Page 1

Service Manual

105953 Rev. C, 2003-02

Page 2

© 1998 Bayer Corporation. All rights reserved.

No part of this manual or the products it describes may be reproduced by

any means or in any form without prior consent in writing from

Bayer Corporation.

The Rapidpoint 400 system is for In Vitro Diagnostic Use.

Rapidpoint, Rapidlink, RapidQC, Quick, and CompleNet are trademarks

of Bayer Corporation.

Intel and Pentium are trademarks of Intel Corporation.

Northbridge is a trademark of Hyundai.

Panellink is a trademark of Silicon Image, Inc.

Sharp is a trademark of Sharp Corporation.

Sound Blaser is a trademark of Creative Technology Ltd.

Velcro is a trademark of Velcro Industries B.V.

Origin: UK

The information in this manual was correct at the time of printing.

However, Bayer Corporation continues to improve products and

reserves the right to change specifications, equipment, and

maintenance procedures at any time without notice.

If the system is used in a manner differently than specified by

Bayer Corporation, the protection provided by the equipment may be

impaired. See warning and hazard statements.

Page 3

Table of Contents

Preface 19

Conventions Used in this Manual 19

Understanding the Symbols 20

Understanding Result Symbols 22

Mechanical Descriptions 23

Overview 25

The Base Model 26

Measurement Cartridge 31

Measurement Cartridge Fluidics 33

Sample Entry 33

Sliding Valve 33

Tubing 35

Reagent System 35

Sensor Module 36

KCl Reservoir 40

Wash/Waste Cartridge 41

Cartridge Interface Module 43

AutomaticQC Cartridge 46

AutomaticQC Cartridge Fluidic Components 47

Rev. C 3

Page 4

AutomaticQC Cartridge Interface 49

Mechanical Components 51

Electronic Components 51

Pumps 52

Display 53

Display Module 53

Liquid Crystal Display 53

Touch Screen 53

Printer 54

Display Board 54

Display Support 54

CO-oximeter Components 55

CO-ox Measurement Components 56

Illumination Housing Assembly 57

Neon Board Assembly 57

Fiber Bundle Assembly 58

Sample Chamber Interface Assembly 58

Co-ox Sample Chamber 60

Polychromator Module 60

Electronic System Overview 63

Overview 67

Electronic System 68

4 Rev. C

Page 5

Contact PC Board 69

Digital Signals 69

Digital Input Signals 69

Digital Output Signals 69

Analog and Other Input Signals 70

Analog and Other Output Signals 72

Circuit Description 74

Amperometric Circuits 74

Potentiometric Circuits 75

Hematocrit/Fluid Detector Circuits 75

Display PC Board 77

Digital Signals 77

Digital Input Signals 77

Digital Output Signals 78

Analog Signals 79

Analog and Other Input Signals 79

Analog and Other Output Signals 80

Circuit Description 80

Microcontroller and Peripheral Circuitry 80

Touch Screen Switches 81

DC-DC Converter Circuit 81

LCD Backlight Inverter Circuit 81

Dualopto PC Board 82

Sensor Circuit 82

Main PC Board 83

Real-Time Processor (RTP) 83

RTP 68332 Processor Circuitry 83

RTP 68332 Address and Data Bus Circuitry 83

RTP EPROM and PSRAM Circuitry 84

Rev. C 5

Page 6

RTP Address Bus Decoder and Memory Controller

Complex Programmable Logic Device Circuitry

RTP Data Bus I/O Latch CPLD Circuitry 85

84

Data Acquisition System (DAS) Front End Circuitry 85

DAS Analog-to-Digital Converter Circuitry 86

DAS Fluid Detector Circuitry 86

RTP/UIP First In First Out (FIFO) Memory

Communications Circuitry

UIP Main Interconnect Board ISA Interface Circuitry 87

UIP Display Module, COM1, COM2/LPT1, and

Utility Circuitry

UIP COM3 Circuitry 87

UIP ISA Address Bus Decoder, Data Bus I/O

Latch CPLD, and Communications Circuitry

Control Micro-stepper Processor, and Sample

and Wash Pump Driver Circuitry

Control Heater DAC, Driver Circuitry, and Valve

Driver Circuitry

86

87

88

88

89

Power System Status Circuitry, Diagnostic LEDs,

and Switches

Control Automatic Quality Control (AQC) Valve

Stepper Circuitry

Power System Protection and Input Circuitry 90

89

90

UIP Main Interconnect Board ISA Interface 92

Digital Input Signals 92

Digital Output Signals 92

Digital Bi-directional Signals 93

UIP COM1 Interface 94

Digital Input Signals 94

Digital Output Signals 94

UIP COM2/LPT1 Interface 95

Digital Input Signals 95

Digital Output Signals 95

Flat Panel Interface 96

Digital Output Signals 96

6 Rev. C

Page 7

UIP Utility Interface 96

Digital Output Signals 96

Display Board Interface 97

Digital Input Signals 97

Digital Output Signals 97

Multiplexer Board Interface 98

Digital Input Signals 98

Digital Output Signals 98

Analog and Other Output Signals 99

Main Interconnect PC Board 100

ISA Connectors 100

Multiplexer PC Board 101

Digital Signals 102

Digital Input Signals 102

Digital Output Signals 102

Analog Signals 103

Analog and Other Input Signals 103

Analog and Other Output Signals 104

Circuit Descriptions 105

Amperometric Isolation Circuits 105

Digital Control Circuit 106

Temperature Circuits 106

Programmable Gain Amplifier Circuitry 106

User Interface Processor PC Board 107

Miscellaneous Functions 108

Keyboard Controller 108

Battery 108

Miscellaneous Function Connector 108

Peripheral Interfaces 109

Serial Ports 109

Rev. C 7

Page 8

Parallel Port 109

Floppy Disk Controller 109

Co-oximeter OMZ Heater PC Board 110

Analog Signals 111

Analog and Other Input Signals 111

Analog and Other Output Signals 111

System Diagrams and Cable Drawings 113

System Diagrams 115

Cable Drawings 130

Calibrations 141

Calibrating the System 143

Calibrating the Touch Screen 145

Emergency Calibration of the Touch Screen 147

Troubleshooting 149

Troubleshooting Problems 155

Button and Parameter Status 155

Symbols on Screens and Reports 162

No Results on Screens and Reports 164

8 Rev. C

Page 9

Unexpected Sodium and Potassium Results 166

Replacing the Measurement Cartridge 167

Replacing the AutomaticQC Cartridge 168

Bar Codes 169

Scanning Technique 172

Bar Code Quality 172

Resetting the Bar Code Scanner 172

Printer 173

Touch Screen 174

Communication 175

Viewing the Events Log 176

System Messages 177

AQC Cartridge Expired 177

AQC Cartridge Not Valid 177

AQC Connector is Open 177

AQC Pending 177

Additional Cal Required 177

Additional Wash Required 178

Analysis is turned off by a remote computer. 178

Bubbles in the Sample. The system cannot

complete analysis. Touch Continue to begin

the sequence to clear the system. Replace

the sample port when prompted. 178

Cal Overdue 179

Cal Not Done 179

Cal Pending 179

COox Chamber Temp Error 179

COox Sample Temp Out of Range 180

D2 Excessive Drift Qualifiers: pH, pO2,

pCO2, Na+, K+, Ca++, Cl-, Glu 181

D2 Excessive Drift: Hct 181

Rev. C 9

Page 10

D2 Excessive Drift: tHb 182

D3 Slope Error: pH, pO2, pCO2, Na+,

K+, Ca++, Cl-, Glu 184

D3 Slope Error: Hct 184

D3 Slope Error: tHb 185

D4 Offset Error: pH, pCO2, Na+, K+,

Ca++, Cl-, Hct 186

D4 Offset Error: Glu, pO2, 186

D21 Processing Error 188

D23 Reagent Error: 1-8 or 10-13 189

D23 Reagent Error: 9 190

D24 AQC Material Error 192

D33 Valve Error: 1 193

D33 Valve Error: 2 194

D35 Electronics Error: 1-13 196

D35 Electronics Error: 14 196

D38 Temp Error: 1 198

D38 Temp Error: 2–13 198

D39 Obstruction 200

D40 Wash Not Detected 201

D41 No AQC Material Detected 202

D60 Communications Error 204

D70 Optics Error: 2 205

D70 Optics Error: 3, 4, 7, 11 205

D70 Optics Error: 9, 12 206

D73 COox Chamber Position Error 209

D75 Lamp Failure 210

D76 COox Electronics Error: 211

D77 Coox Temperature Error 212

Door Error 214

Excessive Bubbles in COox Sample. 214

Incorrect M Cartridge 215

Installation error. Unable to complete

the installation. Try again. 215

10 Rev. C

Page 11

Insufficient Sample Volume. The system

cannot complete analysis. Touch

Continue

to begin the sequence to clear the system.

Replace the sample port when prompted. 216

M Cartridge Expired 216

M Cartridge Not Valid 216

No AQC Cartridge 217

No M Cartridge 217

No Paper in Printer 218

No W Cartridge 219

Out of Reporting Range 219

QC Lot Not Defined 219

QC Material Expired 219

Question Result: 219

Required QC Due 220

Sensors Unavailable For QC 220

SulfHb > 1.5% 220

System Error. Please wait. The system is

trying to recover from the error. 220

System Error. Turn the power switch off.

Wait 10 seconds then turn the switch on. 221

System requires operator attention. 221

Temp Not Ready 222

Temp Out of Range 223

Temp Warning 225

The language cannot be selected because

the current version is not installed. Install

the latest language version to select the language. 226

The system detected an obstruction and

cannot complete analysis. Touch

Continue

to begin the sequence to clear the obstruction.

Replace the sample port when prompted. 227

The system did not detect a sample. Remove

the sample device if present and touch

Continue.

Replace the sample port when prompted 227

This password is about to expire. Renew the

password before access to the system is denied. 228

Rev. C 11

Page 12

This password is expired. Renew the

password to access the system. 228

Uncorrected: 228

Unrecoverable System Error.

Call your service representative for assistance. 228

Unsuccessful Connection. Review the setup

values. Ensure that the cables are connected

and that the network is operating. 229

W Cartridge Expired 229

Diagnostics 230

Printing Diagnostic Reports 231

Testing the Printer 233

Definitions for a Printed Temperature Report 235

Testing the Measurement Valve in Diagnostics 235

Testing the AutomaticQC Cartridge Valve in

Diagnostics

237

Testing the Pumps 238

Using the Measurement Cartridge Simulator 240

Testing the Measurement Channels 240

Testing the Pump Flow 242

Testing the Measurement Cartridge

Valve Alignment

244

Using the AutomaticQC Cartridge Simulator 246

Testing the Valve Alignment 247

Testing the IDEE ROM and Cartridge

Connector Switch.

251

Lamp Calibration Test 252

Wavelength Calibration Test 253

Lamp On/Off Test 254

Sample Chamber Test 255

Shutting Down the System 256

12 Rev. C

Page 13

Recovering from a Power Loss 256

Illustrated Parts Lists 259

Main Assembly Illustrations 261

Main Assembly Parts List 278

Cartridge Interface Assembly Illustrations 281

Cartridge Interface Assembly Parts List 286

Power Module Assembly Illustrations 287

Power Module Assembly Parts List 293

CO-ox Module Components Illustrations 294

Replacing Components 299

Replacing the Sample Port 303

Replacing the Fuses 306

Replacing the CO-ox Lamp 308

Replacing the Cartridge Interface Assembly 309

Rev. C 13

Page 14

Replacing the Connector Block Assembly 313

Removing the AutomaticQC Cartridge 318

Replacing the AutomaticQC

Frame Assembly 320

Replacing the Diskette Drive Assembly 323

Replacing the Display/Printer Assembly 326

Replacing the Paper Cover 330

Replacing the Door Lock Module 333

Replacing the Hard Drive 334

Replacing the Power Supply Module 337

Replacing the Fan 339

Replacing the Power Entry Module

With Switch 340

Replacing the Rear Interconnect Board 343

Replacing the Pump Roller Cages 345

14 Rev. C

Page 15

Replacing the Pump Motors 349

Replacing the Wash/Waste Switch 354

Replacing the Fiber Bundle Assembly 356

Replacing the Neon Board Assembly 358

Replacing the Illumination

Housing Assembly 360

Replacing the Polychromator Module 362

Replacing the Sample Chamber

Interface Assembly 365

Replacing the Main Board 367

Replacing the UIP Board 370

Replacing the Main Interconnect Board 372

Removing the Rear Cover and Power

Module Assembly 375

Installing the Rear Cover, Cartridge Interface

Assembly, and Power Module Assembly 378

Rev. C 15

Page 16

Spare Parts 381

Spare Parts Listing 383

Biohazards and Warnings 387

Protecting Yourself from Biohazards 387

Protecting Yourself from Electrical Shock

Hazards 389

References 390

Installing and Relocating the

Rapidpoint 400 Series

Installing the System 391

Installing the AutomaticQC Cartridge 394

Relocating the System 396

Shipping or Storing the System 397

System 391

Connecting to a Computer System 401

Connecting to a Rapidlink System 401

Using a CompleNet Network Connection 401

Entering IP Addresses 402

Using DHCP 403

Using a Serial (RS-232) Connection 405

Connecting to a Laboratory Information System 407

16 Rev. C

Page 17

Connecting the Bar Code Scanner 409

Swapping Out a Rapidpoint 400 Series

System 411

Removing the Current Rapidpoint 400 Series

System

Installing the New Rapidpoint 400 Series System 414

Restore Setup and Correct the Date and Time 415

Rapidlink Setup 415

Setting Up RapidQC Complete in the

Rapidlink Database

Setting Up RapidQC Hct in the Rapidlink System 417

Finishing the Rapidpoint Setup 417

411

416

Rapidpoint 400 Series Cartridge Usage 419

Overview 419

Verifying Modes of Operation 420

Setting the Rapidpoint 400 Series System to

the FOR DEMONSTRATION ONLY Mode

What Can Go Wrong? 423

Setting the Rapidpoint 400 Series System to

the USER Mode

What Can Go Wrong? 425

Using Simulator Cartridges in the USER Mode 425

421

423

About Rapidpoint 400 Series Calibrations 427

Rev. C 17

Page 18

Overview 427

Calibration Types 427

Retrospective Calibration (Retrocal) 428

Calibration Schedule 429

Interruptible and Uninterruptible Calibrations 429

Cartridge Initialization (Init) 430

Initialization Calibration Timeline 431

Remote Access Setup to the

Rapidlink System 433

Installing and Configuring Remote Access

Setup (RAS) 434

Configuring RAS To Start Automatically 435

Adding Rapidpoint to Users and Groups 435

Adding Upload and Download Directories 436

Index 439

18 Rev. C

Page 19

Preface

This manual is to be used with the Bayer Diagnostics Rapidpoint® 400

series system. It provides the information and procedures necessary to

service the Rapidpoint 400 series system. Related documents include the

following:

• Rapidpoint 400 Series Operator’s Manual

• Rapidpoint 400 Series Reference Guide

• Rapidpoint 400 Series Interface Specification Manual

This manual is designed to meet the needs of Bayer Diagnostics Service

Representatives and biomedical engineers who perform installation,

replace parts, and troubleshoot the Rapidpoint 400 series system.

Conventions Used in this Manual

This manual uses the following text and symbol conventions.

Convention Description

Bold Bold type indicates a button on the screen. For example, if the word

“setup” appears as Setup, it refers to the button labeled Setup.

Buttons that you use frequently are represented on the screen with

a symbol instead of text. In this manual, these button names

appear in bold with the word button after them. For example, “the

Continue button” refers to the button in the lower right corner of the

screen that you touch to advance to the next screen.

You can refer to the Rapidpoint 400 Series Reference Guide on the

system or to Buttons in Section 5 of the Rapidpoint 400 Series

Operator’s Manual to identify the buttons that are represented by

symbols.

italic

Italic type refers to the title of a document or a section title in this

manual. For example, Mechanical Descriptions refers to the first

section of this manual.

Information appropriate for Rapidpoint 405 systems.

Biohazard statements alert you to potentially biohazardous

conditions.

(Continued)

Rev. C Preface 19

Page 20

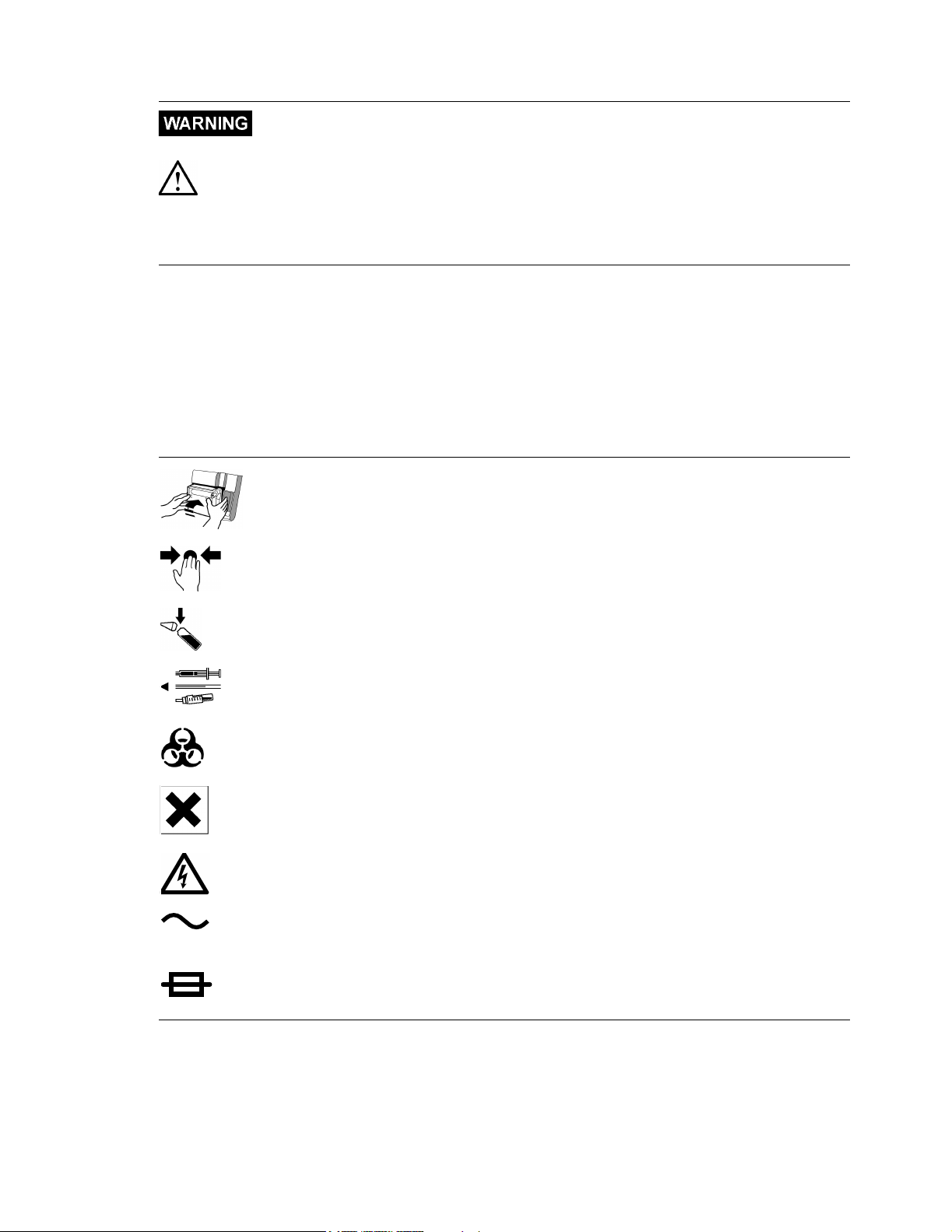

Convention Description

Warning statements provide information about a condition that

may cause personal injury.

Caution statements provide information about conditions that may

cause product damage or loss of data.

NOTE

Note statements alert you to important information that requires

your attention.

Understanding the Symbols

This section describes the symbols that may appear on the exterior of the

system. The symbols provide you with the location of certain components

and with warnings for proper operation.

Symbol Description

This symbol reminds you to push the measurement cartridge

firmly to lock it in place.

This symbol identifies the area on the wash/waste cartridge

where you push to install the cartridge correctly.

This symbol identifies the ampule breaker where you insert

ampules to break off the top.

This symbol indicates where you insert the sample device

(syringe, capillary, or ampule) to perform analysis.

This symbol cautions you about the risk of exposure to

biohazards.

This symbol indicates a hazard or danger is associated with the

product.

This symbol cautions you about the risk of exposure to

potential electrical hazards.

This symbol indicates that the input electricity is alternating

current.

This symbol alerts you to important information about the

fuses.

(Continued)

20 Rev. C

Page 21

Symbol Description

This symbol identifies that the system is type B equipment,

which provides a particular degree of protection against

electric shock.

I

Class 1 This symbol indicates that the system is class 1 type

This symbol indicates that the main power supply is on.

This symbol indicates that the main power supply is off.

equipment, which has basic insulation and additional safety

grounding precautions. Reference Underwriters Laboratories

Document for Medical Electrical Equipment, Part 1: General

Requirements for Safety, UL 2601-1.

This symbol indicates that the system is approved by UL as

meeting U.S. requirements for safety.

This symbol indicates that the system meets the requirements

of the European Union.

This symbol indicates that the system is approved by CSA as

meeting the U.S. and Canadian requirements for safety.

This symbol indicates the type of measurement cartridge that

can be installed on the system.

This symbol indicates the area to write the date the cartridge is

installed on the system, if required.

This symbol cautions you not to spray this area with cleaning

solutions or other fluids that may damage sensitive parts of the

system.

In vitro diagnostic device

Consult instructions for use

Temperature limitation (2°C - 8°C)

Contains sufficient for (n) tests (250 tests)

Catalog number

(Continued)

Rev. C Preface 21

Page 22

Symbol Description

Serial number

Batch code

Manufactured by

Authorized Representative

Understanding Result Symbols

The following symbols identify results that are out of range or that need

your attention. These symbols and results appear in red on the screen.

They also appear on the report. The ranges can appear on the printed

report, if this option is selected in Setup.

This symbol . . . Indicates that . . .

the result is above range.

the result is below range.

– – – – –

– – – – – the result is below the reporting range.

? the system has an atypical response when measuring this

u the hematocrit (Hct) result was not corrected for sodium (Na+)

the result is above the reporting range.

parameter. The system does not report results for other

parameters that use the affected parameter. For example, if ?

appears with the chloride (Cl-) result, the system does not

report a result for anion gap (AnGap).

When this symbol appears with the hematocrit (Hct) result, it

may indicate that the result was not corrected for sodium

(Na+) because sodium failed Required QC analysis.

Analyze the sample again, if possible.

because the sodium sensor is out of calibration or because

the sodium measurement is beyond the reporting range.

22 Rev. C

Page 23

Mechanical Descriptions

Overview 25

The Base Model 26

Measurement Cartridge 31

Measurement Cartridge Fluidics 33

Sample Entry 33

Sliding Valve 33

Tubing 35

Reagent System 35

Sensor Module 36

KCl Reservoir 40

Wash/Waste Cartridge 41

Cartridge Interface Module 43

AutomaticQC Cartridge 46

AutomaticQC Cartridge Fluidic Components 47

AutomaticQC Cartridge Interface 49

Mechanical Components 51

Electronic Components 51

Pumps 52

Display 53

Display Module 53

Rev. C Mechanical Descriptions 23

Page 24

Liquid Crystal Display 53

Touch Screen 53

Printer 54

Display Board 54

Display Support 54

CO-oximeter Components 55

CO-ox Measurement Components 56

Illumination Housing Assembly 57

Neon Board Assembly 57

Fiber Bundle Assembly 58

Sample Chamber Interface Assembly 58

Co-ox Sample Chamber 60

Polychromator Module 60

24 Rev. C

Page 25

Overview

This section describes the mechanical components of the Rapidpoint 400

series systems. Each component contains individual modules that perform

a series of related functions. The Rapidpoint 400 series systems consists

of the following components:

• Measurement cartridge

• Wash/waste cartridge

• AutomaticQC cartridge

•Pumps

• Display

• CO-oximeter

Rev. C Mechanical Descriptions 25

Page 26

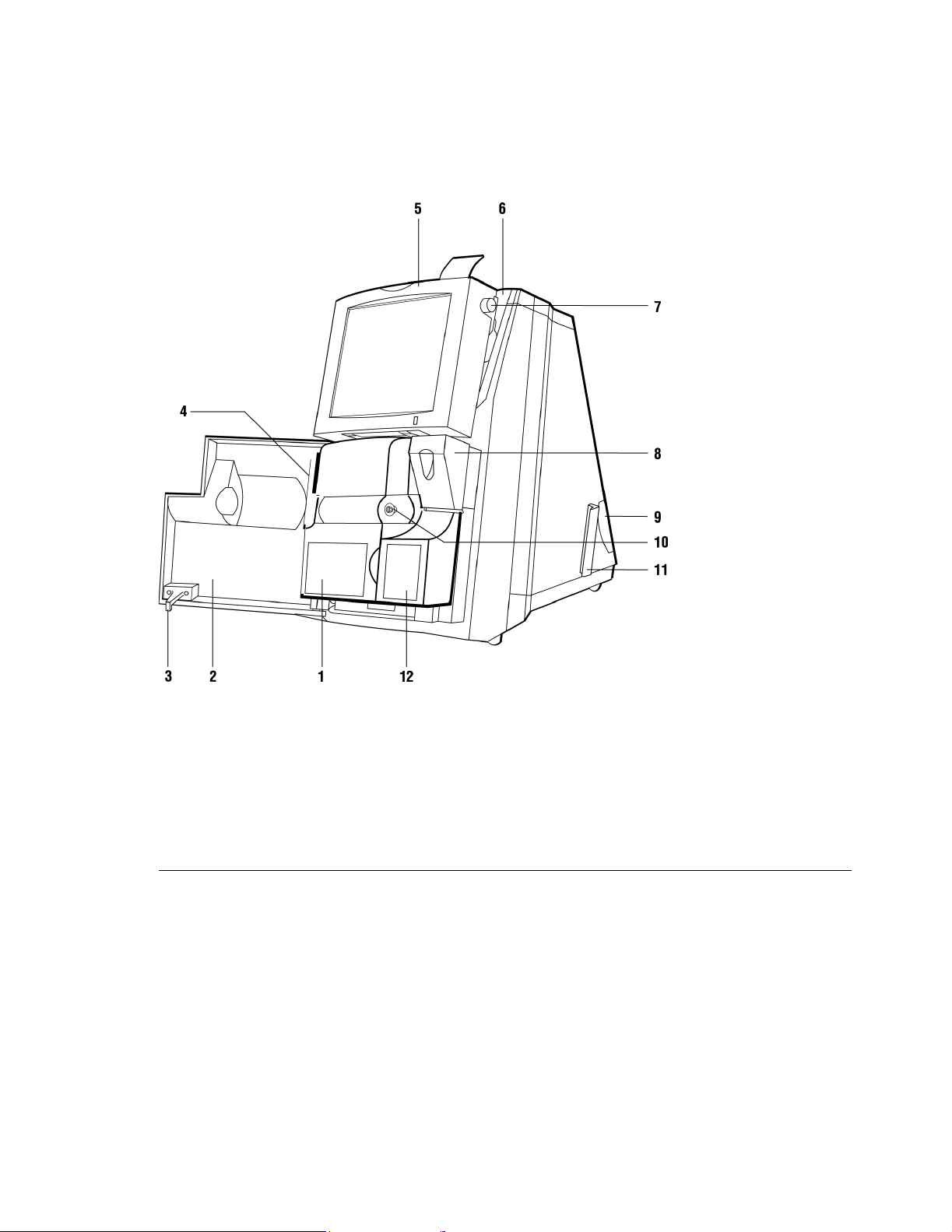

The Base Model

The base model refers to the 400 system model.

Rapidpoint 400 Series System (door open)

1 Measurement cartridge 7 Paper advance knob

2 Door 8 Ampule breaker

3 Door latch 9 Air filter carrier

4 Cartridge handle 10 Sample port

5 Display 11 Support bracket for AutomaticQC cartridge

6 Printer 12 Wash/waste cartridge

26 Rev. C

Page 27

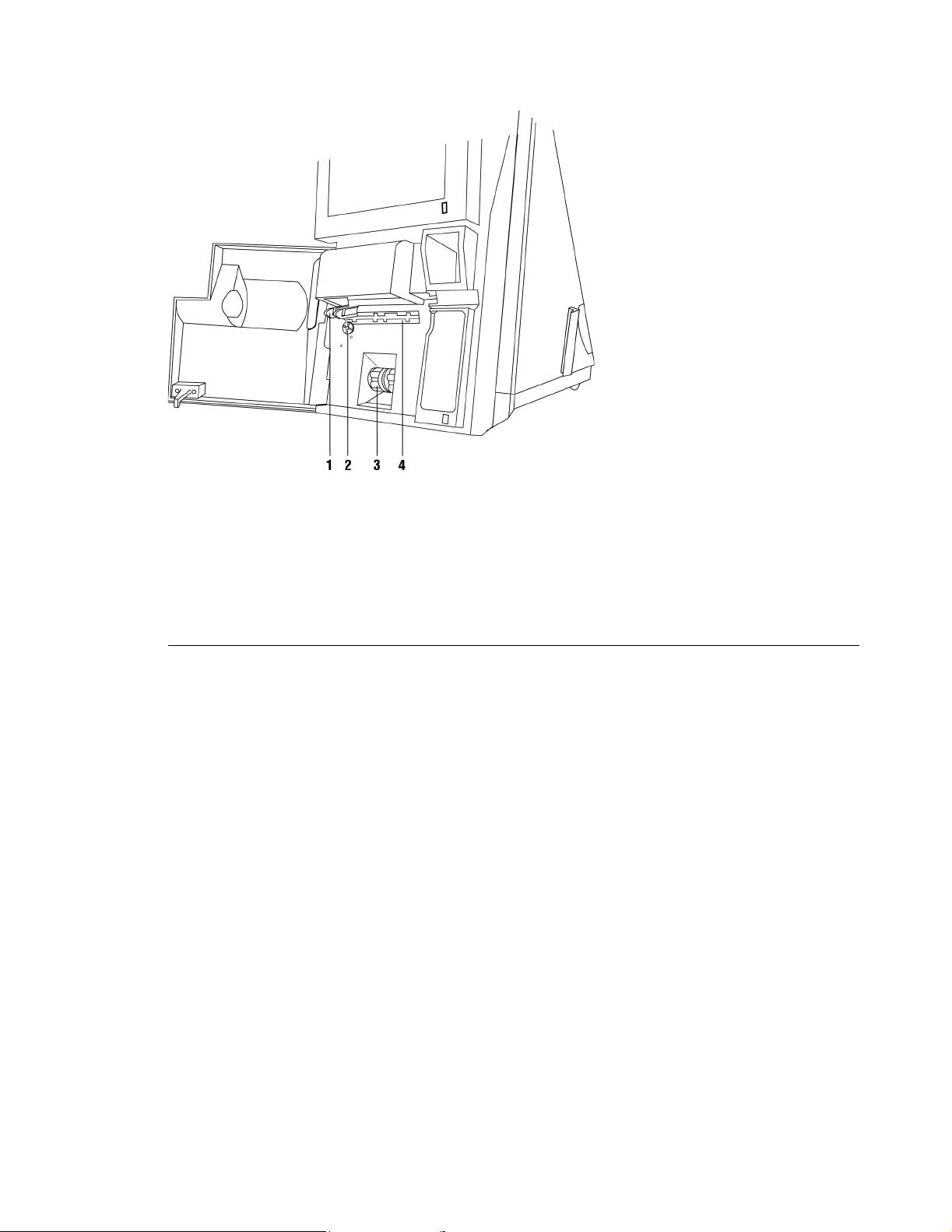

Rapidpoint 405 System (door open)

1 Optic Head Assembly: Delivers and collects light from the CO-ox sample

chamber.

2 Drive Wheel: Opens and closes the CO-ox sample chamber.

3Pumps: Move samples and reagents through the measurement and wash/waste

cartridges.

4 Valve Actuator: Moves the valve that controls flow of the sample and reagents.

Rev. C Mechanical Descriptions 27

Page 28

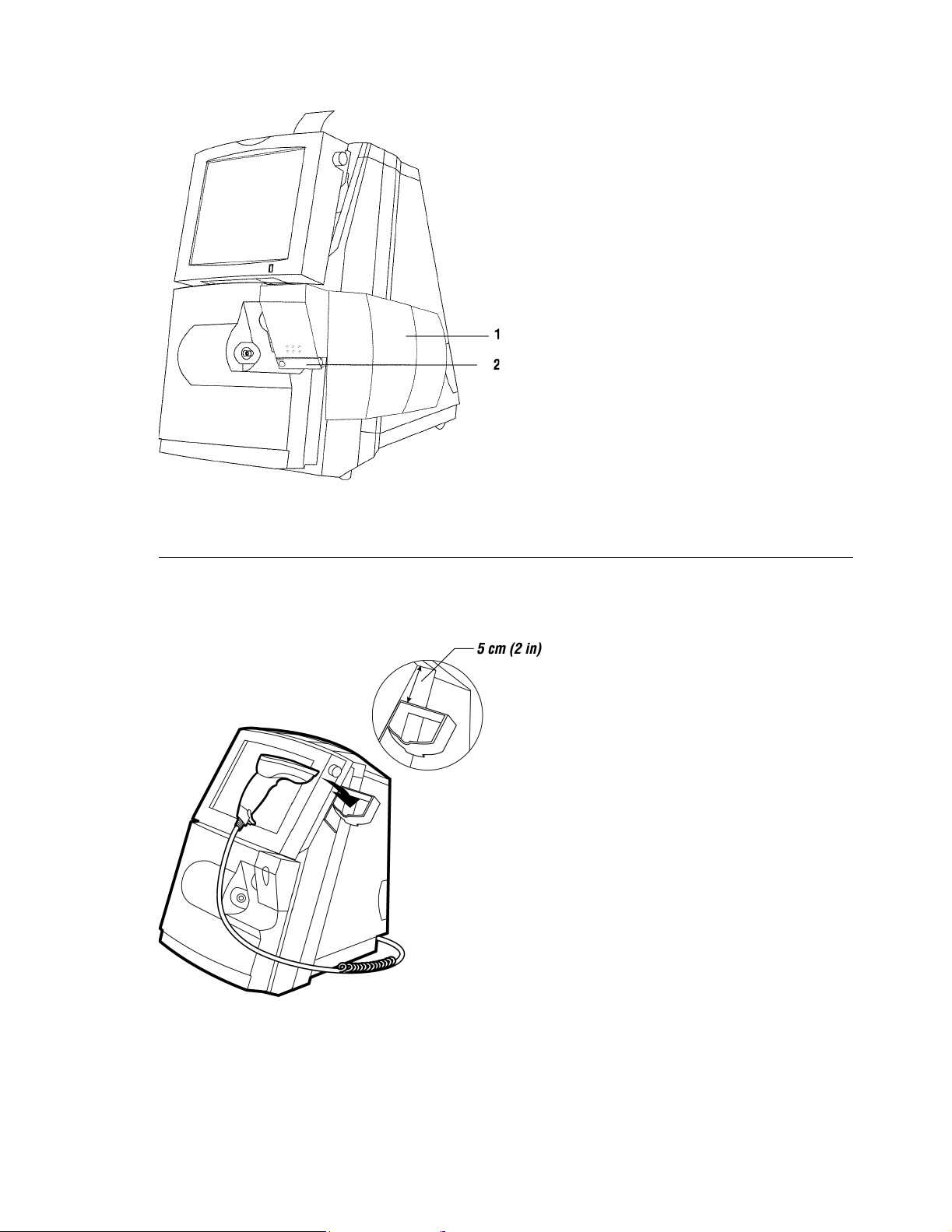

Rapidpoint 400 Series System with AutomaticQC Cartridge Installed

1 AutomaticQC cartridge

2 Cartridge connector

Rapidpoint 400 Series System with Bar Code Scanner Holder

28 Rev. C

Page 29

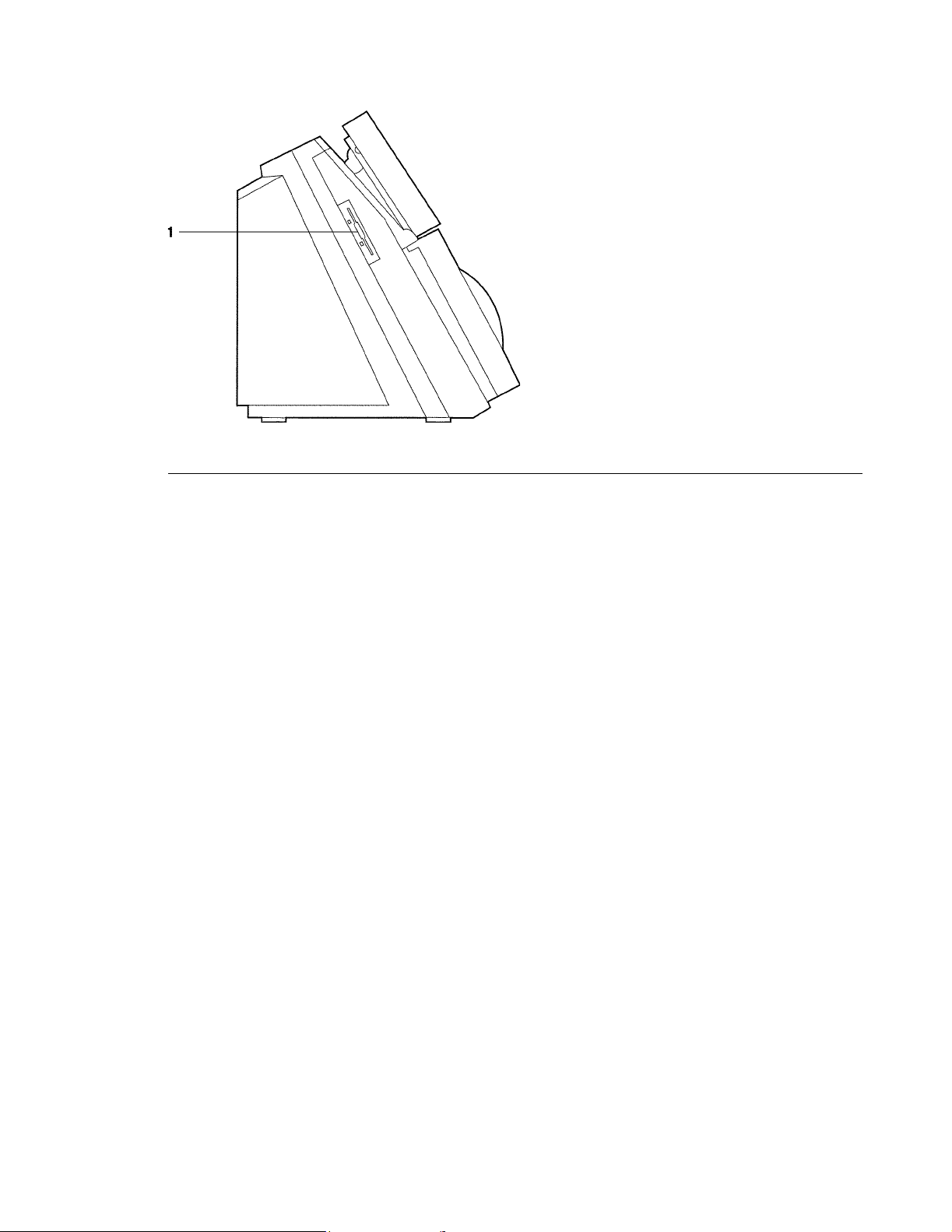

Rapidpoint 400 Series System (left side)

1 Diskette drive

Rev. C Mechanical Descriptions 29

Page 30

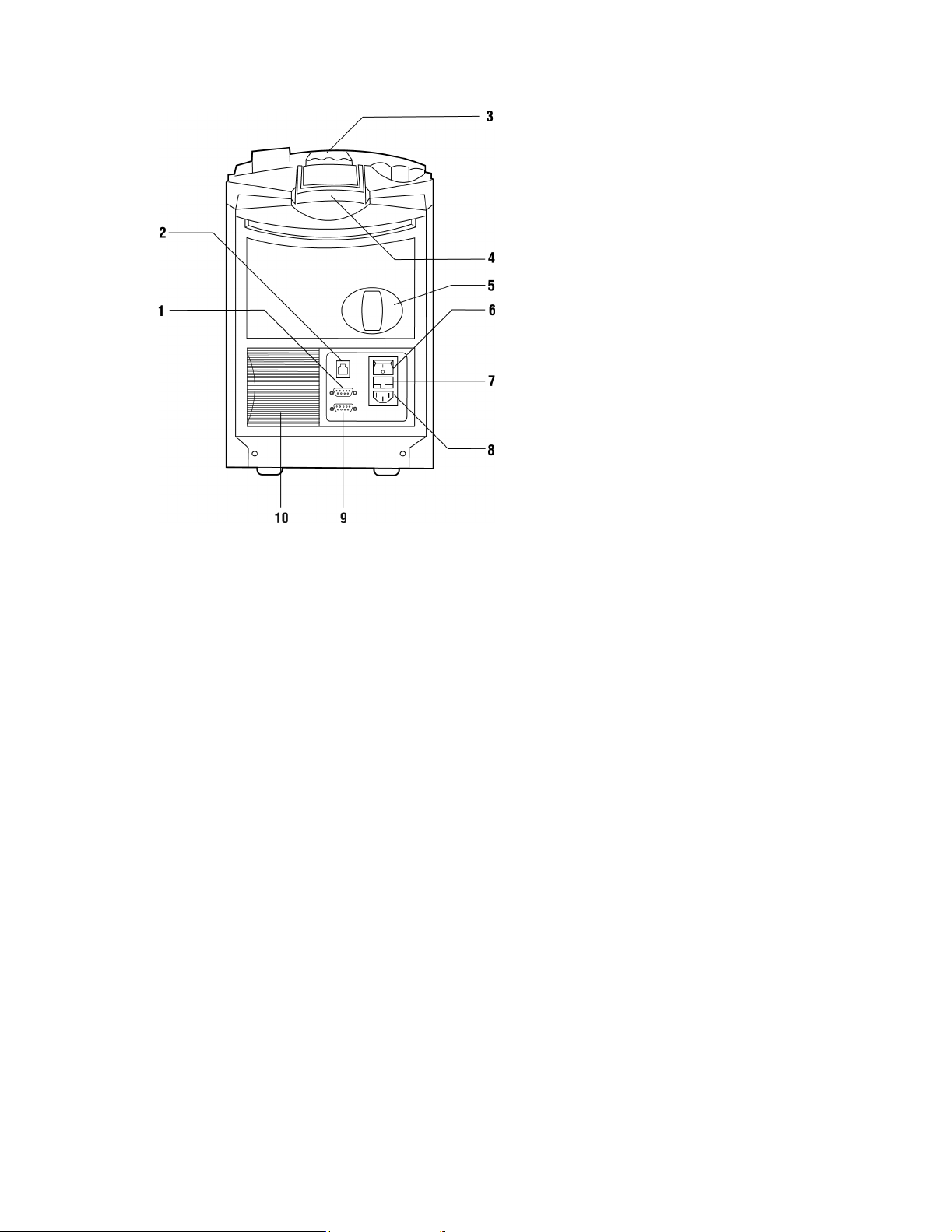

Rapidpoint 400 Series System (rear view)

1 Serial Port: Allows serial connection to a Rapidlink data management system or

an LIS.

2 Network Port: Allows network connection to a Rapidlink data management system.

3 Screen Latch: Allows you to adjust the viewing angle of the screen.

4 Handle: Helps you to move the system.

5 Co-ox Lamp: Appears only in Rapidpoint 405 systems.

6 Power Switch

7 Fuse Compartment

8 Power Input

9 Bar Code Port: Allows you to connect the optional bar code scanner to the system.

The scanner allows you to identify patient and QC samples by scanning their bar

codes.

10 Air Filter

30 Rev. C

Page 31

Measurement Cartridge

The self-contained measurement cartridge is non-serviceable. It consists

of the fluidic components, reagents, and sensors that measure patient and

QC samples.

Measurement Cartridge

1 Internal fluidic components and reagents

2 Sensor module

3 Sample port

4 Input to waste bag

5 Primary alignment pin

6 Output from wash bag

7 Secondary alignment pin

In addition, the measurement cartridge contains the mechanical

components that interface with the following components:

• the reagent system with the peristaltic pumps

• the sensor module with the electronic components

• the wash/waste cartridge

• the thermal control

The external area of the cartridge consists of the platen area which

contains the pump tubing. When the measurement cartridge is installed

and locked into place, the roller cage of the base unit is positioned against

the pump tubing to move the reagents, the samples, and the wash fluids

through the system.

Rev. C Mechanical Descriptions 31

Page 32

The measurement cartridge is protected by a door that locks in place. The

door provides an electrostatic shield for the measurement system. A

mechanical microswitch senses when the door is open or closed.

5 Pump tubing

6 Sliding valve

7 CO-ox Sample chamber

8 Drive wheel interface

Measurement cartridges can analyze a total of 750 patient and/or

QC samples, and measure blood gases, electrolytes, glucose, total

hemoglobin, and hemoglobin derivatives in arterial, venous and capillary

whole blood samples. Each cartridge is stable for 28 days after installation

on the system when the cartridge is installed by the date on the label. The

Install-by date indicates the last date on which the cartridge can be

installed and still have 28 days of use before expiration.

System Parameters Determined and Reported

400 pH, pCO2, pO2, Na+, K+, Ca++, Cl-, glucose, Hct

405 pH, pCO2, pO2, Na+, K+, Ca++, Cl-, glucose, tHb, FO2Hb, FHHb,

FMetHb, FCOHb

If a cartridge is installed after the Install-by date, it is stable for the number

of days remaining before expiration, that is, 28 days minus the number of

days past the Install-by date. View the Status screen to see the number of

days remaining and the expiration date. You cannot install a cartridge if

only 1 day of use is remaining. The system prompts you when you need to

replace the cartridge.

Store cartridges refrigerated at 2 to 8°C. Cartridges can also be stored at

room temperature, not to exceed 25°C, for up to 14 days.

32 Rev. C

Page 33

Measurement Cartridge Fluidics

The fluidic components of the measurement cartridge are part of the

fluidics system, which involves the measurement cartridge, the wash/

waste cartridge, and the pumps. The measurement cartridge fluidics

consist of the following components:

• sample entry

• sliding valve

• tubing

• reagent system

• sensor module

• KCl reservoir

Sample Entry

The sample entry performs the following functions:

• provides an insertion point for syringes and capillaries

• holds syringes, capillaries, or aspiration adapters during sample

aspiration

• connects to the wash and waste ports for automatic cleaning

The sample entry components consist of a luer and capillary seal. The

capillary seal has two passages that provide pathways for the wash and

waste fluids. The sample port attaches to the sliding valve assembly with

two snaps. The capillary seal provides a seal to the sample probe during

aspiration from a capillary.

Sliding Valve

The sliding valve performs the following functions:

• aspirates the wash fluid

• aspirates QC samples

• selects and aspirates reagents

• automatically aspirates samples from capillaries and syringes

• provides a fluid path from the reagent bag to the sensor module

Rev. C Mechanical Descriptions 33

Page 34

The sliding valve consists of a luer, a luer mount, a probe, a probe clamp,

a luer mount cover, a luer mount extension, and a valve seal. The luer and

capillary seal are replaceable. Valve movement is controlled by a valve

actuator motor and a position detector system. The position detector

system accurately positions the valve using two position sensors, which

are part of the cartridge interface.

The sliding valve has nine positions, each of which allows fluid, air, or

sample to be pumped through a thin stainless-steel probe in the center of

the valve. The probe remains stationary while the valve moves back and

forth around the probe to change the hydraulic path of the system.

The following table shows the valve positions and their functions:

Position Name Function

SYRINGE_POS moves the valve to place the probe tip into the syringe

creating the fluid path for sample aspiration

Vent AQC controls the aspiration of an external QC sample, using the

front hole of the probe

Zero Reagent Load aspirates the Zero Calibration Reagent into the sensor

module, using the rear hole in the probe

Hematocrit Reagent

Load

200 Reagent Load aspirates the 200 Calibration Reagent into the sensor

Wash Reagent Load delivers steady wash to the sensor module, using the rear

Luer Wash empties the luer area from a port in the bottom of the sample

Capillary Aspiration aspirates samples from capillary tubes, using the front hole

Vent provides an opening to advance syringe samples while the

Syringe Aspiration aspirates syringe or QC samples

aspirates the Hematocrit Calibration Reagent into the sensor

module, using the rear hole in the probe

module, using the rear hole in the probe

hole in the probe

entry, using the front hole of the probe and aspirates capillary

samples while the device is in place

in the probe

device is in place

34 Rev. C

Page 35

Tubing

All tubing is enclosed within the cartridge, except for the pump tubing in the

platen area at the rear of the cartridge. The platen area has four tubes. The

two tubes on the right serve as the flow paths for foam wash and connect

the measurement cartridge to the wash/waste cartridge. The two tubes on

the left serve as the flow paths for KCl, the sample, and reagents.

The sample tube pulls the sample or reagent through the sensors and

pushes it out into the wash/waste cartridge.

Reagent System

The reagent system delivers reagents and gases to the measurement

cartridge. The measurement cartridge contains enough reagents to

operate the system for 28 days.

The reagents are contained in three foil bags. Each bag contains a fitting.

When the measurement cartridge is installed and locked into place, pierce

pins, which are part of the interface assembly, puncture each bag creating

a fluid path. The pierce pins create a seal between the pierce probes and

fitting on each bag.

The following table describes the measurement cartridge reagents:

Reagent Volume Ingredients Cartridge

Zero 75 mL gases (oxygen, carbon dioxide, nitrogen),

salts (alkali halides), organic buffers,

catalyst, and surfactant

RCx 60 mL gases (oxygen, carbon dioxide, nitrogen),

salts (alkali halides), organic buffers,

surfactant, and preservative

200 230 mL gases (oxygen, carbon dioxide, nitrogen),

salts (alkali halides), organic buffers,

glucose, surfactant, and preservative

Reference 16 mL potassium chloride, silver chloride, and

surfactant

Wash 250 mL gases (oxygen, carbon dioxide, nitrogen),

salts (alkali halides), surfactant, and

preservative

measurement

measurement

measurement

measurement

wash/waste

Rev. C Mechanical Descriptions 35

Page 36

The following table lists the calibration points for each analyte in the

reagents:

Analyte High Calibration Point Low Calibration Point

pH 7.4 6.8

pCO

2

pO

2

+

Na

+

K

++

Ca

-

Cl

Glu 180 mg/dL 0 mg/dL

Hct 45% 0%

tHb 15 g/dL 0

70 mmHg 35 mmHg

154 mmHg 0 mmHg

159 mmol/L 116 mmol/L

8.0 mmol/L 4.0 mmol/L

1.25 mmol/L 0.62 mmol/L

98 mmol/L 69 mmol/L

Sensor Module

The sensor module consists of the following sensors:

• reference sensor

• analyte sensors

• hematocrit sensor

• CO-ox sample chamber

The sample arrives at the sensor module after traveling from a stainless

steel probe, through the sample tubing, and to the preheater. The sample

then passes over the sensors for analysis.

The sensor module provides measurements for pH, pO

potassium, ionized calcium, chloride, glucose, Hct,

total hemoglobin, and

, pCO2, sodium,

2

hemoglobin derivatives in arterial, venous and capillary whole blood

samples.

36 Rev. C

Page 37

The parameters that the Rapidpoint 400 series systems report depend

on the parameters selected in Setup. Refer to Appendix C in the

Rapidpoint 400 Series Operator’s Manual for a detailed description of the

parameters that are available.:

Category Parameter Description

blood gases partial pressure of carbon

dioxide; pCO

2

partial pressure of oxygen;

pO

2

+

H

partial pressure of carbon dioxide

partial pressure of oxygen

hydrogen ion concentration

pH negative log of the hydrogen ion

concentration

electrolytes sodium; Na

potassium; K

ionized calcium; Ca

+

+

++

sodium ion concentration

potassium ion concentration

concentration of ionized calcium, the

physiologically active form of calcium

in the blood

chloride; Cl

-

chloride ion concentration

metabolites glucose; Glu glucose concentration

oxygenation hematocrit; Hct

*

the volume occupied by red blood cells

in a given volume of blood; value is

determined by conductimetric method

metabolic

parameters

temperaturecorrected

parameters

bicarbonate ion;

HCO3act, HCO3-std

the bicarbonate ion concentration and

the bicarbonate ion concentration

normalized to a pCO2 of 40 mmHg

base excess; BE(B),

BE(ecf)

an approximation of the amount of

acid or base needed to titrate a liter of

blood to a pH of 7.4

total carbon dioxide; ctCO2the sum of the dissolved carbon

dioxide and the plasma bicarbonate

temperature-corrected

pH, pCO2, and pO2; pH(T),

blood gas values corrected for entered

patient temperature

pCO2(T), and pO2(T)

respiratory index; RI(T) the ratio of the alveolar-arterial blood

oxygen-pressure difference to arterial

pO2 when both values are corrected

for patient temperature

Rev. C Mechanical Descriptions 37

Page 38

Category Parameter Description

oxygenation

parameters

alveolar-arterial oxygen

tension difference;

pO2(A-a)(T)

arterial-alveolar oxygen

tension ratio; pO2(a/A)(T)

physiologic shunt; Qsp/

†

Qt(T)

estimated physiologic

shunt; Qsp/Qt(T)est

†

estimated oxygen

saturation; O2SAT(est)

hematocrit, Hct

†

estimated total

hemoglobin; ctHb(est)

pO2/FIO

2

an index of gas exchange within the

lungs

an index of oxygenation

percent of blood that does not

participate in external respiration

estimated value for the percent of

blood that does not participate in

external respiration

the ratio of the volume of oxygen

carried to the maximum volume of

oxygen that the hemoglobin can carry

an calculated value determined from

the total hemoglobin value

an estimation of the hemoglobin

contained in the sample

the ratio of arterial pO2 to the fraction of

inspired oxygen

a-v study

parameters

calcium adjusted for pH

7.4; Ca++ (7.4)

the ionized calcium concentration of

blood normalized to pH 7.4

anion gap; AnGap an approximation of the difference

between unmeasured cations and

unmeasured anions in the sample

arterial-venous oxygen

content difference;

†

(a-v)

ctO

2

arterial oxygen content;

ctO2(a)

†

mixed venous oxygen

content; ctO2(v)

†

oxygen consumption rate;

†

VO

2

oxygen delivery; DO

†

2

the difference between arterial and

venous blood oxygen content

the oxygen content of arterial blood

the oxygen content of mixed venous

(pulmonary artery) blood

the volume of oxygen consumed by

the body per minute

the volume of oxygen that is

transported to the tissues per minute

a-v extraction index;

ctO2([a-v]/a)

†

the arterial-venous oxygen content

difference as a percent of arterial

oxygen content

38 Rev. C

Page 39

Category Parameter Description

CO-oximetry

Parameters

total hemoglobin; tHb

oxyhemoglobin; FO2Hb

†

the total of all measured hemoglobin

fractions

†

hemoglobin that is reversibly bound to

oxygen

carboxyhemoglobin;

FCOHb

†

hemoglobin covalently bound to

carbon monoxide

methemoglobin; FMetHb†hemoglobin whose iron is oxidized to

its ferric state and is unable to bind

oxygen

hemoglobin oxygen

saturation; sO

†

2

the ratio of the amount of hemoglobin

bound to oxygen to the total amount of

hemoglobin able to bind oxygen

oxygen binding capacity;

†

BO

2

the maximum amount of oxygen that

can be carried by the hemoglobin in a

given quantity of blood

oxygen tension at 50%

saturation; p50

†

the partial pressure of oxygenated

which the hemoglobin oxygen

saturation is 50%

* These parameters are available only on Rapidpoint 400 systems.

†

These parameters are available only on Rapidpoint 405 systems.

In addition to sensor chips, the sensor module contains:

• fluid detector chips

• a preheater chip

• an IDEE ROM chip

The Rapidpoint 400 series systems use two Hct sensors as fluid detectors.

Fluid detector 1 (FD1) is located in front of the first sensor. Fluid detector 2

(FD2) is located after the last sensor.

The fluid detector chips detect the presence and the continuity of fluids in

the system, and measure sample fluid using alternating current (AC)

conductivity. The system uses information from the detectors to monitor

and control the movement and the positioning of fluids during the system

sequences.

Rev. C Mechanical Descriptions 39

Page 40

The preheater chip is located in front of the measurement block. The

sample passes through the preheater during aspiration. The preheater

temperature range is 37.0 to 37.6°C, with a target preheater temperature

of 37.3°C.

The IDEE ROM chip informs the system that the correct measurement

cartridge is installed and helps in diagnosing cartridge problems. The

IDEE Rom Identifies the following:

• analyzer software version

• date installed on the analyzer

• date removed fro analyzer (if removed normally)

• analyzer serial number

KCl Reservoir

The KCl reservoir continuously refreshes the KCl concentration on the

reference sensor. Each measurement cartridge includes a KCl vial

containing 16 mL of liquid KCl.

The KCl reservoir is clamped closed to prevent it from leaking during

shipment. The tubing on the KCl vial is automatically unclamped allowing

the KCl to flow when the measurement cartridge is installed.

40 Rev. C

Page 41

Wash/Waste Cartridge

The wash/waste cartridge is self contained and non-serviceable. It is

protected by a door that locks in place. The door provides an electrostatic

shield for the measurement system. A mechanical microswitch senses

when the door is open or closed.

The cartridge contains the wash fluid, which cleans the sample path after

analysis and calibration. The cartridge also contains the waste bag, which

stores liquid waste. The wash/waste cartridge consists of the following

components:

• seal septums

• pierce probes

• wash bag

• waste bag

Wash/Waste Cartridge

1 Connectors to measurement cartridge

2 Septum seal for waste bag

3 Primary alignment pin locator hole

4 Septum seal for wash bag

5 Secondary alignment pin locator hole

Rev. C Mechanical Descriptions 41

Page 42

Two seal septums serve as the coupling between the hydraulics of the

wash/waste and the measurement cartridges. When the wash/waste

cartridge is installed, it connects to two wash/waste cartridge fittings that

are located on the outside edge of the measurement cartridge cover.

These fittings provide the interface between the measurement cartridge

and the wash/waste cartridge. The top fitting is the path into the waste bag.

The bottom fitting is the path out of the wash bag. In addition to the wash/

waste fittings on the measurement cartridge, there is a primary and a

secondary alignment pin. These pins align the wash/waste cartridge

fittings with the septums.

When the wash/waste cartridge is placed in the system, the fittings on the

measurement cartridge are inserted into the wash/waste cartridge, and the

pierce probes penetrate the wash and waste bags. In the case of the wash

bag, the pierce probe penetrates the bag and creates a seal inside the

fitting. However, the waste bag is already open and the pierce probe seals

inside the fitting in the bag. Two bag clamps, one at the top of each bag,

hold the bags in position. Two hangers, one at the top of the cartridge and

one at the bottom of the cartridge, hold the waste bag in place as it fills.

Only the replaceable cartridges of the Rapidpoint 400 series systems

come in contact with biohazardous waste fluid. Biohazardous waste fluid

never contacts other components of the system. The waste fluid is

completely enclosed in the waste bag, which accommodates 500 mL of

waste. The waste collection system has sufficient reserve capacity to

prevent overfilling, provided the cartridges are replaced when the operator

is prompted to do so by the system.

The wash/waste cartridge contains 250 mL of wash reagent. The wash

reagent washes the valve and the sample flow path. It consists of gases

(oxygen, carbon dioxide, nitrogen), salts (alkali halides), a surfactant, and

a preservative.

Each wash/waste cartridge is stable for 10 days after installation on the

system and contains enough reagent for 300 patient and QC sample

analyses. The system prompts the user when the cartridge needs to be

replaced.

The wash/waste cartridges may be stored refrigerated or at room

temperature (2 to 25°C).

42 Rev. C

Page 43

Cartridge Interface Module

The cartridge interface module attaches the measurement cartridge to the

system. It consists of the following components:

• interface frame

• location pins

• bag pierce pins

• cable clamps

• cartridge handle

• valve actuator

• optical detector board with bidirectional stepper motor and position

detectors

• pump and motor assembly (refer to Pumps on page 52 for more

detailed information)

• thermal cover

• camshaft

• connector block

The interface frame is secured to the front of the system and holds all

devices and parts necessary to interface the system with the measurement

cartridge.

The location pins position the measurement cartridge on the cartridge

interface frame. Three bag pierce pins are below the location pins. The bag

pierce pins force the pierce probes to puncture the reagent bags creating

a fluid path. The pierce probes engage with the fittings on the reagent bags

to make a seal.

Four cable clamps secure the cables that extend from the connector block,

the stepper motor, and the optical detector board to the main board.

The cartridge handle lifts to unlock and release the measurement cartridge

from the interface module, or pulls down to lock the measurement cartridge

in place on the cartridge interface module.

Rev. C Mechanical Descriptions 43

Page 44

The valve actuator moves the sliding valve. The luer mount extension on

the sliding valve connects with the valve actuator when the measurement

cartridge locks on the cartridge interface module. During cartridge

initialization, the actuator moves back and forth until it automatically

engages the luer mount extension. A stepper motor, which has nine

positions and a left and a right limit stop, controls the actuator.

The bidirectional valve actuator motor and the position detectors, which

are part of the optical detector board, move and position the valve. Two

sensors in conjunction with the position detectors determine valve

position.

The thermal cover attaches to the cartridge interface module and protects

and guides the connector block. The cam shaft, used in conjunction with

the cartridge handle, raises and lowers the connector block.

The connector block provides the electrical and the thermal connections to

the sensors, and connections to the IDEE ROM. The connector block

consists of the following components:

• preheater

• main heater

• contact board

• multiplexer board

• contact system protector

• alignment and locking pins

The preheater contacts the preheater chip in the sensor module to heat

samples to 37°C. The preheater is thermally protected, so that the surface

temperature never exceeds 55°C.

The main heater contacts the heater plate of the sensor module to maintain

the temperature of the sensors and fluids at 37°C. The main heater also

controls the temperature of the preamplifiers. The main heater is thermally

protected, so that the surface temperature never exceeds 55°C.

44 Rev. C

Page 45

The contact board provides the junction between the connector block and

the sensor module. It processes signals from the sensors and provides

biased, filtered, and amplified results to the system. The sample thermistor

is located on the contact board. The sample thermistor senses the

temperature on the back of the sensor chips. If the thermistor detects that

the temperature of the chips is less than 37°C, it signals the main heater to

increase the temperature of the chips to 37°C.

The multiplexer board takes the signals from the contact board and

simultaneously transmits them into one signal that travels back to the

system. A programmable gain amplifier on the multiplexer board provides

the gain and the offset to the signals. The circuitry on the board also

amplifies the signal from the thermistor. Additionally, the multiplexer board

provides various excitation signals to the contact board, such as power and

digital timing signals.

The contact system protector shields the contacts from becoming

damaged when no measurement cartridge is present.

There are four alignment pins on the connector block assembly: two small

pins align the sensor module with the connector block, and two larger pins

guide the connector block into position.

Rev. C Mechanical Descriptions 45

Page 46

AutomaticQC Cartridge

The AutomaticQC cartridge is self-contained and non-serviceable. It

consists of the fluidic, electronic, and mechanical components needed to

deliver QC material to the system’s measurement components. The QC

material is uniquely formulated to provide performance verification at

several points in the clinical range of analytes measured by the

Rapidpoint 400 series systems.

The AutomaticQC cartridge is mounted on the right side of the system

where a support bracket secures it in place. The ampule breaker and an

access panel must be removed before the cartridge is installed. Four

standoffs attach the cartridge to the system where the ampule breaker was

previously mounted.

AutomaticQC cartridges supply sufficient QC material to run at least three

samples of each level three times per day for the life of the cartridge. Each

cartridge is stable for 14 days after installation on the system. The system

prompts the user when the cartridge needs to be replaced.

The cartridges must be stored refrigerated at 2 to 8°C.

AutomaticQC Cartridge Connector in the Open Position

1 Cartridge connector in the open position

46 Rev. C

Page 47

AutomaticQC Cartridge Fluidic Components

The AutomaticQC cartridge contains the following fluidic components:

• valve assembly

• QC material

• tubing

The valve assembly consists of a sliding valve, valve seal, valve lubricant,

and AutomaticQC probe.

The sliding valve is controlled by a stepper motor and a position detector

system that moves the valve and accurately positions it using two position

sensors. The valve has five positions, each of which enables one of the five

QC reagents to be pumped through the stainless steel probe in the center

of the valve. The probe remains stationary while the valve travels vertically

about the probe to change the hydraulic path between the AutomaticQC

cartridge and the measurement cartridge.

The QC material is supplied in five foil laminated bags, each of which holds

one of five levels of QC material. Each bag is firmly secured in place with

an inner and outer polystyrene clamp. Five nylon tubes, each of which

connects one of the five bags to the valve assembly, serve as flow paths for

the QC reagents.

Rev. C Mechanical Descriptions 47

Page 48

AutomaticQC Cartridge

1 Bracket to secure the cartridge to the side of the system

2 Standoffs (4)

3 EEPROM

4 Cartridge connector

5 Cartridge Lever

AutomaticQC Cartridge Indicating Lever Closed Position

1 Cartridge connector

2 Standoffs (4)

48 Rev. C

Page 49

3 Press Cartridge Lever to pierce reagent bags

The following table lists the contents of the AutomaticQC reagent bags:

Level Volume Ingredients

1 75 mL buffered bicarbonate solution with Na+, K+, Ca++, Cl-, carbon

dioxide, oxygen, nitrogen, dye, glucose, surfactant, and

preservative

2 115 mL buffered bicarbonate solution with Na+, K+, Ca++, Cl-, carbon

dioxide, oxygen, nitrogen, dye, glucose, surfactant, and

preservative

3 155 mL buffered bicarbonate solution with Na+, K+, Ca++, Cl-, carbon

dioxide, oxygen, nitrogen, dye, glucose, surfactant, and

preservative

A 60 mL buffered bicarbonate solution with Na+, K+, Ca++, Cl-, carbon

dioxide, oxygen, nitrogen, surfactant, and preservative

B 60 mL buffered bicarbonate solution with Na+, K+, Ca++, Cl-, carbon

dioxide, oxygen, nitrogen, surfactant, and preservative

AutomaticQC Cartridge Interface

Removal of the ampule breaker and an access panel provides access to

the latch assembly where the AutomaticQC cartridge connects to the

system. A sliding metal latch plate in the latch assembly engages four

standoffs on the AutomaticQC cartridge to secure the cartridge to the

system.

A valve actuator that extends through the latch assembly moves the sliding

valve on the AutomaticQC cartridge. Driven by a lead screw follower on the

motor, the actuator moves until it engages a vertical slot in the sliding valve.

The bidirectional stepper motor and position detectors move the valve

along the probe to select the required fluid path for flow of QC material from

the AutomaticQC cartridge to the measurement cartridge. The stepper

motor has five stop positions.

With the AutomaticQC cartridge engaged to the system, the cartridge

connector located on the front of AutomaticQC cartridge connects the

AutomaticQC cartridge to the measurement cartridge. Fluidic connectivity

between the two cartridges is provided by a single 0.5mm I.D. tube that

passes from the base of the sliding valve in the AutomaticQC cartridge

through the cartridge connector and into the measurement cartridge. The

cartridge connector must be closed for the system to operate.

Rev. C Mechanical Descriptions 49

Page 50

The AutomaticQC cartridge is disengaged from the system through a

software procedure that causes the stepper motor to move the sliding

metal latch plate and release the standoffs. If power is lost, the

AutomaticQC cartridge can also be disengaged from the system by

moving a release tab located beneath the stepper motor.

AutomaticQC Interface

1 Latch assembly

2 Locating holes (4)

3 Actuator

4 IDEE Pins

50 Rev. C

Page 51

Mechanical Components

The AutomaticQC cartridge contains the following mechanical

components:

• cartridge lever

• bag pierce pins

• cartridge connector

The cartridge lever is a spring-loaded panel that, when closed (flush with

the AutomaticQC cartridge base plate), causes pins on its underside to

actuate the pierce probes. The pierce probes engage fittings on the

reagent bags to provide a seal and to puncture the bags to create fluid

paths for the QC material to flow from the AutomaticQC cartridge to the

measurement cartridge. A total of three pierce probes service the five

bags. The AutomaticQC cartridge is shipped with the lever in its open

position.

The cartridge connector is mounted on the front of the AutomaticQC

cartridge. During installation of the cartridge, the connector is moved

horizontally and connects with the measurement cartridge. It provides the

sample path from the AutomaticQC cartridge to the measurement

cartridge. The cartridge connector slide must be fully engaged for the

AutomaticQC cartridge to function.

Electronic Components

The AutomaticQC cartridge contains the following electronic components:

• IDEE assembly

• microswitch

The IDEE assembly consists of a PC board and cable. An EEPROM chip

on the PC board signals the system when the AutomaticQC cartridge is

installed. The EEPROM chip also contains target ranges for each level of

QC material in the cartridge. These ranges are automatically downloaded

to the system when the AutomaticQC cartridge is installed. The cable

connects the IDEE PC board to the cartridge connector microswitch.

The microswitch is located where the cable attaches to the bottom of the

valve enclosure. It determines if the cartridge connector is open or closed.

Rev. C Mechanical Descriptions 51

Page 52

Pumps

The pumps move the reagents, samples, and wash reagent through the

Rapidpoint 400 series systems. The sample pump moves the sample and

the reagents through the system. The sample pump also moves KCl

through the reference electrode. The wash pump delivers a mixture of

wash fluid and air to the sample entry port.

Each pump consists of a roller cage, a motor, a pump housing, a motor

mount, a spring plate, and springs. The roller cage presses onto the motor

shaft.

The pump that services the measurement cartridge generates flow by

compressing the tubing against the fixed platen of the cartridge. As the

individual rollers rotate through the platen area, a segment of the tubing is

pinched in two places by adjacent rollers. The fluid is pushed through the

tubing by the peristaltic action of the moving rollers.

A stepper motor drives each pump. Each motor moves 1.8 degrees per

step and 200 steps per revolution. The electrical drive and control for the

pump stepper motors are provided by a microstepping circuit on the main

board. The software controls the speed and direction of each pump.

Stepper Motor Components

52 Rev. C

Page 53

Display

The display is the user interface component of the Rapidpoint 400 series

systems. The display tilts on a horizontal axis and locks at the chosen tilt.

The display consists of the following components:

• display module

• liquid crystal display (LCD)

• touch screen

•printer

• display board

• display support

Display Module

The display module contains the LCD, the touch screen, the printer, the

display board and the display support. In addition, the display module

contains the roll of printer paper and the paper cover.

Liquid Crystal Display

The LCD is a 265 mm (10.4 inch) diagonal display with active matrix color

LCD that provides 256 colors. The display supports an active matrix

color LCD.

Touch Screen

The touch screen is overlaid onto the LCD. The touch screen consists of

two electrically resistive sheets that are superimposed over the viewing

area of the display. The sheets are separated from each other by a small air

gap. When the screen is touched, the two sheets are electrically shorted.

The resolution of the touch screen is determined by the control circuitry.

Rev. C Mechanical Descriptions 53

Page 54

Printer

The built-in thermal-roll printer provides reports for calibrations, samples,

and diagnostics.

The printer consists of a platen, a motor and gear mechanism, a thermal

printhead, and two sensors. One sensor detects when the printhead is up

and the other sensor detects when the printer is out of paper.

The printer is controlled by the display board. The printer cable carries the

signals for the data, the motor control, the paper-empty sensor, and the

printhead-up sensor. The display board communicates with the main

board.

Display Board

The display board contains all the circuitry necessary to drive and control

the LCD, the printer, and the touch screen. There are no service settings or

jumpers on the display board.

Display Support

The display support holds the display to the system and the pawl provides

stability through the stepped mechanism when the display is tilted into the

varying tilt positions.

54 Rev. C

Page 55

CO-oximeter Components

The Rapidpoint 405 system contains the CO-oximeter (CO-ox)

measurement module that provides the capability for measuring the

concentration of total hemoglobin and hemoglobin fractions (tHb, FO

FHHb, FMetHb, FCOH) in whole blood samples.

Measurement occurs as the sample flows through the sample chamber.

Light is transmitted, through a fiber bundle, to the optics head. As the

sample flows through the sample chamber, the light is focused from one

side of the optics head through the sample. The light is collected at the

other side of the optics head and then is carried through a fiber bundle to

the polychromator to be measured.

CO-ox Measurement System

Hb,

2

Rev. C Mechanical Descriptions 55

Page 56

CO-ox Measurement Components

The Rapidpoint 405 system CO-ox components consist of the following:

• illumination housing assembly

• neon board assembly

• fiber bundle assembly

• sample chamber interface

• sample chamber

• polychromator module

• photo-feedback sensor

The CO-ox components are shown in the following figure.

Co-ox Measurement Components

56 Rev. C

Page 57

Illumination Housing Assembly

The CO-ox illumination housing assembly holds the replaceable halogen

lamp. The housing contains optical filters that limit the lamp’s output light

(spectrum) to the visible range, and lenses that collect and focus light into

the fiber bundle.

The lamp’s output intensity is controlled by a closed-loop optical feedback

system. This is accomplished by routing some of the output fibers from the

fiber bundle, which is connected to the illumination housing assembly, to a

photo-feedback sensor located on the main PB board. This sensor

continuously monitors lamp output and generates a signal that regulates

power to the lamp.

Illumination Housing Assembly

Neon Board Assembly

The neon board assembly contains a neon gas discharge lamp, lenses, a

narrow bandpass interference filter, and a driver board. The output light

(monochromatic) from this assembly is used as a reference to check the

polychromator’s wavelength measurement accuracy. This check occurs at

the same time and frequency as the automatic tHb zero. Any optical or

mechanical misalignment in the polychromator, which may cause

wavelength measurement inaccuracies, are corrected during the zero

calibration.

Rev. C Mechanical Descriptions 57

Page 58

Fiber Bundle Assembly

The fiber bundle assembly contains many small diameter optical fibers that

are combined to form a fiber optic cable with four terminals. The bundle

connects to the neon board assembly, illumination housing assembly,

sample chamber interface, and to the photo-feedback sensor on the main

PC board.

The bundle transmits light to the CO-ox components during sample

analysis.

• the fiber bundle transmits light from the illumination housing module to

the optics head of the sample chamber interface, where it is focused

onto the sample chamber

• transmits a small portion light from the illumination module to the

photo-feedback sensor, which controls the halogen lamp output

• transmits light from the neon reference lamp to the sample chamber,

which is used to check the polychromator’s accuracy

NOTE: A separate fiber bundle is attached to the polychromator. This

bundle, which is connected to one side of the optical head, transmits light

from the sample chamber (originating from the neon lamp and from the

halogen lamp) to the polychromator.

Sample Chamber Interface Assembly

The sample chamber interface assembly consists of the following

components:

• optical head with spring link

• detector housing module

• motor

• drive wheel

• PC board

58 Rev. C

Page 59

The optical head contains the optics that deliver light to and collect light

from the sample chamber. The optical head houses four lenses, two

mirrors, and the detector module.Two lenses and mirror direct the light

from the fiber bundle onto the sample chamber. On the other side of the

optical head another mirror and set of lenses collect the light that is not

absorbed by the sample. A fiber bundle, connected from the optical head

to the polychromator, relays the light for measurement. The spring link

holds and locates the optical head.

The detector module uses a thermistor to ensure that the CO-ox sample

chamber temperature is kept constant, and a flag detector system to detect

the position of the sample chamber during measurement. The flag detector

system consists of two emitters and two photo detectors that detect the

position of the sample chamber.

The drive wheel is attached to the drive shaft of the motor, and engages a

mechanism in the measurement cartridge that moves the sample chamber

to the open and closed positions.

CO-ox Sample Chamber Interface

Rev. C Mechanical Descriptions 59

Page 60

Co-ox Sample Chamber

The CO-ox sample chamber is part of the measurement cartridge.The

sample chamber consists of the following components:

•base

• gasket

• seal

• shunt/flag

• sample chamber body

•spring

• cover

•heater chip

The sample chamber is in its measurement position when the motor moves

the shunt into the closed position.

When the shunt returns to the open position, the measurement

cartridge reagent system cleans the sample chamber. A heater chip

ensures that the sample temperature is kept at 37 ± 0.3°C.

Polychromator Module

The polychromator module measures the intensities of light passed

through the sample at a number of different wavelengths.

The polychromator module has the following components:

60 Rev. C

Page 61

• fiber bundle

• diffraction grating

• grating imaging mirror

• collimating mirror

• diode array PC board

• polychromator PC board

The fiber bundle carries light collected by the optics head after passing

through the sample and relays it to the polychromator. The fibers at the end

of the fiber bundle form a line that defines the input slit to the polychromator.

The first mirror collimates light from the slit so that nearly parallel light falls

on the diffraction grating. The diffraction grating disperses the light coming

from the collimating mirror into its component wavelengths or colors. The

second mirror images the light from the grating onto the photodiode array

detector where the various wavelength intensities are measured.

The diode array board converts light into an electrical signal. The

polychromator board converts the signal from the diode array board from

an analog to a digital value for further processing.

Rev. C Mechanical Descriptions 61

Page 62

62 Rev. C

Page 63

Electronic System Overview

Overview 67

Electronic System 68

Contact PC Board 69

Digital Signals 69

Digital Input Signals 69

Digital Output Signals 69

Analog and Other Input Signals 70

Analog and Other Output Signals 72

Circuit Description 74

Amperometric Circuits 74

Potentiometric Circuits 75

Hematocrit/Fluid Detector Circuits 75

Display PC Board 77

Digital Signals 77

Digital Input Signals 77

Digital Output Signals 78

Analog Signals 79

Analog and Other Input Signals 79

Analog and Other Output Signals 80

Circuit Description 80

Microcontroller and Peripheral Circuitry 80

Touch Screen Switches 81

DC-DC Converter Circuit 81

LCD Backlight Inverter Circuit 81

Rev. C Electronic System Overview 63

Page 64

Dualopto PC Board 82

Sensor Circuit 82

Main PC Board 83

Real-Time Processor (RTP) 83

RTP 68332 Processor Circuitry 83

RTP 68332 Address and Data Bus Circuitry 83

RTP EPROM and PSRAM Circuitry 84

RTP Address Bus Decoder and Memory Controller

Complex Programmable Logic Device Circuitry 84

RTP Data Bus I/O Latch CPLD Circuitry 85

Data Acquisition System (DAS)

Front End Circuitry 85

DAS Analog-to-Digital Converter Circuitry 86

DAS Fluid Detector Circuitry 86

RTP/UIP First In First Out (FIFO) Memory

Communications Circuitry 86

UIP Main Interconnect Board ISA Interface Circuitry 87

UIP Display Module, COM1, COM2/LPT1, and Utility

Circuitry 87

UIP COM3 Circuitry 87

UIP ISA Address Bus Decoder, Data Bus I/O Latch

CPLD, and Communications Circuitry 88

Control Micro-stepper Processor, and Sample and

Wash Pump Driver Circuitry 88

Control Heater DAC, Driver Circuitry, and Valve

Driver Circuitry 89

Power System Status Circuitry, Diagnostic LEDs,

and Switches 89

Control Automatic Quality Control (AQC) Valve

Stepper Circuitry 90

Power System Protection and Input Circuitry 90

UIP Main Interconnect Board ISA Interface 92

Digital Input Signals 92

Digital Output Signals 92

Digital Bi-directional Signals 93

64 Rev. C

Page 65

UIP COM1 Interface 94

Digital Input Signals 94

Digital Output Signals 94

UIP COM2/LPT1 Interface 95

Digital Input Signals 95

Digital Output Signals 95

Flat Panel Interface 96

Digital Output Signals 96

UIP Utility Interface 96

Digital Output Signals 96

Display Board Interface 97

Digital Input Signals 97

Digital Output Signals 97

Multiplexer Board Interface 98

Digital Input Signals 98

Digital Output Signals 98

Analog and Other Output Signals 99

Main Interconnect PC Board 100

ISA Connectors 100

Multiplexer PC Board 101

Digital Signals 102

Digital Input Signals 102

Digital Output Signals 102

Analog Signals 103

Analog and Other Input Signals 103

Analog and Other Output Signals 104

Circuit Descriptions 105

Amperometric Isolation Circuits 105

Digital Control Circuit 106

Temperature Circuits 106

Programmable Gain Amplifier Circuitry 106

Rev. C Electronic System Overview 65

Page 66

User Interface Processor PC Board 107

Miscellaneous Functions 108

Keyboard Controller 108

Battery 108

Miscellaneous Function Connector 108

Peripheral Interfaces 109

Serial Ports 109

Parallel Port 109

Floppy Disk Controller 109

Co-oximeter OMZ Heater PC Board 110

Analog Signals 111

Analog and Other Input Signals 111

Analog and Other Output Signals 111

66 Rev. C

Page 67

Overview

This section describes the electronic systems for the Rapidpoint 400 series

systems. It provides circuit descriptions for each printed circuit board in the

Rapidpoint 400 series systems. Each subsection is organized by board

name and circuit description. Assembly drawings for each printed circuit

board are included in Replacing Parts.

The electronic system directs the operation of all Rapidpoint 400 series

systems components, including the fluidic system, the measurement

system, and the sensors. It also receives information from these

components regarding their various functions.

The electronic system performs all calculations required to determine

reported parameters and controls the data communication with the

devices connected to the Rapidpoint 400 series systems.

Rev. C Electronic System Overview 67

Page 68

Electronic System

The Rapidpoint 400 series systems electronic system consists of the

following PC boards:

• Contact

• Display

• Dualopto

•Main

• Main Interconnect

• Multiplexer

• UIP (User Interface Processor)

68 Rev. C

Page 69

Contact PC Board

The Contact PC board amplifies signals from the electrodes before they

are processed by the rest of the system. The Contact board provides the

following:

• low bias, current-transimpedence output amplifiers and bias amplifiers

for four amperometric sensors

• high-impedance differential amplifier for seven potentiometric sensors

• AC current, source and synchronous, differential amplifier for two

hematocrit/fluid detector sensors

• connections for three thermistors organized in a thermal-control loop

that regulate the sample temperature to +37°C

• connections to an EEPROM device located within the sensor module

for storing calibration and configuration information specific to the

measurement cartridge

Digital Signals

Digital Input Signals

Input Signal Description

ID_SDA Serial data line to the EEPROM located in the sensor module.

This signal is bi-directional.

ID_SCK Serial clock line to the EEPROM.

ASAMP Control signal for the charge transfer process in the

hematocrit circuits.

BSAMP Control signal for the charge transfer process in the

hematocrit circuits. The BSAMP signal is out of phase with

the ASAMP signal.

DRIVE This signal provides the AC excitation voltage for the

hematocrit sensors.

Digital Output Signals

Output Signal Description

ID_SDA Serial data line to the EEPROM located in the sensor module.

This signal is bi-directional.

Rev. C Electronic System Overview 69

Page 70

Analog and Other Input Signals

Input Signal Description

+5_VDC_HCT Positive-power supply for the hematocrit circuits. Voltage is

+5.00 V ±5% at 5 mA.

-5_VDC_HCT Negative power supply for the hematocrit circuits. Voltage is

-5.00 V ±5% at 5 mA.

+5_VDC_PO2 Isolated positive power supply for the oxygen circuit. Voltage

is -3.5 ±0.5 V at 250 µA.

-5_VDC_PO2 Isolated negative power supply for the oxygen circuit. Voltage

is +3.5 ±0.5 V at 250 µA.

5_RTN_PO2 Isolated power supply return for the oxygen circuit.

+5_VDC_GLU Isolated positive power supply for the glucose circuit. Voltage

is -3.5 ±0.5 V at 250 µA.

-5_VDC_GLU Isolated negative power supply for the glucose circuit.

Voltage is -3.5 ±0.5 V at 250 µA.

5_RTN_GLU Isolated power supply return for the glucose circuit.

+5_VDC_LAC Isolated positive power supply for the lactate circuit. Voltage

is -3.5 ±0.5 V at 250 µA. For future use.

-5_VDC_LAC Isolated negative power supply for the lactate circuit. Voltage

is -3.5 ±0.5 V at 250 µA. For future use.

5_RTN_LAC Isolated power supply return for the lactate circuit. For future

use.

+5_VDC_CRE Isolated positive power supply for the creatinine circuit.

Voltage is +3.5 ±0.5 V at 250 µA. For future use.

-5_VDC_CRE Isolated negative power supply for the creatinine circuit.

Voltage is -3.5 ±0.5 V at 250 µA. For future use.

5_RTN_CRE Isolated power supply return for the creatinine circuit. For

future use.

REFV_PO2 Isolated +800 mV reference voltage for the oxygen electrode.

REFV_GLU Isolated -400 mV reference voltage for the glucose electrode.

REFV_LAC For future use.

REFV_CRE For future use.

+5_VDC Positive power supply for the potentiometric amplifiers.

Supplies +5.00 V ±5% at 5 mA.

(Continued)

70 Rev. C

Page 71

Input Signal Description

-5_VDC Negative power supply for the potentiometric amplifiers.

Supplies -5.00 V ±5% at 5 mA.

ID_PWR Power supply for the EEPROM in the sensor module.

Supplies +5.00 V ±5% at 5 mA.

ID_RET Power supply return signal for the EEPROM.

PO2_SIG Current output signal of the pO2 electrode.

GLU_WB Current output signal of the glucose (active) electrode.

GLU_WA Current output signal for an inactivated twin of the glucose

electrode.

LAC_WB For future use.

LAC_WA For future use.

CRE_WB For future use.

CRE_WA For future use.

PH_VO Voltage output signal of the pH sensor.

K_VO Voltage output signal of the K+ sensor.

CA_VO Voltage output signal for the Ca++ sensor.

MG_CL_VO Voltage output of the Cl- sensor.

NA_VO Voltage output signal of the Na+ sensor.

BUN_VO For future use.

HCO3_VO Voltage output signal of the HCO3 sensor.

REF_VO Voltage output signal of the reference sensor. The range is

-60 to 140 mV. Impedance is about 10K ohms.

HCT1_HS Signal output of the hematocrit 1 sensor. This sensor

connects to the positive input of the synchronous sampling

differential amplifier on the Contact board. The amplifier