Page 1

Documentation

EP3744-0041 and EP3744-1041

EtherCAT Box with digital inputs, outputs and differential

pressure inputs

Version:

Date:

2.2

2019-03-05

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation Issue Status..............................................................................................................7

2 Product overview.......................................................................................................................................8

2.1 EtherCAT Box - Introduction..............................................................................................................8

2.2 Introduction......................................................................................................................................10

2.3 Technical data .................................................................................................................................11

2.4 Process image.................................................................................................................................12

3 Mounting and connection.......................................................................................................................14

3.1 Mounting..........................................................................................................................................14

3.1.1 Dimensions ...................................................................................................................... 14

3.1.2 Fixing ............................................................................................................................... 15

3.1.3 Nut torque for connectors ................................................................................................ 16

3.2 Connection ......................................................................................................................................18

3.2.1 EtherCAT connection....................................................................................................... 18

3.2.2 EtherCAT - Fieldbus LEDs .............................................................................................. 20

3.2.3 Power Connection ........................................................................................................... 21

3.2.4 Status LEDs for power supply ......................................................................................... 24

3.2.5 Power cables ................................................................................................................... 25

3.2.6 Power cable conductor losses M8 ................................................................................... 26

3.2.7 Signal connection ............................................................................................................ 27

3.2.8 Status LEDs at the signal connections ............................................................................ 28

3.3 UL Requirements.............................................................................................................................29

4 Commissioning/Configuration ...............................................................................................................30

4.1 Inserting into the EtherCAT network................................................................................................30

4.2 Configuration via TwinCAT..............................................................................................................33

4.3 Object overview ...............................................................................................................................41

4.4 Object description and parameterization .........................................................................................47

4.4.1 Objects to be parameterized during commissioning........................................................ 47

4.4.2 Standard objects (0x1000-0x1FFF) ................................................................................. 51

4.4.3 Profile specific objects (0x6000-0xFFFF) ........................................................................ 58

4.5 Settings............................................................................................................................................62

4.6 Restoring the delivery state .............................................................................................................65

4.7 Firmware Update EL/ES/EM/EPxxxx ..............................................................................................66

5 Appendix ..................................................................................................................................................76

5.1 General operating conditions...........................................................................................................76

5.2 EtherCAT Box- / EtherCATPBox - Accessories ............................................................................77

5.3 Support and Service ........................................................................................................................78

EP3744-0041 and EP3744-1041 3Version: 2.2

Page 4

Table of contents

EP3744-0041 and EP3744-10414 Version: 2.2

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATP®, SafetyoverEtherCAT®, TwinSAFE®, XFC® and XTS® are

registered trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

EP3744-0041 and EP3744-1041 5Version: 2.2

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

EP3744-0041 and EP3744-10416 Version: 2.2

Page 7

1.3 Documentation Issue Status

Version Modifications

2.2 • Update technical data

2.1 • Update Safety instructions

• Correction in chapter Process image

• Correction in chapter Power cable

• Update chapter Mounting

2.0.0 • Migration

1.3.0 • Chapter Settings added

1.2.0 • Power Connection updated

1.1.0 • Front page updated

• EP3744-1041 added to EP3744-x041 introduction

• EP3744-1041 added to Technical Data

• Process image heading adapted

• Support and Service updated

• Safety instructions updated

• Notes on the documentation updated

• EtherCAT connection updated

• Nut torques for connectors updated

• EtherCAT cables updated

1.0.0 • First release

0.1.0 • Preliminary version

Foreword

Firmware and hardware versions

This documentation refers to the firmware and hardware version that was applicable at the time the

documentation was written.

The module features are continuously improved and developed further. Modules having earlier production

statuses cannot have the same properties as modules with the latest status. However, existing properties

are retained and are not changed, so that older modules can always be replaced with new ones.

The firmware and hardware version (delivery state) can be found in the batch number (D-number) printed on

the side of the EtherCATBox.

Syntax of the batch number (D-number):

D: WWYYFFHH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with D no. 50 13 03 01:

50 - week of production 50

13 - year of production 2013

03 - firmware version 03

01 - hardware version 01

EP3744-0041 and EP3744-1041 7Version: 2.2

Page 8

Product overview

2 Product overview

2.1 EtherCAT Box - Introduction

The EtherCAT system has been extended with EtherCAT Box modules with protection class IP67. Through

the integrated EtherCAT interface the modules can be connected directly to an EtherCAT network without an

additional Coupler Box. The high-performance of EtherCAT is thus maintained into each module.

The extremely low dimensions of only 126x30x26.5 mm (hxw xd) are identical to those of the Fieldbus

Box extension modules. They are thus particularly suitable for use where space is at a premium. The small

mass of the EtherCAT modules facilitates applications with mobile I/O interface (e.g. on a robot arm). The

EtherCAT connection is established via screened M8connectors.

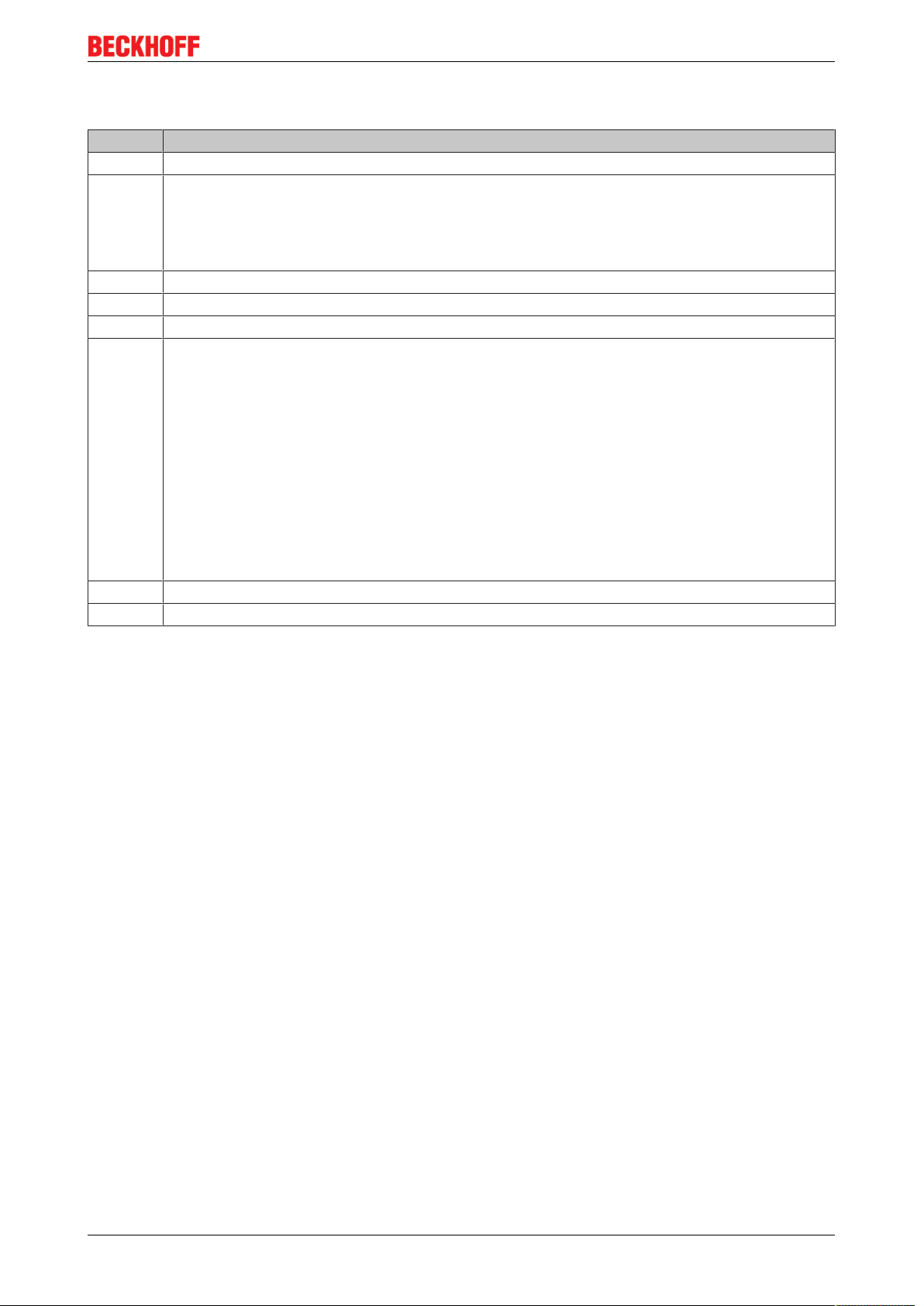

Fig.1: EtherCAT Box Modules within an EtherCAT network

The robust design of the EtherCAT Box modules enables them to be used directly at the machine. Control

cabinets and terminal boxes are now no longer required. The modules are fully sealed and therefore ideally

prepared for wet, dirty or dusty conditions.

Pre-assembled cables significantly simplify EtherCAT and signal wiring. Very few wiring errors are made, so

that commissioning is optimized. In addition to pre-assembled EtherCAT, power and sensor cables, fieldconfigurable connectors and cables are available for maximum flexibility. Depending on the application, the

sensors and actuators are connected through M8 or M12connectors.

The EtherCAT modules cover the typical range of requirements for I/O signals with protection class IP67:

• digital inputs with different filters (3.0ms or 10μs)

• digital outputs with 0.5 or 2A output current

• analog inputs and outputs with 16bit resolution

• Thermocouple and RTD inputs

• Stepper motor modules

XFC (eXtreme Fast Control Technology) modules, including inputs with time stamp, are also available.

EP3744-0041 and EP3744-10418 Version: 2.2

Page 9

Fig.2: EtherCAT Box with M8 connections for sensors/actuators

Product overview

Fig.3: EtherCAT Box with M12 connections for sensors/actuators

Basic EtherCAT documentation

You will find a detailed description of the EtherCAT system in the Basic System Documentation for

EtherCAT, which is available for download from our website (www.beckhoff.com) under Downloads.

EtherCAT XML Device Description

You will find XML files (XML Device Description Files) for Beckhoff EtherCAT modules on our website (www.beckhoff.com) under Downloads, in the Configuration Files area.

EP3744-0041 and EP3744-1041 9Version: 2.2

Page 10

Product overview

2.2 Introduction

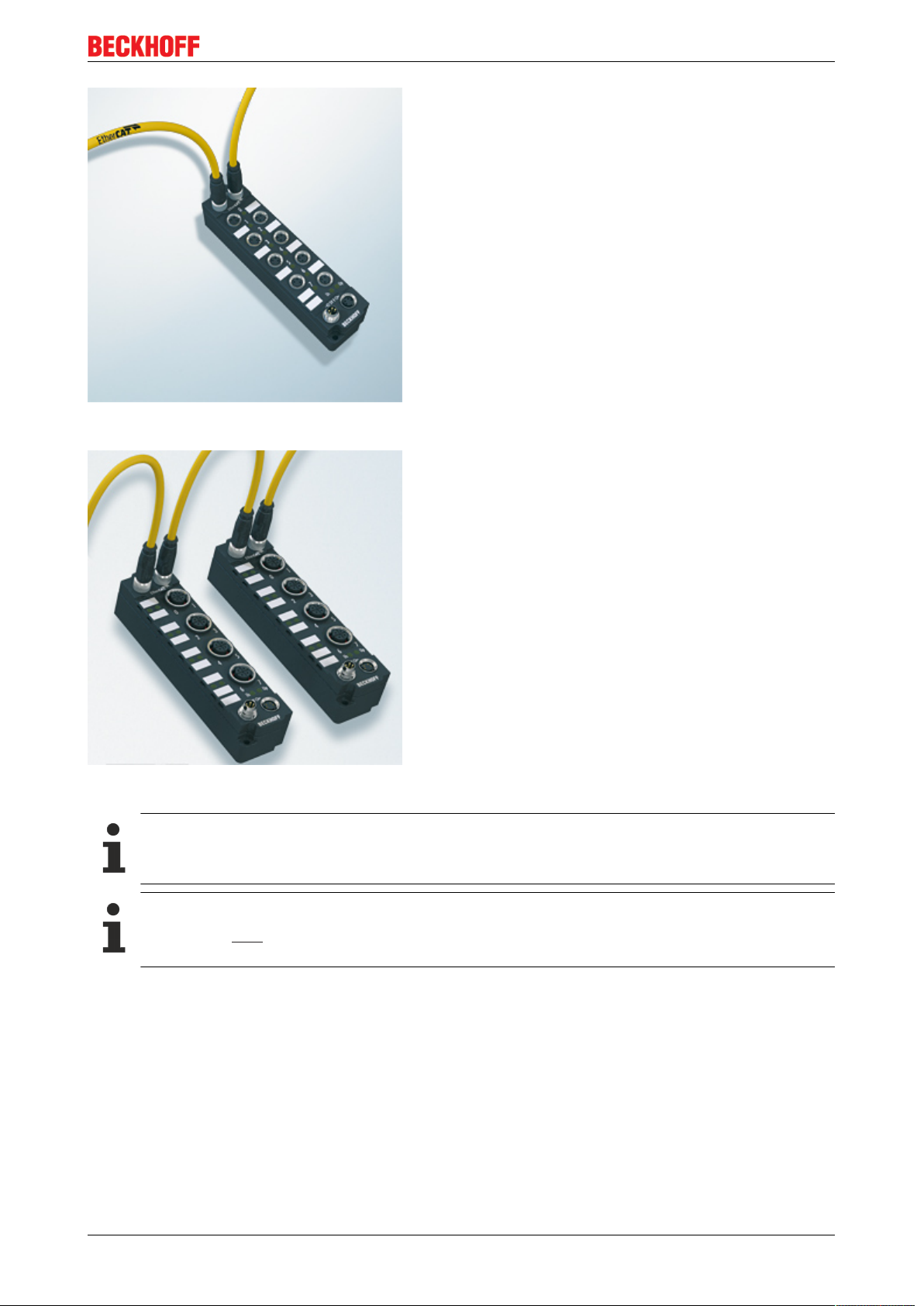

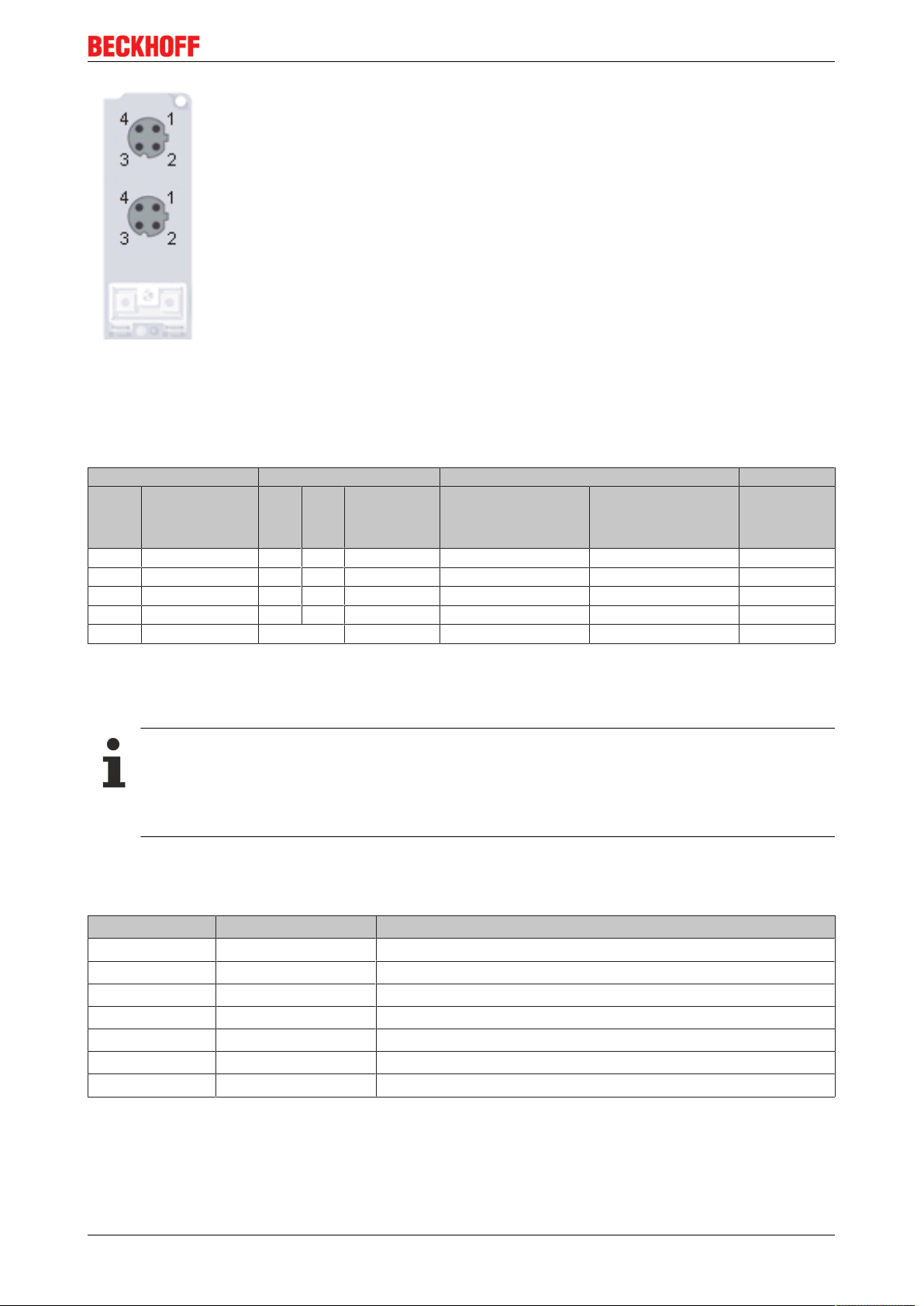

Fig.4: EP3744-0041, EP3744-1041

EtherCAT Box with 6 digital inputs (24VDC, 10µs), 2 digital outputs (24V

pressure inputs

The EP3744-x041 EtherCAT Box with six digital inputs and two digital outputs records binary control signals

from the process level and transfers them, electrically isolated, to the controller. The signal status is

indicated by LEDs, the signals are connected via 3-pole M8 plug connectors (sockets).

Four pneumatic connections (6mm) offer the possibility to directly measure differential pressure. This value

is measured or calculated in relation to the fifth reference pressure connection (6mm).

The sensors and outputs are supplied from the control voltage Us. Since only one GND is available on the

M8 plug for the inputs and outputs, this alternative supply was selected.

The load voltage Up is not used in the input module, but may optionally be connected in order to be relayed

downstream.

Pressure measurement with EP3744-0041

The pressure is measured as an absolute value or as a differential value relative to the fifth connection via

an integrated 6mm fitting. The pressure values are available as 16-bit values. Measurement can take place

between -1bar and +1bar, wherein the value is output relative to the fifth connection, e.g. for vacuum

measurement in relation to the ambient pressure at the suction grippers. In absolute pressure mode,

pressures between 0 and 1bar can be measured.

0.5A) and reference

DC,

Pressure measurement with EP3744-1041

The pressure is measured as an absolute value or as a differential value relative to the fifth connection via

an integrated 6mm fitting. The pressure values are available as 16-bit values. Measurement can take place

between -7bar and +7bar, wherein the value is output relative to the fifth connection, e.g. for vacuum

measurement in relation to the ambient pressure at the suction grippers. In absolute pressure mode,

pressures between 0 and 7bar can be measured.

• Installation [}14]

• UL requirements [}29] for UL-approved modules

EP3744-0041 and EP3744-104110 Version: 2.2

Page 11

Product overview

2.3 Technical data

Technical data EP3744-0041 EP3744-1041

Fieldbus EtherCAT

Fieldbus connection 2 x M8 socket (green)

Number of digital inputs 6 digital inputs

Input connections [}27]

Rated input voltage 24VDC (-15%/+20%)

Input filter 10µs (for digital inputs)

"0" signal voltage -3...+5V (EN61131-2, type3)

"1" signal voltage +11...+30V (EN61131-2, type3)

Input current typically 3mA (EN61131-2, type3)

Number of outputs 2 digital outputs

Output connections [}27]

Rated output voltage 24VDC (-15%/+20%)

Diagnostics Undervoltage detection <18VDC for Us and Up

Number of pressure inputs 4 pressure inputs + 1 reference pressure input, d = 6mm

Pressure connectors Fittings, d=6mm

Pressure sensors 15psi / 1034hPa 100psi / 6894hPa

Technology (optional) • Differential pressure measurement relative to reference

Measuring range differential pressure

measurement

Measuring range absolute pressure

measurement

Permissible media Non-aggressive gases

Resolution 1mbar per digit

Measuring error 3% of full scale value

Max. overload 3 x P

Resolution (raw value) 16bit

Conversion time 5 x cycle time

Min. cycle time 700µsec

Supply of the module circuitry from the control voltage Us

Current consumption of the module circuitry typically 120mA

Sensor supply from the control voltage Us

Sensor current consumption max. 0.5A, short-circuit proof overall

Power supply connection Power supply: 1 x M8 plug, 4-pole

Electrical isolation Control voltage/fieldbus: yes

Permissible ambient temperature during

operation

Permissible ambient temperature during

storage

Vibration/ shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC immunity/emission conforms to EN61000-6-2/ EN61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

Approvals

4 x M8 (sockets 0, 1, 2 and 3)

2 x M8 (sockets 2 and 3)

pressure measuring point (default)

• Absolute pressure measurement

-1...1bar (-15...15psi) -7...7bar (-100...100psi)

0...1bar (0...15psi) 0...7bar (0...100psi)

max

Onward connection: 1 x M8 socket, 4-pole

-25°C ... +60°C

0 °C ... +55 °C (according to cULus, see UL requirements

[}29])

-40°C ... +85°C

CE,cULus [}29]

EP3744-0041 and EP3744-1041 11Version: 2.2

Page 12

Product overview

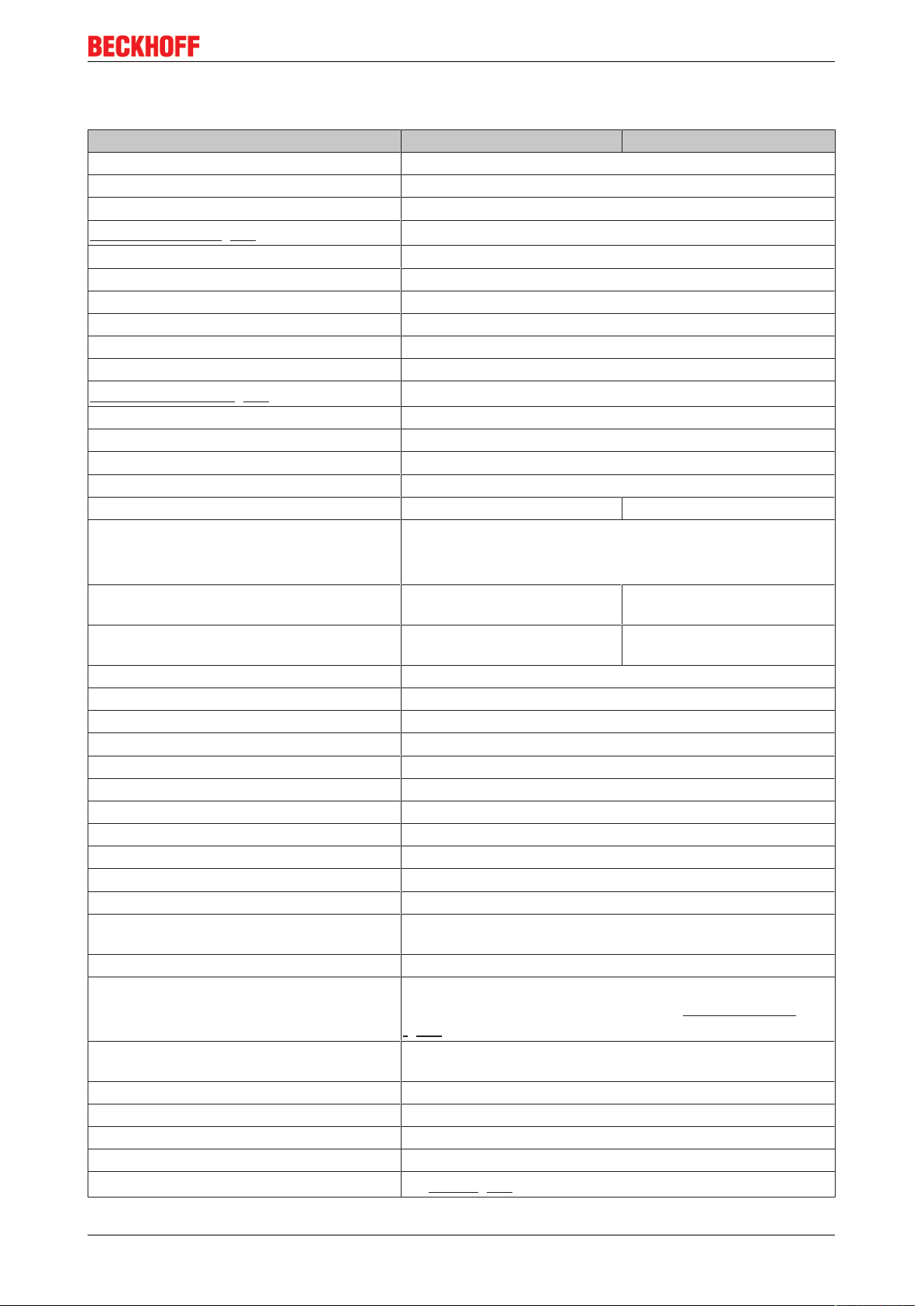

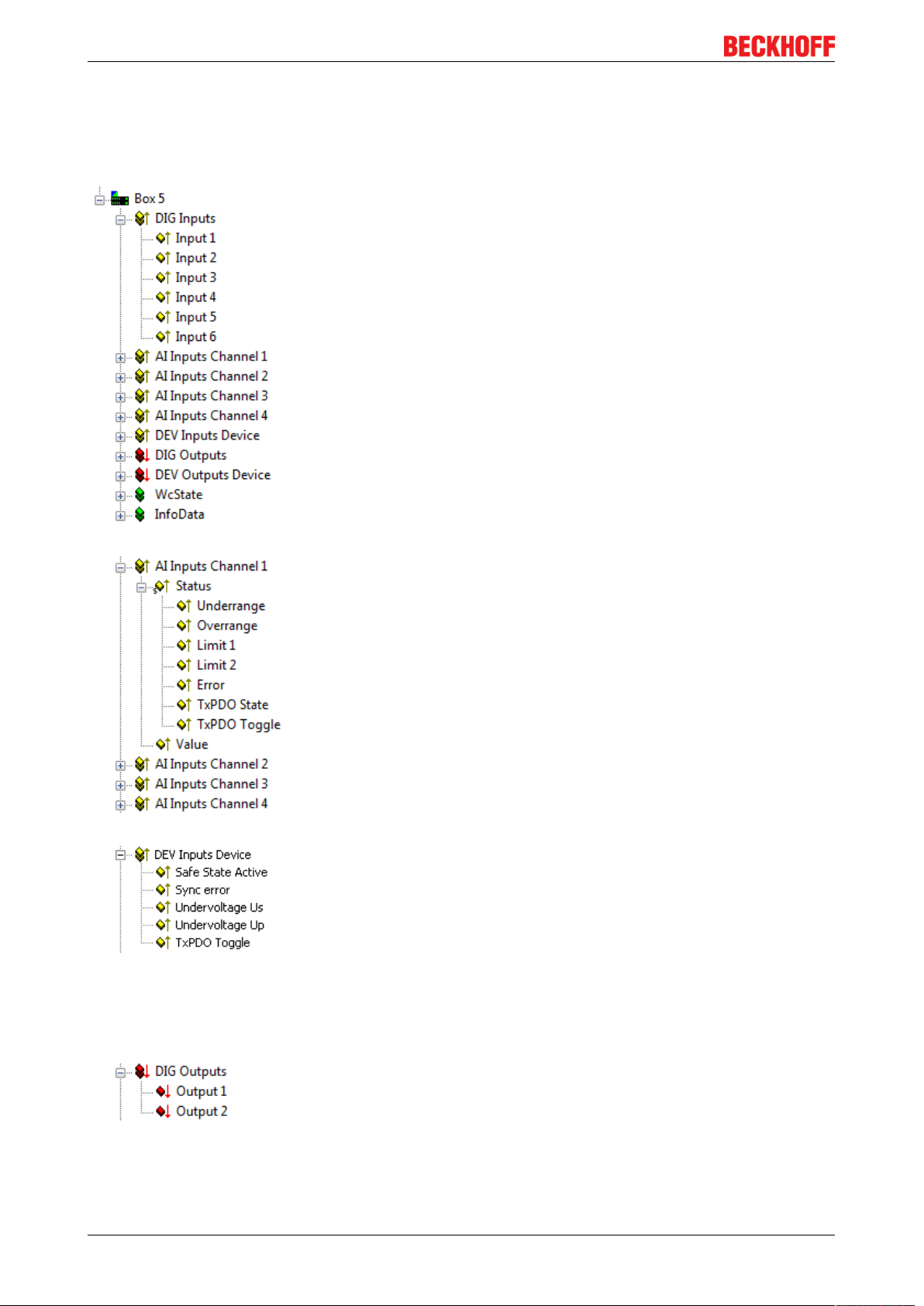

2.4 Process image

Channel 1 to channel 16

The six digital inputs of the module can be found under DIG inputs 1 to 6.

• Input 1 - socket 0, pin 4

• Input 2 - socket 0, pin 2

• Input 3 - socket 1, pin 4

• Input 4 - socket 1, pin 2

• Input 5 - socket 2, pin 4

• Input 6 - socket 3, pin 4

The four pressure measuring inputs of the module can be found under AI

inputs Channel 1 to 4.

• Underrange: the pressure has fallen below the underrange value

• Overrange: the pressure has exceeded the overrange value

• Limit1: the Limit1 value specified in the CoE objects was reached

• Limit2: the Limit2 value specified in the CoE objects was reached

• Error: one of the above events has occurred

• Value: the measured pressure value in the unit pre-scaled in the CoE

objects (e.g. mbar)

The diagnostic data for the module can be found under DEV Inputs Device.

• Safe State Active: there was an interruption in communication, causing the

outputs to change to the safe state

• Sync error: a synchronization error has occurred

• Undervoltage Us: the voltage Us is less than approx. 18V

• Undervoltage Up: the voltage Up is less than approx. 18V

DC

DC

• TxPDO Toggle: EtherCAT variable for displaying a transmitted date of

receipt (see general EtherCAT documentation)

The two digital outputs of the module can be found under DIG outputs 1 and

2.

• Output 1 - socket 2, pin 2

• Output 2 - socket 3, pin 2

EP3744-0041 and EP3744-104112 Version: 2.2

Page 13

Product overview

The output variables for setting or resetting the outputs of the module can be

found under DEV Output Device.

• Set safe state: outputs assume the defined value (see CoE objects)

• Reset Outputs: reserved

These are standard EtherCAT variables; more information in the general

EtherCAT manual.

EP3744-0041 and EP3744-1041 13Version: 2.2

Page 14

Mounting and connection

3 Mounting and connection

3.1 Mounting

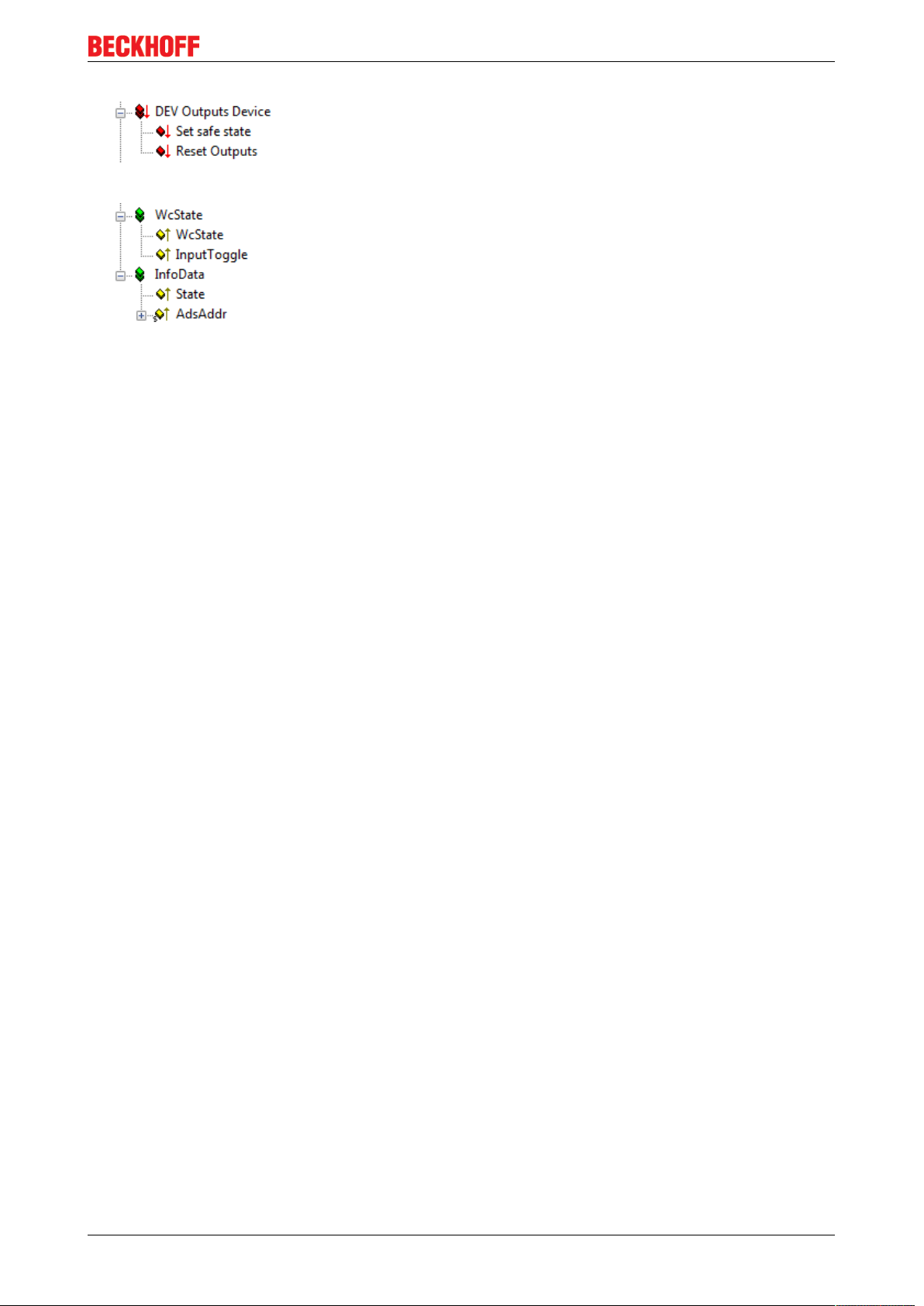

3.1.1 Dimensions

Fig.5: Dimensions of the EtherCAT Box Modules

All dimensions are given in millimeters.

Housing properties

EtherCAT Box lean body wide bodies

Housing material PA6 (polyamide)

Casting compound Polyurethane

Mounting two fastening holes Ø3mm for M3 two fastening holes Ø3mm for M3

two fastening holes Ø4.5mm for M4

Metal parts Brass, nickel-plated

Contacts CuZn, gold-plated

Power feed through max. 4A (M8)

max. 16A (7/8“)

max. 15.5A (B17 5G 1.5mm2)

Installation position variable

Protection class IP65, IP66, IP67 (conforms to EN 60529) when screwed together

Dimensions

(HxWxD)

app. 126 x 30 x 26.5mm app. 126 x 60 x 26,5mm

app. 150 x 60 x 26.5mm (without 7/8", B17)

EP3744-0041 and EP3744-104114 Version: 2.2

Page 15

Mounting and connection

3.1.2 Fixing

Protection of connectors against contamination!

While mounting the modules, protect all connectors, especially the IP-Link, against contamination!

Only with connected cables or plugs the protection class IP67 is guaranteed! Unused connectors

have to be protected with the right plugs! See for plug sets in the catalogue.

Modules with narrow housing are mounted with two M3 bolts.

Modules with wide housing are mounted with two M3 bolts to the fixing holes located at the corners or

mounted with two M4 bolts to the fixing holes located centrally.

The bolts must be longer than 15 mm. The fixing holes of the modules are not threaded.

When assembling, remember that the fieldbus connectors increases the overall height. See chapter

accessories.

Mounting Rail ZS5300-0001

The mounting rail ZS5300-0001 (500 mm x 129 mm) allows the time saving assembly of modules.

The rail is made of stainless steel, 1.5 mm thick, with already pre-made M3 threads for the modules. The rail

has got 5.3 mm slots to mount it via M5 screws to the machine.

Fig.6: Mounting Rail ZS5300-000

The mounting rail is 500 mm long, that way 15 narrow modules can be mounted with a distance of 2 mm

between two modules. The rail can be cut to length for the application.

Mounting Rail ZS5300-0011

The mounting rail ZS5300-0011 (500 mm x 129 mm) has in addition to the M3 treads also pre-made M4

treads to fix 60 mm wide modules via their middle holes.

Up to 14 narrow or 7 wide modules may be mixed mounted.

EP3744-0041 and EP3744-1041 15Version: 2.2

Page 16

Mounting and connection

3.1.3 Nut torque for connectors

M8 connectors

It is recommended to pull the M8 connectors tight with a nut torque of 0.4 Nm. When using the torque control

screwdriver ZB8800 is also a max. torque of 0.5Nm permissible.

Fig.7: EtherCAT Box with M8 connectors

M12 connectors

It is recommended to pull the M12 connectors tight with a nut torque of 0.6 Nm.

Fig.8: EtherCAT Box with M8 and M12 connectors

EP3744-0041 and EP3744-104116 Version: 2.2

Page 17

7/8" plug connectors

We recommend fastening the 7/8" plug connectors with a torque of 1.5Nm.

Fig.9: 7/8" plug connectors

Torque socket wrenches

Mounting and connection

Fig.10: ZB8801 torque socket wrench

Ensure the right torque

Use the torque socket wrenches available by Beckhoff to pull the connectors tight (ZB8800,

ZB8801-0000)!

EP3744-0041 and EP3744-1041 17Version: 2.2

Page 18

Mounting and connection

3.2 Connection

CAUTION

Druckluft

• Before connecting or disconnecting the module, check that the system is under pressure.

ð The compressed air connections must not be opened while the system is under pressure.

• The general safety and installation instructions for handling compressed air must be observed.

3.2.1 EtherCAT connection

For the incoming and ongoing EtherCAT connection,

• the EtherCAT Box (EPxxxx) has two M8 sockets, marked in green

• the Coupler Box (FBB-x110) has two M12 sockets

Fig.11: EtherCAT Box: M8, 30mm housing

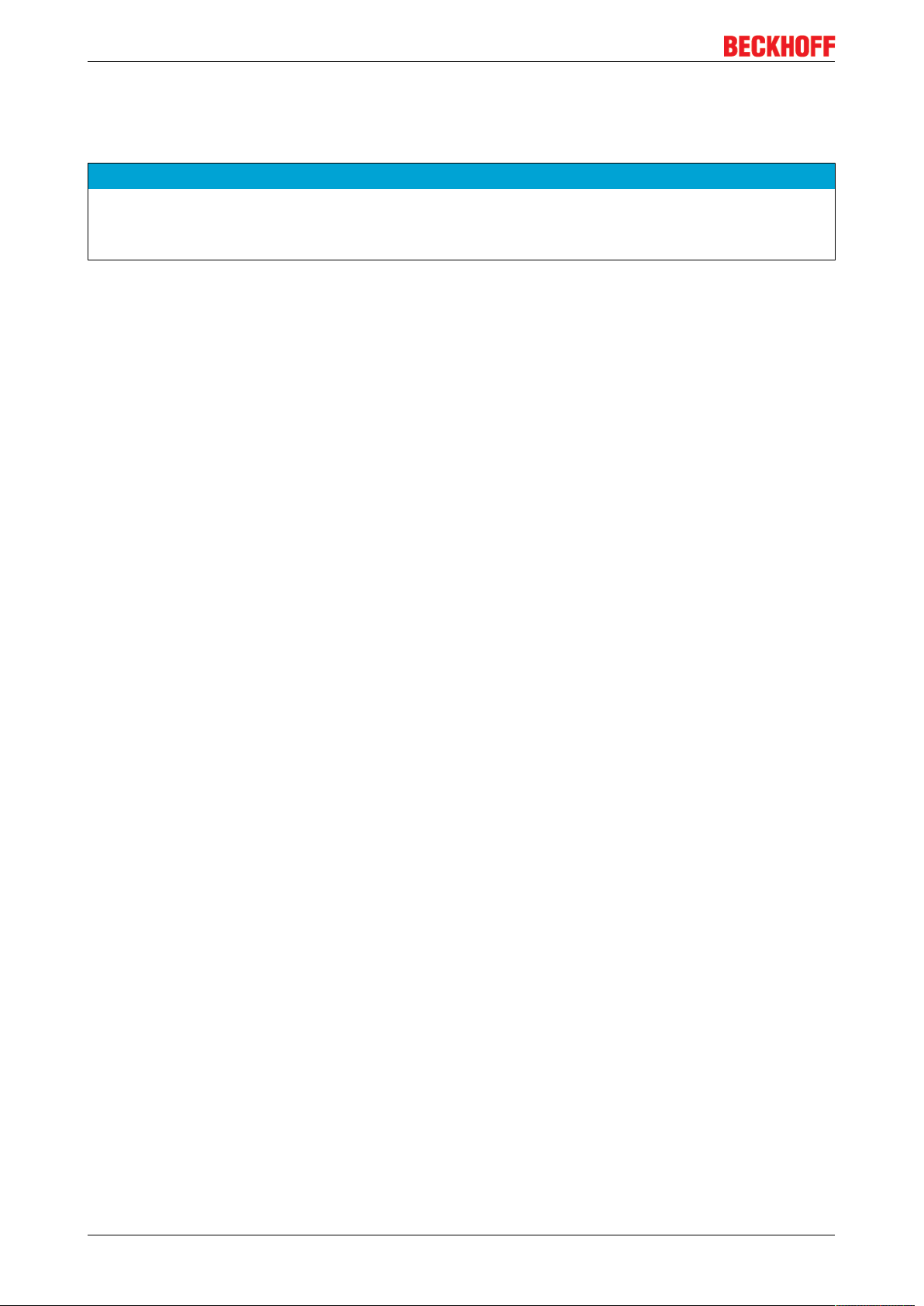

Fig.12: EtherCAT Box: M860mm housing (example: EP9214)

EP3744-0041 and EP3744-104118 Version: 2.2

Page 19

Mounting and connection

Fig.13: Coupler Box: M12

Assignment

There are various different standards for the assignment and colors of connectors and cables for Ethernet/

EtherCAT.

Ethernet/EtherCAT Plug connector Cable Standard

Signal Description M8 M12 RJ45

Tx + Transmit Data+ Pin 1 Pin 1 Pin 1 yellow

Tx - Transmit Data- Pin 4 Pin 3 Pin 2 orange

Rx + Receive Data+ Pin 2 Pin 2 Pin 3 white

Rx - Receive Data- Pin 3 Pin 4 Pin 6 blue

Shield Shield Housing Shroud Screen Screen Screen

1

ZB9010, ZB9020,

ZB9030, ZB9032,

ZK1090-6292,

ZK1090-3xxx-xxxx

2

2

2

2

ZB9031 and old versions

of ZB9030, ZB9032,

ZK1090-3xxx-xxxx

orange/white

orange

blue/white

3

blue

3

3

3

TIA-568B

white/orange

orange

white/green

green

1

) colored markings according to EN 61918 in the four-pin RJ45 connector ZS1090-0003

2

) wire colors according to EN 61918

3

) wire colors

Assimilation of color coding for cable ZB9030, ZB9032 and ZK1090-3xxxx-xxxx (with

M8 connectors)

For unification the prevalent cables ZB9030, ZB9032 and ZK1090-3xxx-xxxx this means the pre assembled cables with M8 connectors were changed to the colors of EN61918 (yellow, orange, white,

blue).So different color coding exists. But the electrical properties are absolutely identical.

EtherCAT connector

The following connectors can be supplied for use in Beckhoff EtherCAT systems.

Name Connector Comment

ZS1090-0003 RJ45 four-pole, IP20, field-configurable

ZS1090-0004 M12, male four-pin, IP67, for field assembly

ZS1090-0005 RJ45 eight-pole, IP20, field-configurable, suitable for gigabit Ethernet

ZS1090-0006 M8 plug connector four-pole, IP67, field-configurable, for cable type ZB903x

ZS1090-0007 M8 socket four-pole, IP67, field-configurable, for cable type ZB903x

ZS1090-1006 M8 plug connector four-pole, IP67, field-configurable up to OD=6.5mm

ZS1090-1007 M8 socket four-pole, IP67, field-configurable up to OD=6.5mm

EP3744-0041 and EP3744-1041 19Version: 2.2

Page 20

Mounting and connection

3.2.2 EtherCAT - Fieldbus LEDs

Fig.14: EtherCAT-LEDs

LED display

LED Display Meaning

IN L/A off no connection to the preceding EtherCAT module

Lit LINK: connection to the preceding EtherCAT module

flashing ACT: Communication with the preceding EtherCAT module

OUT L/A off no connection to the following EtherCAT module

Lit LINK: connection to the following EtherCAT module

flashing ACT: Communication with the following EtherCAT module

Run off Status of the EtherCAT module is Init

flashes quickly Status of the EtherCAT module is pre-operational

flashes slowly Status of the EtherCAT module is safe-operational

Lit Status of the EtherCAT module is operational

EtherCAT statuses

The various statuses in which an EtherCAT module may be found are described in the Basic System Documentation for EtherCAT, which is available for download from our website (www.beck-

hoff.com) under Downloads.

EP3744-0041 and EP3744-104120 Version: 2.2

Page 21

Mounting and connection

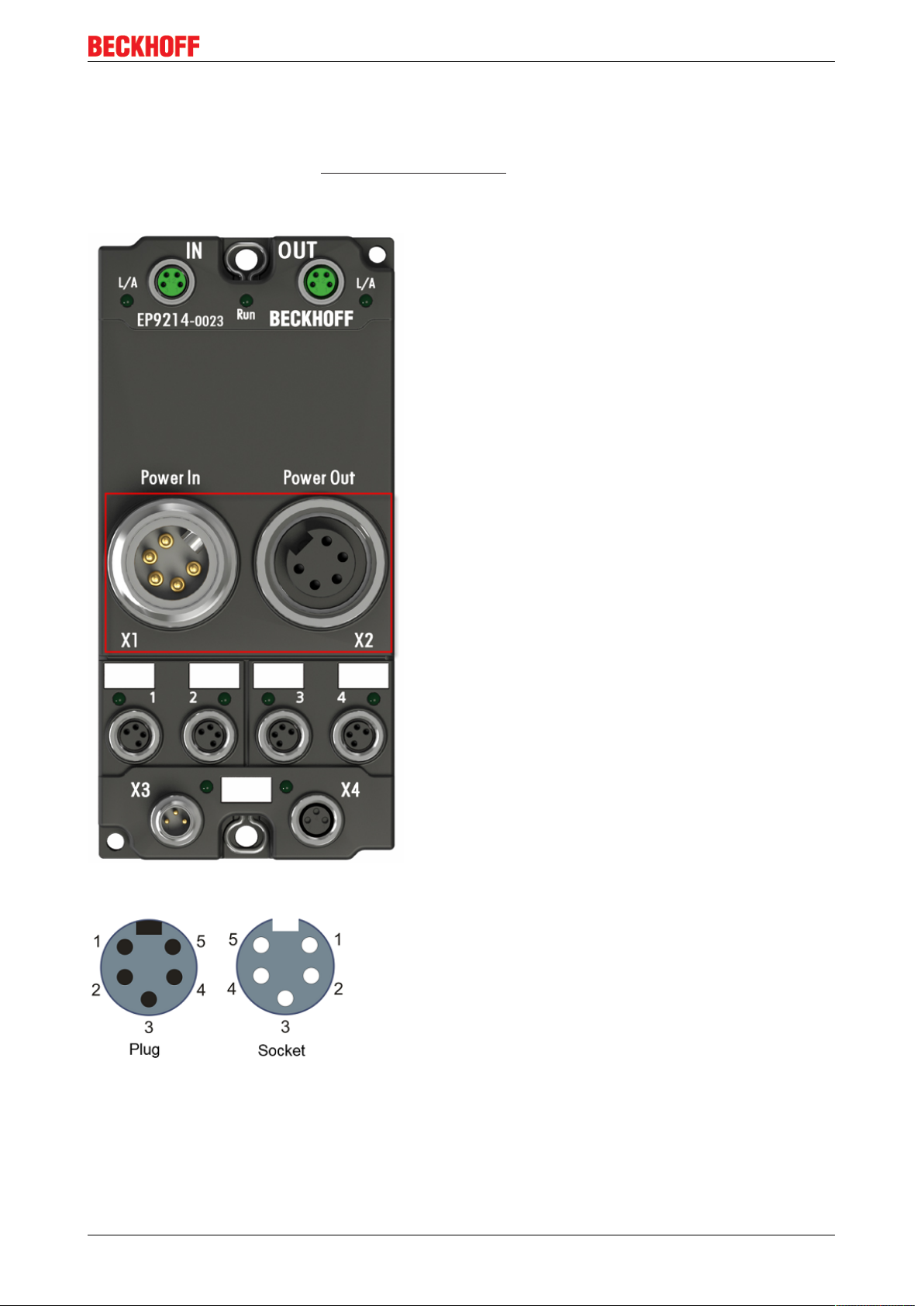

3.2.3 Power Connection

The feeding and forwarding of supply voltages is done via two M8 connectors at the bottom end of the

modules:

• IN: left M8 connector for feeding the supply voltages

• OUT: right M8 connector for forwarding the supply voltages

Fig.15: EtherCAT Box, Connectors for power supply

Fig.16: Pin assignment M8, Power In and Power Out

PIN assignment

Pin Voltage

1 Control voltage Us, +24V

2 Auxiliary voltage Up, +24V

DC

DC

3 GNDs* *) may be connected internally to each other depending on the module: see specific

4 GNDp*

module descriptions

The pins M8 connectors carry a maximum current of 4A.

Two LEDs display the status of the supply voltages.

NOTE

Don't confuse the power connectors with the EtherCAT connectors!

Never connect the power cables (M8, 24VDC) with the green marked EtherCAT sockets of the EtherCAT

Box Modules! This can damage the modules!

Control voltage Us: 24V

Power is supplied to the fieldbus, the processor logic, the inputs and the sensors from the 24VDC control

voltage Us. The control voltage is electrically isolated from the fieldbus circuitry.

DC

Auxiliary voltage Up 24V

DC

The Auxiliary voltage Up supplies the digital outputs; it can be brought in separately. If the load voltage is

switched off, the fieldbus functions and the power supply and functionality of the inputs are retained.

EP3744-0041 and EP3744-1041 21Version: 2.2

Page 22

Mounting and connection

Redirection of the supply voltages

The IN and OUT power connections are bridged in the module (not IP204x-Bxxx and IE204x). The supply

voltages Us and Up can thus easily be transferred from EtherCATBox to EtherCATBox.

NOTE

Pay attention to the maximum permissible current!

Pay attention also for the redirection of the supply voltages Us and Up, the maximum permissible current

for M8 connectors of 4A must not be exceeded!

EP3744-0041 and EP3744-104122 Version: 2.2

Page 23

Mounting and connection

Supply via EP92x4-0023 PowerBox modules

If the machine requires higher current or if the EtherCAT Box Modules are installed far away from the control

cabinet with included power supply, the usage of four cannel power distribution modules EP9214 or EP9224

(with integrated data logging, see www.beckhoff.com/EP9224) is recommended.

With these modules intelligent power distribution concepts with up to 2x16A and a maximum of 2.5mm²

cable cross-section can be realized.

Fig.17: EP92x4-0023, Connectors for Power In and Power Out

Fig.18: Pin assignment 7/8”, Power In and Power Out

EP3744-0041 and EP3744-1041 23Version: 2.2

Page 24

Mounting and connection

Electrical isolation

Digital modules

In the digital input/output modules, the grounds of the control voltage (GNDs) and the auxiliary voltage

(GNDp) are connected to each other!

Check this at the documentation of each used EtherCAT Box.

Analog modules

In the analog input/output modules the grounds of the control voltage (GNDs) and the auxiliary voltage

(GNDp) are separated from each other in order to ensure electrical isolation of the analog signals from the

control voltage.

In some of the analog modules the sensors or actuators are supplied by Up - this means, for instance, that in

the case of 0...10 V inputs, any reference voltage (0...30 V) may be connected to Up; this is then available to

the sensors (e.g. smoothed 10 V for measuring potentiometers).

Details of the power supply may be taken from the specific module descriptions.

NOTE

Electrical isolation may be cancelled!

If digital and analog fieldbus boxes are connected directly via four-core power leads, the analog signals in

the fieldbus boxes may be no longer electrically isolated from the control voltage!

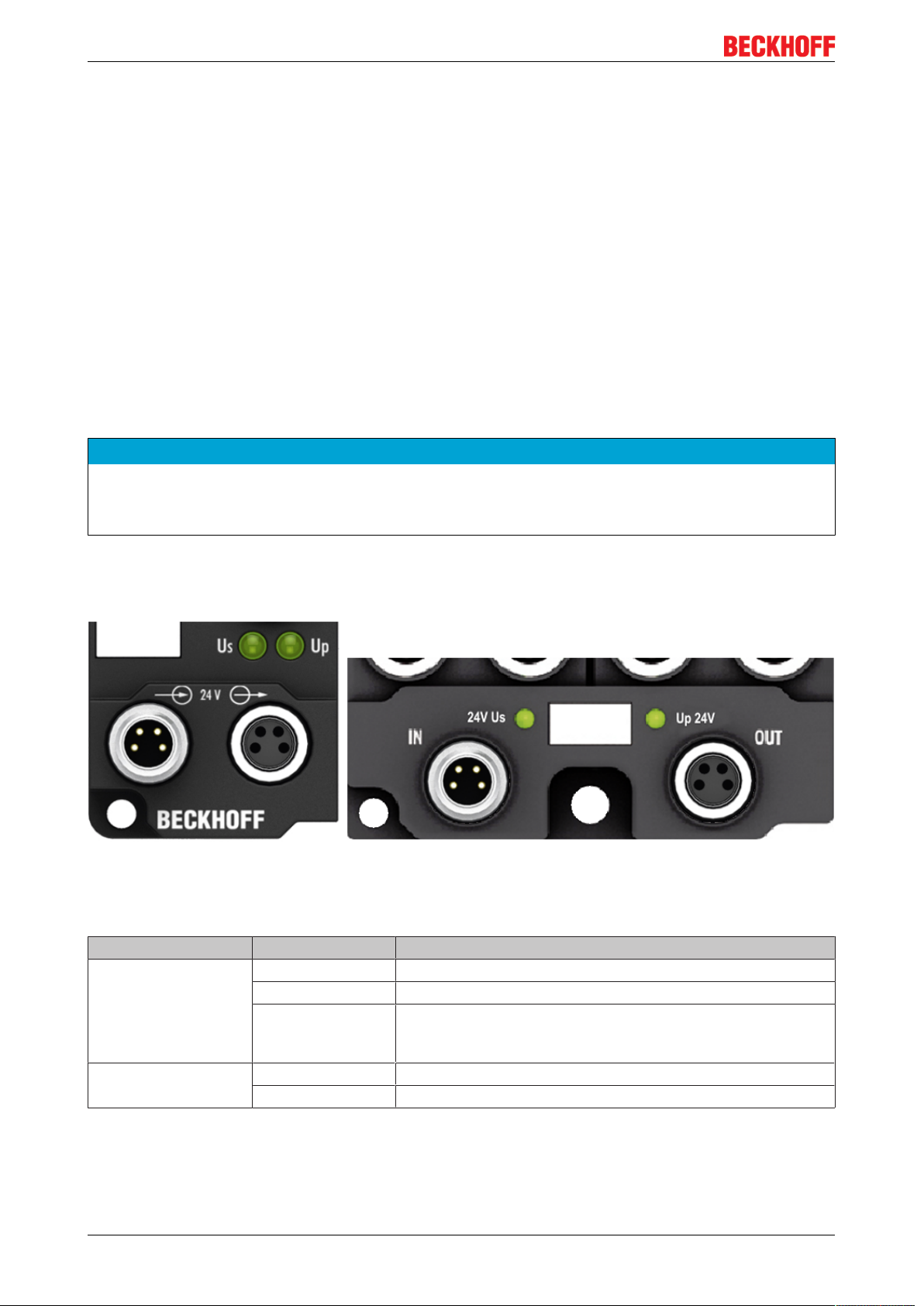

3.2.4 Status LEDs for power supply

Fig.19: Status LEDs for power supply

LED display

LED Display Meaning

Us (Control voltage) off The power supply voltage Us is not present

green illuminated The power supply voltage Us is present

red illuminated Because of overload (current>0.5A) the sensor supply

generated from power supply voltage Us was switched off for

all sensors fed from this.

Up (Auxiliary voltage) off The power supply voltage Up is not present

green illuminated The power supply voltage Up is present

EP3744-0041 and EP3744-104124 Version: 2.2

Page 25

Mounting and connection

3.2.5 Power cables

Ordering data

Order designation Power cable Screw-in connector Contacts Cross-section Length

ZK2020-3200-0020 Straight socket, open end M8 4-pin 0.34 mm

ZK2020-3200-0050 5.00 m

ZK2020-3200-0100 10.00 m

ZK2020-3400-0020 Angled socket, open end 2.00 m

ZK2020-3400-0050 5.00 m

ZK2020-3400-0100 10.00 m

ZK2020-3132-0001 Straight socket, straight

ZK2020-3132-0005 0.50 m

socket

ZK2020-3132-0010 1.00 m

ZK2020-3132-0020 2.00 m

ZK2020-3132-0050 5.00 m

ZK2020-3334-0001 Angled socket, angled

ZK2020-3334-0005 0.50 m

socket

ZK2020-3334-0010 1.00 m

ZK2020-3334-0020 2.00 m

ZK2020-3334-0050 5.00 m

2

2.00 m

0.15 m

0.15 m

Further available power cables may be found in the Beckhoff catalog or on our internet pages (http://

www.beckhoff.com).

Technical data

Technical data

Rated voltage according to IEC61076-2-101 30V

DC

Contamination level according to IEC 60 664-1 3/2

Insulation resistance IEC 60 512-2 >109Ω

Current carrying capacity according to IEC 60512-3 4A

Volume resistance according to IEC 60512-2 <5mΩ

Protection class according to IEC 60529 IP65/66/67, when screwed together

Ambient temperature -30°C to +80°C

EP3744-0041 and EP3744-1041 25Version: 2.2

Page 26

Mounting and connection

3.2.6 Power cable conductor losses M8

The ZK2020-xxxx-yyyy power cables should not exceed the total length of 15m at 4A (with continuation).

When planning the cabling, note that at 24V nominal voltage, the functionality of the module can no longer

be assured if the voltage drop reaches 6V. Variations in the output voltage from the power supply unit must

also be taken into account.

Fig.20: Power cable conductor losses

Example

8m power cable with 0.34mm² cross-section has a voltage drop of 3.2V at 4A.

EP92x4 Power Distribution Modules

With EP9214 and EP9224 Power Distribution Modules intelligent concepts for voltage supply are

available. Further information may be found under www.beckhoff.com/EP9224.

EP3744-0041 and EP3744-104126 Version: 2.2

Page 27

3.2.7 Signal connection

Mounting and connection

Fig.21: Signal connection

Digital inputs/outputs M8, 4-pin

The EP3744 has four 4-pin M8 sockets.

Sockets 0 and 1 each have two digital inputs; sockets 2 and 3 each have one input and one output.

The signals are connected via M8 connectors

Fig.22: Socket 0 and 1

EP3744-0041 and EP3744-1041 27Version: 2.2

Page 28

Mounting and connection

Fig.23: Socket 2 and 3

The sensors are supplied with a common maximum current of 0.5Afrom the control voltage Us.

Light emitting diodes indicate the signal state of the inputs.

Pressure measuring inputs, 6mm pneumatic hose

The connection for pressure measurement is made via fittings for standard pneumatic hoses (6mm). The

values are output as a reference to the lower left measuring channel.

The values of the reference channel are not available in the process data, but in the CoE objects.

3.2.8 Status LEDs at the signal connections

LED displays

LED Display Meaning

STATUS

1-4

Us off The supply voltage, Us, is not present

Up off The supply voltage, Up, is not present

green

illuminated

green

illuminated

red illuminated short circuit on the power supply for sensor outputs of Us

green

illuminated

a signal (24V) is present on at least one input of channels 1-6 or one of the

outputs 1 or 2 is switched on

The supply voltage, Us, is present

The supply voltage, Up, is present

EP3744-0041 and EP3744-104128 Version: 2.2

Page 29

Mounting and connection

3.3 UL Requirements

The installation of the EtherCAT Box Modules certified by UL has to meet the following requirements.

Supply voltage

CAUTION

CAUTION!

This UL requirements are valid for all supply voltages of all marked EtherCAT Box Modules!

For the compliance of the UL requirements the EtherCAT Box Modules should only be supplied

• by a 24 VDC supply voltage, supplied by an isolating source and protected by means of a fuse (in accordance with UL248), rated maximum 4 Amp, or

• by a 24 VDC power source, that has to satisfy NEC class 2.

A NEC class 2 power supply shall not be connected in series or parallel with another (class 2) power

source!

CAUTION

CAUTION!

To meet the UL requirements, the EtherCAT Box Modules must not be connected to unlimited power

sources!

Networks

CAUTION

CAUTION!

To meet the UL requirements, EtherCAT Box Modules must not be connected to telecommunication networks!

Ambient temperature range

CAUTION

CAUTION!

To meet the UL requirements, EtherCAT Box Modules has to be operated only at an ambient temperature

range of 0 to 55°C!

Marking for UL

All EtherCAT Box Modules certified by UL (Underwriters Laboratories) are marked with the following label.

Fig.24: UL label

EP3744-0041 and EP3744-1041 29Version: 2.2

Page 30

Commissioning/Configuration

4 Commissioning/Configuration

4.1 Inserting into the EtherCAT network

Installation of the latest XML device description

Please ensure that you have installed the latest XML device description in TwinCAT. This can be

downloaded from the Beckhoff website (http://www.beckhoff.de/english/download/elconfg.htm?

id=1983920606140) and installed according to the installation instructions.

At the Beckhoff TwinCAT System Manager the configuration tree can be build in two different ways:

• by scanning [}30] for existing hardware (called "online") and

• by manual inserting/appending [}30] of fieldbus devices, couplers and slaves.

Automatic scanning in of the box

• The EtherCAT system must be in a safe, de-energized state before the EtherCAT modules are

connected to the EtherCAT network!

• Switch on the operating voltage, open the TwinCAT System Manager [}33] (Config mode), and scan

in the devices (see Fig. 1). Acknowledge all dialogs with "OK", so that the configuration is in "FreeRun"

mode.

Fig.25: Scanning in the configuration (I/O Devices -> right-click -> Scan Devices...)

Appending a module manually

• The EtherCAT system must be in a safe, de-energized state before the EtherCAT modules are

connected to the EtherCAT network!

• Switch on the operating voltage, open the TwinCAT System Manager [}33] (Config mode)

• Append a new I/O device. In the dialog that appears select the device EtherCAT (Direct Mode), and

confirm with OK.

EP3744-0041 and EP3744-104130 Version: 2.2

Page 31

Commissioning/Configuration

Fig.26: Appending a new I/O device (I/O Devices -> right-click -> Append Device...)

Fig.27: Selecting the device EtherCAT

• Append a new box.

Fig.28: Appending a new box (Device -> right-click -> Append Box...)

• In the dialog that appears select the desired box (e.g. EP2816-0008), and confirm with OK.

EP3744-0041 and EP3744-1041 31Version: 2.2

Page 32

Commissioning/Configuration

Fig.29: Selecting a Box (e.g. EP2816-0008)

Fig.30: Appended Box in the TwinCAT tree

EP3744-0041 and EP3744-104132 Version: 2.2

Page 33

Commissioning/Configuration

4.2 Configuration via TwinCAT

In the left-hand window of the TwinCAT System Manager, click on the branch of the EtherCAT Box you wish

to configure (EP2816-0008 in this example).

Fig.31: Branch of the EtherCAT box to be configured

In the right-hand window of the TwinCAT System manager, various tabs are now available for configuring

the EtherCAT Box.

General tab

Fig.32: General tab

Name Name of the EtherCAT device

Id Number of the EtherCAT device

Type EtherCAT device type

Comment Here you can add a comment (e.g. regarding the system).

Disabled Here you can deactivate the EtherCAT device.

Create symbols Access to this EtherCAT slave via ADS is only available if this checkbox is

activated.

EP3744-0041 and EP3744-1041 33Version: 2.2

Page 34

Commissioning/Configuration

EtherCAT tab

Fig.33: EtherCAT tab

Type EtherCAT device type

Product/Revision Product and revision number of the EtherCAT device

Auto Inc Addr. Auto increment address of the EtherCAT device. The auto increment address can

be used for addressing each EtherCAT device in the communication ring through

its physical position. Auto increment addressing is used during the start-up phase

when the EtherCAT master allocates addresses to the EtherCAT devices. With

auto increment addressing the first EtherCAT slave in the ring has the address

0000

. For each further slave the address is decremented by 1 (FFFF

hex

, FFFE

hex

etc.).

EtherCAT Addr. Fixed address of an EtherCAT slave. This address is allocated by the EtherCAT

master during the start-up phase. Tick the checkbox to the left of the input field in

order to modify the default value.

Previous Port Name and port of the EtherCAT device to which this device is connected. If it is

possible to connect this device with another one without changing the order of the

EtherCAT devices in the communication ring, then this combobox is activated and

the EtherCAT device to which this device is to be connected can be selected.

Advanced Settings This button opens the dialogs for advanced settings.

hex

The link at the bottom of the tab points to the product page for this EtherCAT device on the web.

Process Data tab

Indicates the configuration of the process data. The input and output data of the EtherCAT slave are

represented as CANopen process data objects (PDO). The user can select a PDO via PDO assignment and

modify the content of the individual PDO via this dialog, if the EtherCAT slave supports this function.

EP3744-0041 and EP3744-104134 Version: 2.2

Page 35

Commissioning/Configuration

Fig.34: Process Data tab

Sync Manager

Lists the configuration of the Sync Manager (SM).

If the EtherCAT device has a mailbox, SM0 is used for the mailbox output (MbxOut) and SM1 for the mailbox

input (MbxIn).

SM2 is used for the output process data (outputs) and SM3 (inputs) for the input process data.

If an input is selected, the corresponding PDO assignment is displayed in the PDO Assignment list below.

PDO Assignment

PDO assignment of the selected Sync Manager. All PDOs defined for this Sync Manager type are listed

here:

• If the output Sync Manager (outputs) is selected in the Sync Manager list, all RxPDOs are displayed.

• If the input Sync Manager (inputs) is selected in the Sync Manager list, all TxPDOs are displayed.

The selected entries are the PDOs involved in the process data transfer. In the tree diagram of the System

Manager these PDOs are displayed as variables of the EtherCAT device. The name of the variable is

identical to the Name parameter of the PDO, as displayed in the PDO list. If an entry in the PDO assignment

list is deactivated (not selected and greyed out), this indicates that the input is excluded from the PDO

assignment. In order to be able do select a greyed out PDO, the currently selected PDO has to be

deselected first.

EP3744-0041 and EP3744-1041 35Version: 2.2

Page 36

Commissioning/Configuration

Activation of PDO assignment

• the EtherCAT slave has to run through the PS status transition cycle (from pre-operational to

safe-operational) once (see Online tab [}39]),

• and the System Manager has to reload the EtherCAT slaves ( button)

PDO list

List of all PDOs supported by this EtherCAT device. The content of the selected PDOs is displayed in the

PDO Content list. The PDO configuration can be modified by double-clicking on an entry.

Column Description

Index PDO index.

Size Size of the PDO in bytes.

Name Name of the PDO.

If this PDO is assigned to a Sync Manager, it appears as a variable of the slave with this

parameter as the name.

Flags F Fixed content: The content of this PDO is fixed and cannot be changed by the System

Manager.

M Mandatory PDO. This PDO is mandatory and must therefore be assigned to a Sync Manager!

Consequently, this PDO cannot be deleted from the PDO Assignment list

SM Sync Manager to which this PDO is assigned. If this entry is empty, this PDO does not take part in

the process data traffic.

SU Sync unit to which this PDO is assigned.

PDO Content

Indicates the content of the PDO. If flag F (fixed content) of the PDO is not set the content can be modified.

Download

If the device is intelligent and has a mailbox, the configuration of the PDO and the PDO assignments can be

downloaded to the device. This is an optional feature that is not supported by all EtherCAT slaves.

PDO Assignment

If this check box is selected, the PDO assignment that is configured in the PDO Assignment list is

downloaded to the device on startup. The required commands to be sent to the device can be viewed in the

Startup [}36] tab.

PDO Configuration

If this check box is selected, the configuration of the respective PDOs (as shown in the PDO list and the

PDO Content display) is downloaded to the EtherCAT slave.

Startup tab

The Startup tab is displayed if the EtherCAT slave has a mailbox and supports the CANopen over EtherCAT

(CoE) or Servo drive over EtherCAT protocol. This tab indicates which download requests are sent to the

mailbox during startup. It is also possible to add new mailbox requests to the list display. The download

requests are sent to the slave in the same order as they are shown in the list.

EP3744-0041 and EP3744-104136 Version: 2.2

Page 37

Fig.35: Startup tab

Column Description

Transition Transition to which the request is sent. This can either be

• the transition from pre-operational to safe-operational (PS), or

• the transition from safe-operational to operational (SO).

If the transition is enclosed in "<>" (e.g. <PS>), the mailbox request is fixed and cannot be

modified or deleted by the user.

Protocol Type of mailbox protocol

Index Index of the object

Data Date on which this object is to be downloaded.

Comment Description of the request to be sent to the mailbox

Commissioning/Configuration

Move Up This button moves the selected request up by one position in the list.

Move Down This button moves the selected request down by one position in the list.

New This button adds a new mailbox download request to be sent during startup.

Delete This button deletes the selected entry.

Edit This button edits an existing request.

CoE - Online tab

The additional CoE - Online tab is displayed if the EtherCAT slave supports the CANopen over EtherCAT

(CoE) protocol. This dialog lists the content of the object directory of the slave (SDO upload) and enables the

user to modify the content of an object from this list. Details for the objects of the individual EtherCAT

devices can be found in the device-specific object descriptions.

EP3744-0041 and EP3744-1041 37Version: 2.2

Page 38

Commissioning/Configuration

Fig.36: CoE - Online tab

Object list display

Column Description

Index Index and subindex of the object

Name Name of the object

Flags RW The object can be read, and data can be written to the object (read/write)

RO The object can be read, but no data can be written to the object (read only)

P An additional P identifies the object as a process data object.

Value Value of the object

Update List The Update list button updates all objects in the displayed list

Auto Update If this check box is selected, the content of the objects is updated automatically.

Advanced The Advanced button opens the Advanced Settings dialog. Here you can specify which

objects are displayed in the list.

EP3744-0041 and EP3744-104138 Version: 2.2

Page 39

Commissioning/Configuration

Fig.37: Advanced settings

Online

- via SDO information

Offline

- via EDS file

Online tab

If this option button is selected, the list of the objects included in the object

directory of the slave is uploaded from the slave via SDO information. The list

below can be used to specify which object types are to be uploaded.

If this option button is selected, the list of the objects included in the object

directory is read from an EDS file provided by the user.

Fig.38: Online tab

EP3744-0041 and EP3744-1041 39Version: 2.2

Page 40

Commissioning/Configuration

State Machine

Init This button attempts to set the EtherCAT device to the Init state.

Pre-Op This button attempts to set the EtherCAT device to the pre-operational state.

Op This button attempts to set the EtherCAT device to the operational state.

Bootstrap This button attempts to set the EtherCAT device to the Bootstrap state.

Safe-Op This button attempts to set the EtherCAT device to the safe-operational state.

Clear Error This button attempts to delete the fault display. If an EtherCAT slave fails during

change of state it sets an error flag.

Example: An EtherCAT slave is in PREOP state (pre-operational). The master now

requests the SAFEOP state (safe-operational). If the slave fails during change of

state it sets the error flag. The current state is now displayed as ERR PREOP. When

the Clear Error button is pressed the error flag is cleared, and the current state is

displayed as PREOP again.

Current State Indicates the current state of the EtherCAT device.

Requested State Indicates the state requested for the EtherCAT device.

DLL Status

Indicates the DLL status (data link layer status) of the individual ports of the EtherCAT slave. The DLL status

can have four different states:

Status Description

No Carrier / Open No carrier signal is available at the port, but the port is open.

No Carrier / Closed No carrier signal is available at the port, and the port is closed.

Carrier / Open A carrier signal is available at the port, and the port is open.

Carrier / Closed A carrier signal is available at the port, but the port is closed.

File Access over EtherCAT

Download With this button a file can be written to the EtherCAT device.

Upload With this button a file can be read from the EtherCAT device.

EP3744-0041 and EP3744-104140 Version: 2.2

Page 41

Commissioning/Configuration

4.3 Object overview

EtherCAT XML Device Description

The display matches that of the CoE objects from the EtherCAT XML Device Description. We recommend downloading the latest XML file from the download area of the Beckhoff website and installing it according to installation instructions.

Index (hex) Name Flags Default value

1000 [}51]

1008 [}51]

1009 [}52]

100A [}52]

1011

[}47]

1018

[}52]:0

10F0

[}52]:0

1600

[}52]:0

1601

[}52]:0

1A00

[}53]:0

1A01

[}53]:0

Subindex Restore default parameters RO 0x01 (1

0x1011:01 SubIndex 001 RW 0x00000000 (0

Subindex Identity RO 0x04 (4

0x1018:01 Vendor ID RO 0x00000002 (2

0x1018:02 Product code RO 0x0EA04052 (245383250

0x1018:03 Revision RO 0x00000000 (0

0x1018:04 Serial number RO 0x00000000 (0

Subindex Backup parameter handling RO 0x01 (1

0x10F0:01 Checksum RO 0x00000000 (0

Subindex DIG RxPDO-Map Outputs RO 0x03 (3

0x1600:01 SubIndex 001 RO 0x7010:01, 1

0x1600:02 SubIndex 002 RO 0x7010:02, 1

0x1600:03 SubIndex 003 RO 0x0000:00, 14

Subindex DEV RxPDO-Map Outputs Device RO 0x02 (2

0x1601:01 SubIndex 001 RO 0xF700:01, 1

0x1601:02 SubIndex 002 RO 0x0000:00, 15

Subindex DIG TxPDO-Map Inputs RO 0x07 (7

0x1A00:01 SubIndex 001 RO 0x6000:01, 1

0x1A00:02 SubIndex 002 RO 0x6000:02, 1

0x1A00:03 SubIndex 003 RO 0x6000:03, 1

0x1A00:04 SubIndex 004 RO 0x6000:04, 1

0x1A00:05 SubIndex 005 RO 0x6000:05, 1

0x1A00:06 SubIndex 006 RO 0x6000:06, 1

0x1A00:07 SubIndex 007 RO 0x0000:00, 10

Subindex AI TxPDO-Map Inputs Ch.1 RO 0x09 (9

0x1A01:01 SubIndex 001 RO 0x6020:01, 1

0x1A01:02 SubIndex 002 RO 0x6020:02, 1

0x1A01:03 SubIndex 003 RO 0x6020:03, 2

0x1A01:04 SubIndex 004 RO 0x6020:05, 2

0x1A01:05 SubIndex 005 RO 0x6020:07, 1

0x1A01:06 SubIndex 006 RO 0x0000:00, 7

0x1A01:07 SubIndex 007 RO 0x6020:0F, 1

0x1A01:08 SubIndex 008 RO 0x6020:10, 1

0x1A01:09 SubIndex 009 RO 0x6020:11, 32

Device type RO 0x00001389 (5001

Device name RO EP3744-0041

Hardware version RO 00

Software version RO 03

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

EP3744-0041 and EP3744-1041 41Version: 2.2

Page 42

Commissioning/Configuration

Index (hex) Name Flags Default value

1A02

[}53]:0

1A03

[}54]:0

1A04

[}54]:0

1A05

[}54]:0

1C00

[}55]:0

1C12

[}55]:0

1C13

[}55]:0

Subindex AI TxPDO-Map Inputs Ch.2 RO 0x09 (9

0x1A02:01 SubIndex 001 RO 0x6030:01, 1

0x1A02:02 SubIndex 002 RO 0x6030:02, 1

0x1A02:03 SubIndex 003 RO 0x6030:03, 2

0x1A02:04 SubIndex 004 RO 0x6030:05, 2

0x1A02:05 SubIndex 005 RO 0x6030:07, 1

0x1A02:06 SubIndex 006 RO 0x0000:00, 7

0x1A02:07 SubIndex 007 RO 0x6030:0F, 1

0x1A02:08 SubIndex 008 RO 0x6030:10, 1

0x1A02:09 SubIndex 009 RO 0x6030:11, 32

Subindex AI TxPDO-Map Inputs Ch.3 RO 0x09 (9

0x1A03:01 SubIndex 001 RO 0x6040:01, 1

0x1A03:02 SubIndex 002 RO 0x6040:02, 1

0x1A03:03 SubIndex 003 RO 0x6040:03, 2

0x1A03:04 SubIndex 004 RO 0x6040:05, 2

0x1A03:05 SubIndex 005 RO 0x6040:07, 1

0x1A03:06 SubIndex 006 RO 0x0000:00, 7

0x1A03:07 SubIndex 007 RO 0x6040:0F, 1

0x1A03:08 SubIndex 008 RO 0x6040:10, 1

0x1A03:09 SubIndex 009 RO 0x6040:11, 32

Subindex AI TxPDO-Map Inputs Ch.4 RO 0x09 (9

0x1A04:01 SubIndex 001 RO 0x6050:01, 1

0x1A04:02 SubIndex 002 RO 0x6050:02, 1

0x1A04:03 SubIndex 003 RO 0x6050:03, 2

0x1A04:04 SubIndex 004 RO 0x6050:05, 2

0x1A04:05 SubIndex 005 RO 0x6050:07, 1

0x1A04:06 SubIndex 006 RO 0x0000:00, 7

0x1A04:07 SubIndex 007 RO 0x6050:0F, 1

0x1A04:08 SubIndex 008 RO 0x6050:10, 1

0x1A04:09 SubIndex 009 RO 0x6050:11, 32

Subindex DEV TxPDO-Map Inputs Device RO 0x07 (7

0x1A05:01 SubIndex 001 RO 0xF600:01, 1

0x1A05:02 SubIndex 002 RO 0x0000:00, 15

0x1A05:03 SubIndex 003 RO 0xF611:01, 1

0x1A05:04 SubIndex 004 RO 0xF611:02, 1

0x1A05:05 SubIndex 005 RO 0x0000:00, 13

0x1A05:06 SubIndex 006 RO 0xF611:10, 1

0x1A05:07 SubIndex 007 RO 0x0000:00, 96

Subindex Sync manager type RO 0x04 (4

0x1C00:01 SubIndex 001 RO 0x01 (1

0x1C00:02 SubIndex 002 RO 0x02 (2

0x1C00:03 SubIndex 003 RO 0x03 (3

0x1C00:04 SubIndex 004 RO 0x04 (4

Subindex RxPDO assign RW 0x02 (2

0x1C12:01 SubIndex 001 RW 0x1600 (5632

0x1C12:02 SubIndex 002 RW 0x1601 (5633

Subindex TxPDO assign RW 0x06 (6

0x1C13:01 SubIndex 001 RW 0x1A00 (6656

0x1C13:02 SubIndex 002 RW 0x1A01 (6657

0x1C13:03 SubIndex 003 RW 0x1A02 (6658

0x1C13:04 SubIndex 004 RW 0x1A03 (6659

0x1C13:05 SubIndex 005 RW 0x1A04 (6660

0x1C13:06 SubIndex 006 RW 0x1A05 (6661

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

EP3744-0041 and EP3744-104142 Version: 2.2

Page 43

Commissioning/Configuration

Index (hex) Name Flags Default value

1C32

[}56]:0

1C33

[}57]:0

6000

[}59]:0

6020

[}58]:0

6030

[}58]:0

Subindex SM output parameter RO 0x20 (32

0x1C32:01 Sync mode RW 0x0001 (1

0x1C32:02 Cycle time RW 0x003D0900 (4000000

0x1C32:03 Shift time RO 0x00000384 (900

0x1C32:04 Sync modes supported RO 0xC007 (49159

0x1C32:05 Minimum cycle time RO 0x000F4240 (1000000

0x1C32:06 Calc and copy time RO 0x00000000 (0

0x1C32:07 Minimum delay time RO 0x00000384 (900

0x1C32:08 Command RW 0x0000 (0

0x1C32:09 Maximum delay time RO 0x00000384 (900

0x1C32:0B SM event missed counter RO 0x0000 (0

0x1C32:0C Cycle exceeded counter RO 0x0000 (0

0x1C32:0D Shift too short counter RO 0x0000 (0

0x1C32:20 Sync error RO 0x00 (0

Subindex SM input parameter RO 0x20 (32

0x1C33:01 Sync mode RW 0x0022 (34

0x1C33:02 Cycle time RW 0x003D0900 (4000000

0x1C33:03 Shift time RO 0x00000384 (900

0x1C33:04 Sync modes supported RO 0xC007 (49159

0x1C33:05 Minimum cycle time RO 0x000F4240 (1000000

0x1C33:06 Calc and copy time RO 0x00000000 (0

0x1C33:07 Minimum delay time RO 0x00000384 (900

0x1C33:08 Command RW 0x0000 (0

0x1C33:09 Maximum delay time RO 0x00000384 (900

0x1C33:0B SM event missed counter RO 0x0000 (0

0x1C33:0C Cycle exceeded counter RO 0x0000 (0

0x1C33:0D Shift too short counter RO 0x0000 (0

0x1C33:20 Sync error RO 0x00 (0

Subindex Dig Inputs RO 0x06 (6

0x6000:01 Input 1 RO 0x00 (0

0x6000:02 Input 2 RO 0x00 (0

0x6000:03 Input 3 RO 0x00 (0

0x6000:04 Input 4 RO 0x00 (0

0x6000:05 Input 5 RO 0x00 (0

0x6000:06 Input 6 RO 0x00 (0

Subindex AI Inputs Ch.1 RO 0x11 (17

0x6020:01 Underrange RO 0x00 (0

0x6020:02 Overrange RO 0x00 (0

0x6020:03 Limit 1 RO 0x00 (0

0x6020:05 Limit 2 RO 0x00 (0

0x6020:07 Error RO 0x00 (0

0x6020:0F TxPDO State RO 0x00 (0

0x6020:10 TxPDO Toggle RO 0x00 (0

0x6020:11 Value RO 0x00000000 (0

Subindex AI Inputs Ch.2 RO 0x11 (17

0x6030:01 Underrange RO 0x00 (0

0x6030:02 Overrange RO 0x00 (0

0x6030:03 Limit 1 RO 0x00 (0

0x6030:05 Limit 2 RO 0x00 (0

0x6030:07 Error RO 0x00 (0

0x6030:0F TxPDO State RO 0x00 (0

0x6030:10 TxPDO Toggle RO 0x00 (0

0x6030:11 Value RO 0x00000000 (0

)

dec

dec

dec

dec

dec

dec

)

dec

)

dec

dec

dec

dec

dec

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

)

dec

)

)

)

)

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

)

dec

)

)

)

)

dec

)

dec

EP3744-0041 and EP3744-1041 43Version: 2.2

Page 44

Commissioning/Configuration

Index (hex) Name Flags Default value

6040

[}58]:0

6050

[}59]:0

7010

[}59]:0

8010

[}47]:0

8011

[}47]:0

8020

[}48]:0

802E

[}59]:0

802F

[}59]:0

Subindex AI Inputs Ch.3 RO 0x11 (17

0x6040:01 Underrange RO 0x00 (0

0x6040:02 Overrange RO 0x00 (0

0x6040:03 Limit 1 RO 0x00 (0

0x6040:05 Limit 2 RO 0x00 (0

0x6040:07 Error RO 0x00 (0

0x6040:0F TxPDO State RO 0x00 (0

0x6040:10 TxPDO Toggle RO 0x00 (0

0x6040:11 Value RO 0x00000000 (0

Subindex AI Inputs Ch.4 RO 0x11 (17

0x6050:01 Underrange RO 0x00 (0

0x6050:02 Overrange RO 0x00 (0

0x6050:03 Limit 1 RO 0x00 (0

0x6050:05 Limit 2 RO 0x00 (0

0x6050:07 Error RO 0x00 (0

0x6050:0F TxPDO State RO 0x00 (0

0x6050:10 TxPDO Toggle RO 0x00 (0

0x6050:11 Value RO 0x00000000 (0

Subindex Dig Outputs RO 0x02 (2

0x7010:01 Output 1 RO 0x00 (0

0x7010:02 Output 2 RO 0x00 (0

Subindex Safe state active RW 0x02 (2

0x8010:01 Output 1 RW 0x00 (0

0x8010:02 Output 2 RW 0x00 (0

Subindex Safe state value RW 0x02 (2

0x8011:01 Output 1 RW 0x00 (0

0x8011:02 Output 2 RW 0x00 (0

Subindex AI Settings Ch.1 RW 0x19 (25

0x8020:01 Enable user scale RW 0x00 (0

0x8020:06 Enable filter RW 0x01 (1

0x8020:07 Enable limit 1 RW 0x00 (0

0x8020:08 Enable limit 2 RW 0x00 (0

0x8020:0A Enable user calibration RW 0x00 (0

0x8020:0B Enable vendor calibration RW 0x01 (1

0x8020:11 User scale offset RW 0x00000000 (0

0x8020:12 User scale gain RW 0x00010000 (65536

0x8020:13 Limit 1 RW 0x0000 (0

0x8020:14 Limit 2 RW 0x0000 (0

0x8020:15 Filter settings RW 0x0000 (0

0x8020:17 User calibration offset RW 0x00000000 (0

0x8020:18 User calibration gain RW 0x4000 (16384

0x8020:19 Range RW 0x0008 (8

Subindex AI Internal data Ch.1 RO 0x01 (1

0x802E:01 ADC raw value RO 0x00000000 (0

Subindex AI Vendor data Ch.1 RW 0x04 (4

0x802F:01 Calibration offset pressure RW 0x00000000 (0

0x802F:02 Calibration gain pressure RW 0x4000 (16384

0x802F:03 Calibration offset temp RW 0x00000000 (0

0x802F:04 Calibration gain temp RW 0x0000 (0

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

dec

dec

dec

dec

)

dec

)

dec

dec

)

dec

)

dec

)

dec

)

dec

)

)

)

)

dec

)

dec

)

)

dec

)

dec

)

dec

)

dec

)

EP3744-0041 and EP3744-104144 Version: 2.2

Page 45

Commissioning/Configuration

Index (hex) Name Flags Default value

8030

[}49]:0

803E

[}59]:0

803F

[}60]:0

8040

[}50]:0

804E

[}60]:0

804F

[}60]:0

Subindex AI Settings Ch.2 RW 0x19 (25

0x8030:01 Enable user scale RW 0x00 (0

0x8030:06 Enable filter RW 0x01 (1

0x8030:07 Enable limit 1 RW 0x00 (0

0x8030:08 Enable limit 2 RW 0x00 (0

0x8030:0A Enable user calibration RW 0x00 (0

0x8030:0B Enable vendor calibration RW 0x01 (1

0x8030:11 User scale offset RW 0x00000000 (0

0x8030:12 User scale gain RW 0x00010000 (65536

0x8030:13 Limit 1 RW 0x0000 (0

0x8030:14 Limit 2 RW 0x0000 (0

0x8030:15 Filter settings RW 0x0000 (0

0x8030:17 User calibration offset RW 0x00000000 (0

0x8030:18 User calibration gain RW 0x4000 (16384

0x8030:19 Range RW 0x0008 (8

Subindex AI Internal data Ch.2 RO 0x01 (1

0x803E:01 ADC raw value RO 0x00000000 (0

Subindex AI Vendor data Ch.2 RW 0x04 (4

0x803F:01 Calibration offset pressure RW 0x00000000 (0

0x803F:02 Calibration gain pressure RW 0x4000 (16384

0x803F:03 Calibration offset temp RW 0x00000000 (0

0x803F:04 Calibration gain temp RW 0x0000 (0

Subindex AI Settings Ch.3 RW 0x19 (25

0x8040:01 Enable user scale RW 0x00 (0

0x8040:06 Enable filter RW 0x01 (1

0x8040:07 Enable limit 1 RW 0x00 (0

0x8040:08 Enable limit 2 RW 0x00 (0

0x8040:0A Enable user calibration RW 0x00 (0

0x8040:0B Enable vendor calibration RW 0x01 (1

0x8040:11 User scale offset RW 0x00000000 (0

0x8040:12 User scale gain RW 0x00010000 (65536

0x8040:13 Limit 1 RW 0x0000 (0

0x8040:14 Limit 2 RW 0x0000 (0

0x8040:15 Filter settings RW 0x0000 (0

0x8040:17 User calibration offset RW 0x00000000 (0

0x8040:18 User calibration gain RW 0x4000 (16384

0x8040:19 Range RW 0x0008 (8

Subindex AI Internal data Ch.3 RO 0x01 (1

0x804E:01 ADC raw value RO 0x00000000 (0

Subindex AI Vendor data Ch.3 RW 0x04 (4

0x804F:01 Calibration offset pressure RW 0x00000000 (0

0x804F:02 Calibration gain pressure RW 0x4000 (16384

0x804F:03 Calibration offset temp RW 0x00000000 (0

0x804F:04 Calibration gain temp RW 0x0000 (0

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

dec

dec

dec

dec

)

dec

)

dec

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

dec

dec

dec

dec

)

dec

)

dec

dec

)

dec

)

dec

)

)

)

)

dec

)

dec

)

)

dec

)

dec

)

dec

)

dec

)

)

dec

)

dec

)

)

)

)

dec

)

dec

)

)

dec

)

dec

)

dec

)

dec

)

EP3744-0041 and EP3744-1041 45Version: 2.2

Page 46

Commissioning/Configuration

Index (hex) Name Flags Default value

8050

[}51]:0

805E

[}60]:0

805F

[}60]:0

F000

[}60]:0

F008 [}60]

F010

[}61]:0

F600

[}61]:0

F611

[}61]:0

F700

[}61]:0

F800

[}61]:0

F80E

[}61]:0

F80F

[}62]:0

Subindex AI Settings Ch.4 RW 0x19 (25

0x8050:01 Enable user scale RW 0x00 (0

0x8050:06 Enable filter RW 0x01 (1

0x8050:07 Enable limit 1 RW 0x00 (0

0x8050:08 Enable limit 2 RW 0x00 (0

0x8050:0A Enable user calibration RW 0x00 (0

0x8050:0B Enable vendor calibration RW 0x01 (1

0x8050:11 User scale offset RW 0x00000000 (0

0x8050:12 User scale gain RW 0x00010000 (65536

0x8050:13 Limit 1 RW 0x0000 (0

0x8050:14 Limit 2 RW 0x0000 (0

0x8050:15 Filter settings RW 0x0000 (0

0x8050:17 User calibration offset RW 0x00000000 (0

0x8050:18 User calibration gain RW 0x4000 (16384

0x8050:19 Range RW 0x0008 (8

Subindex AI Internal data Ch.4 RO 0x01 (1

0x805E:01 ADC raw value RO 0x00000000 (0

Subindex AI Vendor data Ch.4 RW 0x04 (4

0x805F:01 Calibration offset pressure RW 0x00000000 (0

0x805F:02 Calibration gain pressure RW 0x4000 (16384

0x805F:03 Calibration offset temp RW 0x00000000 (0

0x805F:04 Calibration gain temp RW 0x0000 (0

Subindex Modular device profile RO 0x02 (2

0xF000:01 Module index distance RO 0x0010 (16

0xF000:02 Maximum number of modules RO 0x0006 (6

Code word RW 0x00000000 (0

Subindex Module list RW 0x06 (6

0xF010:01 SubIndex 001 RW 0x00000118 (280

0xF010:02 SubIndex 002 RW 0x00000118 (280

0xF010:03 SubIndex 003 RW 0x0000012C (300

0xF010:04 SubIndex 004 RW 0x0000012C (300

0xF010:05 SubIndex 005 RW 0x0000012C (300

0xF010:06 SubIndex 006 RW 0x0000012C (300

Subindex DEV Inputs Safe State Active RO 0x01 (1

0xF600:01 Safe State Active RO 0x00 (0

Subindex DEV Inputs Undervoltage RO 0x10 (16

0xF611:01 Undervoltage Us RO 0x00 (0

0xF611:02 Undervoltage Up RO 0x00 (0

0xF611:10 TxPDO Toggle RO 0x00 (0

Subindex DEV Outputs Set Safe State RO 0x01 (1

0xF700:01 Set safe state RO 0x00 (0

Subindex AI Settings Reference RW 0x18 (24

0xF800:0A Enable user calibration RW 0x00 (0

0xF800:0B Enable vendor calibration RW 0x01 (1

0xF800:17 User calibration offset RW 0x00000000 (0

0xF800:18 User calibration gain RW 0x4000 (16384

Subindex AI Internal data Reference RO 0x02 (2

0xF80E:01 ADC raw value 1 RO 0x00000000 (0

0xF80E:02 ADC raw value 2 RO 0x00000000 (0

Subindex AI Vendor data Reference RW 0x04 (4

0xF80F:01 Calibration offset pressure RW 0x00000000 (0

0xF80F:02 Calibration gain pressure RW 0x4000 (16384

0xF80F:03 Calibration offset temp RW 0x00000000 (0

0xF80F:04 Calibration gain temp RW 0x0000 (0

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

dec

dec

dec

dec

)

dec

)

dec

dec

)

dec

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

dec

)

dec

)

dec

)

)

)

)

dec

)

dec

)

)

dec

)

dec

)

dec

)

dec

)

)

dec

)

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

dec

)

EP3744-0041 and EP3744-104146 Version: 2.2

Page 47

Commissioning/Configuration

Legend

Flags:

RO = Read Only

RW = Read/Write

4.4 Object description and parameterization

EtherCAT XML Device Description

The display matches that of the CoE objects from the EtherCAT XML Device Description. We recommend downloading the latest XML file from the download area of the Beckhoff website and installing it according to installation instructions.

Parameterization via the CoE list (CAN over EtherCAT)

The EtherCAT device is parameterized via the CoE - Online tab [}37] (double-click on the respective object) or via the Process Data [}34] tab (allocation of PDOs).

Introduction

The CoE overview contains objects for different intended applications:

• Objects required for parameterization [}47] during commissioning

• Objects for indicating internal settings [}51] (may be fixed)

• Further profile-specific objects [}58] indicating inputs, outputs and status information

The following section first describes the objects required for normal operation, followed by a complete

overview of missing objects.

4.4.1 Objects to be parameterized during commissioning

Index 1011 Restore default parameters

Index (hex) Name Meaning Data type Flags Default

1011:0 Restore default pa-

rameters

1011:01 SubIndex 001 If this object is set to "0x64616F6C" in the set value dia-

Index 8010 Safe state active

Index (hex) Name Meaning Data type Flags Default

8010:0 Safe state active UINT8 RO 0x02 (2

8010:01 Output 1 0 Output State will remain unchanged during OP->

8010:02 Output 2 0 Output State will remain unchanged during OP->

Restore default parameters UINT8 RO 0x01 (1

log, all backup objects are reset to their delivery state.

SafeOP

1 Output will go to Safe State during OP-> SafeOP

SafeOP

1 Output will go to Safe State during OP-> SafeOP

UINT32 RW 0x00000000

BOOLEAN RW 0x00 (0

BOOLEAN RW 0x00 (0

(0

)

dec

)

dec

)

dec

)

dec

)

dec

Index 8011 Safe state value

Index (hex) Name Meaning Data type Flags Default

8011:0 Safe state value UINT8 RO 0x02 (2

8011:01 Output 1 0 Output -> 0 in case of Safe State condition BOOLEAN RW 0x00 (0

1 Output -> 1 in case of Safe State condition

8011:02 Output 2 0 Output -> 0 in case of Safe State condition BOOLEAN RW 0x00 (0

1 Output -> 1 in case of Safe State condition

EP3744-0041 and EP3744-1041 47Version: 2.2

)

dec

)

dec

)

dec

Page 48

Commissioning/Configuration

Index 8020 AI settings Ch.1 (parameterization of channel 1)

Index (hex) Name Meaning Data type Flags Default

8020:0 AI Settings Ch.1 Maximum subindex UINT8 RO 0x19 (25

8020:01 Enable user scale 1 User scale is active. BOOLEAN RW 0x00 (0

8020:06 Enable filter 1 Enable filter, which makes PLC-cycle-synchronous

BOOLEAN RW 0x01 (1

data exchange unnecessary

8020:07 Enable limit 1 1 Limit 1 enabled BOOLEAN RW 0x00 (0

8020:08 Enable limit 2 1 Limit 2 enabled BOOLEAN RW 0x00 (0

8020:0A Enable user calibra-

1 Enabling of the user calibration BOOLEAN RW 0x00 (0

tion

8020:0B Enable vendor cali-

1 Enabling of the vendor calibration BOOLEAN RW 0x01 (1

bration

8020:11 User scale offset User scale offset INT32 RW 0x00000000

(0

8020:12 User scale gain User scale gain.

The gain is represented in fixed-point format, with the

-16

factor 2

.

The value 1 corresponds to 65535

and is limited to +/- 0x7FFFF

(0x00010000

dez

INT32 RW 0x00010000

)

hex

(65536

8020:13 Limit 1 First limit value for setting the status bits INT16 RW 0x0000 (0

8020:14 Limit 2 Second limit value for setting the status bits INT16 RW 0x0000 (0

8020:15 Filter settings This object determines the digital filter settings for all

UINT16 RW 0x0000 (0

channels of the module, if it is activated via Enable filter

(index 0x80n0:06). The possible settings are sequentially

numbered.

0 50Hz FIR

1 60Hz FIR

2 IIR 1

3 IIR 2

4 IIR 3

5 IIR 4

6 IIR 5

7 IIR 6

8 IIR 7

9 IIR 8

8020:17 User calibration offset INT32 RW 0x00000000

(0

8020:18 User calibration gain INT16 RW 0x4000

(16384

8020:19 Range Permissible values: UINT16 RW 0x0008 (8

8 Differential pressure measurement relative to the

reference sensor

7 Absolute pressure measurement

dec

dec

dec

dec

dec

dec

dec

)

dec

)

dec

)

dec

)

dec

)

)

)

)

)

)

)

)

dec

)

dec

)

dec

)

dec

EP3744-0041 and EP3744-104148 Version: 2.2

Page 49

Commissioning/Configuration

Index 8030 AI settings Ch.2 (parameterization of channel 2)

Index (hex) Name Meaning Data type Flags Default