Page 1

Installation- and Operating instructions for

DVI Splitter

CU8810-0000

Version: 1.1

Date: 2015-03-25

Page 2

Page 3

Table of contents

Table of contents

1.

General instructions 2

Notes on the Documentation 2

Liability Conditions 2

State at Delivery 2

Description of safety symbols 2

2.

Product Description 3

Product Overview 3

Power supply 4

Data Connectors 4

USB type B Port (X20) (standard cable) 4

RJ 45 Port (X30, X31, X32, X33) (standard CAT5 cable) 4

DVI-IN (X40, X41) (standard DVI cable) 4

DVI-OUT (X50, X51, X52, X53) (standard DVI cable) 5

LED Diagnostics 5

3.

Installation Instructions 6

Transport and Unpacking 6

Transport 6

Unpacking 6

Mounting / Unmounting 7

Connecting devices 8

Connecting cables 8

Check voltage rating and connect 8

4.

Operating Instructions 9

Configuration 9

DIP Switch 1 (SW1) 9

DIP Switch 2 (SW2) 11

DIP Switch 3 (SW3) 12

Architecture Description 13

Version 1 13

Version 2 13

Version 3 13

Version 4 14

5.

Appendix 15

Assembly dimensions 15

Beckhoff Support & Service 16

Beckhoff branches and partner companies 16

Beckhoff Headquarters 16

Beckhoff Support 16

Beckhoff Service 16

Technical data 17

Approvals for USA and Canada 17

FCC: Federal Communications Commission Radio Frequency Interference

Statement 17

FCC: Canadian Notice 17

CU8810-0000 1

Page 4

General instructions

General instructions

Notes on the Documentation

This description is only intended for the use of trained specialists in control

and automation engineering who are familiar with the applicable national

standards. It is essential that the following notes and explanations are

followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the

products described satisfy all the requirements for safety, including all the

relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described

are, however, constantly under development. For that reason the

documentation is not in every case checked for consistency with

performance data, standards or other characteristics. None of the

statements of this manual represents a guarantee (Garantie) in the

meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of

§ 434 par. 1 sentence 1 BGB. In the event that it contains technical or

editorial errors, we retain the right to make alterations at any time and

without warning. No claims for the modification of products that have

already been supplied may be made on the basis of the data, diagrams

and descriptions in this documentation.

© This documentation is copyrighted. Any reproduction or third party use of

this publication, whether in whole or in part, without the written permission

of Beckhoff Automation GmbH & Co. KG, is forbidden.

State at Delivery

i

Danger

Warning

Note

All the components are supplied in particular hardware and software

configurations appropriate for the application. Modifications to hardware or

software configurations other than those described in the documentation

are not permitted, and nullify the liability of Beckhoff Automation GmbH &

Co. KG.

Description of safety symbols

The following safety symbols are used in this operating manual. They are

intended to alert the reader to the associated safety instructions.

This symbol is intended to highlight risks for the life or health of personnel.

This symbol is intended to highlight risks for equipment, materials or the

environment.

This symbol indicates information that contributes to better understanding.

2 CU8810-0000

Page 5

Product Description

Product Description

Product Overview

View of the CU8810-0000

DVI splitter

A common application in machine and plant construction is the

simultaneous display of a PC screen on several monitors. Up to four

DVI/USB Control Panels can be connected to a PC via the CU8810 DVI

splitter. Thanks to DVI/USB extension technology, the Control Panels can

each be connected at distances of 50 m from the DVI splitter. PCs with two

DVI outputs, which are configured as extended desktops, generate two

different screen contents. Both DVI outputs can be fed into the DVI splitter.

Using DIP switches, the four DVI outputs can each be assigned to one of

the two DVI inputs, so that the Control Panels show either the left or the

right half of the desktop, as selected. Other outstanding features are:

• User-friendly installation via integrated top hat rail adapter

• 24 V

• 12 Mbit and 1.5 Mbit support for compatibility to the USB1.1 standard

• Standard CAT5 network cable for USB extended

• Compact industrial design

• Clear quick diagnosis by separate LEDs.

supply voltage – the standard in industrial environments

DC

CU8810-0000 3

Page 6

Product Description

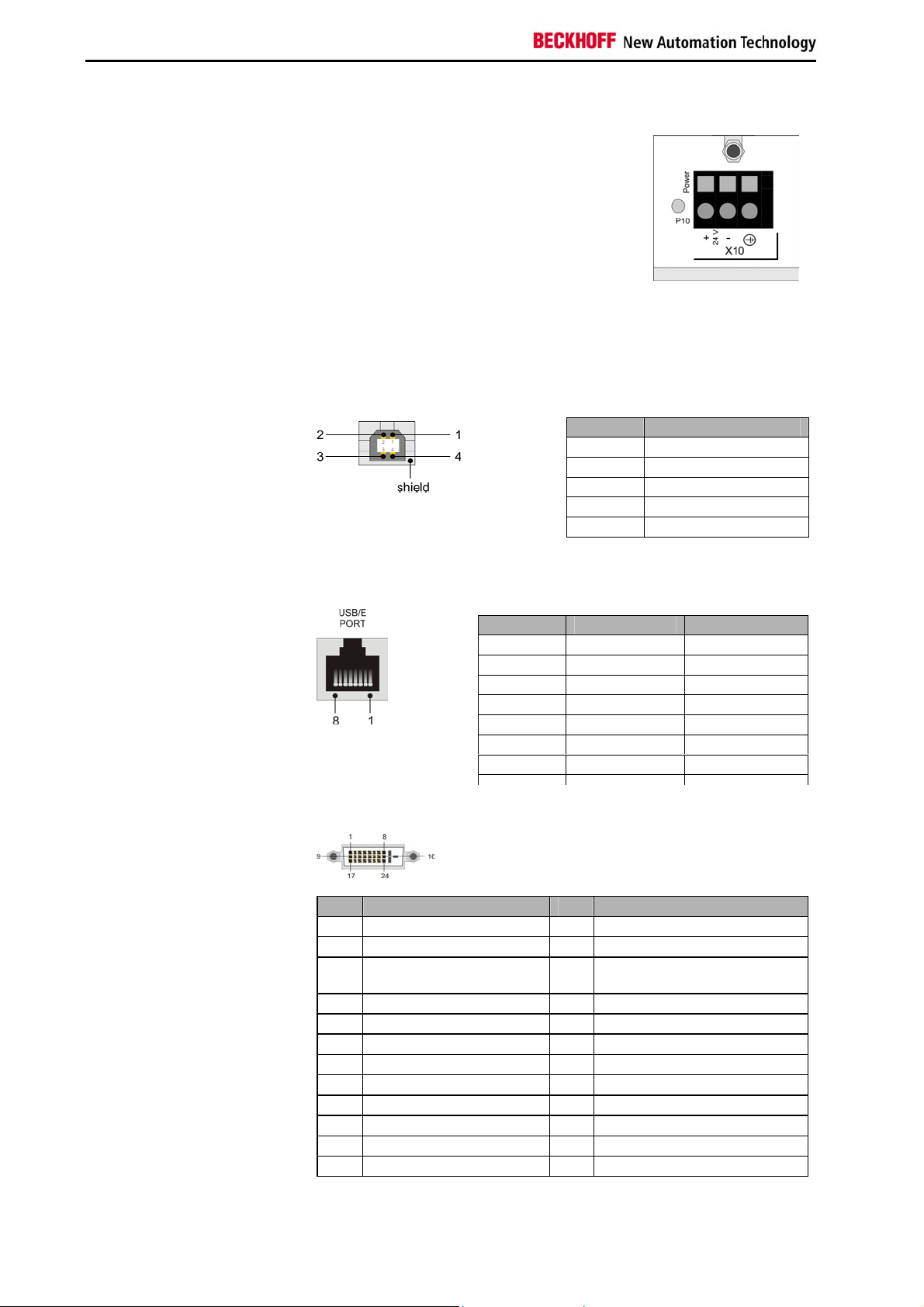

Power supply

24 VDC power supply

The DVI splitter CU8810 will be powered by a

24 V

power supply (X10). The pins have to

DC

be connected as shown on the front panel of

the CU8810 device.

Data Connectors

The CU8810 has three kinds of connectors: USB type B, RJ45 and

DVI. The pin layouts are described below.

USB type B Port (X20) (standard cable)

USB type B Port

RJ 45 Port (X30, X31, X32, X33) (standard CAT5 cable)

Pin Assignment

1 VCC

2 Data 3 Data +

4 GND

Shield Shield

RJ 45 Port

DVI-IN

Pin Signal Assignment

1 15 V 15 V +

2 GND Ground

3 TX USB TX

4 RX USB RX

5 RX USB RX

6 TX USB TX

7 15 V 15 V +

DVI-IN (X40, X41) (standard DVI cable)

Pin Assignment Pin Assignment

1 TMDS Data 2 - 13 Not connected

2 TMDS Data 2 + 14 + 5 V Power

3 TMDS Data 2/4 Shield 15

4 Not connected 16 Hot Plug Detect

5 Not connected 17 TMDS Data 0 6 DDC Clock 18 TMDS Data 0 +

7 DDC Data 19 TMDS Data 0/5 Shield

8 Analog Vertical Sync 20 Not connected

9 TMDS Data 1 - 21 Not connected

10 TMDS Data 1+ 22 TMDS Clock Shield

11 TMDS Data 1/3 Shield 23 TMDS Clock +

12 Not connected 24 TMDS Clock -

Ground ( + 5 V, Analog H/V

Sync)

4 CU8810-0000

Page 7

Product Description

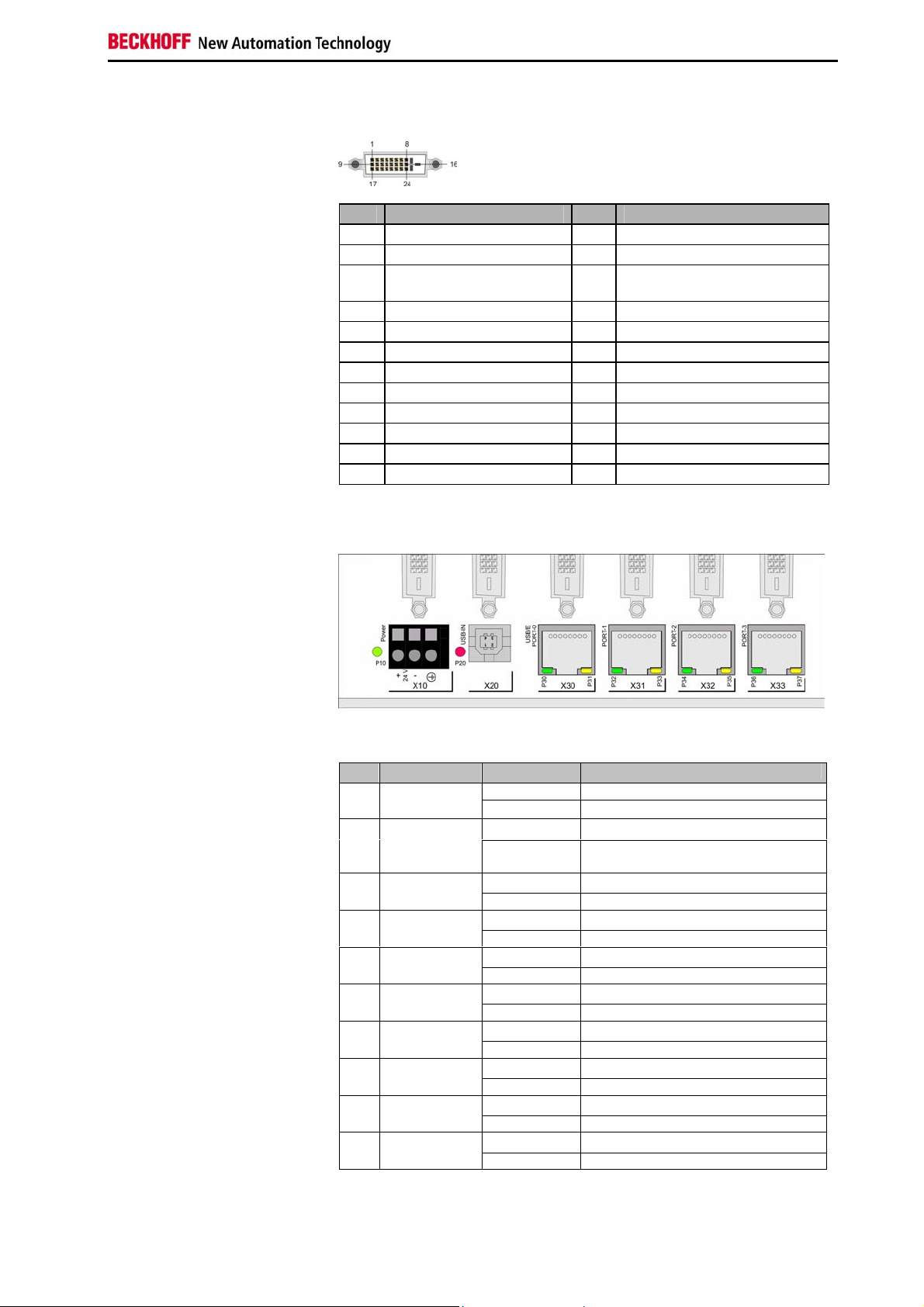

DVI-OUT (X50, X51, X52, X53) (standard DVI cable)

DVI-Out

Pin Assignment Pin Assignment

1 TMDS Data 2 - 13 Not connected

2 TMDS Data 2 + 14 + 5 V Power

3 TMDS Data 2/4 Shield 15

4 Not connected 16 Hot Plug Detect

5 Not connected 17 TMDS Data 0 6 DDC Clock 18 TMDS Data 0 +

7 DDC Data 19 TMDS Data 0/5 Shield

8 Analog Vertical Sync 20 Not connected

9 TMDS Data 1 - 21 Not connected

10 TMDS Data 1 + 22 TMDS Clock Shield

11 TMDS Data 1/3 Shield 23 TMDS Clock +

12 Not connected 24 TMDS Clock -

Ground ( + 5 V, Analog H/V

Sync)

LED Diagnostics

LED Diagnostics

The following table shows the possible states for the LEDs:

LED Assignment Status Meaning

off No power supply connected P10 Power supply

Port

Port 0

Port 0

Port 1

Port 1

Port 2

Port 2

Port 3

Port 3

lights green

off USB is operational P20 USB/IN

lights red USB is in suspend mode/ no device

off No 15 V supplied to USB/E Port P30 USB/E

lights green 15 V supplied to USB/E Port

off No suspend P31 USB/E

lights yellow Suspend

off No 15 V supplied to USB/E Port P32 USB/E

lights green 15 V supplied to USB/E Port

off No suspend P33 USB/E

lights yellow Suspend

off No 15 V supplied to USB/E Port P34 USB/E

lights green 15 V supplied to USB/E Port

off No suspend P35 USB/E

lights yellow Suspend

off No 15 V supplied to USB/E Port P36 USB/E

lights green 15 V supplied to USB/E Port

off No suspend P37 USB/E

lights yellow Suspend

connected

24 V

DC

connected

CU8810-0000 5

Page 8

Installation Instructions

Installation Instructions

Warning

Please also refer to chapter General instructions.

Transport and Unpacking

The specified storage conditions must be observed (see chapter Technical

data).

Transport

Despite the robust design of the unit, the components are sensitive to

strong vibrations and impacts. During transport, the unit should therefore

be protected from excessive mechanical stress. Therefore, please use the

original packaging.

Danger of damage to the unit!

If the device is transported in cold weather or is exposed to extreme

variations in temperature, make sure that moisture (condensation) does not

form on or inside the device.

Prior to operation, the unit must be allowed to slowly adjust to room

temperature. Should condensation occur, a delay time of approximately 12

hours must be allowed before the unit is switched on.

Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important

information for handling the unit.

5. Check the contents for visible shipping damage.

6. If you notice any shipping damage or inconsistencies between the

contents and your order, you should notify Beckhoff Service.

6 CU8810-0000

Page 9

Installation Instructions

Mounting / Unmounting

Mounting the DVI splitter

The CU8810 can be snapped onto a 35 mm mounting rail conforms to

EN 50022.

Just push the unit on the lower side under the rail (1) and snap in the upper

side (2) as shown below:

Unmounting the DVI splitter

To release the CU8810 from the mounting rail push up the unit (3) and pull

off the device from the rail (4):

CU8810-0000 7

Page 10

Installation Instructions

Connecting devices

Warning

The power supply plug must be withdrawn!

Please read the documentation for the external devices prior to connecting

them.

During thunderstorms, plug connector must neither be inserted nor

removed.

When disconnecting a plug connector, always handle it at the plug. Do not

pull the cable!

Connecting cables

The connectors are documented in the section Product Description.

When connecting the cables to the CU8810, proceed according to the

following sequence:

• Switch off all the devices that are to be connected.

• Disconnect all the devices that are to be connected from the power

supply.

• Connect all the cables between the CU8810 and to the devices

that are to be connected.

• Reconnect all devices to the power supply.

Check voltage rating and connect

1. Check that the external power supply is providing the correct

voltage.

2. Connect the unit to your external 24 V

power supply.

DC

8 CU8810-0000

Page 11

Operating Instructions

Operating Instructions

Configuration

Front view

Opening the enclosure

DIP Switch 1 (SW1)

Front view of the CU8810 with

opened enclosure.

The device is configured by a set of three switches. The switches are

covered by an enclosure on the upper right side on the front. To open the

enclosure you need to remove the two screws, as shown below:

There are three DIP switches and two status LEDs covered by the plate.

The detailed functions are described in the following.

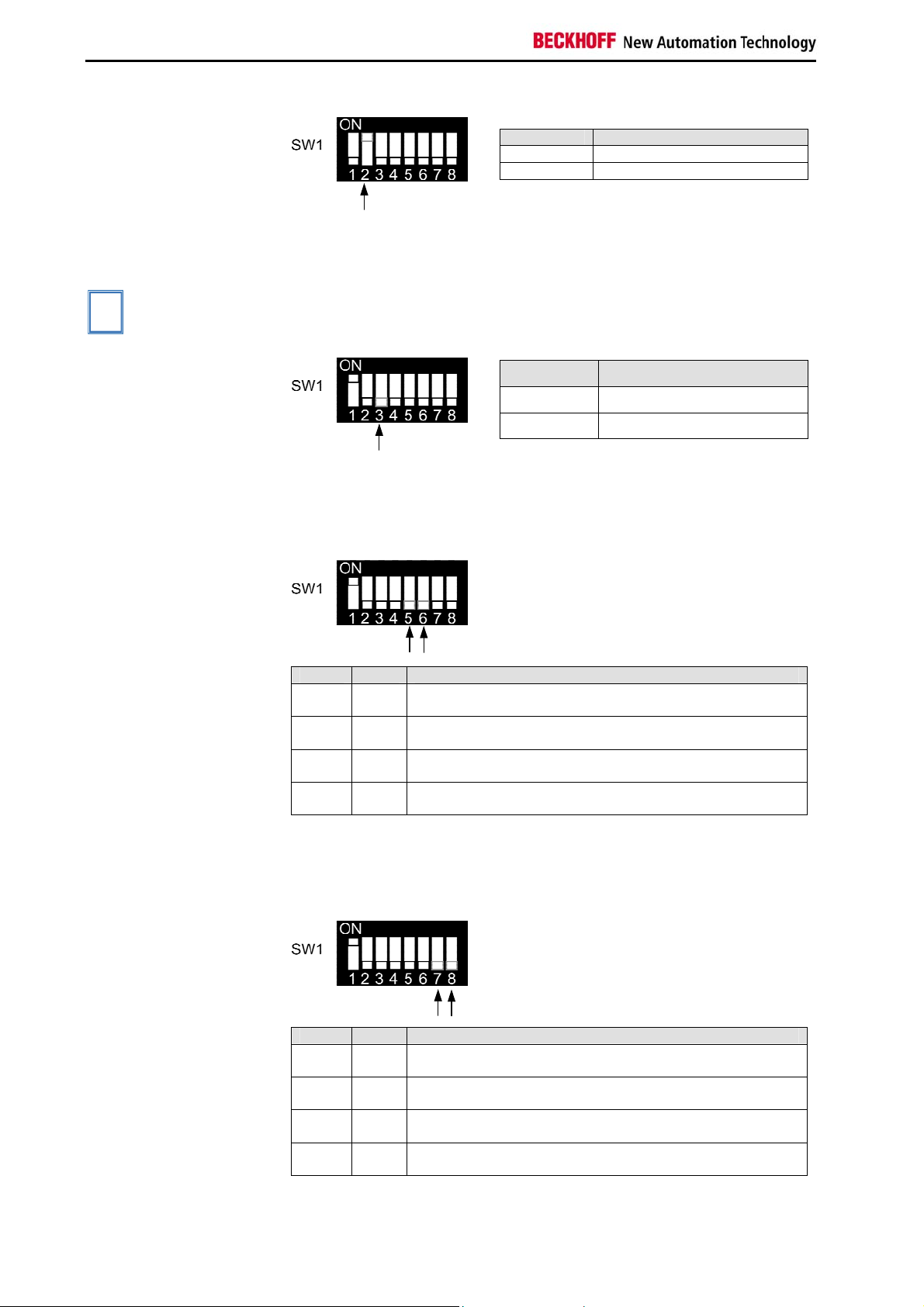

DIP Switch 1 (SW1)

This DIP switch configures the DVI input sources and the DDC signals.

Switch Name Function

1 PWRDVI 1 Activate DVI Input Port 0 (X40)

2 PWRDVI 2 Activate DVI Input Port 1 (X41)

3 OUT-LEVEL Set output level for DVI Output

4 N.C. Not used

5 A0_0 Address switch A0 for DVI Input Port 0 (X40)

6 A1_0 Address switch A1 for DVI Input Port 0 (X40)

7 A0_1 Address switch A0 for DVI Input Port 1 (X41)

8 A1_1 Address switch A1 for DVI Input Port 1 (X41)

The first two switches are used to enable/ disable the two DVI Input Ports:

PWRDVI 1

PWRDVI1 Function

on DVI Input Port 0 is activated

off DVI Input Port 0 is deactivated

CU8810-0000 9

Page 12

Operating Instructions

PWRDVI 2

PWRDVI2 Function

on DVI Input Port 1 is activated

off DVI Input Port 1 is deactivated

OUT-LEVEL

The next switch 3 is used to set the back termination for the output level.

The use of back terminations is highly recommended for best signal

integrity.

This switch is set to off by factory and should only be changed after

i

Note

consultation with the Beckhoff Support.

OUT-LEVEL Function

on No back termination is used

off Back termination is used

Switch 5 and 6

Switch 5 and 6 are paired to select the source for the DDC signal for

DVI Input Port 0. The DCC signal from the selected port is send to the

device connected to DVI Input Port 0.

Switch 7 and 8

The following table shows the possible selections.

5 6 Function

off off The DDC-channel from DVI Input Port 0 (X40) is connected to

DDC-channel to DVI Output Port 0 (X50)

on off The DDC-channel from DVI Input Port 0 (X40) is connected to

DDC-channel to DVI Output Port 1 (X51)

off on The DDC-channel from DVI Input Port 0 (X40) is connected to

DDC-channel to DVI Output Port 2 (X52)

on on The DDC-channel from DVI Input Port 0 (X40) is connected to

DDC-channel to DVI Output Port 3 (X53)

Switch 7 and 8 are paired to select the source for the DDC signal for

DVI Input Port 1. The DCC signal from the selected port is send to the

device connected to DVI Input Port 1.

The following table shows the possible selections.

7 8 Function

off off The DDC-channel from DVI Input Port 1 (X41) is connected to

DDC-channel to DVI Output Port 0 (X50)

on off The DDC-channel from DVI Input Port 1 (X41) is connected to

DDC-channel to DVI Output Port 1 (X51)

off on The DDC-channel from DVI Input Port 1 (X41) is connected to

DDC-channel to DVI Output Port 2 (X52)

on on The DDC-channel from DVI Input Port 1 (X41) is connected to

DDC-channel to DVI Output Port 3 (X53)

10 CU8810-0000

Page 13

Operating Instructions

i

Note

DIP Switch 2 (SW2)

i

Note

The DDC-channel of one DVI Output Port must not be mapped to both

DVI Input Ports. If there is no collision the green LED lights up. If there is a

collision the red LED lights up and the user has to change the DDCchannel settings.

o.k. collision

DIP Switch 2 (SW2)

This DIP switch block configures the signal parameters for

DVI Output Ports.

These switches are set as default from factory and should not be changed.

The default settings are:

Switch Setting

1 on

2 off

3 on

4 off

5 on

6 off

7 on

8 off

CU8810-0000 11

Page 14

Operating Instructions

p

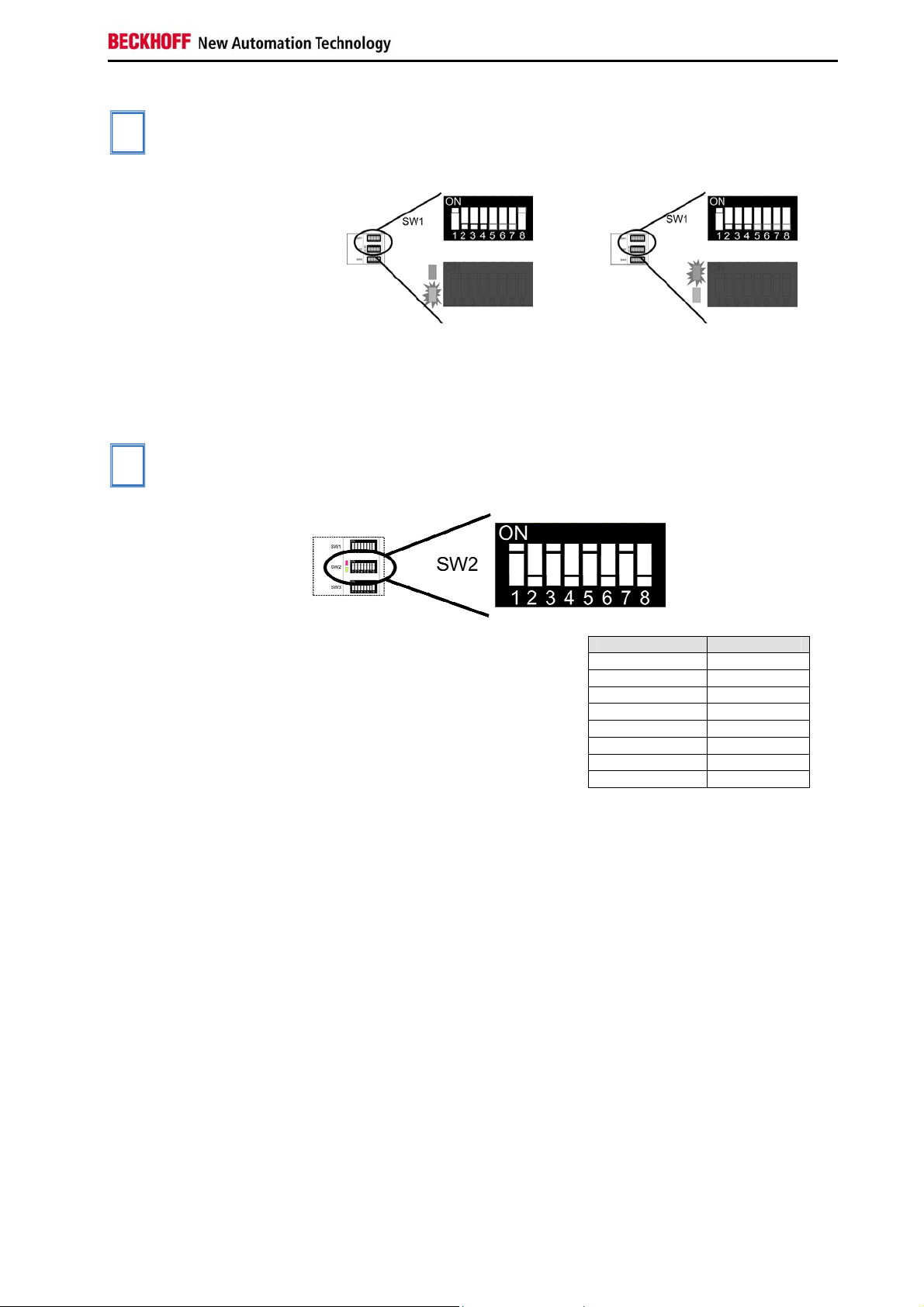

DIP Switch 3 (SW3)

DIP Switch 3 (SW3)

This switch configures the output ports of the device. For each output port

there are two switches to select an input source.

Example

DVI Out

Switch Name Port Function

1 IN_SEL0_high 0

2 IN_SEL0_low 0

3 IN_SEL1_high 1

4 IN_SEL1_low 1

5 IN_SEL2_high 2

6 IN_SEL2_low 2

7 IN_SEL3_high 3

8 IN_SEL3_low 3

(X50)

(X50)

(X51)

(X51)

(X52)

(X52)

(X53)

(X53)

DVI Data Input Select Switch 1

for DVI Output Port 0 (X50)

DVI Data Input Select Switch 2

for DVI Output Port 0 (X50)

DVI Data Input Select Switch 1

for DVI Output Port 1 (X51)

DVI Data Input Select Switch 2

for DVI Output Port 1 (X51)

DVI Data Input Select Switch 1

for DVI Output Port 2 (X52)

DVI Data Input Select Switch 2

for DVI Output Port 2 (X52)

DVI Data Input Select Switch 1

for DVI Output Port 3 (X53)

DVI Data Input Select Switch 2

for DVI Output Port 3 (X53)

IN_SELx_high IN_SELx_low

off off Disable the DVI Output Port x

off on Select DVI Input Port 1 (X41) for

on off Select DVI Input Port 0 (X40) for

on on Illegal

Function

DVI Output Port x

DVI Output Port x

The displayed DIP Switch settings result

in the following functions:

Switch Setting

1 off

2 off

3 off

4 on

5 on

6 off

7 on

8 off

Function

Disable DVI Output Port 0 (X50)

Select DVI Input Port 1 (X41)

for DVI Output Port 1 (X51)

Select DVI Input Port 0 (X40)

for DVI Output Port 2 (X52)

Select DVI Input Port 0 (X40)

for DVI Output Port 3 (X53)

ut Port 0 1 2 3

12 CU8810-0000

Page 15

Operating Instructions

Architecture Description

Version 1

A PC with DVI output transfers an identical display image to up to four Control Panels. Command signals

can be transferred to the PC via USB from each Control Panel.

Version 2

If two PCs with one DVI output each are used, two different images can be transferred to the Control

Panels. The two images may have different screen resolutions.

Version 3

The two-PC principle also works using a PC with Core™ Duo technology. If two DVI outputs are used, two

different images can be transferred to the Control Panels. The two images may have different screen

resolutions. The two-channel C9900-A185 ADD2 card offers a simple option for installing an additional

DVI output. The card has two external DVI ports and enables direct connection of two DVI/USB Control

Panels to C5102, C6140, C6150, C6240 or C6250 PCs. Via the CU8810, these two DVI outputs can be

branched further to up to four Control Panels.

CU8810-0000 13

Page 16

Operating Instructions

Version 4

If a Panel PC with DVI output is used (e.g. “Economy” Panel PC CP62xx), the DVI splitter can be used to

transfer an image that differs from the main image on the Panel PC to up to four Control Panels. In this

case commands can also be transferred via USB from the individual Control Panels to the Panel PC.

14 CU8810-0000

Page 17

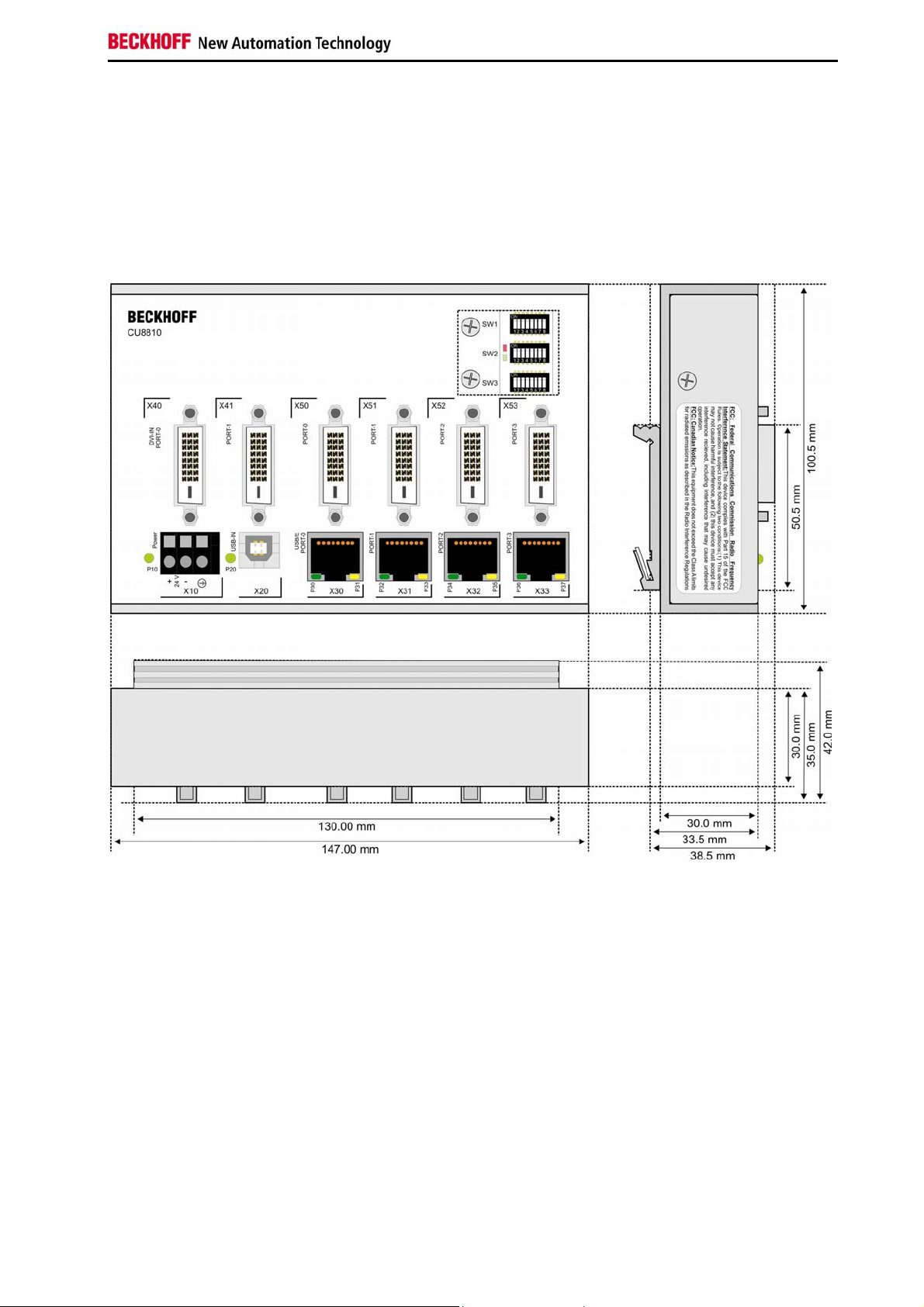

Appendix

Appendix

Assembly dimensions

The product is characterized by small overall installed size. With a height of

approx. 100 mm, the module dimensions exactly match those of the

Beckhoff Bus Terminals. Together with the lowered connector surfaces,

this means that it can be used in a standard terminal box with a height of

120 mm.

CU8810-0000 15

Page 18

Appendix

Beckhoff Support & Service

Quote the project number

Beckhoff and their partners around the world offer comprehensive support

and service, guaranteeing fast and competent assistance with all questions

related to Beckhoff products and system solutions.

Beckhoff branches and partner companies

Please contact your Beckhoff branch office or partner company for local

support and service on Beckhoff products!

The contact addresses for your country can be found in the list of Beckhoff

branches and partner companies: www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone:

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

+49(0)5246/963-0

Beckhoff Support

Beckhoff offers you comprehensive technical assistance, helping you not

only with the application of individual Beckhoff products, but also with wideranging services:

• worldwide support

• design, programming and commissioning of complex automation

systems

• training program for Beckhoff system components

Hotline:

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

+49(0)5246/963-157

Beckhoff Service

The Beckhoff service center supports you in all matters of after-sales

service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline:

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

If servicing is required, please quote the project number of your product.

+49(0)5246/963-460

16 CU8810-0000

Page 19

Appendix

Technical data

Number of ports

Supported standard

Supported baud rates

Status display

USB extension wiring

USB Type B ports (downstream): 1

USB Extender Rx ports (RJ45): 4

DVI Input Ports: 2

DVI Output Ports: 4

USB 1.1

12 Mbit (Full Speed), 1.5 Mbit (Low Speed)

12 LEDs

Maximum 50 meters

length

USB wiring length

Power supply

Maximum 1 meters

24 V

(-15% to +20%), protected against polarity reversal.

DC

To meet the UL requirements use 4 A fuse or class 2 power supply!

Power consumption

Max. current input from 5 V

Maximum 2.7 W

Maximum 0 mA @ 5V

DC

USB

Current output over USB/E

Maximum 500 mA @ 15V

DC

The following conditions must be observed during operation:

Environmental conditions

Ambient temperature: 0 to 55°C (operation)

-25°C to +70°C (transport/ storage)

Atmospheric humidity: Maximum 95%, non-condensing

Vibration/ Shock resistance

EMC resistance burst/ ESD

Protection class

EN 60068-2-6 / EN 60068-2-27

EN 60000-6-2 / EN 60000-6-4

IP20

Do not use the CU8810 in

areas of explosive hazard

Dimensions (W x H x D)

Weight

Assembly

Installation position

Approvals

FCC Approval for USA

FCC Approval for Canada

The DVI splitter may not be used in areas of explosive hazard.

Approx. 146mm x 100mm x 42mm (with mounting for DIN rail)

Approx. 580 g

On 35 mm mounting rail conforms to EN 50022

Any

CE

Approvals for USA and Canada

FCC: Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

FCC: Canadian Notice

This equipment does not exceed the Class A limits for radiated emissions as

described in the Radio Interference Regulations of the Canadian Department of

Communications.

CU8810-0000 17

Loading...

Loading...