Page 1

CX1000 Embedded PC

Hardware documentation

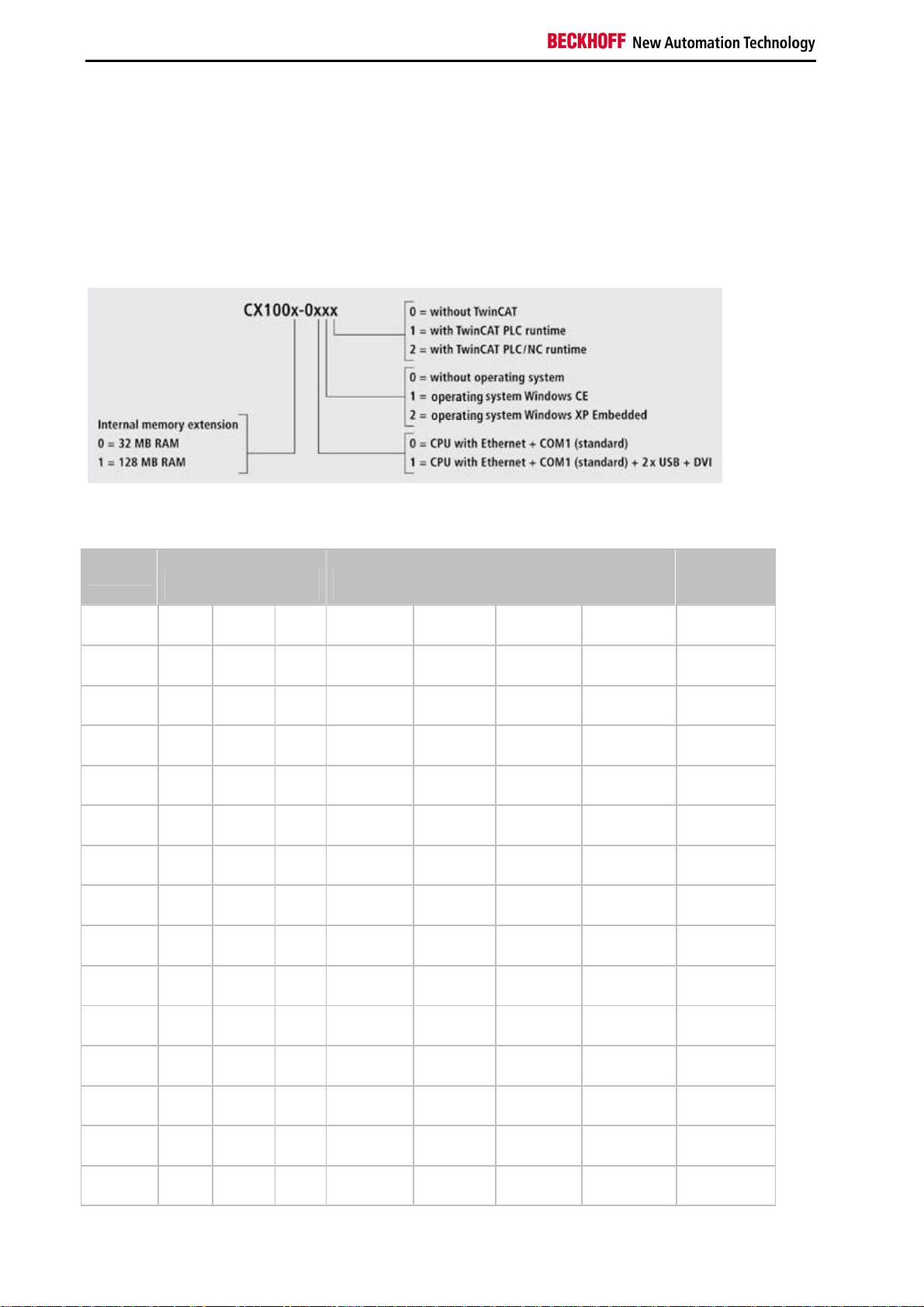

CX1000-0xxx

CX1000-Nxxx

version: 1.1

date: 2006-06-21

Page 2

Page 3

Table of contents

CX1000 Hardware Documentation

1. Foreword

Notes on the Manual

Safety instructions 4

Documentation Issue Status 5

2. Product Overview 6

Appropriate Use 6

System Overview 7

Base Modules 9

Technical Data 9

Types 10

Connections 12

Compact flash insert 14

Compact flash card 14

PC 104 bus 15

Table of contents

System interfaces 17

Technical Data 17

Connections CX1000-N001 18

Connections CX1000-N002 20

Connections CX1000-N003 21

Connections CX1000-N005 22

Power supply 24

Technical data CX1100-0001 24

Technical data CX1100-0002 / CX1100-0003 25

Connections CX1100-0001 26

Connections CX1100-0002 27

Connections CX1100-0003 28

LCD display 29

3. Transport 30

Unpacking, installation and transport 30

4. Fitting and wiring 31

Mechanical mounting 31

Dimensions 31

Mechanical Assembly of the base module 32

Mechanical Mounting of the Fieldbus modules 35

5. Error handling and diagnostics 37

CPU base module 37

LED CPU base module 37

Embedded PC 1

Page 4

Table of contents

Power supplys 38

LED CX1100-0001 38

LED CX1100-0002 39

LED CX1100-0003 41

Trouble shooting 43

6. Decommissioning 44

Removal and disposal 44

7. Appendix 46

Accessories 46

Support 47

Certificates 48

2 Embedded PC

Page 5

Foreword

1. Foreword

Notes on the Manual

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards. It is essential that the following notes and explanations are followed

when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. None of the statements of this manual represents a guarantee (Garantie) in the

meaning of § 443 BGB of the German Civil Code or a statement about the contractually expected fitness for a

particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this

documentation.

© This manual is copyrighted. Any reproduction or third party use of this publication, whether in whole or in part,

without the written permission of Beckhoff Automation GmbH, is forbidden.

Associated publication

For commissioning the use of the appropriate hardware documentation is recommended apart from this

documentation.

Embedded PC 3

Page 6

Foreword

Safety Instructions

Safety Rules

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the application.

Modifications to hardware or software configurations other than those described in the documentation are not

permitted, and nullify the liability of Beckhoff Automation GmbH.

Personnel Qualification

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards.

Description of safety symbols

The following safety symbols are used in this operating manual. They are intended to alert the reader to the

associated safety instructions.

Danger

This symbol is intended to highlight risks for the life or health of personnel.

Warning

This symbol is intended to highlight risks for equipment, materials or the environment.

Note

This symbol indicates information that contributes to better understanding.

4 Embedded PC

Page 7

Documentation Issue Status

Version Changes

1.1 comments on hardware watchdog added

1.0 updated version

0.1 preliminarily version

Foreword

Embedded PC 5

Page 8

Product Overview

2. Product Overview

Appropriate Use

The CX1000 device series is a modular control system that can be mounted on top hat rails. Its components are

plugged together and installed in the control cabinet or junction box, depending on the required function.

6 Embedded PC

Page 9

Product Overview

System Overview

The System

The CX1000 system covers the whole range of Beckhoff control technology both in terms of price and performance:

The new product range is designed for tasks requiring the characteristics and computing capacity of Industrial PCs,

but whose budget does not stretch to full-blown Industrial PCs.

The system only uses those components that are actually required. For example, a CX1000 can be operated in

„headless“mode, i.e. without display or keyboard; in this case, the associated interface is not required. Whilst the

resulting control system has no visualisation, it does have communications capability via the built-in Ethernet and RS

232 interfaces.

If local visualisation is required, this can be implemented via a DVI (digital video interface), to which all Beckhoff

Control Panels and all commercially available monitors with DVI-input can be connected. The touch screen signal is

read via one of the two available USB interfaces.

The components

The modules of the CX1000 series system are connected with each other via the standardised PC104 bus (16 bit).

The individual system components are modules that can be arranged in series. The basic unit consists of a CPU

module(CX1000-0000) and a power supply module(CX1100-000x). Further system interfaces for serial

communication(2x RS 232, and RS422, RS485) as well as audio signals are available separately.

CPU base module

The CPU module is available in several variants. These relate to:

– Internal memory configuration: there are two options – either 16 MB Flash/32 MB RAM or 64 MB Flash / 128 MB

RAM. The latter is required if the system is to be equipped with Windows XP Embedded.

– System interface configuration: as an option, a DVI and two USB Interfaces can be added to the combination of

Ethernet and RS 232 that is always present.

– Operating system: There is a choice between Microsoft Windows CE.NET and Microsoft Windows XP Embedded.

– Pre-installed TwinCAT software: CX1000 can be preinstalled without a TwinCAT system, with TwinCAT CE PLC or

with TwinCAT CE NC PTP, or with the associated full version of the individual TwinCAT levels for PLC and Motion

Control.

Embedded PC 7

Page 10

Product Overview

System interfaces

Further system interfaces for serial communication(2x RS 232, and RS422, RS485) as well as audio signals are

available separately.

Fieldbus interfaces

The range of optional modules for theCX1000 is complemented by fieldbus connectionsfor Profibus, CANopen,

DeviceNet,SERCOS interface and Lightbus, both asmaster and slave versions.

The following fieldbus interfaces are available:

Beckhoff Lightbus (master and slave), Profibus DP (master and slave), CANopen (master and slave), DeviceNet

(master and slave) und SERCOS Interface (only master).

The use of fieldbus master modules in a CX1000 system enables the utilisation of all Beckhoff fieldbus components

(e. g. Bus Coupler, Bus Terminal Controller, drive technology) as distributed control components for the assembly of

complex systems

The use of fieldbus slave modules enables the utilisation of a CX1000 system as subordinate distributed control for

the configuration of complex or modular systems.

The Software

In combination with the TwinCAT automation software, the CX1000 Industrial PC becomes a powerful IEC 61131-3

PLC with up to four user tasks. Additionally, MotionControl tasks can also be executed. Depending on the required

cycle time, several servo axes can be controlled. Even special functions such as flying saw, electronic gearbox and

cam plate can be realised.

The CX1000 system can be programmed in two ways, depending on the operating system used:

Remote programming via Ethernet

This option is used if the basic unit is equipped with Windows CE.NET. In this case, the system is programmed via a

laptop or a desktop PC, which is connected to the CX1000 via Ethernet (network or crossover cable). The programs

are developed on the laptop with a standard TwinCAT software licence and then loaded into the target device.

Visualisation

The Beckhoff OPC server is available for interfacing with SCADA software on both operating system variants

Windows CE.NET or Windows XP Embedded. In other words, the CX1000 also offers unproblematic visualisation

and simultaneous control in realtime on a single system. Beckhoff control devices

8 Embedded PC

Page 11

Base Modules

Technical Data

Product Overview

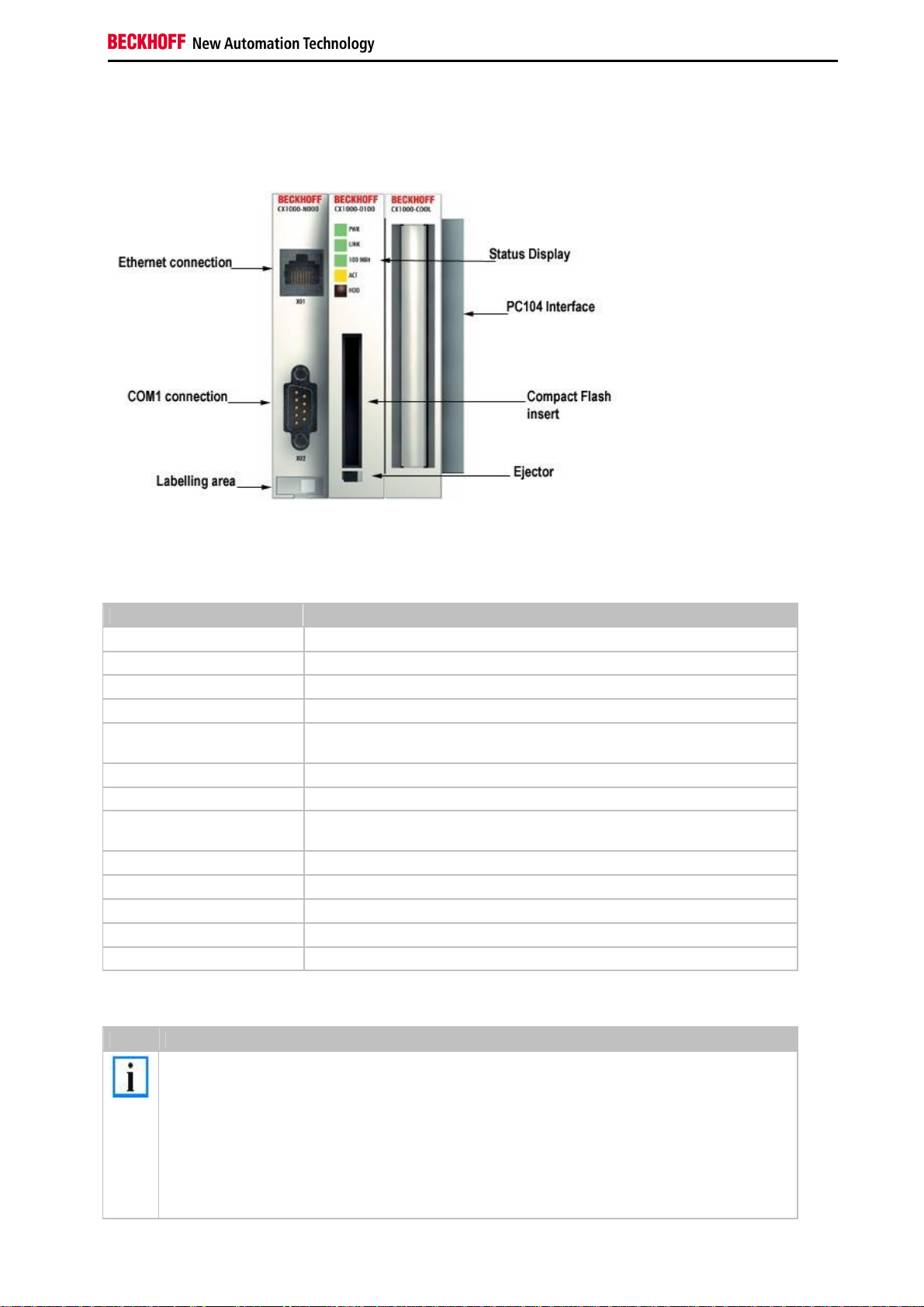

The CX1000 CPU module is the basic module of the CX system. It comprises the CPU and the internal flash memory

in two implementation levels and offers the option to operate an additional memory medium in Compact Flash type II

format. Ethernet and an RS 232 interface are also part of the basic configuration. All other CX family components can

be connected via the PC104 interface that is available on both sides. The CPU module requires a CX1100 type

power supply module.

Technical data CX1000-0000

Processor compatible with Pentium MMX, clock frequency 266 MHz

Flash memory 64 MByte Compact Flash card

Internal main memory 32 MByte RAM (expandable to 128 MByte)

Interfaces 1 x RJ45 (Ethernet) and 1 x 9-pinD-Sub (RS 232)

Diagnostics LED 1 x Power, 1 x Link, 1x 100 MBit , 1 x LAN Aktivität,

1 x Flash access

Expansion slot 1 x Compact Flash type II insert with ejector

Clock battery-powered internal clock for time and date

Operating system Microsoft Windows CE.NET or Microsoft

Windows XP Embedded

Control software TwinCAT PLC Runtime or TwinCAT NC PTP Runtime

System bus 16 Bit ISA (PC104 standard)

Power supply via system bus (through CX1100 power supply module)

Dimensions 57 mm x 100 mm x 91 mm

Weight approx. 355 g ( with DVI/USB 435 g)

The passive cooling module CX1000-COOL is included in the scope of supply.

Note

The Watchdog function is only supported by Beckhoff in combination of TwinCAT with WINDOWS

NT based systems. For other operating systems without TwinCAT it is not possible to give a general

solution. The user must find a solution to the implementation of watchdog access on his own. As the

only support Beckhoff can provide

the processor hardware description

the CX-architecture description (CX1100-000x power supply manual)

The documents can be found in the Download area of our webserver (www.beckhoff.com)..

Embedded PC 9

Page 12

Product Overview

Types

The CPU module can be equipped with different hardware and software options: the internal memory is expandable

to 32 MB Flash/128 MB RAM; the operating systems can be Windows CE.NET or Windows XP Embedded. The

TwinCAT automation software transforms a CX1000 system into powerful PLC and Motion Control system that can

be operated with or without visualisation. Further system interfaces (pre-installed in the factory) or fieldbus

connections can be added to the basic CPU module.

Since not all combinations are sensible, the following table contains a breakdown of the permissible combinations.

The CX 1000 modules are available in the following types:

Modules

CX10000010

CX10000011

CX10000012

CX10000110

CX10000111

CX10000112

CX10010000

CX10010010

CX10010011

CX10010012

CX10010020

CX10010021

CX10010022

CX10010110

CX10010111

16/32 MB64/128 MBDVI /

USB

* * *

* * *

* * *

* * * *

* * * *

* * * *

*

* * *

* * *

* * *

* * *

* * *

* * *

* * * *

* * * *

Windows

CE.NET

Windows

XPE

without

TwinCAT

TwinCAT

PLC

Runtime

TwinCAT NC

PTP

Runtime

10 Embedded PC

Page 13

Product Overview

CX10010112

CX10010120

CX10010121

CX10010122

CX1000 systems with Windows XP Embedded require a Compact Flash card with a minimum capacity of 128 MB.

Note:

A list of the different software images can be found in the CX1000 Software Documentation.

* * * *

* * * *

* * * *

* * * *

Embedded PC 11

Page 14

Product Overview

Connections

The basic CPU module is available with different hardware and software options. It is supplied from the power supply

unit, so that only the connections are described here.

Basic CPU module with Ethernet RJ 45 and COM1 (RS232) interface:

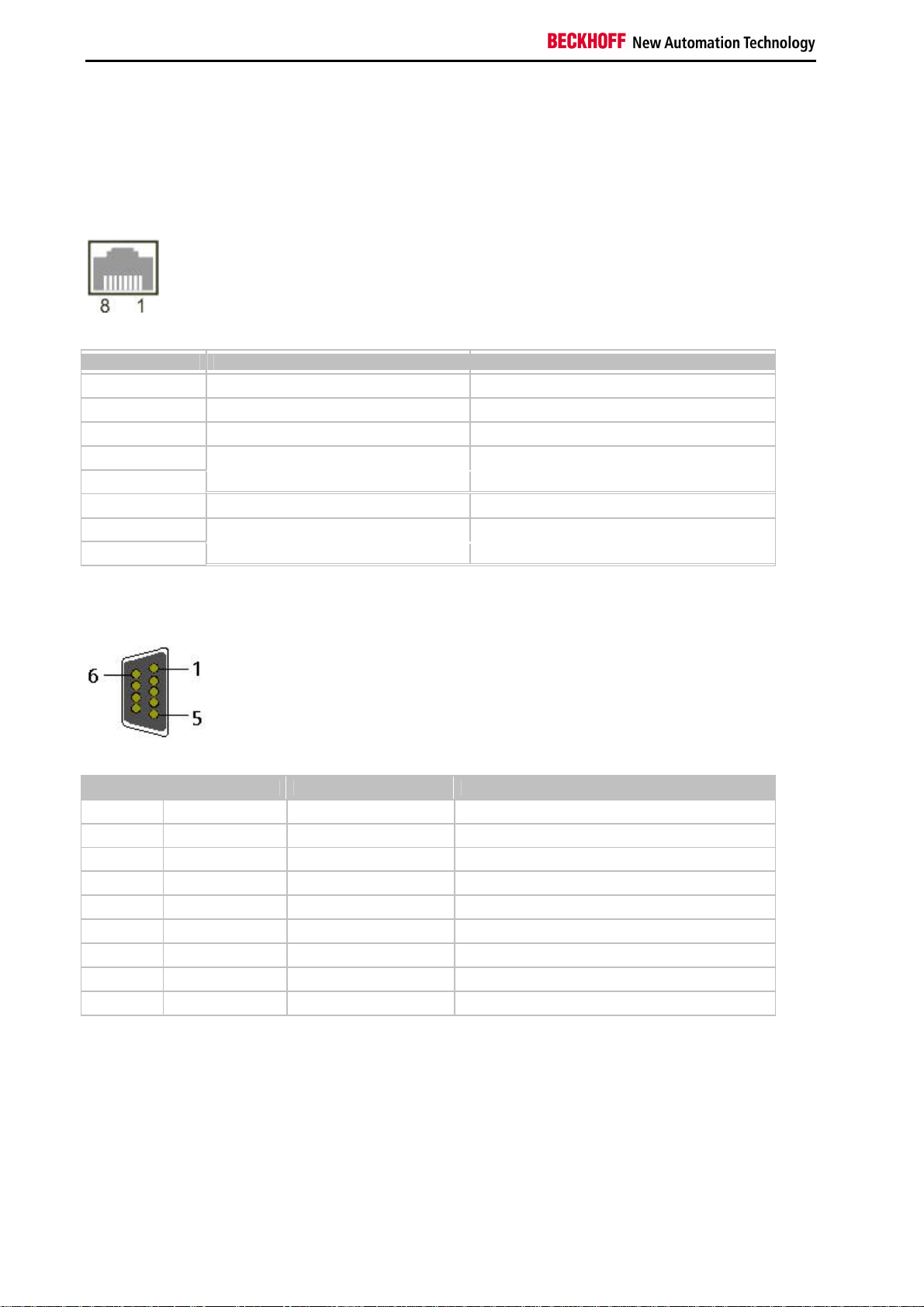

RJ 45 interface (socket):

Assignment of the RJ45 interface:

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit 3 RD + Receive +

4

5

6 RD - Receive 7

8

TD & RD are exchanged at the hubs or between two PCs.

connected not used

connected not used

COM1 interface (connector):

Assignment of the COM1 interface:

PIN Signal Type Description

1 DCD Signal in Data Carrier Detect

2 RxD Signal in Receive Data

3 TxD Signal out Transmit Data

4 DTR Signal out Data Terminal Ready

5 GND Ground Ground

6 DSR Signal in Data Set Ready

7 RTS Signal out Request to Send

8 CTS Signal in Clear to Send

9 RI Signal in Ring Indicator

12 Embedded PC

Page 15

Product Overview

Basic CPU module with DVI/USB interface:

In addition to the Ethernet and COM interface, this basic module features a DVI-I and two USB interfaces. The pin

assignment of the basic CPU module with two USB and a DVI-I interface is explained under the associated system

interface CX1000-N001.

Applicable to all basic CPU modules:

LED

The green power LED (PWR) is on if the basic CPU module is connected correctly to a live power supply unit.

Compact Flash slot

Further information can be found under Compact Flash slot.

PC 104 Bus

The PC 104 bus is a standardised bus with 104 ISA signals for compact embedded systems.

Embedded PC 13

Page 16

Product Overview

Compact Flash slot

A Compact Flash slot is provided at the front of the basic CPU module. This enables an additional Compact Flash

memory medium (format I or II) to be operated. The change is only allowed while the system is powered down otherwise the system could crash. The card can be removed for maintenance or to extend the system storage

capacity. The Compact Flash cards (CF cards) are available as accessories with different storage capacities. It is

Activating the eject mechanism below the slot with a screwdriver causes the card to be ejected by approx. 4 mm

(FIGURE 1), so that it can be pulled out (FIGURE 2). If the card is pushed in (FIGURE 3), the eject mechanism will

re-engage. The card is positioned correctly, if it is located approx. 1 mm lower than the front of the housing.

Figure 1 Ejecting the CF card Figure 2 Removing CF-card

Figure 3 Inserting the CF card

Warning

The Compact Flash slot is a memory interface, not an I/O type CF slot.

Compact-Flash card

The Compact Flash card (CF card) is a non-volatile memory medium.

Data to be retained in the event of a power failure should be saved on the CF card. The CF card operates similar to a

hard disk.

Warning

It is recommended only use CF cards supplied by Beckhoff Automation GmbH.

The CF cards are made for industrial use. They possess a higher number of read / write cycles and

an enhance temperature range (up to + 85°C).

A proper operation of the CX-System can only be guaranteed with the use of CF cards from

Beckhoff Automation GmbH!

14 Embedded PC

Page 17

Product Overview

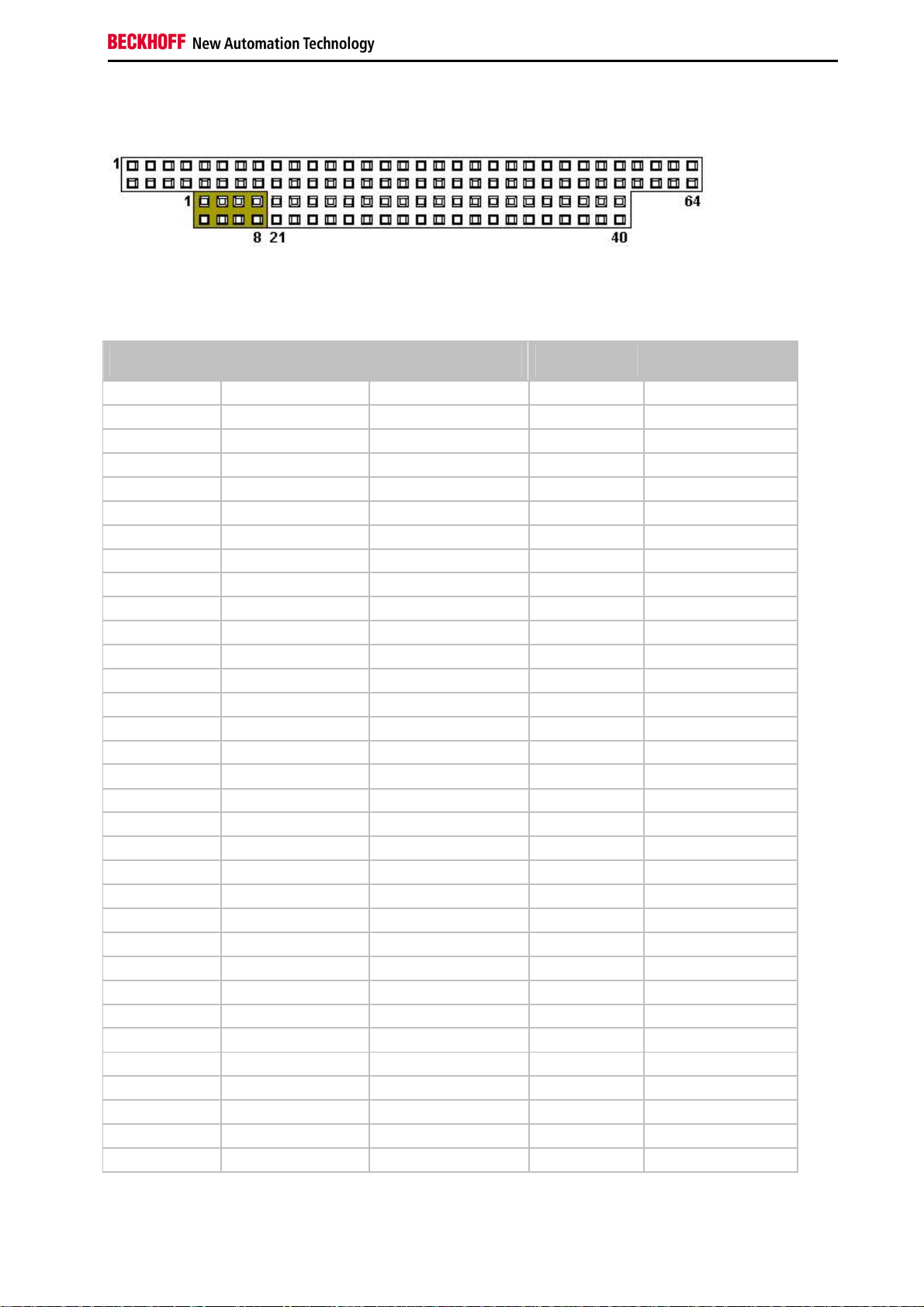

PC 104 Bus

The PC 104 bus is a standerdised bus with 104ISA signals for compact embedded systems.

For the functionality of the CX1000 modules eight further signals have been added ( here marked with color).

Pin assignment of 16 bit PC 104 bus:

Pin

Number

0 -- -- GND GND

1 IOCHCHK* GND SBHE* MEMCS16*

2 SD7 RESETDRV LA23 IOCS16*

3 SD6 +5V LA22 IRQ10

4 SD5 IRQ9 LA21 IRQ11

5 SD4 -5V LA20 IRQ12

6 SD3 DRQ2 LA19 IRQ13

7 SD2 -12V LA18 IRQ14

8 SD1 ENDXFR* LA17 DACK0*

9 SD0 +12V MEMR* DRQ0

10 IOCHRDY (KEY)² MEMW* DACK5*

11 AEN SMEMW* SD8 DRQ5

12 SA19 SMEMR* SD9 DACK6*

13 SA18 IOW* SD10 DRQ6

14 SA17 IOR* SD11 DACK7*

15 SA16 DACK3* SD12 DRQ7

16 SA15 DRQ3 SD13 +5V

17 SA14 DACK1* SD14 MASTER*

18 SA13 DRQ1 SD15 GND

19 SA12 REFRESH* (KEY)² GND

20 SA11 SYSCLK -- -21 SA10 IRQ7 -- -22 SA9 IRQ6 -- -23 SA8 IRQ5 -- -24 SA7 IRQ4 -- -25 SA6 IRQ3 -- -26 SA5 DACK2* -- -27 SA4 TC -- -28 SA3 BALE -- -29 SA2 +5V -- -30 SA1 OSC -- -31 SA0 GND -- -32 GND GND -- --

J1/P1

Row A

J1/P1

Row B

J1/P1

Row C

J1/P1

Row D

Embedded PC 15

Page 18

Product Overview

Remarks:

2. B10 and C19 are key locations.

3. Signal timing and function are as specified in ISA specification.

4. Signal source/sink current differ from ISA values.

Pin assignment of the addtional signals

Pin number Assignment

1 I²C SCL

2 USB D+

3 I²C SDA

4 USB D5 ONCTRL

6 U

7 POR

8 PWRBTN

Note:

Further information about the PC 104 bus can be found under http://www.pc104.org

stby

5 V

16 Embedded PC

Page 19

System interfaces

Technical Data

Product Overview

Unlike other CX components, the system interfaces cannot be upgraded or expanded in the field. They are supplied

ex factory in the specified configuration and cannot be separated from the CPU module. The system interfaces run

through the internal PC104, so that further CX components can be connected. The power supply of the system

interface modules is ensured via the internal PC104 bus.

Technical

data CX1000-N001 CX1000-N002 CX1000-N003 CX1000-N005*

Interfaces 1 x DVI +

2 x USB 1.1

Connection

type

Properties DVI-I interface also

Power

supply

Dimensions 19 mm x 100 mm x 91 mm

Weight

approx.

DVI-I 29-pin socket

+ 2 USB ports type

A

carries out VGA

signals (DVI-A)

via system bus (through CX1100 power supply module)

80 g

1 x COM2 +

1 x COM3

2 x 9-pin D-Sub 3.5 mm socket

max. Baud rate 115 kBaud on

both interfaces COM1: RXD,

TXD, DTR COM2: RXD, TXD

Line IN,

Line Mic IN,

Line OUT

for jack plug

built-in PC

Beeper

Line OUT

output, max.

200 mW,

suitable for

earphones

1 x COM2 +

1 x COM3

2 x 9-pin D-Sub

max. Baud rate 115

kBaud on both

interfaces

2 x RS485/422,

optically isolated

* can only be used instead of and not at the same time as CX1000-N002

Embedded PC 17

Page 20

Product Overview

CX1000-N001 connections

In addition to the Ethernet and RS232 interface, this module features a DVI-I and two USB interfaces.

DVI-I interface

The DVI-I interface transfers analog and digital data and is suitable for connection to analog graphics cards with 15

pin D-Sub connector and digital graphics cards with DVI-D output. The resolution at the screen or the Beckhoff

Control Panel depends on the distance (maximum 7 m).

The DVI interface uses VGA signals, so that the connection of CRT VGA monitors to the CX1000 system using a DVI

to VGA adapter is also possible.

This adapter is available as an accessory.

DVI-I socket:

Pin Assignment Pin Assignment Pin Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 02 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 not connected 12 not connected 20 not connected

5 not connected 13 not connected 21 not connected

6 DDC Clock 14 + 5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground ( +5V, Analog H/V Sync) 23 TMDS Clock +

8 Analog Vertical Sync 16 Hot Plug Detect 24 TMDA Clock -

Pin assignment (cross)

Pin Assignment

C1 Analog Red Video Out

C2 Analog Green Video Out

C3 Analog Blue Video Out

C4 Analog Horizontal Sync

Resolution at the monitor:

Resolution in pixels Distance of the interface from the monitor

1024 x 768 5 m

800 x 600 6 m

640 x 480 7 m

18 Embedded PC

Page 21

USB interface:

The USB socket is a type A socket. The USB interface complies to USB 1.1 specification

Pin Assignment Typical assignment

1 VBUS Red

2 D- White

3 D+ Green

4 GND Black

Shell Shield Drain Wire

Product Overview

Embedded PC 19

Page 22

Product Overview

CX1000-N002 connections

The CX1000-N002 system interface features two RS232 interfaces, COM2 and COM3 (9 pin Sub-D plug connector).

The maximum baud rate on both channels is 115 kBit.

RS232 COM interface (connector):

Pin assignment of the COM2 interface:

PIN Signal Type Description

2 RxD Signal in Receive Data

3 TxD Signal out Transmit Data

4 DTR Signal out Data Terminal Ready

5 GND Ground Ground

The pins not listed are not used.

Pin assignment of the COM3 interface:

PIN Signal Type Description

2 RxD Signal in Receive Data

3 TxD Signal out Transmit Data

5 GND Ground Ground

The pins not listed are not used.

20 Embedded PC

Page 23

Product Overview

CX1000-N003 connections

This system interface contains the audio interfaces Line In, Mic In (microphone signal input) and Line Out (also for

earphones), max. 200 mW.

It also features a PC beeper.

The 3.5 mm sockets are designed for jack plugs.

Line In / Line Out stereo jack plugs:

Pin assignment Line In /Line Out:

Signal Description

L Left Signal

R Right Signal

Gound Ground

The left channel is transferred via the tip of the jack plug, the right channel via the first ring. The remainder of the

sleeve is used for earthing.

Mic In mono jack plug:

The only existing channel is transferred via the tip, the remainder of the sleeve is used for earthing.

Embedded PC 21

Page 24

Product Overview

CX1000-N005 connections

The system interface CX1000-N005 contains two RS422, RS485 interfaces, COM2 and COM3 (9 pin Sub-D plug

connector).

The maximum baud rate on both channels is 115 kBit.

COM interface (plug):

Pin assignment of the COM interface:

PIN Signal Type Description

2 TxD+ Data-Out + Transmit 422

3 RxD+ Data-In + Receive 422

5 GND Ground Ground

6 VCC VCC +5V

7 TxD- Data-Out - Transmit 422

8 RxD- Data-In - Receive 422

For RS 485 Pin 2 and 3 ( Data +) as well as Pin7 and 8 (Data -) have to be connected.

The pins not listed are not used.

Settings DIP switches RS485:

RS485 without Echo, End-Point ( Terminated) DEFAULT SETTING

DIP Status Function

1 off Echo on

2 on Echo off

3 on Auto send on

4 off Always send on

5 on Auto receive on

6 off Always receive on

7 on Term on

8 on Term on

RS485 with Echo, End-Point ( Terminated)

DIP Status Function

1 on Echo on

2 off Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 on Term on

8 on Term on

22 Embedded PC

Page 25

RS485 without Echo, Drop-Point ( without Termination)

DIP Status Function

1 off Echo on

2 on Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 off Term on

8 off Term on

RS485 with Echo, Drop-Point ( without Termination)

DIP Status Function

1 on Echo on

2 off Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 off Term on

8 off Term on

Product Overview

Settings DIP Switches RS422:

RS422 full duplex end point

DIP Status Function

1 on Echo on

2 off Echo off

3 off Auto send on

4 on Always send on

5 off Auto receive on

6 on Always receive on

7 on Term on

8 on Term on

The dip switches for the configuration of the RS485/422 interfaces can be found at the left side of the module. If you

remove the grey cover you can see the switch.

Embedded PC 23

Page 26

Product Overview

Power supply

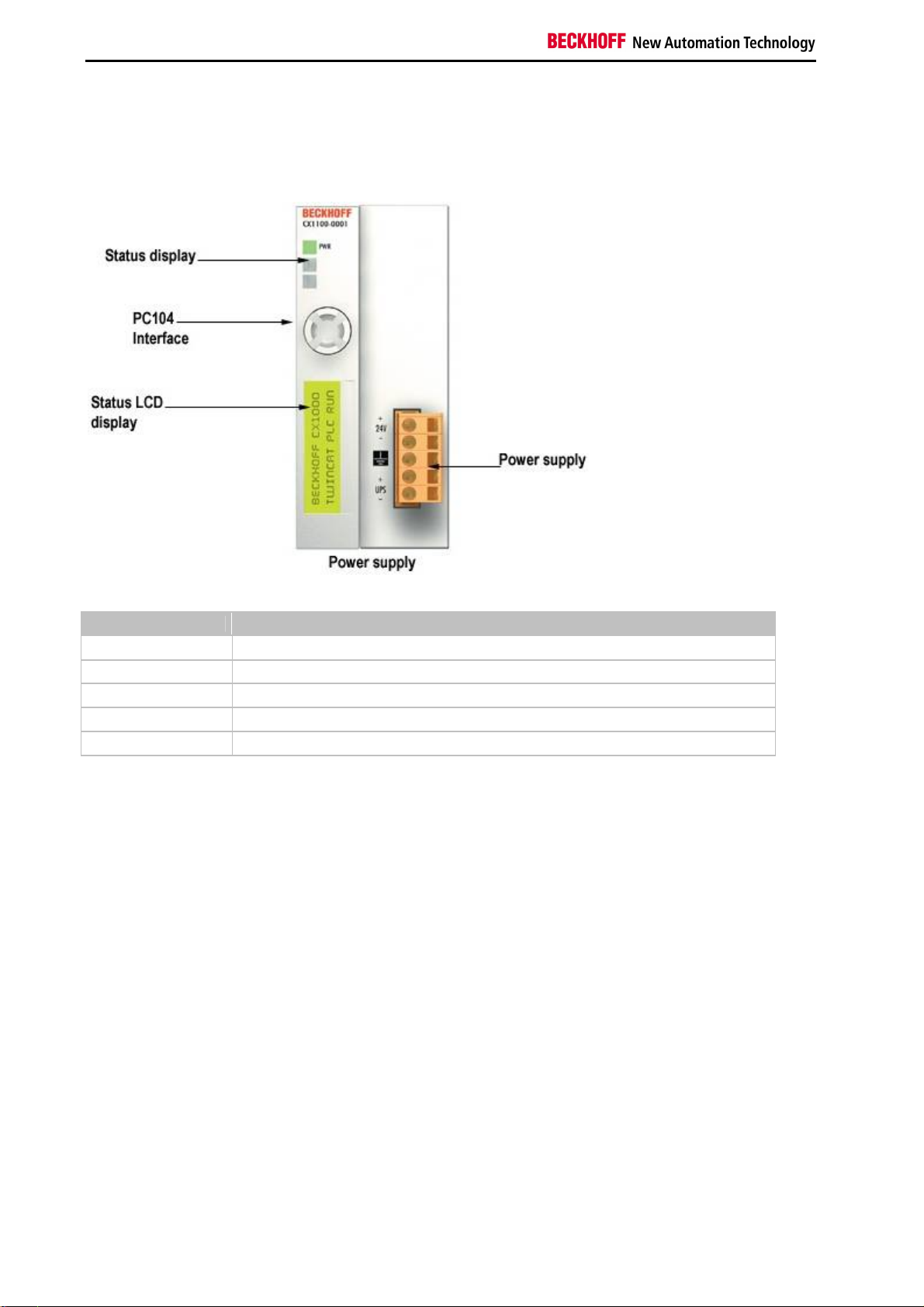

Technical Data CX1100-0001

One of three power supply modules can be selected for a CX1000 system. The power supply of all other system

components is ensured via the internal PC104 bus; no separate supply lines are required. However, the CX1100

components offer further important characteristics that go beyond a pure power supply: an integrated NOVRAM

enables the fail-safe storage of process data, an LCD display with two lines of 16 characters each is used for

displaying system and user messages.

The power supply CX1100-N001 has no I/O interfaces.

Technical data CX1100-0001

Power supply 24 V DC (-15%/+20%)

Dieletric strength 500 Veff (supply / internal electronics)

Max. power consumption 30 W

Recommended fuse at 24 V 2 A

K-Bus connection IP-Link connection Connection type 1 x open pluggable connector, 5-pin

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

I/O-DPRAM Diagnostics LED 1 x PWR

Dimensions 45 mm x 100 mm x 91 mm

Weight approx. 180 g

24 Embedded PC

Page 27

Product Overview

Technical Data CX1100-0002 / CX1100-0003

Local I/O signals are connected via the CX1100-0002 power supply variant, to which all Beckhoff Bus Terminals can

be connected, or via CX1100-0003, which in addition to the Bus Terminals enables the connection of Extension Box

IExxxx type Beckhoff Fieldbus Box modules. The option to connect Bus Terminals or a Fieldbus Box creates a

control system with a very variable, expandable I/O level with large signal variety. The I/O data are stored in a

DPRAM, which is accessible by the CPU via the system bus. The power supplies of the CX system can be changed

in the field.

Technical Data CX1100-0002 CX1100-0003

Power supply 24 V DC (-15%/+20%)

Dielectric strength 500 Veff (supply / internal electronics)

Max. power consumption 30 W

Recommended fuse at 24 V 2 A

K-Bus connection yes (adapter terminal)

IP-Link connection - yes

Connection type Cage Clamp (adapter terminal)

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

I/O-DPRAM 2 kByte 4 kByte

Diagnostics LED 1 x PWR, 1 x I/O Run, 1 x I/O Err

Dimensions 39 mm x 100 mm x 91 mm 58 mm x 100 mm x 91 mm

Weight approx. 250 g 330 g

Embedded PC 25

Page 28

Product Overview

CX1100-0001 Connections

This power supply unit does not have an I/O interface. The power supply is therefore connected through the 5-pin

open pluggable connector. The power supply unit supplies all further system components with a voltage of 24 V DC (15 %/+20%) via the PC104 bus. The dielectric strength of the power supply unit is 500 V

The integrated NOVRAM permits storage of process data that is safe against power failure.

rms

.

Pin Allocation Open Style Connector:

Pin Assignment

1 +24 V DC

2 0 V DC

3 GROUND

4 +UPS (+ 24 V DC)

5 -UPS (0 V DC)

LED:

With proper connection of the power supply unit and with power supply turned on, the power LED (PWR) lights up

green. In the case of a short-circuit, it lights up red.

26 Embedded PC

Page 29

Product Overview

CX1100-0002 Connections

This power supply unit is equipped with an I/O interface, which permits connection of the Beckhoff Bus Terminals.

The power is supplied via the upper spring-loaded terminals labelled “24V” and “0V”.

The supply voltage feeds the CX system and supplies a voltage of 24 V DC (-15 %/+20%) to the Bus Terminals via

the K-Bus. The dielectric strength of the power supply unit is 500 V

on, a further power supply is necessary for the Bus Terminals. This is provided by means of the power contacts,

which are not connected to the power supply.

The integrated NOVRAM permits storage of process data that is safe against power failure.

. Since the K-Bus does no more than pass data

rms

LED:

With proper connection of the power supply unit and with power supply turned on, the power LED (PWR) lights up

green. In the case of a short-circuit, it lights up red.

The I/O LEDs display the operation status of the Bus Terminals. Error-free start-up of the configuration is signalled by

the red "I/O ERR" LED being extinguished. If the ”I/O ERR" LED blinks, an error in the area of the terminals is

indicated. The error code can be determined from the frequency and number of blinks.

PE power contacts

The ”PE" power contact must not be used for other potentials.

Embedded PC 27

Page 30

Product Overview

CX1100-0003 Connections

This power supply unit permits not only the connection of the Beckhoff Bus Terminals, but also the serial connection

of the Beckhoff fieldbus box modules of the type extension box IExxxx. The power is supplied via the upper springloaded terminals labelled “24V” and “0V”.

The supply voltage feeds the CX system and, over the K-Bus, the Bus Terminals. Since the K-Bus does no more

than pass data on, a further power supply is necessary for the Bus Terminals. This is provided by means of the

power contacts, which are not connected to the power supply.

Fieldbus connection:

Plug the IP link connector into the respective connections, i.e. one fibre-optic cable each into IN (x03) and OUT (x04).

You then connect the other end with the corresponding IP link interface of the extension box. The connection must be

made so that the output of the fieldbus connection is connected to the input of the extension box and vice versa.

LED:

With proper connection of the power supply unit and with power supply turned on, the power LED (PWR) lights up

green. In the case of a short-circuit, it lights up red. The I/O LEDs display the operation status of the Bus Terminals.

Error-free start-up of the configuration is signalled by the red "I/O ERR" LED being extinguished. If the ”I/O ERR" LED

blinks, an error in the area of the terminals is indicated. The error code can be determined from the frequency and

number of blinks.

PE power contacts

The ”PE" power contact must not be used for other potentials.

28 Embedded PC

Page 31

Product Overview

LCD Display

The LCD display of the power supply units has two rows of 16 characters each and is used for displaying system and

user messages.

"Index-Group/Offset" Specification for the LCD Display

ADS Port 300

Index

Group Index Offset Access

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0xFFFF90FF R&W Cursor OFF

0xFFFF91FF R&W Cursor ON

0xFFFF92FF R&W Cursor blink

0xFFFF93FF R&W Cursor blink ON

0xFFFF94FF R&W Display OFF

0xFFFF95FF R&W Display ON

0xFFFF96FF R&W Backlight OFF

0xFFFF97FF R&W Backlight ON

0xFFFFA0FF R&W Write Text line 1

0xFFFF00FF R&W Write Text line 2

Data

type

Phys.

unit

Def.

range Description Remarks

OFF

Embedded PC 29

Page 32

Transport

3. Transport

Unpacking, installation and transport

The specified storage conditions must be adhered to (see "Technical data").

Dimensions and weight of the individual modules:

Dimensions (W x H x D): 19 x 100 x 91 mm (system interface) to 58 x 100 x 91 mm (power supply unit with I/O

interface)

Weight: 80 g (system interface) to 435 g (basic module)

Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

6. If you notice any shipping damage or inconsistencies between the contents and your order, you should notify

Beckhoff Service.

Warning

Danger of damage to the unit!

During transport in cold conditions, or if the unit is subjected to extreme temperature swings, condensation on and

inside the unit must be avoided.

Prior to operation, the unit must be allowed to slowly adjust to room temperature. Should condensation occur, a delay

time of approximately 12 hours must be allowed before the unit is switched on.

Installation

The devices are designed for installation in control cabinets.

You will find installation instructions on the following pages.

Shipping and relocation

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts. During

transport, your computer should therefore be protected from excessive mechanical stress. Therefore, please use the

original packaging.

30 Embedded PC

Page 33

Fitting and wiring

4. Fitting and wiring

Mechanical mounting

Dimensions

The CX1000 product range is characterised by small overall installed size and high modularity. For project planning

purposes, a CPU module, a power supply unit and the associated system interfaces and fieldbus interfaces have to

be provided.

The overall width of the application is made up of the individual modules.

With a height of 100 mm, the module dimensions exactly match those of the Beckhoff Bus Terminals. Together with

the lowered connector surfaces, this means that it can be used in a standard terminal box with a height of 120 mm.

Basic CX1000 CPU modules:

The basic CPU module measures 57 x 100 x 91mm.

CX1000-N00x system interfaces:

The four system interfaces all measure 19 x 100 x 91 mm.

CX1100-000x power supplies:

CX1100-0001

Power supply without I/O interface

Dimensions in mm: 45 x 100 x 91

CX1100-0002

Power supply with I/O interface

Dimensions in mm: 39 x 100 x 91

CX1100-0003

Power supply with I/O interface and IP-Link

Dimensions in mm: 58 x 100 x 91

CX1100-0900 UPS module:

Dimensions in mm: 57 x 100 x 91

CX1500-Mxxx and CX1500-Bxxx fieldbus connections

The modules for the fieldbus connections measure 38 x 100 x 91 mm, irrespective of whether a master or slave type

connection is used.

Embedded PC 31

Page 34

Fitting and wiring

Mechanical Assembly of the base module

The installation of the modules takes place in three steps:

1. The Sequence of the Modules

The CPU basic module with system interfaces, which are factory-installed on the left side, is extended with the power

supply unit on the right and with the fieldbus connection (master or slave) left side if available. The mounting of an

filedbus module is described on the next page.

2. Assembly with Other Modules

The attachment of the individual modules is done by simple plugging them together (FIG. 1). Care must be taken that

the plug of the PC104 interface is not damaged.

When correctly assembled, no significant gap can be seen between the attached housings.

FIG. 1: Engaging of the Modules

3. Engaging on the top-hat rail

On the bottom of the modules, there is a white tension strap, which is connected with a latching mechanism. These

tension straps must be pulled down before attaching to the mounting rail. This can be done with a slotted screwdriver

and a small rotation. (FIG. 4). After engaging the module on the top-hat rail successfully (FIG. 5), the tension straps

must be shifted into the starting position again (FIG. 6).

FIG. 4: Tension straps down FIG. 5: Engaging on the top-hat rail

32 Embedded PC

Page 35

Fitting and wiring

FIG. 6: Tension straps back in starting position FIG.7: Tension straps not engaged / engaged

Note:

A locking mechanism prevents the individual housings from being pulled off again. More detailed information about

disassembling the CX configuration from the top-hat rail can be found on the page decommissioning.

By lowering the front surfaces, which contain the interfaces, installation can easily be done in a standard terminal box

of 120 mm height.

Installation position:

Warning

The CPU module installed on a top-hat rail may be operated only in case of ambient temperatures

up to 55°C. The orientation in which the device is fitted must be selected in such a way that cooling

air can flow vertically through the ventilation holes. The images show the permitted ( FIG. 8 and

FIG. 9) as well as a forbidden installation positions (FIG. 10).

Observe minimum clearance!

Mounting must provide a clearance of 30 mm both above and below a CX1000 device combination

to ensure adequate ventilation of the CPU base module and the power supply unit.

FIG. 8: Allowable installation position

Embedded PC 33

Page 36

Fitting and wiring

FIG. 9: Allowable installation position

FIG. 10: Unallowable installation position

34 Embedded PC

Page 37

Fitting and wiring

Mechanical mounting of the Fieldbus modules

The mounting of the Fieldbus modules takes place in several

steps:

1. Remove cover at CX1000/CX1020 basic module

In order to be able to fasten the connection of the fieldbus connection to the CPU basic module, the cover must first

be removed (FIG 1, 2). This can be achieved by a small pressure against the cover.

FIG.1+2: Remove Cover

2. Assembly with CX1000/CX1020 configuration

Because the CX1000 configuration is already on the top-hat rail, the fieldbus module first has to be pressed on the

top-hat rail. For that purpose the locking of the latching mechanism with the white tension straps (pull down) is

required.

The attachment of the individual modules is done by simple plugging them together (FIG. 3). Care must be taken that

the plug of the PC104 interface is not damaged.

When correctly assembled, no significant gap can be seen between the attached housings. At the end the white

tension strips must be shifted into the starting position again in order that the latching mechanism locks.

FIG. 3: Stick modules together

Embedded PC 35

Page 38

Fitting and wiring

FIG. 4: Tension straps back in starting position

3. Attach Cover

If the connection area does not have a closing cover on the left-hand side, the cover that was previously removed

should be pressed over the connections until it audibly engages.

Note:

If the CX1000/CX1020 configuration is not positioned on the top-hat rail it is possible to join the connection first with

the CX1000/CX1020 configuration, as shown in FIG. 3, and then to clip the entire module onto the top-hat rail.

Note:

A locking mechanism prevents the individual housings from being pulled off again.

36 Embedded PC

Page 39

5. Error handling and diagnostics

CPU base module

LEDs of the basic CPU module

Display LED Meaning

PWR Power supply

The Power LED comes on when the device is connected to a live power supply

unit.

Link LAN Link 10 MBit

This LED comes on when the network speed is 10 MBit or 100 MBit (if the device

is part of a network).

100MBit LAN Link 100 MBit

This LED comes on when the network speed is 100 MBit (if the device is part of a

network).

Activity Transmit /Receive Packets

This LED flashes once when data packets are being transferred within the LAN.

HDD Read/Write Compact Flash

Indicates access to the CF card.

Error handling and diagnostics

Network speed LED

The LINK LED comes on when the network speed is 10 MBit or 100 MBit.

The 100 MBit LED comes on when the network speed is 100 MBit.

Embedded PC 37

Page 40

Error handling and diagnostics

Power supplys

CX1100-0001 power supply LEDs

Display LED Meaning

Power Power supply

The LED lights up green when the power supply is correct, but red if there is a short

circuit.

38 Embedded PC

Page 41

Error handling and diagnostics

CX1100-0002 power supply LEDs

After switching on, the power supply immediately checks the connected Bus Terminal configuration. Error-free startup is signalled by the red "I/O ERR” LED being extinguished. If the ”I/O ERR" LED blinks, an error in the area of the

terminals is indicated. The error code can be determined from the frequency and number of blinks. This permits rapid

rectification of the error.

Display LED Meaning

Power Power supply

The LED lights up green when the power supply is correct, but red if there is a

short circuit.

I/O

Run

I/O

Error

The I/O error LED blink code

Fast blinking Start of the error code

First slow sequence Error code

Second slow sequence Error code argument

K-Bus diagnostics

The green LED lights up in order to indicate fault-free operation. "Fault-free"

means that the communication with the fieldbus system is also running.

K-Bus diagnostics

The red LED flashes to indicate an error. The red LED blinks with two different

frequencies.

LEDs for K-Bus diagnosis

Error code

Error code

Persistent,

continuous

blinking

1 pulse

2 pulses

3 pulses 0 K-Bus command error - No Bus Terminal inserted

4 pulses

5 pulses n K-Bus error in register

argument Description Remedy

EMC problems - Check power supply for overvoltage or

undervoltage peaks

- Implement EMC measures

- If a K-Bus error is present, it can be localised

by a restart of the power supply (by switching

it off and then on again)

0 EEPROM checksum error Revert to the manufacturer’s setting

1 Code buffer overflow Insert fewer Bus Terminals. The programmed

configuration has too many entries in the table

2 Unknown data type Software update required for the power supply

0 Programmed configuration

has an incorrect table entry

n (n > 0) Table comparison (Bus

Terminal n)

0 K-Bus data error, break

behind the power supply

n Break behind Bus Terminal nCheck whether the Bus End Terminal 9010 is

communication with Bus

Terminal n

0 Checksum error in Flash

program

n (n>0) Bus Terminal n is not Revert to the manufacturer's setting which will

Check programmed configuration for

correctness

Incorrect table entry

- One of the Bus Terminals is defective; halve

the number of Bus Terminals attached and

check whether the error is still present with the

remaining Bus Terminals. Repeat until the

defective Bus Terminal is located.

Check whether the n+1 Bus Terminal is

correctly connected; replace if necessary.

connected.

Exchange the nth bus terminal

Revert to the manufacturer’s setting9 pulses

Embedded PC 39

Page 42

Error handling and diagnostics

consistent with the

configuration that existed

when the boot project was

created

14 pulses n nth Bus Terminal has the

wrong format

15 pulses n Number of Bus Terminals is

no longer correct

16 pulses n Length of the K-Bus data is

no longer correct

Error code argument

The number of pulses indicates the position of the last Bus Terminal before the fault. Passive Bus Terminals, such as

a power feed terminal, are not included in the count.

In the case of some errors, rectification does not cause the power supply to leave the blink sequence. The power

supply can only be restarted by switching its supply voltage off and on again.

Note:

The supply voltage of the power supply unit, which is necessary to supply power to the CX1000 system, must not be

interrupted in the middle of operation. Switching off the supply voltage to the power supply unit refers here to the

power supply on the power contacts.

clear the boot project.

Start the power supply again, and if the error

occurs again then exchange the Bus

Terminal.

Start the power supply up again.

Start the power supply up again.

40 Embedded PC

Page 43

Error handling and diagnostics

CX1100-0003 power supply LEDs

After switching on, the power supply immediately checks the connected Bus Terminal configuration. Error-free startup is signalled by the red "I/O ERR” LED being extinguished. If the ”I/O ERR" LED blinks, an error in the area of the

terminals is indicated. The error code can be determined from the frequency and number of blinks. This permits rapid

rectification of the error.

Display LED Meaning

Power Power supply

The LED lights up green when the power supply is correct, but red if there is a

short circuit.

I/O

Run

I/O

Error

The I/O error LED blink code

Fast blinking Start of the error code

First slow sequence Error code

Second slow sequence Error code argument

K-Bus diagnostics

The green LED lights up in order to indicate fault-free operation. "Fault-free"

means that the communication with the fieldbus system is also running.

K-Bus diagnostics

The red LED flashes to indicate an error. The red LED blinks with two different

frequencies.

LEDs for K-Bus diagnosis

Error code

Error code

Persistent,

continuous

blinking

1 pulse

2 pulses

3 pulses 0 K-Bus command error - No Bus Terminal inserted

4 pulses

5 pulses n K-Bus error in register

argument Description Remedy

EMC problems - Check power supply for overvoltage or

undervoltage peaks

- Implement EMC measures

- If a K-Bus error is present, it can be localised

by a restart of the power supply (by switching

it off and then on again)

0 EEPROM checksum error Revert to the manufacturer’s setting

1 Code buffer overflow Insert fewer Bus Terminals. The programmed

configuration has too many entries in the table

2 Unknown data type Software update required for the power supply

0 Programmed configuration

has an incorrect table entry

n (n > 0) Table comparison (Bus

Terminal n)

0 K-Bus data error, break

behind the power supply

n Break behind Bus Terminal nCheck whether the Bus End Terminal 9010 is

communication with Bus

Terminal n

0 Checksum error in Flash

program

n (n>0) Bus Terminal n is not Revert to the manufacturer's setting which will

Check programmed configuration for

correctness

Incorrect table entry

- One of the Bus Terminals is defective; halve

the number of Bus Terminals attached and

check whether the error is still present with the

remaining Bus Terminals. Repeat until the

defective Bus Terminal is located.

Check whether the n+1 Bus Terminal is

correctly connected; replace if necessary.

connected.

Exchange the nth bus terminal

Revert to the manufacturer’s setting9 pulses

Embedded PC 41

Page 44

Error handling and diagnostics

consistent with the

configuration that existed

when the boot project was

created

14 pulses n nth Bus Terminal has the

wrong format

15 pulses n Number of Bus Terminals is

no longer correct

16 pulses n Length of the K-Bus data is

no longer correct

Error code argument

The number of pulses indicates the position of the last Bus Terminal before the fault. Passive Bus Terminals, such as

a power feed terminal, are not included in the count.

In the case of some errors, rectification does not cause the power supply to leave the blink sequence. The power

supply can only be restarted by switching its supply voltage off and on again.

Note:

The supply voltage of the power supply unit, which is necessary to supply power to the CX1000 system, must not be

interrupted in the middle of operation. Switching off the supply voltage to the power supply unit refers here to the

power supply on the power contacts.

clear the boot project.

Start the power supply again, and if the error

occurs again then exchange the Bus

Terminal.

Start the power supply up again.

Start the power supply up again.

42 Embedded PC

Page 45

Error handling and diagnostics

Störungen

Lesen Sie dazu auch das Kapitel Sicherheitshinweise.

Mögliche Störungen und ihre Beseitigung

Bitte geben Sie im Servicefall die Projektnummer Ihres PCs an, welche Sie dem Typenschild entnehmen können.

Die BECKHOFF-Support Nummer:

für Deutschland: 05246/963-157

international: +49-5246/963-157

Störung Ursache Maßnahmen

keine Funktion nach Starten des

Embedded-PCs

Der Embedded-PC bootet nicht

vollständig

Rechner bootet, Software wird

gestartet, aber Steuerung

arbeitet nicht einwandfrei

Fehler bei CF Card Zugriff Fehlerhafte CF Card, fehlerhafter CF

Embedded-PC funktioniert nur

teilweise oder nur zeitweise

fehlende Stromversorgung des

Embedded-PCs

andere Ursachen

Festplatte beschädigt (z.B. durch

Abschalten bei laufender Software),

Setupeinstellungen fehlerhaft,

andere Ursachen

Fehlerursache liegt bei der Software oder

bei Anlagenteilen außerhalb des

Embedded-PCs

Einschub

Komponenten im Embedded-PC defekt Beckhoff Support anrufen

1.Sicherung prüfen

2. Anschlussspannung

messen,

Steckerbelegung prüfen

Beckhoff Support anrufen

Setupeinstellungen prüfen

Beckhoff Support anrufen

Rufen Sie den Maschinenoder Softwarehersteller an.

Mit einer anderen CF Card

den CF Einschub überprüfen

Beckhoff Support anrufen

Embedded PC 43

Page 46

Decommissioning

6. Decommissioning

Removal and disposal

A CX1000 hardware configuration is dismantled in 2 stages:

1. Removing from the top-hat rail:

The white straps on the underneath of all the modules must be pulled downwards (FIG 1). This can be done using an

ordinary screwdriver and a slight turn. The latching mechanism that provides fixing to the top-hat rail opens up (this

procedure is not visible).

If the configuration has a power supply unit with an I/O interfaces, it is first necessary to release the first terminal from

the top-hat rail (FIG 2) so that the CX1000 configuration can be separated from the I/O hardware, allowing the

module to be removed from the top-hat rail (FIG 3).

FIG 1: Straps down FIG. 2: Releasing the I/O terminal from the top-hat rail

FIG. 3: Separating the module from the top-hat rail

2. Separating the individual modules:

Before separating the individual modules from one another, the entire CX1000 hardware block must first be removed

from the top-hat rail, as described in Step 1. The individual modules can then be separated from one another by

means of the separation mechanism mounted on the rear, as shown in Fig 4. This is done by inserting a flat

screwdriver with dimensions 1.0 x 5.5 x 150 mm into the locking mechanism, and then operating the slider by turning

it about 90 degrees. The rear-mounted locking mechanism creates a separation of approx. 2-3 mm in the mechanical

engagement of the modules, pushing them apart, so that the PC 104 interface connectors can then carefully be

pulled apart (FIG 5). Modules that cannot be separated from one another do not have a slider slot, but merely a

marking point (which may or may not be sealed with red lacquer). Applying force to these elements will destroy them.

44 Embedded PC

Page 47

Decommissioning

FIG. 4: Undoing the latching mechanism FIG 5: Separating the modules

The CPU can be separated from the power supply unit and the fieldbus connections in this way.

Note:

If the configuration has a power supply unit with an I/O interface, it is first necessary to release one terminal from the

top-hat rail so that the configuration can be separated from the I/O hardware.

Note:

The embedded PC must be shut down and the power supply disconnected before dismantling!

Warning

Forcibly opening the module housing (e.g. removing the cover) will destroy the housing.

Disposal

The device must be fully dismantled in order to dispose of it.

Electronic parts must be disposed of in accordance with national electronics scrap regulations.

Embedded PC 45

Page 48

Appendix

7. Appendix

Accessories

Compact flash cards

order number Description

CX1900-0015 128 MByte compact flash card type I

CX1900-0017 256 MByte compact flash card type I

CX1900-0021 512 MByte compact flash card type I

CX1900-0023 1 GByte compact flash card type I

CX1900-0025 2 GByte compact flash card type I

CX1900-0027 4 GByte compact flash card type I

Connectors and Adaptors

order

number Description

CX1900-0101 DVI-to-VGA passive Adaptor for connecting a standard desktop VGA monitor to the CX1000

system

– singles out the VGA signals of the DVI-I interface of the CX1000-N001 module

– 29-pin male DVI-A connector (bottom) to 15-pin female connector (top)

– weight approx. 40 g

– dimensions (W x H x D) 40 x 42 x 15 mm

Labelling Tags

order number Description

CX1900-0200 Universal plastic labels for the CX1000 system (package contains 1000 labels)

– snaps into the premoulded spots on the CX1000 components

– labelling can be done with a X-Y plotter

– dimension of the single label 15 x 5 mm

– material: white coloured plastic

– Murrplastik type KMR 5/15, order number 86401014

46 Embedded PC

Page 49

Appendix

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast and

competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of individual

Beckhoff products, but also with other, wide-ranging services:

world-wide support

design, programming and commissioning of complex automation systems

and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

on-site service

repair service

spare parts service

hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

You will find further support and service addresses on our Internet pages under http://www.beckhoff.com.

Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Embedded PC 47

Page 50

Appendix

Certifications

All products of the Embedded PC family are CE, UL and GOST-R certified. Since the product family is continuously

developed further, we are unable to provide a full listing here. The current list of certified products can be found on

the Embedded PC certificates web page or at www.beckhoff.de under Embedded PC.

48 Embedded PC

Loading...

Loading...