Page 1

PARTS & ACCESSORIES

Model 7590

Gas Power Burner Control

Description / Applications

The Beckett GeniSys Gas Power Burner Control is a

safety control designed for use on gas power burners.

This control is intended for use in residential and light

commercial gas heating applications. Applications may

include boilers, furnaces, water heaters, space heating

and commercial cooking equipment. The 7590 provides

supervision of a separate 120 Vac igniter, a 120 Vac

combustion blower motor, a 24 Vac gas valve and 24

Vac connections for an air proving switch (on 7590C,

D). The control uses ame rectication principles to

prove the presence of the burner ame. Basic diagnostic

information is provided through 3 LEDs. Additional

diagnostic information and control setup will be available

through a separate diagnostic tool.

Page 2

Contents

Features........................................................................................3

Specications .............................................................................. 4

Electrical Ratings .......................................................................... 4

Electrical Connections ................................................................... 4

Environmental Ratings .................................................................. 4

Approvals ...................................................................................... 4

Lockout Sequence Options ........................................................... 4

Timings ......................................................................................... 4

Control Cycling Rate ..................................................................... 4

Installation ....................................................................................6

Mounting ....................................................................................... 7

Transformer Sizing ........................................................................ 7

Spark Gap ..................................................................................... 7

Wiring ...........................................................................................7

Operation .....................................................................................8

7590T ............................................................................................ 8

Status & Diagnostics .................................................................. 8

Flame Signal Strength Indication .................................................. 9

Lockout .......................................................................................... 9

Reset from Lockout ....................................................................... 9

Lockout with Retry (Optional) ........................................................ 9

Stop/Hold Button ......................................................................... 10

Safety Check ............................................................................... 10

Check Safety Timings ................................................................. 10

Check for Normal Operation ....................................................... 10

Simplied Sequence of Operation ................................................11

Troubleshooting ........................................................................13

Troubleshooting Sequence ......................................................15

Limited Warranty Information ..................................................20

Hazard Denitions:

Indicates a hazardous situation that, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation that, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation that, if not avoided, could result

in minor or moderate injury.

Used to address practices not related to physical injury.

Safety instructions signs indicate specic safety-related

instructions or procedures.

2

Page 3

Features

◦ For use in Natural Gas or LP gas applications.

◦ Controls 120 Vac spark igniter, motor/blower and 24 Vac gas valve, 50/60 HZ

◦ Provides proof of ame through ame rectication using a separate ame rod

◦ Checks combustion air proving switch contacts (24 Vac) on 7590C and 7590D

models to prove moving combustion air and guard against welded contacts.

◦ Field selectable for either lockout or recycle on loss of combustion air

◦ Field selectable relight or recycle operation on loss of ame (may be factory locked)

◦ Field selectable single or multiple trials for ignition on some models (may be locked)

◦ Field selectable ignition timing on some models (may be factory locked)

◦ Field selectable pre-purge timing (may be factory locked)

◦ The microprocessor is checked for proper operation prior to each ignition cycle

◦ Check for welded valve relays on each cycle

◦ Mounts on standard 4 x 4 junction box

◦ 3 status LEDs supply basic diagnostics, additional diagnostic information and eld

conguration will be available through a separate diagnostic tool

◦ An optional separate alarm module provides alarm contacts (dry contacts)

◦ A reset button is standard on all controls, non-volatile manual reset logic is available

on specic models (7590C).

◦ Communication Port to connect diagnostic tool and alarm module

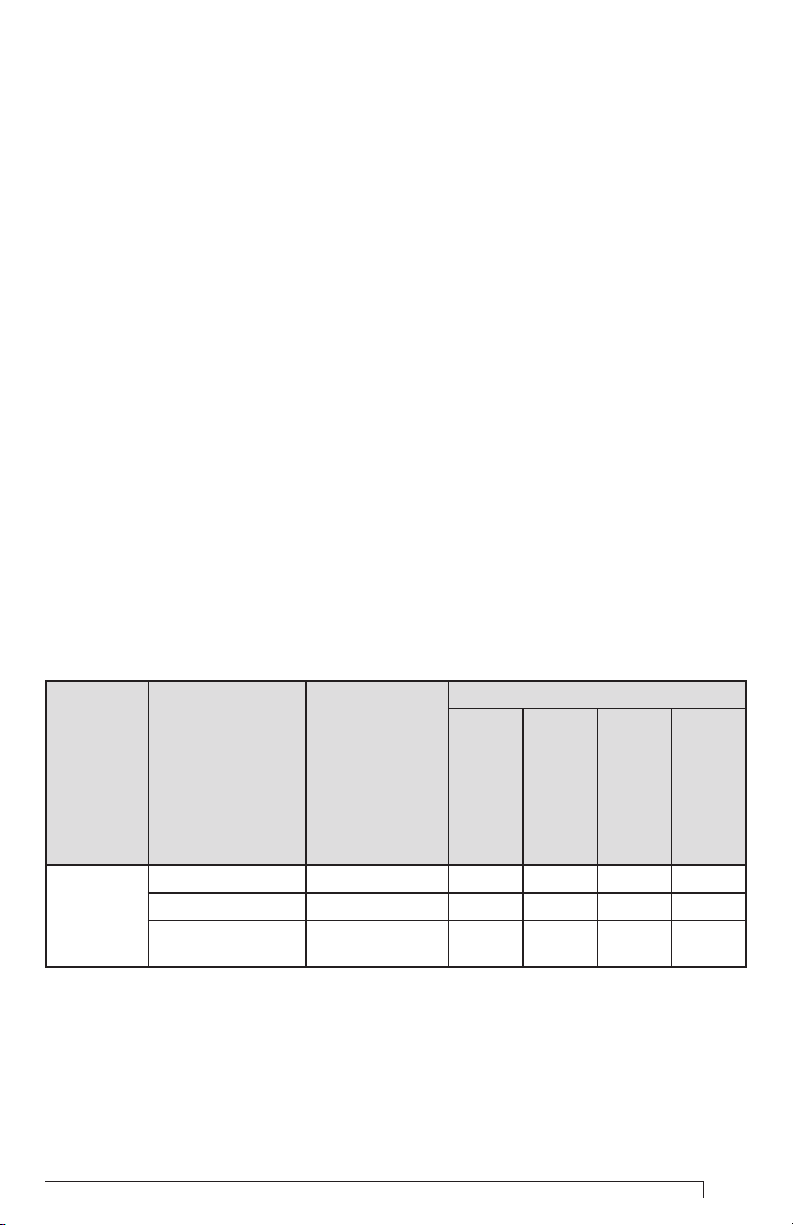

Table 1 - Ignition Model Numbers

Feature

Model Line Model Description Part Number

output

120 volt Igniter

and blower motor

Standard 7590DYYYY X X X

Gas Power

Burner

The standard model 7590 is designed for use on applications below 400,000 BTUs. For

applications above 400,000 BTUs, contact Beckett’s Engineering Group.

*Non-volatile lockout cannot be cleared by removing power from the control. The

control must be reset by pressing the Status/Reset button when the control is powered.

GeniSys Gas Power Burner Control Installation and Operation Manual

No Pressure Switch 7590TYYYY X X

Non-volatile Manual

Reset

7590CYYYY X X X X

output

24 volt gas valve

for

lockout*

Non-volatile

pressure switch

2 Pin- connector

3

Page 4

Specications

Electrical Ratings

◦ Voltage: 120 volts 50/60 Hz (igniter,

motor) 24 volts (18-30 Vac) 50/60Hz

(gas valve and air proving switch)

◦ Current Draw (run): 0.2 Amps (control

only)

◦ Main Valve Rating: 2.0 Amps

◦ Motor Relay Rating: 7.4 Amps (120V)

◦ Igniter Relay Rating: 1.0 Amp (120V)

◦ Minimum Flame Current Required:

1.0 µA

◦ Flame Failure Response Time: 0.8

Seconds (Max.)

◦ Control is not polarity sensitive

◦ Heat Anticipator Setting: 0.2 amp + gas

valve current draw

Electrical Connections

◦ Two T-T screw terminals (on top) (see

Figure 1)

◦ 1/4” Quick Connects (6 total on bottom)

─ Igniter, L2

─ Motor, L2

─ L1, L2

◦ 3/16” Remote Sense quick connect

terminal (on bottom)

◦ 6-Pin (24V) connector (on bottom)

24 Volt Input, Gas Valve, Burner

Ground

◦ 2-Pin (24 V) connector (on bottom)

Air Pressure Switch

◦ Micro-USB Communications Port (on

side of control) for diagnostic tool and

alarm module (COM1).

◦ Additional Features

◦ 3 Diagnostic LEDs; Status (red), Flame

(yellow), MV (green)

◦ Alarm Contacts (optional module)

Environmental Ratings

◦ Operating Temperature Range: -40°F

to +175°F (-40°C to +79.4°C).

◦ Relative Humidity Operating Range 5%

- 95% (non-condensing).

Not intended for outdoor use unless

mounted in appropriate enclosure.

Approvals

ETL listed per ANSI Z21.20 and CSA

C22.2#199

Lockout Sequence Options

◦ Sequence is usually factory selected

◦ Lockout after single try for ignition

◦ Lockout with retrial every 1-8 hours

◦ Lockout after 3 trials for ignition

◦ Manual Reset logic: shutdown after

failure to light during trial for ignition

timing or after ame failure, (no relight

attempt), after 5 minute minimum

waiting time, 1 retry attempt allowed,

then non-volatile lockout. Lockout

must be manually reset.

Timings

◦ All timings can be factory locked.

Timings below may be eld selectable

on some models.

◦ Ignition Timing: 4-15 seconds (4

seconds if Manual Reset)

◦ Pre-purge timing: 1-240 seconds

◦ Inter-purge timing: 90-300 seconds

Control Cycling Rate

The 7590 is designed for use in typical

heating applications which cycle a

few times per hour during the heating

season. More rapid cycling of the control

will shorten the useful life of the control.

Controls in rapid cycling applications

should be checked monthly for proper

operation. All controls should be checked

at least annually for proper operation.

4

Page 5

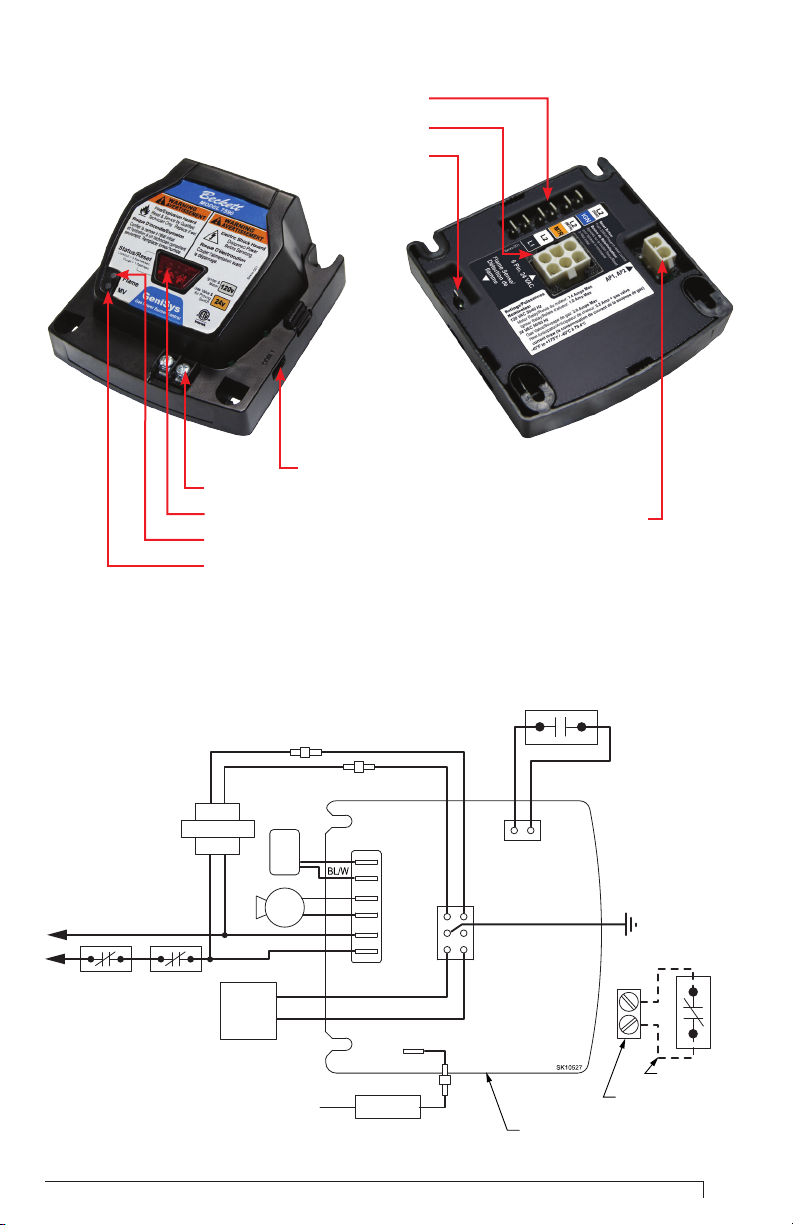

Figure 1 - Getting to know the control

1/4” Terminal Connections

6-Pin 24 V Connector

Flame Sense

Com Port (COM 1)

Thermostat Terminals

Status/Reset LED Button

Flame LED

MV LED

Figure 2 - Gas Conversion Burner Hookup Drawing

Air Pressure Switch

Transformer

W W

B

Limit

(If Required)

LWCO

Y/W

Y BK

Igniter

B

W

Burner

Motor

B

Gas

Valve

(1/4” QC)

W

W

O

W

V

L2 (IGN)

Igniter

L2 (MTR)

Motor

L2

L1

Valve Common

Sense

(3/16” QC)

Flame Sensor

W/R

Valve

24V

24V GROUND

Y

Y

AP1

GeniSys Gas Power Burner Control Installation and Operation Manual

Air Pressure

Switch

BR

BR

AP2

Burner Ground

G

Com Port (COM 1)

on side of control

Thermal

Switch

T

T

Field Wiring

TT Terminals on top

of control

5

Page 6

Installation

Professional

Service Required

Incorrect installation or

misuse of this control could

result in severe personal

injury, death, or substantial

property damage from explosion or re.

Read and understand this manual. This

control must be installed, congured

and put into operation only by a qualied

individual or service agency that is:

• Licensed or certied to install and

provide technical service to gas

heating systems.

• Experienced with all applicable

codes, standards and ordinances.

• Responsible for the correct

installation and commissioning of

this equipment.

The installation must strictly comply

with all applicable codes and authorities

having jurisdiction and the latest

revision of the National Fire Protection

Association Standard or CSA Standard

for the installation of gas controls in the

appropriate gas appliance.

Regulation by these authorities

take precedence over the general

instructions provided in this

installation manual.

Fire or Explosion

Hazard

Can cause severe injury, death,

or property damage.

If You Smell Gas or Believe a Leak May

Exist

• Turn off the manual gas valve to

the appliance.

• Leave the building.

• Do not try to light the appliance.

• Do not touch any electrical switch.

• Do not use a telephone within the

building.

• Leave the building before calling

the appropriate gas organization

Explosion, Fire,

Scald, and Burn

Hazard

Can cause severe injury, death,

or property damage.

• The control can malfunction if it gets

wet, leading to an accumulation of

explosive gas vapors.

• Never install where water can ood,

drip or condense on the control.

• Never use a control that has been

wet - replace it.

--------------------------------------

All heating appliances must have HIGH

LIMIT protection to interrupt electrical

power and shutdown the burner if

operating or safety controls fail and

cause a runaway condition.

• Follow the appliance

manufacturer’s wiring diagrams

and note all required safety

controls.

• Typical safety controls include

high temperature or pressure

limits, low water cutoffs, pressure

relief valves and blocked ue

sensing switches.

• Verify all limit and safety controls

are installed and functioning

correctly, as specied by the

manufacturer, applicable

safety standards, codes and all

authorities having jurisdiction.

• Ensure that gas or gas vapors

have not accumulated in the

appliance before starting or

resetting the burner.

Electrical Shock

Hazard

Electrical shock can cause

severe personal injury or

death.

• Disconnect ALL electrical power to

the appliance/burner circuit before

installing or servicing this control.

• Provide ground wiring to the

appliance and burner.

• Perform wiring in compliance with

the National Electrical Code ANSI/

NFPA 70 (Canada CSA C22.1).

6

Page 7

No User

Serviceable Parts

• Do not open control.

• Do not attempt to replace any

components.

Mounting

The control should be mounted

in accordance with the burner

manufacturer’s or appliance

manufacturer’s instructions. If this is

a replacement application, mount the

control in the same location as the existing

control. The 7590 control is designed to

mount on a 4” x 4” junction box on the

burner. Avoid mounting locations where

water could drip on the control. Mounting

location must remain within the -40°F

(-40°C) to +175°F (79.4°C) operating

temperature range.

Mounting location should protect against

moisture, corrosive chemicals, excessive

dust or water. If any of the above

elements are present, control should be

mounted in a NEMA 4 rated enclosure.

Transformer Sizing

A transformer with a 24 volt secondary

is required to power the control and gas

valve. To calculate the minimum VA

transformer needed:

Voltage X Amperage = VA rating needed

Voltage = 24 Vac

Amps (0.2 amps + gas valve current draw)

Example:

0.2A (7590) + 0.5A (gas valve) = 0.7 A

0.7A X 24V = 16.8 VA or 20 VA transformer

Spark Gap

Follow appliance manufacturer’s or burner

manufacturer’s instructions for setting the

proper ignition electrode spark gap.

Wiring

Reference Figure 2 for wiring diagram.

Electrical Shock

Hazard

Electrical shock can cause

severe personal injury or

death.

Make sure all wiring is securely installed

on the control. Failure to secure the wiring

properly can lead to electrical shock.

To Prevent

Shock or

Damage to the Appliance or the

Control, Remove Power Before

Making Any Wiring Connections.

Do not short out gas valve or control

terminals during testing. Shorting could

cause damage to the thermostat or

control and could cause personal injury or

property damage.

Incorrect Wiring

Will Result in

Improper Control Operation

• Label all wires prior to

disconnection when servicing

controls

• GeniSys wiring order and colors

may not match the wire order and

colors of the appliance or other

manufacturers’ controls.

• The GeniSys Control should be

wired according to the appliance

manufacturer’s instructions.

DO NOT connect

any cell phone,

tablet or computer to the

communications port. Any device

connected to the port will be

damaged.

GeniSys Gas Power Burner Control Installation and Operation Manual

7

Page 8

Wiring must comply with all national and

local codes. Wiring must follow appliance

and burner manufacturer’s instructions.

Follow the appropriate hook up drawing

for the application in which the control is

being installed.

The ignition cable length

should be 3 feet or less,

or meet igniter manufacturer’s specied

length. Avoid placing the ignition cable in

direct contact with metal surfaces as

reduced spark voltage could result. Use

plastic or ceramic standoffs if necessary.

The control, electrode

and ame sensor must

have a common ground with the main

burner for proper operation. Failure to

provide proper ground for the control,

electrode and sensor may result in a failure

to sense the presence of ame. Failure to

sense ame will result in lockout or

continued cycling of the ignition sequence.

On models with Air

Pressure Switch

terminals (7590C, D), do not place a

jumper on the Air Pressure Switch

terminals. Placing a jumper on the

terminals will cause the control to lockout.

The Air Pressure Switch must be in place

for the control to operate properly

Frozen Plumbing

and Water

Damage Hazard

If the residence is unattended in

severely cold weather, burner primary

control safety lockout, heating system

component failures, power outages or

other electrical system failures could

result in frozen plumbing and water

damage in a matter of hours.

For protection, take preventive actions

such as having a security system installed

that operates during power outages,

senses low temperature and initiates an

effective action. Consult with your heating

contractor or a home security agency.

Operation

Fire or Explosion

Hazard

Can cause severe injury, death,

or property damage.

Replacement control must be congured

to match all timings, settings, and pre-

purge of the control being replaced.

• DO NOT USE A TRIAL FOR

IGNITION TIMING LONGER

THAN THE TIMING ON THE

ORIGINAL CONTROL. Severe

injury, death, or substantial

property damage could result from

a longer trial for ignition timing.

• MATCH THE LOCKOUT LOGIC

SEQUENCE TO THE ORIGINAL

CONTROL. If the original control

is a single trial for ignition or

allows three trials for ignition

before lockout, the replacement

control must match the number of

ignition trials.

Fire or Explosion

Hazard

Can cause severe injury, death,

or property damage.

USE 7590 GAS BURNER CONTROL ONLY

WITH BECKETT 7474001 GAS IGNITER.

Use with other igniters could result in

allowing gas ow when ame is not

present.

7590T

The 7590T may replace some existing burner

controls designed for 24 volt gas valves. The

7590T cannot be used to replace controls

designed for use with line voltage (120 Vac)

gas valves or controls with pressure switch

connections. Settings are locked after 4

hours of burner operation.

Status & Diagnostics

The 7590 module has 3 LED lights

8

Page 9

that help provide status and diagnostic

information. Reference Figure 1. The

three LEDs are Status, Flame, and MV

(main valve). The LEDs use 4 modes;

On, Off, Slow Flash, Fast Flash.

◦ The air pressure switch fails to close

after the motor/blower starts

If the control is programmed for 3 trials for

ignition, the control will lockout after the

3rd unsuccessful attempt.

◦ Flame (yellow) = Flame Sense, Flame

Strength

◦ MV (green) = Gas Valve On/Off

◦ Status/Reset (red) = Power, Lockout,

Pre-Purge, or Waiting

The tables on Normal LED Sequence,

LED Diagnostic Help and Troubleshooting

describe the information available through

the LEDs.

Flame Signal Strength

Indication

The 7590 uses ame rectication to

prove the presence of the burner ame.

For reliable operation, a strong ame

current is needed. The yellow Flame LED

provides a reliable indication of the ame

current strength.

When the burner is lit;

◦ A continuously on Flame LED indicates

a strong ame current.

◦ A slowly ashing Flame LED indicates

a marginal ame current strength.

Consider adjusting the electrode or

ame rod to improve the ame signal.

If the Flame LED is off, no ame is being

detected. Refer to the Troubleshooting

Section to resolve the issue.

Lockout

If the red Status/Reset button is ashing

rapidly (3 times per second), the control is

in lockout. All control outputs are turned off

and the control will not respond to a call for

heat. The control enters lockout when:

◦ The control fails to prove ame during

the trial for ignition period

◦ The control fails the relay check

◦ The air pressure switch is closed(stuck)

at the beginning of the ignition

sequence

Fire or Explosion

Hazard

Can cause severe injury, death,

or property damage.

• Be sure that gas or gas vapors

have not built up in or around

the appliance before starting or

resetting the burner.

• Turn thermostat or controller

off and wait 5 minutes before

attempting to start or reset burner.

Reset from Lockout

To reset the control from lockout, push the

red Status/Reset button when there is power

to the control. The button does not need

to be held down for the control to reset.

Following reset, the control will start the

ignition sequence. The standard control can

also be reset by removing power from the

control for 10 seconds, then restoring power.

Standard Control Models: 7590D or T

have volatile lockout and can be reset by

removing, then restoring power or pushing

the red Status/Reset button.

Non-Volatile Lockout Model: 7590C cannot

be reset by removing and restoring power.

Lockout must be reset by pushing the

Status/Reset button while the control is

powered.

Lockout with Retry (Optional)

Interruptions in the gas supply can prevent

the burner from lighting during the trial for

ignition and cause the control to lockout. If

the house or building is unoccupied for long

periods during cold weather, a lockout can

lead to low temperatures or freezing in the

structure.

GeniSys Gas Power Burner Control Installation and Operation Manual

9

Page 10

The 7590D and T models can be congured

to automatically allow an ignition retry

once every 1-8 hours (selectable using the

diagnostic tool or by factory conguration).

This conguration may help by allowing

periodic ignition retries until the gas supply

is restored. The ignition retries will only

happen if there is power to the burner and

there is a call for heat from the thermostat or

controller. The control will not allow retry if

the lockout was caused by a failed gas valve

relay check. This retrial feature may not be

available (factory locked) in some controls

including the 7590C version.

If the red Status/Reset button is ashing

slowly (1 time per second) and the motor/

blower is off, the control is waiting for retrial.

When the standard control (7590D and T) is

in the waiting period, it can only be reset by

removing power from the control.

Stop/Hold Button

Holding the Status/Reset button down for

more than 1 second will interrupt the ignition

sequence. The control will enter a hold

mode and all control functions will stop.

When the Status/Reset button is released,

the control will start the ignition sequence

over (including pre-purge).

supply system using a soap and water

solution or electronic detection.

Check Safety Timings

◦ Turn off gas supply to appliance.

◦ Restore power to the appliance.

◦ Turn the thermostat or controller up

to call for heat. Status LED should be

powered. Motor should start.

◦ Following pre-purge, the control will

energize the separate igniter, spark

should be present at the burner head.

MV LED should light and gas valve

should open.

◦ Spark should stay on for the entire

ignition timing.

◦ Spark should switch off at the end of the

ignition timing. Gas valve and MV LED

should turn off.

◦ If the control is programmed for single

trial for ignition, the Status LED will ash

rapidly to indicate lockout.

◦ For controls programmed for multiple

trials for ignition, allow the control to

continue retrials until lockout occurs.

Status LED will ash slowly during

waiting period between ignition cycles.

Safety Check

Before starting appliance, make sure that

all wiring is correct and secure. Repair or

replace any loose connections or damaged

wire. Use only wire rated for the application.

◦ Use UL approved wire of the gauge

and temperature rating specied by the

appliance or burner manufacturer for any

replacement wiring.

◦ Use UL approved solid conductor ignition

cable. Cable must meet the temperature

and voltage ratings specied by the

manufacturer. Use insulated boots or

terminals, if needed, to prevent sparking

to burner parts.

Perform a visual

inspection of all system

components including the gas supply

system. Check for any leaks in the gas

10

Check for Normal Operation

◦ Restore power to the appliance.

◦ If control is in lockout push Status/Reset

button.

◦ Turn manual gas cock to on position.

◦ Turn gas valve to on position using either

the manual gas knob or the electrical

switch on the valve.

◦ Turn the thermostat or controller up to

call for heat. Status LED should be

powered. Motor should start.

◦ Following pre-purge, the igniter will be

turned on and spark should be present

at the burner head. The MV LED should

turn on and the gas valve should open.

Motor continues running.

◦ When the burner is lit by spark, ignition

Page 11

will shut off and the main gas valve will

remain open.

◦ Multiple ignition trials may be needed to

establish gas ow on new installations or

if burner has been out of use. If control

locks out, push Status/Reset button to

restart ignition sequence.

◦ When the burner lights, the Flame LED

should be on continuously.

◦ Check burner for proper combustion per

burner or appliance instructions.

◦ Remove call for heat by turning the

thermostat or controller down.

◦ The MV LED, Flame LED and Status

LED should go off. The valve should

close. Motor should turn off.

◦ The burner should turn off quickly.

Simplied Sequence of Operation

(Reference Table 2)

◦ Call for heat, Status LED is turned on.

◦ Control performs safe-start check

◦ If safe-start fails, control locks out.

◦ If safe-start passes, control checks for

presence of ame.

◦ If ame is present, control will enter hold

state until ame is no longer present.

Flame LED and Status LED will ash

until ame is no longer present.

◦ If ame is not present, control will check

status of air proving switch. If switch is

closed, (indicating the pressure switch is

stuck) control will enter lockout.

◦ If the air proving switch is open, the

motor will start. Once the air proving

switch closes, pre-purge will begin

(lasting 1-240 seconds). Pre-purge or

ignition timings will not start until the air

proving switch closes.

◦ The air proving switch must close to

prove combustion air is present. If switch

fails to close during the specied period,

the control will enter lockout.

◦ When pre-purge is completed, the control

turns on the igniter and the gas valve.

MV LED will turn on.

◦ Spark continues until end of ignition

timing or until ame is proved.

◦ Once ame is proved, The Flame LED is

turned on and the spark is turned off. The

gas valve and MV LED remain energized.

◦ If ame is not proved, the control will

lockout or enter the inter-trial waiting

period. Status LED will ash rapidly for

lockout or slowly for inter-trial waiting.

◦ If multiple trial logic is used, the control

will complete the trials for ignition

◦ When ame is proved the control will

continue in run mode until the end of

the call for heat.

◦ When the call for heat is ended, the

gas valve, MV LED, Flame LED, Status

LED and motor turn off.

Table 2 - Operating Sequence

Call for Heat

LEDs

Timers &

Timings

Flame Check On On On On On

Motor/Blower Blower Starts On On On Off

Air Switch Check On Air Switch Closes On On On

Igniter On Off Off

Gas Valve On On Off

GeniSys Gas Power Burner Control Installation and Operation Manual

FLAME

MV STATUS

Status LED

turns on

Motor Start

FLAME

MV STATUS

Status LED

ON

Pre-purge

FLAME

MV STATUS

Status LED

Flashes

Pre-purge Timer

1 - 240 Seconds

Ignition

FLAME

MV STATUS

Status, MV

LEDs On

Ignition Trial

Timer

4 - 15 Seconds

Run

FLAME

MV STATUS

Status, MV,

Flame LEDs On

End Call for Heat

FLAME

MV STATUS

LEDs Off

11

Page 12

LED Key:

= OFF

= ON

= FLASHING

For below charts, “Troubleshooting” &

“Troubleshooting Sequence” sections.

Table 3 - Normal LED Sequence

LED LED STATE CONTROL STATE

All LEDs off No call for heat or no power to

FLAME

MV STATUS

appliance

Note: On a call for heat, after the motor/blower starts, the air proving switch must

close before pre-purge or trial for ignition timers can start. The Status LED may turn

on momentarily while waiting for the air pressure switch to close. If pre-purge is set

for 1 second, once the air pressure switch closes, the control will move directly to trial

for ignition without ashing the Status LED for pre-purge.

FLAME

MV STATUS

FLAME

MV STATUS

Status LED ashes slowly

(once per second) but only if

control is set up for pre-purge

of 2 seconds or more

Status and MV LEDs on

continuously

Pre-purge or waiting period

between trials for ignition,

motor should be running

Trial for Ignition, motor should

be running and ignition should

be sparking

Status, Flame and MV LEDs

FLAME

MV STATUS

all on continuously

Table 4 - Additional LED Diagnostic Help

LED LED STATE CONTROL STATE

FLAME

MV STATUS

FLAME

MV STATUS

FLAME

MV STATUS

FLAME

MV STATUS

Status LED is ashing quickly,

3 times per second

Status,Flame and MV LEDs all

ashing

Status and Flame LEDs

ashing

Status and MV LEDs on

continuously, Flame LED

ashing

Main ame has been proved,

Control is in run mode and will

continue in run mode until call

for heat ends

Control is in lockout,

follow reset steps under

troubleshooting box “If the red

Status LED is ashing quickly”

Control failure - internal error,

try resetting the control once, if

problem reoccurs, replace the

control

Flame has been sensed when

ame should not be present,

follow troubleshooting under

“If the red Status and yellow

Flame LEDs are both ashing”

Flame signal is weak, follow

troubleshooting steps under “Is

the yellow Flame LED on?”

12

Page 13

Troubleshooting

Check LEDs First - Find the box on the left that matches the LED display you are seeing.

When all three LEDs are on continuously and the burner is lit, the system is

operating normally. The troubleshooting information is intended as a guide and may

not cover all possibilities in every application.

Table 5 - Troubleshooting

If the red Status LED is off:

▪ No power to the control.

▪ Check that the thermostat or controller is calling for heat.

▪ Check for power to the appliance.

▪ Check that limit is closed, check that the thermal (blocked vent)

switch is closed.

FLAME

MV STATUS

FLAME

MV STATUS

FLAME

MV STATUS

FLAME

MV STATUS

GeniSys Gas Power Burner Control Installation and Operation Manual

▪ Check for power to the system transformer.

▪ Check all wiring and secure all connections

▪ With the controller calling for heat, use a volt meter to measure 24

volts to the control. Place one probe on the right thermostat terminal

and the other probe on an unpainted portion of the burner. If no

voltage is measured, there is no power to the control. If 24 volts is

measured, move the rst probe from the right thermostat terminal

to the left thermostat terminal. If 24 volts is measured on the left

terminal and the red Status LED is off, replace the control. If no

voltage is measured on the left terminal, the thermal switch is open.

If only the red Status LED is on steadily:

▪ If motor is off—air pressure switch is closed (stuck), will wait for

switch to open.

▪ If motor is on—waiting for air pressure switch to close.

▪ If switch fails to open or close within a specied time, control will lockout.

▪ If switch opens and closes properly, control will move to pre-purge.

If the red Status LED is ashing quickly (3 times per sec.)

▪ Control is in lockout.

▪ Check the air pressure switch. If the air pressure switch is stuck in

the closed position or if the air pressure switch has been jumpered,

the control will lockout. The control will also lockout if the air pressure

switch fails to close when the motor/blower starts. Check to make

sure motor and blower are running during trial for ignition.

▪ Push the reset button or turn the thermostat or controller to off posi-

tion, wait 10 seconds then turn thermostat or controller to call for heat.

▪ If control is a non-volatile lockout model (7590C), the control can only

be reset using the reset button while the module is powered.

▪ Control should start ignition sequence. Motor/blower should be on.

▪ If burner does not light properly, follow the troubleshooting sequence.

If the red Status LED is ashing slowly (1 time per sec.)

▪ If motor/blower is running, control is in pre-purge or control is in a

waiting period between trials for ignition. If motor is not running, con-

trol is in soft lockout waiting to retry in 1-8 hours (reset control).

▪ The pre-purge period is 1-240 seconds, depending on setting.

▪ The control waiting period is 90 seconds to 5 minutes, depending on

setting.

▪ Either wait for pre-purge/waiting period to nish, OR

▪ Turn thermostat or controller off for 5 minutes to let accumulated gas

disperse, (LED should turn off) then turn thermostat or controller back

on to restart ignition sequence. Allow the control to go through pre-

purge, if any, and complete the trial for ignition sequence.

▪ If burner does not light properly, follow the troubleshooting sequence.

Table 5 continued on next page ►

13

Page 14

Table 5 (continued)

FLAME

MV STATUS

FLAME

MV STATUS

FLAME

MV STATUS

If the red Status LED and green MV LED are on continuously

▪ Call for heat is active.

▪ Control is powered.

▪ Igniter should be energized and sparking at the burner head, gas

valve should be open, motor should be running.

▪ If no sparking at the burner, follow the troubleshooting sequence.

If the Status and MV LEDs are on continuously and the Flame LED is

ashing

▪ The ame signal is weak

▪ Try to improve ame signal strength by following steps in the Trouble-

shooting Sequence under “Is the yellow Flame LED on?”

If the red Status and yellow Flame LEDs are both ashing

▪ The control is sensing ame when no ame should be present.

▪ The control enters a hold state, this is not a lockout.

▪ Control will remain in hold state until ame is no longer present.

▪ Check for ame in the burner.

▪ Check gas valve for leakage through the valve, replace valve if leak-

ing.

▪ Measure gas pressure to make sure pressure does not exceed valve

rating.

▪ Maximum gas pressure rating will often be listed on gas valve.

▪ If pressure is too high, adjust gas pressure at system regulator or

contact gas utility for help.

▪ High gas pressure can damage gas valves, if gas pressure exceeding

the rating of the valve is measured, the gas valve should be replaced.

FLAME

MV STATUS

▪ An internal error has been detected, try resetting the control once, if

the problem reoccurs, replace the control

If all the LEDs are on continuously and the burner is lit

If all the LEDs are ashing

FLAME

MV STATUS

▪ The control is in the run mode and is functioning properly.

Fire or Explosion

Hazard

Can cause severe injury, death,

or property damage.

Do not use a ame simulation device for

troubleshooting. Using a ame simulator

could by-pass system safety and allow

gas ow without ame. Use the Flame

LED to conrm the ame signal presence

and strength.

14

Page 15

Troubleshooting Sequence

Start with gas supply off and set thermostat or controller to call for heat.

Is the red

Status LED on?

YES

Pre-Purge

FLAME

MV STATUS

Pre-purge

complete?

1-240 sec.

YES

NO

NO

FLAME

MV STATUS

▪ No power to the module.

▪ Check to make sure thermostat or controller is calling for

heat and limit is closed.

▪ See instructions in troubleshooting box “If the red Status

LED is off”.

▪ If red Status LED is ashing slowly (1 time per second)

control is in pre-purge, motor should be running.

▪ If red Status LED is ashing quickly (3 times per second)

control is in lockout. Check the air pressure switch and

follow steps under troubleshooting box “If the red Status LED

is ashing quickly”.

▪ If red Status LED is on steadily, the control is waiting for the

air pressure switch. See instructions “If the red Status LED

is on steadily”.

▪ Status LED will ash approximately once per second during

pre-purge. Burner motor should be running.

▪ Wait for the control to complete the pre-purge timing.

▪ Note: Status LED does not ash for a 1 second pre-purge.

Trial for Ignition

FLAME

MV STATUS

Is the igniter

sparking during

NO

trial for ignition?

YES

Continued on

next page

GeniSys Gas Power Burner Control Installation and Operation Manual

▪ If both Status and MV LEDs are lit, control is in trial for

ignition, the igniter should be sparking and motor running.

▪ Check incoming line voltage to burner and control (120 V)

▪ With power off, check all wiring and connections to igniter.

▪ Check for correct spark gap on ignition electrode.

▪ Check ignition cable and ground wire for continuity, replace

if necessary.

▪ If ignition cable shows signs of melting or wear, replace and

reroute or shield cable.

▪ Check ceramic insulator around the electrode for cracking

or chipping, replace if needed.

▪ With power off, loosen 7590 from junction box, carefully

remove female quick connect terminals from Igniter and L2

male terminals. Restore power and start ignition sequence.

With the Status and MV LEDs on, carefully measure the

voltage between male Igniter and L2 terminals. Voltage

should be 120 Vac. If no voltage, replace control.

▪ If voltage between Igniter and L2 terminals is 120 volts and

all connections to igniter, electrode and ground are good,

replace igniter.

15

Page 16

Troubleshooting Sequence (continued)

► Turn the thermostat or controller off to end the call for heat.

► Turn on the gas supply.

► Turn the thermostat or controller back on to call for heat.

The ignition sequence will start over.

Repeat the steps above and proceed to lighting the burner.

FLAME

MV STATUS

Does the burner

light?

YES

NO

▪ If burner fails to light, control will lockout or enter waiting period.

▪ If gas was owing, wait for gas to disperse.

▪ Reset the control and repeat the ignition sequence.

▪ It may take more than one ignition cycle for gas to reach the

burner after being off. Reset the control if needed.

▪ Make sure the gas supply and all manual shutoffs are open.

▪ With the MV LED on, check for 24 volts at the gas valve.

▪ If 24 volts is not present at the valve, check any safety device in

gas valve wiring.

▪ Turn off power and check all wiring for continuity between the

control module and the gas valve. Turn power back on.

▪ If all wiring is good and still no voltage is present at the gas

valve with MV LED on, replace the control module.

▪ Check gas supply for any leaks using a soap and water solution

or electronic detection.

▪ Measure gas pressure for low input pressure. Pressure must

match gas input pressure listed on rating plate.

▪ Adjust gas pressure at system regulator if necessary or contact

gas utility for help.

▪ If there is gas pressure at the valve inlet and 24 volts is present

at the gas valve but no gas ow through the valve, replace the

gas valve

Continued on

next page

16

Page 17

Is the yellow

Flame LED on?

YES

NO

FLAME

MV STATUS

▪ Flame is not being proven, control will lockout or enter waiting period.

▪ With power off, check the electrical connections from the control to

the ame rod.

▪ Make sure all connections are clean and free of corrosion or build up.

▪ Check the continuity of the ground wire and the sense wire.

▪ The control, electrode and ame sensor must have a common ground

with the burner for proper operation.

▪ Check the ceramic on the ame rod for any chips or cracks, replace

if needed.

▪ Check the ame rod for build up and clean or replace if needed.

▪ Make sure the electrode and ame rod are covered with a steady,

stable ame, adjust ame rod or electrode if needed.

▪ Restore power, if ame is still not being proven, replace the control.

FLAME

MV STATUS

FLAME

MV STATUS

Note: If Flame LED is ashing slowly,

follow these same steps to improve

ame signal strength and reliability.

Normal run mode

FLAME

MV STATUS

▪ When the burner lights successfully, turn the thermostat or controller off to end the call for heat.

▪ The burner should go out quickly. All LEDs on the control should go out.

▪ If the burner remains lit for more than a few seconds, and the MV LED is out, replace the gas valve.

▪ If the LEDs remain lit, check the thermostat or controller for proper operation.

▪ Repeat the ignition sequence several times to make sure the system is operating properly.

GeniSys Gas Power Burner Control Installation and Operation Manual

17

Page 18

Page intentionally left blank

18

Page 19

Page intentionally left blank

GeniSys Gas Power Burner Control Installation and Operation Manual

19

Page 20

Limited Warranty Information

The R. W. BECKETT CORPORATION (“Beckett”) warrants to persons who

purchase its “Products” from Beckett for resale, or for incorporation into a

product for resale (“Customers”), that its equipment is free from defects in

material and workmanship. To qualify for warranty benets, products must be

installed by a qualied service agency in full compliance with all codes and

authorities having jurisdiction, and used within the tolerances of Beckett’s

dened product specications.

To review the complete warranty policy and duration of coverage for a specic

product, or obtain a written copy of warranty form 61545, please choose one of

the following options:

1. Visit our website at: www.beckettcorp.com/warranty

2. Email your request to: rwb-customer-service@beckettcorp.com

3. Write to: R. W. Beckett Corporation, P. O. Box 1289, Elyria, OH 44036

NOTE: Beckett is not responsible for any labor cost for removal and

replacement of equipment.

THIS WARRANTY IS LIMITED TO THE PRECISE TERMS SET FORTH

ABOVE, AND PROVIDES EXCLUSIVE REMEDIES EXPRESSLY IN LIEU

OF ALL OTHER REMEDIES, AND IN PARTICULAR THERE SHALL BE

EXCLUDED THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT WILL BECKETT

BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGE OF ANY

NATURE. Beckett neither assumes, nor authorizes any person to assume

for Beckett, any other liability or obligation in connection with the sale of this

equipment. Beckett’s liability and Customer’s exclusive remedy is limited to the

cost of the product.

Canada: R.W. Beckett Canada, Ltd. ● Unit #3, 430 Laird Road ● Guelph, Ontario N1G 3X7

USA: P.O. Box 1289 ● Elyria, OH 44036

www.beckettcorp.com

Form No. 61981-001 R01 , Printed in USA 01/14

Loading...

Loading...