Baumer BMxx, GBxxx, GXxxx User Manual

Manual

Absolute encoder with EtherCAT,

Power over EtherCAT (PoE)

(with bus cover)

Firmware version 5.00 and up

09.14 · 174.02.064/3

Subject to technical and design modifications.

www.baumer.com Errors and omissions excepted.

Content Page

Introduction 4 1.

1.1 Scope of delivery 4

1.2 Product classification 4

Safety and operating instructions 5 2.

Bus cover – functional principle 6 3.

Encoder operating parameters 7 4.

Encoder data 8 5.

5.1 PDO (Process Data Object) 8

5.2 SDO (Service Data Objects) 9

5.3 Parameterization 17

5.4 Free Run Mode (default) 18

5.5 Distributed Clocks Mode 19

5.5.1 Activation Distributed Clocks under TwinCAT 19

5.6 Network management 21

Terminal assignment and commissioning 23 6.

6.1 Mechanical mounting 23

6.2 Electrical connection 23

6.2.1 Initialising under TwinCAT system manager 24

6.2.2 Terminal assignment 25

6.3 Display elements 26

6.3.1 State indicator 26

6.3.2 Link/Activity indicator 26

6.4 Bus cover Power over EtherCAT (PoE) 27

6.5 Cycle times 28

6.6 Configuration 10 Byte PDO / 4 Byte PDO / 2 Byte PDO by TwinCAT 29

6.7 Speed Value as an alternative to System Time 30

**TwinCAT is a trademark of the company BECKHOFF Industrie Elektronik

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 2/30 www.baumer.com

30.09.14

Disclaimer of liability

The present manual was compiled with utmost care, errors and omissions reserved. For this reason

Baumer rejects any liability for the information compiled in the present manual.

Baumer nor the author will accept any liability for direct or indirect damages resulting from the use of the

present information.

At any time we should be pleased receiving your comments and proposals for further improvement of the

present document.

Created by:

Baumer IVO GmbH & Co. KG

Villingen-Schwenningen, Germany

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 3/30 www.baumer.com

30.09.14

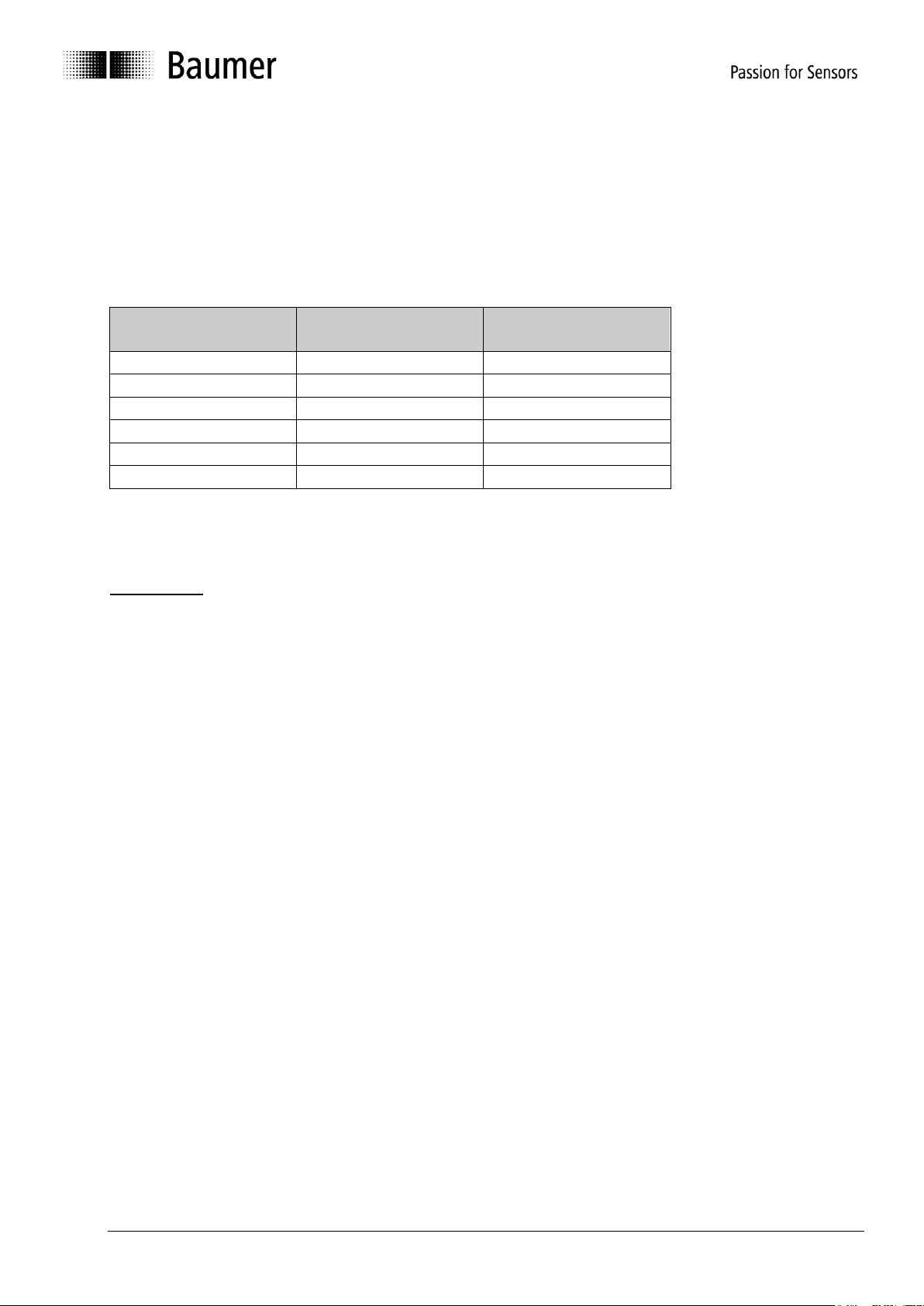

Product mechanics

Solid / Hollow shaft / Kit

Product name

(according to object 1008)

Description

BMMV / BMMH / BMMK

GCMMW_H

MT, MAGRES

BMSV / BMSH / BMSK

GCAMW_H

ST, MAGRES

GBMMW / GBMMS / -

GBMMW_H

MT, Optical, 18 Bit ST

GBAMW / GBAMS / -

GBAMW_H

ST, Optical, 18 Bit ST

GXMMW / GXMMS / -

GXMMW_H

MT, Optical, 13 Bit ST

GXAMW / GXAMS / -

GXAMW_H

ST, Optical, 13 Bit ST

Introduction 1.

1.1 Scope of delivery

Please check the delivery upon completeness prior to commissioning.

Depending on encoder configuration and part number delivery is including:

Basic encoder, bus cover and CD with describing file and manual (also available as download)

1.2 Product classification

Note:

Ever apply the matching device file (BAUMER Group absolute EtherCAT encoders.xml) on the above device

types.

Explanation:

MT Multiturn encoder

ST Singleturn encoder

MAGRES Extremely robust encoder with magnetic sensing principle

18 Bit ST High resolution encoder – up to 18 bit physical singleturn resolution, i.e. 218 steps / revolution

13 Bit ST Max. 13 bit physical singleturn resolution, i.e. 213 steps / revolution

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 4/30 www.baumer.com

30.09.14

Safety and operating instructions 2.

Supplementary information

This manual is intended as supplement to already existing documentation (e.g. catalogues, data sheet

and mounting instructions).

The manual must be read carefully prior to initial commissioning of the equipment.

Intended purpose of the equipment

The encoder is a precision measurement device. It is used to determine angular positions and revolutions

and to prepare and supply measured values in the form of electrical output signals for control systems.

The encoder must not be used for any other purpose.

Commissioning

Encoders may only be installed and mounted by suitably qualified experts.

Observe the operating instructions of the machine manufacturer.

Safety remarks

Prior to commissioning of the equipment, check all electrical connections.

If installation, electrical connections or any other work performed at the encoder or at the equipment is not

correctly executed, this can result in encoder malfunction or failure.

Steps must be taken to exclude any risk of personal injury, damage to facility or operating appliances as a

result of encoder failure or malfunction by providing suitable safety precautions.

The encoder must not be operated beyond the specified limits (see further documentation).

Failure to comply with the safety remarks can result in malfunctions, personal injury or material damage!

Transport and storage

Only ever transport or store encoders in their original packaging.

Never drop encoders or expose them to major vibrations.

Mounting

Avoid impacts or shocks on housing and shaft.

Avoid any twist or torsion on housing.

Do not open the encoder or proceed any mechanical modifications.

Shaft, ball bearings, glass disc or electronic components might be damaged. In this case, safe and reliable

operation is no longer guaranteed.

Electrical commissioning

Do not proceed any electrical modifications at the encoder.

Do not proceed any wiring work while encoder is under power supply.

Never plug or unplug connector while encoder is under power supply.

Ensure that the entire system is installed in line with EMC/EMI requirements. Operating environment and

wiring have an impact on the electromagnetic compatibility of the encoder. Install encoder and supply

cables separately or far away from sources with high emitted interference (frequency converters,

contactors, etc).

When working with consumers with high emitted interference provide separate encoder supply voltage.

Completely shield encoder housing and connecting cables..

Connect encoder to protective earth (PE) using shielded cables. The braided shield must be connected to

the cable gland or connector. Ideally, aim at dual connection to protective earth (PE), i.e. housing by

mechanical assembly and cable shield by the downstream devices. In case of earth loop problems, earth

at least on one side.

Failure to observe these instructions can result in malfunctions, material damage or personal injury!

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 5/30 www.baumer.com

30.09.14

Bus cover – functional principle 3.

The product family architecture is modular. Depending on what is required from the encoder, the basic

encoder and bus covers can be combined at will with the selected bus system.

The basic encoders differ in terms of accuracy, ambient conditions and the utilized sensing principle.

Bus cover

The bus cover accommodates the entire electronics for measured value processing and for Ethernet

communication.

The bus covers differ by the respectively integrated bus interface.

Available bus interfaces: CANopen®, DeviceNet, EtherCAT, Ethernet/IP, Profibus-DP, Profinet, Powerlink,

Power over EtherCAT, SAE J1939, SSI.

All encoders enable parameterization by bus interface.

Functional principle:

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 6/30 www.baumer.com

30.09.14

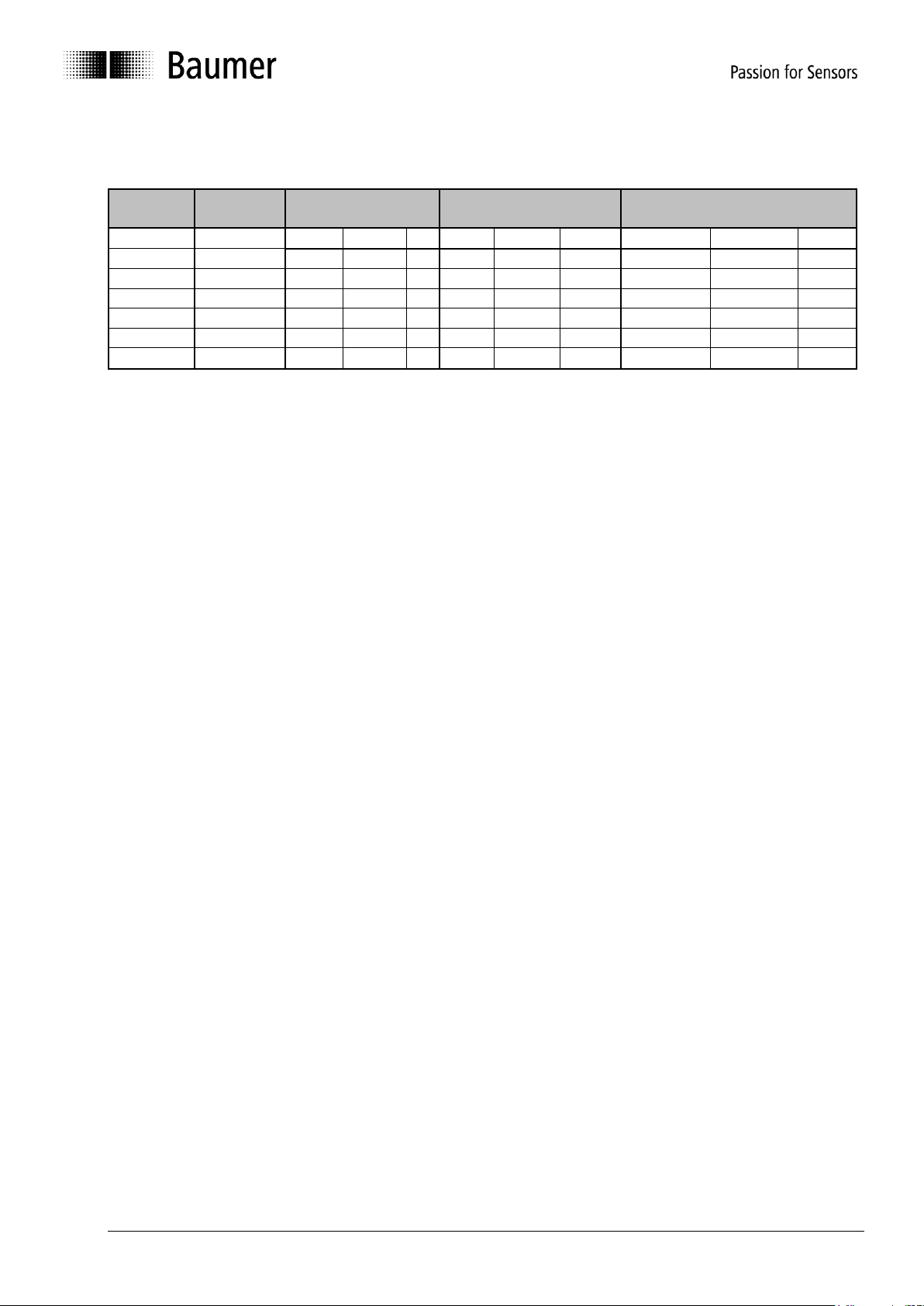

Product

Device

Name

Resolution per turn

0x6001

Number of turns

0x6502

Measuring range

0x6002

Dezimal

Hex

Bit

Dezimal

Hex

Bit

Dezimal

Hex

Bit

BMSx

GCAMW_H

4096

1000

12 1 1 0 4096

1000

12

BMMx

GCMMW_H

4096

1000

12

65536

10000

16

268435456

10000000

28

GXAMW(S)

GXAMW_H

8192

2000

13 1 1 0 8192

2000

13

GXMMW(S)

GXMMW_H

8192

2000

13

65536

10000

16

536870912

20000000

29

GBAMW(S)

GBAMW_H

262144

40000

18 1 1 0 262144

40000

18

GBMMW(S)

GBMMW_H

262144

40000

18

16384

4000

14

4294967296

100000000

32

Encoder operating parameters 4.

Significance of operating parameters

The enabled scaling functionality in CoE is prerequisite for further user-specific parameterization

such as resolution, total measuring range, direction of rotation and preset.

See chapter: SDO (Service Data Objects)

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 7/30 www.baumer.com

30.09.14

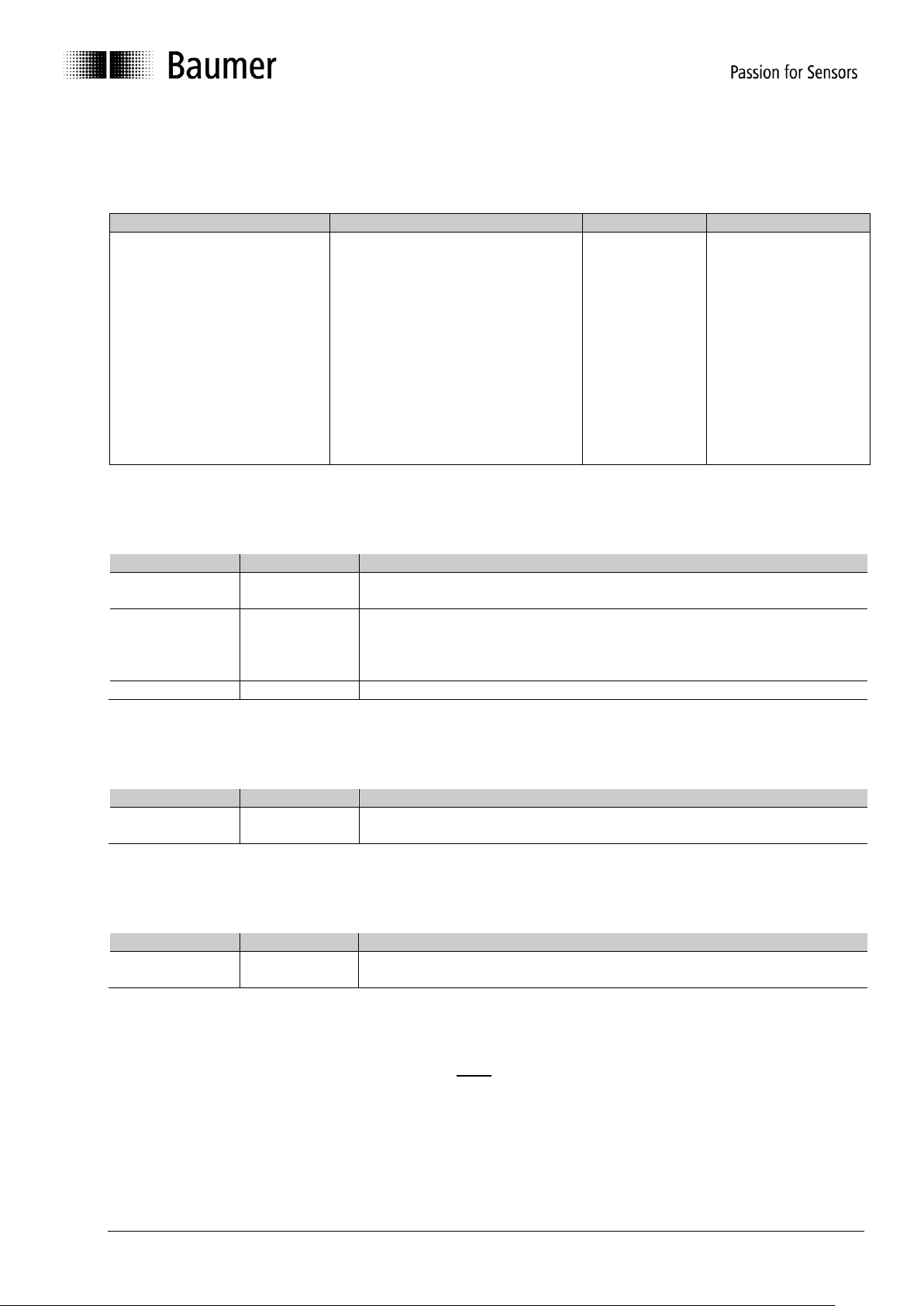

XML file

PDO Mapping

Product code

Applied in version

BAUMER Group absolute

EtherCAT encoders.xml

10Byte PDO: (default)

4 Byte Position value

2 Byte Warnings

4 Byte System Time/Speed value

or

4Byte PDO: (configurable)

4 Byte Position value

2Byte PDO: (configurable)

2 Byte Position value

20

25

30

V5.00 and up

Value

Data type

Explanation

Position value

UDINT

Current absolute encoder position value. For range-related information

refer to „Encoder operating parameters“

Warnings

UINT

Warnings

Bit 2: 1 Lithium battery power low

Bit 4: 1 Excess shaft turns during power-off

Bit 5: 1 Incorrect encoder configuration

System Time

UDINT

Present system time, resolution in ns, alternative Speed Value DINT

Value

Data type

Explanation

Position value

UDINT

Current absolute encoder position value. For range-related information

refer to „Encoder operating parameters“

Value

Data type

Explanation

Position value

UINT

Current absolute encoder position value. For range-related information

refer to „Encoder operating parameters“

Encoder data 5.

5.1 PDO (Process Data Object)

Depending on the configuration, the encoder will provide the following process data (input data):

10Byte PDO (Default)

4Byte PDO

2Byte PDO

The configuration 4Byte PDO / 2Byte PDO allows for shorter cycle times.

Cycle times are configuration-related, see chapter cycle times

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 8/30 www.baumer.com

30.09.14

5.2 SDO (Service Data Objects)

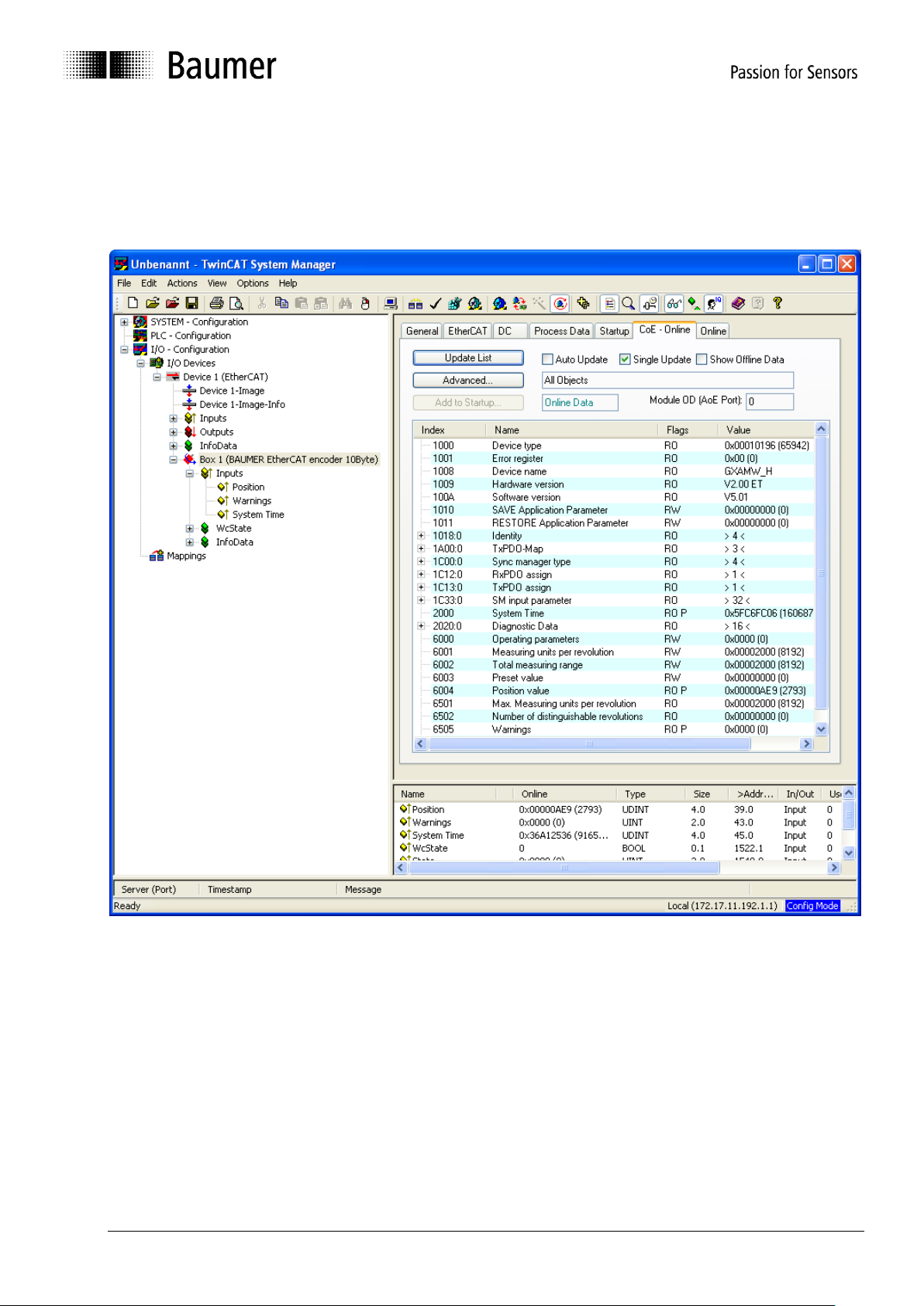

SDOs access is in the TwinCAT System under tab CoE - Online (CANopen over EtherCAT).

Since there is a large variety of CANopen device and application profiles they may be applied in EtherCAT

slaves.

EtherCAT encoders provide partial implementation of the CANopen DS406 encoder device profile.

Please consider that every CoE access (mailbox communication) will shortly interrupt generation of encoder

input data for the time of mailbox communication. With short cycle times in Distributed Clocks Mode this may

imply that not in every Sync cycle a new position is detected.

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 9/30 www.baumer.com

30.09.14

Loading...

Loading...