Page 1

1 INTRODUCTION AND

1 OF 8

GENERAL DESCRIPTION

Introduction ......................................................................................... 2

Features ............................................................................................... 3

General Specifications ......................................................................... 5

NEXT

Page 2

INTRODUCTION AND GENERAL DESCRIPTION

1.1 Introduction

2 OF 8

This manual is to be used in conjunction with the Clinitek Sta

in performing routine troubleshooting and service on an instrument. Each section of

the service manual is dedicated to specific areas of interest: General features,

methods overview, troubleshooting, error code descriptions, repair, functional

diagrams, and parts breakdown. Any future service information or instrument

revisions would be covered through service bulletins and/or revisions of this manual.

The CLINITEK

capable of reading a range of Bayer Urine Reagent Strips along with the Bayer

Clinitest hCG Immunoassay Cassette. It was developed as a next generation

instrument combining features of the CLINITEK® 50 along with the CLINITEK® 100

plus the ability to read and interpret immunoassay cassette tests.

®

Status instrument is a small, portable urine chemistry analyzer

tus Operator’s Manual

NEXT

Page 3

INTRODUCTION AND GENERAL DESCRIPTION

3 OF 8

1.2 Features

The major feature is the lower cost and size, portability, centered around small office

placement, converting from visual user to instrument. Thus, reducing the

subjectivity in visual interpretation and combined with better patient to sample

tracking.

•

Touch screen display for easier and faster operation,

Internal automatic calibration to improve reliability of readings,

•

•

Memory recall which allows customers to display the test results from specific

samples,

Entry of patient information along with operator for each test result for improved

•

traceability,

•

Allows for entry of color and clarity of sample which can be printed along with

results,

•

User Interface available in English, German, French, Spanish, Italian, and

Swedish.

NEXT

Page 4

INTRODUCTION AND GENERAL DESCRIPTION

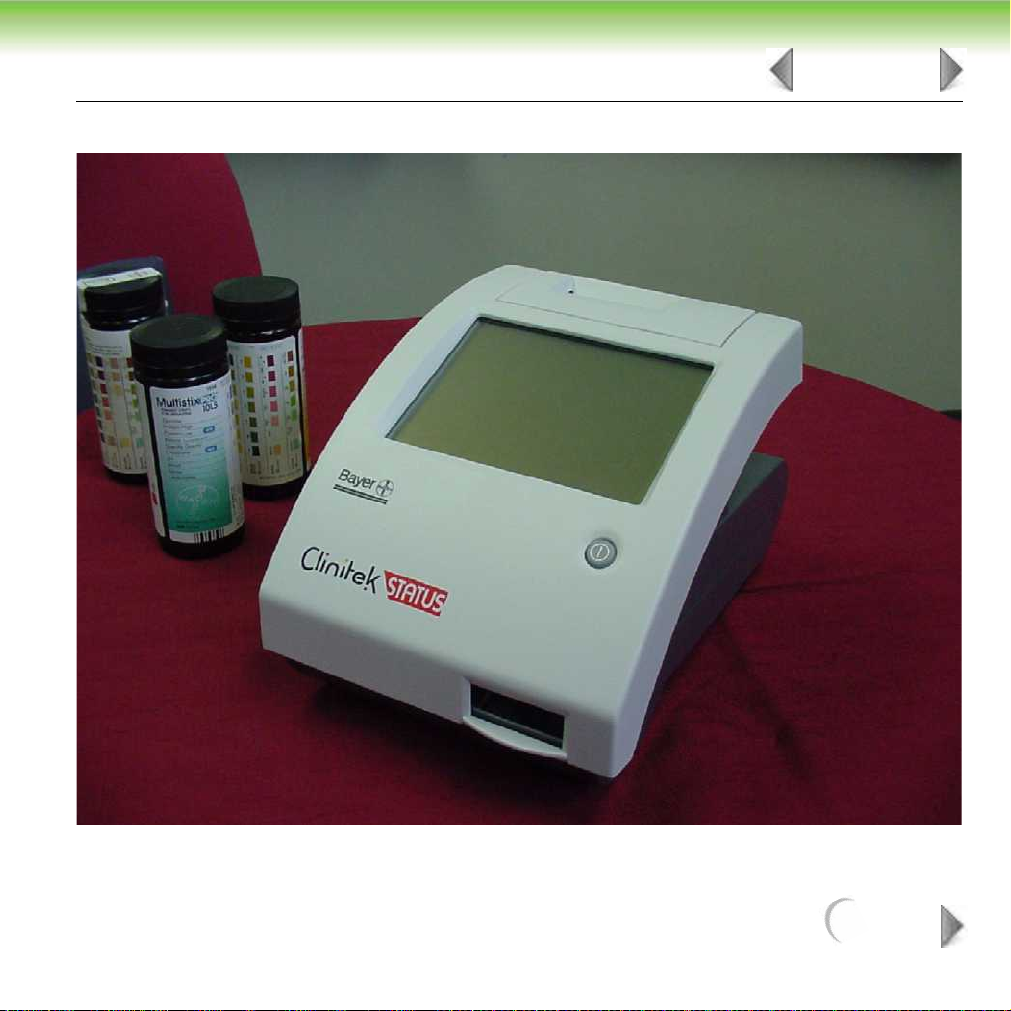

Figure 1-1: Clinitek Status

4 OF 8

NEXT

Page 5

INTRODUCTION AND GENERAL DESCRIPTION

1.3 General Specifications

SIZE:

Depth – 27.2 cm (10.7 in.)

Width – 17.1 cm (6.7 in.)

H

eight – 15.8 cm (6.2 in.)

WEIGHT:

1.66 Kg (3.65 lb)

INPUT VOLTAGE:

110 VAC ± 20%

45-65 Hz (US only)

220 VAC ± 20%

45-65 Hz (European)

9 VDC

5 OF 8

(6 AA Batteries)

MAXIMUM POWER INPUT:

Maximum power input to battery eliminator is 18.4 VA

Maximum power output from battery eliminator / input to instrument is 7.2 VA

NEXT

Page 6

INTRODUCTION AND GENERAL DESCRIPTION

THERMAL OUTPUT:

Battery eliminator 62.7 BTU/hr

Instrument 24.6 BTU/hr

Line Leakage Current:

170 microamperes in normal condition

Power supply is double insulated type, no leakage in fault condition.

(Testing protocol and allowable limits as specified by the safety standards for

laboratory equipment outlined in UL 3101-1; CSA 22.2 No. 1010.1; IEC 1000-4

Sections 2, 3, 4, 5, 6, 8, and 11; CISPR 11; EN 50082-1 Jan. 1992; EN60950 5.2.2

and 5.2.3; and EN 50081-1 Jan. 1992.)

AMBIENT OPERATING TEMPERATURE RANGE:

10˚C to 40˚C (50˚F to 104˚F)

AMBIENT OPERATING HUMIDITY RANGE:

10% to 90% relative humidity

6 OF 8

OPTIMUM OPERATING CONDITIONS:

18˚C to 30˚C (64˚F to 86˚F)

10% to 85% relative humidity

This device complies to FCC Part 15 as a Class A device.

COMPUTER INTERFACE:

9-Pin RS-232 protocol with comma deliminated output. Null modem cable required.

NEXT

Page 7

INTRODUCTION AND GENERAL DESCRIPTION

PRINTER PAPER:

(Ludlow C-696)

Width — 5.8 cm (2.28 in.)

Length — 2500 cm (82 ft.)

Shelf Life — 5 years

Storage — <25˚C; <65% RH

DEFAULT SETTINGS:

Default settings are defined in the Operator’s Manual. New instruments are shipped

from the manufacture set to English-Conventional.

7 OF 8

NEXT

Page 8

INTRODUCTION AND GENERAL DESCRIPTION

Instrument Programmed Reagent Strip Multiples and Cassettes:

8 OF 8

Multistix® 10 SG (N-Multistix® SG-L)

Multistix® 8 SG (Multistix® GP)

Multistix® 7

Multistix® 5

Multistix® SG

Multistix PRO® 10LS

Multistix PRO® 7PH

Multistix PRO® 7G

Multistix PRO® 6B

Multistix PRO® 6K

N-Multistix® SG

Uro-Hema-Combistix® SG-L

Uro-Hema-Combistix

Hema-Combistix

®

®

Uristix® 4

Uristix

®

Labstix® SG

N-Neostix

Uro-Uristix

®

®

Combistix® SG

Clinitek® Microalbumin

Clinitest® hCG

TO TOP

BACK

Page 9

2 METHODS OVERVIEW

1 OF 2

Introduction ........................................................................................ 2

NEXT

Page 10

METHODS OVERVIEW

2 OF 2

2.1 Introduction

The CLINITEK® Status instrument is a reflectance photometer, which reads the

changes in color of the Bayer urine reagent strips and immunoassay cassettes. A

series of six light emitting diodes (LED) each at a different wavelength illuminates

the entire strip or cassette length. Reflected light from the strip is then passed

through a lens and focused on a photodiode detector array (CCD) which then

converts the light energy into an electronic signal. This signal is then passed

through an A/D converter and then onto a microprocessor. Once there, the signal

is processed into percent reflectances and then decodes. These decode values

are compared to lookup tables containing specific decode ranges for each

reagent and their respective clinical values. Results are reported to the customer

via the touch screen, onboard printer, and/or through a computer interface.

For methods used on the urine reagent strips and immunoassay cassettes, refer

to their specific product inserts.

TO TOP

BACK

Page 11

3 INSTALLATION

Introduction ........................................................................................ 2

1 OF 2

NEXT

Page 12

INSTALLATION

3.1 Introduction

2 OF 2

Refer to Section 1 “Introduction”

Manual for the proper installation and set up of the CLINITEK

1

Unpack the instrument from the shipping packaging.

2

Remove package tape from the front of the instrument, table shutter.

3

Insert test table with table insert approximately one half to two thirds of the

way into the instrument.

Plug the power supply into a mains outlet.

4

5

Connect the power supply plug into the back of the instrument using the

power jack on the instrument.

6

Push the power button momentarily to turn instrument on, instrument should

beep once.

7

For initial, first time power up for the instrument, follow the “Start-Up Wizard.”

8

Subsequent power ups after the initial, the instrument should return to the

“Select Ready” screen after instrument hardware and software checks.

and Section 3 “Start-Up Wizard” of the Operators

®

Status Analyzer.

TO TOP

BACK

Page 13

4 OPERATIONS /

1 OF 18

PROCEDURES

Introduction.......................................................................................... 1

Urinalysis Strip Test ............................................................................ 3

Cassette Method ................................................................................ 12

NEXT

Page 14

OPERATIONS / PROCEDURES

2 OF 18

4.1 Introduction

Refer to Section 4 “Instrument Operations” of the Operators Manual for the

operation of the CLINITEK® Status Analyzer. This section describes both strip and

cassette test procedures.

NEXT

Page 15

OPERATIONS / PROCEDURES

3 OF 18

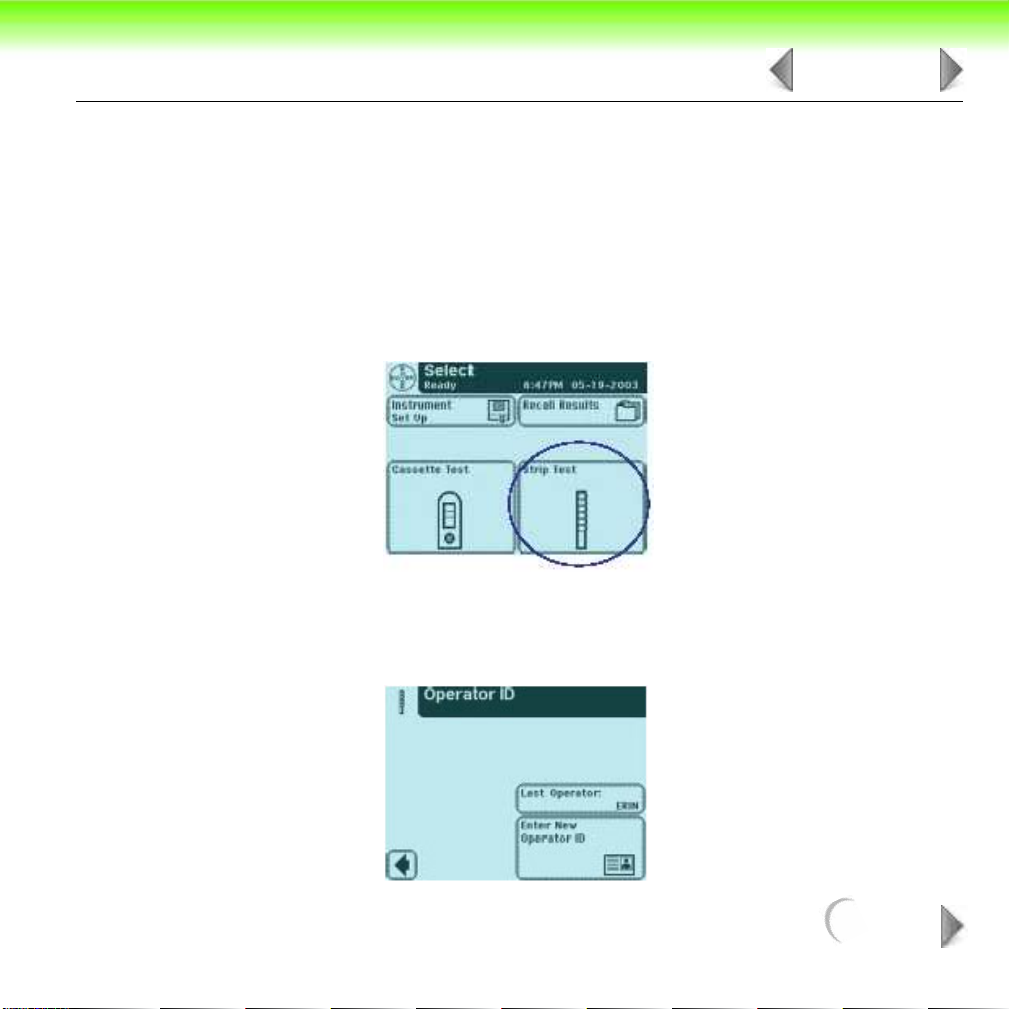

4.2 Urinalysis Strip Test

A Full Strip Test allows you the option to enter an Operator ID, Patient Name and/or

Patient ID prior to inserting a strip. The procedures to enter the Operator and

Patient data are presented in this section. The strip testing process is identical to a

Quick Strip Test.

Testing is started from the main Select screen.

Touch Strip Test to conduct a Bayer urinalysis strip test.

The next screen that appears is Operator ID.

NEXT

Page 16

OPERATIONS / PROCEDURES

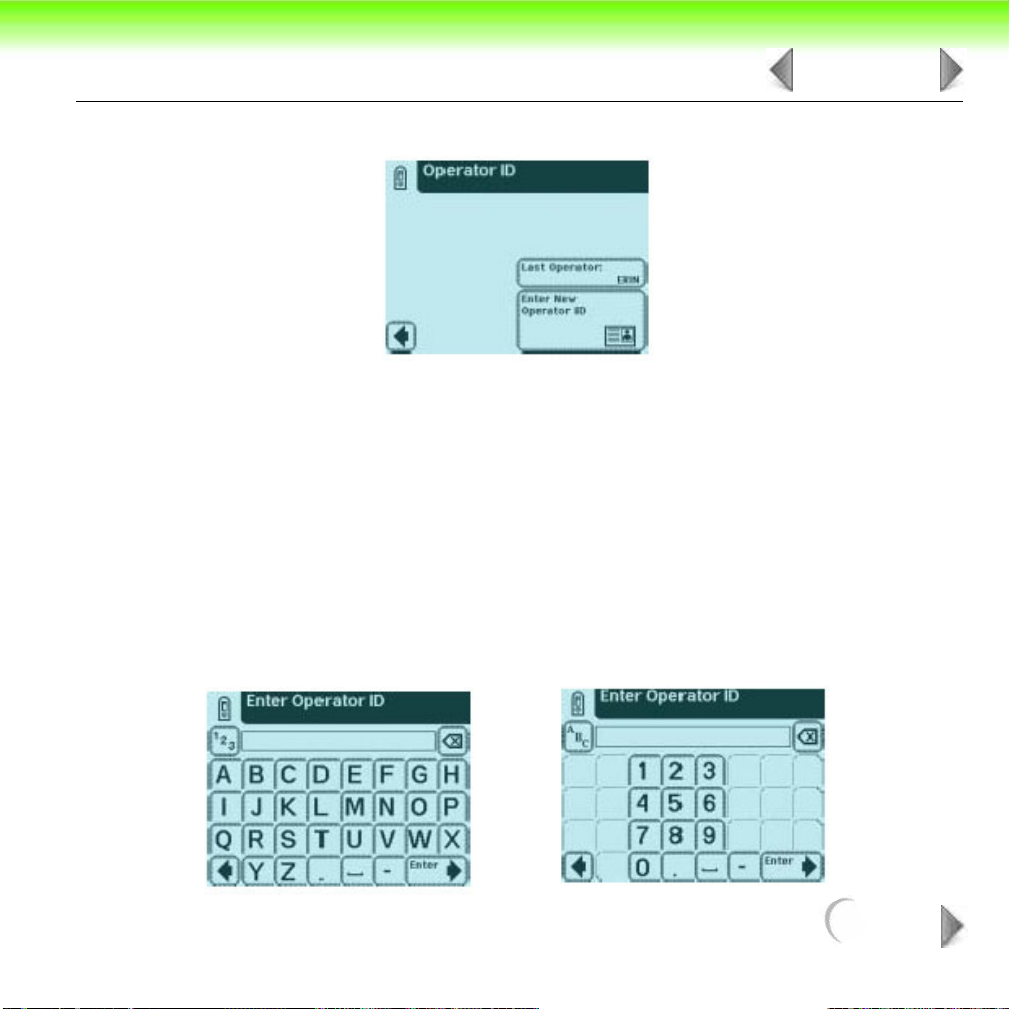

There are two options under Operator ID: Last Operator or Enter New

Operator ID.

OPTION 1: LAST OPERATOR

If this option is enabled, the last operator that entered his/her ID will be displayed on

the screen in the lower right side of the box. If you are this operator, then touch the

Last Operator button to proceed.

OPTION 2: ENTER NEW OPERATOR ID

In order to enter the information for a new operator, touch Enter New Operator ID

button. The next screen that is displayed is Enter Operator ID.

4 OF 18

NEXT

Page 17

OPERATIONS / PROCEDURES

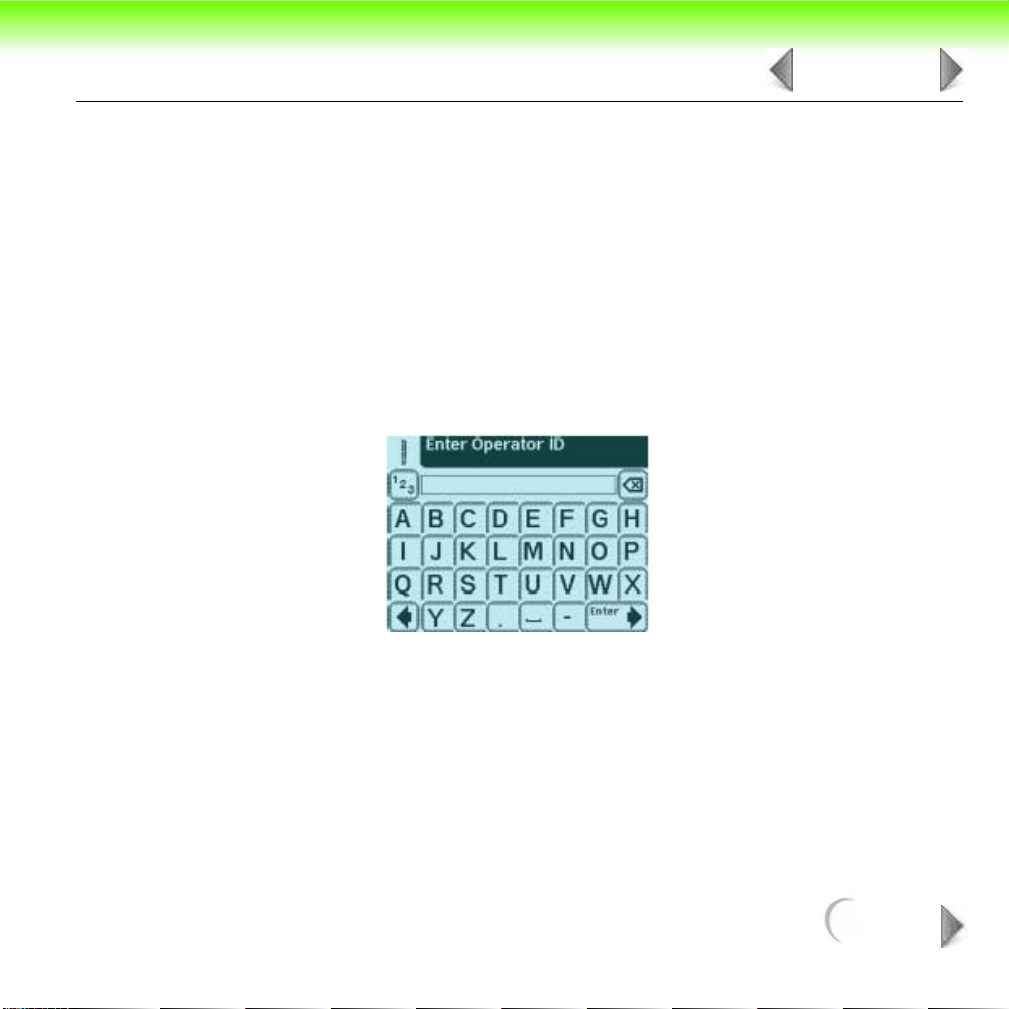

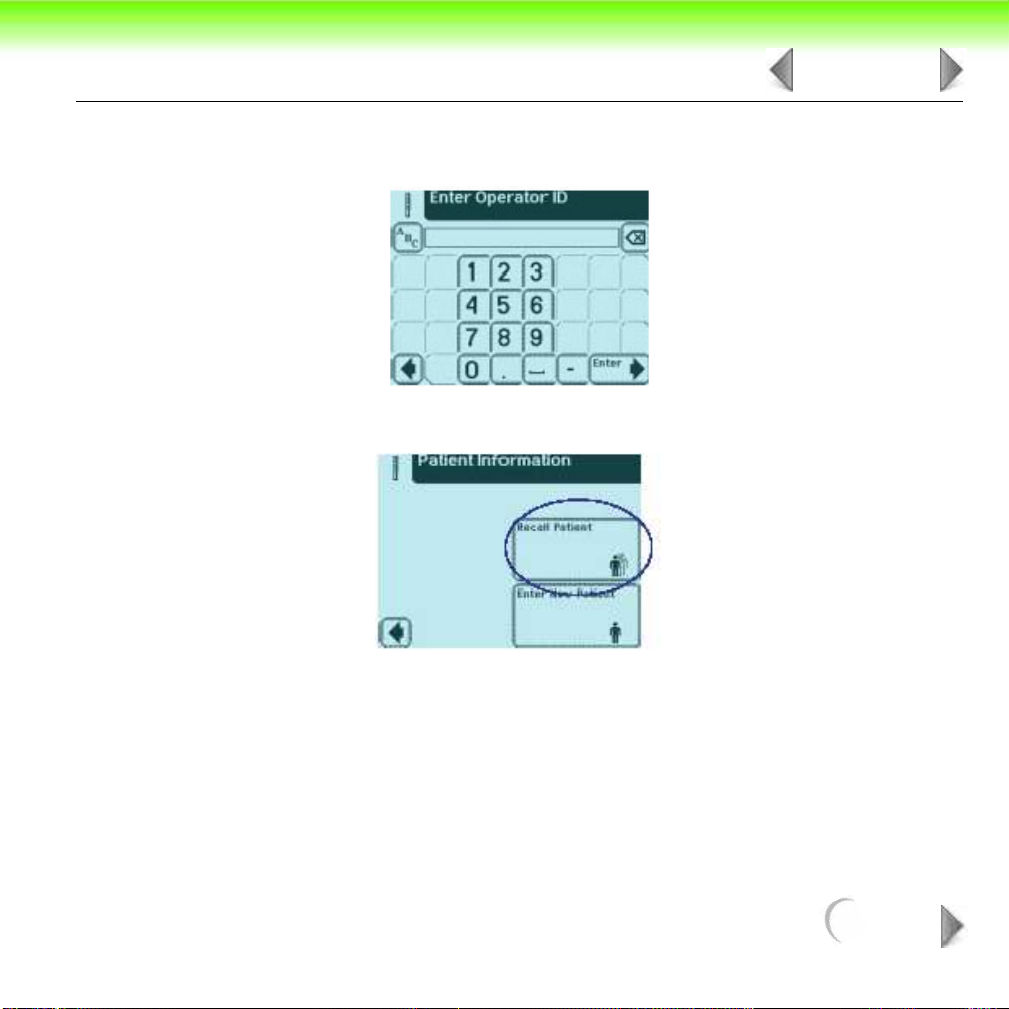

Use the keyboards to enter Operator ID using a maximum of 13 characters. Touch

Enter when you have finished entering the ID and to move to the next screen.

The next screen displayed is Patient Information.

5 OF 18

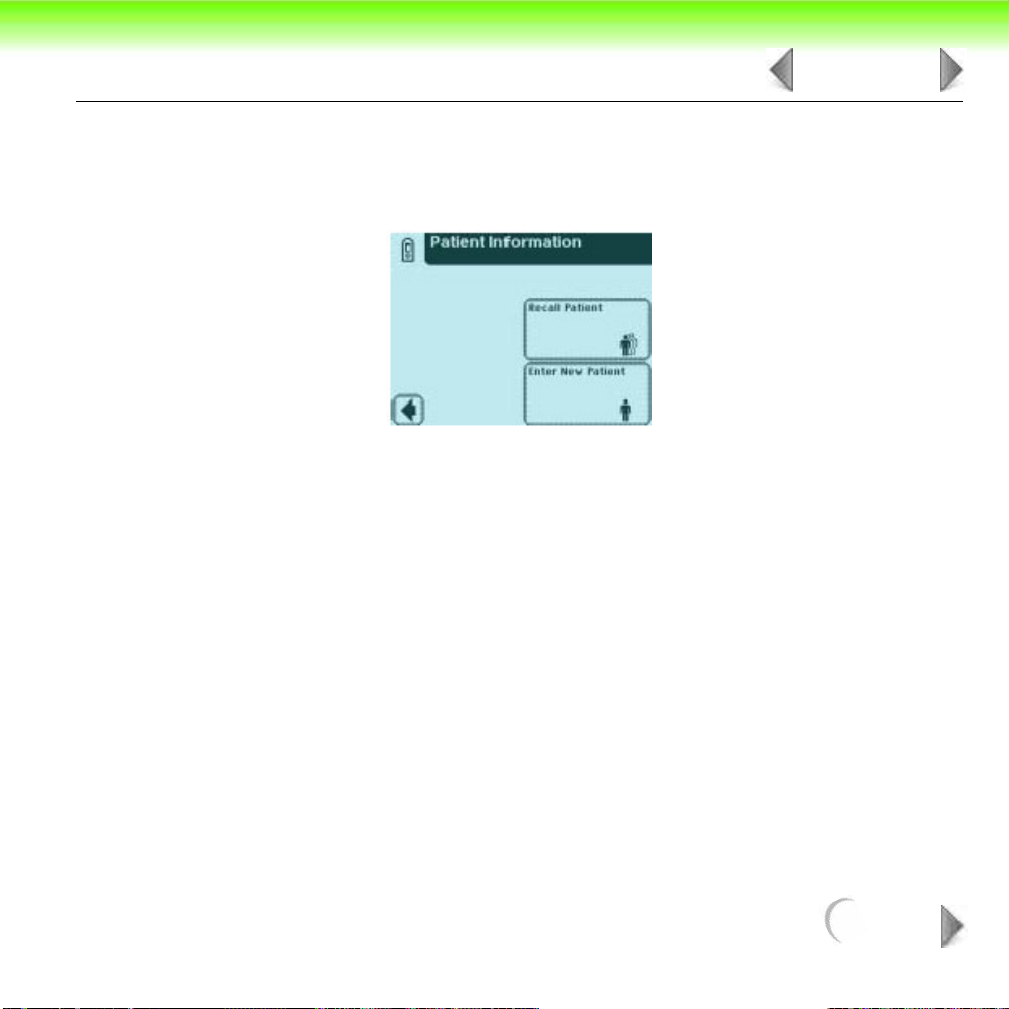

There are two options under Patient Information: Recall Patient or Enter New

Patient.

NEXT

Page 18

OPERATIONS / PROCEDURES

6 OF 18

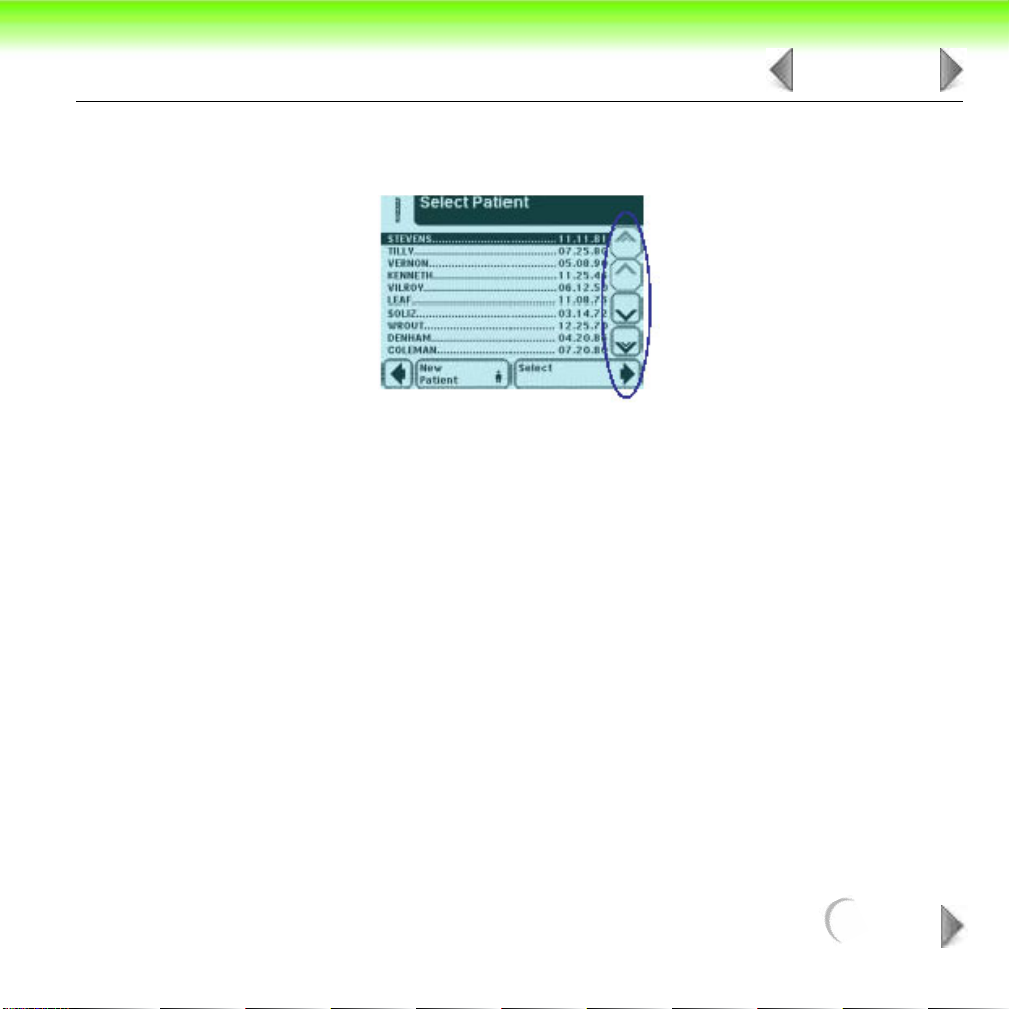

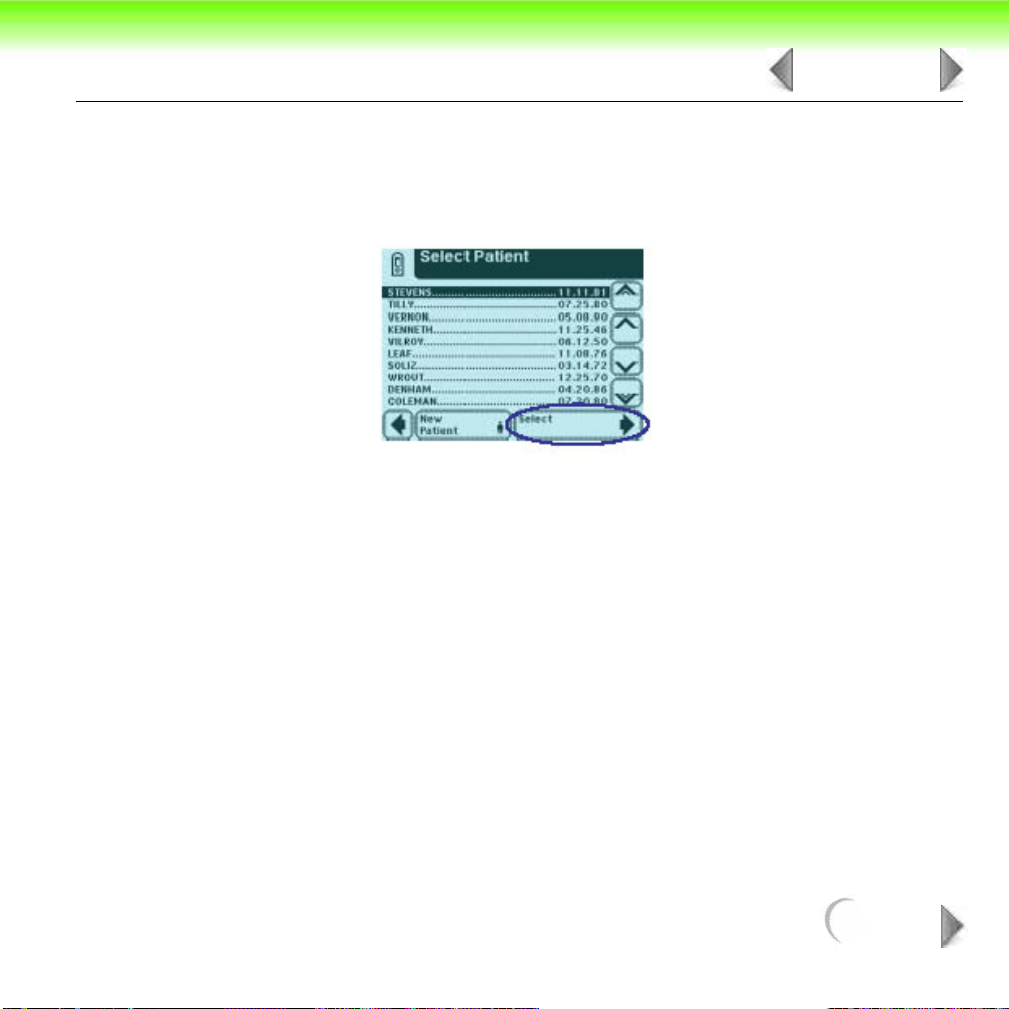

OPTION 1: RECALL PATIENT

In order to look up previous patients, touch Recall Patient.

If previous patient identification has been entered, a list of up to 200 patient results

will appear on the screen. Use the up and down arrow buttons to scroll through the

list of patients. The most recently performed test will be shown at the top. Once the

patient is highlighted, touch Select button.

The next screen will be Prepare Test.

NOTE: A total of 200 patient tests can be stored in the analyzer. The tests are listed in

chronological order. When the limit of 200 has been reached, the oldest test will be

deleted from the analyzer. Deleted information cannot be retrieved from the

analyzer.

NEXT

Page 19

OPERATIONS / PROCEDURES

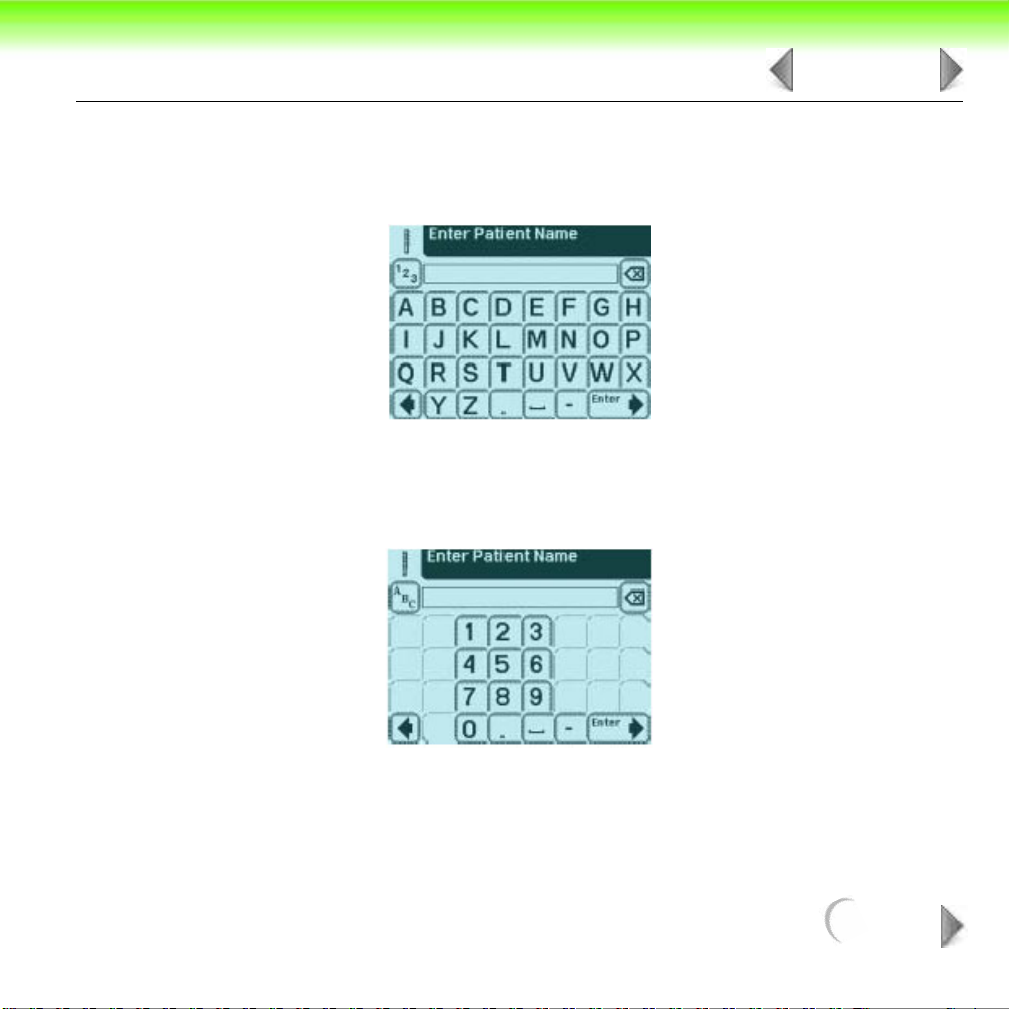

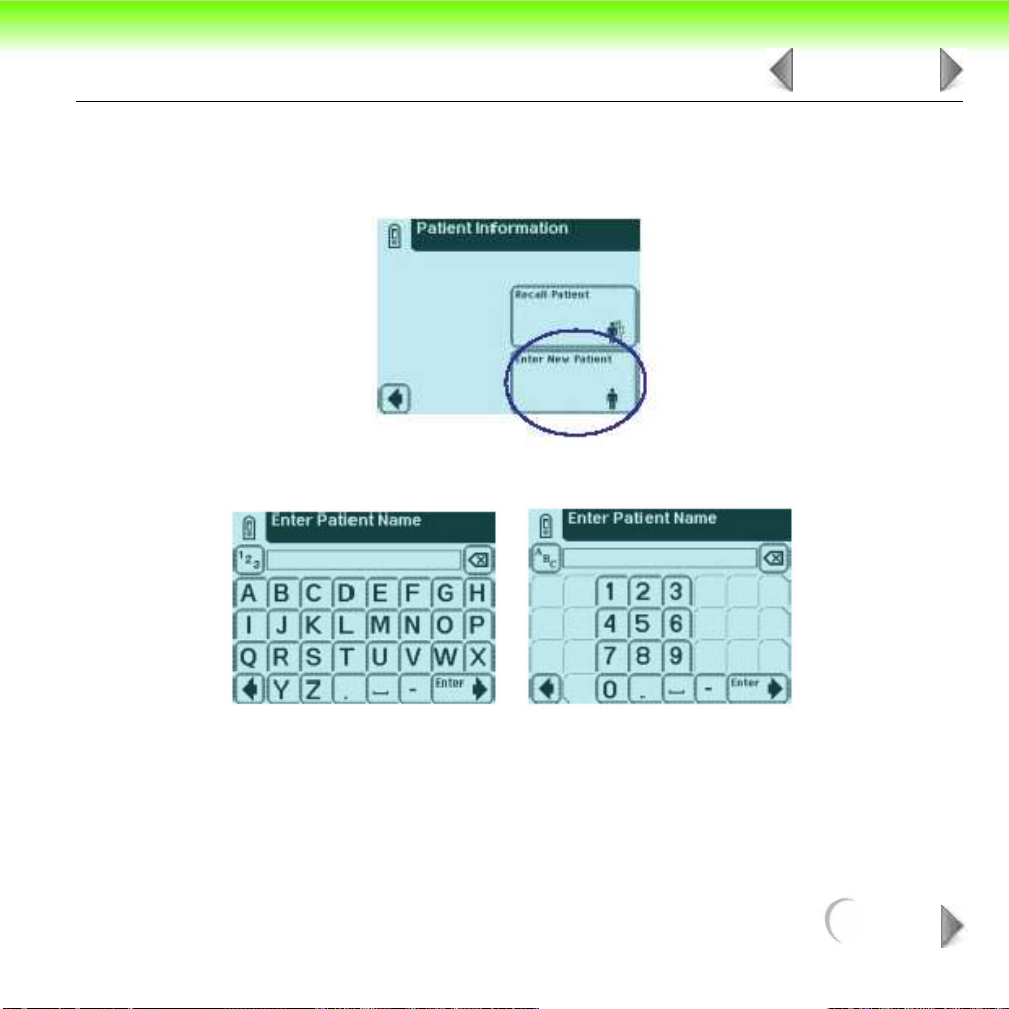

OPTION 2: ENTER NEW PATIENT

In order to enter the information for a new patient, touch Enter New Patient button.

The next screen displayed is Enter Patient Name.

Use the keyboards to enter Patient Name using a maximum of 20 characters. Touch

Enter when you have finished entering the patient’s name and to proceed to the

next screen.

7 OF 18

The next screen that appears is Prepare Test.

While the strip is being analyzed, a Select Appearance screen will be displayed.

The urine sample must be visually observed and then the appropriate color and

clarity must be selected.

NEXT

Page 20

OPERATIONS / PROCEDURES

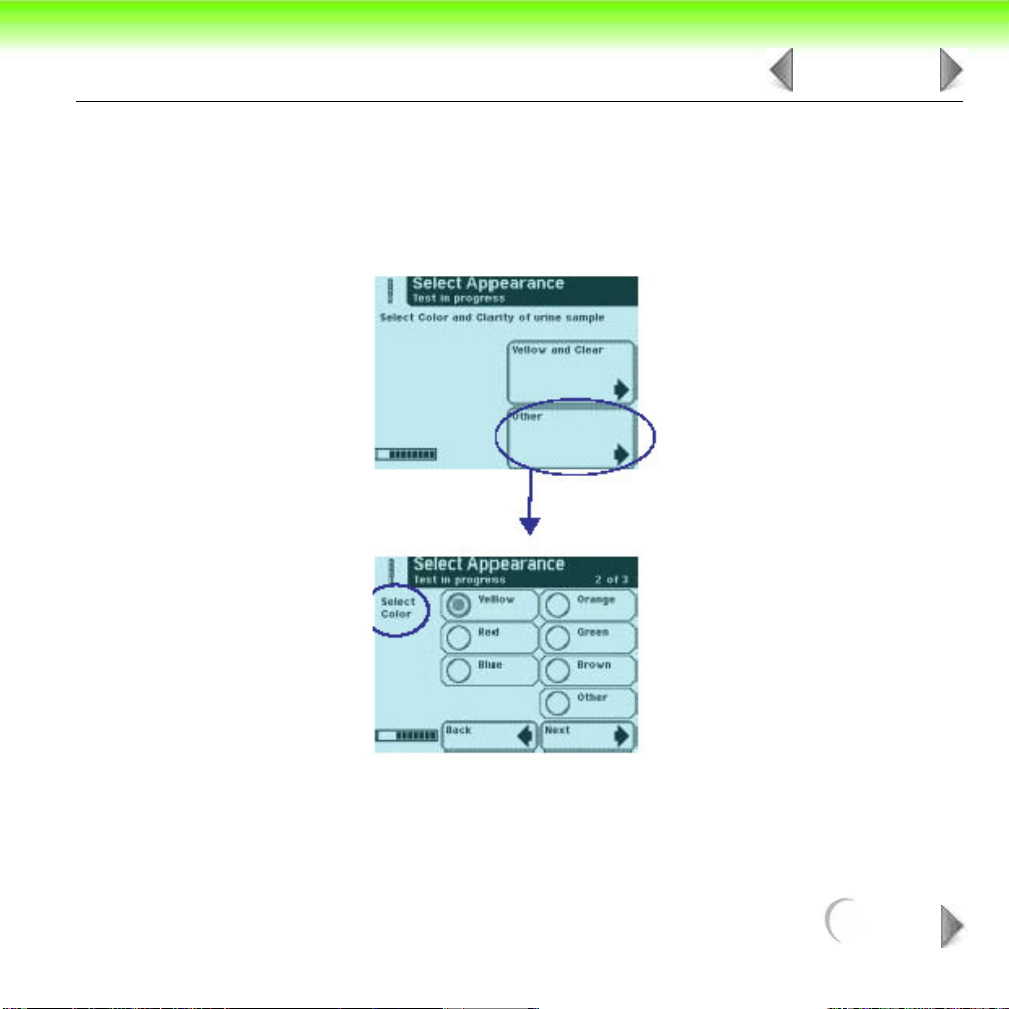

If the urine sample is yellow and clear, touch the Yellow and Clear button.

If the urine sample is not yellow and clear, touch the Other button for more choices.

If you touched the Other button, then select the appropriate color by touching the

circle button that corresponds to the correct description.

8 OF 18

NEXT

Page 21

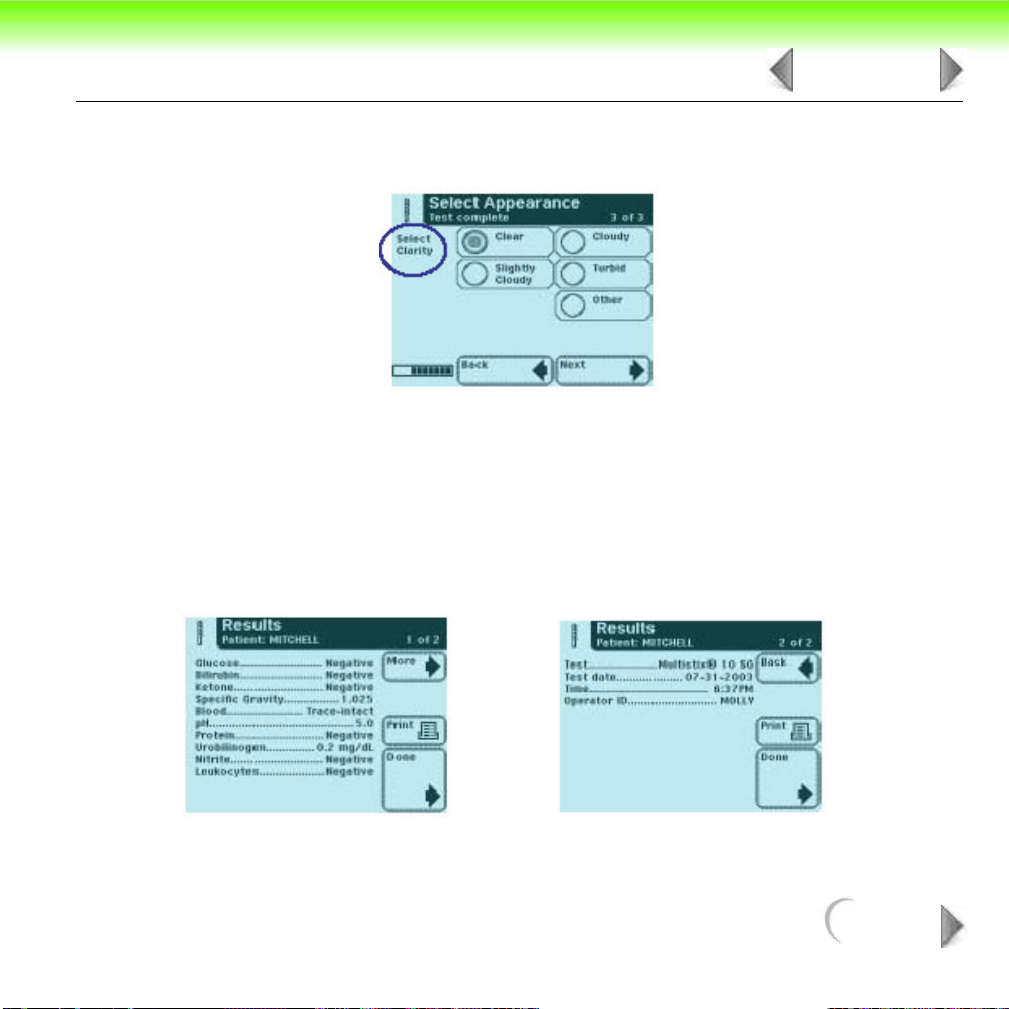

OPERATIONS / PROCEDURES

Select the clarity by touching the circle that corresponds to the correct description.

Then touch Next.

There is a time indicator on the Select Appearance screen that is counting down

the time remaining in the analysis of the strip.

After color and clarity have been entered the next screen displayed will either be:

9 OF 18

• Analyzing — if the strip is still being analyzed

• Results — if analyzing the strip has been completed

NEXT

Page 22

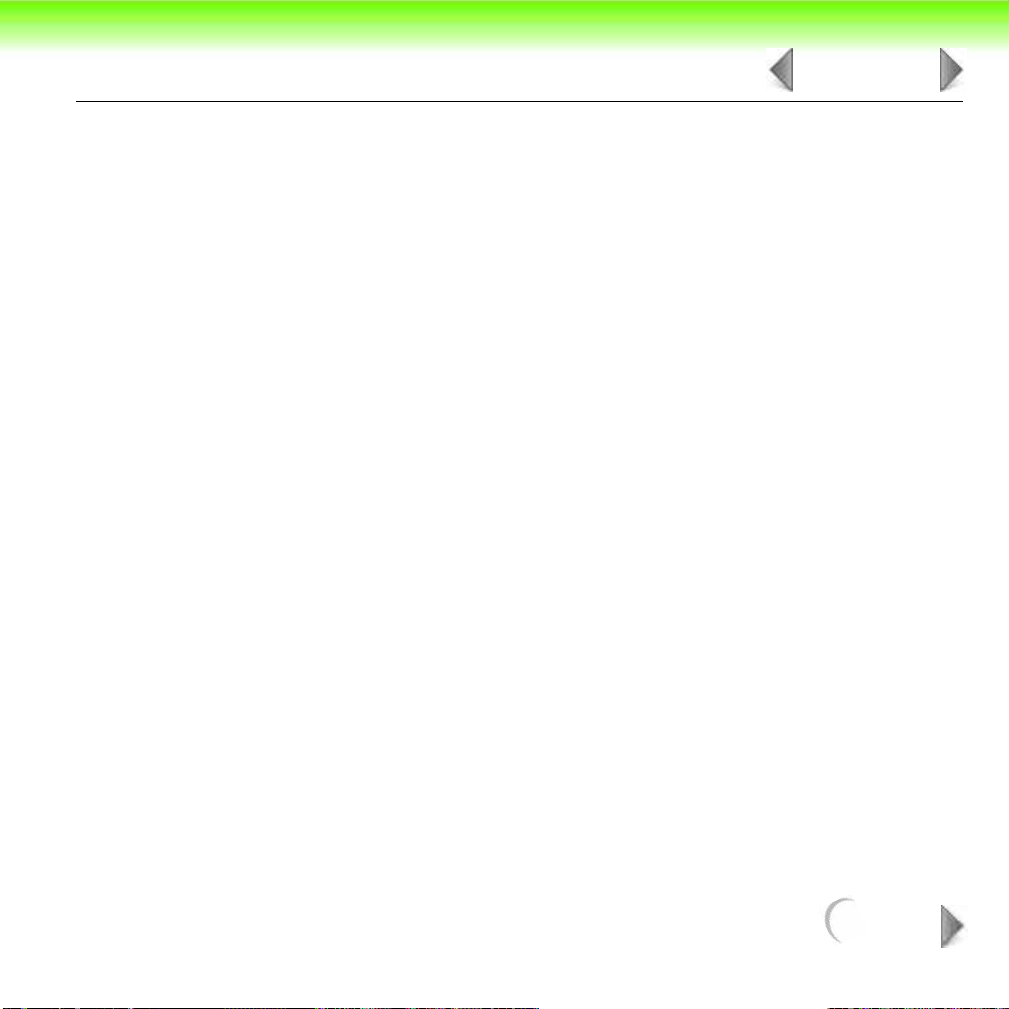

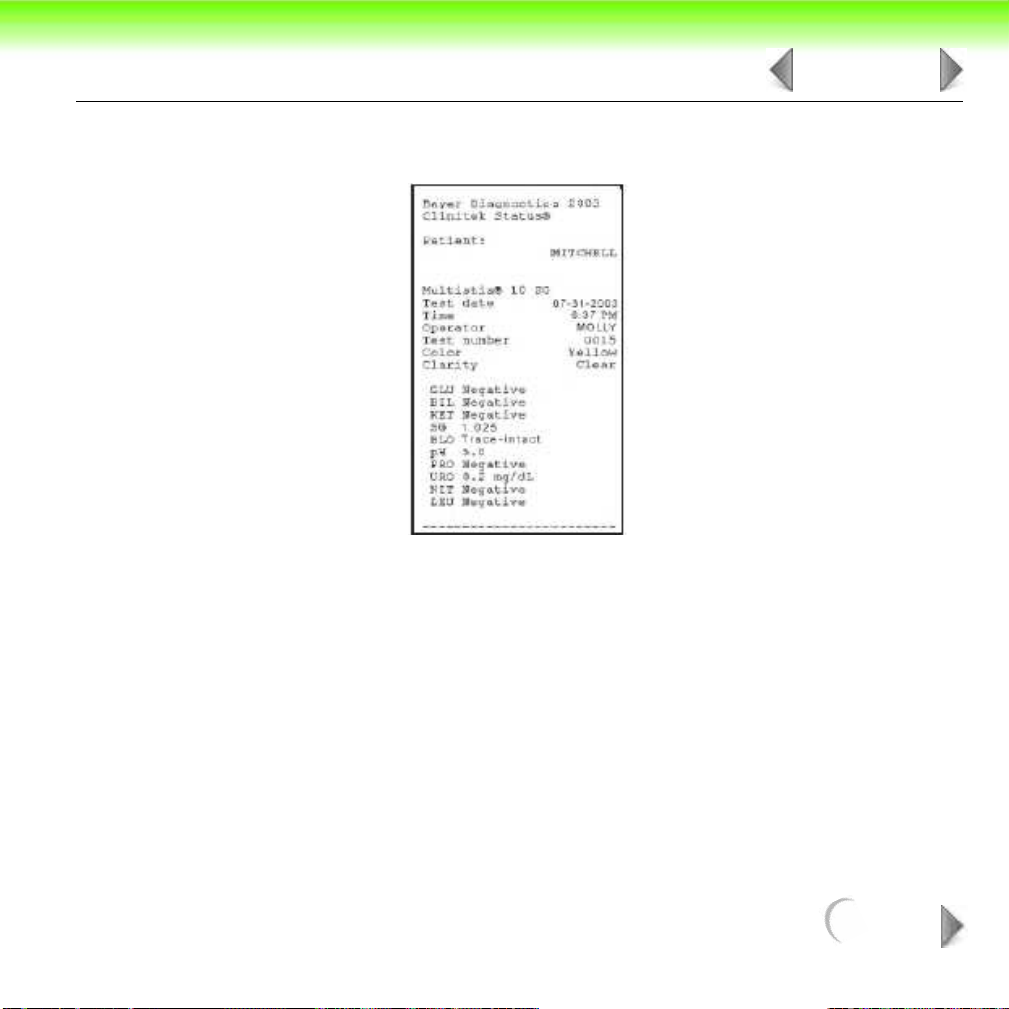

OPERATIONS / PROCEDURES

The test results displayed on the screen and the printout will include the following

information:

10 OF 18

• Patient Name or ID

• Type of strip used

• Test date

• Time

• Operator

• Test Number

• Color

• Clarity

• Results

NEXT

Page 23

OPERATIONS / PROCEDURES

NOTE: If the results are positive, an asterisk* will appear next to the results (if “mark

positive results” was selected in Instrument Set Up).

11 OF 18

NEXT

Page 24

OPERATIONS / PROCEDURES

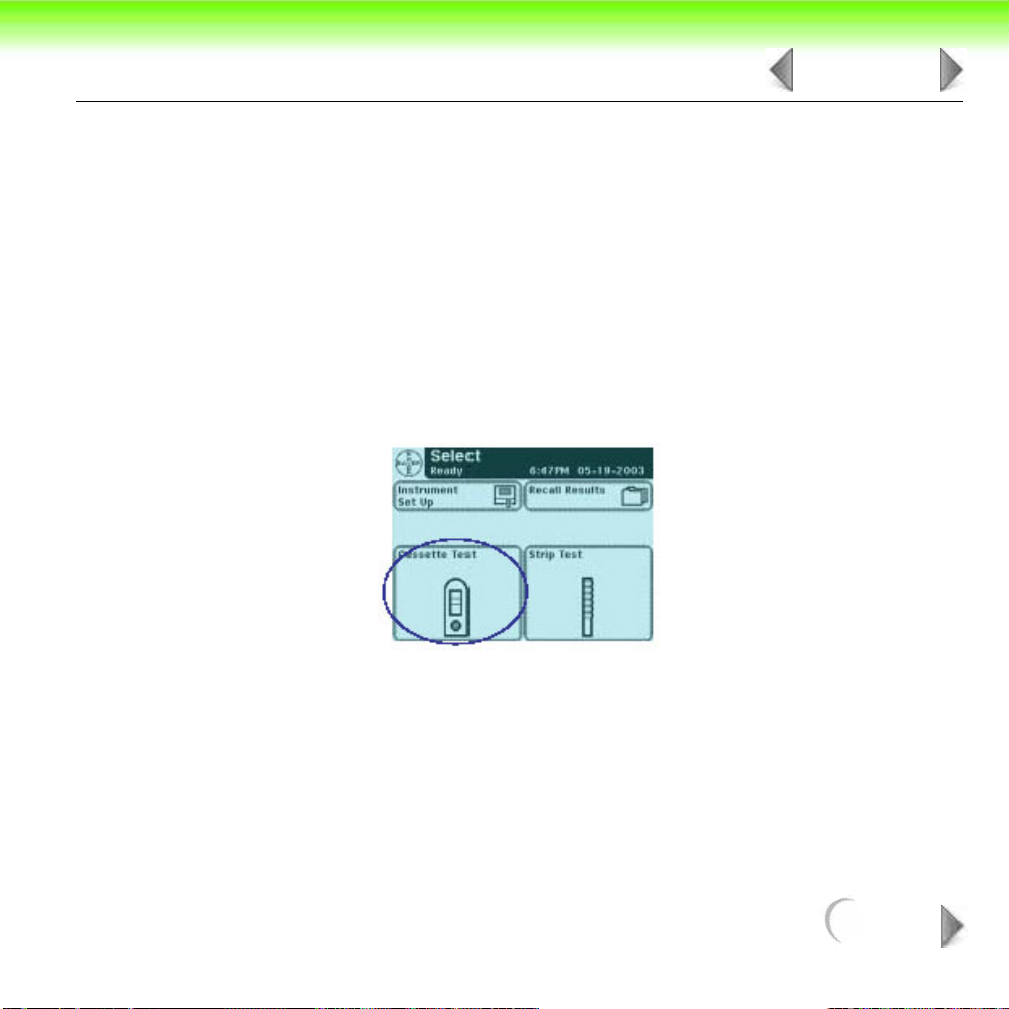

4.3 Cassette Method

A Full Cassette Test allows you the option to enter an Operator ID,

Patient Name and/or Patient ID prior to inserting a cassette.

The procedures to enter the Operator and Patient data are

presented in this section.

The cassette testing process is identical to a Quick Cassette Test.

Testing is started from the main Select screen.

12 OF 18

Touch Cassette Test to conduct an hCG pregnancy test.

NEXT

Page 25

OPERATIONS / PROCEDURES

The next screen that appears is Operator ID.

There are two options under Operator ID: Last Operator or Enter New Operator ID.

OPTION 1: LAST OPERATOR

If this option is enabled, the last operator that entered his/her ID will be displayed on

the screen in the lower right side of the box. If you are this operator, then touch the

Last Operator button to proceed.

OPTION 2: ENTER NEW OPERATOR ID

In order to enter the information for a new operator, touch Enter New Operator ID

button. The next screen that is displayed is Enter Operator ID.

13 OF 18

NEXT

Page 26

OPERATIONS / PROCEDURES

Use the keyboards to enter Operator ID using a maximum of 13 characters. Touch

Enter when you have finished entering the ID and to move to the next screen.

The next screen displayed is Patient Information.

There are two options under Patient Information: Recall Patient or Enter New

Patient.

OPTION 1: RECALL PATIENT

In order to look up previous patients, touch Recall Patient.

14 OF 18

NEXT

Page 27

OPERATIONS / PROCEDURES

15 OF 18

If the previous patient identification has been entered, a list of up to 200 patients will

appear on the screen. Use the up and down arrow buttons to scroll through the list

of patients. The most recently performed test will be shown at the top. Once the

patient is highlighted, touch the Select button.

The next screen will be Test Type.

NOTE: A total of 200 patient tests can be stored in the analyzer. The tests are listed in

chronological order. When the limit of 200 has beenreached, the oldest test will be

deleted from the analyzer. Deleted information cannot be retrieved from the

analyzer.

NEXT

Page 28

OPERATIONS / PROCEDURES

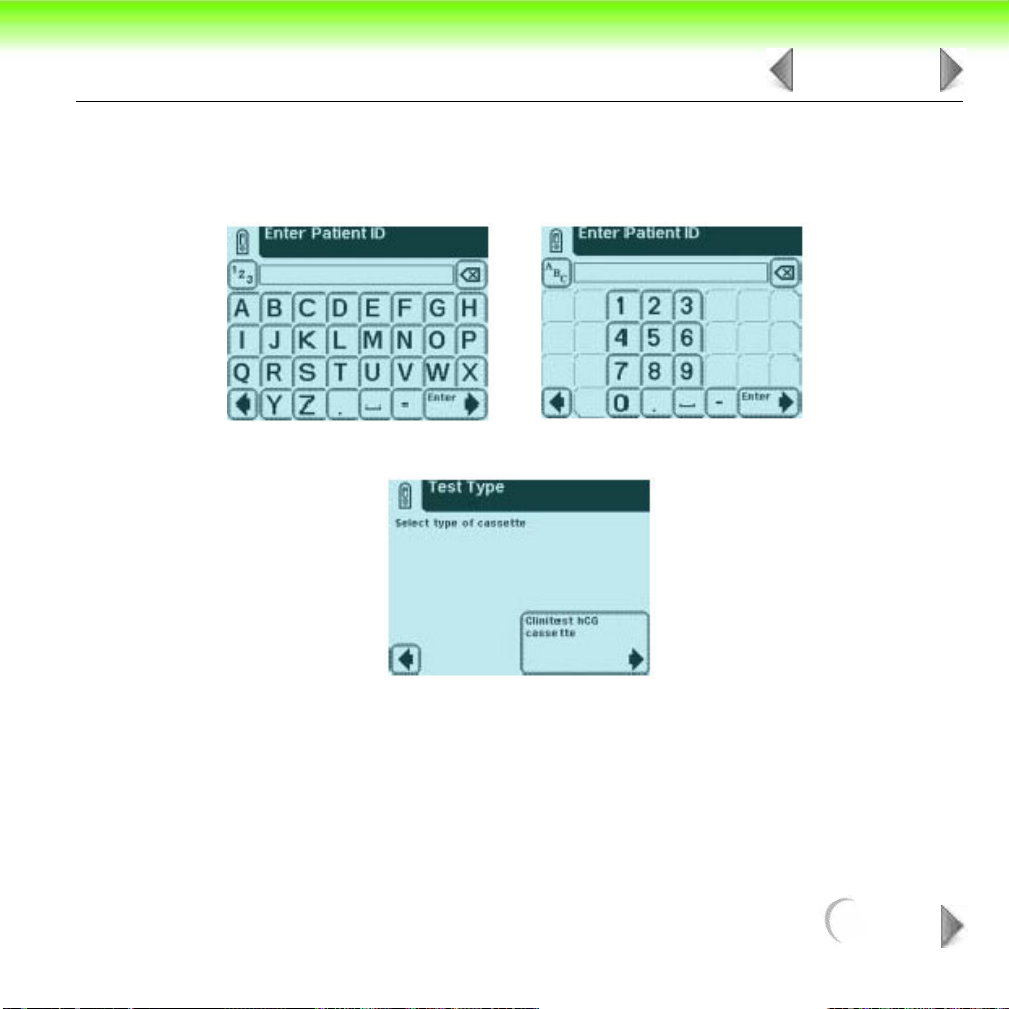

OPTION 2: ENTER NEW PATIENT

In order to enter the information for a new patient, touch the Enter New Patient

button.

The next screen displayed is Enter Patient Name.

16 OF 18

Use the keyboards to enter Patient Name using a maximum of 20 characters. Touch

Enter when you have finished entering the patient’s name and to move to the next

screen.

NEXT

Page 29

OPERATIONS / PROCEDURES

The next screen displayed is Enter Patient ID. Use the keyboards to enter Patient

Identification using a maximum of 13 characters. Touch Enter when you have

finished entering the patient’s ID and are ready to proceed to the next screen.

The next screen that appears is Test Type.

17 OF 18

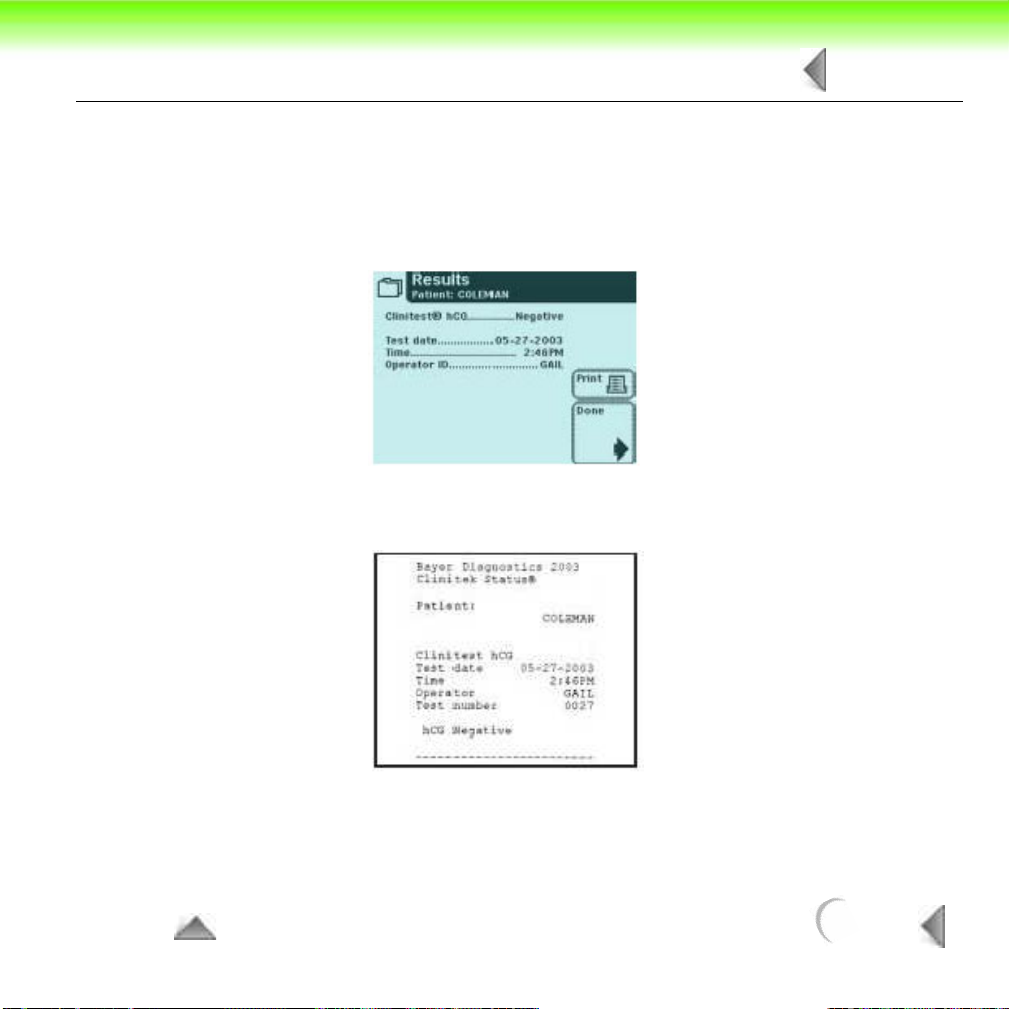

The test results displayed on the screen and the printout will include the following

information:

• Patient Name or ID

• Type of Clinitest cassette test

• Test date

NEXT

Page 30

OPERATIONS / PROCEDURES

18 OF 18

• Time

• Operator

• Tes t N u m b e r

• Result

NOTE: If the result is positive, an asterisk* will appear next to the result (if “mark positive

results” was selected in Instrument Set Up).

TO TOP

BACK

Page 31

5 PREVENTIVE

1 OF 7

MAINTENANCE

Introduction ........................................................................................ 2

Cleaning.............................................................................................. 3

NEXT

Page 32

PREVENTIVE MAINTENANCE

2 OF 7

5.1 Introduction

This section describes cleaning and preventative maintenance test procedures that

should be performed as a matter of routine anytime that a CLINITEK® Status

instrument is in Bayer Diagnostics possession. Following these procedures will help

identify possible system weaknesses prior to them manifesting themselves as field

failures.

Wear disposable surgical gloves when working with reagents, fluids, or

cleaning the instrument.

Place all cleaning or disposable items in a biohazard bag.

NEXT

Page 33

PREVENTIVE MAINTENANCE

3 OF 7

5.2 Cleaning

Refer to Section 8 “Maintenance” of the CLINITEK® Status Operators Manual for

specific cleaning and disinfecting instructions for the instrument, test table insert

and test table.

CAUTION:

Care should be taken when handling the test table to insure that the

calibration bar is not damaged, scratched or marred in any way. If any

damage does occur, the test table must be replaced.

Daily

1

With the instrument power on, gently pull the test table carriage from the instrument.

Remove the test table insert and drain the drip tray if required.

2

3

Examine the calibration strip for any dust, dirt, scratches, or mars.

Do not touch the calibration strip.

4

Using a cotton tipped applicator and distilled water, thoroughly scrub the strip

channel and surrounding area of the insert and also scrub the drip tray. Rinse

the entire test table insert under running water.

Dry insert with a soft lint-free cloth or tissue.

5

If the calibration strip appears dirty, gently clean with a new cotton tipped

6

applicator and distilled water. Allow to air dry and examine again. Obtain a new

test table if the calibration strip can not be cleaned, is scratched or marred.

NEXT

Page 34

PREVENTIVE MAINTENANCE

Refer to “Disinfecting Test Table and Test Table Insert” for disinfecting the test

7

table and test table insert.

8

To reinstall test table and insert, gently push table into instrument until halfway in.

4 OF 7

Disinfecting Test Table and Test Table Insert

If the test table or insert needs to be disinfected the following solutions may be used:

CAUTION:

CAUTION:

Precept

Cidex™ (3.2% glutaraldehyde solution)

Amphyl™ liquid

Theracide™ liquid

Preparation and use of the above products or their equivalents should be in

accordance with their product directions.

Do not allow the disinfection solution to come in contact with the white

calibration strip.

Any solutions other than these listed may damage the test table and

insert.

NEXT

Page 35

PREVENTIVE MAINTENANCE

Household Bleach (5% sodium hypochlorite)

Can be used either full strength or diluted to as much as a 20:1 dilution (5 mL of 5%

sodium hypochlorite to 95 mL of water). Full strength 10% bleach should not be

used since any residue not thoroughly rinsed off can affect several of the reagent

chemistries.

Isopropyl alcohol (70% - 85% or undiluted)

Remove the test table and insert and clean according to “Disinfecting Test Table

1

and Test Table Insert” .

2

Fill a tall, narrow container to a depth of about 4 inches (10 cm) with the

prepared disinfecting solution. An empty Multistix bottle makes an ideal

container.

Place the test table or insert in the solution making sure the calibration strip does

3

not come into contact with solution.

4

Soak the table or insert for no longer than 10 minutes then rinse thoroughly with

water.

5 OF 7

5

Dry with a soft cloth or tissue and replace test table and table insert in the

instrument.

NEXT

Page 36

PREVENTIVE MAINTENANCE

6 OF 7

Removing Heavy Buildup

If the test table and table insert are cleaned regularly, heavy buildup should not

occur. However, if urine has been allowed to dry on the table and insert a strong

solution may be required to clean.

CAUTION:

1

Remove the test table and insert from instrument. Wet a cotton-tipped applicator

with 0.1N sodium hydroxide (NaOH).

Clean the strip holding channel, surrounding areas, drip tray and table insert

2

until all traces of urine has been removed.

Rinse thoroughly with water.

3

Dry with a soft cloth or tissue and replace into instrument.

4

Do not allow the solution to come in contact with the white calibration

strip.

NEXT

Page 37

PREVENTIVE MAINTENANCE

7 OF 7

General Instrument Cleaning

T

he outside of the CLINITEK Status instrument should be kept free of dust, dirt,

and urine. If the instrument requires cleaning, turn the instrument off by pressing

the power button for 2 seconds. The instrument can be wiped off with a damp

cloth and any of the disinfection solutions listed or a mild detergent.

CAUTION:

Care should be taken to insure that no liquid is allowed to enter the

printer compartment.

TO TOP

BACK

Page 38

6 THEORY OF OPERATION

1 OF 11

General Description ............................................................................ 2

LCD display and Touch Screen assembly .......................................... 3

Main PCB ............................................................................................ 4

Printer ................................................................................................. 9

Interconnection ....................................................................... 10

Block Diagram ........................................................ 11

NEXT

Page 39

THEORY OF OPERATION

2 OF 11

6.1 General Description

The Clintiek Status urine analyzer is a reflectance photometer designed to provide

semiquantative clinical results when used with Bayer Urinalysis test strips and

imuno assay cassettes. The instrument can be broken down into the following

subsystems:

Optical system

The Processor

User interface

The optical system provides both llimation of the test cassette of strip using light

from six LEDs. This light is directed on to the test surface by a light plastic light

guide that provides unforim ilumation across the length of the read area. This light

is then reflected off the read area to a mirer which directs the light to a lens that

focuses the reflected image onto a CCD array.

The Clinitek Status optical system reads the entire length of the read area in one

reading. The image of the read area is refected and focused on the CCD array, each

element of the CCD array is then clocked out, amplified ,sent to a 10 bit A/D

convertor, and the digital value to each ellemnt is then stored in an array in the

instruments memory. This entire process is refered to a “Scan”. When a test is

processed the system will scan the read area ten times and averaged, thus the

average of the ten scans are used in the instrument aliogrothms for generating the

clinical results. At the start of eact test the instrument scans the white calibration

bar on the table to calibrate the instrument so that the sample refletance readings

can be determined. Test results are displayed on the screen, they can also be printed

on the internal printer or sent out the serial communcations port.

NEXT

Page 40

THEORY OF OPERATION

3 OF 11

6.2 LCD display and Touch Screen assembly

The LCD display and Touch Screen assembly is the primary user interface for the

instrument. The LCD and integrated touch panel are supplied as a semi–

customised assembly with a housing that directly attaches to the upper cover of the

instrument. This provides a fluid resistant and electrically resistant seal to the

housing. The assembly contains electronics that convert a serial stream of 4 bit

wide data along with some necessary control signals to the electrical signals

necessary to excite the LCD panel itself. The LCD then provides a 320 by 240

monochrome, single level (Black or background) display for viewing by the user

from a single 5V supply and TTL/CMOS signals. An analog voltage input from the

main PCB can then vary the contrast of the whole display. The LCD is interfaced

directly to the main PCB by a single 14 way Flexible cable with printed connector.

The 8 by 6 touch screen overlay is completely passive and contains no electronics.

It provides an 8 by 6 crosspoint matrix of normally open resistive switches on a

second 14 pin flexible cable with printed connector for direct interface to the main

PCB. These crosspoints are scanned sequentially by the main board electronics for

any closures. Should multiple closures be detected (which may be ambiguous), the

software in the main board decides on the outcome of these scenariosThis unit

contains embedded electronics to format a 4-bit wide data stream into a 320 by 240

pixel display and control the contrast of the display. The resistive touch screen

provides an 8 by 6 passive overlay on the LCD.

NEXT

Page 41

THEORY OF OPERATION

4 OF 11

6.3 Main PCB

A single PCB that contains all of the necessary control circuits is mounted on the

This “Main PCB “contains the following:

a.

The Microcontroller used to control most of the functions within the instrument is

a Hitachi H8/3006. This component incorporates an internal 32 bit CPU architecture with a 16 bit register set along with embedded RAM, timers, serial communications, memory interface, DMA, I/O ports, ADC and DAC functions. In this

design it is powered from the 5V supply and receives a system clock from an

external oscillator at a frequency of 18.432MHz. External RAM and ROM

(Flash) support the Microcontroller. A large number of the pins / ports on the

device are used for this high-speed interface.

The on chip serial communications controllers are used to interface with the

external RS232 interface, an internal serial interface to a future expansion card

and to the SIP bus that communicates with the NVM, MMC card and RTC.

In general, the I/O ports on the processor are used as inputs and the output

functions are segregated to the U26 CPLD, as there are insufficient on-chip

ports to meet all of the system requirements. The digital input ports come from

the touch screen sensing, power state sensing, drawer position sensing & printer

status.

The timer / counters are used to provide:

A general system timing function.

The sounder drive.

The PWM modulation for controlling the speed of the drawer mechanism.

NEXT

Page 42

THEORY OF OPERATION

The LCD interface which stimulates the DMA to transfer the display image

repeatedly independent of the CPU operation.

The CCD interface which stimulates the ADC and DMA to transfer data from the

CCD into memory independent of the CPU operation.

The 8 bit DAC’s are used to set the LED illumination level when scanning the

sample, the contrast level on the LCD and the offset adjustment to the CCD

variable gain amplifier.

The 10 bit ADC is used in conjunction with its input multiplexer to sample analog

voltages from the CCD, the raw supply voltage, the printer head current and

head temperature and the drawer motor current.

The Microcontroller is reset by an external device (U11, via U26). U11 also

provides a watchdog function so that the instrument is stopped from operating in

the event of a timeout.

b.

The External Memory provided consists of a single 512K byte Static RAM device

for transient data and a single 1 M byte Flash ROM device for the program

memory and static data. The ROM is initially assembled onto the PCB with a

boot loader pre-loaded into it. Subsequently, the ROM has the ‘Status’

application loaded into it during board test using the serial port at high speed. In

service, the ROM can be updated either from an MMC card being inserted into

the MMC connector from under the printer cover of the instrument or from the

serial connection should it be required.

5 OF 11

The Programmable logic device (CPLD - U26) is generally used to provide

c.

output latches and hardware processing functions that were not available on the

Microcontroller. The device is a flash memory programmable device and can be

reprogrammed in-situ by attaching a programmer to the connector position

NEXT

Page 43

THEORY OF OPERATION

provided on the PBA. The CPLD complexity is quite low (72 storage elements)

and so only provides simple functions. In particular, it converts and re-times the

8 bit data into 4bit data for interface to the LCD, drives the touch screen inputs,

the printer head and paper feed functions, the sounder, the sample drawer driver,

the CCD amplifier gain and the power switching functions.

The LED Driver circuit has a digital part that switches on the appropriate LED

d.

when required (under CPU control) and an analog part that converts the voltage

output of one of the Microcontroller DAC’s to a current output. The current is

then used to vary the drive level of the LED’s used for illuminating the sample.

Additionally, two of the digital outputs from this circuit control the power to the

drawer position sensing opto-couplers.

The Variable Gain Amplifier is used to amplify the signal from the CCD on the

e.

Emitter / Detector PCB before application to the ADC in the Microcontroller. The

gain of this amplifier is by default set to +2, but may be set to gains of +1, +3 and

+4 as well when required by the Microcontroller via output ports in the CPLD. To

accommodate the voltage offset from ground of the CCD signal compensation is

applied to the amplifier by a DAC on the Microcontroller.

6 OF 11

f.

The Drawer Motor Driver takes a PWM signal from the Microcontroller, a

direction signal and control signals from the CPLD and produces a high current

‘H Bridge’ drive to the brushed dc. motor. This allows the drawer motor speed

and direction to be altered by the Microcontroller as well as providing braking of

the motor when required. A circuit to allow sampling of the drawer motor current

for future use is also provided that feeds into an ADC channel on the

Microcontroller.

NEXT

Page 44

THEORY OF OPERATION

The Drawer position sensors mounted on the flexible cable assembly are driven

g.

by two outputs from the LED driver circuit and the signals returned from the

sensors interfaced to digital inputs on the Microcontroller via the CPLD.

Additionally two signals are generated by the CPLD to drive interrupt inputs on

the Microcontroller in order to provision for fast servicing of the drawer position

state when required.

h.

The non-volatile memory (NVM) device is a serial EEPROM device that can

store 256k bits of data as 32K bytes of storage that is retained without power on

the instrument. The device is used amongst other things for the storage of

instrument set-up data and calibration data.

The Real Time Clock (RTC) device is a serial device that stores the current date

i.

and time and is powered from the Instrument 5V supply when it is present or

from a permanently fitted primary lithium cell when the instrument supply is not

present. The device communicates over the SPI bus with the Microcontroller,

using its own protocol. The device has its own 32.786KHz crystal timing source.

j.

The Multi-Media Card (MMC) interface is comprised of a connector and some

protection components, so that an MMC card can be inserted into the connector

and read over the SPI bus, using the SPI protocol. The data recorded on the

card is for the purposes of software updates in the field. A specially formatted

card is recognised at power up and read into memory so that reprogramming of

the software application can take place.

7 OF 11

The Sounder is a simple ceramic capsule fitted to the main PCB. The sounder is

k.

driven in a bridge mode from two outputs of the CPLD. The frequency of the

sound is derived from one of the timers on the Microcontroller.

NEXT

Page 45

THEORY OF OPERATION

The Printer Paper Feed Driver is a stepping motor driver that is stepped using

l.

two signals from output latches in the CPLD using a gray code sequence. The

device boosts the current capabilities of the CPLD and provides a bipolar drive

for each winding of the motor. An analog circuit monitors the current that the

motor windings are consuming and chops the waveform to keep the current at or

below one of two predetermined levels that can be set by the Microcontroller.

m.

The Printer Head monitoring circuits buffer and amplify the head current and

head temperature signals before sending them to the ADC on the

Microcontroller. The head temperature should not normally exceed a pre-set

temperature, in the event that it does the software turns off the instrument. The

printer head current is monitored by amplifying the voltage across a low value

resistor in series with the head elements. The signal is then sent to the ADC on

the Microcontroller.

n.

The Printer “head up” and paper out opto sensors on the printer are powered by

main board through resistor feeds and are interfaced back to the Microcontroller

for digital sensing of the states of these signal in order to inhibit printing under

paper out or head up conditions.

8 OF 11

The RS232 Interface acts as a level changer between the 5V logic levels

o.

required at the Microcontroller pins and the +/- 6V (min) signals required to meet

the RS232 specification at the connector on the end of the flexible cable

assembly. The device used is a +/- 15KV ESD compliant part with on board

charge pumps to generate the required voltages for the interface.

NEXT

Page 46

THEORY OF OPERATION

9 OF 11

6.4 Printer

The printer is a thermal printer that prints rows of 384 dots as required across the

special paper supplied from a roll. The paper is then moved so that the next row of

dots can be printed to build up a pixel by pixel graphical image on the paper. The

electronics in the printer takes a serial stream of 8 parallel inputs and determines

which of the thermal heads should be energized. The printing head electronics also

contains a temperature sensor that monitors the temperature of the printhead. This

electronics is connected directly to the main PCB via a high current, 20 way flexible

cable with printed connector.

The paper feed to expose the paper and print the next row of dots is driven by a

simple stepping motor. There are no electronics to drive this motor in the printer.

The two motor windings are presented directly to the main PCB electronics via a 9

way flexible cable with printed connector. On the same flexible cable, the

connections to two opto-couplers that sense the printer head position and paper

present conditions are provided for action by the main PCB electronics.

A 5V logic supply and a 4.2 – 8.5V power source from the main PCB power the

printer. The current taken by the printer has to be actively managed by the main

board electronics to provide an acceptably dense and even image and regulate how

much power is consumed at each printing operation.

NEXT

Page 47

THEORY OF OPERATION

10 OF 11

6.5 Interconnection

A flexible printed circuit assembly provides the interconnections between the main

PCB to the power supply, Drawer mechanism, battery pack and RS232 connector.

At one end it has a 30 way FPC male connector printed within it for connection to

the main PCB. The connections from the main board connector are then distributed

to the other connectors and assemblies directly attached to exposed pads on the

flexible printed circuit.

Connections are made to:

The power inlet connector (with EMC ferrite in line), the RS232 connector with

a.

EMC ferrite on connector pins.

b.

The battery pack via soldered interconnect leads.

The drawer opto-coupler positional feedback devices mounted on a small rigid

c.

section of this circuit.

d.

The drawer motor and noise suppression component(s).

NEXT

Page 48

THEORY OF OPERATION

6.6 Block Diagram

Figure 6-1: Block Diagram

11 OF 11

TO TOP

BACK

Page 49

7 DIAGNOSTICS

1 OF 60

TROUBLESHOOTING

Introduction ........................................................................................ 2

Troubleshooting Table ....................................................................... 3

Instrument Diagnostic Screens ........................................................ 40

NEXT

Page 50

DIAGNOSTICS TROUBLESHOOTING

2 OF 60

7.1 Introduction

This chapter is divided into two different sections. The first section is devoted to

troubleshooting tables and error code tables giving a brief description and steps the

customer and service individual would need to take. The second section goes into a

description of the diagnostic screens available on the instrument.

NEXT

Page 51

DIAGNOSTICS TROUBLESHOOTING

3 OF 60

7.2 Troubleshooting Table

The following table is provided to assist in troubleshooting the CLINITEK Status

system. The first four columns are similar to those found in the Operators Manual

under troubleshooting with the exception that “Contact Bayer Service” has been

removed from Customer Remedy column and replaced with “Replace instrument.”

The fifth column, “Service Remedy,” gives a more advanced troubleshooting guide

that should be utilized by Bayer Service Personnel or under the guidance of trained

personnel. The items are listed in increasing order of technical difficulty.

In some isolated cases, the power plug must be unplugged from the back of the

instrument in order to turn the instrument off or batteries removed. Once the plug or

batteries has been replaced, the power button on front of the instrument must be

pressed to turn the instrument back on.

NEXT

Page 52

DIAGNOSTICS TROUBLESHOOTING

4 OF 60

Symptom

or Error

Touch

screen

does not

respond

Meaning Possible

Cause

Electronic lock-upHave the customer

Faulty touch

screen

Loose cable Replace instrument Same as above

Customer Remedy Service Remedy

disconnect from

power and

reconnect, and turn

instrument on

Replace instrument

Reseat cables to the

1

main PCB

2

Replace display / bezel

assemble

3

Replace main PCB.

NEXT

Page 53

DIAGNOSTICS TROUBLESHOOTING

5 OF 60

Symptom

or Error

Blank

Display

Meaning Possible

Cause

No power

Defective

Display Unit

Battery

contacts

corroded

Customer Remedy Service Remedy

1

Check that the

power cord is

firmly plugged into

the instrument

and the line cord

is plugged into a

live AC electrical

outlet and firmly

plugged into the

Power Supply.

Replace batteries.

2

Replace instrument

Replace instrument Replace optical chassis

1

Test instrument using a

second power supply

and line cord.

Inspect battery holder

2

and replace batteries

as needed.

1

Remove Bezel and

check that all cables

are properly seated.

Troubleshoot the Main

2

PCB.

NEXT

Page 54

DIAGNOSTICS TROUBLESHOOTING

6 OF 60

Symptom

or Error

Faint

Display

Missing

Character

s or

Strange

Character

s

Meaning Possible

Cause

Possible

low

contrast

setting

Possible low

contrast setting

Faulty display Replace instrument

Electronics

lock-up

Loose Cable Replace instrument Run Display diagnostics

Customer Remedy Service Remedy

Refer to operators

manual for

adjusting contrast

1

Replace display / bezel

assembly

Replace main PCB

2

Disconnect and

reconnect from

power source, and

turn instrument

“on”.

Reseat cables

1

2

Replace Display/Bezel

Assembly

3

Replace Main PCB

Faulty display Replace Instrument Replace Main PCB

Main PCB

Failure

Replace instrument Replace Main PCB

NEXT

Page 55

DIAGNOSTICS TROUBLESHOOTING

7 OF 60

Symptom

or Error

Test Table

cannot be

installed

Meaning Possible

Cause

Broken Table

Guides

Customer Remedy Service Remedy

1

Inspect the Test

Ta ble opening on

the instrument for

any obstructions

nspect bottom of

2

I

Test Table for any

obstructions

blocking the teeth.

3

Tr y inserting a different

Test Table.

Inspect the Test Table

4

opening on the

instrument for any

obstructions such as

bent guide pins.

NEXT

Page 56

DIAGNOSTICS TROUBLESHOOTING

8 OF 60

Symptom

or Error

Instrument

does not

turn “ON”

or turn

“OFF

”

Meaning Possible

Cause

Front

panel

switch is

not

functioni

ng

correctly

No Power

Dirty switch

connect

Main PCB

Failure

Customer Remedy Service Remedy

1

Check that the

power cord is

firmly plugged into

the instrument

and the line cord

is plugged into a

live AC electrical

outlet and firmly

plugged into the

Power Supply.

Replace batteries.

2

Replace instrument

Replace instrument Replace Main PCB

1

Test system using a

second power supply

and line cord.

Inspect battery holder

2

and replace batteries

as needed.

1

Remove Bezel and

clean power switch

and PCB switch contacts Troubleshoot the

Main PCB.

Replace Display/Bezel

2

assembly

NEXT

Page 57

DIAGNOSTICS TROUBLESHOOTING

9 OF 60

Symptom

or Error

Forgot

password

Meaning Possible

Cause

Password set,

and operator

does not know

it

Customer Remedy Service Remedy

1

Have customer

check to see written operators

manual.

From the main

2

screen press

instrument set-up,

then enter the

password ”3654”.

Then select

choose setting

option. Then

select remove

password. Then if

they want to reset

the manual

instruct refer them

to the operators

manual.

From the main screen

press instrument set-up,

then enter the

password”

select choose setting

option. Then select

remove password. Then

if they want to reset the

manual instruct refer

them to the operators

manual.

3654

”. Then

NEXT

Page 58

DIAGNOSTICS TROUBLESHOOTING

10 OF 60

Symptom

or Error

Test Table

does not

move into

instrument

when a

test is

started

Test Table

does not

move into

instrument

when

instrument

is powered

off

Meaning Possible

Cause

Instrument

“Lock-Up”

Broken teeth

on test table

Defective Test

Ta ble Motor

Drive Unit

Instrument

“Lock-Up”

Broken teeth

on test table

Defective Test

Ta ble Motor

Drive Unit

Customer Remedy Service Remedy

Tu rn the instrument

off and on.

Replace table Replace test table

Replace instrument Replace the Optical

1

Tu rn the instrument off and on.

Perform test table

2

diagnostics

Replace instrument Replace Test Table

Replace instrument Replace optical chassis

Perform Table Movement

test through the

Diagnostics menu.

Chassis that contains

the Motor Drive Unit.

NEXT

Page 59

DIAGNOSTICS TROUBLESHOOTING

11 OF 60

Symptom

or Error

Results

are not

printing

Meaning Possible

Cause

Printer option

disabled

Paper in

backwards

Incorrect paper

being used

Batteries are

low

Printer

defective

Printer cable

loose

Customer Remedy Service Remedy

Refer to operators

manual to select

printer option

Refer to operators

manual for how

install paper

Recommend that

they use Bayer

thermal paper

Replace batteries or

use power supply

Run printer

diagnostics; refer to

operators manual

for instructions. If it

fails replace

instrument

Run printer

diagnostics; refer to

operators manual

for instructions. If it

fails replace

instrument

Run printer diagnostics

Check cable

1

connections.

2

Replace printer

Replace main PCB

3

Run printer diagnostics

1

Check cable

connections.

2

Replace printer

3

Replace main PCB

NEXT

Page 60

DIAGNOSTICS TROUBLESHOOTING

12 OF 60

Symptom

Meaning Possible

or Error

E00 Not used

E01

E02

Low

battery

power

Battery

voltage

drops to

5.8 Vdc

Failure of

Calibrati

on data

checksu

m

Cause

Batteries have

low voltage

Battery

contacts

corroded

Power supply

is faulty

Battery

detector circuit

is damaged

Main PCB

failure

Customer Remedy Service Remedy

Replace with fresh

batteries.

Clean if possible,

replace instrument

Replace power

supply

Replace instrument

Return for service Replace Main PCB

Replace with fresh

batteries.

Replace optical chassis

1

Replace power supply

Power input connector

2

damaged, replace

optical chassis

1

Reload instrument

software

Replace main PCB

2

NEXT

Page 61

DIAGNOSTICS TROUBLESHOOTING

13 OF 60

Symptom

or Error

E03

E04

E05

E06

E07

E08

E09

E10

Meaning Possible

Cause

Failure of

Flash

(ROM)

checksu

m

Failure of

RAM

checksu

m

Not used

Loss of

test

results

Memory

checksum

error

Main PCB

failure

(Non Volatile

Memory failure

during storage

of test results)

Customer Remedy Service Remedy

1

If customer has a

program card,

have them

attempt to reload

software

Return for service

2

Return for service Replace Main PCB

Tu rn instrument off

and on and repeat

the test.

1

Reload software

Replace Main PCB

2

Replace Main PCB

NEXT

Page 62

DIAGNOSTICS TROUBLESHOOTING

14 OF 60

Symptom

or Error

E11

Meaning Possible

Cause

Failure of

test table

Ta ble

fails to

move 2

steps in

<4

seconds.

Insert or

Cassette not

fully into table

Ta ble bumped Disconnect from

Customer Remedy Service Remedy

1

Reseat the table

insert.

Remove the table

2

inset and inspect

that there is no

debris in the table

preventing the

insert from

seating.

3

Clean and inspect

the table insert, if

damaged replace

the insert.

Confirm that the

test table is in

place.

power source to

reset and clear the

error (

Tur ning

instrument “off” and

“on” will not reset

and clear the error

Run table diagnostics to

troubleshoot.

Replace test table.

Replace lower optical

chassis.

).

NEXT

Page 63

DIAGNOSTICS TROUBLESHOOTING

15 OF 60

Symptom

Meaning Possible

or Error

E12

E13 Not used

E20

Failure of

LED

During

the

calibratio

n step

the

instrume

nt could

not set

the

current

gain on

one or

more of

the Led

Real time

clock

failure

Customer Remedy Service Remedy

Cause

Calibration

strip dirty

Failure of LED Replace the

Main PCB

failure

Electronics

lock-up

Main PCB

failure

1

Remove the table

and clean the

table as directed

in the operators

manual

Replace the table

2

Replace the

instrument

instrument

Replace the

instrument

Tu rn instrument off

and on.

Run electronics

diagnostics.

Run light source

diagnostics.

Replace the table

Replace lower optical

chassis

Replace the Main PCB

Run electronics

diagnostics.

Replace Main PCB

E21 Not used

NEXT

Page 64

DIAGNOSTICS TROUBLESHOOTING

16 OF 60

Symptom

or Error

E23

Meaning Possible

Cause

Low

battery

power

approach

ing (one

segment

on

battery

icon on

display

Battery

voltage is

below

6.6Vdc

Batteries have

low voltage

Battery

contacts

corroded.

Power supply

is faulty

)

Battery

detector circuit

is damaged

Customer Remedy Service Remedy

Replace with fresh

batteries.

Clean if possible,

replace instrument

Replace power

supply

Replace instrument

Replace with fresh

batteries.

Replace optical chassis

1

Replace power supply

2

Power input connector

damaged, replace

optical chassis

1

Reload instrument

software

2

Replace main PCB

NEXT

Page 65

DIAGNOSTICS TROUBLESHOOTING

17 OF 60

Symptom

Meaning Possible

or Error

E24 No

printer

paper

Cause

No printer

paper

Printer

defective

Main PCB

failure

Customer Remedy Service Remedy

Replace the printer

paper

If paper is in

installed:

1 Cycle power off

and on

2 Replace

instrument.

If paper is in

installed:

1 Cycle power off

and on

2 Replace

instrument

Replace the printer

paper and check that

flex cables from printer

to main PCB are seated

in their connectors

Replace printer

Replace Main PCB

E25 Auto

Calibrati

on failure

Same as

E12

Same as E12 Same as E12 Same as E12

NEXT

Page 66

DIAGNOSTICS TROUBLESHOOTING

18 OF 60

Symptom

Meaning Possible

or Error

E27 Set up

failure

(loss of

test

results or

instrume

nt set up

due to

checksu

m failure)

E28 Printer

error

Cause

Instrument

lock-up

Main PCB

Failure

Printer paper

release lever

arm is not

down.

Printer cable

not seated fully

in connector

Printer

defective

Customer Remedy Service Remedy

Tu rn instrument off

and on.

Replace instrument Replace Main PCB

Lift the printer cover

and push the paper

holding arm back

into position.

Replace instrument Check that printer cable

Replace instrument Replace printer

Cycle instrument power

off and on.

Lift the printer cover and

push the paper holding

arm back into position

in fully seated and

locked in place

Main PCB

Failure

Replace instrument Replace Main PCB

NEXT

Page 67

DIAGNOSTICS TROUBLESHOOTING

19 OF 60

Symptom

Meaning Possible

or Error

E48 Loss of

test

results.

The

same as

E10

Cause

(Non Volatile

Memory failure

during storage

of test results)

Customer Remedy Service Remedy

Tu rn instrument off

and on and repeat

the test.

Replace Main PCB

NEXT

Page 68

DIAGNOSTICS TROUBLESHOOTING

20 OF 60

Symptom

Meaning Possible

or Error

E50 Incorrect

strip type

(Failure

to

identify

strip)

Cause

Strip type used

does not

match setting

selected.

Instrument

failed to read

correctly

match strip ID

bands to pad

configuration.

Customer Remedy Service Remedy

Ensure that the strip

type selected in

Instrument set up is

being used (see

Section 6, Select

Instrument Tests).

1 If the correct type

of strip is being

used, check the

instrument operation by running

another test

using.

2 Excess sample is

on the color ID

bands, instruct the

customer on

proper dipping

technique (refer to

Operators

manual).

3 Have the

customer run a

Control such as

Chek-Stix.

NEXT

Page 69

DIAGNOSTICS TROUBLESHOOTING

21 OF 60

Symptom

or Error

Meaning Possible

Cause

Strip was

slightly tilted on

table

Instrument

problem Test

Ta ble, Main

PCB, or Lower

Chassis

Customer Remedy Service Remedy

1 Have customer

rerun the sample.

2 Have the

customer run a

Control such as

Chek-Stix.

Replace instrument

1 Replace Test Table

2 Replace Main PCB

3 Replace lower optical

assembly.

NEXT

Page 70

DIAGNOSTICS TROUBLESHOOTING

22 OF 60

Symptom

Meaning Possible

or Error

E52 Invalid

cassette

barcode

Area of

barcode

on

cassette

does not

match

supporte

d

cassette

tests

Cause

Cassette

barcode label

damaged

Cassette not

seated in

insert.

Insert not

installed in to

table correctly

Insert

damaged

Ta ble

damaged

Instrument

failure

Customer Remedy Service Remedy

Repeat the test

using a Bayer

cassette.

Clean insert and

retest

Clean table and

retest

Replace insert

Replace table.

Replace instrument

1 Replace test table

2 Replace lower Optical

assembly.

3 Replace Main PCB

NEXT

Page 71

DIAGNOSTICS TROUBLESHOOTING

23 OF 60

Symptom

Meaning Possible

or Error

E53 Strip Test

selected

but

cassette

detected

Cassette

barcode

detected

Cause

Incorrect test

was selected

Instrument

failure

Customer Remedy Service Remedy

Repeat the test

using the

appropriate test

routine.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed replace

instrument.

If CSCC tests are

successfully, have

customer run

controls.

Replace lower Optical

assembly.

Replace Main PCB

NEXT

Page 72

DIAGNOSTICS TROUBLESHOOTING

24 OF 60

Symptom

Meaning Possible

or Error

E54 Cassette

Test

selected

but strip

detected

No

barcode

detected

but a test

is

present

Cause

Incorrect test

was selected

Instrument

failure

Customer Remedy Service Remedy

Repeat the test

using the

appropriate test

routine.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed replace

instrument.

If CSCC tests are

successfully, have

customer run

controls.

Replace lower Optical

assembly.

Replace Main PCB

NEXT

Page 73

DIAGNOSTICS TROUBLESHOOTING

25 OF 60

Symptom

Meaning Possible

or Error

E55 Strip

being

used on

cassette

side of

table

insert

%R in all

areas is

> black

and no

cue mark

is

detected

Cause

Incorrect side

of insert being

used

Instrument

optical error

Customer Remedy Service Remedy

1 Tu rn the test table

insert over so that

the strip holder

face of the insert

is upwards.

2 Repeat the test.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

If CSCC tests are

successfully, have

customer run

controls

1 Replace lower Optical

assembly.

2 Replace Main PCB

NEXT

Page 74

DIAGNOSTICS TROUBLESHOOTING

26 OF 60

Symptom

Meaning Possible

or Error

E56 Incorrect

size test

table

4.25”

strip on a

3.25” test

table

Cause

Long strip

being used on

a short strip

insert

Instrument

failure

Customer Remedy Service Remedy

Verify that the

customer is using

the correct insert

with the strip that

they are using.

Repeat the test

using the correct

test table.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

If CSCC tests are

successfully, have

customer run

controls

Replace lower Optical

assembly.

Replace Main PCB

NEXT

Page 75

DIAGNOSTICS TROUBLESHOOTING

27 OF 60

Symptom

Meaning Possible

or Error

E57 Missing

strip or

cassette

%R in all

areas is

equal to

black

Cause

Test started

with out either

a strip in the

insert

Test started

without an

insert in table

Instrument

failure

Customer Remedy Service Remedy

Repeat the test

ensuring that the

strip or cassette is

correctly positioned

when the test is

started

Repeat testing

using the correct

insert installed on

the table

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

If CSCC tests are

successfully, have

customer run

controls Replace

Instrument.

1 Replace lower Optical

assembly.

2 Replace Main PCB

NEXT

Page 76

DIAGNOSTICS TROUBLESHOOTING

28 OF 60

Symptom

Meaning Possible

or Error

E58 Misplace

d strip

845nm%

R <20%

from cue

mark +

50 pixels

and

565nm%

R >17%

Cause

Test strip is not

correctly

positioned in

the insert; the

tip is not to the

end of the

channel.

Customer Remedy Service Remedy

1 Repeat the test

ensuring that the

strip is correctly

positioned on the

test table.

2 Have customer

clean the insert,

checking to see

that there is not

any build up near

edges of the

channel Repeat

the test ensuring

that the strip is

correctly

positioned on the

test table.

3 Have the

customer remove

the table and

clean the gears.

4 Replace the Insert

5 Replace the table

NEXT

Page 77

DIAGNOSTICS TROUBLESHOOTING

29 OF 60

Symptom

or Error

Meaning Possible

Cause

Instrument

failure

Customer Remedy Service Remedy

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

If CSCC tests are

successful, have

customer run

controls

Replace the

instrument

1 Replace lower Optical

assembly.

2 Replace Main PCB

NEXT

Page 78

DIAGNOSTICS TROUBLESHOOTING

30 OF 60

Symptom

Meaning Possible

or Error

E59 Inverted

strip

Cause

Strip placed

upon the table

upside down.

Instrument

failure

Customer Remedy Service Remedy

Repeat the test

ensuring that the

strip is correctly

positioned on the

test table.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

If CSCC tests are

successfully, have

customer run

controls.

Replace the

instrument

1 Replace lower Optical

assembly.

2 Replace Main PCB

NEXT

Page 79

DIAGNOSTICS TROUBLESHOOTING

31 OF 60

Symptom

Meaning Possible

or Error

E60 Tilted

strip

Cause

Strip not laying

flat in the insert

channel

Insert not flat

in the table

Customer Remedy Service Remedy

1 Repeat the test

ensuring that the

strip is correctly

positioned on the

test table.

2 Have customer

clean the insert,

checking to see

that there is not

any build up near

edges of the

channel. Repeat

the test ensuring

that the strip is

correctly

positioned on the

test table.

Have the customer

clean and inspect

the table for

anything that might

prevent the insert

from sitting flat in

the table.

NEXT

Page 80

DIAGNOSTICS TROUBLESHOOTING

32 OF 60

Symptom

or Error

Meaning Possible

Cause

Instrument

failure

Customer Remedy Service Remedy

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

If CSCC tests are

successfully, have

customer run

controls.

Replace the

instrument

1 Replace lower Optical

assembly.

2 Replace Main PCB

NEXT

Page 81

DIAGNOSTICS TROUBLESHOOTING

33 OF 60

Symptom

or Error

E61 Dry strip Strip was not

Meaning Possible

Cause

fully dipped in

to the sample.

Instrument

failure

Customer Remedy Service Remedy

Refer the customer

to the operators

manual section 4 on

dipping the strips.

Repeat the test.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed replace

instrument.

If CSCC tests are

successfully, have

customer run

controls.

Replace the

instrument.

1 Replace lower Optical

assembly.

2 Replace Main PCB

NEXT

Page 82

DIAGNOSTICS TROUBLESHOOTING

34 OF 60

Symptom

Meaning Possible

or Error

E62 Light

ingress

Cause

Light is leaking

into the

instrument.

Instrument

failure

Customer Remedy Service Remedy

If instrument is in

direct sunlight or

strong side lighting,

move out of bright

light.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed replace

instrument.

If CSCC tests are

successfully, have

customer run

controls

Replace the

instrument

1 Check shutter door for

proper operation.

Clean and repair if possible.

2 Replace lower optical

chassis.

3 Replace Main PCB

NEXT

Page 83

DIAGNOSTICS TROUBLESHOOTING

35 OF 60

Symptom

Meaning Possible

or Error

E63 Failure to

find end

of strip

(Fails to

locate

cue mark

on table

insert,

strip

side)

Cause

Insert dirty or

damaged

Ta ble

damaged

Instrument

failure

Customer Remedy Service Remedy

1 Have the cus-

tomer clean and

inspect the insert

to see the white

line at the end of

the channel is

present.

2 Replace the insert

3 Repeat the test

ensuring that the

strip is correctly

positioned on the

test table.

Have the customer

make sure table is

clean and not

damaged.

Have the customer

use the CSCC test

to confirm

instrument failure.

1 Replace lower Optical

assembly.

2 Replace Main PCB

If confirmed replace

instrument.

If CSCC tests are

successfully, have

customer run

controls

Replace the

instrument

NEXT

Page 84

DIAGNOSTICS TROUBLESHOOTING

36 OF 60

Symptom

Meaning Possible

or Error

E64 Over-

range

CAL strip

Cause

Calibration bar

is dirty.

Instrument

failure

Customer Remedy Service Remedy

1 Clean and inspect

the calibration bar.

2 Replace Test

Ta ble

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed replace

instrument.

If CSCC tests are

successfully, have

customer run

controls

Replace the

instrument

1 Replace Optical chas-

sis

2 Replace Main PCB

NEXT

Page 85

DIAGNOSTICS TROUBLESHOOTING

37 OF 60

Symptom

Meaning Possible

or Error

E65 Dirty

CAL strip

Cause

Calibration bar

is dirty

Instrument

failure.

Customer Remedy Service Remedy

1 Clean and inspect

the calibration bar.

2 Replace Test

Ta ble

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

If CSCC tests are

successfully, have

customer run

controls

Replace the

instrument

1 Replace Optical chas-

sis

2 Replace Main PCB

NEXT

Page 86

DIAGNOSTICS TROUBLESHOOTING

38 OF 60

Symptom

Meaning Possible

or Error

E66 Dry

cassette

Cause

Insufficient

sample

Instrument

failure

Customer Remedy Service Remedy

1 Review the direc-

tions for applying

the sample to the

cassette with the

customer.

2 Repeat the test

3 Have customer

run a control.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed replace

instrument.

If CSCC tests are

successfully, have

customer run

controls Replace

the instrument

1 Replace Optical chas-

sis

2 Replace Main PCB

NEXT

Page 87

DIAGNOSTICS TROUBLESHOOTING

39 OF 60

Symptom

Meaning Possible

or Error

E67 Insufficie

nt

sample

Cause

Poor immune

flow

Instrument

failure

Customer Remedy Service Remedy

1 Review the direc-

tions for applying

the sample to the

cassette.

2 Repeat the test

ensuring that the

sample is

correctly

dispensed into the

cassette and/or

there is enough

sample in the

pipette before

dispensing into

the cassette.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed,

replace instrument.

1 Replace Optical chas-

sis

2 Replace Main PCB

If CSCC tests are

successfully, have

customer run

controls

Replace the

instrument

NEXT

Page 88

DIAGNOSTICS TROUBLESHOOTING

40 OF 60

Symptom

Meaning Possible

or Error

E68 Insufficie

nt

sample

Cause

Poor immune

flow

Instrument

failure

Customer Remedy Service Remedy

1 Review the direc-

tions for applying

the sample to the

cassette.

2 Repeat the test

ensuring that the

sample is

correctly

dispensed into the

cassette and/or

there is enough

sample in the

pipette before

dispensing into

the cassette.

Have the customer

use the CSCC test

to confirm

instrument failure.

If confirmed replace

instrument.

1 Replace Optical chas-

sis

2 Replace Main PCB

If CSCC tests are

successfully, have

customer run

controls

Replace the

instrument

NEXT

Page 89

DIAGNOSTICS TROUBLESHOOTING

41 OF 60

Symptom

or Error

E90

E91

E92

E93

Meaning Possible

Cause

Not Used

Customer Remedy Service Remedy

NEXT

Page 90

DIAGNOSTICS TROUBLESHOOTING

42 OF 60

7.3 Instrument Diagnostic Screens

The following section is provided to assist in troubleshooting the CLINITEK Status

system. This section explains the different diagnostic screens available on the

instrument.

Diagnostics Screens: Initial Screens

The following is done in order to access the instruments diagnostic features.

Figure 7-1: Ready for Test Screen

1 From the ready screen, select “Instrument Set Up” by pressing the screen

button.

2 If the customer has set a Password to access the instrument set up, then you

must use the default password, 3654, to gain access to the Settings Menu.

NEXT

Page 91

DIAGNOSTICS TROUBLESHOOTING

Press the “123” button on the “Enter Password” screen to get the number pad

and enter 3654 then “Enter.”

43 OF 60

3 You then get the following menu options. Press the down arrow button to scroll

down until “Diagnostics” is highlighted.

4 Once highlighted, press the “Select” button to proceed to the next menu screen.

5 If you want to exit any screen without proceeding to any of the listed options,

simply press the “Done” button to return to the previous menu screen or the

ready screen.

NEXT

Page 92

DIAGNOSTICS TROUBLESHOOTING

44 OF 60

Diagnostics Screens: Display

The display test is the first test on the menu. This test is designed to highlight all 48

areas of the touch screen/display through an alternating checker board pattern. If

any area is not properly displayed then there may be a problem with the display

cable, display, or main PCB.

1 Scroll down using the down arrow to highlight the desired menu option.

The above screen is displayed once “Display” was selected.

2 Select “Run Test.”

3 These two screens will alternate back and forth several times in 20 seconds.

Make sure all areas are displayed in order to pass the test. If any area is not

NEXT

Page 93

DIAGNOSTICS TROUBLESHOOTING

properly displayed then follow the troubleshooting for missing characters or

strange characters in “

When the instrument has finished the test, the following screen is displayed.

Troubleshooting Table” .

45 OF 60

4 Select “Done” to return to the diagnostics menu screen or “Repeat Test” if

needed.

NEXT

Page 94

DIAGNOSTICS TROUBLESHOOTING

46 OF 60

Diagnostics Screens: Touch Screen

The touch screen test is designed to test the touch screen portion of the display. All

48 quadrants are highlighted and numbered. You are instructed to physically touch

all 48 areas. The touch screen will respond to the pressure of the touch by

changing the number into a forward arrow. An area not responding can indicate a

problem with either the touch screen cable, touch screen, or main PCB.

1 Scroll down using the down arrow to select “Touch Screen” and press “Select.”

NEXT

Page 95

DIAGNOSTICS TROUBLESHOOTING

47 OF 60

Once “Touch Screen” was selected this screen is displayed.

2 Press “Run Test.”

Each of the 48 touch areas are displayed with a number except the last one

which is the enter/done key.

NEXT

Page 96

DIAGNOSTICS TROUBLESHOOTING

48 OF 60

3 Press each numbered area to change the number into an arrow icon by starting

at 1 and ending at 47.

4 Press the last button to proceed to final screen.

Either “Test Passed” will be displayed (if all areas successfully changed to

arrows) or the “Test was not successful” screen will be shown. If the latter

screen is displayed then follow the troubleshooting guide for “Touch screen does

not respond” in “

Troubleshooting Table” .

NEXT

Page 97

DIAGNOSTICS TROUBLESHOOTING

49 OF 60

Diagnostics Screens: Printer

The printer test is to be used to test the printer by generating a test print. This test

print is designed to utilize all areas of the thermal print head. If there are problems

with the print head, voids in the printing would be seen or no printing at all. If the

printer fails to respond to the test then there may be other problems like printer

cables bad, printer bad, or main PCB bad.

1 Highlight “Printer” by scrolling

down using the down arrow and

then pressing “Select.”

Once “Select” was press, this

screen will be displayed.

2 Press “Run Test” to continue.

NEXT

Page 98

DIAGNOSTICS TROUBLESHOOTING

The “Please Wait” screen is displayed while the printer is printing.

The Final screen is displayed.

50 OF 60

3 Select “Done” to return to the diagnostic menu screen or repeat as needed.

Follow the troubleshooting guide for “Results are not printing” in “

Table” if the printer fails to work properly.

Troubleshooting

NEXT

Page 99

DIAGNOSTICS TROUBLESHOOTING

51 OF 60

Diagnostics Screens: Test Table

The “Test Table” diagnostics feature allows for the user to test the table drive

components along with the table position sensor. In this test the table gets drawn