Page 1

Manual | EN

CX8191

Embedded PC with BACnet/IP

6/29/2020 | Version: 1.0

Page 2

Page 3

Table of contents

Table of contents

1 Notes on the documentation ....................................................................................................................5

1.1 Representation and structure of warnings.........................................................................................6

1.2 Documentation issue status ..............................................................................................................7

2 For your safety...........................................................................................................................................8

2.1 Intended use......................................................................................................................................8

2.2 Staff qualification ...............................................................................................................................8

2.3 Safety instructions .............................................................................................................................9

3 Transport and storage.............................................................................................................................10

4 Product overview.....................................................................................................................................11

4.1 Structure ..........................................................................................................................................13

4.2 Name plate ......................................................................................................................................14

4.3 Ethernet interfaces ..........................................................................................................................15

4.4 BACnet/IP........................................................................................................................................18

4.5 MicroSD card...................................................................................................................................19

4.6 Reset button ....................................................................................................................................19

5 Commissioning........................................................................................................................................20

5.1 Mounting..........................................................................................................................................20

5.1.1 Dimensions ...................................................................................................................... 20

5.1.2 Note the permissible installation positions....................................................................... 21

5.1.3 Securing on mounting rail ................................................................................................ 23

5.2 Connecting the power supply ..........................................................................................................24

6 Configuration ...........................................................................................................................................26

6.1 Operating system ............................................................................................................................26

6.1.1 Features included ............................................................................................................ 27

6.1.2 Update image .................................................................................................................. 28

6.1.3 FTP Server ...................................................................................................................... 29

6.2 IP address .......................................................................................................................................31

6.2.1 Setting with DIP switches ................................................................................................ 31

6.2.2 Setting in the operating system ....................................................................................... 32

6.3 Web service.....................................................................................................................................33

6.3.1 Starting the Beckhoff Device Manager ............................................................................ 33

6.3.2 Enabling a remote display ............................................................................................... 34

6.3.3 Changing the IP address of the Ethernet interfaces (X101, X102).................................. 35

6.3.4 Starting a remote connection........................................................................................... 36

6.4 TwinCAT..........................................................................................................................................37

6.4.1 Connecting to the CX81xx ............................................................................................... 37

6.4.2 Scanning for devices ....................................................................................................... 39

6.4.3 Creating a BACnet server and a device object................................................................ 40

6.4.4 Linking to IO task ............................................................................................................. 42

7 Programming ...........................................................................................................................................45

7.1 Seconds UPS ..................................................................................................................................45

7.1.1 Function block.................................................................................................................. 47

7.1.2 Data types........................................................................................................................ 49

CX8191 3Version: 1.0

Page 4

Table of contents

7.1.3 PlcAppSystemInfo ........................................................................................................... 50

7.2 Function F_CX81xx_ADDRESS......................................................................................................51

7.3 Real Time Clock (RTC)....................................................................................................................51

8 Ethernet X001 Interface...........................................................................................................................52

8.1 Ethernet ...........................................................................................................................................52

8.2 Topology example ...........................................................................................................................54

8.3 ADS-Communication .......................................................................................................................54

9 Error handling and diagnosis.................................................................................................................56

9.1 Diagnostic LEDs ..............................................................................................................................56

9.2 K-bus ...............................................................................................................................................56

9.3 E-bus ...............................................................................................................................................59

10 Care and maintenance ............................................................................................................................60

10.1 Replace the battery .........................................................................................................................60

11 Technical data..........................................................................................................................................61

12 Appendix ..................................................................................................................................................63

12.1 Certification......................................................................................................................................63

12.1.1 FCC ................................................................................................................................. 63

12.2 Support and Service ........................................................................................................................64

CX81914 Version: 1.0

Page 5

Notes on the documentation

1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning the components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCAT G®, EtherCAT G10®, EtherCAT P®, Safety over EtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702

with corresponding applications or registrations in various other countries.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

CX8191 5Version: 1.0

Page 6

Notes on the documentation

1.1 Representation and structure of warnings

The following warnings are used in the documentation. Read and follow the warnings.

Warnings relating to personal injury:

DANGER

Hazard with high risk of death or serious injury.

WARNING

Hazard with medium risk of death or serious injury.

CAUTION

There is a low-risk hazard that can result in minor injury.

Warnings relating to damage to property or the environment:

NOTE

There is a potential hazard to the environment and equipment.

Notes showing further information or tips:

This notice provides important information that will be of assistance in dealing with the product or

software. There is no immediate danger to product, people or environment.

CX81916 Version: 1.0

Page 7

1.2 Documentation issue status

Version Comment

1.0 First version

Notes on the documentation

CX8191 7Version: 1.0

Page 8

For your safety

2 For your safety

Read the chapter on safety and follow the instructions in order to protect from personal injury and damage to

equipment.

Limitation of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Unauthorized modifications and changes to the hardware or software configuration, which go

beyond the documented options, are prohibited and nullify the liability of Beckhoff Automation GmbH & Co.

KG.

In addition, the following actions are excluded from the liability of Beckhoff Automation GmbH & Co. KG:

• Failure to comply with this documentation.

• Improper use.

• Untrained personnel.

• Use of unauthorized replacement parts.

2.1 Intended use

The CX81xx Embedded PC is a control system and is intended for mounting on a DIN rail in a control

cabinet or terminal box.

The Embedded PC series is used in conjunction with Bus Terminals for recording digital or analog signals

from sensors and transferring them to actuators or higher-level controllers.

The Embedded PC is designed for a working environment that meets the requirements of protection class

IP20. This involves finger protection and protection against solid foreign objects up to 12.5 mm, but not

protection against water. Operation of the devices in wet and dusty environments is not permitted, unless

specified otherwise. The specified limits for electrical and technical data must be adhered to.

Improper use

The Embedded PC is not suitable for operation in the following areas:

• Potentially explosive atmospheres.

• Areas with an aggressive environment, e.g. aggressive gases or chemicals.

• Living areas. In living areas, the relevant standards and guidelines for interference emissions must be

adhered to, and the devices must be installed in housings or control boxes with suitable attenuation of

shielding.

2.2 Staff qualification

All operations involving Beckhoff software and hardware may only be carried out by qualified personnel with

knowledge of control and automation engineering. The qualified personnel must have knowledge of the

administration of the Embedded PC and the associated network.

All interventions must be carried out with knowledge of control programming, and the qualified personnel

must be familiar with the current standards and guidelines for the automation environment.

CX81918 Version: 1.0

Page 9

For your safety

2.3 Safety instructions

The following safety instructions must be followed during installation and working with networks and the

software.

Mounting

• Never work on live equipment. Always switch off the power supply for the device before installation,

troubleshooting or maintenance. Protect the device against unintentional switching on.

• Observe the relevant accident prevention regulations for your machine (e.g. the BGV A 3, electrical

systems and equipment).

• Ensure standard-compliant connection and avoid risks to personnel. Ensure that data and supply

cables are laid in a standard-compliant manner and ensure correct pin assignment.

• Observe the relevant EMC guidelines for your application.

• Avoid polarity reversal of the data and supply cables, as this may cause damage to the equipment.

• The devices contain electronic components, which may be destroyed by electrostatic discharge when

touched. Observe the safety precautions against electrostatic discharge according to DIN EN

61340-5-1/-3.

Working with networks

• Limit physical and electronic access to all devices to an authorized group of persons.

• Change the default passwords to reduce the risk of unauthorized access. Regularly change the

passwords.

• Install the devices behind a firewall.

• Apply the IT security precautions according to IEC 62443, in order to limit access to and control of

devices and networks.

Working with the software

• Use up-to-date security software. The safe function of the Embedded PC can be compromised by

malicious software such as viruses or Trojans.

• The sensitivity of an Embedded PC against malicious software increases with the number of installed

and active software.

• Uninstall or disable unnecessary software.

Further information about the safe handling of networks and software can be found in the Beckhoff

Information System:

http://infosys.beckhoff.com

Document name

Documentation about IPC Security

CX8191 9Version: 1.0

Page 10

Transport and storage

3 Transport and storage

Transport

NOTE

Short circuit due to moisture

Moisture can form during transport in cold weather or in the event of large temperature fluctuations.

Avoid moisture formation (condensation) in the Embedded PC, and leave it to adjust to room temperature

slowly. If condensation has occurred, wait at least 12 hours before switching on the Embedded PC.

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts. During

transport the Embedded PC must be protected from

• mechanical stress and

• use the original packaging.

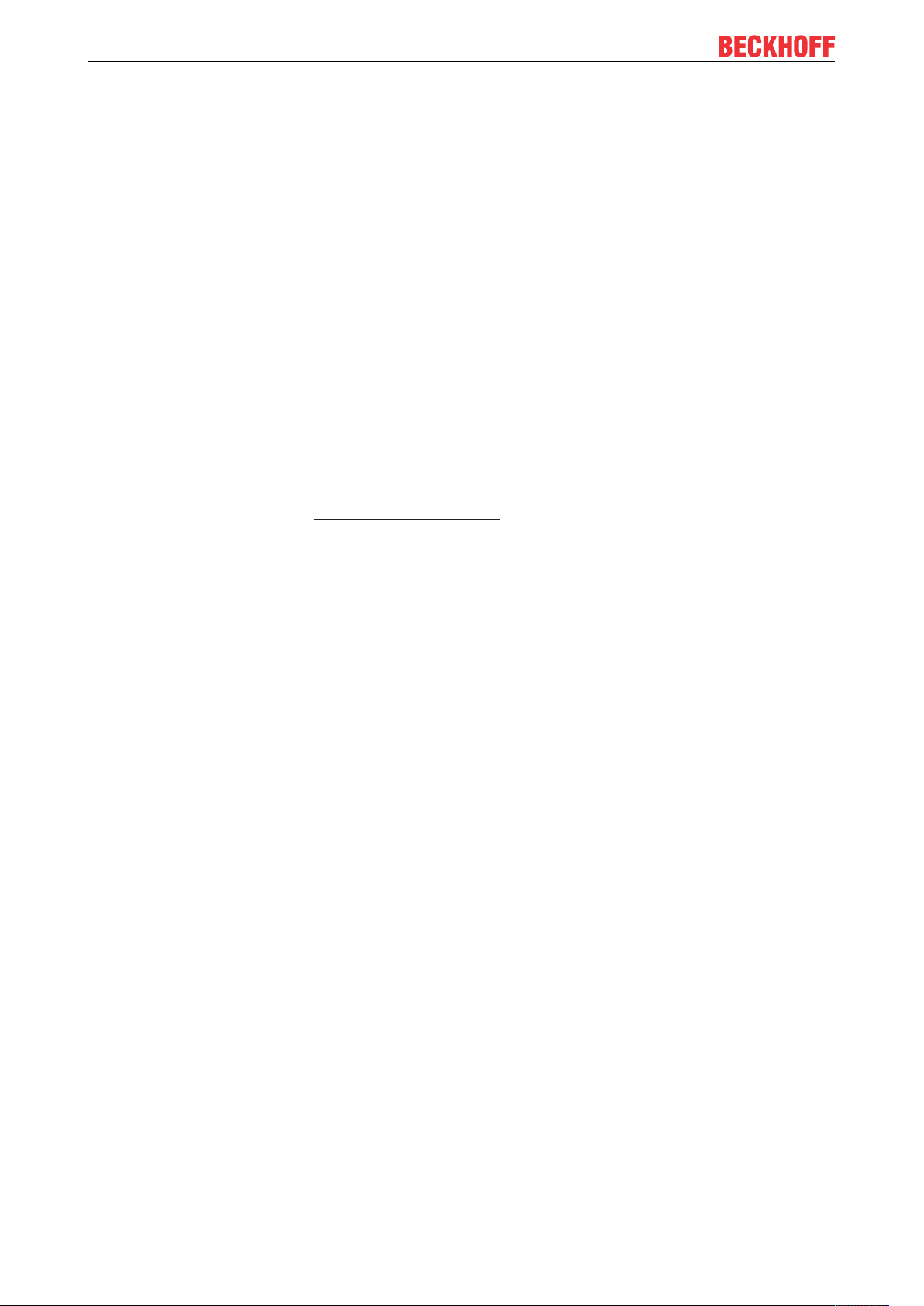

Table1: Dimensions and weight of the CX8191 Embedded PC.

CX8191

Dimensions (WxHxD) 71 mm x 100 mm x 73 mm

Weight 230g

Storage

• The battery should be removed if the Embedded PC is stored at temperatures above 60°C. The

battery should be stored separate from the Embedded PC in a dry environment at a temperature

between 0 °C and 30 °C.

The preset date and time are lost if the battery is removed.

• Store the Embedded PC in the original packaging.

CX819110 Version: 1.0

Page 11

Product overview

4 Product overview

CX8100 designates a product family of Embedded PCs based on a 32-bit ARM CPU. The CX8100

Embedded PC is programmable and is able to execute its own control program. In addition to that the

Embedded PC acts as a slave device of a higher-level fieldbus system.

The CX8100 Embedded PC has the following basic configuration:

• a 512MB MicroSD card,

• an Ethernet interface

• as well as two switched Ethernet interfaces (2 x RJ45, switched).

You can use the CX8100 Embedded PCs as decentralized controllers and in this way ensure that the local

program continues to be executed on the CX8100 in the event of an interruption in the higher-level fieldbus

system.

The operating system is Microsoft Windows Embedded Compact 7. Because there is no monitor port, the

operating system and its "virtual" display can only be accessed via the network. Beckhoff Device Manager

and Remote Display (Cerhost)

The Embedded PC features an internal 1-second UPS as persistent data memory. The 1-second UPS

enables persistent data to be saved to the MicroSD card in the event of a power failure.

Power supply terminal

The power supply terminal for the Embedded PC is located on the right-hand side. Bus Terminals (K-bus) or

EtherCAT Terminals (E-bus) can be attached on the right-hand side of the power supply terminal. The power

supply terminal automatically recognizes the respective bus system (K-bus or E-bus).

The use of EtherCAT Terminals (E-bus) enables further options, such as the implementation of different

topologies, the integration of further bus systems such as CANopen, PROFIBUS and PROFINET and – with

the EtherCAT Box Modules – connection to the IP67 world.

Fieldbus interface

CX8100 devices are being prepared for further fieldbus systems such as EtherCAT (slave), PROFINET,

EtherNet/IP, CANopen, PROFIBUS and other communication systems.

Available fieldbus systems:

• CX8110: EtherCAT

• CX8180: RS232/485

• CX8190: Ethernet (Realtime Ethernet, ADS UDP, ADS TCP, EAP, Web Services)

• CX8191: BACnet (client and server)

Programming

The CX8100 Embedded PCs are programmed according to the high-performance IEC61131-3 standard.

The TwinCAT 3 automation software forms the basis for the programming of the Embedded PC.

Configuration

The CX8100 Embedded PC is commissioned via the Ethernet interface. The fieldbus interface and all

connected devices such as EtherCAT Terminals or Bus Terminals are then read out via TwinCAT 3. The

configuration is stored on the Embedded PC after the parameterization. The configuration thus created can

be accessed again later.

The shortest usable task time is 500µs, although this is only achievable with a very small system load. A

task time of 1 to 50ms is recommended for the I/O data. Other tasks can also be set slower. When using

shorter cycle times, the total system load is to be observed.

CX8191 11Version: 1.0

Page 12

Product overview

If too short a cycle time is selected, the Web visualization and Remote Display may operate very slowly or

cause timeouts. The user is responsible for configuring his system such that it is not overloaded.

CX819112 Version: 1.0

Page 13

Product overview

1

2

7

4

8

10

11

12

14

3

13

15

5

6

9

10

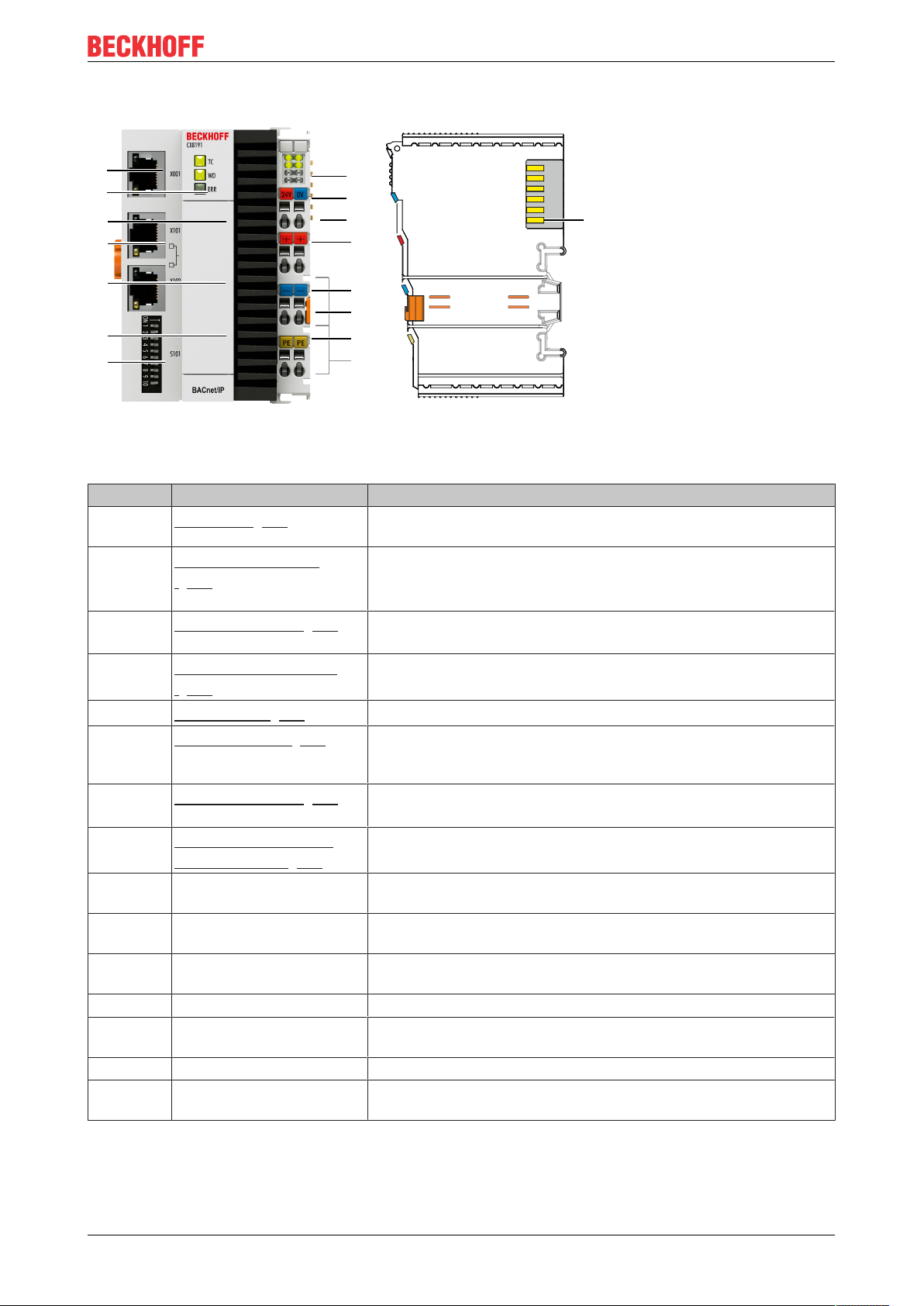

4.1 Structure

Fig.1: Sample configuration of a CX8191 Embedded PC.

Table2: Legend for the configuration.

No. Component Description

1

2

3

4

5

6

7

8

9 Spring-loaded terminals,

10 Terminal bus (K-bus or E-

11 Spring-loaded terminal,

12 Spring-loaded terminal, 0V Power supply for Bus Terminals via power contact.

13 Terminal release Releases the power supply terminal and therefore the Embedded

14 Spring-loaded terminal, PE Spring-loaded terminal for power contact PE.

15 Power contacts, +24V,

Also see about this

2 Setting with DIP switches [}31]

CX8191 13Version: 1.0

DIP switch [}31] (S101).

Battery compartment

[}60] (under the front

flap).

MicroSD card slot [}19]

(under the front flap).

Ethernet interfaces RJ45

[}15] (X101, X102).

Reset button [}19]

Diagnostic LEDs [}56].

Ethernet interface [}15]

(X001).

Diagnostic LEDs, power

supply terminal [}56].

+24V and 0V

bus)

+24V

0V, PE

You can set the IP address for the X101/X102 switched Ethernet

interfaces with the DIP switch.

Power supply for the battery-backed clock for time and date.

Slot for industrial MicroSD cards.

BACnet/IP (client and server)

This switches the Embedded PC to Config mode.

Diagnostic LEDs. You can create your own diagnostic messages

for the WD and ERR diagnostic LEDs (see: Controlling CX8190

LEDs).

Interface for commissioning and programming the Embedded PC.

Diagnosis of the power supply for the Embedded PC and the

terminal bus. Status of the E-bus and K-bus communication.

Power supply for Embedded PC.

Interface for EtherCAT Terminals or Bus Terminals. Data exchange

and supply.

Power supply for Bus Terminals via power contact.

PC from the mounting rail.

Power contacts for Bus Terminals.

Page 14

Product overview

1

2

5

3

4

6

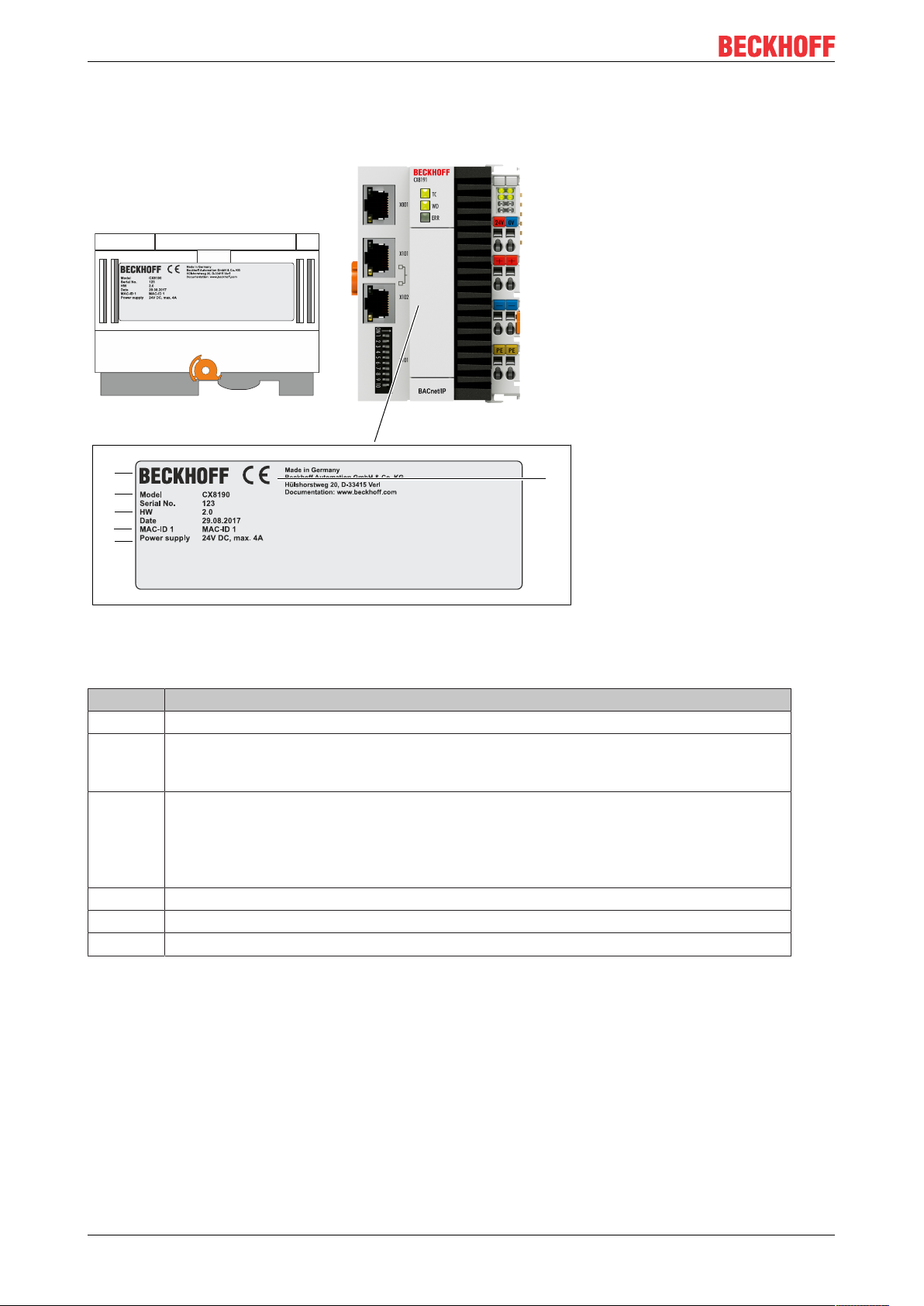

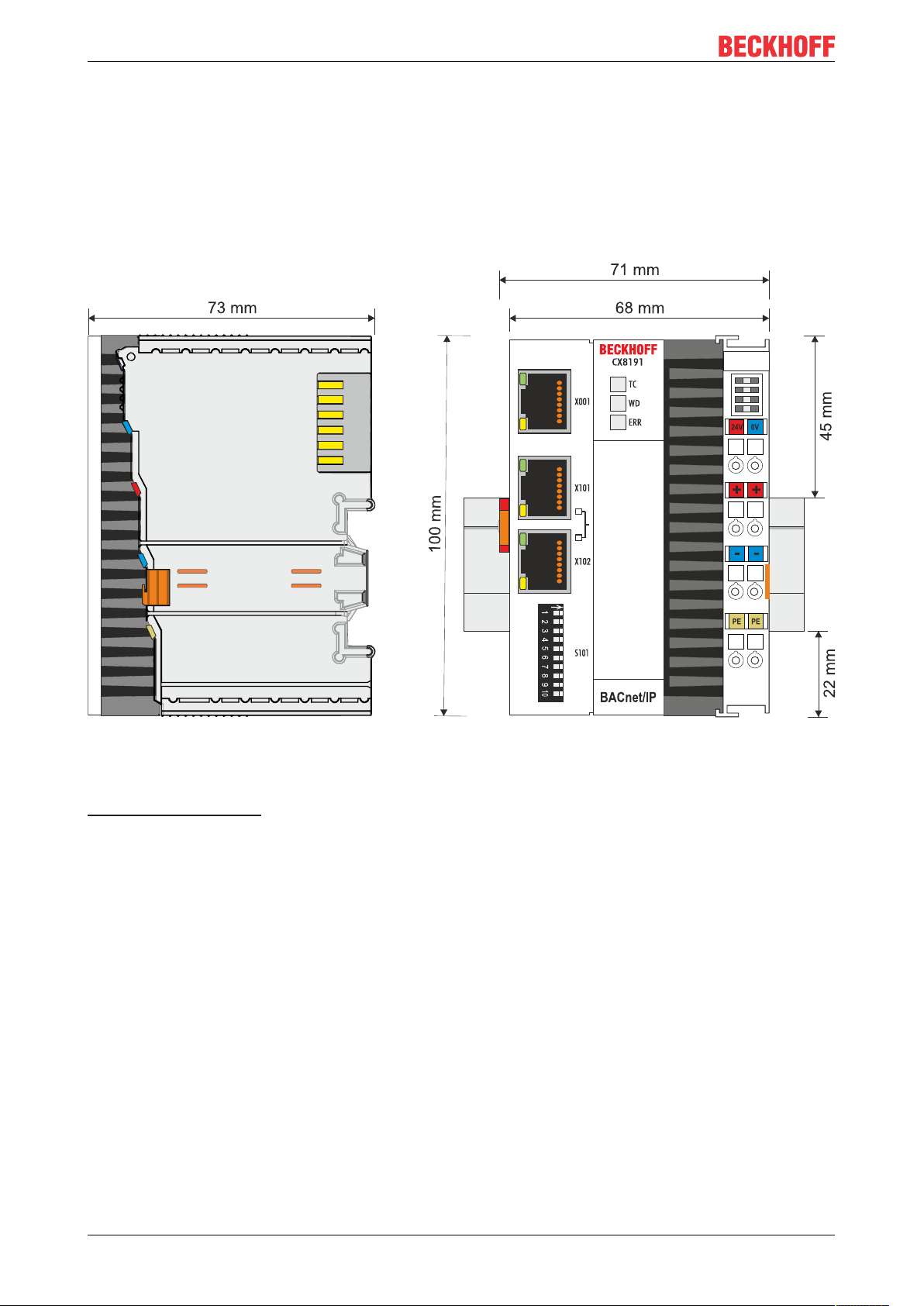

4.2 Name plate

The CX8191 Embedded PC features a name plate on the left-hand side of the housing.

Fig.2: CX8191 name plate.

Table3: Legend for the name plate.

No. Description

1 Information on the power supply unit. 24VDC, 4A max.

2 MAC address of the Ethernet interface X001.

By default, the host name is formed from CX plus the last 3 bytes of the MAC address:

for example, the MAC address: 00-01-05-aa-bb-cc results in the host name CX-aabbcc.

3 Information on:

• serial number,

• hardware version

• and date of manufacture.

4 Information on the model. The last two numbers code the version of the Embedded PC.

5 Vendor data including address.

6 CE conformity.

CX819114 Version: 1.0

Page 15

Product overview

4.3 Ethernet interfaces

You can program and commission the CX8191 Embedded PC via the X001 Ethernet interface. The Ethernet

interface achieves speeds of 10/100Mbit/s.

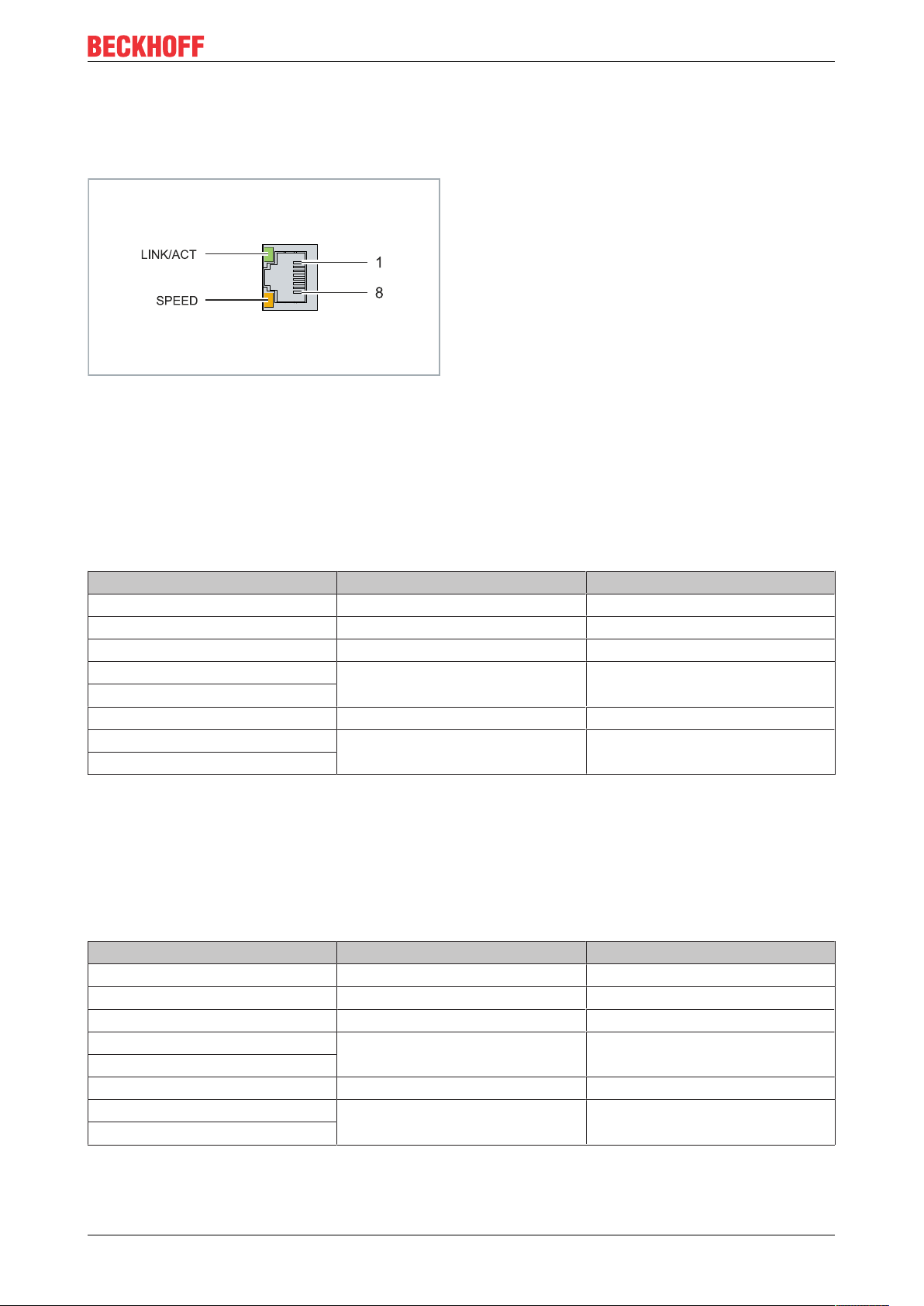

Fig.3: Ethernet interface X001, X101, X102.

The LEDs on the left of the interfaces indicate the connection status. The upper LED (LINK/ACT) indicates

whether the interface is connected to a network. If this is the case the LED is green. The LED flashes when

data transfer on the interface is in progress.

The lower LED (SPEED) indicates the connection speed. The LED is not lit if the speed is 10Mbit/s. At

100MBit/s, the LED lights up orange.

Table4: Ethernet interface X001, pin assignment.

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit -

3 RD + Receive +

4 connected reserved

5

6 RD - Receive -

7 connected reserved

8

Ethernet interfaces X101 and X102

Both Ethernet interfaces are switched and independent of each other. Both Ethernet interfaces reach speeds

of 100Mbit/s.

The switched interface can be used for BACnet or OPC UA protocols.

Table5: Ethernet interfaces X101 and X102, pin assignment.

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit -

3 RD + Receive +

4 connected reserved

5

6 RD - Receive -

7 connected reserved

8

CX8191 15Version: 1.0

Page 16

Product overview

Transmission standards

10Base5

The transmission medium for 10Base5 consists of a thick coaxial cable ("yellow cable") with a max.

transmission speed of 10Mbaud arranged in a line topology with branches (drops) each of which is

connected to one network device. Because all the devices are in this case connected to a common

transmission medium, it is inevitable that collisions occur often in 10Base5.

10Base2

10Base2 (Cheaper net) is a further development of 10Base5, and has the advantage that the coaxial cable is

cheaper and, being more flexible, is easier to lay. It is possible for several devices to be connected to one

10Base2 cable. It is frequent for branches from a 10Base5 backbone to be implemented in 10Base2.

10BaseT

Describes a twisted pair cable for 10Mbaud. The network here is constructed as a star. It is no longer the

case that every device is attached to the same medium. This means that a broken cable no longer results in

failure of the entire network. The use of switches as star couplers enables collisions to be reduced. Using

full-duplex connections they can even be entirely avoided.

100BaseT

Twisted pair cable for 100MBaud. It is necessary to use a higher cable quality and to employ appropriate

hubs or switches in order to achieve the higher data rate.

10BaseF

The 10BaseF standard describes several optical fiber versions.

Short description of the 10BaseT and 100BaseT cable types

Twisted pair copper cable for star topologies, where the distance between two devices may not exceed 100

meters.

UTP

Unshielded twisted pair

This type of cable belongs to category 3, and is not recommended for use in an industrial environment.

S/UTP

Screened/unshielded twisted pair (screened with copper braid)

Has a general screen of copper braid to reduce influence of external interference. This cable is

recommended for use with Bus Couplers.

FTP

Foiled shielded twisted pair (screened with aluminum foil)

This cable has an outer screen of laminated aluminum and plastic foil.

S/FTP

Screened/foiled-shielded twisted pair (screened with copper braid and aluminum foil)

Has a laminated aluminum screen with a copper braid on top. Such cables can provide up to 70dB reduction

in interference power.

CX819116 Version: 1.0

Page 17

Product overview

STP

Shielded twisted pair

Describes a cable with an outer screen, without defining the nature of the screen any more closely.

S/STP

Screened/shielded twisted pair (wires are individually screened)

This identification refers to a cable with a screen for each of the two wires as well as an outer shield.

ITP

Industrial Twisted-Pair

The structure is similar to that of S/STP, but, in contrast to S/STP, it has only one pair of conductors.

CX8191 17Version: 1.0

Page 18

Product overview

4.4 BACnet/IP

BACnet (Building Automation Control Network) is a standardized, manufacturer-independent communication

protocol for building automation. The protocol is used in HVAC, lighting control, security and fire alarm

applications.

As a BACnet building controller (B-BC), the CX8191 Embedded PC meets the following requirements:

• Certification to BACnet standard ISO 16484-5 Revision 14

• Support of the AS-B profile (extended functional range) according to AMEV BACnet 2017

• Integration of the BACnet protocol into the TwinCAT System Manager

• Newly developed library that can be used to create and change BACnet objects directly in the PLC

runtime and to store the properties persistently

• All string encoding character sets defined in the BACnet standard (UTF8, USC2, USC2, ISO8859 ...)

are supported )

BACnet supplement TF8020

The BACnet supplement TF8020 is pre-installed on the CX8191 in delivery state. No further installations or

keys are required. The TF8020 BACnet supplement can only be used via the X101/102 Ethernet interfaces.

Further Information:

TF8020 supplement description: https://beckhoff.de/tf8020/

Adding the OPC UA TF6100 supplement

In contrast to the CX8091 predecessor device, the OPC UA TF6100 supplement is not pre-installed on the

CX8191. OPC UA and other protocols such as Modbus/TCP can be activated and licensed later using the

license manager.

Memory usage

Under certain circumstances, the RAM available on the CX8191 can be ‘eaten up’ with trend log objects.

Check whether enough RAM is available for your application. Beckhoff recommends a maximum of 750

BACnet objects.

This is a guide value; the actual value may be higher or lower. It depends on the CPU and RAM load and on

the BACnet objects used.

CX819118 Version: 1.0

Page 19

Product overview

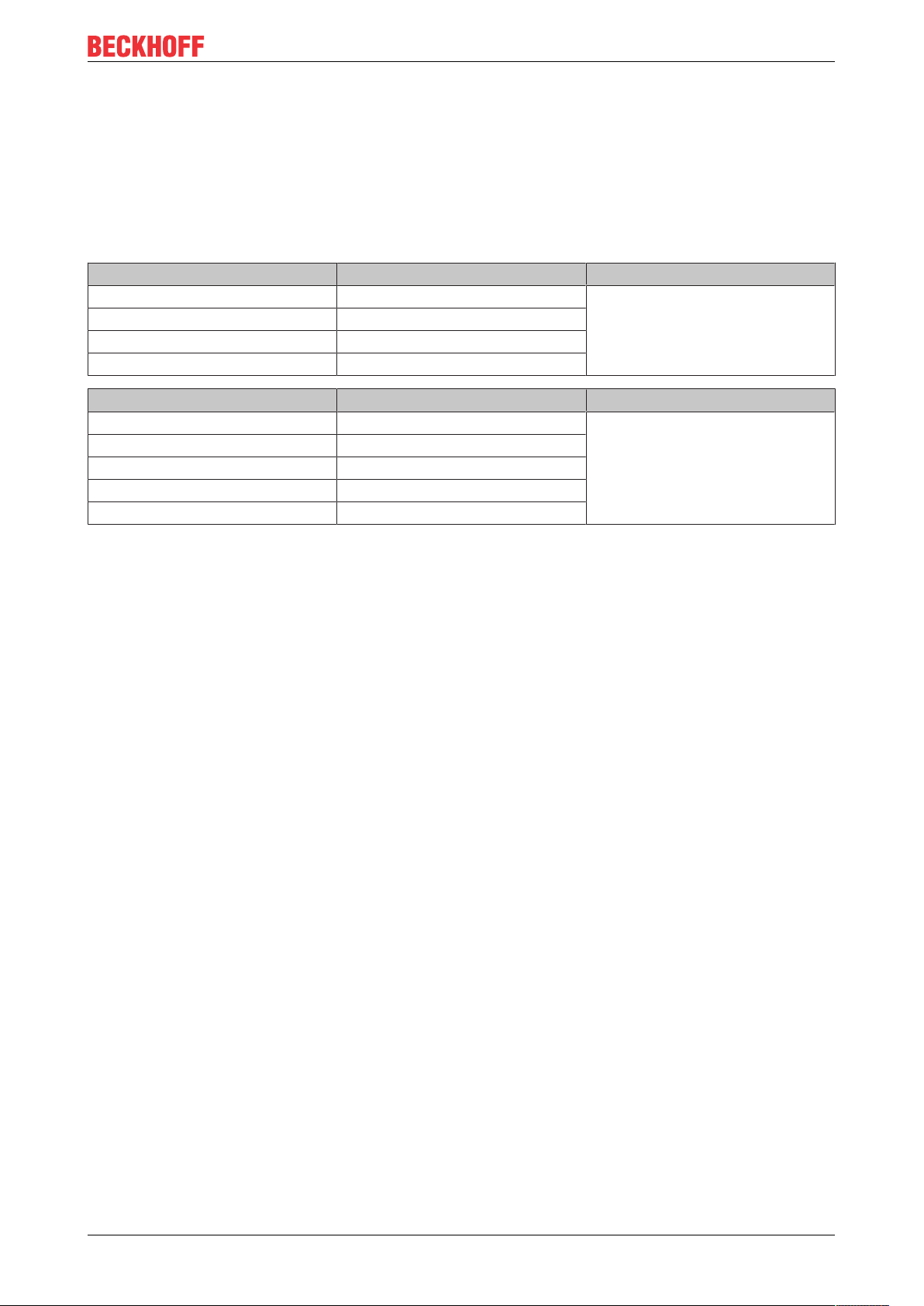

4.5 MicroSD card

In the basic configuration, the CX81xx contains a MicroSD card with 512MB. You can order it as an option

with larger cards (up to 8GB).

The cards employed are SLC memory with extended temperature range for industrial applications. Use

exclusively MicroSD cards approved by Beckhoff.

Example of a MicroSD card:

Order designation Capacity Description

CX1900-0123 1GB MicroSD card (SLC memory) with

CX1900-0125 2GB

CX1900-0127 4GB

CX1900-0129 8GB

Order designation Capacity Description

CX1900-0122 512MB MicroSD card (SLC memory) with

CX1900-0124 1GB

CX1900-0126 2GB

CX1900-0128 4GB

CX1900-0130 8GB

extended temperature range for

industrial applications instead of

the 512MB card (ordering option)

extended temperature range for

industrial applications as spare

part.

4.6 Reset button

Use the Reset button to activate Config mode. You can use this function if the PLC program unexpectedly

causes an error. To do this, keep the Reset button pressed during the restart for an extended period.

Activate Config mode as follows:

1. Open the front flap.

2. Switch off the Embedded PC.

3. Start the Embedded PC and keep the Reset button pressed until the ERR LED turns red and then

yellow.

ð The CX81xx Embedded PC is put into Config mode.

CX8191 19Version: 1.0

Page 20

Commissioning

5 Commissioning

5.1 Mounting

5.1.1 Dimensions

Fig.4: Dimensions of the CX81xx Embedded PC.

Technical drawings in DWG and STP formats can be found at:

http://www.beckhoff.com

CX819120 Version: 1.0

Page 21

Commissioning

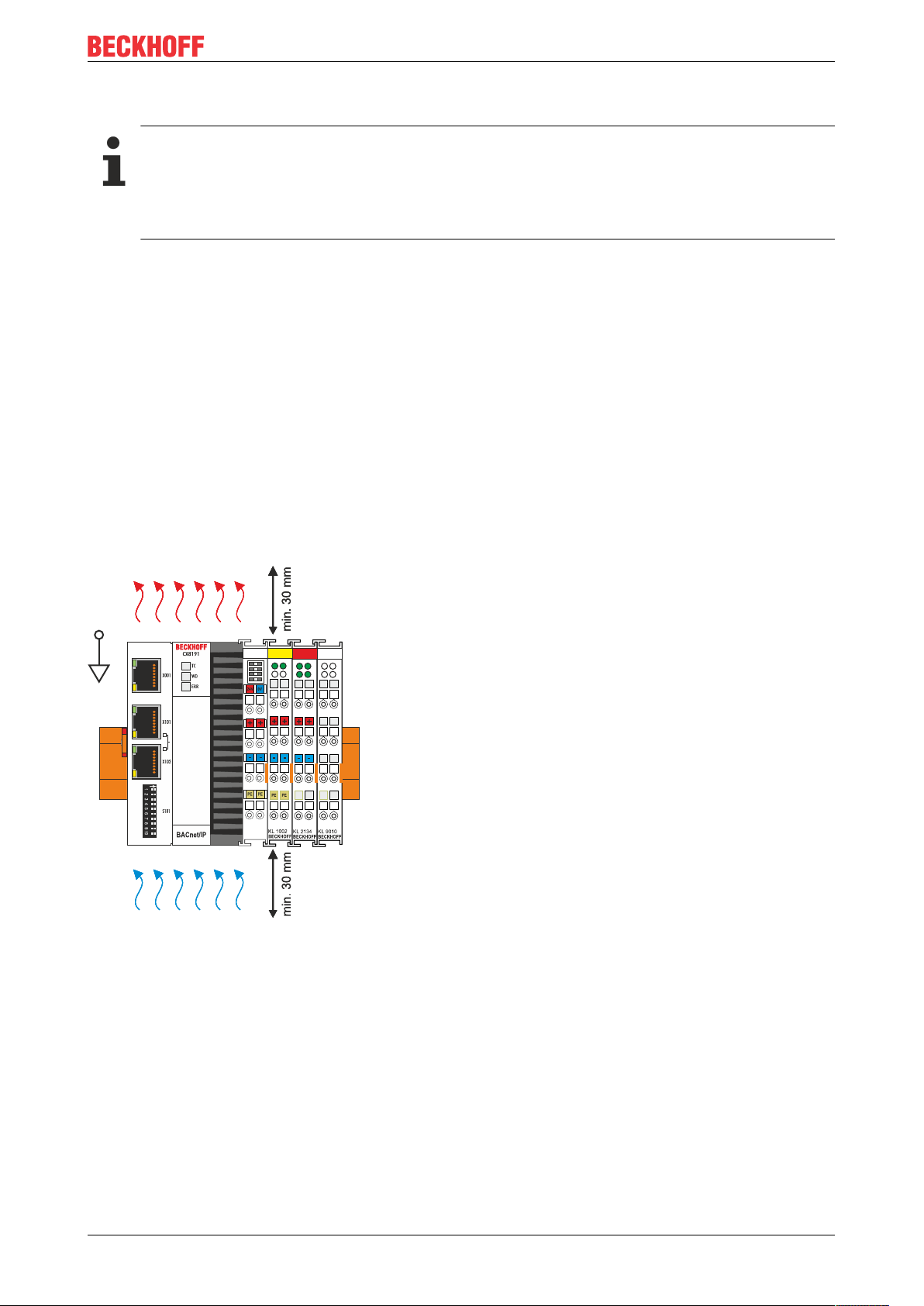

5.1.2 Note the permissible installation positions

Increased heat generation

The Embedded PC may overheat if the installation position is incorrect or the minimum distances

are not adhered to.

Ensure adequate ventilation. A horizontal installation position is ideal. Leave at least 30 mm clearance above and below the Embedded PC.

Note the following specifications for the control cabinet:

• Keep to the prescribed ambient temperature. Measure the temperature below the Embedded PC at a

distance of 30mm to the cooling fins, in order to determine the ambient temperature correctly.

• Adhere to the minimum distances of 30mm above and below the Embedded PCs.

• Additional electrical equipment affects the heat generation in the control cabinet. Select a suitable

control cabinet enclosure depending on the application, or ensure that excess heat is dissipated from

the control cabinet.

Prescribed installation position for temperatures up to 60°C

Install the Embedded PC horizontally in the control cabinet on a mounting rail, in order to ensure optimum

heat dissipation.

Ventilation openings are located at the top and bottom of the housing. This ensures an optimum airflow

through the Embedded PC in vertical direction. In addition, a minimum clearance of 30mm above and below

the Embedded PCs is required, in order to ensure adequate ventilation.

Fig.5: Embedded PC CX8191, horizontal installation position.

CX8191 21Version: 1.0

Page 22

Commissioning

Installation positions with reduced temperature range up to 50°C

You can also mount the Embedded PC vertically or horizontally on the mounting rail. Note that you can then

only operate the Embedded PC up to an ambient temperature of 50°C.

Fig.6: Embedded PC CX8191, vertical installation position.

Fig.7: Embedded PC CX8191, horizontal installation position.

Ensure that Bus Terminals that are connected to the Embedded PC are designed for operation in vertical or

horizontal position.

CX819122 Version: 1.0

Page 23

Commissioning

5.1.3 Securing on mounting rail

The housing is designed such that the Embedded PC can be pushed against the mounting rail and latched

onto it. The Embedded PC is fastened to the DIN rail by means of a catch on the left side of the Embedded

PC.

Requirements:

• Mounting rail of type TS35/7.5 or TS35/15 according to DIN EN 60715.

Secure the Embedded PC on the mounting rail as follows:

1. Place the Embedded PC at the front of the mounting rail. Slightly press the Embedded PC onto the

mounting rail until a soft click can be heard and the Embedded PC has latched.

2. Subsequently, lock the catch on the left side of the Embedded PC. Use a screwdriver to do this.

ð Double-check the correct installation and latching of the Embedded PC on the mounting rail.

CX8191 23Version: 1.0

Page 24

Commissioning

5.2 Connecting the power supply

NOTE

Damage to the Embedded PCs

The Embedded PCs may be damaged during wiring.

• The cables for the power supply should only be connected in de-energized state.

The power supply terminals require an external voltage source, which provides 24VDC (-15% / +20%). The

power supply terminal must provide 4A at 24V, in order to ensure the operation of the Embedded PCs in all

situations.

The cabling of the Embedded PC in the control cabinet must be done in accordance with the standard EN

60204-1:2006 PELV = Protective Extra Low Voltage:

• The "PE" and "0V" conductors of the voltage source for a basic CPU module must be on the same

potential (connected in the control cabinet).

• Standard EN 60204-1:2006, section 6.4.1:b stipulates that one side of the circuit, or a point of the

energy source for this circuit must be connected to the protective earth conductor system.

Connection example

Table6: Legend for the connection example

No. Description

1 The upper spring-loaded terminals identified with "24V" and "0V" supply the Embedded

PC and the terminal bus (data transfer via K-bus or E-bus).

2 The spring-loaded terminals identified as "+", "-" and "PE" supply the Bus Terminals via

the power contacts and the sensors or actuators connected to the Bus Terminals.

CX819124 Version: 1.0

Page 25

Commissioning

Opening and closing spring-loaded terminals:

The cables of an external voltage source are connected to the power supply unit with spring-loaded

terminals. Connect the cables as follows:

Table7: Required wire cross-sections and strip lengths

Wire cross-section 0.5 ... 2.5 mm

2

AWG 20 .. AWG 14

Strip length 8 ... 9 mm 0.33 inch

The voltage source has been connected to the power supply unit

successfully when the two upper power supply terminal LEDs light up in

green.

• The left LED (Us) indicates the supply of the basic CPU module and

terminal bus.

• The red LED (Up) indicates the Bus Terminal supply via the power

contacts.

NOTE

Interrupting / switching off the power supply

To switch off the Embedded PC, do not disconnect the ground (0 V), because otherwise current may continue to flow via the shielding, depending on the device, and damage the Embedded PC or peripheral devices.

• Always disconnect the 24 V line. Devices connected to the Embedded PC, which have their own power

supply (e.g. a Panel) must have the same potential for "PE" and "0 V" as the Embedded PC have (no

potential difference).

Observe the UL requirements

The CX8191 Embedded PCs are UL certified. The corresponding UL label can be found on the type plate.

The CX8191 Embedded PCs can thus be used in areas in which special UL requirements have to be met.

These requirements apply to the system voltage (Us) and to the power contacts (Up). Application areas

without special UL requirements are not affected by UL regulations.

UL requirements

• The Embedded PCs must not be connected to unlimited voltage sources.

• Embedded PCs may only be supplied from a 24 V DC voltage source. The voltage source must be

insulated and protected with a fuse of maximum 4 A (corresponding to UL248).

• Or the power supply must originate from a voltage source that corresponds to NEC class 2. An NEC

class 2 voltage source must not be connected in series or parallel with another NEC class 2 voltage

source.

CX8191 25Version: 1.0

Page 26

Configuration

6 Configuration

6.1 Operating system

The Microsoft Windows Embedded Compact 7 operating system is used on the CX8191 Embedded PC. This

operating system is optimized for the CX8191 Embedded PC. This means that not all features of Windows

Embedded Compact 7 are available.

Security

For reasons of security the CERHOST and TELNET services are deactivated in the delivery state. To

reactivate these services, you need a MicroSD card reader.

CERHOST

CERHOST is deactivated by current images on first start-up via the registry file

CeRemoteDisplay_Disable.reg, which is located in the folder RegFiles.

To reactivate CERHOST you have to delete the file CeRemoteDisplay_Disable.reg from the folder RegFiles

and also the folder Documents and Settings

Then reinsert the MicroSD card in the Embedded PC and reboot. The Embedded PC creates a new

Document and Settings directory and then reboots automatically.

The Embedded PC is then accessible again via CERHOST.

TELNET

TELNET is deactivated by current images on first start-up via the registry file Telnet_Disable.reg, which is

located in the folder RegFiles.

To reactivate TELNET you have to delete the file Telnet_Disable.reg from the folder RegFiles and also the

folder Documents and Settings.

Then reinsert the MicroSD card in the Embedded PC and reboot. The Embedded PC creates a new

Document and Settings directory and then reboots automatically.

CX819126 Version: 1.0

Page 27

6.1.1 Features included

Features CX8191

ATL X

MFC X

XML DOM X

XML Minimal Parser X

COM X

DCOM X

COM Storage X

Winsock X

TCP/IP X

TCP/IPv6 X

Firewall X

Network Utilities (IpConfig, Ping, Route) X

Object Exchange Protocol OBEX -

Message Queuing MSMQ -

UPnP

Control Point -

Device Host X

SOAP

Client -

Server -

Server -

File Server (SMB/CIFS) X

FTP Server X

Print Server (SMB/CIFS) -

RAS Server / PPTP Server X

Simple Network Time Protocol (SNTP) X

SNTP Client Service X

Simple Network Management Protocol (SNMP) X

Telnet Server X

Web Server (HTTPD) / Active Server Pages (ASP)

Support / JScript 5.8 / VBScript 5.8

X

Configuration

Internet Explorer 7.0 -

NET Compact Framework v3.5

RDP Client (Remote Desktop protocol) -

CAB File Installer/Uninstaller X

CX8191 27Version: 1.0

Page 28

Configuration

6.1.2 Update image

NOTE

Loss of data

All data on the MicroSD card will be deleted. Backup any data that you may have on the MicroSD card before proceeding.

The new image will be copied directly to the MicroSD card in order to update the image of the Embedded

PC.

The new image is made available by Beckhoff Service. Perform the update only after consulting with

Beckhoff Service.

Requirements:

• Card reader for MicroSD cards.

Update the image as follows:

1. Switch the Embedded PC off and remove the MicroSD card from the Embedded PC.

2. Insert the MicroSD card into an external card reader and open the MicroSD card's folder tree.

3. Delete all files and folders on the MicroSD card.

4. Copy all files and folders of the new image to the empty MicroSD card.

5. Install the MicroSD card in the Embedded PC again.

6. Start the Embedded PC.

ð The Embedded PC is started and saves the current hardware configuration in the folder Documents and

Settings. The image has now been successfully updated.

CX819128 Version: 1.0

Page 29

Configuration

6.1.3 FTP Server

Restricted access through firewall

From image version "CX8100_WEC7_LF_v604h_TC31_B4022.20", the firewall for the CX8191 is

enabled by default. This means that a passive FTP connection (as used by Microsoft, for example)

cannot be established. We therefore recommend using active FTP access. Enter TCP ports 20 and

21 in the firewall.

The File Transfer Protocol (FTP) is based exclusively on TCP-based communication connections. FTP

specifies two TCP ports, which are important for data transfer:

• Port 20/tcp: This port is also referred to as data port and is used to send/receive files and directory

lists.

• Port 21/tcp: This port is generally referred to as command port and is used to exchange status

information between the client and server.

Separate TCP connections are used for sending and receiving files (data port) and for transmitting

commands (command port). With FTP, two connection modes are available for setting up such connections:

"Active FTP" and "Passive FTP". Depending on the connection mode, the two ports mentioned above are

initiated differently, which is described in more detail below.

Active FTP

With active FTP, the client connects to the command port of the FTP server. The client uses a random port

N, e.g. 4242/tcp, as source port. The client then listens on port N+1 and notifies the server of this port. The

server then connects to the client on port N+1 and uses its data port as the source port.

A problem with active FTP is that the client itself does not establish a connection to the server's data port,

but communicates a port (N+1) to the server, which then connects to the client via its data port. In the case

of firewalls or NAT devices that are located upstream of the client, this could involve additional configuration

effort on the client side, since the data port of the client behind the firewall must be accessible to the server

(see figure "Connect 4243").

Passive FTP

This method is used when the client is not directly accessible by the server. This is the case, for example, if

the client is behind a firewall that uses NAT to rewrite the client's address. With passive FTP, the FTP client

initiates a connection via two random TCP ports N (command port) and N+1 (data port). The first port is used

to connect to the server's command port. However, instead of the client communicating its port N+1 to the

server so that the server can open a connection to it (see active FTP), the client first transmits a so-called

PASV command. The server now knows that the connection is via passive FTP. As a result, the server

opens a (random) port P as data port and transmits it to the client. The client then initiates a connection with

port P and uses port N+1 (data port) as the source port. This connection is then used to transfer the data.

CX8191 29Version: 1.0

Page 30

Configuration

On closer examination it becomes apparent that the firewall problem of active FTP is reversed with passive

FTP. On the server side, the firewall should be configured such that the data port of the server can be

reached by the client. Many FTP servers offer the option to configure the data ports to be used.

CX819130 Version: 1.0

Page 31

Configuration

6.2 IP address

6.2.1 Setting with DIP switches

You can set the IP address for the switched Ethernet interfaces X101/X102 with the DIP switches S101. The

DIP switches have no meaning for the Ethernet interface X001.

Fig.8: DIP switch S101, switches 1 to 10.

Right switch position: on "1".

Left switch position: off "0".

You can edit the last byte of the IP address with DIP switches 1 to 8. The DIP switches take priority over the

settings in the operating system. The changes are only accepted after restarting the Embedded PC.

Table8: Meaning of the DIP switch S101.

DIP switch S101 Meaning

10 on and 9 off. DHCP active. Standard setting ex factory.

The DIP switches 1 to 8 then have no meaning.

10 off and 9 off. DHCP inactive.

The fixed IP address 192.168.1.xxx and subnet mask 255.255.255.0

are used as standard.

The last byte of the IP address 192.168.1.xxx is edited with DIP

switches 1 to 8.

You can change the first three bytes of the IP address in the operating

system [}32] or via the web interface (Beckhoff Device Manager)

[}35]. You can edit the last byte of the IP address again with the DIP

switches.

10 off and 9 off

1 to 8 all on

The complete IP address is adopted from the operating system or the

web interface (Beckhoff Device Manager).

Example

If you wish to set the IP address for the Ethernet interface X101/X102 to 192.168.1.67 using the DIP

switches, you have to configure the DIP switches as follows:

DIP 1 DIP 2 DIP 3 DIP 4 DIP 5 DIP 6 DIP 7 DIP 8 DIP 9 DIP 10

On On Off Off Off Off On Off off off

The following value for the last byte of the IP address then results from the switched-on DIP switches:

20 + 21 + 26 = 67

Table9: Values for the individual DIP switches.

DIP 1 DIP 2 DIP 3 DIP 4 DIP 5 DIP 6 DIP 7 DIP 8

Value 2

0

1

2

2

2

3

2

4

2

5

2

6

2

7

2

CX8191 31Version: 1.0

Page 32

Configuration

6.2.2 Setting in the operating system

The two Ethernet interfaces X001 and X101/X102 are displayed with Windows Embedded Compact 7 as

EMAC1 and TCCCATMP1.

Fig.9: Ethernet interfaces with Windows Embedded Compact 7.

EMAC1 (X001)

As standard, DHCP is active and the IP address is assigned automatically. You can deactivate DHCP and

assign a static IP address.

TCCCATMP1 (X101/102)

As standard the first three bytes of the IP address (standard: 192.168.1) are assigned in the operating

system. The last byte of the IP address (192.168.1.xxx) can be set using the DIP switches.

The DIP switches are set ex factory such that DHCP is active for the Ethernet interfaces (X101, X102). The

DIP switches take priority over the settings in the operating system. As a result, the settings in the operating

system or via the web interface are not adopted.

You have to set the DIP switches appropriately in order to set the last byte of the IP address in the operating

system. Set the DIP switches 10 and 9 to "off" and 1 to 8 to "on" so that the complete IP address is adopted

from the operating system.

EtherCAT interface

The EtherCAT interface is a further Ethernet interface that is not visible in the operating system for the IP

addressing.

CX819132 Version: 1.0

Page 33

Configuration

6.3 Web service

6.3.1 Starting the Beckhoff Device Manager

Using the Beckhoff Device Manager, an Industrial PC can be configured by remote access with the aid of a

web browser. Depending on the image version, access takes place via different protocols and requires

different open ports. For older image versions access takes place via the HTTP protocol and Port 80 (TCP).

More up-to-date image versions use HTTPS and Port 443 (TCP).

Requirements:

• Host PC and Embedded PC must be located in the same network. Depending on the operating system

version, the network firewall must allow access via port 80 (HTTP) or port 443 (HTTPS).

• IP address or host name of the Embedded PC.

Table10: Access data for the Beckhoff Device Manager on delivery.

User name Password

Administrator 1

Start the Beckhoff Device Manager as follows:

1. Open a web browser on the host PC.

2. Enter the IP address or the host name of the Industrial PC in the web browser to start the Beckhoff

Device Manager.

• Example with IP address: https://169.254.136.237/config

• Example with host name: https://CX-16C2B8/config

3. Enter the user name and password. The start page appears:

ð Navigate forward in the menu and configure the Industrial PC. Note that modifications only become

active once they have been confirmed. It may be necessary to restart the Industrial PC.

CX8191 33Version: 1.0

Page 34

Configuration

6.3.2 Enabling a remote display

So that you can remotely access an Industrial PC with CE operating system, you must first activate Remote

Display in the Beckhoff Device Manager. The remote display is disabled by default.

Requirements:

• Host PC and Embedded PC must be located in the same network. Depending on the operating system

version, the network firewall must allow access via port 80 (HTTP) or port 443 (HTTPS).

• The IP address or the host name of the Embedded PC must be known.

Table11: Access data for the Beckhoff Device Manager on delivery.

Operating system Access data

Windows Embedded Compact 7 User name: Administrator

Password: 1

Enable the remote display as follows:

1. Open a web browser on the host PC.

2. Enter the IP address or the host name of the Industrial PC in the web browser to start the Beckhoff

Device Manager.

• Example with IP address: https://169.254.136.237/config

• Example with host name: https://CX-16C2B8/config

3. Enter the user name and password. The start page appears.

4. In the menu under Device click on Boot Opt.

5. Under Remote Display select the option On and confirm the settings.

6. In the information window click OK to accept the settings.

ð You have successfully activated Remote Display on the Industrial PC. After restarting, you can remotely

access your Industrial PC.

CX819134 Version: 1.0

Page 35

Configuration

6.3.3 Changing the IP address of the Ethernet interfaces (X101, X102)

DIP switches take priority

The DIP switches are set ex factory such that DHCP is active for the Ethernet interfaces (X101,

X102). As a result, the settings in the operating system or via the web interface are not adopted.

Deactivate DHCP using the DIP switches. Set the DIP switches 10 and 9 to "off" and 1 to 8 to "on"

so that the settings are adopted from the operating system or the web interface.

In this work step you will learn how to change the IP address of the Ethernet interface (X101, X102) via the

web interface (Beckhoff Device Manager).

Requirements:

• Set the DIP switches correctly so that the IP address is adopted completely from the operating system.

• Start the web interface (see: Starting the Beckhoff Device Manager).

Change the IP address as follows:

1. Click on Device and then on Connectivity.

2. Click on the wrench symbol to configure the network settings.

3. Change the network settings and assign a new IP address.

ð Save the settings to confirm all changes.

CX8191 35Version: 1.0

Page 36

Configuration

6.3.4 Starting a remote connection

With the aid of the Remote Display Control program (CERHOST), a remote connection can be established

and an Industrial PC with CE operating system can be remotely controlled from a host PC.

Requirements:

• Remote Display is active. See: Enabling a remote display.

• Host name of the Embedded PC.

• Remote Display Control (CERHOST). Download under: https://infosys.beckhoff.com/content/1033/

CX8191_HW/Resources/zip/5047075211.zip

Start the remote connection as follows:

1. Unpack the zip file on the host PC and run cerhost.exe.

2. Click on File in the menu bar and then on Connect.

3. Enter the host name of the Embedded PC in the Hostname field.

ð The remote connection is started and the Windows Embedded CE 7 start screen appears.

CX819136 Version: 1.0

Page 37

Configuration

6.4 TwinCAT

6.4.1 Connecting to the CX81xx

Before you can work with the CX81xx you must connect your local computer to the CX81xx (target system).

Then you can search for devices such as EtherCAT terminals with the help of the IP address or the host

name.

The local PC and the target system must be connected to the same network or directly to each other via an

Ethernet cable. In TwinCAT a search can be performed for all devices in this way and project planning

subsequently carried out.

Requirements for this step:

• TwinCAT 3 must be in Config mode.

• IP address or host name of the Embedded PC.

Establish a connection as follows:

1. In the menu at the top click on File > New > Project and create a new TwinCAT XAE project.

2. In the tree view on the left click on SYSTEM, and then Choose Target.

3. Click on Search (Ethernet).

4. Type the host name or the IP address of the device into the Enter Host Name / IP box and press

[Enter].

CX8191 37Version: 1.0

Page 38

Configuration

5. Mark the device found and click on Add Route.

The Logon Information window appears.

Enter the user name and password for the CX in the User Name and Password fields and click OK.

The following information is set as standard in CX devices:

User name: Administrator Password: 1

6. If you do not wish to search for any further devices, click on Close to close the Add Route window.

The new device is displayed in the Choose Target System window.

7. Select the device you want to specify as target system and click OK.

ð You have successfully searched for a device in TwinCAT and inserted the device as the target system.

The new target system and the host name are displayed in the menu bar.

Using this procedure you can search for all available devices and also switch between the target systems

at any time. Next, you can append the device to the tree view in TwinCAT.

CX819138 Version: 1.0

Page 39

Configuration

6.4.2 Scanning for devices

As soon as the CX81xx has been inserted as the target system in TwinCAT you can scan for further devices

and in this way, for example, insert all the EtherCAT Terminals or Bus Terminals connected to the CX81xx

into the TwinCAT tree view.

Requirements for this step:

• The CX81xx is connected as the target system to TwinCAT (see: Connecting to the CX81xx [}37]).

• TwinCAT 3 is in ConfigMode.

Scan for devices as follows:

1. In the tree view on the left, right-click on Devices under I/O.

2. In the context menu click on Scan.

3. Select the devices you want to use and confirm the selection with OK.

Depending on whether EtherCAT terminals or Bus Terminals are connected to the CX81xx, the K-bus

interface (Bus Terminals) or the EtherCAT interface (EtherCAT terminals) will be found.

4. Confirm the request with Yes, in order to look for boxes.

5. In the Scanning BACnet Clients window, select the devices to which you want to establish a BACnet

communication and click Add Clients.

6. Confirm the request whether to enable FreeRun with Yes.

ð The devices are created in the tree view. Depending on the connected terminals, either a Bus Coupler or

an EtherCAT coupler with the associated terminals will be displayed.

In the next step you can create a small program.

CX8191 39Version: 1.0

Page 40

Configuration

6.4.3 Creating a BACnet server and a device object

This step shows how to create a BACnet server. Additionally, it shows how to create the device object for the

BACnet device and two FILE objects (configuration and persistence file).

Proceed as follows:

1. In the tree view on the left, right-click on BACnet IP Device.

2. Click on Add New Item in the context menu.

3. Select BACnet Server (Module) and confirm with OK.

The device object of the BACnet device and two FILE objects (configuration and persistence file) are

created.

4. Select the BACnet server in the tree view on the left and click the Settings tab.

CX819140 Version: 1.0

Page 41

5. Then select EtherCAT/K-Bus AutoMapping and click the Map button.

Configuration

6. Confirm the settings in the IoBusMappingDialog window by clicking on Map.

ð BACnet objects of type Analog Input, Analog Output, Binary Input or Binary Output are created for each

of the four signal types: analog input, analog output, binary input and binary output

CX8191 41Version: 1.0

Page 42

Configuration

6.4.4 Linking to IO task

In this step the functionality without a PLC project is demonstrated. If the terminals are connected to a PLC

project, this step is not required. In this case the terminals are addressed by the PLC task.

In order for the connected terminals to be addressed cyclically without a PLC project, the EtherCAT device,

in this example "Device 2", must be linked to an IO task.

Proceed as follows:

1. Click Add New Item under SYSTEM > Tasks on the left side of the tree view.

2. Assign a name to the task and select the option TwinCAT Task With Image.

3. Accept the default values for the task.

CX819142 Version: 1.0

Page 43

4. Right-click Inputs on the left side of the tree view, then click Add New Item.

Configuration

5. Create a UINT variable with a size of two bytes.

6. Link the UINT variable to the EtherCAT device, in this example "Device 2“.

7. To do this, right-click on the created UINT variable in the tree view on the left, then click Change Link.

ð All variables of type UINT are available for selection.

CX8191 43Version: 1.0

Page 44

Configuration

8. Now link the UINT variable to a variable of the EtherCAT device, e.g. SlaveCount.

9. Activate the configuration and restart the TwinCAT system when requested.

10. For the first binary output, click the Online tab and set the value under PresentValue to "active“. The

digital output is activated.

Alternatively, you can connect a switch to a digital input of the EL1004 terminal. When the switch is

operated, the value "active" appears under PresentValue of the BACnet object“.

ð This completes the sample configuration. If your PC has a network chipset from Intel, you can now

operate this PC as a BACnet client, scan the BACnet network, add the CX8191 and control the digital

output with the BACnet client. Ensure that you are in the same IP network.

CX819144 Version: 1.0

Page 45

7 Programming

7.1 Seconds UPS

Loss of data

The use of the 1-second UPS outside of the documented possibilities can lead to loss or corruption

of data.

Use only TwinCAT to control the 1-second UPS and save only persistent data with a maximum size

of 1 MB.

The 1-second UPS is an UltraCap capacitor that continues to

supply the processor with power in the event of a power failure.

During this period persistent data can be saved, which are

available on switching on again.

Since the 1-second UPS is designed for the entire service life,

the holding time is considerably longer with new devices. The

capacitors age over the course of time and the holding time

decreases. Therefore a maximum of 1MB persistent data can

be reliably saved over the entire service life.

Do not save any other data and do not use any other

applications to control the 1-second UPS.

Programming

Please note that the 1-second UPS does not supply power to the K-bus or the E-bus and that their data may

already be invalid when the 1-second UPS is activated. Also, the fieldbus system (or Ethernet) may not work

or not work properly once the 1-second UPS was activated.

Storage location and names of the files:

The persistent data are saved by default in the TwinCAT boot directory:

Development environment File path File name

TwinCAT 3 \\TwinCAT\3.1\Boot\Plc Port_85x.bootdata

Port_85x.bootdata-old (backup)

The x in the file name stands for

the number of the runtime system.

Configure the 1-second UPS as follows in order to save persistent data:

• Declare important data such as counter values in the PLC as VAR PERSISTENT. Then call the

function block FB_S_UPS_CX81xx cyclically in TwinCAT with the fastest task in order to control the 1-

second UPS (see: Function block [}47]).

• Select the mode in the function block in order to specify what should happen in the case of a power

failure. Specify, for example, whether persistent data are saved and a quick shutdown is executed

(see: Data types [}49]).

• You can then check the validity of the variables and monitor whether the persistent variables are

loaded without error (see: PlcAppSystemInfo).

Components Version

TwinCAT on the development PC and on the control

system

TwinCAT 3.1 Build 4020.16 or higher

CX8191 45Version: 1.0

Page 46

Programming

Saving and loading persistent data

The persistent data are saved in the Port_85x.bootdata file on the MicroSD card. On starting the PLC the

Port_85x.bootdata file is loaded from the MicroSD card, backed up there as Port_85x.bootdata_old (backup)

and then deleted.

Another current Port_85x.bootdata file is not written until the system is shut down or the 1-second UPS is

activated.

If no Port_85x.bootdata file exists when starting the Embedded PC, the persistent data are invalid and will be

deleted (standard setting). The reason for this is that the 1-second UPS was activated before the TwinCAT

PLC was started during startup of the Embedded PC. In this case no persistent data were saved, since the

system was unable to ensure sufficient buffer time for saving the data.

Always call the function block from the PLC and always use the fastest task to do so. In the case of a power

failure Beckhoff recommends not calling the rest of the application in order to ensure that sufficient time

remains for writing the data.

IF NOT FB_S_UPS_CX81xx.bPowerFailDetect THEN

;//Call programs and function blocks

END_IF

The rest of the application influences the CPU load and the CPU load in turn affects the period during which

the persistent data are written.

Loading a backup of the persistent data

A registry setting can be used to determine whether the backup file is deleted or used. The backup file is

used by default (setting 0):

[HKEY_LOCAL_MACHINE\SOFTWARE\Beckhoff\TwinCAT\Plc]"ClearInvalidPersistentData"= 0

If the backup file is to be deleted, the value of "ClearInvalidPersistentData" in the registry must be set to 1.

It is also possible in TwinCAT to specify on the left in the tree view under PLC > CX8190 whether the backup

file is to be used or not.

Fig.10: Loading a backup of the persistent data. Settings in TwinCAT 3.

The backup files will be deleted if the option Clear Invalid Persistent Data is activated. Corresponds to

registry entry 1.

CX819146 Version: 1.0

Page 47

Programming

7.1.1 Function block

FUNCTION_BLOCK FB_S_UPS_CX81xx

The function block FB_S_UPS_CX81xx can be used on CX81xx devices with second UPS, in order to

control the second UPS from the PLC. This enables the persistent data to be saved according to the

selected mode in the event of a power failure. The default input values of the FB_S_UPS_CX81xx should be

retained.

The second UPS does not have sufficient capacity for bridging power failures. Saving can take place only on

MicroSD cards.

The 1-second UPS can be used only for a few seconds in the event of a power failure in order, to save

persistent data. The data must be saved in the fast “persistent mode” “SPDM_2PASS”, even though this can

lead to real-time violations. Make sure you configure adequate router memory for saving the persistent data.

Regardless of the mode and therefore irrespective of whether data were saved or a quick shutdown was

performed, the UPS switches off the mainboard after the capacitors have been discharged, even if the

voltage has returned in the meantime.

NOTE

Loss of data

If other applications or the PLC keep further files open or write to them, file errors may occur if the 1-second

UPS switches off the controller.

Function block modes

A QuickShutdown is performed automatically in the eSUPS_WrPersistData_Shutdown mode (standard

setting) after the storage of the persistent data.

In the eSUPS_WrPersistData_NoShutdown mode only the persistent data are saved, no QuickShutdown is

performed.

In eSUPS_ImmediateShutdown mode a quick shutdown is executed immediately, without saving data.

In the eSUPS_CheckPowerStatus mode only a check is performed as to whether a power failure has

occurred. If this is the case, the function block only switches back to the PowerOK state after the expiry of

tRecoverTime (10s).

VAR_INPUT

VAR_INPUT

sNetID:T_AmsNetId:='';(*''=localnetid*)

iPLCPort:UINT:=0;(*PLCRuntimeSystemforwritingpersistentdata*)

tTimeout:TIME:=DEFAULT_ADS_TIMEOUT;(*ADSTimeout*)

eUpsMode:E_S_UPS_Mode:=eSUPS_WrPersistData_Shutdown;(*UPSmode(w/

wowritingpersistentdata,w/woshutdown)*)

ePersistentMode:E_PersistentMode:=SPDM_2PASS;(*modeforwritingpersistentdata*)

tRecoverTime:TIME:=T#10s;(*ONtimetorecoverfromshortpowerfailureinmodeeSUPS_Wr

PersistData_NoShutdown/eSUPS_CheckPowerStatus*)

END_VAR

sNetID: AmsNetID of the controller (type: T_AmsNetID)

iPLCPort: Port number of the PLC runtime system (851 for the first PLC runtime system, 852 for the second

PLC runtime system, …). If no port number is specified, iPLCPortis0. The function block then automatically

determines the port of the PLC runtime system.

tTimeout: Timeout for writing of the persistent data or the quick shutdown.

CX8191 47Version: 1.0

Page 48

Programming

eUpsMode: Defines whether persistent data are to be written and whether a quick shutdown is to be

executed. The default value is eSUPS_WrPersistData_Shutdown, i.e. a quick shutdown is executed

automatically once the persistent data have been saved. (Type: E_S_UPS_Mode)

ePersistentMode: Mode for the writing of the persistent data. Default value is SPDM_2PASS.

tRecoverTime: Time after which the UPS returns to PowerOK state in UPS modes without quick shutdown.

The tRecoverTime must be greater than the maximum charging time of the UPS, otherwise the UPS may

discharge too much in the event of short, consecutive power failures, which could result in the charge being

insufficient for storing the persistent data.

VAR_OUTPUT

VAR_OUTPUT

bPowerFailDetect:BOOL;(*TRUEwhilepowerfailureisdetected*)

eState:E_S_UPS_State:=eSUPS_PowerOK;(*currentupsstate*)

END_VAR

bPowerFailDetect: TRUE during power failure. FALSE if the supply voltage is present.

eState: Internal state of the function block (type: E_S_UPS_State)

VAR_GLOBAL

VAR_GLOBAL

eGlobalSUpsState:E_S_UPS_State;(*currentupsstate*)

END_VAR

eGlobalSUpsState: Internal state of the function block as global copy of VAR_OUTPUT

eState: For values see E_S_UPS_State

Requirements

Development environment

Target platform Hardware PLC libraries to be

linked

TwinCAT v3.1 CX81xx Seconds UPS Tc2_SUPS

CX819148 Version: 1.0

Page 49

Programming

7.1.2 Data types

E_S_UPS_Mode

eSUPS_WrPersistData_Shutdown:SchreibenderpersistentenDatenunddannQuickShutdown

eSUPS_WrPersistData_NoShutdown:NurSchreibenderpersistentenDaten(keinQuickShutdown)

eSUPS_ImmediateShutdown:NurQuickShutdown(keinSchreibenderpersistentenDaten)

eSUPS_CheckPowerStatus:NurStatusermitteln(wederSchreibenderPersistentenDatennochQuickShutd

own)

E_S_UPS_State

eSUPS_PowerOK:

inallenModi:VersorgungsspannungistOK

eSUPS_PowerFailure:

inallenModi:Versorgungsspannungfehlerhaft(stehtnureinenZyklusan)

eSUPS_WritePersistentData:

imModuseSUPS_WrPersistData_Shutdown:SchreibenderpersistentenDatenistaktiv

imModuseSUPS_WrPersistData_NoShutdown:SchreibenderpersistentenDatenistaktiv

eSUPS_QuickShutdown:

imModuseSUPS_WrPersistData_Shutdown:QuickShutdownistaktiv

imModuseSUPS_ImmediateShutdown:QuickShutdownistaktiv

eSUPS_WaitForRecover:

imModuseSUPS_WrPersistData_NoShutdown:WartenaufWiederkehrderSpannung

imModuseSUPS_CheckPowerStatus:WartenaufWiederkehrderSpannung

eSUPS_WaitForPowerOFF:

imModuseSUPS_WrPersistData_Shutdown:WartenaufdasAbschaltendurchdieUSV

imModuseSUPS_ImmediateShutdown:WartenaufdasAbschaltendurchdieUSV

Requirements

Development environment

Target platform Hardware PLC libraries to be

linked

TwinCAT v3.1 CX81xx Seconds UPS Tc2_SUPS

CX8191 49Version: 1.0

Page 50

Programming

7.1.3 PlcAppSystemInfo

Each PLC contains an instance of type 'PlcAppSystemInfo' with the name '_AppInfo'.

The corresponding namespace is 'TwinCAT_SystemInfoVarList'. This must be specified for use in a library,

for example.

TYPEPlcAppSystemInfo

STRUCT

ObjId:OTCID;

TaskCnt:UDINT;

OnlineChangeCnt:UDINT;

Flags:DWORD;

AdsPort:UINT;

BootDataLoaded:BOOL;

OldBootData:BOOL;

AppTimestamp:DT;

KeepOutputsOnBP:BOOL;

ShutdownInProgress: BOOL;

LicensesPending: BOOL;

BSODOccured: BOOL;

TComSrvPtr:ITComObjectServer;

AppName:STRING(63);

ProjectName:STRING(63);

END_STRUCT

END_TYPE

ObjId Object ID of the PLC project instance

TaskCnt Number of tasks in the runtime system

OnlineChangeCnt Number of online changes since the last complete download

Flags Reserved

AdsPort ADS port of the PLC application

BootDataLoaded PERSISTENT variables: LOADED (without error)

OldBootData PERSISTENT variables: INVALID (the back-up copy was loaded, since no

valid file was present)

AppTimestamp Time at which the PLC application was compiled

KeepOutputsOnBP The flag can be set and prevents that the outputs are zeroed when a

breakpoint is reached. In this case the task continues to run. Only the

execution of the PLC code is interrupted.

ShutdownInProgress This variable has the value TRUE if a shutdown of the TwinCAT system is in

progress. Some parts of the TwinCAT system may already have been shut

down.

LicensesPending This variable has the value TRUE if not all licenses that are provided by

license dongles have been validated yet.

BSODOccured This variable has the value TRUE if Windows is in a BSOD.

TComSrvPtr Pointer to the TcCOM object server

AppName Name generated by TwinCAT, which contains the port.

ProjectName Name of the project

CX819150 Version: 1.0

Page 51

7.2 Function F_CX81xx_ADDRESS

VAR_INPUT

VAR_INPUT

iCX_Typ:INT;(* Use product code without ‘CX’ e.g.: CX8180 -> 8180 *)

END_VAR

VAR_OUTPUT

F_CX80xx_ADDRESS:INT;

F_CX80xx_ADDRESS : -1, non-implemented CX, address of the switch

Requirements

Programming

Development environment

TwinCAT v3.1 Build

4022.30

Target platform Hardware PLC libraries to include

ARM CX8191 Tc2_SystemCX

7.3 Real Time Clock (RTC)

The real-time clock (RTC) is read out via the function blocks FB_LocalSystemTime and can be set with the

function block NT_SetLocalTime (see TcUtilities.lib). The RTC is supplied by the battery and can thus

continue to run in the power-off state.

Real-time clock (RTC) running too slow

TwinCAT uses its own real-time driver. This has the advantage that the quality of the real-time has been

much improved, and the jitter of the task has been reduced to a minimum. This calls the operating system

from TwinCAT. The RTC on the operating system is controlled via TwinCAT and must be called at certain

times.

If the task cycle time on the TwinCAT side is very long and the CPU load is high, the operating system is no

longer called with sufficient frequency. As a result, the RTC on the operating system is slow. If you have

noticed that the RTC is slow and the time on the CX8191 is also slow, you can apply the following

troubleshooting procedure.

Remedy

The call of the RTC is always linked to a reading of the hardware RTC. This has the disadvantage of a

slightly higher CPU load, but since the CPU load is already high due to your application, the additional CPU

load is negligible. Adjust the settings in the registry:

[HKEY_LOCAL_MACHINE\Platform]

“SoftRTC"=dword:0

Table12: Description of the SoftRTC registry key

Value Description

0 The hardware RTC is always read out when the Windows time is

requested.

1 The hardware RTC is read out once at startup. From then on, the

Windows clock continues to run via the internal system tick.

Standard setting: "SoftRTC"=dword:1

CX8191 51Version: 1.0

Page 52

Ethernet X001 Interface

8 Ethernet X001 Interface

8.1 Ethernet

Ethernet was originally developed by DEC, Intel and XEROX (as the "DIX" standard) for passing data

between office devices. The term nowadays generally refers to the IEEE802.3 CSMA/CD specification,

published in 1985. Because of the high acceptance around the world this technology is available everywhere

and is very economical. This means that it is easy to make connections to existing networks.

There are now a number of quite different transmission media: coaxial cable (10Base5), optical fiber

(10BaseF) or twisted pairs (10BaseT) with shield (STP) or without shield (UTP). Using Ethernet, different

topologies can be built such as ring, line or star.

Ethernet transmits Ethernet packets from a sender to one or more receivers. This transmission takes place

without acknowledgement, and without the repetition of lost packets. To achieve reliable data

communication, there are protocols, such as TCP/IP, that can run on top of Ethernet.

MAC-ID

The sender and receiver of Ethernet packets are addressed by means of the MAC-ID. The MAC-ID is a 6byte identification code unique to every Ethernet device in the world. The MAC-ID consists of two parts. The