Page 1

Manual

Absolute Encoder with shaft and Interbus

Version from 1.10

Baumer IVO GmbH & Co. KG

Dauchinger Strasse 58-62

DE-78056 Villingen-Schwenningen

Phone +49 (0)7720 942-0

Fax +49 (0)7720 942-900 05.11 · 174.02.058/2

info.de@baumerivo.com Subject to technical and design modifications.

www.baumer.com Errors and omissions excepted.

Page 2

Contents

1 Introduction 3

1.1 Scope of delivery 3

1.2 Product assignment 3

2 Illustration of Encoder Data within Master 4

2.1 Position of the Encoder Data within the 2-word Addresses 4

2.2 Significance of the OUT Data (Data from the Master to the Encoder) 4

2.3 Significance of the IN Data (Data from Encoder to Master) 4

3 Possible Modes of Operation 5

4 Behavior of Encoder after Power ON 5

5 Parameterization 5

6 Examples 8

7 Disturbance messages 10

8 Contact description 10

8.1 Description for bus cover 10

8.2 Contact descriptions for bus cover 10

8.3 Settings of user adresses 11

8.4 EMV-cable gland 11

8.5 Contact description for C-plug 12

8.6 Pin assignment for C-plug 12

9 Technical data 13

9.1 Part number 13

9.2 Accessories 13

9.3 Dimensions 14

Manual_GXP6W_EN.doc 2/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 3

Disclaimer of liability

The present manual was compiled with utmost care, errors and omissions reserved. For this reason

Baumer IVO GmbH & Co. KG rejects any liability for the information compiled in the present manual.

Baumer IVO nor the author will accept any liability for direct or indirect damages resulting from the use of the

present information.

At any time we should be pleased receiving your comments and proposals for further improvement of the

present document.

1 Introduction

1.1 Scope of delivery

Please check the delivery upon completeness prior to commissioning.

Depending on encoder configuration and part number delivery is including:

• Encoder

• Manual available as download in the Internet

1.2 Product assignment

Shaft encoder

Product Product family

GXP6W Multiturn

Manual_GXP6W_EN.doc 3/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 4

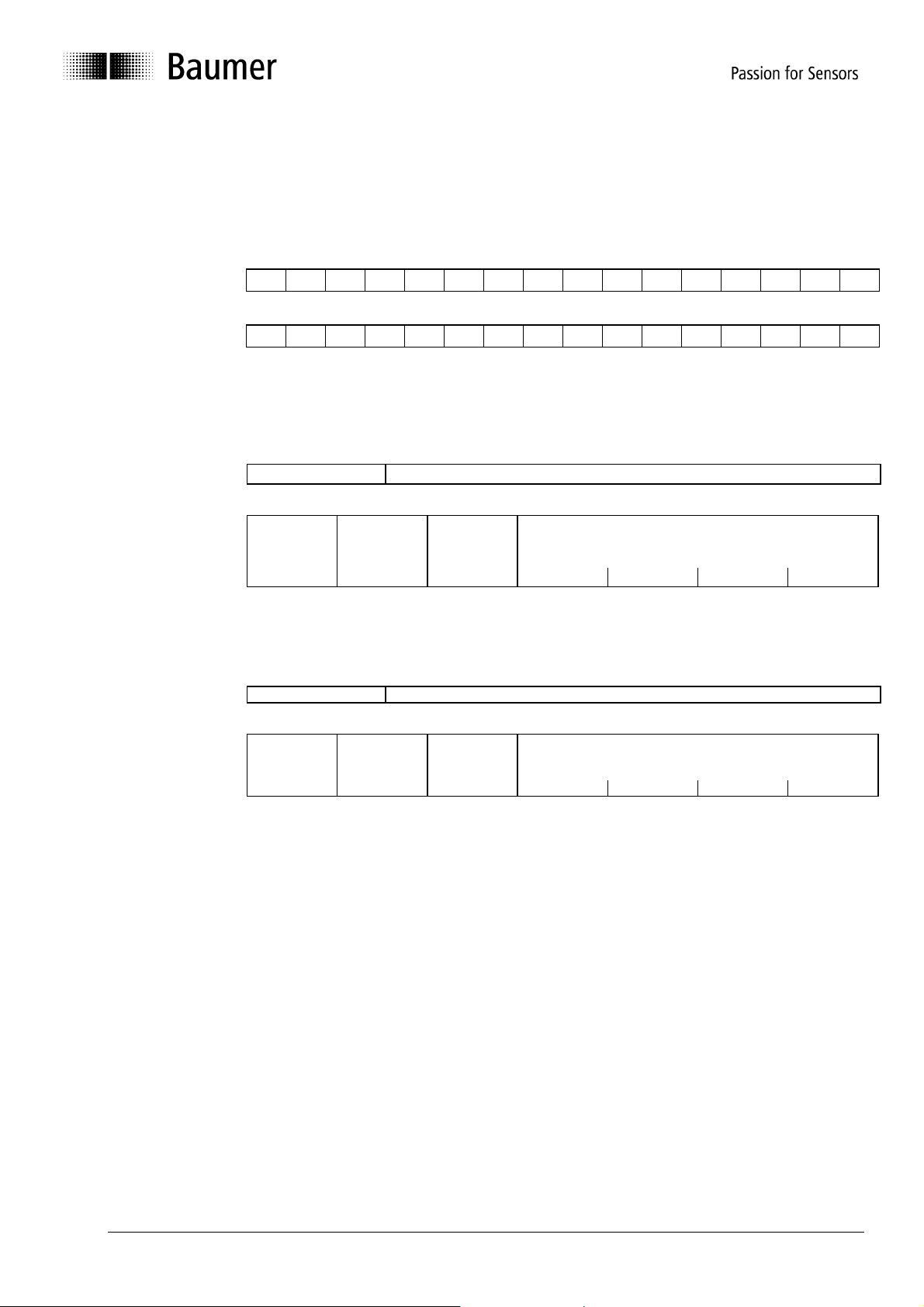

2 Illustration of Encoder Data within Master

2.1 Position of the Encoder Data within the 2-word Addresses

Word 0 (Byte 0,1) 231 230 229 228 227 226 225 224 223 222 221 220 219 218 217 216

MSB LSB

Word 1 (Byte 2,3) 215 214 213 212 211 210 29 28 27 26 25 24 23 22 21 20

MSB LSB

2.2 Significance of the OUT Data (Data from the Master to the Encoder)

2.3 Significance of the IN Data (Data from Encoder to Master)

The IN as well as OUT data of the encoder are assigned 2-word addresses within the master (control). The absolute

position of these word addresses depends on the position of the encoder on the Interbus ring.

Please find below the value of the encoder data relating to the relative word address.

D31

OUT Data:

Control

word:

D31

IN Data: Status word Actual position value or disturbance number

Status

word:

D31 D30 D29 D28 D27 D26 D25

Control word Parameter

Enable

operation

D31 D30 D29 D28 D27 D26 D25

Actual

position value

not valid

D25

Set zero

offset

D25

Parameterizat

ion

D24

D0

Specific to

manufacturer

D24

D0

Specific to

manufacturer

Disturbance number in case of error

otherwise 0000

Parameter No.

Manual_GXP6W_EN.doc 4/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 5

3 Possible Modes of Operation

Normal Operation

Control

word:

Actual

position value

Set zero

offset

Specific to

manufacturer

Parameter No.

not valid

D31 D30 D29 D28 D27 D26 D25

Operation 0 0 0 0

Parameterization

Control

word:

Actual

position value

Set zero

offset

Specific to

manufacturer

Parameter No.

not valid

D31 D30 D29 D28 D27 D26 D25

Parameteri

0 0 X 1...7 or 15

zation

Enable

0>1 0 X 0

operation

4 Behavior of Encoder after Power ON

After power has been turned on, the following steps will take place during the initialization phase of encoder:

Test of battery tension

Switch to parameter mode

Loading of the most recent parameter data from EEPROM

Checking of parameter data as to their validity

After initialization the encoder switches to the OPERATION state and emits the current position value. In case of an

error (battery tension too low or parameter loss), however, the encoder commutes to the ERROR state.

5 Parameterization

The parameters of a profile K3 encoder can be transferred via the bits 0 to 24 of the process data channel to the

encoder. To this effect, the encoder has to be set to the parameterization state by a allotting parameter number not

equal to zero to the bits 9 to 12 of the control word (bit 25 to 28 of the process data channel).

Parameter No.

D28 D25

0 0 0 1 Resolution: Sub-parameter Steps 1..33554431 8192

0 0 1 0 Resolution: Sub-parameter Revolutions 1..4096 1

0 0 1 1 Coding of actual position value 1..6 3

0 1 0 0 Preset value 0..33554431 0

0 1 0 1 Zero offset 0..33554431 0

0 1 1 0 Offset 0..33554431 0

0 1 1 1 Reset of encoder - 1 1 1 1 Measuring range 1..4096 4096

Resolution

The resolution of the encoder is adjusted via the sub-parameters „Steps“ and „Revolutions“ and the resolution is

calculated according to the formula: Resolution = Steps / Revolutions.

The parameters Steps = 1000 and Revolutions = 3 result in a resolution of 333.333.. steps/revolution.

Function Value range

maximum

Factory

setting

Manual_GXP6W_EN.doc 5/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 6

Coding of Actual position value

The parameter defines the coding of the actual value of the position allotted during OPERATION state.

Dual code with plus/minus sign (Integer)

Ascending code for sense of rotation 'right' (clockwise) with view on shaft

Dual code with plus/minus sign (Integer)

Ascending code for sense of rotation 'left' (counter-clockwise) with view on shaft

Dual code without plus/minus sign (Unsigned)

Ascending code for sense of rotation 'right' (clockwise) with view on shaft

Dual code without plus/minus sign (Unsigned)

Ascending code for sense of rotation 'left' (counter-clockwise) with view on shaft

Gray code without plus/minus sign

Ascending code for sense of rotation 'right' (clockwise) with view on shaft

Gray code without plus/minus sign

Ascending code for sense of rotation 'left' (counter-clockwise) with view on shaft

Preset Value

The value of the parameter 'Preset Value’ is used to find out the zero offset.

If the control command Set Zero Offset (control bit D30) is triggered by the master, the parameter Zero Offset is set

within the encoder to the value resulting from the following formula:

NPV = PW - API

The abbreviations stand for:

NPV Zero offset

PW Preset value

API Absolute actual value of position

Remark:

The calculated NPV value is not stored in E²Prom if activated by control bit D30. Due to the limited writing

cycles of the E²Prom, this value gets lost in case of power loss. However, when setting parameters, for

example preset, also the current NPV value is stored in E²Prom.

Manual_GXP6W_EN.doc 6/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 7

Zero Offset

The parameter Zero Offset refers to the difference between the zero point of the installation and the zero point of the

encoder. The actual position value is calculated according to the following formula:

PI = API + NPV

The abbreviations stand for:

PI Actual position value (is transferred)

API Absolute actual value of position

NPV Zero set off

Offset

The parameter 'Offset' is an additional possibility to offset the actual position value.

The actual position value is calculated according to the following formula:

PI = API + NPV + O

The abbreviations stand for:

PI Actual position value (is transferred)

API Absolute actual value of position

NPV Zero offset

O Offset

Resetting Encoder

When the parameter 'Reset Encoder' is transmitted to the encoder, all parameters are set back to their factory setting.

Measuring Range

It is possible to adjust the entire range of the position value via the parameter 'Measuring Range’. The unit for the

measuring range is the number of revolutions. If, for example, a resolution of 200 steps per revolution and a

measuring range of 5 revolutions are chosen, there ensues a total range of:

Total range = Resolution * Measuring range = 200 * 5 = 1000 steps

The total range of the position value thus stretches in the process data output without plus/minus signs from 0..999

and in the process data output with plus/minus signs from -500..499.

Manual_GXP6W_EN.doc 7/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 8

6 Examples

Example 1: Example for a parameter transfer

Host to Encoder Encoder to Host Remarks

Control word Status word

D31 D25-

D28

D0-D24 D30-

D31

D25-

D28

D0 D24

1 0 0 x 0 0 0 Actual

value

2 0 P. No. Parameter 0 0 0 Actual

value

3 0 P. No. Parameter 0 0 0 Actual

value

4 0 P. No. Parameter 1 1 1) Para-

meter

5 0 P. No. Parameter 1 1 1) Para-

meter

6 0 P. No. Parameter 1 1 P. No. Para-

meter

7 1 0 0 1 1 P. No. Para-

meter

8 1 0 0 0 0 0 Actual

value

9 0 0 0 0 0 0 Actual

value

Normal operation

Host sends parameter to encoder,

encoder shows no reaction yet

Host continues to wait for encoder

confirmation

Encoder has taken over parameter and

starts processing

Parameter processing within encoder is

still running

Parameter processing has been finished,

encoder remains in "Parameterization"

state

Device control command "Enable

operation " from Host to encoder. Encoder

shows no reaction yet

Encoder is again in "Operation" state

Back again to normal operation state of

both participants

1): It must be ensured not to transfer the same parameter number as already confirmed by the encoder when

transmitting a parameter. It is not allowed to repeat the transfer of the same parameter without leaving the

"Parameterization" state.

The parameter number must be consistent.

When transferring several parameters, steps 4 to 6 must be repeated.

It must be ensured when transmitting a parameter that the parameter number is not allotted by the

parameter.

If parameters are transferred that are not valid or do not harmonize, the encoder will turn to the "Disturbance"

state when trying to enable operation.

Manual_GXP6W_EN.doc 8/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 9

Example 2: Procedure when transferring non-harmonizing parameters

Host to Encoder Encoder to Host Remarks

Control word Status word

D31 D25-

D28

1 0 0 x 0 0 1) Actual

D0-D24 D30-

D31

D25-

D28

D0 D24

Normal operation

value

2 0 2 20 000 0 0 1) Actual

value

3 0 2 20 000 0 0 1) Actual

value

Host sends value in order to program

resolution (number of revolutions)

Host continues to wait for encoder

confirmation

4 0 2 20 000 1 1 1) 20 000 Encoder has taken over parameter and

starts processing

5 0 2 20 000 1 1 1) 20 000 Parameter processing within encoder is

still running

6 0 2 20 000 1 1 2 20 000 Parameter processing has been

finished, encoder remains in

"Parameterization" state

7 0 3 1 1 1 2 20 000 Host sends value to program coding of

actual position value

8 0 3 1 1 1 2 20 000 Host continues to wait for encoder

confirmation

9 0 3 1 1 1 2 1 Encoder has accepted parameter and

starts processing

10 0 3 1 1 1 3 1 Parameter processing has been

finished, encoder remains in

"Parameterization" state

11 1 0 0 1 1 3 1 Device control command "Enable

operation " from Host to encoder.

Encoder shows no reaction yet

12 1 0 0 0 1 1 0 Encoder switches to "Disturbance"

state, the disturbance code is "1". The

actual position value is not allotted on

the process data channel.

Here a try has been made to set the resolution of the encoder to 20 000 revolutions. The encoder reacts to

this inadmissible parameter setting by switching to the "Disturbance" state and by emitting the disturbance

code "1".

Manual_GXP6W_EN.doc 9/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 10

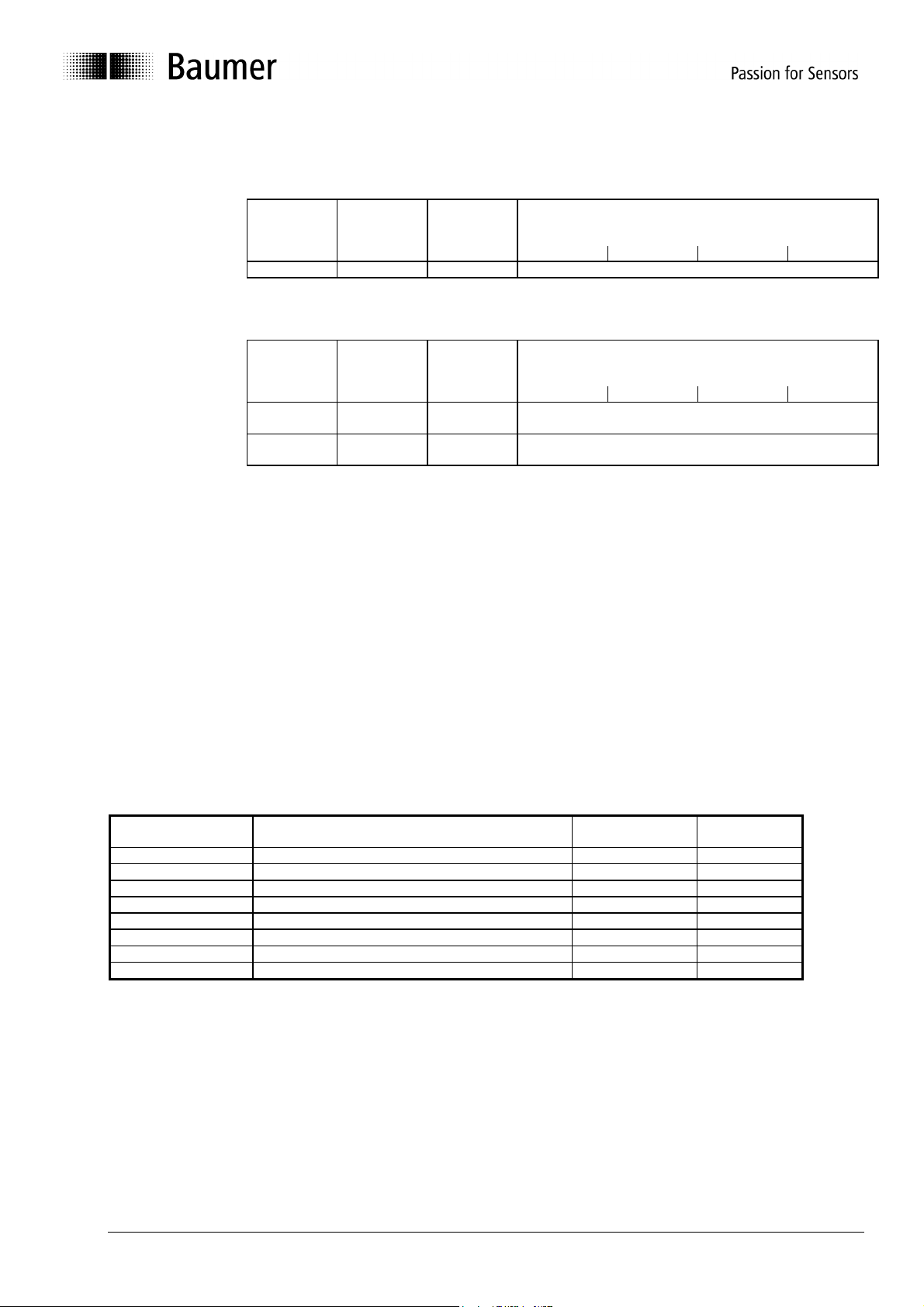

7 Disturbance messages

If there occurred an error when turning power on or during parameterization, the encoder switches to the

DISTURBANCE state after the user has passed the device control command ENABLE OPERATION and allots a

disturbance number to the bits D25-D28 of the status word. If an error occurs within the encoder during the

OPERATION state (e.g.: disturbance number 15), the encoder automatically switches to the DISTURBANCE state.

Disturbance No.

Significance

D28 D25

0 0 0 0 No disturbance

0 0 0 1 Inadmissible parameter from Master

0 0 1 0 Unknown parameter number

0 0 1 1 Parameter loss

1 1 0 1 Error when storing into EEPROM

1 1 1 0 Warning: Battery tension too low

1 1 1 1 Faulty value of encoder disk

8 Contact description

8.1 Description for bus cover

O N

1

GNDB

10-30 V

D01/

DI1

DI1/

GNDI

D02

D01

D02/

GNDB

D12

D12/

GND

10-30 V

8.2 Contact descriptions for bus cover

D01, D01 Incoming long-distance bus (A1) galvanically

DI1, DI1 separated from remaining encoder electronics

GND I Galvanically separated reference mass for incoming long-distance bus (A1).

Models without electrical isolation combined with GND.

UB Contacts for encoder supply

GND B incorporated within the bus (A1), UB = 10...30 VDC

D02, D02 Relaying long-distance bus (W1)

DI2, DI2

GND Reference mass for relaying long-distance bus (W1)

UB Contacts for GND B encoder supply either

GND B incorporated within bus (W1) or furnished via PG7, UB = 10 ... 30 VDC. Connected

internally with UB/GND B from A

Manual_GXP6W_EN.doc 10/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 11

8.3 Settings of user adresses

Cable

Screen

ON

Last user

1

ON

8.4 EMV-cable gland

The shielding of the contact cables must be done at the PG cable glands (PG7 and PG9).

The following are used:

1 x PG7 for voltage supply

2 x PG9 for data lines

Mounting: Strip the oversheath of the cable to ca. 35 mm (Picture 1), use connector sleeves

with litz cables. Push cap nut and seal insert onto cable sheath, shorten aluminum

foil,

if available, put braided screen over seal insert and shorten to 15 mm (Picture 2),

slide seal with cable into EMC PG cable gland and fix with cap nut.

Wire Screen

ca. 5 15

20

Picture 1 Picture 2

The following cable cross-sections are admitted for the PGs:

PG7: Cable cross-section - 4,0mm - 6,0mm

PG9: 2-piece seal insert: - 5,0mm - 7,0mm

- 7,0mm - 10mm

Cable

1

User X

Wire

SealAlu film

Manual_GXP6W_EN.doc 11/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 12

8.5 Contact description for C-plug

D01, D01 Incoming long-distance bus (A1) galvanically

DI1, DI1 separated from remaining encoder electr.

GNDI Galvanically separated reference mass for incoming long-distance bus (A1).

Models without electrical isolation combined with GND.

UB Contacts for encoder supply incorporated

GNDB within the bus (A1), UB = 10...30 VDC. Current load max. 700 mA

D02, D02 Relaying long-distance bus (W1)

DI2, DI2

GND Reference mass for relaying long-distance bus (W1)

UB Contacts for encoder supply within bus

GNDB (W1), UB = 10 ... 30 VDC. Connected internally with UB/GND B from A1

PE Screening combined with encoder housing

RBST Recognition of further bus users

Open contact: Last user

Contact to GND: User X

8.6 Pin assignment for C-plug

8

1

2

7

9

3

6

4

5

8

1

7

9

2

6

3

5

4

Incoming interface Outgoing interface

(pin) (socket)

Pin Assignment Pin Assignment

1 D01 1 D02

2 D01 2 D02

3 DI1 3 DI2

4 DI1 4 DI2

5 GNDI 5 GND

6 PE 6 PE

7 UB 7 UB

8 GNDB 8 GNDB

9 – 9 RBST

Manual_GXP6W_EN.doc 12/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 13

9 Technical data

9.1 Part number

Order no. Flange / Shaft

0 Clamping flange / 10 mm IP 54

A Clamping flange / 10 mm IP 65

1 Synchro flange / 6 mm IP 54

B Synchro flange / 6 mm IP 65

Voltage

10 10 ... 30 VDC with electr. isolation

20 10 ... 30 VDC without electr. isolation

Connection

A0 C-plug 2 x 9 pins axial

A1 C-plug 2 x 9 pins radial

A2 C-plug 2 x 9 pins axial, with 4 LED´s

A3 C-plug 2 x 9 pins radial, with 4 LED´s

20 Bus cover, 2 LED´s

Software

01 Profile K3

GXP6W.

9.2 Accessories

Order no.

Z 119.015 Mounting bell for synchro flange

Z 119.017 Angular fixing for clamping flange

Z 119.018 Eccentric fixing + screws

Z 121.C01 Spring-washer coupling, bore holes 6 mm / 10 mm

Z 121.C02 Spring-washer coupling, bore holes 6 mm / 6 mm

Z 121.C03 Spring-washer coupling, bore holes 10 mm / 10 mm

Z 153.B01 Connector socket, 9 pins

Z 153.S01 Connector plug, 9 pins

Manual_GXP6W_EN.doc 13/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Page 14

9.3 Dimensions

GXP6W clamping flange and bus cover

120°

42 ±0.1

50h7

58

M4 / 7 deep

14.3

90

GXP6W clamping flange and 2 C-plugs radial

outgoing

interface (socket)

Incoming

120°

interface (pin)

10

4

9.

3

3

3

5.5

3

ø6f8

Window for LED:

green: Maintained light for stand-by

red: Maintained light in case of

disconnection of relaying long distance bus

62

ca.17

9

ø10 h6

ø58

ø36 f8

M3 / 7 tief

48 ±0.1

15

80

10

20

59

GXP6W clamping flange and 2 C-plugs axial

120°

M3 / 7 tief

48 ±0.1

3

3

9

ø10 h6

ø58

ø36 f8

70 10

15

20

Incoming

interface (pin)

outgoing

interface (socket)

GXP6W optional: As above versions but with synchro flange and square flange

M4 / 7 deep

120°

42 ±0.1

50h7

58

10

4

9.

ø6f8

5.5

3

3

620

15

4(0.16")

(0.34")

ø9.52h7

8.76

(1.25")

ø31.75h7

(0.375")

Manual_GXP6W_EN.doc 14/14 Baumer IVO GmbH & Co. KG

04.05.11 Villingen-Schwenningen, Germany

Loading...

Loading...