Page 1

Documentation

EL6900-FB, KL6904-FB

TwinCAT function blocks for TwinSAFE logic terminals

Version: 2.4.1

Date: 2015-03-11

Page 2

Page 3

Table of contents

Table of contents

1 Foreword 5

1.1 Notes on the manual 5

1.1.1 Disclaimer 5

1.1.2 Brands 5

1.1.3 Patents 5

1.1.4 Copyright 5

1.1.5 Delivery conditions 5

1.2 Safety instructions 6

1.2.1 Delivery state 6

1.2.2 Operator's obligation to exercise diligence 6

1.2.3 Description of safety symbols 7

1.2.4 Origin of the document 7

1.2.5 Documentation issue status 8

2 System description 9

2.1 TwinSAFE logic terminals EL6900/KL6904 9

2.1.1 TwinSAFE group 9

2.1.2 TwinSAFE connection 11

2.1.3 System diagnosis 11

3 Function blocks 17

3.1 The AND function block 17

3.1.1 Functional description 17

3.1.2 Signal description 18

3.1.3 FB AND configuration in the TwinCAT System Manager 20

3.2 The OR function block 21

3.2.1 Functional description 21

3.2.2 Signal description 22

3.2.3 FB OR configuration in the TwinCAT System Manager 24

3.3 The OPMODE function block 25

3.3.1 Functional description 25

3.3.2 Signal description 26

3.3.3 FB OPMODE configuration in the TwinCAT System Manager 29

3.4 The ESTOP function block 30

3.4.1 Functional description 30

3.4.2 Signal description 31

3.4.3 FB ESTOP configuration in the TwinCAT System Manager 33

3.5 The MON function block 35

3.5.1 Functional description 35

Function blocks for TwinSAFE logic terminals 1

Page 4

Table of contents

3.5.2 Signal description 37

3.5.3 FB MON configuration in the TwinCAT System Manager 39

3.6 The DECOUPLE function block 41

3.6.1 Functional description 41

3.6.2 Signal description 42

3.6.3 FB DECOUPLE configuration in the TwinCAT System Manager 45

3.7 The TWO-HAND function block 46

3.7.1 Functional description 46

3.7.2 Signal description 47

3.7.3 FB TWO-HAND configuration in the TwinCAT System Manager 49

3.7.4 Examples of two-hand control types according to DIN EN 574 : 1996 50

3.8 The MUTING function block 51

3.8.1 Functional description 51

3.8.2 Signal description 52

3.8.3 FB MUTING configuration in the TwinCAT System Manager 55

3.9 The EDM function block 61

3.9.1 Functional description 61

3.9.2 Signal description 62

3.9.3 FB EDM configuration in the TwinCAT System Manager 63

3.10 The RS function block 64

3.10.1 Functional description 64

3.10.2 Signal description 65

3.10.3 FB RS configuration in the TwinCAT System Manager 66

3.11 The SR function block 67

3.11.1 Functional description 67

3.11.2 Signal description 68

3.11.3 FB SR configuration in the TwinCAT System Manager 69

3.12 The TON function block 70

3.12.1 Functional description 70

3.12.2 Signal description 71

3.12.3 FB TON configuration in the TwinCAT System Manager 72

3.13 The TOF function block 73

3.13.1 Functional description 73

3.13.2 Signal description 74

3.13.3 FB TOF configuration in the TwinCAT System Manager 75

3.14 The CONNECTION SHUTDOWN function block 76

3.14.1 Functional description 76

3.14.2 Signal description 78

3.14.3 FB ConnectionShutdown configuration in the TwinCAT System Manager 80

2

Function blocks for TwinSAFE logic terminals

Page 5

Table of contents

4 Appendix 81

4.1 Beckhoff Support and Service 81

4.1.1 Beckhoff branches and partner companies Beckhoff Support 81

4.1.2 Beckhoff company headquarters 81

Function blocks for TwinSAFE logic terminals 3

Page 6

Page 7

Foreword

1 Foreword

1.1 Notes on the manual

This description is only intended for the use of trained specialists in control and automation technology

familiar with the applicable national standards. It is essential that the following notes and explanations are

followed when installing and commissioning these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

safety requirements, including all the relevant laws, regulations, guidelines and standards.

1.1.1 Disclaimer

This documentation has been prepared with care. The products described are, however, constantly under

development. For this reason, the documentation may not always have been fully checked for

consistency with the performance data, standards or other characteristics described.

If it should contain technical or editorial errors, we reserve the right to make changes at any time and

without notice.

No claims for the modification of products that have already been supplied may be made on the basis of

the data, diagrams and descriptions in this documentation.

1.1.2 Brands

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

The use by third parties of other brand names or trademarks contained in this documentation may lead to

an infringement of the rights of the respective trademark owner.

1.1.3 Patents

The EtherCAT technology is patent protected, in particular by the following applications and patents:

EP1590927, EP1789857, DE102004044764, DE102007017835 with the corresponding applications and

registrations in various other countries.

The TwinCAT technology is patent protected, in particular by the following applications and patents:

EP0851348, US6167425 with the corresponding applications and registrations in various other countries.

1.1.4 Copyright

©

Beckhoff Automation GmbH & Co. KG.

The copying, distribution and utilization of this document as well as the communication of its contents to

others without express authorization is prohibited. Offenders shall be held liable for damages. All rights

conferred by patent grant or registration of a utility model or registered design are reserved.

1.1.5 Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

Function blocks for TwinSAFE logic terminals 5

Page 8

Foreword

1.2 Safety instructions

1.2.1 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

1.2.2 Operator's obligation to exercise diligence

The operator must ensure that

• the TwinSAFE products are only used as intended (see section Product description);

• the TwinSAFE products are only operated in sound condition and in working order.

• the TwinSAFE products are operated only by suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational safety and environmental

protection aspects, and is familiar with the operating instructions and in particular the safety

instructions contained herein.

• the operating instructions are in good condition and complete, and always available for reference

at the location where the TwinSAFE products are used.

• none of the safety and warning notes attached to the TwinSAFE products are removed, and all

notes remain legible.

6

Function blocks for TwinSAFE logic terminals

Page 9

Foreword

1.2.3 Description of safety symbols

The following safety symbols are used in these operating instructions. They are intended to alert the

reader to the associated safety instructions.

Serious risk of injury!

DANGER

WARNING

CAUTION

Attention

Note

Failure to follow the safety instructions associated with this symbol directly endangers

the life and health of persons.

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life

and health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries

to persons.

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the

environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

1.2.4 Origin of the document

This documentation was originally written in German. All other languages are derived from the German

original.

Function blocks for TwinSAFE logic terminals 7

Page 10

Foreword

1.2.5 Documentation issue status

Version Comment

2.4.1

• Markings removed

2.4.0

2.3.0

2.2.0

2.1.0

2.0.0

1.1.1

1.1.0

1.0.0

• Company address changed

• Document origin and versions added

• EDM extended with standard In

• MUTING status information expanded

• Two-hand diagnostic information expanded

• TwinSAFE connection info data expanded

• FB ESTOP info data expanded

• FB OPMODE description expanded

• Service/support information modified

• EL6900 blocks added

• Corrections during the translation into English

• Amendments in the application examples

• First released version

8

Function blocks for TwinSAFE logic terminals

Page 11

System description

2 System description

The TwinSAFE system consists of safe inputs (EL/KL1904), safe outputs (EL/KL2904) and logic modules

(KL6904/EL6900). The TwinSAFE logic terminal (KL6904/EL6900) contains function blocks, which can be

parameterized and connected to each other and form the safety-related logic. Free programming is not

possible. In addition to the non-safety-related logic configuration a fieldbus configuration is required for

mapping the TwinSAFE data packets. These functions are realized via the TwinCAT System Manager.

The safety-related TwinSAFE Verifier, which is available at the moment as a separate installation, deals

with the loading and testing of the TwinSAFE project onto the EL6900/KL6904.

The TwinSAFE logic terminal can communicate, via the fieldbus-independent and certified TwinSAFEprotocol with safe input and output terminals, and also via further logic terminals. The TwinSAFE protocol

is a Safety over EtherCAT (FSoE) protocol with one byte of safe user data. It is openly available via the

EtherCAT Technology Group (www.ethercat.org).

2.1 TwinSAFE logic terminals EL6900/KL6904

The configuration of a TwinSAFE logic terminal consists of function blocks that are consolidated into one

or several TwinSAFE groups. TwinSAFE groups can be started and stopped independently of each other.

The execution sequence of the function blocks corresponds to the TwinCAT System Managers project

structure sequence illustrated. This sequence can be changed in the System Manager by Drag’n Drop.

The function blocks have parameters which must be configured by the user.

The inputs and outputs of the function blocks are assigned to the inputs and outputs of the TwinSAFE

terminals, to other function blocks or to the input and output variable of the standard PLC by the user.

A TwinSAFE connection involves unambiguous assignment of a TwinSAFE device (EL/KL1904,

EL/KL2904, EL6900/KL6904) to TwinSAFE group. Only function blocks which belong to this TwinSAFE

group can be linked with the input and outputs of an assigned TwinSAFE connection. The DECOUPLE

block can be used if it is necessary for other groups to access the inputs and outputs (see chapter 3.6).

Errors of the TwinSAFE communication within the TwinSAFE group and errors within a function block

affect the complete TwinSAFE group. The TwinSAFE group then stops all associated function blocks,

which then switch their outputs into a safe state.

Errors in the TwinSAFE Logic result in it switching off completely.

2.1.1 TwinSAFE group

The function blocks are assigned to TwinSAFE groups. These have a characteristic that results in the

return of all group outputs to a safe state (a safe state is always a wattless state at the output,

corresponding to a logical 0) such as, in case of a communication error of an assigned TwinSAFE

connection, in case of an error in assigned function blocks (e.g. excessive discrepancy time) or an error in

the local assigned outputs. I.e. the TwinSAFE connection data and thus TwinSAFE input or output

terminal are always exactly assigned to a TwinSAFE group.

A communication error is displayed on the output (COM ERR) of the TwinSAFE group and acknowledged

on the input (ERR ACK). A function block error is displayed on the output (FB ERR) and acknowledged

on the same input (ERR ACK) as the communication error. An error on the local outputs (only KL6904) is

displayed on the third output (OUT ERR) and once again acknowledged (ERR_ACK) on the same input.

The safe state of the TwinSAFE group outputs is removed once the error is no longer present and has

been acknowledged.

The error acknowledgement is not carried out automatically, i.e. the "ERR ACK" input must always be

Function blocks for TwinSAFE logic terminals 9

Page 12

System description

linked.

Apart from this the TwinSAFE group has an input (RUN), with which the processing of the assigned

function blocks can be stopped and started. All TwinSAFE group assigned outputs are in a safe state

when stopped.

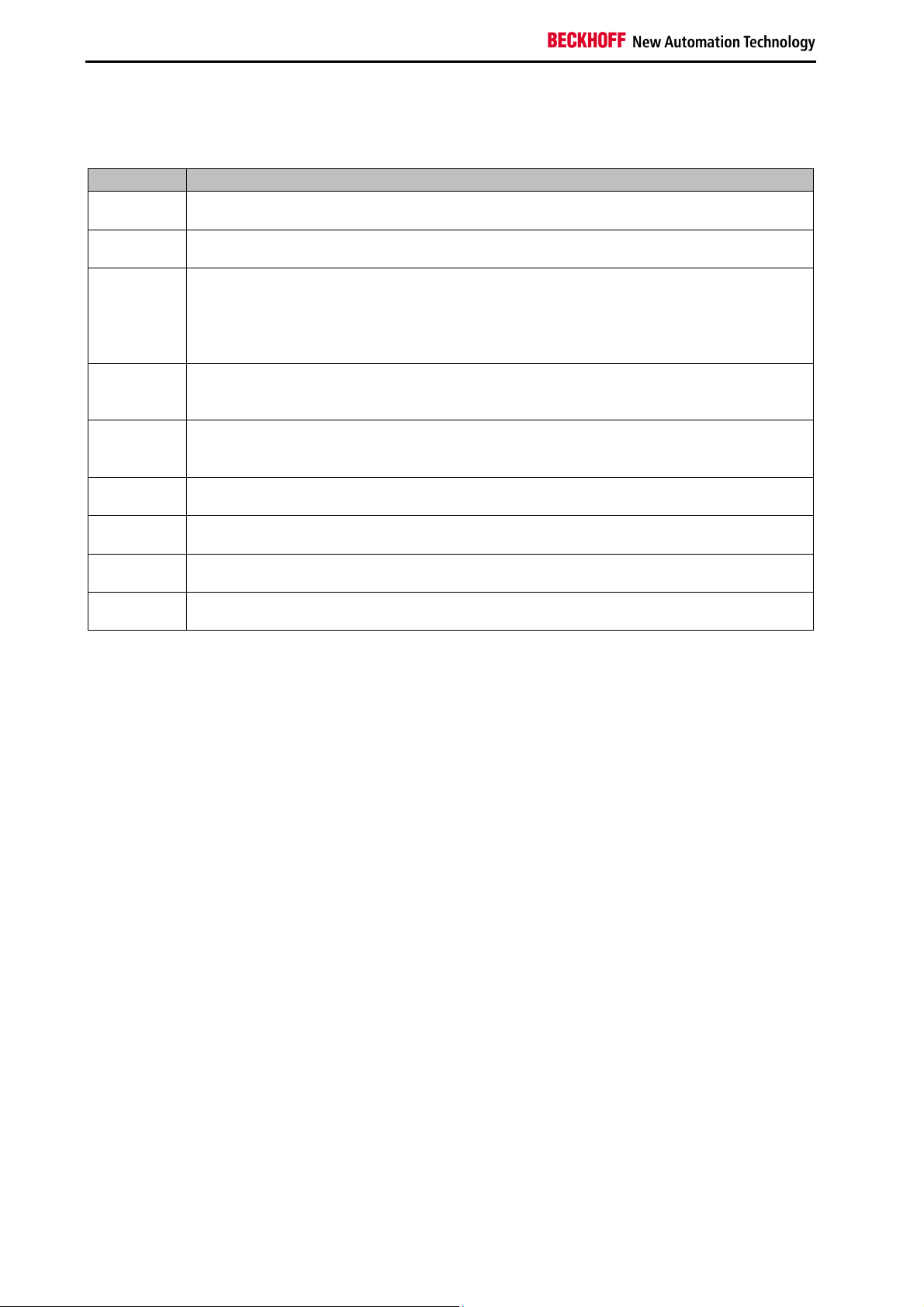

2.1.1.1 TwinSAFE group inputs and outputs

Table 2-1: TwinSAFE group inputs

Name Permitted type Description

RUN FB-Out

Standard-In

TRUE:

The function blocks assigned to the TwinSAFE group are executed

FALSE:

All assigned function blocks of the TwinSAFE group are at a STOP

state and thus all associated outputs are in a safe state

When the input is not linked it is in the TRUE state

ERR ACK FB-Out

Standard-In

All pending errors in the assigned function blocks and in the

TwinSAFE connections are acknowledged by the FALSE->TRUE>FALSE signal sequence.

Table 2-2: TwinSAFE group outputs

Name Permitted type Description

FB ERR TwinSAFE-Out

FB-In

Standard-Out

Local-Out

COM ERR TwinSAFE-Out

FB-In

Standard-Out

Local-Out

OUT ERR TwinSAFE-Out

FB-In

Standard-Out

Local-Out

TRUE:

At least one assigned function block has an error

FALSE:

All assigned function blocks have no errors

TRUE:

At least one TwinSAFE connection of TwinSAFE group has an error

FALSE:

All TwinSAFE connections of the TwinSAFE group have no errors

TRUE:

At least one local output assigned to the TwinSAFE group has an

error

FALSE:

All of the local outputs assigned to the TwinSAFE group have no

errors

Always FALSE for EL6900, since the device has no local outputs.

10

Function blocks for TwinSAFE logic terminals

Page 13

System description

2.1.2 TwinSAFE connection

Each safe communication path between the TwinSAFE logic and TwinSAFE inputs, TwinSAFE outputs or

other TwinSAFE logic terminals are referred to as TwinSAFE connection.

A communication partner is thus always the TwinSAFE master, the other the TwinSAFE slave. The

TwinSAFE logic is in a TwinSAFE connection to a TwinSAFE input or TwinSAFE output is always

TwinSAFE master. The TwinSAFE connection to another TwinSAFE logic can be TwinSAFE slave on the

other hand, whereby the TwinCAT System Manager automatically defines this assignment.

Both the TwinSAFE master and the TwinSAFE slave have a FSoE (Safety over EtherCAT) address that

can be set on the respective TwinSAFE terminal via a DIP switch in order to ensure that any mix-up of the

TwinSAFE data packets is always detected. These FSoE addresses are checked within the TwinSAFE

communication and must be unambiguous in the control system. The TwinSAFE Verifier for each

TwinSAFE logic terminal checks that. The TwinSAFE logic control system may contain several TwinSAFE

logic terminals, although the TwinSAFE Verifier can only be active for one TwinSAFE logic terminal at a

time. The user must therefore ensure that multiple allocation of FSoE addresses is avoided.

For each TwinSAFE connection a watchdog time and the corresponding FSoE address for the

communication devices can be set. In addition there is a possibility to adjust the SIL level, however this

setting is not supported at the moment and has no effects on the safety behavior of the system. In

another configuration option a module error in the TwinSAFE communication partner can be set to trigger

a communication error in the TwinSAFE group.

2.1.3 System diagnosis

The states of the TwinSAFE groups, FBs and connections can be checked in the System Manager. The

diagnostic information can be copied into the cyclic process image.

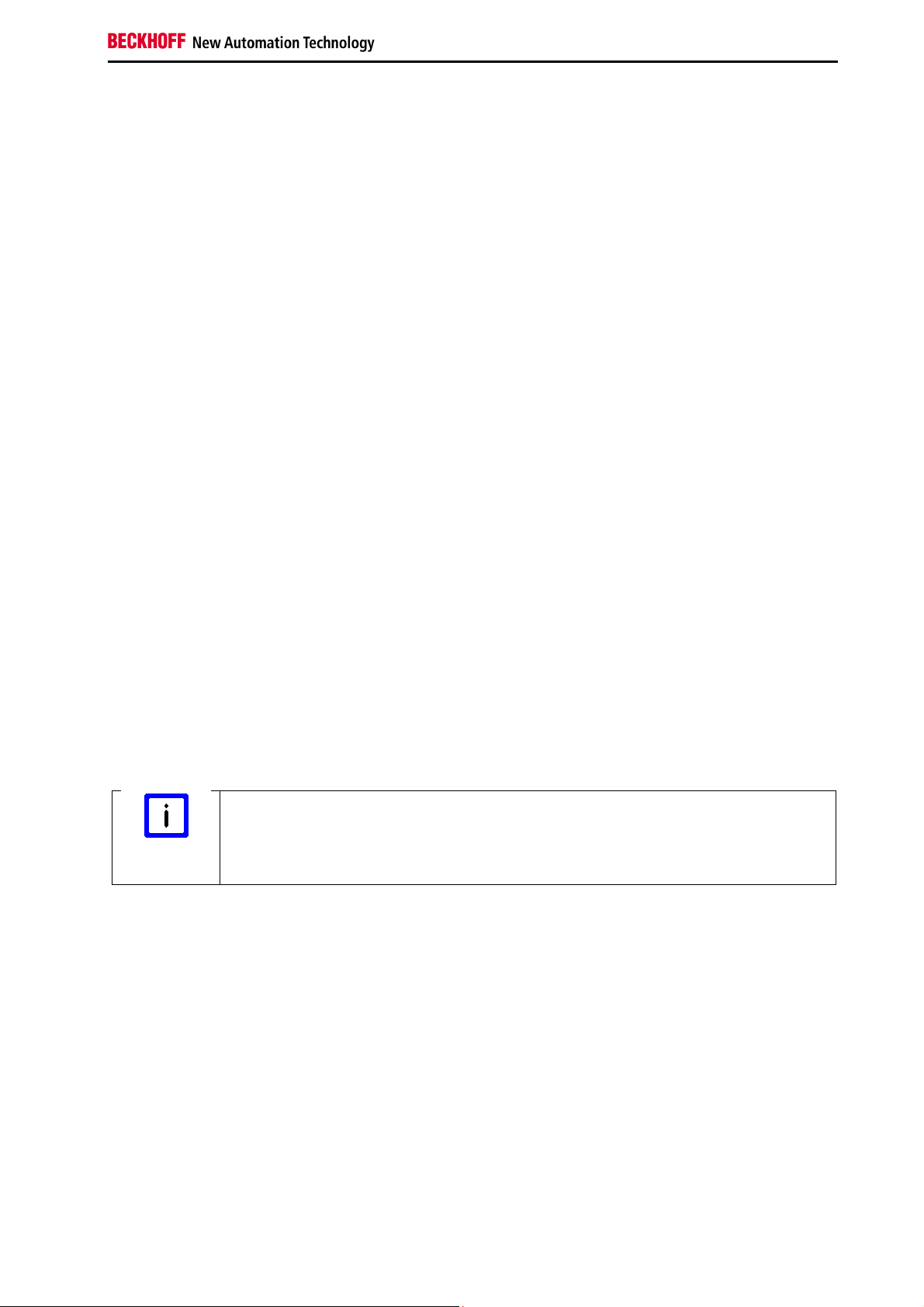

TwinSAFE groups have inputs and outputs of associated Screenshots assigned offline and which can be

considered online.

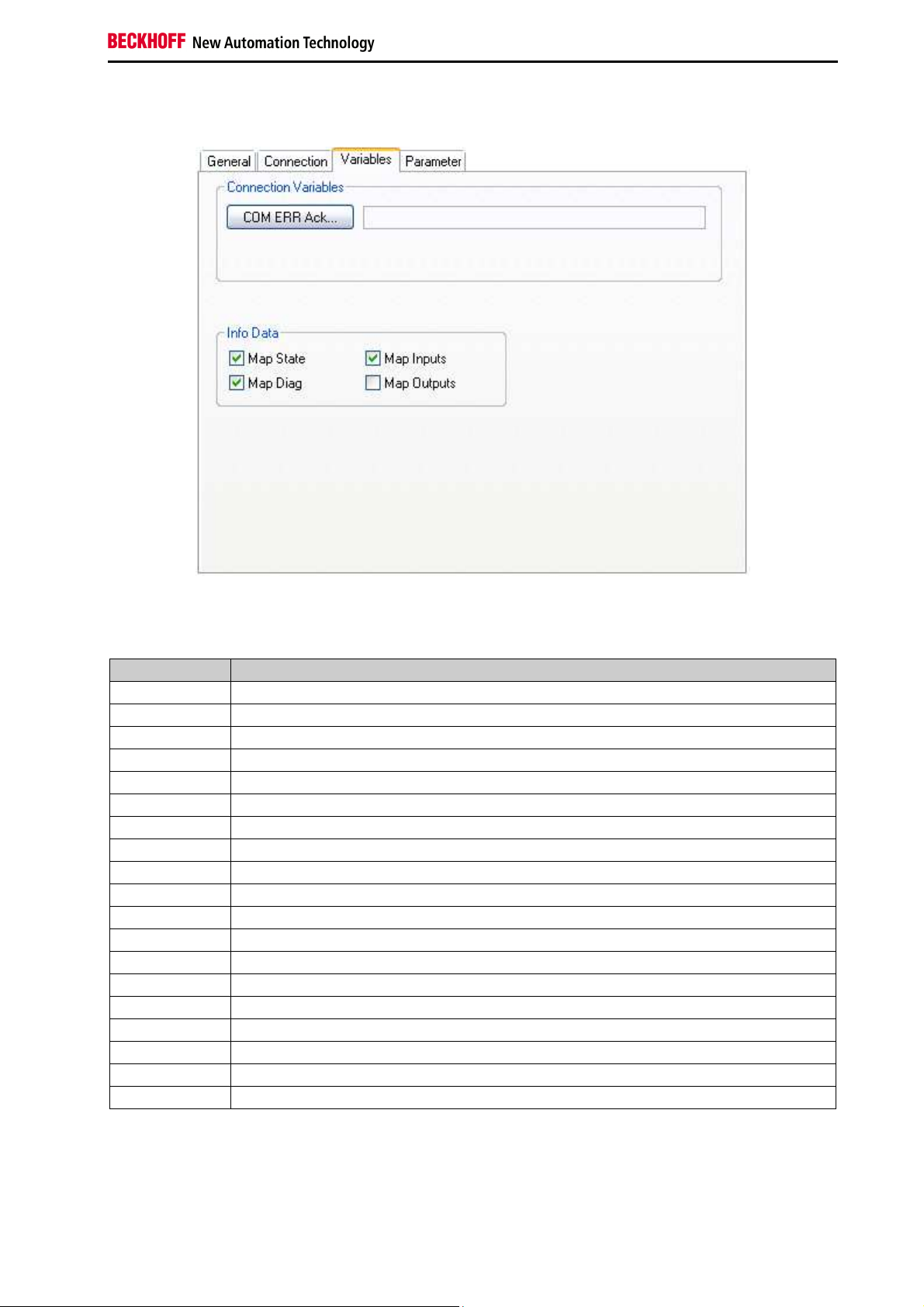

If the checkboxes ‘Map State’ and ‘Map Diag’ are set, the state and diagnostic data for the group are

copied into the cyclic process image and can be linked directly with PLC variables. The diagnostic data

are currently always 0.

KL6904

Note

With the KL6904 copying of the diagnostic information to the cyclic process image is

only possible to a limited extent. The checkboxes ‘Map State’ and ‘Map Diag’ are not

available.

Function blocks for TwinSAFE logic terminals 11

Page 14

System description

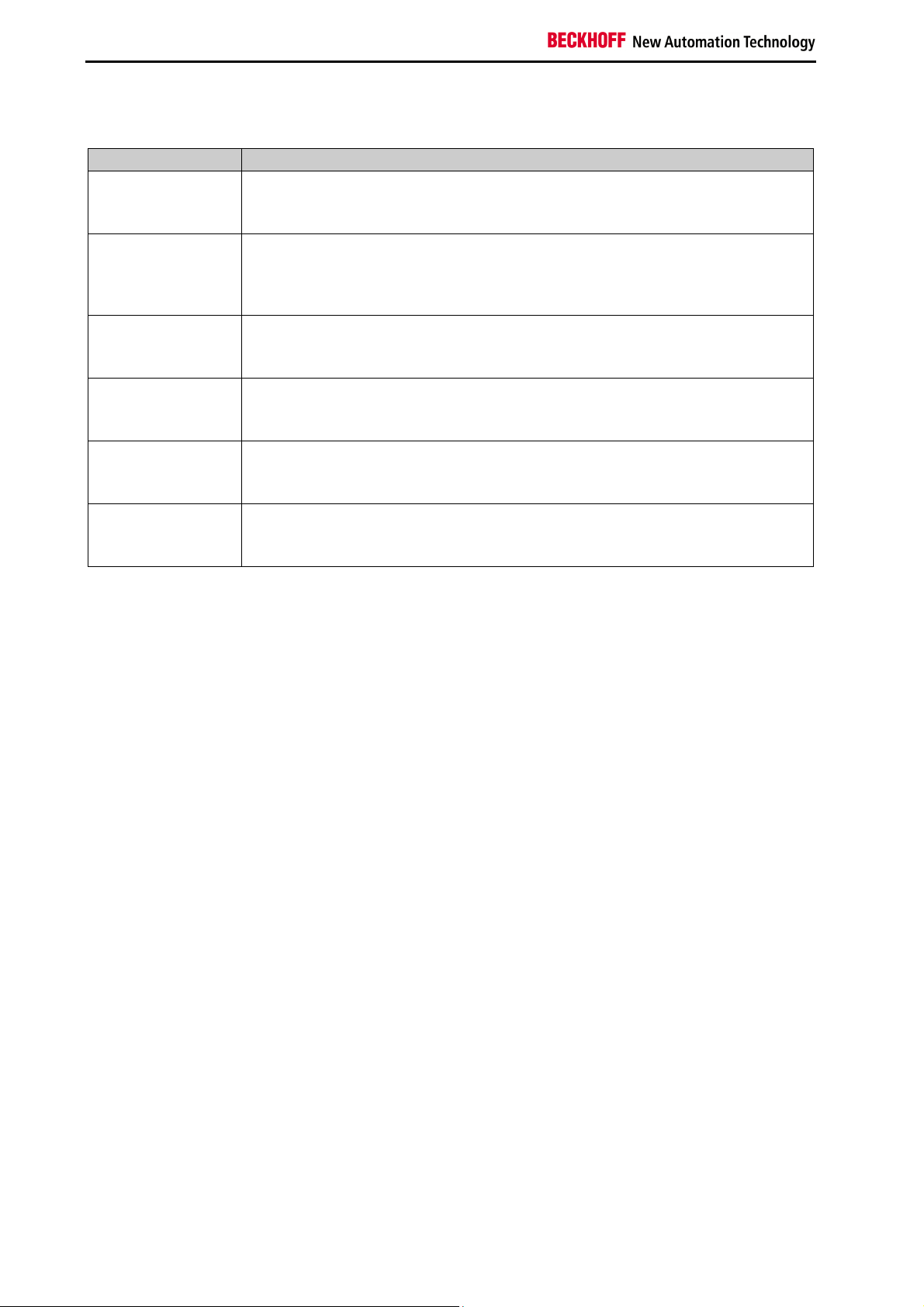

Figure 2-1: Inputs/Outputs

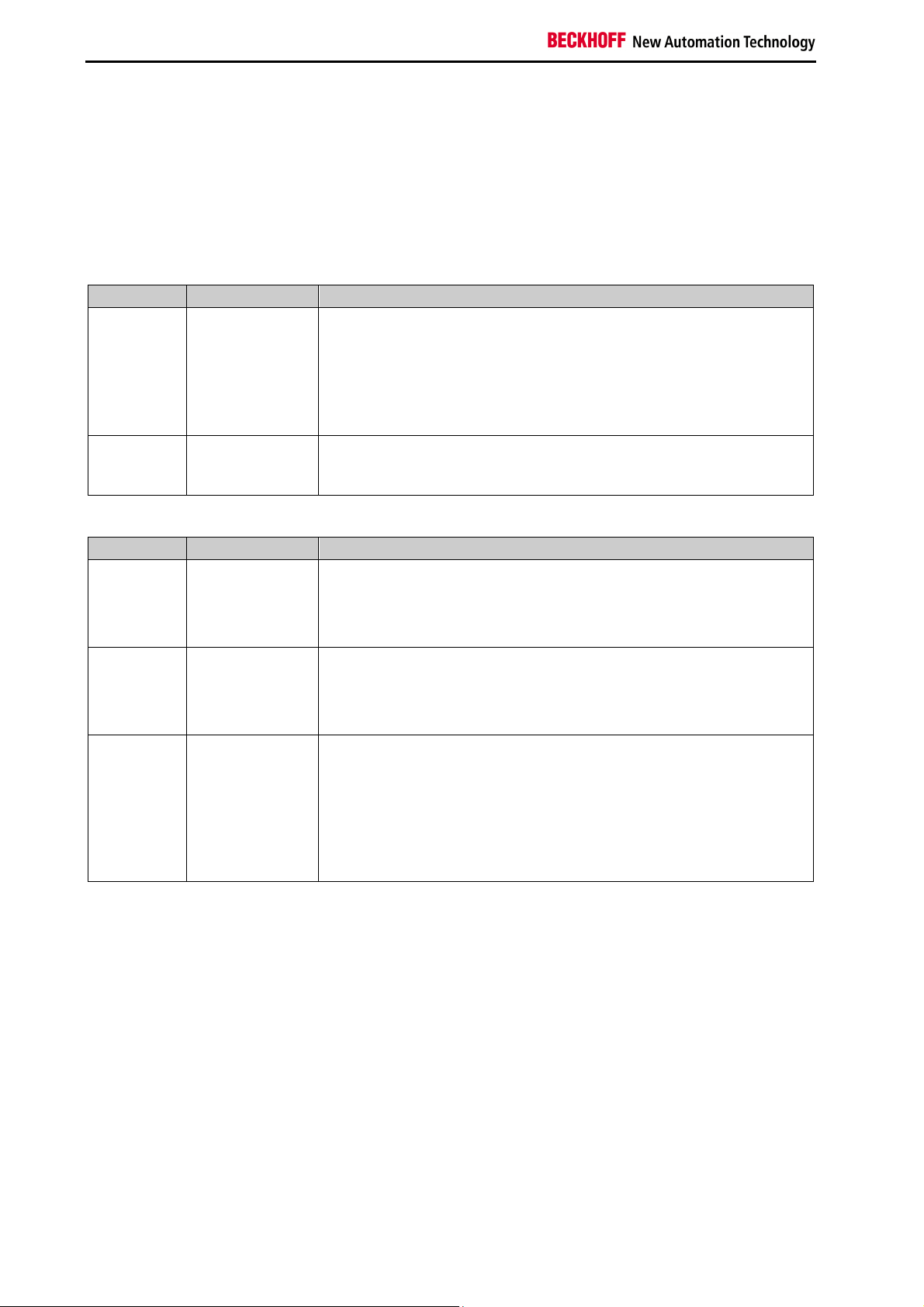

Table 2-3: Status information

Value Status Description

1 RUN

All function blocks and TwinSAFE connections assigned to the TwinSAFE

group operate properly, and all TwinSAFE connections assigned to the

TwinSAFE group are up and running

2 STOP State after initialization

3 SAFE

All function blocks and TwinSAFE connections assigned to the TwinSAFE

group operate properly, and at least one of the TwinSAFE connections

assigned to the TwinSAFE group is not yet up and running

4 ERROR

At least one assigned function block or one assigned TwinSAFE connection

has reported an error

5 RESET

A positive edge (FALSE->TRUE) for acknowledgement of a function block

or a TwinSAFE connection error was detected on the ERR_ACK input. The

system is waiting for the negative edge of the ERR_ACK input

12

Function blocks for TwinSAFE logic terminals

Page 15

System description

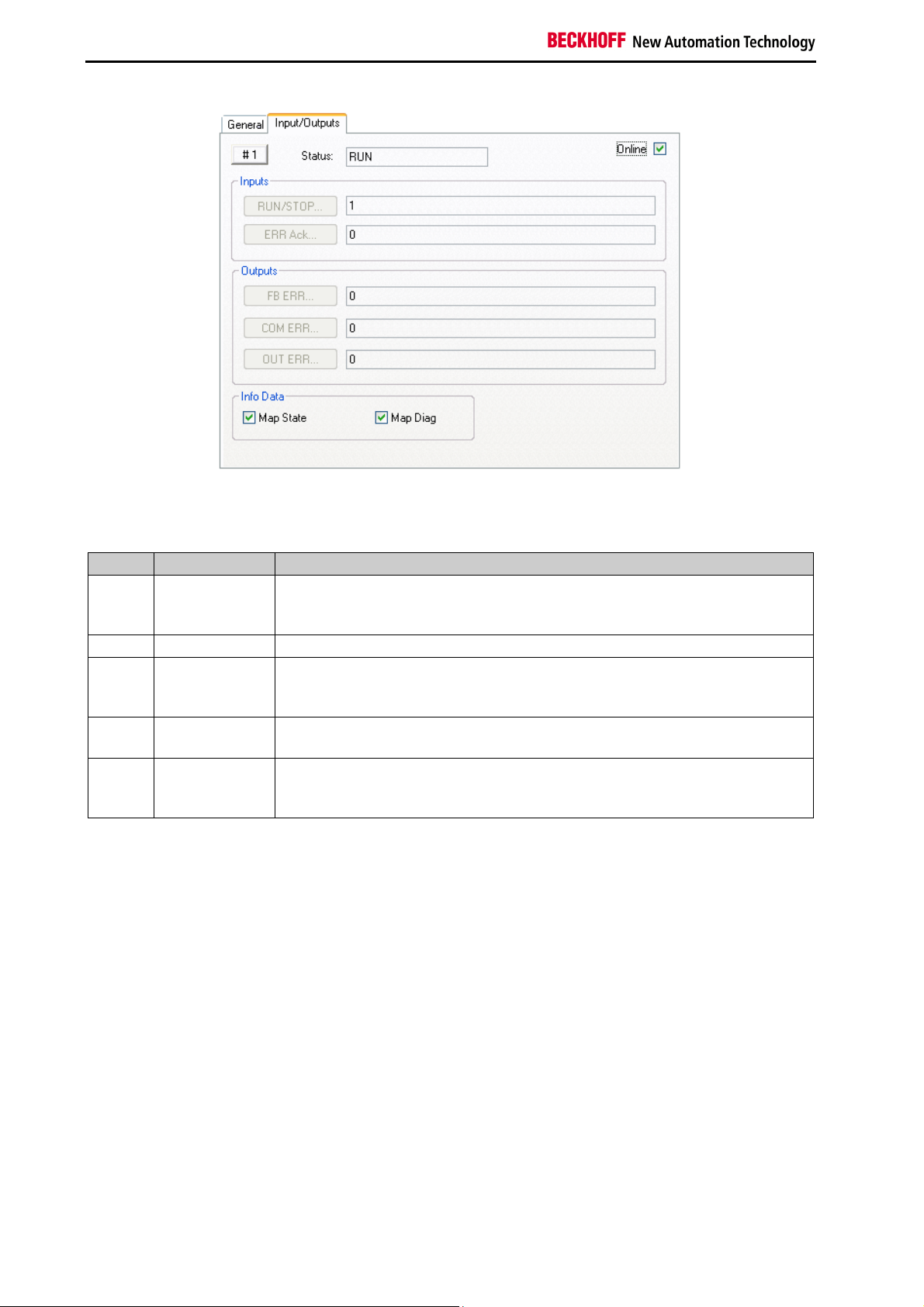

Figure 2-2: Inputs/Outputs

The status of TwinSAFE FBs is displayed on online summary. The current status data are read from the

EL6900/KL6904 via a manual refresh.

Figure 2-3: Function Block List

If the checkboxes ‘Map State’ and ‘Map Diag’ for the individual TwinSAFE FBs are set, the status and

diagnostic data for the FBs are copied into the cyclic process image and can be linked directly with PLC

variables. The description of the status and diagnostic values can be found under the respective FBs.

Function blocks for TwinSAFE logic terminals 13

Page 16

System description

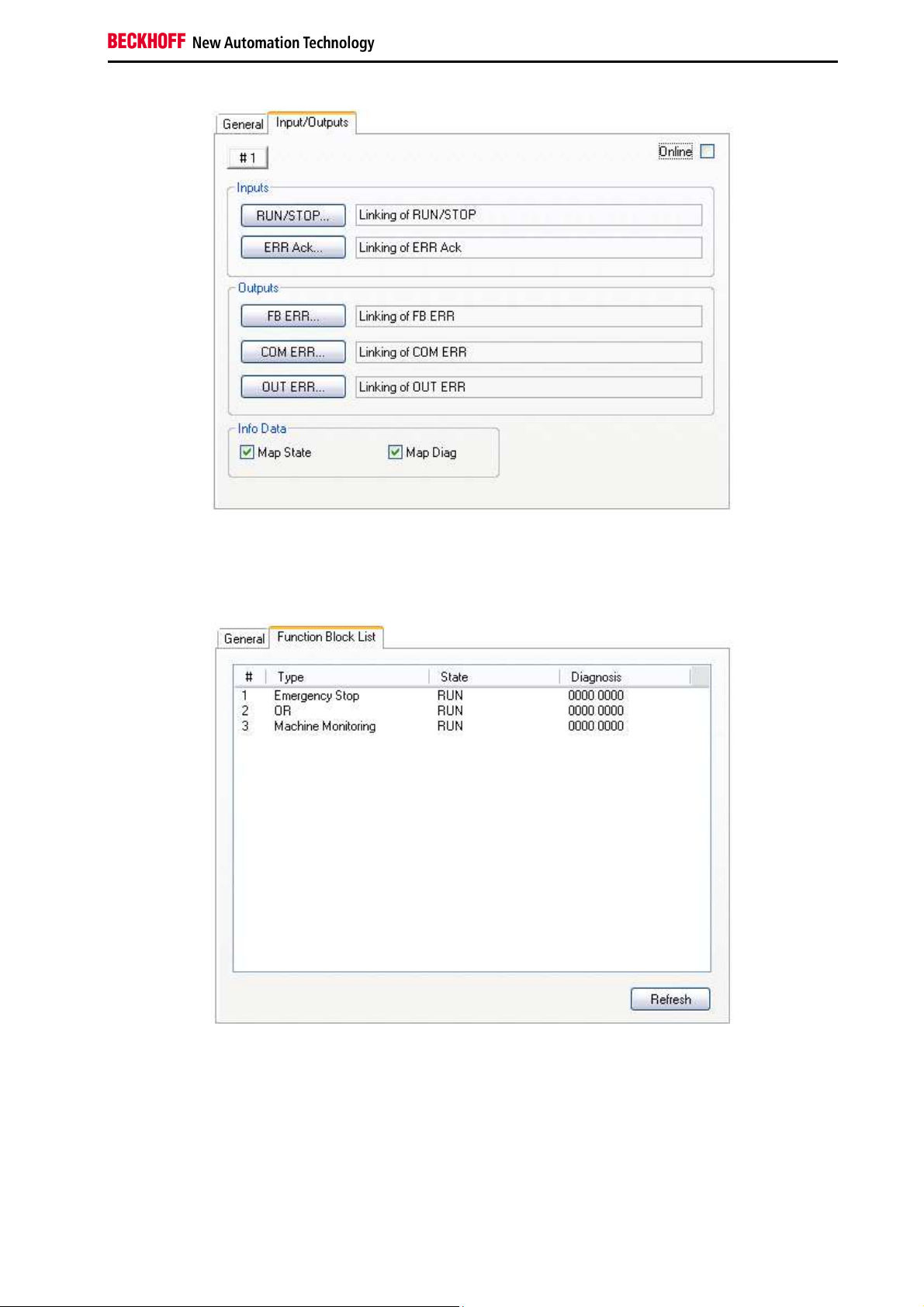

KL6904

Note

With the KL6904 copying of the diagnostic information to the cyclic process image is

only possible to a limited extent. The checkboxes ‘Map State’ and ‘Map Diag’ are not

available.

Figure 2-4: Emergency Stop

The TwinSAFE connections status is displayed on the TwinSAFE connection list summary under the

"Connection List" tab. Diagnostics bits are also set in addition to the status.

Figure 2-5: Connection List

If the checkboxes ‘Map State’ and ‘Map Diag’ for the individual TwinSAFE connections are set, the status

and diagnostic data for the connections are copied into the cyclic process image and can be linked

directly with PLC variables. In addition, the safe inputs and outputs can be copied into the cyclic process

image and used for diagnostic purposes.

KL6904

Note

With the KL6904 copying of the diagnostic information to the cyclic process image is

only possible to a limited extent. The checkboxes ‘Map State’, ‘Map Diag’‚ ‘Map Inputs’

and ‘Map Outputs’ are not available. The button “Com Err Ack” is also not available.

14

Function blocks for TwinSAFE logic terminals

Page 17

System description

Figure 2-6: Variables

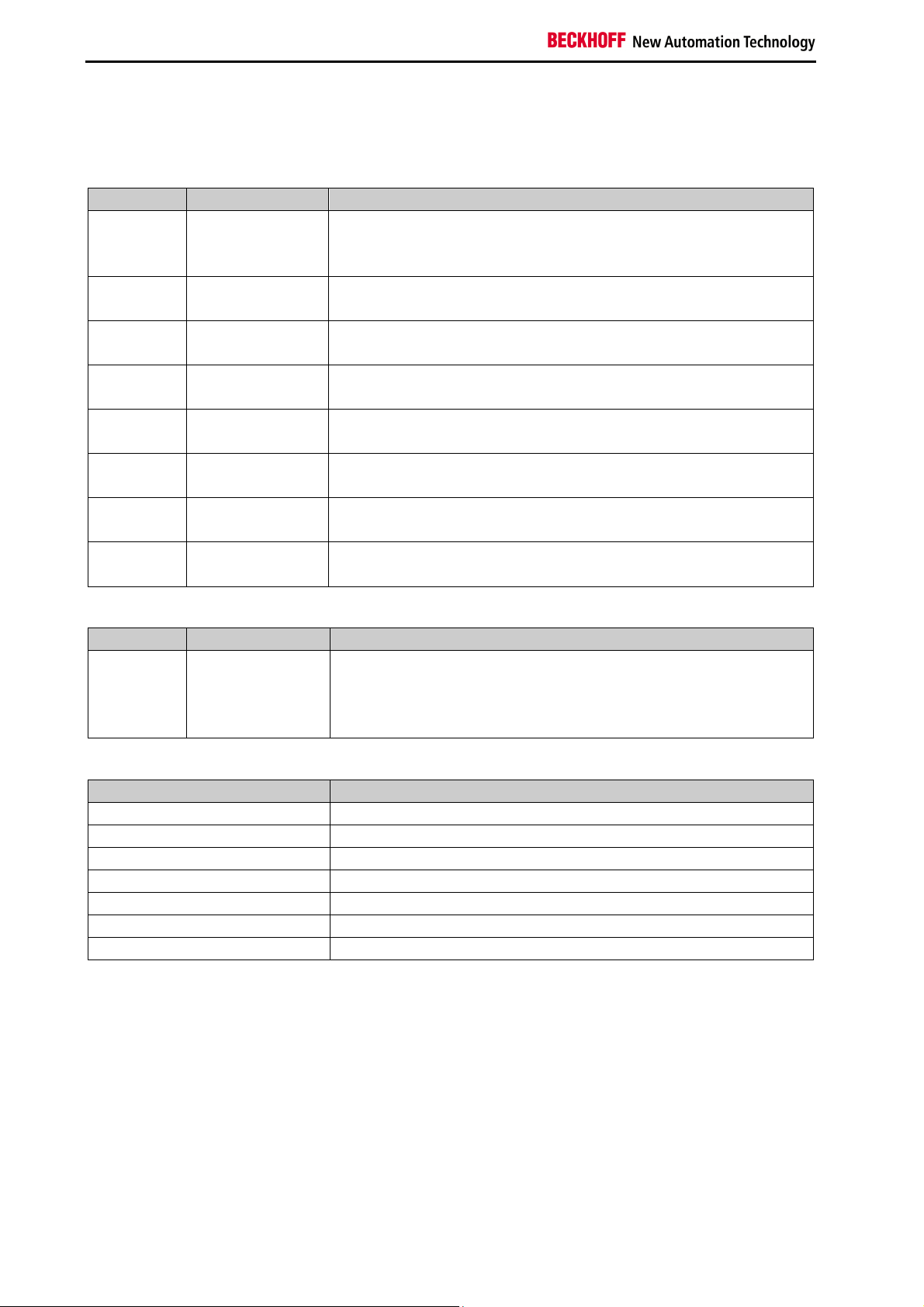

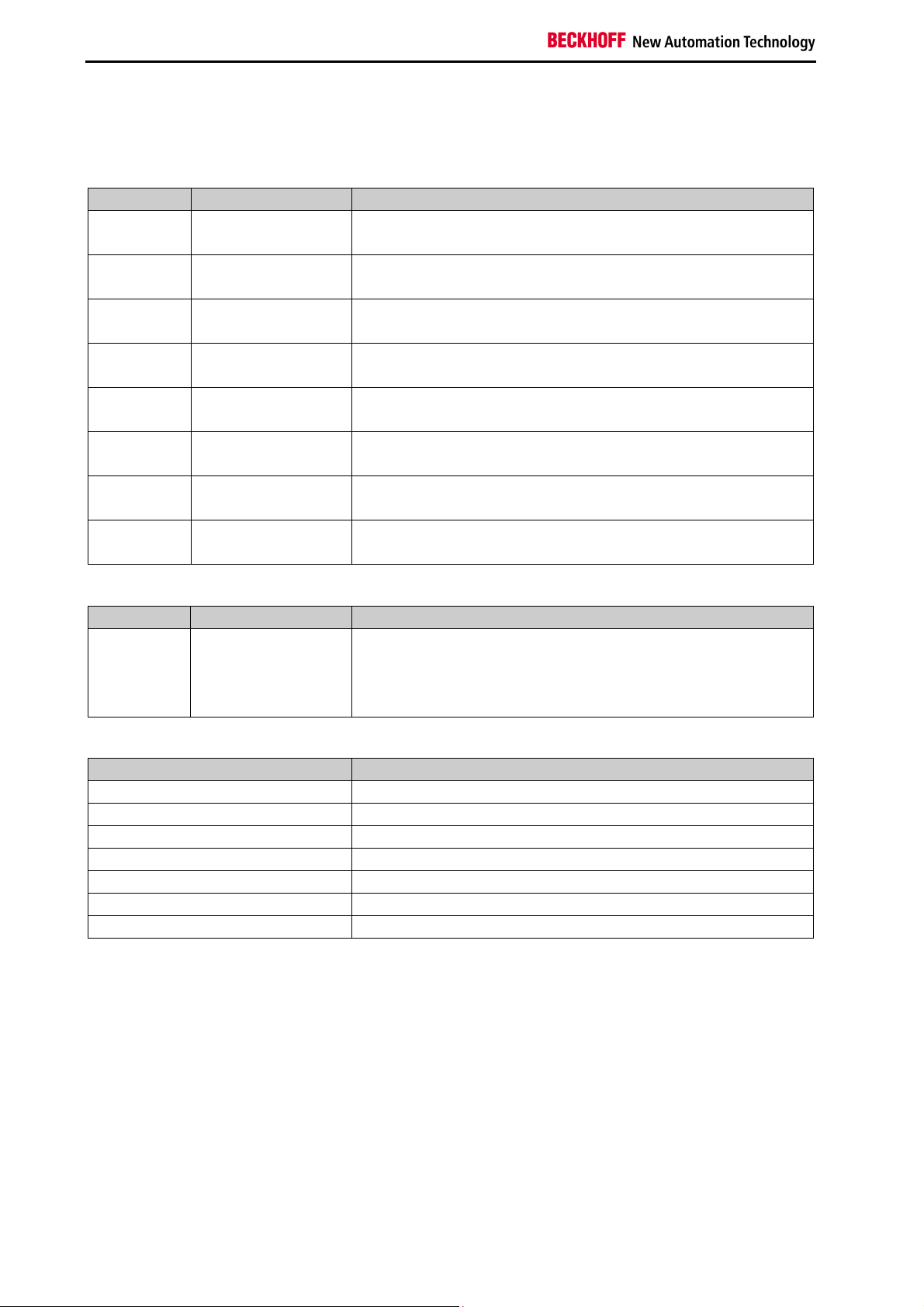

Table 2-4: Diagnostic information for a connection

Value Description

xxxx 0001 Invalid command

xxxx 0010 Unknown command

xxxx 0011 Invalid connection ID

xxxx 0100 Invalid CRC

xxxx 0101 Watchdog time elapsed

xxxx 0110 Invalid FSoE address

xxxx 0111 Invalid data

xxxx 1000 Invalid communication parameter length

xxxx 1001 Invalid communication parameters

xxxx 1010 Invalid user parameter length

xxxx 1011 Invalid user parameters

xxxx 1100 FSoE master reset

xxxx 1101 Module error detected on slave, with option "Module error is ComError" activated

xxxx 1110 Module error detected on EL290x, with option "Error acknowledge active" activated

xxxx 1111 Slave not yet started, or unexpected error argument

xxx1 xxxx FSoE slave error detected

xx1x xxxx FSoE slave reports Failsafe Value active

x1xx xxxx StartUp

1xxx xxxx FSoE master reports Failsafe Value active

Function blocks for TwinSAFE logic terminals 15

Page 18

System description

Table 2-5: Status information for a connection

Value Description

100 (0x64) Reset state:

The reset state is used to re-initialize the Safety over EtherCAT connection after

the power-on or a Safety over EtherCAT communication error.

101 (0x65) Session state:

During the transition to or in the session state a session ID is transferred from

the Safety over EtherCAT master to the Safety over EtherCAT slave, which in

turn responds with its own session ID.

102 (0x66) Connection state:

In the connection state a connection ID is transferred from the Safety over

EtherCAT master to the Safety over EtherCAT slave.

103 (0x67) Parameter state:

In the parameter state safe communication- and device-specific application

parameters are transferred.

104 (0x68) Data state:

In the data state Safety over EtherCAT cycles are transferred until either a

communication error occurs or a Safety over EtherCAT node is stopped locally.

105 (0x69) Shutdown state:

In the shutdown state the connection was shut down by one of the

communication partners.

Further information can be found in the Safety over EtherCAT specification.

16

Function blocks for TwinSAFE logic terminals

Page 19

Function blocks

3 Function blocks

The function blocks have a specified functionality that still must be configured via a parameter. The inputs

or outputs of a function block can be inputs or outputs of a local process image, but function block outputs

and inputs can be can be linked.

3.1 The AND function block

3.1.1 Functional description

With the FB AND several input signals can be linked via AND to one output signal. In addition each input

can still be set even if the input signal is a normally closed contact (Break contact) or normally open

contact (Make contact). A normally open contact means that the corresponding input signal is negated,

before it affects the AND.

The AndIn1 input differs from the AndIn2-AndIn8 inputs in such a way that it can also be linked with a

standard input. This makes it possible to switch off a safe output using a standard signal. Outputs cannot

be switched on but only released using a standard signal, since at least two inputs must always be linked

for FB AND (and the second input is a safe one, which prevents switching on).

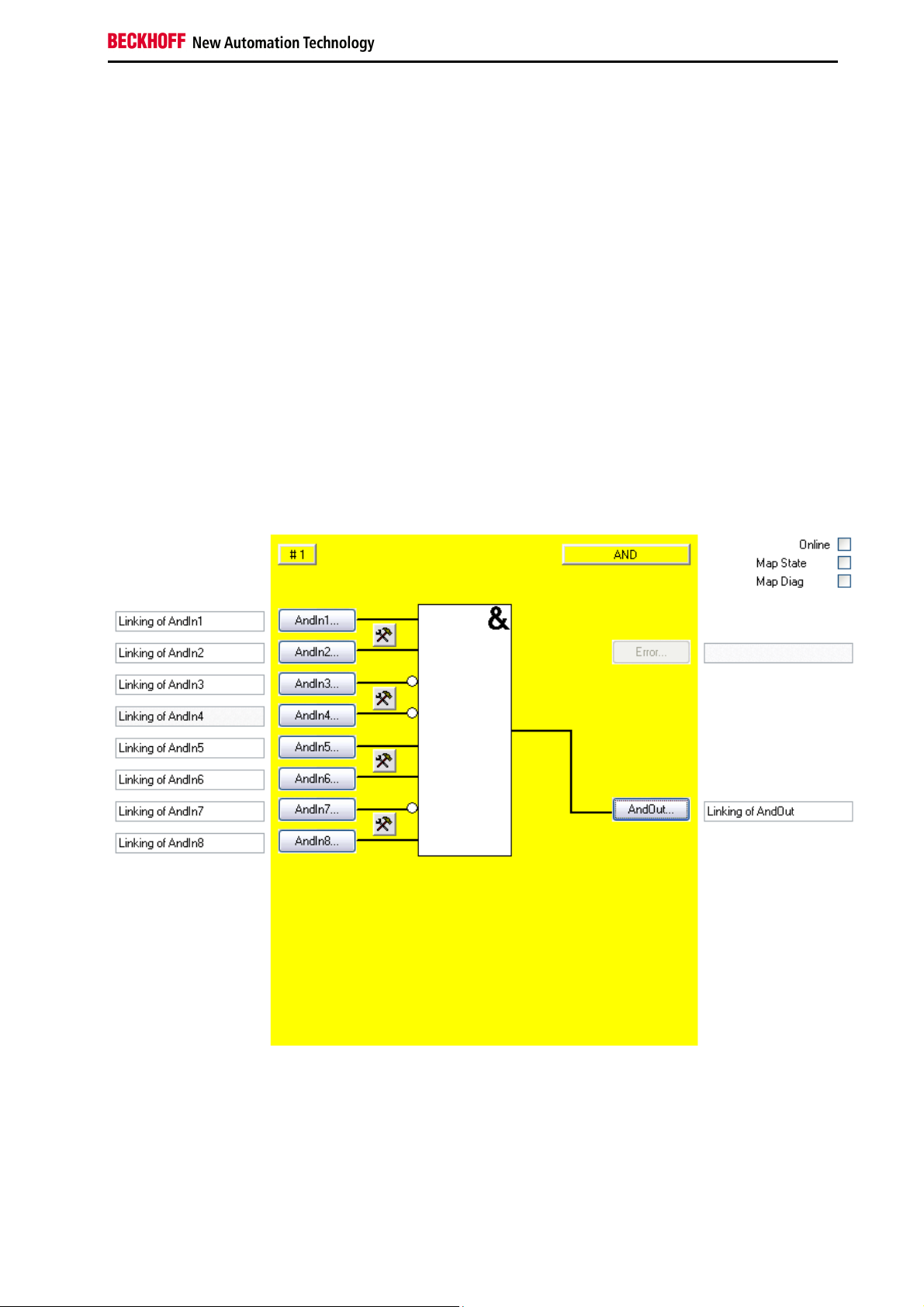

Figure 3-1: AND function block

Function blocks for TwinSAFE logic terminals 17

Page 20

Function blocks

3.1.2 Signal description

Table 3-1: FB AND inputs

Name Permitted type Description

AndIn1 TwinSAFE-In

FB-Out

Standard-In

AndIn2 TwinSAFE-In

FB-Out

AndIn3 TwinSAFE-In

FB-Out

AndIn4 TwinSAFE-In

FB-Out

AndIn5 TwinSAFE-In

FB-Out

AndIn6 TwinSAFE-In

FB-Out

AndIn7 TwinSAFE-In

FB-Out

AndIn8 TwinSAFE-In

FB-Out

1st input channel

2nd input channel

3rd input channel

4th input channel

5th input channel

6th input channel

7th input channel

8th input channel

Table 3-2: FB AND outputs

Name Permitted type Description

AndOut TwinSAFE-Out

Output channel

FB-In

Standard-Out

Local-Out

Table 3-3: FB AND input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Local-Out TwinSAFE output at the KL6904 (not available for EL6900)

18

Function blocks for TwinSAFE logic terminals

Page 21

Function blocks

3.1.2.1 Diagnostic and status information for FB AND

Table 3-4: Diagnostic information (16-bit value)

Index Description

0-15 always 0

Table 3-5: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

3 SAFE

KL6904

Note

The checkboxes ‘Map State’ and ‘Map Diag’ are not available for the KL6904.

Function blocks for TwinSAFE logic terminals 19

Page 22

Function blocks

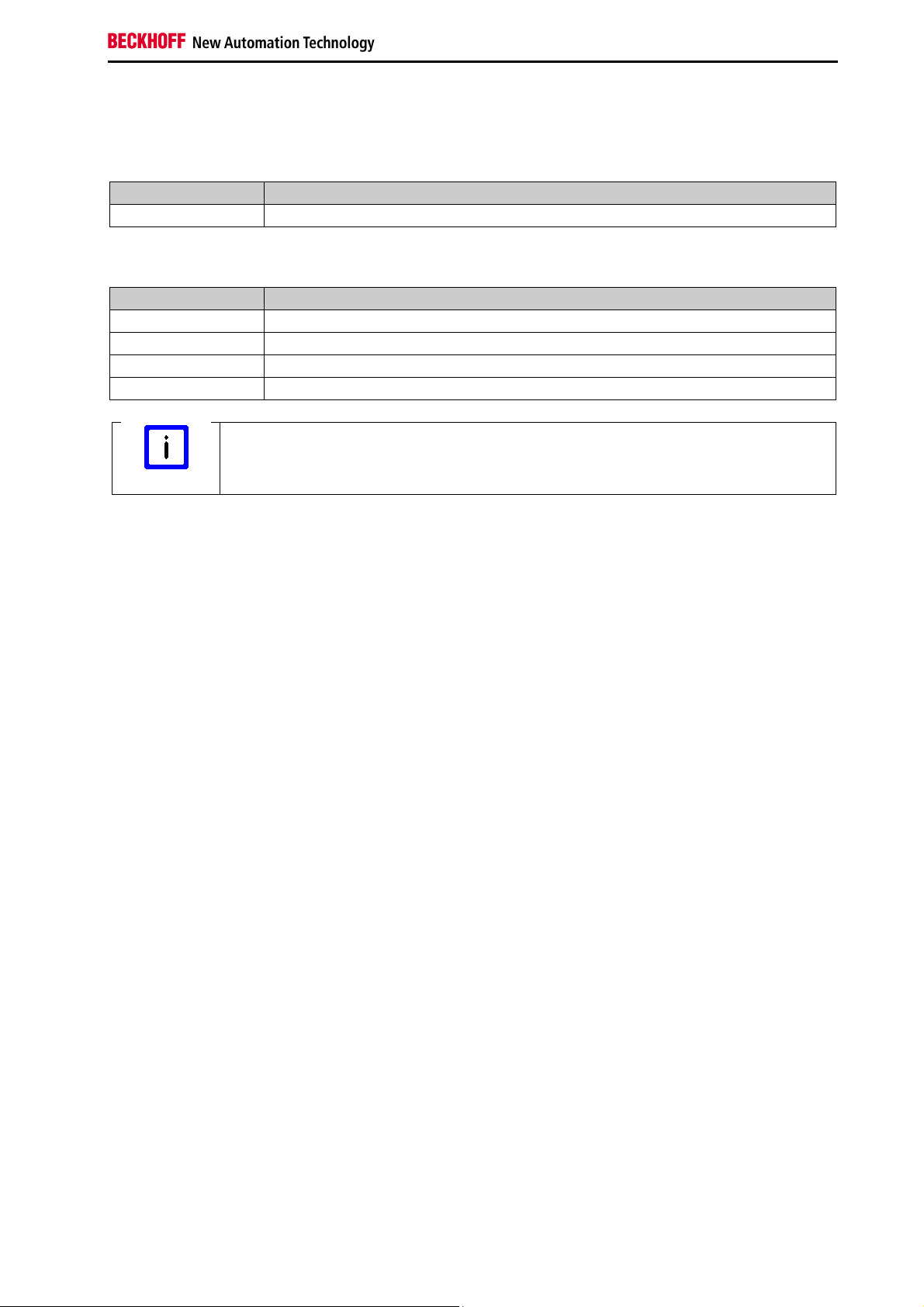

3.1.3 FB AND configuration in the TwinCAT System Manager

Figure 3-2: FB AND configuration

Their characteristics are configured with the setting buttons on the right near the two AndIn inputs,

whereby the inputs are always single-channel ones. A discrepancy monitoring cannot be used for the

AND.

The 'AndIn(x)' buttons can only be selected when the corresponding input has been activated. All inputs

are deactivated in the default setting.

The FB AND input variables are linked using the 'AndIn(x)' buttons.

The output variable of the FB AND are linked using the 'AndOut' button.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

The FB AND does not supply any error information and therefore the error button is basically deactivated.

20

Function blocks for TwinSAFE logic terminals

Page 23

Function blocks

3.2 The OR function block

3.2.1 Functional description

With the FB OR several input signals can be linked via OR to one output signal. In addition each input

can still be set even if the input signal is a normally closed contact (Break contact) or normally open

contact (Make contact). A normally open contact means that the corresponding input signal is negated,

before it affects the OR.

Figure 3-3: OR function block

Function blocks for TwinSAFE logic terminals 21

Page 24

Function blocks

3.2.2 Signal description

Table 3-6: FB OR inputs

Name Permitted type Description

OrIn1 TwinSAFE-In

FB-Out

OrIn2 TwinSAFE-In

FB-Out

OrIn3 TwinSAFE-In

FB-Out

OrIn4 TwinSAFE-In

FB-Out

OrIn5 TwinSAFE-In

FB-Out

OrIn6 TwinSAFE-In

FB-Out

OrIn7 TwinSAFE-In

FB-Out

OrIn8 TwinSAFE-In

FB-Out

1st input channel

2nd input channel

3rd input channel

4th input channel

5th input channel

6th input channel

7th input channel

8th input channel

Table 3-7: FB OR outputs

Name Permitted type Description

OrOut TwinSAFE-Out

Output channel

FB-In

Standard-Out

Local-Out

Table 3-8: FB OR input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Local-Out TwinSAFE output at the KL6904 (not available for EL6900)

22

Function blocks for TwinSAFE logic terminals

Page 25

Function blocks

3.2.2.1 Diagnostic and status information for FB OR

Table 3-9: Diagnostic information (16-bit value)

Index Description

0-15 always 0

Table 3-10: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

3 SAFE

KL6904

Note

The checkboxes ‘Map State’ and ‘Map Diag’ are not available for the KL6904.

Function blocks for TwinSAFE logic terminals 23

Page 26

Function blocks

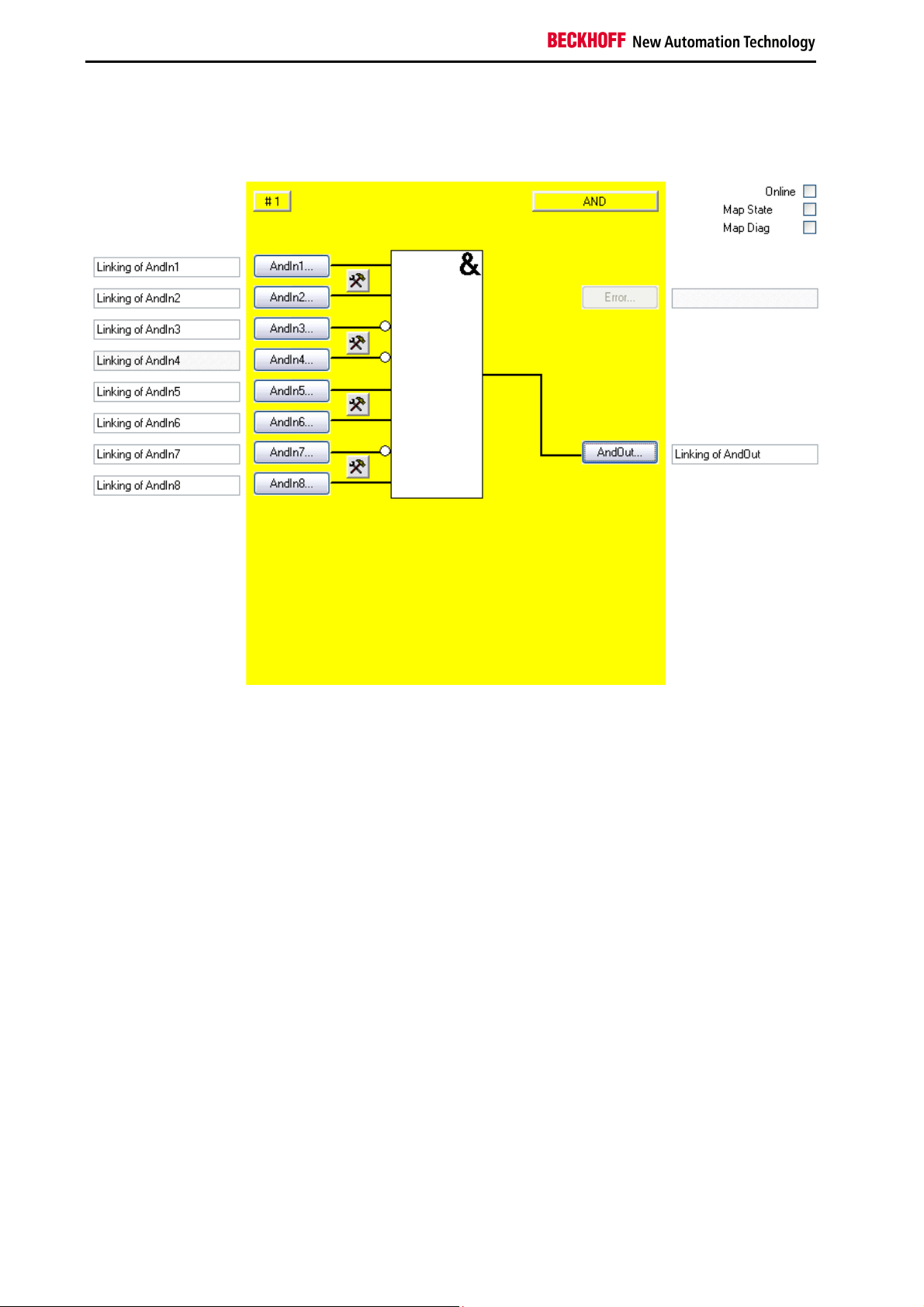

3.2.3 FB OR configuration in the TwinCAT System Manager

Figure 3-4: FB OR configuration

Their characteristics are configured with the setting buttons on the right near the two OrIn inputs, whereby

the inputs are always single-channel. A discrepancy monitoring cannot be used for the OR.

The ‘OrIn(x)’ buttons are only available once the corresponding input was activated. In the default setting

all inputs are disabled.

The FB OR input variables are linked using the 'OrIn(x)' buttons.

The output variable of the FB OR are linked using the 'OrOut' button.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

The FB OR does not supply any error information and therefore the error button is basically deactivated.

24

Function blocks for TwinSAFE logic terminals

Page 27

Function blocks

3.3 The OPMODE function block

3.3.1 Functional description

Operating mode selectors can be realized with the FB OPMODE. The function block has 8 inputs and 8

outputs, which are looped through one-to-one, whereby up to 8 different operating modes can be

selected. The FB OPMODE sets the corresponding output, only when an input is precisely set ("1"),

whereby the other outputs remain in a safe (“0”) state. All outputs are in a safe state if there is none or

more than one input is set. The output safe state can only be exited during start and change of operating

modes using a 0->1->0 signal sequence on the restart input, once the restart input is activated. In

addition a discrepancy time can be given, with which the change of operating mode can be monitored.

Figure 3-5: Function block OPMODE

Number of inputs

Note

Function blocks for TwinSAFE logic terminals 25

At least two inputs of FB OPMODE must be connected.

Page 28

Function blocks

3.3.2 Signal description

Table 3-11: FB OPMODE inputs

Name Permitted type Description

Restart TwinSAFE-In

FB-Out

Standard-In

OpIn1 TwinSAFE-In

FB-Out

OpIn2 TwinSAFE-In

FB-Out

OpIn3 TwinSAFE-In

FB-Out

OpIn4 TwinSAFE-In

FB-Out

OpIn5 TwinSAFE-In

FB-Out

OpIn6 TwinSAFE-In

FB-Out

OpIn7 TwinSAFE-In

FB-Out

OpIn8 TwinSAFE-In

FB-Out

The 0->1->0 signal sequence must be detected on the restart input,

before the safe state of the outputs can be removed, when starting the

FB or when all outputs are switched to the safe state.

1st input channel

2nd input channel

3rd input channel

4th input channel

5th input channel

6th input channel

7th input channel

8th input channel

26

Function blocks for TwinSAFE logic terminals

Page 29

Function blocks

Table 3-12: FB OPMODE outputs

Name Permitted type Description

Error TwinSAFE-Out

FB-In

Standard-Out

Local-Out

TRUE:

The discrepancy time monitoring or the input monitoring has

found an error. The acknowledgement of the error must be

carried out via the ERR_ACK input of the related TwinSAFE

group

FALSE:

No error was found.

OpOut1 TwinSAFE-Out

1st output channel

FB-In

Standard-Out

Local-Out

OpOut2 TwinSAFE-Out

2nd output channel

FB-In

Standard-Out

Local-Out

OpOut3 TwinSAFE-Out

3rd output channel

FB-In

Standard-Out

Local-Out

OpOut4 TwinSAFE-Out

4th output channel

FB-In

Standard-Out

Local-Out

OpOut5 TwinSAFE-Out

5th output channel

FB-In

Standard-Out

Local-Out

OpOut6 TwinSAFE-Out

6th output channel

FB-In

Standard-Out

Local-Out

OpOut7 TwinSAFE-Out

7th output channel

FB-In

Standard-Out

Local-Out

OpOut8 TwinSAFE-Out

8th output channel

FB-In

Standard-Out

Local-Out

Function blocks for TwinSAFE logic terminals 27

Page 30

Function blocks

Table 3-13: FB OPMODE input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Local-Out TwinSAFE output at the KL6904 (not available for EL6900)

3.3.2.1 Diagnostic and status information for FB OPMODE

Table 3-14: Diagnostic information (16-bit value)

Index Description

0 Discrepancy monitoring error

Table 3-15: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

3 SAFE

4 ERROR

5 RESET

6 START

KL6904

Note

The checkboxes ‘Map State’ and ‘Map Diag’ are not available for the KL6904.

28

Function blocks for TwinSAFE logic terminals

Page 31

Function blocks

3.3.3 FB OPMODE configuration in the TwinCAT System Manager

Figure 3-6: FB OPMODE configuration

The manual restart is activated using the "'Activated' " checkbox on the right near the 'Restart' button.

The inputs are activated via the 'Activated' check boxes to the right of the 'OpIn (x)' button.

The 'Restart' or 'OpIn(x)' buttons can only be selected, once the corresponding check box has been

selected.

The FB OPMODE input variables are linked using the 'Restart' and 'OrIn(x)' buttons.

The FB OPMODE output variables are linked using the 'Error' and 'OpOut(x)' buttons.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

The discrepancy time is configured using the 'Discrepancy' selection box.

Function blocks for TwinSAFE logic terminals 29

Page 32

Function blocks

3.4 The ESTOP function block

3.4.1 Functional description

An emergency stop circuit with up to eight emergency stop inputs (EStopIn1-EStopIn8) can be realized

with the FB ESTOP. Each of the eight inputs can be used as normally closed contact (Break contact - 0

requests the safe state) or normally open contacts (Make contact - 1 request the safe state). The first

output (EStopOut) goes immediately, and the second output (EStopDelOut) after a configurable time

delay, into the safe state ("0"), once an input requests the safe state. Several immediate (EStopOut) or

delayed switch-off (EStopDelOut) outputs can be realized with only one FB ESTOP, due to the possibility

to link the FB output to several outputs. The 0->1->0 signal sequence must be detected on the restart

input, before the safe state of the outputs can be exited.

Figure 3-7: Function block ESTOP

Apart from this a feedback loop can be activated for both outputs, whereby the EStopOut output is fed

back to the EDM1 input and the EStopDelOut output is fed back to the EDM2 output, using an external

circuit. The EDM inputs are tested as soon as the safe state on the restart input should be exited using

the 0->1->0 signal sequence. If the EDM inputs don't have the "1" signal state, the FB ESTOP goes into

error state and sets the output error to 1. The error state can only be exited again by a 0->1->0 signal

sequence on the ERR_ACK input of the related TwinSAFE group.

Furthermore each time 2 inputs (EStopIn1 and EStopIn2, EStopIn3 and EStopIn4, EStopIn5 and

EStopIn6 and EStopIn7 and EStopIn8) can be consolidated as input pairs, whereby the signal states of

both inputs can only deviate from each other within a configurable discrepancy time. If this discrepancy

time is exceeded for an input pair, the FB ESTOP will also go into the error state. The outputs go into the

safe state "0" if the FB is in error state. The characteristics for acknowledging a discrepancy error can be

set via the checkbox Safe Inputs after Disc Error. If the checkbox is set, both inputs of the input group that

has caused the discrepancy error have to return logical zero simultaneously before the error can be reset.

30

Function blocks for TwinSAFE logic terminals

Page 33

Function blocks

3.4.2 Signal description

Table 3-16: FB ESTOP inputs

Name Permitted type Description

Restart TwinSAFE-In

FB-Out

Standard-In

EStopIn1 TwinSAFE-In

FB-Out

EStopIn2 TwinSAFE-In

FB-Out

EStopIn3 TwinSAFE-In

FB-Out

EStopIn4 TwinSAFE-In

FB-Out

EStopIn5 TwinSAFE-In

FB-Out

EStopIn6 TwinSAFE-In

FB-Out

EStopIn7 TwinSAFE-In

FB-Out

EStopIn8 TwinSAFE-In

FB-Out

EDM1 TwinSAFE-In

FB-Out

Standard-In

EDM2 TwinSAFE-In

FB-Out

Standard-In

The 0->1->0 signal sequence must be detected on the restart input,

during start (when the related TwinSAFE group is started), or restart

(when an input has requested the safe state), before the safe state of

the outputs can be removed.

1st input channel: The parameterization determines, whether the input

will be a normally closed contact (Break contact – safe state will be

requested by logical 0) or normally open contact (Make contact – safe

state will be requested by logical 1).

2nd input channel, behaves like EStopIn1

If the discrepancy time is not equal 0, the 1st and 2nd input channel are

considered to be the 1st input pair and a discrepancy time monitoring is

carried out between both channels.

3rd input channel or 1st input channel of the 2nd input pair, otherwise

corresponds with EStopIn1

4th input channel or 2nd input channel of the 2nd input pair, otherwise

corresponds with EstopIn2

5th input channel or 1st input channel of the 3rd input pair, otherwise

corresponds with EStopIn1

6th input channel or 2nd input channel of the 3rd input pair, otherwise

corresponds with EstopIn2

7th input channel or 1st input channel of the 4th input pair, otherwise

corresponds with EStopIn1

8th input channel or 2nd input channel of the 4th input pair, otherwise

corresponds with EstopIn2

EDM1 is the feedback loop for the non-delayed output channel

(EStopOut). If this input is parameterized as active, the safe state of the

outputs will only be exited during restart, when the EDM1 supplies the

"1" signal.

EDM2 is the feedback loop for the delayed switching of the output

channel (EStopDelOut). If this input is parameterized as active, the safe

state of the outputs will only be exited during restart, when the EDM2

supplies the "1" signal.

Function blocks for TwinSAFE logic terminals 31

Page 34

Function blocks

Table 3-17: FB ESTOP outputs

Name Permitted type Description

Error TwinSAFE-Out

FB-In

Standard-Out

Local-Out

TRUE:

The discrepancy time monitoring of an input pair, or one of the

feedback loops, has found an error. The error reset must be

carried out via the ERR_ACK input of the related TwinSAFE group.

FALSE:

No error was found.

EStopOut TwinSAFE-Out

1st output channel, the safe state corresponds to a logical 0.

FB-In

Standard-Out

Local-Out

EStopDelOut TwinSAFE-Out

FB-In

Standard-Out

2nd output channel, the safe state corresponds to a logical 0. The

safe state is output with a delay, which corresponds to the

parameterized Delay Time.

Local-Out

Table 3-18: FB ESTOP input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Local-Out TwinSAFE output at the KL6904 (not available for EL6900)

3.4.2.1 Diagnostic and status information for FB ESTOP

Table 3-19: Diagnostic information (16-bit value)

Index Description

0 Discrepancy error input group 1

1 Discrepancy error input group 2

2 Discrepancy error input group 3

3 Discrepancy error input group 4

4 EDM monitoring error EDM1

5 EDM monitoring error EDM2

6 7 8

Discrepancy error input group 1 with activated option "Safe Inputs after Disc Error"

(set in addition to bit 0)

9

Discrepancy error input group 2 with activated option "Safe Inputs after Disc Error"

(set in addition to bit 1)

10

Discrepancy error input group 3 with activated option "Safe Inputs after Disc Error"

(set in addition to bit 2)

11

Discrepancy error input group 4 with activated option "Safe Inputs after Disc Error"

(set in addition to bit 3)

32

Function blocks for TwinSAFE logic terminals

Page 35

Function blocks

Table 3-20: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

3 SAFE

4 ERROR

5 RESET

6 START

8 DELAYOUT

KL6904

Note

The checkboxes ‘Map State’, ‘Map Diag’ and ‘Safe Inputs after Discrepancy Error’ are

not available in the KL6904.

3.4.3 FB ESTOP configuration in the TwinCAT System Manager

Figure 3-8: FB ESTOP configuration

The characteristics of an input pair are configured with the setting buttons on the right near the two

EStopIn inputs of this input pair.

The 'EStopIn(x)' buttons can only be selected when the associated input has been activated. All inputs

are deactivated in the default state.

Function blocks for TwinSAFE logic terminals 33

Page 36

Function blocks

The FB ESTOP input variables are linked using the 'Restart', 'EStopIn(x)' and 'EDM(x)' buttons.

The corresponding feedback loop is activated using the 'Activated' checkbox on the right near the

'EDM(x)' buttons. The 'EDM(x)' button can only be selected, if the associated feedback loop is activated.

The FB ESTOP output variables are linked using the 'Error', 'EStopOut' and 'EStopDelOut' buttons.

The delay time of the 'EStopDelOut' output is configured via the selection box 'Delay-Time'.

The characteristics for acknowledging a discrepancy error can be set via the checkbox ‘Safe Inputs after

Disc Error’. If the checkbox is set, both inputs of the input group that has caused the discrepancy error

have to return logical zero simultaneously before the error can be reset.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

34

Function blocks for TwinSAFE logic terminals

Page 37

Function blocks

3.5 The MON function block

3.5.1 Functional description

A safety door circuit with up to four inputs (MonIn(x)) can be realized with the FB MON for example. Each

of the four inputs can be used as normally closed contact (Break contact - 0 requests the safe state) or

normally open contact (Make contact - 1 request the safe state). The first output (MonOut) goes

immediately, and the second one (MonDelOut) after a configurable time delay, into the safe state "0",

once an input requests the safe state. Several immediate (MonOut) or delayed switch-off (MonDelOut)

outputs can be realized with only one FB MON, due to the linking possibility of the FB output with several

outputs.

In addition there are two Secure inputs, with which the request of the safe state can be bypassed through

the MonIn inputs. The Secure inputs can also be realized as normally closed contacts (Break contact) or

normally open contacts (Make contact).

The FB restart input can be activated. The 0->1->0 signal sequence must be detected on the restart

input, in case of an active restart, before the safe state of the outputs is exited. In case of an inactive

restart the safe state is exited once the MonIn or Secure inputs no longer request the safe state.

Figure 3-9: MON function block

In addition, a feedback loop can be activated for each output, whereby the MonOut output is fed back to

the EDM1 input and the MonDelOut output is fed back to the EDM2 input, using an external circuit. Die

EDM-inputs are tested once the safe state should be exited. The FB MON goes into error state in the

case of activated restart and sets the output error to 1, when the EDM inputs don't have the "1" signal

state. The FB MON remains in the safe state in the case of deactivated restart, when the EDM inputs

don't have the "1" signal state at the restart moment. An EDM error can therefore only be detected, when

the manual restart is active. The error state can only be exited again by a 0->1->0 signal sequence on the

Function blocks for TwinSAFE logic terminals 35

Page 38

Function blocks

ERR_ACK input of the related TwinSAFE group.

Furthermore each time 2 inputs (MonIn1 and MonIn2, MonIn3 and MonIn4 and Secure1 and Secure2)

can be consolidated as input pairs, whereby the signal states of both inputs can only deviate from each

other within a configurable discrepancy time. If this discrepancy time is exceeded for an input pair, the FB

MON will also go into the error state. The characteristics for acknowledging a discrepancy error can be

set via the checkbox ‘Safe Inputs after Disc Error’. If the checkbox is set, both inputs of the input group

that has caused the discrepancy error have to return logical zero simultaneously before the error can be

reset.

The safe state must have been requested at least once on each active MonIn input after starting the FB

MON if the manual function test is active, before an edge of the restart input reacts.

36

Function blocks for TwinSAFE logic terminals

Page 39

Function blocks

3.5.2 Signal description

Table 3-21: FB MON inputs

Name Permitted type Description

Restart TwinSAFE-In

FB-Out

Standard-In

MonIn1 TwinSAFE-In

FB-Out

MonIn2 TwinSAFE-In

FB-Out

MonIn3 TwinSAFE-In

FB-Out

MonIn4 TwinSAFE-In

FB-Out

Secure1 TwinSAFE-In

FB-Out

Secure2 TwinSAFE-In

FB-Out

EDM1 TwinSAFE-In

FB-Out

Standard-In

EDM2 TwinSAFE-In

FB-Out

Standard-In

The 0->1->0 signal sequence must be detected at the restart input,

during the start of the FB or when an input request the safe state, in

case a manual restart is active, before the safe state of the outputs is

exited.

This input is not used if the manual restart is inactive. Both starting and

exiting the safe state is carried out automatically, as long as no input

requests any longer the safe state.

1st input channel: The parameterization determines, whether the input

is linked to a normally closed contact (Break contact – safe state will

be requested by logical 0) or normally open contact (Make contact –

safe state will be requested by logical 1).

2nd input channel, behaves like MonIn1

If the discrepancy time is activated or used, the 1st and 2nd input

channels are considered to be the 1st input pair and a discrepancy time

monitoring is carried out between both channels.

3rd input channel or 1st input channel of the 2nd input pair, otherwise

corresponds with MonIn1

4th input channel or 2nd input channel of the 2nd input pair, otherwise

corresponds with MonIn2

If the Secure1 or Secure2 are parameterized as active, the evaluation

of the MonIn(x) inputs can be switched off. If Secure1 or Secure2 are

parameterized as normally closed contact (Break contact), the

MonIn(x) inputs are ignored if Secure1 and/or Secure2 are "1". If

Secure1 or Secure2 are parameterized as normally open contact

(Make contact), the MonIn(x) inputs are ignored if Secure1 and/or

Secure2 are "0". If the discrepancy time is activated or used, Secure1

and Secure2 are considered as an input pair and a discrepancy time

monitoring is carried out between both channels.

Secure2 is the 2nd channel of the input pair and otherwise corresponds

to Secure1.

EDM1 is the feedback loop for the non-delayed output channel

(MonOut). If this input is parameterized as active, the safe state of the

outputs will only be exited, when the EDM1 supplies the "1" signal.

EDM2 is the feedback loop for the delayed switching of the output

channel (MonDelOut). If this input is parameterized as active, the safe

state of the outputs will only be exited, when the EDM2 supplies the

"1" signal.

Function blocks for TwinSAFE logic terminals 37

Page 40

Function blocks

Table 3-22: FB MON outputs

Name Permitted type Description

Error TwinSAFE-Out

FB-In

Standard-Out

Local-Out

TRUE:

The discrepancy time monitoring of an input pair, or one of the

feedback loops, has found an error. The error reset must be

carried out via the ERR_ACK input of the related TwinSAFE

group.

FALSE:

No error was found.

MonOut TwinSAFE-Out

1st output channel, the safe state corresponds to a logical 0.

FB-In

Standard-Out

Local-Out

MonDelOut TwinSAFE-Out

FB-In

Standard-Out

2nd output channel, the safe state corresponds to a logical 0. The

safe state is output with a delay, which corresponds to the

parameterized Delay Time.

Local-Out

Table 3-23: FB MON input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Local-Out TwinSAFE output at the KL6904 (not available for EL6900)

3.5.2.1 Diagnostic and status information for FB MON

Table 3-24: Diagnostic information (16-bit value)

Index Description

0 Discrepancy error input group 1

1 Discrepancy error input group 2

2 Discrepancy error in Secure input group

4 EDM monitoring error EDM1

5 EDM monitoring error EDM2

38

Function blocks for TwinSAFE logic terminals

Page 41

Function blocks

Table 3-25: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

3 SAFE

4 ERROR

5 RESET

6 START

7 ERRORDELAY

8 DELAYOUT

9 FUNCTEST

KL6904

Note

The checkboxes ‘Map State’, ‘Map Diag’ and ‘Safe Inputs after Discrepancy Error’ are

not available in the KL6904.

3.5.3 FB MON configuration in the TwinCAT System Manager

Figure 3-10: FB MON configuration

The manual restart is activated using the "Manual" checkbox on the right near the 'Restart' button. The

'Restart' button can only be selected, if the manual restart is activated.

The characteristics of the input pair are configured with the setting buttons on the right near the two

Function blocks for TwinSAFE logic terminals 39

Page 42

Function blocks

MonIn or Secure inputs of an input pair. The 'MonIn(x)' or 'Secure(x)' buttons can only be selected when

the associated input has been activated. All inputs are deactivated by default.

The corresponding feedback loop is activated using the 'Activated' checkbox on the right near the

'EDM(x)' buttons. The 'EDM(x)' button can only be selected, if the associated feedback loop is activated.

The FB MON input variables are linked using the 'Restart', 'MonIn(x)', 'Secure(x)' and 'EDM(x)' buttons.

The manual function test is activated using the 'Manual Function Test' checkbox.

The FB MON output variables are linked using the 'Error', 'MonOut' and 'MonDelOut' buttons.

The FB MON output variables are linked using the 'Error', 'MonOut' and 'MonDelOut' buttons.

The characteristics for acknowledging a discrepancy error can be set via the checkbox ‘Safe Inputs after

Disc Error’. If the checkbox is set, both inputs of the input group that has caused the discrepancy error

have to return logical zero simultaneously before the error can be reset.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

40

Function blocks for TwinSAFE logic terminals

Page 43

Function blocks

3.6 The DECOUPLE function block

3.6.1 Functional description

The FB DECOUPLE is for uncoupling of signals from a TwinSAFE connection. The function block has 8

inputs and 8 outputs, whereby the inputs are looped one-to-one on the outputs. The associated output

must be linked as soon as one of the block inputs is used. The converse is also valid.

Figure 3-11: DECOUPLE function block

It is possible to subdivide and decouple the signals of a TwinSAFE connection into several TwinSAFE

groups, using the FB DECOUPLE, since a TwinSAFE connection is always assigned to a TwinSAFE

group. The block within an existing TwinSAFE group can be used to subdivide the signals. The block

must be used in a separate TwinSAFE group in case the signals should be decoupled, since all used

outputs of the TwinSAFE group can be switched off in case of a connection communication error. The

input signals of a TwinSAFE connection can now be linked with the FB DECOUPLE inputs, and the

outputs distributed over the different TwinSAFE groups. It operates the same way in the other directions,

the outputs of a TwinSAFE connection are linked with the FB DECOUPLE outputs, the FB DECOUPLE

inputs can once again come from various TwinSAFE groups.

Function blocks for TwinSAFE logic terminals 41

Page 44

Function blocks

3.6.2 Signal description

Table 3-26: FB DECOUPLE inputs

Name Permitted type Description

DecIn1 TwinSAFE-In

FB-Out

DecIn2 TwinSAFE-In

FB-Out

DecIn3 TwinSAFE-In

FB-Out

DecIn4 TwinSAFE-In

FB-Out

DecIn5 TwinSAFE-In

FB-Out

DecIn6 TwinSAFE-In

FB-Out

DecIn7 TwinSAFE-In

FB-Out

DecIn8 TwinSAFE-In

FB-Out

1st input channel

2nd input channel

3rd input channel

4th input channel

sht

5

input channel

6th input channel

7th input channel

8th input channel

42

Function blocks for TwinSAFE logic terminals

Page 45

Function blocks

Table 3-27: FB DECOUPLE outputs

Name Permitted type Description

DecOut1 TwinSAFE-Out

1st output channel

FB-In

Standard-Out

Local-Out

DecOut2 TwinSAFE-Out

2nd output channel

FB-In

Standard-Out

Local-Out

DecOut3 TwinSAFE-Out

3rd output channel

FB-In

Standard-Out

Local-Out

DecOut4 TwinSAFE-Out

4th output channel

FB-In

Standard-Out

Local-Out

DecOut5 TwinSAFE-Out

5th output channel

FB-In

Standard-Out

Local-Out

DecOut6 TwinSAFE-Out

6th output channel

FB-In

Standard-Out

Local-Out

DecOut7 TwinSAFE-Out

7th output channel

FB-In

Standard-Out

Local-Out

DecOut8 TwinSAFE-Out

8th output channel

FB-In

Standard-Out

Local-Out

Table 3-28: FB DECOUPLE input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Local-Out TwinSAFE output at the KL6904 (not available for EL6900)

Function blocks for TwinSAFE logic terminals 43

Page 46

Function blocks

3.6.2.1 Diagnostic and status information for FB DECOUPLE

Table 3-29: Diagnostic information (16-bit value)

Index Description

0 always 0

Table 3-30: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

KL6904

Note

The checkboxes ‘Map State’ and ‘Map Diag’ are not available for the KL6904.

44

Function blocks for TwinSAFE logic terminals

Page 47

Function blocks

3.6.3 FB DECOUPLE configuration in the TwinCAT System Manager

Figure 3-12: FB DECOUPLE configuration

The FB DECOUPLE input variables are linked using the 'DecIn(x)' buttons.

The FB DECOUPLE output variables are linked using the 'DecOut(x)' buttons.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

The FB DECOUPLE does not supply any error information and therefore the error button is basically

deactivated.

Function blocks for TwinSAFE logic terminals 45

Page 48

Function blocks

3.7 The TWO-HAND function block

3.7.1 Functional description

The FB TWO-HAND is used to realize a two-hand control unit in which both input groups have to be

operated simultaneously in order to switch the output. Repeated setting of the output is only possible if

both input groups were on logic 0 at the same time.

An input group can be configured as a single-channel input, two-channel input or two-channel input with

discrepancy time monitoring. In addition, time monitoring up to 2500 ms between the two input groups

can be defined. Each input can be configured as normally closed contact (NC) or normally open contact

(NO).

46

Note

Figure 3-13: TWO-HAND function block

KL6904

The two-hand block is not available in the KL6904.

Function blocks for TwinSAFE logic terminals

Page 49

Function blocks

3.7.2 Signal description

Table 3-31: FB TWO-HAND inputs

Name Permitted type Description

Twohand1

Twohand2

Twohand3

Twohand4

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

1st input channel. The parameterization determines, whether the

input is linked to a normally closed contact (safe state will be

requested by logical 0) or normally open contact (safe state will

be requested by logical 1).

2nd input channel, behaves like Twohand1

If the discrepancy time is not equal 0, the 1st and 2nd input

channel are considered to be the 1st input group and a

discrepancy time monitoring is carried out between both

channels, if one of the two input channels requests the safe

state.

3rd input channel or 1st input channel of the 2nd input group,

otherwise corresponds with Twohand1

4th input channel or 2nd input channel of the 2nd input group,

otherwise corresponds with Twohand2

Table 3-32: FB TWO-HAND outputs

Name Permitted type Description

Error

TwinSAFE-Out

FB-In

Standard-Out

TRUE:

The discrepancy time monitoring for a 2-channel input group has

detected an error. The error must be acknowledged via the

ERR_ACK input of the corresponding TwinSAFE group

FALSE:

No error was found

TwoHandOut

TwinSAFE-Out

1st output channel, the safe state corresponds to a logical 0.

FB-In

Standard-Out

Table 3-33: FB TWO-HAND input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Function blocks for TwinSAFE logic terminals 47

Page 50

Function blocks

3.7.2.1 Diagnostic and status information for FB TWO-HAND

Table 3-34: Diagnostic information (16-bit value)

Index Description

0 Discrepancy error input group 1

1 Discrepancy error input group 2

2 Discrepancy error between the two input groups

6 Two-hand error

Table 3-35: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

3 SAFE

4 ERROR

5 RESET

6 START

11 1BUTTON

12 2BUTTON

13 RELEASE

48

Function blocks for TwinSAFE logic terminals

Page 51

Function blocks

3.7.3 FB TWO-HAND configuration in the TwinCAT System Manager

Figure 3-14: FB TWO-HAND configuration

Discrepancy time monitoring for the two input groups is activated via the “Discrepancy” checkbox. The

discrepancy time can be set in the selection box next to the checkbox.

The characteristics of the input pair are configured with the setting buttons on the right near the two

TwoHand(x) inputs of an input pair. The 'TwoHand(x)' buttons can only be selected when the associated

input has been activated. All inputs are deactivated in the default state.

The FB TWO-HAND input variables are linked using the 'TwoHand(x)' buttons.

The buttons ‘Error’ and ‘TwoHandOut’ are used to link the output variables of FB Two-hand.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

Function blocks for TwinSAFE logic terminals 49

Page 52

Function blocks

3.7.4 Examples of two-hand control types according to DIN EN 574 : 1996

Figure 3-15: Type IIIC - category 4 application according to EN954-1:1996 with synchronous actuation

Figure 3-16: Type I - category 1 application according to EN954-1:1996 without synchronous actuation

50

Function blocks for TwinSAFE logic terminals

Page 53

Function blocks

3.8 The MUTING function block

3.8.1 Functional description

FB MUTING is used to realize specified suppression of the protective function, e.g. for transporting

material into the protection zone. The output of the block remains set, despite interruption of the

connected sensors.

The muting inputs are used to verify that they are operated in a defined order. Muting can be activated via

the Enable input. If the input is logic 0 an interruption of the protective device results in immediate

shutdown of the FB output. Otherwise only if the muting sequence is violated. The ‘SequentialInputs’

input can be used to specified whether 2 inputs are checked in parallel or sequentially. A filter time up to

500 ms can be set for the muting inputs in order to prevent bouncing of the muting signals and therefore

violation of the muting sequence. The maximum duration of the muting process can be monitored via the

‘Max. MutingTime’. The muting process starts with a logic 1 signal of the first muting input and ends with

the logic 0 signal of the last muting input. The value can be set to a maximum of 10 minutes or to 0, which

corresponds to deactivation of the monitoring. During this period the ‘MutingActive’ output of the block is

set. The protective device (AOPD - Active Opto-electronic Protection Device), for example a light grid, is

connected at the ‘OSSDIn(x)’ inputs. Feedback signals can be connected at the EDM inputs. In the

default setting the inputs are disabled. Direct outputs are connected via the ‘MuteOut’ button, outputs that

are delayed by up to 30 seconds via the ‘MuteDelOut’ button.

Figure 3-17: MUTING function block

KL6904

Note

Function blocks for TwinSAFE logic terminals 51

The Muting block is not available in the KL6904.

Page 54

Function blocks

3.8.2 Signal description

Table 3-36: FB MUTING inputs

Name Permitted type Description

Enable

MutingIn1

MutingIn2

MutingIn3

MutingIn4

EDM1

EDM2

OSSDIn1

OSSDIn2

TwinSAFE-In

FB-Out

Standard-In

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

Standard-In

TwinSAFE-In

FB-Out

Standard-In

TwinSAFE-In

FB-Out

TwinSAFE-In

FB-Out

Muting can be activated via the Enable input. If the input is logic 0 an

interruption of the protective device results in immediate shutdown of

the FB output.

The muting inputs are used to verify that they are operated in a

defined order.

1st input channel. The parameterization is used to specify whether

the input has to be negated or is used directly.

2nd input channel, behaves like MutingIn1

If the discrepancy time is not equal 0, the 1st and 2nd input channel

are considered to be the 1st input group and a discrepancy time

monitoring is carried out between both channels, if one of the two

input channels requests the safe state.

3rd input channel or 1st input channel of the 2nd input group, otherwise

corresponds with MutingIn1

4th input channel or 2nd input channel of the 2nd input group,

otherwise corresponds with MutingIn2

EDM1 is the feedback loop for the outlet channel (MuteOut), which is

switched off immediately. If this input as activated, the safe output

state is only exited when EDM1 is set to 1.

EDM2 is the feedback loop for the output channel (MuteDelOut),

which is switched off with a delay. If this input as activated, the safe

output state is only exited when EDM2 is set to 1.

The protective device (AOPD - Active Opto-electronic Protection

Device), for example a light grid, is connected at the ‘OSSDIn’ inputs.

1st input channel. The parameterization is used to specify whether

the input has to be negated or is used directly.

OSSDIn2 is the 2nd channel for the protective device and otherwise

matches OSSDIn1

52

Function blocks for TwinSAFE logic terminals

Page 55

Function blocks

Table 3-37: FB MUTING outputs

Name Permitted type Description

Error TwinSAFE-Out

FB-In

Standard-Out

TRUE:

The discrepancy time monitoring for a 2-channel input group

has detected an error, the muting sequence was violated, or

the maximum muting time exceeded. The error must be

acknowledged via the ERR_ACK input of the corresponding

TwinSAFE group.

FALSE:

No error was found

MutingActive TwinSAFE-Out

FB-In

1st outlet channel. It indicates the current muting process

through logic 1.

Standard-Out

MuteOut TwinSAFE-Out

1st output channel, the safe state corresponds to a logical 0.

FB-In

Standard-Out

MuteDelOut TwinSAFE-Out

FB-In

Standard-Out

2nd output channel, the safe state corresponds to a logical 0.

The safe state is output with a delay, which corresponds to the

parameterized Delay Time.

Table 3-38: FB MUTING input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

Function blocks for TwinSAFE logic terminals 53

Page 56

Function blocks

3.8.2.1 Diagnostic and status information for FB MUTING

Table 3-39: Diagnostic information (16-bit value)

Index Description

0 Discrepancy error in muting input group 1

1 Discrepancy error in the OSSD input group

2 Discrepancy error in muting input group 2

4 EDM monitoring error EDM1

5 EDM monitoring error EDM2

6 Muting sequence was violated

7 Maximum muting time was exceeded

Table 3-40: Status information (8-bit value)

Index Description

0 undefined

1 RUN

2 STOP

3 SAFE

4 ERROR

5 RESET

6 not used

7 not used

8 DELAYOUT

9 MUTING1

10 MUTING2

11 MUTING3

12 MUTING4

13 MUTING5

14 MUTING6

15 MUTING7

16 MUTING8

17 MUTING9

54

Function blocks for TwinSAFE logic terminals

Page 57

Function blocks

3.8.3 FB MUTING configuration in the TwinCAT System Manager

Figure 3-18: FB MUTING configuration

An input through which muting can be enabled can be connected via the ‘Enable’ button.

The ‘Muting(x)’ buttons are used to connect the muting sensors to the block. Use the Settings buttons to

the right of two muting inputs to configure them. The 'Muting (x)' buttons can only be selected when the

corresponding input has been activated. All inputs are deactivated in the default setting. Two-channel

evaluation with or without discrepancy time monitoring can be set if the checkbox “Sequential Inputs” is

not set. If the “Sequential Inputs” checkbox is set, only single-channel evaluation can be configured via

the Settings button. In addition, each input can be configured as a normally closed contact (NC) or as a

normally open contact (NO).

The maximum permitted muting period can be set via the ‘Max. Muting Time’ text box. If this time

exceeded the block switches to ERROR state. The maximum muting period is 10 minutes. It the value is

set to 0 minutes, monitoring is disabled.

A filter time up to 500 ms can be activated for the Muting(x) inputs via the “Filtertime Muting Inputs”

checkbox.

The ‘OSSDIn(x)’ inputs are connected with the signals from the protective device. Use the Settings button

to the right of the OSSDIn inputs to configure them. The setting options include single- or two-channel

evaluation or two-channel evaluation with discrepancy time monitoring.

Direct outputs are connected via the ‘MuteOut’ button, delayed outputs via the ‘MuteDelOut’ button. The

delay time of the 'MuteDelOut' output is configured via the selection box 'Delay-Time'.

The corresponding feedback loop is active using the 'Activated' checkbox on the right near the 'EDM(x)'

buttons. The 'EDM(x)' button can only be selected, if the associated feedback loop is activated.

The error state can be connected via the ‘Error’ button.

Function blocks for TwinSAFE logic terminals 55

Page 58

Function blocks

Via the ‘MutingActive’ button a signal can be linked that can be used for a muting lamp, for example.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

56

Function blocks for TwinSAFE logic terminals

Page 59

Function blocks

3.8.3.1 Configuration example with 4 individual muting sensors

Figure 3-19: Configuration example with FB MUTING

The following screenshot shows the parameterization of FB Muting for this case. The checkbox

‘Sequential Inputs’ is set, and the 4 muting inputs are configured and connected as single-channel inputs.

Figure 3-20: Muting example

Function blocks for TwinSAFE logic terminals 57

Page 60

Function blocks

Figure 3-21: Muting FB sequence

58

Function blocks for TwinSAFE logic terminals

Page 61

Function blocks

3.8.3.2 Configuration example with two two-channel muting sensors

Figure 3-22: Configuration example with two two-channel muting sensors

The following screenshot shows the parameterization of FB MUTING for this case. The checkbox

‘Sequential Inputs’ is not set, and the 4 muting inputs are configured and connected as two-channel

inputs with discrepancy time monitoring.

Figure 3-23: Muting example

Function blocks for TwinSAFE logic terminals 59

Page 62

Function blocks

Figure 3-24: Muting FB sequence

60

Function blocks for TwinSAFE logic terminals

Page 63

Function blocks

3.9 The EDM function block

3.9.1 Functional description

The FB EDM (External Device Monitor) is used for time monitoring of signals Mon1 and Mon2. Switch-on

and switch-off monitoring can be configured. Both monitoring functions are inactive by default.

Switch-on monitoring checks whether signal Mon2 is set to 0 within the set time (maximum 10000 ms)

following a switch from 0 to 1 of signal Mon1.

Switch-off monitoring checks whether signal Mon2 is set to 1 within the set time (maximum 10000 ms)

following a switch from 1 to 0 of signal Mon1.

If the set monitoring time is exceeded the error output for the block is set. It can be reset via the ErrAck

signal for the TwinSAFE group.

Figure 3-25: EDM function blocks

KL6904

Note

Function blocks for TwinSAFE logic terminals 61

The EDM block is not available in the KL6904.

Page 64

Function blocks

3.9.2 Signal description

Table 3-41: FB EDM inputs

Name Permitted type Description

Mon1

Mon2

Table 3-42: FB EDM outputs

Name Permitted type Description

Error

TwinSAFE-In

FB-Out

Standard-In

TwinSAFE-In

FB-Out

Standard-In

TwinSAFE-Out

FB-In

Standard-Out

1st input. The input can be parameterized as an normally closed

contact or an normally open contact.

2nd input, which has to assume a value opposite to input 1 within the

set times.

TRUE:

SwitchOn or SwitchOff times were exceeded.

FALSE:

No error occurred.

Table 3-43: FB EDM input and output types

Type Description

TwinSAFE-In TwinSAFE input at an EL1904/KL1904

Standard-In Standard PLC variable (output in the PLC %Q*)

FB-Out TwinSAFE FB output

TwinSAFE-Out TwinSAFE output at an EL2904/KL2904

Standard-Out Standard PLC variable (input in the PLC %I*)

FB-In TwinSAFE FB input

3.9.2.1 Diagnostic and status information for FB EDM

Table 3-44: Diagnostic information (16-bit value)

Index Description

0 Switch-OFF timer elapsed

1 Switch-ON timer elapsed

Table 3-45: Status information (8-bit value)

Index Description

0 undefined

2 STOP

4 ERROR

5 RESET

14 MON_OFF

15 MON_ON

62

Function blocks for TwinSAFE logic terminals

Page 65

Function blocks

3.9.3 FB EDM configuration in the TwinCAT System Manager

Figure 3-26: FB EDM configuration

The FB EDM input variables are linked using the 'Mon1' and 'Mon2' buttons.

Use the Settings button to right or the two Mon inputs to configure them. Only single-channel evaluation is

available. In addition the inputs can be configured as normally open contact (NO) or normally close

contact (NC).

Use the ‘Switch-On Monitoring’ and ‘Switch-Off Monitoring’ selection boxes to set the switch-on and

switch-off delay time. Use the checkboxes to the left of the text fields to activate the corresponding

monitoring time. The default state is deactivated.

Use the ‘Error’ button to transfer a block error to the connected output variable. In online mode the state

and error IDs are filled with corresponding information.

The ‘MapState’ and ‘MapDiag’ checkboxes are used to specify which FB diagnostic functions are mapped

to the cyclic process image.

Function blocks for TwinSAFE logic terminals 63

Page 66

Function blocks

3.10 The RS function block

3.10.1 Functional description