Page 1

Manual

Absolute Encoder Profibus-DPV0

(with bus cover and SSI coupler)

Firmware version from 1.20

Baumer IVO GmbH & Co. KG

Dauchinger Strasse 58-62

DE-78056 Villingen-Schwenningen

Phone +49 7720 942-0

Fax +49 7720 942-900 11.12 · 174.02.024/8

info.de@baumerivo.com Subject to modification in technic and design.

www.baumer.com Errors and omissions excepted.

Page 2

Contents

Page

1. Introduction 3

1.1. Scope of delivery 3

1.2. Product assignment 4

2. Safety and operating instructions 5

3. Product families 6

4. Profibus-DP 7

5. Encoder operating parameters 8

6. Data exchange between Profibus-DP devices 9

6.1. Telegram structure 9

6.2. Initialization, restarting and user data communication 9

7. Parameterization and configuration 10

7.1. Parameterization 10

7.2. Configuration 13

8. Diagnostic signals 14

8.1. Description of the diagnosis data Slave_Diag 14

8.2. Parameter values of the diagnosis data Slave_Diag 17

8.3. User data 18

8.4. Preset function 18

9. Entering parameters 19

10. Terminal assignment and commissioning 21

10.1. Mechanical mounting 21

10.2. Electrical connection 21

10.2.1. Setting the user address 21

10.2.2. Terminating resistor 22

10.2.3. Bus cover connection 22

10.2.4. Terminal assignment 25

10.3. Display element (status display) 25

10.3.1. Profibus cable 26

Manual_ProfibusDPV0_BIDE_EN.docx 2/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 3

Disclaimer of liability

The present manual was compiled with utmost care, errors and omissions reserved. For this reason

Baumer IVO GmbH & Co. KG rejects any liability for the information compiled in the present manual.

Baumer IVO nor the author will accept any liability for direct or indirect damages resulting from the use of the

present information.

At any time we should be pleased receiving your comments and proposals for further improvement of the

present document.

Registered trademarks

SIEMENS®, SIMATIC®, Step7® und S7® are registered trademarks of Siemens AG. PROFIBUS, the

PROFIBUS Logo and PROFIdrive are registered trademarks of the PROFIBUS user organization respectively

of PROFIBUS International (PI).These and other names applied in the present manual that at the same time

are registered trademarks are not correspondingly marked. Having omitted the respective marking does not

necessarily imply that the names are not registered trademarks or that there are no existing patents and

protected patented designs.

1. Introduction

1.1. Scope of delivery

Please check the delivery upon completeness prior to commissioning.

Depending on encoder configuration and part number delivery is including:

Basic encoder

Profibus bus cover

Sealing bolt for any unused cable gland

CD with GSD file and manual (also available as download in the Internet)

Manual_ProfibusDPV0_BIDE_EN.docx 3/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 4

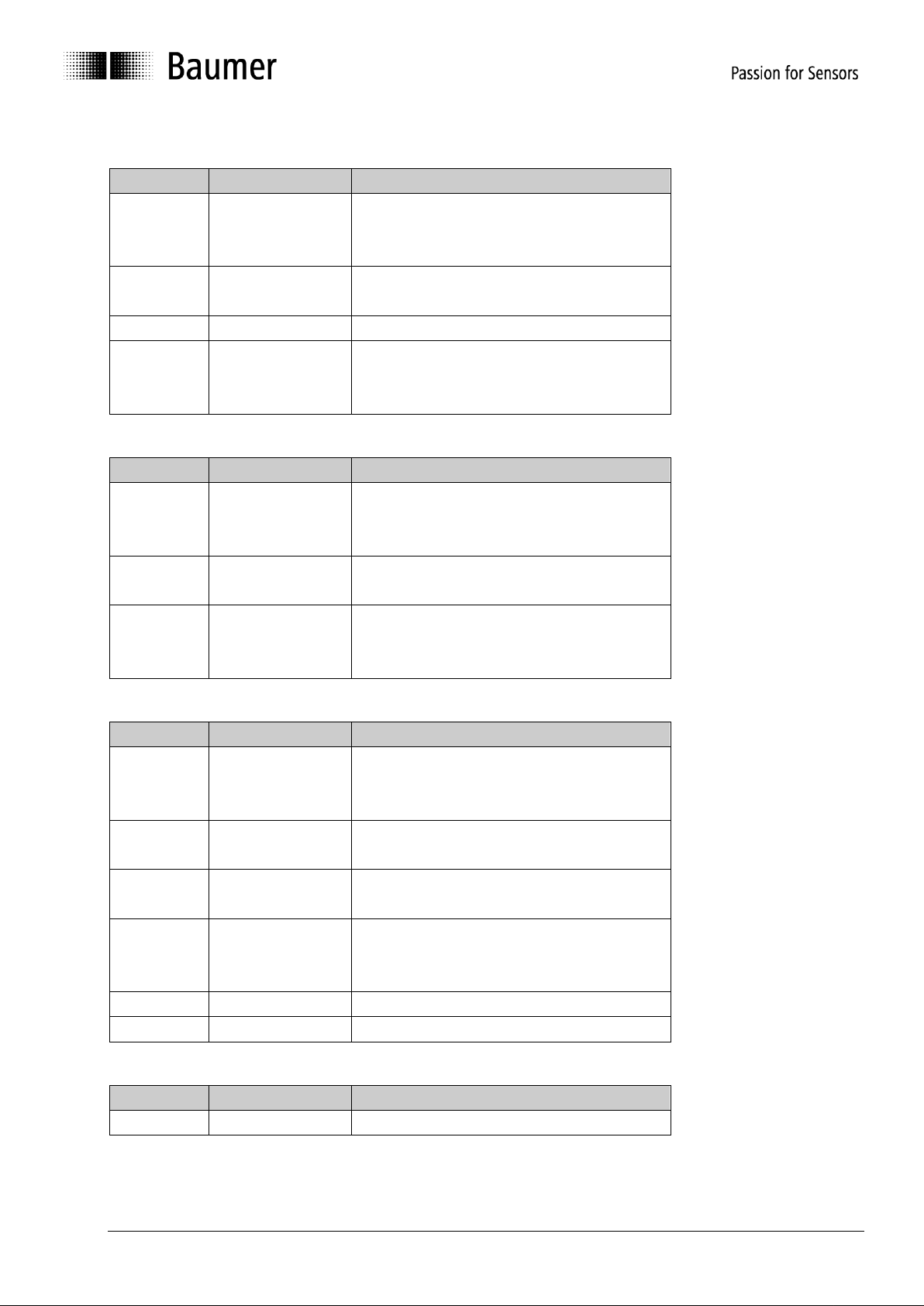

1.2. Product assignment

Product

GSD-file

Product family

GBAMW

GBAM059B.gsd

multivoPlus - Singleturn

GBMMW

GBMM059B.gsd

multivoPlus - Multiturn

GBLMW

GBMM059B.gsd

multivoPlus - Multiturn

GCAMW

GCAM059B.gsd

magtivo® - Singleturn

GCMMW

GCMM059B.gsd

magtivo® - Multiturn

GEMMW

GXMM059B.gsd

multivo® - Multiturn (stainless steel)

GXAMW

GXAM059B.gsd

multivo® - Singleturn

GXLMW

GXMM059B.gsd

multivo® - Multiturn

GXMMW

GXMM059B.gsd

multivo® - Multiturn

Product

GSD-file

Product family

GBAMS

GBAM059B.gsd

multivoPlus - Singleturn

GBMMS

GBMM059B.gsd

multivoPlus - Multiturn

GBLMS

GBMM059B.gsd

multivoPlus - Multiturn

GCAMS

GCAM059B.gsd

magtivo® - Singleturn

GCMMS

GCMM059B.gsd

magtivo® - Multiturn

GXAMS

GXAM059B.gsd

multivo® - Singleturn

GXLMS

GXMM059B.gsd

multivo® - Multiturn

GXMMS

GXMM059B.gsd

multivo® - Multiturn

Product

GSD-file

Product family

G0AMH

GXAM059B.gsd

multivo® - Singleturn

G0MMH

GXMM059B.gsd

multivo® - Multiturn

G0LMH

GXMM059B.gsd

multivo® - Multiturn

G1AMH

GXAM059B.gsd

multivo® - Singleturn

G1MMH

GXMM059B.gsd

multivo® - Multiturn

G2AMH

GXAM059B.gsd

multivo® - Singleturn

G2MMH

GXMM059B.gsd

multivo® - Multiturn

GBAMH

GBAM059B.gsd

multivoPlus - Singleturn

GBLMH

GBMM059B.gsd

multivoPlus - Multiturn

GBMMH

GBMM059B.gsd

multivoPlus - Multiturn

GEMMH

GXMM059B.gsd

multivo® - Multiturn (stainless steel)

GFMMH

GXMM059B.gsd

multivo® - Multiturn (stainless steel)

Product

GSD-file

Product family

GK410

GXMM059B.gsd

multivo® - Multiturn

Shaft encoder

End shaft encoder

Hollow shaft encoder

Interface converter

Manual_ProfibusDPV0_BIDE_EN.docx 4/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 5

2. Safety and operating instructions

Supplementary information

This manual is intended as a supplement to already existing documentation (e.g. catalogues, data sheets

and assembly instructions).

The manual must be read without fail before initial commissioning of the equipment.

Intended purpose of the equipment

The encoder is a precision measurement device. It is used to determine angular positions and

revolutions, and to prepare and supply measured values in the form of electrical output signals for the

follow-on device systems. The encoder may only be used for this purpose.

Commissioning

The encoder may only be installed and assembled by suitably qualified experts.

Observe the operating instructions of the machine manufacturer.

Safety remarks

Prior to commissioning the equipment, check all electrical connections.

If installation, electrical connection or any other work performed at the encoder or at the equipment is not

correctly executed, this can result in a malfunction or failure of the encoder.

Steps must be taken to exclude any risk of personal injury, damage to the plant or to the operating

equipment as a result of encoder failure or malfunction by providing suitable safety precautions.

Encoders must not be operated outside the specified limited values (see further documentation).

Failure to comply with the safety remarks can result in malfunctions, personal injury or damage to property.

Transport and storage

Only ever transport or store encoders in their original packaging.

Never drop encoders or expose them to major vibrations.

Assembly

Avoid impacts or shocks on housing and shaft/end shaft.

End shaft/Hollow shaft encoder: Open clamping ring completely before mounting the encoder

Avoid any twist or torsion on the housing.

Shaft encoders: never make rigid connections between encoder shaft and drive shaft.

Do not open the encoder or proceed any mechanical modifications.

The shaft, ball bearings, glass pane or electronic components can be damaged. In this case, safe and reliable

operation cannot be guaranteed.

Electrical commissioning

Do not make any electrical changes at the encoder.

Do not carry out any wiring work when the encoder is live.

Never plug or unplug the electrical connection when the encoder is live.

Ensure that the entire plant is installed in line with EMC requirements. The installation environment and

wiring affect the electromagnetic compatibility of the encoder. Install the encoder and supply cables

separately or at a long distance from cables with high interference emissions (frequency converters,

contactors etc.)

Where working with consumers which have high interference emissions, make available a separate

power supply for the encoder.

Completely shield the encoder housing and connecting cable.

Connect the encoder to the protective earth (PE) conductor using shielded cable. The braided shield must

be connected to the cable gland or plug. Ideally, aim at bilateral connection to protective earth (PE), the

housing via the mechanical assembly, the cable shield via the downstream connected devices. In case of

earth loop problems, earth on one side only as a minimum requirement.

Failure to observe these instructions can result in malfunctions, material damage or personal injury.

Manual_ProfibusDPV0_BIDE_EN.docx 5/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 6

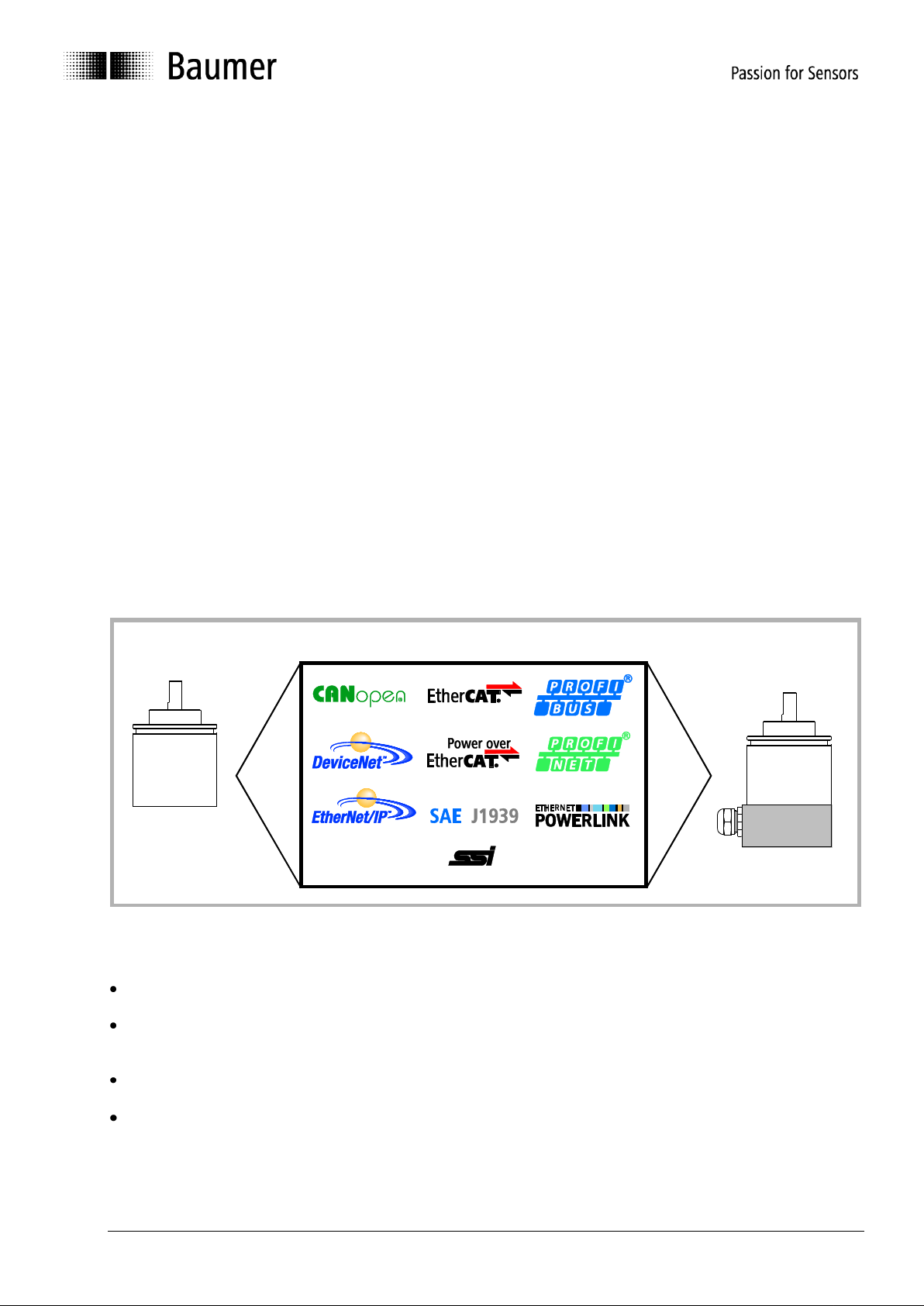

3. Product families

bus cover

complete encoder

basic encoder

The product family architecture is modular. Depending on what is required from the encoder, the basic

encoder and bus covers can be combined at will with the selected bus system.

The basic encoders differ in terms of accuracy, ambient conditions and the utilized sensing principle.

Bus cover

The bus cover accommodates the field bus interface and the complete electronics for processing the

measured values. EtherNet/IP communication is performed via the specialized EtherNet/IP-ASIC ERTEC200

with integrated high-performance microcontroller ARM9.

Magres / magtivo®

Utilizes a magnetic sensing principle and endures harsh industrial environments.

Procoder / multivo®

Utilizes a photoelectric sensing principle and is the recommended product for precise applications.

Dignalizer / activo® / multivoPlus®

Utilizes a photoelectric sensing principle with integrated analog/digital signal conversion and is the product to

choose for ultra-precise sensing applications.

The bus covers differ by the respectively integrated bus interface.

Available bus interfaces: CANopen, DeviceNet, EtherCAT, Ethernet/IP, Profibus-DP, Profinet, Powerlink,

Power over EtherCAT, SAE J1939, SSI.

All encoders enable parameterization by bus interface.

Functional principle:

Speed signal

Baumer Profibus encoders with bus cover concept permit readout of the current rotary speed. There are four

different scaling systems available:

Manual_ProfibusDPV0_BIDE_EN.docx 6/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

RPM

Readout of the speed in revolutions per minute.

Steps/s

Readout of the speed in units of the parameterized singleturn resolution per second. The speed is

measured over a period of 200 ms in each case and then updated.

Steps/100 ms

Readout of the speed in units of the parameterized singleturn resolution per 100 ms.

Steps/10 ms

Readout of the speed in units of the parameterized singleturn resolution per 10 ms.

Page 7

4. Profibus-DP

General

Bus systems are connecting structures which generate communication between several components.

The Profibus-DP is a manufacturer-independent open communication system for applications in the fields of

production, process and building automation. It is broken down into three variants:

Profibus FMS for data communication between control units on the production and process management

level.

Profibus PA for process engineering applications.

Profibus DP for fast data exchange between control units and decentral peripherals in automation

engineering applications.

The Profibus system comprises the following device types:

DP master class 1 (DPM1) is a control system which cyclically exchanges information with a DP slave.

DP master class 2 (DPM2) are programming or project processing devices or controllers.

DP slave is a peripheral device which receives output data and forwards input data to the programmable

logic controller.

The Profibus system is broken down into a monomaster system and a multimaster system by the number of

active masters in operation during the operating phase.

In a monomaster system, only one master class 1 and the DP slaves are active in the bus.

In a multimaster system, several masters and the DP slaves are active in the bus. The masters can

optionally either belong to class 1 or class 2.

The Profibus DP is characterized by the following features:

Short response times (1 ms with 32 users and 12 MBaud)

Reliable transmission procedure (Hamming distance 4)

Availability of a wide range of standardized system components

Good diagnostic capability

Simple handling and facility for upgrading

User-oriented bus system

Open system

Profibus-DP is standardized by standard EN 50170 Vol. 2. This standard defines the communication and user

profiles. The user profile for interface converters is profile 1.1. The user profile is differentiated depending on

the number of supported functions according to device class 1 and 2. Device class 2 has a greater number

and contains all the functions of class 1. Parameterization and preset functions are supported only by class 2.

The device supports classes 1 and 2.

GSD file

The device master data file (GSD file) is a descriptive file which describes all the encoder data required for

operation. The data itself is filed in the ROM of the encoder. The data can be subdivided into two sections.

General definitions contain information such as the manufacturer's name, product designation, Ident.

number, Profibus-specific parameters and baud rates.

Application-related definitions include configuration possibilities, parameters, parameter descriptions,

hardware and software status and diagnostic possibilities.

The format and content are defined in line with the EN 50170 standard.

The GSD file has the ident no. 059B for all the described products. This GSD file is an essential condition for

parameterization and configuration of the encoder with a configuration tool.

Manual_ProfibusDPV0_BIDE_EN.docx 7/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 8

5. Encoder operating parameters

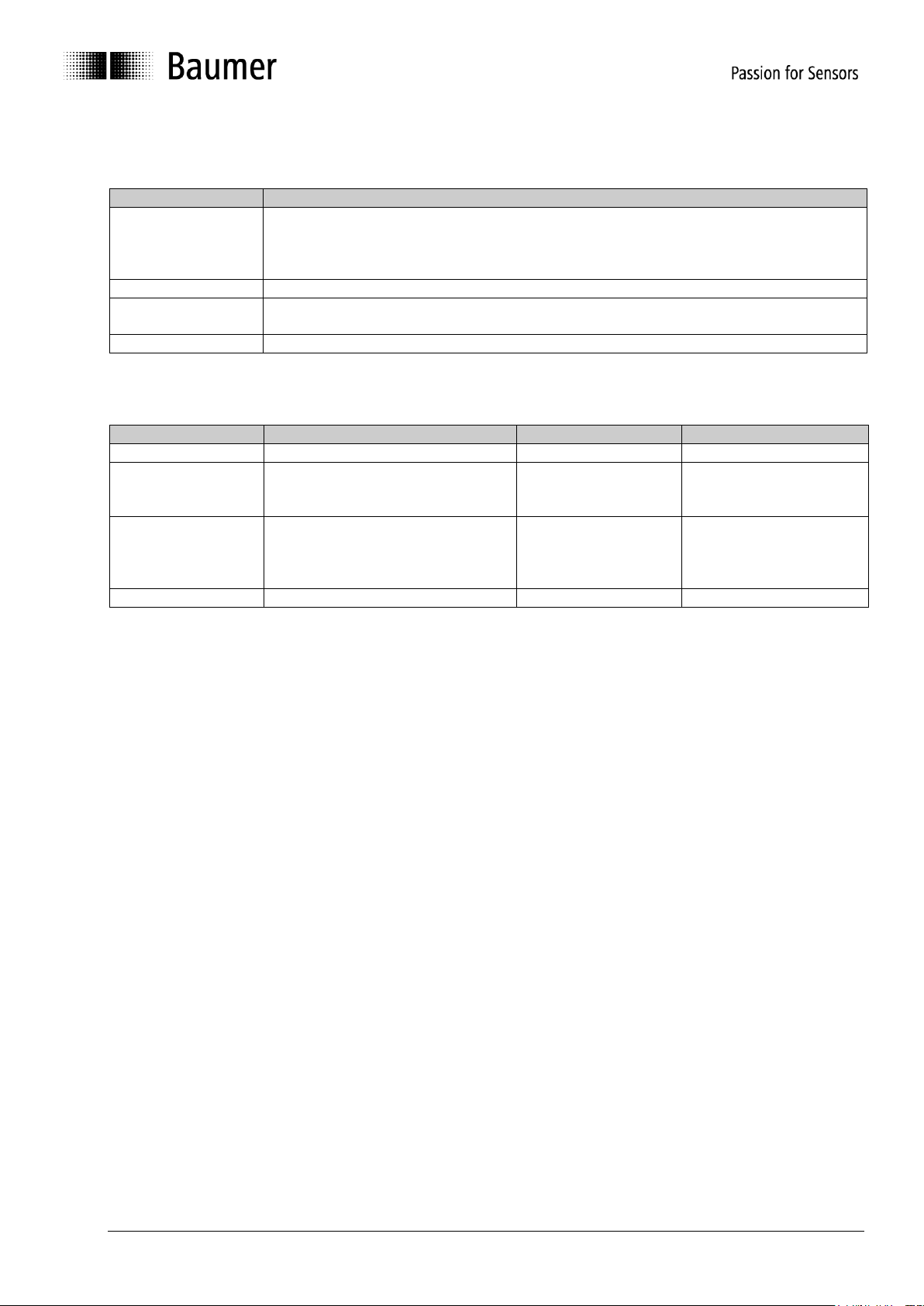

Parameter

Significance

Sense of rotation

Behaviour of the output code depending on the sense of rotation of the shaft seen

looking at the flange

CW = Increasing values with clockwise rotation

CCW = Increasing values with counterclockwise rotation

Resolution

Number of steps per revolution, input in integral steps

Measurement range

Total resolution = number of steps per revolution x number of revolutions,

input in integral steps

Preset value

A certain output value is assigned to the current position value (referencing)

Parameter

Value range

Default setting

Data type

Sense of rotation

CW/CCW

CW

Octet string

Resolution

1 to 4096 – magtivo

1 to 8192 – multivo

1 to 262144 – activo/multivoPlus

4096

8192

262144

Unsigned 32

Measurement range

1 to 67108864 (226) – magtivo

1 to 536870912 (229) – multivo

1 to 2147483648 (231)

– activo/multivoPlus

67108864

536870912

2147483648

Unsigned 32

Preset value

0 to (measurement range - 1 step)

0

Unsigned 32

Description of operating parameters

Operating parameter values

Manual_ProfibusDPV0_BIDE_EN.docx 8/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 9

6. Data exchange between Profibus-DP devices

DP Master

Triggering telegram

DP Slave

Footer info

Output data

Header info Reply telegram

Header info

Input data

Footer info

6.1. Telegram structure

The diagram illustrates the telegram structure.

Telegram structure

6.2. Initialization, restarting and user data communication

Before an exchange of useful information between the master and slave, every slave is re-initialized. The

master transmits parameterization and configuration data to the slave. Only when the parameterization and

configuration data is in agreement with the data stored in the slave can user data be exchanged. This takes

place in the following way:

Diagnostic request from the master

The master transmits a Diagnosis Request to a slave (Slave_Diag), and the slave responds with a Slave

Diagnosis Response.

The master uses this data to check whether the slave exists in the bus and is ready for parameterization and

configuration.

Parameterization of the slave

The master transmits a Parameter Request to the slave (Set_Prm).

The Slave receives information about the current bus parameters, surveillance times and slave-specific

parameters via the parameterization data. The parameters are taken over during the project processing

phase partially directly or indirectly from the GSD file. The slave compares this parameterization data with its

own stored data.

Configuration of the slave

The master transmits a Check Configuration Request (Chk_Cfg).

The master informs the slave of the scope (number of data bytes) and the structure (data consistency) of the

input and output ranges to be exchanged. The slave compares this configuration with its own configuration.

Diagnosis request prior to data exchange

The master transmits another Slave Diagnosis Request (Slave_Diag), the slave answers with a Slave

Diagnosis Response.

The master now checks whether the parameterization and configuration agree with the data stored in the

slave. If the data requested by the master is admissible and if no error exists, the slave signals its readiness

for the transfer of user data by means of the diagnosis data.

Data_Exchange

The slave now responds exclusively to the master which has parameterized and configured it.

The master transmits a user data request (Data_Exchange), the slave answers with a user data response. In

this response, the slave informs the master whether current diagnosis results are available. The slave only

makes known the actual diagnosis and status information after the master's diagnosis telegram.

Manual_ProfibusDPV0_BIDE_EN.docx 9/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 10

7. Parameterization and configuration

Device

class

Parameter

Octet no.

Significance

1

Station status

1

Definition of Profibus-specific data

Sync mode/freeze mode active

Response monitoring active

Master assigned

1

Response monitoring time

2 to 3

Recognition of master failure, master must respond

within this period

1

Min. station delay responder

(tsdr)

4

Minimum time which the slave must wait until it may

respond to a request by the master

1

Ident_number

5 to 6

Device identifier which must be unique for each type

of device, saved and reserved by the PNO

1

Group_ident_number

7

Profibus-specific data

1

Operating parameter

8

Profibus-specific data

1

Operating parameter

9

Definition of application-specific data

Counting direction

Functional scope of the encoder, defined in

appliance class 1 and 2

Scaling function

2

Single-turn resolution

10 to 13

Definition of the number of measurement steps per

revolution

2

Total resolution in steps

14 to 17

Definition of the total resolution in steps

Total resolution is the number of measurement

steps x the number of revolutions

2

Scaling the speed signal

26

Definition of the unit of measurement in which the

speed signal (if selected) is read out (e.g. rpm)

7.1. Parameterization

Parameterization refers to the transfer of information which the slave requires for exchanging process data.

The information comprises Profibus-specific data (Octets 1 to 6) and user-specific information. The userspecific information can be entered via an input window during the project processing phase.

The slave compares the data transmitted by the master with the data it has stored. However, the slave does

not inform the master of the result until the diagnosis request following configuration.

Description of parameters for the parameterization function (Set_Prm)

Manual_ProfibusDPV0_BIDE_EN.docx 10/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 11

Value of parameters of the parameterization function (Set_Prm)

Device

class

Parameter

Data type

Octet

no.

Value range

Default value

In the GSD file

1

Station status

Octet

string

1

Sync and freeze

mode supported

Supported baud

rates

1

Response monitoring time

Octet

string

2 to 3

Profibus-specific data

1

Minimum Station Delay

Responder

Octet

string

4

Baud rate dependent

1

Ident number

Octet

string

5 to 6

059B

1

Group ident no.

Octet

string

7

00

1

Operating parameter

Octet

string

8

Profibus-specific data

1

Operating parameter

Octet

string

9

Bit 0 = 0/1 CW/CCW

Bit 1 = 0/1 Device

class 2 off/on

Bit 3 = 0/1 Scaling

function off/on

CW

Class 2

Device class 2 on

Scaling function on

2

Signal turn resolution

Unsigned

32

10 to 13

Octet 10 is MSB

1 to 1024 – magtivo

1 to 8192 – multivo

1 to 262144

– activo/multivoPlus

1024

8192

262144

2

Total resolution in steps

Unsigned

32

14 to 17

Octet 14 is MSB

1 to 67108864 (226)

– magtivo

1 to 536870912 (229)

– multivo

1 to 2147483648(231)

– activo/multivoPlus

67108864

536870912

2147483648

2 Reserved (system-specific)

18 to 25

0

2

Scaling Speed signal

Octet

string

26

0 to 3

0: steps/s

1: steps/100 ms

2: steps/10 ms

3: RPM

3

Manual_ProfibusDPV0_BIDE_EN.docx 11/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 12

Important note for multiturn encoder operation

This encoder supports „Endless Operation“ automatically if required.

Thus, there are no special requirements for the encoder parameters “total measuring range” and “measuring

units per revolution” to stand in a certain ratio.

With endless operation active, the encoder shaft must not rotate when the encoder is not powered. In

those cases where powerless motion cannot be avoided, the encoder has to be referenced (presetted) after

each power-up. With Endless Operation inactive, the encoder shaft may rotate unlimited when encoder not

powered.

How to determine if „Endless Operation“ is in use:

Multiply the encoder’s „max. possible revolutions“ (depending on encoder 16 bit = 65536 or 13 bit =

8192) by your chosen parameter „measuring units per revolution“.

Divide this value by your chosen „total measuring range“.

If there is a division remainder, endless operation is in use.

Example for parameters without endless operation:

Maximum possible revolutions 65536 (16 bit multiturn)

Measuring units per revolution 3600

Total measuring range 29.491.200 (8192 x 3600)

Calculation: 65536 x 3600 / 29.491.200 = 8 (no remainder)

Example for parameters with endless operation:

Maximum possible revolutions 65536 (16 bit multiturn)

Measuring units per revolution 3600

Total measuring range 100.000

Calculation: 65536 x 3600 / 100.000 = 2359 remainder 29600

Manual_ProfibusDPV0_BIDE_EN.docx 12/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 13

7.2. Configuration

Device

Class

Configuration

Significance

1

D1h

2 words input data with data consistency for position values to max. 31 bit

2

F1h

2 words output data with data consistency for preset value to max. 31 bit

2 words input data with data consistency for position values to max. 31 bit

1

D0h

1 word input data with data consistency for position values to max. 15 bit

2

F0h

1 word output data with data consistency for preset values to max. 15 bit

1 word input data with data consistency for position values to max. 15 bit

1

D1h, D0h

2 words input data with data consistency for position values to max. 31 bit

1 word input data with data consistency for speed values to max. 16 bit

2

F1h, D0h

2 words output data with data consistency for preset value to max. 31 bit

2 words input data with data consistency for position values to max. 31 bit

1 word input data with data consistency for speed values to max. 16 bit

1

D0h, D0h

1 word input data with data consistency for position values to max. 15 bit

1 word input data with data consistency for speed values to max. 16 bit

2

F0h, D0h

1 word output data with data consistency for preset values to max. 15 bit

1 word input data with data consistency for position values to max. 15 bit

1 word input data with data consistency for speed values to max. 16 bit

Configuration refers to the definition of type, length and data direction of the process data, as well as the way

in which the data is further processed. The type stipulates the data type and whether the data is contiguous

(consistent). The length determines the number of data bytes available for use. The data direction defines

whether data is transferred from master to slave or vice versa. The encoder is able to read preset values or

transmit position values and if applicable also transmit speed values. The length is optionally 1 or 2 words,

and the data is consistent in both cases. The configuration is compared with the configuration stored in the

slave. The slave informs the master of the result in the following diagnosis request.

The position values of the encoder from the view point of the master are input data, preset values and output

data.

Admissible configurations

Manual_ProfibusDPV0_BIDE_EN.docx 13/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 14

8. Diagnostic signals

Device

class

Diagnosis data

Octet no.

Significance

1

Station status 1

1

Status of

Parameterization

Configuration

Diagnostic data (Diag.ext. bit and Diag.stat. bit in case of

alarm and warning signals)

1

Station status 2

2

Status of

Response monitoring

Freeze or Sync mode

1

Station status 3

3

Not supported

1

Diag_Master

4

Address of the master which first parameterized the slave

1

Ident_number

5 to 6

Device identifier

Unique for each device type

Reserved and stored with the PNO

1

Extended diagnosis

header

7

Length of the encoder diagnosis including diagnosis header

byte in the case of extended diagnosis

1

Alarm signals

8

Display of malfunctions which could lead to incorrect position

values.

Triggered by

Code consistency error or inadmissible preset value

Preset value is outside the admissible value range.

1

Operating status

9

Indication of supported user-specific data

Counting direction

Functional scope of the encoder, defined in device class 1

and 2

Extended diagnosis

Scaling function

1

Encoder type

10

Indication of encoder type

1

Steps per revolution

11 to 14

Maximum resolution per revolution of the encoder

1

Number of revolutions

15, 16

Maximum number of revolutions of the encoder

2

Additional alarm

signals

17

Not supported

2

Supported alarm signals

18

Indication of which alarm is supported

Incorrect position value

Diagnostic signals contain data relating to the respective status of the encoder. The diagnostic signals

comprise Profibus-relevant information and device-specific information. The master controls communication

with the slave using this information, or forwards it to the higher-level system.

The master requests diagnosis data both prior to parameterization and after configuration of the slave.

This ensures that the slave is present in the bus and that the data stored in the control system software is in

agreement with the data stored in the slave. The slave can also register a diagnosis event in the

Data_Exchange mode. The master then requests the diagnosis data. The user-specific information is defined

in the EN 50170 standard under Encoder profile 1.1.

The display element integrated in the bus cover (dual red/green LED) indicates part of this information.

8.1. Description of the diagnosis data Slave_Diag

Continued on next page.

Manual_ProfibusDPV0_BIDE_EN.docx 14/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 15

Description of diagnosis data Slave_Diag (contd.)

Device

class

Diagnosis data

Octet no.

Significance

2

Warnings

20, 21

Indicates when parameters are not within the admissible

tolerance. In contrast to alarm signals, these events do not

result in incorrect position values.

Voltage of the lithium cell has dropped below the critical

value (only multiturn encoders)

2

Supported warning

signals

22, 23

Indicates which warning signal is supported

Voltage of the lithium cell has dropped below the prescribed

value (only multiturn encoders)

2

Profile version

24, 25

Profile version of the encoder profile in revision number and

index

2

Software version

26, 27

Indicates the software version in revision number and index,

identical to the indication on the rating plate of the encoder.

2

Operating hours counter

28 to 31

Not supported

2

Offset value

32 to 35

Indicates the offset value stored in the EEPROM after a

preset

2

Manufacturer offset

36 to 39

Not supported, reserved for servicing purposes

2

Steps per revolution

40 to 43

Indicates the programmed steps per revolution of the encoder

2

Total resolution in steps

44 to 47

Indicates the programmed total resolution in steps of the

encoder

2

Serial number

48 to 57

Not supported

2

Reserved

58, 59

Not supported, reserved for servicing purposes

Manual_ProfibusDPV0_BIDE_EN.docx 15/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 16

Alarm signal position error

The alarm signal is triggered by two events:

Code consistency error due to a malfunction in the optoelectronic/magnetic system

Preset value outside the admissible value range

The angular position of the shaft is sampled cyclically via the encoded glass panel. Two

consecutive position values are compared to each other. If the value change exceeds a

certain number of steps, the last position value is implausible.

The encoder sets the Ext_diag. bit and bit 0 to the alarm signal status.

In case of a code consistency error, the Ext_diag. bit is automatically reset after 2.5 s. If a

further event occurs during this time, the period is automatically extended by 2.5 s.

In the event of an inadmissible preset value, the Ext_diag bit remains set until the master has

transmitted the correct value.

Code consistency errors and inadmissible preset values are indicated by the display element

in the bus cover.

If the encoder is receiving no operating voltage, the internal lithium cell supplies the necessary

supply voltage for the part of the circuit necessary for counting revolutions and storing them in

the ASIC. When the operating voltage is switched on, the stored value is read out, the position

change within one revolution is picked up by the optoelectronic or magnetic singleturn system.

Position changes in the OFF status are brought about for example by run-on of the shaft or

subsequent manual adjustment.

The lithium cell voltage is internally monitored. If the voltage drops below the prescribed value,

the encoder internally sets the Diag_ext error bit and indicates the event via bit 5 in the warning

signal. However, the revolution counting and saving functions are only guaranteed for a certain

time when powered by the lithium cell.

Once this period is exhausted, the encoder must be decommissioned or permanently powered

by an external voltage supply.

The amount of time for which the encoder can continue to be operated depends on recognition

of the event.

Status signal already exists at encoder power on.

If the time of first occurrence is not known, the encoder must be withdrawn from service

immediately.

Status signal occurs during operation in the Data_Exchange mode.

Once the status signal is active, the encoder will continue to function for several weeks

without problems before it needs to be exchanged.

Warning signal lithium cell voltage (only multiturn encoders)

Manual_ProfibusDPV0_BIDE_EN.docx 16/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 17

8.2. Parameter values of the diagnosis data Slave_Diag

Device

class

Diagnostic data

Data type

Octet no.

Value range

1

Station status

Octet string

1 to 3

Profibus-specific data

1

Diag_master

Octet string

4

Profibus-specific data

1

Ident_number

Octet string

5 to 6

059B

1

Extended diagnosis

Octet string

7

16 byte with class 1

57 byte with class 2

1

Alarm signals

Octet string

8

Bit 0 = 1 position error

1

Operating status

Octet string

9

Bit 0 = 0 Cw

Bit 0 = 1 Ccw

Bit 1 = 1 (Encoder supported Class 2

Functionality)

Bit 3 = Scaling function on/off

1

Encoder type

Octet string

10

01h = Multiturn / 00h = Singleturn

1

Singleturn resolution

Unsigned

32

11 to 14

Octet 11 is MSB

1 to 4096 – magtivo

1 to 8192 – multivo

1 to 262144 – activo/multivoPlus

1

Number of revolutions

Unsigned

16

15, 16

Octet 15 is MSB

1 to 65535 – magtivo

1 to 65535 – multivo

1 to 8192 – activo/multivoPlus

2

Additional alarm signals

Octet string

17

Not supported

2

Supported alarm signals

Octet string

18, 19

Octet 19

Bit 0 = 1 Position error supported

2

Warnings

Octet string

20, 21

Octet 21

Bit 5 = 1 Lithium cell voltage drops below

specified value (only multiturn encoder)

2

Supported warning signals

Octet string

22, 23

Octet 2 is MSB

Bit 5 = 1 lithium cell voltage (only multiturn

encoder) supported

2

Profile version

Octet string

24, 25

Encoder profile 1.10

2

Software version

Octet string

26, 27

Additional stored on the rating plate

2

Hours-run counter

Octet string

28 to 31

Not supported

2

Offset value

Octet string

32 to 35

Dependent on preset value

2

Manufacturer offset

Octet string

36 to 39

Not supported

2

Steps per revolution

Unsigned

32

40 to 43

Octet 40 is MSB

1 to 4096 – magtivo

1 to 8192 – multivo

1 to 262144 – activo/multivoPlus

2

Total resolution in steps

Unsigned

32

44 to 47

Octet 44 is MSB

1 to 67108864 (226) – magtivo

1 to 536870912 (229) – multivo

1 to 2147483648(231) – activo/multivoPlus

2

Serial number

ASCII string

48 to 57

Not supported,

all digits (Octet) "*" corresponds to "2Ah"

2

Reserved

Octet string

58, 59

Reserved for servicing purposes

Manual_ProfibusDPV0_BIDE_EN.docx 17/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 18

8.3. User data

Conversely to diagnostic data, user data is data which refers to the process being monitored or controlled. In

the case of this encoder, this data takes the form of the position and where applicable the speed which the

Profibus transmits to the control system (master), and in the other direction a preset value with which the

encoder (slave) can be pre-set to a certain position value.

User data is exchanged in the Data_Exchange mode. The framework conditions for the exchange (e.g.

encoder resolution, word length) are previously defined in the configuration.

The slave can also indicate the presence of a diagnosis event during data exchange. The master then

requests diagnostic and status information by means of a diagnosis request.

In order to set a preset, the master transmits the preset value (depending on the configuration either 16 or 32

bit) to the slave (see "preset function").

In the "Data Exchange" status, the dual LED lights up continuously in green on the bus cover.

8.4. Preset function

The preset function is only available in the encoder's "Class2" operating mode.

The control system can transmit a preset value to the encoder and so set the encoder, given a prescribed

mechanical position, to a certain position value. The preset value must lie within the programmed overall

measurement range.

To ensure optimum coordination between the mechanical position and the preset value, the preset value

should only be set when the encoder is at a standstill. However, where the requirements are not particularly

stringent, this can also be performed during rotary movement.

In order to set a preset, the control system transmits the preset value twice to the encoder: Once with the

most significant bit (MSB) set and then again with the MSB reset. In this way, the MSB acts in a certain

manner as a "clock" bit. For this reason, the transmitted preset value is limited to the value range up to 15 bit

(encoder class 2, 16 bit) or 31 bit (encoder class 2, 32 bit).

The first transmission is authoritative in determining the time of acceptance.

Example: Zeroing the encoder (preset value = 0, encoder class 2, 32 bit)

Step 1: Control transmits 80000000h (preset adoption)

Step 2: Control transmits 00000000h (control bit return)

The encoder calculates an offset value for internal purposes from the differential between the current position

and preset value. This value generally has no bearing on the application, but can be read out if required

among the diagnostic data.

The offset value is stored on a non-volatile basis in an EEPROM chip. The EEPROM is capable of at least 1

million write cycles. However, despite the high number of possible write cycles, frequent program or eventcontrolled preset setting could mean reaching the service life limit. A certain degree of care is therefore called

for when designing the control software at this point.

Manual_ProfibusDPV0_BIDE_EN.docx 18/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 19

9. Entering parameters

Total resolution

= 3600 steps per revolution x

256 revolutions

= 921600

Conversion into hexadecimal format

= E1000

Subdivision into “hi”

= 000E

Conversion into decimal format

= 14

Subdivision into “lo”

= 1000

Conversion into decimal format

= 4096

Total measuring range (units) hi

= 14

Total measuring range (units) lo

= 4096

Steps per revolution

= 3600 steps

= 3600

Measuring units per rev. hi

= 0

Measuring units per rev. lo

= 3600

The following parameter data is stored in the GSD file in the form of 32-bit values

(double words, format "unsigned32"):

- Steps per revolution

- Total resolution

Many configuration programs for Profibus masters (including also Step7® from SIEMENS) do not support this

word length during parameter input. The upper and lower 16 bits of these parameters ("hi" and "low" block)

must accordingly be entered separately, and in decimal form.

In the case of parameters smaller than 65535 (16 bit), all that is necessary is to enter the block "hi" = 0 and

the parameter itself is entered directly in the "lo" block.

Parameters greater than 65535 (16 bit), must be separated beforehand using the formula described below

and then recalculated. A calculator with hexadecimal function of the type provided among the "Windows

accessories" is helpful here.

Conversion of the required parameter value from the decimal format into hexadecimal format

Subdivision of the hexadecimal value into two blocks, "hi" and "lo". The block length in each case is two

words

Conversion of the hexadecimal format of the two blocks "hi" and "lo" back into decimal format

Input into the input mask using the decimal format

Example

Manual_ProfibusDPV0_BIDE_EN.docx 19/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 20

Example for entering parameters

Manual_ProfibusDPV0_BIDE_EN.docx 20/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 21

10. Terminal assignment and commissioning

Example: 23

10.1. Mechanical mounting

Shaft encoder

Mount the encoder housing using the fastening holes on the flange side with three screws (square flange

with four screws), paying attention to the thread diameter and thread depth.

Alternatively, the encoder can be mounted in any angular position using three eccentric fastenings - see

accessories.

Connect the drive shaft and encoder shaft using a suitable coupling. The ends of the shafts must not be

touching. The coupling must be capable of compensating for displacement due to temperature and

mechanical backlash. Pay attention to the admissible axial or radial shaft loads. For suitable connecting

devices, see under accessories.

Tighten the fastening screws

End shaft / Hollow shaft encoder

Clamping ring fixture

Prior to mounting the encoder open the clamping ring completely. Push encoder onto the drive shaft and

tighten the clamping ring firmly.

Encoder torque pin

Slide encoder onto the drive shaft and insert torque pin into the adjusting element provided by customer.

Adjusting element with rubberized spring element

Push the encoder on to the drive shaft and insert the parallel pin into the mounted adjusting element (not

supplied) (with rubberized spring element)

Adjusting bracket

Push the encoder over the drive shaft. Insert the adjusting bracket into the rubberized spring element of

the encoder and fasten the adjusting bracket on the contact surface (not supplied).

Shoulder screw

Push the encoder over the drive shaft and insert the shoulder screw (not supplied) in the rubberized spring

element of the encoder.

Coupling spring

Mount the coupling spring with screws onto the fixing holes of the encoder housing.

Push the encoder over the drive shaft and fasten the coupling spring on the contact surface.

10.2. Electrical connection

Only ever store or transport the bus cover in the ESD bag. The bus cover must rest fully against the housing

and be firmly screwed in place.

For electrical connection, pull off the bus cover using the following method:

Release the fastening screws of the bus cover

Carefully loosen the bus cover and lift off in the axial direction

10.2.1. Setting the user address

The user address is set decimally using two rotary switches in the bus cover.

The maximum number of users is 99. The address is read in once during power-up.

Set the user address decimally using the two rotary switches 1 and 2 (default setting 00).

Manual_ProfibusDPV0_BIDE_EN.docx 21/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 22

10.2.2. Terminating resistor

both ON = Final user

both OFF = user X

Terminal

Resistor

A to GND

390 Ohm

B to +5 V

390 Ohm

A to B

220 Ohm

Bus cable

Supply voltage cable

If the connected encoder is the last one in the bus line, the bus must be terminated with a resistor.

The resistors are integrated in the bus cover and are connected using a two-pole DIP switch.

The internal terminating resistors must be set to "ON" in the last user with the two-pole DIP switch

(default setting OFF).

10.2.3. Bus cover connection

Release the cap nut of the cable gland.

Push the cap nut and seal insert with contact sleeve onto the cable sheath.

Strip the cable sheath and cores, shorten the shield film where this exists (see Fig.)

Bend over the braided screen by approx. 90°.

Push the sealing insert with contact sleeve along as far as the braided shield. Insert the sealing insert

with contact sleeve and cable flush into the cable gland and tighten the cap nut.

For standard encoder

For G0AMH, G0MMH, GBAMH and GBMMH

Terminals with the same designation are internally interconnected.

For the power supply, use only cable gland 3. For the bus lines, cable gland 1 or 2 can be optionally

selected. For the bus lines, cable glands 1 or 2 can be freely selected. Observe the admissible cable

cross sections.

Insert the cores using the shortest route from the cable gland to the terminal strip. Observe the admissible

core cross-section. Use isolated core end sleeves.

Avoid crossing over data lines with the supply voltage line.

Manual_ProfibusDPV0_BIDE_EN.docx 22/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 23

Bus cover – shaft/end shaft

1 2 3

Cable gland

M12-connector

1 2 3

Bus cover – hollow shaft G1 and G2

Manual_ProfibusDPV0_BIDE_EN.docx 23/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 24

Bus cover – hollow shaft G0 and GB

The connection cable is wired to the 8-pin terminal block inside the interface converter.

The additional functions Zero and UP/DOWN provided by the encoder are to be assigned as follows for

optimum interference immunity:

- Zero additionally assigned to GND

- UP/DOWN additionally assigned to UB

The encoder outputs DV, DV-MT may either be cut off and isolated or assigned to the available terminals

NC1(DV) respectively NC2 (DV-MT).

Interface converter - GK410

Manual_ProfibusDPV0_BIDE_EN.docx 24/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 25

10.2.4. Terminal assignment

Pin

Terminal

Explanation

Pin 1

UB

Supply voltage 10...30 VDC

Pin 3

GND

Ground connection relating to UB

Pin 2

A

Negative serial data line

Pin 4

B

Positive serial data line

M12-connector

For serial data line

for supply voltage

male female

Colour

Status

Green alight

Encoder in "Data_Exchange" mode

Yellow alight

Encoder ramping up

Red alight for 2.5 s

Wrong position value, caused by code constancy error

Red flashing, 1 Hz

Parameterization error

Red flashing, 5 Hz

Transmitted preset value in inadmissible value range

Terminals with the same significance are internally connected and identical in their functions. Max. load on

the internal terminal connections UB-UB and GND-GND is 1 A.

A and B are each isolated for 12 MBaud operation with an inductivity of 100 nH

Carefully plug the bus cover onto the D-SUB plug of the basic encoder, then press only via the sealing

rubber, taking care not to tilt it. The bus cover must rest fully against the basic encoder.

Tighten both the fastening screws firmly in the same direction.

The encoder housing and braided shield of the connecting cable are only ideally connected if the bus cover is

resting fully on the basic encoder (positive locking).

10.3. Display element (status display)

A dual LED is integrated at the back of the bus cover.

Manual_ProfibusDPV0_BIDE_EN.docx 25/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Page 26

10.3.1. Profibus cable

Features

Data

Shaft resistance in Ohm

135 to 165 at 3 to 20 MHz

Operating capacity (pF/m)

Less than 30

Loop resistance (Ohm/km)

Less than 110

Core diameter (mm)

Greater than 0.64

Core cross section (mm)

Greater than 0.34

Baud rate in

kBaud

9.6

19.2

93.75

187.5

500

1500

3000

12000

Cable length

in m

1200

1200

1200

1000

400

200

100

100

EN 50170 specifies two types of cable, A and B. Cable type B is obsolete and should no longer be used for

new applications. With cable type A, all transmission rates up to 12 MBaud can be used.

Transmission speed depending on cable length

Manual_ProfibusDPV0_BIDE_EN.docx 26/26 Baumer IVO GmbH & Co. KG

22.11.12 Villingen-Schwenningen, Germany

Loading...

Loading...