Page 1

Manual

Absolute encoder with Profibus-DP

with functional extensions according to

Profibus-DPV1 and DPV2

Firmware Version 1.00 and up

Baumer IVO GmbH & Co. KG

Dauchinger Strasse 58-62

DE-78056 Villingen-Schwenningen

Phone +49 7720 942-0

Fax +49 7720 942-900 05.12 · 174.01.050/4

info.de@baumerivo.com Irrtum sowie Änderungen in

www.baumer.com Technik und Design vorbehalten.

Page 2

Contents Page

1. Introduction 5

1.1. Scope of delivery 5

1.2. Product classification 5

2. Safety and operating instructions 6

3. Product family 7

4. Commissioning 8

4.1. Mechanical mounting 8

4.2. Electrical connection 8

4.2.1. Cabling 8

4.2.2. Setting the user address 9

4.2.3. Terminating resistor 9

4.2.4. Connecting the bus cover 9

5. Projecting 11

5.1. Importing the GSD file 11

5.2. Encoder bus implementation 11

5.3. Assigning the user address 11

5.4. Assigning addresses for input and output data 11

5.5. Parameterization 12

5.5.1. General 12

5.5.2. Parameter Assignment 12

5.5.3. Clock synchronisation 15

5.6. Implementing the system functions for alarm handling 16

5.7. Compilation and load of hardware and software configuration 16

6. Profibus operation 17

6.1. Master Class 1 (Parameterization master) 17

6.2. Status indicator (multi-colour LED) 17

6.3. Telegram 81 of profile PROFIdrive 18

6.4. Position readout 19

6.5. Error signals in G1_XIST2 19

6.6. Preset function 19

6.7. Alarms 20

6.8. Warnings 21

6.9. Acyclic data communication according to DPV1 21

6.9.1. Overview 21

6.9.2. DS_Write 21

6.9.3. DS_Read 22

6.9.4. PROFIdrive parameter 918 PROFIBUS node ID 23

6.9.5. PROFIdrive parameter 922 telegram type 24

6.9.6. PROFIdrive parameter 964 device ID 25

6.9.7. PROFIdrive parameter 965 profile number 26

6.9.8. PROFIdrive parameter 971 transfer to non-volatile memory 27

6.9.9. PROFIdrive parameter 979 sensor format 28

6.9.10. Profile parameter 65000 preset value 30

6.9.11. I&M parameter 65000 block 0 31

7. System documentation: Profibus-DP 33

7.1. General information 33

7.2. GSD file 33

7.3. Encoder operating paramters 34

7.4. Data exchange between PROFIBUS-DP devices 35

7.5. Parameterization and configuration 36

7.5.1. Parameterization 36

7.5.2. Configuration 36

7.6. Diagnostic signals 36

7.6.1. Description of the diagnostic data block 37

7.6.2. Alarms 37

8. Troubleshooting – FAQ 38

Manual_ProfibusDPV2_BIDE_EN.docx 2/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 3

8.1. FAQ: Projecting 38

8.1.1. Where do I get an encoder manual? 38

8.1.2. Where do I get the appropriate GSD file? 38

8.1.3. Class3 or Class4 parameterization? 38

8.1.4. Input of 32bit parameter data in Siemens Step7 software 38

8.2. FAQ: Operation 39

8.2.1. Position readout 39

8.2.2. How to set and save a preset value ? 39

8.2.3. What is the LED in the bus cover for? 39

8.2.4. How to alter the resolution ? 40

8.2.5. How to read diagnostic data out of the control? 40

8.3. FAQ: Troubleshooting 40

8.3.1. No encoder communication (LED yellow continuous) 40

8.3.2. No encoder communication (LED flashing red once per second) 41

Manual_ProfibusDPV2_BIDE_EN.docx 3/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 4

Disclaimer of liability

The present manual was compiled with utmost care, errors and omissions reserved. For this reason

Baumer IVO GmbH & Co. KG rejects any liability for the information compiled in the present manual.

Baumer IVO nor the author will accept any liability for direct or indirect damages resulting from the use of the

present information.

At any time we should be pleased receiving your comments and proposals for further improvement of the

present document.

Registered trademarks

SIEMENS®, SIMATIC®, Step7® und S7® are registered trademarks of Siemens AG. PROFIBUS, the

PROFIBUS Logo and PROFIdrive are registered trademarks of the PROFIBUS user organization respectively

of PROFIBUS International (PI).These and other names applied in the present manual that at the same time

are registered trademarks are not correspondingly marked. Having omitted the respective marking does not

necessarily imply that the names are not registered trademarks or that there are no existing patents and

protected patented designs.

Manual_ProfibusDPV2_BIDE_EN.docx 4/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

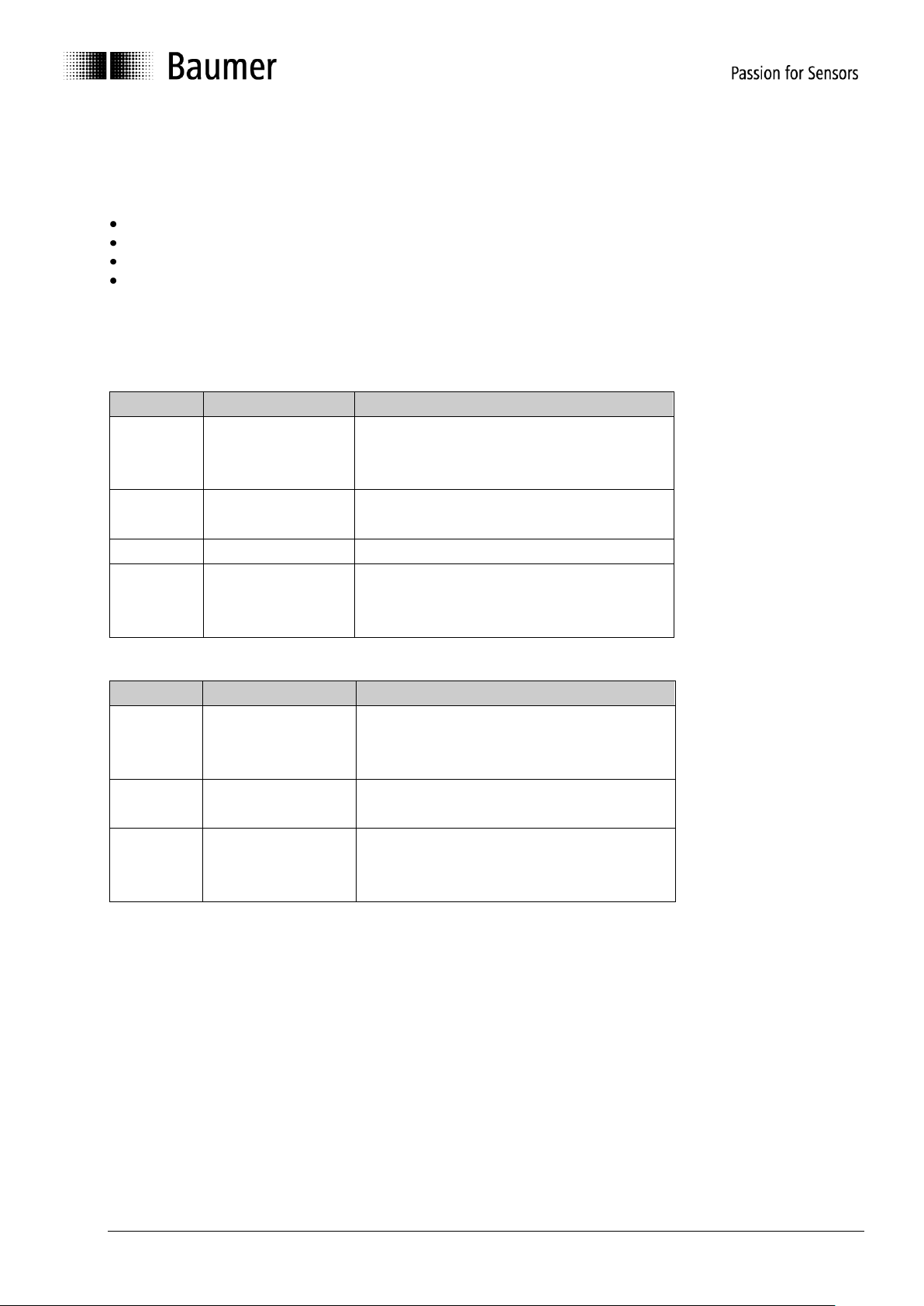

Page 5

1. Introduction

Product

GSD file

Product family

GBAMW

GBAM09F6.gsd

multivoPlus - Singleturn

GBLMW

GBMM09F6.gsd

multivoPlus - Multiturn

GBMMW

GBMM09F6.gsd

multivoPlus - Multiturn

GCAMW

GCAM09F6.gsd

magtivo® - Singleturn

GCMMW

GCMM09F6.gsd

magtivo® - Multiturn

GEMMW

GXMM09F6.gsd

multivo® - Multiturn (stainless steel)

GXAMW

GXAM09F6.gsd

multivo® - Singleturn

GXLMW

GXMM09F6.gsd

multivo® - Multiturn

GXMMW

GXMM09F6.gsd

multivo® - Multiturn

Product

GSD file

Product family

GBAMS

GBAM09F6.gsd

multivoPlus - Singleturn

GBLMS

GBMM09F6.gsd

multivoPlus - Multiturn

GBMMS

GBMM09F6.gsd

multivoPlus - Multiturn

GCAMS

GCAM09F6.gsd

magtivo® - Singleturn

GCMMS

GCMM09F6.gsd

magtivo® - Multiturn

GXAMS

GXAM09F6.gsd

multivo® - Singleturn

GXLMS

GXMM09F6.gsd

multivo® - Multiturn

GXMMS

GXMM09F6.gsd

multivo® - Multiturn

1.1. Scope of delivery

Please check the delivery upon completeness prior to commissioning.

Depending on encoder configuration and part number delivery is including:

Basic encoder

Profibus bus cover

Sealing bolt for any unused cable gland

CD with GSD file and manual (also available as download in the Internet)

1.2. Product classification

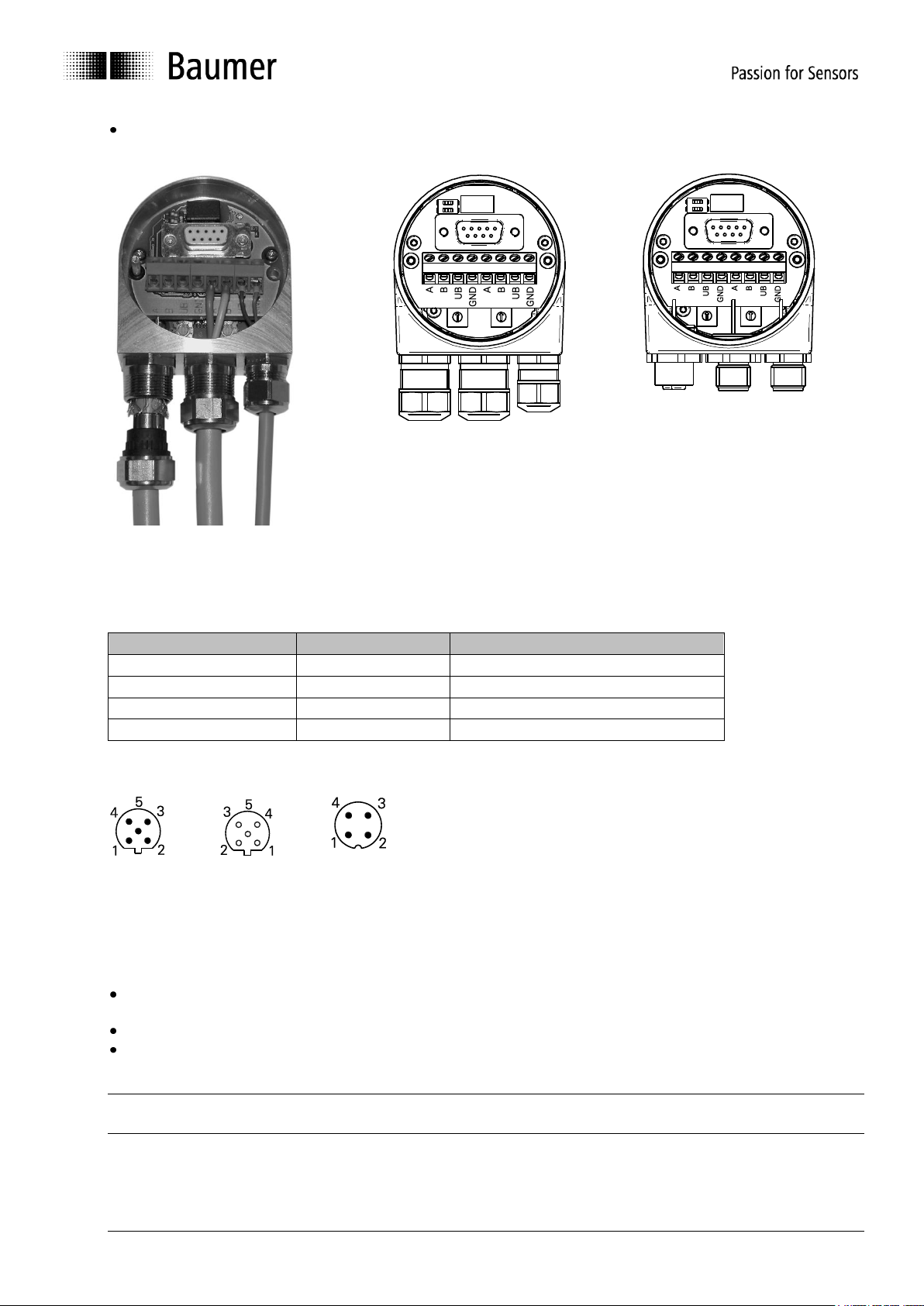

Shaft encoders

End shaft encoders

Manual_ProfibusDPV2_BIDE_EN.docx 5/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 6

2. Safety and operating instructions

Supplementary information

The present manual is intended as a supplement to already existing documentation (catalogues, product

data sheets and mounting instructions).

The manual must be studied carefully prior to initial commissioning of the equipment.

Intended purpose of the equipment

The encoder is a precision measurement device. It is utilized to determine angular positions and

revolutions, and to prepare and supply measured values in the form of electrical output signals for the

downstream device. Encoders may only be used for this purpose.

Commissioning

The encoder must be initialised and mounted only by a qualified expert.

Observe the operating instructions of the machine manufacturer.

Safety instructions

Check all electrical connections prior to commissioning of the equipment.

If mounting, electrical connections or any other work performed at the encoder and the equipment is not

correctly executed this can result in malfunction or failure of the encoder.

Corresponding safety precautions must be provided and observed to exclude any risk of personal injury,

damage to material or operating equipment as a result of encoder failure or malfunction.

Encoders must not be operated outside the specified limited values (see further documentation).

Failure to observe these safety instructions can result in malfunctions, material damage or personal injury.

Transport and storage

Only ever transport or store the encoder in its original packaging.

Never drop the encoder nor expose it to major shocks.

Mounting

Avoid impacts or shocks on housing and shaft/end shaft.

End shaft/Hollow shaft encoder: Open clamping ring completely before mounting the encoder

Avoid any twist or torsion on the housing.

Shaft encoders: never make rigid connections between encoder shaft and drive shaft.

Do not open the encoder or proceed any mechanical modifications.

Shaft, ball bearings, glass pane or electronic components can be damage thereby and a safe and reliable

operation is no longer guaranteed.

Electrical commissioning

Do not proceed any electrical modifications at the encoder.

Do not proceed any wiring work while encoder is live.

Never plug or unplug connector while encoder is live (the bus cover however may be removed or docked

to the basic encoder when live).

Ensure that the entire system is installed in line with EMC/EMI requirements. Operating environment and

wiring have an impact on the electromagnetic compatibility of the encoder. Install encoder and supply

cables separately or far away from sources with high emitted interference (frequency converters,

contactors, etc).

When working with consumers with high emitted interference provide separate encoder supply voltage.

Completely shield encoder housing and connecting cables..

Connect encoder to protective earth (PE) using shielded cables. The braided shield must be connected to

the cable gland or connector. Ideally, aim at dual connection to protective earth (PE), i.e. housing by

mechanical assembly and cable shield by the downstream devices. In case of earth loop problems, earth

at least on one side.

Failure to observe these instructions can result in malfunctions, material damage or personal injury!

Manual_ProfibusDPV2_BIDE_EN.docx 6/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 7

3. Product family

bus cover

complete encoder

basic encoder

The product family architecture is modular. Depending on what is required from the encoder, the basic

encoder and bus covers can be combined at will with the selected bus system.

The basic encoders differ in terms of accuracy, ambient conditions and the utilized sensing principle.

Bus cover

The bus cover accommodates the field bus interface and the complete electronics for processing the

measured values. EtherNet/IP communication is performed via the specialized EtherNet/IP-ASIC ERTEC200

with integrated high-performance microcontroller ARM9.

Magres / magtivo®

Utilizes a magnetic sensing principle and endures harsh industrial environments.

Procoder / multivo®

Utilizes a photoelectric sensing principle and is the recommended product for precise applications.

Dignalizer / activo® / multivoPlus®

Utilizes a photoelectric sensing principle with integrated analog/digital signal conversion and is the product to

choose for ultra-precise sensing applications.

The bus covers differ by the respectively integrated bus interface.

Available bus interfaces: CANopen, DeviceNet, EtherCAT, Ethernet/IP, Profibus-DP, Profinet, Powerlink,

Power over EtherCAT, SAE J1939, SSI.

All encoders enable parameterization by bus interface.

Functional principle:

Manual_ProfibusDPV2_BIDE_EN.docx 7/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 8

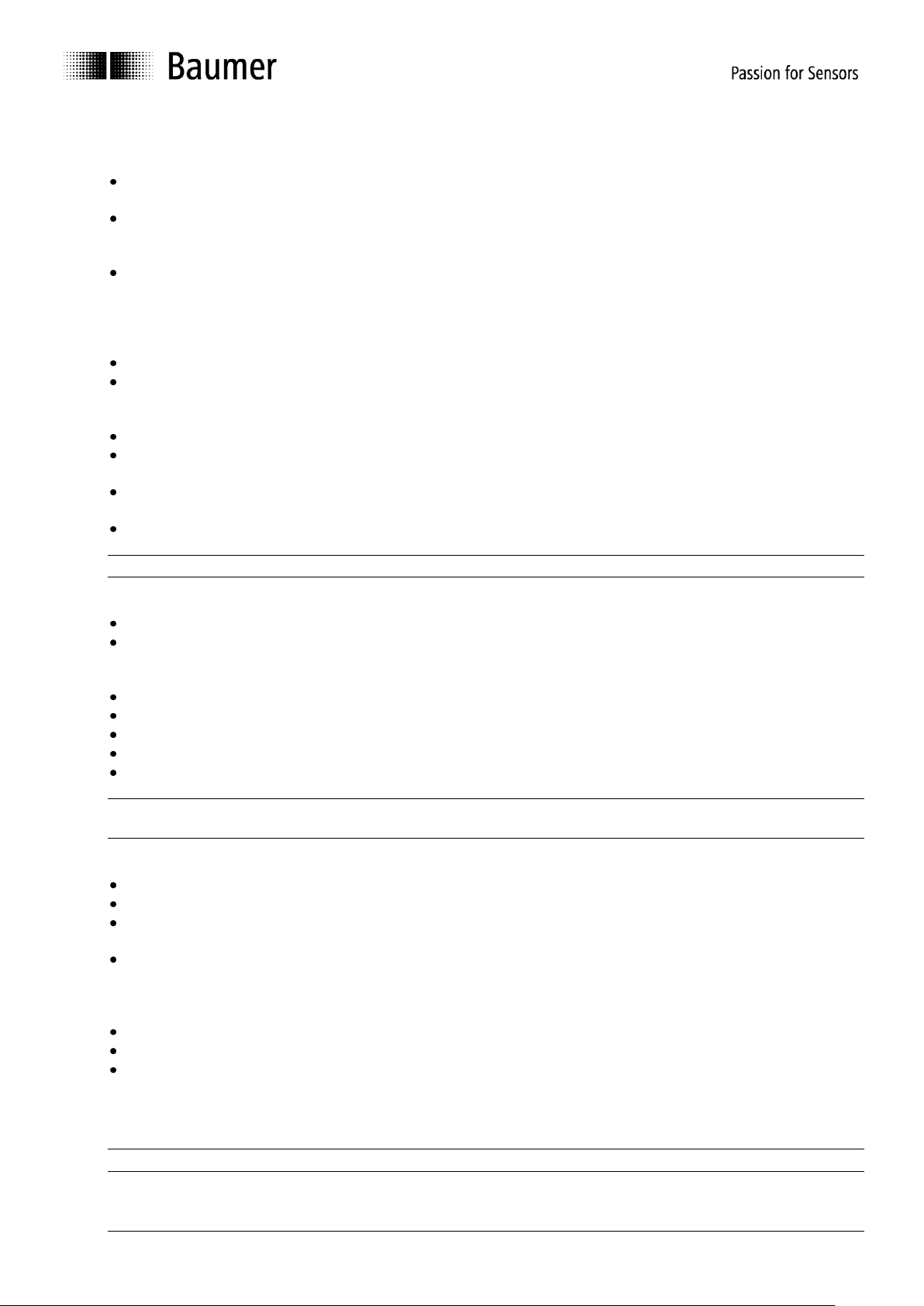

4. Commissioning

Properties

Data

Impedance in Ohm

135 to 165 at 3 to 20 MHz

Operating capacity (pF/m)

less than 30

Loop impedance (Ohm/km)

less than 110

Core diameter (mm)

greater than 0.64

Core cross section (mm)

greater than 0.34

Baudrate in

kBaud

9,6

19,2

93,75

187,5

500

1500

3000

6000

12000

Line distance

in m

1200

1200

1200

1000

400

200

100

100

100

4.1. Mechanical mounting

Shaft encoders

Mount the encoder by help of the mounting holes and three screws (square flange: 4 screws) provided at

the encoder flange. Observe thread diameter and depth.

There is an alternative mounting option in any angular position by eccentric fixings, see under

accessories.

Connect drive shaft and encoder shaft by using an appropriate coupling. The shaft ends must not touch

each other. The coupling must compensate temperature and mechanical tolerances. Observe the

maximum permitted axial or radial shaft load. For appropriate couplings please refer to accessories.

Tighten the mounting screws firmly.

End shaft/hollow shaft encoders

Mounting by clamping ring

Prior to mounting the encoder open the clamping ring completely. Push encoder onto the drive shaft and

tighten the clamping ring firmly.

Adjusting element with rubber buffer

Push the encoder onto the drive shaft and insert the cylindrical pin into the adjusting element (provided by

customer) and the rubber buffer.

Adjusting angle

Push the encoder onto the drive shaft. Insert adjusting angle into the encoder’s rubber buffer and fasten

the adjusting angle at the contact surface.

Stud screw

Push the encoder onto the drive shaft and insert the stud screw provided by customer into the encoder’s

rubber buffer.

Spring coupling

Fasten the spring coupling at the mounting holes of the encoder housing using screws. Push the encoder

onto the drive shaft and mount the spring coupling to the contact surface.

4.2. Electrical connection

Ever store and transport the bus cover in the ESD bag only.

For electrical connection remove the bus cover as follows:

Release the fastening screws of the bus cover

Carefully loosen the bus cover and lift off in an axial direction

4.2.1. Cabling

EN 50170 specifies two types of PROFIBUS cable, type A and B. Type B is obsolete and should not be used

in new applications. With type A all transmission rates up to 12Mbit/s are possible. Common baud rate in

clock synchronous operation according to PROFIBUS-DPV2 is 12Mbit/s.

Transmission speed depending on line distance

Manual_ProfibusDPV2_BIDE_EN.docx 8/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 9

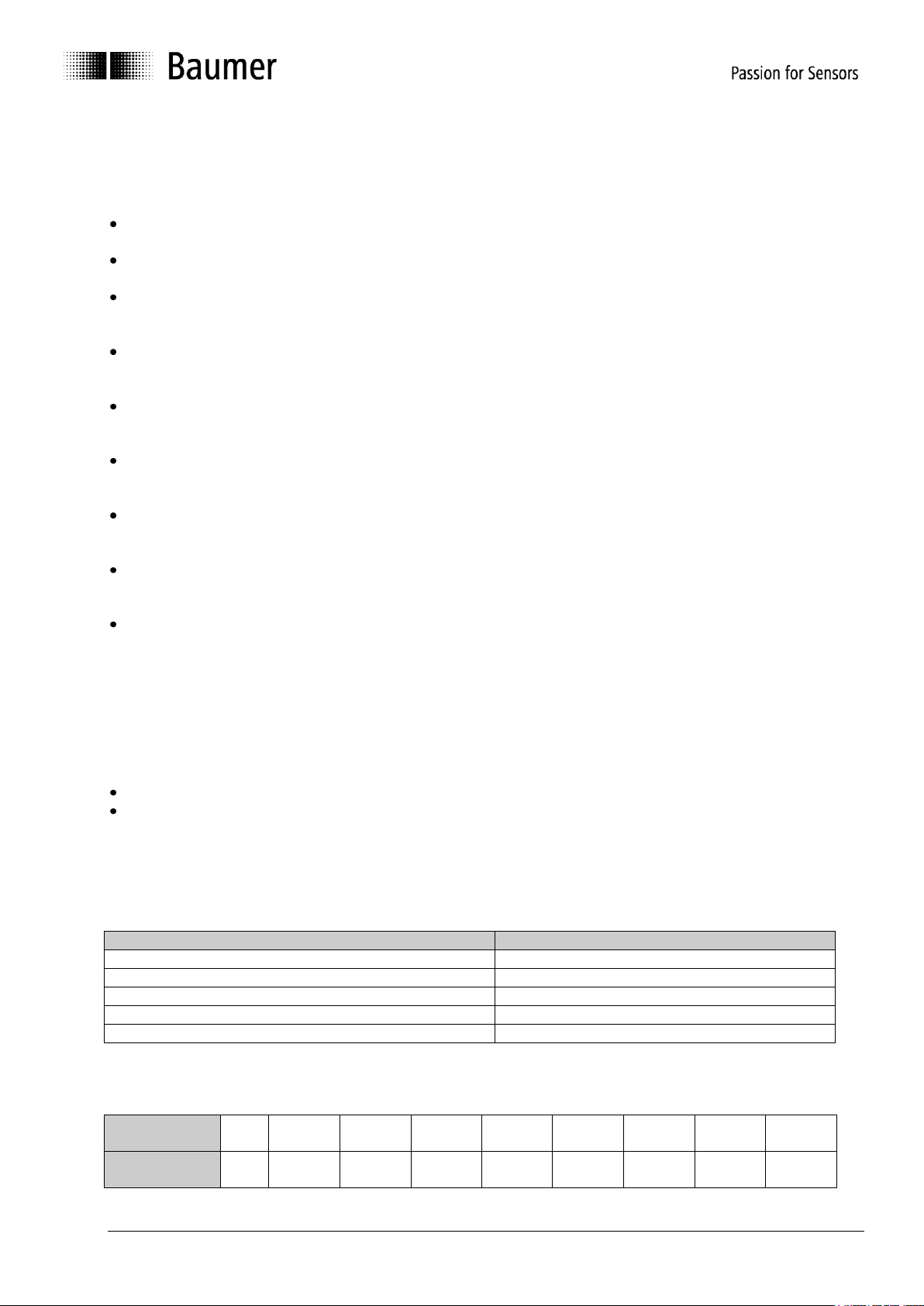

4.2.2. Setting the user address

Example: 23

both ON = final user

both OFF = all other users

Clamp

Resistance

A to GND

390 Ohm

B to +5 V

390 Ohm

A to B

220 Ohm

The user address is set decimally using the two rotary switches provided in the bus cover.

The maximum number of users is 99.

Decimal setting of the user address by the help of rotary switches 1 and 2 (default setting 00).

4.2.3. Terminating resistor

If the encoder is the final device in the bus line it is mandatory to terminate the bus by resistors. The resistors

are integrated in the bus cover and connected by means of a two-pole DIP switch.

The internal terminating resistors must be switched to „ON“ in case of final user by help of the 2-pole DIP

switch (default setting OFF). The two switches must always be set in the same direction.

4.2.4. Connecting the bus cover

Release the cap nut of the cable gland

Push the cap nut and seal insert with contact sleeve onto the cable sheath.

Strip the cable heath and cores, shorten the shield film where it exists (see fig.)

Bend over the braided shield by approx. 90°.

Push the sealing insert with contact sleeve along as far as the braided shield. Insert the sealing insert

with contact sleeve and cable flush into the cable gland and tighten the cap nut.

Take care that by no means the voltage supply is assigned to bus terminals A/B, this could damage

electronics components in the bus cover.

Avoid stub lines, especially with bus clocks greater than 1.5Mbit/s

Clamps with the same designation are internally connected to each other and identical in functionality.

Maximum load on the internal clamped connections UB-UB and GND-GND is 1 A each.

Signals A and B are decoupled at 100 nH inductivity each.

For voltage supply use cable gland 3 only. For the bus lines, either cable gland 1 or 2 may be used.

Please observe the admissible cable cross-sections.

Guide the cores the shortest way from the cable gland to the terminal connector. Observe the admissible

core-cross sections, use ferrules with flexible cores.

Avoid any crossings of data lines and supply line.

Manual_ProfibusDPV2_BIDE_EN.docx 9/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 10

Seal up the unused cable gland using a sealing bolt (included in the delivery).

1 2 3

Cable gland

M12 connector

M12 connector

Clamp:

Significance

M12, 4 pins: Pin 1

UB

Supply voltage 10...30 VDC

M12, 4 pins: Pin 3

GND

Ground connection related to UB

M12, 5 pins: Pin 2

A

Negative serial data line

M12, 5 pins: Pin 4

B

Positive serial data line

M12 connector

for serial data lines

for voltage supply

male female

Terminal assignment

Clamps with the same designation are internally connected to each other and identical in function.

Maximum load on the internal clamped connections UB-UB and GND-GND is 1 A each.

Signals A and B are decoupled with an inductivity of 100 nH each.

Assembly of basic encoder and bus cover:

Carefully plug the bus cover onto the D-SUB connector of the basic encoder, then press it over the seal

taking care not to tilt it.

Tighten both fastening screws firmly in the same direction.

The bus cover must fully rest on the housing of the basic encoder and be firmly screwed on.

The encoder housing and braided shield of the connecting cable are only ideally connected if the bus cover is

resting fully on the basic encoder (positive locking).

Manual_ProfibusDPV2_BIDE_EN.docx 10/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 11

5. Projecting

All examples in the present manual relate to SIEMENS® controls and the corresponding projecting software

Step7® , since they are commonly used as PROFIBUS controls. Please proceed in a corresponding way with

other controls.

5.1. Importing the GSD file

To implement the DP-Slave in the projecting software first the attached GSD file must be imported. All

required modifications of basic settings are implemented by parameterization (see “Parameterization”). The

GSD file itself is not modified.

Step7® software is imported in the hardware window („Extras – install GSD-files“). Prior to the import

operation the actual hardware project must be closed („Station - close“). Now the encoder appears at right in

the hardware catalogue under „PROFIBUS-DP“ – „More field devices“ – „Encoder“ – (xx corresponding to

the encoder type).

5.2. Encoder bus implementation

Use the mouse to drag text „GxxMW_H IsoM“ from the right out of the hardware catalogue to the bus bar. A

window pops up to enter the PROFIBUS node ID that must correspond to the settings of the BCD switch in

the bus cover. All other entries may remain unchanged. Close the entry by OK.

Use the mouse again to drag encoder module „telegram 81“ from the right out of the hardware catalogue to

plug-in position 1 of the module window at left below in the hardware window. Do not utilize the universal

module, this is not considered.

5.3. Assigning the user address

If not already done in a previous step or if required at a later date you may alter the PROFIBUS node ID of

the encoder. Upon a double click the window „Properties – DP-Slave“ pops up. Click on „PROFIBUS…“ and

enter the required node ID here. The node ID must correspond to the settings of the BCD switch in the bus

cover.

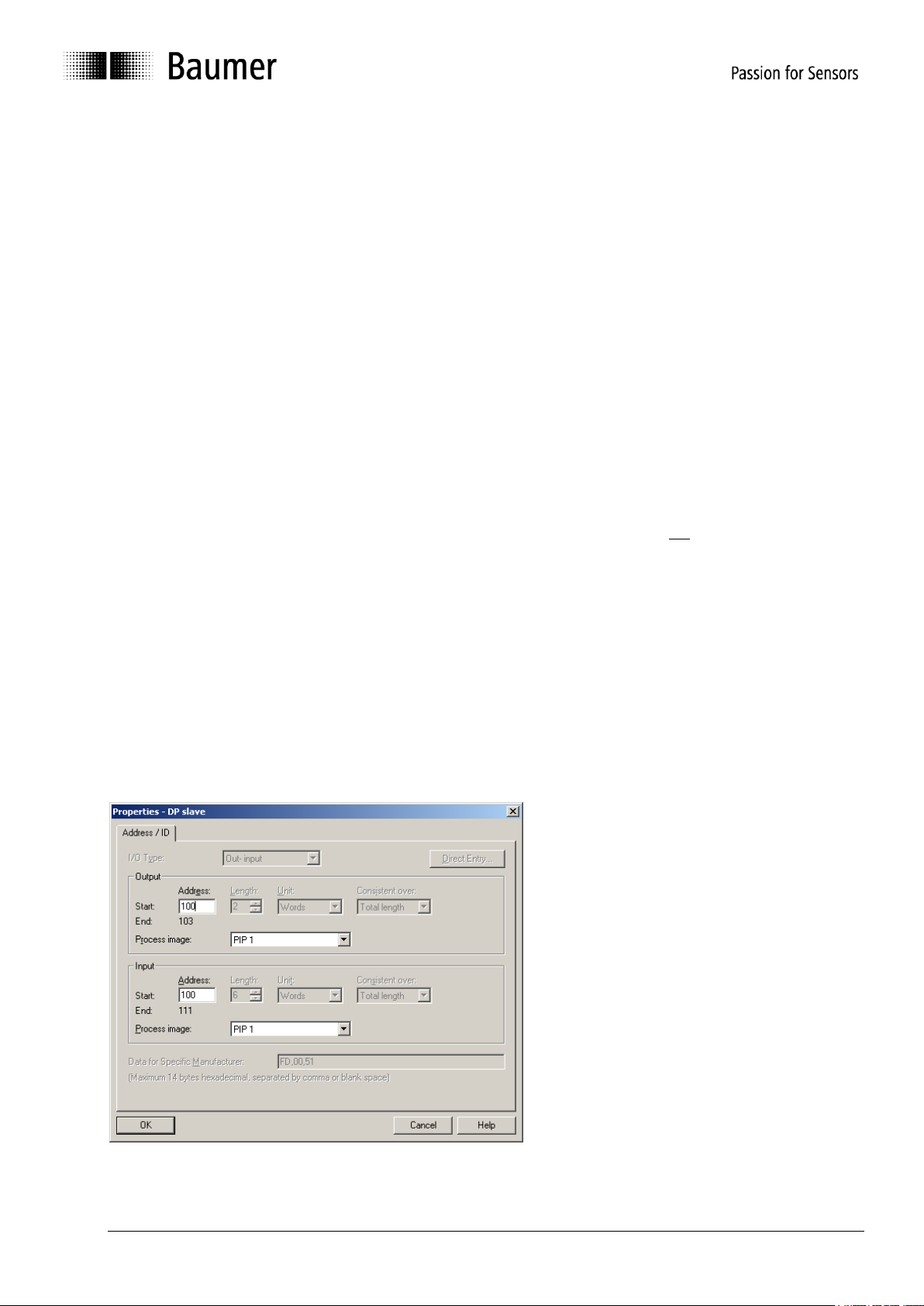

5.4. Assigning addresses for input and output data

Later access to encoder input and output data via master software requires assigning E/A addresses to the

input and output data. Click on the encoder icon on the bus bar HW config of Step7 to select the encoder.

Then double-click on module “telegram 81” (plug-in position 1) at left below. The window “Properties - DPslave” with tab “Address/ID” pops up (see screenshot).

Enter the respective initial addresses. It is admissible to use Identical or overlapping addresses for output and

input.

Manual_ProfibusDPV2_BIDE_EN.docx 11/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 12

E/A fields require defining partial process images in clock-synchronous operation, in the example it is TPA1.

Take care that the selected partial process image comprises the initial address. If not it will result in an error

signal when interpreting the project.

5.5. Parameterization

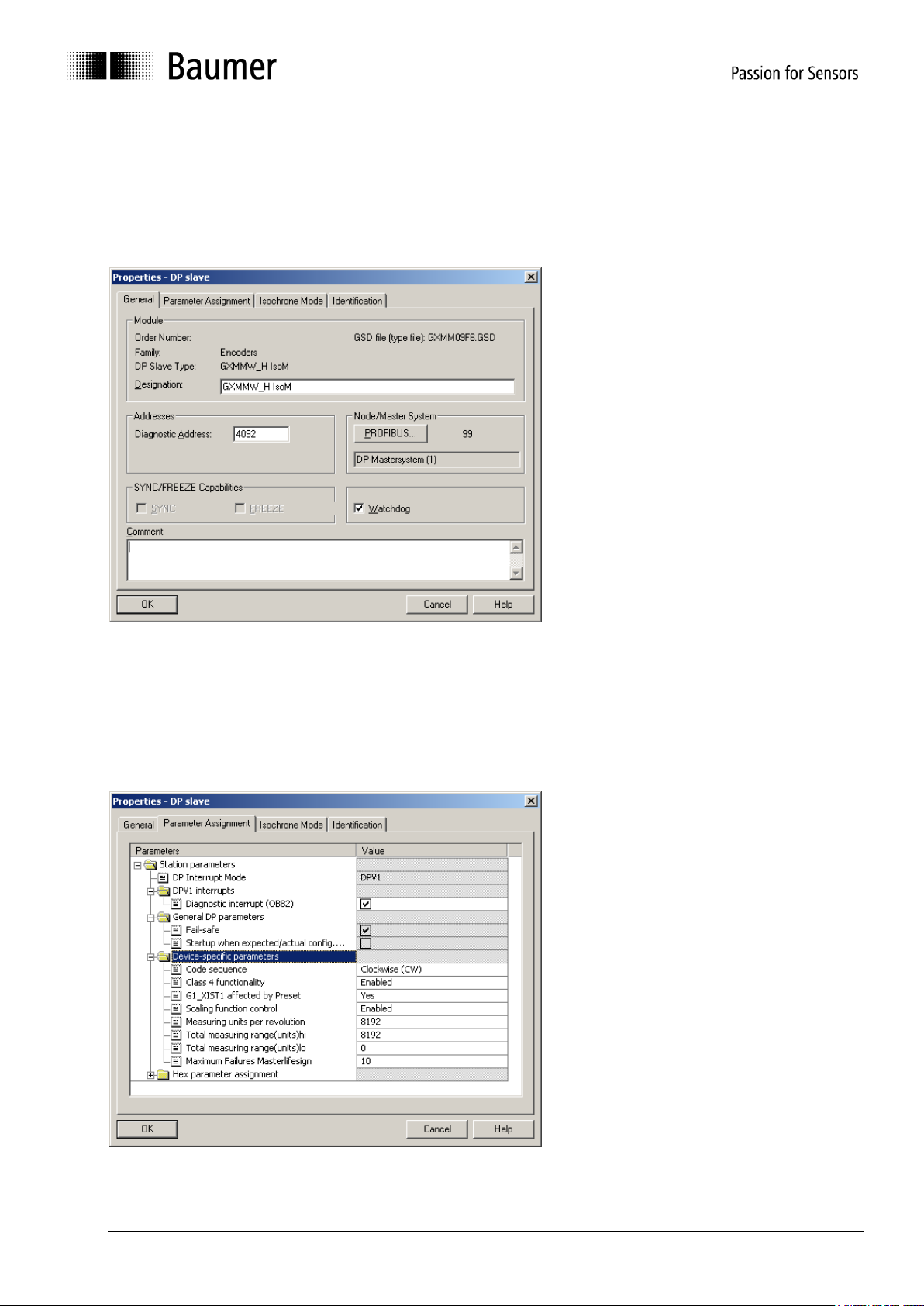

Upon double-click on the encoder icon at the bus bar, the window „Properties-DP-Slave“ pops up, showing

the tabs “General”, “Parameter Assignment” and “Clock synchronisation”.

5.5.1. General

System parameters under tab „General“ may usually be adopted without modifications.

If required, encoder name, diagnosis address and node ID under button „Profibus…” may be altered. Further

here is the option to deactivate the encoder’s response monitoring.

5.5.2. Parameter assignment

Manual_ProfibusDPV2_BIDE_EN.docx 12/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 13

Device-specific parameters

Code sequence

Behaviour of the position data in relation to the sense of rotation of the encoder shaft when looking at

flange.

CW („clockwise“) = Ascending values with clockwise rotation

CCW („counter-clockwise“) = Ascending values with counter-clockwise rotation

Class 4 functionality

If active („enabled“), the encoder operates as a Class 4 Device of the encoder profile.

If not active ( „disabled), the encoder operates as a Class 3 Device of the encoder profile.

Here setting a preset is disabled.

G1_XIST1 affected by preset

If active (“Yes”), setting a preset will affect both the left-aligned position value G1_XIST1 and the

right-aligned position value G1_XIST2.

If not active (“No”), the left-aligned position value G1_XIST1 is not added an offset that is internally

calculated upon setting a preset. In this case, both position values G1_XIST1 and G1_XIST2 may be

different!

Scaling function control

If active (“enabled”), resolution („steps per revolution“, “measuring units per revolution”) and the total

measuring range can be parameterized at will within the admissible limits.

If not active (“disabled”), the previous encoder settings for resolution and total measuring range will

remain, i.e. the maximum limits. Any try to enter deviating parameters will result in a parameterization

error signal.

Measuring units per revolution

Parameterization of the required resolution („steps per revolution“, „measuring units per revolution“).

Admissible values range from 1 to the maximum encoder resolution. Usually the limits are indicated

in the parameterization software.

multivoPlus encoders require a 32 bit value here to get two input fields, i.e. „measuring units per

revolution (hi)“ and „(lo)“. Ho to split the 32 bit value into two 16 bit values please see under 8.1.4.

A re-parameterization may clear the previous offset value (see “note” under 6.6. Preset function).

Total measuring range (units)

Parameterization of the required total measuring range, „TMR“.

Singleturn encoders require here the same parameter as for the resolution (“Measuring units per

revolution“).

Admissible values range from 2 to the product of programmed resolution multiplied by maximum

number of revolutions. The maximum limit of the parameterization software is only applicable if the

resolution is also the maximum.

All multiturn encoders and multivoPlus singleturn encoders need a 32 bit value here to get two input

fields, „Total measuring range (units) hi“ and „lo“. How to split up the 32 bit value into two 16 bit

values please see under 8.1.4.

Any alteration of the total measuring range clears the previous offset value (see “note” under 6.6

Preset Function)

Manual_ProfibusDPV2_BIDE_EN.docx 13/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 14

Important note for multiturn encoder operation

This encoder supports „Endless Operation“ automatically if required.

Thus, there are no special requirements for the encoder parameters “total measuring range” and

“measuring units per revolution” to stand in a certain ratio.

With endless operation active, the encoder shaft must not rotate when the encoder is not

powered. In those cases where powerless motion cannot be avoided, the encoder has to be

referenced (presetted) after each power-up. With Endless Operation inactive, the encoder shaft may

rotate unlimited when encoder not powered.

How to determine if „Endless Operation“ is in use:

Multiply the encoder’s „max. possible revolutions“ (depending on encoder 16 bit = 65536 or 13

bit = 8192) by your chosen parameter „measuring units per revolution“.

Divide this value by your chosen „total measuring range“.

If there is a division remainder, endless operation is in use.

Example for parameters without endless operation:

Maximum possible revolutions 65536 (16 bit multiturn)

Measuring units per revolution 3600

Total measuring range 29.491.200 (8192 x 3600)

Calculation: 65536 x 3600 / 29.491.200 = 8 (no remainder)

Example for parameters with endless operation:

Maximum possible revolutions 65536 (16 bit multiturn)

Measuring units per revolution 3600

Total measuring range 100.000

Calculation: 65536 x 3600 / 100.000 = 2359 remainder 29600

Maximum Failures Master lifesign

Designation of the maximum number of tolerated failures in master lifesign transmission in output

word STW2. Upon exceeding the number of tolerated failures an error signal is output in G1_XIST2

which has to be acknowledged.

Any monitoring of the Master lifesign will only take place respectively begin if the values transmitted

by the control in master lifesign are unequal to zero.

Hex parameterization

The hexadecimal data described only reflect the actual settings in the form they are transmitted to the

encoder and by no means should be altered in any way.

Manual_ProfibusDPV2_BIDE_EN.docx 14/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 15

5.5.3. Clock synchronisation

Clock-synchronous operation is activated by a tick on “SynchronizeDP-Slave at equidistant DP-cycle“.

Time Ti marks the time before the equidistant bus clock (Global Control Message, GC) where the encoder is

sensing the position data with micro-second precision. It should be aimed at the smallest possible value.

250 µs minimum is admissible if encoder operation is without scaling, i.e. always with the maximum

resolution. For enabled scaling the minimum value is 375µs. In case several clock-synchronous DP-slaves

exist in the bus that require more time for data evaluation automatically the maximum value will be utilized.

Time To is insignificant to the encoder. Usually the projecting software makes a proposal under consideration

of correlations to other bus parameters.

Manual_ProfibusDPV2_BIDE_EN.docx 15/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 16

Also in the encoder hardware configuration, under „Properties - DP-Slave“ – „PROFIBUS...“ – „Properties“ –

„Network settings“ – the “options” „Activate constant bus cycle time” and „Times Ti and To the same for all

slaves” must be ticked, otherwise the control may not perform the clock-synchronous operation.

5.6. Implementing the system functions for alarm handling

Make sure that the system components necessary for alarm handling have been implemented in the project.

With regard to Siemens Step7 projects there are in particular OB82 ("I/O Point Fault") and OB86 ("Loss Of

Rack Fault"). Missing these components will result in a control STOP in case of alarm.

5.7. Compilation and load of hardware and software configuration

After the complete hardware project configuration and once entered all parameters the project has to be

compiled and exported to the control.

Manual_ProfibusDPV2_BIDE_EN.docx 16/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 17

6. Profibus operation

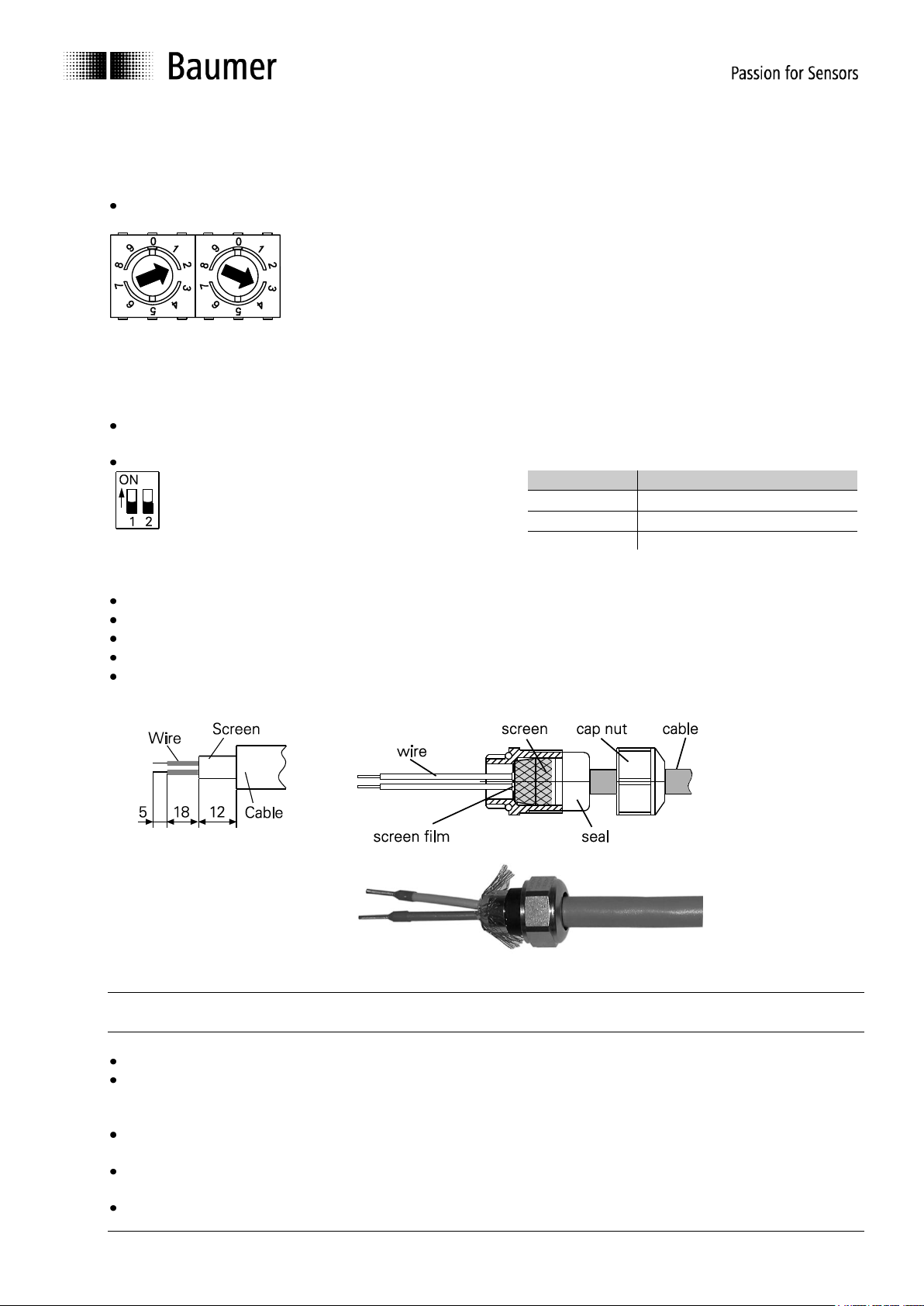

Colour

Status

LED yellow continuous

Encoder not active in the bus, not (yet) parameterized.

LED green continuous

Encoder in „Data_Exchange“ mode.

Active data exchange.

LED red continuous 2,5 s

Inadmissible position leap or the maximum electric speed is

exceeded

LED red flashing slowly (1 Hz)

Parameterization error

LED red flashing fast (5 Hz)

Transmitted preset value beyond the admissible value range

6.1. Master Class 1 (Parameterization master)

After encoder connection and start of master class 1 (parameterization master) PROFIBUS boots up

automatically. Based on the inactive status „Wait Prm“ (wait for parameterization) the encoder will go through

the operating statuses “Parameterization” and “Configuration” until the final status “Data Exchange” where it

usually remains.

6.2. Status indicator (multi-colour LED)

The back of the bus cover provides an integrated multi-colour LED indicating the encoder operating status.

When the encoder is under power supply, always one the following operation statuses is indicated by the

LED:

At encoder power on the LED remains yellow continuous until the PROFIBUS master (PLC) has begun data

communication with the slave (encoder). Usually this status is just an instant and nearly unnoticed since

normally the encoder is immediately tracked by master. However, yellow continuous may remain in case of

unsuccessful data communication, for example in case of an incorrect address or failure in the PROFIBUS

cable.

After successful encoder configuration and parameterization (automated process) the encoder goes to „Data

Exchange“ starting cyclic data communication. A green LED now signalizes cyclic transmission of position

data to the master.

Upon occurrence of a position leap („code consistency error“) or speed exceeding approx. 6200 rpm the LED

is red continuous for at least 2.5 s. If the indicated error remains or occurs repeatedly within this time, the red

continuous period is correspondingly extended.

If the encoder is transmitted a preset value outside the limits the LED will change to red flashing fast (5 Hz).

This status remains until the encoder receives an admissible preset value.

In case of inadmissible parameterization by master the LED is flashing red slowly (1 Hz) what may occur with

incorrect parameter input in the projecting phase. Most of incorrect inputs are compensated by the GSD file,

but it is impossible to eliminate every error.

Manual_ProfibusDPV2_BIDE_EN.docx 17/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 18

6.3. Telegram 81 of profile PROFIdrive

ZSW2

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Slave Sign-of-Life

0 0 0 0 0 0 0 0 0 0 0

0

G1_ZSW1

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

SE

PS

TA

PA

EA 0 0 0 0 0 0 0 0 0 0

0

G1_XIST1

31

0

encoder position (left-aligned) with / less preset offset

G1_XIST2

31

0

Encoder position (right-aligned) or error message

STW2

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Master Sign-of-Life

0 0 0 0 0 0 0 0 0 0 0

0

G1_STW1

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

SEA

PS

TA

PR

REL 0 0 0 0 0 0 0 0 0 0

0

In line with PROFIBUS DP-V2 profile the encoder applies for cyclic communication in clock-synchronous

operation telegram81 of the PROFIdrive profile which means cyclic and clock-synchronous transmission of

12 bytes input data and 4 bytes output data.

Input data

There is a cyclic transmission of input data from encoder to control.

Bit SE: Sensor Error

If this bit is set, G1_XIST2 will come with an error code instead of the position value

Bit PS: Parking Sensor Active (Acknowledgement)

If this bit is set, the function „Parking Sensor“ will be enabled (error output suppressed)

Bit TA: Transmit absolute value cyclically (Acknowledgement)

If this bit is set, there will be cyclic position transmission in G1_XIST2.

This always applies to the present encoder.

Bit PA: Preset Acknowledgement

When this bit is set, the preset setting operation at the encoder was successful. The bit

mirrors the preset bit of the output data and is automatically taken back after reset.

Bit EA: Error Acknowledge Required

If this bit is set, an encoder error will have to be acknowledged. This is not general practice

with the present encoder (bit ever 0)

Position data are transmitted by both input double words G1_XIST1 and G1_XIST2. G1_XIST1

comprises the left-aligned position value, e.g. bit 31 = 1 as maximum position value (corresponding to

scaling). G1_XIST2 contains the right-aligned position value in the standard structure. G1_XIST2

further comprises an error code in case of error. The scaling operation always affects both double

words. The effect of the preset on position value G1_XIST1 can be eliminated by parameterization

(„G1_XIST1 affected by Preset“). In this case G1_XIST1 and G1_XIST2 show different position

values. G1_XIST2 is always affected by preset.

Output data

There is a cyclic transmission of output data to the encoder.

Bit SEA: Sensor Error Acknowledgement

If this bit is set, the error code in G1_XIST2 will be acknowledged what is not

not necessarily required with the present encoder.

Bit PS: Parking Sensor Active (acknowledgement)

It this bit is set, the function „Parking Sensor“ will be enabled (error output suppressed

Bit TA: Transmit absolute value cyclically (Acknowledgement)

If this bit is set, there will be a cyclic position transmission in G1_XIST2.

This ever applies to the present encoder, no matter if the bit is set or not.

Manual_ProfibusDPV2_BIDE_EN.docx 18/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 19

Bit PR: Preset

Value

Error

Significance

0x0001

Position error

Presently the encoder cannot provide a

correct position

0x0F01

Unknown command

In G1_STW1 the master has transmitted a

command which is unknown to the encoder

0x0F02

Sign-of-Life error (Master)

Number of admissible failures in the mastersign-of-life has been exceeded

0x0F04

Synchronisation error

Number of admissible failures in the bus

cycle signal has been exceeded

If bit PR is set, the preset operation will be enabled. Once the Preset Acknowledge bit of the

input data is set, bit PR should be reset.

Bit REL: Preset Relative

If this bit is set, the function Preset Relative will be enabled, e.g. the actual position is added

the preset value as offset (negative values as complement on two). If this bit is not set, the

preset operation will be absolute. In other words, the encoder position is set to the preset

value.

6.4. Position readout

Position data are transmitted by telegram81 of the PROFIdrive profile as described above. Control access to

the data should only be enabled during clock-synchronous alarm. Only then it is guaranteed that the encoder

position is derived from the desired clock-synchronous bus cycle.

By principle, there could also be a direct control access to the parameterized I/O address using the peripheral

input words. We strongly recommend to refrain from this in clock-synchronous operation, since in this case

consistency and clock synchrony are not ensured.

6.5. Error signals in G1_XIST2

Bit 15 in G1_ZSW1 means that the value in G1_XIST2 is not a position value but an error code. Should

several errors occur at the same time only the first one will be transmitted.

6.6. Preset function

Preset default setting is 0. Preset alteration is enabled by acyclic parameter 65000. The value is saved

volatile, i.e. it is lost at encoder power off. For non-volatile saving utilize parameter 971.

The actual preset operation is triggered by output word „G1_STW1“ bit 12. A feedback after a successful

operation is given by input word „G1_ZSW1“, bit12. This bit remains until the control will reset the

corresponding bit in the output word.

The preset value (volatile) must not be confused with the internal preset offset (non-volatile). The preset-

offset is automatically saved in the non-volatile memory so that the encoder will be in the same position after

power off and at power on.

The preset effect on position value G1_XIST1 can be compensated by parameterization („G1_XIST1 affected

by Preset“). In this case G1_XIST1 and G1_XIST2 provide different position values. G1_XIST2 is always

affected by preset.

Upon performing a preset operation an internal offset value is calculated and immediately saved non-volatile

in EEPROM. EEPROM provides 1 million writing cycles, however, frequent software or event-triggered preset

operations can exhaust the service life despite this high number of writing cycles. This should be considered

in the control software layout.

Manual_ProfibusDPV2_BIDE_EN.docx 19/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 20

Note:

Data Unit:

Value

Significance

Octet 1

Station_status_1

Diverse bits, see PROFIBUS literature (e.g. Ext. Diagnose

Bit)

Octet 2

Station_status_2

Diverse bits, see PROFIBUS literature (e.g. Stat. Diagnose

Bit)

Octet 3

Station_status_3

External diagnosis overflow bit

Octet 4

Diag_Master_Add

Master address after parameterization (otherwise 0xFF)

Octet 5

Ident_Number

Ident number high byte

Octet 6

Ident_Number

Ident number low byte

Octet 7

Block Length

0x07

Following block length in bytes (including this one)

Octet 8

Alarmtyp

0x01

1 = Diagnostic alarm

Octet 9

Slot

0x01

Slot number

Octet 10

Alarm Spec

xx

Alarm Specifier (in / out) and sequence number (0..31)

Octet 11

Header

0x81

see DPV2 encoder profile

Octet 12

Channel

0x40

see DPV2 encoder profile

Octet 13

Type of Diagnosis

0x16

see DPV2 encoder profile / Alarm definition

At altering the encoder’s total measuring range during re-parameterization the internal preset-offset-value will

be cleared. This is insignificant for the application since in this case the relation to the position gets lost

anyway. The preset value saved by parameter 971 will of course remain. It must be ensured however that the

former preset value is within the new total measuring range, otherwise a new value has to be stored.

6.7. Alarms

Diagnosis alarms are triggered in line with acyclic services according to DPV1.

A diagnosis alarm is triggered upon the encoder having detected a probably incorrect position. The next

position data telegram is added a high priority bit in the function code (bit 1) by the encoder what makes the

control transmit a acyclic diagnosis alarm request. The encoder responds by an acyclic diagnosis telegram.

“Data Unit” (DU) of this telegram provides the following structure: Octets 1 to 6 correspond to the diagnosis

telegram of cyclic data exchange.

The alarm is acknowledged by the control under reference to the running alarm sequence number.

The encoder will only consider value 22 (0x16) indicating a position error as „Type of Diagnosis / Alarm

Definition).

A diagnosis alarm is triggered once with each inbound and outbound event. An outbound event alarm

comprises an „Alarm Specifier“ for „outbound event“ together with a specific sequence number that is

incremented towards the inbound event.

Siemens controls proceed diagnosis OB82 in case of alarm. If this is not implemented in the project the

control will go to STOP in case of alarm.

Alarms resulting from a probably incorrect position can be signalized in three different ways:

DPV1 Diagnosis alarm (as described)

Error signal in G1_XIST2 (see under „Error signals in G1_XIST2“)

LED in the bus cover is red continuous for at least 2.5 s

Manual_ProfibusDPV2_BIDE_EN.docx 20/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 21

6.8. Warnings

Called parameter

Value

Example

ID

Slot no.1 (E/A address telegram81)

Slot no.0 (diagnisos address slave)

0x0200

0xFFD

Index

47 = 0x2F

255 = 0xFF

0x2F

0xFF

Length

Length of data to be exported out of

the data block (write)

0x0A

Byte

Significance

Explanation

Example

0

Request Reference

Selectable at will by master, mirrored

in response

0xAA

1

Request ID

Request=1 Change=2

0x01

2

Shaft no.

0= whole slave

0x00

3

Number of parameters

Only one parameter: 1

0x01

4

Attribute

0x10=Value = 0x20=Description

0x30=Text

0x10

5

Number of parameter elements

Several elements (Sub-IDs) during

read/write, counted from Sub-ID

0x04

6

Prm_no hi

High byte of parameter number,

in the example 65000=$FDE8

0xFD

7

Prm_no lo

Low byte of parameter number

0xE8

8

Subindex hi

0x00

9

Subindex lo

0x02

Supplementary bytes 10...15 only with “Change Parameter”:

A diagnostic warning is triggered upon the encoder recognizing that specific internal tolerance limits have

been achieved. Conversely to alarms a warning does not consequently mean a position error.

The process sequence of a diagnostic warning is fully identical to that of a diagnosis alarm described in the

above. The difference is made in „Type of Diagnosis“ defining several reasons for warning.

Type of diagnosis:

16 (0x10): “Frequency exceeded” (threshold signal when exceeding the maximum encoder

speed)

17 (0x11): „Light Control“ (threshold signal for being at the infrared LED regulating limit)

20 (0x14): “Battery Voltage Low” (threshold signal for low battery voltage)

6.9. Acyclic data communication according to DPV1

6.9.1. Overview

The parameterization master utilizes acyclic telegrams in line with PROFIBUS-DPV1 to read and if required

to write addressed data in the DP slave by slot, index and parameter number. Prior condition is that the DP

slave is in Data Exchange mode.

Acyclic data communication utilizes system functions DS_Read and DS_Write. DS_Write is appropriate for

writing parameters („Change Parameter“).

A parameter reading operation by DS_Read („Request Parameter“) is always preceded by DS_Write

supplying the slave with all necessary information on the requested parameter read access. Successful exit

of DS_Write may take several bus cycles, afterwards DS_Read can be launched.

6.9.2. DS_Write

SIEMENS controls apply system function SFB53 / WRREC for DS_Write. Parameters to be delivered are

among others index and ID (Slot), “Index=47” as encoder profile parameter, Index=255“ for I&M parameters.

The slot address is the “ID”. For Slot1 it is the programmed E/A address of telegram 81, in the examples

below 512 = 0x200. Slot0 is addressed via the diagnosis address of the DP-Slaves, in the examples below

4093 = 0xFFD.

An additional data block must be prepared for accommodating more parameters. The schematic structure of

this data block is described in the following. Length depending on read/ write access and parameter length

are between 10 and 16 bytes.

DS_WRITE

Data block (write)

Manual_ProfibusDPV2_BIDE_EN.docx 21/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 22

10

Format of the following parameter

0x40=Zero 41=Byte 42=Word

43=Dword 44=Error

0x43

11

Number of parameter values

Encoder: ever “1”

0x01

12

Value

with byte: Parameter

with word: Parameter Hi Byte (MSB)

with Dword: Parameter Byte 3 (MSB)

0x00

13

Value

with Word: Parameter Lo Byte (LSB)

with Dword: Parameter Byte 2

0x01

14

Value

with Dword: Parameter Byte 1

0x00

15

Value

with Dword: Parameter Byte 0 (LSB)

0x00

Called parameter

Value

Example

ID

Slot no.1 (E/A address telegram81)

Slot no.0 (diagnosis address slave)

0x0200

0xFFD

Index

47 = 0x2F

255 = 0xFF

0x2F

0xFF

Length

Maximum length of data to be

transmitted that can be imported in

data block

0x40

Byte

Significance

Explanation

Example

0

Request Reference

Mirrored value out of DS_Write

0xAA

1

Response ID

0x01 = Request parameter (success)

0x02 = Change parameter(success)

0x81 = Request parameter(error)

0x82 = Change parameter(error)

0x01

2

Shaft no.

always 0= whole slave

0x00

3

Number of parameters

Only one parameter: 1

0x01

4

Format

0x01 = Boolean

0x02 = Integer8

0x03 = Integer16

0x04 = Integer32

0x05 = Unsigned8

0x06 = Unsigned16

0x07 = Unsigned32

0x08 = FloatingPoint

0x09 = VisibleString

0x10 = OctetString

0x10

5

Number of values

0xnn

6

Value 1

7

Value 2

8

Value 3

9

Value n

6.9.3. DS_Read

Controls by SIEMENS apply system function SFB52 / RDREC for DS_Read. Index and ID (Slot) parameters

correspond to those of DS_Write. Parameter MLEN corresponds to the size of the import data block. It may

always remain the maximum amount (for example 64).

An additional data block of sufficient capacity must be provided to accommodate the imported data. A volume

of 68 byte is sufficient for parameters implemented in the encoder. Its content according to DS_Read is

described in the following.

DS_READ

Data block (read)

The following acyclic functional parameters of the PROFIdrive profile V3.3 (parameter numbers 9xx)

respectively of DPV2 encoder profile V3.2 (65xxx) are supported by GXMMW:

Manual_ProfibusDPV2_BIDE_EN.docx 22/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 23

Parameter 918 (read only) Profibus node ID (BCD switches)

Called parameter

Value

Example

Function ID

Permanent for DS_Write

0x5F

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Length

10 = 0x0A

0x0A

Byte #

Example

0

Request Reference (Example)

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Attribute = “Value”

0x10

5

Number of parameter elements

0x01

6

Prm_no hi: 918 = 0x0396

0x03

7

Prm_no lo: 918 = 0x0396

0x96

8

Subindex hi

0x00

9

Subindex lo

0x00

Called parameter

Value Function ID

Permanent for DS_Read

0x5E

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Max.length

64 = 0x40

0x40

Byte #

Example

0

Request Reference: mirrored

0xAA

1

Request ID (not: Change)

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Format: Unsigned16

0x06

5

Number of values

0x01

6

Value (hi): ever 0

0x00

7

Value (lo): Node address

0x37

Parameter 922 (read only) Telegram type (=81)

Parameter 964 (read only) Device identification

Parameter 965 (read only) Profile number (3.2)

Parameter 971 (read/write) Transfer to non-volatile memory

Parameter 979 (read only) Sensor format

Parameter 65000 (read/write) Preset value

All parameters are accessed by Slot 1 (indicate E/A address under „ID“ in Step7), index 47 and subindex 0.

Additional access to block 0 of I&M functions (Identification and Maintenance ) via index 255, Slot 0 or 1,

parameter 65000.

6.9.4. PROFIdrive parameter 918 PROFIBUS node ID

Readout of the PROFIBUS node ID (BCD switch). Example node ID: 55 (0x37)

DS_WRITE

DP-V1 Header

Data Unit - (write):

DS_READ

DP-V1 Header

Data Unit - (read):

Manual_ProfibusDPV2_BIDE_EN.docx 23/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 24

6.9.5. PROFIdrive parameter 922 telegram type

Called parameter

Value

Example

Function ID

Permanent for DS_Write

0x5F

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Length

10 = 0x0A

0x0A

Byte #

Example

0

Request Reference (example)

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Attribute = “Value”

0x10

5

Number of parameter elements

0x01

6

Prm_no hi: 922 = 0x039A

0x03

7

Prm_no lo: 922 = 0x039A

0x9A

8

Subindex hi

0x00

9

Subindex lo

0x00

Called parameter

Value Function ID

Permanent for DS_Read

0x5E

ID

Slot No.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Max.Length

64 = 0x40

0x40

Byte #

Example

0

Request Reference: mirrored

0xAA

1

Request ID (not: Change)

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Format: Unsigned16

0x06

5

Number of values

0x01

6

Value (hi): ever 0

0x00

7

Value (lo): telegram no.

0x51

Readout of the telegram type. The DPV2 encoder applies always telegram 81 (0x51).

DS_WRITE

DP-V1 Header

Data Unit - (write):

DS_READ

DP-V1 Header

Data Unit - (read):

Manual_ProfibusDPV2_BIDE_EN.docx 24/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 25

6.9.6. PROFIdrive parameter 964 device ID

Called parameter

Value

Example

Function ID

Permanent for DS_Write

0x5F

ID

Slot no.1 (E/A address/telegram81)

0x0200

Index

47 = 0x2F

0x2F

Length

10 = 0x0A

0x0A

Byte #

Example

0

Request Reference (Example)

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Achse Nr. (0=whole device)

0x00

3

Number of parameters

0x01

4

Attribute = “Value”

0x10

5

Number of parameter elements

0x01

6

Prm_no hi: 964 = 0x03C4

0x03

7

Prm_no lo: 964 = 0x03C4

0xC4

8

Subindex hi

0x00

9

Subindex lo

0x00

Called parameter

Value Function ID

Permanent for DS_Read

0x5E

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Max.Length

64 = 0x40

0x40

Byte #

Example

0

Request Reference: mirrored

0xAA

1

Request ID (not: Change)

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Format: Array of U16

0x06

5

Number of values

0x05

6

Manufacturer ID Baumer IVO=012A

0x01

7

(LSB)

0x2A

8

Device Type (Manufacturer specific)

0x00

9

(LSB)

0x00

10

Firmware Version e.g. V1.00

0x10

11

(LSB)

0x00

12

Firmware date (year), e.g. 2007

0x07

13

(LSB)

0xD7

14

Firmware date (day) , e.g. 17

0x11

15

Firmware date (month), e.g. 09

0x09

Readout of the device ID (device identification data). This data block provides information on manufacturer,

device name, firmware version and firmware date. This information can be called up individually utilizing the

sub indexes.

DS_WRITE

DP-V1 Header

Data Unit - (write):

DS_READ

DP-V1 Header

Data Unit - (read):

Manual_ProfibusDPV2_BIDE_EN.docx 25/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 26

6.9.7. PROFIdrive parameter 965 profile number

Called up

parameter

Value

Example

Function ID

Permanent for DS_Write

0x5F

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Length

8 = 0x08

0x08

Byte #

Example

0

Request Reference (example)

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Attribute = “Value”

0x10

5

Number of parameter elements

0x01

6

Prm_no hi: 965 = 0x03C5

0x03

7

Prm_no lo: 965 = 0x03C5

0xC5

Called parameter

Value Function ID

Permanent for DS_Read

0x5E

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Max.Length

64 = 0x40

0x40

Byte #

Example

0

Request Reference: mirrored

0xAA

1

Request ID

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Format: Unsigned16

0x06

5

Number of values

0x01

6

Profile number (hi)

0x03

7

Profile number (lo)

0x02

Readout of the profile number. The encoder relates to the DPV2 encoder profile (PNO Order Nr 3.162),

version V3.2 of December 2004. For this reason the value replied is ever 0x03, 0x02.

DS_WRITE

DP-V1 Header

Data Unit - (write):

DS_READ

DP-V1 Header

Data Unit - (read):

Manual_ProfibusDPV2_BIDE_EN.docx 26/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 27

6.9.8. PROFIdrive parameter 971 transfer to non-volatile memory

Called parameter

Value

Example

Function ID

Permanent for DS_Write

0x5F

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Length

10 = 0x0A

0x0A

Byte #

Example

0

Request Reference (example)

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Attribute = “Value”

0x10

5

Number of parameter elements

0x01

6

Prm_no hi: 971 = 0x03CB

0x03

7

Prm_no lo: 971 = 0x03CB

0xCB

8

Subindex hi

0x00

9

Subindex lo

0x00

10

Format Word

0x06

11

Number of values

0x01

12

Save command (MSB)

0x00

13

Save command (LSB)

0x01

Called parameter

Value Function ID

Permanent for DS_Read

0x5E

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Max.Length

64 = 0x40

0x40

Byte #

Example

0

Request Reference: mirrored

0xAA

1

Request ID (not: Change)

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Format: Unsigned16

0x06

5

Number of values

0x01

6

Value (hi): ever 0

0x00

7

Value (lo): ever 0

0x00

By calling this parameter all volatile parameter are stored into the encoder’s non-volatile memory. At the

present DPV2 encoder this procedure relates only to the preset value (profile parameter 65000). The saving

operation is performed in DS_WRITE.

DS_WRITE

DP-V1 Header

Data Unit - (write):

DS_READ

DP-V1 Header

Data Unit - (read):

Manual_ProfibusDPV2_BIDE_EN.docx 27/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 28

6.9.9. PROFIdrive parameter 979 sensor format

Called parameter

Value

Example

Function ID

Permanent for DS_Write

0x5F

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Length

10 = 0x0A

0x0A

Byte #

Example

0

Request Reference (example)

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Attribute = “Value”

0x10

5

Number of parameter elements

0x06

6

Prm_no hi: 979 = 0x03D3

0x03

7

Prm_no lo: 979 = 0x03D3

0xD3

8

Subindex hi

0x00

9

Subindex lo

0x00

Readout of data block „Sensor Format“. The data block informs on sensor parameters as sensor type,

programmed singleturn resolution, shift factor for G1_XIST1 and G1_XIST2 as well as the number of possible

turns (multiturn encoders). This information can also be called up individually utilizing the sub indexes.

The example shows how to call all elements of an encoder with a parameterized resolution of 8192

steps/revolution, revolution counter 65536 revs. (in this case 0xFFFF). Left-aligned display in G1_XIST1 by

shift factor =3.

DS_WRITE

DP-V1 Header

Data Unit - (write):

Manual_ProfibusDPV2_BIDE_EN.docx 28/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 29

DS_READ

Called parameter

Value Function ID

Permanent for DS_Read

0x5E

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Max.Length

64 = 0x40

0x40

Byte #

Example

0

Request Reference: mirrored

0xAA

1

Request ID (not: Change)

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Format: Array of U32

0x07

5

Number of values

0x06

6

Header Prm.979 lt. Profidrive Profile

0x00

7

0x00

8

0x51

9

0x11

10

Sensor Type lt. Profidrive Profile (fix)

0x80

11

0x00

12

0x00

13

0x02

14

param. steps per revolution (MSB)

0x00

15

0x00

16

0x20

17

(LSB)

0x00

18

shift factor” for G1_XIST1 (MSB)

0x00

19

0x00

20

0x00

21

(LSB)

0x03

22

shift factor” for G1_XIST2 (MSB)

0x00

23

0x00

24

0x00

25

(LSB)

0x00

26

number of revolutions (MSB)

0x00

27

0x00

28

0xFF

29

(LSB)

0xFF

DP-V1 Header

Data Unit - (read):

Manual_ProfibusDPV2_BIDE_EN.docx 29/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 30

6.9.10. Profile parameter 65000 preset value

Called parameter

Value

Example

Function ID

fix für DS_Write

0x5F

ID

Slot-Nr.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Length

8= 0x08

0x08

Byte #

Example

0

Request reference (example)

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Attribute = “Value”

0x10

5

Number of parameter elements

0x01

6

Prm_no hi: 65000 = 0xFDE8

0xFD

7

Prm_no lo: 65000 = 0xFDE8

0xE8

Called parameter

Value Function ID

Permanent for DS_Read

0x5E

ID

Slot no.1 (E/A address telegram81)

0x0200

Index

47 = 0x2F

0x2F

Max.Length

64 = 0x40

0x40

Byte #

Example

0

Request reference: mirrored

0xAA

1

Request ID=0x01 Change ID=0x02

0x01

2

Shaft no. (0=whole device)

0x00

3

Number of parameters

0x01

4

Format: Unsigned32

0x07

5

Number of values

0x01

6

Preset value (hi byte)

0xXX

7

Preset value

0xXX

8

Preset value

0xXX

9

Preset value (lo byte)

0xXX

This parameter is to read or write the preset value the encoder is set to upon having accomplished the preset

command using output data word G1_STW1, bit „PR“. The preset value is not automatically saved (see

parameter 971 to save).

Note:

It goes without saying that the absolute encoder position will remain also during power off and at power on,

even if the encoder received a preset command before.

DS_WRITE

DP-V1 Header

Data Unit - (write):

DS_READ

DP-V1 Header

Data Unit - (read):

Manual_ProfibusDPV2_BIDE_EN.docx 30/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 31

6.9.11. I&M parameter 65000 block 0

Called parameter

Value

Example

Function ID

Permanent for DS_Write

0x5F

ID

Slot 0 (diagnosis address DP-Slave)

0x0FFD

Index

255 = 0xFF

0xFF

User data length

4 = 0x04

0x04

Example

EXTENDED_

FUNCTION_NUM

0x08 permanent for CALL

0x08

reserved

ever 0x00

0x00

IM_INDEX (hi)

65000 = 0xFDE8

0xFD

IM_INDEX (lo)

65000 = 0xFDE8

0xE8

Called parameter

Value

Example

Function ID

Permanent for DS_Read

0x5E

ID

Slot 0 (Diagnose-Adresse DP-Slave)

0x0FFD

Index

255 = 0xFF

0xFF

Usere data length

68 = 0x44 max.

0x40

Example

EXTENDED_

FUNCTION_NUM

0x08 permanent for CALL

0x08

reserved

ever 0x00

0x00

IM_INDEX (hi)

65000 = 0xFDE8

0xFD

IM_INDEX (lo)

65000 = 0xFDE8

0xE8

Byte #

Example

0...9

Header

0x00

10

I&M Block

MANUFACTURER_ID

0x01

11

MANUFACTURER_ID

0x2A

12...31

ORDER_ID (20)

0x20

32...47

SERIAL_NUMBER (16)

0x20

48

HARDWARE_REVISION

0x00

49

HARDWARE_REVISION

0x00

50

SOFTWARE_REVISION (*4)

0x56 = ‘V’

51

SOFTWARE_REVISION

0x31 = ‘1’

I&M is a concept for uniform identification of field devices and is neither manufacturer nor industry-specific.

For this purpose, the field device provides particular information on an electronic product label.

Readout of block 0 of I&M functions (I&M0) is in line with PROFIBUS Identification & Maintenance Guideline

3502 and DPV2 encoder profile 3162. Data blocks I&M1 to I&M4 are not implemented.

I&M functions are accessed by Slot 0 or Slot 1 and index 255. Access to block I&M0 is by parameter number

65000 (0xFDE8).

Slot 0 of SIEMENS controls is addressed by the diagnosis address of the DP slave, in the example below

4093 (0x0FFD).

DS_WRITE

DP-V1 Header

Data Unit - Call Header (read):

DS_READ

DP-V1 Header

Data Unit - Call Header (read):

Data Unit - Body (read):

Manual_ProfibusDPV2_BIDE_EN.docx 31/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 32

52

SOFTWARE_REVISION

0x30 = ‘0’

53

SOFTWARE_REVISION

0x30 = ‘0’

54

REVISION_COUNTER

0x00

55

REVISION_COUNTER

0x00

56

PROFILE_ID (*2)

0x3D

57

PROFILE_ID

0x00

58

PROFILE_SPECIFIC_TYPE

0x00

59

PROFILE_SPECIFIC_TYPE

(*1)

60

IM_VERSION

0x01

61

IM_VERSION

0x01

62

IM_SUPPORTED

0x00

63

IM_SUPPORTED

0x01

(*1) 0x00 for singleturn encoders; 0x01 for multiturn encoders

(*2) 0x3D00 permanent for DPV2 encoder profile

(*3) 0x012A manufacturer ID of Baumer IVO GmbH & Co. KG

(*4) ‘V’(ersion,official),’R’(evision),’P’(rototype),’U’(nder Field Test) or ‘T’(est Device)

Manual_ProfibusDPV2_BIDE_EN.docx 32/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 33

7. System documentation: Profibus-DP

7.1. General information

PROFIBUS is a manufacturer-unspecific open communication system for applications in the fields of

production, process and building automation. It is broken down into three variants:

PROFIBUS FMS for data communication between control units on the production and process

management level.

PROFIBUS PA for process engineering applications.

PROFIBUS DP for fast data exchange between control units and decentralized peripherals in process

automation.

PROFIBUS-DP is characterized by the following properties:

Short response times (1 ms with 32 users and 12 MBaud)

Reliable transmission procedure (Hamming distance 4)

Availability of a wide range of standardized system components

Good diagnostic capability

Simple handling and facility for upgrading

User-oriented bus system

Open system

PROFIBUS-DP ist standardized by EN 50170 Vol. 2 defining communication and user profiles. To clocksynchronous encoders applies „Profile for DP-V2 Encoders Version 3.2, Order No: 3.162“ in the respective

actual amendment.

The profile differs by the number of supported functions according to device class 3 and 4. Device class 4

comprises functional extensions and all functions of class 3. Parameterization and preset functions are only

supported by class 4. The product supports classes 3 and 4.

7.2. GSD file

The device master data file (GSD file) describes all encoder data required for operation. Format and content

are defined by standard EN 50170.

The GSD file provides ident number 09F6 for all encoders described. The GSD file is an essential

configuration tool for encoder parameterization and configuration.

The GSD file provides two kinds of information:

General information such as manufacturer’s name, product designation, ident number, PROFIBUS -

specific parameters and Baud rates.

Application-relevant information such as configuration options, parameters, parameter descriptions,

hardware and software status and diagnostic possibilities.

Manual_ProfibusDPV2_BIDE_EN.docx 33/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 34

7.3. Encoder operating parameters

Parameter

Significance

Sense of rotation

Behaviour of the output code relating to the shaft’s sense of rotation when looking at

the flange.

CW („clockwise“) = ascending values with clockwise rotation

CCW („counter-clockwise“) = ascending values with counter-clockwise rotation

Resolution

(„Measuring units

per revolution“)

Number of steps per revolution, input in integral steps

Measuring range

(„Total Measuring

Range“)

Total resolution = number of steps per revolution x number of revolutions,

input in integral steps

Steps

The actual encoder position is assigned to a certain position value (referencing)

Parameter

Value range

Default setting

Data type

Sense of rotation

CW/CCW

CW

Byte

Resolution

1 to 4096 – magtivo

1 to 8192 – multivo

1 to 262144 – multivoPlus

4096

8192

262144

Unsigned 32

Measuring range

1 to 67108864 (226) – magtivo

1 to 536870912 (229) – multivo

1 to 2147483648 (231) – multivoPlus

67108864

536870912

2147483648

Unsigned 32

Peset value

0 to (measuring range - 1 step)

0

Unsigned 32

Description of operating parameters

Operating parameter values

Manual_ProfibusDPV2_BIDE_EN.docx 34/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 35

7.4. Data exchange between PROFIBUS-DP devices

Initializing, restart and user data communication

Prior to any user data exchange between master and slave every slave is re-initialized. The master transmits

parameterization and configuration data to the slave. Only if the parameterization and configuration data

coincide with the data stored in the slave the user data exchange will be proceeded as follows:

Diagnostic request by master

The master transmits a Slave Diagnose Request (Slave_Diag), the slave responds by a Slave Diagnose

Response.

This way, the master verifies whether the slave exists in the bus and is ready for parameterization and

configuration.

Slave parameterization

The master transmits a Slave Parameter Request (Set_Prm).

By the parameterization data the slave is informed about actual bus parameters, monitoring times and slavespecific parameters. During the projecting process the parameters are directly or indirectly adopted by the

GSD file. The slave compares these parameterization data with its own stored data.

Slave configuration

The master transmits a Check Configuration Request (Chk_Cfg).

The master informs the slave about volume (number of data bytes) and structure (data consistency) of the

input and output ranges to be exchanged. The slave compares this configuration with its own configuration.

Diagnosis request prior to data exchange

The master transmits another Slave Diagnose Request (Slave_Diag), the slave responds by a Slave

Diagnose Response.

The master now verifies if parameterization and configuration coincide with the data stored in the slave. If the

data requested by master is admissible and correct the slave signalizes its readiness for user data transfer

via the diagnostic data.

Data_Exchange

The slave now will react exclusively to the master it was parameterized and configured by.

The master transmits a user data request (Data_Exchange), the slave responds by a user data response

informing the master about any current diagnostic events. The slave provides the true diagnosis and status

information only after the master’s diagnosis telegram.

Manual_ProfibusDPV2_BIDE_EN.docx 35/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 36

7.5. Parameterization and configuration

7.5.1. Parameterization

By parameterization the control provides the slave with information required for process data exchange. The

information comprises PROFIBUS –specific data (octet 1 to 6) and user-specific information as for example

the required measuring resolution. User-specific information can be altered any time during the projecting

phase using an input window.

The slave verifies the data transmitted by master with its own stored data upon admissibility. The slave will

not inform the master of the result until a diagnosis request after configuration.

7.5.2. Configuration

Configuration defines the scope of cyclic process data communication in both directions. The slave compares

the target configuration with its own stored one and informs the master about the result in a subsequent

diagnosis request.

From the master’s point of view, encoder position values are input data and data transmitted to the encoder

are output data.

The present clock-synchronous encoder applies telegram 81 of the PROFIdrive profile. This telegram

comprises two words output data and 6 words input data.

7.6. Diagnostic signals

Clock-synchronous encoders utilize alarms in line with PROFIBUS DP-V1 replacing device-specific

diagnostic signals as per DP-V0. There is no distinction between alarms and warnings.

Diagnostic data comprise the standard diagnosis (bytes 1 to 6) and, in case several alarms must be

transmitted, both the length of the diagnosis extension and the channel-specific diagnosis (3 bytes each) of

each alarm to enable a clear alarm specification.

Manual_ProfibusDPV2_BIDE_EN.docx 36/41 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 37

7.6.1. Description of the diagnostic data block

Byte no.

Diagnostic data

Significance

1

Station status 1

Status of

parameterization

configuration

diagnostic data (diag.ext. bit and d diag.stat. bit at alarms and

warnings)

2

Station status 2

Status of

Response monitoring

Freeze or Sync mode

3

Station status 3

Not supported

4

Diagnostic_Master_Address

Address of master that proceeded the initial slave parameterization.

0xFF before successful parameterization

5

Ident number high byte

0x09 (device ident number 0x09F6)

6

Ident number low byte

0xF6 (device ident number 0x09F6)

7

Extended diagnosis: length

Length of the extended encoder diagnosis including this diagnosis

header byte

8

Alarm type

Channel-specific diagnosis – byte 1

0x01: diagnosis alarm

0x02: process alarm

9

Slot no.

Channel-specific diagnosis – byte 2

10

Alarm specifier

Channel-specific diagnosis Diagnose – byte 3

Sequence number of the higher six bytes bit

Alarm specifier in lower two bits

- 01: alarm inbound, slot error

- 10: alarm outbound, slot ok again

- 11: alarm outbound, more slot errors

7.6.2. Alarms

The following alarms are supported:

Position error alarm

The encoder has recognized a probably incorrect actual position value. The last two consecutive position

values are continuously compared to each other. If the value exceeds a certain number, the last position

value is implausible.

This alarm is also triggered upon exceeding the electrical admissible maximum speed of 6000 rpm or in case

of an inadmissible (too high) preset value. The alarm will disappear automatically without acknowledgement

after 2.5 s. If another event occurs during this time, the period is automatically extended by 2.5 s.

In case of an inadmissible preset value the alarm remains until the master has transmitted the correct value.

Code consistency errors and inadmissible preset values are also visualized by the LED in the bus cover.

Warning lithium cell voltage (only with multiturn encoders)

The alarm is triggered if the lithium cell voltage drops below the prescribed value.