Beckett HeatManager 2.5 7516 User Manual

INSTALLATION INSTRUCTIONS for Form 7516 rev. 0

HeatManager™ 2.5 model 7516 (145 PSI max. operating pressure)

LIGHT COMMERCIAL STEAM HEATING SYSTEM ECONOMIZER

Description

The HeatManager™2.5 is a patented microprocessorcontrolled fuel-saving device for steam heating systems. It

reduces fuel consumption, wear on boiler parts and burner

emissions by actively managing the burner, in conjunction with

the boiler’s controls, to more efficiently match the boiler output

to the required load.

Operation

After installation, setting the switch on the unit to the ‘ON’

position activates the device. The LCD display indicates the

various ‘modes’ of the device, and sensed Pressures and

Temperatures. The possible messages and their explanatio n

are:

‘STANDBY MODE’ - The boiler is operating under its own

internal controls, which have turned the burner off. This occurs

for a period of time after the burner has shut down.

‘ECONOMIZER MODE’ - The boiler’s controls have requested

the burner to come on but the HeatManager™ has sensed that

there is available steam which can be used without burning

fuel. The burner will remain off and useful energy will be

extracted from the boiler’s existing supply of steam.

‘HEATING MODE’ – The burner is allowed to fire.

‘HEATING LOW LIMIT’ - The unit has switched the burner on

due to an increase in load. This condition may occur

occasionally. If this message appears frequently, the boiler’s

pressure controls are set too low and should be incre ased in 2

PSI increments until the message stops appearing frequently.

During normal operation, one of the above messages will be

alternated with the message(s) below.

‘STEAM PRESS = ‘ - The measured value of the boiler steam

pressure is displayed in PSIG.

‘DOM. TEMP = ‘ - The measured value of the domestic hot

water outflow temperature is displayed in degrees F. *

* Note: This message will only appear if the boiler supplies

domestic hot water and the optional second sensor is installed

(see Sensor Section of these instructions).

In the event that a sensor fails, the HEATMANAGER™ will

return full control of the burner to the boiler’s controls, the

‘Power/Normal’ indicator will blink, and the following message

will be displayed:

‘SENSOR FAILURE ‘

If this message appears, see the instructions under Service

and Troubleshooting or call your installer for service.

Installation

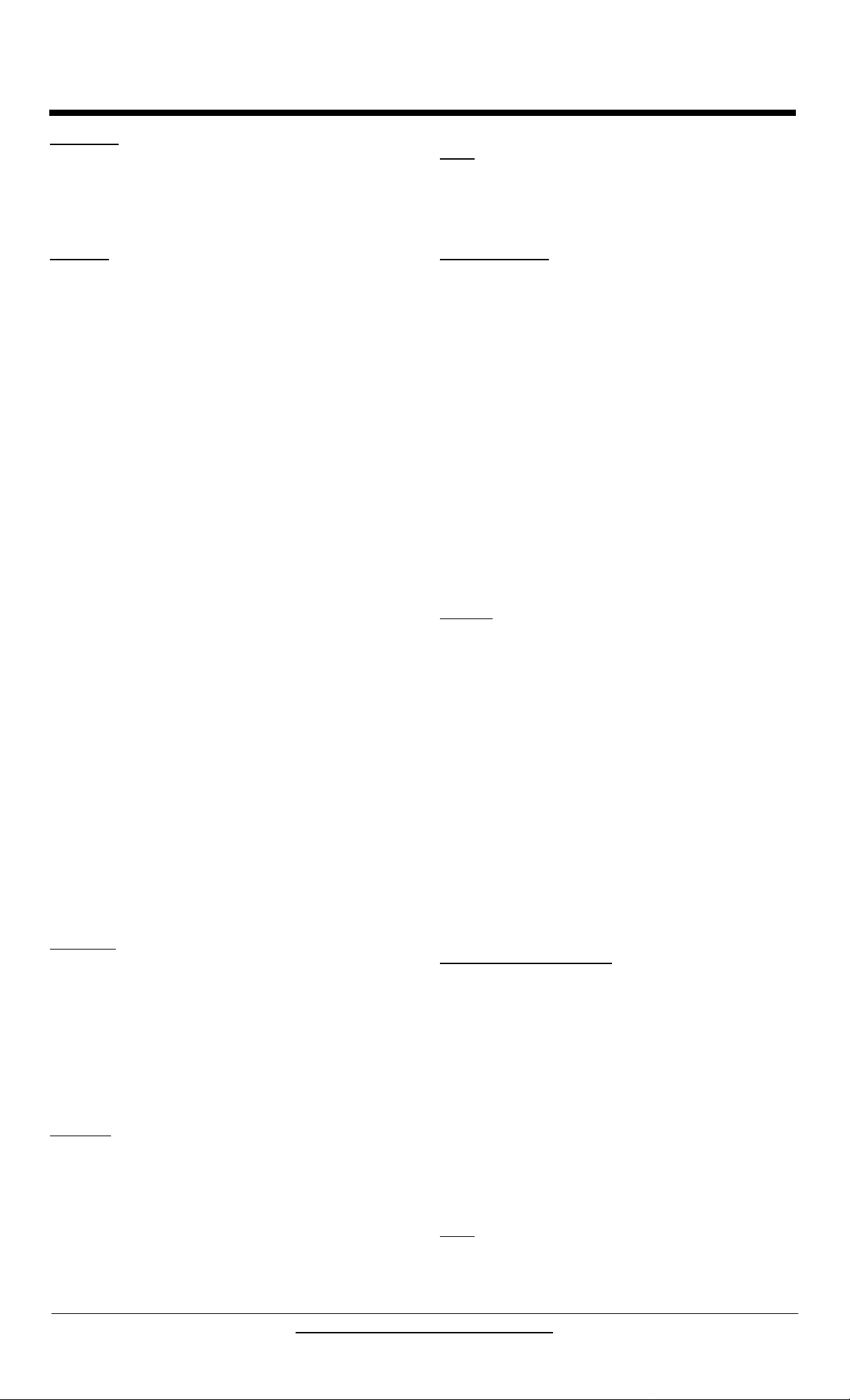

The HeatManager™ is electrically installed in series with the

boiler pressuretrol as shown in the wiring diagram (Fig. 1a or

Fig.1b on the reverse side of this page). Check the shipping

box label for correct model. The HEATMANAGER™ can be

used with 24, 115 and 220 Volts for power and control.

For safety, power to the boiler must be shut off during

installation. For improved savings, it is recommended that

the low pressure setting of the boiler’s controls be set no lower

than 30 PSI. If the setting is found to be lower, it should be

raised to at least 30 PSI .

Positioning

The unit can be mounted in any position. For readability of the

display, the vertical position is preferred. Depending on the

boiler’s configuration, the unit can be mounted on an electric

junction box or directly on an external pressuretrol. Remove a

knockout from the junction box or pressuretrol and mount the

unit using the standard ½’ electrical fitting on the case, and the

supplied lock-nut.

Wiring

All wiring and connections must comply with Local and National

Electrical Codes. The unit should be wired as shown in the

wiring diagram (Fig. 1a or Fig. 1b) on the reverse side.

NOTE: All unused leads should be trimmed and individually

insulated.

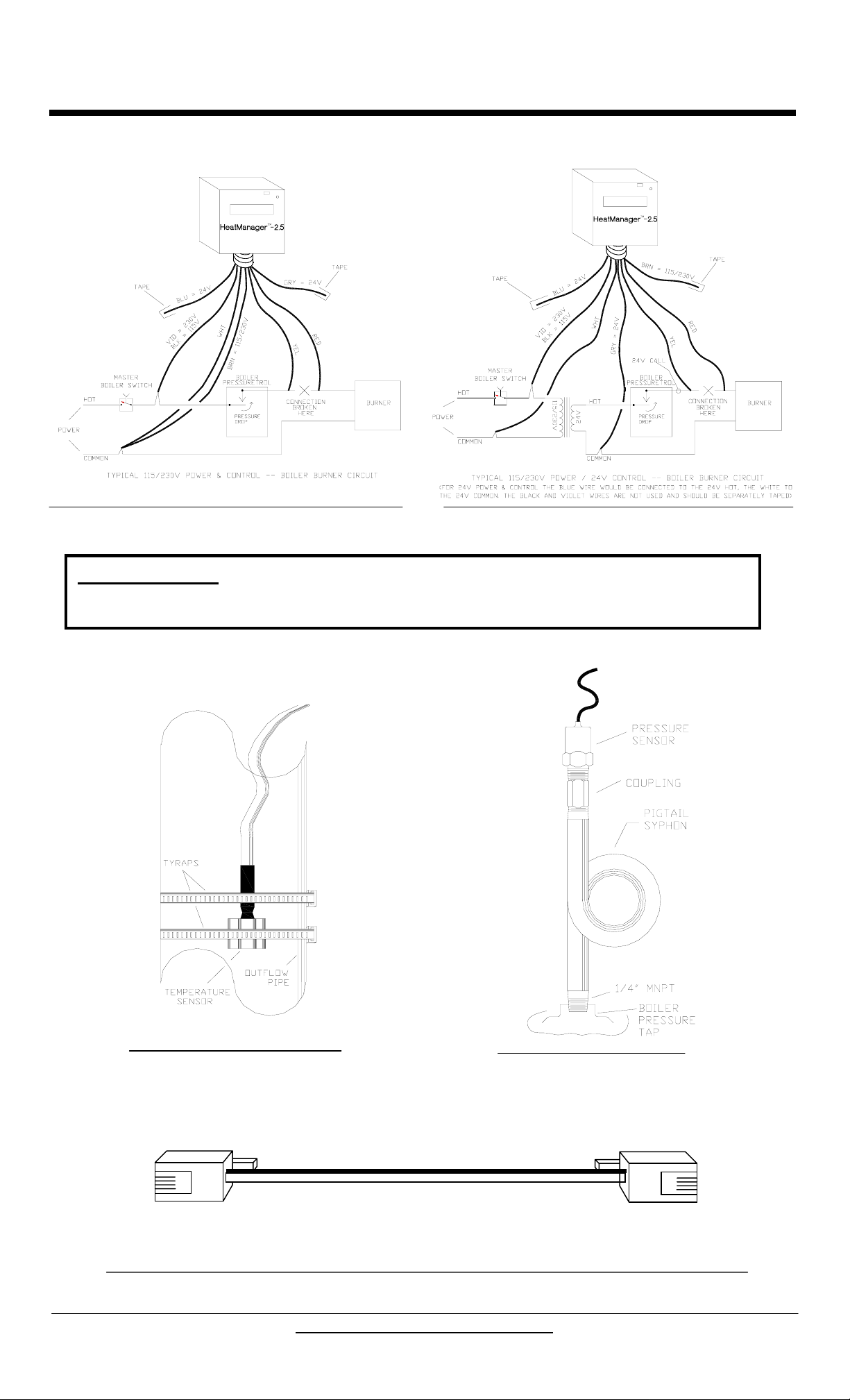

Sensors Installation

Attach the pressure sensor to the boiler using standard plumbing

practices for the pressures involved. The pressure sensor must

be mounted to a ‘steam pigtail siphon tube’ to protect the sensor

from high temperatures (see fig. 3). Failure to do so will void the

sensor warranty. Route the sensor wire back to the

HeatManager™ controller in a workman like manner. Insert the

sensor connector into the ‘Steam Pressure Sensor’ jack on the

unit.

For boilers that also supply domestic hot water; attach a

temperature sensor (as shown in fig. 2) to the domestic hot water

outflow-pipe at the storage tank (if used) or at the boiler’s

domestic water coil outlet-pipe, if no storage tank is used, and

insulate. Route the sensor wire back to the HeatManager™

controller in a workman like manner and insert the tempe rature

sensor connector into the ‘Domestic Water Sensor’ jack. This

sensor should not be used if the boiler does not supply heat for

domestic hot water.

If any of the sensor leads are too short, they can be extended by

using HeatManager™ extension cables, or mak e your own usin g

standard ‘modular telephone’ wire and connectors (see Fig. 4).

Checkout

Recheck wiring one last time and make sure that the sensor(s) is

plugged into the proper jack(s). The sensor(s) is only detected

during power-up. Set the HEATMANAGER™’ switch to

‘Off/Bypass’ and restore power to the boiler. Reset the switch to

‘On’. After a brief check of the electronics, the sensor(s) will be

detected and the green ‘Power/Normal’ indicator should light

continuously. It is important to verify recognition of the sensors

by viewing the reading(s), on the display. If the installed sensors

are not detected, the HEATMANAGER™ will not function

properly. If the green indicator is blinking or if the display does

not verify the installed sensors, turn the HEATMANAGER™ ‘Off’

and recheck the sensor installation. After the sensor-check,

depending upon the condition of the boiler, the

HEATMANAGER™ will go into one of its various modes. Note,

and write down, the Boiler’s pressure contro l setting. You

should be able to get the HEATMANAGER™ to change modes

by temporarily setting the controls higher or lower. This indicates

the unit is operating normally. If the HeatManager™ do es not

change modes when the boiler’s controls are adjusted, the unit is

probably wired incorrectly; see the WIRING NOTE. Make sure

to return the Boiler’s control settings to their original

position.

Service and Troubleshooting

The HeatManager™ doesn’t require any maintenance and will

provide years of trouble free operation. The unit may be

disconnected at any time by putting the switch to the

‘OFF/BYPASS’ position. In this position, the unit has no effect

on the system and the boiler functions as it did prior to the

HeatManager™ installation. This allows service personnel to

diagnose any boiler problems without the unit intervening.

If at any time the ‘SENSOR FAILURE’ message appears on the

front panel display, a sensor is not operating properly and the

HeatManager™ has returned full burner control back to the

Boilers’ controls. The failed sensor can be identified by turning

the HeatManager™ off, then back on, and observing the display

to see which connected sensor is not recognized. Replace the

unrecognized sensor with a known good one, and repeat the

above test. If the sensor still isn’t recognized, there is a problem

with the HeatManager™ which should be returned for service.

NOTE

future reference.

: Installer, please leave these instructions with the unit for

R.W. Beckett Corporation, Elyria, Ohio USA

INSTALLATION INSTRUCTIONS for Form 7516 rev. 0

r

f

HeatManager™ 2.5 model 7516 (145 PSI max. operating pressure)

LIGHT COMMERCIAL STEAM HEATING SYSTEM ECONOMIZER

Fig. 1a Fig. 1b

WIRING NOTE: The HeatManager

™

2.5 has separate return wires for the Power and Burne

circuits. It is necessary that these wires be connected to the appropriate returns for the circuit. I

this is not done; the unit will not function properly. Unused wires MUST be separately taped!

Fig. 2 Fig. 3

The temperature sensor wire(s) can be extended using standard, 4 conductor modular telephone wire, connectors,

and couplers. The correct extension wire would have the same order of wire colors, from top to bottom, with the

connectors held as shown above.

Fig. 4

R.W. Beckett Corporation, Elyria, Ohio USA

Loading...

Loading...