Page 1

User Manual

FEEDBACK DESTROYER FBQ1000

Automatic and Ultra-Fast Feedback Destroyer/Parametric EQ

with 24 FBQ Filters

Page 2

2 FEEDBACK DESTROYER FBQ1000 User Manual

Table of Contents

Thank you .......................................................................2

Important Safety Instructions ...................................... 3

Legal Disclaimer ............................................................. 3

Limited warranty ............................................................ 3

1. Introduction ............................................................... 4

2. Applications ............................................................... 5

3. A Few Quick Steps to EliminateFeedback .............. 6

4. Control Elements ....................................................... 6

5. FBQ1000 Architecture:

Presets, Filters, Operating Modes ................................ 7

6. Operating Modes of the FBQ1000 ............................ 8

7. Working with Presets ................................................8

8. Problems Do Have A Cause ... ................................. 10

9. MIDI Control ............................................................. 10

10. Installation ............................................................. 11

11. Appendix ................................................................12

12. Specications ......................................................... 15

Thank you

Thank you very much for expressing your condence in BEHRINGER products by

purchasing the FEEDBACK DESTROYER FBQ1000. With the FEEDBACK DESTROYER

you have acquired a highly useful device for the control of sound reinforcement

systems, which will enable you to focus your attention on what is essential:

your music. The fully featured FBQ1000 not only suppresses feedback but also

incorporates a wealth of additional functions in one single unit. Its 24 separate

lters can be edited in all parameters, and automatically detect and suppress

feedback frequencies. With its pro-level internal processing circuitry, the unit can

also be used as a high-end equalizer for stage and studio applications. The MIDI

interface allows for integrating the FBQ1000 into any MIDI system, and the open

system architecture enables you to update the system software whenever you

want. In short: the FBQ1000 will be your reliable “workhorse” over many years

tocome.

Page 3

3 FEEDBACK DESTROYER FBQ1000 User Manual

9. Do not defeat the safety purpose of the polarized

TO BIND MUSICGROUP BY ANY EXPRESS OR IMPLIED

Important Safety Instructions

Terminals marked with this symbol carry

electrical current of su cient magnitude

to constitute risk of electric shock.

Use only high-quality professional speaker cables with

¼" TS or twist-locking plugs pre-installed. Allother

installation or modi cation should be performed only

by quali edpersonnel.

This symbol, wherever it appears,

alertsyou to the presence of uninsulated

dangerous voltage inside the

enclosure-voltage that may be su cient to constitute a

risk ofshock.

This symbol, wherever it appears,

alertsyou to important operating and

maintenance instructions in the

accompanying literature. Please read the manual.

Caution

To reduce the risk of electric shock, donot

remove the top cover (or the rear section).

No user serviceable parts inside. Refer servicing to

quali ed personnel.

Caution

To reduce the risk of re or electric shock,

do not expose this appliance to rain and

moisture. The apparatus shall not be exposed to dripping

or splashing liquids and no objects lled with liquids,

suchas vases, shall be placed on the apparatus.

Caution

These service instructions are for use

by quali ed ser vice personnel only.

Toreduce the risk of electric shock do not perform any

servicing other than that contained in the operation

instructions. Repairs have to be performed by quali ed

servicepersonnel.

or grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding-type plug

has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. Ifthe

provided plug does not t into your outlet, consult an

electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or

pinched particularly at plugs, convenience receptacles,

and the point where they exit from the apparatus.

11. Use only attachments/accessories speci ed by

themanufacturer.

12. Use only with the

cart, stand, tripod, bracket,

or table speci ed by the

manufacturer, orsold with

the apparatus. When a cart

is used, use caution when

moving the cart/apparatus

combination to avoid

injury from tip-over.

13. Unplug this apparatus during lightning storms or

when unused for long periods of time.

14. Refer all servicing to quali ed service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power supply cord or plug

is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed

to rain or moisture, does not operate normally, or has

beendropped.

15. The apparatus shall be connected to a MAINS socket

outlet with a protective earthing connection.

16. Where the MAINS plug or an appliance coupler is

used as the disconnect device, the disconnect device shall

remain readily operable.

UNDERTAKING OR REPRESENTATION. THIS MANUAL

IS COPYRIGHTED. NO PART OF THIS MANUAL MAY

BE REPRODUCED OR TRANSMITTED IN ANY FORM

OR BY ANY MEANS, ELECTRONIC OR MECHANICAL,

INCLUDING PHOTOCOPYING AND RECORDING OF ANY

KIND, FOR ANY PURPOSE, WITHOUT THE EXPRESS

WRITTEN PERMISSION OF MUSICGROUPIPLTD.

ALL RIGHTS RESERVED.

© 2013 MUSICGroupIPLtd.

Trident Chambers, Wickhams Cay, P.O. Box 146,

Road Town, Tortola, British Virgin Islands

LIMITED WARRANTY

For the applicable warranty terms and conditions

and additional information regarding MUSIC Group’s

Limited Warranty, please see complete details online at

www.music-group.com/warranty.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as

radiators, heat registers, stoves, or other apparatus

(including ampli ers) that produce heat.

LEGAL DISCLAIMER

TECHNICAL SPECIFICATIONS AND APPEARANCES

ARE SUBJECT TO CHANGE WITHOUT NOTICE AND

ACCURACY IS NOT GUARANTEED. BEHRINGER,

KLARKTEKNIK, MIDAS, BUGERA, AND TURBOSOUND

ARE PART OF THE MUSIC GROUP MUSICGROUP.COM.

ALL TRADEMARKS ARE THE PROPERTY OF THEIR

RESPECTIVE OWNERS. MUSICGROUP ACCEPTS NO

LIABILITY FOR ANY LOSS WHICH MAY BE SUFFERED

BY ANY PERSON WHO RELIES EITHER WHOLLY OR

IN PART UPON ANY DESCRIPTION, PHOTOGRAPH

OR STATEMENT CONTAINED HEREIN. COLORS AND

SPECIFICATIONS MAY VARY FROM ACTUAL PRODUCT.

MUSIC GROUP PRODUCTS ARE SOLD THROUGH

AUTHORIZED FULLFILLERS AND RESELLERS ONLY.

FULLFILLERSAND RESELLERS ARE NOT AGENTS OF

MUSICGROUP AND HAVE ABSOLUTELY NO AUTHORITY

Page 4

4 FEEDBACK DESTROYER FBQ1000 User Manual

1. Introduction

1.1 The design concept

The philosophy behind BEHRINGER products guarantees a no-compromise

circuit design and employs the best choice of components. A 24-bit DSP is

used as the heart of the FEEDBACK DESTROYER, which belongs to the best

components available owing to its outstanding specications and excellent sonic

characteristics. What is more, high-quality 24-bit A/D and D/A converters ensure

the accurate processing of all signals. Additionally, the FEEDBACK DESTROYER

uses high-quality resistors and capacitors with very tight tolerances, high-grade

switches, and further selected components.

The FEEDBACK DESTROYER employs SMD technology (Surface Mounted Device).

These subminiature components known from aerospace technology allow for

an extreme packing density and improve the unit’s reliability even further.

Additionally, the FBQ1000 was manufactured in compliance with an ISO9000

certied management system.

1.2 Before you begin

Your FEEDBACK DESTROYER was carefully packed in the factory and

the packaging was designed to protect the unit from rough handling.

Nevertheless,werecommend that you carefully examine the packaging and its

contents for any signs of physical damage, which may have occurred in transit.

◊ If the unit is damaged, please do not return it to us, but notify your

dealer and the shipping company immediately, otherwise claims for

damage or replacement may not be granted. Shipping claims must be

made by the consignee.

The BEHRINGER FEEDBACK DESTROYER requires one standard 19" unit of

rack space. Please allow at least an additional 4" depth for the connectors on the

backpanel.

Be sure that there is enough space around the unit for cooling and please do not

place the FEEDBACK DESTROYER on high-temperature devices such as power

ampliers, etc. to avoid overheating.

◊ Before you connect your FEEDBACK DESTROYER to the mains,

please make sure that your local voltage matches the voltage required

by the unit:

The fuse holder on the female mains connector has 3 triangular markings, with

two of these triangles opposing each other. The FEEDBACK DESTROYER is set to the

operating voltage printed next to these markers and can be set to another voltage

by turning the fuse holder by 180°. CAUTION: This instruction does not apply to

export models exclusively designed, e.g. for 115-V operation!

Please use the enclosed power cord to connect the unit to the mains. The cord

complies with all applicable safety standards.

◊ Please note that all units must be grounded properly. For your own

safety, you should never remove any ground connectors from electrical

devices or power cords or render them inoperative.

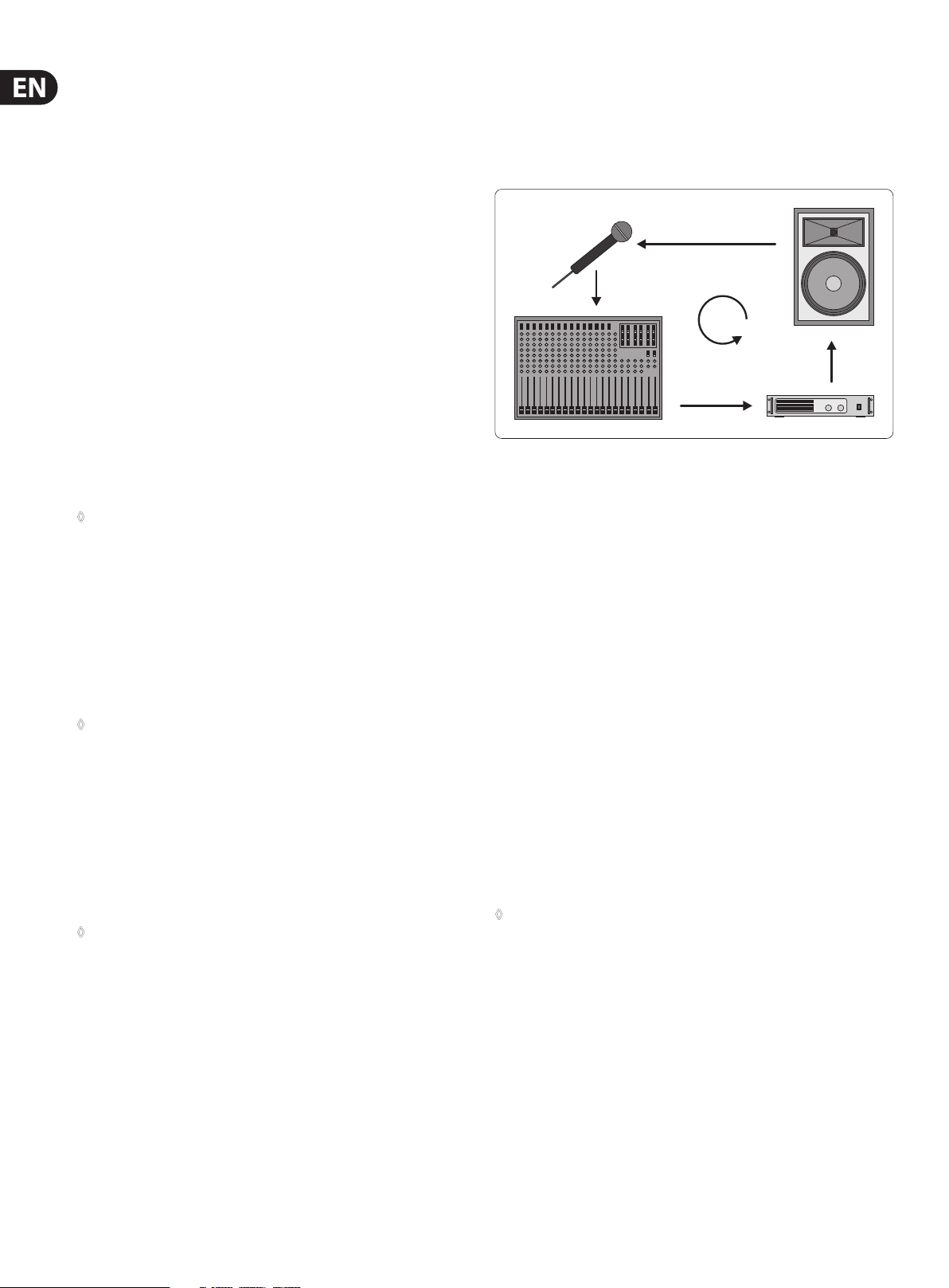

1.3 Background: How is feedback produced?

A feedback loop is produced when a microphone signal is reproduced by an

amplication system and is subsequently picked up again (with identical phase)

by the microphone. If this happens repeatedly, such a feedback loop can become

ever more persistent.

Fig. 1.1: How a feedback loo p is produced

1.3.1 Background: front of house mix (FOH)

There are two main sec tions in any sound reinforcement system, which are liable

to produce feedback: the rst section is the so-called front of house mix (FOH),

i.e. the “public address” mix, which is reproduced by one or several ampliers

plus several loudspeakers directed at the audience.

1.3.2 Background: monitor mix

The monitor mix, which is often derived from the same console, feeds one or

several stage-mount monitor speakers. Unlike FOH systems, stage monitors

are used to provide the individual musicians with a monitor signal, because it

is often dicult to hear oneself or each other on the stage, which can be due

to the high volume levels produced by the FOH systems, or to dierent volume

levels of the stage-mount instruments and ampliers. It is therefore not unusual

to give each musician his or her own monitor speaker, which is why there are

usually several monitor speakers placed along the stage. This is the only way to

provide each musician with a directed and focused monitor signal. In an ideal

situation, eachmonitor provides a specic mix, comprising e.g. vocals, drums and

keyboards, foreach individual musician on the stage.

Unfortunately, it is anything but easy to nd perfect positions for the various

stage monitors, because the distance between speaker and microphone must be

kept very short, which in turn increases the risk of feedback.

◊ In contrast to FOH systems, it is common practice to create two or even

more dedicated monitor mixes, which also involves the use of several

monitor speakers. Again, this can lead to increased feedback.

As a standard, the BEHRINGER FEEDBACK DESTROYER is equipped with

electronically servo-balanced inputs and outputs. The circuit design features

automatic hum and noise reduction for balanced signals and thus allows for

trouble-free operation, even at high operating levels. Externally induced mains

hum, etc. will be eectively suppressed. The automatic servo-function recognizes

the presence of unbalanced connectors and adjusts the nominal level internally

to avoid level dierences between the input and output signals (6-dB correction).

The MIDI interfaces IN, OUT, and THRU are on standardized DIN connectors.

Dataare transmitted via potential-free opto couplers.

Page 5

5 FEEDBACK DESTROYER FBQ1000 User Manual

2. Applications

The FBQ1000 is used exclusively to eliminate feedback in FOH and

monitormixes.

Before you go on, please note the following two remarks:

◊ The FEEDBACK DESTROYER is not intended to be connected directly

to the microphones! If this is unavoidable, then we recommend our

proven BEHRINGER SHARK FBQ100 instead, which is equipped with a

dedicated microphone preamplifier.

◊ No processing device can undo the mistakes made when placing the

microphones! So, when you set up your mics, use them according to

their directivity and feedback susceptibility (see chapter 8 “Problems

Do Have A Cause ...”).

2.1 Level setting

Take care to set levels properly on the FBQ1000, so as to successfully employ

the FEEDBACK DESTROYER to remove feedback. Use the LED LEVEL METER (1).

Makesure that the top Clip LEDs icker only rarely, but never light up all the time.

Low levels deteriorate the dynamics of the music signal, which results in a

poor, weak and noisy sound. On the other hand, excess levels overdriving the

converters in the FEEDBACK DESTROYER should also be avoided. Digitaldistortion

is (unlike its analog counterpart) very unpleasant to hear as it does not occur

gradually but abruptly.

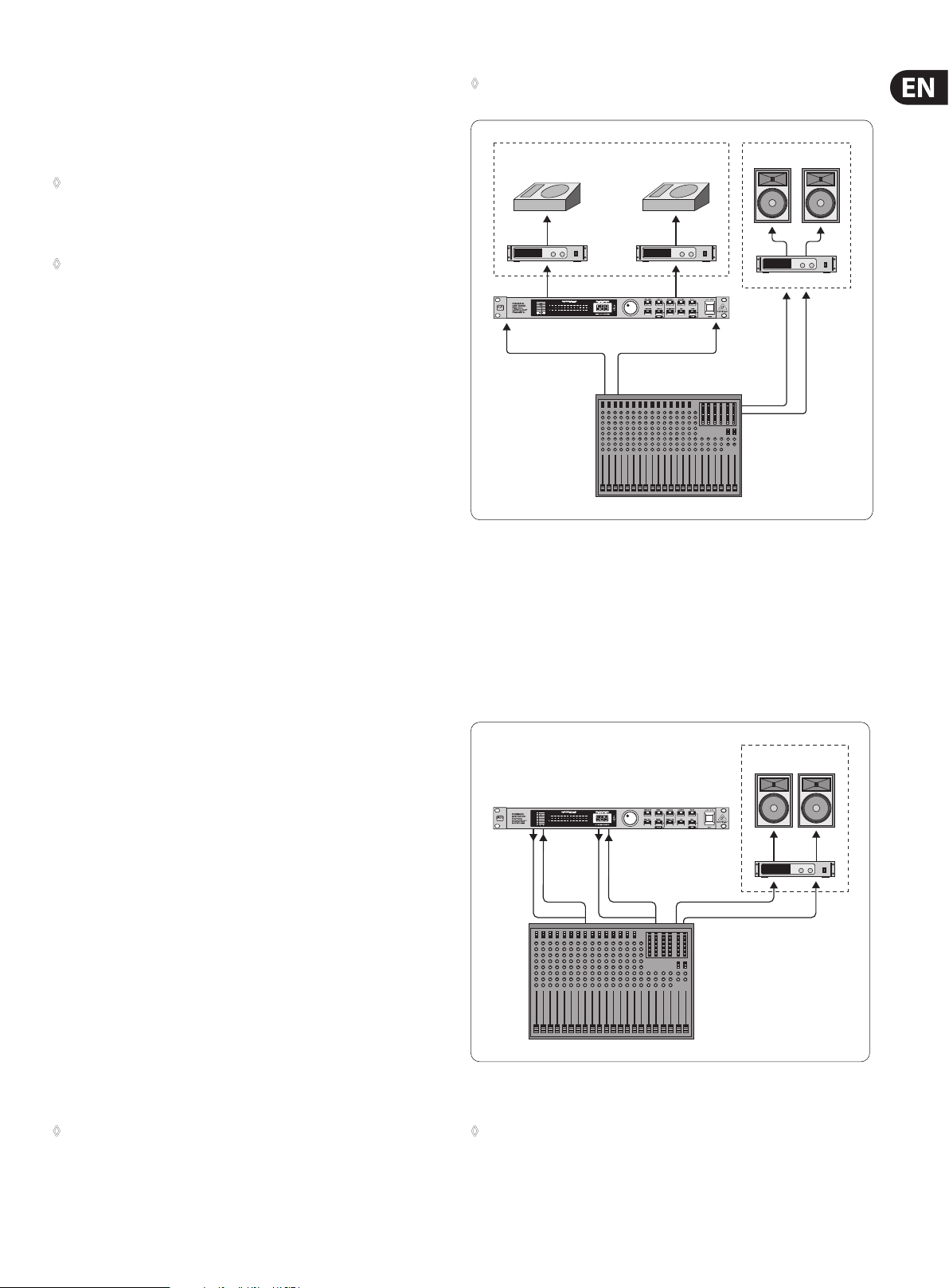

2.2 Using the FEEDBACK DESTROYER in the

monitor path

Your FBQ1000 is equipped with two channels. In Couple mode (see control

elements (8) and (9) ), these two channels are linked. But you can also

use them separately, for example, to protect two dedicated monitor paths

againstfeedback.

Monitor mixes are realized either via the pre-fader Aux Sends on an FOH console,

or via a (usually stage-mount) monitor mixer. When using an additional monitor

mixer on the stage, you need a so-called splitter to route the single microphone

signals both to the FOH console and to the monitor mixer. When using the FOH

console for the monitor mix, the stage microphones are connected directly to the

console (if necessary, via a so-called stage box).

◊ If possible, all monitor paths should be set pre-fader, as this leaves the

monitor mix unaf fected from any changes made to the FOH mix.

Monitor System

Monitor 1

Power Amp

Output 1

Input 1

Pre-Fader

Aux Send 1

Fig. 2.1: Using the FBQ1000 in th e monitor sends

Monitor 2

(Mono)

Output 2

Input 2

Pre-Fader

Aux Send 2

P.A. System

Master

Out

2.3 Using the FEEDBACK DESTROYER

in the FOH mix

Since you want to make sure that deliberately produced feedback signals, such as

“guitar feedback”, are not eliminated, you should tr y inserting the FBQ1000 into

those channels that are susceptible to feedback. For example, you could process

a vocal microphone that is liable to produce feedback by connecting the FBQ1000

to the insert points of the respective channel.

P.A. System

In both cases, separate monitor mixes are created for the musicians, which can

then be provided from the console outputs (usually via the Aux Send outputs).

Owing to its 2-channel design, your FEEDBACK DESTROYER allows you to protect

two monitor paths against feedback. To do so, connect the pre-fader Aux Send

outputs on your console to the inputs of the FBQ1000 (as shown in g.2.1).

Then,connect the inputs of the monitor power amps to the outputs of the

FEEDBACK DESTROYER (see g. 2.1).

As already mentioned, monitor paths are particularly susceptible to feedback.

When vocal microphones are not installed in a xed position, things become even

worse, so it really makes sense to protect the monitor paths against feedback.

Another positive side eect of using the FBQ1000 in the monitor path is the fact

that you can raise the volume levels considerably.

As you can see, your FBQ1000 is a perfect tool to protect two independent

monitor paths. But why is that so important? Because “monitoring” is a complex

task. Usually, each monitor path is used for an independent mix comprising a

variety of signal sources. This is the only way to ensure that each performer on

the stage can hear exactly what he or she wants.

◊ Owing to its 2-channel design, the FBQ1000 is the perfect tool for

application in two separate monitor paths. However, if you need to

protect four monitors against feedback, we recommend that you use a

second FBQ1000.

Outp. 1 Inp. 1

Outp. 2

Channel

Insert

Fig. 2.2: Using the FBQ1000 for specic mics (connecting the FEEDBACK DESTROYER in either channel

or sub-group inserts)

Inp. 2

Channel

Insert

Master Out

◊ When processing a microphone signal with the FBQ1000 and a

compressor inserted into the same channel insert point, the FEEDBACK

DESTROYER should always be used pre-compressor: in this way,

the signal is taken at the insert jack, passes the FBQ1000, then the

compressor, and is finally routed back to the insert jack.

Page 6

6 FEEDBACK DESTROYER FBQ1000 User Manual

Ideally, your mixer has sub-groups with dedicated insert points to connect

the FBQ1000! Route all channels that are susceptible to feedback (e.g. all vocal

mics) to one sub-group. While the other signals (e.g. line level signals, low-level

instrumental mics) pass unaected, all critical microphone channels are

monitored by the FBQ1000.

If your mixer has no sub-group inserts, we recommend that you connect the

FBQ1000 as follows: connect the sub-group output to one input on the FBQ1000,

and the corresponding output to a free line input of a mixing console channel

or one of the Aux Return inputs on the console. As long as ENGINE L and ENGINE

R are not linked, you would even have the second channel of your FEEDBACK

DESTROYER free for other applications (e.g. channel inserts).

2.4 Using the FEEDBACK DESTROYER

in a studio environment

With its highly exible conguration the FBQ1000 also delivers good results in a

professional studio or home recording environment, as it provides a maximum of

12 fully parametric equalizers per channel in Parametric EQ mode. Thus, you can

realize any application ranging from slight processing to the total manipulation

of music signals. For example, you can use the FBQ1000 as an equalizer for your

studio monitors or to enhance the EQs in your mixing console, as these are often

only semi-parametric.

3. A Few Quick Steps to

EliminateFeedback

Irrespective of whether you need the FBQ1000 to protect the FOH or the monitor

mix against feedback, the following procedure is always the same and should be

done before the concer t, so as to eliminate basic feedback problems right before

the show begins:

• Check the setting of the OPERATING LEVEL switch on the rear of the unit.

For most P.A. systems, this switch should be set to +4 dB. In doubt,

pleaseconsult the user’s manual of your mixing console. Always make sure

that the audio signal levels are set correctly (see control element (1))

• Switch on the unit, and use the JOG WHEEL (rotary control) to select preset1.

The preset table (see table 11.3) lists the various FBQ1000 presets available

• Using the FBQ1000 in the monitor path: Turn up the Aux Send or Mon.

controls in the rst mic channel, until the microphone starts to produce

feedback. If more than one monitor paths is being used, this procedure must

be done separately for each path. Repeat for each susceptible mic channel

• Using the FBQ1000 on channel/sub-group inserts: Deliberately induce

feedback by setting the channel/sub-group faders to 0 dB and raising the

gain controls for the individual microphones in turn

In either case, the FEEDBACK DESTROYER will suppress feedback as soon as it is

produced—the corresponding LED will stop ashing and stay lit. The various edit

options available are described in chapter 7. But don’t let us do the second step

before the rst:

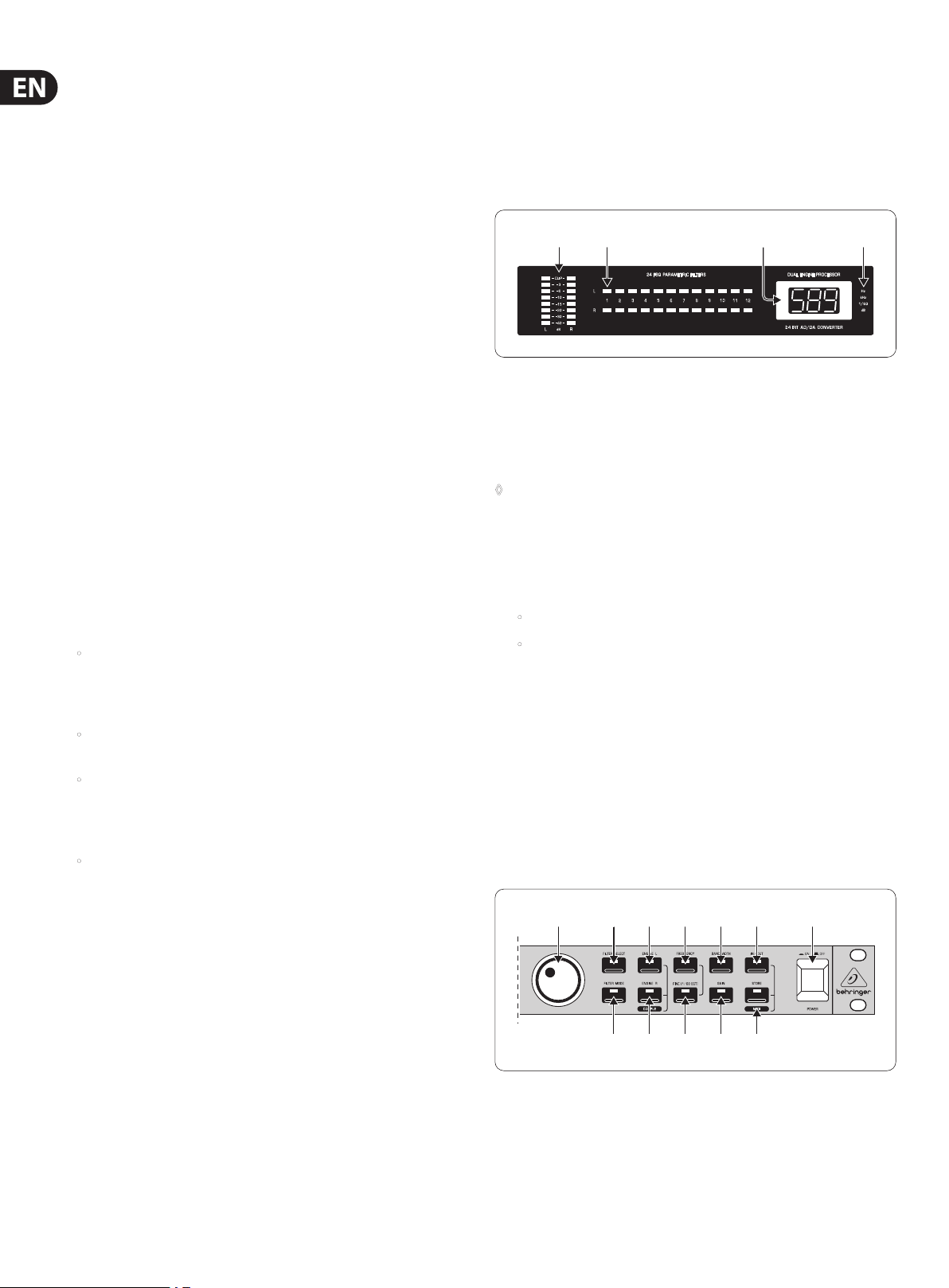

4. Control Elements

The BEHRINGER FEEDBACK DESTROYER is equipped with ten parameter keys,

one JOG WHEEL (rotary control) and a numeric LED DISPLAY. By means of an

8-segment LED meter, each of the two fully independent channels can be

monitored. Each of the 24 lters has one LED assigned to it, which informs about

the status of the lter.

(1) (2) (4)(3)

Fig. 4.1: Display sect ion of the FEEDBACK DEST ROYER

(1) The LED METER is used to monitor the output level. Each channel has eight

LEDs assigned to it. When the Clip LED lights up frequently, this warns you

of digital distortion. If the FBQ1000 is set to Total Bypass mode (see (14)),

thelevel meter reads the input level.

◊ Please always use appropriate level settings, as this is essential for

successful feedback elimination.

(2) The FBQ1000 features 24 lters, i.e. 12 lters per channel. These lters

can be monitored conveniently with the STATUS INDICATOR next to the

Display. 12LEDs inform you about the status of the lters on each channel

(left/right). Aconstantly lit LED signals the following conditions:

• A lter has been “set”, i.e. it is already suppressing feedback; or

• A lter is set to Parametric EQ mode (gain ≠ 0 dB)

Cyclically ashing LEDs signal that a lter is searching feedback frequencies

in Single-Shot or Auto mode (see chapters 5 and 6.3). Inactive lters (“OF”)

and lters in Parametric EQ mode (see 6.2), with a gain setting of 0 dB,

areindicated by unlit LEDs.

(3) The LED DISPLAY consists of a clearly visible, two-digit numeric

display. After power-up, it reads the number of the last preset used.

Additionally,theLED-DISPLAY shows the absolute values of the parameters

that are beingedited.

(4) The INDICATORS to the right of the DISPLAY (Hz, kHz, 1/60 and dB)

lightup when you edit the associated parameters in Edit mode. For example,

whenyou raise the level of a lter, the “dB” indicator lights up.

(5) (6)

(8) (10) (12) (14) (16)

(7) (9) (11) (13) (15)

Fig. 4.2: Func tion keys and Jog Wh eel

Page 7

7 FEEDBACK DESTROYER FBQ1000 User Manual

(5) With the JOG WHEEL, a continuous rotary control, you can freely edit

the selected parameters. Turn the wheel clockwise to increase the values,

orcounterclockwise to reduce them.

(6) With the FILTER SELECT key activated, you can use the Jog Wheel to select

one of the 12 lters per channel. Subsequently, you can edit the lters.

(7) The FILTER MODE key gives you access to the four operating modes for the

individual lters: “O mode (OF)”, “Parametric EQ (PA)”, “Single-Shot

mode (SI)” and “Auto mode (AU)”. Please read chapter 6 “Operating Modes

of the FBQ1000”.

◊ Pressing the FILTER MODE and GAIN keys simultaneously allows you

to adjust the sensitivity of the feedback suppression trigger circuit.

The setting range is from -3 through -9 dB and can be adjusted with the

JOG WHEEL. The default value is -6 dB, as this setting usually delivers

the best results.

(20)

(22)

Fig. 4.3: Rear pan el connector s and control elemen ts

(17) Use the OPERATING LEVEL switch to change from home recording level

(-10 dBV) to studio level (+4 dBu), and vice versa. The level meters are

adapted automatically to the selected nominal level, so that the FEEDBACK

DESTROYER will always work in its optimum operating range.

(18) These are the balanced INPUTS of the FBQ1000, which are on ¼" TRS and

XLR connectors.

(19) (17)(21) (18)

(8) Use the ENGINE L key to select the left audio channel.

(9) Use the ENGINE R key to select the right audio channel. If you wish to

process both channels at the same time (Couple mode), press both Engine

keys together. In Couple mode both ENGINE LEDs light up. Whenever

you edit one of the two audio channels and then switch to Couple mode,

theparameters of the active channel will be copied to the other, i.e. if you

press ENGINEL before ENGINER, left will be copied to right.

Items (10) through (13) refer to Parametric EQ mode only

(see chapters 5 and 7.3).

(10) Press the FREQUENCY key to select the frequency you wish to process.

Theadjustable frequency range is from 20 Hz through 20 kHz, which are split

up by the FBQ1000 into the 31 standard ISO values of a graphic equalizer

(seechapter 11.1 in the appendix).

(11) The FINE key allows you to ne tune the standard ISO frequencies (in1/60-

octave steps), within a tuning range of 1/3 octave (-9/60 to +10/60).

(12) BANDWIDTH determines the lter bandwidth (Q factor) of the selected

lter. This adjustable lter quality ranges from 1/60 octave to 2 octaves

(120/60 octave).

(13) The GAIN key sets the desired boost/cut of the selected lter in

dB(+16dB/-48 dB).

(14) The IN/OUT key allows for optional bypassing of the parametric lters or

all lters. By shortly pressing the IN/OUT key, only the Parametric EQ

lters will be deactivated, and the green LED goes out. Hold down the key

for about two seconds to deactivate all lters. This “Total Bypass” mode is

indicated by the cyclic ashing of the green LED. Another short IN/OUT key

press reactivates all lters. Additionally, the LED ashes when relevant MIDI

data are being received.

◊ If the control LED of the IN/OUT key flashes, all functions (including all

automatic filters used for feedback suppression) are disabled

(“Total Bypass”). In all other modes, at least the Single-Shot and Auto

filters are active (“Bypass”).

◊ Please use the “Total Bypass” function only with caution, because the

deactivation of the filters possibly unlocks suppressed feedback.

(15) Any modications made to a preset can be stored with the STORE ke y,

inaccordance with the number shown by the Display. Ten presets are

available on the FBQ1000. Press the IN/OUT and STORE keys simultaneously

to enter MIDI Setup mode.

(19) The two OUTPUTS of your FEEDBACK DESTROYER are also on balanced ¼"

TRS and XLR connectors.

(20) SERIAL NUMBER. Please take the time to ll in and return the warranty card

within 14 days after the date of purchase, so as to benet from our extended

warranty. Or use our online registration option available on the World Wide

Web at behringer.com.

(21) The FBQ1000 features a complete set of MIDI functions. In addition to the

usual MIDI IN and MIDI OUT ports, the MIDI THRU allows you to loop

through MIDI data.

(22) FUSE HOLDER / VOLTAGE SELECTOR. Please make sure that your local

voltage matches the voltage indicated on the unit, before you attempt to

connect and operate the unit. Blown fuses may only be replaced by fuses of

the same type and rating. Some models allow for inserting the fuse holder

in two dierent positions, in order to switch over from 230-V to 115-V

operation, and vice versa. Please note that for 115-V operation outside

Europe, you need to use a fuse of a higher rating (see chapter 1.2). Use the

enclosed power cord to connect the unit to the mains.

5. FBQ1000 Architecture: Presets, Filters, Operating Modes

In order to avoid confusion, let us give you a concise description of the FBQ1000’s

operating principle, so as to make the three relevant points clear right from the

start. Example: You have set up your P.A. system and connected all signal sources

to the console. The FBQ1000 has been inserted into the monitor path (see g.2.1)

or in single channel or sub-group inserts (see g. 2.2); afterpower-up preset

1was loaded with the JOG WHEEL. Now, you can start to purposefully produce

feedback, as described in chapter 3. Depending on the room acoustics,

variousfeedback frequencies can occur. What exactly does the FBQ1000 do?

As can be seen from table 11.3, each of the ten presets on your FBQ1000

comprises 24 separate lters, which can, however, be set to dierent

operating modes: In our example, the rst nine lters of the selected preset

are set to Single-Shot mode (“SI”, see chapter 6.3). This mode is designed

to detect feedback frequencies at xed resonance values, and to suppress

them consistently. So, these lters cannot be unlocked (status “LO” (locked)).

Their bandwidth and gain reduction can be adapted if required, however, the

frequency setting remains the same. In our example, the FBQ1000 is used to

prevent nine xed frequencies from “making trouble”.

(16) Use the POWER switch to switch the FEEDBACK DESTROYER on or o.

Page 8

8 FEEDBACK DESTROYER FBQ1000 User Manual

The three remaining lters (all set to Auto mode “AU”, see chapter 6.3) areused

to detect and suppress new feedback frequencies, which can be produced,

e.g.when the singer moves around the stage with the vocal mic in his/her hand.

Since the FBQ1000 can by no means “know” whether or not the risk of feedback

has been eliminated (e.g. when the singer moves to another position), the rst

AU lter of the unit locks to the detected frequency, while the remaining two

AU lters are used to suppress any new trouble frequencies that may occur.

Only when all AU lters have been used, will the rst AU lter used (here: 10)

beunlocked, so as to be able to detect new feedback frequencies.

Basically, all active lters (both in “AU” or “SI” mode) are represented by ashing

LEDs in the STATUS INDICATOR (2). When feedback has been detected and is

being suppressed, the associated lter LED lights up constantly. Filters set to

Parametric EQ mode (see chapter 6.2) also have constantly lit LEDs.

◊ Please read the detailed description of all operating modes (chapter 6)!

5.1 “Priming” the FBQ1000 for P.A.

and monitor applications

With the FBQ1000 you can improve the protection against feedback even before

the show begins, by “tuning in” your sound reinforcement system. We already

dealt with this in chapter 3. But now it’s not about using a preset, but about

how to determine in which modes the lters are used: Set some of the lters to

Single-Shot mode (see (7)).

First, let’s take a look at the monitor path: Open all microphone channels, turnup

the Aux Send controls on all channels you wish to route to the monitor mix,

then slowly move up the monitor master faders. For the front mix do as follows:

Slowly move up the channel and master faders. In both cases, the rst feedback

frequencies can be heard after some time.

Without the FEEDBACK DESTROYER you could not increase the volume level of

your system any further. With the FBQ1000, however, you can considerably

enhance the system headroom! Let the Single-Shot lters on the FBQ1000

suppress feedback as it occurs. Then cut back the volume to the level required

for the show. In this way, you can be sure that there is enough system headroom

should it become necessary to raise the volume level during the concert.

Experience has shown that musicians want to have the volume of their

instrument increased on the monitor as the concer t goes on. With the FEEDBACK

DESTROYER you can turn up the volume without having to fear feedback

problems. When the show begins you should set several lters to Auto mode,

in order to suppress feedback produced by “moving” (vocal) microphones.

Moreinformation on Auto mode can be found in chapters 5 and 6.3.

6.3 Automatic lters (“SI” and “AU”)

Automatic lters operate in two modes: Single-Shot (SI) and Auto mode (AU).

In order to nd a feedback frequency, the FEEDBACK DESTROYER divides the

entire frequency band into 1/60 octave steps (20 Hz to 20 kHz) and determines

the respective level of these individual bands. The unit then compares this value

to the level of the entire signal. The dierence between these levels determines

whether a lter is set or not. The FEEDBACK DESTROYER gives you the unique

possibility of adapting this parameter according to your own needs. You can edit

the feedback sensitivity (i.e. the dierence value) within a range from -3 to -9dB,

in 1-dB steps: Simultaneously press the FILTER MODE and GAIN keys, then use

the JOG WHEEL to select a value. The standard value for this parameter is -6 dB,

which provides for an optimum detection of feedback in most applications.

Example: During a pure speech transmission, the feedback sensitivity can be

lowered to -9 dB. In this way, the algorithm would recognize and suppress

feedback even faster. On the other hand, a higher setting, e.g. -3 dB, allows you

to leave those signals unaected which you don’t want to suppress (e.g. guitar or

keyboard signals).

Filters in Single-Shot mode automatically analyze the music signal to detect

feedback frequencies. Having detected such a frequency, the lter automatically

congures its parameters to suppress feedback as eciently as possible. As the

lter is locked to the detected frequency, this mode is ideally suited to suppress

feedback of constant frequency. Possible applications are “xed-position”

microphones (e.g. on the drums). After the lter has adjusted itself automatically,

it enters a special Locked mode (see chapter 6.4), which means that although the

frequency remains xed, the width and depth of the lter are still being adapted

to the feedback frequency, i.e. the width is increased as soon as the feedback

frequency begins to shift, and the gain is cut if feedback prevails. The gain is not

reduced to prevent feedback from recurring.

All microphones that are moved during a performance (e.g. vocal mics)

veryoften have varying feedback frequencies. This type of feedback should be

suppressed in Auto mode. As in Single-Shot mode, the lter automatically

selects an ideal setting for feedback suppression. However, in Auto mode the

rst AU lter set is unlocked to suppress new feedback. The optimum frequency

is selected automatically and the lter is set to narrow-band mode, so as to

inuence the music signal as little as possible. If your music contains wanted

feedback elements (e.g. guitar feedback), it is highly probable that these will be

suppressed too in Auto mode, because it is impossible from a physical point of

view to distinguish “wanted” from “unwanted” feedback. Please read chapter 2.3

to nd some information on how to work around this situation.

6.4 Locked mode (“LO”)

6. Operating Modes of the FBQ1000

The individual lters on the BEHRINGER FEEDBACK DESTROYER can operate in

four dierent modes (see (7)). An additional mode called “Locked” mode will be

described specically. Basically, each of the 2 x 12 lters on the FBQ1000

can be set to any of the four operating modes. To meet more complex

requirements with regard to exible signal processing, these modes can be

combined in a program and stored in a preset.

6.1 O mode “OF”

In O mode, the corresponding lter is deac tivated and can be activated by

selecting one of the modes described below.

6.2 Manual lters (“PA”) / Parametric equalizer

To raise or lower specic frequencies in level, you can select these frequencies

directly by setting the manual lters to Parametric EQ mode. Each lter has

the functionality of a fully parametric EQ, i.e. you can set the center frequency

(FREQUENCY key (10)), the bandwidth (BANDWIDTH key (12)) and the amount of

boost/cut (in dB) using the GAIN key (13) .

When the FBQ1000 detects a feedback frequency in Single-Shot mode

(seechapter 6.3), it automatically enters Locked mode, i.e. the lter locks to the

trouble frequency and “keeps an eye” on it. To unlock such a lter, you need to

switch it back to Single-Shot mode (see (7) and chapter 7.2).

7. Working with Presets

In order to store your favorite settings, the FBQ1000 has ten user presets and one

default preset. All operating parameters can be stored, so that your programs

are recalled in full detail. Owing to state-of-the-art circuitry, no internal battery

is needed, hence the memor y contents will not get lost. In the default preset

(Display: “--”), which serves as a starting point for your own programs, all lters

remain in Parametric EQ mode, with bandwidth set to 1 octave, frequency to

500 Hz and 0 dB gain.

Page 9

9 FEEDBACK DESTROYER FBQ1000 User Manual

7.1 Recalling presets

The FEEDBACK DESTROYER has ten presets, which can be overwritten.

Afterpower-up, the unit restores the last preset used. Use the JOG WHEEL to

select another preset. The default preset is located before the rst program.

◊ Please note that the FEEDBACK DESTROYER generally activates the

newly selected presets only after about one second, which is indicated

by a dot in the lower right corner of the DISPLAY. After loading the data,

the FEEDBACK DESTROYER enables the preset and the dot disappears.

This brief interruption of the signal path avoids the direc t activation of

each preset, as you scroll through the preset list with the Jog Wheel.

Thus, the FBQ1000 makes sure that no “unwanted” programs are

loaded unintentionally. Additionally, you can rotate the Jog Wheel at

high speed and still have the time to specif ically select the preset of

your choice, instead of any of its “neighbors”.

7. 2 Selecting the lter operating mode

Each lter mode has two letters assigned to it, which appear in the DISPLAY after

pressing the FILTER MODE key. The following display messages are available:

Display Operating mode

OF O

PA Parametric EQ

AU Auto

SI Single-Shot

LO Locked

Tab. 7.1: FEEDBACK DESTROYER lter operating modes

As already mentioned, the operating mode of a lter can be changed as follows:

Press the FILTER SELECT key and specify the lter number (1 through 12) with the

Jog Wheel. Using the two ENGINE keys, you can select the lef t (ENGINE L) or right

audio channel (ENGINE R), or both at the same time by pressing the two ENGINE

keys simultaneously.

7. 3 Editing lter parameters

◊ Remember: Your FBQ1000 has ten pre-configured user presets,

each comprising 12 filters per channel. Each individual filter can be

selected in any of the four operating modes!

◊ However, the “Locked” mode cannot be selected directly: when a filter

which was selec ted as “Single-Shot” detects a feedback frequency,

the filter is automatically set and “locked”, i.e. the filter is locked to the

problem frequency and “keeps an eye” on it.

◊ In Single-Shot and Auto modes, the filter parameter cannot be edited

but only displayed. Editing can be done in Parametric EQ mode only:

To change lter settings manually, the respective lter must be set to

Parametric EQ mode. Press and keep the FILTER MODE key for about one second.

Now, you can adapt the frequency after pressing FREQUENCY. Depending on

the preset frequency, either the “Hz” or the “kHz” indicator to the right of the

DISPLAY lights up. For example, when the lter is set to 160 Hz, the numeric

Display will read the value and the “Hz” indicator lights up. To raise the frequency

to 2,700 Hz, turn the Jog Wheel clockwise until the ISO frequency (2.5 kHz;

seeTab. 11.2) next to this value appears in the Display and the “kHz” indicator

lights up. The FINE key allows you to ne tune the chosen standard ISO frequency

within a tuning range of 1/3 octave (in 1/60-octave steps). The mathematical

proportion between the displayed value and the absolute frequency, as well

as a guide to nd the desired frequency quickly, are listed in the appendix

(chapter11.1 – frequency chart). The bandwidth of the lter (quality) can be

adjusted by selecting the BANDWIDTH key. The adjustable bandwidth ranges

from 2 octaves down to 1/60 octave. By pressing the GAIN key, it is possible to set

the desired boost or cut of the selected frequency. A “+” or “-” signals that the

level is being increased or decreased respectively.

◊ Filters in Single-Shot or Auto mode can be transformed into parametric

filters with the same frequency, quality and 0 dB gain by pressing the

FILTER MODE key for about one second. Only then will it be possible to

edit the filter parameters.

Now, press the FILTER MODE key and select the mode of your choice with the

Jog Wheel. The display message “LO” (= “Locked”) informs you that a lter set

to Single-Shot mode before is already suppressing feedback. As described in

chapter 6.4, this lter is set to Locked mode automatically. You can unlock such

a lter by switching it back to Single-Shot mode. As soon as a new feedback

frequency will be found, the FEEDBACK DESTROYER switches the lter from the

old frequency to the new one. If you leave Auto or Single-Shot mode and enter

parametric EQ mode, the lter’s parameter settings remain unchanged.

◊ To avoid inadvertent changing of filter modes, the filter mode selection

takes place after about one second, which is indicated by a dot in the

lower right corner of the Display.

◊ Press the FILTER MODE and GAIN keys at the same time, and use the JOG

WHEEL to adjust the feedback threshold (= feedback sensitivity) within

a range from -3 to -9 dB.

7.4 Storing presets

Whenever you edit a preset, the LED in the STORE key starts ashing.

Basically,all edits in Parametric EQ mode and the lter deactivation in O

mode can be stored. Filters in Single-Shot or Auto mode adjust and store their

parameters automatically. However, these data will get lost when you switch

o the unit. To avoid that, please write the edited setting to a preset before you

switch the FBQ1000 o:

Press the STORE key once, so that the DISPLAY starts ashing. If you wish to

preserve the original preset, use the Jog Wheel to select another preset number,

which can be overwritten. Then, press STORE again to save your edits to the

selected preset. If you wish to overwrite the original preset, simply press the

STORE key twice after editing, so as to save all edits to the same preset.

7. 5 Restoring the factory presets

Press and keep the FILTER SELECT and STORE keys pressed before you switch on

the FEEDBACK DESTROYER. After power-up keep the switches pressed for another

second. The preset numbers are counted up and the presets are reset to their

original default values.

Page 10

10 FEEDBACK DESTROYER FBQ1000 User Manual

8. Problems Do Have A Cause ...

Feedback is one of the major problems encountered in live P.A. applications. Ina

worst-case scenario every microphone signal passing an amplier can cause

feedback. Still, there’s a lot you can do even before the show begins:

• Place the microphones at some distance to the FOH and monitor speakers

• Make sure that the levels of the microphone channels are adjusted correctly

(see user’s manual of your console)

• Use the microphones according to their polar patterns (e.g. omnidirectional,

cardioid, super-cardioid)

• Poor room acoustics should be improved. Tiled walls and oors, which are

highly reective, can be covered with curtains or carpet

• Use a graphic equalizer to adapt the overall sound to the room acoustics

• To a certain degree, feedback can also be suppressed manually with a

graphic EQ

9. MIDI Control

Use the MIDI key combination to select the MIDI parameters you wish to

adjust. To do so, press and keep the IN/OUT and STORE keys at the same time.

Allparameters can be edited with the JOG WHEEL and these two keys. TheMIDI

menu includes six pages, which you can select by pressing the IN/OUT key

(forward) and the STORE key (backward) several times.

On the rst page, you can select the MIDI channel. The DISPLAY reads a small “c”

(= channel). The JOG WHEEL adjusts a channel from 1 through 16. To switch o

the MIDI function, simply select “0” (displayed as “-”).

On the second page, you can select MIDI Omni mode, i.e. the unit transmits/

receives on all 16 MIDI channels. The DISPLAY reads “O” (= Omni). Use the JOG

WHEEL to activate (“1”) or deactivate (“0”) MIDI Omni mode.

The third page allows for the conguration of controller commands. On its

right-hand side, the DISPLAY reads a capital “C” (= Controller). The JOG WHEEL

selects one of the ve controller modes shown below:

Display Mode

0 No controller data are transmitted

1 Control ler data are receive d but not transmit ted

2 Control ler data are transmi tted but not rece ived

3 Control ler data are transmi tted and receive d

4 As 3, with ad ditionally the aut omatic lter param eters

Tab. 9.1: Controll er settings

The fth page of the MIDI menu shows the “Store Enable” ag represented

by a capital “S” in the DISPLAY. Available values are “0” and “1”. If set to “1”,

theFEEDBACK DESTROYER receives controller 18 as a direct save command,

i.e.the current settings will be stored without further conrmation in the preset

number that corresponds to this controller value. If set to “0”, the FBQ1000

ignores all incoming commands referring to controller 18.

◊ ATTENTION! Store Enable mode has been designed to transmit

several presets as conveniently as possible from an external PC to the

FEEDBACK DESTROYER. In this mode, it is possible that stored presets

will be replaced or altered if controller 18 messages are sent via

MIDI! We therefore recommend that you disable this mode as soon

as the intended data transfer has been completed. During power-up,

this mode is automatically disabled (mode “0”).

On the sixth, and presently the last page you can access the “System Exclusive”

functions, which is indicated by a “d” (= dump) in the DISPLAY. To the left of this

“d”, you can see a “0” if no sys-ex data can be received or transmitted. When you

enter mode “1”, the FBQ1000 will be able to receive sys-ex data. In mode “2”,

theFBQ1000 is ready to dump its entire memory contents with all parameter

settings to an ex ternal MIDI storage medium. Start your sequencer software,

and press the STORE key. To load the data back, select mode “1”, and start your

sequencer software to restore the settings in your FEEDBACK DESTROYER.

If you press the IN/OUT key again on the sixth page, the FEEDBACK DESTROYER

quits MIDI mode. You can also use any other key to leave the MIDI setupmenu.

The full-featured MIDI implementation of the FEEDBACKDESTROYER allows for

easily integrating the unit into any MIDI system.

• MIDI IN

All MIDI data sent to the FBQ1000 (sequencer, MIDI foot controller, etc.)

arereceived via the MIDI IN jack. For example, if you wish to use the FBQ1000

as an eects device for your guitar rack, you can connect the MIDI IN jack

to a MIDI foot controller that allows for selecting program presets. If your

rack includes another MIDI eects device, the data sent from the MIDI foot

controller can be passed on to that device through the MIDI THRU port of the

FEEDBACKDESTROYER.

• MIDI THRU

The MIDI THRU jack is used to loop through incoming MIDI data, i.e. any controller

data received at the MIDI IN of the FEEDBACK DESTROYER will be transmitted via

the MIDI THRU jack to other MIDI devices/instruments.

• MIDI OUT

The MIDI OUT jack allows for transmitting MIDI data that originate from

theFBQ1000.

◊ When you choose value “4”, the FEEDBACK DESTROYER will send the

automatic filter values in addition to the parameter values.

For details on the controller functions, see Tab. 11.5 in the appendix.

The fourth page gives you access to the Program Changes. The DISPLAY reads a

capital “P” (= Program). Four modes are available, which can be selected with

the JOG WHEEL, as follows:

Display Mode

0 No program change data are transmitted

1 Progra m change data are rec eived but not transm itted

2 Progra m change data are tra nsmitted but not r eceived

3 Program change data are transmitted and received

Tab. 9.2: Program cha nge settings

The FEEDBACK DESTROYER Design Editor software enables you to control

the FBQ1000 from an external PC. What is more, you can use the FEEDBACK

DESTROYER to control the editor software, so that both units communicate

with each other. Download the editor free of charge from our web site at

behringer.com.

Page 11

11 FEEDBACK DESTROYER FBQ1000 User Manual

10. Installation

10.1 Audio connections

As a standard, the audio inputs and outputs on the BEHRINGER FEEDBACK

DESTROYER are fully balanced. If possible, connect the unit to other devices in a

balanced conguration to allow for maximum interference immunity.

Unbalanced ¼" TS connector

strain relief clamp

sleeve

tip

sleeve

(ground/shield)

tip

(signal)

Balanced ¼" TRS connector

strain relief clamp

sleeve

ring

tip

sleeve

ground/shield

ring

cold (-ve)

tip

hot (+ve)

For connection of balanced and unbalanced plugs,

ring and sleeve have to be bridged at the stereo plug.

Insert send return ¼" TRS connector

strain relief clamp

sleeve

ring

tip

sleeve

ground/shield

ring

return (in)

tip

send (out)

Connect the insert send with the input and the

insert return with the output of the eects device.

Fig. 10.2: Wiring an insert cable

◊ Please ensure that only qualified persons install and operate the

FEEDBACK DESTROYER. During installation and operation the user must

have sufficient electrical contact to earth. Elec trostatic charges might

affect the operation of the unit.

10.2 MIDI connections

The MIDI connectors found on the rear panel are on internationally standardized

5-pin DIN jacks. You need dedicated MIDI cables to connect the FEEDBACK

DESTROYER to other MIDI equipment. Normally, complete cables will be

purchased for this use, but you can also make your own, using a high-quality

two-conductor shielded cables (e.g. microphone cable) and two rugged 180°

DIN plugs: pin 2 (center) = shield, pins 4 and 5 (right and left of pin 2) = internal

conductors, pins 1 and 3 (the two outer pins) are not used. MIDI cables should

have a maximum length not exceeding 15 meters.

MIDI IN: Receives MIDI control data. The receive channel is determined in the

SETUP menu.

MIDI THRU: Provides an unchanged copy of the signal received at the MIDI IN,

forexample, to daisy-chain several FEEDBACK DESTROYER.

Balanced use with XLR connectors

12

3

input

1 = ground/shield

2 = hot (+ve)

3 = cold (-ve)

1

2

3

output

For unbalanced use, pin 1 and pin 3

have to be bridged

Fig. 10.1: Dierent plug t ypes

MIDI OUT: Transmits MIDI data to a connected computer or other

FEEDBACKDESTROYER. Transmitted are program data as well as status

information for signal processing.

Page 12

12 FEEDBACK DESTROYER FBQ1000 User Manual

11. Appendix

11.1 Frequency chart

Display -9/60 -8/60 -6/6 0 -4/60 -2/6 0 ISO +2/6 0 +4/6 0 +6/60 + 8/60 +10 /6 0 Display

20 Hz — — — — — 20 20,5 21 21,5 22 22,5 20 Hz

25 Hz 22,8 23 23,5 24 24,5 25 2 5,7 26,3 27 2 7,6 28,3 25 Hz

32 Hz 28,6 28,9 29,6 30,2 30,9 31,5 32,4 33,2 34 ,1 34,9 35,8 32 Hz

40 Hz 36,2 36,6 37, 5 38,3 39,2 40 41 42 43 44 45 40 Hz

50 Hz 45,5 46 47 48 49 50 51 53 54 55 57 50 Hz

63 Hz 57 58 59 60 62 63 65 66 68 70 71, 5 63 Hz

80 Hz 72,4 73 75 77 78 80 82 84 86 88 90 80 Hz

100 Hz 91 92 94 96 98 100 103 105 10 8 110 113 100 Hz

125 Hz 114 115 118 120 123 125 12 9 132 136 13 9 143 125 Hz

160 H z 144 146 150 153 15 7 160 164 168 172 176 180 160 H s

,20 kHz 182 184 188 19 2 196 200 205 210 215 220 225 ,20 kHz

,25 kHz 228 230 235 240 24 5 250 257 263 270 276 283 ,25 kHz

,32 kHz 286 289 296 302 309 315 324 332 341 349 358 ,32 kHz

,40 kHz 362 36 6 375 383 392 400 410 420 430 440 450 ,40 kHz

,50 kHz 455 460 470 480 490 500 513 526 539 552 565 ,50 k Hz

,63 kHz 572 578 591 604 617 630 647 664 6 81 698 7 15 ,63 kHz

,80 kHz 724 7 32 749 766 783 800 820 840 860 880 900 ,80 kHz

1,00 kHz 910 920 940 960 98 0 1000 1025 1050 1075 11 00 112 5 1,0 0 kHz

1,25 kHz 11 38 115 0 1175 120 0 12 25 12 50 12 85 1320 135 5 139 0 1425 1,25 kHz

1,60 kHz 144 3 146 0 149 5 153 0 15 65 160 0 1640 168 0 172 0 1760 180 0 1,6 0 kHz

2,0 kHz 1820 18 40 18 80 1920 19 60 2000 2050 2100 2 150 220 0 2250 2,0 kHz

2,5 kHz 2275 2300 2350 240 0 245 0 2500 2565 2630 2695 276 0 2825 2,5 kHz

3,2 kH z 2858 289 0 2955 3020 3085 315 0 3235 3320 3405 3490 3575 3,2 kHz

4,0 kHz 3618 366 0 3745 3830 3915 4000 410 0 420 0 4300 4 400 45 00 4,0 kHz

5,0 kH z 4550 4600 470 0 4800 4900 5000 513 0 5260 5390 5520 5650 5,0 k Hz

6,3 kHz 57 15 5780 5910 6040 6170 6300 6470 6640 6810 6980 715 0 6,3 kHz

8,0 kHz 7235 7320 74 90 7660 7830 8000 820 0 8400 8600 8800 9000 8,0 kHz

10,0 kH z 9100 9200 9400 9600 980 0 10000 102 50 105 00 10750 10000 12 250 10,0 kHz

12,5 kHz 113 75 115 00 117 50 12000 122 50 125 00 12850 13200 1355 0 13900 1425 0 12,5 kHz

16,0 k Hz 14425 146 00 14950 15300 15 650 16000 164 00 16 800 17200

20 kHz 18200 18 400 1880 0 192 00 1960 0 20000 — — — — — 20 kHz

Tab. 11.1: Frequency c hart

1760 0 18000 16,0 k Hz

In order to maintain a better survey only every second value is registered in

the table. The adjustable values do not exactly t into a 1/60 octave interval,

becausealso the ISO frequencies do not per fectly t into a physical 1/3 octave

interval. Rather a linear approximation is used to specify the values.

Background f1,f2, ... ISO frequencies

1 third = 20/60 octave (idealized ISO interval)

increment Δ fn =

(f

– fn)

n+1

20

20 25 31.5 40 50 63 80 100 125 160 200 2 50 315 400 500 630 800

Hz

1 1.25 1.6 2 2.5 3.15 4 5 6.3 8 10 12. 5 16 20 — — —

kHz

Tab. 11.2: Standard ISO freq uencies

Page 13

13 FEEDBACK DESTROYER FBQ1000 User Manual

11. 2 Preset table

Preset Filter 1 Filter 2 Filter 3 Filte r 4 Filter 5 Filter 6 Filte r 7 Filter 8 Fi lter 9 Filt er 10 Filter 11 Filt er 12

1 MONO: 9 single shot lters attenuate room resonances before 3 automatic lters destroy variable feedbacks

L SI SI SI SI SI SI SI SI SI AU AU AU

R SI SI SI SI SI SI SI SI SI AU AU AU

2 2 x MONITOR AS FEEDBACK DESTROY ER ONLY: 7 sing le shots / 5 automat ic lters for mo st monitor set ups

L SI SI SI SI SI SI SI AU AU AU AU AU

R SI SI SI SI SI SI SI AU AU AU AU AU

3 MONO AUTO PILOT: 12 Filters per cha nnel constan tly chase and de stroy feedbac ks

L AU AU AU AU AU AU AU AU AU AU AU AU

R AU AU AU AU AU AU AU AU AU AU AU AU

4 STEREO PARAMETRIC EQ: Pr eset with 12 ISO freq uencies, all se t to 1/3 Oct., Gain + 0 dB

Couple 125 H z 160 Hz 200 Hz 250 Hz 315 H z 400 Hz 500 Hz 630 Hz 800 Hz 1 k 1. 25 k 1.6 k

5 STEREO PARAMETRIC EQ: Pr eset with 12 ISO freq uencies, all se t to 2/3 Oct., Gai n + 0 dB

Couple 40 H z 63 H z 100 Hz 16 0 Hz 250 Hz 400 H z 630 Hz 1 k 1. 6 k 2.5 k 4 k 6.3 k

6 2 x MONO: Sample mo nitoring, lef t for handhel d (lead) micro phone(s), right for x ed (backing) one s

L SI SI SI AU AU AU AU AU PA d ef PA de f PA def PA def

R SI SI SI SI SI AU AU AU PA de f PA def PA def PA def

7 MONO PARAMETRIC AND SINGLE S HOT FILTERS: A go od start for a mo nitor equaliz ation

L SI SI SI SI SI SI SI SI PA de f PA def PA def PA def

R SI SI SI SI SI SI SI SI PA de f PA def PA def PA de f

8 STEREO FOH EQ, prov iding 4 parame tric EQ's (low roll o in lter 1 and 2), plus 8 sin gle shot lter s

PA PA PA d . PA d. SI SI SI SI SI SI SI SI

Couple

9 MONO FREE

L, R

10z STEREO FREE

Couple SI SI SI SI SI SI SI AU AU PA PA PA

Tab. 11.3: Pres et table

40 Hz 8 0 Hz

Channels co upled, changes on o ne channel are valid f or both1 Oct. 1 Oc t.

-8 dB -4 dB

SI SI SI SI SI SI SI AU AU PA PA PA

SI SI SI SI SI SI SI AU AU PA PA PA

Page 14

14 FEEDBACK DESTROYER FBQ1000 User Manual

11. 3 MIDI implementation

Function Transmitted Recognized Remarks

Basic

Channel

Mode

Note Number

Velocity

Af ter Tou ch

Pitch Bender X X

Control O 10 - 19 O 10 - 19 s ee add. Table

Pro gr.

Change True #

System Exclusive O O

System

Common

System

Real Time

Aux

Messages

Notes

O = YES, X = NO

Mode 1:

Mode 2:

Mode 3:

Mode 4:

Tab. 11.4: MIDI imp lementation char t

Default

Changed

Default

Messages

Altered

Tru e Voice

Note ON

Note OFF

Key's

Ch's

Song Pos

Song Sel

Tune

Clock

CommandsXX

Local ON/O FF

All notes OFF

Active Sense

Reset

OMNI ON, POLY

OMNI ON, MONO

OMNI OFF, POLY

OMNI OFF, MONO

OFF, 1 - 16

OFF, 1 - 16

1,2, 3,4

X

X

X

X

X

X

X

X

O (0- 9)

1-10

X

X

X

X

X

X

X

OFF, 1 - 16

OFF, 1 - 16

1,2, 3,4

X

X

X

X

X

X

X

X

O (0- 9)

1-10

X

X

X

X

X

X

X

X

X

memorized

Parameter Name Display Range

Filter Select 1 ..12 10 0..11 — — — — — —

Filter Mode OF, PA, AU, SI 11 0..3 — — — — — —

Engine 12 0,1,2 0 1 2 — — —

Frequency 20 (Hz)..20 (kHz) 13 0..30 — — — — — —

Fine (1/60 Oct) -9 ..+10 14 0 ..19 — — — — — —

Bandwidth 1 ..120 15 0. .119 — — — — — —

Gain - 48 ..+16 16 0..64 — — — — — —

Feedback Sensitivity -3. .-9 17 0..6 — — — — — —

Store 1..1 0 18 0..9 — — — — — —

In/Out 19 0..2 — — — 2 1 0

Tab. 11.5: Contr oller functi ons with MIDI

Midi Control

Number

Contro l Value

Range

LEDs

Couple Left Right IN on IN o IN ashing

Page 15

15 FEEDBACK DESTROYER FBQ1000 User Manual

12. Specications

Audio Inputs

Connectors XLR and ¼" TRS

Type RF-ltered, servo-balanced input

Impedance 60 kΩ balanced, 30 kΩ unbalanced

Nominal operating level -10 dBV to +4 dBu (switchable)

Max. input level +16 dBu at +4 dBu nominal level,

+2 dBV at -10 dBV nominal level

Audio Outputs

Connectors XLR and ¼" TRS

Type Electronically servo-balanced output

stage

Impedance 60 kΩ balanced, 30 kΩ unbalanced

Max. output level +16 dBu at +4 dBu nominal level,

+2 dBV at -10 dBV nominal level

System Specications

Bandwidth 20 Hz to 20 kHz, +0/-1 dB

Noise > 94 dB, unweighted (20 Hz to 20 kHz)

Power Supply

Mains voltages

USA/Canada 120 V~, 60 Hz (T 200 mA L, 250 V)

U.K./Australia 240 V~, 50 Hz (T 100 mA L, 250 V)

Europe 230 V~, 50 Hz (T 100 mA L, 250 V)

Korea 220 V~, 60 Hz (T 100 mA L, 250 V)

China 220 V~, 50 Hz (T 100 mA L, 250 V)

Japan 100 V~, 50/60 Hz (T 200 mA L, 250 V)

Power consumption approx. 15 Watts max.

Mains connection Standard IEC receptacle

Physical

Dimensions (H x W x D) 1.7 x 19 x 7.7" / 44 x 483 x 195 mm

Weight 4.22 lbs / 1.9 kg

BEHRINGER i s constantly str iving to maintain the h ighest profess ional standards. A s a result of these e ffort s,

modific ations may be made f rom time to time to exi sting product s without prio r notice. Specif ications and

appearance m ay differ fro m those listed or illus trated.

THD 0.0075% typ. @ +4 dBu, 1 kHz, Gain 1

Crosstalk < -76 dB

MIDI Interface

Type 5-Pin DIN Socket IN/OUT/THRU

Digital Processing

Converters 24-bit Sigma-Delta,

64/128-times oversampling

Display

Type 2 ½-digit numeric LED display

Page 16

16 FEEDBACK DESTROYER FBQ1000 User Manual

FEDERAL COMMUNICATIONS

COMMISSION COMPLIANCE

INFORMATION

FEEDBACK DESTROYER FBQ1000

Responsible Party Name: MUSIC Group Services US Inc.

Address: 18912 North Creek Parkway,

Suite 200 Bothell, WA 98011,

USA

Phone/Fax No.: Phone: +1 425 672 0816

Fax: +1 425 673 7647

FEEDBACK DESTROYER FBQ1000

complies with the FCC rules as mentioned in the followingparagraph:

This equipment has been tested and found to comply with the limits for a ClassB

digital device, pur suant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a par ticular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined

by turning the equipment o and on, the user is encouraged to tr y to correct the

interference by one or more of the followingmeasures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician forhelp.

This device complies with Part 15 of the FCC rules. Operation is subject to the

following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any inter ference received, including inter ference that may

cause undesired operation.

Important information:

Changes or modications to the equipment not expressly approved by MUSIC Group

can void the user’s authority to use the equipment.

Page 17

We Hear You

Loading...

Loading...