Becker Avionics RT320911, ATC3401 Users Manual

Transponder

ATC 3401

from Serial No. 2001 upwards

INSTALLATION AND OPERATION

Becker Flugfunkwerk GmbH

Baden Airpark Postfach 34 76549 Hügelsheim

Tel. 07229 / 3050 Fax 07229 / 305217

34-50-07 July 15/97

DV 63803.03

© 1997 by Becker Flugfunkwerk GmbH

All rights reserved

INSTALLATION AND OPERATION

ATC 3401

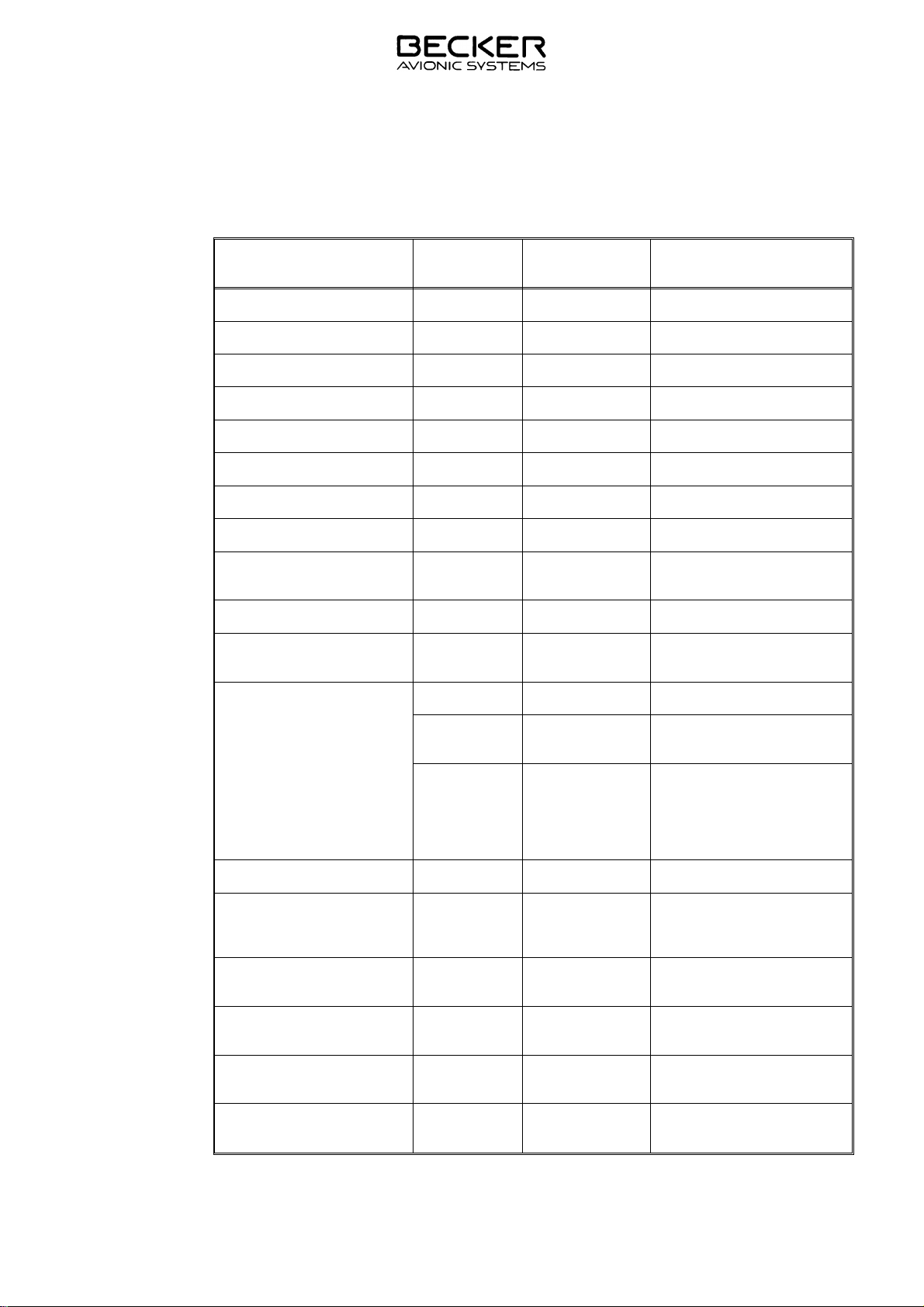

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE SUBJECT PAGE DATE

Title Page 1 July 15/97

List of Effective

Page 1 July 15/97

Table of Contents 1 July 15/97

Introduction 1 July 15/97

General

Description I-I July 15/97

1-1 July 15/97

1-2 July 15/97

1-3 July 15/97

1-4 July 15/97

1-5 July 15/97

1-6 July 15/97

Installation II-I July 15/97

2-1 July 15/97

2-2 July 15/97

2-3 July 15/97

2-4 July 15/97

2-5 July 15/97

2-6 July 15/97

2-7 July 15/97

2-8 July 15/97

2-9 July 15/97

2-10 July 15/97

2-11 July 15/97

2-12 July 15/97

2-13 July 15/97

2-14 July 15/97

Operation III-I July 15/97

3-1 July 15/97

3-2 July 15/97

3-3 July 15/97

3-4 July 15/97

3-5 July 15/97

3-6 July 15/97

3-7 July 15/97

3-8 Blank

LEP Seite 1

34-50-07 July 15/97

INSTALLATION AND OPERATION

ATC 3401

TABLE OF CONTENTS

Page

INTRODUCTION 1

GENERAL DESCRIPTION 1-1

INSTALLATION 2-1

OPERATION 3-1

TOC Page 1

34-50-07 July 15/97

INSTALLATION AND OPERATION

ATC 3401

INTRODUCTION

1. General

This component maintenance manual describes the BECKER transponder

ATC 3401 from serial No. 2001 upwards.

2. Manufacturing

The transponder ATC 3401 is manufactured and product supported by :

Becker Flugfunkwerk GmbH

Baden Airpark

P.O. Box 34

76549 Hügelsheim

Germany

Telephone: 0 72 29 - 305 - 0

Telex: 78 12 71

Telefax: 0 72 29 - 305 - 217

3. Layout of manual

The manual is divided into three sections. Section 1 contains the general description of the transponder and gives the technical data. Section 2 describes the installation instructions and Section 3 the operation of the unit.

INTRO Page 1

34-50-07 July 15/97

INSTALLATION AND OPERATION

ATC 3401

Table of contents

GENERAL DESCRIPTION Page

1. Application 1-1

2. General description 1-1

3. Technical data 1-2

4. System approvals 1-6

5. Available models 1-6

6. Accessories (not contained in the scope of delivery) 1-6

Page I-I

34-50-07 July 15/97

INSTALLATION AND OPERATION

ATC 3401

GENERAL DESCRIPTION

1. Application

The ATC 3401 transponder is the airborne component of the ATCRBS (Air Traffic

Control Radar Beacon System). It operates on the secondary radar principle and

enables the particular ground stations to locate, identify and track aircraft for the

purposes of air traffic control. The transponder can also be used to transmit

special information to the air traffic controllers (ATC) at the same time.

2. General description

A. The ATC 3401 transponder is constructed as a single module unit designed for

installation in the instrument panel or control panel of an aircraft. The dimensions

correspond to the ARINC standard for control panels and it is secured in place

by means of four DZUS fasteners.

B. All controls are located on the front panel of the unit. The unit connector for

connecting the aircraft wiring and the antenna socket are fitted on the back

of the transponder.

C. The control panel contains the electrical modules, processor board and display

board.

D. The electronic equipment of the transceiver consists of the encoder/power supply

module, the receiver/decoder module and the transmitter tube.

The receiver/decoder module can be swung out for servicing, thus making all

the components of the transponder readily accessible. The transmitter tube is

bolted to the side of the unit frame.

E. The transponder is ready to operate within 30 seconds of switch on. During this

period the display test is performed and the transmitter tube is warmed up and

stabilized.

F. The following modes are possible with the transponder :

(1) Standby mode (SBY)

(2) ON mode (mode A) where a code set on the transponder is transmitted

back in response to interrogation from a ground station.

(3) ALT mode (mode C) where in addition to the facility in mode A the

encoded aircraft altitude is also transmitted, provided a coding altimeter

is connected to the transponder.

(4) Indication of flight level (altitude/100) if a coding altimeter is connected

to the transponder.

Page 1-1

34-50-07 July 15/97

(5) Additional identification information whereby the ident button of the trans-

ponder is pressed on instructions from the air traffic controller. The identification pulse (SPI pulse) transmitted in this case enables immediate

identification of the aircraft on the controller’s radar screen, by means of

an additional marking on the object display.

(6) Test function by pressing the TEST push-button in which all digits flash

in the displays and the reply lamp comes on.

3. Technical data

A. General data

Supply voltage 10.0 V - 32.2 V DC

Current consumption 1.5 A at 14 V

(without panel lighting) 0.8 A at 28 V

- in standby mode 0.5 A at 14 V

INSTALLATION AND OPERATION

ATC 3401

0.3 A at 28 V

Panel lighting typ. 480 mA at 14 V

typ. 240 mA at 28 V

typ. 1.5 A at 5 V

Warm-up time approx. 30 s

Fuse protection 2 A medium-blow

Operating temperature range - 20° C bis + 55° C (short-time + 70° C)

Altitude max. 35 000 ft.

EUROCAE/RTCA ED-14C/

DO-160C Cat. A1 C1

(no altitude limitation in pressurized

aircrafts)

Vibration EUROCAE/RTCA ED-14C/

DO-160C Cat. M+N

(rigid mounted in all aircrafts

without limitations)

Environmental conditions EUROCAE/RTCA ED-14C/DO-160C

Env. Cat. [A1C1]-BA(MN)XXXXXX

ZBABATAXXX

Weight 1.2 kg

Mechanical dimensions

Front panel 47.5 x 146 mm (H x W)

Case depth 217 mm above antenna socket

Test and assembly standards JTSO-C74c Class 1A

RTCA DO-150 Cat. B.

(cat. A conversion possible)

Page 1-2

34-50-07 July 15/97

INSTALLATION AND OPERATION

ATC 3401

B. Receiver data

Modes mode A

mode A+C

Receive frequency 1030 MHz ± 0.2 MHz

Sensitivity - 72 dBm (on 90 % reply rate)

Selectivity ± 15 MHz > 40 dB

± 25 MHz > 60 dB

Dynamic range ≥ 50 dB

Bandwidth ± 3 MHz < 3 dB

Side lobe suppression 3-pulse method

C. Transmitter data

Transmit frequency 1090 MHz ± 3 MHz

Power output 250 W min. at the antenna socket

Reply limitation effective as from 1200 replies/s

Output impedance 50 Ω

Reply code (mode A) ICAO coding system with 4096 reply

capacity

Altitude code (mode C) ICAO coding system in 100 ft steps

of -1000 to 62700 ft

Transmit pulse shape pulse width 0.45 µs ± 0.1 µs

rise time 0.05 - 0.1 µs

fall time 0.05 - 0.2 µs

D. Transponder antenna DMNI 70-1

Frequency range 950 MHz - 1220 MHz

Standing wave ratio (VSWR) < 1.5 : 1

Impedance 50 Ω

Type corresponds to λ / 4 rod

Polarization vertical

Type of radiation omnidirectional

Peak power output max. 2 KW

Weight approx. 113 g

34-50-07 July 15/97

Page 1-3

INSTALLATION AND OPERATION

ATC 3401

Connection C socket

DC resistance Idle (∞)

E. Transponder antenna ANT 2000

Frequency range 1030 MHz - 1090 MHz

Standing wave ratio (VSWR) < 1.25 : 1

Impedance 50 Ω

Type corresponds to λ / 4 rod

Polarization vertical

Radiation omnidirectional

Connection BNC socket

Insulation resistance min. 1000 MΩ

Peak power output max. 2 KW

Weight approx. 20 g

F. Transponder antenna CI 100-2

Frequency range 960 MHz - 1220 MHz

Standing wave ratio (VSWR)

at 1030 to 1090 MHz < 1.4 : 1

Standing wave ratio (VSWR)

at 960 MHz to 1220 MHz < 1.6 : 1

Impedance 50 Ω

Type corresponds to λ / 4-rod

Polarization vertical

Type of radiation omnidirectional

Nominally designed for 2.5 mach

Height 66 mm

Weight approx. 136 g

Connection TNC connector

Approvals TSO C66a, C74c, Class A, DO-138

Environmental condition Env. Cat. AASXXXXXXXXX

Page 1-4

34-50-07 July 15/97

INSTALLATION AND OPERATION

ATC 3401

G. Environmental conditions

The following performance standards under environmental test conditions

were verified in accordance with EUROCAE/RTCA ED-14C/DO-160C.

Environmental condition ED - 14C

DO - 160C

Temp. and altitude 4.0 A1C1

Low operating temp. 4.5.1 - 20° C

Low storage temp. - 55° C

High short-time temp. 4.5.2 + 70° C

High operating temp. 4.5.3 + 55° C

High storage temp. + 85° C

Altitude 4.6.1 35 000 ft.

Decompression 4.6.2

Pressure above

atmospheric

Temp. change 5.0 B

Humidity 6.0 A 48 hrs at 50° C and

Shock under: 7.0

4.6.3

Category Performance

≥ 95% air humidity

Operating conditions 7.2 6 G/11 ms for the

three axes

Crash landing

conditions

Vibration 8.0 MN

Magnetic influence 15.0 Z Deflection of a

Changed supply

voltage

Voltage pulses on the

supply voltage

Low frequency interference voltages

Induced magnetic and

electrical fields

7.3 Shock :

15 G/11 ms for the

three axes

Acceleration :

12 G

compass by 1° at a

distance of ≥ 30 cm

16.0 B

17.0 A

18.0 B

19.0 A

Page 1-5

34-50-07 July 15/97

Loading...

Loading...