Page 1

Manual | EN

CX51x0

Embedded-PC

7/13/2020 | Version: 2.7

Page 2

Page 3

Table of contents

Table of contents

1 Notes on the documentation ....................................................................................................................7

1.1 Representation and structure of warnings.........................................................................................8

1.2 Related documents............................................................................................................................9

1.3 Documentation issue status ..............................................................................................................9

2 For your safety.........................................................................................................................................10

2.1 Intended use....................................................................................................................................10

2.2 Staff qualification .............................................................................................................................11

2.3 Safety instructions ...........................................................................................................................11

3 Transport and storage.............................................................................................................................13

4 Product overview.....................................................................................................................................14

4.1 Configuration of the CX51x0 Embedded PC ...................................................................................15

4.2 Name plate ......................................................................................................................................16

4.3 Types...............................................................................................................................................17

4.4 Architecture overview ......................................................................................................................19

5 Description of the interfaces ..................................................................................................................21

5.1 USB (X100, X101, X102, X103) ......................................................................................................21

5.2 Ethernet RJ45 (X000, X001) ...........................................................................................................22

5.3 DVI-I (X200).....................................................................................................................................23

5.4 Optional interfaces...........................................................................................................................24

5.4.1 DVI-D (N010) ................................................................................................................... 24

5.4.2 DisplayPort (N011) .......................................................................................................... 25

5.4.3 Audio interface (N020)..................................................................................................... 26

5.4.4 RS232 (N030).................................................................................................................. 27

5.4.5 RS422/RS485 (N031)...................................................................................................... 28

5.4.6 EtherCAT slave (B110).................................................................................................... 30

5.4.7 PROFIBUS (x310) ........................................................................................................... 31

5.4.8 CANopen (x510) .............................................................................................................. 32

5.4.9 PROFINET RT (x930)...................................................................................................... 33

6 Commissioning........................................................................................................................................34

6.1 Assembly .........................................................................................................................................34

6.1.1 Note the permissible installation positions ...................................................................... 34

6.1.2 Attaching on mounting rail ............................................................................................... 36

6.1.3 MicroSD card installation and removal ............................................................................ 37

6.1.4 CFast card installation and removal ................................................................................ 38

6.1.5 Installing passive EtherCAT Terminals............................................................................ 39

6.2 Connecting the power supply ..........................................................................................................40

6.3 Switching on ....................................................................................................................................42

6.4 Switching off ....................................................................................................................................42

7 Configuration ...........................................................................................................................................43

7.1 Windows Embedded Compact 7 .....................................................................................................43

7.1.1 Setting up the audio interface (N020) .............................................................................. 43

7.2 Windows Embedded Standard 7 P..................................................................................................44

7.2.1 Identification of the Ethernet interfaces (X000, X001) ..................................................... 44

CX51x0 3Version: 2.7

Page 4

Table of contents

7.2.2 Enabling jumbo frames .................................................................................................... 45

7.2.3 Set NIC Teaming ............................................................................................................. 46

7.2.4 Restoring the Beckhoff real-time driver. .......................................................................... 48

7.3 Windows 10 IoT Enterprise LTSB ...................................................................................................49

7.3.1 Identification of the Ethernet interfaces (X000, X001) ..................................................... 49

7.3.2 Enabling jumbo frames .................................................................................................... 50

7.3.3 Set NIC Teaming ............................................................................................................. 51

7.3.4 Restoring the Beckhoff real-time driver ........................................................................... 53

7.3.5 Using serial interfaces N030/N031 .................................................................................. 54

7.4 Beckhoff Device Manager ...............................................................................................................55

7.4.1 Starting the Beckhoff Device Manager ............................................................................ 55

7.4.2 Enabling a remote display ............................................................................................... 56

7.4.3 Starting a remote connection........................................................................................... 57

7.5 TwinCAT..........................................................................................................................................58

7.5.1 Tree view ......................................................................................................................... 58

7.5.2 Searching for target systems ........................................................................................... 59

7.5.3 Scanning an Embedded PC ............................................................................................ 61

7.5.4 Configure the serial interface (N03x) ............................................................................... 62

7.5.5 Configuring EtherCAT cable redundancy. ....................................................................... 64

7.5.6 Using a hardware watchdog ............................................................................................ 66

8 1-second UPS (persistent data)..............................................................................................................68

8.1 BIOS settings...................................................................................................................................69

8.2 Windows write filter..........................................................................................................................71

8.3 FB_S_UPS_CX51x0 .......................................................................................................................72

8.4 Mode and status of the function block .............................................................................................74

8.5 Checking the validity of the variables ..............................................................................................75

8.5.1 SYSTEMINFOTYPE ........................................................................................................ 75

8.5.2 PlcAppSystemInfo ........................................................................................................... 77

9 Error handling and diagnostics..............................................................................................................78

9.1 Diagnostic LEDs ..............................................................................................................................78

9.2 Power supply terminal LEDs in K-bus mode ...................................................................................79

9.3 Power supply terminal LEDs in E-bus mode ...................................................................................82

9.4 Faults...............................................................................................................................................83

10 Care and maintenance ...........................................................................................................................84

10.1 Replace the battery .........................................................................................................................84

11 Decommissioning....................................................................................................................................85

11.1 Removing cables .............................................................................................................................85

11.2 Dismantling the Embedded PC .......................................................................................................86

12 Technical data..........................................................................................................................................87

13 Appendix ..................................................................................................................................................89

13.1 Accessories .....................................................................................................................................89

13.2 Certifications....................................................................................................................................90

13.3 Support and Service ........................................................................................................................91

List of tables.............................................................................................................................................92

CX51x04 Version: 2.7

Page 5

Table of contents

List of figures...........................................................................................................................................94

CX51x0 5Version: 2.7

Page 6

Table of contents

CX51x06 Version: 2.7

Page 7

Notes on the documentation

1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning the components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCAT G®, EtherCAT G10®, EtherCAT P®, Safety over EtherCAT®,

TwinSAFE®, XFC®, und XTS® and XPlanar®, are registered trademarks of and licensed by Beckhoff

Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702

with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

CX51x0 7Version: 2.7

Page 8

Notes on the documentation

1.1 Representation and structure of warnings

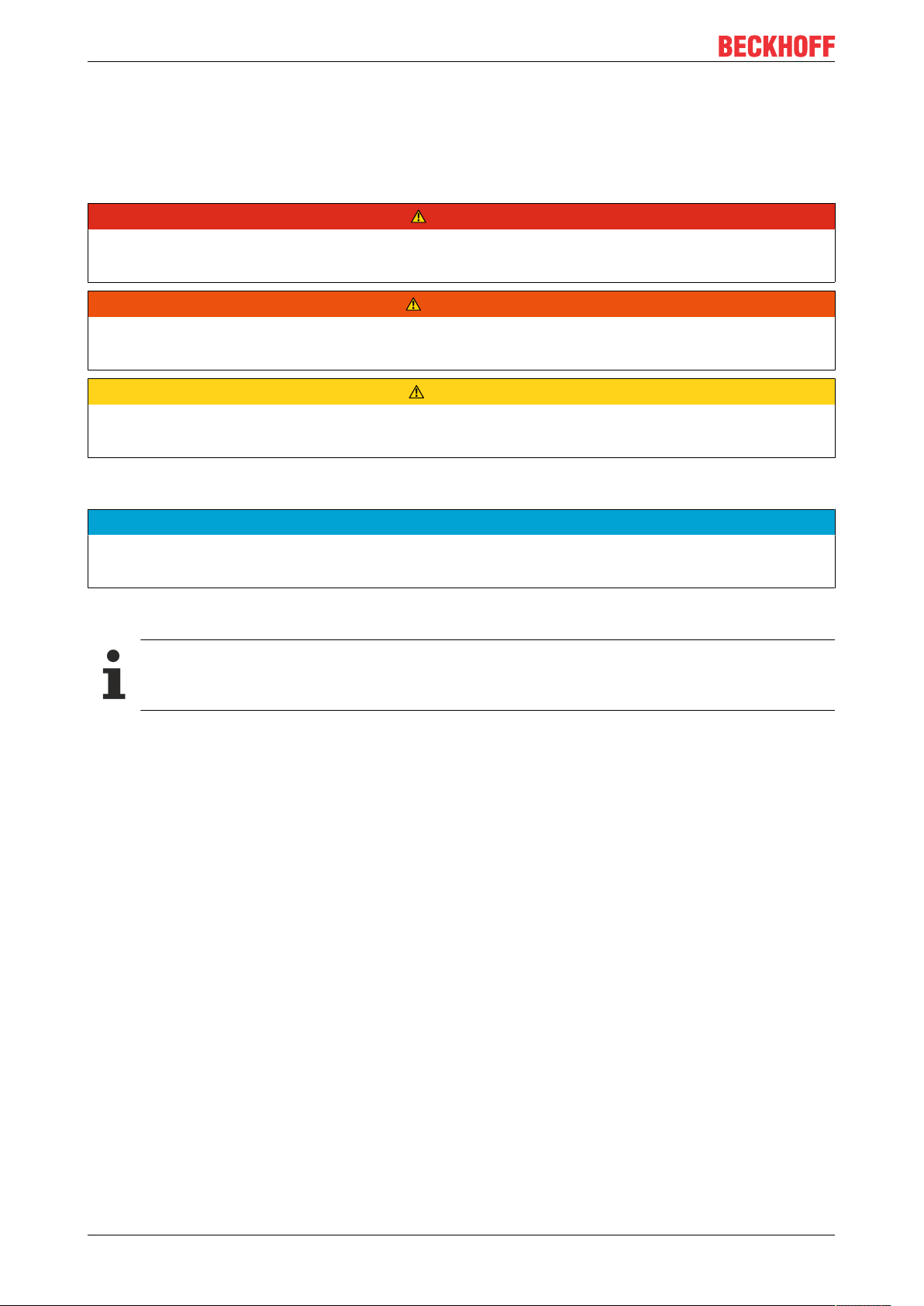

The following warnings are used in the documentation. Read and follow the warnings.

Warnings relating to personal injury:

DANGER

Serious risk of injury

Hazard with high risk of death or serious injury.

WARNING

Risk of injury

Hazard with medium risk of death or serious injury.

CAUTION

Slight risk of injury

There is a low-risk hazard that can result in minor injury.

Warnings relating to damage to property or the environment:

NOTE

Damage to the environment or devices

There is a potential hazard to the environment and equipment.

Notes showing further information or tips:

Tip or pointer

This notice provides important information that will be of assistance in dealing with the product or

software. There is no immediate danger to product, people or environment.

CX51x08 Version: 2.7

Page 9

Notes on the documentation

1.2 Related documents

Information on operation in potentially explosive atmospheres

Please refer to the corresponding documentation for important information and notes regarding operation of

the CX51x0 Embedded PCs in potentially explosive atmospheres. In particular, read and follow the sections

on safety contained in this document:

http://www.beckhoff.de

Document name

Notes on using the CX51x0 in potentially explosive atmospheres.

Retaining the documentation

This documentation is part of the Embedded PC. Keep the documentation in the immediate vicinity of the

device throughout its entire service life. Ensure that personnel have access to the documentation at all times.

Pass on the documentation to subsequent users, and in addition ensure that all supplementary information is

included in the documentation.

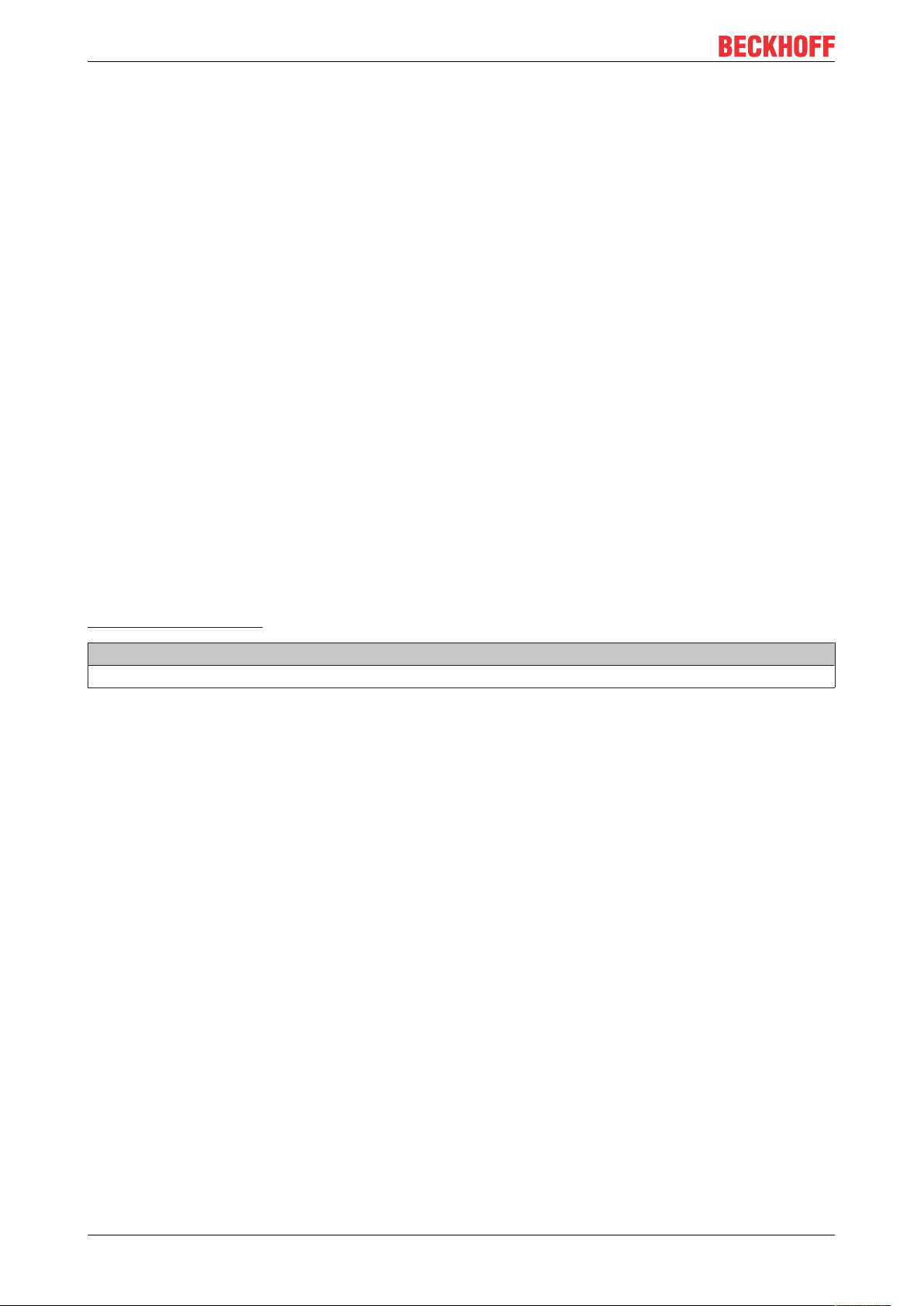

1.3 Documentation issue status

Version Modifications

0.1 Provisional version (original version)

1.0 First release

1.1 UL note expanded

1.2 Values changed in chapter 1-second UPS

1.3 Architecture overview added

1.4 Description of the diagnostic LEDs revised

1.5 Notes on driver support for serial interfaces added

1.6 Chapter Versions revised

1.7 Chapter 1-second UPS revised

1.8 Documentation restructured and revised

1.9 Notes on operation in potentially explosive

atmospheres added.

2.0 Technical data, graphic card specifications adapted.

2.1 Chapter on serial interfaces N030/N031 added.

2.2 Chapter Beckhoff Device Manager revised

2.3 Chapter "RS232 (N030)" adapted.

2.4 Chapter "Power supply" adapted.

2.5 Chapter Technical data adapted.

2.6 Chapter “Types” and “Device Manager” revised.

2.7 Chapter “Connecting the power supply” revised.

CX51x0 9Version: 2.7

Page 10

For your safety

2 For your safety

Read the chapter on safety and follow the instructions in order to protect from personal injury and damage to

equipment.

Limitation of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Unauthorized modifications and changes to the hardware or software configuration, which go

beyond the documented options, are prohibited and nullify the liability of Beckhoff Automation GmbH & Co.

KG.

In addition, the following actions are excluded from the liability of Beckhoff Automation GmbH & Co. KG:

• Failure to comply with this documentation.

• Improper use.

• Use of untrained personnel.

• Use of unauthorized replacement parts.

2.1 Intended use

The CX51x0 Embedded PC is a control system and is intended for mounting on a DIN rail in a control

cabinet or terminal box. The Embedded PC series is used in conjunction with Bus Terminals for recording

digital or analog signals from sensors and transferring them to actuators or higher-level controllers.

The Embedded PC is designed for a working environment that meets the requirements of protection class

IP20. This involves finger protection and protection against solid foreign objects up to 12.5 mm, but not

protection against water. Operation of the devices in wet and dusty environments is not permitted, unless

specified otherwise. The specified limits for electrical and technical data must be adhered to.

Potentially explosive atmospheres

Device modification CX2900-0107 is mandatory for operation of the Embedded PC in potentially explosive

atmospheres, zone 2/22. The device modification includes a factory-installed retainer bracket for

mechanically securing the plug connectors.

The device modification is mandatory for operating the Embedded PC in the following potentially explosive

atmospheres:

1. For Zone 2 atmospheres in which gas is present as a combustible material. Zone 2 means that an explosive atmosphere does usually not occur during normal operation, or only for a short time.

2. For Zone 22 atmospheres in which dust is present as a combustible material. Zone 22 means that an

explosive atmosphere in the form of a cloud does usually not occur during normal operation, or only

for a short time.

The Embedded PC must be installed in a housing, which ensures protection class IP 54 for gas according to

EN 60079-15. A housing with protection class IP 54 is required for non-conductive dust. IP 6X is required for

conductive dust according to EN 60079-31.

Improper use

The Embedded PC is not suitable for operation in the following areas:

• In potentially explosive atmospheres, the Embedded PC may not be used in other zones except for

2/22 and not without a suitable housing.

• Areas with an aggressive environment, e.g. aggressive gases or chemicals.

• Living areas. In living areas, the relevant standards and guidelines for interference emissions must be

adhered to, and the devices must be installed in housings or control boxes with suitable attenuation of

shielding.

CX51x010 Version: 2.7

Page 11

For your safety

2.2 Staff qualification

All operations involving Beckhoff software and hardware may only be carried out by qualified personnel with

knowledge of control and automation engineering. The qualified personnel must have knowledge of the

administration of the Industrial PC and the associated network.

All interventions must be carried out with knowledge of control programming, and the qualified personnel

must be familiar with the current standards and guidelines for the automation environment.

2.3 Safety instructions

The following safety instructions must be followed during installation and working with networks and the

software.

Explosion protection

Device modification CX2900-0107 is mandatory for operation of the Embedded PC in potentially explosive

atmospheres, zone 2/22. The device modification entails the modification and relocation of the device label

and a factory-fitted retainer bracket for mechanically securing the connectors.

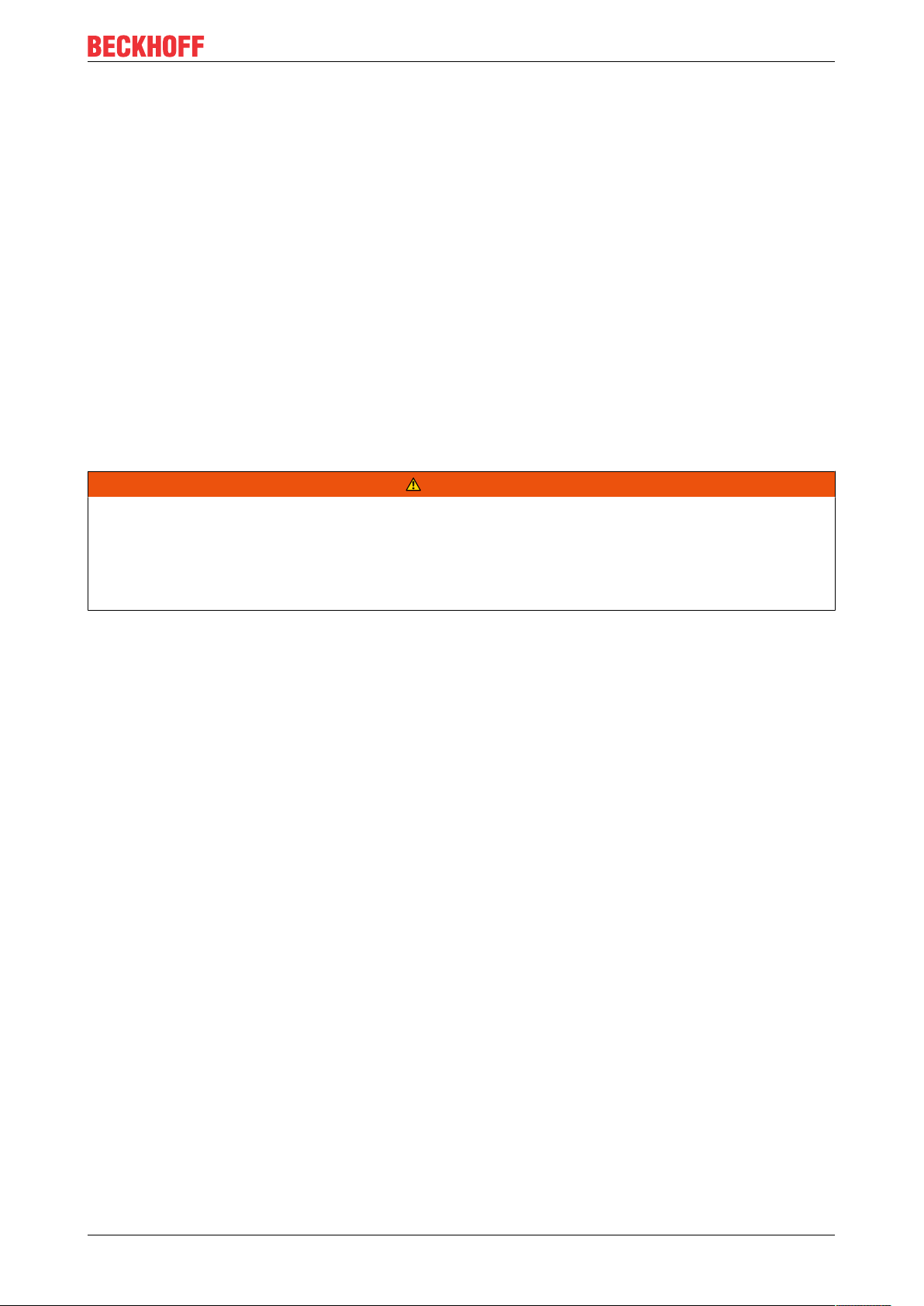

WARNING

Operation without device modification

Without the CX2900-0107 device modification, the USB plug connectors may slip out of the USB ports due

to vibration, which may trigger a deflagration or explosion.

The Embedded PC must only be used with the device modification, and the USB plug connectors must be

secured to the retainer brackets with cable ties.

Tighten the screws of the DVI plug connector and, if present, also the screws of the fieldbus plug connectors,

in order to prevent the plug connectors slipping out. Only use RJ45 connectors with an intact latch. Use

cable ties to secure the USB plug connectors and RJ45 connectors to the retainer brackets.

The CXxxxx-N020 optional interface (audio interface) may not be used in potentially explosive atmospheres.

The Embedded PC must be installed in a housing, which ensures protection class IP54 for gas according to

EN 60079-15. A housing with protection class IP54 is required for non-conductive dust. IP6X is required for

conductive dust according to EN 60079-31.

Observe the temperature at the cable entry points into the housing. If the temperature during nominal

operation is higher than 70 °C at the entry points or higher than 80 °C at the wire branching points, cables

must be selected that are designed for these high temperatures and operation in potentially explosive

atmospheres.

Maintain the prescribed ambient temperature during operation. The permissible ambient temperature lies

within the range from 0 °C ... +60 °C.

Take measures to prevent the rated operating voltage exceeding 119 V through short-term interference

voltages.

Switch off the power supply and ensure that no explosive atmosphere occurs when:

• Bus Terminals are connected or removed,

• the Embedded PC is wired or cables are connected,

• the front flap is opened,

• the CFast card, MicroSD card or battery is replaced.

Mounting

• Never work on live equipment. Always switch off the power supply for the device before installation,

troubleshooting or maintenance. Protect the device against unintentional switching on.

• Observe the relevant accident prevention regulations for your machine (e.g. the BGV A 3, electrical

systems and equipment).

CX51x0 11Version: 2.7

Page 12

For your safety

• Ensure standard-compliant connection and avoid risks to personnel. Ensure that data and supply

cables are laid in a standard-compliant manner and ensure correct pin assignment.

• Observe the relevant EMC guidelines for your application.

• Avoid polarity reversal of the data and supply cables, as this may cause damage to the equipment.

• The devices contain electronic components, which may be destroyed by electrostatic discharge when

touched. Observe the safety precautions against electrostatic discharge according to DIN EN

61340-5-1/-3.

Working with networks

• Restrict access to all devices to an authorized circle of persons.

• Change the default passwords to reduce the risk of unauthorized access. Regularly change the

passwords.

• Protect the devices with a firewall.

• Apply the IT security precautions according to IEC 62443, in order to limit access to and control of

devices and networks.

Working with the software

• Use up-to-date security software. The safe function of the PC can be compromised by malicious

software such as viruses or Trojans.

• The sensitivity of a PC against malicious software increases with the number of installed and active

software.

• Uninstall or disable unnecessary software.

Further information about the safe handling of networks and software can be found in the Beckhoff

Information System:

http://infosys.beckhoff.de

Document name

Documentation about IPC Security

CX51x012 Version: 2.7

Page 13

Transport and storage

3 Transport and storage

Transport

NOTE

Short circuit due to moisture

Moisture can form during transport in cold weather or in the event of large temperature fluctuations.

Avoid moisture formation (condensation) in the Embedded PC, and leave it to adjust to room temperature

slowly. If condensation has occurred, wait at least 12 hours before switching on the Embedded PC.

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts. During

transport the Embedded PC must be protected from

• mechanical stress and

• use the original packaging.

Table1: Dimensions and weight of the individual modules.

CX5120 CX5130 CX5140

Dimensions (W x H x D) 123 mm x 100 mm x 91

mm

Weight approx. 975 g approx. 1095 g approx. 1095 g

142 mm x 100 mm x 91 mm

Storage

• The battery should be removed if the Embedded PC is stored at temperatures above 60°C. The

battery should be stored separate from the Embedded PC in a dry environment at a temperature

between 0 °C and 30 °C.

The preset date and time are lost if the battery is removed.

• Store the Embedded PC in the original packaging.

CX51x0 13Version: 2.7

Page 14

Product overview

4 Product overview

The CX5100 product family comprises three Embedded PCs, which differ in terms of processor type, RAM

and housing size. The CX51x0 Embedded PC is a full-fledged PC with the following basic configuration:

• CFast card slot,

• MicroSD card slot,

• two independent Gbit Ethernet interfaces,

• four USB 2.0 interfaces,

• and a DVI-I interface.

Suitable operating systems are Microsoft Windows 10 IoT Enterprise LTSB, Microsoft Windows Embedded

Standard 7 P or Microsoft Windows Embedded Compact 7.

The Embedded PC features an internal 1-second UPS as persistent data memory. In the event of a power

failure the 1-second UPS can store up to 1 MB of persistent data on the CFast card or MicroSD card.

The Embedded PC can be ordered ex factory with an optional interface. The optional interface cannot be

retrofitted.

Table2: Available optional interfaces for the CX51x0.

CX51x0-xxxx Optional interfaces

CX51x0-N010 DVI-D, additional DVI-D socket for clone and extended display mode.

CX51x0-N011 DisplayPort, additional DisplayPort for clone and extended display mode.

CX51x0-N020 Audio interface, 3 x 3.5 mm jack plug, Line-In, Mic-In, Line-Out

CX51x0-N030 RS232, D-sub connector, 9-pin.

CX51x0-N031 RS422/RS485, D-sub socket, 9-pin.

CX51x0-B110 EtherCAT slave, EtherCAT IN and OUT (2 x RJ45).

CX51x0-M310 PROFIBUS master, D-sub socket, 9-pin.

CX51x0-B310 PROFIBUS slave, D-sub socket, 9-pin.

CX51x0-M510 CANopen master, D-sub connector, 9-pin.

CX51x0-B510 CANopen slave, D-sub connector, 9-pin.

CX51x0-M930 PROFINET RT, controller, Ethernet (2 x RJ-45).

CX51x0-B930 PROFINET RT, device, Ethernet (2 x RJ-45 switch).

1)

1)

1)

Only available for CX5130 and CX5140.

Power supply terminal

The power supply terminal for the Embedded PC is located on the right-hand side. Bus Terminals (K-bus) or

EtherCAT Terminals (E-bus) can be attached on the right-hand side of the power supply unit. The power

supply terminal automatically recognizes the respective bus system (K-bus or E-bus).

Software

In combination with the TwinCAT automation software, the CX51x0 Embedded PC becomes a powerful IEC

61131-3 PLC with up to four user tasks.

Additionally, Motion Control tasks can also be executed. It may be possible to control several servo axes,

depending on the required sampling time. In addition to simple point-to-point movements, it is possible to

execute more complex multi-axis functions such as electronic gear unit, cam plate and flying saw.

In addition to real-time execution of control tasks, the TwinCAT real-time kernel ensures that enough time

remains for the user interface (HMI), to communicate with the real-time components via software interfaces

such as ADS or OPC.

CX51x014 Version: 2.7

Page 15

Product overview

1

2

8

3

5

9

11

12

13

15

4

14

16

6

7

10

11

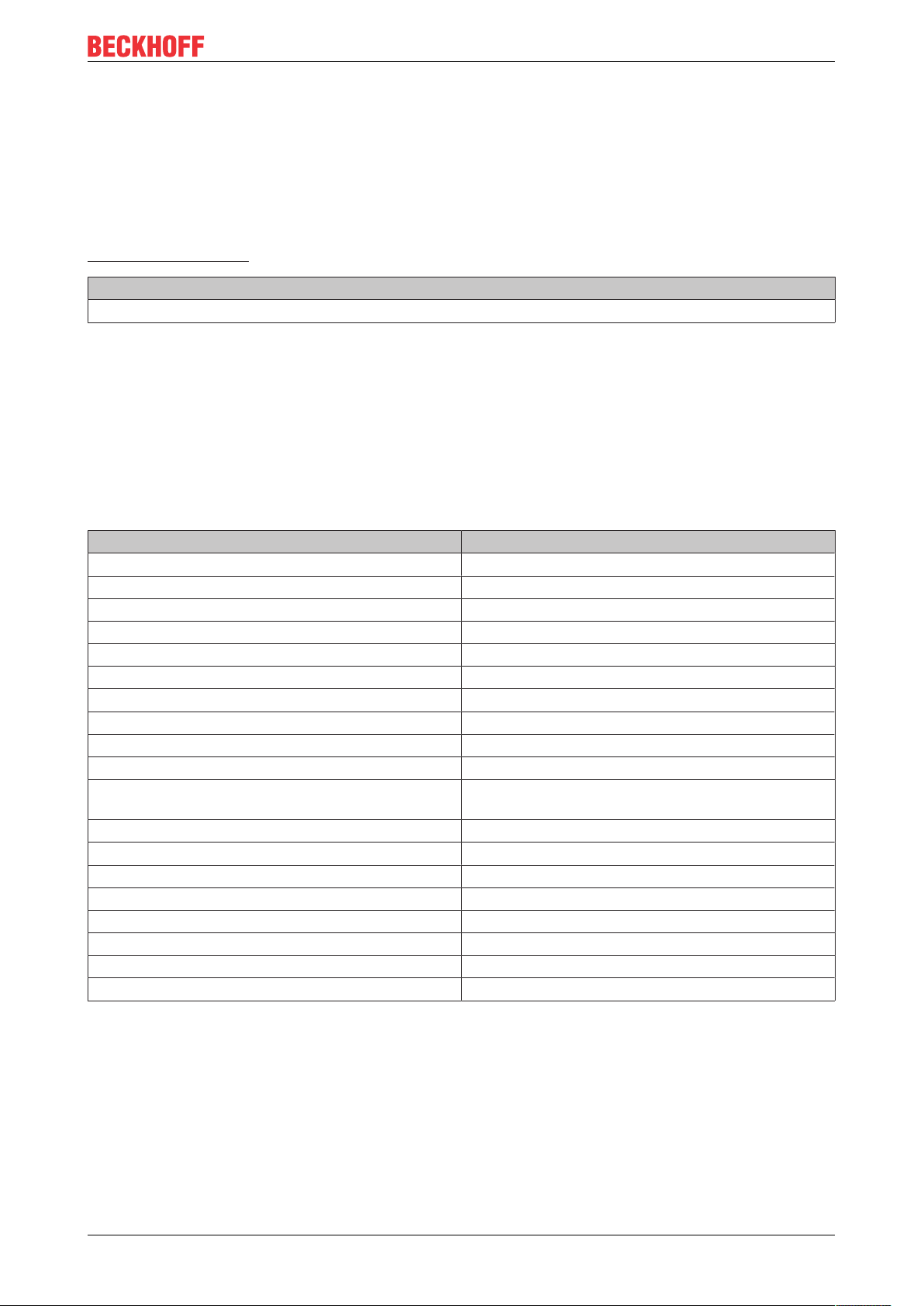

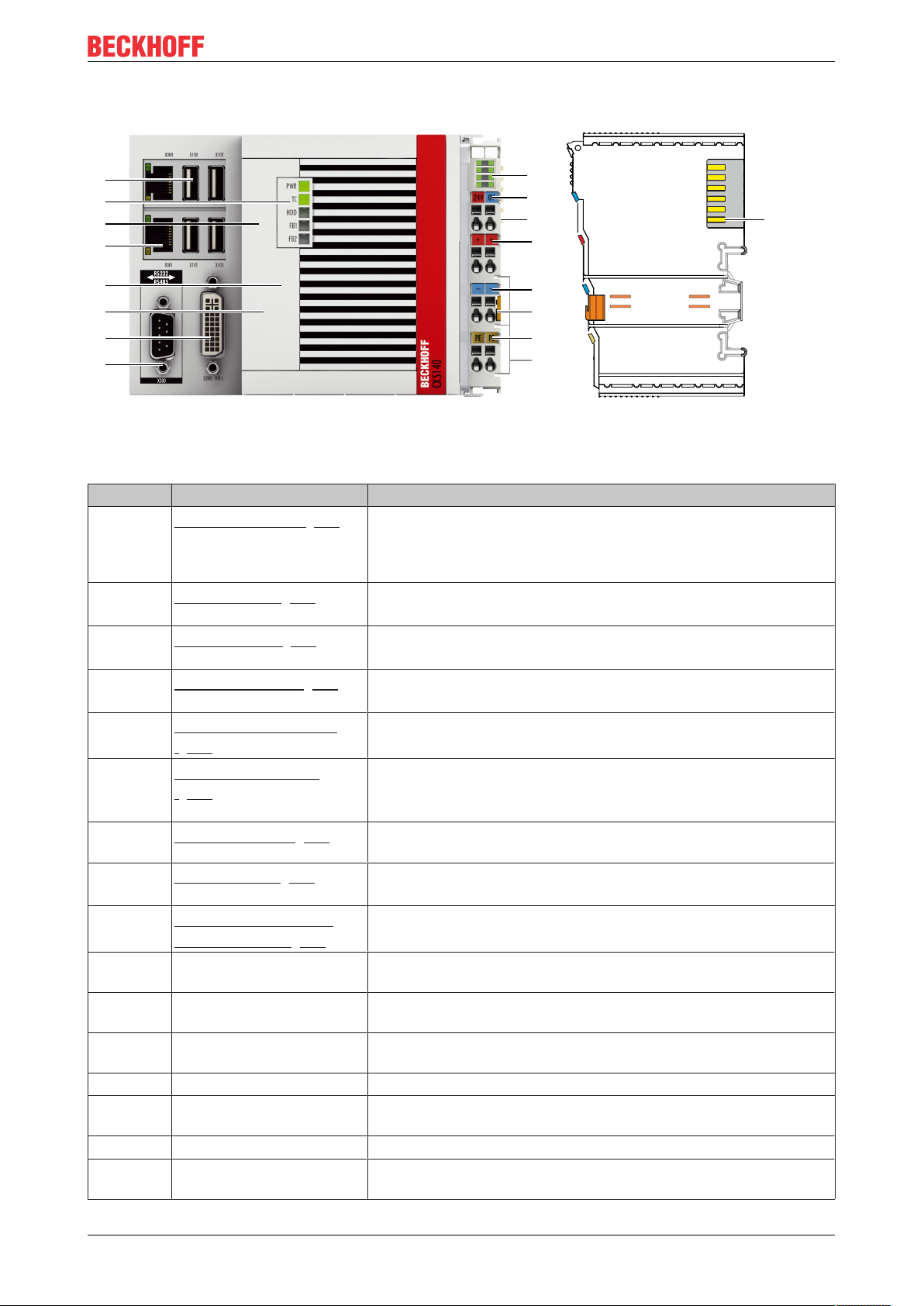

4.1 Configuration of the CX51x0 Embedded PC

Fig.1: Example: CX5140 Embedded PC.

Table3: Legend for the configuration.

No. Component Description

1

2

3

4

5

6

7

8

9

10 Spring-loaded terminals,

11 Terminal bus (K- or E-bus) Interface for EtherCAT Terminals or Bus Terminals. Data exchange

12 Spring-loaded terminal, +24VPower supply for Bus Terminals via power contact.

Optional interface [}24]

(X300).

DVI-I interface [}23]

(X200).

CFast card slot [}38]

(under the front flap).

MicroSD card slot [}37]

(under the front flap).

RJ45 Ethernet interfaces

[}22] (X000, X001).

Battery compartment

[}84] (under the front

flap).

Diagnostic LEDs. [}78]

USB interfaces [}21]

(X100, X101, X102, X103).

Diagnostic LEDs, power

supply terminal. [}79]

+24 V and 0 V

Space for interfaces such as RS232, EtherCAT, CANopen or

others.

The optional interface must be ordered ex factory and cannot be

retrofitted retrospectively.

Interface for a monitor or Panel.

Slot for industrial CFast cards.

Slot for industrial MicroSD cards.

For connecting to local networks or the internet.

Power supply for the battery-backed clock for time and date.

Diagnostic LEDs for power supply, TwinCAT and the optional

interface.

Interfaces for peripherals such as mouse, keyboard or USB

memory.

Diagnosis of the power supply for the Embedded PC and the

Terminal Bus. Status of the E-bus and K-bus communication.

Power supply for Embedded PC.

and supply.

13 Spring-loaded terminal, 0 V Power supply for Bus Terminals via power contact.

14 Terminal release Releases the power supply terminal and therefore the Embedded

PC from the mounting rail.

15 Spring-loaded terminal, PE Spring-loaded terminal for power contact PE.

16 Power contacts, +24 V, 0

V, PE

CX51x0 15Version: 2.7

Power contacts for Bus Terminals.

Page 16

Product overview

1

2

3

6

4

5

7

8

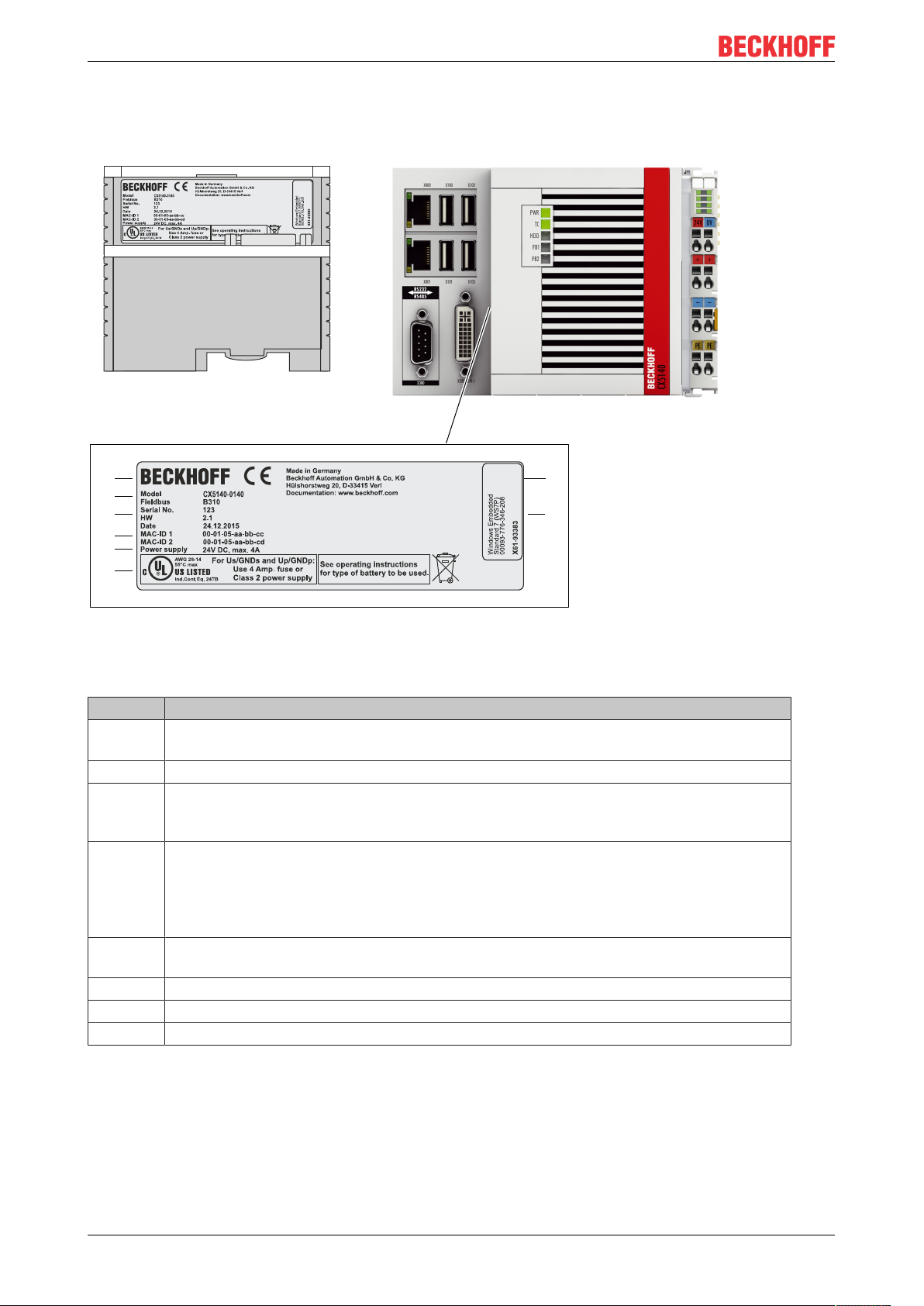

4.2 Name plate

The CX51x0 Embedded PC features a name plate on the left-hand side of the housing.

Fig.2: CX51x0 name plate.

Table4: Legend for the name plate.

No. Description

1 UL approval with prescribed information on power supply, fuse, temperature and cable

cross-sections.

2 Information on the power supply unit. 24 V DC, 4 A max.

3 MAC addresses of the integrated Ethernet ports.

By default, the host name is formed from "CX-" plus the last 3 bytes of the MAC address:

Example: the host name CX-aabbcc is formed from the MAC address 00-01-05-aa-bb-cc.

4 Information on:

• serial number,

• hardware version

• and date of manufacture.

5 Information on the model. The last four numerals relate to the configuration of Embedded

PC.

6 Manufacturer information including address.

7 CE compliant.

8 Windows license sticker (optional).

CX51x016 Version: 2.7

Page 17

Product overview

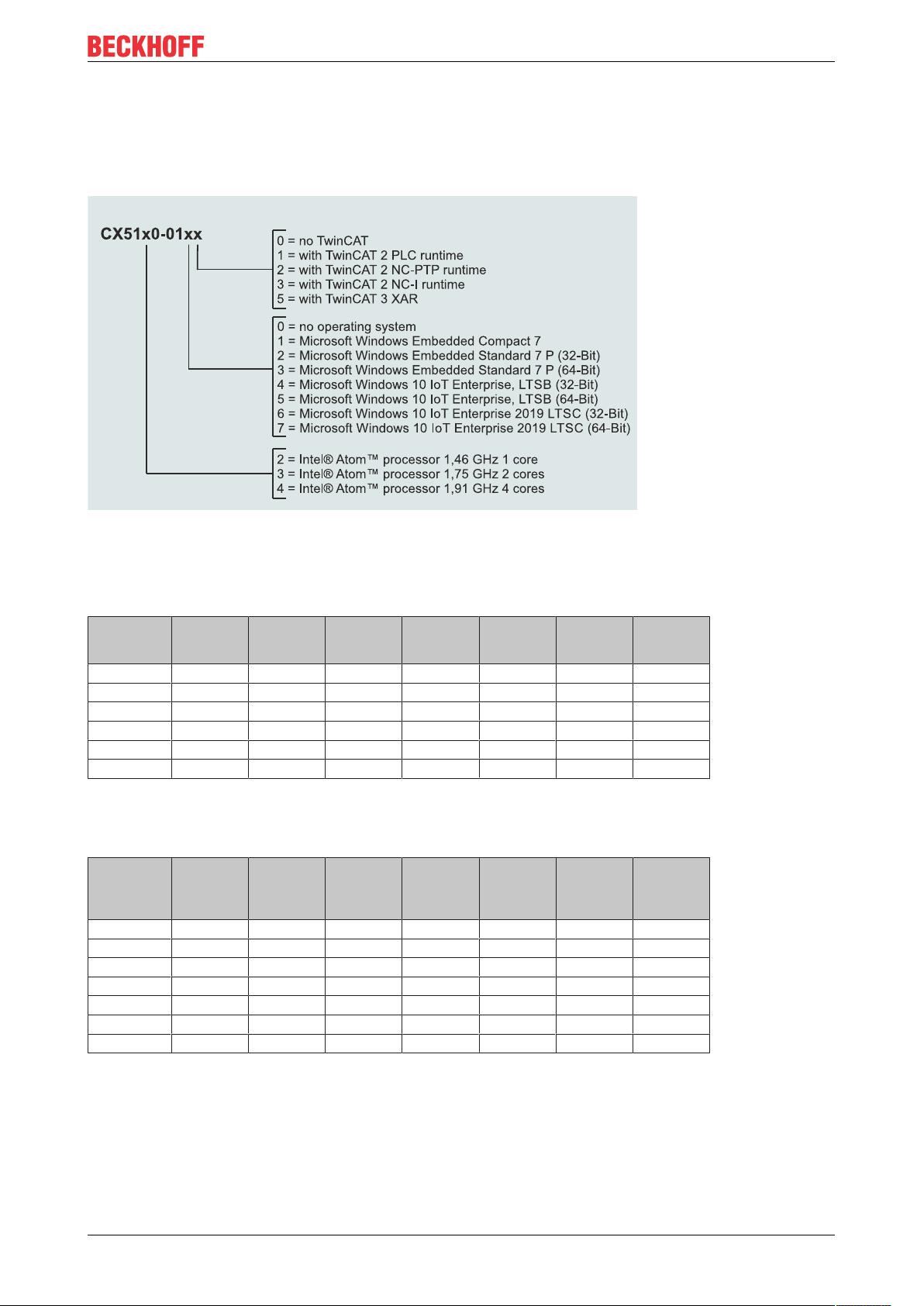

4.3 Types

The CX51x0 Embedded PC can be ordered with different software options. Use this overview in conjunction

with the information on the name plate to ascertain the operating system and the TwinCAT version of the

Embedded PC.

Fig.3: Nomenclature for the CX51x0 Embedded PC.

The Embedded PCs CX5120, CX5130 and CX5140 are available with the following software options:

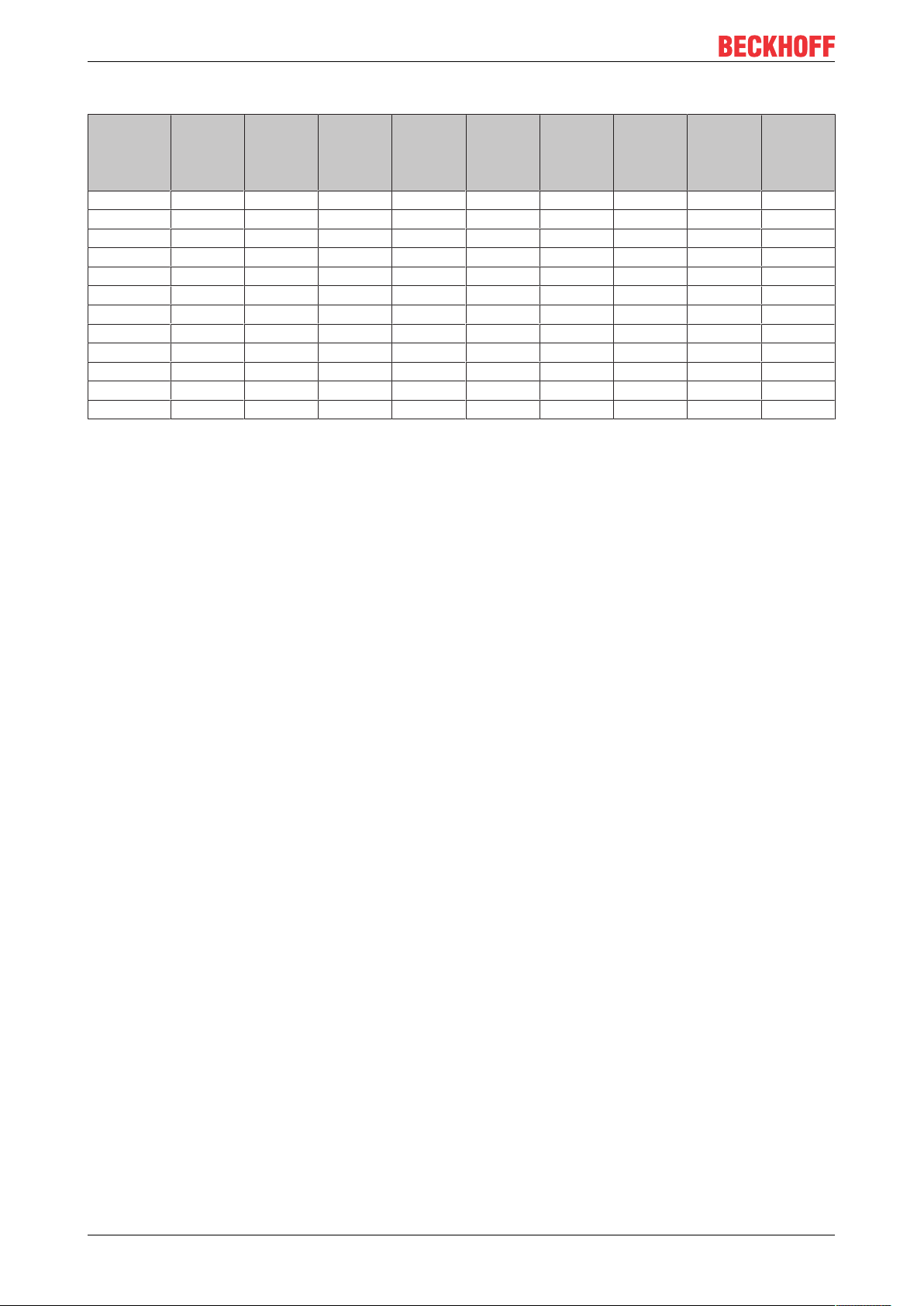

Table5: Order details, CX51x0 with Windows Embedded Compact 7.

Module no

CX51x0-0100 X - X - - - -

CX51x0-0110 - X

CX51x0-0111 - X

CX51x0-0112 - X

CX51x0-0113 - X

CX51x0-0115 - X

1)

Only one CPU core is supported with Microsoft Windows Embedded Compact 7.

operating

system

Windows

Embedded

Compact 7

1)

1)

1)

1)

1)

no

TwinCAT

TwinCAT 2

PLCRuntime

X - - - -

- X - - -

- - X - -

- - - X -

- - - - X

TwinCAT 2

NC-PTPRuntime

TwinCAT 2

NC-IRuntime

TwinCAT 3

XAR

Table6: Order details, CX51x0 with Windows Embedded Standard 7 P.

Module Windows

Embedded

Standard 7

P (32-bit)

CX51x0-0120 X - X - - - -

CX51x0-0121 X - - X - - -

CX51x0-0122 X - - - X - -

CX51x0-0123 X - - - - X -

CX51x0-0125 X - - - - - X

CX51x0-0130 - X X - - - -

CX51x0-0135 - X - - - - X

Windows

Embedded

Standard 7

P (64-bit)

no

TwinCAT

TwinCAT 2

PLCRuntime

TwinCAT 2

NC-PTPRuntime

TwinCAT 2

NC-IRuntime

TwinCAT 3

XAR

CX51x0 17Version: 2.7

Page 18

Product overview

Table7: Order details, CX51x0 with Windows 10 IoT Enterprise.

Module Windows

10 IoT Enterprise

2016 LTSB

32-bit

CX51x0-0140 X - - - X - - - -

CX51x0-0141 X - - - - X - - -

CX51x0-0142 X - - - - - X - -

CX51x0-0143 X - - - - - - X -

CX51x0-0150 - X - - X - - - -

CX51x0-0155 - X - - - - - - X

CX51x0-0160 - - X - X - - - -

CX51x0-0161 - - X - - X - - -

CX51x0-0162 - - X - - - X - -

CX51x0-0163 - - X - - - - X -

CX51x0-0170 - - - X X - - - -

CX51x0-0175 - - - X - - - - X

Windows

10 IoT Enterprise

2016 LTSB

64-bit

Windows

10 IoT Enterprise

2019 LTSC

32-bit

Windows

10 IoT Enterprise

2019 LTSC

64-bit

no

TwinCAT

TwinCAT 2

PLCRuntime

TwinCAT 2

NC-PTPRuntime

TwinCAT 2

NC-IRuntime

TwinCAT 3

XAR

A CX51x0 Embedded PC with Windows Embedded Compact 7 requires a CFast card with a capacity of at

least 20GB. A CFast card with a capacity of at least 40GB is required for Microsoft Windows Embedded

Standard 7 P and Microsoft Windows 10 IoT Enterprise.

CX51x018 Version: 2.7

Page 19

Product overview

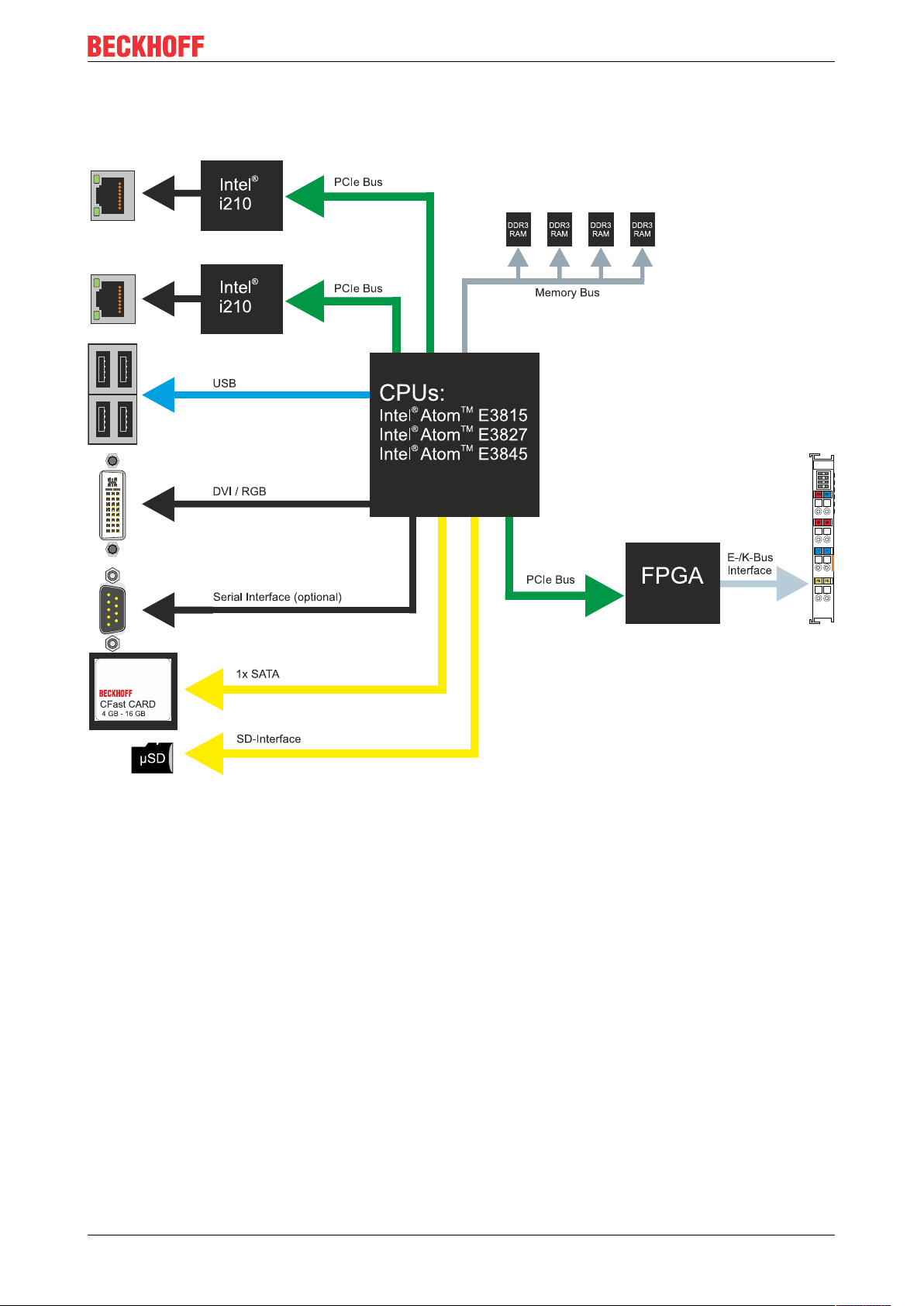

4.4 Architecture overview

The Embedded PCs of the CX51x0 family all have the same architecture. This is described below.

The CX51x0 Embedded PCs are based on the Intel Atom microarchitecture, which was developed by Intel.

The following CPUs are used:

• Intel®AtomTM E3815 (Singlecore)

• Intel®AtomTM E3827 (Dualcore)

• Intel®AtomTM E3845 (Quadcore)

In addition to the arithmetic unit, the CPU also contains the memory controller and the graphics controller.

The processors use the Intel® HD Graphics core. For details on the CPUs please refer to Intel. The memory

is connected directly to the CPU. The Embedded PCs are available in two memory configurations: 2GB or

4GB DDR3 RAM. The memory is not extendable and must be ordered ex factory.

The CPU provides all required interfaces:

• 1 PCI lane for each of the two Intel® i210 Gigabit Ethernet controllers

• 4x USB 2.0 (interfaces)

• DVI-I and DVI-D interface (2nd interface optional in CX51x0-N010)

• Serial interface (CX51x0-N03x)

• 1 PCIe for FPGA for K-/E-bus and NOV-RAM

• 1 SATA for CFast card interface

• 1 IDE for MicroSD card interface

CX51x0 19Version: 2.7

Page 20

Product overview

The interfaces (USB, DVI, and LAN) are standard interfaces. Devices that meet the corresponding standard

can be connected to and operated at these interfaces. A VGA monitor can be connected to the DVI-I

interface with an adapter.

Intel® i210 Gigabit Ethernet controllers are used as network controllers. There are two independent Ethernet

interfaces. Both LAN interfaces are gigabit-capable.

CX51x020 Version: 2.7

Page 21

Description of the interfaces

5 Description of the interfaces

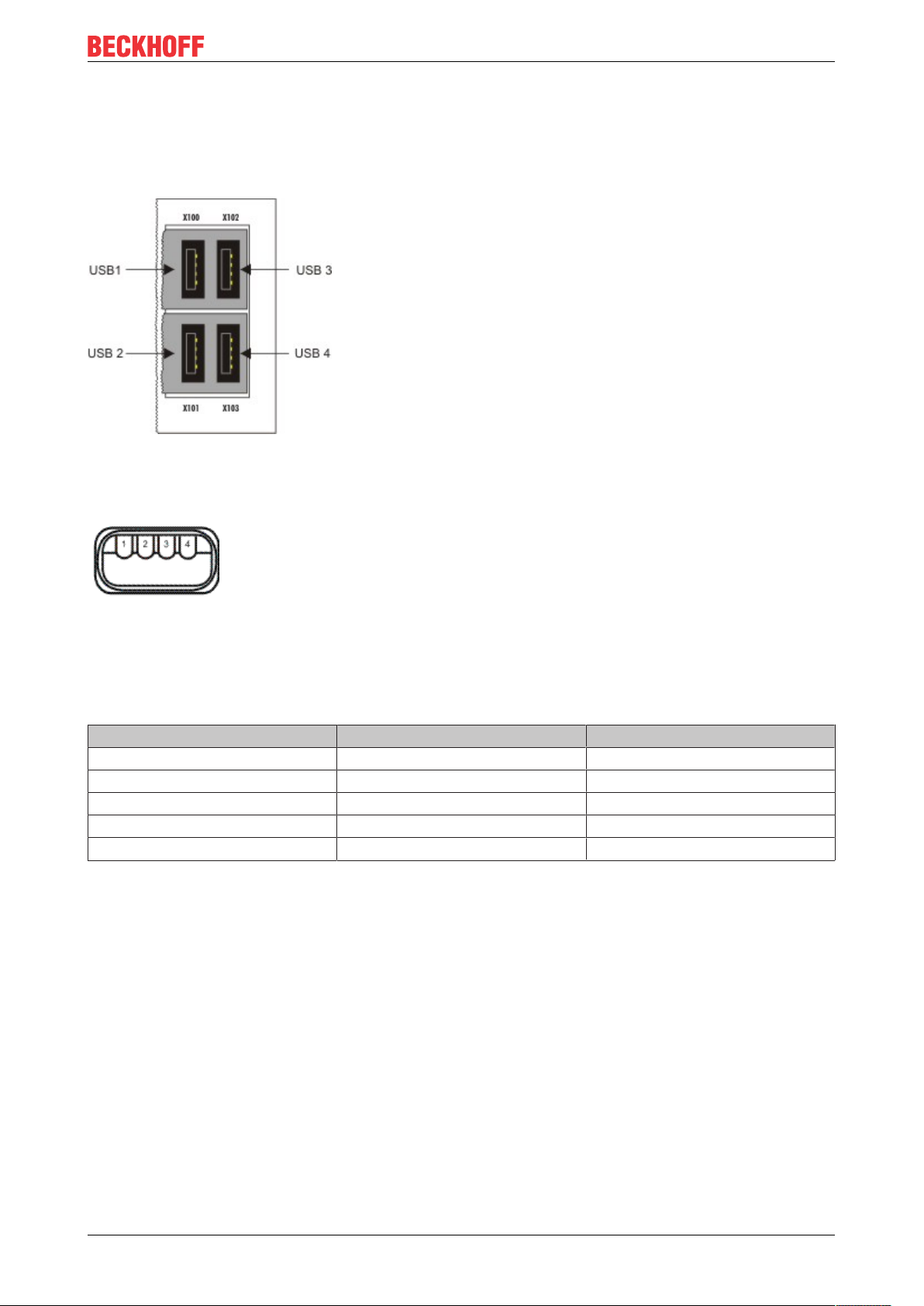

5.1 USB (X100, X101, X102, X103)

Fig.4: USB interfaces (X100, X101, X102, X103).

The Embedded PC has four independent USB interfaces for connecting keyboards, mice, touchscreens and

other input or data storage devices.

Fig.5: USB interface, pin numbering.

Note the power consumption of the individual devices. Each interface is limited to 500mA. The USB

interface is of type A and corresponds to the USB 2.0 specification.

Table8: USB interfaces (X100, X101, X102, X103), pin assignment.

Pin Assignment Typical assignment

1 VBUS Red

2 D- White

3 D+ Green

4 GND Black

Shell Shield Drain Wire

CX51x0 21Version: 2.7

Page 22

Description of the interfaces

X000

X001

LAN 1

LAN 2

LINK / ACT 2

SPEED 2

LINK / ACT 1

SPEED 1

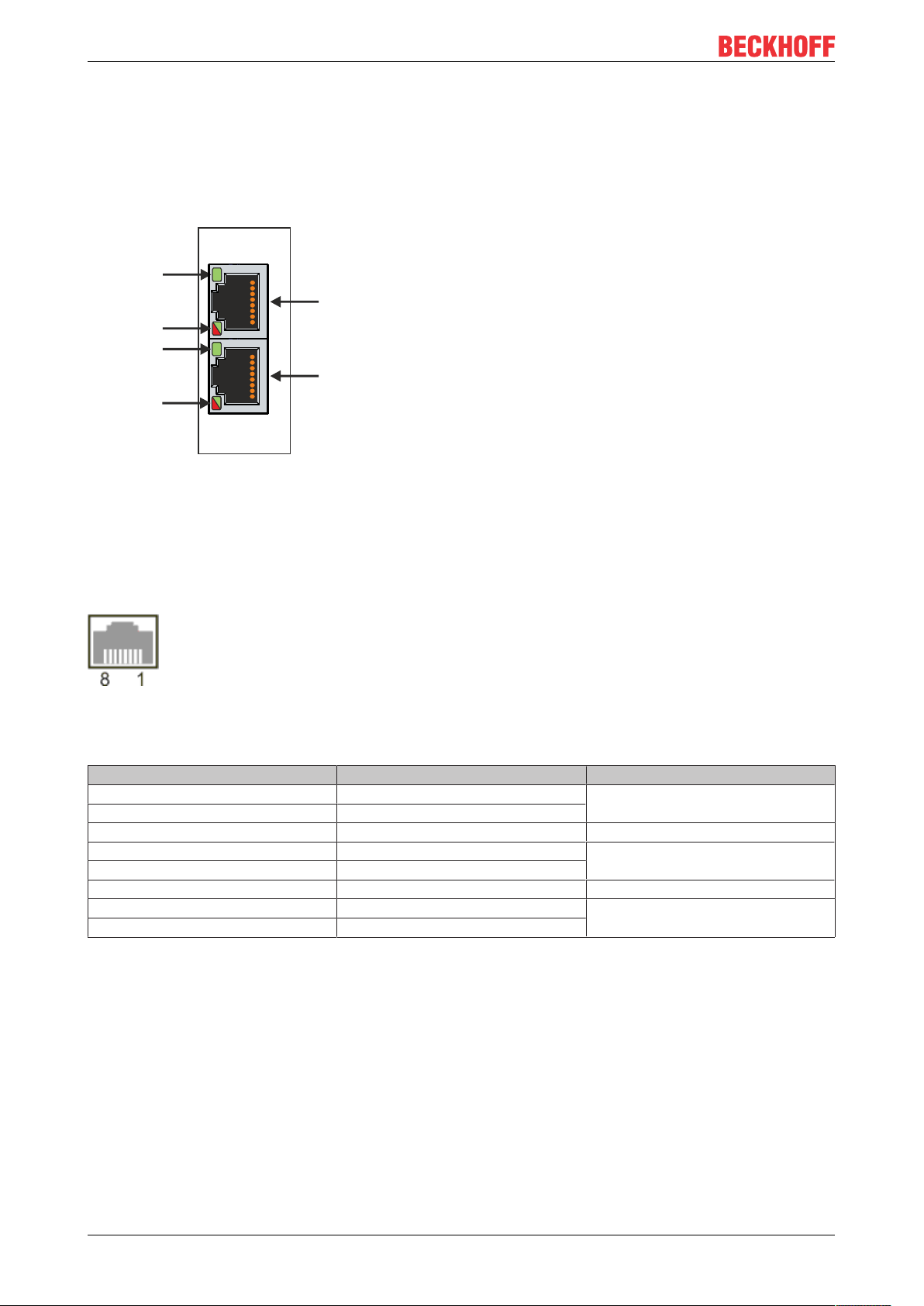

5.2 Ethernet RJ45 (X000, X001)

The two Ethernet interfaces are independent; no switch is integrated. The independent Ethernet interfaces

can be configured in different ways. In delivery state the Ethernet interfaces (X000, X001) are configured for

EtherCAT communication.

Note that an additional switch is required for a line topology.

Fig.6: Ethernet interface X000, X001.

Both Ethernet interfaces reach speeds of 10 / 100 / 1000 Mbit. The LEDs on the left of the interfaces indicate

the connection status. The upper LED (LINK/ACT) indicates whether the interface is connected to a network.

If this is the case the LED is green. The LED flashes when data transfer is in progress.

The lower LED (SPEED) indicates the connection speed. The LED does not light up if the speed is 10 Mbit.

The LED is green if the speed is 100 Mbit. The LED lights up red if the speed is 1000 Mbit (gigabit).

Fig.7: Ethernet interface, pin numbering.

Table9: Ethernet interface X000 and X001, pin assignment.

PIN Signal Description

1 T2 + Pair 2

2 T2 -

3 T3 + Pair 3

4 T1 + Pair 1

5 T1 -

6 T3 - Pair 3

7 T4 + Pair 4

8 T4 -

CX51x022 Version: 2.7

Page 23

Description of the interfaces

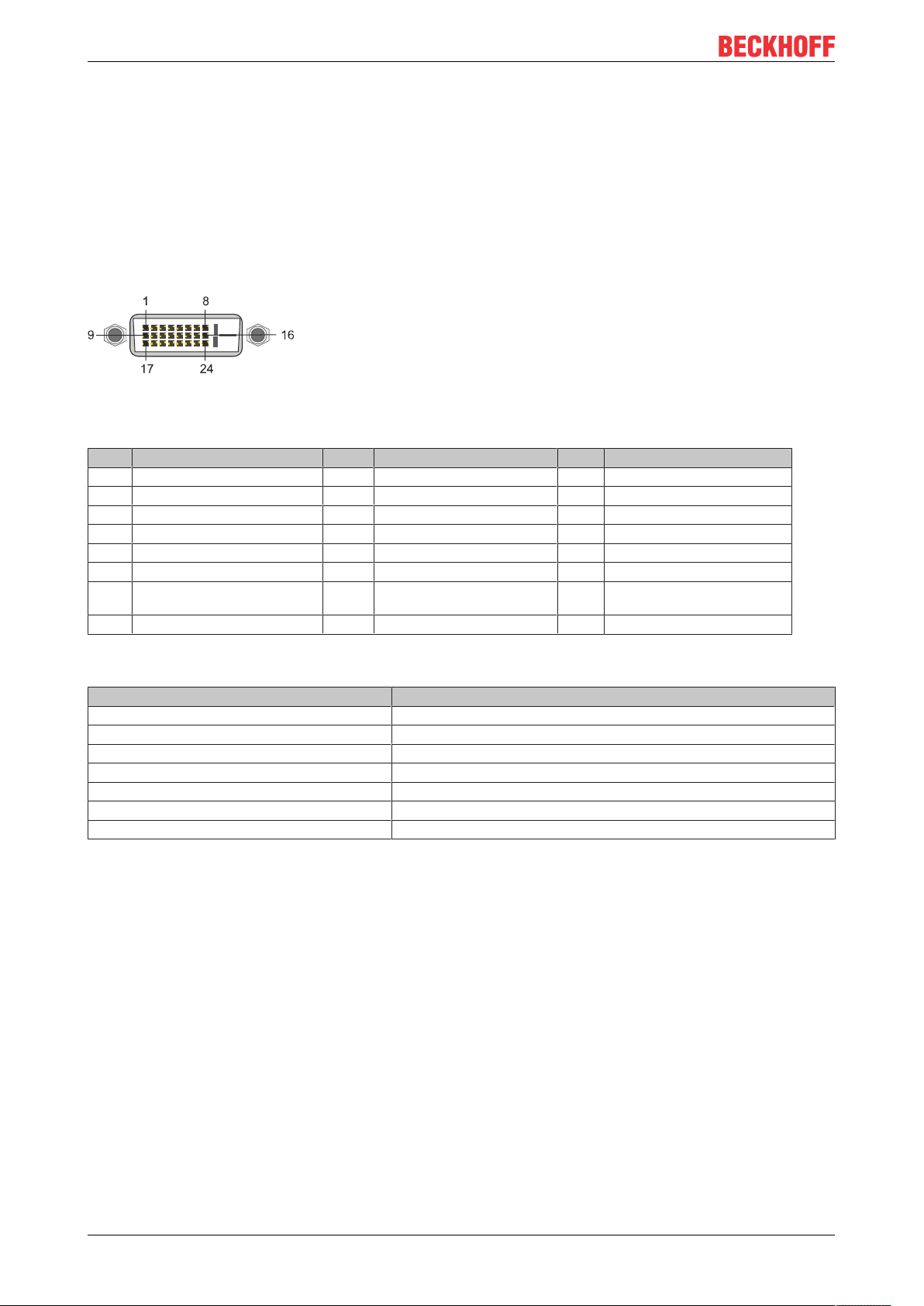

5.3 DVI-I (X200)

The DVI-I interface (X200) transfers digital data and is suitable for connection to digital or analog monitors.

The resolution at the display or the Beckhoff Control Panel depends on the distance from the display device.

The maximum distance is 5 m. Beckhoff offers various Panels with an integrated “DVI extension”. These

make a cable length of up to 50 meters possible.

Fig.8: DVI-I interface X200.

Table10: DVI-I interface X200, pin assignment.

Pin Assignment Pin Assignment Pin Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 0-

2 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 not connected 12 not connected 20 not connected

5 not connected 13 not connected 21 not connected

6 DDC Clock 14 + 5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground ( +5V, Analog H/V

Sync)

8 Analog Vertical Sync 16 Hot Plug Detect 24 TMDA Clock -

23 TMDS Clock +

Table11: DVI-I cross, pin assignment.

Pin Assignment

C1 Analog Red Video Out

C2 Analog Green Video Out

C3 Analog Blue Video Out

C4 Analog Horizontal Sync

Table12: DVI-I interface X200, resolution at the monitor.

Resolution in pixels Distance of the interface from the monitor

1920 x 1200 5 m

1920 x 1080 5 m

1600 x 1200 5 m

1280 x 1024 5 m

1024 x 768 5 m

800 x 600 5 m

640 x 480 5 m

The Embedded PC also supports higher resolutions, based on the DVI standard. A maximum resolution of

2560 x 1440 pixels can be set on the Embedded PC. Whether this resolution is achieved depends on the

monitor, the cable quality and the cable length.

CX51x0 23Version: 2.7

Page 24

Description of the interfaces

5.4 Optional interfaces

5.4.1 DVI-D (N010)

The DVI-D interface (X300) transfers digital data and is suitable for connection to digital displays. If the

optional N010 interface (DVI-D interface) is used, the first DVI-I interface can be operated either in VGA

mode or in DVI mode. The resolution at the display or the Beckhoff Control Panel depends on the distance

from the display device. The maximum distance is 5 m. Beckhoff offers various Panels with an integrated

“DVI extension”. These make a cable length of up to 50 meters possible.

Fig.9: DVI-D interface X300.

Table13: DVI-D interface X300, pin assignment.

Pin Assignment Pin Assignment Pin Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 0-

2 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 not connected 12 not connected 20 not connected

5 not connected 13 not connected 21 not connected

6 DDC Clock 14 + 5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground ( +5V, Analog H/V

Sync)

8 Analog Vertical Sync 16 Hot Plug Detect 24 TMDA Clock -

23 TMDS Clock +

Table14: DVI-D interface X300, resolution at the monitor.

Resolution in pixels Distance of the interface from the monitor

1920 x 1200 5 m

1920 x 1080 5 m

1600 x 1200 5 m

1280 x 1024 5 m

1024 x 768 5 m

800 x 600 5 m

640 x 480 5 m

The Embedded PC also supports higher resolutions, based on the DVI standard. A maximum resolution of

2560 x 1440 pixels can be set on the Embedded PC. Whether this resolution is achieved depends on the

monitor, the cable quality and the cable length.

CX51x024 Version: 2.7

Page 25

Description of the interfaces

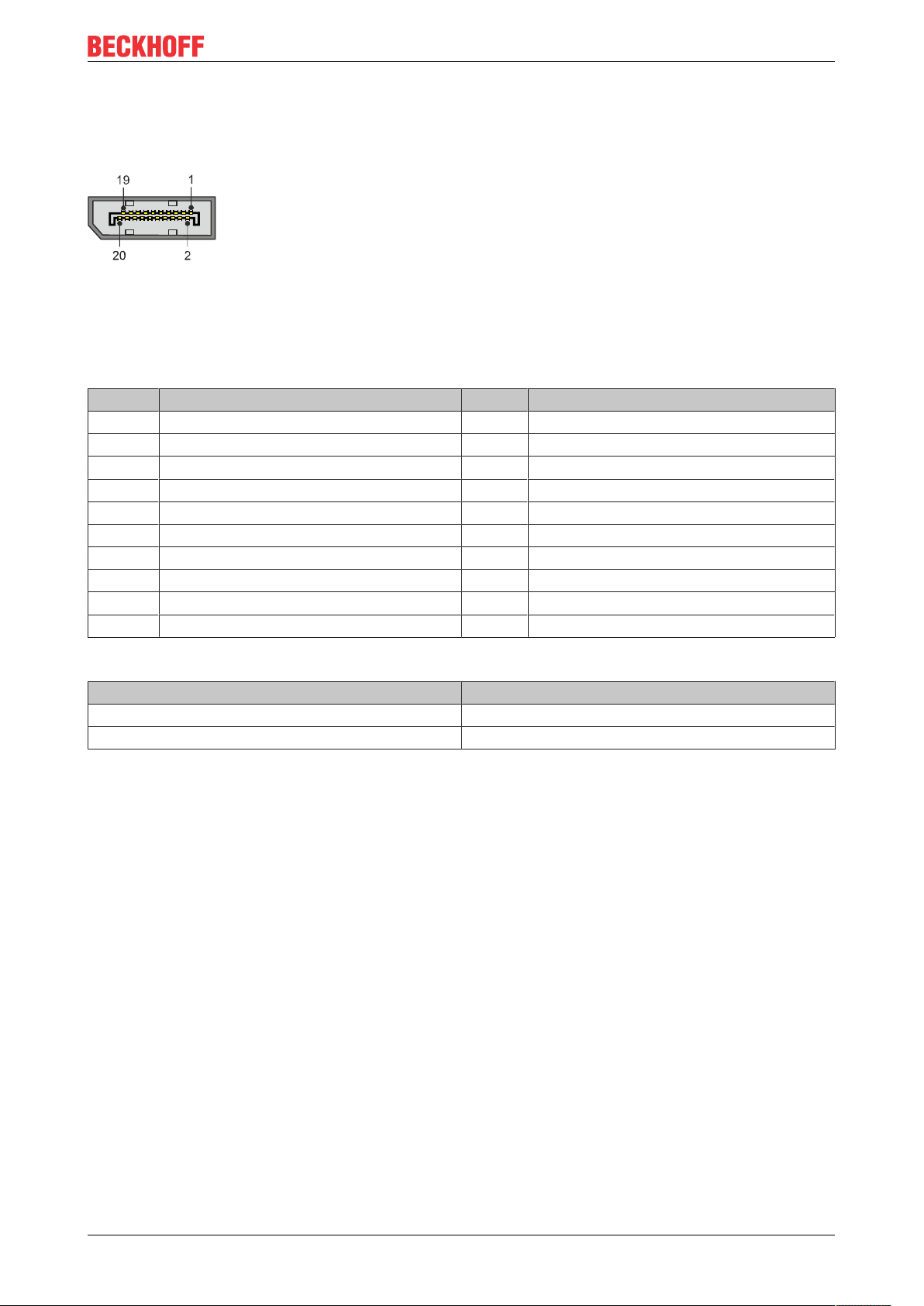

5.4.2 DisplayPort (N011)

The DisplayPort transfers image and audio signal at the same time and is therefore suitable for connecting

panels or monitors to the Embedded PC.

Fig.10: DisplayPort X300.

Version 1.1a of the DisplayPort (DisplayPort++) is installed on the Embedded PC. Adapters from DisplayPort

to DVI-D or DisplayPort to HDMI can be used to connect monitors without DisplayPort to the Embedded PC.

Table15: DisplayPort, pin assignment.

Pin Assignment Pin Assignment

1 LVDS lane 0+ 2 Ground

3 LVDS lane 0- 4 LVDS lane 1+

5 Ground 6 LVDS lane 1-

7 LVDS lane 2+ 8 Ground

9 LVDS lane 2- 10 LVDS lane 3+

11 Ground 12 LVDS lane 3-

13 Config 1 14 Config 2

15 AUX channel+ 16 Ground

17 AUX channel- 18 Hot-plug detection

19 Power supply: ground 20 Power supply: 3.3 V / 500 mA

Table16: DisplayPort X300, resolution at the monitor.

Interface Resolution in pixels

DisplayPort max. 2560 x 1600 @ 60 Hz

DisplayPort with adapter, DisplayPort to DVI-D max. 1600 x 1200 @ 60 Hz

CX51x0 25Version: 2.7

Page 26

Description of the interfaces

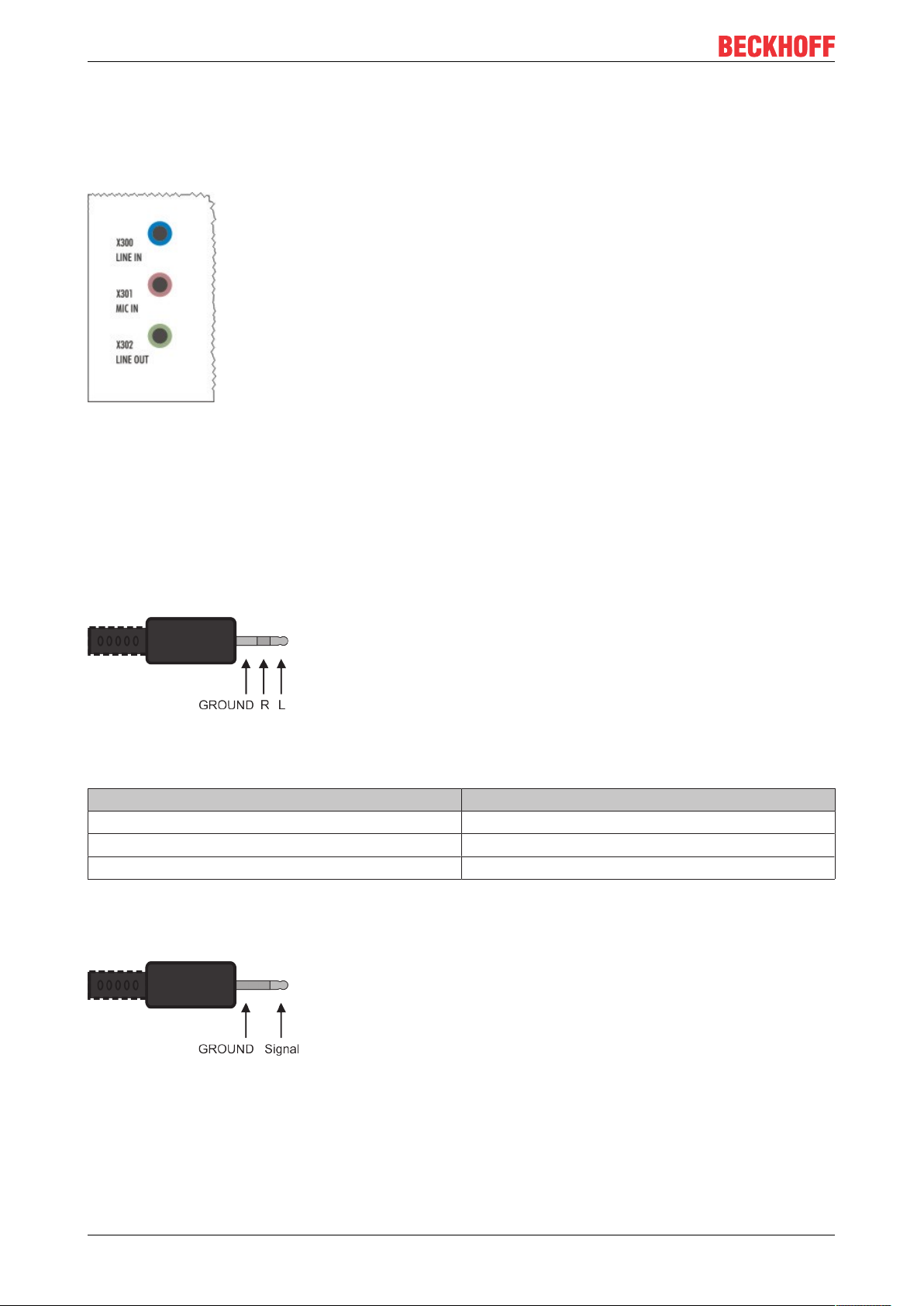

5.4.3 Audio interface (N020)

Two inputs are available: "LINE IN" (X300) and "MIC IN" (X301). The "LINE OUT" interface (X302) is

intended for audio signal output. The 3.5 mm sockets are designed for jack plugs. It can also be used for

connecting headphones with a maximum output of 200 mW.

Fig.11: Audio interface X300, X301, X302.

The audio interfaces are accessed via the operating system.

The audio interface operates in stereo mode as standard, using stereo outputs/inputs and a single-channel

input for the microphone. The inputs should be connected as indicated.

Line In / Line Out jack plugs

The left channel is transferred via the tip of the jack plug, the right channel via the first ring. The remainder of

the sleeve is used for earthing.

Fig.12: Line In / Line Out X300, X302 jack plugs.

Table17: Line In /Line Out jack plugs, pin assignment.

Signal Description

L Left channel

R Right channel

Ground Ground

Mic In jack plug

The only existing channel is transferred via the tip, the remainder of the sleeve is used for earthing.

Fig.13: Mic In X301 jack plug.

CX51x026 Version: 2.7

Page 27

Description of the interfaces

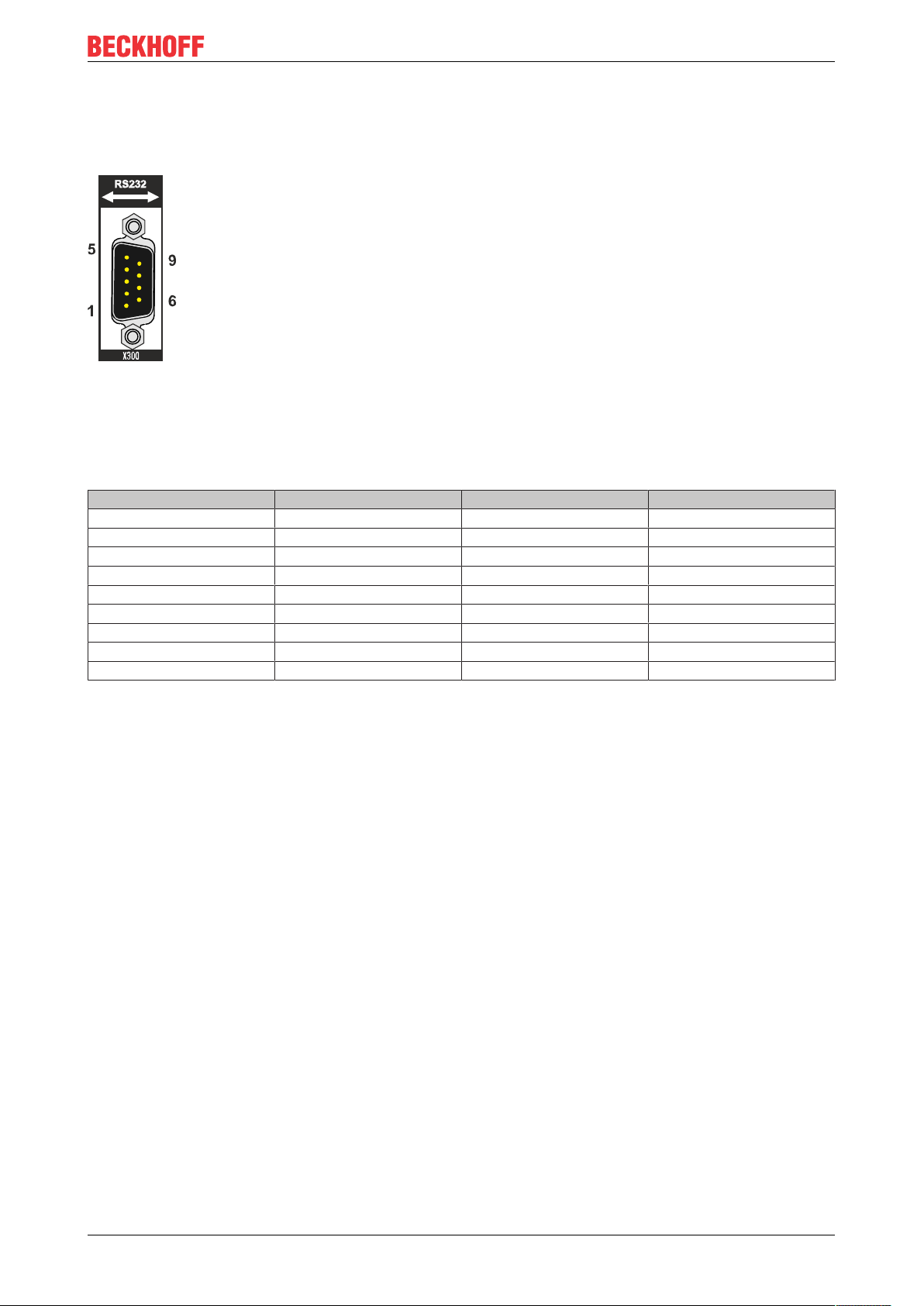

5.4.4 RS232 (N030)

The optional N030 interface provides an RS232 interface (X300). The RS232 interface is implemented on a

9-pin D-sub connector.

Fig.14: RS232 interface X300 with pin numbering.

The maximum baud rate on both channels is 115 kbit. The interface parameters are set via the operating

system or from the PLC program.

Table18: RS232 interface X300, pin assignment.

PIN Signal Type Description

1 - - -

2 RxD Signal in Receive Data

3 TxD Signal out Transmit Data

4 - - -

5 GND Ground Ground

6 - - -

7 RTS Signal out Request to Send

8 CTS Signal in Clear to Send

9 RI Signal in Ring Indicator

Limited driver support

The driver manufacturer does not support all standard functions for the interface. As a result, some

applications may not run properly under Windows.

The following API and IOCTLs are not supported:

• SetupComm

• SetCommBreak

• ClearCommBreak

• EscapeCommFunction (no support for parameters SETBREAK and CLR-BREAK)

• IOCTL_SERIAL_XOFF_COUNTER

• IOCTL_SERIAL_LSRMST_INSERT

• IOCTL_SERIAL_SET_BREAK_ON

• IOCTL_SERIAL_SET_BREAK_OFF

CX51x0 27Version: 2.7

Page 28

Description of the interfaces

5.4.5 RS422/RS485 (N031)

The optional N031 interface provides an RS422 or RS485 interface (X300). The interface is implemented on

a 9-pin D-sub connector.

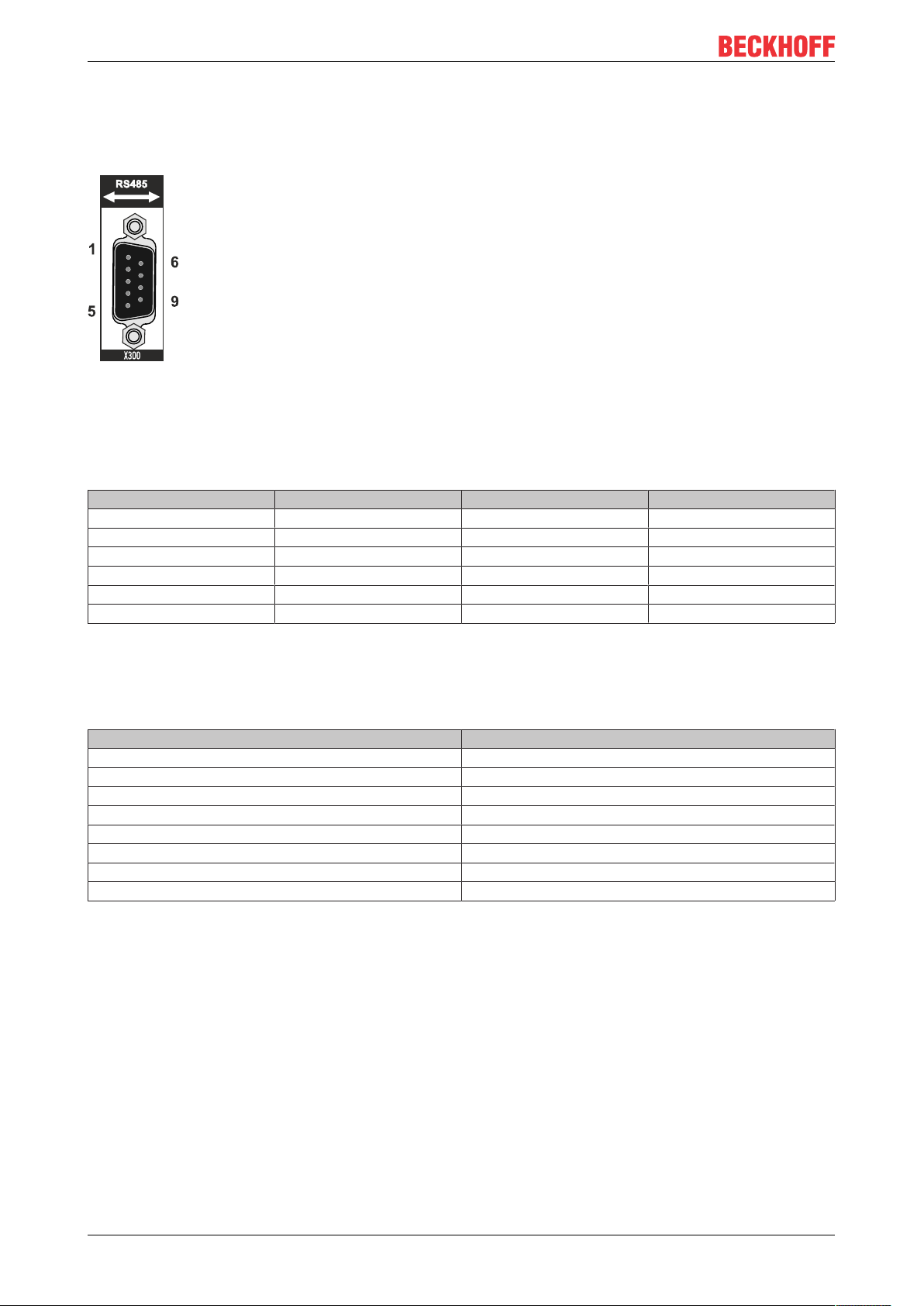

Fig.15: RS485 interface X300 with pin numbering.

The maximum baud rate on both channels is 115 kbit. The interface parameters are set via the operating

system or from the PLC program.

Table19: RS422/485 interface, pin assignment.

PIN Signal Type Description

2 TxD+ Data-Out + Transmit 422

3 RxD+ Data-In + Receive 422

5 GND Ground Ground

6 VCC VCC +5 V

7 TxD- Data-Out - Transmit 422

8 RxD- Data-In - Receive 422

For RS485 pins 2 and 3 (data +) must be connected, and pins 7 and 8 (data –).

By default the interface is parameterized as follows on delivery:

Table20: Default setting, RS485 without echo with end point (terminated).

Function Status

Echo on off

Echo off on

Auto send on on

Always send on off

Auto receive on on

Always receive on off

Term on on

Term on On

Other configurations for the RS485 interface

Other configurations for the RS485 interface can be ordered ex factory. The following options are available:

• N031-0001 RS485 with echo, end point (terminated).

• N031-0002 RS485 without echo, stub (without termination).

• N031-0003 RS485 with echo, stub (without termination).

• N031-0004 RS422 full duplex end point (terminated).

An RS485 interface cannot be configured retrospectively and must always be ordered ex factory as required.

Limited driver support

The driver manufacturer does not support all standard functions for the interface. As a result, some

applications may not run properly under Windows.

The following API and IOCTLs are not supported:

CX51x028 Version: 2.7

Page 29

Description of the interfaces

• SetupComm

• SetCommBreak

• ClearCommBreak

• EscapeCommFunction (no support for parameters SETBREAK and CLR-BREAK)

• IOCTL_SERIAL_XOFF_COUNTER

• IOCTL_SERIAL_LSRMST_INSERT

• IOCTL_SERIAL_SET_BREAK_ON

• IOCTL_SERIAL_SET_BREAK_OFF

CX51x0 29Version: 2.7

Page 30

Description of the interfaces

5.4.6 EtherCAT slave (B110)

The latest generation of Embedded PCs can be ordered ex factory with an EtherCAT slave interface (B110).

On the devices the optional B110 interface is referred to as X300.

Fig.16: EtherCAT slave interface X300.

The incoming EtherCAT signal is connected to the upper LAN interface. The lower LAN interface relays the

signal to other EtherCAT slave devices.

Fig.17: EtherCAT slave LAN interface, pin numbering.

Table21: EtherCAT slave interface X300, pin assignment.

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit -

3 RD + Receive +

4 connected reserved

5

6 RD - Receive -

7 connected reserved

8

For the optional EtherCAT slave interface (B110), documentation with further information is available for

download from the Beckhoff website:

https://www.beckhoff.de/german/download/epc.htm?id=71003127100362

Document name

CXxxx0-B110 optional interface EtherCAT slave.

CX51x030 Version: 2.7

Page 31

5.4.7 PROFIBUS (x310)

Description of the interfaces

Pin 6 transfers 5V

pin 5 transfers GND for the active termination resistor. These must never be used for

DC,

other functions, as this can lead to destruction of the device.

Pins 3 and 8 transfer the PROFIBUS signals. These must never be swapped over, as this will prevent

communication.

Fig.18: PROFIBUS interface X310 with pin numbering.

The Profibus bus line is connected via a 9-pin D sub with the following pin assignment:

Table22: PROFIBUS interface X310, pin assignment.

Pin Assignment

1 Shielding

2 not used

3 RxD/TxD-P

4 not used

5 GND

6 +5 V

DC

7 not used

8 RxD/TxD-N

9 not used

Table23: Wire colors of the PROFIBUS line.

PROFIBUS line D sub

B red Pin 3

A green Pin 8

For the optional PROFIBUS interface (x310), documentation with further information is available for

download from the Beckhoff website:

https://www.beckhoff.de/german/download/epc.htm?id=71003127100362

Document name

CXxxx0-x310 optional Profibus interface.

CX51x0 31Version: 2.7

Page 32

Description of the interfaces

5.4.8 CANopen (x510)

Fig.19: CANopen interface X510 with pin numbering.

The CAN bus line is connected via a 9-pin D-sub socket with the following configuration:

Table24: CANopen interface X510, pin assignment.

Pin Assignment

1 not used

2 CAN low (CAN-)

3 CAN ground (internally connected to pin 6)

4 not used

5 Shield

6 CAN ground (internally connected to pin 3)

7 CAN high (CAN+)

8 not used

9 not used

For the optional CANopen interface (x510), documentation with further information is available for download

from the Beckhoff website:

https://www.beckhoff.de/german/download/epc.htm?id=71003127100362

Document name

CXxxx0-x510 optional CANopen interface.

CX51x032 Version: 2.7

Page 33

5.4.9 PROFINET RT (x930)

Fig.20: PROFINET RT interface X300.

Fig.21: PROFINET RT LAN interface, pin numbering.

Table25: PROFINET RT interface, pin assignment.

Description of the interfaces

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit -

3 RD + Receive +

4 connected reserved

5

6 RD - Receive -

7 connected reserved

8

CX51x0 33Version: 2.7

Page 34

Commissioning

6 Commissioning

6.1 Assembly

6.1.1 Note the permissible installation positions

Increased heat generation

The Embedded PC may overheat if the installation position is incorrect or the minimum distances

are not adhered to.

The Embedded PC may only be operated at ambient temperatures of up to 60 °C. Ensure adequate

ventilation. Select a horizontal installation position. Leave at least 30 mm clearance above and below the Embedded PC.

Install the Embedded PC horizontally in the control cabinet on a mounting rail, in order to ensure optimum

heat dissipation.

Note the following specifications for the control cabinet:

• The Embedded PC should only be operated at ambient temperatures between -25 °C and 60 °C.

Measure the temperature below the Embedded PC at a distance of 30 mm to the cooling fins, in order

to determine the ambient temperature correctly.

• Adhere to the minimum distances of 30 mm above and below the Embedded PCs.

• Additional electrical equipment affects the heat generation in the control cabinet. Select a suitable

control cabinet enclosure depending on the application, or ensure that excess heat is dissipated from

the control cabinet.

Correct installation position

The Embedded PC must be installed horizontally on the mounting rail. Ventilation openings are located at

the top and bottom of the housing. This ensures an optimum airflow through the Embedded PC in vertical

direction. In addition, a minimum clearance of 30 mm above and below the Embedded PCs required, in order

to ensure adequate ventilation.

Fig.22: CX51x0 Embedded PC, permitted installation position.

If vibrations and impact occurs in the same direction as the mounting rail, the Embedded PC must be

secured with an additional bracket, in order to prevent it slipping.

CX51x034 Version: 2.7

Page 35

Incorrect installation positions

Fig.23: CX51x0 Embedded PC, invalid installation positions.

Commissioning

CX51x0 35Version: 2.7

Page 36

Commissioning

6.1.2 Attaching on mounting rail

The housing is designed such that the Embedded PC can be pushed against the mounting rail and latched

onto it.

Requirements:

• Mounting rail of type TS35/7.5 or TS35/15 according to DIN EN 60715.

Secure the Embedded PC on the mounting rail as follows:

1. Unlock the latches at the top and bottom.

2. Place the Embedded PC at the front of the mounting rail. Slightly press the Embedded PC onto the

mounting rail until a soft click can be heard and the Embedded PC has latched.

3. Then lock the latches again.

ð You have installed the Embedded PC successfully. Double-check the correct installation and latching of

the Embedded PC on the mounting rail.

CX51x036 Version: 2.7

Page 37

Commissioning

6.1.3 MicroSD card installation and removal

Loss of data

MicroSD cards are subjected to heavy load during operation and have to withstand many write cycles and extreme ambient conditions. MicroSD cards from other manufacturer may fail, resulting in

data loss.

Only use industrial MicroSD cards provided by Beckhoff.

The MicroSD card slot is intended for a MicroSD card. Data and further programs can be stored here, or

Windows Embedded Compact 7 can be installed instead.

The eject mechanism is based on the push/push principle. The installation and removal of a MicroSD card is

described below.

Requirements:

• The Embedded PC must be switched off. The MicroSD card may only be installed or removed in

switched-off state.

Removing the MicroSD card

1. Gently push the MicroSD card.

A soft click can be heard when the card is released.

2. The card is lifted by approx. 2-3 mm from the housing. Pull out the card.

Installing a MicroSD card

1. Push the MicroSD card into the Micro SD card slot.

2. A soft click can be heard when the MicroSD card engages.

ð The card is positioned correctly, if it is located approx. 1 mm lower than the front of the housing.

CX51x0 37Version: 2.7

Page 38

Commissioning

6.1.4 CFast card installation and removal

Loss of data

CFast cards are subjected to heavy load during operation and have to withstand many write cycles

and extreme ambient conditions. CFast cards from other manufacturer may fail, resulting in data

loss.

Only use industrial CFast cards provided by Beckhoff.

A CFast card is a non-volatile memory. Data to be retained in the event of a power failure should be saved

on the CFast card. The CFast cards supplied by Beckhoff are industrial cards with an increased number of

write cycles and an extended temperature range (+85 °C).

The eject mechanism is based on the push/push principle. The installation and removal of CFast cards is

described below.

Requirements:

• The Embedded PC must be switched off. The CFast cards may only be installed or removed in

switched off state.

Removing a CFast card

1. Gently push the CFast card.

A soft click can be heard when the card is released.

2. The card is lifted by approx. 4 mm from the housing. Pull out the card.

Installing a CFast card

1. Push the CFast card into the CFast card slot.

2. A soft click can be heard when the CFast card engages.

ð The card is seated correctly if it is flush with the front side of the device housing.

CX51x038 Version: 2.7

Page 39

Commissioning

6.1.5 Installing passive EtherCAT Terminals

Incorrectly installed passive EtherCAT Terminals

The E-bus signal between an Embedded PC and the EtherCAT Terminals can be impaired due to

incorrectly installed passive EtherCAT Terminals.

Passive EtherCAT Terminals should not be installed directly on the power supply unit.

EtherCAT Terminals that do not take part in active data exchange are referred to as passive terminals.

Passive EtherCAT Terminals have no process image and do not require current from the terminal bus (Ebus).

Passive EtherCAT Terminals (e.g. EL9195) can be detected in TwinCAT. In the tree structure the EtherCAT

Terminal is displayed without process image, and the value in column “E-bus (mA)” does not change,

compared to the preceding EtherCAT Terminal.

Fig.24: Identifying a passive EtherCAT Terminal in TwinCAT.

The entry "Current consumption via E-Bus" in the technical data of an EtherCAT Terminal indicates whether

a particular EtherCAT Terminal requires power from the terminal bus (E-bus).

The following diagram shows the permissible installation of a passive EtherCAT Terminal. The passive

EtherCAT Terminal was not directly attached to the power supply unit.

Fig.25: Passive EtherCAT Terminals, permissible installation.

The following diagram shows the invalid installation of a passive EtherCAT Terminal.

Fig.26: Passive EtherCAT Terminals, invalid installation.

CX51x0 39Version: 2.7

Page 40

Commissioning

1

2

3

4

8

6.2 Connecting the power supply

NOTE

Damage to the Embedded PCs

The Embedded PCs may be damaged during wiring.

• The cables for the power supply should only be connected in de-energized state.

The power supply terminals require an external voltage source, which provides 24 V DC (-15% / +20%). The

power supply terminal must provide 4 A at 24 V, in order to ensure the operation of the Embedded PCs in all

situations.

The cabling of the Embedded PC in the control cabinet must be done in accordance with the standard EN

60204-1:2006 PELV = Protective Extra Low Voltage:

• The "PE" and "0V" conductors of the voltage source for a basic CPU module must be on the same

potential (connected in the control cabinet).

• Standard EN 60204-1:2006, section 6.4.1:b stipulates that one side of the circuit, or a point of the

energy source for this circuit must be connected to the protective earth conductor system.

Connection example

Table26: Legend for the connection example

No. Description

1 The upper spring-loaded terminals (Us) identified with “24 V“ and “0 V“ supply the

Embedded PC and the Terminal Bus (data transfer via K- or E-bus).

2 The spring-loaded terminals (Up) identified as "+", "-" and "PE" supply the Bus Terminals

via the power contacts and the sensors or actuators connected to the Bus Terminals.

Fuse protection

• When dimensioning the fuse for the system voltage (Us), observe the max. power consumption of the

Embedded PC (see: Technical Data [}87]).

• Protect power contacts (Up) with a fuse of max. 10 A (slow blow).

CX51x040 Version: 2.7

Page 41

Commissioning

The cables of an external voltage source are connected to the power supply unit with spring-loaded

terminals.

Table27: Required wire cross-sections and strip lengths.

Conductor cross-section 0,5 ... 2,5 mm

2

AWG 20 ... AWG 14

Strip length 8 ... 9 mm 0.33 inch

The voltage source has been connected to the power supply unit

successfully when the two upper power supply terminal LEDs light up in

green.

• The left LED (Us) indicates the supply of the basic CPU module and

terminal bus.

• The red LED (Up) indicates the Bus Terminal supply via the power

contacts.

NOTE

Interrupting / switching off the power supply

To switch off the Embedded PC, do not disconnect the ground (0 V), because otherwise current may continue to flow via the shielding, depending on the device, and damage the Embedded PC or peripheral devices.

• Always disconnect the 24 V line. Devices connected to the Embedded PC, which have their own power

supply (e.g. a Panel) must have the same potential for "PE" and "0 V" as the Embedded PC have (no

potential difference).

Observe the UL requirements

The CX51x0 Embedded PCs are UL certified. The corresponding UL label can be found on the type plate.

Fig.27: UL label for CX51x0 Embedded PC.

The CX51x0 Embedded PCs can thus be used in areas in which special UL requirements have to be met.

These requirements apply to the system voltage (Us) and to the power contacts (Up). Application areas

without special UL requirements are not affected by UL regulations.

UL requirements

• The Embedded PCs must not be connected to unlimited voltage sources.

• Embedded PCs may only be supplied from a 24 V DC voltage source. The voltage source must be

insulated and protected with a fuse of maximum 4 A (corresponding to UL248).

• Or the power supply must originate from a voltage source that corresponds to NEC class 2. An NEC

class 2 voltage source must not be connected in series or parallel with another NEC class 2 voltage

source.

CX51x0 41Version: 2.7

Page 42

Commissioning

6.3 Switching on

Please ensure that the Embedded PC is fully configured before switching on the Embedded PC.

Switch on the Embedded PC as follows:

1. Ensure that all extension, system and fieldbus modules are connected correctly.

2. Check whether the right installation position was selected.

3. Check whether the Embedded PC is mounted securely on the DIN rail and all required Bus Terminals

are connected.

4. Only then switch on the power supply for the power supply unit.

ð The Embedded PC starts automatically when the external power supply is switched on. The pre-installed

operating system is started and all connected extension, system and fieldbus modules are configured.

6.4 Switching off

Loss of data

If the Embedded PC is switched off during operation, data on the CFast card or other hard disks

may be lost.

Do not disconnect the Embedded PC during operation.

Switch off the Embedded PC as follows:

1. Stop all running programs properly, e.g. the control software on the Embedded PC.

2. Shut down the operating system.

3. Do not switch off the external power supply until all other tasks have been completed, in order to switch

off the Embedded PC.

CX51x042 Version: 2.7

Page 43

Configuration

7 Configuration

7.1 Windows Embedded Compact 7

7.1.1 Setting up the audio interface (N020)

Under Windows Embedded Compact 7, the Beckhoff CX configuration tool can be used for the audio

settings.

Requirements:

• Embedded PC with audio interface.

• Windows Embedded Compact 7.

Proceed as follows:

1. Open the Beckhoff CX configuration tool under Start > Control Panel > CX Configuration.

The Beckhoff CX configuration tool window opens.

2. Click on the Miscellaneous tab.

3. Tick the Enable Audio Device checkbox.

4. Click on Audio Settings and set the volume for input and output via the sliders.

5. Select the input source under Input Select. Only one input source can be active at any one time.

ð Confirm the settings with OK, once you have set up the audio interface.

CX51x0 43Version: 2.7

Page 44

Configuration

7.2 Windows Embedded Standard 7 P

7.2.1 Identification of the Ethernet interfaces (X000, X001)

Network and Sharing Center

In the Network and Sharing Center the Ethernet interfaces (X000, X001) of the CX51x0 Embedded PC are

identified as follows as standard:

• Local Area Connection corresponds to Ethernet interface X000.

• Local Area Connection 2 corresponds to Ethernet interface X001.

Fig.28: Windows 7, Identification of the Ethernet interfaces (X000, X001) in the Network and Sharing

Center.

Device Manager

In the Device Manager the Ethernet interfaces (X000, X001) of the CX51x0 Embedded PC are identified as

follows as standard:

• TwinCAT Intel PCI Ethernet adapter (gigabit) corresponds to the Ethernet interface X000.

• TwinCAT Intel PCI Ethernet adapter (gigabit) #2 corresponds to the Ethernet interface X001.

Fig.29: Windows 7, identification of the Ethernet interfaces (X000, X001) in the device manager.

CX51x044 Version: 2.7

Page 45

Configuration

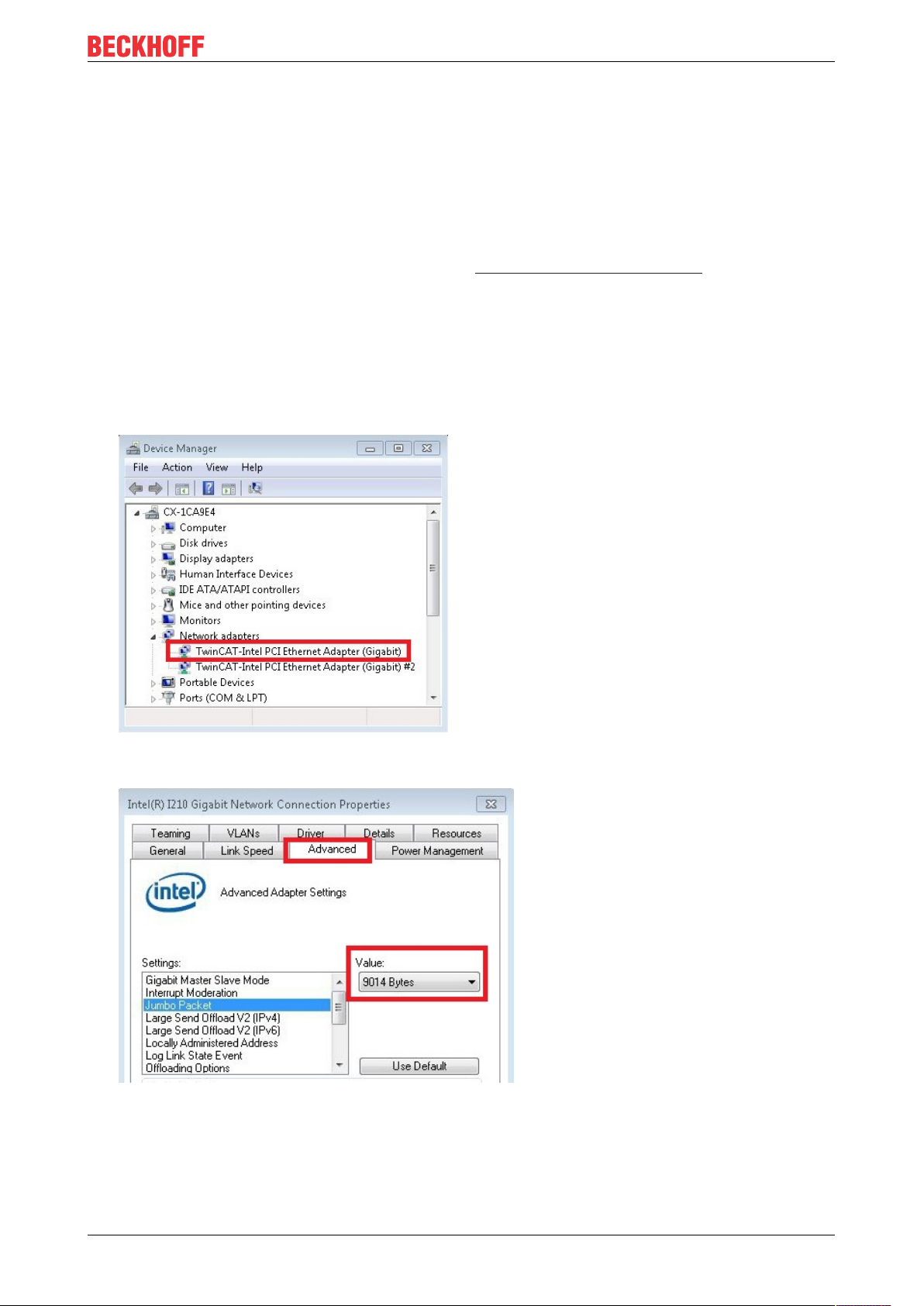

7.2.2 Enabling jumbo frames

Standardized Ethernet frames have a size of 1518 bytes. Ethernet frames that are larger than 1518 bytes

are referred to as jumbo frames. Jumbo frames are used for transferring large data quantities. Jumbo frames

are useful for certain applications, e.g. video cameras.

The Ethernet interfaces (X000, X001) support jumbo frames only if the original Intel® driver is installed.

Requirements:

• The original Intel® driver can be downloaded from https://downloadcenter.intel.com.

• Install the original Intel® driver. Note that this will delete the real-time capable driver from Beckhoff.

• Check whether the peripheral devices support jumbo frames.

Jumbo frames are activated as follows:

1. Under Start > Control Panel > Hardware and Sound click on Device Manager.

2. Double-click on the interface and then on the Advanced tab.

3. Under Settings click on Jumbo Packet, under Value select the option 4088 bytes or 9014 bytes.

ð You have successfully activated jumbo frames, and you can now transfer larger data quantities.

CX51x0 45Version: 2.7

Page 46

Configuration

7.2.3 Set NIC Teaming

NIC Teaming consolidates several physical network cards to group, thereby creating redundancy.

Redundancy can help intercept interference in network cards or in the cabling by assigning the data transfer

to other devices in the group.

Requirements:

• The original Intel® driver can be downloaded from https://downloadcenter.intel.com.

• Install the original Intel® driver for the Network Interface Card. Note that this will delete the real-time

capable driver from Beckhoff.

NIC Teaming is set as follows:

1. Under Start > Control Panel > Hardware and Sound click on Device Manager.

2. Double-click on the interface.

3. Click on the Teaming tab.

4. Click on New Team and follow the installation instructions.

CX51x046 Version: 2.7

Page 47

5. Under Select a team type select the option Adapter Fault Tolerance

Configuration

6. Click on Next to complete the installation.

ð You have successful set NIC Teaming for your Ethernet interfaces. Further settings can be specified or

changed under the Settings tab.

CX51x0 47Version: 2.7

Page 48

Configuration

7.2.4 Restoring the Beckhoff real-time driver.

The Beckhoff real-time driver can be restored if the real-time driver was uninstalled or the original Intel®

driver for jumbo frames or NIC Teaming was installed, for example. This chapter shows you how to use

TcRteInstall.exe to restore the Beckhoff real-time driver. The file is in the TwinCAT directory by default.

Requirements:

• You can find the TcRteInstall.exe in a TwinCAT 2 standard installation under: C:\TwinCAT\Io

\TcRteInstall.exe

• And in a TwinCAT 3 standard installation under: C:\TwinCAT\3.1\System\TcRteInstall.exe

Proceed as follows:

1. Double-click the TcRteInstall.exe file.

The installation dialog appears and shows the compatible Ethernet interfaces under Compatible

devices.

2. Select the Ethernet interfaces for which you wish to restore the Beckhoff real-time driver and click on

Install.

ð The Beckhoff real-time driver is installed. The Ethernet interfaces with installed Beckhoff real-time driver

are shown under Installed and ready to use devices (real-time capable).

CX51x048 Version: 2.7

Page 49

Configuration

7.3 Windows 10 IoT Enterprise LTSB

7.3.1 Identification of the Ethernet interfaces (X000, X001)

Network and Sharing Center

In the Network and Sharing Center the Ethernet interfaces (X000, X001) of the CX51x0 Embedded PC are

identified as follows as standard:

• Ethernet corresponds to the Ethernet interface X000.

• Ethernet 2 corresponds to the Ethernet interface X001.

Fig.30: Windows 10, Identification of the Ethernet interfaces (X000, X001) in the Network and Sharing

Center.

Device Manager

In the Device Manager the Ethernet interfaces (X000, X001) of the CX20x0 Embedded PC are identified as

follows as standard:

• Intel(R) l210 Gigabit Network Connection corresponds to the Ethernet interface X000.

• Intel(R) l210 Gigabit Network Connection #2 corresponds to the Ethernet interface X001.

Fig.31: Windows 10, identification of the Ethernet interfaces (X000, X001) in the device manager.

CX51x0 49Version: 2.7

Page 50

Configuration

7.3.2 Enabling jumbo frames

Standardized Ethernet frames have a size of 1518 bytes. Ethernet frames that are larger than 1518 bytes

are referred to as jumbo frames. Jumbo frames are used for transferring large data quantities. Jumbo frames

are useful for certain applications, e.g. video cameras.

The Ethernet interfaces (X000, X001) support jumbo frames only if the original Intel® driver is installed.

Requirements:

• The original Intel® driver can be downloaded from https://downloadcenter.intel.com.

• Install the original Intel® driver. Note that this will delete the real-time capable driver from Beckhoff.

• Check whether the peripheral devices support jumbo frames.

Jumbo frames are activated as follows:

1. Under Start > Control Panel > Hardware and Sound click on Device Manager.

2. Double-click on the interface and then on the Advanced tab.

3. Under Settings click on Jumbo Packet, under Value select the option 4088 bytes or 9014 bytes.

ð You have successfully activated jumbo frames, and you can now transfer larger data quantities.

CX51x050 Version: 2.7

Page 51

Configuration

7.3.3 Set NIC Teaming

NIC Teaming consolidates several physical network cards to group, thereby creating redundancy.

Redundancy can help intercept interference in network cards or in the cabling by assigning the data transfer

to other devices in the group.

Requirements:

• The original Intel® driver can be downloaded from https://downloadcenter.intel.com.

• Install the original Intel® driver for the Network Interface Card. Note that this will delete the real-time

capable driver from Beckhoff.

NIC Teaming is set as follows:

1. Under Start > Control Panel > Hardware and Sound click on Device Manager.

2. Double-click on the interface.

3. Click on the Teaming tab.

4. Click on New Team and follow the installation instructions.

CX51x0 51Version: 2.7

Page 52

Configuration

5. Under Select a team type select the option Adapter Fault Tolerance

6. Click on Next to complete the installation.

ð You have successful set NIC Teaming for your Ethernet interfaces. Further settings can be specified or

changed under the Settings tab.

CX51x052 Version: 2.7

Page 53

Configuration

7.3.4 Restoring the Beckhoff real-time driver

The Beckhoff real-time driver can be restored if the real-time driver was uninstalled or the original Intel®

driver for jumbo frames or NIC Teaming was installed, for example. This chapter shows you how to use

TcRteInstall.exe to restore the Beckhoff real-time driver. The file is in the TwinCAT directory by default.

Requirements:

• You can find the TcRteInstall.exe in a TwinCAT 2 standard installation under: C:\TwinCAT\Io

\TcRteInstall.exe

• And in a TwinCAT 3 standard installation under: C:\TwinCAT\3.1\System\TcRteInstall.exe

Proceed as follows:

1. Double-click the TcRteInstall.exe file.

The installation dialog appears and shows the compatible Ethernet interfaces under Compatible

devices.

2. Select the Ethernet interfaces for which you wish to restore the Beckhoff real-time driver and click on

Install.

ð The Beckhoff real-time driver is installed. The Ethernet interfaces with installed Beckhoff real-time driver

are shown under Installed and ready to use devices (real-time capable).

CX51x0 53Version: 2.7

Page 54

Configuration

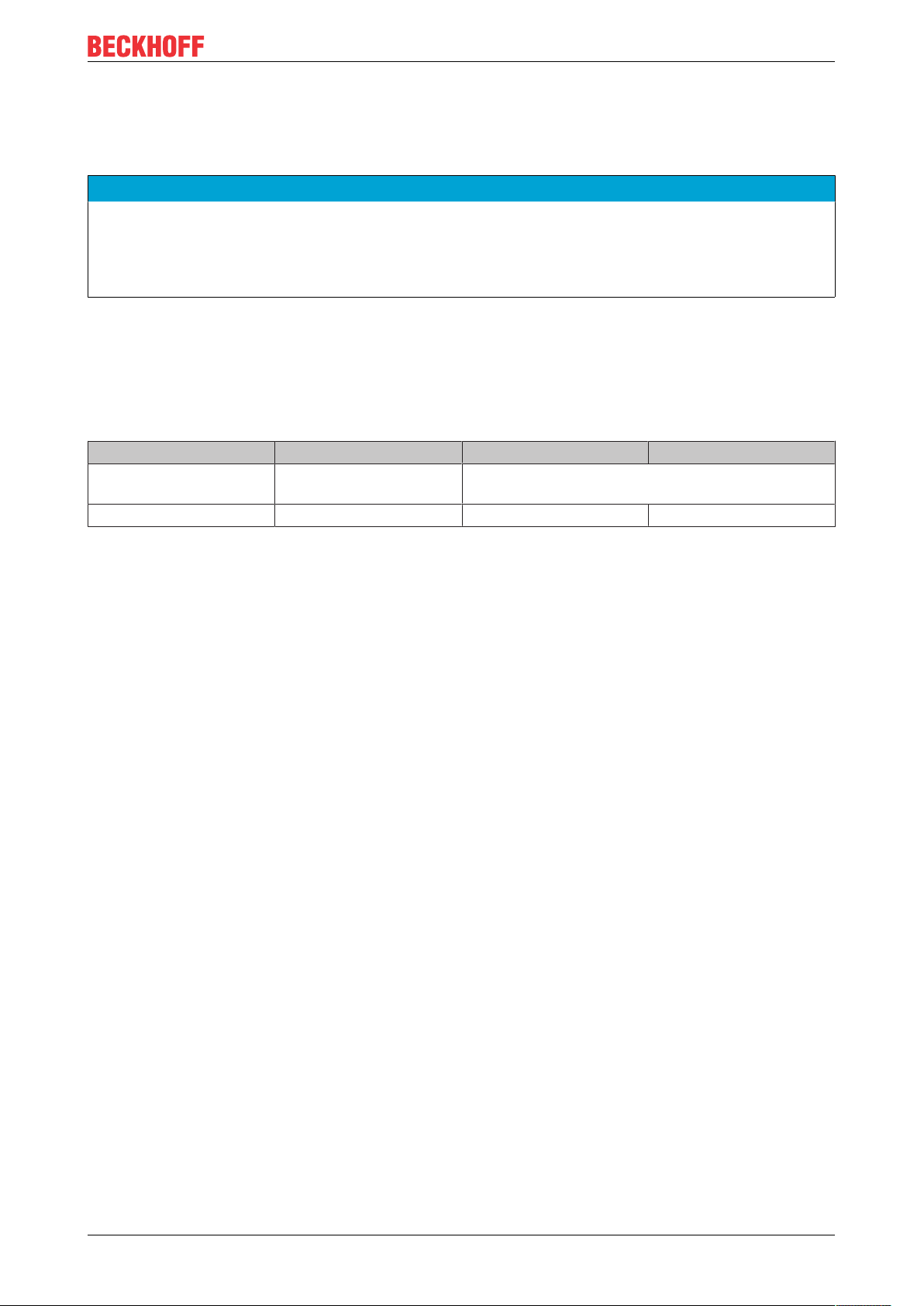

7.3.5 Using serial interfaces N030/N031

With the Embedded PC from the CX5100 series with Windows 10 Image, the serial interfaces are only

supported from a certain BIOS, Image and TwinCAT version onwards.

Table28: System requirements for the operation of the serial interfaces N030 and N031.

Order Option BIOS version Image version TwinCAT version

CX51x0-N030 0.79 CX1800-0501-0011v2.0

CX51x0-N031

The serial interfaces CX51x0-N030 and CX51x0-N031 of the Embedded PC CX51x0 are configured as

standard for operation under TwinCAT. The drivers are not loaded under Windows and you cannot use the

interfaces for custom installed application software.

You can use the interfaces either under Windows 10 or TwinCAT. A mixture of both operating modes is not

possible. The configuration and switching of the operating modes takes place in the BIOS.

Set the BIOS as follows to operate the serial interfaces under Windows 10:

1. Restart the Embedded PC and press [Del] to start the BIOS setup.

The BIOS Setup window appears.

2. Set the option LPSS & SCC Devices Mode to ACPI mode under Advanced > LPSS & SCC

Configuration.

3. Set the option OS Selection to Windows 8.x under Advanced > Miscellaneous Configuration.

4. Press [F4] to save the settings and exit the BIOS setup.

The device is restarted.

CX1800-0511-1011v2.0

2.11.2302

3.1.4022.27

ð After the reboot, the drivers for the serial interfaces are loaded and displayed in the device manager