Page 1

M70

Installation Manual

MAEN843A 2007-12

English

Page 2

Foreword

M70 Installation Manual

Foreword

The handheld operator panel M70 is a portable operating and display device with

rugged design and Windows-CE compatible electronics.

Using a high-performance Intel PXA270 processor and providing a serial interface

or Ethernet, the M70 is ideal for a great variety of applications.

The touch screen and graphic elements in color offer intuitive operation.

High safety is ensured by the emergency stop switch and the enabling switch.

© Beijer Electronics AB, MAEN843A, 2007-12

The information in this document is subject to change without notice and is provided as available at the time

of printing. Beijer Electronics AB reserves the right to change any information without updating this

publication. Beijer Electronics AB assumes no responsibility for any errors that may appear in this document.

Read the entire installation manual prior to installing and using this equipment.

Only qualified personnel may install, operate or repair this equipment. Beijer Electronics AB is not

responsible for modified, altered or renovated equipment.

Because the equipment has a wide range of applications, users must acquire the appropriate knowledge to use

the equipment properly in their specific applications.

Persons responsible for the application and the equipment must themselves ensure that each application is in

compliance with all relevant requirements, standards and legislation in respect to configuration and safety.

Only parts and accessories manufactured according to specifications set by Beijer Electronics AB may be used.

BEIJER ELECTRONICS AB SHALL NOT BE LIABLE TO ANYONE FOR ANY DIRECT, INDIRECT,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE INSTALLATION, USE OR REPAIR OF THIS EQUIPMENT, WHETHER ARISING IN TORT, CONTRACT, OR

OTHERWISE. BUYER'S SOLE REMEDY SHALL BE THE REPAIR, REPLACEMENT, OR REFUND

OF PURCHASE PRICE, AND THE CHOICE OF THE APPLICABLE REMEDY SHALL BE AT THE

SOLE DISCRETION OF BEIJER ELECTRONICS AB.

Beijer Electronics, MAEN843A

Page 3

Contents

Contents

1 Safety Precautions................................................................................... 5

1.1 General ........................................................................................5

1.2 During Use..................................................................................6

1.3 Service and Maintenance..............................................................7

1.4 Dismantling and Scrapping..........................................................7

2 Hazard and Risk Analysis........................................................................ 8

3 Description of Parts................................................................................9

4 Connection........................................................................................... 10

4.1 Cable Entrance Area ..................................................................10

4.2 RS232C Connection..................................................................12

4.3 Ethernet Connection .................................................................13

5 Emergency Stop....................................................................................15

6 Enabling Switch.................................................................................... 16

6.1 Examples of Connecting the Enabling Switch to Hardware........ 17

7 Touch Screen ........................................................................................19

7.1 Screen Saver............................................................................... 19

8 Key Switch............................................................................................20

8.1 Touch Screen Calibration...........................................................20

8.2 Service Menu .............................................................................20

9 USB Memory Sticks ............................................................................. 22

9.1 Connecting a USB Memory Stick..............................................22

9.2 Recommended USB Memory Sticks ..........................................22

10 Configuration Tool for the Operator Panels ......................................... 23

11 Start-up Procedure................................................................................ 24

11.1 Date and Time Handling in the M70 ........................................24

Beijer Electronics, MAEN843A

Page 4

Contents

12 Technical Data...................................................................................... 25

13 Outline Drawings .................................................................................29

14 Connection Box....................................................................................31

14.1 Technical Data of Connection Box.............................................32

14.2 Connecting M70 to Connection Box.........................................33

14.3 Interior View of Connection Box ...............................................34

14.4 Pin Description of X1 Terminal Block........................................35

14.5 Technical Data of the Connection Terminals..............................35

15 Cables and Accessories ..........................................................................37

15.1 Connection Cable ......................................................................37

15.2 Wall Mounting Kit.....................................................................37

Beijer Electronics, MAEN843A

Page 5

Safety Precautions

1 Safety Precautions

Both the installer and the owner and/or operator of the handheld operator panel

must read and understand this installation manual.

1.1 General

– Only qualified personnel may install or operate the handheld operator panel.

– The handheld operator panel must be installed according to the installation

instructions.

– The handheld operator panel is designed for installation where the following

conditions are fulfilled:

• no high explosive risks

• no strong magnetic fields

•no direct sunlight

• no large, sudden temperature changes

– Never allow fluids, metal filings or wiring debris to enter any openings in the

handheld operator panel. This may cause fire or electrical shock.

– The handheld operator panel fulfills the requirements of article 4 of EMC

directive 89/336/EEC.

– The handheld operator panel meets the protective class III in accordance with

EN61131-2 and EN50178.

– When connecting the handheld operator panel, make sure that all voltages

connected to the handheld operator panel are safety extra low voltages and

isolated from the low voltage supply system by a safety transformer or a similar facility. All supply circuits connected to the handheld operator panel must

be protected with a fuse of a maximum of 3.15 A.

– Storing the handheld operator panel where the temperature is lower/higher

than recommended in this manual can cause the LCD display liquid to

congeal/become isotopic.

– The LCD display liquid contains a powerful irritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open, flush with plenty of water and get medical attention.

– The supplier is not responsible for modified, altered or reconstructed

equipment.

Beijer Electronics, MAEN843A 5

Page 6

Safety Precautions

– Use only parts and accessories manufactured according to specifications of the

supplier.

– Peripheral equipment must be appropriate for the application and location.

– The figures in this manual serves an illustrative purpose. Because of the many

variables associated with any particular installation, the supplier cannot

assume responsibility for actual use based on the figures.

– The supplier neither guarantees that the handheld operator panel is suitable

for your particular application, nor assumes responsibility for your product

design, installation or operation.

1.2 During Use

– Keep the handheld operator panel clean.

– Do not use too much force or sharp objects when touching the keys, display

etc.

– Do not lay the handheld operator panel down with the operating side facing

down, since this may cause unintentional activation of the handheld operator

panel, or damage the operating elements.

Emergency Stop Button

– Not fully functional emergency stop devices may have fatal consequences!

Emergency stop switches which are red-yellow marked must be effective

under all circumstances in all operating modes of a machine or plant.

– Store handheld panels with not operational red-yellow emergency stop

switches on a place where the operator cannot see it, so that he cannot mistake

the device.

– Resetting an activated emergency stop facility must not result in uncontrolled

start-up of machines or installations.

– The emergency stop button does not replace other safety facilities.

– The emergency stop button on the handheld operator panel does not replace

the emergency stop buttons to be mounted directly on the machine.

– Some mechanical errors in emergency stop switches can be recognized at

operation only.

– Test the function of the emergency stop switch if the handheld operator panel

has been exposed to mechanical shock (e.g. fallen on the ground).

6 Beijer Electronics, MAEN843A

Page 7

Safety Precautions

Enabling Switch

– The enabling switch is only suitable as safety function if the operator activat-

ing the enabling switch recognizes the dangerous situation in time so that he

can immediately take the necessary measures to avoid such situations.

– As additional measure reduced speed of the movement can be necessary. The

allowed speed must be determined by means of a risk assessment.

– The enabling switch is only used to enable commands for performing danger-

ous movements. The commands themselves must be activated by a separate

operating element (key on handheld operator panel).

– Only the person who operates the enabling switch is allowed to work in the

dangerous area.

Note:

The enabling switch is hardware dependent, and are separa ted from the soft ware

running in the operator panel. The panel will functio n no rmal ly, regardless of t he

status of the enabling switch. See section Enabling Switch for information.

1.3 Service and Maintenance

– Only qualified personnel should carry out repairs.

– The agreed warranty applies.

– Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

– Clean the display and surrounding front cover with a soft cloth and mild

detergent.

1.4 Dismantling and Scrapping

– The handheld operator panel or parts thereof shall be recycled according to

local regulations.

– The following components contain substances that might be hazardous to

health and the environment: electrolytic capacitor and display.

Beijer Electronics, MAEN843A 7

Page 8

Hazard and Risk Analysis

2 Hazard and Risk Analysis

For manual control of machines in special operating modes, where safety depends on the timely reaction of the operating staff, it is absolutely essential that

the operator can overlook the operating area.

The handheld operator panel has the advantage that the operator can get very

close to the control panel. At the same time, the danger of misuse increases with

mobility since, in remote locations where it is not possible to observe the operating area, machine movements can also be set in motion with the handheld operator panel, knowingly or unknowingly. The machine operator has to find the

right compromise between necessary flexibility and a reasonable limitation of

the working range when selecting the cable length for the handheld operator

panel.

If the machine or equipment is operated with the handheld operator panel, care

must be taken at this time to ensure that operation can only be controlled by the

handheld panel and cannot be operated from any other point on the equipment.

The hazard zone may only be entered by the person who is operating the handheld panel. If it should be necessary for more than one person to work in the

hazard zone at the same time, each person present requires an enabling device

and machinery movement may only be allowed after all the enabling devices

have been activated.

For the right projecting of the handheld operator panel, a hazard and risk analysis must be carried out. In addition to chapter 1 Safety Precautions, the following safety aspects is to be considered:

– Which is the correct cable length for limitation of work space?

– Is an emergency stop button necessary and permissible?

– Is the safety category for the application sufficient?

The handheld operator panel may be operated in faultless condition only and

the operating instructions must be observed.

Moving around with a cable connected device also requires consideration. To

avoid damage to the cable or the cable sheath, the cable must not be squeezed or

laid over sharp edges.

See also chapters 5 Emergency Stop and 6 Enabling Switch.

8 Beijer Electronics, MAEN843A

Page 9

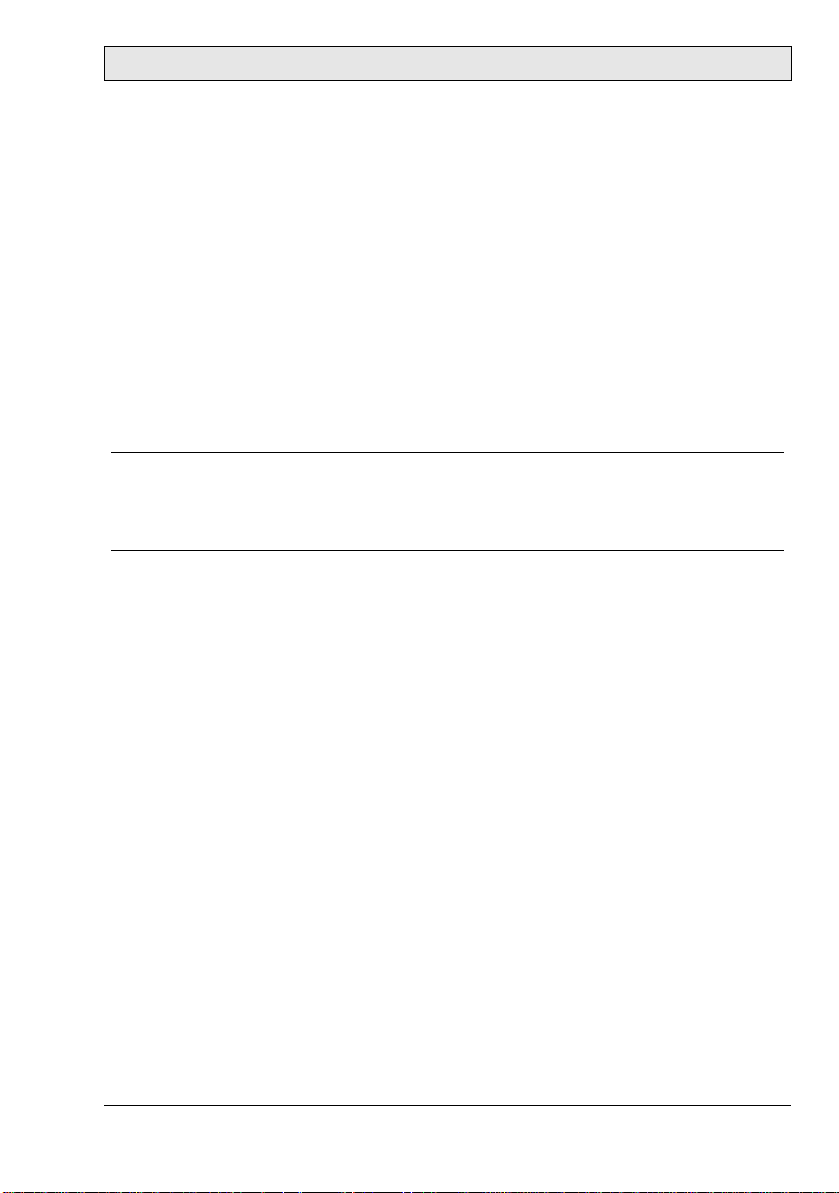

3 Description of Parts

Key switch

USB memory stick

protection cover

4 function keys

Power LED

Two 3-position enabling

switches, twin circuit

Description of Parts

Emergency stop switch

Touch stylus

(integrated in housing)

Color display with touch

screen

4 function keys

4 function keys

Multigrip handle

Cable entrance area

Blind plug for cable outlet not used

Strain relief and bend protection

for connection cable

(to meet protection degree IP 65)

Beijer Electronics, MAEN843A 9

Page 10

Connection

4 Connection

4.1 Cable Entrance Area

RS-232-C (S11)

for data exchange

Summer

S11

Main Plug (S22)

Powersupply,

Enabling device,

E-Stop

Sealing Plug

Must be used

to ensure

impermeability!

1

S20

B4H1B3

Serien-Art.-Nr. E tikett

USB-Client (S12)

S12

B5 B2

CAS-220T B1

CAS-220TB1

S28

S10

Reset button

Restarts device.

All unsa ved data will be lost

Strain Relief of Cable

for connecting cable

(on left or right side).

ATTENTION:

Use blind plug on

cable outlet not used.

Dip switches

Configuration RS-422-A or RS-232-C

(default RS-422-A but only RS-232-C

is supported)

ETHERNET (S4)

for data exchange

S4

B1

Note:

When the cable entrance area is open, the M70 is sensitive to electrostatic discharge.

10 Beijer Electronics, MAEN843A

Page 11

Connection

Cable Routing in Cable Entrance Area

Cable routing makes it possible to adapt the M70 to suit either a right- or lefthanded user better.

After opening the cable entrance area, the connecting lines can be routed as described in the following section. Before opening the M70 please pay attention

to the safety instructions below.

Instructions for opening the cable entrance area:

– Place the M70 with the display facing down onto a plane and clean table

(preferable on ESD pad) and take care not to damage the M70 and its operating elements.

– For opening and closing the cable entrance area a Phillips size 2 screwdriver

is used.

Instructions for modifications in the cable entrance area:

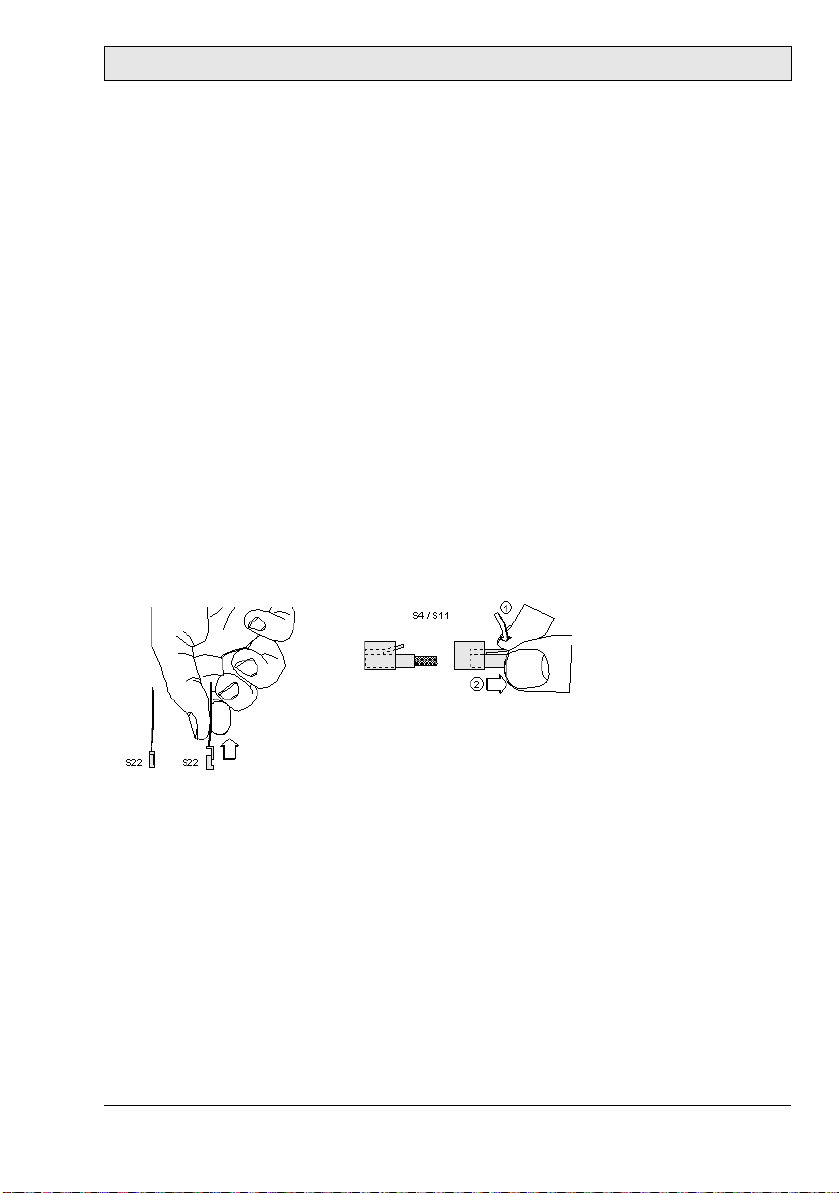

– Unplug the main connector (S22) by pulling on its wires with your fingers.

Do not use any sharp objects.

– For unplugging the RJ-45 jack (S11or S4), actuate the locking lever:

Make sure that the connectors S22 and S4 / S11 correctly snap in when you plug

them in. Otherwise the emergency stop functionality (S22) or the correct shielding (S4 / S11) might not be given anymore.

Instructions for closing the cable entrance area:

– Make sure that the sealing is clean, not damaged and correctly positioned in

the cable entrance area.

– Make sure that no cables are squeezed in.

– Make sure that the cover of the cable entrance area is attached again with all

6 screws (torque: 0.4 - 0.5 Nm).

Otherwise the protection degree cannot be guaranteed.

Beijer Electronics, MAEN843A 11

Page 12

Connection

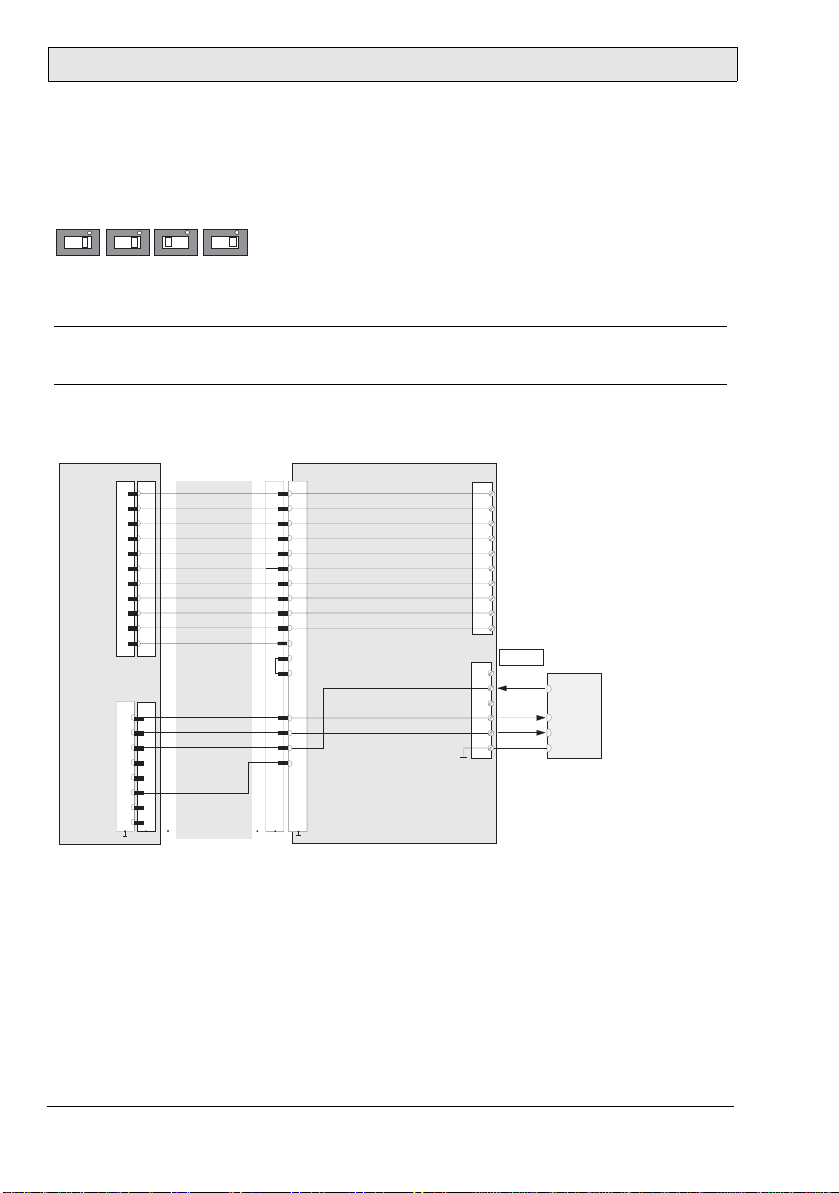

4.2 RS232C Connection

The serial interface is used as an RS232C interface. The dip switches has to be

set according to below for RS232C communication:

B5

B4 B2B3

The COM-SIO connector S11 in the cable entrance area of the M70 is used.

Note:

The RS232C connection cannot be used simultaneously with an Ethernet connection.

4.2.1 RS232C Wiring Diagram

TxD

RTS

RxD

M70

S22 K3

S6

6

7

8

9

10

11

1

2

3

4

5

K2

1

2

3

6

Connection cable

CABTTxxx

pink

black

brown-green

white-green

grey-pink

red-blue

brown

yellow

green

grey

violet

blue

white

orange

red

K1

K1

1

2

3

4

5

6

7

8

12

17

11

9

10

S1

1

13

14

15

16

Connection box CB211

E-STOP_ES1+

E-STOP_ES2+

ENABLE_ED1+

ENABLE_ED1-

ENABLE_ED2+

ENABLE_ED2-

+24 V DC

GND

E-STOP_ES1-

E-STOP_ES2-

RxD

TxD

RTS

SHIELD

X1

1

24 VDC

GND_IN

2

3

Emergency stop, circuit 1

Emergency stop, circuit 1

4

5

Emergency stop, circuit 2

6

Emergency stop, circuit 2

7

Enabling switch, circuit 1, pos.

8

Enabling switch, circuit 1, neg.

9

Enabling switch, circuit 2, pos.

10

Enabling switch, circuit 2, neg.

RS-232-C

X3

1

2

3

4

5

6

External device

TxD

RxD

CTS

GND

12 Beijer Electronics, MAEN843A

Page 13

Connection

4.2.2 RS232C Cable Outlet

The drawing below illustrates the cable outlet when the RS232C interface is

used.

S12

1

S20

B4H1B3B5

B2

CAS-220TB1B1CAS-220TB1

Serien-Art.-Nr. Etikett

S11

S10

right left

S4

S28

S12

1

S20

B5

B4H1B3

B2

CAS-220TB1

CAS-220TB1

Serien-Art.-Nr. Etikett

S11

S10

S4

S28

B1

4.3 Ethernet Connection

The M70 is equipped with an Ethernet interface based on the 10 Base T specification and suitable for half-duplex mode.

The Ethernet connector S4 (marked ETHERNET) in the cable entrance area of

the M70 is used.

The following interface parameters are defined and cannot be changed:

–10 Mbit/s

– TCP/IP protocol

If the M70 and the control do not communicate via a point-to-point connection, it may happen that the keypad data, for example, are transmitted with a

delay. To avoid this, it is advisable to establish the connection via an Ethernet

switch which enables a point-to-point connection.

The positions of the dip switches in the cable entrance area are not relevant for

this interface.

Note:

The Ethernet connection cannot be used simultaneously with an RS23 2C connection.

Beijer Electronics, MAEN843A 13

Page 14

Connection

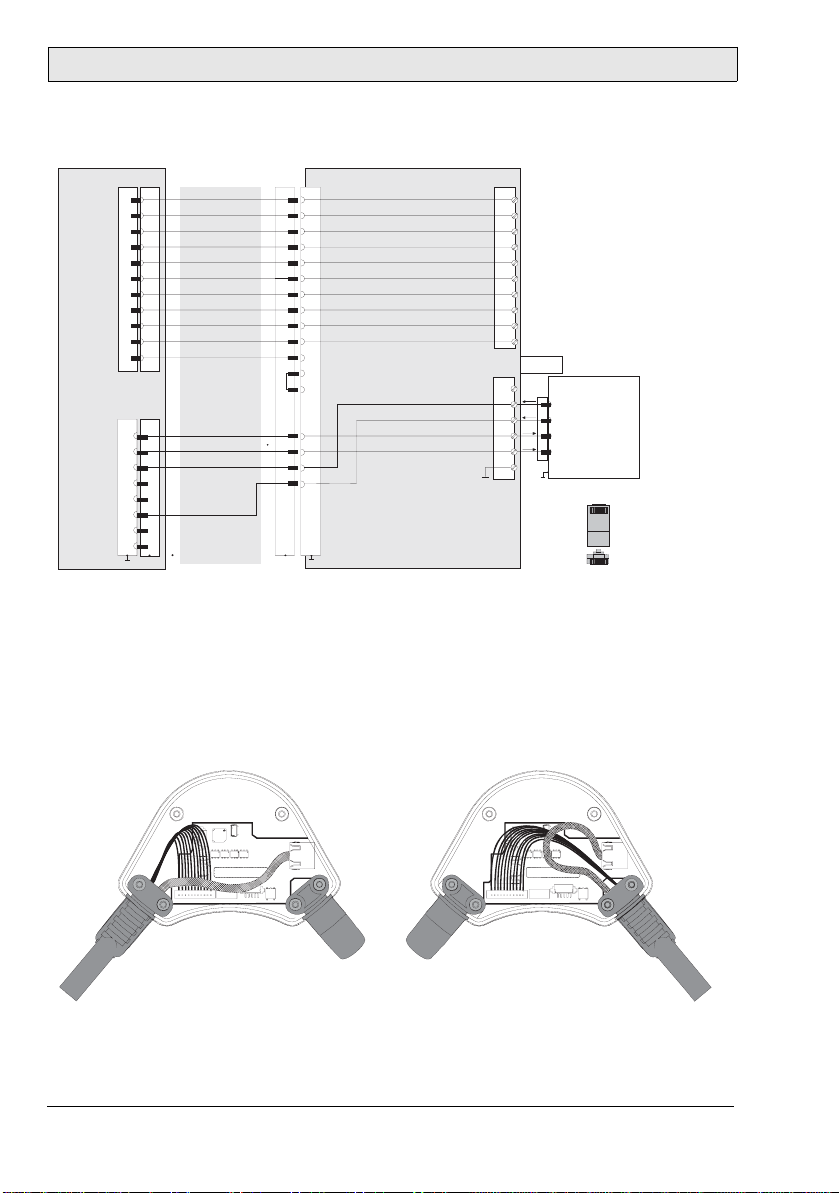

4.3.1 Ethernet Wiring Diagram

M70 Connection Box CB211

S22 K3

S4

TD+

TD-

RD+

RD-

6

7

8

9

10

11

1

2

3

4

5

K2

1

2

3

6

Connection cable

CABTTxxx

pink

black

brown-green

white-green

grey-pink

red-blue

brown

yellow

green

grey

violet

blue

white

orange

red

K1

K1

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

12

12

17

17

not used

11

11

9

not used

9

not used

10

10

E-STOP_ES1+

E-STOP_ES1-

E-STOP_ES2+

E-STOP_ES2-

ENABLE_ED1+

ENABLE_ED1-

ENABLE_ED2+

ENABLE_ED2-

S1

1

13

13

14

14

15

15

16

16

+24 V DC

GND

RD+

RDTD+

TD-

SHIELD)

X1

1

24 VDC

GND_IN

2

3

Emergency stop, circuit 1

Emergency stop, circuit 1

4

5

Emergency stop, circuit 2

6

Emergency stop, circuit 2

7

Enabling switch, circuit 1, pos.

8

Enabling switch, circuit 1, neg.

9

Enabling switch, circuit 2, pos.

10

Enabling switch, circuit 2, neg.

Ethernet

RJ45

External device

Hub / PC

3 (RD+) /

6 (RD-) /

1 (TD+) /

2 (TD-) /

X3

1

2

3

4

5

6

Pin numbering RJ45:

Top:

Front:

e.g.:

18

18

1 (TD+)

2 (TD-)

3 (RD+)

6 (RD-)

4.3.2 Ethernet Cable Outlet

The drawing below illustrates the cable outlet when the Ethernet interface is

used.

S12

1

S20

B4H1B3B5

B2

CAS-220TB1B1CAS-220TB1

S11

Serien-Art.-Nr. Etikett

S10

S4

S28

S12

1

S20

B5

B4H1B3 B2

CAS-220TB1

CAS-220TB1

S11

Serien-Art.-Nr. Etikett

S10

S4

S28

B1

right left

14 Beijer Electronics, MAEN843A

Page 15

Emergency Stop

5Emergency Stop

Not fully functional emergency stop devices may have fatal consequences!

Emergency stop switches which are red-yellow marked must be effective under

all circumstances in all operating modes of a machine or plant.

The emergency stop switch used on the M70 features two circuits. The contacts

are normally closed.

The emergency stop switch of the M70 meets the requirements of the EN 418.

It must be designed as an emergency stop of category 0 or category 1 (see EN

60204-1) on the basis of the risk assessment for the machine. The connection of

the positive-break contacts to an appropriate monitoring system must meet the

safety category which is defined by means of the risk assessment (in accordance

with EN 954-1) of the machine.

Please see chapter 1 Safety Precautions for safety precautions regarding the emergency stop switch.

Note for maintenance:

The emergency stop switch must be tested cyclic (every 6 months). Watch the

machine stopping after the emergency stop switch had been pushed.

The manufacturer guarantees a lifetime of > 50,000 switching cycles.

See also chapter 2 Hazard and Risk Analysis.

Beijer Electronics, MAEN843A 15

Page 16

Enabling Switch

6 Enabling Switch

The M70 is equipped with two enabling switches, one at the left and one at the

right side of the device. This allows a left- and right-hand operation of the enabling switch. Both enabling switches are equivalent and parallel switched,

which means that for enabling, only one of both enabling switches must be activated.

Note:

The enabling switches are hardware dependent, and are separated from the software running in the operator panel. The panel will function normally, regardless of

the status of the enabling switches.

Please see chapter 1 Safety Precautions for safety precautions regarding enabling

switches.

The enabling switch consists of a 3-position operating element and an separated

evaluation electronics. An essential feature are the continuous two-channel

circuits beginning from the actuating elements up to the connecting terminals.

For the evaluation circuits different technologies and circuits are used. Due to

the electronic switching contacts, their lifetime does not depend on the load provided the nominal values of the load (ohmic, inductive and capacitive) are not

exceeded.

The switching elements of the enabling switches are protected against reversed

polarity. The outputs of both circuits are protected against short circuits and

overload.

Circuit 1: thermal protective circuit

Circuit 2: fold back line

The actuating element consists of two symmetrically arranged slides. The position of these slides is detected by electrical switches and transmitted to the evaluation electronics.

Positions of enabling switch:

Position Function Enabling switch Contacts

1 Home position Not pressed Enabling outputs are open

2 Enabling Pressed Enabling outputs are closed

3 Panic Pressed strongly Enabling outputs are open

16 Beijer Electronics, MAEN843A

Page 17

Enabling Switch

6.1 Examples of Connecting the Enabling Switch to Hardware

Connection with PILZ PST1 Control Relay

M70

(2 enabling switches with

3 positions and 2 circuits each)

ZT

L

123

ZT

L1

ZT

321

R

ZT

R1

+24 VDC

F2

F3

F1

1A

A1(+) 23 S11

PILZ

PST1

A2(-)

GND

4A(t)

or

6A(f)

Feedback

control loop

KA KB

13

X1 X2

K1

K2

14 24 S23 S24

KA KB

GND GND

F4

4A(t)

3,15A

or

6A(f)

123

ZT

L2

DC/DC

converter

67

S19:

K3:

67

K3:

+24V GND ED1+ ED1- ED2+ ED2-

X1

X2

+24V GND ED1+ ED1- ED2+ ED2-K4:

S12

Evaluatio n electr onics

Circuit 1 Circuit 2

12 34

12 34

GND

321

Connection cab le

Terminal block socket K3

on connectio n box

Female connector X1

on connectio n box

Connection box

Male connector X2

on conncectio n bo x

Terminal block socket K4

on connectio n box

Note: All contacts of KA and KB must be forced-guided!

ZT

CAB TTxxx

L1 L2 L3

KA

KB

R2

Enabling of

dangerous

movement!

M

Beijer Electronics, MAEN843A 17

Page 18

Enabling Switch

Connection with ELAN SRB-NA-R-C.27/S1 Control Relay

M70

(2 enabling switches with

3 positions and 2 circuits each)

ZT

L

123

ZT

L1

ZT

321

R

ZT

R1

10

S4

10

S1

Rear side of

component

123

ZT

L2

DC/DC

converter

67

S19:

K3:

67

K3:

+24V GND ED1+ ED1- ED2+ ED2-

X1

X2

+24V GND ED1+ ED1- ED2+ ED2-K4:

+24VDC

Circuit 1 Circuit 2

12 34

12 34

GND

+24VDC

C1

C

F2

F1

D

L13

GND

Evaluation electr onics

KA KB

S11

S1K1K2

K3

L11

321

ZT

R2

Connection cable

CAB TTxxx

Terminal block socket K3

on connection box

Female connector X1

on connection box

Connection box

Male connector X2

on conncect ion box

Terminal block socket K4

on connection box

min. 0,3 mm² Cu

S21S13

S12

K1K1K2

D2

L14

Notes: 1) All co ntacts of KA and KB must be forced-guided.

13

S41

K3

K1

Short-circuit

detection

K2

S4

K3K2K1

K3

14 24

KA KB

2) S4 and S1 on the rear side of the component

L1

41

33

23

42

34

N

L1 L2 L3

KA

KB

Enabling of

dangerous

movement!

M

must be set to the position 0.

See also chapters 2 Hazard and Risk Analysis and 14.4 Pin Description of X1 Ter-

minal Block.

18 Beijer Electronics, MAEN843A

Page 19

Tou c h S cr e en

7Touch Screen

The touch screen is to be operated with a finger or with the included touch stylus. Never use sharp objects, such as a screwdriver, for operating the touch

screen.

The touch screen is already calibrated when the M70 is delivered.

If a recalibration is required for any reason (humidity of air, temperature, etc.),

turn the key to the left, and follow the instructions on displayed on the screen.

It is also possible to use the Service Menu for calibration. See section 8.2 Service

Menu.

7.1 Screen Saver

To extend the lifetime of the background lighting the screen saver is activated

after 15 minutes.

It is possible to set a different screen saver activation time, or to disable it, under

Setup/Terminal Options in the configuration tool for the operator panels.

Note:

The screen saver does not make the screen totally dark; it is still possible to see

objects on the screen. When the screen saver is activated, the screen has to be

touched once in order to inactivate the screen saver and to receive operator input.

Note:

The Dim back register (available from Setup/System Signals in the configuration

tool for the operator panels) cannot make the display of the M70 totally dimmed.

Beijer Electronics, MAEN843A 19

Page 20

Key Switch

8 Key Switch

The key switch can be set in three positions.

Key switch position Function

Left Enables touch screen calibration

Center Normal use

Right Opens the service menu

8.1 Touch Screen Calibration

The left-hand key switch position can be used if the touch screen has lost its orientation or if the Service menu for some reason is unavailable. Follow the instructions on the screen to calibrate the touch screen.

8.2 Service Menu

The right-hand key switch position opens the Service Menu.

8.2.1 Network Settings

Select the Network Settings option to make settings for TCP/IP, network services (SMTP client) and network accounts (also available from the configuration

tool for the operator panels).

8.2.2 Erase Project Memory

This option erases the project memory.

8.2.3 Update System Program from Memory Card

Insert a USB memory stick with a new system program and follow the instructions. The system program can also be updated via the configuration tool for the

operator panels.

Note:

The M70 requires a *.cab file of another type than other operator panels in the

same series. The *.cab files for the other panels may not be used in the M70.

20 Beijer Electronics, MAEN843A

Page 21

Key Switch

8.2.4 Calibrate Touch Screen

Follow the instructions on the screen to calibrate the touch screen. See also 8.1

Touch Screen Calibration.

8.2.5 Update Image

Select the Update Image option to open up the ImageUpdate tool.

Insert a USB memory stick with a new image (*.bin file). The buttons have the

following functions:

Browse

Select the image file. Hard Disk drive represents the USB memory stick.

Version Info

Presents the image version number of the installed image, and the image version

number of the selected file.

Test File

Checks the selected file for validity.

Compare File

Compares the selected file with the installed image.

Start Update

Starts the image update. The progress status is displayed in a progress bar.

Note:

Do not remove the power or the USB memory stick from the panel during the update.

After a completed update, the panel is automatically restarted.

Beijer Electronics, MAEN843A 21

Page 22

USB Memory Sticks

9 USB Memory Sticks

The USB connector is located under a protection cover on the M70.

Note:

The protection degree IP 65 is not guaranteed while the protection cover is open.

9.1 Connecting a USB Memory Stick

Follow the steps below to connect a USB memory stick:

1. Open the protection cover.

2. Plug in the USB memory stick until it snaps.

The USB memory stick will be detected immediately.

Never unplug the USB memory stick during read/write operations.

After removing the USB memory stick, the protection cover must be closed

completely to obtain the IP 65 protection degree.

9.2 Recommended USB Memory Sticks

The following USB memory sticks have been tested and are recommended for

the use in the M70:

Manufacturer USB stick Type Size

Kingston Kingston Data Traveler USB 2.0 128 MB or more

Transcend Transcend JetFlash USB 2.0 128 MB or more

USB memory sticks from other manufacturers have not been tested, and can

cause problems.

22 Beijer Electronics, MAEN843A

Page 23

Configuration Tool for the Operator Panels

10 Configuration Tool for the Oper ator

Panels

The M70 panel project is configured using the configuration tool for the operator panels. Function keys, touch keys and a number of other objects, as well as

panel settings, are available in the configuration tool. Please see the reference

manual for the configuration tool for information. Not all functions in the configuration tool are supported by the M70.

Beijer Electronics, MAEN843A 23

Page 24

Start-up Procedure

11 Start-up Procedure

Perform the following steps when starting the M70.

1. Connect the cables for RS232C or Ethernet communication.

2. Connect the M70 to the power supply.

3. A dialog for setting of date and time is displayed.

4. If time and date are of importance of the application, set date and time, and

click OK. See section 11.1 Date and Time Handling in the M70.

5. Wait for the dialog to disappear (regardless if date and time were set or not).

6. The system program will start in approximately 40 seconds, and the appli-

cation is ready to use.

11.1 Date and Time Handling in the M70

Date and time are not stored in the M70, since the real time clock has no battery

backup. If date and time are of importance in the application, for example to log

data or for trends, they have to be set every time the M70 is turned on.

If date and time are not set at start-up, M70 will start with default values.

To set the clock during runtime, a maneuverable clock object can be included in

the panel project.

24 Beijer Electronics, MAEN843A

Page 25

Technical Data

12 Technical Data

M70 specifications

Parameter M70

Size, diameter

height (incl. handle)

Seal IP65 (when USB host cover is closed).

Keyboard material Membrane keypad with tactile feedback.

Front panel Touch screen: Polyester on glass, 1 million finger touch

Housing Double-walled ABS housing. Withstands grease, oil,

Flammability class UL 94-V0

Weight 1.25 kg (incl. emergency stop and key switch, excl.

Serial port RS232C 9-pin D-sub contact, male with standard locking screws

Ethernet 10 Mbit/s

USB USB 1.1 host interface

Flash memory for

application

Real time clock Without battery backup

Power consumption at

rated voltage

Display TFT-LCD. 640 x 480 pixels, 64K color.

Active area of display,

W x H

250 mm

114 mm

operations.

lubricants, alcohol, etc.

cable)

4-40 UNC.

USB 1.1 client interface

64 MB

9.6 W (400 mA at 24 V DC)

Normal: 0.4 A

Maximum: 0.9 A

Analog-resistive touch screen.

Background lightning: 2 CCFT cold cathode tubes with

50,000 h lifetime at 25 °C in continuous operation.

6,5" (132x 98 mm)

Beijer Electronics, MAEN843A 25

Page 26

Technical Data

Parameter M70

Power supply +24 V DC (voltage tolerance 19.2 - 30 V DC according to

EN 61131-2).

CE: The power supply must conform with the

requirements for SELV or PELV according to IEC 950 or

IEC 742.

UL: The power supply must conform with the

requirements for class II power supplies.

Key switch 3 positions - internal connection

Ambient temperature 0 ° to +50 °C

Storage temperature -20 ° to +70 °C

Relative humidity 5 - 95% non-c ondensed

Vibration resistance

(operation)

Shock resistance

(operation)

EMC tests on the

operator panel

UL UL508, UL1740

10 Hz ≤ f < 57 Hz with 0.15 mm

9 Hz ≤ f < 150 Hz with 2 g

(IEC 60068-2-6)

25 g / 11 ms

(IEC 60068-2-27)

EC Council Directive relating to machinery 98/37/EC and

its amendment 98/79/EC:

EN 418

EN 954-1

EN 60204-1

EC Council Directive relating to electromagnetic com-

patibility 89/336/EEC and its amendments 92/31/EEC

and 93/68/EEC:

EN 61131-2

Additional emergency stop switch specifications

Parameter Emergency stop switch

Connection Twin circuit - external connection

Rated voltage 24 V DC

Min. current 10 mA (each contact)

Max. current 1000 mA (each contact)

Utilization category DC-13 (in accordance with IEC 60947-5-1)

26 Beijer Electronics, MAEN843A

Page 27

Technical Data

Additional enabling switch specifications

The M70 has two 3-position enabling switches.

Parameter Enabling switch

Connection Twin circuit - external connection

Output type Solid-state output

Rated voltage 24 V DC (voltage tolerance 19.2 V DC to 30 V DC according

to EN 61131-2)

Rated current 500 mA (max.)

Max. current up to

output cutoff

Max. inductive load Circuit 1 145mJ / 1.16 H @ 24 V DC, 500 mA

Reverse polarity

protection

Short circuit and

overload protection

Operating cycle 2nd position 105

Actuating force From 1st position to 2nd position 5 N typically

Circuit 1 1.5 A

Circuit 2 0.8 A

(comparable with DC13 according to EN

60947-5-1)

Circuit 2 145mJ / 1.16 H @ 24 V DC, 500 mA

(comparable with DC13 according to EN

60947-5-1)

Circuit 1 Yes

Circuit 2 Yes

Circuit 1 Yes (by integration in output-FET)

Circuit 2 Yes (by protective circuit)

3rd position 5 x 104

From 2nd position to 3rd position 20 N typically

Beijer Electronics, MAEN843A 27

Page 28

Technical Data

Cable specifications of CABTTxxx connection cable

When planning the power supply, take into account the voltage drop on the

M70 connection cable.

Parameter CABTTxxx

Specification of power

supply lines in CABTTxxx

Nominal supply voltage

directly on the handheld

panel (without CABTTxxx)

Maximum interruption

time of supply voltage

Cross section: AWG24 (0.24mm²)

Material: zinc-coated copper strand

Line resistance:= 90 Ohm/km (= 145 Ohm/mile)

+24 V DC (fully operational in the range: 19.2 - 30 V

DC).

≤ 10 ms (lt. IEC 61131)

28 Beijer Electronics, MAEN843A

Page 29

13 Outline Drawings

Outline Drawings

Beijer Electronics, MAEN843A 29

Page 30

Outline Drawings

30 Beijer Electronics, MAEN843A

Page 31

Connection Box

14 Connection Box

The connection box CB211 is used for integration of the M70 in the machine/

system. It is suitable for wall mounting.

The connection box is described below:

3

2

4

5

70

6

165

1

140

Parts of connection box, numbers according to drawing above

1 Status and error LEDs 4 Coninvers female connector for

M70 connection cable

2 PG gland (M20) for voltage supply ,

5 PG glands (M16)for data lines

enabling switch and emergency

stop

3 PG gland (M16) for separate func-

tional ground (status as supplied

6 PG glands (M16) for data lines (sta-

tus as supplied with dummy plugs)

with dummy plugs)

Beijer Electronics, MAEN843A 31

Page 32

Connection Box

14.1 Technical Data of Connection Box

Parameter Connection Box CB211

Rated supply voltage 24 V DC (voltage tolerance 19.2 V DC to 30 V DC

according to EN 61131-2)

Maximum interruption time

of supply voltage

Power consumption

with M70

without M70

Inrush current Max. 5.6 A (by implemented inrush current limiter)

Protective class Class III equipment (in accordance with EN 61131-2

Housing construction Double-walled ABS housing

Flammability class UL94-V0

Dimensions, W x H x D 160 x 140 x 70 mm

Weight 0.5 kg

Protection degree IP65

Display Status LEDs

Operating temperature 0 °C to 50 °C

Storage temperature -20 °C to +70 °C

Relative humidity 5% to 95% non-condensed

Vibration resistance

(operation)

Shock resistance (operation) 15 g / 11 ms (IEC 60068-2-27)

≤ 10 ms (lt. IEC 31131)

3.6 W (150 mA at 24 V DC)

10.8 W (450 mA at 24 V DC)

and EN 50178)

Withstands grease, oil, lubricants, alcohol, etc.

5 < f < 9 Hz 7 mm

9 < f < 150 Hz 2g (IEC 60068-2-6)

32 Beijer Electronics, MAEN843A

Page 33

Connection Box

14.2 Connecting M70 to Connection Box

Connection between the M70 and the connection box is made according to the

illustration below.

Connection box CB211

Power supply,

emergency switch,

enabling switch

CABTTxxx

RS232C/

Ethernet

Minimum Bending Radius of Cable

The drawing below shows the minimum distance required outside and inside

the control cabinet.

Beijer Electronics, MAEN843A 33

Page 34

Connection Box

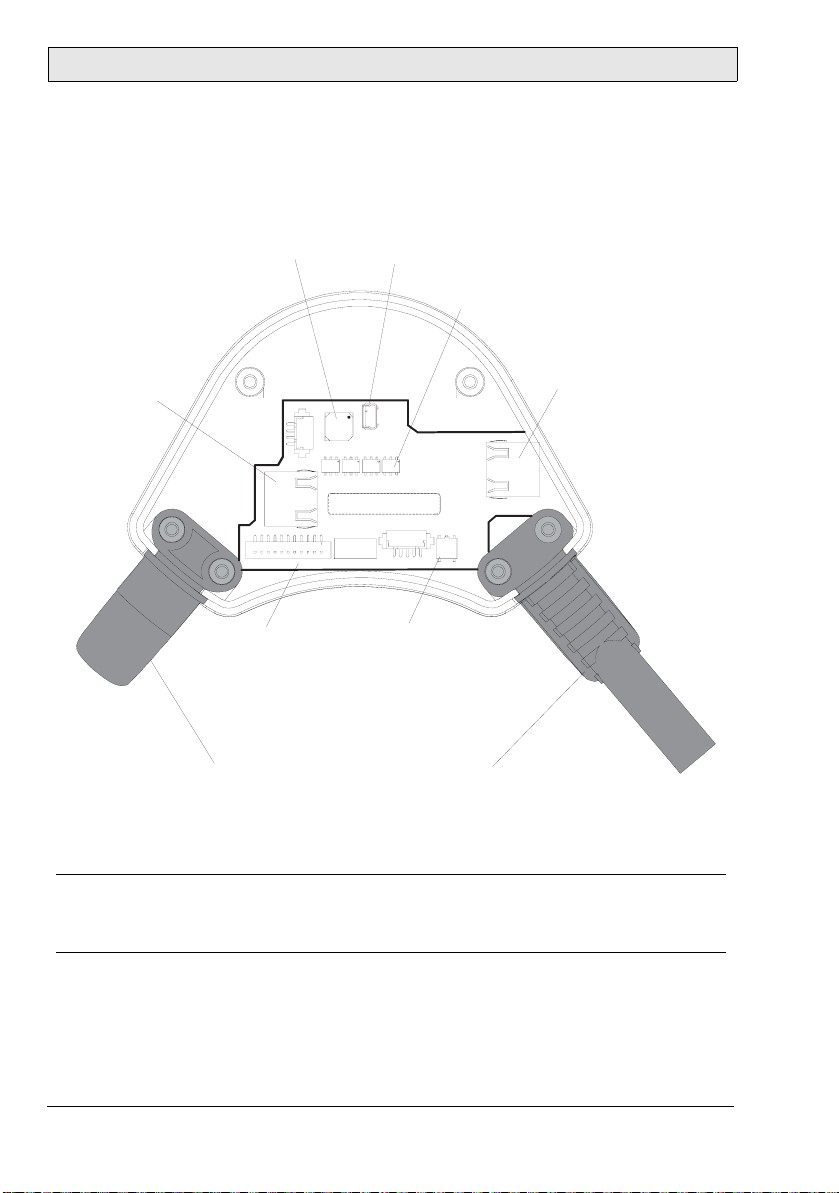

14.3 Interior View of Connection Box

Parts of connection box, marking according to drawing above

K1 17-pin female connector

(Coninvers) for CABTTxxx

connection cable

X1 Terminal block for power

and control lines (enabling

switch and emergency stop)

X3 Terminal block for data lines

SHIELD Cable shield clamp with connection

surface for cable shield of data lines (not

used for strain-relief of the cable!)

34 Beijer Electronics, MAEN843A

Page 35

Connection Box

14.4 Pin Description of X1 Terminal Block

Pin 1 24 V DC Pin 6 Emergency stop, circuit 2

Pin 2 GND_IN Pin 7 Enabling switch, circuit 1, pos.

Pin 3 Emergency stop, circuit 1 Pin 8 Enabling switch, circuit 1, neg.

Pin 4 Emergency stop, circuit 1 Pin 9 Enabling switch, circuit 2, pos.

Pin 5 Emergency stop, circuit 2 Pin 10 Enabling switch, circuit 2, neg.

For connection details such as Ethernet and RS232C wiring diagrams, see chapter 4 Connection.

14.5 Technical Data of the Connection Terminals

The following technical data apply to the X1 and X3 connector terminal blocks

already available in the connection box:

Parameter Connection box

Connection capacity

rigid

flexible

wire gages

Connection capacity flexible with wire end ferrules

without plastic sleeve

with plastic sleeve

Grid dimension 3.81

Insulation length 7 mm²

Tightening torque 0.22-0.25 Nm

0.14-1.5 mm²

0.14-1.5 mm²

28-16 A WG

0.25-1.5 mm²

0.25-0.5 mm²

PHOENIX Order Data

Gateway terminal block PHOENIX type Part no.

X1 MCVR 1.5/6-ST-3.81 1827169

X3 MCVR 1.5/7-ST-3.81 1827172

X4, X4B MCVR 1.5/10-ST-3.81 1827208

Beijer Electronics, MAEN843A 35

Page 36

Connection Box

Note:

Consider the connection capacity of the terminal blocks when selecting connection

cable.

Multi-line connections (2 wires in one terminal) are not allowed. Use the X4B

terminal block for continuing the field bus.

A screwdriver with the following specifications are used to connect the wires to

the terminal blocks:

– Blade: 0.4 x 2.5 x 80 mm

– Length: 160 mm

36 Beijer Electronics, MAEN843A

Page 37

Cables and Accessories

15 Cables and Accessories

Cables and wall mounting kit can be ordered from the M70 supplier.

15.1 Connection Cable

The following cables are available for connection between the M70 and the connection box:

–CABTT50 (5 m)

– CABTT100 (10 m)

– CABTT150 (15 m)

15.2 Wall Mounting Kit

–WB095

Beijer Electronics, MAEN843A 37

Loading...

Loading...