Page 1

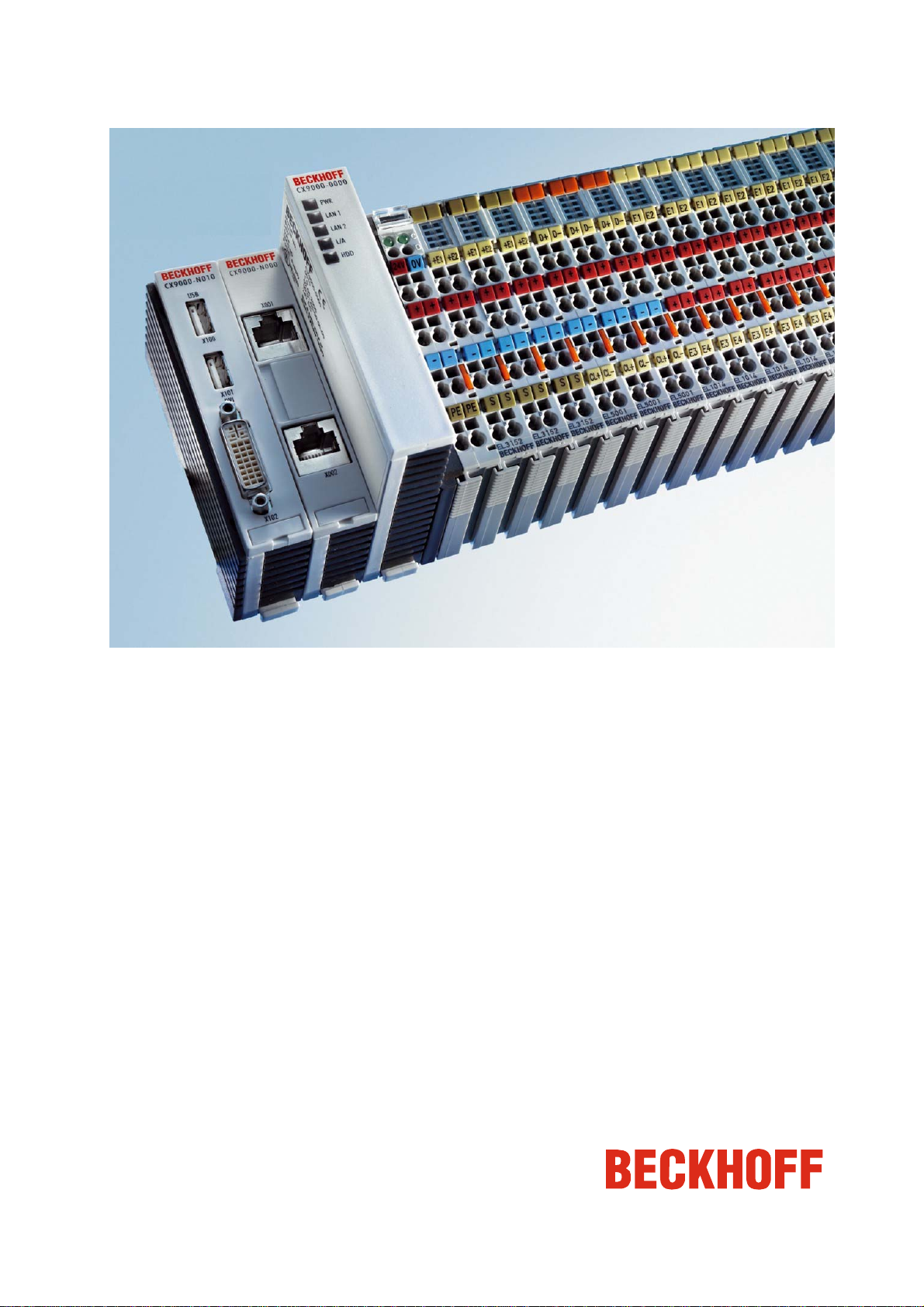

Hardware documentation

for CX90x0 Ethernet controller

CX900x-xxxx

CX901x-xxxx

CX90x0-Nxxx

version:2.4

date:2008-06-11

Page 2

Page 3

Table of contents

Table of contents

1. Foreword

Notes on the documentation

Safety instructions 4

Documentation issue status 6

2. Product overview 7

Appropiate use 7

System overview 8

Basic modules 9

Technical data 9

CX900x-0xxx (E-bus) 10

CX900x-1xxx (K-bus)

CX9010-0xxx (E-bus)

CX9010-1xxx (K-bus) 13

Configurations CX9000 14

Configurations CX9010 15

Connections 16

Battery compartment 20

DIP switch settings 21

11

12

System interfaces 24

Technical data 24

Connections CX9000-N010 25

Connections CX9000-N030 27

Connections CX9000-N031 28

3. Transport 31

Unpacking, installation and transport 31

4. Assembly and connecting 32

Mechanical assembly 32

Dimensions 32

Mechanical assembly of basic module 35

Mechanical assembly of UPS module 37

Start-up procedure 40

Start-up procedure 40

5. Error handling and diagnostics 41

CPU basic module 41

LED basic module E-Bus 41

LED basic module K-Bus 42

K-Bus diagnosis with TwinCAT 44

6. Decomissioning 46

Removal and disposal 46

Embedded PC

Page 4

Table of contents

7. Appendix 48

Update image 48

Accessories 57

Certifications 58

Support and service 59

2 Embedded PC

Page 5

Foreword

1. Foreword

Notes on the Documentation

This description is only intended for the use of trained specialists in control and automatio n engineering who are

familiar with the applicable national standards. It is essential that the following notes and explanati ons are followed

when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. None of the statements of this manual represents a guarantee (Garantie) in the

meaning of § 443 BGB of the German Civil Code or a statement about the contractually expected fitness for a

particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this

documentation.

© This documentation is copyrighted. Any reproduction or third party use of this publication, whether in whole or in

part, without the written permission of Beckhoff Automation GmbH, is forbidden.

Embedded PC 3

Page 6

Foreword

Safety Instructions

Safety Rules

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the application.

Modifications to hardware or software configurations other than those described in the documentation are not

permitted, and nullify the liability of Beckhoff Automation GmbH.

Personnel Qualification

This description is only intended for the use of trained specialists in control and automatio n engineering who are

familiar with the applicable national standards.

Description of safety symbols

The following safety symbols are used in this operating manual. They are intended to alert the reader to the

associated safety instructions

Danger

This symbol is intended to highlight risks for the life or health of personnel.

Warning

This symbol is intended to highlight risks for equipment, materials or the environment.

Note

This symbol indicates information that contributes to better understanding.

Operator's obligation to exercise diligence

The operator must ensure that

· the product is only used for its intended purpose.

· the product is only operated in sound condition and in working order.

· the instruction manual is in good condition and complete, and always available for reference at the location where

the products are used.

· the product is operated only by suitably qualified and authorised personnel.

· the personnel is instructed regularly about relevant occupational safety and environmental protection aspects, and is

familiar with the operating manual and in particular the safety notes contained herein.

National regulations depending on the machine type

Depending on the type of machine and plant in which the product is used, national reg ulations governing the

controllers of such machines will apply, and must be observed by the operator. These regulations cover, amongst

4 Embedded PC

Page 7

Foreword

other things, the intervals between inspections of the controller. The operator must initiate such inspections in good

time.

Operator requirements

Read the operating instructions

All users of the product must have read the operating instructions for the system they work with.

System know-how

All users must be familiar with all accessible functions of the product.

Embedded PC 5

Page 8

Foreword

Documentation Issue Status

Version Changes

2.4 system interfaces CX1200-xxxx removed

2.3 new installation positions are added

2.2 changes in names of system interfaces CX90x0-N070 and CX90x0-N080 inserted

2.1 notes on new system interfaces CX90x0-N070 and CX90x0-N08 0 added

2.0 notes on UL added

1.9 order information changed

1.8 notes on K-Bus diagnosis added

1.7 notes on USV and CF card handling added title picture changed

1.6 Notes on software image update

1.5 cable length for DVI cable corrected

1.4 consumption value for CX1020-A001 added

1.3 notes on dip switches and image update added

1.2 information for CF-cards changed, errors in product numbers corrected

1.1 notes for system interface N010 added

1.0 revised version

0.0.1 preliminarily version

6 Embedded PC

Page 9

Product overview

2. Product overview

Appropriate Use

The CX-SYSTEM device series is a modular control system designed for top-hat rail installation. The system is

scalable, so that the required modules can be assembled and installed in the control cabinet or terminal box as

required.

Only switch the PC off after closing the software

Before the Embedded PC is switched off, the software currently running on it should be stopped properly in order to

avoid data loss on the hard disk. Please read the section on “Switching off”.

Switch off all system components and uncouple the Industrial PC from the system if the PC is not used for control

purposes, e.g. during a function test.

System components that have been switched off must be secured against being switched on again.

The power supply unit of the Embedded PC requires a 24 V DC supply.

Danger

Do not exchange any parts when under power!

When components are being fitted or removed, the supply voltage must be switched off.

Software knowledge

Warning

Mandatory software knowledge!

Every user must be familiar with any of the functions of the software installed on the PC that he can reach.

Embedded PC 7

Page 10

Product overview

System overview

Ethernet-Controller CX9000

With the Ethernet controller CX9000, Beckhoff presents a further extension of the family of CX-type embedded

controllers. The CX9000 is a compact, high-performance yet cost-effective PLC and motion controller for 30 mm DIN

rail mounting. Within the Beckhoff control world it is positioned between the Bus Terminal Controller series BX and

the Embedded PC CX1000. The main feature of this devices is an energy-saving 266 MHz Intel® IXP420 CPU with

XScale® technology that runs under the Microsoft Windows CE operating system. It thus offers adequate computing

capacity even for complex automation tasks. The CX9000 requir es no external storage media – the device boots the

operating system from the internal fl ash. Due to the low power consumption, within the specified operating range no

fan is required. The CX9000 therefore requires no rotating components. As usual for the CX series, the device

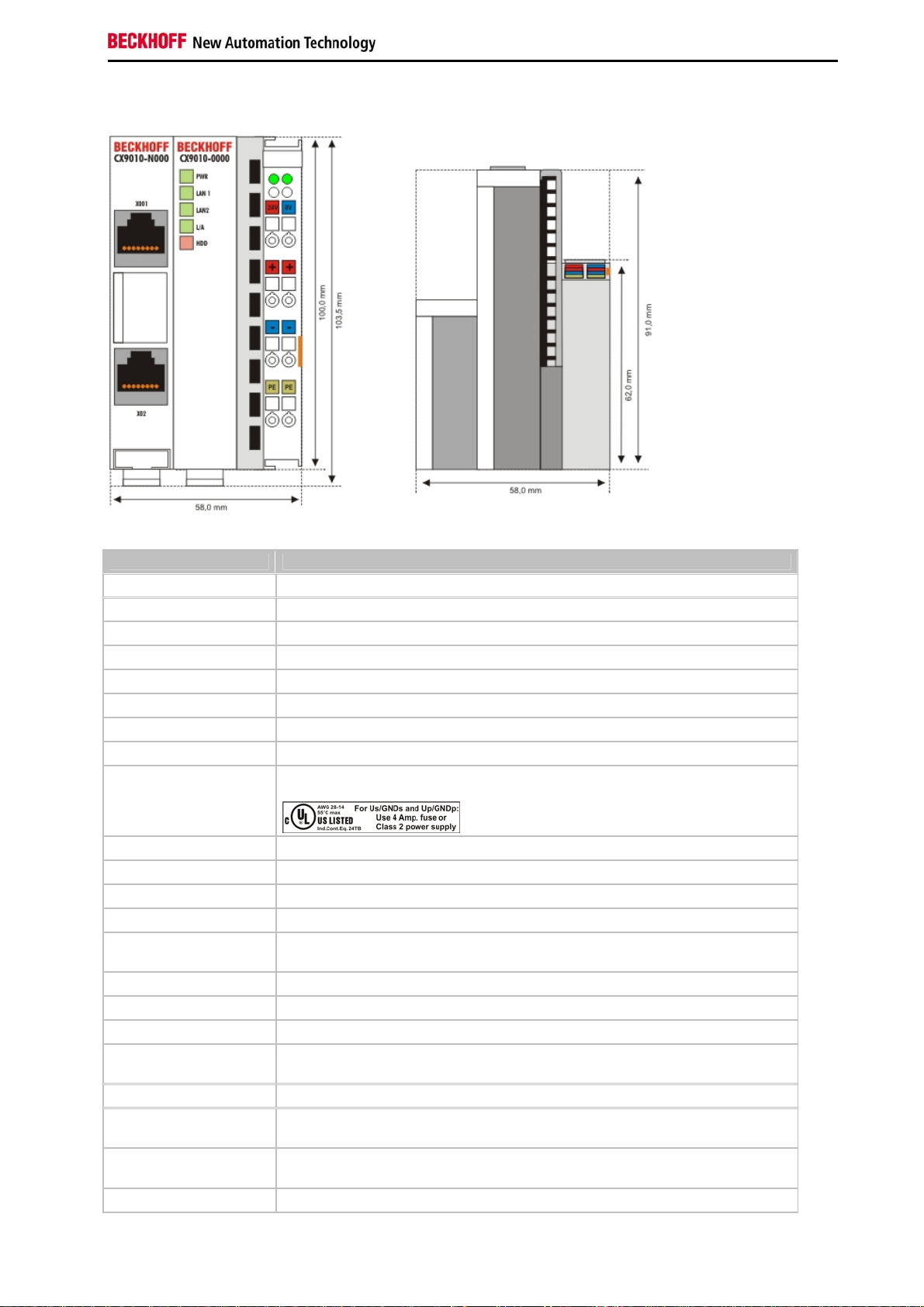

features a modular mechanical design. In its basic configuration, the compact device only measures 58 x 100 x 91

mm.

EtherCAT as fast I/O-System / K-Bus as alternative I/O-System

The CX9000 is available in two versions: with K-bus for direct connection of Bus Terminals, and as a n E-bus version

for direct connection of EtherCAT Terminals. In the basic confi guration, two RJ 45 sockets that are internally

connected to an integrated switch are available as interfaces. This simplifies wiring of several CX9000 within a line

topology. No separate switch hardware is required. The t wo externally accessible Ether net ports are independent of

the EtherCAT interface, which is served by a second MAC (media access controller) provided by the CPU.

Basic module and Systeminterfaces

Further interfaces may be added ex works as required: A screen display can be realized using a CX9000-N001

device, i.e. a module combining DVI/ VGA + 2 x USB 2.0. The combination of DVI and USB enables all types of

Beckhoff Control Panel with DVI/USB interface to be used. Touch functionality is connected via USB. As a further

option, two RS232 modules or two RS422/RS485 modules can be configured as COM1 and COM2. All serial

interfaces feature opto-decoupling. Mass storage in form of a Compact Flash card can be used via the CX9000-A000

module, which offers physical storage capacity in the range of several gigabytes.

SPS, Motion Control and Visualization

Like for all Beckhoff controllers, TwinCAT is used for programming the CX9000 as an automation device. The device

itself contains the run-time environment for PLC and Motion Control. One of the two Ethernet interfaces is used as

programming interface.

Software

Microsoft Windows CE enables the creation of fully graphic user programs,which are able to satisf y high

expectationsthanks to the graphics chip integrated in the CX9000.

In summary, the CX9000 is a compact Ethernet controller, which in combination with EtherCAT I/O allows very fast

I/O control cycles. Windows CE and TwinCAT CE constitute the powerful software architecture for this controller.

8 Embedded PC

Page 11

Product overview

Basic modules

Ethernet-Controller CX90x0

The CX9000 is a compact, top hat rail-mountable Ethernet Controller with direct connection to the Beckhoff I/O

systems in IP 20. The CX90x0 is available in four basic versions: two version for Bus Terminals with K-bus, the other

two for EtherCAT Terminals with E-bus. The CX90x0 comprises the CPU (available in 266 MHz an d 533 MHz), the

internal flash memory with two configuration options, the main memory (RAM) (available in two different sizes), and

NOVRAM as non-volatile memory. Two Ethernet RJ 45 interfaces are also part of the basic configuration. These

interfaces are connected to an internal switch and offer a simple option for creating a line topology without the need

for additional Ethernet switches. A memory medium in Compact Flash format I and II is available as an optional

module.(only in combination with system interface CX90x0-N010) The operating system is Microsoft W indows CE.

The TwinCAT automation software transforms a CX90x0 system into powerful PLC and Motion Control system that

can be operated with or without visualization. Further system interfaces can be connected to the CPU module ex

works. The CX9000-N010 option can be connected to Beckhoff Control Panels or standard monitors with DVI or VGA

input via the DVI and USB interfaces. Devices such as printer, scanner, mouse, keyboard, mass storage, CR-RW etc.

can be connected via the USB2.0 interfaces. The module CX90x0-N030 of fers two serial RS232 interfaces with a

maximum transfer speed of 115 kbaud. These two interfaces can be implemented as RS422/RS48 5, in which case

they are identified as CX90x0-N031.

The Ethernet-Controller CX90xx is offered in four versions:

• CX900x-0000 E-bus connection

• CX900x-1000 K-bus connection

• CX9010-0000 E-bus connection

• CX9010-1000 K-bus connection

Embedded PC 9

Page 12

Product overview

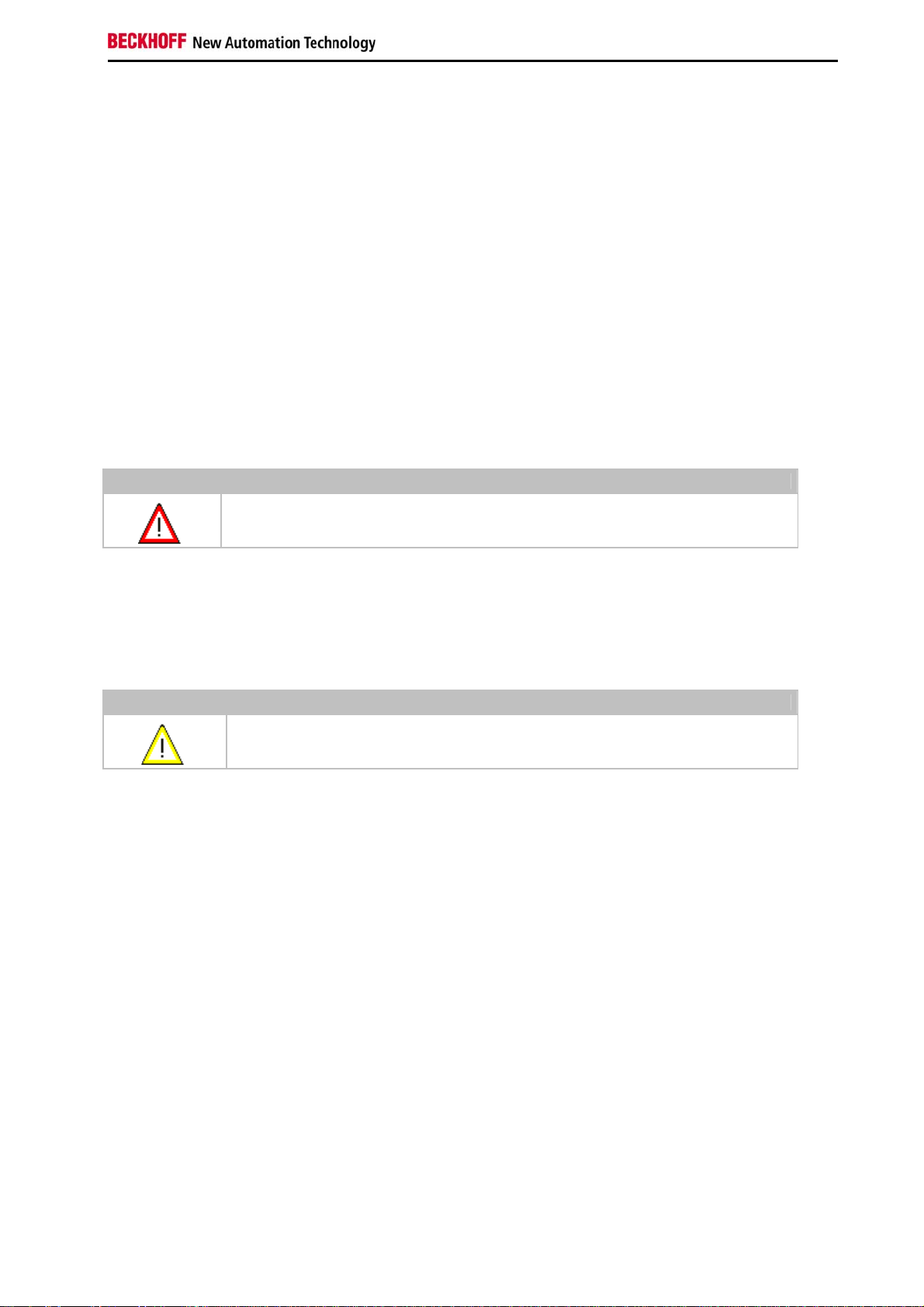

Technical data – CX9000-0000 E-bus connection

Technical data CX9000-0000

Processor Intel® IXP420 with Xscale® Te chnology, 266-MHz clock rate

Internal flash memory 16 Mbyte Flash (internal, expandable up to 32 Mbyte)

Internal main memory 64 Mbyte RAM (internal, expandable up to 128 Mbyte)

interfaces 2 x RJ 45 (internal Switch), 10/100 Mbit

Diagnostics LEDs 1 x Power, 2 x LAN, 1 x L/A, 1 x flash access

Clock internal battery-backed clock for time and date

Operating system Microsoft Windows CE

Control software TwinCAT-CE-PLC-Runtime or TwinCAT-CE-NC-PTP-Runtime

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

I/O connection E-bus (EtherCAT Terminals)

NOVRAM 128 kByte

I/O-DPRAM Power supply I/O

terminals

Max. power loss 6 W (including CX9000-xxxx system interfaces)

Dimensions (W x H x D) 59 mm x 100 mm x 91 mm

weight ca. 250 g

Operating / storage

temperature

Relative humidity 95% no condensation

Vibration/shock

resistance

EMC resistance

burst/ESD

Protection class IP 20

2 A

0° C ... +50° C / -25° C ... +85° C

conforms to EN 60068-2-6 / EN 60068-2-27/29

conforms to EN 61000-6-2/EN 61000-6-4

(supply/internal electronics)

rms

10 Embedded PC

Page 13

Product overview

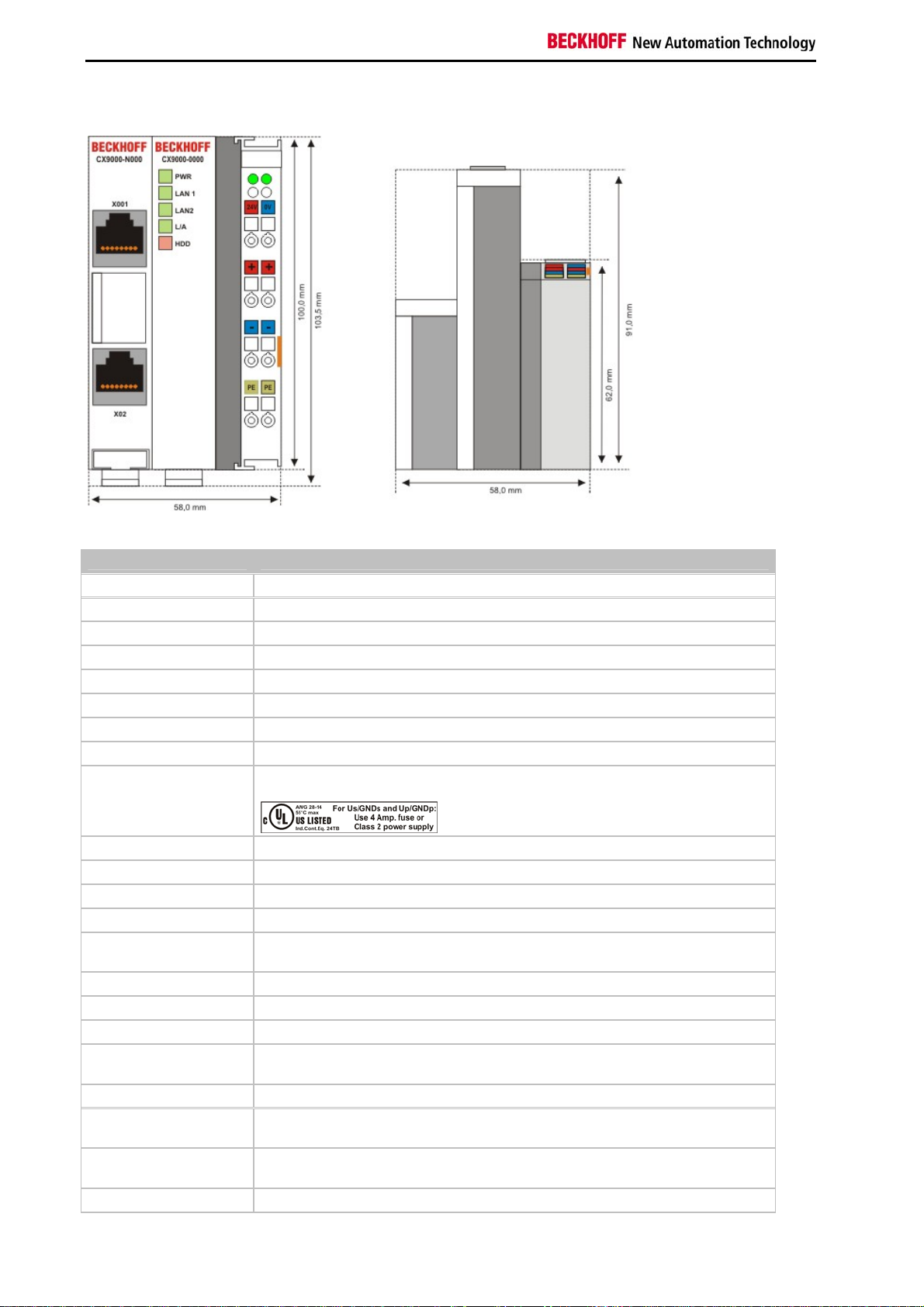

Technical data CX9000-1000 K-bus connection

Technical data CX9000-1000

Processor Intel® IXP420 with XScale® Technology, 266-MHz clock rate

Internal flash memory 16 MByte Flash (internal, expandable up to 32 MByte)

Internal main memory 64 MByte RAM (internal, expandable up to 128 MByte)

interfaces 2 x RJ 45 (internal Switch), 10/100 MBit

Diagnostics LEDs 1 x Power, 2 x LAN, 1 x K-Bus, 1 x Flash-Zugriff

Clock internal battery-backed clock for time and date

Operating system Microsoft Windows CE

Control software TwinCAT-CE-PLC-Runtime or TwinCAT-CE-NC-PTP-Runtime

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

(supply/internal electronics)

rms

I/O connection K-bus (Bus Terminals)

NOVRAM 128 kByte

I/O-DPRAM 4 kByte

Power supply I/O

2 A

terminals

Max. power loss 6 W (including CX9000-xxxx system interfaces)

Dimensions (W x H x D) 59 mm x 100 mm x 91 mm

weight ca. 250 g

Operating / storage

0° C ... +50° C / -25° C ... +85° C

temperature

Relative humidity 95% no condensation

Vibration/shock

conforms to EN 60068-2-6 / EN 60068-2-27/29

resistance

EMC resistance

conforms to EN 61000-6-2/EN 61000-6-4

burst/ESD

Protection class IP 20

Embedded PC 11

Page 14

Product overview

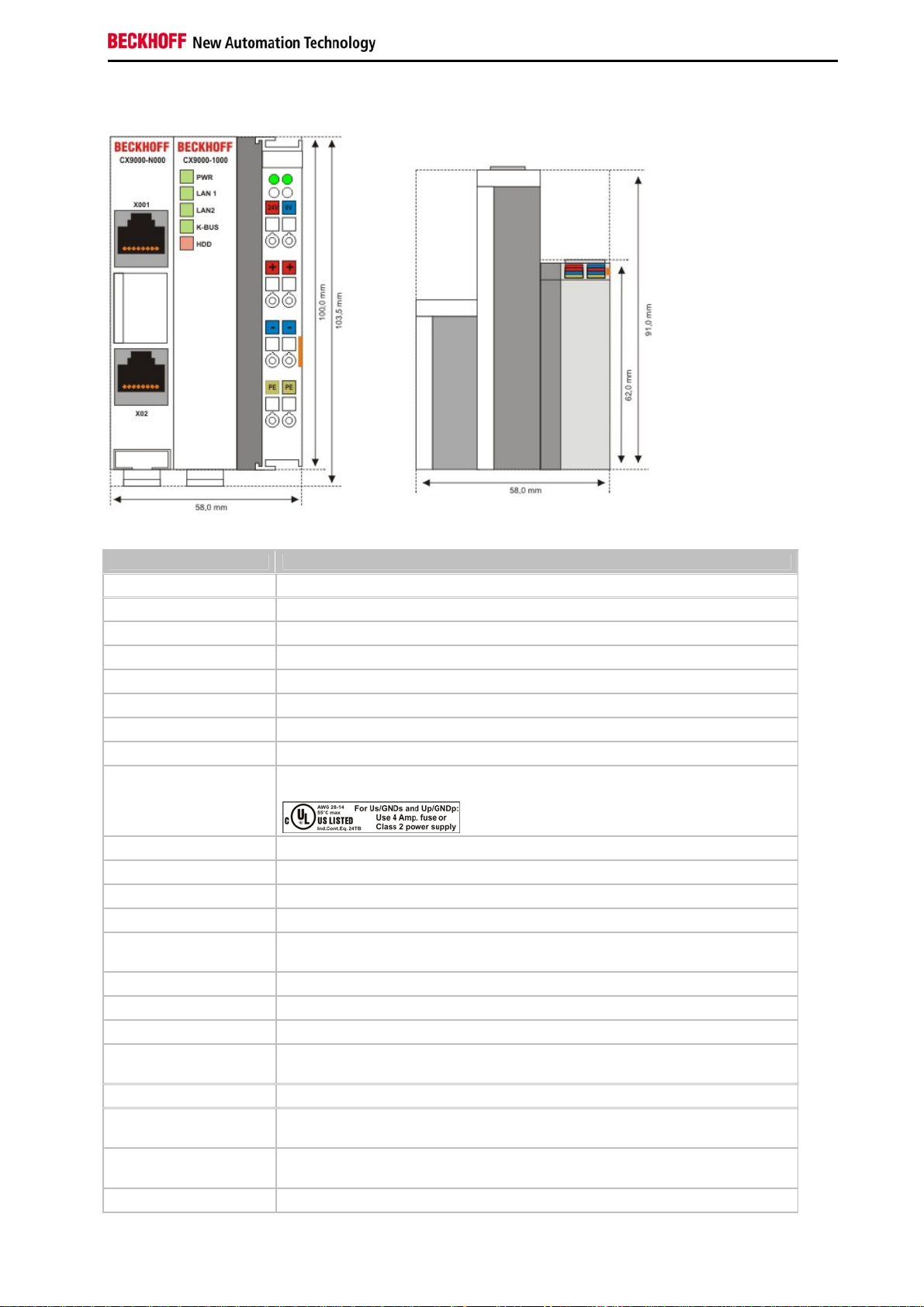

Technical data – CX9010-0000 E-bus connection

Technical data CX9010-0000

Processor Intel® IXP420 with Xscale® Te chnology, 533-MHz clock rate

Internal flash memory 32 Mbyte Flash (internal)

Internal main memory 128 Mbyte RAM (internal)

interfaces 2 x RJ 45 (internal Switch), 10/100 Mbit

Diagnostics LEDs 1 x Power, 2 x LAN, 1 x L/A, 1 x flash access

Clock internal battery-backed clock for time and date

Operating system Microsoft Windows CE

Control software TwinCAT-CE-PLC-Runtime or TwinCAT-CE-NC-PTP-Runtime

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

I/O connection E-bus (EtherCAT Terminals)

NOVRAM 128 kByte

I/O-DPRAM Power supply I/O

terminals

Max. power loss 7 W (including CX9000-xxxx system interfaces)

Dimensions (W x H x D) 59 mm x 100 mm x 91 mm

weight ca. 250 g

Operating / storage

temperature

Relative humidity 95% no condensation

Vibration/shock

resistance

EMC resistance

burst/ESD

Protection class IP 20

2 A

0° C ... +50° C / -25° C ... +85° C

conforms to EN 60068-2-6 / EN 60068-2-27/29

conforms to EN 61000-6-2/EN 61000-6-4

(supply/internal electronics)

rms

12 Embedded PC

Page 15

Product overview

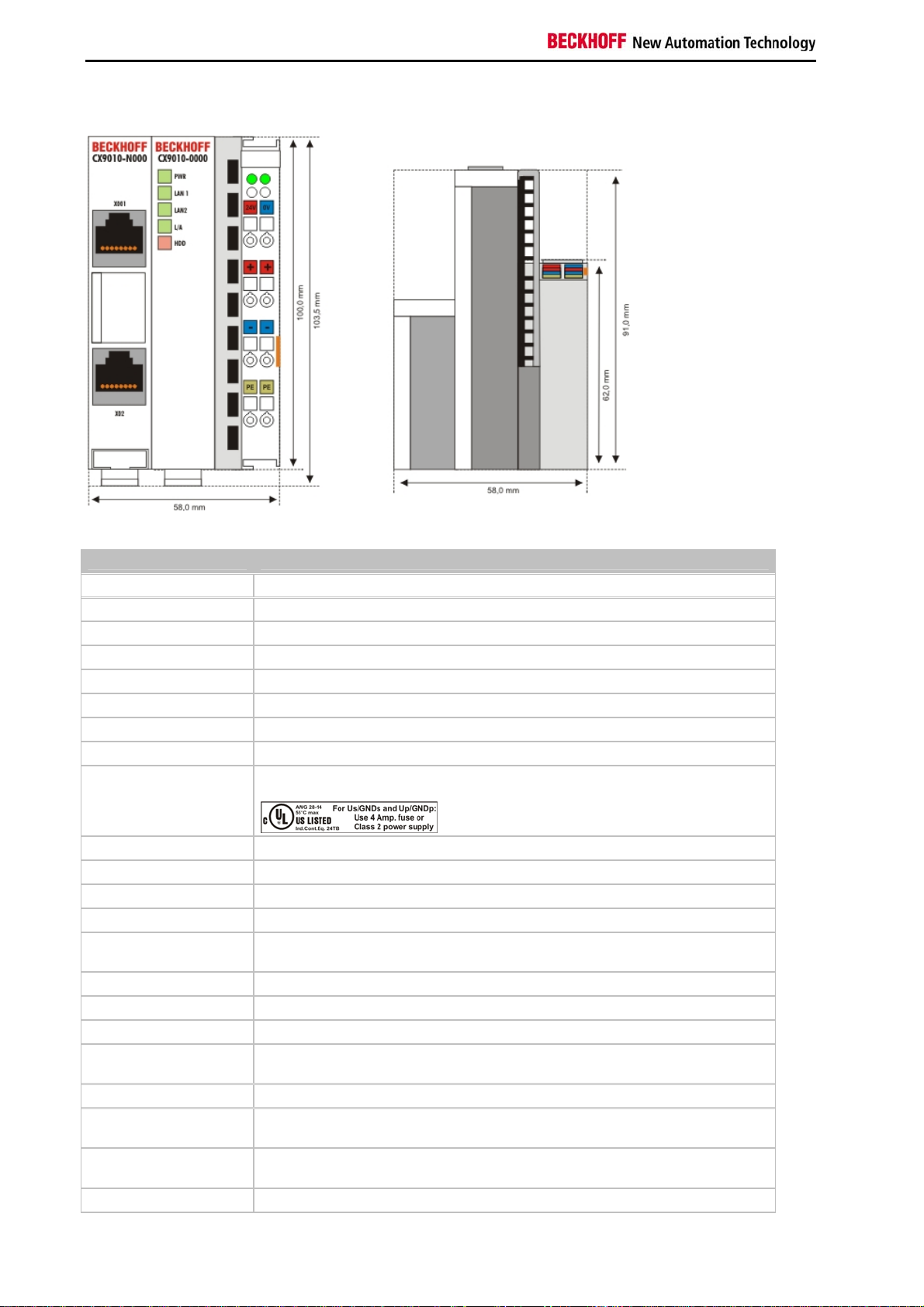

Technical data CX9010-1000 K-bus connection

Technical data CX9010-1000

Processor Intel® IXP420 with XScale® Technology, 533-MHz clock rate

Internal flash memory 32 MByte Flash (internal)

Internal main memory 128 MByte RAM (internal)

interfaces 2 x RJ 45 (internal Switch), 10/100 MBit

Diagnostics LEDs 1 x Power, 2 x LAN, 1 x K-Bus, 1 x Flash-Zugriff

Clock internal battery-backed clock for time and date

Operating system Microsoft Windows CE

Control software TwinCAT-CE-PLC-Runtime or TwinCAT-CE-NC-PTP-Runtime

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

(supply/internal electronics)

rms

I/O connection K-bus (Bus Terminals)

NOVRAM 128 kByte

I/O-DPRAM 4 kByte

Power supply I/O

2 A

terminals

Max. power loss 7 W (including CX90x0-xxxx system interfaces)

Dimensions (W x H x D) 59 mm x 100 mm x 91 mm

weight ca. 250 g

Operating / storage

0° C ... +50° C / -25° C ... +85° C

temperature

Relative humidity 95% no condensation

Vibration/shock

conforms to EN 60068-2-6 / EN 60068-2-27/29

resistance

EMC resistance

conforms to EN 61000-6-2/EN 61000-6-4

burst/ESD

Protection class IP 20

Embedded PC 13

Page 16

Product overview

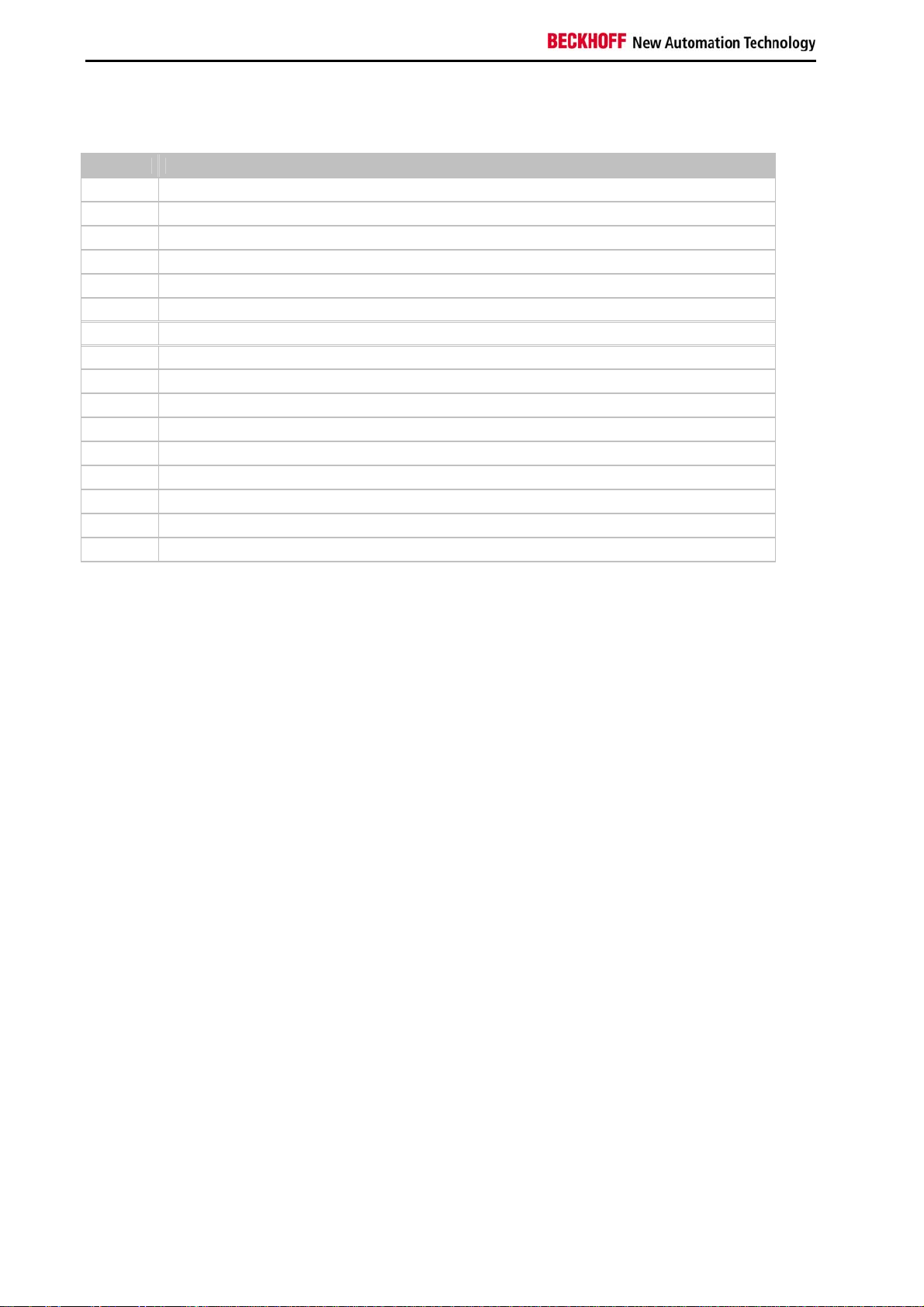

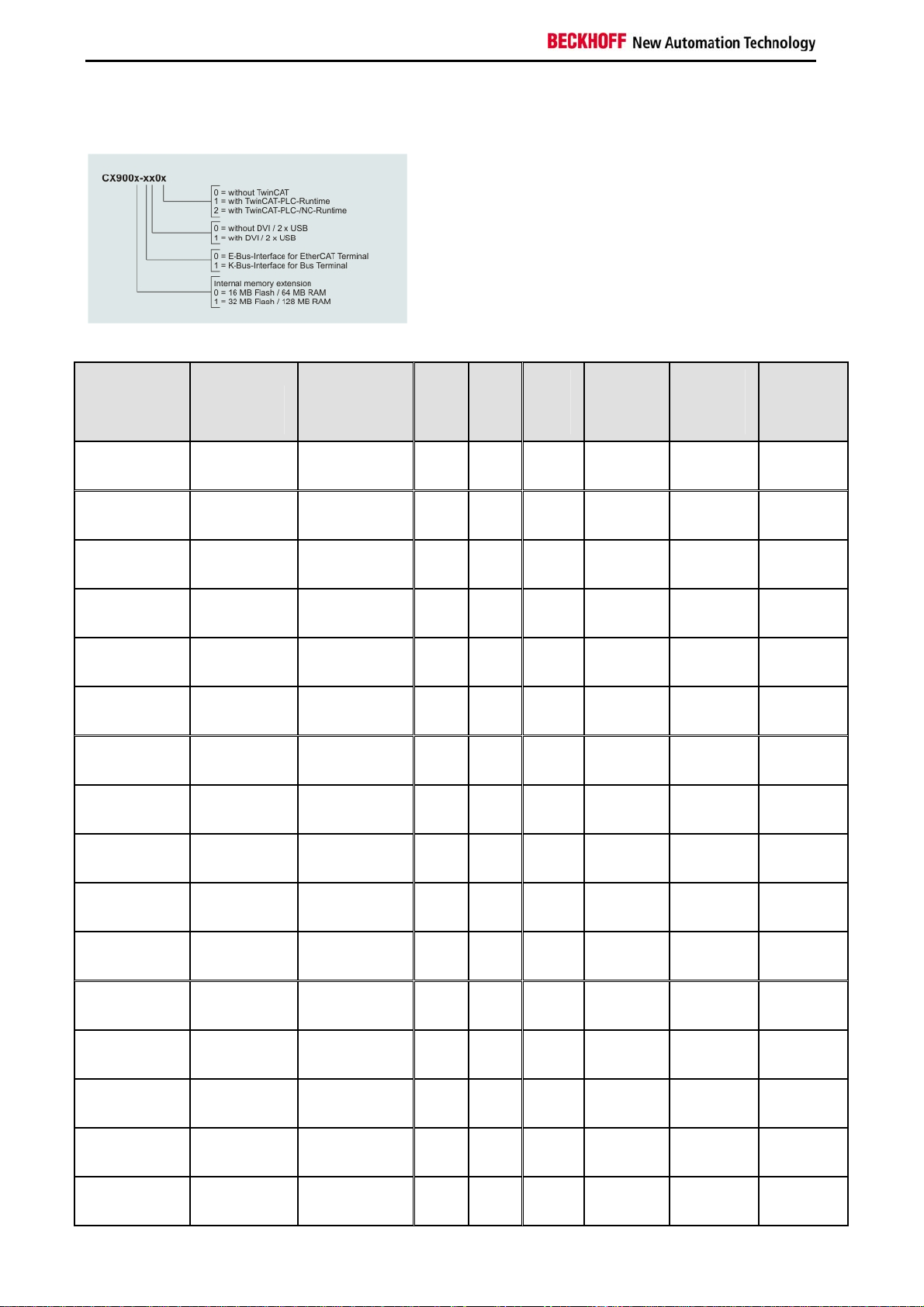

Configurations CX9000

The order identifier of the basic CPU module is derived as follows:

Following CX9000 configurations are available:

Ordering

information

CX9000-0000

CX9000-0001

CX9000-1000

CX9000-1001

CX9001-0000

CX9001-0001

CX9001-0002

CX9001-0100

16 MB Flash

64 MB RAM

32 MB Flash

128 MB RAM E-Bus K-Bus

X - x -

X - x -

X - - x

DVI,

2 x

USB

-

-

-

no

TwinCAT

X - -

- x -

x - -

TwinCATPLCRuntime

X - - x - - x -

- x x - - x - -

- x x - - - x -

- x x - - - x x

- x x - x x - -

TwinCATNCRuntime

CX9001-0101

CX9001-0102

CX9001-1000

CX9001-1001

CX9001-1002

CX9001-1100

CX9001-1101

CX9001-1102

- x x - x - x -

- x x - x - x x

- x - x - x - -

- x - x - - x -

- x - x - - x x

- x - x x x - -

- x - x x - x -

- x - x x - x x

14 Embedded PC

Page 17

Product overview

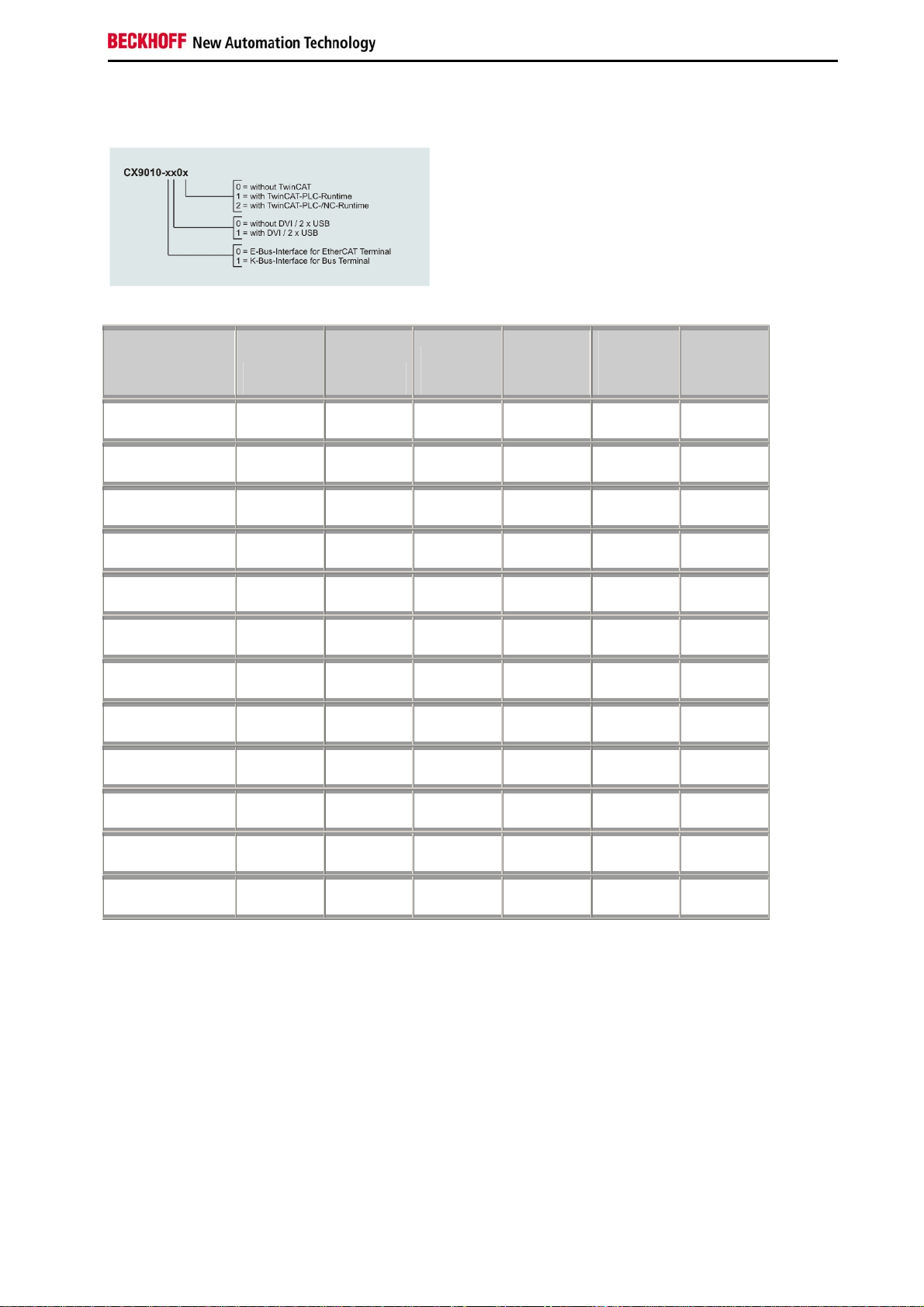

Configurations CX9010

The order identifier of the basic CPU module is derived as follows:

Following CX9000 configurations are available:

Ordering

information E-Bus K-Bus

CX9010-0000

CX9010-0001

CX9010-0002

CX9010-0100

CX9010-0101

CX9010-0102

CX9010-1000

CX9010-1001

CX9010-1002

x - - x - -

x - - - x -

x - - - x x

x - x x - -

x - x - x -

x - x - x x

- x - x - -

- x - - x -

- x - - x x

DVI, 2 x

USB

no

TwinCAT

TwinCATPLCRuntime

TwinCATNCRuntime

CX9010-1100

CX9010-1101

CX9010-1102

- x x x - -

- x x - x -

- x x - x x

Embedded PC 15

Page 18

Product overview

Connections

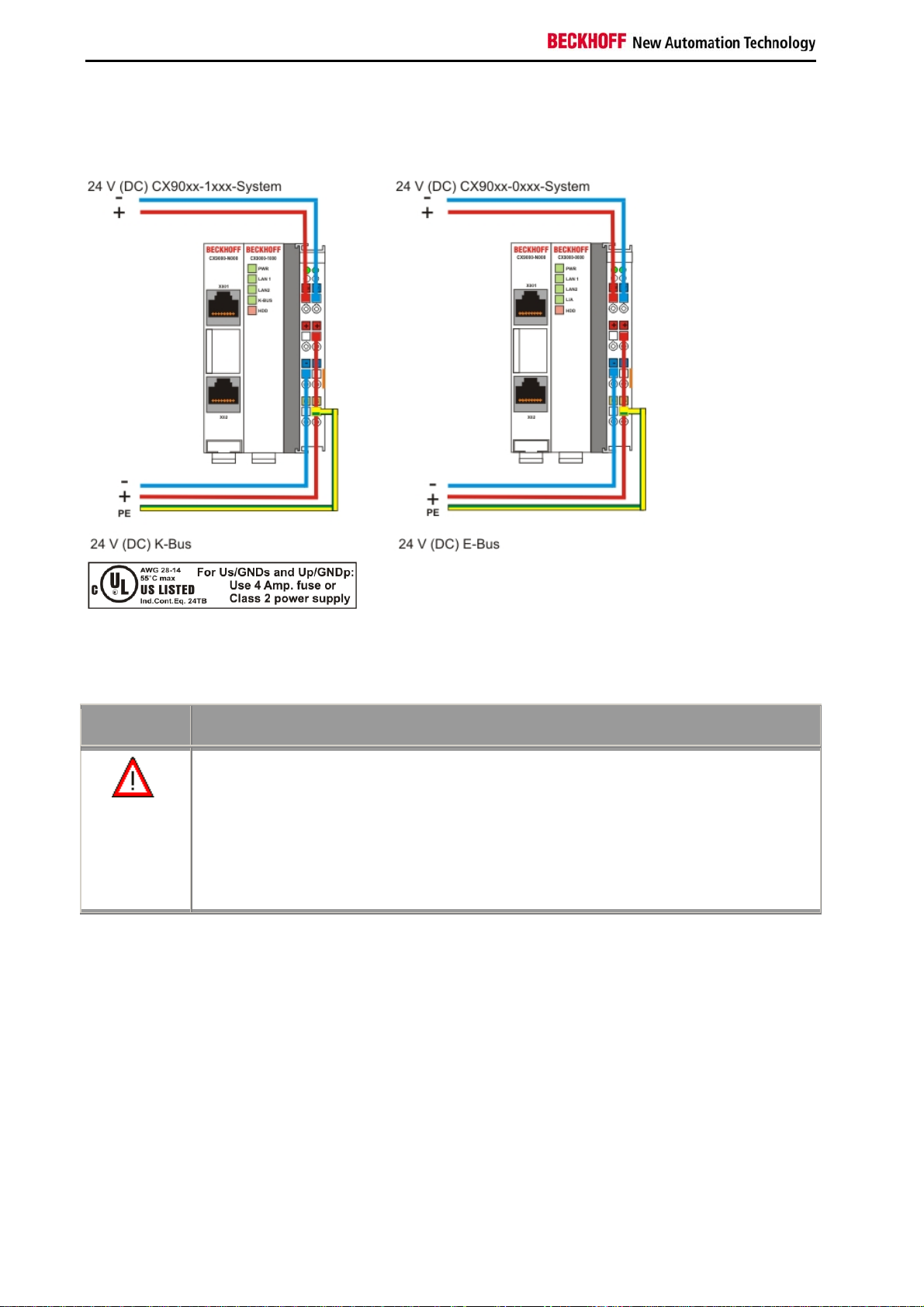

The system is supplied with power via the integrated power supply. This is wired as follows:

The basic module is powered via the upper connectors with 24 V DC. The terminal bus can be supplied via the lower

connections.

UL requirements

Danger

For the compliance of the UL requirements the CX-Controllers should only be supplied

• by a 24 V

fuse (in accordance with UL248), rated maximum 4 Amp.

• by a 24 V

supply voltage, supplied by an isolating source and protected b y means of a

DC

power source, that has to satisfy NEC class 2.

DC

A NEC class 2 power supply shall not be connected in series or parallel with another

(class 2) power source!

These UL requirements are valid for all supply voltages of the CX-Controllers!

16 Embedded PC

Page 19

Product overview

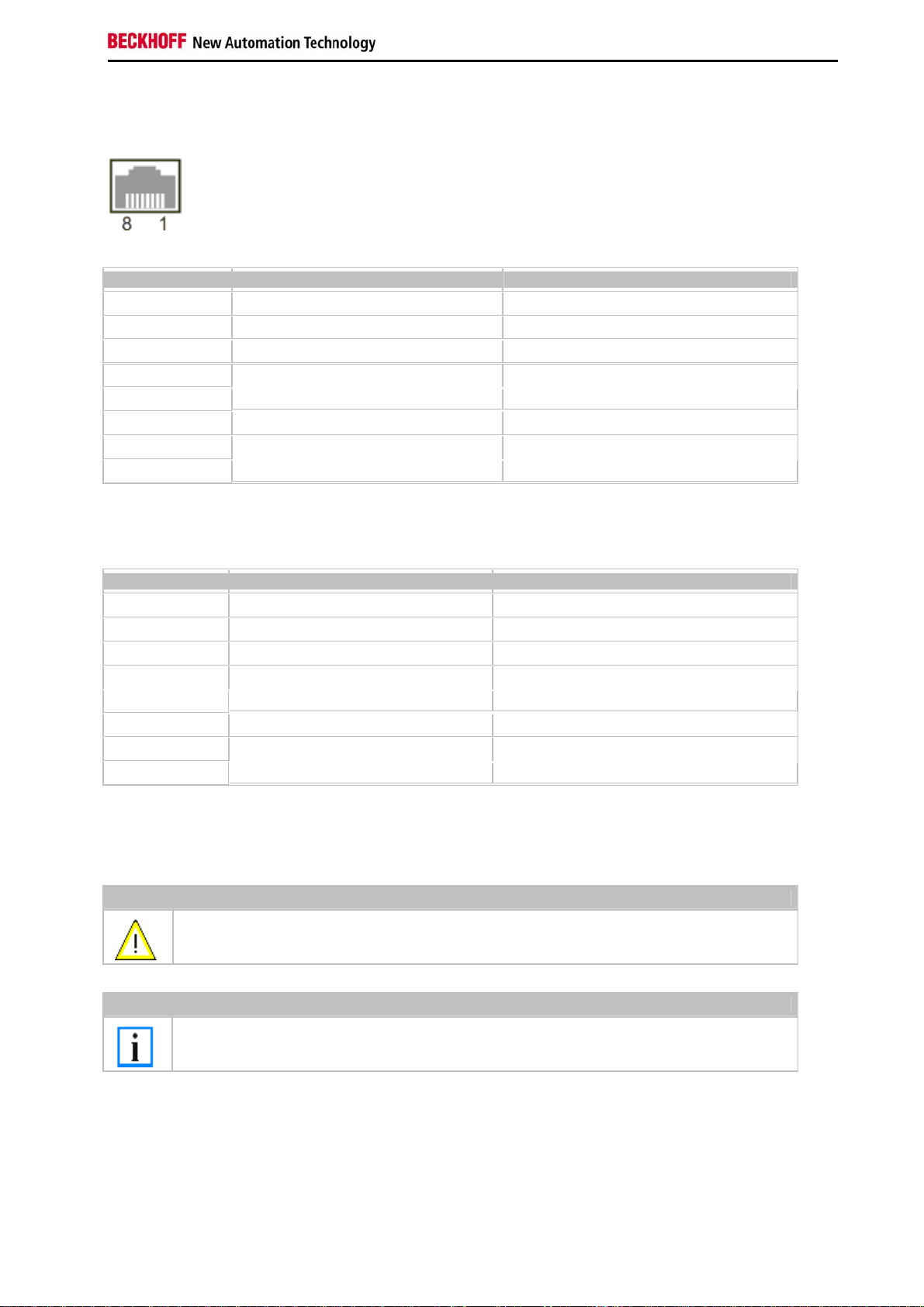

CPU basic module with 2 Ethernet RJ 45 connectors:

RJ 45 interface (socket):

Assignment of the RJ45-interface, Port 1:

PIN Signal Desciption

1 TD + Transmit +

2 TD - Transmit 3 RD + Receive +

4

5

6 RD - Receive 7

8

TD & RD are exchanged at the hubs or between two PCs.

connected not used

connected not used

Assignment of the RJ45 interface, Port 2:

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit 3 RD + Receive +

4

5

6 RD - Receive 7

8

TD & RD are exchanged at the hubs or between two PCs.

connected not used

connected not used

Connection of the Ethernet ports:

Warning

The two Ethernet ports of a basic CPU module must not be connected to the same external switch!

Note

Only for use in LAN, not for connection to telecommunication circuits.

Schematic structure of the network components:

The CX9000 features two MAC blocks. The first one (MAC1) operates the network interfaces for the Ethernet ports.

The two outputs are connected via a switch. In this way a line structure can be configured as described belo w. From

an operating system perspective this represents a single connection. The second block (MAC2) operates the

extended PC104 bus. The second physical network connection is used to run the E-bus connection. (in version

CX900x-0xxx) The signals are connected to and FPGA. This unit converts the Ethernet signals to E-bus signals. So

EtherCAT terminals can be connected to the system.

Embedded PC 17

Page 20

Product overview

If K-bus is used as terminal bus (CX900x-1xxx), the second MAC-interface is not connected.

Operating system perspective:

The operating system only sees one of the connections for the network interface. The status is always connected,

since the switch is connected directly.

18 Embedded PC

Page 21

Product overview

These interfaces are connected to an internal 3-port switch and offer a simple option for creating a line topology

without the need for additional Ethernet switches.

Basic CPU module with DVI/USB interface:

In addition to the two Ethernet ports, this basic module also features DVI/USB interfaces. The pin assignment of the

basic CPU module with two USB and a DVI-I interface is explained under the associated CX9000-N010 s ystem

interface.

Applicable to all basic CPU modules:

LED

The green power LED (PWR) is on if the basic CPU module is connected correctly to a live power supply unit.

Compact Flash slot

Further information can be found under Compact Flash slot.

Embedded PC 19

Page 22

Product overview

Battery compartment

The battery compartment is located on the left-hand side of the CPU module, between the two Ethernet ports.

It can be opened with the aid of a screwdriver (proceed carefully in order to avoid damage).

The battery is a CR2032 type from Panasonic

with the following specification:

Battery

type

CR2032 3.0 V 225 mAh 0.20 mA 20.00 mm 3.2 mm 3.1 g

Danger

Electrical properties (at 20° C) Standard charge Dimensions

nominal voltage nominal capacity continuous load Diameter Height Weight

Replace Battery Part. No. CR2032 manufactured by Sanyo or Panasonic Only.

Use of Another Battery May Present A Risk Of Fire Or Explosion.

WARNING, Battery may explode if mistreated. Do Not Recharge, Disassemble or

Dispose of in fire.

Spare batteries can be ordered from Beckhoff Service.

20 Embedded PC

Page 23

Product overview

Dip switch settings

General

Warning

In general there is no need to change the dip switch settings. The switches are installed in case of

major faults, to reset the system, provide debug messages, bypass TwinCAT start and update the

image.

Never change a running system !

To get access to the dip switches, you have to open the over of the battery compartment. It is located between the

two ethernet connectors on the front of the CX9000-N000 module. To open the cover proceed as follows:

1. Power down the CX9000

2. Open the battery compartment (located between two ethernet ports)

It can be opened with the aid of a screwdriver (proceed carefully in order to avoid damage).

Once the compartment is opened, the four dip switches can be accessed. They are located left of the battery holder.

On normal operation mode all switches are set to OFF. (All switches are down).

To change the settings of a dip switch its is advised to use a screwdriver with a small blade (2.5 mm x 7.5 cm length

and parallel shaft, Beckhoff order number: ZB8700). Use the edge to move the switches with caution!

The switches have four functions:

1. Reset CX9000-Sytem to defaults

2. Send debug codes to COM1 (if connected)

3. Update mode to obtain a new image via PC server (Boot menu via COM1)

4. Force TwinCAT to start in config mode

The functions are described in detail below:

Embedded PC 21

Page 24

Product overview

Reset to Factory Settings:

1. Set dip switch 1 to ON (move switch 1 up).

2. Connect CX-System to power and boot system. After a complete boot, the registry is regenerated.

3. Set dip switch 1 back to OFF (switch 1 down) and close cover.

Report debug messages to COM1:

1. Set dip switch 2 to ON (move switch 2 up).

2. Connect a serial monitor device (printer or terminal) to COM1 port. The settings for the interface are: 38400

baud, 8 bits , NO parity and 1 stop bit (38400,8,N,1).

3. Connect CX-System to power and boot system. Debug messages are sent to the monitor device.

4. After finishing diagnosis power set dip switch 2 back to OFF (switch 2 down) and close cover.

Bootstrap Mode for updates:

The Bootstrap Mode is implemented for image updates. The procedure is more comple x so it is described in an own

part of the documentation. Refer to the instruction for the process.

22 Embedded PC

Page 25

Product overview

Force TwinCAT in "Config Mode":

For some cases (e.g. errors in boot project) it is necessary to start TwinCAT in Config mode. So the boot project can

be corrected or other settings can be (re)setted.

1. Set dip switch 4 to ON (move switch 4 up).

2. Connect CX-System to power and boot system.

3. Make changes to the PLC

4. power down the system. Set dip switch 4 back to OFF (switch 4 down) and close cover.

Embedded PC 23

Page 26

Product overview

System interfaces - technical data

Dimensions:

Like for the other members of the CX family, a number of optional interface modules are available for the basic

CX9000 CPU module that can be installed ex works. The following interfaces are availabl e:

• CX9000-N010 DVI / USB Module

• CX9000-N030 serial interface for RS323

• CX9000-N031 serial interface for RS422 / RS485

The CX9000-N010 option can be connected to Beckhoff Control Panels or standard monit ors with DVI or VGA input

via the DVI or USB interfaces.Devices such as printer, scanner, mouse, keyboard, mass storage, CR-RW etc. can be

connected via the USB 2.0 interfaces. The modules CX9000-N030 offers two serial RS232 interfaces with a

maximum transfer speed of 115 kbaud. These interfaces can be implemented in pairs as RS422/RS48 5, in which

case they are identified as CX9000-N031 respectively. The system interfaces cannot be retrofitted or expanded in

the field. They are supplied ex factory in the specified configuration and cannot be s eparated from the CPU module.

The system interfaces run through the internal PC104 bus, so that further CX components can be connected. The

power supply of the system interface modules is ensured via the internal PC104 bus.

Technische Daten CX9000-N010 CX9000-N030 CX9000-N031

Interfaces 1 x DVI +

2 x USB 2.0

Connection type DVI-I 29-pin socket +

2 USB Ports type A

Properties DVI-I interface also

carries out VGA signals

(DVI-A)

Power supply via system bus (Through internal power supply in CX9000 module)

Dimensions 19 mm x 100 mm x 51 mm

Operating

temperature

Storage

temperature

Relative humidity 95% no condensations

Vibration/Shock

resistance

EMC resistance

burst / ESD

Protection class IP 20

wight app. 80 g

0 °C ... +55 °C

-25 °C ... +85 °C

conforms to EN 60068-2-6 / EN 60068-2-27/29

conforms to EN 61000-6-2/EN 61000-6-4

1 x COM1+2, RS232

1 x COM3+4, RS232

2 x D-Sub plug 9-pin 2 x D-Sub plug 9-pin

max. baud rate

115 kbaud,

can not be used

simultaneously with

N031/N041

1 x COM1+2, RS422/RS485

1 x COM3+4,RS422/RS485

max. baud rate 115 kbaud,

can not be used simultaneously

with N030/N040

24 Embedded PC

Page 27

Product overview

CX9000-N010 connections

In addition to the two Ethernet interfaces, this module features a DVI-I and two USB interfaces.

Note

The system interface CX9000-N010 can only be used in CX9000 system with large memory

(CX9001-x00x).

DVI-I interface

The DVI-I interface transfers analog and digital data and is suitable for connection to analog graphics cards with 15

pin D-Sub connector and digital graphics cards with DVI-D output. The resolution at the screen or the Beckhoff

Control Panel depends on the distance (maximum 5 m).

The DVI interface uses VGA signals, so that the connection of CRT VGA monitors to the CX-System using a DVI to

VGA adapter is also possible.

This adapter is available as an accessory.

DVI-I socket:

Pin Assignment Pin Assignment Pin Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 02 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 not connected 12 not connected 20 not connected

5 not connected 13 not connected 21 not connected

6 DDC Clock 14 + 5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground ( +5V, Analog H/V Sync) 23 TMDS Clock +

Embedded PC 25

Page 28

Product overview

8 Analog Vertical Sync 16 Hot Plug D etect 24 TMDA Clock -

Pin assignment (cross)

Pin Assignment

C1 Analog Red Video Out

C2 Analog Green Video Out

C3 Analog Blue Video Out

C4 Analog Horizontal Sync

Resolution at the monitor:

Resolution in pixels Distance of the interface from the monitor

1600 x 1200 5 m

1280 x 1024 5 m

1024 x 768 5 m

800 x 600 5 m

640 x 480 5 m

USB interface:

The USB socket is a type A socket. The USB interface complies to USB 2.0 specification

Pin Assignment Typical assignment

1 VBUS Red

2 D- White

3 D+ Green

4 GND Black

Shell Shield Drain Wire

26 Embedded PC

Page 29

Product overview

CX9000-N030 connections

The CX9000-N030 system interface features two RS232 interfaces, COM1 and COM2 (9 pin Sub-D plug connector).

The maximum baud rate on all channels is 115 kBit. The pin assignment for all interfaces is equal and described

below. The interface parameter can be set in the operating system or in the PLC program.

RS232 COM interface (connector):

Pin assignment COM interface:

PIN Signal Type Description

1 DCD Sign al in Data Carrier Detected

2 RxD Signal in Receive Data

3 TxD Signal out Transmit Data

4 DTR Signal out Data Terminal Ready

5 GND Ground Ground

6 DSR Signal in Dataset Ready

7 RTS Signal out Request to Send

8 CTS Signal in Clear to Send

9 RI Signal in Ring Indicator

Note

The system interface CX9000-N30 can only be used instead and not simultaneously with system

interface CX9000-N031.

The system interface CX9000-N31 can only be used instead and not simultaneously with system

interface CX9000-N030.

Embedded PC 27

Page 30

Product overview

CX9000-N031 connections

The CX9000-N031 system interface features two RS422 / RS 485 interf aces, COM1 and COM2 (9 pin Sub-D plug

connector). The maximum baud rate on all channels is 115 kBit. The pin assignment for all interfaces is equal and

described below. The interface parameter can be set in the operating system or in the PLC program.

RS232 COM interface (connector):

Pin assignment COM interface:

PIN Signal Type Description

2 TxD+ Data-Out + Transmit 422

3 RxD+ Data-In + Receive 422

5 GND Ground Ground

6 VCC VCC +5V

7 TxD- Data-Out - Transmit 422

8 RxD- Data-In - Receive 422

For RS 485 Pin 2 and 3 ( Data +) as well as Pin7 and 8 (Data -) have to be connected..

28 Embedded PC

Page 31

Product overview

Setting the interface parameter

If the system interface CX9000-N031 resides at the end of the CX9000-system block, it is easy to access the dip

switches. The dip switches for the configuration of the RS485/422 interfaces can be fo und at the left side of the

module. If you remove the grey cover you can see the switch:

The upper switch sets the parameters for the upper interface, the lower switch sets the parameter for the lower

interface. The system must be powered down, if the settings of the switches are changed! The settings for default

use should be mentioned by ordering the interface module.

Settings DIP switches RS485:

RS485 without Echo, End-Point ( Terminated) DEFAULT setting

DIP Status Function

1 off Echo on

2 on Echo off

3 on Auto send on

4 off Always send on

5 on Auto receive on

6 off Always receive on

7 on Term on

8 on Term on

RS485 with Echo, End-Point ( Terminated)

DIP Status Function

1 on Echo on

2 off Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 on Term on

8 on Term on

Embedded PC 29

Page 32

Product overview

RS485 without Echo, Drop-Point ( without Termination)

DIP Status Function

1 off Echo on

2 on Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 off Term on

8 off Term on

RS485 with Echo, Drop-Point ( without Termination)

DIP Status Function

1 on Echo on

2 off Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 off Term on

8 off Term on

Setting DIP-Switches RS422:

RS422 full duplex end point

DIP Status Function

1 on Echo on

2 off Echo off

3 off Auto send on

4 on Always send on

5 off Auto receive on

6 on Always receive on

7 on Term on

8 on Term on

Note

The system interface CX9000-N31 can only be used instead and not at the same time with system

interface CX9000-N030.

The system interface CX9000-N30 can only be used instead and not at the same time with system

interface CX9000-N031.

30 Embedded PC

Page 33

Transport

3. Transport

Unpacking, installation and transport

The specified storage conditions must be adhered to (see "Technical data").

Dimensions and weight of the individual modules:

Dimensions (W x H x D): 19 x 100 x 91 mm (system interface) , 58 x 100 x 91 mm (basic module)

Weight: 80 g (system interface) to 250 g (basic module)

Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

6. If you notice any shipping damage or inconsistencies between the contents and your order, you should notify

Beckhoff Service.

Achtung

Danger of damage to the unit!

During transport in cold conditions, or if the unit is subjected to extreme temperature swings, condensation on and

inside the unit must be avoided.

Prior to operation, the unit must be allowed to slowly adjust to room temperature. Should condensation oc cur, a delay

time of approximately 12 hours must be allowed before the unit is switched on.

Installation

The devices are designed for installation in control cabinets. You will find installation instructions in the chapter

mechanical mounting.

Shipping and relocation

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts. During

transport, your computer should therefore be protected from excessive mechanical stress. Therefore, please use the

original packaging.

Embedded PC 31

Page 34

Assembly and connecting

4. Assembly and connecting

Mechanical assembly

Dimensions

The CX-System product range is characterized by small overall installed size and high modularity. For project

planning purposes, a CPU module, a power supply unit and the associated system interfaces and fieldbus interfaces

have to be provided. The overall width of the application is made up of the individual modules. With a he ight of 100

mm, the module dimensions exactly match those of the Beckhoff Bus Terminals. Together with the lowered

connector surfaces, this means that it can be used in a standard terminal box with a height of 120 mm.

Warning

To ensure cooling to the device in operation it is important keep the safety distances.

CX9000-xxxx CPU Basic module:

CX90x1-xxxx and CX1010-xxxx CPU Basic module:

32 Embedded PC

Page 35

Assembly and connecting

CX9000-N0x0 System interfaces:

CX1100-09x0 UPS module:

CX1100-0900

Embedded PC 33

Page 36

Assembly and connecting

CX1100-0910

CX1100-0920

34 Embedded PC

Page 37

Assembly and connecting

Mechanical assembly of the basic module

The installation of the modules takes place in three steps:

1. The sequence of the modules

The basic CPU module with system interfaces, which are factory-installed on the left side, is extended with the power

supply unit on the right and with the fieldbus connection (master or slave) left side if available.

2. Engaging on the top-hat rail

On the bottom of the modules, there is a white tension strap, which is connected with a latching mechanism. These

tension straps must be pulled down before attaching to the top-hat rail. This can be done using an ordinary

screwdriver and a slight turn.

Then fix the CX9000 block on the top hat-rail using the latching straps. You should hear a soft click.

Do not force the module or apply

excessive pressure!

Only apply pressure at insensitive points of the housing (edges). Never apply pressure on the display, the buttons or

movable parts of the CX-System.

After successful latching on the top-hat rail the straps should be pushed back to their original position.

Note:

A locking mechanism prevents the individual housings from being pulled off again. Detailed information relating to

disassembly of the CX-SYSTEM configuration from the top-hat rail can be found on page "Removal an d disposal".

Embedded PC 35

Page 38

Assembly and connecting

Installation position:

Warning

Correct installation position:

The high-performance CX9000 system generates a significant amount of heat, which is dissipated via a passive

ventilation system. This system requires the unit to be mounted correctly. Ventilation openings are located at the top

and bottom of the housing. The system therefore has to be installed horizontally. This ensures optimum air flow.

The maximum ambient temperature for CPU modules mounted on a top-hat rail is 55°C. T he

orientation in which the device is fitted must be selected in such a way that cooling air can flow

vertically through the ventilation holes. The images show the correct installation position.

Observe minimum clearance!

Mounting must provide a clearance of 30 mm both above and below a CX-System device

combination to ensure adequate ventilation of the base CPU module and the power supply unit.

Illegal installation positions:

36 Embedded PC

Page 39

Assembly and connecting

Mechanical installation of the UPS Module

Note

The UPS module for CX9000 is not fully supported by TwinCAT yet.

The UPS module should be connected the described way. T o get the po wer fail signal (pin 3 on UPS)

must be connected to a digital input terminal. In this way the PLC can

access the power fail signal and save the data or shut down the system. The shutdown time can only

be set by the selector on the front side of the UPS (best choice is 0).

In case of shutdown the UPS will restart the system after power fail.

0. Switching off and disconnecting the power supply

Before a CX9000 system can be dismantled, the system should be switched off, and the power supply should be

disconnected.

1. Removing from the top-hat rail:

Before the individual CX9000 modules are disconnected, the whole CX9000 hardware block should be removed from

the top-hat rail. Proceed as follows:

1.1. Release and remove the first Terminal next to the power supply unit on the top-hat rail.

First remove any wiring from power supply unit and

supply unit. If the wiring is to be reused for another system, it is advisable to make a note of the connections. Then

pull the orange terminal release (see arrow) to release the terminal and pull it out.

then from the first terminal on the top-hat rail next to the power

1.2. Releasing the CX9000 system

In order to release the CX-block, pull the white straps at the bottom of the module in the direction of the arrows. They

will lock in the extended position. After pulling the terminal release of the power supply unit, the block can be

removed carefully

from the top-hat rail.

Embedded PC 37

Page 40

Assembly and connecting

2 Assembly of the CPU basic module with UPS module

2.1 Assembly the the CX9000 system block

In order to be able to connect the UPS to the basic CX9000 module, the cover of the basic module has to be

removed first. This is achieved by applying slight pressure on the cover. The individual modules are sim ply plugged

together. The PC104 connector plugs should be handled carefully in order to avoid damage. When correctly

assembled, no significant gap can be seen between the attached housings. If the modules are assembled the cover

can be replaced.

2.2 Engaging on the top-hat rail

Before engaging the system back on the top-hat rail the user should ensure all white tension straps are pulled down.

The user should take care of the space between the terminals and the Embedded PC system. The space for the

removed terminal must be kept to reinstall the terminal.

Then fix the CX9000 block on the top hat-rail using the latching straps. You should hear a soft click.

38 Embedded PC

Page 41

Assembly and connecting

Do not force the module or apply

excessive pressure!

Only apply pressure at insensitive points of the housing (edges). Never apply pressure on the display, the buttons or

movable parts of the CX-System.

After successful latching on the top-hat rail the straps should be pushed back to their original position.

2.3 Connecting the Embedded PC to the terminal bus

By reinstalling the once removed terminal the system is connected to the bus.

Finally the wiring must be reinstalled. The removed terminal is reconnected as before. The power suppl y is now

connected via the UPS-connectors. (see chapter connections for details)

Embedded PC 39

Page 42

Assembly and connecting

Start-up procedure

Switching the PC on and off

Switching on

The power supply for the basic CPU module comes from the power supply unit. The basic CPU module starts

automatically when the power supply unit is connected to the mains.

Switching on for the first time

When you switch on the PC for the first time, the pre-installed operating system (optional) will be started.

Switching off

The Embedded PC switches off when the power supply unit is switched off. The control software typicall y running on

Embedded PCs should be shut down or stopped correctly. A user who may not close software may also not switch

the Embedded PC off, since data can be lost from the hard disk by switching off while software is running.

Once the software has been stopped, the operating system can be shut down. Only then should the power supply be

interrupted.

40 Embedded PC

Page 43

Error handling and diagnostics

5. Error handling and diagnostics

CPU basic module

LEDs Basic CPU-module (E-Bus)

Display LED Meaning

PWR

LAN 1 LAN Link , (green)

LAN 2 LAN Link, (green)

L / A (Link Activity) flashes in traffic on E-bus.

HDD Read/Write Compact Flash (red)

red TwinCAT is in STOP mode

green TwinCAT is in RUN mode

blue TwinCAT is in CONFIG mode

off System is offline

LINK/ACTIVITY for first switched LAN PORT (CX9000_N000)

LINK/ACTIVITY for second switched LAN PORT (CX9000_N000)

Indicates access to the CF card.

Embedded PC 41

Page 44

Error handling and diagnostics

LEDs Basic CPU-module (K-Bus)

Display LED Meaning

PWR

LAN 1 LAN Link , (green)

LAN 2 LAN Link, (green)

K-Bus flashes in traffic on K-bus / reports errors

HDD Read/Write Compact Flash (red)

The I/O error K-Bus LED blink code

Fast blinking Start of the error code

First slow sequence

Second slow sequence

red TwinCAT is in STOP mode

green TwinCAT is in RUN mode

blue TwinCAT is in CONFIG mode

off System is offline

LINK/ACTIVITY for first switched LAN PORT (CX9000_N000)

LINK/ACTIVITY for second switched LAN PORT (CX9000_N000)

K-Bus not active (off)

K-Bus running (flashes green)

K-Bus error (red) see tables below

Indicates access to the CF card.

Error code

Error code argument

LEDs for K-Bus diagnosis

Error

Error code

Persistent,

continuous

blinking

1 pulse

2 pulses

3 pulses

4 pulses

5 pulses

9 pulses

code

argument

EMC problems

0 EEPROM checksum error Revert to the manufacturer’s setting

1 Code buffer overflow

2 Unknown data type Software update required for the power supply

0

n (n > 0)

0 K-Bus command error

0

n Break behind Bus Terminal n

n

0

n (n>0)

Programmed configuration

has an incorrect table entry

Table comparison (Bus

Terminal n)

K-Bus data error, break

behind the power supply

K-Bus error in register

communication with Bus

Terminal n

Checksum error in Flash

program

Bus Terminal n is not

consistent with the

configuration that existed

Description Remedy

- Check power supply for overvoltage or undervoltage

peaks

- Implement EMC measures

- If a K-Bus error is present, it can be localised by a

restart of the power supply (by switching it off and then

on again)

Insert fewer Bus Terminals. The programmed

configuration has too many entries in the table

Check programmed configuration for correctness

Incorrect table entry

- No Bus Terminal inserted

- One of the Bus Terminals is defective; halve the

number of Bus Terminals attached and check whether

the error is still present with the remaining Bus

Terminals. Repeat until the defective Bus Terminal is

located.

Check whether the n+1 Bus Terminal is correctly

connected; replace if necessary.

Check whether the Bus End Terminal 9010 is

connected.

Exchange the nth bus terminal

Revert to the manufacturer’s setting

Revert to the manufacturer's setting which will clear the

boot project.

42 Embedded PC

Page 45

Error handling and diagnostics

when the boot project was

created

14 pulses

15 pulses

16 pulses

Error code argument

The number of pulses indicates the position of the last Bus Terminal before the fault. Passive Bus Terminals, such as

a power feed terminal, are not included in the count.

In the case of some errors, rectification does not cause the power supply to leave the blink sequence. The power

supply can only be restarted by switching its supply voltage off and on again.

n

n

n

nth Bus Terminal has the

wrong format

Number of Bus Terminals is

no longer correct

Length of the K-Bus data is

no longer correct

Start the power supply again, and if the error occurs

again then exchange the Bus Terminal.

Start the power supply up again.

Start the power supply up again.

Embedded PC 43

Page 46

Error handling and diagnostics

Terminal Bus Analysis in PLC-Program

To analyze the terminal bus (K-Bus) the programmer can access the registers described in the architecture. The

access to the PLC-program is realized via TwinCAT. The registers are described in the architecture of the terminal

bus connectors (CX1100-000x.

For analysis four signals / variables are used:

• BusState (describes the state of the bus: 0 -> no error, 1 -> bus error)

• ErrorCode (same error code as the LED blink code)

• ErrorArg (same argument code LED blink code)

• Request[0] (output to request error codes / reset bus)

In the PLC program some external variables must be defined:

VAR

k_bus_request AT %QX0.0 : BOOL;

k_bus_err_code AT %IB0 : USINT;

k_bus_err_arg AT %IB1 : USINT;

k_bus_state AT %IB2 : USINT;

END_VAR

In the PLC program the analysis can be done as follows: (this is only pseudo code)

....

IF k_bus_state = 1 THEN (* an error occured on K-Bus*)

k_bus_request := TRUE; (* request vaules for ErrCode and ErrArg *)

CASE k_bus_err_code OF

0 : return; (* should not happen, though an error occured *)

1 : CASE k_bus_arg OF

0 : report error; (* EEPROM checksum error *)

1 : report error; (* overflow in code buffer *)

2 : report error; (* unknown datatype *)

END_CASE;

2 : CASE k_bus_arg OF

0 : report error; (* programmed configuration, wrong table entry *)

ELSE report error; (* wrong table entry *)

END_CASE;

3 : report error (* K-Bus command error *)

4 : CASE k_bus_arg OF

0 : report error; (* break after power supply *)

ELSE report error; (* break after terminal 'k_bus_arg' *)

END_CASE;

5 : report error (* K-Bus-error during register-communication with

terminal 'k_bus_arg' *)

9 : CASE k_bus_arg OF

0 : report error; (* checksum error in program flash *)

ELSE report error; (* terminal 'k_bus_arg' does not exist in boot

configuration *)

44 Embedded PC

Page 47

Error handling and diagnostics

END_CASE;

14 : report error (* 'k_bus_arg'-th terminal has wrong format *)

15 : report error (* wrong number of bus terminals *)

16 : report error (* length of K-Bus data is invalid *)

END_CASE

k_bus_request := TRUE; (* reset bus, if reason for error is removed, bus

starts again *)

....

To make the control work, the register and the program must be linked in System Manager. If the PLC program is

attached in System Manager the following signals are available:

Analog the registers of the terminal bus are shown in System Manager:

Link signals and variables:

k_bus_err_code with ErrorCode

k_bus_err_arg with ErrorArg

k_bus_state with BusState

and

k_bus_request with Request[0]

If all signals are linked the programmer can load configuration and PLC program onto the system.

Embedded PC 45

Page 48

Decomissioning

6. Decomissioning

Removal and disposal

A CX9000 hardware configuration is dismantled in 2 stages:

0. Switching off and disconnecting the power supply

Before a CX-System can be dismantled, the system should be switched off, and the power supply shoul d be

disconnected.

1. Removing from the top-hat rail:

Before the individual CX-System modules are disconnected, the whole CX- hardware block should be removed from

the top-hat rail. Proceed as follows:

1.1. Release and remove the first Terminal next to the power supply unit on the top-hat rail.

First remove any wiring from power supply unit and

supply unit. If the wiring is to be reused for another system, it is advisable to make a note of the connections. Then

pull the orange terminal release (see arrow) to release the terminal and pull it out.

then from the first terminal on the top-hat rail next to the power

1.2. Releasing the CX-System

In order to release the CX-block, pull the white straps at the bottom of the module in the direction of the arrows. They

will lock in the extended position. After pulling the terminal release of the power supply unit, the block can be

removed carefully

from the top-hat rail.

46 Embedded PC

Page 49

Decomissioning

2. Separating the individual modules

2.1. Separating the power supply unit, the CX-System CPU and other components

Place the CX-block onto a suitable support with the front facing down. Then insert a flat screwdriver with dimensions

1.0 x 5.5 x 150 mm into the locking mechanism, and then operating the sli der by turning it about 90 degrees. The

locking mechanism on the rear affects an approx. 2-3 mm wide clearance of the module latching mechanism,

pushing them apart. The plug connectors of the PC 104 interface can then be pulled apart carefully.

Only modules (CPU, fieldbus connections and UPS modules) that can be separated non-destructively feature a

release device. Modules that cannot be separated only feature a marking poin t (with or without red paint seal).

Applying force to these elements will destroy them.

Warning

Forcibly opening the module housing (e.g. removing the cover) will destroy the housin g.

Disposal

The device must be fully dismantled in order to dispose of it.

Electronic parts must be disposed of in accordance with national electronics scrap regulations.

Embedded PC 47

Page 50

Appendix

7. Appendix

Update Image

General

Warning

In general an update of the image is not necessary: The basic functionality of TwinCAT and

TwinCAT PLC are working fine.

Update the Image ONLY if there is an advice from BECKHOFF Automation GmbH. Never

change a running system !

If the image update is required, here some basic information for overview:

• One single file "BOOT.BIN" is required to update the image : BOOT.BIN contains full CE operating system

but also the TwinCAT functionality.

• This single file can NOT just xcopied to the target CX9000 device

Note

There are two ways to update the image of the CX9000-System:

Short description:

The general steps to update an CX9000-image are:

1. download the new image and the required tool from BECKHOFF FTP server

2. provide the new image on the host PC (notebook, PC ..)

3. start the image-server-tool on the host pc: this tool is listening on network to be connected from CX9000

device.

4. The initial activity to get a new image is started by the CX9000 device: This will happen if CX9000 is

configured to start in boot-strap mode.

5. after downloading the image from host pc the CX9000 will reorganize itself, this will take some time

(several minutes)

6. You may not power cycle during this phase otherwise the device will be damaged!

7. After all activities have been finished, power down the CX9000 device, deactivate "boot strap" and power on

device.

Update mechanism has been finished.

Step by step

1. Images on BECKHOFF FTP

Link to CX9000 images on Beckhoff FTP Server:

1. via Image-Server

2. interactive tool on CX9000

• For CX9000-x00x (16 MB flash) use CX9000 LF:

ftp.beckhoff.com/Software/embPC-Control/CE/Platforms/CX1800-0100-0003_LF

• For CX9001-x00x (32 MB flash) use CX9000 HMI:

ftp.beckhoff.com/Software/embPC-Control/CE/Platforms/CX1800-0101-0003_HMI

• The tool "Image-Server" for host PC is available in both HMI and LF folder (same tool in two folders),

download file "CX9000_ImageUpdate.zip"

Keep the structure of the zip file when unzipping.

48 Embedded PC

Page 51

Appendix

2. Prepare Image-Server (once)

Provide the image server on the host PC, the components are:

• Two batchfiles "CxImgSrv_HMI.bat" and "CxImgSrv_LF.bat"

Note that the CX9000 is shipped with different hardware environment (e.g. more or less flash memory).

• Folder "\Tools" contains the image server itself: CxImageSrv.exe

• Folder "\Images" contains the HMI and LF subfolders with the required file "Boot.bin"

If you receive a new NK.BIN file, just rename it to "Boot.bin" and provide it in the correct subfolder

3. Prepare CX9000

Prepare the "Boot-Strap Mode" on CX9000. There are two ways to set the CX9000 into "Boot-Strap Mode":

• set a DIP-switch on CX9000

• start a program, to set the CX9000 into"Boot-Strap Mode".

Prepare the CX9000 to start in "boot-strap" mode.

1. Power down the CX9000

2. Open the battery compartment (located between two ethernet ports)

It can be opened with the aid of a screwdriver (proceed carefully in order to avoid damage).

3. Find the dip switches 1,2,3,4 and set switch 3 from OFF to ON

Alternative the administrator can start a tool on the CX-Systems to set the CX9000 into "Boot-Strap Mode". First the

program must be downloaded from the BECKHOFF FTP-Server. If the CX9000 has no USB the tool can be

transferred via ftp onto the system. Use CERHOST-Tools to control the CX9000 remote via Ethernet. Activate the

FTP server on the CX, if not it is disabled. The necessary configuration is shown below:

Embedded PC 49

Page 52

Appendix

It is a good idea to choose "\Temp" or "\Public" as target directory, though this range is mapped into the RAM regions

instead of the hard disc located in flash memory. For operation the system must be rebooted.Just follow the

instructions on the screen. After restart of the CX9000 the program can be copied easily to the CX9000 with the

explorer:

50 Embedded PC

Page 53

Appendix

Warning

Via CERHOST the program will be started with a double click on the icon. Warning: Do NOT

start the program if you have no image-Server ( see below) AND a correct image!

The CX9000 is now no longer useable for PLC until an update was made!

The reset to operational is done automatically if the the update has taken place.

connect CX9000 to ethernet network

Note

Image server will listen in complete network to be contacted by CX9000

Two solutions to be sure that you just update your CX9000 device.... and not others in

network !

(for details see network notes below)

4

. Start image server

Start the image server on the host PC:

• start the correct batch file "CxImgSrv_HMI.bat" or "CxImgSrv_LF.bat" (to let image-server provide the HMI

or the LF image in network)

The batch file will start a command-shell and prompt : "Waiting for download request..."

5. Phases during image update

Start CX90x0 to initiate the download procedure :

• Initial phase :

Start CX90x0 to initiate the download procedure :power on CX90x0

The CX90x0 tries to find an image server on network to download an image.

• Download phase :

Image server will prompt a message in command shell if an image is downloaded to CX90x0

Message is like :

Boot image request from device CX90x0_BA23

Working directory is Image\HMI

Calling TFTP.exe -i <CX90x0-IP> PUT boot.bin

On CX90x0 the HDD led will light up : The CX- device is erasing and copying new image.

• Reorganisation phase :

The image server will prompt a message, that the download of new image has been finished.

Now, close command shell. (Press <CTRL> + <c> or close the window)

• Set system back to operation mode; to avoid the system to run the update procedure again.

Set the dip switch 3 back to "off" and close the battery compartment.

Embedded PC 51

Page 54

Appendix

7. Finish Update

Update is now complete. Reconnect the CX90x0-System to the network. The CX-System can now be used as before.

NOTES on network configuration:

• Image server will listen in complete network to be contacted by CX9000

Two solutions to be sure that you just update your CX9000 device.... and not others in network !

1a.

provide a subnet (like a second network card in host PC)

or

1b.

connect host-pc and CX9000 directly without involving company network

or

2.

The image server can be configured to let CX directly request image from specific IP address.

Step 1: connect CX9000 with PC, get IP address of PC like 192.16.18.123

Step 2: edit the image-server-batch-file and add the IP address to the commandline. (Sample : Tools\CxImageSrv

Images\HMI 192.16.18.123 )

Step 3: proceed with booting CX9000 in boot strap mode. Now the CX will try do request image from IP address

192.16.18.123

Warning

The CX90x0 is still working to initialize the flash ! DO NOT POWER DOWN THE CX90x0 !

Wait until CX90x0 PWR led is BLUE or GREEN again: The device will reboot after

it has finished update!

52 Embedded PC

Page 55

Appendix

Interactive tool on CX9000:

First the program "Cx9ImageUpdate.exe" must be downloaded from BECKHOFF FTP-Server. If the CX9000 has no

USB the tool can be transferred via ftp onto the system. Use CERHOST-Tools to control the CX9000 remote via

Ethernet. Activate the FTP server on the CX, if not it is disabled. The necessary configuration is shown below:

It is a good idea to choose "\Temp" or "\Public" as target directory, though this range is mapped into the RAM regions

instead of the hard disc located in flash memory. For operation the system must be rebooted.Just follow the

instructions on the screen. After restart of the CX9000 the program can be copied easily to the CX9000 with the

explorer:

Embedded PC 53

Page 56

Appendix

If there is enough free space on the CX9000 (big memory) the image can be copied together with to tool. Otherwise

the image file can be accessed via network drive. In this case you should map the drive to the CX9000:

If the image is copied to the CX9000 or the network drive is mapped to the system the update tool can be started by

double click on the icon. The program ask for the filename of the image. The complete path to the file must be

entered now. Depending on the network configuration the password is requested again.

54 Embedded PC

Page 57

Appendix

After click on "FLASH IMAGE" button a request box appears to confirm the image file. This is the last chance to

abort the update process.

When confirming the image file a warning appears on the screen.

The progress is shown in the status line in the bottom of the tool.

When the update is complete the following message appears in the status field:

Embedded PC 55

Page 58

Appendix

The CX9000 can be rebooted now. If the system has started again it can be used as before. The update tool and the

image are removed if they were copied on the RAM drive.

56 Embedded PC

Page 59

Appendix

Accessories

Compact flash cards

order number Description

CX1900-0023 1 GByte compact flash card type I

CX1900-0025 2 GByte compact flash card type I

CX1900-0027 4 GByte compact flash card type I

Connectors and Adaptors

order

number

CX1900-0101 DVI-to-VGA passive Adaptor for connecting a standard desktop VGA monitor to the

Description

CX-System

– singles out the VGA signals of the DVI-I interface

– 29-pin male DVI-A connector (bottom) to 15-pin female connector (top)

– weight approx. 40 g

– dimensions (W x H x D) 40 x 42 x 15 mm

Labeling Tags

order number Description

CX1900-0200 Universal plastic labels for the CX-System (package contains 1000 labels)

– snaps into the premoulded spots on the CX-System components

– labeling can be done with a X-Y plotter

– dimension of the single label 15 x 5 mm

– material: white colored plastic

– Murrplastik type KMR 5/15, order number 86401014

replacement battery for CX-System

order number Description

CX1900-0102 Battery for das CX-System

- original product description: Panasonic type CR2032 3V/225mAh

Embedded PC 57

Page 60

Appendix

Certifications

All products of the Embedded PC family are CE, UL and GOST-R certified. Since the product family is continuousl y

developed further, we are unable to provide a full listing here. The current list of certified products can be found on

the Embedded PC certificates web page or at www.beckhoff.de under Embedded PC.

58 Embedded PC

Page 61

Appendix

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast and

competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of individual

Beckhoff products, but also with other, wide-ranging services:

• world-wide support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

You will find further support and service addresses on our Internet pages under http://www.beckhoff.com.

Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Embedded PC 59

Loading...

Loading...