BBK ABS730X Service Manual

SERVICE MANUAL

ABS730X

CONTENTS

1. SAFETY PRECAUTIONS

2. PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENSITIVE(ES)DEVICES

3. CONTROL BUTTON LOCATIONS AND EXPLANATIONS

4. PREVERTION OF STATIC ELECTRICITY DISCHARGE

5. ASSEMBLING AND DISASSEMBLING THE MECHANISM UNIT

5.1 OPTICAL PICKUP UNIT EXPLOSED VIEW AND PART LIST

5.2 MISCELLANEOUS

6. ELECTRICAL CONFIRMATION

6.1 VIDEO OUTPUT (LUMINANCE SIGNAL) CONFIRMATION

6.2 VIDEO OUTPUT(CHROMINANCE SIGNAL) CONFIRMATION

7. AML3298

1

1

2

3

4

5

5

6

6

7

8

8. SCHEMATIC & PCB WIRING DIAGRAM

9. SPARE PARTS LIST 35

11

1.1 GENERAL GUIDELINES

1. SAFETY PREAUTIONS

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO

ELECTROSTATICALLY SENSITIVE(ES)DEVICES

1

1. When servicing, observe the original lead dress. if a short circuit is found, replace all parts which have

been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barrier, insulation papers

shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed

to shock hazards.

Some semiconductor(solid state)devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive(ES)Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially

availabel discharging ESD wrist strap, which should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, alminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD).

notice (1885x323x2 tiff)

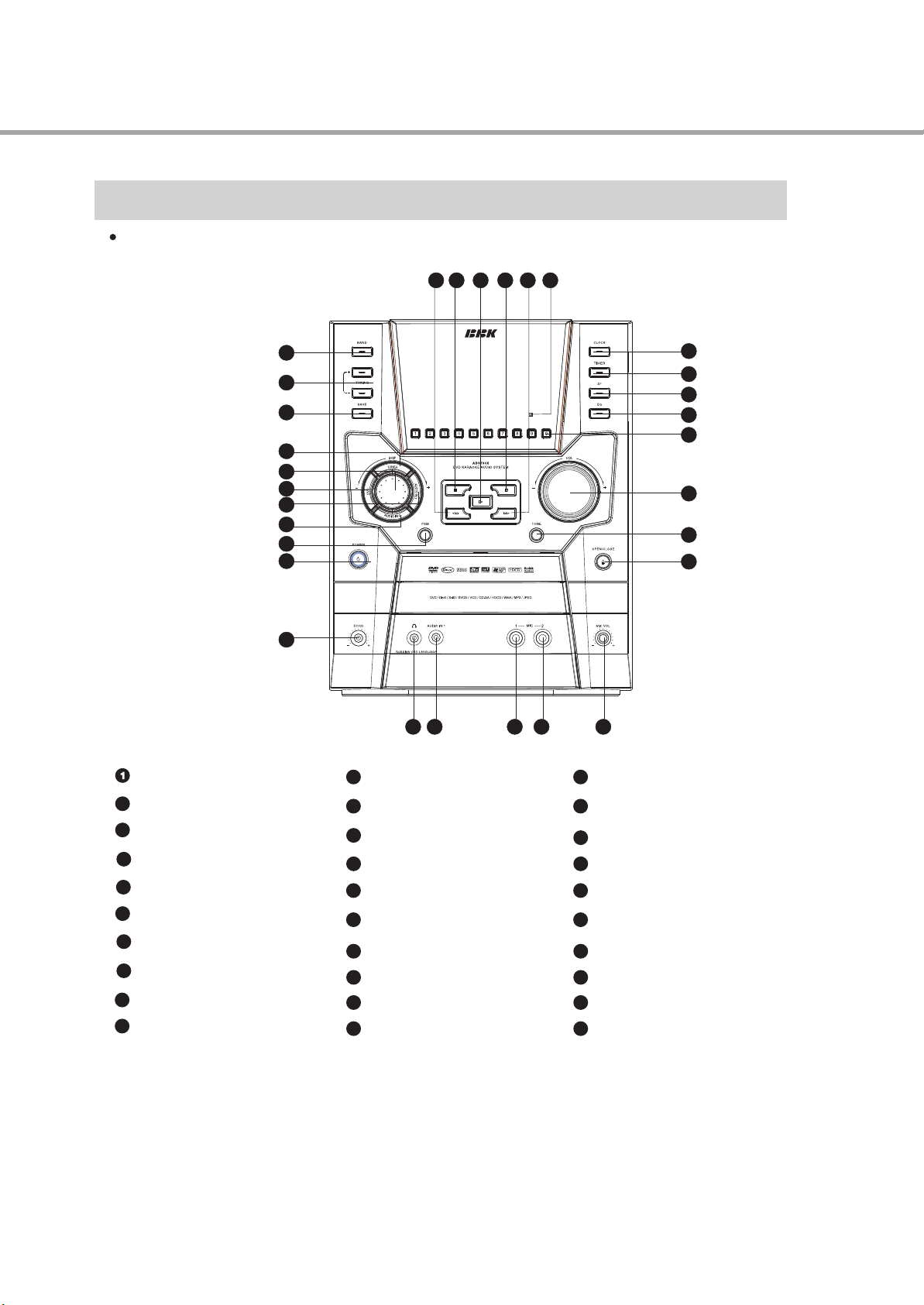

Control Button Locations and Explanations

2

Rear panel illustration

Front Panel Illustration 1

252627282930

BAND switch

2

TUNING+ -

3

SAVE button

4

TUNER button

5

SKIP knob

6

DVD button

7

AUDIO IN 1 button

8

AUDIO IN 2 button

9

PSM button

10

Power switch

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16

11 21

Echo button

12 22

Headphone jack

13

Audio in 1

14 24

MIC 1 jack

15 25

MIC 2 jack

16 26

MIC VOL knob

17 27

OPEN/CLOSE button

18 28

TONE button

19 29

VOL +/- button

20 30

Number buttons

EQ button

SF button

23

TIMER button

CLOCK button

IR sensor

FW

D button

STOP button

PLAY button

PAUSE button

REW button

24

23

22

21

20

19

18

17

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human

body. Use due caution to electrostatic breakdown when servicing and handling the laser diode.

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged

by static electricity in the working environment.Proceed servicing works under the working environment where

1. Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the

3. The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

3

4.PREVENTION OF STATIC ELECTRICITY DISCHARGE

4.1.Grounding for electrostatic breakdown prevention

grounding works is completed.

4.1.1. Worktable grounding

sheet.

4.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity from your body.

safety_3 (1577x409x2 tiff)

4.1.3.Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before

installation, the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure. (See this Technical Guide).

2. Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

4.2. Handling precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2. When replacing the optical pickup, install the flexible cable and cut is short land with a nipper. See the

optical pickup replacement procedure in this Technical Guide. Before replacing the traverse unit, remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

43

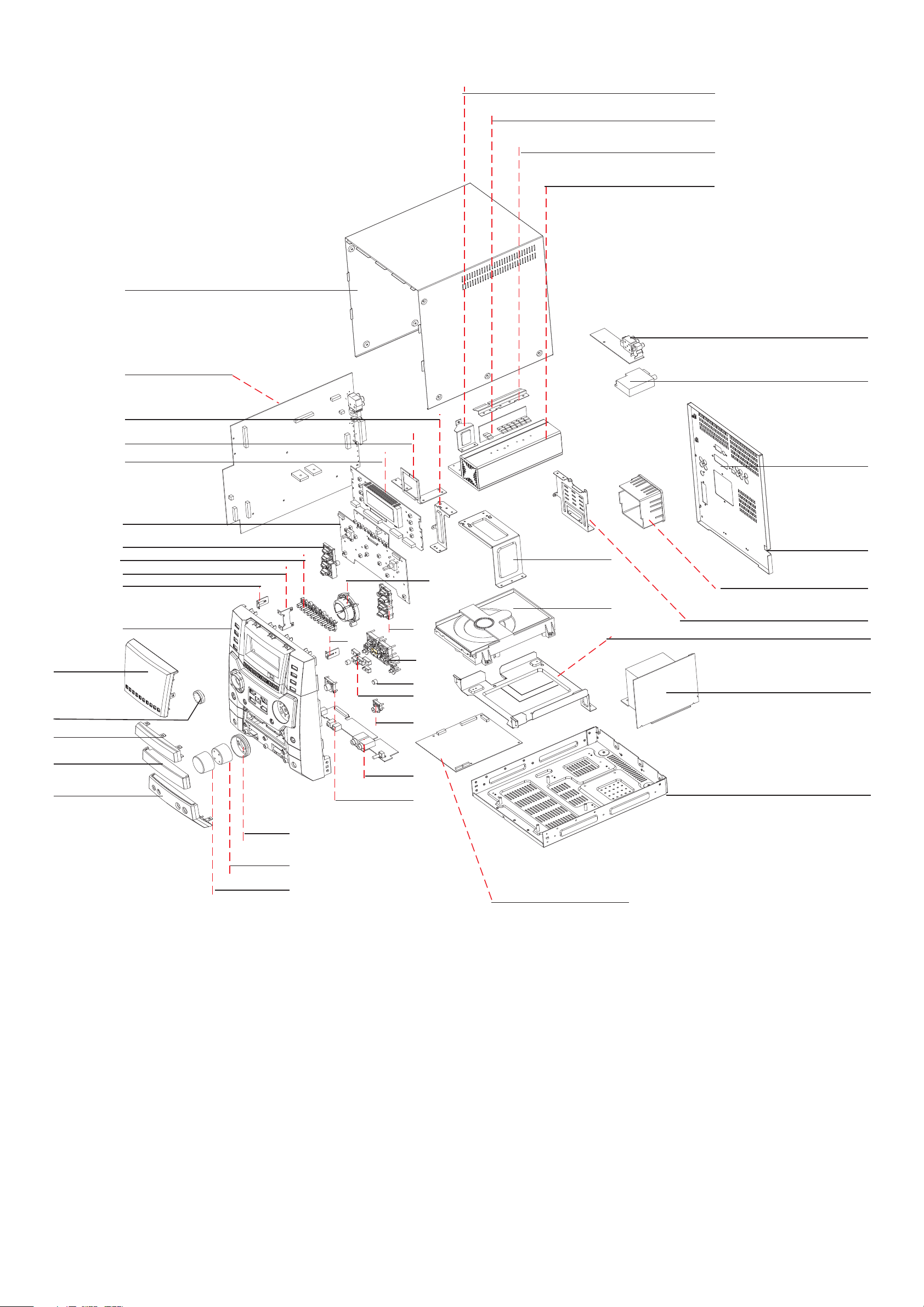

5. Assembling and disassembling the mechanism unit

4

42

41

40

1

39

12

13

14

2

3

4

5

6

7

8

9

10

11

10

26

25

24

23

22

27

38

37

36

28

35

29

34

33

32

15

16

21

20

19

18

17

5.1 Optical pickup unit explosed view and partlist

1 Upper cover

2 Power amplifier PCB

3 Left bracket of heat radiator

4 Backing plate

5 Display PCB

6 Front panel PCB

7 Left function button

8 Number button

9 PCB bracket

10 Bracket of upper casing

11 Surface casing

12 Display glass

13 Left function button

14 Upper decorative board

15 Door

16 Lower decorative board

17 Knob cover

18 Volume knob

19 Light conduct ring

20 Power button

21 MIC PCB

22 Open button

23 Cap of function button

24 Decorative button

25 5-direction function button

26 Right function knob

27 4-direction function button

28 Right bracket of heat radiator

29 Loader

30 Decode board

31 Bottom board

32 Power board

33 Loader bracket

34 Rear bracket of heat radiator

35 Cover for ventilation of heat radiator

36 Power cord

37 Rear board

38 Tuner

39 Output board

40 Heat radiator

41 IC press plate

42 Supplementary power board

43 Power amplifier PCB bracket

31

30

2 MISCELLANEOUS

5

5.

5.2.1 Protection of the LD(Laser diode)

Short the parts of LD circuit pattern by soldering.

5.2.2 Cautions on assembly and adjustment

Make sure that the workbenches,jigs,tips,tips of soldering irons and measuring instruments are

grounded,and that personnel wear wrist straps for ground.

Open the LD short lands quickly with a soldering iron after a circuit is connected.

Keep the power source of the pick-up protected from internal and external sources of electrical

noise.

Refrain from operation and storage in atmospheres containing corrosive gases (such as H2S,SO2,

NO2 and Cl2)or toxic gases or in locations containing substances(especially from the organic silicon,cyan,

formalin and phenol groups)which emit toxic gases.It is particularly important to ensure that none of the

above substances are present inside the unit.Otherwise,the motor may no longer run.

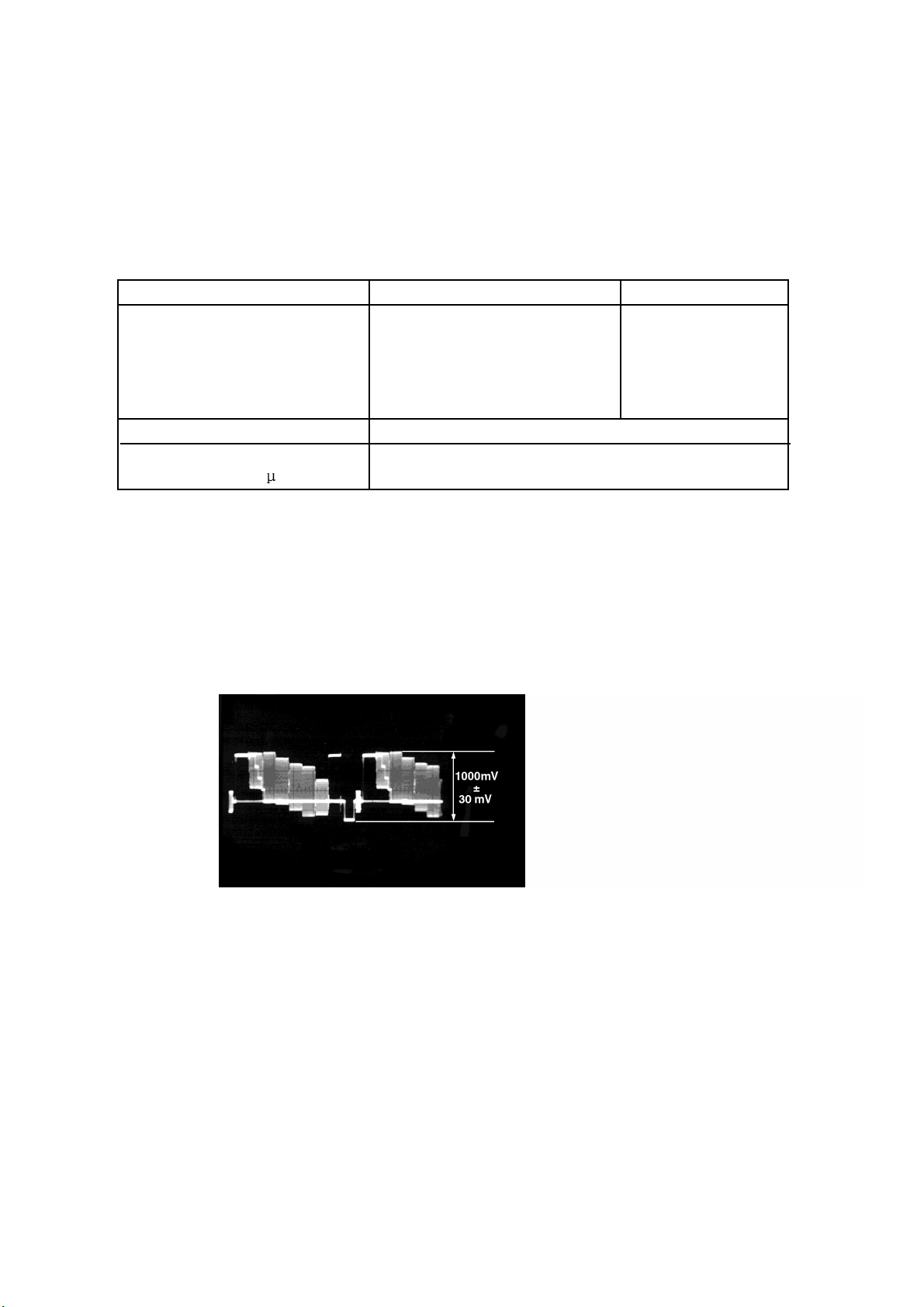

6.1. Video Output (Luminance Signal) Confirmation

6.Electrical Confirmation

6

DO this confirmation after replacing a P.C.B.

Measurement point

Video output terminal

Measuring equipment,tools

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

Confirmation value

1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

Do the confirmation after replacing P.C.B.

Screwdriver,Oscilloscope

6.2 Video Output(Chrominance Signal) Confirmation

7

Measurement point

Video output terminal

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

621mVp-p±30mV

DVDT-S15

or

DVDT-S01

Audio

Scaling

interface

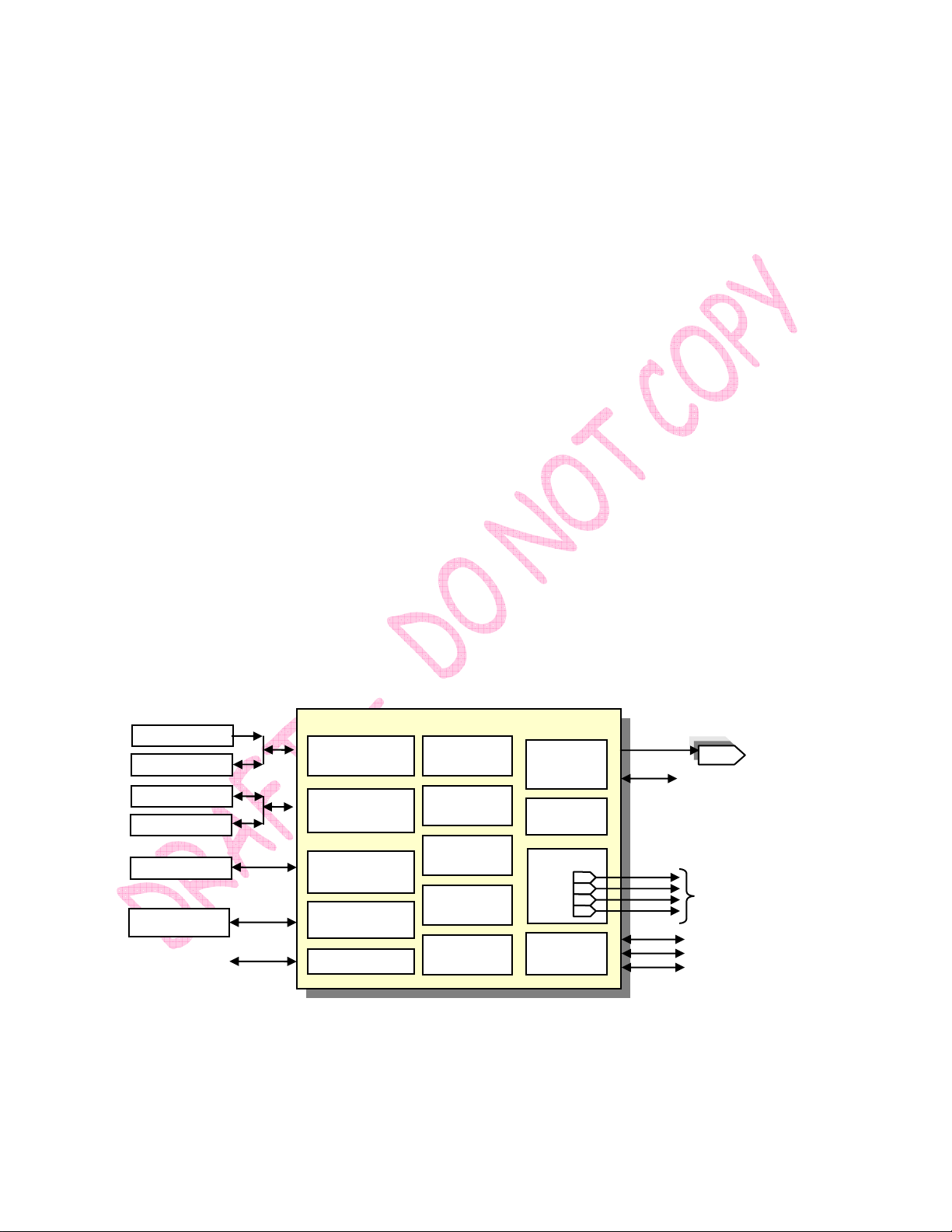

7. AML3298

1 Overview

The AML3298 A/V processor is a completely integrated system targeting all types of Audio/Video decoder

applications that provide connectivity to hard disk, digital camera, MP3 players and other external digital

consumer devices. The target market for AML3298 A/V processor is feature rich DVD players, audio receivers,

DVD/receiver combo players, digital media players, portable DVD players, and portable media players.

The AML3298 combines full function of MPEG-1, MPEG-2 and MPEG-4 decoding, numerous dedicated and

general-purpose peripherals, and a high speed 32-bit host CPU in a single device. The AML3298 has two built-in

AMRISC

The AML3298 also provides a high speed interface to external USB 1.1/2.0 chip for connectivity to popular USB

devices like hard disk, Flash memory, digital camera and MP3 players.

The embedded 32-bits host CPU handles system initialization, DVD navigation, and other system applications.

The AML3298 A/V processor provides a glueless interface to all external components: ATAPI loaders, USB

interface chip, audio DACs and memory. Numerous general-purpose I/O pins can be used to control the front

panel display and other miscellaneous tasks. The Flash interface allows the Flash memory to be shared with the

front-end chip to reduce system cost in mono-board designs. Together, the embedded host CPU and special

glueless interfaces reduce the total system cost for all A/V applications from any media.

The AML3298 A/V processor also integrates an NTSC/PAL TV encoder that supports S-Video, composite, YUV

component and RGB. The video encoder also supports high-quality de-interlaced progressive scan (480p/576p)

with full Macrovision support. Contrast enhancement, hue adjustment, video scaling, video interpolation, panscan, letter-box, and zoom are also supported. In addition, four built in video DACs complement the video

encoder further reducing system cost. In addition, the AML3288 devices can also provide CCIR601 and VGA

video output.

The integrated AMRISC

coded engine provides support for all existing audio formats and it also has enough flexibility to accommodate

new audio standards. Popular audio formats like Dolby AC-3 5.1, HDCD, MP-3 and WMA are supported. In

addition, SPDIF (IEC958) input and outputs are supported.

TM

RISC processors with special instructions to accommodate audio and video digital signal processing.

TM

RISC processor is designed to support advanced digital audio processing. The micro-

DVD-ROM

IDE HDD

FLASH

USB 1.1/2.0

SDRAM

JTAG

UART_RX

UART_TX

AML3298 A/V Processor

ATAPI / HDD

Flash Controller /

USB DMA Engine

DRAM Controller

32-bit CPU

UART

Amlogic, Inc.

Audio

AMRISC

Audio

Decoder

Audio/Video

Stream Praser

Video Decoder

Enhancement

Video

AMRISC

Figure 1 AML3298 Block Diagram

Audio

Interface

Video

& Conversion

Video

GPIO

ADATA

DACs

SPDIF (IEC958)

S-Video

CVBS

Component

Progressive

RGB

VD [7:0]

NGP[5:0]

IIS[7:0]

Company Confidential 8

2 Features

MPEG 1/2/4 Decoding

- MPEG-4 and Divx 3.x/4.x/5.x complaint

- MPEG-2 ML/MP conforming to ISO-13818

- MPEG-1 ML/MP conforming to ISO-11172

- On-chip CSS descrambler

- Flexible DRM engine for content management

- Compliant with DVD Specification 1.0 for read-only Disc

decoding

- Advanced error detection, concealment, and recovery

scheme

- Backward compatible VCD (1.0 - 2.0) decoding

- Super VCD decoding

- Built-in AMRISC

instruction extensions designed specifically for MPEG

decoding

TM

24-bit 133 MHz RISC CPU with special

Video

- Full MPEG-2 main profile @ main level 4:2:0 video

decoding

- Advanced pixel based de-interlacing algorithm

- On-Screen-Display (OSD) capable of supporting up to 256

prefixed colors or 16 programmable colors

- OSD Alpha-blending over video display

- Automatic scaling of sub-standard size DivX clips

- Video Zoom in for visual effects

- Built-in full screen NTSC to PAL scaling or vice-versa

- Built-in contrast enhancement and hue adjustment

- Built-in hardware for video interpolation and decimation

- Supports maximum zoom ratio up to 8X

Graphics

- Anti-flicker hardware for interlaced video

- Supports high speed block move for panning

- Built-in 2D graphics accelerator

- Dedicated graphics display controller separate from MPEG

engine for optimal video overlay performance

- Supports NTSC and PAL graphics modes with maximum

64K color

- Video overlay with graphics and vice-versa

- Unified MPEG and graphics memory architecture for

maximum flexibility and system cost savings

Built-in TV encoder

- Quad 10-bit video DACs

- Real-time Interlaced NTSC output 720x480 at 30 fps and

PAL 720x576 at 25 fps. Macrovision 7.1L1 anti-taping

process

- NTSC Progressive output (480p) at 60fps, PAL Progressive

(576p) at 50fps. Macrovision 1.03 anti-taping process

- Interlaced: S-Video, component, composite and SCART

output

- Close caption

Progressive RGB

-

Audio

- Built-in AMRISC

designed for Audio Processing

- Compliant with Dolby AC-3 5.1 channel decoding

- AC-3 two channel down-mixing

- SPDIF (IEC958) input and output

- Full MPEG audio layers I, II and III (MP3)

- Supports 8 channel linear PCM output

- DTS, HDCD, MP3 and WMA

TM

RISC CPU with extensions specifically

Built-in Host CPU

- 133Mhz 32-bit CPU dedicated for user applications

- Embedded debug interface using ICE/JTAG

- Able to utilize MPEG SDRAM as run time data storage for

minimal system cost

- Configurable for 16-bit wide SDRAM

- Support 8 or 16-bit FLASH

- FLASH memory can be shared with Front-End chips

Peripherals and Interface

- High speed (DMA) direct connection to third party USB chip

- Supports glueless interface to DVD DSP, CD DSP, and

DVD-ROM devices

- Direct connection to Audio DACs using I

- General Purpose I/O pins

- IDE with DMA transfer supporting up to 2 IDE devices such

as ATAPI DVD-ROM and IDE hard disk

- ISA interface

2

S

Miscellaneous

- 208-pin PQFP

- 1.8V operating voltage, 5V tolerant inputs, 3.3V output

Amlogic, Inc.

Company Confidential 9

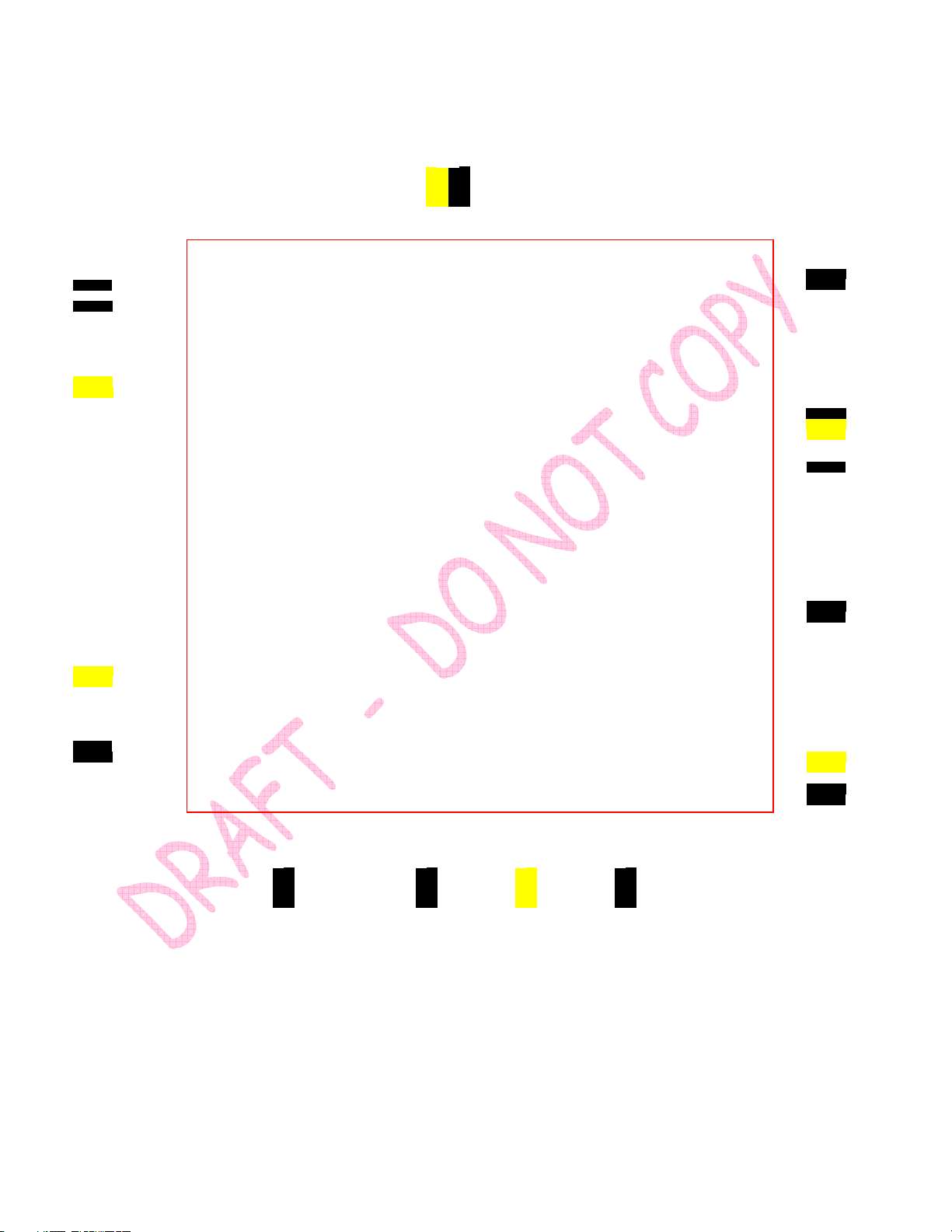

AML3298 A/V Connectivity Processor

208 207 206 205 204 203 202 201 200 199 198 197 196 195 194 193 192 191 190 189 188 187 186 185 184 183 182 181 180 179 178 177 176 175 174 173 172 171 170 169 168 167 166 165 164 163 162 161 160 159 158 157

5354555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899

100

101

102

103

04

AOCLK ADATA

ADATA

IEC

IIS

IIS

IIS

IIS

IIS

IIS

IIS

IIS

DD

VDD

VSS

VSS

VDD

DD

D

DMACK

DIOW

DIOR

CS

CS

DMARQ CSEL TDO RESET

TEST

TRST

TCK TDI T

AICLK

AICLK

SCLK

SCLK

DVDD

VSS

A

DVDD

DVSS

AVDD

AVSS

AVDD

AVSS

AVDD

AVSS

AVDD

AVSS

AVSS

AVDD

3 AML3298 – 208 Pin Package Diagram

ADATA_1

ADATA_0

ALRCLK

VSS_3.3V

AMCLK

VDD_3.3V

DD_13

DD_14

DD_15

DA_0

DA_1

DA_2

VSS_1.8V

VDD_1.8V

NGP_5

NGP_4

IVDD_DAC1 (1.8V)

VSS_DAC1 (1,8V)

IOX

_DAC1_X (3.3V)

_DAC1_X (3.3V)

IOB

_DAC1_B (3.3V)

-DAC1_B (3.3V)

IOG

-DAC1_G (3.3V)

-DAC1_G (3.3V)

IOR

_DAC1_R (3.3V)

_DAC1_R (3.3V)

COMP1

RSET1

VREF1_OUT

VREF1_IN

_DAC1 (3.3V)

_DAC1 (3.3V)

NGP_3

NGP_2

NGP_1

VDD_1.8V

VSS_1.8V

M2_CLKO

M2_DQM1

M2_BA1

M2_BA0

M2_SCS_N

VSS_3.3V

VDD_3.3V

UART_RX

UART_TX

NGP_0

VD_7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

_2

_3

958

_0

_1

_6 VD_5 VD_4 VD_3 VD_2 VD_1 VD_0

VD

V

V

V

V

_3.3

_1.8

_3.3

_4

_5

_6

_7

_12 DD_11 DD_10 DD_9 DD_8 DD_7 DD_6 DD_5 DD_4

_2

_3

_1.8

AML3298

V

V

_3.3

_3.3

VDD

VSS

N

N

0

_

_

_5

_9

_11

A

A

A

RAS

CAS

2_

M

DQM

2_

2_

2_

2_

2_

M

M

M

M

M

V

N

V

_

_13

_8

_11

_12

_14

D

D

D

D

2_

2_

2_

2_

M

M

M

M

_10

_7

D

D

WE

2_

M

A

_3.3

_3.3

2_

2_

2_

VDD

M

M

M

VSS

_3

_9

D

2_

M

_2 DD_1 DD_0

D

_6

_8

A

A

2_

2_

M

M

N

_

N

V

_

ECS

_1.8

2_

VSS

M

T

1

1

N

N

_

N

_

0_

N

N

1_

_

N

N

_

_

XOUT

XIN

XOU

_

_

_

MS

0

XIN

_

0

1

PLL

PLL

PLL

PLL

_

_

_

_

PLL

_

VDD

AVSS_PLL0

156

AVDD_PLL0

155

VDD_3.3V

154

VSS_3.3V

153

M1_A_3

152

M1_A_2

151

M1_A_1

150

M1_A_0

149

M1_A_10

148

M1_A_11

147

M1_BA1

146

M1_BA0

145

M1_SCS_N

144

M1_RAS_N

143

M1_CAS_N

142

VDD_3.3V

141

VDD_1.8V

140

VSS_1.8V

139

DIORDY

138

IRQ14

137

VSS_3.3V

136

M2_D_15

135

M2_D_1

134

M2_D_2

133

M2_D_3

132

M2_D_4

131

M2_D_5

130

M2_D_6

129

M2_D_0

128

M2_D_7

127

M2_A_0

126

M2_A_1

125

M2_A_10

124

VDD_3.3V

123

VSS_3.3V

122

M2_A_2

121

M2_A_3

120

M2_A_4

119

M2_EOE_N

118

M1_EOE_N

117

M1_WE_N

116

M1_A_4

115

M1_A_5

114

M1_A_6

113

M1_A_7

112

M1_A_8

111

M1_A_9

110

VDD_1.8V

109

VSS_1.8V

108

M1_CLKO

107

VDD_3.3V

106

VSS_3.3V

105

1

N

V

_

_0

_1

_2

ECS

D

D

D

_1.8

1_

1_

1_

1_

VDD

M

M

M

M

V

V

_6

_7

_15

_14

_13

_3

_4

_5

D

1_

M

D

D

D

_3.3

_3.3

1_

1_

1_

VDD

M

VSS

M

M

_12

D

D

D

D

D

1_

1_

1_

1_

1_

M

M

M

M

M

1

_11

D

1_

M

0

_10

_9

_8

D

D

D

DQM

DQM

1_

1_

1_

1_

1_

M

M

M

M

M

Amlogic, Inc.

Company Confidential 10

A

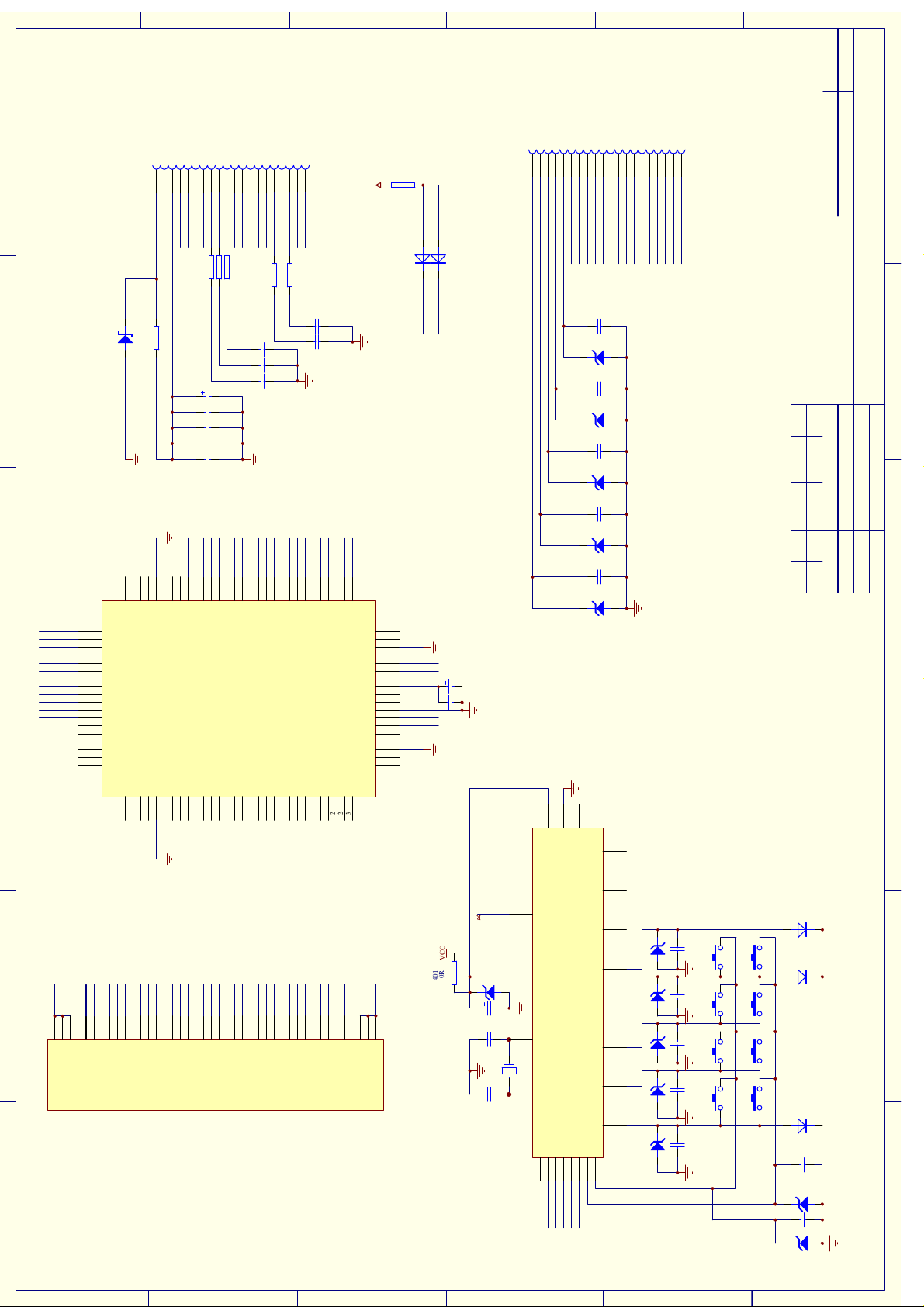

8. SCHEMATIC & PCB WIRING DIAGRAM SCHEMATIC & PCB WIRING DIAGRAM

FRONT SCHEMATIC DIAGRAM

11

B

C

D

E

F

1.0

6

XS403

XS19

19

IR

GND

+40V

FIL-

FIL+

VCC

R407

XS402

ZENER

10K

GND

100R

R405

VFD_CLK

100R

R406

VFD_STB

111214151613171820

100R

R404

VFD_DATA

GND

9107

VOL2-

VOL1-

5

TC402

100uF/100V

C408104

C407104

C406104

C405104

+40V+40V

SEG14

SEG15

SEG16

SEG17

SEG18

GRID1

GRID2

GRID3

GRID4

75

78

80

79

U402

PT6305

NC

NC

81

GRID5

GRID6

GRID7

GRID8

GRID9

GRID10

GRID11

GRID12

GRID13

GRID14

GRID15

GRID16

HVO24

82

HVO25

83

HVO26

84

HVO27

85

HVO28

86

HVO29

87

HVO30

88

HVO31

89

HVO32

90

HVO33

91

HVO34

92

HVO35

93

HVO36

94

HVO37

95

HVO38

96

HVO39

97

HVO40

98

HVO41

99

NC

100

NC1VDD22NC3NC4VSS25NC6NC7HOV428HOV439HOV4410HOV4511HOV4612HOV4713HOV4814NC15NC16NC17NC18NC19NC20NC21NC22NC23NC24NC25NC26NC27NC28NC29NC

VDD2

73

76

NC74NC

NC77NC

VSS2

CON4

VOL1+

VOL2+

R403100R

CON1

C402101

C401101

C423101

SEG10

SEG11

SEG12

SEG13

HVO1060HVO1161HVO1262HVO1363HVO1464HVO1565HVO1666HVO1767HVO1868HVO1969HVO2070HVO2171HVO2272HVO23

CON2

SEG9

59

2341568

CON3

R402100R

SEG8

GND

SEG7

C404

101

C403

101

SEG2

SEG3

SEG4

SEG5

SEG6

R408

4.7K

VCC

IR

1N4148

1N4148

VD404

VD403

VSDA-IR

IR#

SEG1

VDD2

HVO151HVO252HVO353HVO454HVO555HVO656HVO757HVO858HVO9

NC

NC

VSS2

NC

BK

PCB

LATB

VDD1

NC

NC

VSS1

CLKB

DI

NC

NC

VSS2

NC

NC

VDD2

30

+40V

50

49

48

47

46

45

CON2

44

CON1

TC403

VCC

VFD_STB

VFD_CLK

VFD_DATA

+40V

100uF/100V

C424

104

43

42

41

40

39

38

37

36

35

34

33

32

31

XS401

2341568

KX1

KX2

KX3

U401

SEL9VSS12CSS

9107

KX4

KX5K0K1K2K3K4VCC

22

111214151613171820

IR#

VOL1+

VOL2+

VOL2-

GND

47P

C415

ZD404

5.1V

47P

C414

ZD403

5.1V

47P

C413

ZD402

5.1V

47P

C412

ZD407

5.1V

47P

C416

ZD406

5.1V

HT6222

KEY7

14

XS20

19

第 1 张共 1 张 版次:

比例 质量 数量

BBK

VOL1-

CON3

CON4

GND

6

广东步步高电子工业有限公司AV厂

: 4S538SB

ABS538T

更改 数量 更改单号 签 名日期

主面板电路原理图

标准化

审 核

设 计

板号

5

批 准

REM

23 4

FIL+

GRID1

GRID2

GRID3

GRID4

GRID5

GRID6

GRID7

GRID8

42

38

F40F41F

VFD401

SEG18

GRID9

GRID10

GRID11

GRID12

GRID13

GRID14

GRID15

25

24

29

9G308G317G326G335G344G353G362G371G

P18

13G2612G2711G2810G

7

VSDA-IR

13

VCC

ZD401

3.3V

R401

100R

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

GRID16

21

16G2215G2314G

SEG15

12

P913P814P715P616P517P418P319P220P1

FIL-

SEG16

SEG17

TC401

3

F1F2F

P175P166P157P148P139P1210P1111P10

VFD-538

47uF/16V

8

C409

151

10

X401

455E

11

C410

151

KX023KX124KX21KX32KX43KX54KX65KX6

KX1

VDD

OSC0

OSC1

KX2

KEY6

15

/DREN

KEY5

16

C42247P

ZD413 5.1V

C421 47P

ZD412 5.1V

C420 47P

ZD411 5.1V

C419 47P

ZD410 5.1V

C418 47P

ZD409 5.1V

KX3

KX4

KX5

KEY4

17

KEY3

18

KEY2

19

KEY1

20

KEY0

21

6

KX7

KX6

1

A

B

C

D

E

VD405

SW1

SW1

SW1

SW1

1N4148

VD402

1N4148

VD401

1N4148

47P

C417

ZD408

5.1V

C41147P

K4

SW404

SW1

SW405

K3

SW403

SW1

SW408

K2

SW402

SW1

SW407

K1

SW401

SW1

SW406

K0

1234

ZD405

5.1V

F

Loading...

Loading...