Beckett 7556 User Manual

GeniSys

™

12V

PARTS & ACCESSORIES

Model 7556

Advanced 12 Vdc Burner Control

Description / Applications

The Beckett GeniSysTM 12V Advanced Burner Control is a

12 Vdc primary safety control for oil burners used in special

applications including, but not limited to, water heaters,

pressure washers, crack sealers and portable heaters having

fi ring rates less than 5.5 GPH. The GeniSys

with a suitable cad cell fl ame sensor to control the oil burner

motor, igniter, and optional solenoid valve. It has 12 volt enable

input compatible with mechanical and high limit switches. It

can provide interrupted or intermittent duty ignition, and it has

a 15 second lockout time on fl ame failure.

TM

12V is used

Features

Welded Relay Protection

◦

Limited Relight

◦

Valve-On Delay / Motor-Off Delay (Field

◦

programmable with Beckett’s Contractor

Tool)

◦

15 Second Lockout Time

◦

Interrupted Ignition

◦

Communication Port

◦

Lockout Alarm Output

Specifi cations

CAUTION

Application that is Not Within the Ratings

Listed in This Section. Improper Control

Operation May Result.

CAUTION

Electrical Ratings

Inputs:

Voltage: 12 Vdc nominal (11 to 16 Vdc)

◦

Current: 160 mA nominal (500 mA max at

◦

16 Vdc)*

Enable Load: 40mA at 12 Vdc

◦

Outputs:

Motor:

◦

◦

◦

◦

*

12 Vdc, 20 full load amps (FLA), 100

locked rotor amps (LRA)

Igniter: 12 Vdc, 5 A

Solenoid Valve: 12 Vdc, 2 A

Lockout Alarm: 12 Vdc, 2A

NOTICE

standby state. If the red control wire is left

powered without a battery charging system,

it can drain a standard 45 Amp hour

automotive battery in two to four weeks.

Do Not Use This

Control in an

Do Not Use This

Control Above 5.5 GPH

The 7556 control

draws 60-75mA in the

WARNING

Maintain Specifi ed

Voltage

A low or erratic power supply could result

in impaired burner operation, severe

delayed ignition or an explosion inside the

heat exchanger resulting in a burn and/or

asphyxiation hazard.

Beckett DC Burners require a continuous

•

supply of 11 to 16 volts DC (at 15 amps for

Model ADC or 25 amps for Model SDC),

measured at the burner during operation.

Consult other DC burner manufacturers’

•

specifi cations for the correct voltage range.

Special Note: The 7556 Control shuts the

•

burner down if the input voltage drops to

a sustained level of 10 volts DC, or below.

Operation resumes at a sustained input

voltage of 11 volts DC, or above.

An automotive or small engine charging

•

system that is capable of supplying the

required continuous voltage/amperage is

recommended with certain road equipment,

such as asphalt hot patchers and similar

applications.

This is especially true while maintaining

•

nominal load temperatures during idle periods.

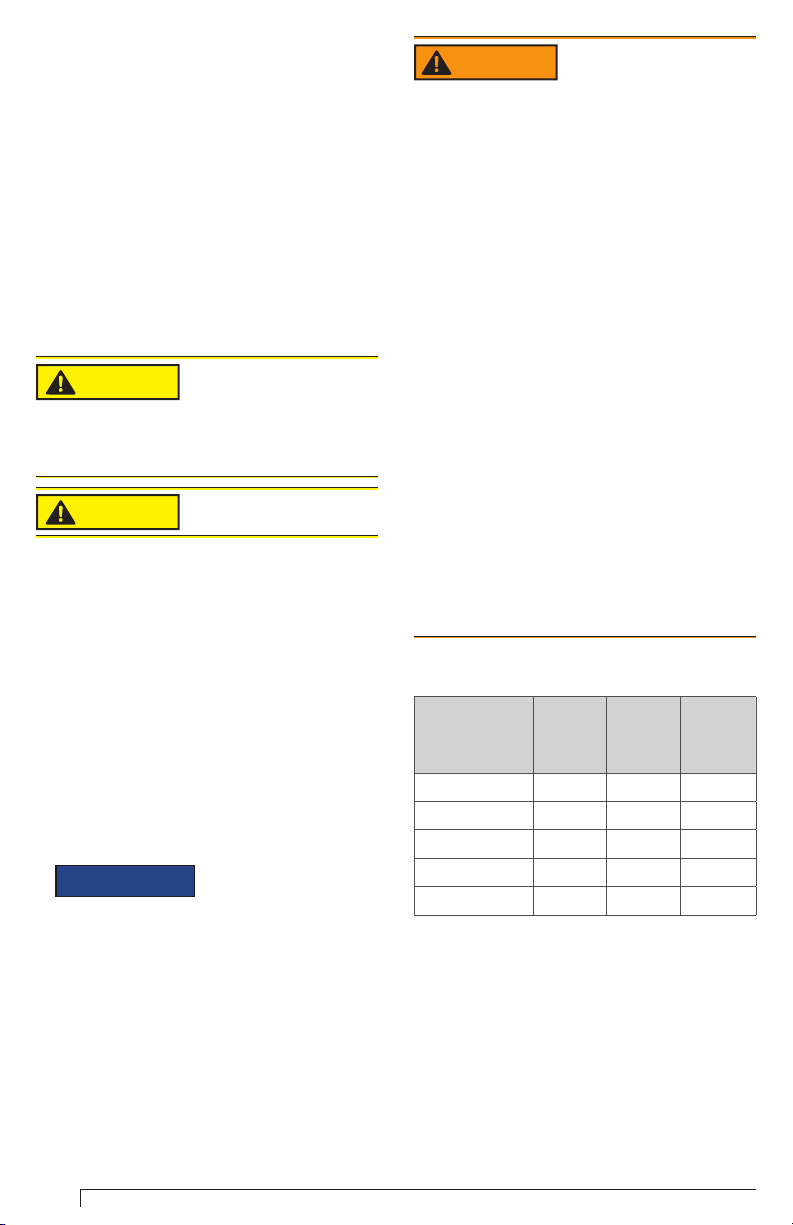

Table 1 - Model Guide

Beckett

GeniSys

12V Control

Part No.

7556A 0000

7556P 1530

7556P 151M

7556P 152M

7556P 158M

1 - Valve-on delay and motor-off delay timings on all models are

programmable with the Beckett Contractor Tool. Other factory

set timings are available. Contact Beckett for alternate timings.

Lockout

Time

1

15 sec 0 sec 0 sec

1

15 sec 15 sec 30 sec

1

15 sec 15 sec 1 min

1

15 sec 15 sec 2 min

1

15 sec 15 sec 8 min

Valve-on

delay

time

Motor-

off

delay

1

time

1

Environmental Ratings:

Storage and Operating Ambient

◦

Temperature:

+71°C)

Moisture: 5 to 95% RH, condensing

◦

-40°F to +160°F (-40°C to

2

Installation/Operation/Maintenance

WARNING

Incorrect installation or misuse of this control

could result in severe personal injury or death

from heavy smoke, explosion or fi re.

Please read and understand the manual supplied

with this control. This control must be installed,

adjusted and put into operation only by a qualifi ed

individual or service agency that is:

•

Licensed or certifi ed to install and provide

technical service to oil heating systems.

•

Experienced with all applicable codes,

standards and ordinances.

•

Responsible for the correct installation and

commission of this equipment.

Skilled in the adjustment of oil burners using

•

combustion test instruments.

The installation must strictly comply with all

applicable codes, authorities having jurisdiction and

the latest revision of the National Fire Protection

Association Standard for the Installation of OilBurning Equipment, NFPA 31 (or CSA-B139 and

CSA-B140 in Canada) for stationary equipment.

Regulation by these authorities take precedence

over the general instructions provided in this

installation manual.

Professional

Service Required.

WARNING

All heating equipment must have

HIGH LIMIT controls to protect

against excessive temperature

interrupt electrical power and shutdown the

burner, if operating or safety controls fail and

cause a runaway condition.

•

•

•

•

•

and/or pressure. The control must

Follow the equipment manufacturer’s wiring

diagrams and note all required safety controls.

Typical safety controls include high

temperature or pressure limits, low water

cutoffs, pressure relief valves and blocked fl ue

sensing switches.

Verify all limit and safety controls are installed

and functioning correctly, as specifi ed by the

manufacturer, applicable safety standards,

codes and all authorities having jurisdiction.

Insure that the equipment is free of oil and oil

vapor before starting or resetting the burner.

Do not wire power directly to the burner

motor. Only wire the motor as shown in

Figure 2. If instant burner heat is required

by the application, purchase or program

a control with a long motor-off delay time,

which will ensure instant heat if a new call

for heat is received within the motor-off

delay time.

Explosion, Fire,

Scald, & Burn

Hazard

WARNING

Electrical shock can cause severe personal

injury or death.

•

Disconnect ALL electrical power to the

equipment/burner circuit before installing or

servicing this control.

Provide ground wiring to the equipment, burner

•

and metal control mounting box.

Perform all wiring in compliance with the

•

National Electrical Code ANSI/NFPA 70

(Canada CSA C22.1).

GeniSys 12V Control Installation and Operation Manual

Electrical Shock

Hazard

Mounting:

Mount the control on a 4” x 4” junction box

on the burner, or inside the equipment

cabinet. In replacement applications,

mount the new control in the same location

as the old control. In some replacement

applications, it may be necessary to rotate

the control on the 4” x 4” box for best fi t.

Mounting orientation: any orientation is

acceptable with the exception of up-side

down.

3

Loading...

Loading...