Page 1

User Manual

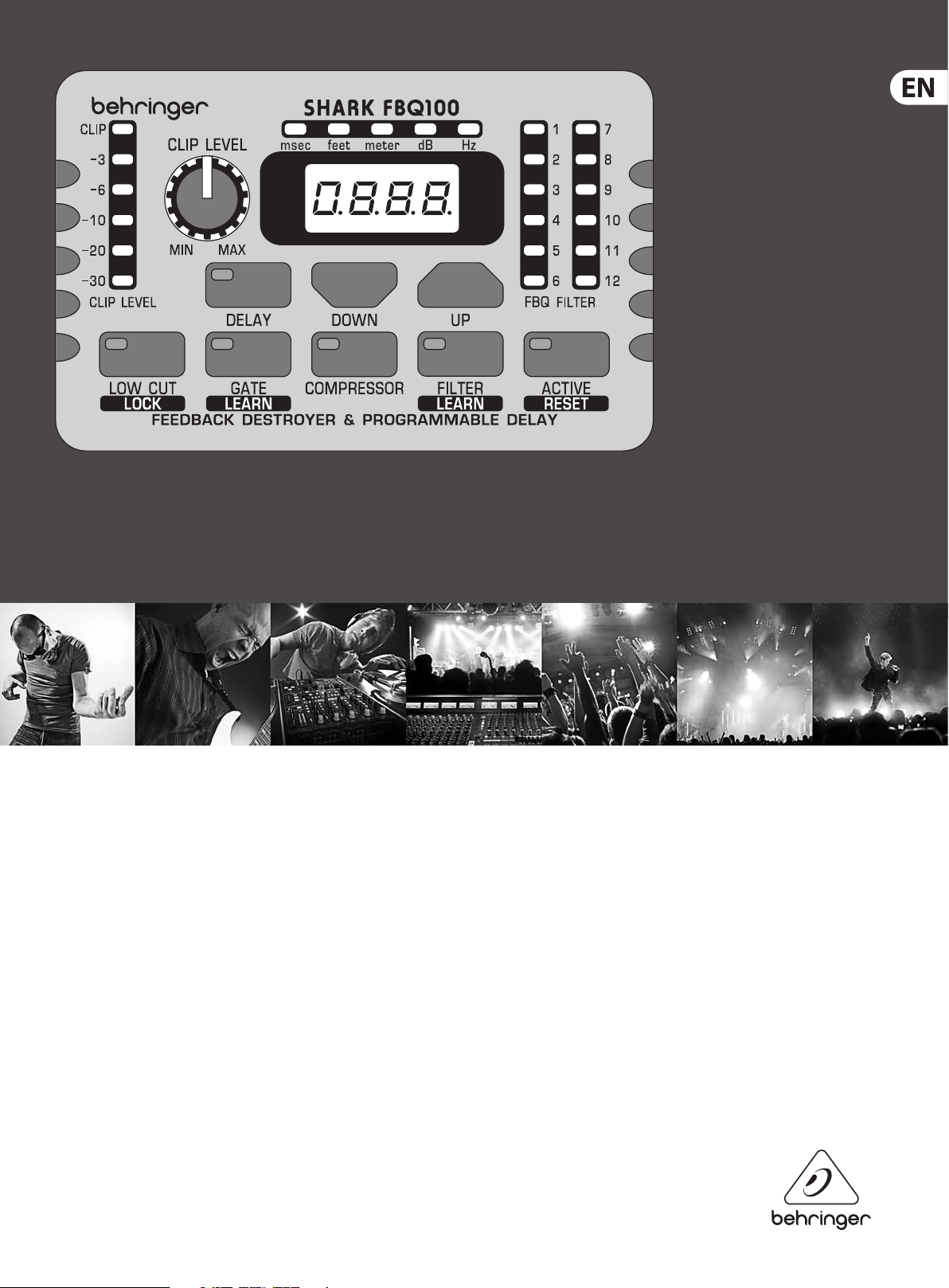

SHARK FBQ100

Automatic Feedback Destroyer with Integrated Microphone Preamp,

Delay Line, Noise Gate and Compressor

Page 2

2 SHARK FBQ100 User Manual

Table of Contents

Thank you .......................................................................2

Important Safety Instructions ...................................... 3

Legal Disclaimer ............................................................. 3

Limited warranty ............................................................ 3

1. Introduction ............................................................... 4

1.1 The concept .......................................................................... 4

1.2 Before you begin ................................................................ 4

1.3 Control elements ................................................................ 4

2. Applications ............................................................... 6

2.1 Wiring the FBQ100: general remarks ........................... 6

2.1.1 Connection between microphone

and mixingconsole ................................................................. 6

2.1.2 Connection between line-level source

and mixingconsole ................................................................. 6

2.1.3 Connection between mixing console

and poweramplier ............................................................... 6

2.1.4 The SHARK used in the monitor path .................... 6

2.1.5 The SHARK used in single channels

and subgroups .......................................................................... 7

2.1.6 Automatic “tuning in” of P.A. and

monitor systems ....................................................................... 7

2.2 The feedback destroyer in the SHARK ........................ 7

2.3 The integrated delay ......................................................... 7

2.4 The noise gate function ................................................... 8

2.5 The low cut lter in the SHARK ...................................... 8

2.6 The compressor function ................................................ 8

3. Installation ................................................................. 8

3.1 Audio connections ............................................................. 8

4. Specications ............................................................. 9

5. Rackmount (Optional) ............................................. 10

Thank you

Thank you very much for expressing your condence in BEHRINGER products by

purchasing the SHARK FBQ100.

Page 3

3 SHARK FBQ100 User Manual

9. Do not defeat the safety purpose of the polarized

TO BIND MUSICGROUP BY ANY EXPRESS OR IMPLIED

Important Safety Instructions

Terminals marked with this symbol carry

electrical current of su cient magnitude

to constitute risk of electric shock.

Use only high-quality professional speaker cables with

¼" TS or twist-locking plugs pre-installed. Allother

installation or modi cation should be performed only

by quali edpersonnel.

This symbol, wherever it appears,

alertsyou to the presence of uninsulated

dangerous voltage inside the

enclosure-voltage that may be su cient to constitute a

risk ofshock.

This symbol, wherever it appears,

alertsyou to important operating and

maintenance instructions in the

accompanying literature. Please read the manual.

Caution

To reduce the risk of electric shock, donot

remove the top cover (or the rear section).

No user serviceable parts inside. Refer servicing to

quali ed personnel.

Caution

To reduce the risk of re or electric shock,

do not expose this appliance to rain and

moisture. The apparatus shall not be exposed to dripping

or splashing liquids and no objects lled with liquids,

suchas vases, shall be placed on the apparatus.

Caution

These service instructions are for use

by quali ed service personnel only.

Toreduce the risk of electric shock do not perform any

servicing other than that contained in the operation

instructions. Repairs have to be performed by quali ed

servicepersonnel.

or grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding-type plug

has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. Ifthe

provided plug does not t into your outlet, consult an

electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or

pinched particularly at plugs, convenience receptacles,

and the point where they exit from the apparatus.

11. Use only attachments/accessories speci ed by

themanufacturer.

12. Use only with the

cart, stand, tripod, bracket,

or table speci ed by the

manufacturer, orsold with

the apparatus. When a cart

is used, use caution when

moving the cart/apparatus

combination to avoid

injury from tip-over.

13. Unplug this apparatus during lightning storms or

when unused for long periods of time.

14. Refer all servicing to quali ed service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power supply cord or plug

is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed

to rain or moisture, does not operate normally, or has

beendropped.

15. The apparatus shall be connected to a MAINS socket

outlet with a protective earthing connection.

16. Where the MAINS plug or an appliance coupler is

used as the disconnect device, the disconnect device shall

remain readily operable.

UNDERTAKING OR REPRESENTATION. THIS MANUAL

IS COPYRIGHTED. NO PART OF THIS MANUAL MAY

BE REPRODUCED OR TRANSMITTED IN ANY FORM

OR BY ANY MEANS, ELECTRONIC OR MECHANICAL,

INCLUDING PHOTOCOPYING AND RECORDING OF ANY

KIND, FOR ANY PURPOSE, WITHOUT THE EXPRESS

WRITTEN PERMISSION OF MUSICGROUPIPLTD.

ALL RIGHTS RESERVED.

© 2013 MUSICGroupIPLtd.

Trident Chambers, Wickhams Cay, P.O. Box 146,

Road Town, Tor tola, British Virgin Islands

LIMITED WARRANTY

For the applicable warranty terms and conditions

and additional information regarding MUSIC Group’s

Limited Warranty, please see complete details online at

www.music-group.com/warranty.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as

radiators, heat registers, stoves, or other apparatus

(including ampli ers) that produce heat.

LEGAL DISCLAIMER

TECHNICAL SPECIFICATIONS AND APPEARANCES

ARE SUBJECT TO CHANGE WITHOUT NOTICE AND

ACCURACY IS NOT GUARANTEED. BEHRINGER,

KLARKTEKNIK, MIDAS, BUGERA, AND TURBOSOUND

ARE PART OF THE MUSIC GROUP MUSICGROUP.COM.

ALL TRADEMARKS ARE THE PROPERTY OF THEIR

RESPECTIVE OWNERS. MUSICGROUP ACCEPTS NO

LIABILITY FOR ANY LOSS WHICH MAY BE SUFFERED

BY ANY PERSON WHO RELIES EITHER WHOLLY OR

IN PART UPON ANY DESCRIPTION, PHOTOGRAPH

OR STATEMENT CONTAINED HEREIN. COLORS AND

SPECIFICATIONS MAY VARY FROM ACTUAL PRODUCT.

MUSIC GROUP PRODUCTS ARE SOLD THROUGH

AUTHORIZED FULLFILLERS AND RESELLERS ONLY.

FULLFILLERSAND RESELLERS ARE NOT AGENTS OF

MUSICGROUP AND HAVE ABSOLUTELY NO AUTHORITY

Page 4

4 SHARK FBQ100 User Manual

1. Introduction

1.1 The concept

With the SHARK FBQ100 you purchased a device that combines an automatic

Feedback Destroyer using the ingenious search algorithms of our FEEDBACK

DESTROYERFBQ1000, a variable Delay Line (adjustable in msec, feet and

meter), aULN (Ultra-Low Noise) microphone pre-amp with Phantom Power,

anautomatic Noise Gate, a variable Low Cut lter and a Compressor—all in

one ultra-rugged and compact case. Still, the SHARK can be operated intuitively

and expanded to a multi-channel system using another four SHARKs and

an optionally available 19" rack mount kit. The SHARK’s 24-bit A/D and D/A

converters guarantee a precise reproduction of your program material.

High volume levels and the use of ever more sophisticated monitoring systems

with a multitude of speaker cabinets have led to a greater potential risk of

feedback loops in sound reinforcement systems. So far, audio engineers

have been using conventional 1/3-octave equalizers to suppress unwanted

feedback. However, the individual lters of such an EQ, with their relatively

wide bandwidth, have quite an impac t on the sound image. With the

BEHRINGER SHARK (minimum bandwidth: 1/60 of an octave) you are now free

to either choose the trial and error method to suppress feedback with graphic

equalizers, or to assign this task to the FBQ100, so that you can give your

music your undivided attention. Using extremely narrow-bandwidth lters,

the SHARKFBQ100 eliminates only unwanted feedback, without aecting

yourmusic.

Please use the enclosed power supply to connect the unit to the mains.

Thesupply complies with all applicable safety standards.

◊ Please note that all units must be grounded properly. For your own

safety, you should never remove any ground connectors from electrical

devices or power cords or render them inoperative.

Further information can be found in chapter 3 “Installation”.

As a standard the audio inputs and outputs of the BEHRINGER SHARK FBQ100

are fully balanced. If possible, connect the unit to other devices in a balanced

conguration to allow for maximum interference immunity. The automatic servo

function detects unbalanced connections and compensates the level dierence

automatically (6dB correction).

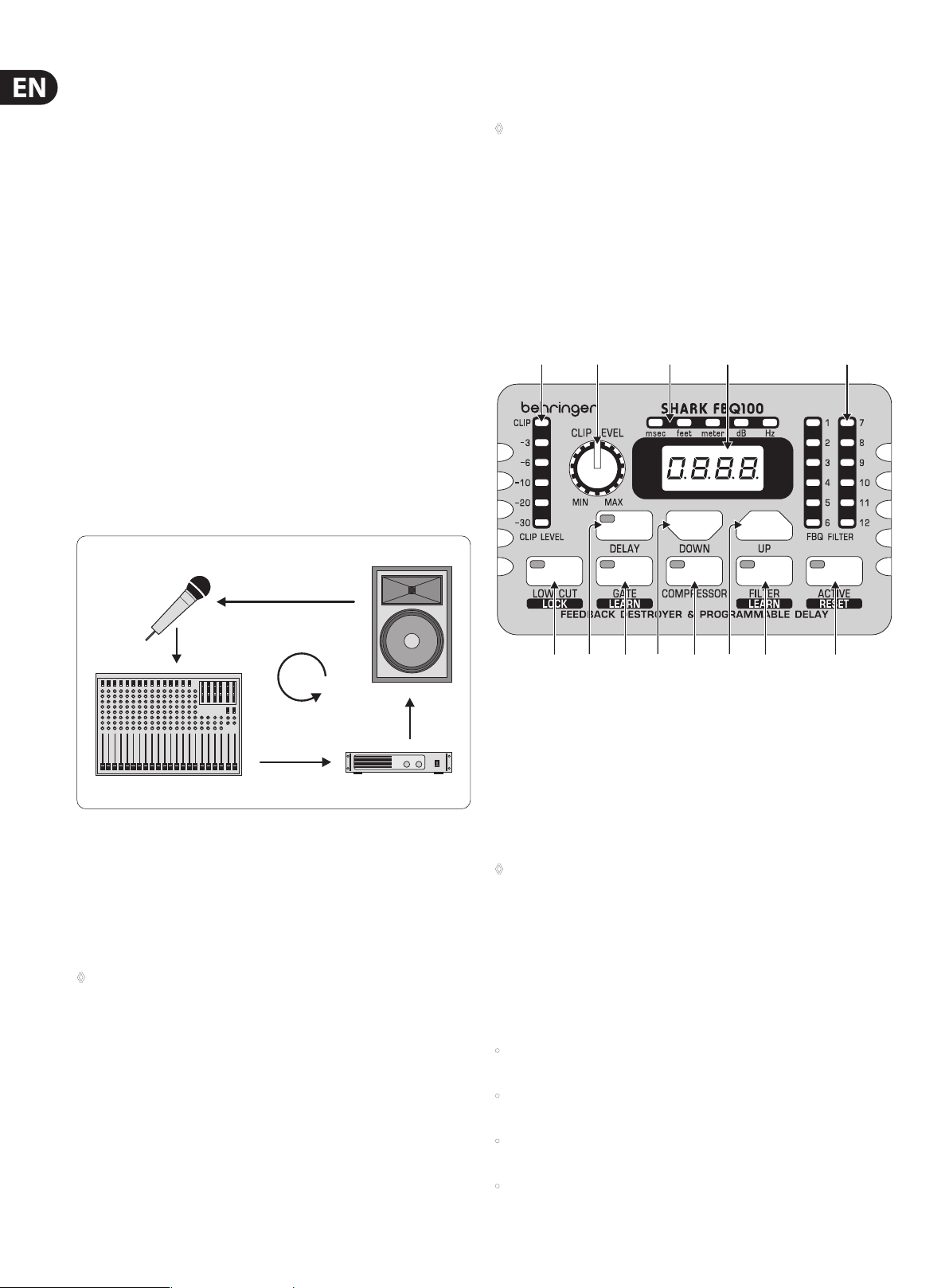

1.3 Control elements

(1)

(2) (3) (4) (5)

Speaker Box

Microphone

Mixing Console

Fig. 1.1: Typical feedback loop

Power Amp

1.2 Before you begin

Your SHARK was carefully packed in the factory and the packaging is designed

to protect the unit from rough handling. Nevertheless, we recommend that you

carefully examine the carton and its contents for any signs of physical damage,

which may have occurred during transit.

◊ If the unit is damaged, please do not return it to BEHRINGER, but notify

your dealer and the shipping company immediately, otherwise claims

for damage or replacement may not be granted. Shipping claims must

be made by the consignee.

The optionally available rack mount kit allows you to mount your BEHRINGER

SHARK in a standard 19" rack, together with another four SHARKs. The rack

mount kit requires 2U of rack space.

Be sure that there is enough air space around the unit for cooling and please do

not place the SHARK on high-temperature devices such as power amps, etc. to

avoid overheating.

(9) (10) (11) (12) (13)

Fig. 1.2: Front p anel control eleme nts of the FBQ100

(7)(6) (8)

(1) The CLIP LEVEL METER shows you whether or not the digital circuitry is

driven correctly. Any corrections can be made with the CLIP LEVEL control

(2). Be sure that the CLIP LED won’t light up.

(2) The CLIP LEVEL control lets you adapt the internal gain optimally to the

digital circuitry. If gain is too high (CLIP LED lights up), raise the CLIP LEVEL

value by turning the control to the right (and vice versa). Thus, you can shift

the operating level upwards/downwards.

◊ The CLIP LEVEL control does not affect the input/output levels,

but adapts the audio signal as optimally as possible to the threshold of

the digital circuitry.

(3) These ve LEDs symbolize the units of the parameters that can be adjusted

on the display (4).

(4) The 4-digit DISPLAY reads the absolute values of the adjusted parameters.

(5) The FB-D FILTER STATUS LEDs display the status of each of the 12 individual

lters. The SHARK uses four dierent lter modes:

• Disabled lters (which can be re-enabled with the ACTIVE button). When a

lter is o, its LED is not lit.

• Free lters which automatically search for feedback frequencies and whose

activity is shown by a ashing LED.

• Set lters which can be recongured as free (searching) lters, when all

lters are currently in use.

• Permanently set lters which must be RESET to be recongured as

freelters.

Once a lter has been set, its LED lights up.

Page 5

5 SHARK FBQ100 User Manual

(6) The DELAY button allows you to adjust the Delay Line time. Press the button

several times to either choose msec, feet or meter. The last unit selected will

be stored and recalled next time you use the DELAY function. The control LED

lights up while you are making your entries. The setting range is from 0 to

2,500.0 msec, 0 to 2,818.2 feet, and 0 to 859.00 meters. When you are using

high values, the 4-digit display reads the last gure only when you start

editing with the UP/DOWN buttons. Example: for a value of 1,500.0 msec,

the display reads “1500” when you press the DELAY button, and “500.0”

when you start editing. In this way, you can use extremely small steps when

editing parameters.

◊ To speed up the selection, briefly press the key located next to the

UP or DOWN key. The selection speed will be increased with each

additional key press. This function can be used for all parameter edits.

(7) The DOWN button lowers the parameter values shown in the display (4).

(8) The UP button raises these parameter values.

(9) The LOW CUT button lets you enter the high pass lter’s cut-o frequency

(20 to 150 Hz). When set to OFF the lter is inoperative. The control and “Hz”

LEDs light up while you are entering a value. Use the UP/DOWN buttons to

edit. Pressing the LOW CUT button for a longer time (please wait, until all

ve parameter LEDs light up) enables the keypad lock feature which prevents

inadvertent editing of parameters and settings. When the keypad lock is

enabled, the LOW CUT key’s control LED starts ashing.

(10) Use the GATE button to adjust the threshold of the internal Noise Gate

(-96 dB through -44 dB). When set to OFF, the Noise Gate is inoperative.

The control LED of the GATE button lights up while you are entering

a value. Pressing the GATE button for a longer time (please wait,

untilall ve parameter LEDs light up) enables the GATE LEARN function,

whichautomatically sets the Noise Gate threshold by analyzing the program

material and adjusting the value accordingly (value detected plus 2 dB).

InGATE LEARN mode, the GATE key’s control LED starts ashing. As long as

the LED ashes, the detected value is read on the display, when the LED stops

ashing, the value is raised by +2 dB.

The FILTER LEARN function generates short feedback-causing signals that

are sent back to the FBQ100’s input, where feedbacks are detected and

suppressed. The FILTER LEARN function is an useful tool for live concerts that

prevents lters from being released prematurely. Fixed lters can only be

recongured as free, searching lters by means of a RESET. In normal mode,

which is activated after power-up, set lters are automatically released

one after the other, when free lters are needed to search and destroy

feedbackfrequencies.

◊ To ensure that the FILTER LEARN function works properly, the short

feedback-causing signals are output with a level of -18 dB below digital

maximum. However, the feedback caused during the FILTER LEARN

procedure will be limited by the compressor to -30 dB below digital

maximum. Please note that considerable volume levels can still occur,

which is why you should use the FILTER LEARN function only before the

concert/event begins.

(13) Enable the ACTIVE button to set inoperative lters to automatic search

mode. When this button is up (control LED is o), those lters are inoperative

which have not yet found a feedback frequency. Pressing the ACTIVE button

for a longer time (please wait, until all ve parameter LEDs light up) enables

the RESET function. All lters will be reset, i.e. set to automatic search mode.

(14)

(15) (16)(23)

(11) The COMPRESSOR button gives you access to two parameters that let

you adapt the FBQ100’s Compressor function to the program material.

Press the button once to adjust the DENSITY parameter, which controls the

compression density from 0 (no processing) to 100 (maximumcompression).

Press the COMPRESSOR button a second time to adjust the SPEED

parameter which controls the Compressor’s attack and release times

from 10 to 1000msec. The “msec” LED lights up as soon as you select the

SPEEDparameter.

(12) The FILTER key allows you to set the feedback detection sensitivity within a

range from 1 (no sensitivity) through 100 (full sensitivity). The default value

is 50. The control LED lights up during data entry. Briey press the FILTER key

a second time to edit the maximum attenuation of the FB-D lter (from -3dB

through -48 dB in steps of 3). Pressing the FILTER key longer (please wait,

until all ve parameter LEDs light up) activates the FILTER LEARN function,

which automatically searches for feedback frequencies and assigns free

lters to the frequencies found. Now you can enter the number of lters

(standard: 9) to be used for permanent feedback suppression. Although the

remaining lters are also used to eliminate feedback frequencies, theyare

released once new feedback occurs. Pressing the FILTER key once again

activates the FILTER LEARN function.

◊ When both FILTER LED and display stop flashing, the FILTER LEARN

function has been completed. Press the FILTER key to cancel the

function. After a short delay, the unit returns to the FILTER menu.

(17) (18) (20) (22)(19) (21)

Fig 1.3: Rear panel co ntrol elements a nd connector s of the FBQ100

(14) This is the SHARK’s balanced XLR OUTPUT.

(15) This is the SHARK’s balanced XLR INPUT.

(16) The MIC GAIN control adjust the input signal gain, when the INPUT LEVEL

switch (21) has been pressed (position: MIC). To adjust microphone levels

you can use the CLIP LEVEL indicator, by setting the CLIP LEVEL control to

mid-travel position. Please make sure that the CLIP LED will not light up.

(17) Use the POWER SUPPLY CONNECTOR to hook up the SHARK’s external

power supply.

(18) This is the SHARK’s balanced JACK OUTPUT, which carries the same signal as

the XLR output.

(19) The OUTPUT LEVEL switch controls the reference level provided by the

outputs of the FBQ100. Possible values are: +4 dBu or microphone level.

(20) This is the SHARK’s balanced JACK INPUT, which is wired in parallel to the

XLR input.

Page 6

6 SHARK FBQ100 User Manual

(21) Use the INPUT LEVEL switch to select the input sensitivity (microphoneor

line levels). In LINE mode, you can use the CLIP LEVEL control to adapt the

internal level settings to the digital circuitry. Please make sure that the

CLIP-LED will not light up.

(22) The PHANTOM switch enables the Phantom Power supply required for

condenser microphones.

(23) The PHANTOM CONTROL LED lights up when Phantom Power is on.

2. Applications

2.1 Wiring the FBQ100: general remarks

With its great versatility the SHARK can be used for a variety of applications.

Thischapter describes connection and conguration examples of the most

common applications.

2.1.1 Connection between microphone and

mixingconsole

In live applications it is of ten useful to protect specic single microphones against

feedback. We therefore recommend that you connect the SHARK between your

microphone and a microphone input on your mixing console (OUTPUT LEVEL

switch set to MIC). If all mic inputs are in use, you can set the SHARK’s OUTPUT

switch to +4dBu (switch pressed) and adapt the output signal of your SHARK to

a line input on your console using the MIC GAIN control. To prevent the occurrence

of subsonics you can activate the SHARK’s Low Cut lter. Switch on Phantom

Power when you are using condenser microphones.

2.1.3 Connection between mixing console and

poweramplier

When you use the SHARK as a Delay Line unit for speaker systems placed at

various positions (see chapter 2.3), you should connect the SHARK between the

console’s output and the input of the power amp driving the “delayed” speakers.

Delayed Speakers Speakers on Stage

Master Out

+4 dBu

Line

Fig. 2.3: The SHARK connected between console and power amp

Mic In / Line In

Mic / +4 dBu Mic

Fig. 2.1: The SHARK connec ted between mic rophone and micr ophone input on con sole

2.1.2 Connection between line-level source and

mixingconsole

At rst sight, this conguration may seem to make no sense, because line-level

sources usually have no problems with feedback frequencies. However,acoustic

instruments are often equipped with so-called piezo pickups which are

susceptible to feedback. In such a case, we recommend that you route the audio

signal through the SHARK before feeding it into the console.

Line In

2.1.4 The SHARK used in the monitor path

Inserting the FBQ100 in the monitor path of your mixing console gives you

utmost protection against unwanted feedback. Monitor paths are particularly

susceptible to feedback, because on stage there are usually several microphones

and speakers placed close to each other. Especially vocal microphones pose

some problems, because their volume levels must be fairly high to be able to

“compete” with other instruments, and often these microphones are hand-held

and hence carried around on stage. It is therefore useful to protect the monitor

path against feedback. In particular, when used in the monitor path, the SHARK

produces a positive side eect in that it improves both sound and volume of the

monitors. By ltering interference it makes the sound more transparent and by

eliminating unwanted feedback it allows for raising the volume of the monitors,

an eect that is usually welcomed by musicians on stage. Another advantage

when using this conguration: one SHARK can control several microphones. Asat

least four monitor paths are used in a typical live application, all you need are

four SHARKs to give you optimum feedback protection.

+4 dBu Line

Fig. 2.2: The SH ARK connected be tween acousti c guitar and line inp ut on console

Page 7

7 SHARK FBQ100 User Manual

Monitoring P.A.

If you are using not just one FBQ100 for the monitor path, you should employ

some additional units to safeguard critical signal paths. Experience has shown

that during a concert the musicians on stage usually want their instruments

made louder in the monitors. With the SHARK you can raise the volume without

running the risk of feedback. When the concert begins the FBQ100 automatically

tracks and removes varying feedback signals produced by “moving”

vocalmicrophones.

2.2 The feedback destroyer in the SHARK

Monitor

+4 dBu Line

Fig. 2.4: Two SHARKs in th e monitor path

Out

Master Out

2.1.5 The SHARK used in single channels and subgroups

Whenever you want to make sure that wanted feedback such as the feedback

sounds produced by a guitar won’t be removed, you should insert one or several

FBQ100 into “feedback-prone” single channels (e.g. vocals) or subgroups of your

mixing console! Route all channels that are susceptible to feedback (e.g. all vocal

mics) to one or several subgroups, in which you insert one or several SHARKs.

Inthis way, all channels that are less liable to produce feedback (e.g. those

carrying line-level signals, or instrumental microphones with lower volumes)

can pass the console unaltered, while only critical microphone channels are

controlled by the FBQ100. Thus, you can protect your sound reinforcement system

against feedback and still use wanted feedback sounds.

Send

Return

+4

dBu

Line

In

Ground

Mixer

Insert Point

Fig. 2.5: The SHARK in the insert path

Out

Return

Send Ground

2.1.6 Automatic “tuning in” of P.A. and monitor systems

With the FBQ100 you can improve the protection against feedback even before

a concert begins, simply by “tuning in” your sound reinforcement system:

oncethe system has been installed and set up, open all microphone channels

and monitor paths, then enable FILTER LEARN mode on your FBQ100. The SHARK

generates short feedback-causing signals, which are then sent back to its input

and suppressed by the lters. These lters are permanently assigned and can

be recongured as free searching lters only by means of a RESET. Without the

SHARK you could raise the overall volume level only until the rst feedback

occurs. But with the FBQ100 you’ve got considerably more headroom! Please note

that the FILTER LEARN mode is limited to about 15 seconds.

The SHARK identies feedback by splitting the entire frequency spectrum

(20 Hz to 20 kHz) into sections of 1/60 of an octave and determining the level

of each of these bands. The values calculated are then referenced to the level

of the overall signal. The resulting level dierence determines whether or not

a lter is set. The SHARK allows you to adapt these decisive parameter to your

needs: withina range from 1 through 100 you can edit the feedback detection

sensitivity. Thestandard setting is 50, which ensures the best possible detection

of feedback for the majority of applications. For speech-only applications you can

raise the feedback detection threshold towards 100, which enables the algorithm

to detect and remove feedback even more quickly. Vice versa, lowervalues

provide for a more stable feedback suppression responding less to wanted

feedback-like signal portions produced by guitars or keyboards.

In FILTER LEARN mode, feedback is generated and suppressed automatically.

Whenever it detects feedback, the FBQ100 selects the lter parameters

automatically to eciently remove the feedback. As the lter is set to the

frequency detected, this mode is ideally suitable for suppressing constant

feedback frequencies produced by “xed” microphones, e.g. those used on

drums. Once set, the lters automatically enters lock mode, i.e. the frequenc y

remains xed but width and depth of the lter are still being adapted to the

signal. The lter width is enlarged whenever the feedback frequency shifts

slightly. If feedback persists, gain is reduced even more and kept low to prevent

feedback from recurring.

All microphones that are moved during a performance (e.g. hand-held

vocal microphones) are usually susceptible to varying feedback frequencies,

whichshould be suppressed in automatic search mode (entered when you

power up the SHARK). Much like in FILTER LEARN mode, a lter automatically

determines the ideal settings for all parameters, in order to suppress feedback.

However, onceall lters have been set, the lter rst ac tivated gets reset to

automatic search mode. Thus, the SHARK makes sure that there is always one free

lter to identify and remove new feedback frequencies. If your music contains

wanted feedback elements (e.g. guitar feedback), the SHARK will suppress these

too, because it is impossible from a physical point of view to distinguish wanted

from unwanted feedback. Section 2.1.6 provides some information on how to get

around this physical problem.

2.3 The integrated delay

In addition to speakers on or near the stage, major-scale installations often

have speaker groups positioned at a distance to the stage or own above the

audience, in order to provide listeners away from the stage with direct sound.

However, since sound needs some time to travel around (343.6 m/sec at 20°C,

acceleratesby 0.6 m/sec per °C), it reaches the audience not simultaneously

but gets delayed by a certain amount. To make up for the dierent run times

between stage and remote speakers, the latter must be provided with an

electronically delayed signal, which is usually done by means of special-purpose

Delay devices. Youwon’t need them, however, when you’ve got a SHARK,

asthe FBQ100 integrates a Delay Line circuit giving you the same convenience

of operation as dedicated devices. Simply measure the distance between the

various speaker groups and enter this value (in meters or feet). Chapter 2.1.3

shows you how to wire the FBQ100 in this type of application.

Page 8

8 SHARK FBQ100 User Manual

Gallery

Speaker

Stage

Speaker

Stage

Fig. 2.6: Sound reinforcement application with dierent speaker positions

Gallery

2.5 The low cut lter in the SHARK

In miking it is quite common to fade out low-frequency signal por tions such as

stage rumble, pop sounds or other types of interference. Frequencies of that kind

often have high amplitudes and not only aect the sound image but can also

damage power amps and/or loudspeakers. The SHARK is equipped with a tunable

high pass lter that features a very high slope. Press the LOW CUT button to tune

the cuto frequency from 20 Hz through 150 Hz with the UP/DOWN buttons,

sothat interference noise is faded out as perfectly as possible, while the wanted

signals remains unaected.

2.6 The compressor function

2.4 The noise gate function

The main task of a Noise Gate is to separate unwanted background noise from

wanted signals and remove noise “inaudibly”. A so-called downward Expander

automatically reduces the overall level of all signals below an adjustable

threshold and thus expands the dynamic range of the program material.

In live or stage applications and multi-microphone systems, in particular, the

SHARK has a variety of possible uses: as a moderately and accurately set Gate it

eciently suppresses background noise, compressor-induced noise build-up and

crosstalk bet ween microphones, without producing any unpleasant side eects.

A typical Gate application is the processing of vocal tracks. Especially when using

a Compressor, the distance between microphone and singer is critical: asthe

distance increases, more and more disturbing background noise is picked up.

Use the Gate function to fade out unwanted interference “inaudibly” during

music pauses. In live applications, e.g. crosstalk of drum and piano tracks can be

suppressed or acoustically “contaminated” recordings can be cleaned.

When a singer sings into a stage microphone, the background noise is masked

and hence not perceived. During music pauses, however, the microphone picks

up the noise produced by the P.A. system and monitor speakers, which can lead

to unpleasant feedback.

When you insert the SHARK in a vocal channel and adjust it so that it mutes the

channel, as long as the microphone is not in use, susceptibility to feedback can

be reduced enormously. Basically, all stage microphones should be treated in

thisway.

The GATE LEARN function helps you adjust the Gate threshold. Use this func tion

before the concert and after the sound check. If the adjusted value yields

unsatisfactory results, the UP/DOWN buttons can be used to ne-tune the Gate,

until it closes only during signal pauses and suppresses interference eciently.

In broadcast and recording applications, signal levels often exceed the

headroom of signal-processing devices, which means that the dynamic range

must be reduced to avoid distortion. This is usually accomplished by the use of

Compressors or Limiters, which use an automatic gain control circuit to reduce

the signal level during loud passages. In this way, it is possible to compress the

dynamics of a microphone channel from 90 dB to 50 dB or less, whichensures

the troublefree further processing of signals, e.g. in broadcast, stage or

recordingapplications.

The Compressor monitors the program material using an adjustable threshold

and continuous level control process, i.e. above threshold the signal gain is

reduced, depending on threshold overshoot. Usually, the threshold is set to

somewhere below the operating level to allow for a musical compression of the

upper level range.

The FBQ100 allows you to set two Compressor parameters. The rst one, DENSITY,

compresses the program material in a range from 0 (bypass) through100

(max. compression). The second parameter, SPEED, allows you to adjust the

Compressor function in the time domain. Here, you can set the control speed

of the Compressor from 10 through 1000 msec. Use small values to make the

Compressor respond to smallest level dierences, and high values to process

dynamics “inaudibly”.

3. Installation

3.1 Audio connections

As standard, the BEHRINGER FBQ100 is installed with electronically ser vobalanced inputs and outputs. The new circuit design features automatic hum and

noise reduction for balanced signals and thus allows for trouble-free operation,

even at high operating levels. Externally induced mains hum etc. will be

eectively suppressed.

Output Cable Input

Pin 1

2 1

Pin 2 = (+) Signal

3

Pin 3 = (-) Signal

Fig. 3.1: Compensation of interference with balanced connections

Shield

(+) Signal + Hum

(-) Signal + Hum

RFI and Hum

1 2

3

Ground

Positive

Negative

(+)Hum + Signal

(-)Hum + Signal

2 x Signal

= Signal + 6 dB

Page 9

9 SHARK FBQ100 User Manual

Unbalanced ¼" TS connector

strain relief clamp

sleeve

tip

sleeve

(ground/shield)

tip

(signal)

Balanced ¼" TRS connector

strain relief clamp

sleeve

ring

tip

sleeve

ground/shield

ring

cold (-ve)

tip

hot (+ve)

For connection of balanced and unbalanced plugs,

ring and sleeve have to be bridged at the stereo plug.

4. Specications

Audio Inputs

Connectors XLR and ¼" TRS jack

Impedance 6 kΩ balanced, 3 kΩ unbalanced

Nominal operating level Microphone or line level source

(switchable)

Max. input level +19 dBu at microphone level and

linelevel

Audio Outputs

Connectors XLR and ¼" jack

Impedance 60 Ω balanced, 30 Ω unbalanced

Nominal operating level Microphone level source or +4 dBu

(switchable)

Max. output level +20 dBu at +4 dBu nominal level,

-12 dBu at microphone level

System Specications

Frequency response 10 Hz to 21 kHz

Noise > 92 dB at line level, unweighted,

22 Hz to 22 kHz

> 89 dB at microphone level,

unweighted,

22 Hz to 22 kHz

Balanced use with XLR connectors

12

3

input

1 = ground/shield

2 = hot (+ve)

3 = cold (-ve)

1

2

3

output

For unbalanced use, pin 1 and pin 3

have to be bridged

Fig. 3.2: Di erent plug type s

◊ Please ensure that only qualified persons install and operate the

SHARK. During installation and operation the user must have sufficient

electrical contact to earth. Electrostatic charges might affect the

operation of the SHARK!

THD 0.007% typ. @ +4 dBu, 1 kHz, gain 1

Digital Processing

Converters 24-bit Sigma-Delta,

64/128-times oversampling

Display

Type 4-digit numeric LED display

Power Supply

Mains Voltages/Power Consumption

USA/Canada 120 V~ 60 Hz 19 W

U.K./Australia 240 V~ 50 Hz 20.5 W

Europe 230 V~ 50 Hz 20 W

Korea 220 V~ 50 Hz 20 W

China 220 V~ 50 Hz 20 W

Japan 100 V~ 50/60 Hz 18 W

Physical

Dimensions (H x W x D)

approx. 2.2 x 3.5 x 5.2" / 56 x 88 x 132 mm

Net Weight approx. 0.84 lbs / 0.38 kg

BEHRINGER i s constantly str iving to maintain the h ighest profess ional standards. A s a result of these e ffort s,

modific ations may be made f rom time to time to exi sting product s without prio r notice. Specif ications and

appearance m ay differ fro m those listed or illus trated.

Page 10

10 SHARK FBQ100 User Manual

5. Rackmount (Optional)

With the available rackmount (optional) you have the possibilit y to place ve

SHARKs on two units of space in your rack.

◊ Before you begin with the work, please disconnect the Power Supply

Units from the SHARKs!

To mount the SHARKs on the rackmount you should use the supplied screws

(typeM3). You need two screws to x one FBQ100 onto the rackmount. In the

bottom of your SHARK you will nd two little threads. You have to position the

single SHARKs on the rackmount, so that the threads correspond to the cutouts

of the rackmount (see g.5.1). Now you can x the FBQ100 onto the rackmount.

Just take a cross-point screwdriver and tighten both screws loosely. After you

have xed all SHARKs on the rackmount, you can adjust the devices and tighten

all screws solidly.

Bottom FBQ100

Thread 1

Thread 2

Cutout 1

Cutout 2

Front Rackmount (Bottom View)

Fig. 5.1: Installation of t he FBQ100 on the available r ackmount (optional )

◊ Please, only use the supplied screws to install the SHARKs on the

rackmount. Longer or thicker screws can damage the electronics inside

of the device and doing so will void your warranty rights.

You will need 2 units of space for the FBQ100 rackmount. For technical reasons a

little gap remains above the rackmount.

Page 11

11 SHARK FBQ100 User Manual

FEDERAL COMMUNICATIONS

COMMISSION COMPLIANCE

INFORMATION

SHARK FBQ100

Responsible Party Name: MUSIC Group Services US Inc.

Address: 18912 North Creek Parkway,

Suite 200 Bothell, WA 98011,

USA

Phone/Fax No.: Phone: +1 425 672 0816

Fax: +1 425 673 7647

SHARK FBQ100

complies with the FCC rules as mentioned in the followingparagraph:

This equipment has been tested and found to comply with the limits for a ClassB

digital device, pur suant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined

by turning the equipment o and on, the user is encouraged to try to correc t the

interference by one or more of the followingmeasures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician forhelp.

This device complies with Part 15 of the FCC rules. Operation is subject to the

following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any inter ference received, including inter ference that may

cause undesired operation.

Important information:

Changes or modications to the equipment not expressly approved by MUSIC Group

can void the user’s authority to use the equipment.

Page 12

We Hear You

Loading...

Loading...