Page 1

Documentation for

CU2608

8-Port Ethernet switch with IP67 protection class

Version: 1.0.0

Date: 2014-07-23

Page 2

Page 3

Table of contents

Table of contents

CU2608 - Ethernet Switch (IP67)

1. Foreword 1

Notes on the documentation 1

Safety instructions Fehler! Textmarke nicht definiert.

Documentation issue status 3

2. Product overview 4

Introduction 4

Baiscs of the functionality 5

Technical data 6

3. Mounting and cabling 7

Dimensions 7

Mounting 8

Nut torque for connectors 9

Ethernet cable 10

Power cables 12

Power cable conductor losses 13

Status LEDs 14

4. Appendix 16

General operating conditions 16

Accessories 17

Support and Service 18

CU2608

Page 4

Page 5

Foreword

1. Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automatio n engineering who are

familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing an d commissioning these

components.

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

For that reason the documentation is not in every case checked for consistency with performance data, standards or

other characteristics.

In the event that it contains technical or editorial errors, we retain the right to make alterations at any time and without

warning.

No claims for the modification of products that have already been supplied may be made on the basis of the data,

diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered trademarks

of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own purposes

could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and patents:

EP1590927, EP1789857, DE102004044764, DE102007017835

with corresponding applications or registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and patents:

EP0851348, US6167425 with corresponding applications or registratio ns in various other countries.

Copyright

© Beckhoff Automation GmbH, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others

without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent,

utility model or design.

CU2608 1

Page 6

Foreword

Safety instructions

Safety rules

Consider the following safety instructions and descriptions!

Product specific safety instructions are to be found on the following pages or in the areas mounting, wiring,

commissioning etc.

Disclaimer

All the components are supplied in particular hardware and software configurations appropriate for the application.

Modifications to hardware or software configurations other than those described in the documentation are not

permitted, and nullify the liability of Beckhoff Automation GmbH.

Personnel qualification

This description is only intended for the use of trained specialists in control, automation a nd drive engineering who

are familiar with the applicable national standards.

Description of symbols

The following symbols with a adjoining safety advise or notice are used in this documentation. You have to read the

safety advices carefully and adhere them strictly!

Acute risk of injury!

If you do not adhere the safety advise adjoining this symbol, there is immediate danger to

life and health of individuals!

DANGER

Risk of injury!

If you do not adhere the safety advise adjoining this symbol, there is danger to life and

health of individuals!

WARNING

Hazard to individuals!

If you do not adhere the safety advise adjoining this symbol, there is obvious hazard to

individuals!

CAUTION

Hazard to devices and environment

If you do not adhere the notice adjoining this symbol, there is obvious hazard to materials

and environment.

Attention

Note or pointer

This symbol indicates information that contributes to better understanding.

Note

2 CU2608

Page 7

Foreword

Documentation issue status

Version Comment

1.0.0 first release (technical data updated)

0.5.0 preliminary

CU2608 3

Page 8

Product overview

2. Product overview

Introduction

8-port Ethernet Switch with IP67 protection class

The CU2608 Ethernet Switch offers eight d-coded M12 Ethernet ports. Switches relay incoming Ethernet frames to

the destination ports. In full duplex mode, they prevent collisions.

They can be used universally in automation and office net works. Mounting can be carried out alternatively with two

central 4 mm screws or via two diagonal placed 3 mm screws.

The CU2608 meets the special requirements of real-time-capable Industrial Ethernet solutions through several

outstanding features:

• compact design in IP67 plastic housing

• eight d-coded M12 sockets

• 10/100 Mbaud, half or full duplex, with automatic baud rate detection

• cross-over detection: automatic detection and correction of crossover and straight-through Ethernet cables

• clear, quick diagnosis, 1 LED for each Ethernet port

• easy on-site installation

4 CU2608

Page 9

Product overview

Basic Function Principles

Store and Forward

The switch operates according to the store-and-forward principle. Frames that are faulty (CRC error), too short (< 64

bytes) or too long (> 1536 bytes) are not passed on in general.

Address Memory

The switch learns the MAC addresses of the connected devices for each port. Only frames that have these

addresses, broadcast/or multi-cast addresses, or which have unknown addresses are passed on to this port.

Because the switch remembers more than 1000 addresses for each port, it is also suitable for connecting entire

network segments. After approx. 5 minutes (Aging Time) unused addresses are removed from the memory – if

required, they are re-learnt again later.

Throughput

The switch can pass through up to 148800 Ethernet frames per second (Wire Speed).

PoE - Power over Ethernet

The switches CU20xx, CU22xx and CU26xx do not support the PoE acc. to IEEE 802.3, they do not indicate as a

PSE (power sourcing equipment) or PD (powered devices). Therefore, a PSE, which is connected to the switch, must

not put on voltage.

A passive transmitting or distribution is not intended in the standard

Jumbo Frames

Jumbo Frames are oversized Ethernet telegrams with a length of more than 1518 bytes. They are used in

applications that require very high data throughput, for example.

The CU2208 (from hardware version 01) supports Jumbo Frames up to 9720 bytes on all ports. Please note the

following:

• Jumbo Frames only supported by ports with Gbit link

• Jumbo Frames place high demands on internal data transmission. It is therefore necessary to assess the

data throughput that can be achieved through the CU2208 for each indiv idual application. Under full load no

more than 2 ports can be used for Jumbo Frames at the same time.

Jumbo Frames are not subject to standardization. It is therefore necessary to verify that the frames used by the

application are supported by the CU2208.

CU2608 5

Page 10

Product overview

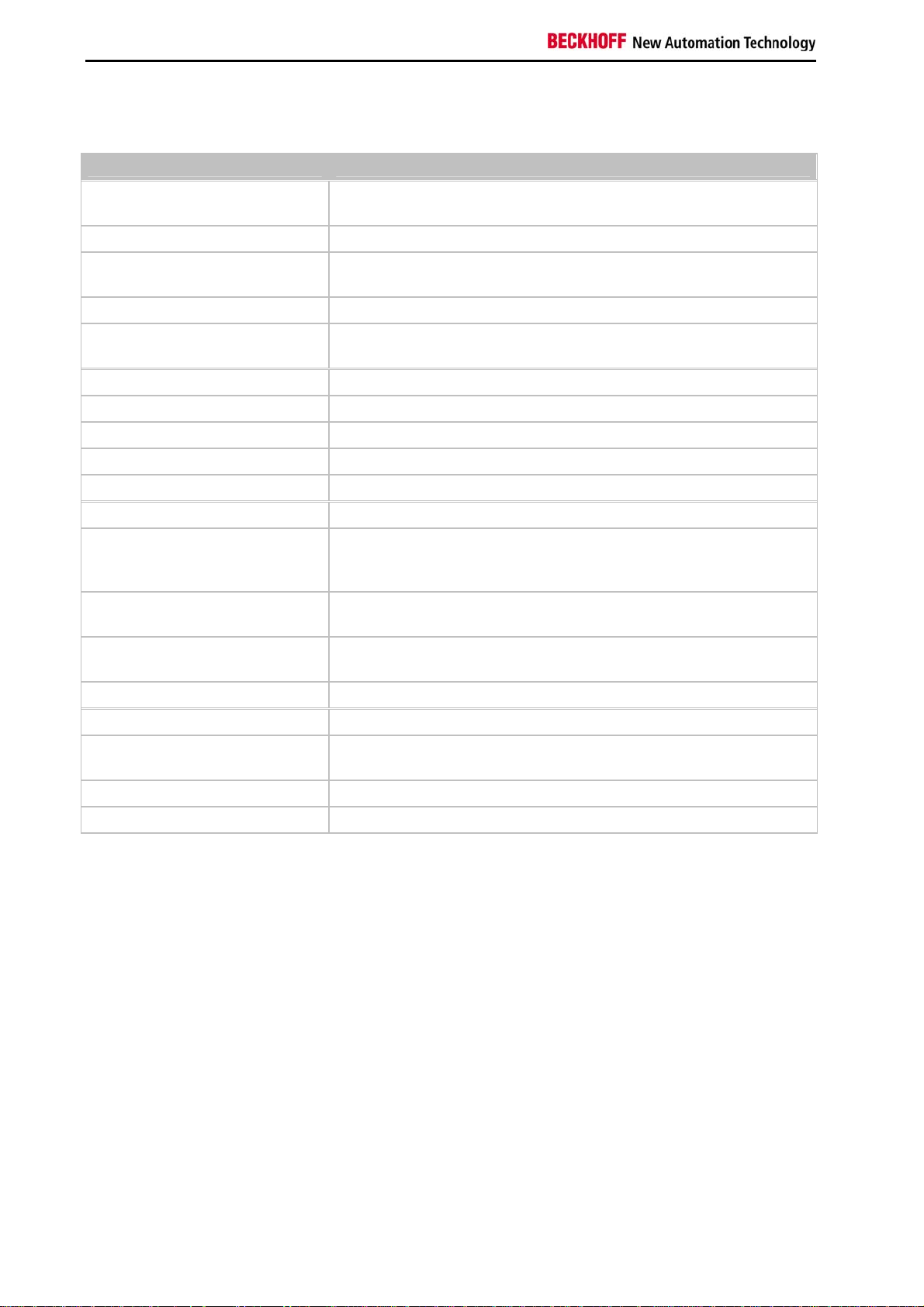

Technical Data

Technical Data CU2608-0000

Bus system all Ethernet based protocols (IEEE 802.3)

Store-and-Forward switching mode, unmanaged

Number of Ethernet-Ports 8

Ethernet Interface 10BASE-T/100BASE-TX

Ethernet with M12, d-coded

Cable length up to 100 m CAT5, switches cascadable without restriction

Baud rate 10/100 Mbit/s, IEEE 802.3u auto-negotiation,

half or full duplex at 10 and 100 Mbit/s possible, automatic settings

Diagnosis 1 LED per channel: Link/Activity, LED for power supply

Power Supply feed and downstream connection via M8 connectors, 4-pin

Supply voltage 24 VDC (-15 %/+20 %)

Current consumption typically 120 mA

Weight app. 350 g

Dimensions without plugs (w x h x d) app. 126 x 60 x 26.5 mm

Mounting • Directly to mounting surface via two central 4 mm screws or via two

diagonal placed 3 mm screws.

• On Mounting Rail ZS5300-0001.

Permissible ambient temperature

range during operation

Permissible ambient temperature

range during storage

Vibration / shock resistance according to EN 60068-2-6 / EN 60068-2-27

EMC resistance burst / ESD according to EN 61000-6-2 / EN 61000-6-4

Protection class (according

toEN 60529)

Installation position variable

Approvals CE

-30°C ... + 70°C

-40°C ... + 85°C

IP65, IP66, IP67

6 CU2608

Page 11

Mounting and cabling

3. Mounting and cabling

Dimensions

All dimensions are given in millimeters.

Housing properties

EtherCAT Box lean body wide body

Housing material PA6 (polyamide)

Casting compound Polyurethane

Mounting two fastening holes Ø 3 mm for M3 two fastening holes Ø 3 mm for M3

two fastening holes Ø 4,5 mm for M4

Metal parts Brass, nickel-plated

Contacts CuZn, gold-plated

Power feed through max. 4 A

Installation position variable

Protection class IP65/66/67 (conforms to EN 60529) when screwed together

Dimensions (H x W x D) ca. 126 x 30 x 26,5 mm ca. 126 x 60 x 26,5 mm

Weight approx. 125 g, depending on module type approx. 250 g, depending on module type

Approvals CE, cULus CE

CU2608 7

Page 12

Mounting and cabling

Fixing

Note or pointer

While mounting the modules, protect all connectors, especially the IP-Link, against

contamination!

Note

Modules with narrow housing are mounted with two M3 bolts.

Modules with wide housing are mounted with two M3 bolts to the fixing holes locate d at the corners or mounted with

two M4 bolts to the fixing holes located centrally.

The bolts must be longer than 15 mm. The fixing holes of the modules are not threaded.

When assembling, remember that the fieldbus connectors increases the overall height. See chapter accessories.

Only with connected cables or plugs the protection class IP67 is guaranteed!

Unused connectors have to be protected with the right plugs! See for plug sets in the

catalogue.

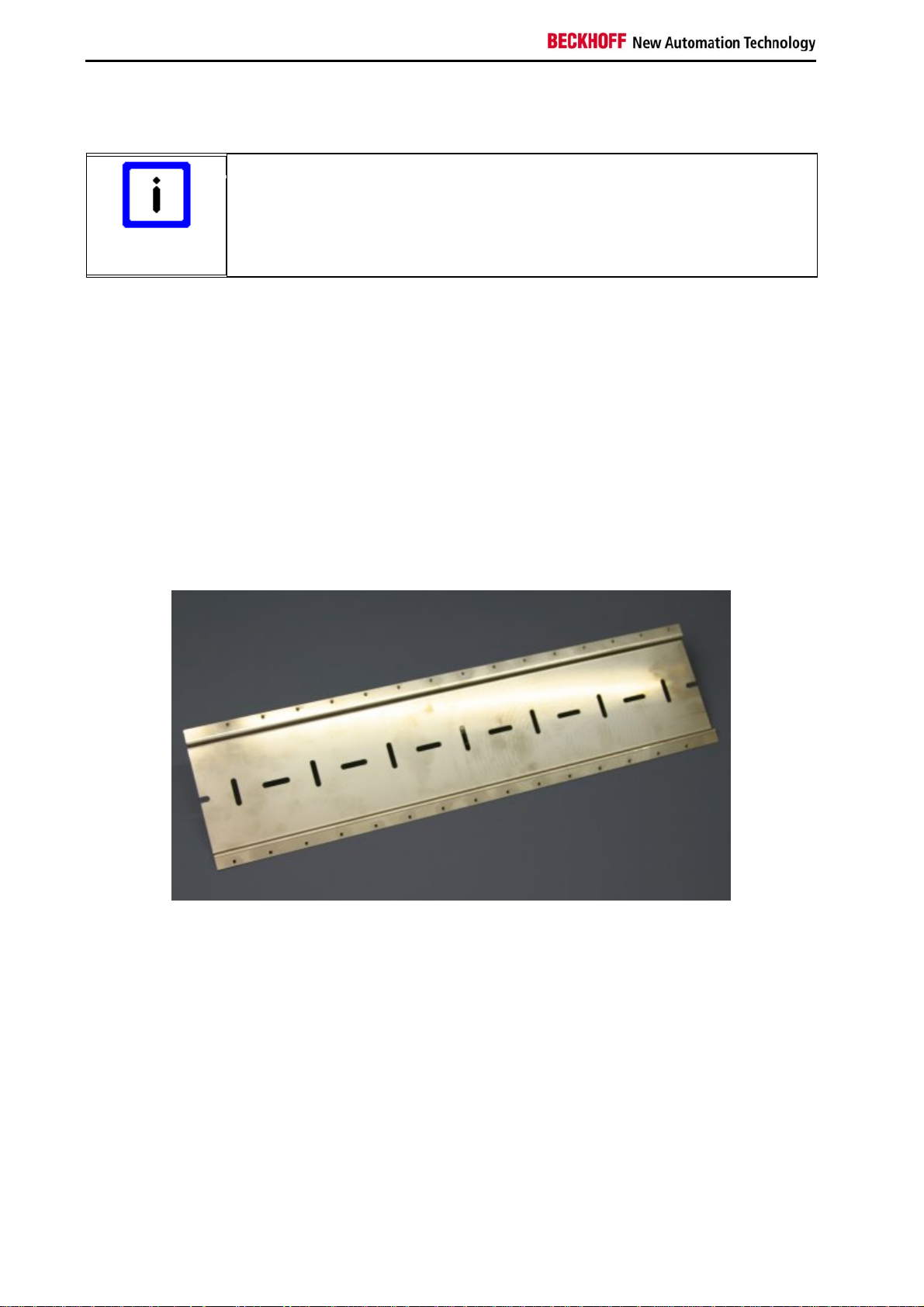

Mounting Rail ZS5300-0001

The mounting rail ZS5300-0001 (500 mm x 129 mm) allows the time saving assembly of modules.

The rail is made of stainless steel, 1.5 mm thick, with already pre-made M3 threads for the modules. The rail has got

5.3 mm slots to mount it via M5 screws to the machine.

The mounting rail is 500 mm long, that way 15 narrow modules can be mounted with a distance of 2 mm between

two modules. The rail can be cut to length for the application.

8 CU2608

Page 13

Mounting and cabling

Nut torque for connectors

M8 connectors

It is recommended to pull the M8 connectors tight with a nut torque of 0.4 Nm.

M12 connectors

It is recommended to pull the M12 connectors tight with a nut torque of 0.6 Nm.

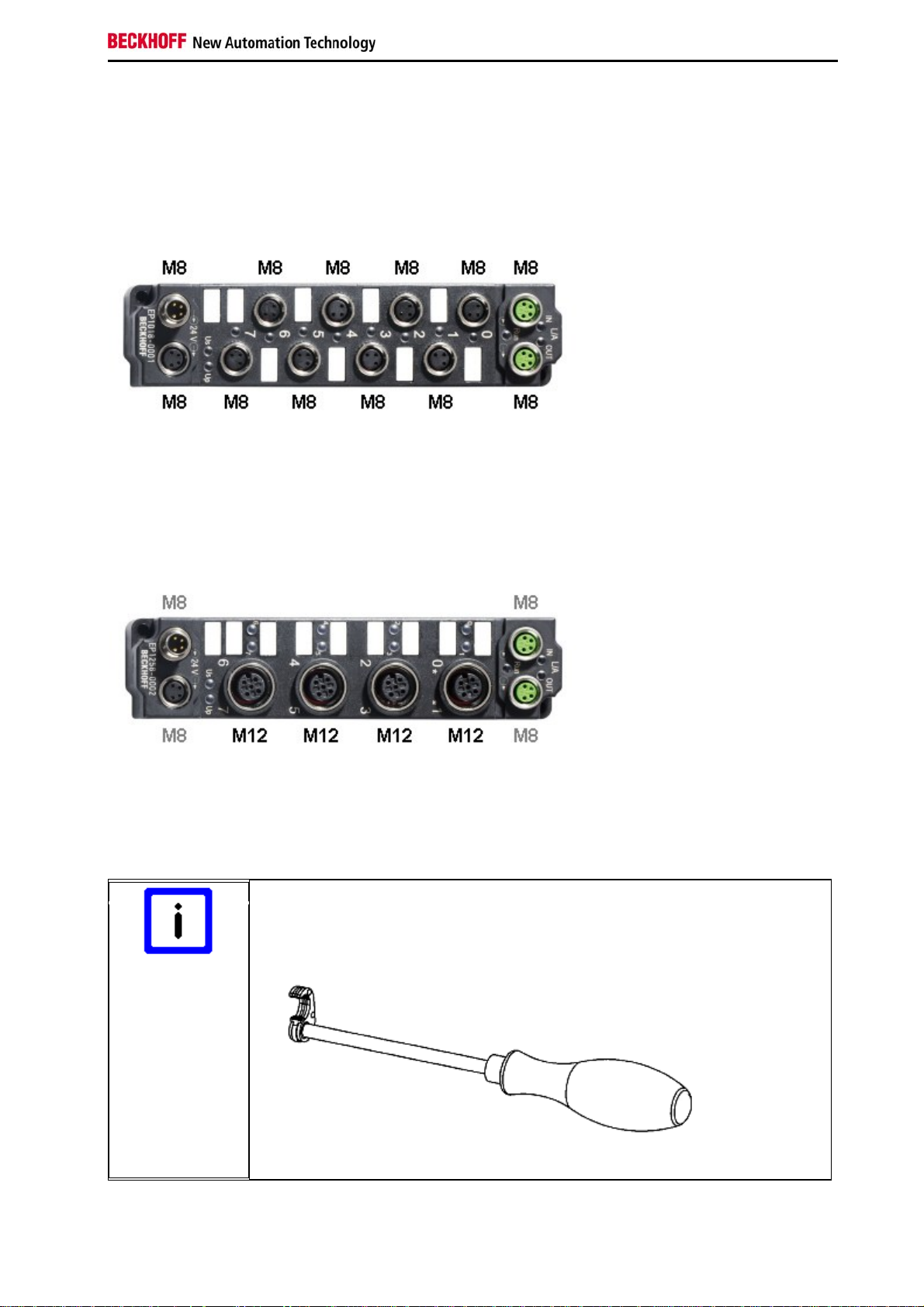

Torque socket wrenches

Ensure the right torque

Use the torque socket wrenches available by Beckhoff to pull the connectors tight (see

accessories)!

Note

CU2608 9

Page 14

Mounting and cabling

Ethernet cables

For connecting Ethernet devices only shielded Ethernet cables that meet the requirements of at least category 5

(CAt5) according to EN 50173 or ISO/IEC 11801 should be used.

Recommendations about cabling

You may get detailed recommendations about cabling Ethernet from the documentation

"Recommendations for the design of the infrastructure for EtherCAT/Ethernet", that is

available for download at www.Beckhoff.com.

Note

Ethernet uses 4 wires for signal transfer. Due to automatic cable detection (auto-crossing) symmetric (1:1) or crossover cables can be used between Ethernet devices from Beckhoff.

A selection of cables for Ethernet (her only up to 10m) follows. Other cables with various lengths will be found in the

full Beckhoff catalogue, and under www.beckhoff.com.

Sold by meter

Designation Description

ZB9010 CAT 5e, 4-core, for fixed laying, not for M8 connectors

ZB9020 CAT 5e, 4-core, suitable for drag chain use, not for M8 connectors

ZB9030 PVC, dia. 4.9 mm for M8 connectors

ZB9031 PUR, dia. 4.8 mm for M8 connectors

ZB9032 PUR, dia. 5.4 mm for M8 connectors, high flexibility

Pre assembled cables

ZK1090-6161-0xxx: M12 plug - M12 plug, PUR, ready-assembled

ZK1090-6161- 0005 0010 0020 0025 0050 0100

Length

0.5 m 1.0 m 2.0 m 2.5 m 5.0 m 10 m

10 CU2608

Page 15

Mounting and cabling

ZK1090-6191-0xxx: M12 plug - RJ45 plug, ready-assembled

ZK1090-6191- 0005 0010 0020 0025 0050 0100

Length

0.5 m 1.0 m 2.0 m 2.5 m 5.0 m 10 m

ZK1090-6292-0xxx: M12 socket - RJ45 plug, ready-assembled

ZK1090-6292- 0005 0020 0050 0100

Length

0.5 m 2 m 5 m 10 m

ZK1090-9191-0xxx: 2 x RJ45 plug, patch cable

ZK1090-9191- 0001 0002 0005 0010 0020 0030 0040 0050 0100 0150

Length

0.17 m 0.26 m 0.5 m 1.0 m 2.0 m 3.0 m 4.0 m 5.0 m 10 m 15 m

ZK1090-9191- 0200 0250 0300 0350 0400 0450 0500

Length

20 m 25 m 30 m 35 m 40 m 45 m 50 m

CU2608 11

Page 16

Mounting and cabling

Power cables

Ordering data

Screw-in

Order designation Power lead

ZK2020-3200-0020 2.00 m

ZK2020-3200-0050 5.00 m

ZK2020-3200-0100

ZK2020-3400-0020 2.00 m

ZK2020-3400-0050 5.00 m

ZK2020-3400-0100

ZK2020-3132-0001 0.15 m

ZK2020-3132-0005 0.50 m

ZK2020-3132-0010 1.00 m

ZK2020-3132-0020 2.00 m

ZK2020-3132-0050

ZK2020-3334-0001 0.15 m

ZK2020-3334-0005 0.50 m

ZK2020-3334-0010 1.00 m

ZK2020-3334-0020 2.00 m

ZK2020-3334-0050

Further available power cables may be found in the Beckhoff catalog or on our internet pages

(http://www.beckhoff.com).

Straight socket, open end

Angled socket, open end

Straight socket, straight socket

Angled socket, angled socket

connector Contacts

M8 4-pin 0.34 mm2

Crosssection Length

10.00 m

10.00 m

5.00 m

5.00 m

Technical data

Technical data

Rated voltage according to IEC60 664-1 60 VAC / 75 VDC

Contamination level according to IEC 60 664-1 3/2

Insulation resistance IEC 60 512-2 >109 Ω

Current carrying capacity according to IEC 60512-3 4 A

Volume resistance according to IEC 60512-2 < 5 mΩ

Protection class according to IEC 60529 IP65/66/67, when screwed together

Ambient temperature -30°C to +80°C

12 CU2608

Page 17

Mounting and cabling

Power cable conductor losses

The ZK2020-xxxx-yyyy power cables should not exceed the total length of 15 m at 4 A (with continuation). When

planning the cabling, note that at 24 V nominal voltage, the functionality of the module can no longer be assured if the

voltage drop reaches 6 V. Variations in the output voltage from the power supply unit must also be taken into

account.

Example

8 m power cable with 0.34 mm² cross-section has a voltage drop of 3.2 V at 4 A.

CU2608 13

Page 18

Mounting and cabling

LED Displays

Ethernet

For each of the eight channels 1 LEDs show the current status.

LED display per channel

LED Display

Link

Act

off no connection

on connection established (Link)

flashing data transmission active (Act)

14 CU2608

Page 19

Mounting and cabling

Power Supply

Present supply voltage (24 VDC) is shown by the green power LED.

LED Display Meaning

24V Us

(Control voltage)

(Auxiliary voltage)

The auxiliary voltage Up is not used within the CU2608 but it is fed trough.

off The power supply voltage Us is not present

green illuminated The power supply voltage Us is present

red illuminated Caused by overload (current > 0,5 A) the sensor supply generated

from supply voltage Us has been switched off for all sensors.

off The power supply voltage Up is not present 24V Up

green illuminated The power supply voltage Up is present

CU2608 15

Page 20

Appendix

4. Appendix

General operating conditions

Protection degrees (IP-Code)

The standard IEC 60529 (DIN EN 60529) defines the degrees of protection in different classes.

1. Number: dust

protection

and touch guard Definition

0

1 Protected against access to hazardous parts with the back of a hand. Protected against solid

2 Protected against access to hazardous parts with a finger. Protected against solid foreign

Non-protected

foreign objects of Ø50 mm

objects of Ø12,5 mm.

3 Protected against access to hazardous parts with a tool. Protected against solid foreign objects

Ø2,5 mm.

4 Protected against access to hazardous parts with a wire. Protected against solid foreign objects

Ø1 mm.

5 Protected against access to hazardous parts with a wire. Dust-protected. Intrusion of dust is not

totally prevented, but dust shall not penetrate in a quantity to interfere with satisfactory

operation of the device or to impair safety.

6 Protected against access to hazardous parts with a wire. Dust-tight. No intrusion of dust.

2. Number:

water* protection Definition

0

1 Protected against water drops

2 Protected against water drops when enclosure tilted up to 15°.

3 Protected against spraying water. Water sprayed at an angle up to 60° on either side of the

4 Protected against splashing water. Water splashed against the disclosure from an y direc tion

5

Non-protected

vertical shall have no harmful effects.

shall have no harmful effects

Protected against water jets

6 Protected against powerful water jets

7 Protected against the effects of temporary immersion in water. Intrusion of water in quantities

causing harmful effects shall not be possible when the enclosure is temporarily immersed in

water for 30 min. in 1 m depth.

*) These protection classes define only protection against water!

16 CU2608

Page 21

Appendix

Chemical Resistance

The Resistance relates to the Housing of the Fieldbus Box and the used metal parts.

Character Resistance

Steam at temperatures >100°C: not resistant

Sodium base liquor

(ph-Value > 12)

Acetic acid not resistant

Argon (technical clean) resistant

Key

resistant: Lifetime several months

non inherently resistant: Lifetime several weeks

not resistant: Lifetime several hours resp. early decomposition

at room temperature: resistant

> 40°C: not resistant

EtherCAT Box - Accessories

Fixing

Ordering information Description

ZS5300-0001 Mounting rail (500 mm x 129 mm)

Marking material, plugs

Ordering information Description

ZS5000-0000 Fieldbus Box set M8 (contact lab els, plugs)

ZS5000-0002 Fieldbus Box s et M12 (contact labels, plugs)

ZS5000-0010 plugs M8, IP67 (50 pieces)

ZS5000-0020 plugs M12, IP67 (50 pieces)

ZS5100-0000 marking labels, not printed, 4 stripes at 10 pieces

ZS5100-xxxx printed marking labels, on request

Tools

Ordering information Description

ZB8800 Torque socket wrench with ratchet wrench for M8 connectors (over molded)

ZB8800-0001 ratchet wrench for M8 connectors (field assembly)

ZB8800-0002 ratchet wrench for M12 conne c tors (over molded)

Further accessories

Further accessories may be found at the price list for Beckhoff fieldbus components and at

the internet under www.beckhoff.com.

Note

CU2608 17

Page 22

Appendix

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast and

competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of individual

Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

18 CU2608

Loading...

Loading...