Page 1

Documentation | EN

EL72x1-901x

Servo Motor Terminals with OCT and STO, 50 V DC

2020-09-24 | Version: 2.0

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................7

1.1 Notes on the documentation..............................................................................................................7

1.2 Safety instructions .............................................................................................................................8

1.2.1 Delivery state ..................................................................................................................... 8

1.2.2 Operator's obligation to exercise diligence ........................................................................ 8

1.2.3 Description of instructions.................................................................................................. 9

1.3 Documentation issue status ............................................................................................................10

1.4 Version identification of EtherCAT devices .....................................................................................10

1.4.1 Beckhoff Identification Code (BIC)................................................................................... 15

2 Product overview.....................................................................................................................................17

2.1 Product overview Servomotor terminal with OCT and STO ............................................................17

2.2 Introduction......................................................................................................................................17

2.3 Technical data .................................................................................................................................20

2.4 Technology ......................................................................................................................................22

2.5 Start-up............................................................................................................................................24

3 Basics communication ...........................................................................................................................25

3.1 EtherCAT basics..............................................................................................................................25

3.2 EtherCAT cabling – wire-bound.......................................................................................................25

3.3 General notes for setting the watchdog...........................................................................................26

3.4 EtherCAT State Machine.................................................................................................................28

3.5 CoE Interface...................................................................................................................................30

3.6 Distributed Clock .............................................................................................................................35

4 Installation................................................................................................................................................36

4.1 Safety instructions ...........................................................................................................................36

4.2 Environmental conditions ................................................................................................................36

4.3 Transport / storage ..........................................................................................................................36

4.4 Control cabinet / terminal box..........................................................................................................36

4.5 Instructions for ESD protection........................................................................................................37

4.6 Installation on mounting rails ...........................................................................................................37

4.7 Installation position for operation with or without fan.......................................................................40

4.8 Positioning of passive Terminals .....................................................................................................43

4.9 Installation instructions for enhanced mechanical load capacity .....................................................44

4.10 Connection ......................................................................................................................................45

4.10.1 Connection system .......................................................................................................... 45

4.10.2 Wiring............................................................................................................................... 46

4.11 Example configuration for temperature measurement ....................................................................48

4.12 Shielding concept ............................................................................................................................48

4.13 UL notice - Compact Motion............................................................................................................50

4.14 Notes on current measurements using Hall sensors.......................................................................51

4.15 EL72x1-9014 - LEDs and connection..............................................................................................53

5 Commissioning........................................................................................................................................57

5.1 TwinCAT Quick Start .......................................................................................................................57

5.1.1 TwinCAT2 ....................................................................................................................... 60

EL72x1-901x 3Version: 2.0

Page 4

Table of contents

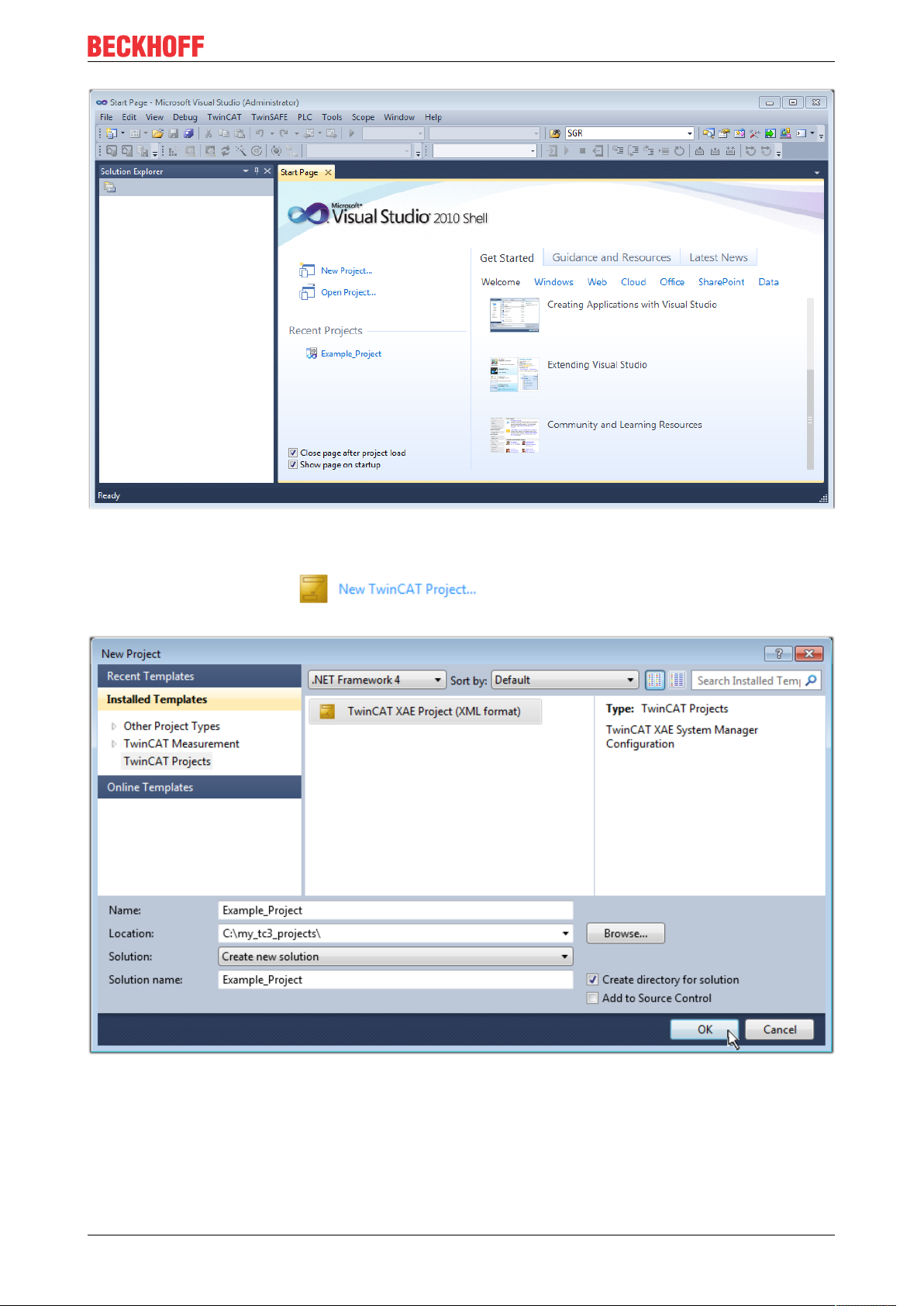

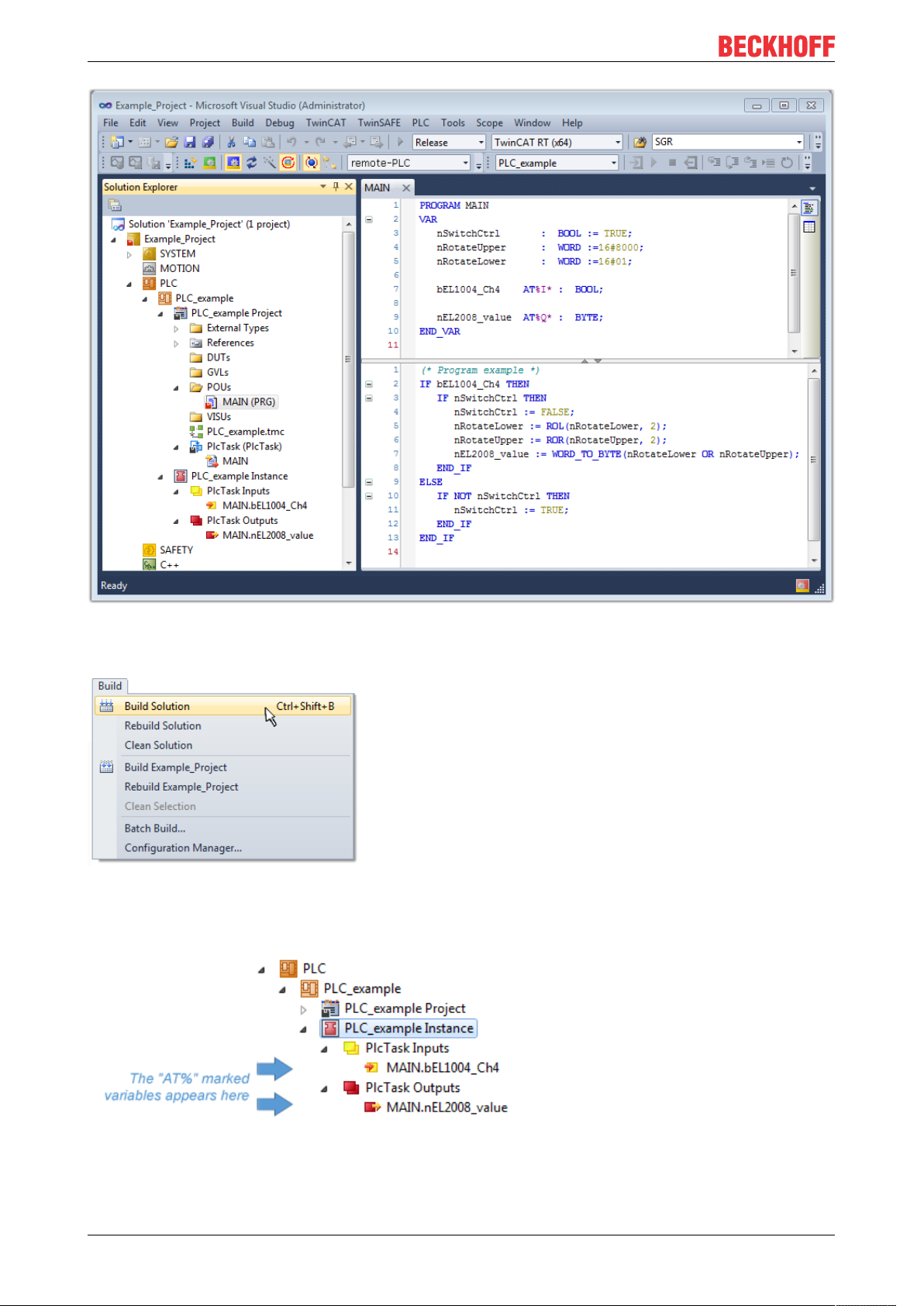

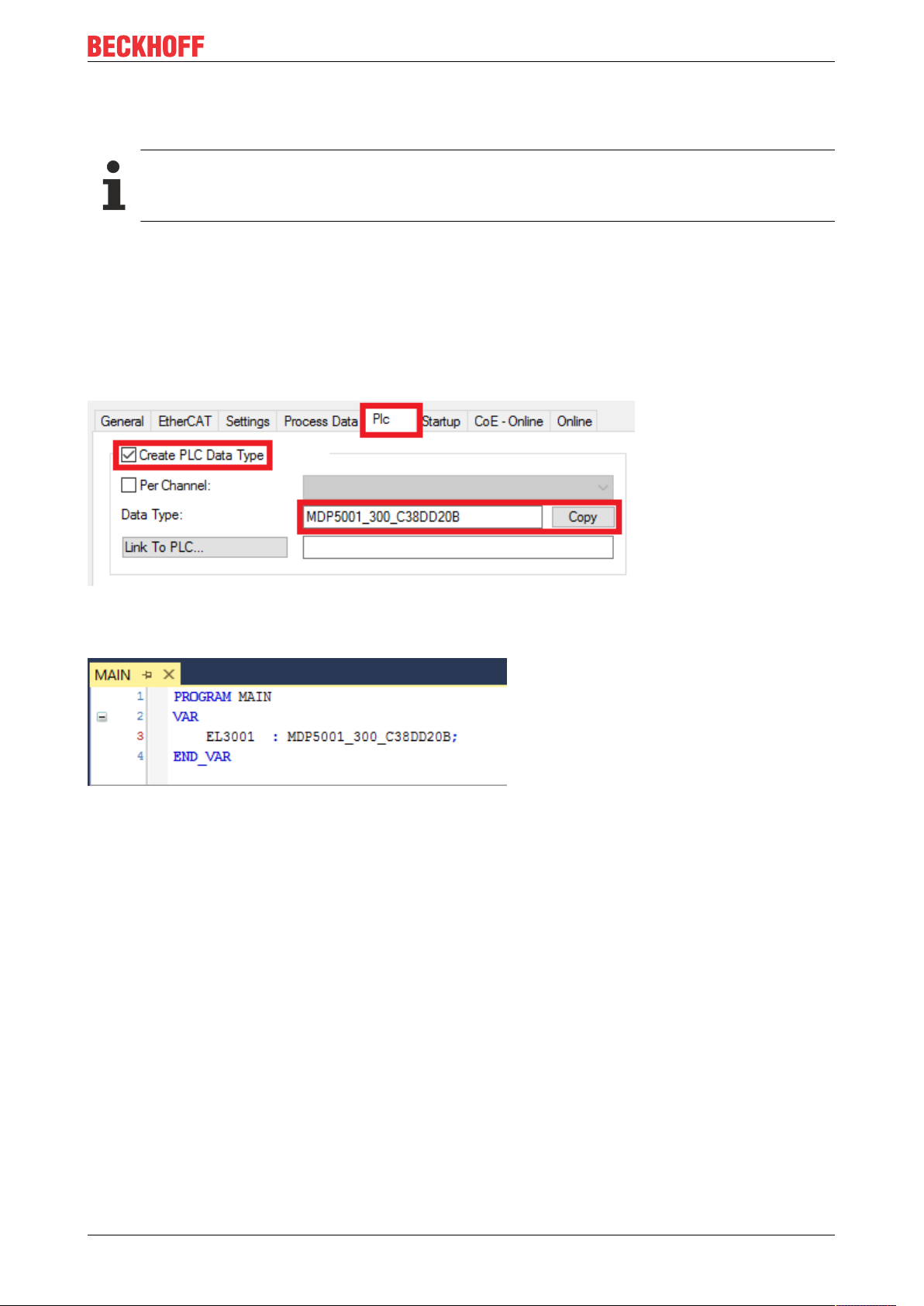

5.1.2 TwinCAT 3 ....................................................................................................................... 70

5.2 TwinCAT Development Environment ..............................................................................................83

5.2.1 Installation of the TwinCAT real-time driver..................................................................... 84

5.2.2 Notes regarding ESI device description........................................................................... 89

5.2.3 TwinCAT ESI Updater ..................................................................................................... 93

5.2.4 Distinction between Online and Offline............................................................................ 93

5.2.5 OFFLINE configuration creation ...................................................................................... 94

5.2.6 ONLINE configuration creation ........................................................................................ 99

5.2.7 EtherCAT subscriber configuration................................................................................ 107

5.3 Start-up and parameter configuration............................................................................................116

5.3.1 Integration into the NC configuration ............................................................................. 116

5.3.2 Settings with the Drive Manager.................................................................................... 120

5.3.3 Settings in the CoE register ........................................................................................... 125

5.3.4 NC settings .................................................................................................................... 129

5.3.5 Application example....................................................................................................... 135

5.3.6 Commissioning without NC, status word/control word................................................... 140

5.3.7 Settings for the automatic configuration ........................................................................ 144

5.3.8 Configuring the limit switch ........................................................................................... 146

5.3.9 Homing .......................................................................................................................... 147

5.3.10 Touch Probe .................................................................................................................. 150

5.4 Operation modes ...........................................................................................................................153

5.4.1 Overview........................................................................................................................ 153

5.4.2 CSV ............................................................................................................................... 153

5.4.3 CST................................................................................................................................ 157

5.4.4 CSTCA........................................................................................................................... 160

5.4.5 CSP ............................................................................................................................... 164

5.5 Profile MDP 742 or DS 402 ...........................................................................................................168

5.6 MDP742 process data ...................................................................................................................168

5.7 DS402 process data ......................................................................................................................172

6 Integrated safety....................................................................................................................................177

6.1 Safety regulations..........................................................................................................................177

6.2 Description of product and function ...............................................................................................177

6.2.1 Intended use .................................................................................................................. 177

6.2.2 Dimensions .................................................................................................................... 178

6.2.3 TwinSAFE reaction times .............................................................................................. 179

6.2.4 Application example for STO function (Cat. 3, PL d) ..................................................... 181

6.3 Maintenance ..................................................................................................................................187

6.4 Service life .....................................................................................................................................187

7 Object description and parameterization............................................................................................189

7.1 EL72x1-9014 (MDP742)................................................................................................................189

7.1.1 Restore object................................................................................................................ 189

7.1.2 Configuration data ......................................................................................................... 189

7.1.3 Configuration data (vendor-specific).............................................................................. 196

7.1.4 Command object............................................................................................................ 196

7.1.5 Input data....................................................................................................................... 196

EL72x1-901x4 Version: 2.0

Page 5

Table of contents

7.1.6 Output data .................................................................................................................... 198

7.1.7 Information / diagnosis data .......................................................................................... 200

7.1.8 Standard objects............................................................................................................ 203

7.2 EL72x1-9014 (DS402)...................................................................................................................212

7.2.1 Configuration data ......................................................................................................... 213

7.2.2 Configuration data (vendor-specific).............................................................................. 218

7.2.3 Command object ........................................................................................................... 218

7.2.4 Input/output data............................................................................................................ 219

7.2.5 Information / diagnosis data .......................................................................................... 224

7.2.6 Standard objects............................................................................................................ 227

8 Error correction .....................................................................................................................................234

8.1 Diagnostics – basic principles of diag messages ..........................................................................234

9 Appendix ................................................................................................................................................244

9.1 EtherCAT AL Status Codes...........................................................................................................244

9.2 Firmware compatibility...................................................................................................................244

9.3 Firmware Update EL/ES/EM/ELM/EPxxxx ....................................................................................245

9.3.1 Device description ESI file/XML..................................................................................... 246

9.3.2 Firmware explanation .................................................................................................... 249

9.3.3 Updating controller firmware *.efw................................................................................. 250

9.3.4 FPGA firmware *.rbf....................................................................................................... 252

9.3.5 Simultaneous updating of several EtherCAT devices.................................................... 256

9.4 Restoring the delivery state ...........................................................................................................257

9.5 Certificates.....................................................................................................................................258

9.6 Support and Service ......................................................................................................................259

EL72x1-901x 5Version: 2.0

Page 6

Table of contents

EL72x1-901x6 Version: 2.0

Page 7

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing and commissioning

these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Origin of the document

This original documentation is written in German. All other languages are derived from the German original.

Currentness

Please check whether you are using the current and valid version of this document. The current version can

be downloaded from the Beckhoff homepage at http://www.beckhoff.com/english/download/twinsafe.htm.

In case of doubt, please contact Technical Support [}259].

Product features

Only the product features specified in the current user documentation are valid. Further information given on

the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative.

Disclaimer

The documentation has been prepared with care. The products described are subject to cyclical revision. For

that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. We reserve the right to revise and change the documentation at any time

and without prior announcement. No claims for the modification of products that have already been supplied

may be made on the basis of the data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EL72x1-901x 7Version: 2.0

Page 8

Foreword

EtherCAT® and Safety over EtherCAT® are registered trademarks and patented technologies, licensed by

Beckhoff Automation GmbH, Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

1.2 Safety instructions

1.2.1 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

1.2.2 Operator's obligation to exercise diligence

The operator must ensure that

• the TwinSAFE products are only used as intended (see chapter Product description);

• the TwinSAFE products are only operated in sound condition and in working order.

• the TwinSAFE products are operated only by suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational safety and environmental protection

aspects, and is familiar with the operating instructions and in particular the safety instructions contained

herein.

• the operating instructions are in good condition and complete, and always available for reference at the

location where the TwinSAFE products are used.

• none of the safety and warning notes attached to the TwinSAFE products are removed, and all notes

remain legible.

EL72x1-901x8 Version: 2.0

Page 9

1.2.3 Description of instructions

In these operating instructions the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to the environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Foreword

Tip or pointer

This symbol indicates information that contributes to better understanding.

EL72x1-901x 9Version: 2.0

Page 10

Foreword

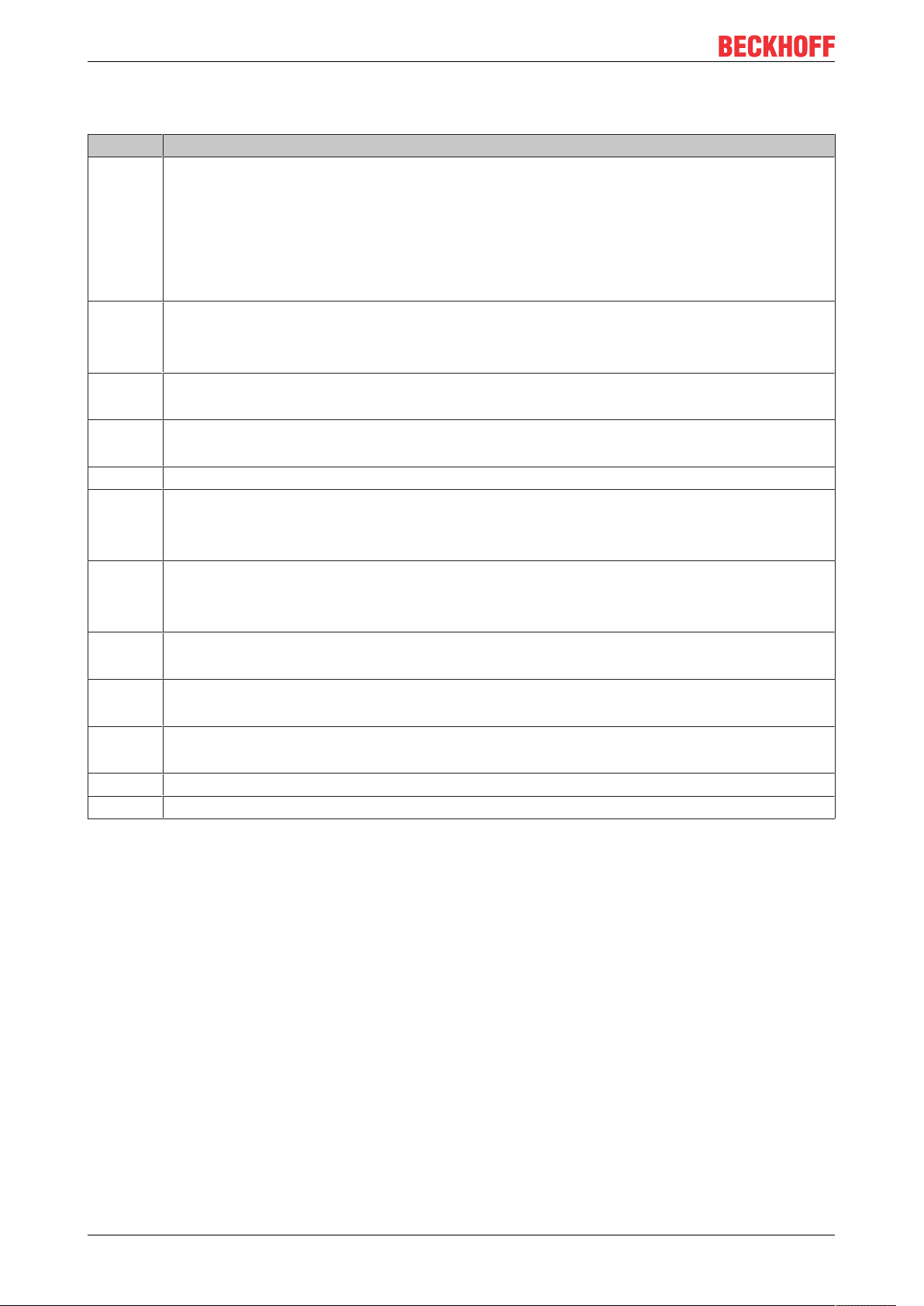

1.3 Documentation issue status

Version Comment

2.0 • Update chapter “Introduction”

• Update chapter “Technical data”

• Update chapter “Technology”

• Update chapter “LEDs and connection”

• Update revision status

• Update structure

1.9 • Note for fuse protection of the supply voltage added

• Update revision status

• Update structure

1.8 • Update chapter “Object description”

• Update structure

1.7 • Update chapter “Introduction”

• Update structure

1.6 • EL7221-901x added

1.5 • Addenda chapter “UL notice – Compact motion”

• Update revision status

• Update structure

1.4 • Update chapter “Object description and parameterization”

• Update revision status

• Update structure

1.3 • Update revision status

• Update structure

1.2 • Update chapter “Technical Data”

• Update structure

1.1 • Commissioning: chapter Quickstart added

• TwinCAT Development Environment: TwinCAT 3 added

1.0 • First published (only German)

0.1 - 0.5 • Preliminary versions (for internal use only)

1.4 Version identification of EtherCAT devices

Designation

A Beckhoff EtherCAT device has a 14-digit designation, made up of

• family key

• type

• version

• revision

EL72x1-901x10 Version: 2.0

Page 11

Foreword

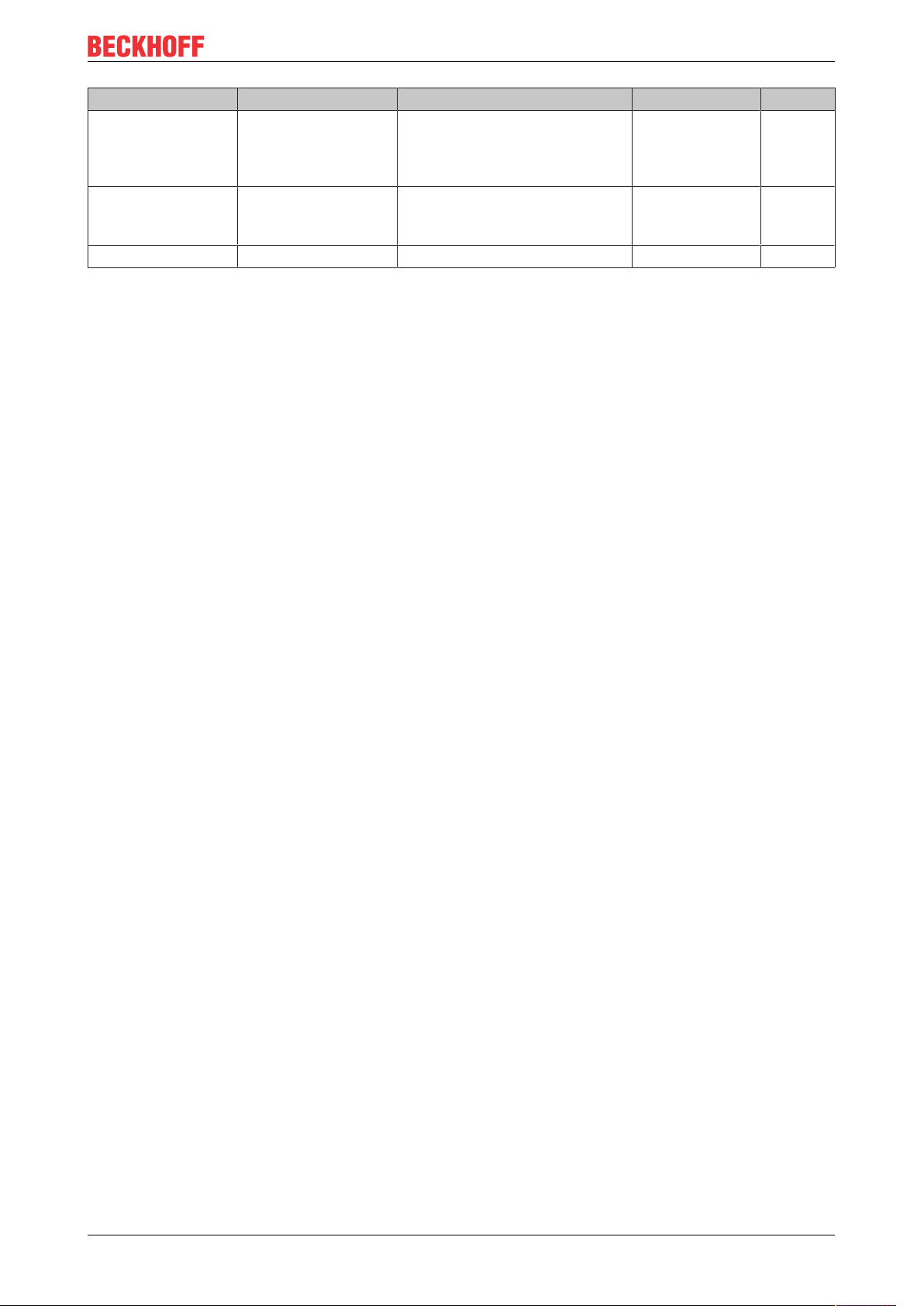

Example Family Type Version Revision

EL3314-0000-0016 EL terminal

(12 mm, nonpluggable connection

level)

ES3602-0010-0017 ES terminal

(12 mm, pluggable

connection level)

CU2008-0000-0000 CU device 2008 (8-port fast ethernet switch) 0000 (basic type) 0000

Notes

• The elements mentioned above result in the technical designation. EL3314-0000-0016 is used in the

example below.

• EL3314-0000 is the order identifier, in the case of “-0000” usually abbreviated to EL3314. “-0016” is the

EtherCAT revision.

• The order identifier is made up of

- family key (EL, EP, CU, ES, KL, CX, etc.)

- type (3314)

- version (-0000)

• The revision -0016 shows the technical progress, such as the extension of features with regard to the

EtherCAT communication, and is managed by Beckhoff.

In principle, a device with a higher revision can replace a device with a lower revision, unless specified

otherwise, e.g. in the documentation.

Associated and synonymous with each revision there is usually a description (ESI, EtherCAT Slave

Information) in the form of an XML file, which is available for download from the Beckhoff web site.

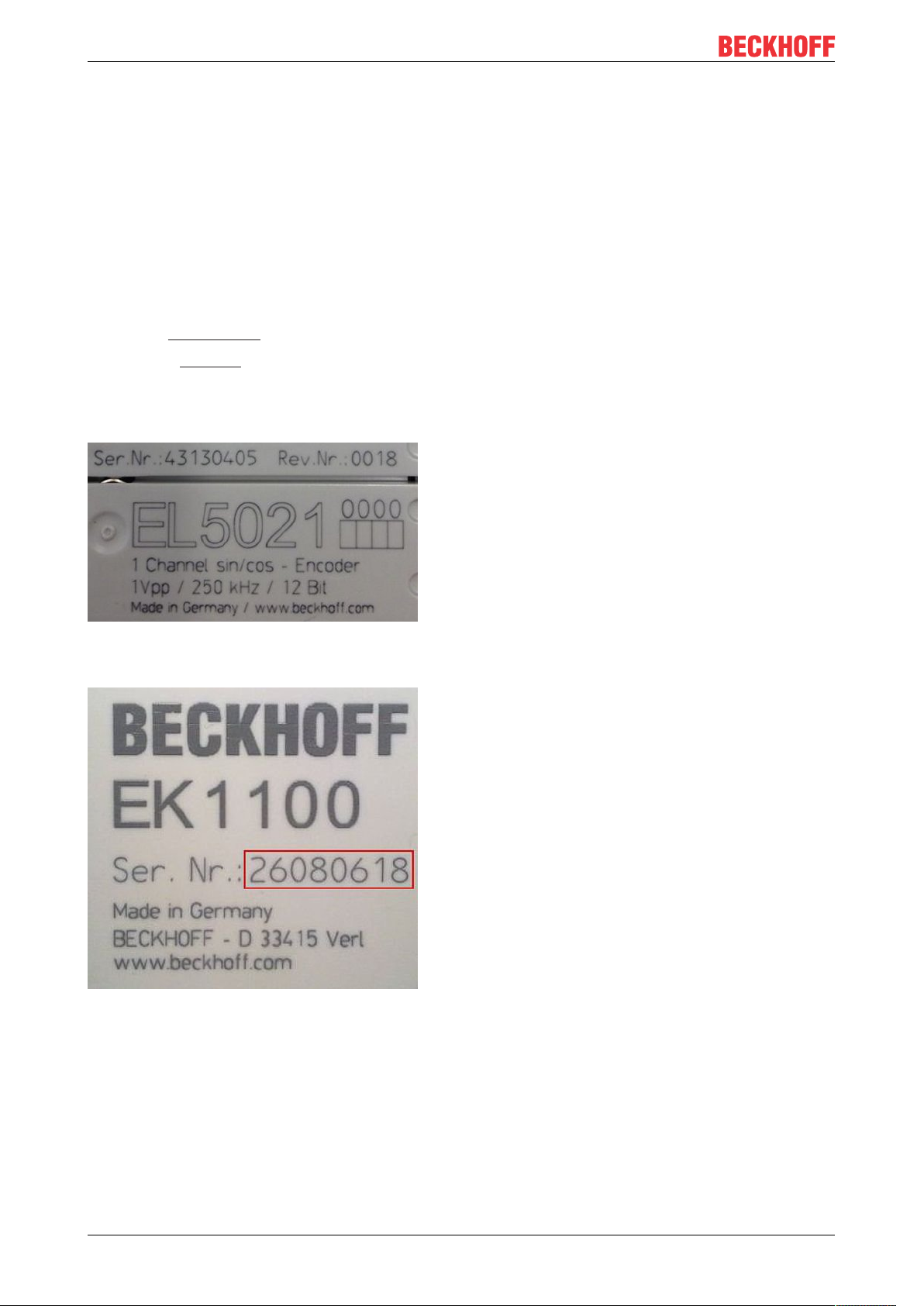

From 2014/01 the revision is shown on the outside of the IP20 terminals, see Fig. “EL5021 EL terminal,

standard IP20 IO device with batch number and revision ID (since 2014/01)”.

• The type, version and revision are read as decimal numbers, even if they are technically saved in

hexadecimal.

3314 (4-channel thermocouple

terminal)

3602 (2-channel voltage

measurement)

0000 (basic type) 0016

0010 (highprecision version)

0017

Identification number

Beckhoff EtherCAT devices from the different lines have different kinds of identification numbers:

Production lot/batch number/serial number/date code/D number

The serial number for Beckhoff IO devices is usually the 8-digit number printed on the device or on a sticker.

The serial number indicates the configuration in delivery state and therefore refers to a whole production

batch, without distinguishing the individual modules of a batch.

Structure of the serial number: KKYYFFHH

KK - week of production (CW, calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with

Ser. no.: 12063A02: 12 - production week 12 06 - production year 2006 3A - firmware version 3A 02 hardware version 02

Exceptions can occur in the IP67 area, where the following syntax can be used (see respective device

documentation):

Syntax: D ww yy x y z u

D - prefix designation

ww - calendar week

yy - year

x - firmware version of the bus PCB

EL72x1-901x 11Version: 2.0

Page 12

Foreword

y - hardware version of the bus PCB

z - firmware version of the I/O PCB

u - hardware version of the I/O PCB

Example: D.22081501 calendar week 22 of the year 2008 firmware version of bus PCB: 1 hardware version

of bus PCB: 5 firmware version of I/O PCB: 0 (no firmware necessary for this PCB) hardware version of I/O

PCB: 1

Unique serial number/ID, ID number

In addition, in some series each individual module has its own unique serial number.

See also the further documentation in the area

• IP67: EtherCAT Box

• Safety: TwinSafe

• Terminals with factory calibration certificate and other measuring terminals

Examples of markings

Fig.1: EL5021 EL terminal, standard IP20 IO device with serial/ batch number and revision ID (since

2014/01)

Fig.2: EK1100 EtherCAT coupler, standard IP20 IO device with serial/ batch number

EL72x1-901x12 Version: 2.0

Page 13

Fig.3: CU2016 switch with serial/ batch number

Foreword

Fig.4: EL3202-0020 with serial/ batch number 26131006 and unique ID-number 204418

Fig.5: EP1258-00001 IP67 EtherCAT Box with batch number/ date code 22090101 and unique serial

number 158102

Fig.6: EP1908-0002 IP67 EtherCAT Safety Box with batch number/ date code 071201FF and unique serial

number 00346070

EL72x1-901x 13Version: 2.0

Page 14

Foreword

Fig.7: EL2904 IP20 safety terminal with batch number/ date code 50110302 and unique serial number

00331701

Fig.8: ELM3604-0002 terminal with unique ID number (QR code) 100001051 and serial/ batch number

44160201

EL72x1-901x14 Version: 2.0

Page 15

Foreword

1.4.1 Beckhoff Identification Code (BIC)

The Beckhoff Identification Code (BIC) is increasingly being applied to Beckhoff products to uniquely identify

the product. The BIC is represented as a Data Matrix Code (DMC, code scheme ECC200), the content is

based on the ANSI standard MH10.8.2-2016.

Fig.9: BIC as data matrix code (DMC, code scheme ECC200)

The BIC will be introduced step by step across all product groups.

Depending on the product, it can be found in the following places:

• on the packaging unit

• directly on the product (if space suffices)

• on the packaging unit and the product

The BIC is machine-readable and contains information that can also be used by the customer for handling

and product management.

Each piece of information can be uniquely identified using the so-called data identifier

(ANSIMH10.8.2-2016). The data identifier is followed by a character string. Both together have a maximum

length according to the table below. If the information is shorter, spaces are added to it. The data under

positions 1 to 4 are always available.

The following information is contained:

EL72x1-901x 15Version: 2.0

Page 16

Foreword

Item

Type of

no.

information

1 Beckhoff order

number

2 Beckhoff Traceability

Number (BTN)

3 Article description Beckhoff article

4 Quantity Quantity in packaging

5 Batch number Optional: Year and week

6 ID/serial number Optional: Present-day

7 Variant number Optional: Product variant

...

Explanation Data

Beckhoff order number 1P 8 1P072222

Unique serial number,

see note below

description, e.g.

EL1008

unit, e.g. 1, 10, etc.

of production

serial number system,

e.g. with safety products

number on the basis of

standard products

Number of digits

identifier

S 12 SBTNk4p562d7

1K 32 1KEL1809

Q 6 Q1

2P 14 2P401503180016

51S 12 51S678294104

30P 32 30PF971, 2*K183

incl. data identifier

Example

Further types of information and data identifiers are used by Beckhoff and serve internal processes.

Structure of the BIC

Example of composite information from item 1 to 4 and 6. The data identifiers are marked in red for better

display:

BTN

An important component of the BIC is the Beckhoff Traceability Number (BTN, item no.2). The BTN is a

unique serial number consisting of eight characters that will replace all other serial number systems at

Beckhoff in the long term (e.g. batch designations on IO components, previous serial number range for

safety products, etc.). The BTN will also be introduced step by step, so it may happen that the BTN is not yet

coded in the BIC.

NOTE

This information has been carefully prepared. However, the procedure described is constantly being further

developed. We reserve the right to revise and change procedures and documentation at any time and without prior notice. No claims for changes can be made from the information, illustrations and descriptions in

this information.

EL72x1-901x16 Version: 2.0

Page 17

Product overview

2 Product overview

2.1 Product overview Servomotor terminal with OCT and STO

EL7201-9014 [}17] servo motor terminal with OCT and STO, 48 VDC, 2.8 A

EL7201-9015 [}17] servo motor terminal with OCT and STO, 48 VDC, 2.8 A

EL7211-9014 [}17] servo motor terminal with OCT and STO, 48 VDC, 4.5 A

EL7211-9015 [}17] servo motor terminal with OCT and STO, 48 VDC, 4.5 A

EL7221-9014 [}17] servo motor terminal with OCT and STO, 48 VDC, 7…8 A

EL7221-9015 [}17] servo motor terminal with OCT and STO, 48 VDC, 7…8 A

2.2 Introduction

, MDP742 profile

rms

, DS402 profile

rms

, MDP742 profile

rms

, DS402 profile

rms

, MDP742 profile

rms

, DS402 profile

rms

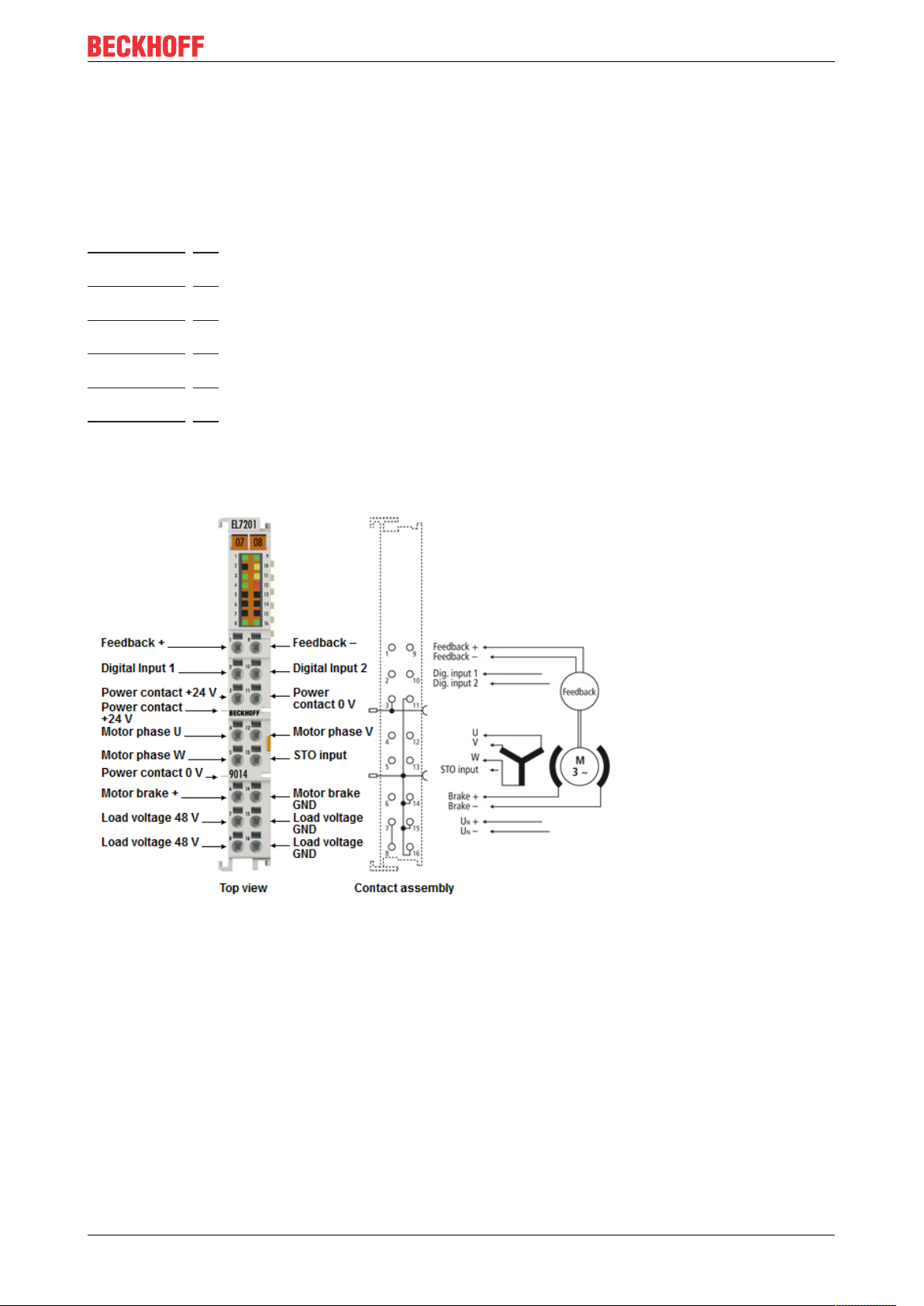

Fig.10: EL7201-901x

EL72x1-901x 17Version: 2.0

Page 18

Product overview

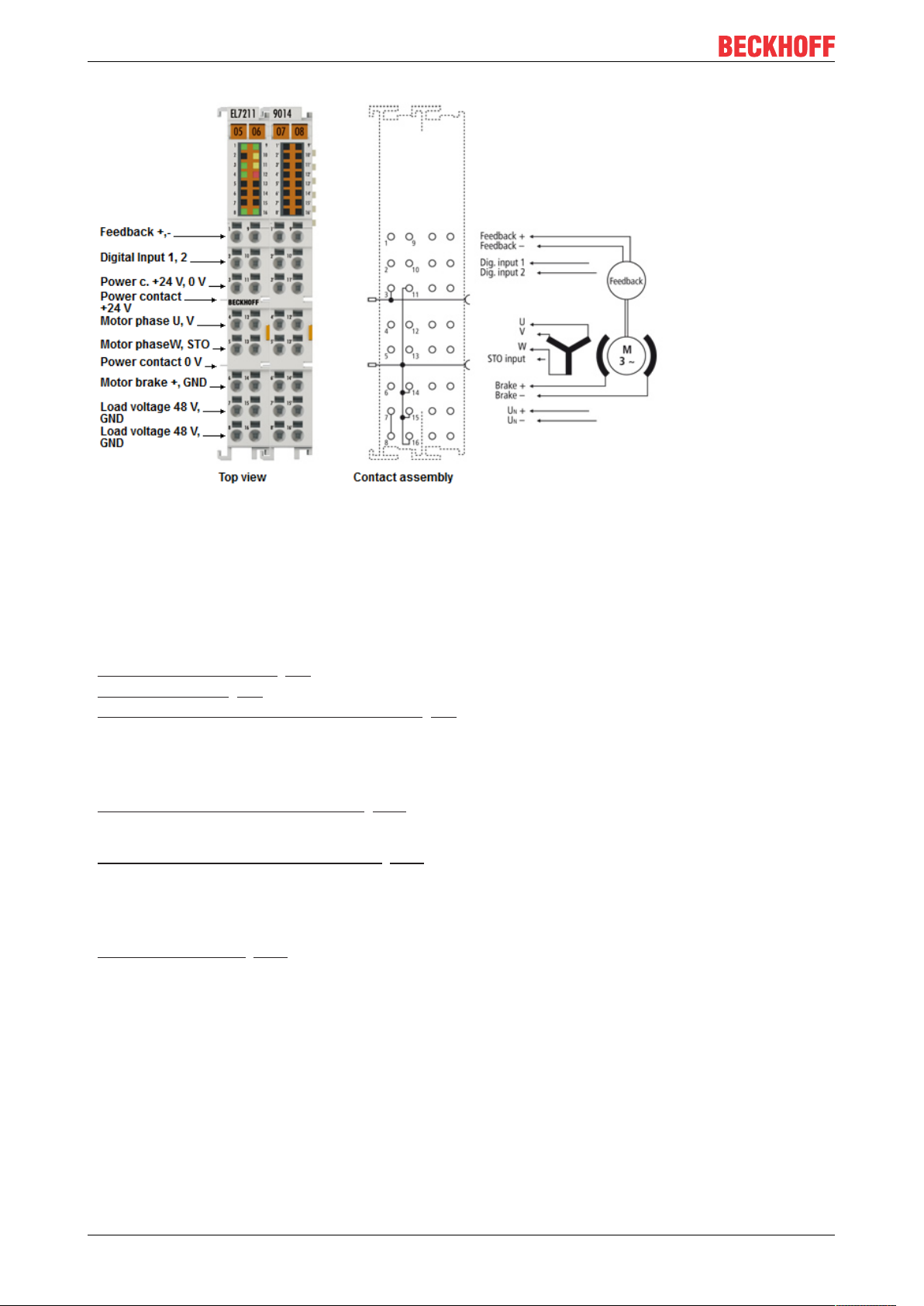

Fig.11: EL7211-901x, EL7221-901x

Quick links

Connection instructions

Chapter "Mounting and wiring",

- LEDs and pin assignment [}53]

- Shielding concept [}48]

- Notes on current measurement via Hall sensor [}51]

Configuration instructions

Chapter "Commissioning",

- Configuration of the main parameters [}116]

Chapter "Configuration with the TwinCAT System Manager",

- Object description and parameterization [}189]

Application example

Chapter "Commissioning",

- Application example [}135]

Servo motor terminals with OCT and STO input

The servo-motor EtherCAT terminals EL7201-901x (48VDC, 2.8A

EL7221-901x (48VDC, 7…8A

) with integrated absolute value interface, offer high servo performance in a

rms

), EL7211-901x (48VDC, 4.5A

rms

rms

) and

very compact design. The EL72x1-901x were designed for the motor types of the AM81xx series from

Beckhoff Automation.

The fast control technology, based on field-orientated current and PI speed control, supports fast and highly

dynamic positioning tasks. The monitoring of numerous parameters, such as overvoltage and undervoltage,

overcurrent, terminal temperature or motor load via the calculation of a I²T model, offers maximum

operational reliability.

EL72x1-901x18 Version: 2.0

Page 19

Product overview

EtherCAT, as a high-performance system communication, and CAN-over-EtherCAT (CoE), as the

application layer, enable ideal interfacing with PC-based control technology.

The latest power semiconductors guarantee minimum power loss and enable feedback into the DC link when

braking.

The LEDs indicate status, warning and error messages as well as possibly active limitations.

With the One Cable Technology (OCT) the encoder cable is omitted by transmitting the signals of the

encoder digitally via the existing motor cable. The option to read the electronic type plates of suitable motors

from the AM81xx series enables a plug-and-play solution for maximum convenience during commissioning.

The EL72x1-901x provides an STO input with which the motor connected to the terminal can be switched

torque-free. This STO input is connected to a safe output of an EL2904.

Performance Level d, Category 3 according to DIN EN ISO 13849-1:2015 is attained for the SFO safety

function of the EL72x1-901x together with an EL2904.

Recommended TwinCAT version

In order to be able to utilize the full power of the EL72x1-901x, we recommend using the

EL72x1-901x with TwinCAT 2.11 R3 or higher!

Mandatory hardware

The EL72x1-901x must be operated with a real-time capable computer and distributed clocks!

Approved motors

The EL72x1-901x may be operated only with the following Beckhoff motors.

- AM8111-xF1x, AM8112-xF1x, AM8113-xF1x, AM8121-xF1x, AM8122-xF1x, AM8131-xF1x,

AM8132-xJ1x, AM8133-xJ1x, AM8141-xJ1x

- AM8111-xF2x, AM8112-xF2x, AM8113-xF2x, AM8121-xF2x, AM8122-xF2x, AM8131-xF2x,

AM8132-xJ2x, AM8133-xJ2x, AM8141-xJ2x

Operation of the EL7221-901x with fan cartridge ZB8610

Due to the increased thermal load, the EL7221-091x must only be operated in conjunction with the

fan cartridge ZB8610 in order to avoid malfunctions.

EL72x1-901x 19Version: 2.0

Page 20

Product overview

2.3 Technical data

EL72x1-901x20 Version: 2.0

Page 21

Product overview

Technical data EL7201-901x EL7211-901x EL7221-901x

Number of outputs 3 motor phases, 2 motor holding brake

Number of inputs 2 (4) DC link voltage, 2 absolute feedback,

DC link supply voltage 8...48V

Supply voltage 24VDC via the power contacts / via the E-bus

Output current

Peak current 5.7A

Rated power

Motor holding brake output voltage 24V (+ 6 %, - 10 %)

Max. motor holding brake output cur-

rent

Load type permanently excited synchronous motors, inductive

PWM switching frequency 16kHz

Current controller frequency double PWM switching frequency

Velocity controller frequency 16 kHz

Diagnostic LED Status, warning, errors and limits

Power loss typ. 1.6W

Current consumption via E-bus typ. 120 mA

Current consumption from the 24 V typ. 55 mA + holding brake

Supports NoCoeStorage [}30] function

Reverse voltage protection 24 V power supply yes, through the body diode of the overvoltage protection device

Fuse protection

(to be carried out by the user)

Electrical isolation 500 V (E-bus/signal voltage)

Possible EtherCAT cycle times Multiple of 125µs

Configuration no address setting required

Weight approx. 60 g approx. 95 g

Permissible ambient temperature

range during operation

Permissible ambient temperature

range during storage

Permissible relative humidity 95%, no condensation

Dimensions (W x H x D) approx. 15 mm x 100 mm x 70

Mounting [}37]

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27,

EMC immunity / emission conforms to EN 61000-6-2 / EN 61000-6-4

EMC category Category C3 - standard

Protection class IP20

Installation position

Approval CE

2 digital inputs. 1 STO input

DC

2.8A

(without fan cartridge

rms

ZB8610)

4.5A

(with fan cartridge

rms

ZB8610)

for 1 second 2.8A

rms

(without fan cartridge ZB8610)

9A

for 1 second 2.8A

rms

4.5A

rms

7A

up to 55°C (with fan car-

rms

tridge ZB8610)

8A

up to 45°C (with fan car-

rms

tridge ZB8610)

9A

rms

for 1 second

rms

16A

for 1 second (with fan

rms

cartridge ZB8610)

rms

(with fan cartridge ZB8610)

170 W (without fan cartridge

ZB8610)

276 W (with fan cartridge

ZB8610)

276 W

428 W up to 55°C (with fan

cartridge ZB8610)

490 W up to 45°C (with fan

cartridge ZB8610)

max. 0.5 A

(series AM81xx)

Yes

50 V power supply yes, through the body diode of the overvoltage protection device

24 V power supply 10 A

50 V power supply 10 A

configuration via TwinCAT System Manager

0°C ... + 55°C

-25°C ... + 85°C

approx. 27 mm x 100 mm x 70

mm (width aligned: 12 mm)

mm (width aligned: 24 mm)

on 35 mm mounting rail conforms to EN 60715

see also installation instructions [}44] for enhanced mechanical load capacity

according to IEC/EN 61800-3

Category C2, C1 - auxiliary filter required

without fan cartridge ZB8610: standard installing position

with fan cartridge ZB8610: standard installing position, other installing positions (example 1 & 2)

see notice [}40]!

cULus [}50]

TÜV-Süd [}258]

EL72x1-901x 21Version: 2.0

Page 22

Product overview

2.4 Technology

The very compact EL72x1-xxxx servomotor terminal integrates a complete servo drive for servomotors up to

276W.

Servomotor

The servomotor is an electrical motor. Together with a servo amplifier the servomotor forms a servo drive.

The servomotor is operated in a closed control loop with position, torque or speed control.

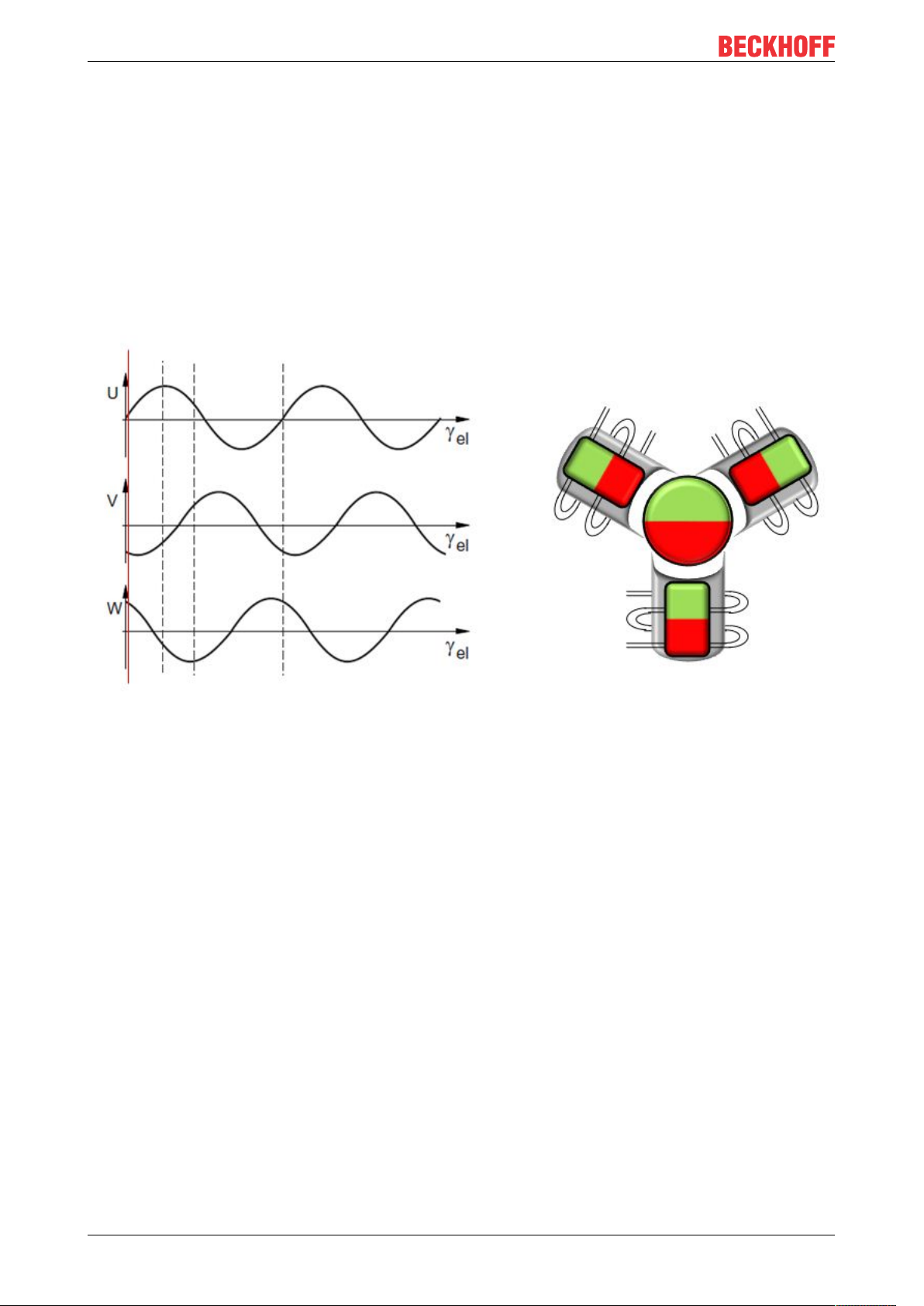

The servo terminal EL72x1-xxxx supports control of permanent magnet synchronous motors. These consist

of 3 coils which are offset by 120° and a permanent magnet rotor.

Fig.12: Three synchronous motor coils, each offset by 120°

Servomotors particularly demonstrate their advantages in highly dynamic and precise positioning

applications:

• very high positioning accuracy in applications where maximum precision is required through integrated

position feedback

• high efficiency and high acceleration capacity

• servomotors are overload-proof and therefore have far greater dynamics than stepper motors, for

example.

• load-independent high torque right up to the higher speed ranges

• maintenance requirements reduced to a minimum

The EtherCAT servomotor terminal offers users the option to configure compact and cost-effective systems

without having to give up the benefits of a servomotor.

The Beckhoff servo terminal

The EL72x1-xxxx is a fully capable servo drive for direct connection to servomotors in the lower performance

range. There is no need for further modules or cabling to make a connection to the control system. This

results in a very compact control system solution. The E-Bus connection of the EL72x1-xxxx makes the full

functionality of EtherCAT available to the user. This includes in particular the short cycle time, low jitter,

simultaneity and easy diagnostics provided by EtherCAT. With this performance from EtherCAT the

dynamics that a servomotor can achieve can be used optimally.

EL72x1-901x22 Version: 2.0

Page 23

Product overview

With a rated voltage up to 48VDC and a rated current of up to 4.5A, this enables the user to operate a

servomotor with a power of up to 276W. Permanent magnet synchronous motors with a rated current of up

to 4.5A can be connected as loads. The monitoring of numerous parameters, such as overvoltage and

undervoltage, overcurrent, terminal temperature or motor load, offers maximum operational reliability.

Modern power semiconductors guarantee minimum power loss and enable feedback into the DC link when

braking.

With the integration of a complete servo drive into a standard EL7201 EtherCAT Terminal only 12mm wide,

Beckhoff is setting new standards in matters of size. This small manufactured size is possible thanks to the

latest semiconductor technology and the resulting very high power factor. And yet, despite the small

dimensions, nothing has to be sacrificed.

The integrated fast control technology, with a field-orientated current and PI speed control, supports highly

dynamic positioning tasks. Apart from the direct connection of motor and resolver, the connection of a motor

holding brake is also possible.

The EL72x1-xx1x EtherCAT terminal has two digital inputs that can be used for the “Touch Probe” function.

The status of the inputs can be read by “Select Info Data” (MDP742 profile and DS402 profile).

Connection to the control system

A further big advantage of the EL72x1-xxxx is the easy incorporation into the control solution. The complete

integration into the control system simplifies commissioning and parameterization. As with all the other

Beckhoff terminals, the EL72x1-xxxx is simply inserted into the terminal network. Then the full terminal

network can be scanned by the TwinCAT System Manager or manually added by the application engineer.

In the System Manager the EL72x1-xxxx can be linked with the TwinCAT NC and parameterized.

Scalable motion solution

The servo terminal complements the product range of compact drive technology for Beckhoff I/O systems

that are available for stepper motors, AC and DC motors. With the EL72x1-xxxx, the range of servo drives

becomes even more finely scalable: from the miniature servo drive up to 170 W in the EtherCAT Terminal

through to the AX5000 servo drive with 118 KW, Beckhoff offers a wide range including the servomotors.

The AM81xx series was specially developed for the servomotor terminal EL72x1-xxxx.

One Cable Technology (OCT)

In the servomotors from the AM8100-xF2 x series the feedback signals are transmitted directly via the power

supply cable, so that power and feedback system are combined in a single motor connection cable. With the

use of the One Cable technology, the information is sent reliably and without interference through a digital

interface. Since a cable and plug are omitted at both the motor and controller end, the component and

commissioning costs are reduced.

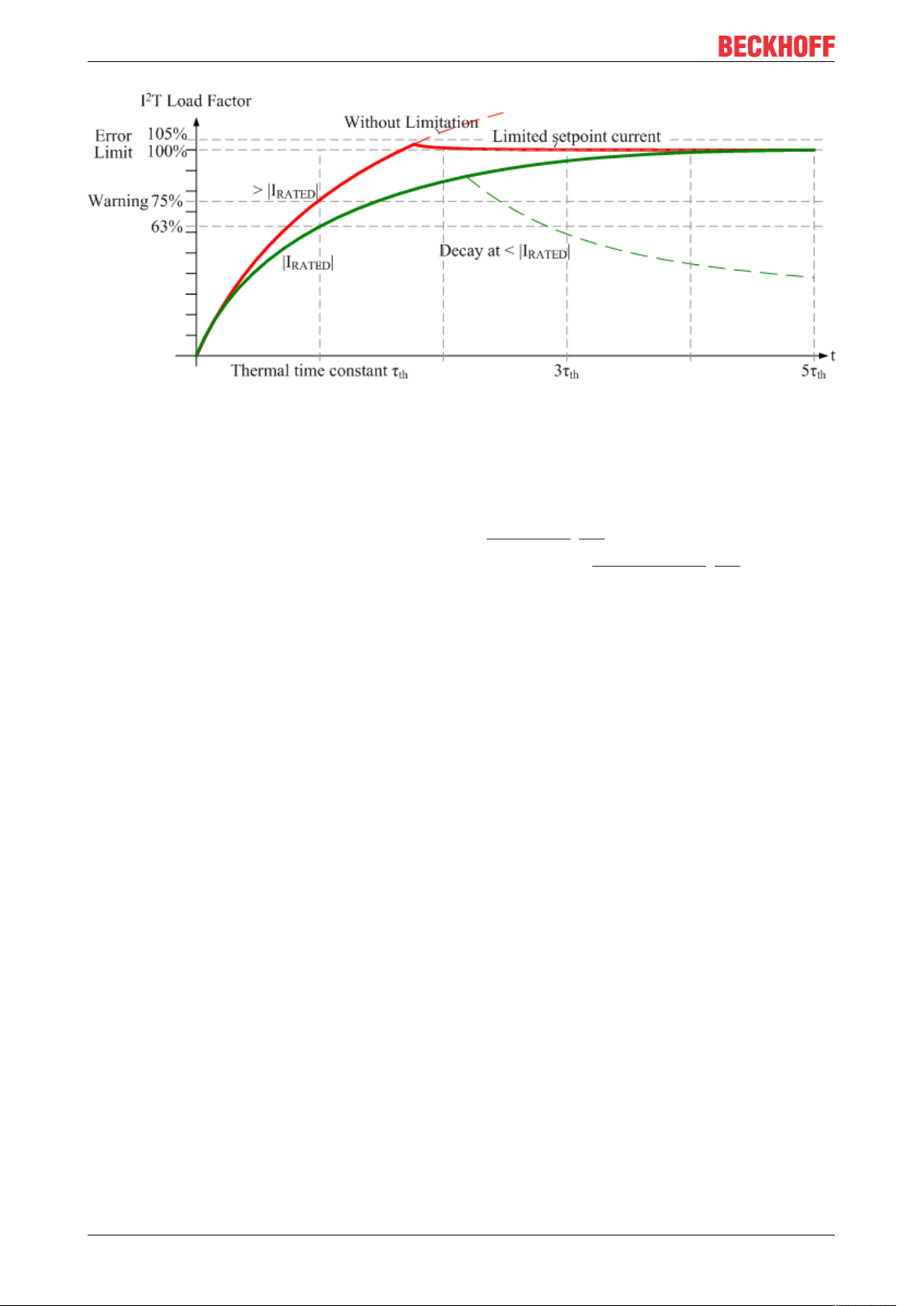

Thermal I²T motor model

The thermal I²T motor model represents the thermal behavior of the motor winding taking into account the

absolute thermal resistance Rth and the thermal capacity Cth of motor and the stator winding.

The model assumes that the motor reaches its maximum continuous operating temperature T

continuous operation with rated current I

. This temperature corresponds to 100% motor load. During

nom

nom

during

operation at rated current the motor model reaches a load of 63% after a time of τth=Rth∙Cth and slowly

reaches its continuous operating temperature.

If the motor is operated with a current that is greater than the rated current, the model reaches 100% load

more quickly.

If the load of the I²T model exceeds 100%, the requested set current is limited to the rated current, in order to

protect the motor winding thermally. The load reduces to a maximum of 100%. If the current falls below the

rated current, the load falls below 100% and the set current limitation is cancelled.

For a motor that has been cooled to ambient temperature, the time for reaching 100% load with a set current

that exceeds the rated current can be estimated with τth∙I

nom

²/I

actual

².

The actual load must be known for exact calculation of the time when the 100% load threshold is exceeded.

EL72x1-901x 23Version: 2.0

Page 24

Product overview

Fig.13: Limitation to the rated motor current

2.5 Start-up

For commissioning:

• mount the EL72x1-901x as described in the chapter Installation [}36].

• configure the EL72x1-901x in TwinCAT as described in the chapter Commissioning [}57].

EL72x1-901x24 Version: 2.0

Page 25

Basics communication

3 Basics communication

3.1 EtherCAT basics

Please refer to the EtherCAT System Documentation for the EtherCAT fieldbus basics.

3.2 EtherCAT cabling – wire-bound

The cable length between two EtherCAT devices must not exceed 100 m. This results from the FastEthernet

technology, which, above all for reasons of signal attenuation over the length of the cable, allows a maximum

link length of 5 + 90 + 5 m if cables with appropriate properties are used. See also the Design

recommendations for the infrastructure for EtherCAT/Ethernet.

Cables and connectors

For connecting EtherCAT devices only Ethernet connections (cables + plugs) that meet the requirements of

at least category 5 (CAt5) according to EN 50173 or ISO/IEC 11801 should be used. EtherCAT uses 4 wires

for signal transfer.

EtherCAT uses RJ45 plug connectors, for example. The pin assignment is compatible with the Ethernet

standard (ISO/IEC 8802-3).

Pin Color of conductor Signal Description

1 yellow TD + Transmission Data +

2 orange TD - Transmission Data 3 white RD + Receiver Data +

6 blue RD - Receiver Data -

Due to automatic cable detection (auto-crossing) symmetric (1:1) or cross-over cables can be used between

EtherCAT devices from Beckhoff.

Recommended cables

Suitable cables for the connection of EtherCAT devices can be found on the Beckhoff website!

E-Bus supply

A bus coupler can supply the EL terminals added to it with the E-bus system voltage of 5V; a coupler is

thereby loadable up to 2A as a rule (see details in respective device documentation).

Information on how much current each EL terminal requires from the E-bus supply is available online and in

the catalogue. If the added terminals require more current than the coupler can supply, then power feed

terminals (e.g. EL9410) must be inserted at appropriate places in the terminal strand.

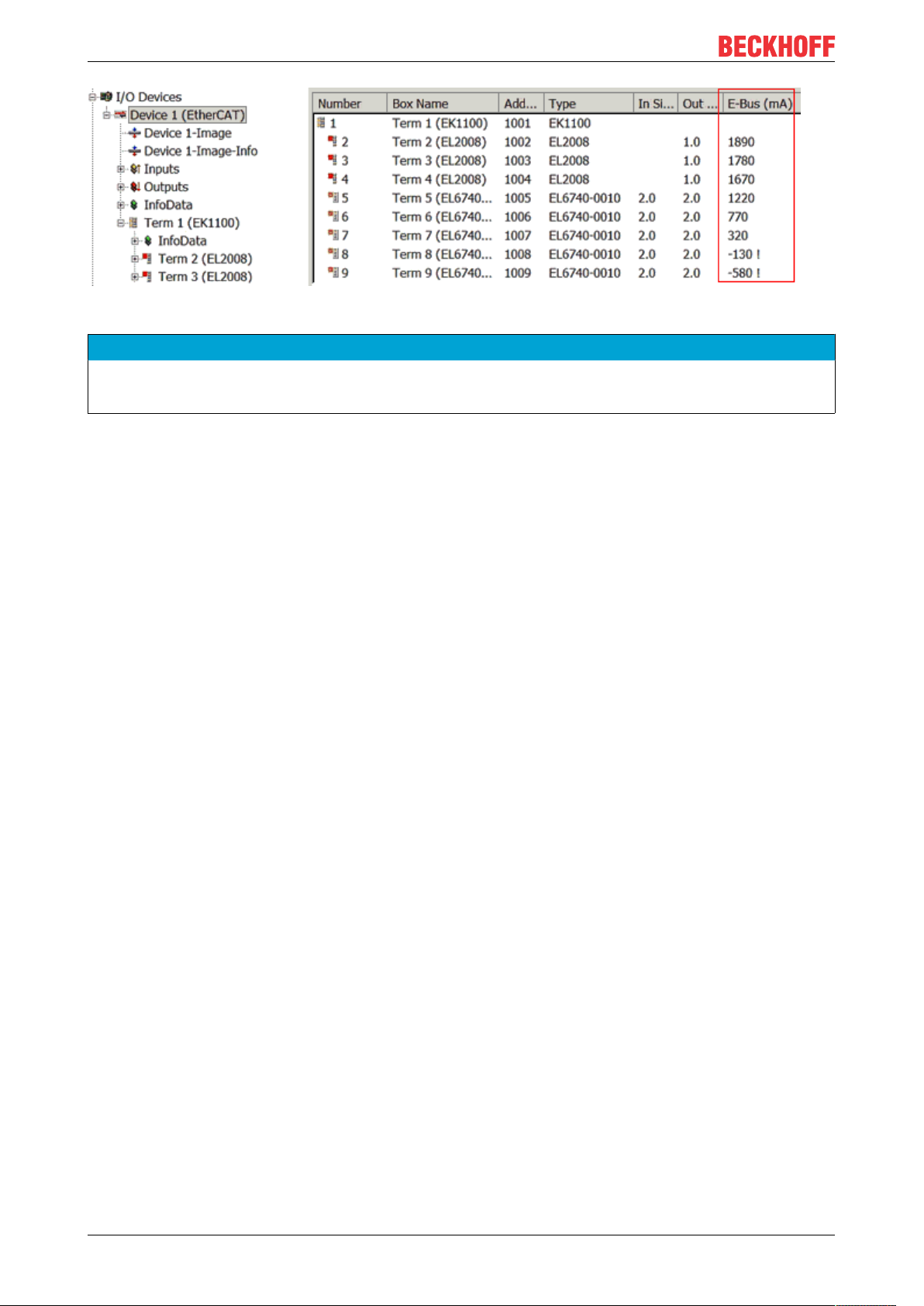

The pre-calculated theoretical maximum E-Bus current is displayed in the TwinCAT System Manager. A

shortfall is marked by a negative total amount and an exclamation mark; a power feed terminal is to be

placed before such a position.

EL72x1-901x 25Version: 2.0

Page 26

Basics communication

Fig.14: System manager current calculation

NOTE

Malfunction possible!

The same ground potential must be used for the E-Bus supply of all EtherCAT terminals in a terminal block!

3.3 General notes for setting the watchdog

ELxxxx terminals are equipped with a safety feature (watchdog) that switches off the outputs after a

specifiable time e.g. in the event of an interruption of the process data traffic, depending on the device and

settings, e.g. in OFF state.

The EtherCAT slave controller (ESC) in the EL2xxx terminals features two watchdogs:

• SM watchdog (default: 100 ms)

• PDI watchdog (default: 100 ms)

SM watchdog (SyncManager Watchdog)

The SyncManager watchdog is reset after each successful EtherCAT process data communication with the

terminal. If no EtherCAT process data communication takes place with the terminal for longer than the set

and activated SM watchdog time, e.g. in the event of a line interruption, the watchdog is triggered and the

outputs are set to FALSE. The OP state of the terminal is unaffected. The watchdog is only reset after a

successful EtherCAT process data access. Set the monitoring time as described below.

The SyncManager watchdog monitors correct and timely process data communication with the ESC from the

EtherCAT side.

PDI watchdog (Process Data Watchdog)

If no PDI communication with the EtherCAT slave controller (ESC) takes place for longer than the set and

activated PDI watchdog time, this watchdog is triggered.

PDI (Process Data Interface) is the internal interface between the ESC and local processors in the EtherCAT

slave, for example. The PDI watchdog can be used to monitor this communication for failure.

The PDI watchdog monitors correct and timely process data communication with the ESC from the

application side.

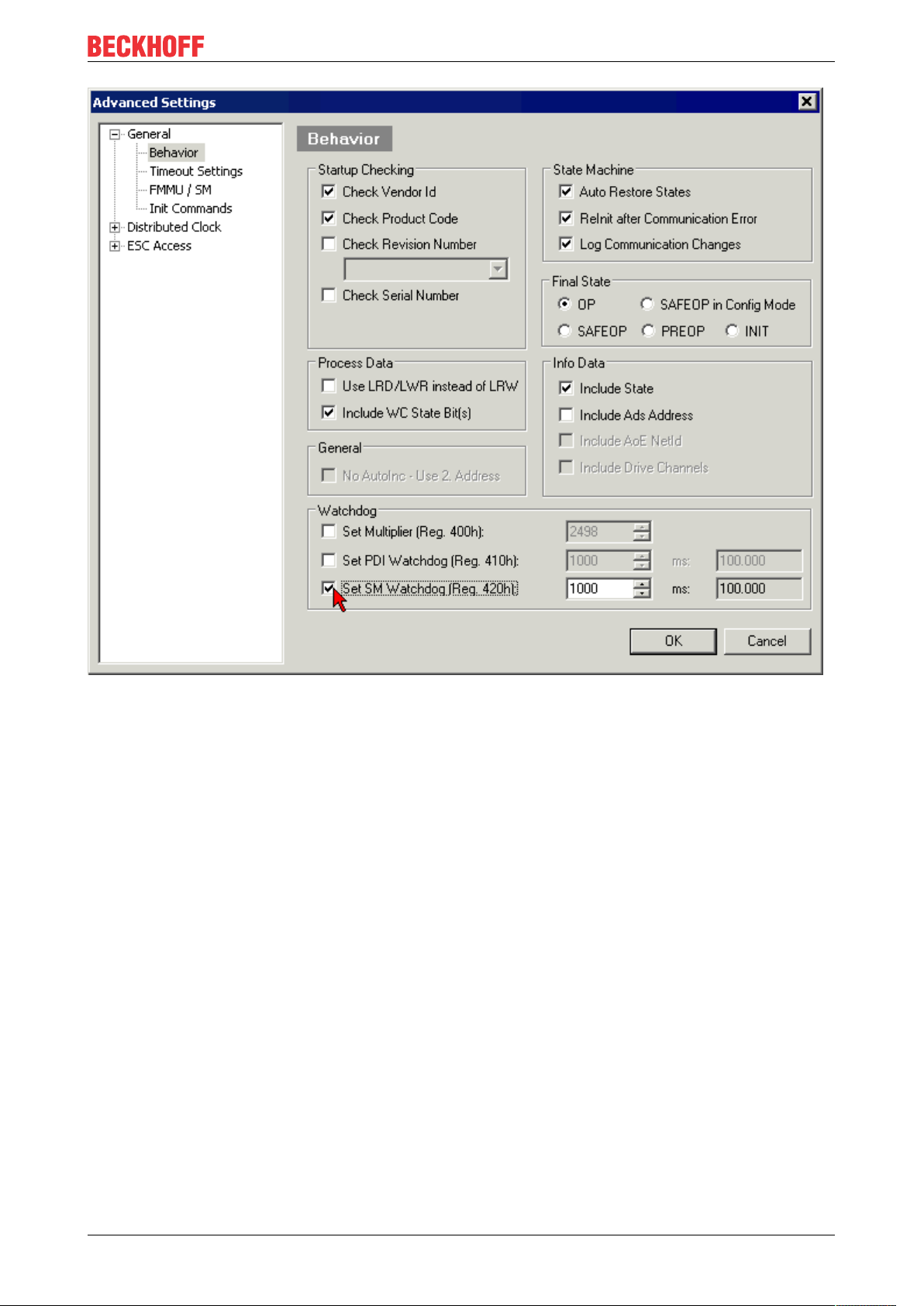

The settings of the SM- and PDI-watchdog must be done for each slave separately in the TwinCAT System

Manager.

EL72x1-901x26 Version: 2.0

Page 27

Basics communication

Fig.15: EtherCAT tab -> Advanced Settings -> Behavior -> Watchdog

Notes:

• the multiplier is valid for both watchdogs.

• each watchdog has its own timer setting, the outcome of this in summary with the multiplier is a

resulting time.

• Important: the multiplier/timer setting is only loaded into the slave at the start up, if the checkbox is

activated.

If the checkbox is not activated, nothing is downloaded and the ESC settings remain unchanged.

Multiplier

Multiplier

Both watchdogs receive their pulses from the local terminal cycle, divided by the watchdog multiplier:

1/25 MHz * (watchdog multiplier + 2) = 100µs (for default setting of 2498 for the multiplier)

The standard setting of 1000 for the SM watchdog corresponds to a release time of 100ms.

The value in multiplier + 2 corresponds to the number of basic 40 ns ticks representing a watchdog tick.

The multiplier can be modified in order to adjust the watchdog time over a larger range.

EL72x1-901x 27Version: 2.0

Page 28

Basics communication

Example “Set SM watchdog”

This checkbox enables manual setting of the watchdog times. If the outputs are set and the EtherCAT

communication is interrupted, the SM watchdog is triggered after the set time and the outputs are erased.

This setting can be used for adapting a terminal to a slower EtherCAT master or long cycle times. The

default SM watchdog setting is 100ms. The setting range is 0...65535. Together with a multiplier with a

range of 1...65535 this covers a watchdog period between 0...~170 seconds.

Calculation

Multiplier = 2498 → watchdog base time = 1 / 25MHz * (2498 + 2) = 0.0001seconds = 100µs

SM watchdog = 10000 → 10000 * 100µs = 1second watchdog monitoring time

CAUTION

Undefined state possible!

The function for switching off of the SM watchdog via SM watchdog = 0 is only implemented in terminals

from version -0016. In previous versions this operating mode should not be used.

CAUTION

Damage of devices and undefined state possible!

If the SM watchdog is activated and a value of 0 is entered the watchdog switches off completely. This is

the deactivation of the watchdog! Set outputs are NOT set in a safe state, if the communication is interrupted.

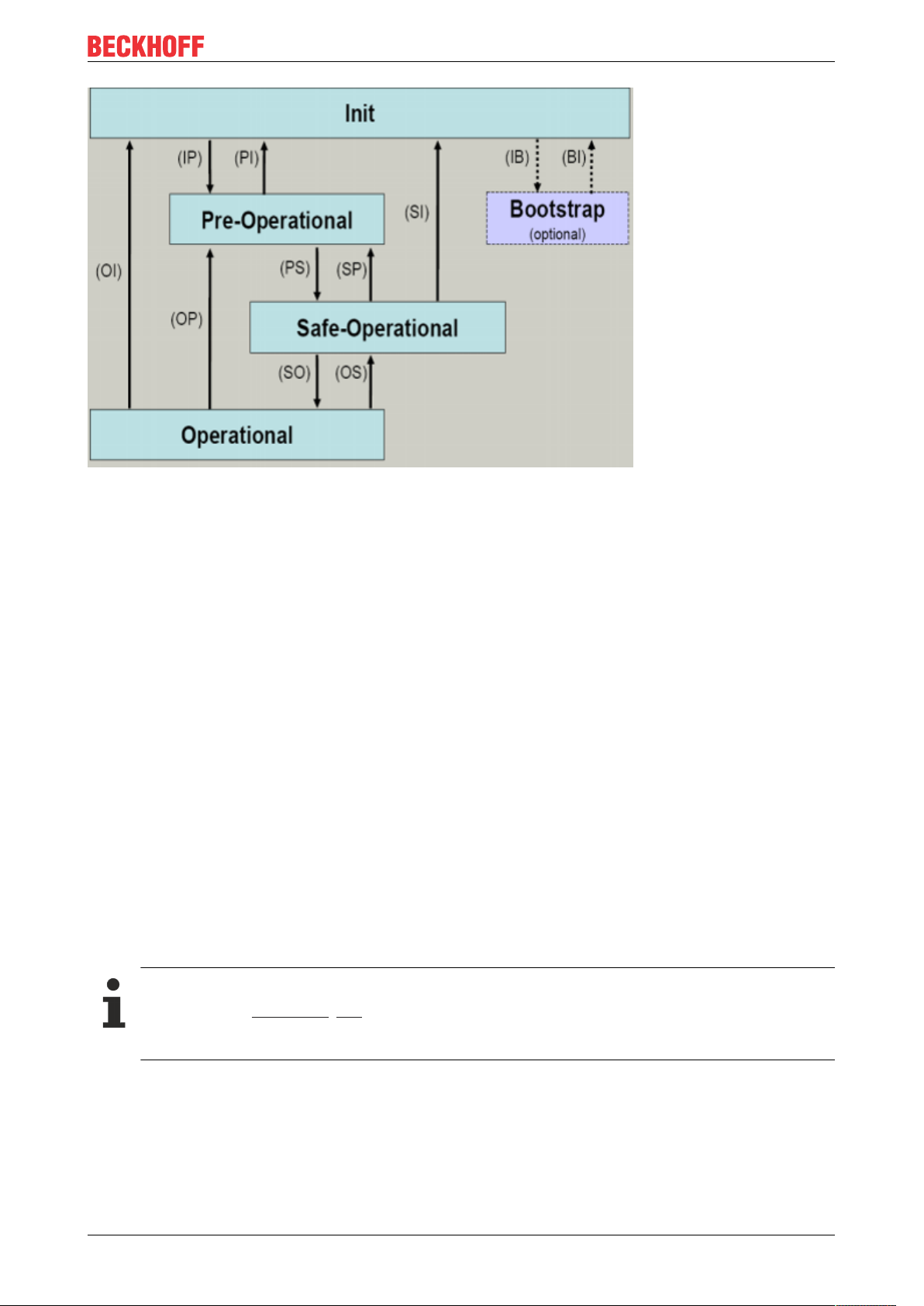

3.4 EtherCAT State Machine

The state of the EtherCAT slave is controlled via the EtherCAT State Machine (ESM). Depending upon the

state, different functions are accessible or executable in the EtherCAT slave. Specific commands must be

sent by the EtherCAT master to the device in each state, particularly during the bootup of the slave.

A distinction is made between the following states:

• Init

• Pre-Operational

• Safe-Operational and

• Operational

• Boot

The regular state of each EtherCAT slave after bootup is the OP state.

EL72x1-901x28 Version: 2.0

Page 29

Fig.16: States of the EtherCAT State Machine

Basics communication

Init

After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible.

The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication.

Pre-Operational (Pre-Op)

During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized

correctly.

In Pre-Op state mailbox communication is possible, but not process data communication. The EtherCAT

master initializes the sync manager channels for process data (from sync manager channel 2), the FMMU

channels and, if the slave supports configurable mapping, PDO mapping or the sync manager PDO

assignment. In this state the settings for the process data transfer and perhaps terminal-specific parameters

that may differ from the default settings are also transferred.

Safe-Operational (Safe-Op)

During transition between Pre-Op and Safe-Op the EtherCAT slave checks whether the sync manager

channels for process data communication and, if required, the distributed clocks settings are correct. Before

it acknowledges the change of state, the EtherCAT slave copies current input data into the associated DPRAM areas of the EtherCAT slave controller (ECSC).

In Safe-Op state mailbox and process data communication is possible, although the slave keeps its outputs

in a safe state, while the input data are updated cyclically.

Outputs in SAFEOP state

The default set watchdog [}26] monitoring sets the outputs of the module in a safe state - depending on the settings in SAFEOP and OP - e.g. in OFF state. If this is prevented by deactivation of the

watchdog monitoring in the module, the outputs can be switched or set also in the SAFEOP state.

Operational (Op)

Before the EtherCAT master switches the EtherCAT slave from Safe-Op to Op it must transfer valid output

data.

In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox

communication is possible.

EL72x1-901x 29Version: 2.0

Page 30

Basics communication

Boot

In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state.

In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no

other mailbox communication and no process data communication.

3.5 CoE Interface

General description

The CoE interface (CAN application protocol over EtherCAT)) is used for parameter management of

EtherCAT devices. EtherCAT slaves or the EtherCAT master manage fixed (read only) or variable

parameters which they require for operation, diagnostics or commissioning.

CoE parameters are arranged in a table hierarchy. In principle, the user has read access via the fieldbus.

The EtherCAT master (TwinCAT System Manager) can access the local CoE lists of the slaves via

EtherCAT in read or write mode, depending on the attributes.

Different CoE parameter types are possible, including string (text), integer numbers, Boolean values or larger

byte fields. They can be used to describe a wide range of features. Examples of such parameters include

manufacturer ID, serial number, process data settings, device name, calibration values for analog

measurement or passwords.

The order is specified in two levels via hexadecimal numbering: (main)index, followed by subindex. The

value ranges are

• Index: 0x0000 …0xFFFF (0...65535

• SubIndex: 0x00…0xFF (0...255

dez

)

dez

)

A parameter localized in this way is normally written as 0x8010:07, with preceding “0x” to identify the

hexadecimal numerical range and a colon between index and subindex.

The relevant ranges for EtherCAT fieldbus users are:

• 0x1000: This is where fixed identity information for the device is stored, including name, manufacturer,

serial number etc., plus information about the current and available process data configurations.

• 0x8000: This is where the operational and functional parameters for all channels are stored, such as

filter settings or output frequency.

Other important ranges are:

• 0x4000: here are the channel parameters for some EtherCAT devices. Historically, this was the first

parameter area before the 0x8000 area was introduced. EtherCAT devices that were previously

equipped with parameters in 0x4000 and changed to 0x8000 support both ranges for compatibility

reasons and mirror internally.

• 0x6000: Input PDOs (“input” from the perspective of the EtherCAT master)

• 0x7000: Output PDOs (“output” from the perspective of the EtherCAT master)

Availability

Not every EtherCAT device must have a CoE list. Simple I/O modules without dedicated processor

usually have no variable parameters and therefore no CoE list.

If a device has a CoE list, it is shown in the TwinCAT System Manager as a separate tab with a listing of the

elements:

EL72x1-901x30 Version: 2.0

Page 31

Basics communication

Fig.17: “CoE Online” tab

The figure above shows the CoE objects available in device “EL2502”, ranging from 0x1000 to 0x1600. The

subindices for 0x1018 are expanded.

Data management and function “NoCoeStorage”

Some parameters, particularly the setting parameters of the slave, are configurable and writeable. This can

be done in write or read mode

• via the System Manager (Fig. “CoE Online” tab) by clicking

This is useful for commissioning of the system/slaves. Click on the row of the index to be

parameterized and enter a value in the “SetValue” dialog.

• from the control system/PLC via ADS, e.g. through blocks from the TcEtherCAT.lib library

This is recommended for modifications while the system is running or if no System Manager or

operating staff are available.

Data management

If slave CoE parameters are modified online, Beckhoff devices store any changes in a fail-safe

manner in the EEPROM, i.e. the modified CoE parameters are still available after a restart.

The situation may be different with other manufacturers.

An EEPROM is subject to a limited lifetime with respect to write operations. From typically 100,000

write operations onwards it can no longer be guaranteed that new (changed) data are reliably saved

or are still readable. This is irrelevant for normal commissioning. However, if CoE parameters are

continuously changed via ADS at machine runtime, it is quite possible for the lifetime limit to be

reached. Support for the NoCoeStorage function, which suppresses the saving of changed CoE values, depends on the firmware version.

Please refer to the technical data in this documentation as to whether this applies to the respective

device.

• If the function is supported: the function is activated by entering the code word 0x12345678 once

in CoE 0xF008 and remains active as long as the code word is not changed. After switching the

device on it is then inactive. Changed CoE values are not saved in the EEPROM and can thus

be changed any number of times.

• Function is not supported: continuous changing of CoE values is not permissible in view of the

lifetime limit.

EL72x1-901x 31Version: 2.0

Page 32

Basics communication

Startup list

Changes in the local CoE list of the terminal are lost if the terminal is replaced. If a terminal is replaced with a new Beckhoff terminal, it will have the default settings. It is therefore advisable to link

all changes in the CoE list of an EtherCAT slave with the Startup list of the slave, which is processed whenever the EtherCAT fieldbus is started. In this way a replacement EtherCAT slave can

automatically be parameterized with the specifications of the user.

If EtherCAT slaves are used which are unable to store local CoE values permanently, the Startup

list must be used.

Recommended approach for manual modification of CoE parameters

• Make the required change in the System Manager

The values are stored locally in the EtherCAT slave

• If the value is to be stored permanently, enter it in the Startup list.

The order of the Startup entries is usually irrelevant.

Fig.18: Startup list in the TwinCAT System Manager

The Startup list may already contain values that were configured by the System Manager based on the ESI

specifications. Additional application-specific entries can be created.

Online/offline list

While working with the TwinCAT System Manager, a distinction has to be made whether the EtherCAT

device is “available”, i.e. switched on and linked via EtherCAT and therefore online, or whether a

configuration is created offline without connected slaves.

In both cases a CoE list as shown in Fig. “CoE online tab” is displayed. The connectivity is shown as offline/

online.

• If the slave is offline

◦ The offline list from the ESI file is displayed. In this case modifications are not meaningful or

possible.

◦ The configured status is shown under Identity.

◦ No firmware or hardware version is displayed, since these are features of the physical device.

◦ Offline is shown in red.

EL72x1-901x32 Version: 2.0

Page 33

Basics communication

Fig.19: Offline list

• If the slave is online

◦ The actual current slave list is read. This may take several seconds, depending on the size and

cycle time.

◦ The actual identity is displayed

◦ The firmware and hardware version of the equipment according to the electronic information is

displayed

◦ Online is shown in green.

Fig.20: Online list

EL72x1-901x 33Version: 2.0

Page 34

Basics communication

Channel-based order

The CoE list is available in EtherCAT devices that usually feature several functionally equivalent channels.

For example, a 4-channel analog 0...10V input terminal also has four logical channels and therefore four

identical sets of parameter data for the channels. In order to avoid having to list each channel in the

documentation, the placeholder “n” tends to be used for the individual channel numbers.

In the CoE system 16 indices, each with 255 subindices, are generally sufficient for representing all channel

parameters. The channel-based order is therefore arranged in 16

dec

/10

steps. The parameter range

hex

0x8000 exemplifies this:

• Channel 0: parameter range 0x8000:00 ... 0x800F:255

• Channel 1: parameter range 0x8010:00 ... 0x801F:255

• Channel 2: parameter range 0x8020:00 ... 0x802F:255

• ...

This is generally written as 0x80n0.

Detailed information on the CoE interface can be found in the EtherCAT system documentation on the

Beckhoff website.

EL72x1-901x34 Version: 2.0

Page 35

Basics communication

3.6 Distributed Clock

The distributed clock represents a local clock in the EtherCAT slave controller (ESC) with the following

characteristics:

• Unit 1 ns

• Zero point 1.1.2000 00:00

• Size 64 bit (sufficient for the next 584 years; however, some EtherCAT slaves only offer 32-bit support,

i.e. the variable overflows after approx. 4.2 seconds)

• The EtherCAT master automatically synchronizes the local clock with the master clock in the EtherCAT

bus with a precision of < 100 ns.

For detailed information please refer to the EtherCAT system description.

EL72x1-901x 35Version: 2.0

Page 36

Installation

4 Installation

4.1 Safety instructions

Before installing and commissioning the TwinSAFE components please read the safety instructions in the

foreword of this documentation.

4.2 Environmental conditions

Please ensure that the TwinSAFE components are only transported, stored and operated under the specified

conditions (see technical data)!

WARNING

Risk of injury!

The TwinSAFE components must not be used under the following operating conditions.

• under the influence of ionizing radiation (that exceeds the level of the natural environmental radiation)

• in corrosive environments

• in an environment that leads to unacceptable soiling of the TwinSAFE component

NOTE

Electromagnetic compatibility

The TwinSAFE components comply with the current standards on electromagnetic compatibility with regard

to spurious radiation and immunity to interference in particular.

However, in cases where devices such as mobile phones, radio equipment, transmitters or high-frequency

systems that exceed the interference emissions limits specified in the standards are operated near TwinSAFE components, the function of the TwinSAFE components may be impaired.

4.3 Transport / storage

Use the original packaging in which the components were delivered for transporting and storing the

TwinSAFE components.

CAUTION

Note the specified environmental conditions

Please ensure that the digital TwinSAFE components are only transported and stored under the specified

environmental conditions (see technical data).

4.4 Control cabinet / terminal box

The TwinSAFE terminals must be installed in a control cabinet or terminal box with IP54 protection class

according to IEC60529 as a minimum.

EL72x1-901x36 Version: 2.0

Page 37

Installation

4.5 Instructions for ESD protection

NOTE

Destruction of the devices by electrostatic discharge possible!

The devices contain components at risk from electrostatic discharge caused by improper handling.

• Please ensure you are electrostatically discharged and avoid touching the contacts of the device directly.

• Avoid contact with highly insulating materials (synthetic fibers, plastic film etc.).

• Surroundings (working place, packaging and personnel) should by grounded probably, when handling

with the devices.

• Each assembly must be terminated at the right hand end with an EL9011 or EL9012 bus end cap, to ensure the protection class and ESD protection.

Fig.21: Spring contacts of the Beckhoff I/O components

4.6 Installation on mounting rails

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the bus terminals!

EL72x1-901x 37Version: 2.0

Page 38

Installation

Assembly

Fig.22: Attaching on mounting rail

The bus coupler and bus terminals are attached to commercially available 35mm mounting rails (DIN rails

according to EN60715) by applying slight pressure:

1. First attach the fieldbus coupler to the mounting rail.

2. The bus terminals are now attached on the right-hand side of the fieldbus coupler. Join the components with tongue and groove and push the terminals against the mounting rail, until the lock clicks

onto the mounting rail.

If the terminals are clipped onto the mounting rail first and then pushed together without tongue and

groove, the connection will not be operational! When correctly assembled, no significant gap should

be visible between the housings.

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting rail. At

the installation, the locking mechanism of the components must not come into conflict with the fixing

bolts of the mounting rail. To mount the mounting rails with a height of 7.5mm under the terminals

and couplers, you should use flat mounting connections (e.g. countersunk screws or blind rivets).

EL72x1-901x38 Version: 2.0

Page 39

Disassembly

Fig.23: Disassembling of terminal

Each terminal is secured by a lock on the mounting rail, which must be released for disassembly:

Installation

1. Pull the terminal by its orange-colored lugs approximately 1cm away from the mounting rail. In doing

so for this terminal the mounting rail lock is released automatically and you can pull the terminal out of

the bus terminal block easily without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower grooved

housing surfaces and pull the terminal out of the bus terminal block.

Connections within a bus terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realized by

joining the components:

• The six spring contacts of the K-Bus/E-Bus deal with the transfer of the data and the supply of the Bus

Terminal electronics.

• The power contacts deal with the supply for the field electronics and thus represent a supply rail within

the bus terminal block. The power contacts are supplied via terminals on the Bus Coupler (up to 24V)

or for higher voltages via power feed terminals.

Power Contacts

During the design of a bus terminal block, the pin assignment of the individual Bus Terminals must

be taken account of, since some types (e.g. analog Bus Terminals or digital 4-channel Bus Terminals) do not or not fully loop through the power contacts. Power Feed Terminals (KL91xx, KL92xx

or EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail.

PE power contact

The power contact labeled PE can be used as a protective earth. For safety reasons this contact mates first

when plugging together, and can ground short-circuit currents of up to 125A.

EL72x1-901x 39Version: 2.0

Page 40

Installation

Fig.24: Power contact on left side

NOTE

Possible damage of the device

Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively coupled to the

mounting rail. This may lead to incorrect results during insulation testing or to damage on the terminal (e.g.

disruptive discharge to the PE line during insulation testing of a consumer with a nominal voltage of 230V).

For insulation testing, disconnect the PE supply line at the Bus Coupler or the Power Feed Terminal! In order to decouple further feed points for testing, these Power Feed Terminals can be released and pulled at

least 10mm from the group of terminals.

WARNING

Risk of electric shock!

The PE power contact must not be used for other potentials!

4.7 Installation position for operation with or without fan

NOTE

Constraints regarding installation position and operating temperature range

When installing the terminals ensure that an adequate spacing is maintained between other components

above and below the terminal in order to guarantee adequate ventilation!

Prescribed installation position for operation without fan

The prescribed installation position requires the mounting rail to be installed horizontally and the connection

surfaces of the EL/KL terminals to face forward (see Fig. “Recommended distances of installation position for

operating without fan“).

The terminals are ventilated from below, which enables optimum cooling of the electronics through

convection.

EL72x1-901x40 Version: 2.0

Page 41

Installation

Fig.25: Recommended distances of installation position for operating without fan

Compliance with the distances shown in Fig. “Recommended distances of installation position for operating

without fan” is recommended.

For further information regarding the operation without fan refer to the Technical Data of the terminal.

Standard installation position for operation with fan

The standard installation position for operation with fan requires the mounting rail to be installed horizontally

and the connection surfaces of the EL/KL terminals to face forward (see Fig. Recommended distances for

installation position for operation with fan).

The terminals are ventilated fan supported (e.g. with fan cartridge ZB8610) from below.

EL72x1-901x 41Version: 2.0

Page 42

Installation

Fig.26: Recommended distances for installation position for operation with fan

Other installation positions

Due to the enforced effect of the fan on the ventilation of the terminals, other installation positions (see Fig.

“Other installation positions, example 1 + 2“) may be permitted where appropriate.

See corresponding notes in the Technical Data of the terminal.

Fig.27: Other installation positions, example 1

EL72x1-901x42 Version: 2.0

Page 43

Fig.28: Other installation positions, example 2

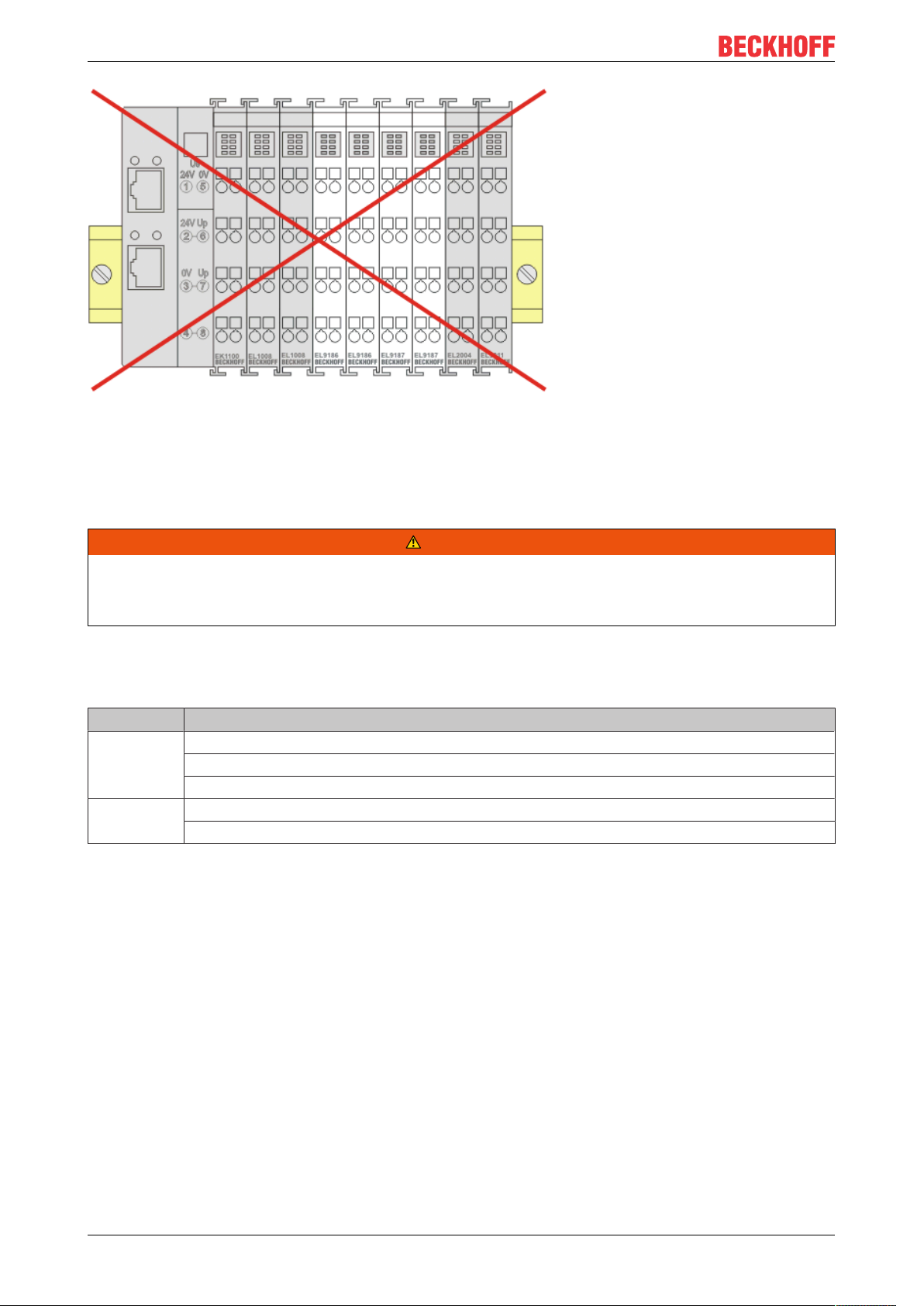

4.8 Positioning of passive Terminals

Installation

Hint for positioning of passive terminals in the bus terminal block

EtherCAT Terminals (ELxxxx / ESxxxx), which do not take an active part in data transfer within the

bus terminal block are so called passive terminals. The passive terminals have no current consumption out of the E-Bus.

To ensure an optimal data transfer, you must not directly string together more than two passive terminals!

Examples for positioning of passive terminals (highlighted)

Fig.29: Correct positioning

EL72x1-901x 43Version: 2.0

Page 44

Installation

Fig.30: Incorrect positioning

4.9 Installation instructions for enhanced mechanical load capacity

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminal system into a safe, de-energized state before starting mounting, disassembly or

wiring of the Bus Terminals!

Additional checks

The terminals have undergone the following additional tests:

Verification Explanation

Vibration 10 frequency runs in 3 axes

6 Hz < f < 60 Hz displacement 0.35 mm, constant amplitude

60.1Hz<f<500Hz acceleration 5g, constant amplitude

Shocks 1000 shocks in each direction, in 3 axes

25 g, 6 ms

Additional installation instructions

For terminals with enhanced mechanical load capacity, the following additional installation instructions apply:

• The enhanced mechanical load capacity is valid for all permissible installation positions

• Use a mounting rail according to EN 60715 TH35-15

• Fix the terminal segment on both sides of the mounting rail with a mechanical fixture, e.g. an earth

terminal or reinforced end clamp

• The maximum total extension of the terminal segment (without coupler) is:

64 terminals (12mm mounting with) or 32 terminals (24mm mounting with)

• Avoid deformation, twisting, crushing and bending of the mounting rail during edging and installation of

the rail

• The mounting points of the mounting rail must be set at 5 cm intervals

• Use countersunk head screws to fasten the mounting rail

• The free length between the strain relief and the wire connection should be kept as short as possible. A

distance of approx. 10cm should be maintained to the cable duct.

EL72x1-901x44 Version: 2.0

Page 45

Installation

4.10 Connection

4.10.1 Connection system

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the bus terminals!

Overview

The Bus Terminal system offers different connection options for optimum adaptation to the respective

application:

• The terminals of ELxxxx and KLxxxx series with standard wiring include electronics and connection

level in a single enclosure.

• The terminals of ESxxxx and KSxxxx series feature a pluggable connection level and enable steady

wiring while replacing.

• The High Density Terminals (HD Terminals) include electronics and connection level in a single

enclosure and have advanced packaging density.

Standard wiring (ELxxxx / KLxxxx)

Fig.31: Standard wiring

The terminals of ELxxxx and KLxxxx series have been tried and tested for years.

They feature integrated screwless spring force technology for fast and simple assembly.

Pluggable wiring (ESxxxx / KSxxxx)

Fig.32: Pluggable wiring

The terminals of ESxxxx and KSxxxx series feature a pluggable connection level.

The assembly and wiring procedure is the same as for the ELxxxx and KLxxxx series.

The pluggable connection level enables the complete wiring to be removed as a plug connector from the top

of the housing for servicing.

The lower section can be removed from the terminal block by pulling the unlocking tab.

Insert the new component and plug in the connector with the wiring. This reduces the installation time and

eliminates the risk of wires being mixed up.

The familiar dimensions of the terminal only had to be changed slightly. The new connector adds about 3

mm. The maximum height of the terminal remains unchanged.

EL72x1-901x 45Version: 2.0