C, 0x24

“BE”

0x42, 0x45

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

A.3.7. 8 (0x08) Diagnostics

MODBUS function code 08 provides a series of tests for checking the communication system between a client

(Master) device and a server (Slave), or for checking various internal error conditions within a server.

The function uses a two–byte sub-function code field in the query to define the type of test to be performed. The

server echoes both the function code and sub-function code in a normal response. Some of the diagnostics cause

data to be returned from the remote device in the data field of a normal response.

• Request

• Response

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 67

67 MODBUS Programmable I/O NA-9379 FnIO S-Series

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0000(0)

Any

Echo Request Data

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0001(1)

0x0000, 0xFF00

Echo Request Data

Reset

0x0001(1)

0x55AA

Echo Request Data

Reset with Factory Default*

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000A(10)

0x0000

Echo Request Data

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000B(11)

0x0000

Total Message Count

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000C(12)

0x0000

CRC Error Count

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000D(13)

0x0000

Exception Error Count

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000E(14)

0x0000

Slave Message Count

Sub-function 0x0000(0) Return Query Data

The data passed in the request data field is to be returned (looped back) in the response.

The entire response message should be identical to the request.

Sub-function 0x0001(1) Restart Communications Option

The remote device could be initialized and restarted, and all of its communications event counters are cleared.

Especially, data field 0x55AA makes the remote device to restart with factory default setup of EEPROM.

*All expansion slot configuration parameters are cleared.

Sub-function 0x000A(10) Clear Counters and Diagnostic Register

The goal is to clear all counters and the diagnostic register. Counters are also cleared upon power–up.

Sub-function 0x000B(11) Return Bus Message Count

The response data field returns the quantity of messages that the remote device has detected on the

communications system since its last restart, clear counters operation, or power–up.

Sub-function 0x000C(12) Return Bus Communication Error Count

The response data field returns the quantity of CRC errors encountered by the remote device since its last restart,

clear counters operation, or power–up.

Sub-function 0x000D(13) Return Bus Exception Error Count

The response data field returns the quantity of MODBUS exception responses returned by the remote device since

its last restart, clear counters operation, or power–up.

Exception responses are described and listed in section 6.2.11.

Sub-function 0x000E(14) Return Slave Message Count

The response data field returns the quantity of messages addressed to the remote device, or broadcast, that the

remote device has processed since its last restart, clear counters operation, or power–up.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 68

68 MODBUS Programmable I/O NA-9379 FnIO S-Series

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000F(15)

0x0000

Slave No Response Count

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0064(100)

0x0000

MODBUS,

Extension module Status

Same as status 1word

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0065(101)

0x0000

Watchdog Error Count

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0066(102)

0x0000

Echo Request Data

Ready output,

Automatically turns

Normal output

0x0066(102)

0x0001, 0x0002, 0x0003

Echo Request Data

Clear output

0x0066(102)

0x0004

Echo Request Data

Normal output

0x0066(102)

0x0005, 0x0006, 0x0007

Echo Request Data

Fault output

Sub-function 0x000F(15) Return Slave No Response Count

The response data field returns the quantity of messages addressed to the remote device for which it has returned no

response (neither a normal response nor an exception response), since its last restart, clear counters operation, or power–up.

Sub-function 0x0064(100) Return Slave MODBUS, Extension module Status

The response data field returns the status of MODBUS and Extension module addressed to the remote device.

This status values are identical with status 1word of input process image. Refer to 5.3.1.

Sub-function 0x0065(101) Return Slave MODBUS, Error Count

The response data field returns the quantity of watchdog error addressed to the remote device since its last restart,

clear counters operation, or power–up.

Sub-function 0x0066(102) Change Slave IO Output Status

The sub-function with data fields is to clear watchdog counter and change IO output status. This may be used to simulate

Clear output and fault output.

Copyright(C) CREVIS Co.,Ltd Support +82-31-899-4599 URL : www.crevis.co.kr

Page 69

69 MODBUS Programmable I/O NA-9379 FnIO S-Series

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x0F

0x0F

“0F”

0x30, 0x46

Starting Address Hi

0x10

0x10

“10”

0x31, 0x30

Starting Address Lo

0x00

0x00

“00”

0x30, 0x30

Quantity of Outputs Hi

0x00

0x00

“00”

0x30, 0x30

Quantity of Outputs Lo

0x0A

0x0A

“0A”

0x30, 0x41

Byte Count

0x02

0x02

“02”

0x30, 0x32

Output Value #0

0x55

0x55

“55”

0x35, 0x35

Output Value #1

0x01

0x01

“01”

0x30, 0x31

Error Check (CRC/LRC)

-

0x21, 0XC9

“78”

0x37, 0x38

End of Frame

-

t1-t2-t3

CR, LF

0x0D, 0xA

Field name

Example

RTU

ASCII

ASCII (bus line)

Start of Frame

-

t1-t2-t3

“,”

0x3A

Slave Address

0x07

0x07

“07”

0x30, 0x37

Function Code

0x0F

0x0F

“0F”

0x30, 0x46

Starting Address Hi

0x10

0x10

“10”

0x31, 0x30

Starting Address Lo

0x00

0x00

“00”

0x30, 0x30

Quantity of Outputs Hi