Page 1

Operating instructions for

EL6930

TwinSAFE Logic Terminal with PROFIsafe gateway

Version: 1.1.1

Date: 2015-03-11

Page 2

Page 3

Table of contents

Table of contents

1 Foreword 3

1.1 Notes on the manual 3

1.1.1 Disclaimer 3

1.1.2 Brands 3

1.1.3 Patents 3

1.1.4 Copyright 3

1.1.5 Delivery conditions 3

1.2 Safety instructions 4

1.2.1 Delivery state 4

1.2.2 Operator's obligation to exercise diligence 4

1.2.3 Description of safety symbols 5

1.2.4 Origin of the document 5

1.2.5 Documentation issue status 6

2 System description 7

2.1 The Beckhoff Bus Terminal system 7

2.1.1 Bus Coupler 8

2.1.2 Bus Terminals 9

2.1.3 E-bus 9

2.1.4 Power contacts 9

2.2 TwinSAFE 10

2.2.1 The I/O construction kit is extended safely 10

2.2.2 Safety concept 10

2.2.3 EL1904, EL2904 - Bus Terminals with 4 fail-safe inputs or outputs 11

2.2.4 EL6930 - TwinSAFE logic terminal with PROFIsafe gateway 11

2.2.5 The fail-safe principle (Fail Stop) 11

3 Product description 12

3.1 General description 12

3.2 Intended use 13

3.3 Technical data 14

3.4 Safety parameters 15

3.5 Dimensions 15

4 Operation 16

4.1 Installation 16

4.1.1 Safety instructions 16

4.1.2 Transport / storage 16

4.1.3 Mechanical installation 17

EL6930 1

Page 4

Table of contents

4.1.4 Electrical installation 19

4.1.5 Tested EL2904 devices 23

4.1.6 Tested EL1904 devices 23

4.2 Configuration of the EL6930 in the TwinCAT System Manager 24

4.2.1 Configuration requirements 24

4.2.2 Inserting a Beckhoff Bus Coupler 24

4.2.3 Inserting a Beckhoff Bus Terminal 25

4.2.4 Inserting an EL6930 25

4.2.5 Address settings on the TwinSAFE terminals 26

4.2.6 Entering the TwinSAFE addresses in the System Manager 27

4.2.7 Creating a TwinSAFE group 28

4.2.8 Append a function block 31

4.2.9 EL6930 user and version administration 37

4.2.10 Loading the project into the EL6930 38

4.2.11 Communication between TwinCAT controllers 40

Creating the PROFIsafe slave connection 44

4.3 Commissioning on Siemens F-CPU 47

4.3.1 Requirement 47

4.3.2 Installing the EL6930 in Step7 47

4.3.3 Configuration of the hardware 48

4.4 Diagnostics 51

4.4.1 Diagnostic LEDs 51

4.4.2 Diagnostic object 52

4.4.3 Status LEDs 53

4.5 Maintenance 54

4.5.1 Cleaning 54

4.6 Service life 54

4.6.1 Decommissioning 54

4.6.2 Disposal 54

5 Appendix 55

5.1 Beckhoff Support and Service 55

5.1.1 Beckhoff branches and partner companies Beckhoff Support 55

5.1.2 Beckhoff company headquarters 55

5.2 Certificates 56

2

EL6930

Page 5

Foreword

1 Foreword

1.1 Notes on the manual

This description is only intended for the use of trained specialists in control and automation technology

familiar with the applicable national standards. It is essential that the following notes and explanations are

followed when installing and commissioning these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

safety requirements, including all the relevant laws, regulations, guidelines and standards.

1.1.1 Disclaimer

This documentation has been prepared with care. The products described are, however, constantly under

development. For this reason, the documentation may not always have been fully checked for

consistency with the performance data, standards or other characteristics described.

If it should contain technical or editorial errors, we reserve the right to make changes at any time and

without notice.

No claims for the modification of products that have already been supplied may be made on the basis of

the data, diagrams and descriptions in this documentation.

1.1.2 Brands

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

The use by third parties of other brand names or trademarks contained in this documentation may lead to

an infringement of the rights of the respective trademark owner.

1.1.3 Patents

The EtherCAT technology is patent protected, in particular by the following applications and patents:

EP1590927, EP1789857, DE102004044764, DE102007017835 with the corresponding applications and

registrations in various other countries.

The TwinCAT technology is patent protected, in particular by the following applications and patents:

EP0851348, US6167425 with the corresponding applications and registrations in various other countries.

1.1.4 Copyright

©

Beckhoff Automation GmbH & Co. KG.

The copying, distribution and utilization of this document as well as the communication of its contents to

others without express authorization is prohibited. Offenders shall be held liable for damages. All rights

conferred by patent grant or registration of a utility model or registered design are reserved.

1.1.5 Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

EL6930 3

Page 6

Foreword

1.2 Safety instructions

1.2.1 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

1.2.2 Operator's obligation to exercise diligence

The operator must ensure that

• the TwinSAFE products are only used as intended (see section Product description);

• the TwinSAFE products are only operated in sound condition and in working order.

• the TwinSAFE products are operated only by suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational safety and environmental

protection aspects, and is familiar with the operating instructions and in particular the safety

instructions contained herein.

• the operating instructions are in good condition and complete, and always available for reference

at the location where the TwinSAFE products are used.

• none of the safety and warning notes attached to the TwinSAFE products are removed, and all

notes remain legible.

4

EL6930

Page 7

Foreword

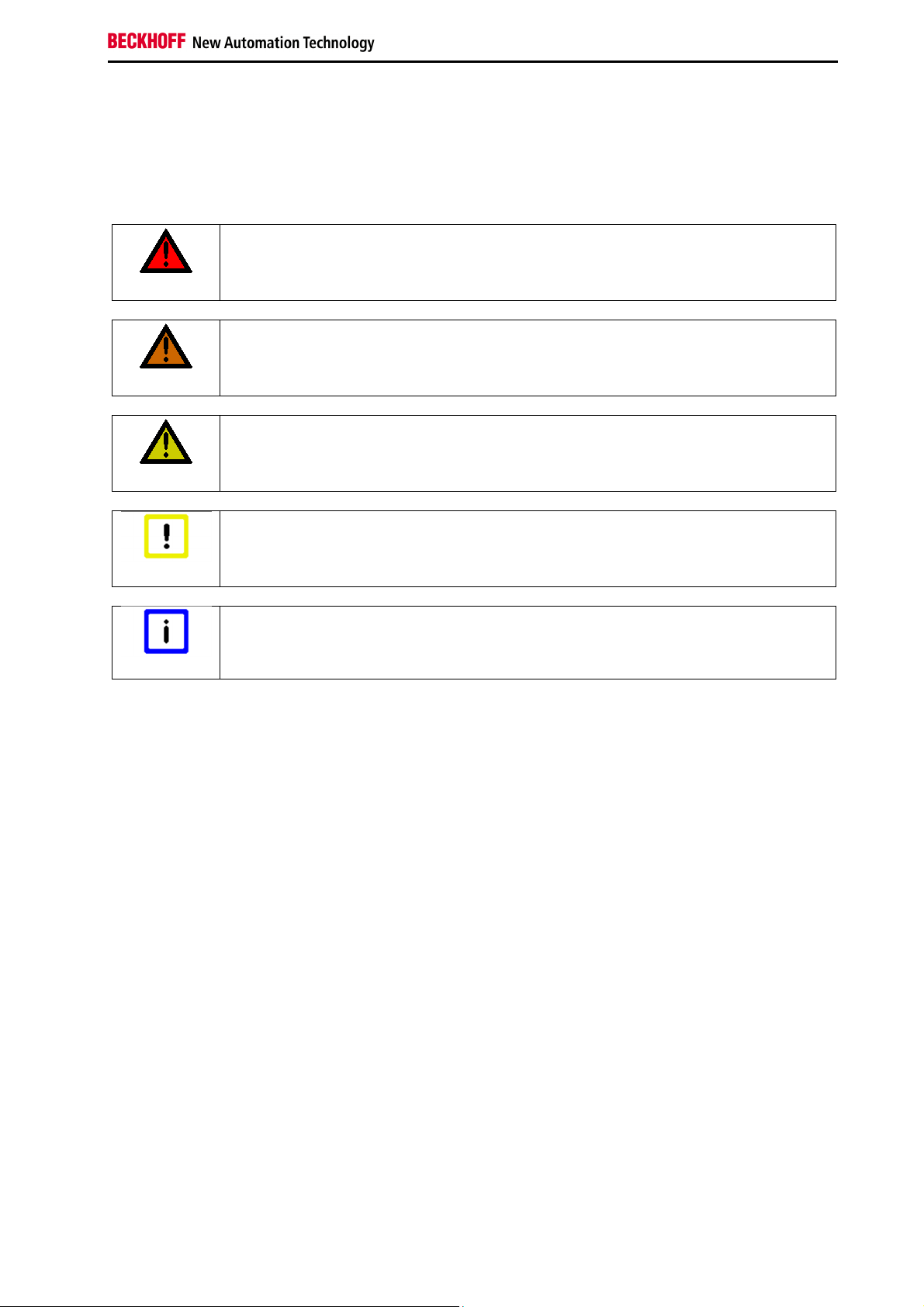

1.2.3 Description of safety symbols

The following safety symbols are used in these operating instructions. They are intended to alert the

reader to the associated safety instructions.

Serious risk of injury!

DANGER

WARNING

CAUTION

Failure to follow the safety instructions associated with this symbol directly endangers

the life and health of persons.

Caution - Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life

and health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries

to persons.

Damage to the environment or devices

Attention

Note

Failure to follow the instructions associated with this symbol can lead to damage to the

environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

1.2.4 Origin of the document

These operating instructions were originally written in German. All other languages are derived from the

German original.

EL6930 5

Page 8

Foreword

1.2.5 Documentation issue status

Version Comment

1.1.1

• Certificate updated

1.1.0

1.0.2

1.0.1

1.0.0

• Company address amended

• Documentation versions added

• References to EN954 removed

• Document origin added

• Description of PROFIsafe connection expanded

• Reference to EN 60068-2-29 removed

• First released version

6

EL6930

Page 9

System description

2 System description

2.1 The Beckhoff Bus Terminal system

The Beckhoff Bus Terminal system is used for decentralized connection of sensors and actuators to a

control system. The Beckhoff Bus Terminal system components are mainly used in industrial automation

and building management applications. In its minimum configuration, a bus station consists of a Bus

Coupler or a Bus Terminal Controller and Bus Terminals connected to it. The Bus Coupler forms the

communication interface to the higher-level controller, and the terminals are the interface to sensors and

actuators. The whole bus station is clipped onto a 35 mm DIN mounting rail (EN 60715). The mechanical

cross connection of the bus station is established via a slot and key system at the Bus Coupler and the

Bus Terminals.

The sensors and actuators are connected with terminals via the screwless Cage Clamp© connection

system.

In order to accommodate the wide range of different communication standards encountered in industrial

automation, Beckhoff offers Bus Couplers for a number of common bus systems (e.g. EK1100 for

EtherCAT).

EL6930 7

Page 10

System description

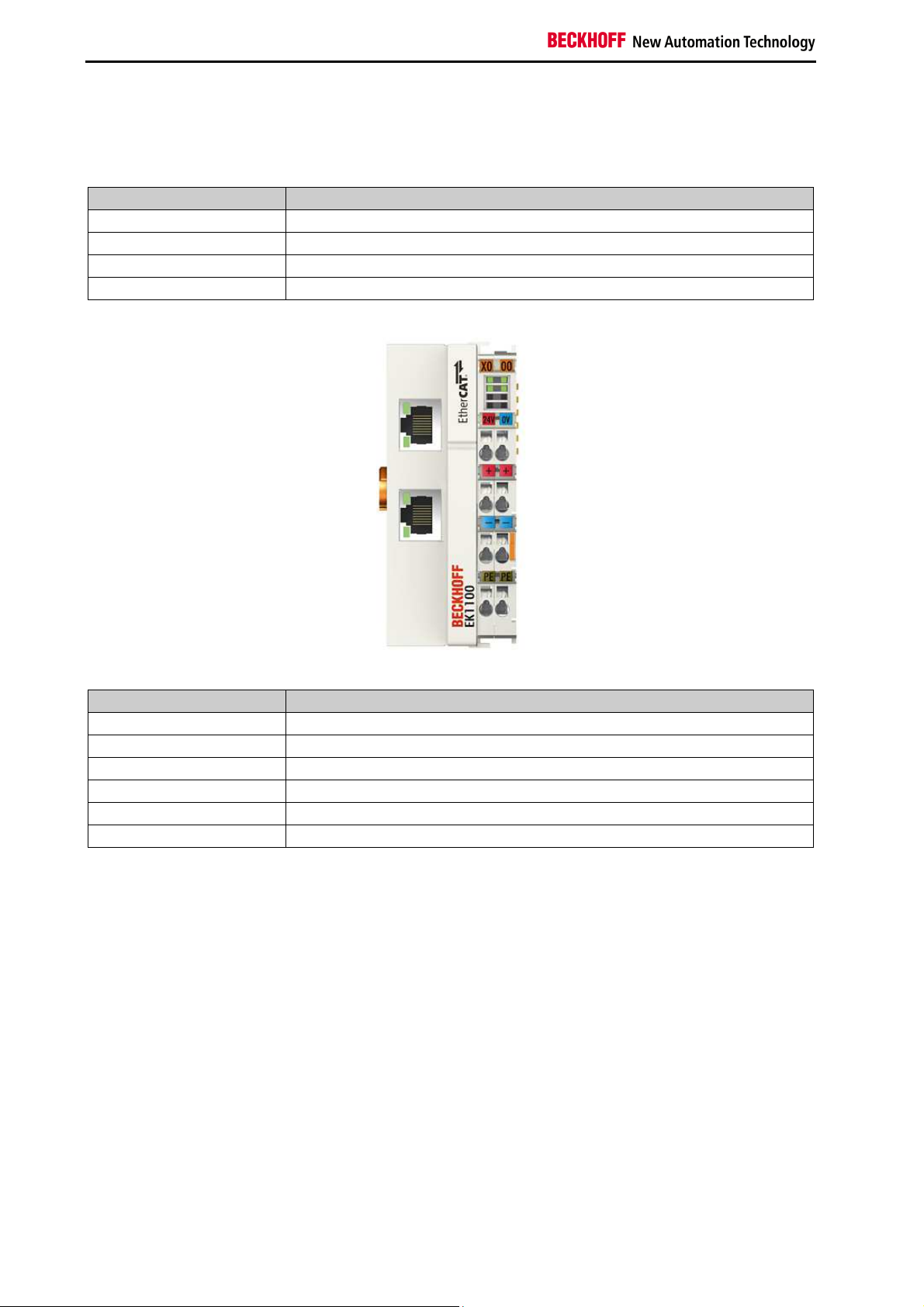

2.1.1 Bus Coupler

Mechanical data

Mechanical data Bus Coupler

Material polycarbonate, polyamide (PA6.6).

Dimensions (W x H x D) 44 mm x 100 mm x 68 mm

Installation on 35 mm mounting rail (EN50022) with locking

Attachable by double slot and key connection

Connection technology

Connection technology Bus Coupler

Wiring cage Clamp® spring-loaded system

Connection cross-section 0.08 mm2 ... 2.5 mm2, stranded wire, solid wire

Fieldbus connection depending on fieldbus

Power contacts 3 spring contacts

Current load 10 A

Rated voltage 24 VDC

8

EL6930

Page 11

System description

2.1.2 Bus Terminals

Mechanical data

Mechanical data Bus Terminal

Material polycarbonate, polyamide (PA6.6).

Dimensions (W x H x D) 12 mm x 100 mm x 68 mm or 24 mm x 100 mm x 68 mm

Installation on 35 mm mounting rail (EN50022) with locking

Attachable by double slot and key connection

Connection technology

Connection technology Bus Terminal

Wiring cage Clamp® spring-loaded system

Connection cross-section 0.08 mm2 ... 2.5 mm2, stranded wire, solid wire

Fieldbus connection E-bus

Power contacts up to 3 blade/spring contacts

Current load 10 A

Rated voltage depends on Bus Terminal type

2.1.3 E-bus

The E-bus is the data path within a terminal strip. The E-bus is led through from the Bus Coupler through

all the terminals via six contacts on the terminals' side walls.

2.1.4 Power contacts

The operating voltage is passed on to following terminals via three power contacts. Terminal strip can be

split into galvanically isolated groups by means of potential feed terminals as required. The power feed

terminals play no part in the control of the terminals, and can be inserted at any locations within the

terminal strip.

EL6930 9

Page 12

System description

2.2 TwinSAFE

2.2.1 The I/O construction kit is extended safely

With the TwinSAFE Terminals, Beckhoff offers the option of simply expanding the proven Bus Terminal

system, and to transfer the complete cabling for the safety circuit into the already existing fieldbus cable.

Safe signals can be mixed with standard signals without restriction. This saves design effort, installation

and material. Maintenance is simplified significantly through faster diagnosis and simple replacement of

only a few components.

The new ELx9xx series Bus Terminals only include three basic functionalities: digital inputs EL19xx,

digital outputs EL29xx and a logic unit EL6930. For a large number of applications, all sensors and

actuators can be wired on these Bus Terminals. The required logical link of the inputs and the outputs is

handled by the EL6930. For small to medium-sized configurations, the tasks of a fail-safe PLC can thus

be handled within the Bus Terminal system.

2.2.2 Safety concept

TwinSAFE: Safety and I/O technology in one system

• Extension of the familiar Beckhoff I/O system with TwinSAFE terminals

• Freely selectable mix of safe and standard signals

• Logical link of the I/Os in the EL6930 TwinSAFE logic terminal

• Safety-relevant networking of machines via bus systems

TwinSAFE protocol (FSoE)

• Transfer of safety-relevant data via any media (“genuine black channel”)

• TwinSAFE communication via fieldbus systems such as EtherCAT, Lightbus, PROFIBUS or

Ethernet

• IEC 61508:2010 SIL 3 compliant

Configuring instead of wiring: the TwinSAFE configurator

• Configuration of the TwinSAFE system via the TwinCAT System Manager

• System Manager for editing and displaying all bus parameters

• Certified function blocks such as emergency stop, operation mode, etc.

• Simple handling

• Typical function blocks for machine safety

• any bus connection with the EL6930 TwinSAFE logic terminal

TwinSAFE logic Bus Terminal EL6930

• Link unit between TwinSAFE input and output terminals

• Configuration of a simple, flexible, cost-effective, decentralized safety controller

• No safety requirements for higher-level control system

• TwinSAFE enables networks with up to 65535 TwinSAFE devices

• TwinSAFE logic terminal can establish up to 127 connections (TwinSAFE connections) and a

PROFIsafe slave connection to a PROFIsafe master controller.

• Several TwinSAFE logic terminals are cascadable in a network

• Safety functions such as emergency stop, protective door etc. are already included

• Suitable for applications up to SIL 3 according to IEC 61508:2010 and

DIN EN ISO 13849-1:2006 (Cat 4, PL e).

10

EL6930

Page 13

System description

TwinSAFE digital input (EL1904) and output terminal (EL2904)

• All current safety sensors can be connected

• Operation with a TwinSAFE logic terminal

• EL1904 with 4 fail-safe inputs for sensors (24 VDC) with floating contacts

• EL2904 with four safe channels for actuators (24 VDC, 0.5 A per channel)

• Conforming to IEC 61508:2010 SIL 3 and DIN EN ISO 13849-1:2006 (Cat 4, PL e) requirements.

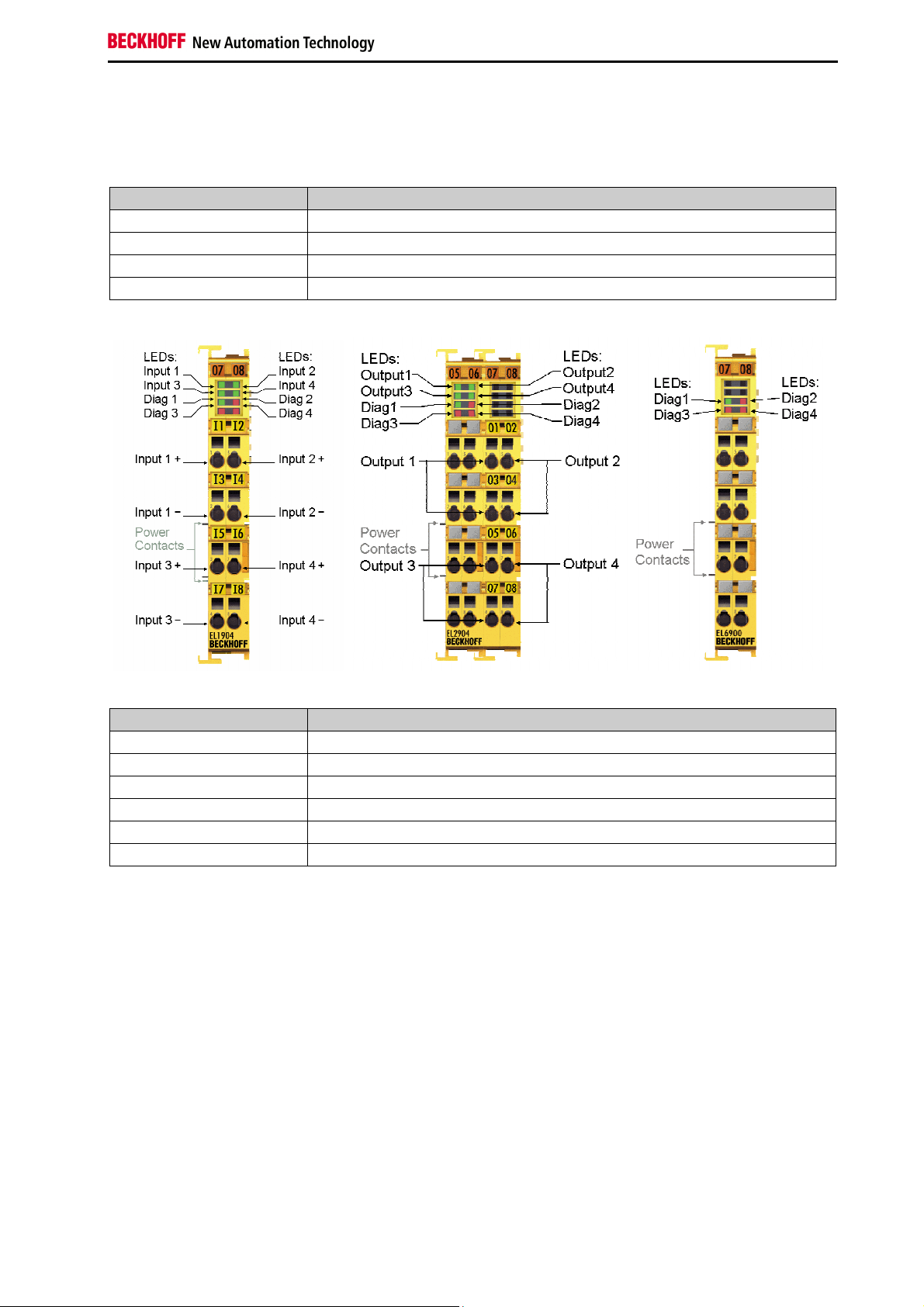

2.2.3 EL1904, EL2904 - Bus Terminals with 4 fail-safe inputs or outputs

The EL1904 and EL2904 Bus Terminals enable connection of common safety sensors and actuators.

They are operated with the EL6930 TwinSAFE logic terminal. The TwinSAFE logic terminal is the link unit

between the TwinSAFE input and output terminals. It enables the configuration of a simple, flexible and

cost-effective decentralized safety control system.

Therefore, there are no safety requirements for the higher-level controller! The typical safety functions

required for the automation of machines, such as emergency stop, protective door, two-hand etc., are

already permanently programmed in the EL6930. The user configures the EL6930 terminal according to

the safety requirements of his application.

2.2.4 EL6930 - TwinSAFE logic terminal with PROFIsafe gateway

The TwinSAFE logic terminal is the link unit between the TwinSAFE input and output terminals and a

gateway to a PROFIsafe master controller. The EL6930 meets the requirements of IEC 61508:2010 SIL 3

and DIN EN ISO 13849-1:2006 (Cat 4, PL e).

2.2.5 The fail-safe principle (Fail Stop)

The basic rule for a safety system such as TwinSAFE is that failure of a part, a system component or the

overall system must never lead to a dangerous condition. The safe state is always the switched off and

wattless state.

EL6930 11

Page 14

Product description

3 Product description

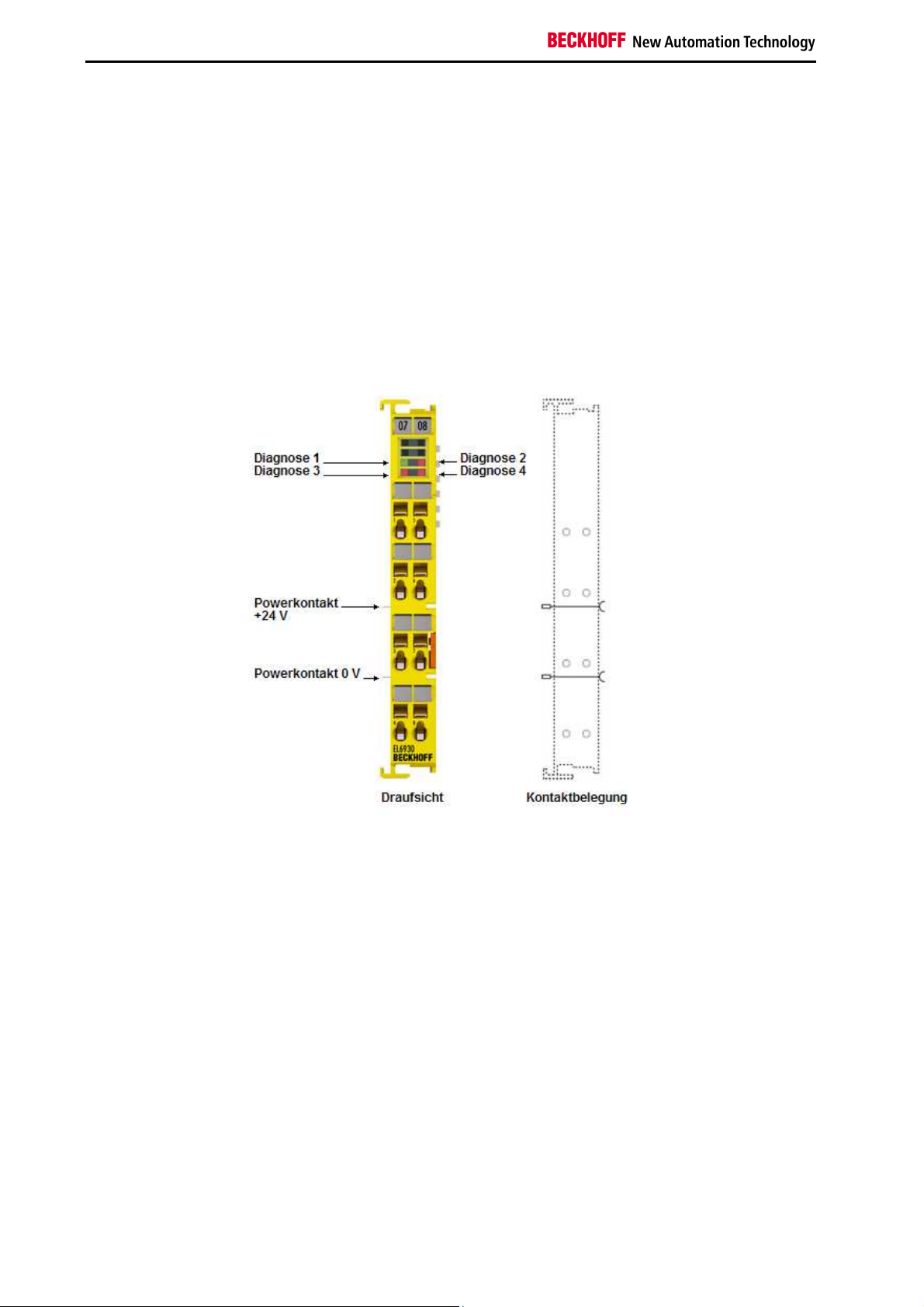

3.1 General description

EL6930 - TwinSAFE logic terminal / PROFIsafe gateway

The TwinSAFE logic terminal is the link unit between the TwinSAFE input and output terminals.

The EL6930 meets the requirements of IEC 61508:2010 SIL 3, DIN EN ISO 13849-1:2006 (Cat 4, PL e),

NRTL, UL508, UL1998 and UL991.

The TwinSAFE terminal has the typical design of an EtherCAT terminal.

12

EL6930

Page 15

Product description

3.2 Intended use

Caution - Risk of injury!

WARNING

The TwinSAFE terminals expand the application range of Beckhoff Bus Terminal system with functions

that enable them to be used for machine safety applications. The TwinSAFE terminals are designed for

machine safety functions and directly associated industrial automation tasks. They are therefore only

approved for applications with a defined fail-safe state. This safe state is the wattless state. Fail-safety

according to the relevant standards is required.

The TwinSAFE terminals enable connection of:

• 24 VDC sensors (EL1904) such as

emergency stop push buttons, pull cord switches, position switches, two-hand switches, safety

mats, light curtains, light barriers, laser scanners etc.

• 24 VDC actuators (EL2904) such as

contactors, protective door switches with tumbler, signal lamps, servo drives etc.

TwinSAFE terminals may only be used for the purposes described below!

Test pulses

Note

When selecting actuators please ensure that the EL2904 test pulses do not

lead to actuator switching or diagnostic message from the EL2904.

The following modules were developed for these tasks:

• The EL1904 terminal is an input module with digital inputs.

• The EL2904 terminal is an output module with digital outputs.

• The EL6930 terminal is a logic module.

These modules are suitable for operation with

• Beckhoff EKxxxx series Bus Couplers

• Beckhoff CXxxxx series Embedded PCs with E-bus connection

Follow the machinery directive

CAUTION

The TwinSAFE terminals may only be used in machines according to the Machinery

Directive.

Ensure traceability

CAUTION

The buyer has to ensure the traceability of the device via the serial number.

EL6930 13

Page 16

Product description

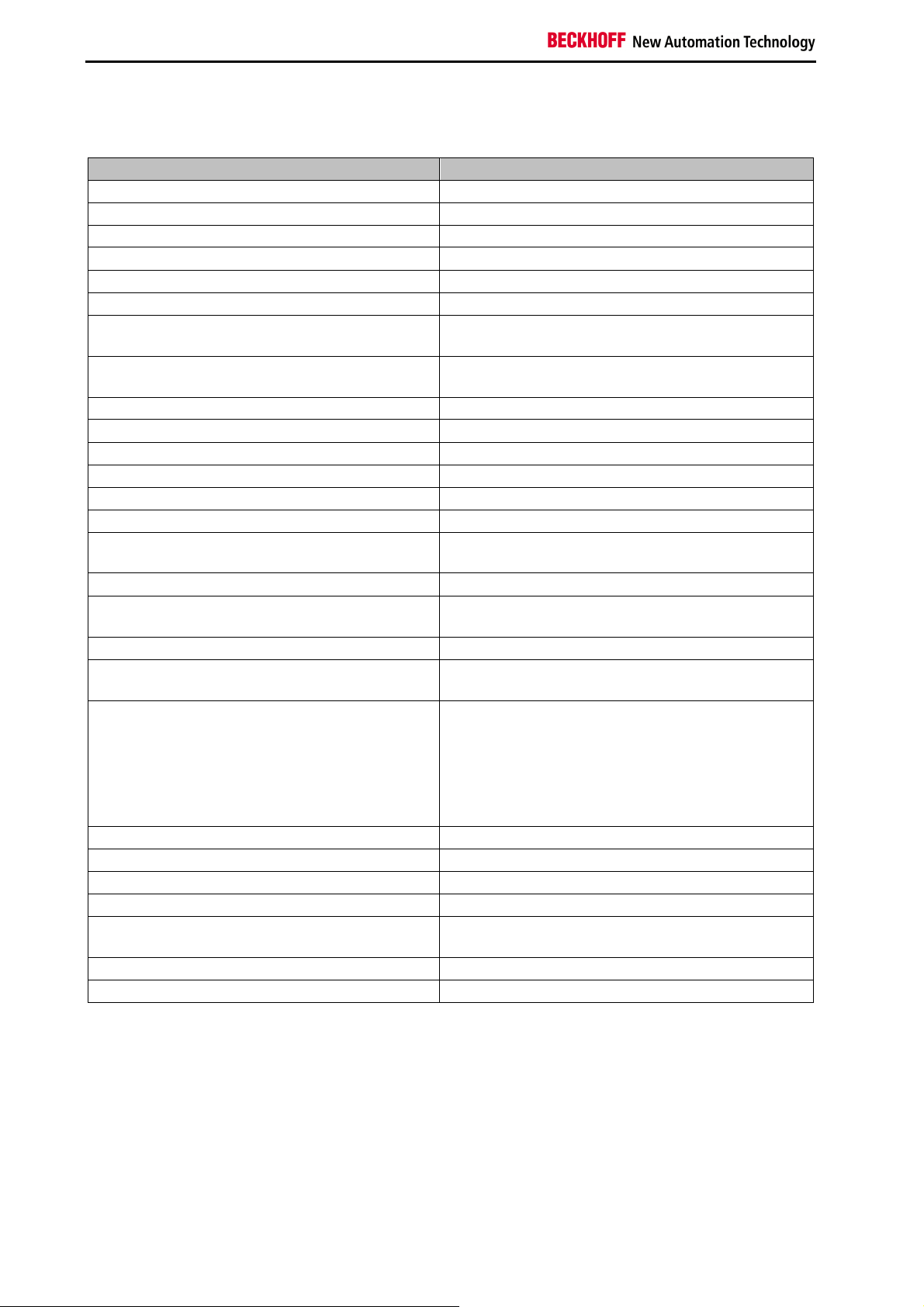

3.3 Technical data

Product designation EL6930

Number of inputs 0

Number of outputs 0

Status display 4 diagnostic LEDs

Minimum cycle time approx. 500 µs

Error reaction time ≤ watchdog times

Watchdog time min. 1 ms, max. 60,000 ms

Input process image

Output process image

EL6930 supply voltage 24 VDC (-15%/+20%)

Current consumption from the E-bus approx. 188 mA

Power dissipation of the terminal typically 1 W

Dimensions (W x H x D) 12 mm x 100 mm x 68 mm

Weight approx. 50 g

Permissible ambient temperature (operation) 0 ℃ to +55 ℃

Permissible ambient temperature

(transport/storage)

Permissible air humidity 5 % to 95 %, non-condensing

Permissible air pressure

(operation/storage/transport)

Climate category according to EN 60721-3-3 3K3

Permissible level of contamination

Impermissible operating conditions

Vibration / shock resistance according to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission according to EN 61000-6-2 / EN 61000-6-4

Shocks 15 g with pulse duration 11 ms in all three axes

Protection class IP20

Permitted operating environment

Permissible installation position

Approvals CE, TÜV SÜD

Dynamic according to the TwinSAFE configuration in

the TwinCAT System Manager

Dynamic according to the TwinSAFE configuration in

the TwinCAT System Manager

-25 ℃ to +70 ℃

750 hPa to 1100 hPa

level of contamination 2

(comply with the chapter Cleaning)

TwinSAFE terminals must not be used under the

following operating conditions:

• under the influence of ionizing radiation

• in corrosive environments

• in an environment that leads to

unacceptable soiling of the Bus Terminal

control cabinet or terminal box with minimum

protection class IP54 according to IEC 60529

see section Installation position

14

EL6930

Page 17

Product description

3.4 Safety parameters

Key figures EL6930

Lifetime [a] 20

Prooftest Intervall [a] not required 1)

PFH 1.03E-09

%SIL3 1.03%

PFD 8.23E-05

%SIL3 8.23%

MTTFd [a] >100

DC >99%

Performance level PL e

Category 4

HFT 1

Element classification* Type A

*) Classification according to IEC 61508-2:2010 (see chapters 7.4.4.1.2 and 7.4.4.1.3)

The EL6930 EtherCAT Terminal can be used for safety-related applications within the meaning of

IEC 61508:2010 up to SIL3 and EN ISO 13849-1 up to PL e (Cat4).

1)

Special proof tests are not required during the entire service life of the EL6930 EtherCAT terminal.

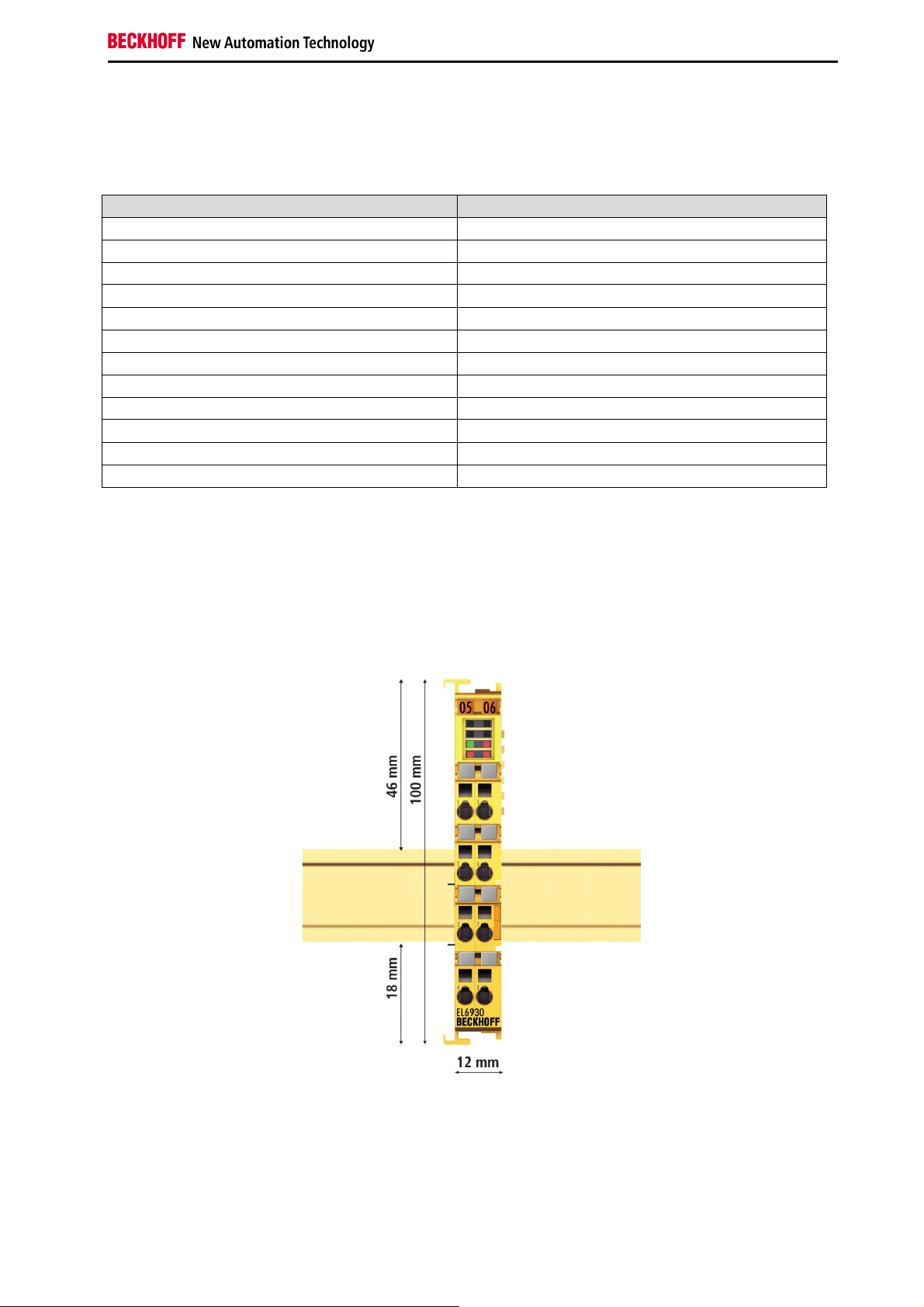

3.5 Dimensions

Width: 12 mm (side-by-side installation)

Height: 100 mm

Depth: 68 mm

EL6930 15

Page 18

Operation

4 Operation

Please ensure that the TwinSAFE terminals are only transported, stored and operated under the specified

conditions (see technical data)!

Caution - Risk of injury!

WARNING

4.1 Installation

4.1.1 Safety instructions

The TwinSAFE terminals must not be used under the following operating conditions:

• under the influence of ionizing radiation

• in corrosive environments

• in an environment that leads to unacceptable soiling of the Bus Terminal

Before installing and commissioning the TwinSAFE terminals please read the safety notes in the foreword

of this documentation.

4.1.2 Transport / storage

Use the original packaging for transporting or storing the digital TwinSAFE terminals.

Note the specified environmental conditions

CAUTION

Please ensure that the digital TwinSAFE terminals are only transported and stored

under the specified environmental conditions (see technical data).

16

EL6930

Page 19

Operation

4.1.3 Mechanical installation

Serious risk of injury!

DANGER

4.1.3.1 Control cabinet

The TwinSAFE terminals must be installed in a control cabinet or terminal box with IP54 protection class

according to IEC 60529 as a minimum.

4.1.3.2 Installation position

For the prescribed installation position the mounting rail is installed horizontally and the mating surfaces

of the EL/KL terminals point toward the front (see illustration below). The terminals are ventilated from

below, which enables optimum cooling of the electronics through convection. "From below" is relative to

the acceleration of gravity.

Bring the bus system into a safe, de-energized state before starting installation,

disassembly or wiring of the Bus Terminals!

EL6930 17

Page 20

Operation

4.1.3.3 Mounting rail installation

Installation

The Bus Couplers and Bus Terminals are attached to commercially available 35 mm mounting rails

(according to EN 60715) by applying slight pressure:

1. First attach the Fieldbus Coupler to the mounting rail.

2. The Bus Terminals are now attached on the right-hand side of the fieldbus Coupler. Join the

components with slot and key and push the terminals against the mounting rail, until the lock

clicks onto the mounting rail.

If the terminals are clipped onto the mounting rail first and then pushed together without slot

and key, the connection will not be operational! When correctly assembled, no significant gap

should be visible between the housings.

3. During the installation of the Bus Terminals, the locking mechanism of the terminals must not

come into conflict with the fixing bolts of the mounting rail.

18

EL6930

Page 21

Operation

Removal

1. Carefully pull the orange-colored lugs approximately 1 cm out of the disassembled terminal, until

they protrude loosely. The lock with the mounting rail is now released for this terminal, and the

terminal can be pulled from the mounting rail without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower

grooved housing surfaces and pull the terminal away from the mounting rail.

4.1.4 Electrical installation

4.1.4.1 Connections within a Bus Terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realised by

joining the components:

• The six spring contacts of the E-bus deal with the transfer of the data and the supply of the Bus

Terminal electronics.

Note the maximum E-bus current!

Note

• The power contacts deal with the supply for the field electronics and thus represent a supply rail

within the Bus Terminal block. The power contacts are supplied via terminals on the Bus Coupler.

Note

Observe the maximum current that your Bus Coupler can supply to the E-bus!

Use the EL9400 Power Supply Terminal if the current consumption of your

terminals exceeds the maximum current that your Bus Coupler can feed to the

E-bus supply.

Note the pin assignment of the power contacts!

During the design of a Bus Terminal block, the pin assignment of the individual

Bus Terminals must be taken account of, since some types (e.g. analog Bus

Terminals or digital 4-channel Bus Terminals) do not or not fully loop through the

power contacts.

Power Feed Terminals (EL91xx, EL92xx) interrupt the power contacts and thus

represent the start of a new supply rail.

EL6930 19

Page 22

Operation

PE power contact

The power contact labelled PE can be used as a protective earth. For safety reasons this contact mates

first when plugging together, and can ground short-circuit currents of up to 125 A.

Insulation tests

CAUTION

DANGER

Note that, for reasons of electromagnetic compatibility, the PE contacts are

capacitatively coupled to the mounting rail. This may lead to incorrect results during

insulation testing or to damage on the terminal (e.g. disruptive discharge to the PE line

during insulation testing of a consumer with a rated voltage of 230 V).

For insulation testing, disconnect the PE supply line at the Bus Coupler or the Power

Feed Terminal! In order to decouple further feed points for testing, these Power Feed

Terminals can be released and pulled at least 10 mm from the group of terminals.

Serious risk of injury!

The PE power contact must not be used for other potentials!

20

EL6930

Page 23

Operation

4.1.4.2 Wiring

Up to eight connections enable the connection of solid or finely stranded cables to the Bus Terminals.

The terminals are implemented in spring force technology. Connect the cables as follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the

square opening above the terminal.

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire safely

and permanently.

Wire cross section

Strip length

0.08... 2.5 mm

8 ...9 mm

2

EL6930 21

Page 24

Operation

EL6930 pin assignment

Terminal

Output Signal

point

1 - not used, no function

2 not used, no function

3 - not used, no function

4 not used, no function

5 - not used, no function

6 not used, no function

7 - not used, no function

8 not used, no function

22

EL6930

Page 25

Operation

4.1.5 Tested EL2904 devices

The following list contains devices that were tested together with the EL2904 TwinSAFE terminal. The

results only apply for the current device hardware version at the time of testing. The tests were carried out

in a laboratory environment. Modifications of these products cannot be considered here. If you are unsure

please test the hardware together with the TwinSAFE terminal.

Manufacturer Type Comment

Beckhoff AX5801 TwinSAFE Drive option card: safe restart lock

Beckhoff AX2000 Option AS safe restart lock

Siemens

Telemecanique LP1K09 Contactor

The tests were carried out as function tests only. The information provided in the respective manufacturer

documentation remains valid.

SIRIUS Serie S00

Contactor

3RT1016-1BB42

Recommended protective circuits

Note

We recommend R/C or diode-based protective circuits for these devices.

Varistor-based protective circuits should not be used.

4.1.6 Tested EL1904 devices

The following list contains devices that were tested together with the EL1904 TwinSAFE terminal. The

results only apply for the current device hardware version at the time of testing. The tests were carried out

in a laboratory environment. Modifications of these products cannot be considered here. If you are unsure

please test the hardware together with the TwinSAFE terminal.

Manufacturer Type Comment

SICK C4000

SICK

Wenglor

S3000 Safety laser scanner

SG2-14ISO45C1 Safety light grids

Leuze lumiflex ROBUST 42/43/44 Safety light barriers

Schmersal BNS250-11ZG Safety switch

ifm GM701S Inductive safety sensor

The tests were carried out as function tests only. The information provided in the respective manufacturer

documentation remains valid.

Safety light curtain

EL6930 23

Page 26

Operation

4.2 Configuration of the EL6930 in the TwinCAT System

Manager

Do not change the register values!

CAUTION

Do not change any of the CoE objects in the TwinSAFE terminals. Any modifications

(e.g. via the System Manager) of the CoE objects would permanently set the terminals

to the Fail-Stop state.

4.2.1 Configuration requirements

Version 2.11 build 2208 or higher of the TwinCAT automation software is required for configuring the

EL6930. The current version is available for download from the Beckhoff website at www.beckhoff.de.

4.2.2 Inserting a Beckhoff Bus Coupler

See TwinCAT automation software documentation.

24

EL6930

Page 27

Operation

4.2.3 Inserting a Beckhoff Bus Terminal

See TwinCAT automation software documentation.

4.2.4 Inserting an EL6930

An EL6930 is inserted in the same way as any other Beckhoff Bus Terminal. In the list open Safety

Terminals (ELx9xx) and select the EL6930.

Size of the process image

Note

The process image of the EL6930 is adjusted dynamically based on the TwinSAFE

configuration created in the TwinCAT System Manager.

EL6930 25

Page 28

Operation

4.2.5 Address settings on the TwinSAFE terminals

The TwinSAFE address of the terminal is set via the 10-way DIP switch on the left-hand side of the

TwinSAFE Bus Terminal. TwinSAFE addresses between 1 and 1023 are available.

DIP switch Address

1 2 3 4 5 6 7 8 9 10

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF 0

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF OFF OFF OFF OFF OFF OFF OFF 1

ON

OFF OFF OFF OFF OFF OFF OFF OFF 2

OFF OFF OFF OFF OFF OFF OFF OFF 3

ON

OFF

ON

ON ON

OFF OFF OFF OFF OFF OFF OFF 4

OFF OFF OFF OFF OFF OFF OFF 5

OFF OFF OFF OFF OFF OFF OFF 6

OFF OFF OFF OFF OFF OFF OFF 7

... ... ... ... ... ... ... ... ... ... ...

ON ON ON ON ON ON ON ON ON ON

1023

Unique TwinSAFE address

WARNING

Each TwinSAFE address may only be used once within a network!

26

EL6930

Page 29

Operation

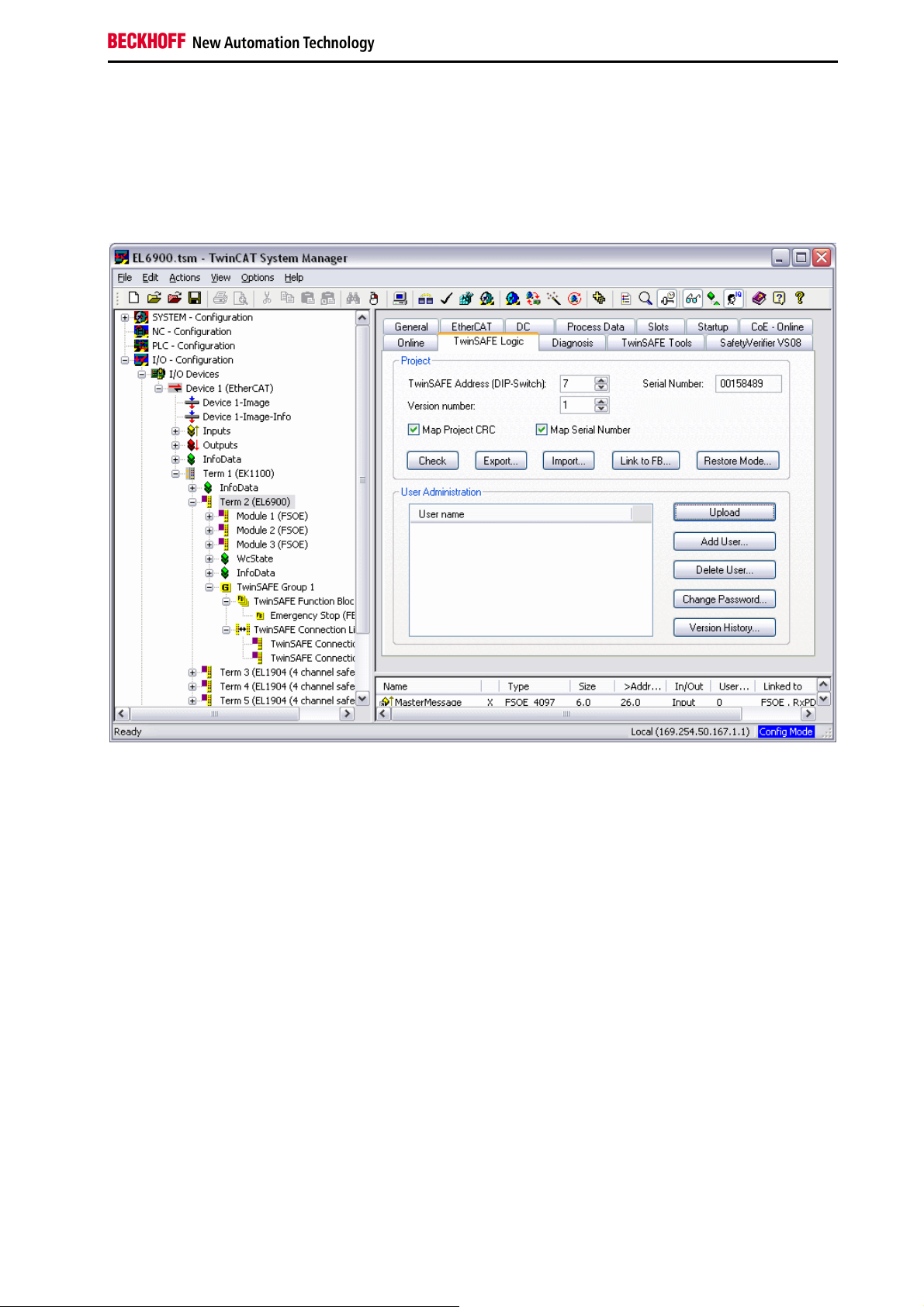

4.2.6 Entering the TwinSAFE addresses in the System Manager

The TwinSAFE address set at the DIP switch must also be entered under the TwinSAFE Logic tab

(TwinSAFE address entry).

EL6930 27

Page 30

Operation

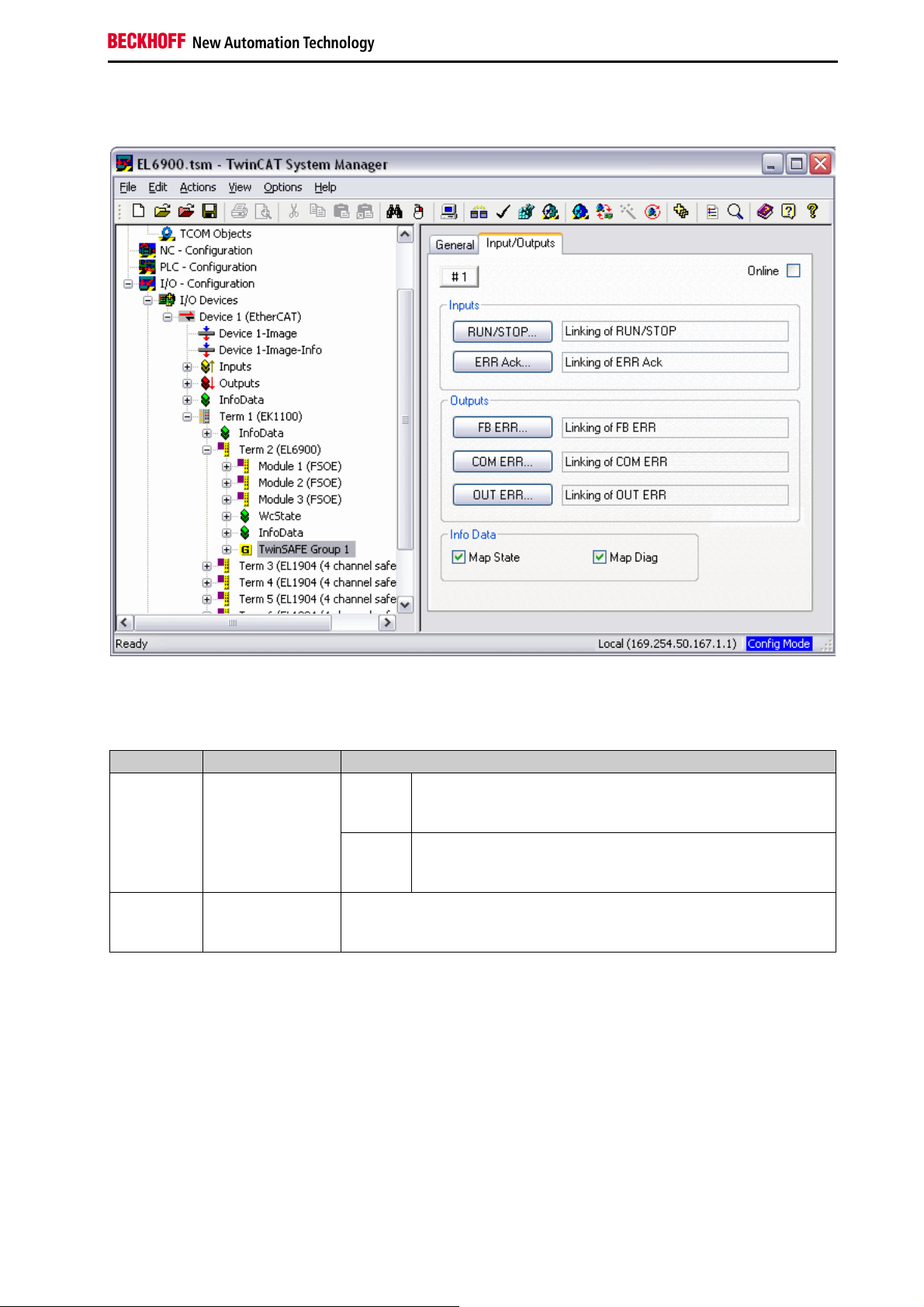

4.2.7 Creating a TwinSAFE group

A TwinSAFE group is a group of TwinSAFE terminals (inputs and outputs) that are logically linked via a

EL6930. Any communication faults in the TwinSAFE connections of this group lead to the whole group

being switched off. Other TwinSAFE groups are not affected.

A TwinSAFE group is added by right-clicking on the associated EL6900/EL6930 in the tree structure and

selecting Append TwinSAFE group in the dialog box (see diagram).

28

EL6930

Page 31

Operation

4.2.7.1 TwinSAFE group signals

TwinSAFE group inputs

Name Permitted type Description

RUN FB-Out

TRUE:

Standard-In

FALSE:

ERR Ack FB-Out

Standard-In

All pending errors in the assigned function blocks and in the

TwinSAFE connections are acknowledged by the FALSE->TRUE>FALSE signal sequence.

The function blocks assigned to the TwinSAFE group are

executed. When the input is not linked it is in the TRUE

state

All of the TwinSAFE group assigned function blocks are at

a STOP state and thus all associated outputs are in a safe

state.

EL6930 29

Page 32

Operation

TwinSAFE group outputs

Name Permitted type Description

FB ERR TwinSAFE-Out

TRUE: At least one assigned function block has an error

FB-In

Standard-Out

FALSE: All assigned function blocks have no errors

COM ERR TwinSAFE-Out

FB-In

Standard-Out

OUT ERR TwinSAFE-Out

FB-In

Standard-Out

TRUE:

At least one TwinSAFE connection of TwinSAFE group

has an error

FALSE:

All TwinSAFE connections of the TwinSAFE group have

no errors

Always FALSE, since the EL6930 has no local outputs

30

EL6930

Page 33

Operation

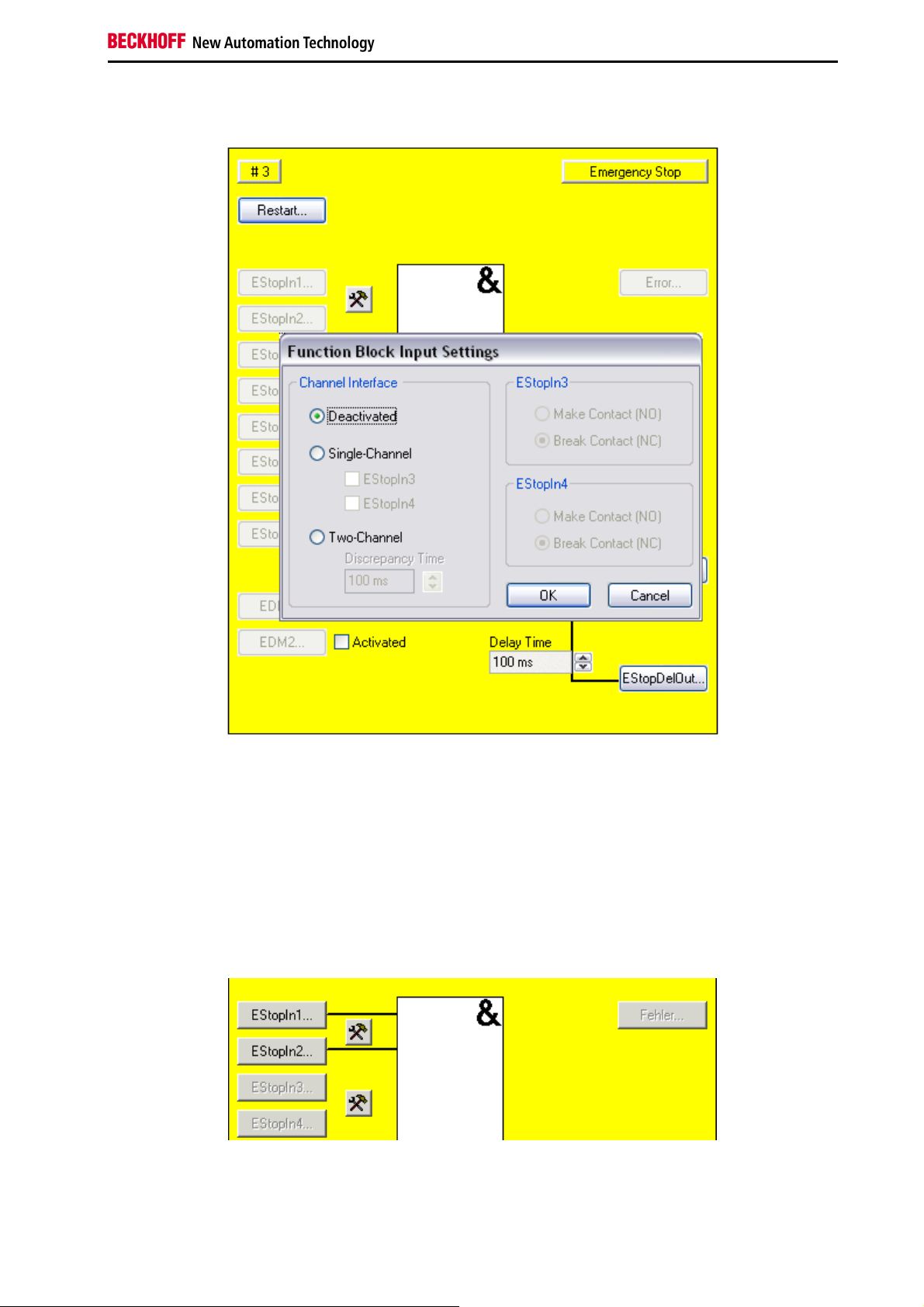

4.2.8 Append a function block

The EL6900/EL6930 TwinSAFE logic terminal features the following blocks: Emergency Stop, Machine

Monitoring, AND, OR, Decoupler, Operation Mode, etc.

A function block is added by right-clicking on the associated TwinSAFE function block list in the tree

structure and selecting Append Function Block in the dialog box with the left mouse button (see diagram).

The required function block can then be selected from the following window.

EL6930 31

Page 34

Operation

Appended Emergency Stop block

32

EL6930

Page 35

Operation

4.2.8.1 Activating and configuring the block inputs

The following parameters can be set:

Deactivated: The input is not used

Single-channel: The inputs are linked independent of each other

Two-channel: The inputs are monitored for equality or inequality, depending on the contact type

setting. A Discrepancy Time can be set for monitoring the two inputs for simultaneous

switching.

Make Contact: Contact type setting

Break Contact Contact type setting

The inputs are now activated.

EL6930 33

Page 36

Operation

The inputs can now be linked.

Select the variable type:

34

EL6930

Page 37

Operation

Clicking on the New button opens the following dialog:

All available channels are displayed as selected.

The desired channel is selected and marked with the mouse. The selection is confirmed via the OK

button.

EL6930 35

Page 38

Operation

The name of the variables should now be entered in the Link Alias field.

Repeat the process for the other inputs. Inputs that are already in use are identified with an arrow.

36

EL6930

Page 39

Operation

4.2.9 EL6930 user and version administration

The EL6930 has a user administration function. The administrator can create further users and issue

associated passwords.

Clicking on the Version History button will bring up the version history for the EL6930 (which cannot be

deleted) that indicates who activated what version of a project on the EL6930, and when.

EL6930 37

Page 40

Operation

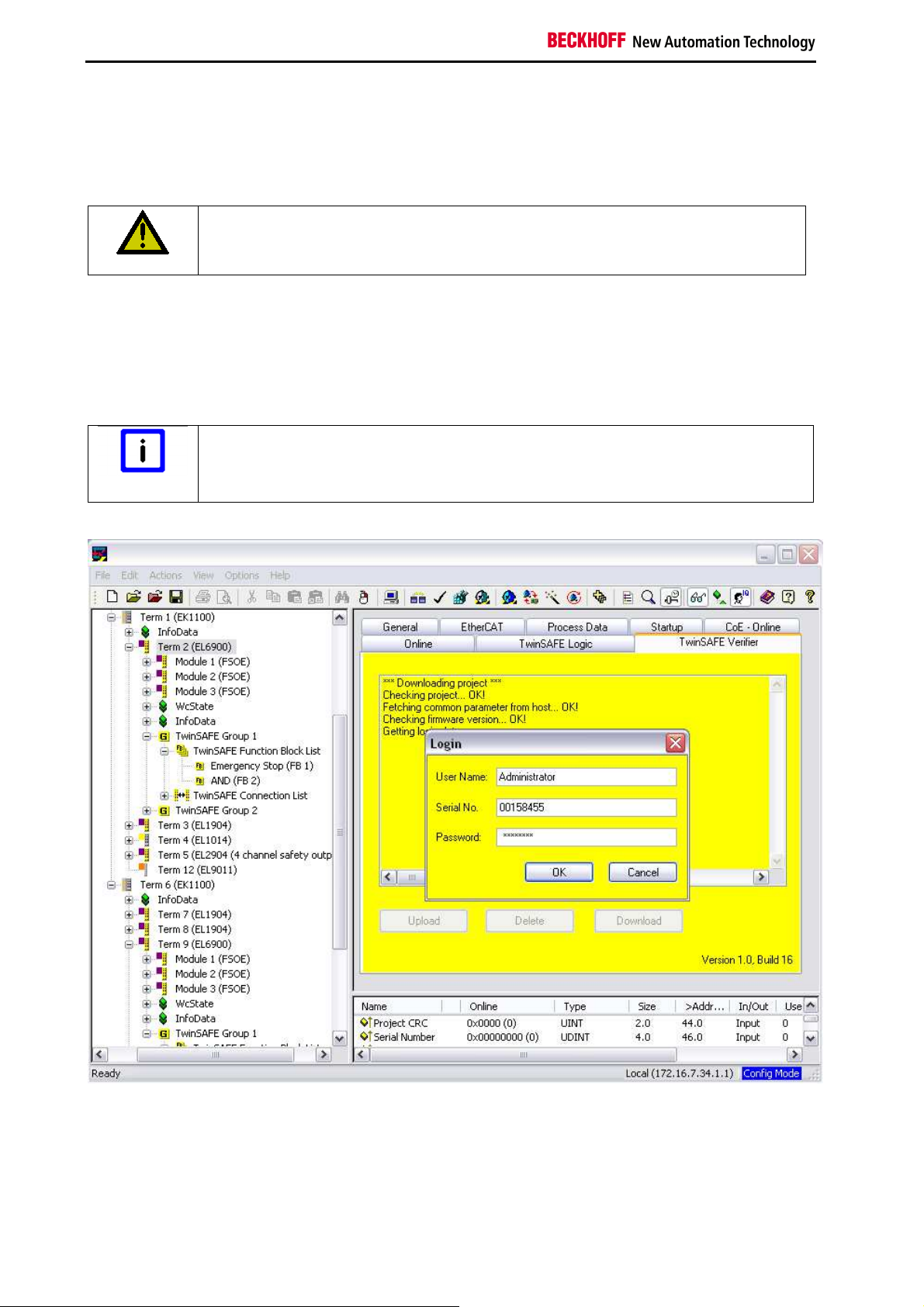

4.2.10 Loading the project into the EL6930

The project is loaded into the EL6930 via the fieldbus.

Use only qualified tools

CAUTION

Click the Download button on the TwinSAFE Verifier tab for loading the project.

The user must enter

• his user name (default: Administrator),

• the terminal serial number (printed on the outside, e.g. 197535), and

• his password (default: TwinSAFE).

Note

Only use a qualified tool for loading, verifying and enabling the project on the EL6930!

Case-sensitive

Pay attention to upper/lower case characters for the user name and password.

User name and password are case-sensitive!

The project is then displayed in text mode, and the user has to confirm consistency between the

information displayed and the currently projected application by re-entering the password. The project is

then started on the EL6900/EL6930.

38

EL6930

Page 41

Operation

4.2.10.1 EL6930 project design limits

TwinSAFE connections

PROFIsafe connections

Supported hardware for EL6930

TwinSAFE connections

Safe data per connection

TwinSAFE blocks

TwinSAFE groups

Standard PLC inputs

Standard PLC outputs

TwinSAFE connection

max. 127 (with 1 or 2 bytes safe user data per connection)

max. 50 connections per TwinSAFE group

Only 16 connections of an EL6930 can be slave connections.

1 PROFIsafe slave connection (must always be the first connection

in the configuration)

EL1904 (all)

EL2904 (all)

EL2902 (all)

KL1904 (from 2008)

KL2904 (from 2008)

KL6904 as slave (from 2008)

AX5805 (all)

up to 14 bytes safe user data (correspondingly lower total number

of connections)

255 max.

32 max.

dynamic up to 255-bit

dynamic up to 255-bit

Note

Only one TwinSAFE connection between two TwinSAFE terminals is possible.

Between two EL6900/EL6930 logic terminals a connection can be set up that may

contain up to 14 bytes safe user data.

EL6930 39

Page 42

Operation

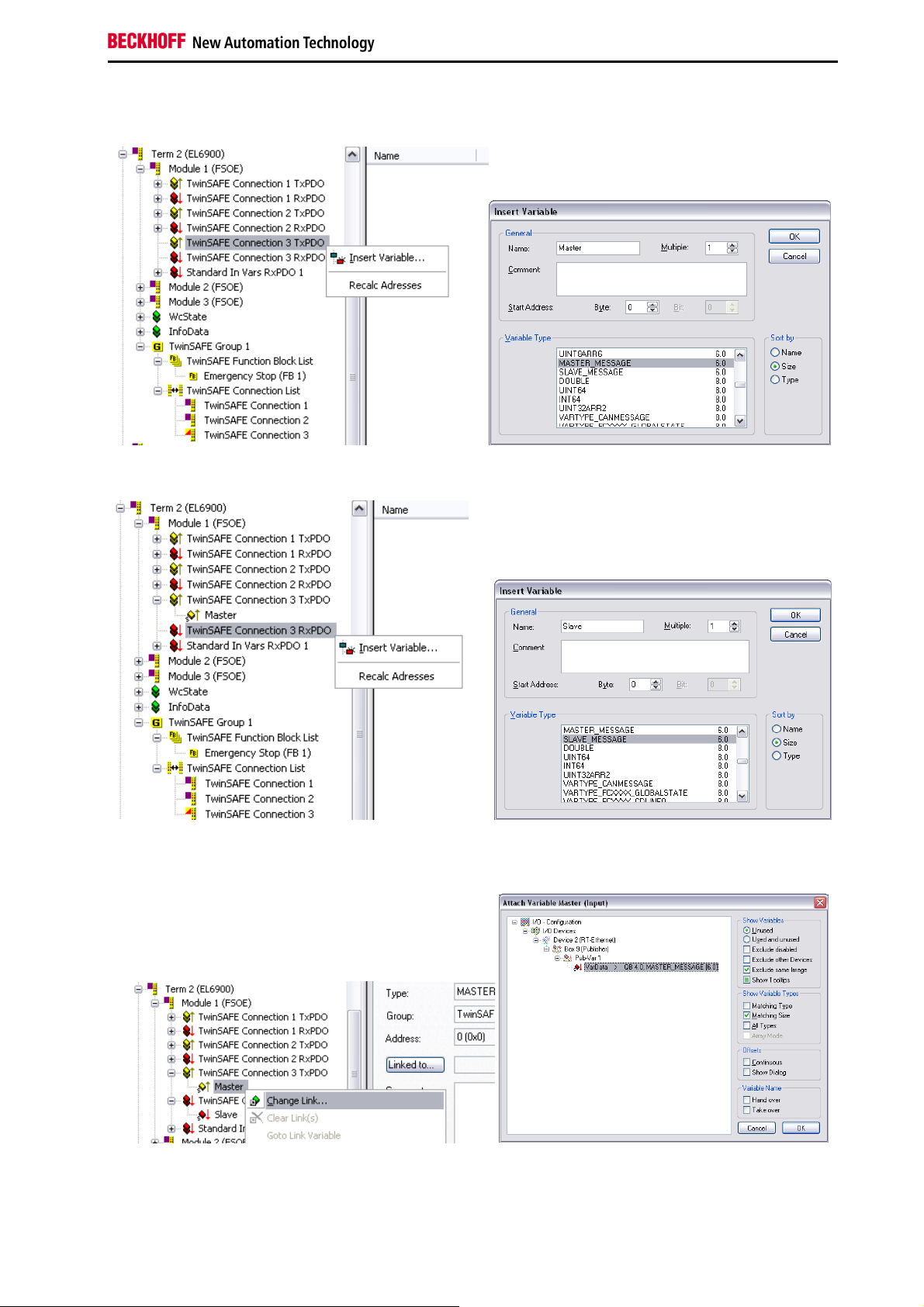

4.2.11 Communication between TwinCAT controllers

The MASTER_MESSAGE and SLAVE_MESSAGE data types are used for communication between two

or more TwinCAT controllers via network variables.

Associated variables have to be created under Publisher and Subscriber on the communicating

controllers.

During TwinSAFE communication one side acts as the master, the other one as the slave.

This results in the following data types:

TwinSAFE Master Publisher MASTER_MESSAGE

TwinSAFE Master Subscriber SLAVE_MESSAGE

TwinSAFE Slave Publisher SLAVE_MESSAGE

TwinSAFE Slave Subscriber MASTER_MESSAGE

The link with the via TwinSAFE logic terminal EL6930 is established with the following dialog:

The connection created must now be made known to the TwinSAFE logic terminal. This is done by

marking the TwinSAFE connection list and pressing the right mouse button.

Create a new connection in the list of connections and create associated variables of the required type

40

EL6930

Page 43

Operation

under Module1 (FSoE).

These newly-created variables are now linked with the network variables already created. This is carried

out for both the master and the slave message.

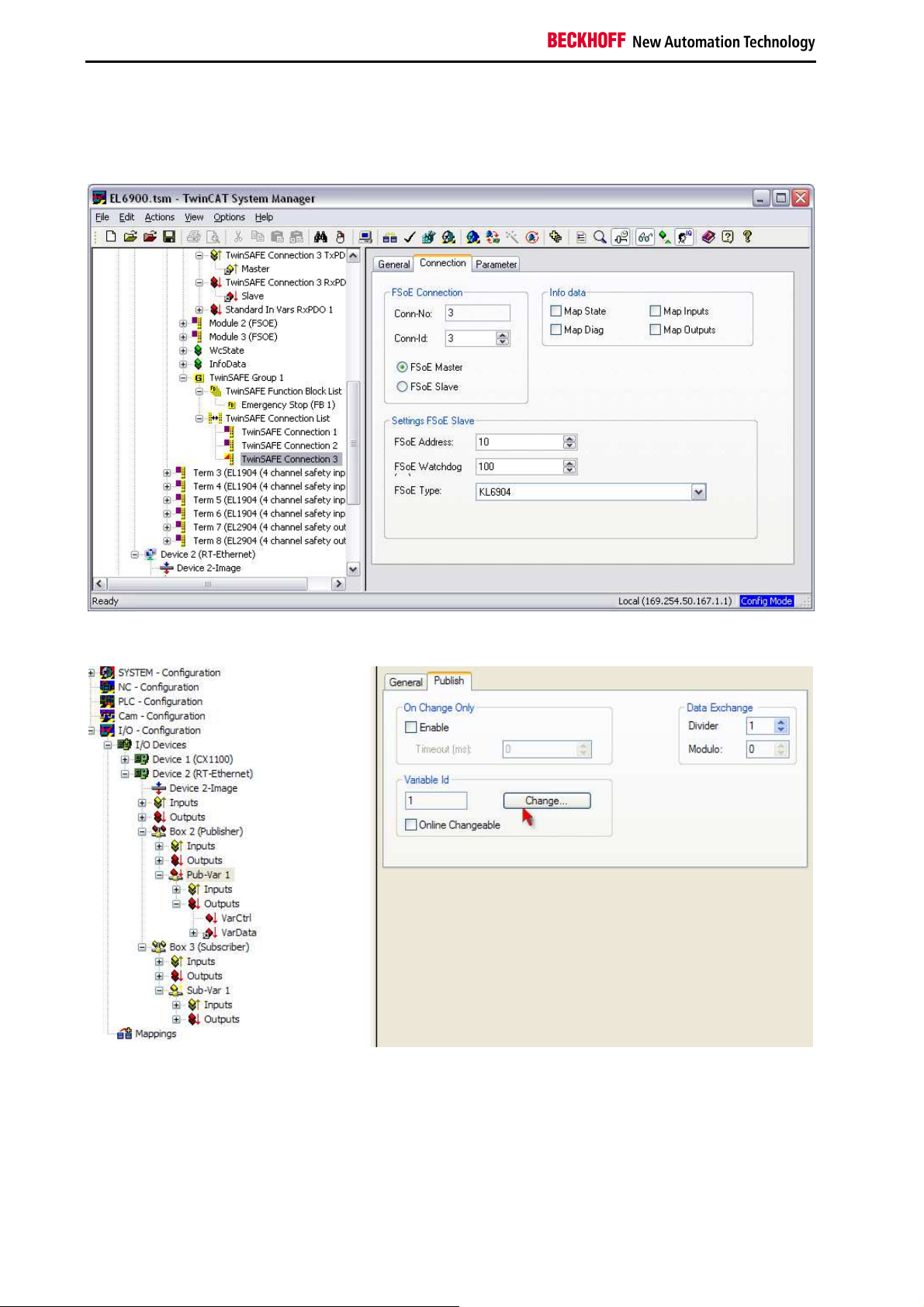

EL6930 41

Page 44

Operation

The settings for the TwinSAFE connection can then be set, including FSoE address, FSoE watchdog and

the communication device type. In addition, the connection can be identified as FSoE master or FSoE

slaves, and the information to be mapped in the cyclic process image can be specified.

If several connections are to be established, a unique ID must be set for each Publisher variable.

This ID must also be set on the partner device, i.e. the Subscriber.

42

EL6930

Page 45

Operation

The network variables can now be used in the project. The inputs are shown TwinSAFE Input, the outputs

under TwinSAFE Output.

EL6930 43

Page 46

Operation

Creating the PROFIsafe slave connection

The EL6930 supports a PROFIsafe slave connection, which must always be created as the first

TwinSAFE connection. The procedure for this is as follows:

1. Append a TwinSAFE message structure to the TwinSAFE connection list of the first TwinSAFE

Group:

2. Insert the corresponding PROFIsafe message variable (VARTYPE_PROFISAFEMESSAGE_5 for

a 5-byte PROFIsafe message (1 byte safe data), VARTYPE_PROFISAFEMESSAGE_6 for a 6byte PROFIsafe message (2 bytes safe data), VARTYPE_PROFISAFEMESSAGE_8 for an 8byte PROFIsafe message (4 bytes safe data)) on the first TxPDO under module 1 of the EL6930:

44

EL6930

Page 47

Operation

3. Link the variable with the appropriate variable of the PROFIsafe module:

4. Insert the corresponding PROFIsafe message variable on the first RxPDO under module 1 of the

EL6930:

EL6930 45

Page 48

Operation

5. Link the variable with the appropriate variable of the PROFIsafe module:

6. Set the connection type PROFIsafe Slave on the Connection tab of the TwinSAFE connection

added in step 1:

46

EL6930

Page 49

Operation

4.3 Commissioning on Siemens F-CPU

4.3.1 Requirement

The requirement for the commissioning of the EL6930 with a PROFIsafe connection is a safety controller

with PROFIBUS or PROFINET and with a certified PROFIsafe host. Furthermore the Simatic Step7

program with the extension S7 distributed Safety is needed for the configuration.

4.3.2 Installing the EL6930 in Step7

So that the EL6930 is selectable later in the device catalogue, the device description file for PROFIBUS

(GSD) or PROFINET (GSDML) must be installed first. This can be done in the Step7 program HW Config

as follows:

EL6930 47

Page 50

Operation

4.3.3 Configuration of the hardware

First of all the head station must be selected from the device catalogue of the HW Config (CX8031 with

Profibus is used here as an example).

The EL6930 presents itself to this head station as a normal module and can be added in the usual way.

48

EL6930

Page 51

Operation

The F-parameters can be adjusted by double-clicking on the module.

4.3.3.1 F_Check_SeqNr

Valid only for PROFIsafe version 1. With this you can set whether or not the SeqNr is included in the CRC

calculation of the PROFIsafe telegram (default is No Check).

4.3.3.2 F_SIL

Specification of the SIL level; the EL6930 always has SIL3.

EL6930 49

Page 52

Operation

4.3.3.3 F_CRC_Length

Length of the checksum in the PROFIsafe telegram; the EL6930 has a 2-byte checksum for PROFIsafe

version 1 and a 3-byte checksum for version 2. This value must be consistent with the parameter

F_PAR_Version.

4.3.3.4 F_PAR_Version

Indicates the version of the PROFIsafe connection. The EL6930 supports PROFIsafe versions 1 and 2.

This value must be consistent with the parameter F_CRC_Length.

4.3.3.5 F_Source_Add

Address of the PROFIsafe host; this is specified by the configuration program.

4.3.3.6 F_Dest_Add

Address of the PROFIsafe device; this is assigned by the user and must be unique in the entire safety

network.

4.3.3.7 F_WD_Time

This parameter sets the watchdog for the safety connection. The value must always be higher than the

cycle time of the fieldbus, since it can take several fieldbus cycles before a PROFIsafe telegram is

dispatched.

50

EL6930

Page 53

Operation

4.4 Diagnostics

4.4.1 Diagnostic LEDs

The LEDs Diag 1 to Diag 4 display diagnostic information for the EL6930.

4.4.1.1 Diag 1 LED (green)

The Diag 1 LED is currently always on when a project is loaded into the terminal.

Display Meaning

lit A project is stored in the terminal.

4.4.1.2 Diag 2 LED (red)

The Diag 2 LED indicates internal process variable errors (in preparation).

Display Meaning

in preparation

4.4.1.3 Diag 3 LED (red)

The Diag 3 LED provides further details for the Diag 4 LED (see below).

4.4.1.4 Diag 4 LED (red) if Diag 3 LED (red) is lit

If the Diag 3 LED is lit, the Diag 4 LED indicates internal terminal errors.

Diag 3 LED Diag 4 LED Source of error

lit flashing µC1

lit off µC2

Returning the terminal

Note

EL6930 51

These errors lead to the shutdown of the terminal (global fault). The terminal must be

checked by Beckhoff Automation GmbH & Co. KG.

Page 54

Operation

4.4.1.5 Diag 4 LED (red) if Diag 3 LED (red) is not lit.

If the Diag 3 LED is not lit, the Diag 4 LED indicates the state of the TwinSAFE terminal.

Diag 3 LED Diag 4 LED: Flashing Code Meaning

off 1 flash pulse (uniform flashing) Function block error in one of the TwinSAFE

groups

off 2 flash pulses (2 pulses with longer

pause in between)

off 3 flash pulses (3 pulses with longer

pause in between)

Communication error in one of the TwinSAFE

groups

Function block and communication error in

one of the TwinSAFE groups

off Steadily lit Supply voltage or internal temperature of the

terminal outside the permissible range. The

diagnostic object FA00

provides you with

hex

more detailed information.

4.4.2 Diagnostic object

The CoE object FA00

displays further diagnostic information.

hex

Do not change CoE objects!

Do not change any of the CoE objects in the TwinSAFE terminals! Any modifications

CAUTION

(e.g. using the TwinCAT system manager) of the CoE objects would permanently set

the terminals to the Fail-Stop state.

Index FA00

: Diagnostic object

hex

Index Name Meaning Flags

FA00:0 Diag RO

FA00:03

Temper

ature

error

0005

0006

0007

Maximum temperature exceeded RO 0000

hex

Temperature fell below minimum

hex

hex

Temperature difference between the measuring

points exceeded

Supply

error

0101

0102

0103

0104

max. supply voltage µC1 exceeded

hex

max. supply voltage µC2 exceeded

hex

voltage fell below max. supply voltage µC1

hex

voltage fell below max. supply voltage µC2

hex

Default

value

hex

52

EL6930

Page 55

Operation

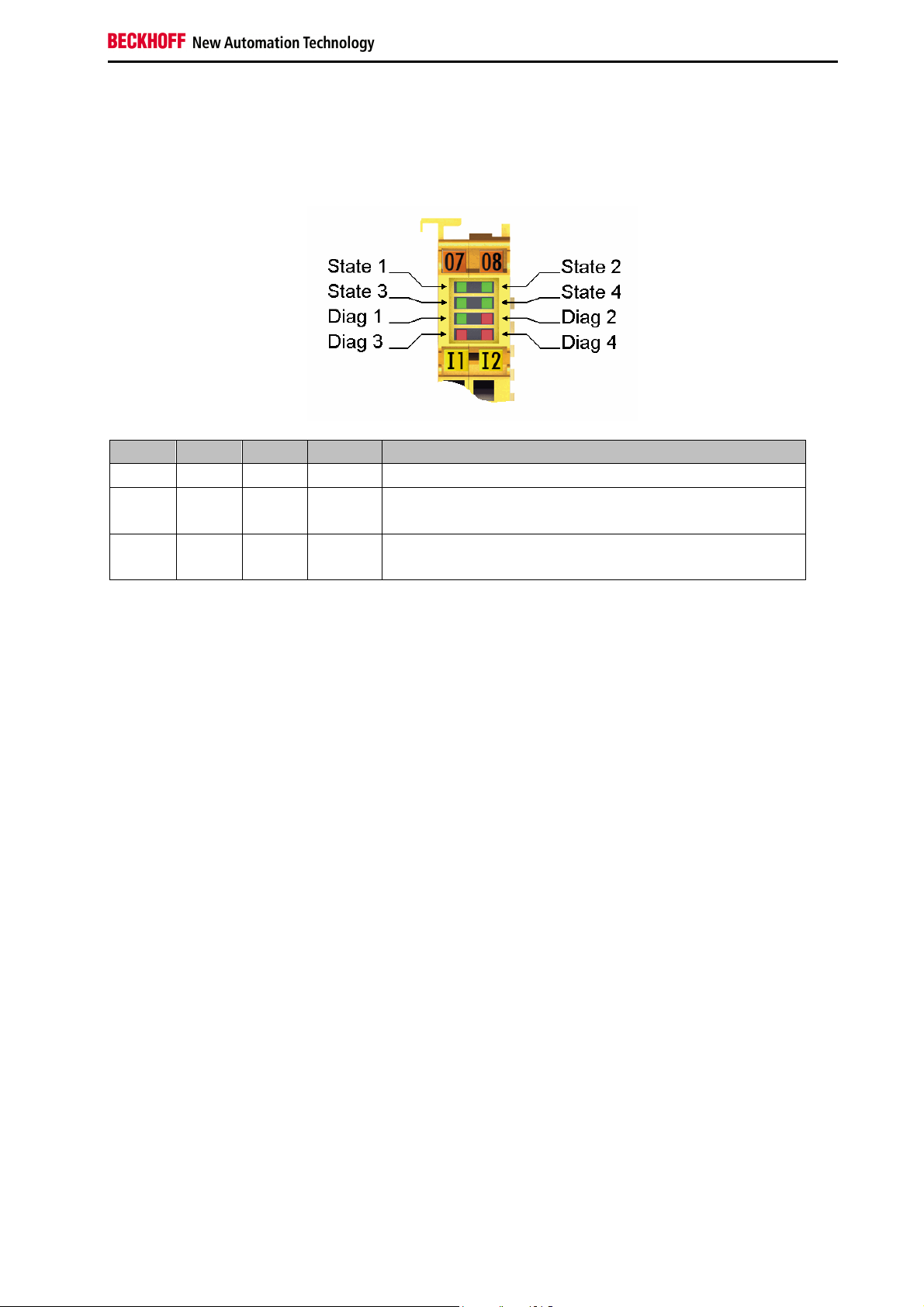

4.4.3 Status LEDs

The LEDs State 1 to State 4 indicate the current status of the EL6900.

State 1 State 2 State 3 State 4 Meaning

off off off lit

off off lit lit

lit lit lit lit

• No project present on the terminal

• Project present on the terminal

• EtherCAT status: Pre-Operational (Pre-OP)

• Project present on the terminal

• EtherCAT status: Operational (OP)

EL6930 53

Page 56

Operation

4.5 Maintenance

The TwinSAFE terminals are maintenance-free!

Observe the specified environmental conditions!

WARNING

If the terminal is operated outside the permitted temperature range it will switch to the Global Fault state

(see section Diagnose).

4.5.1 Cleaning

Protect the TwinSAFE terminals from unacceptable soling during operation and storage!

If the TwinSAFE terminals were subjected to unacceptable soiling it may no longer be operated!

Please ensure that the TwinSAFE terminals are only stored and operated under the

specified conditions (see technical data).

Have soiled terminals checked!

WARNING

Cleaning of the TwinSAFE terminals by the user is not permitted!

Please send soiled terminals to the manufacturer for inspection and cleaning!

4.6 Service life

The TwinSAFE terminals are designed for a service life of 20 years.

Due to the high diagnostic coverage within the lifecycle no special proof tests are required.

4.6.1 Decommissioning

Serious risk of injury!

DANGER

4.6.2 Disposal

In order to dispose of the device, it must be removed and fully dismantled.

• Housing components (polycarbonate, polyamide (PA6.6)) are suitable for plastic recycling.

• Metal parts can be sent for metal recycling.

• Electronic parts such as disk drives and circuit boards must be disposed of in accordance with

national electronics scrap regulations.

Bring the bus system into a safe, de-energized state before starting disassembly of the

Bus Terminals!

54

EL6930

Page 57

Appendix

5 Appendix

5.1 Beckhoff Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

5.1.1 Beckhoff branches and partner companies Beckhoff Support

Please contact your Beckhoff branch office or partner company for local support and service on Beckhoff

products!

The contact addresses for your country can be found in the list of Beckhoff branches and partner

companies: www.beckhoff.com. You will also find further documentation for Beckhoff components there.

5.1.2 Beckhoff company headquarters

Beckhoff Automation GmbH & Co.KG

Huelshorstweg 20

33415 Verl

Germany

Phone: + 49 (0) 5246/963-0

Fax: + 49 (0) 5246/963-198

E-mail: info@beckhoff.com

Web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• world-wide support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: + 49 (0) 5246/963-157

Fax: + 49 (0) 5246/963-9157

E-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: + 49 (0) 5246/963-460

Fax: + 49 (0) 5246/963-479

E-mail: service@beckhoff.com

EL6930 55

Page 58

Appendix

5.2 Certificates

56

EL6930

Page 59

Appendix

EL6930 57

Loading...

Loading...