Page 1

INSTRUCTION MANUAL

FOR

INSTANTANEOUS OVERCURRENT RELAY

BE1-50

Publication: 9171000990

Revision: F 01/13

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-50

Instantaneous Overcurrent Relay. To accomplish this, the following information is provided:

General Information and Specifications

Controls and Indicators

Functional Description

Installation

Testing

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12 AWG

copper wire attached to the ground terminal on the rear of the unit case. When

the relay is configured in a system with other devices, it is recommended to use a

separate lead to the ground bus from each unit.

9171000990 Rev F BE1-50 Introduction i

Page 4

First Printing: November 1986

Printed in USA

© 2013 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

January 2013

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use, subject

to return on request, and with the mutual understanding that it will not be used in

any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-50 Introduction 9171000990 Rev F

Page 5

REVISION HISTORY

The following information provides a historical summary of the changes made to the BE1-50 instruction

manual (9171000990). Revisions are listed in reverse chronological order.

Manual

Revision and Date

F, 01/13

E, 09/07

D, 12/01

C, 11/98

B, 06/93

—, 01/86

Updated case and cover drawings in Section 4.

Added manual part number and revision to footers.

Updated Output Contact ratings in Section 1.

Updated Power Supply Burden data in Section 1.

Updated front panel illustrations to show laser graphics.

Updated Target Indicator description in Section 3.

Added GOST-R to Section 1, General Information.

Moved content of Section 7, Manual Change Information to Manual

Introduction.

Moved content of Section 6, Maintenance to Section 4, Installation.

Updated cover drawings in Section 4 to reflect new drawings.

Deleted all references to Service Manual.

Updated Style Chart by adding Option 3-6 Power Supply Status

Output, changing Power Supply Type T from “230 Vac” to “240 Vac”,

deleted “Selectable” from Type S, and added Note 6.

Deleted 500 Vdc from Output Circuits in Specifications.

Added Note to Table 1-1.

Added new power supply information and Fast Transient to

Specifications.

Corrected Figure 2-1 from “Instantaneous Undercurrent Relay” to

Instantaneous Overcurrent Relay”.

Added new power supply information to Section 3 starting with

“Basler Electric enhanced the power supply design…”

Divided Section 4, Installation into two sections Section 4, Installation

and Section 5, Testing.

Added new dimension figures to include all options available (S1

single-ended and double-ended, and both mounting positions) to

Section 4.

Changed Output Connection diagrams to include Sensing Type E or

G and Output F or H, Sensing Type J and Output J or K, and Sensing

Type F and output E or G.

Corrected minor errors and changed the format of the manual.

Added UL Recognition statement, page 1-5.

Added new Figures 4-6 through 4-9.

Initial release

Change

9171000990 Rev F BE1-50 Introduction iii

Page 6

This page intentionally left blank.

iv BE1-50 Introduction 9171000990 Rev F

Page 7

CONTENTS

SECTION 1 GENERAL INFORMATION ................................................................................................ 1-1

PURPOSE ........................................................................................................................................... 1-1

APPLICATION .................................................................................................................................... 1-1

Ground Fault Detection ................................................................................................................ 1-1

Phase Fault Detection .................................................................................................................. 1-1

Combination with Other Protective Devices ................................................................................. 1-2

MODEL AND STYLE NUMBER .......................................................................................................... 1-2

Style Number Example ................................................................................................................. 1-3

SPECIFICATIONS .............................................................................................................................. 1-3

Current Sensing ............................................................................................................................ 1-3

Pickup Range ............................................................................................................................... 1-4

Pickup Accuracy ........................................................................................................................... 1-4

Dropout ......................................................................................................................................... 1-4

Timing ........................................................................................................................................... 1-4

Output Contacts ............................................................................................................................ 1-4

Power Supply................................................................................................................................ 1-5

Target Indicators ........................................................................................................................... 1-5

Type Tests .................................................................................................................................... 1-5

Physical ........................................................................................................................................ 1-5

Agency Recognition/Certification.................................................................................................. 1-6

SECTION 2 CONTROLS AND INDICATORS ....................................................................................... 2-1

INTRODUCTION ................................................................................................................................. 2-1

SECTION 3 FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

INTRODUCTION ................................................................................................................................. 3-1

STEP-DOWN TRANSFORMER ......................................................................................................... 3-1

FULL-WAVE RECTIFIERS ................................................................................................................. 3-1

RESPONSE CHARACTERISTICS ..................................................................................................... 3-1

PICKUP SETTINGS ............................................................................................................................ 3-2

PICKUP COMPARATORS.................................................................................................................. 3-2

PULSE STRETCHERS ....................................................................................................................... 3-2

OUTPUTS ........................................................................................................................................... 3-2

TIMING ................................................................................................................................................ 3-2

OUTPUTS ........................................................................................................................................... 3-2

PUSH-TO-ENERGIZE OUTPUT PUSHBUTTONS ............................................................................ 3-2

POWER SUPPLY STATUS OUTPUT ................................................................................................ 3-2

POWER SUPPLY ............................................................................................................................... 3-2

TARGET INDICATORS ...................................................................................................................... 3-2

Internally Operated Targets .......................................................................................................... 3-2

Current Operated Targets ............................................................................................................ 3-3

SECTION 4 INSTALLATION .................................................................................................................. 4-1

INTRODUCTION ................................................................................................................................. 4-1

RELAY OPERATING GUIDELINES AND PRECAUTIONS ............................................................... 4-1

MOUNTING ......................................................................................................................................... 4-1

CONNECTIONS ................................................................................................................................ 4-14

MAINTENANCE ................................................................................................................................ 4-20

STORAGE ......................................................................................................................................... 4-20

SECTION 5 TESTING ............................................................................................................................ 5-1

INTRODUCTION ................................................................................................................................. 5-1

OPERATIONAL TEST ........................................................................................................................ 5-1

9171000990 Rev F BE1-50 Introduction v

Page 8

This page intentionally left blank.

vi BE1-50 Introduction 9171000990 Rev F

Page 9

SECTION 1 • GENERAL INFORMATION

PURPOSE

Instantaneous overcurrent relays provide phase and ground fault protection for distribution circuits,

generators, motors, transformers, and other major components of power systems. BE1-50 Instantaneous

Overcurrent relays have a wide range of pickup settings and input configurations to accommodate

protection requirements for power systems. BE1-50 relays are available in single or multi-phase for power

units.

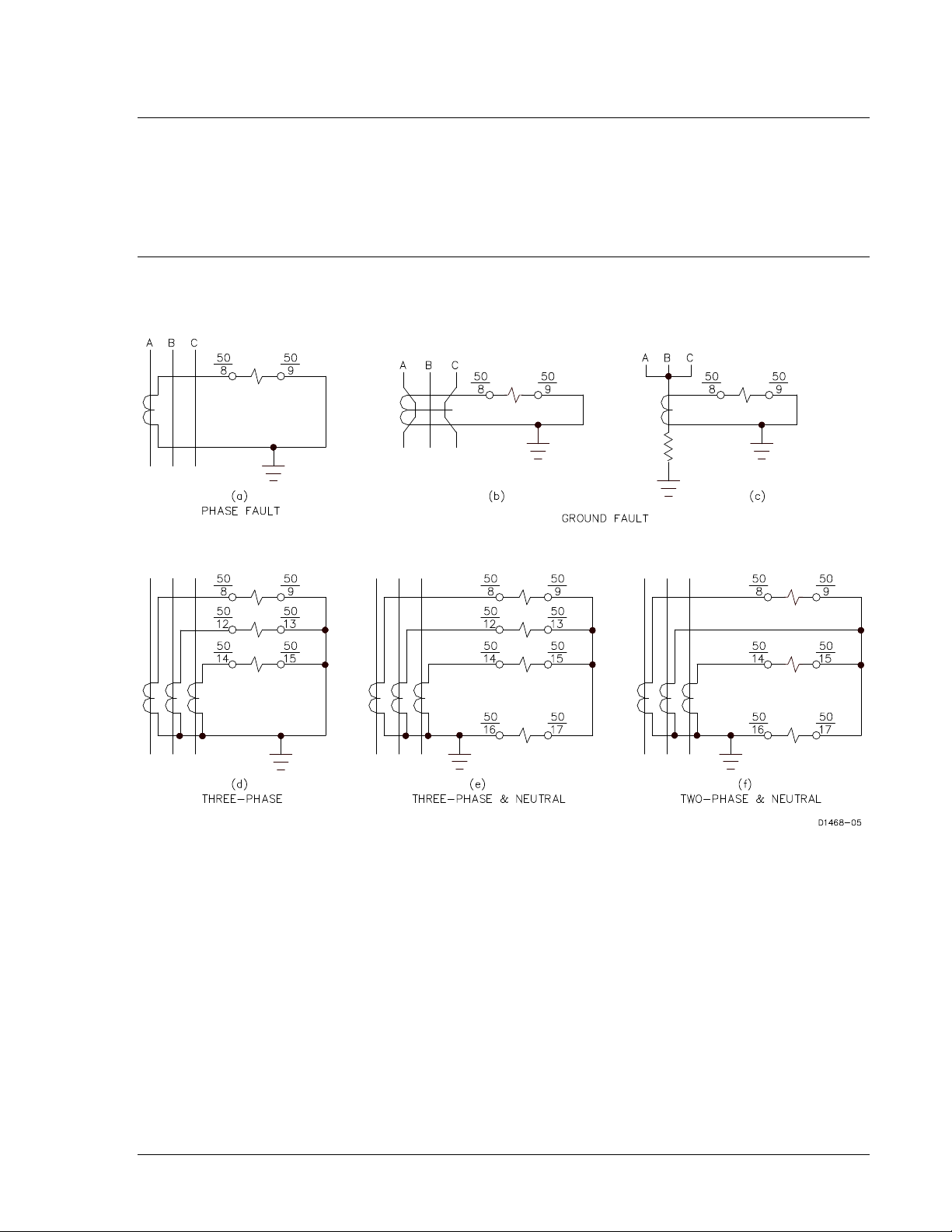

APPLICATION

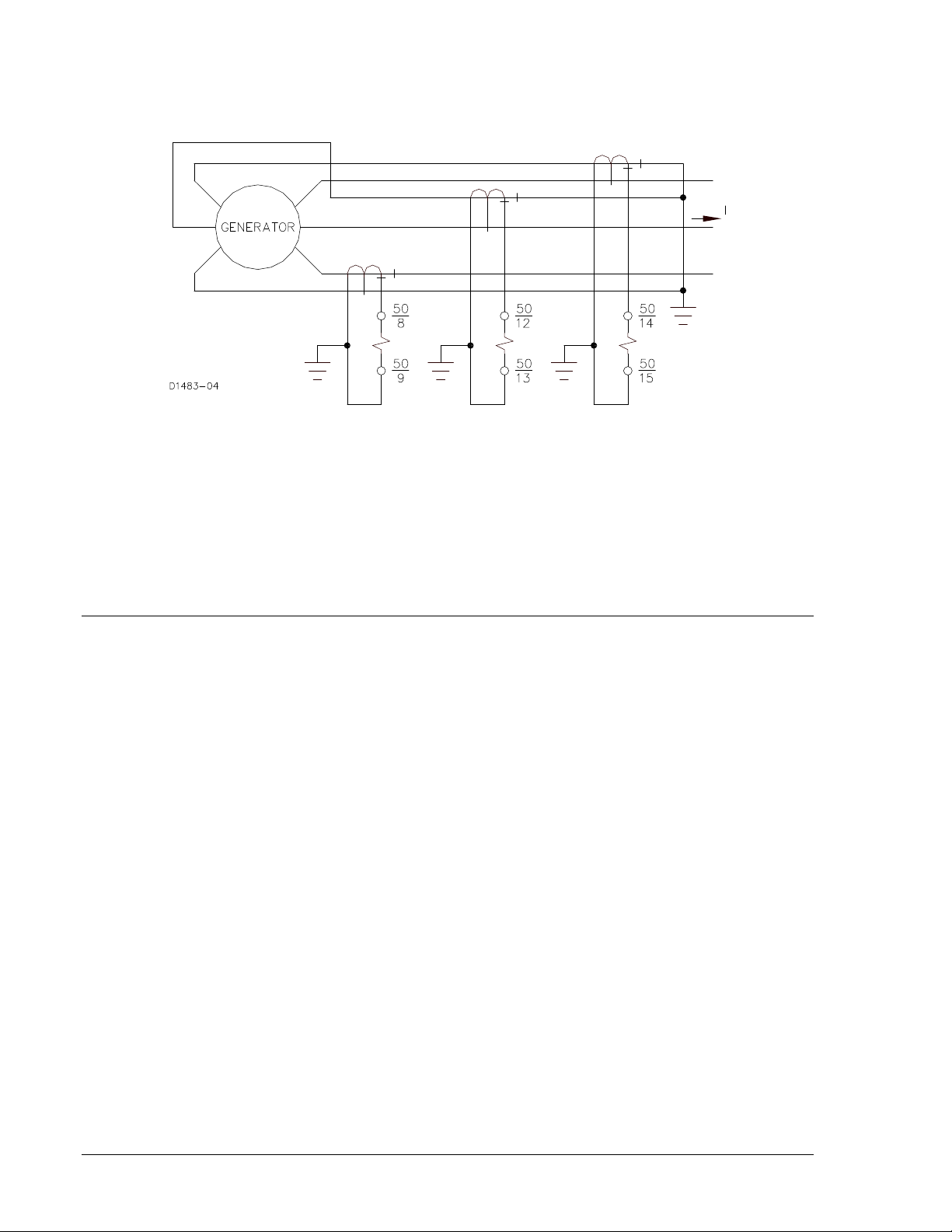

Some applications are illustrated in Figure 1-1.

Figure 1-1. Typical BE1-50 Applications

Ground Fault Detection

BE1-50 relays can be applied to monitor zero sequence currents that are indicative of ground faults. The

most sensitive method of ground fault protection utilizes a single current transformer through which all the

conductors are passed (Figure 1-1b). Another method uses the residual connection of the three-phase

CTs (Figure 1-1d) with the relay set higher than the normal system unbalance. The most direct method is

to place a CT in the neutral of a grounded wye connection for equipment such as power transformers or

generators (Figure 1-1c).

Phase Fault Detection

BE1-50 relays can be used in two ways to detect phase faults. The first method is to place an

instantaneous overcurrent element in each phase with the setting higher than expected load current for

any power system element (Figure 1-1a, d, e, f). The second method is called self-balancing differential

protection (Figure 1-2).

9171000990 Rev F BE1-50 General Information 1-1

Page 10

In this application, the two leads of each phase of the protected motor or generator are passed through

the window of the same associated phase current transformer so that the resulting secondary current is

zero under normal operating conditions.

Figure 1-2. Self-Balancing Differential Protection

Combination with Other Protective Devices

Because BE1-50 relays can provide complete phase and ground fault protection in one unit (and with

independent settings for phase and ground), they are often used to supervise other relay functions. In

distance protection, BE1-50 relays can be used to prevent misoperation for light loading conditions by

requiring a minimum current level before enabling the distance relay. As a fault detector, they are

particularly effective because of their sensitivity, speed, and dropout ratio.

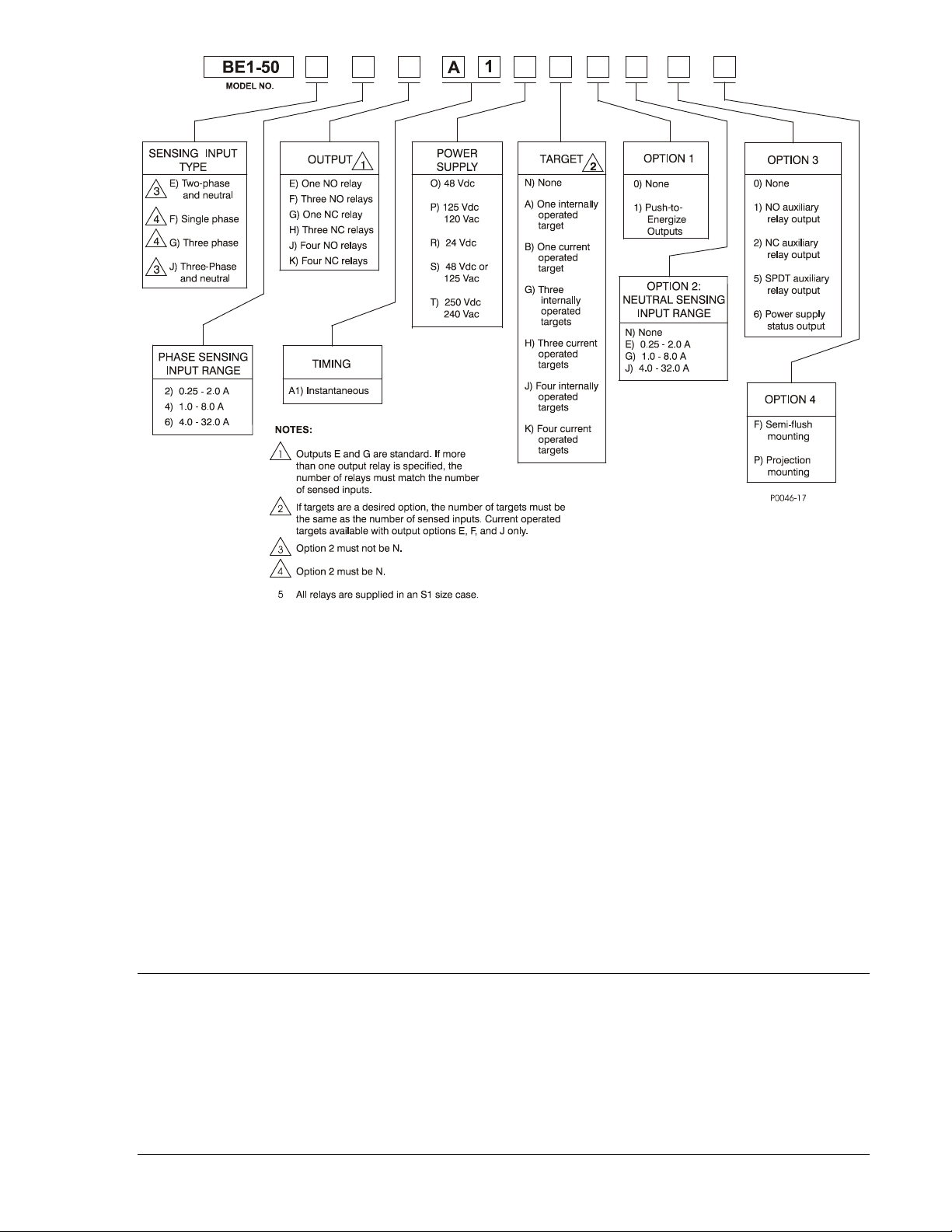

MODEL AND STYLE NUMBER

BE1-50 electrical characteristics and operational features are defined by a combination of letters and

numbers that make up the style number. Model number BE1-50 designates the relay as a Basler Electric

Instantaneous Overcurrent Relay. The model number, together with the style number, describes the

options included in a specific device and appears on the front panel, draw-out cradle, and inside the case

assembly.

The style number identification chart for the BE1-50 relay is illustrated in Figure 1-3.

1-2 BE1-50 General Information 9171000990 Rev F

Page 11

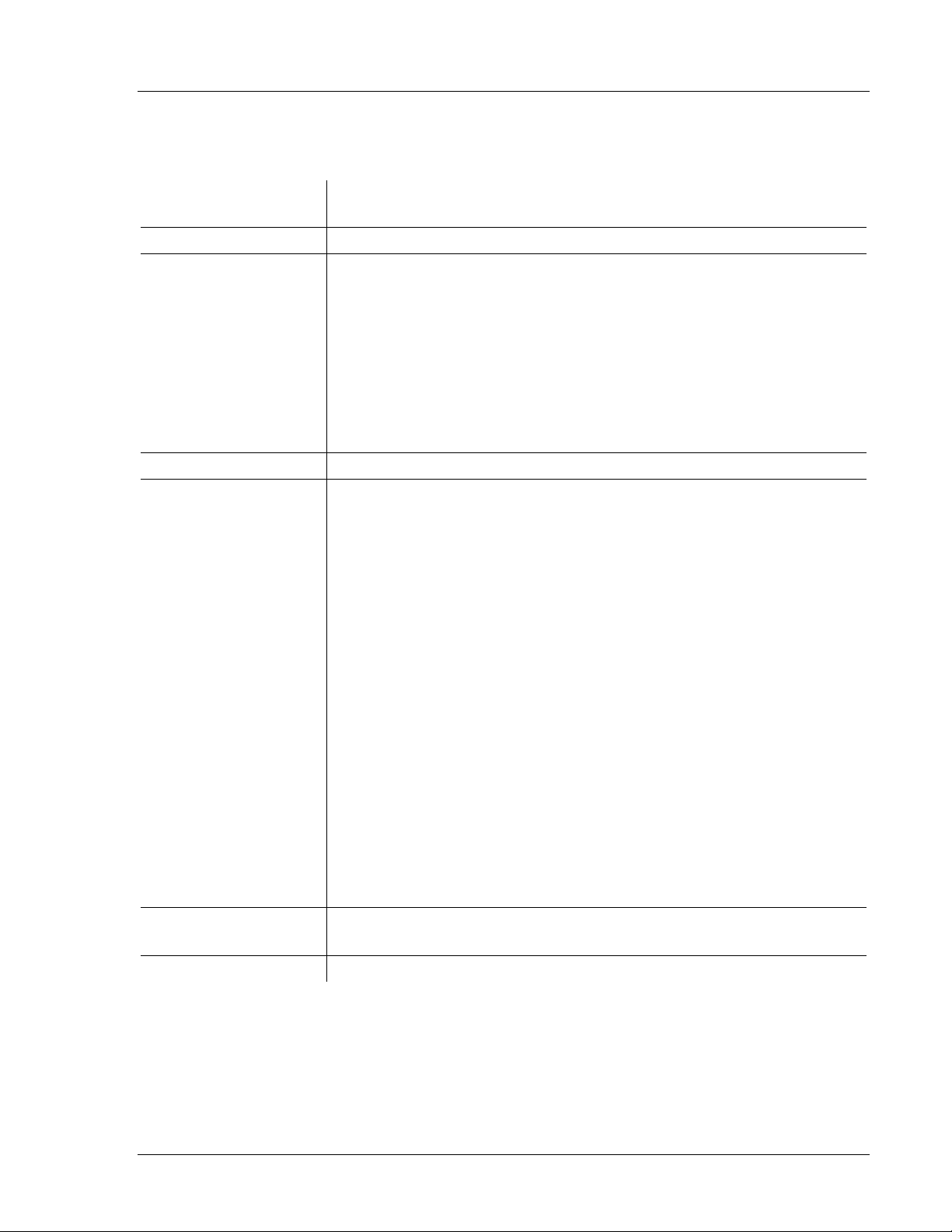

Figure 1-3. BE1-50 Style Identification Chart

Style Number Example

If a BE1-50 relay has a style number of J6J–A1P–J1E1F, the relay has the following features:

J -------- Three-phase-and-neutral current sensing

6 -------- 8.0 to 16.0 A phase sensing input range

J -------- Four output relays with normally open contacts

A1 ------ Instantaneous timing

P -------- Operating power derived from 125 Vdc or 120 Vac

J -------- Four internally operated targets

1 -------- Push-to-energize outputs

E -------- 0.5 to 1.0 A neutral sensing input range

1 -------- One auxiliary output relay with normally open contacts

F -------- Semi-flush mounting case

SPECIFICATIONS

BE1-50 electrical and physical specifications are listed in the following paragraphs.

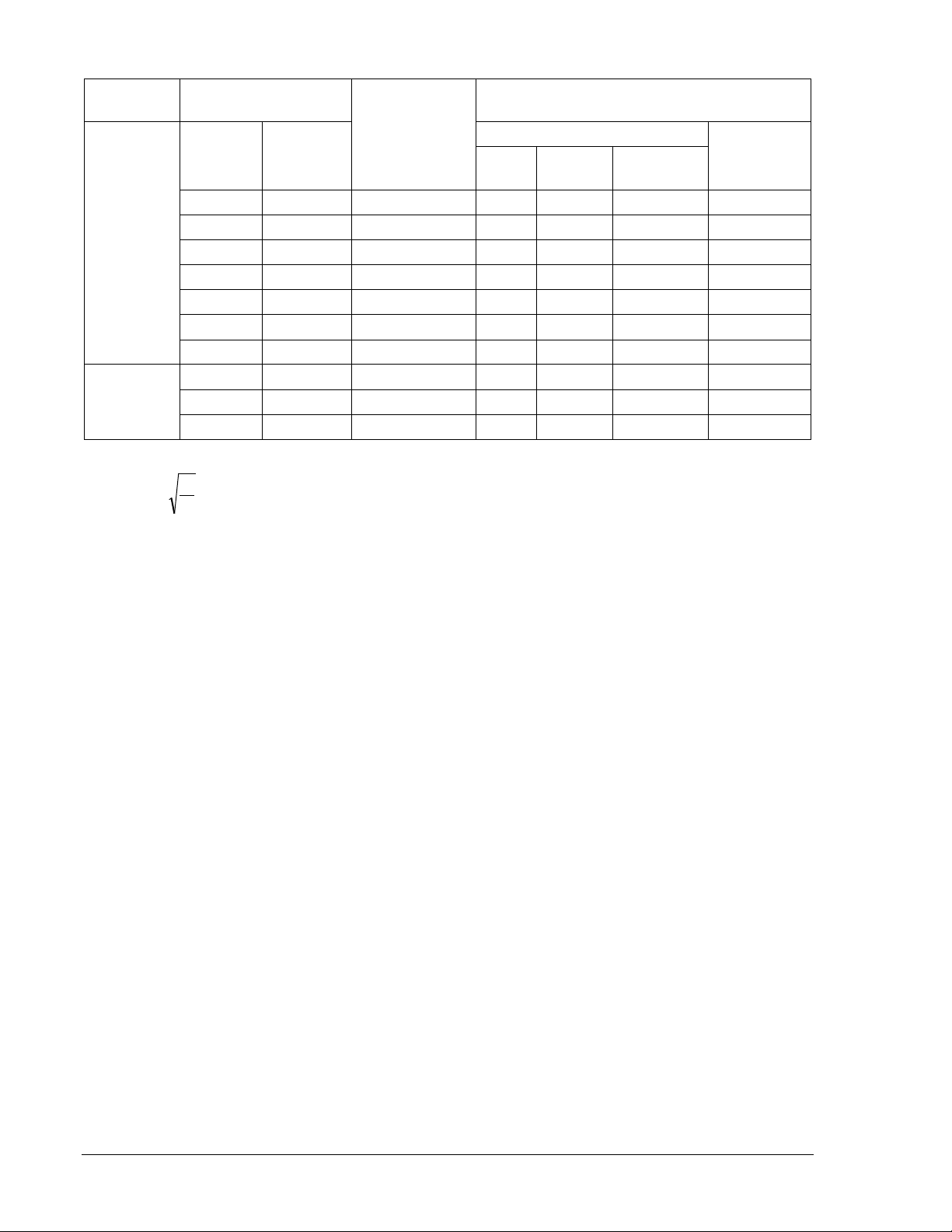

Current Sensing

Sensing inputs are nominally rated at 50/60 Hz and have a frequency range of 40 to 70 Hz. Current

ratings and sensing burdens depend on the sensing range and power supply type (defined by the style

number), and are shown in Table 1-1.

9171000990 Rev F BE1-50 General Information 1-3

Page 12

Table 1-1. Current Ratings and Sensing Burdens

t

K

I =

where:

Power

Supply

F, G, or H

†

O, P, R, S,

or T

∗ Ratings other than continuous may be calculated using the equation:

Sensing Range

Designation

Actual Sensing

For

Phase

1 D 0.25 - 0.5 A 144 12.0 A 0.75 A 8.5 VA

2 E 0.5 - 1.0 A 144 12.0 A 1.5 A 8.5 VA

3 F 1.0 - 2.0 A 625 25.0 A 3 A 8.5 VA

4 G 2.0 to 4.0 A 2500 50.0 A 6 A 8.5 VA

5 H 4.0 to 8.0 A 10000 100 A 12 A 8.5 VA

6 J 8.0 - 16.0 A 40000 200 A 20 A 9.5 VA

7 K 16.0 - 32.0 A 90000 300 A 20 A 14.0 VA

2 E 0.25 - 2.0 A 10000 100 A 5 A 0.2 VA

4 G 1.0 - 8.0 A 90000 300 A 10 A 0.6 VA

6 J 4.0 - 32.0 A 90000 300 A 20 A 4.8 VA

For

Neutral

Range

the indicated value

K =

the time in seconds

T =

maximum current

I =

K ∗

Maximum Rating 50 or 60 Hz

Second

Current

1

Continuous

Burden Per

Input

† Power Supply types F, G, and H are no longer available.

Pickup Range

Continuously adjustable over the range defined by the style number with independent ranges and

adjustments for each phase and neutral pickup.

Pickup Accuracy

±2% or ±40 mA of pickup setting, whichever is greater.

Dropout

Within 2% of pickup.

Timing

1.5 cycles or less from onset of overcurrent condition. (30 milliseconds at 50 Hz, 25 milliseconds at 60

Hz.)

Output Contacts

Resistive Ratings

120 Vac: Make, break, and carry 7 Aac continuously

250 Vdc: Make and carry 30 Adc for 0.2 s, carry 7 Adc continuously,

break 0.3 Adc

500 Vdc: Make and carry 15 Adc for 0.2 s, carry 7 Adc continuously,

break 0.3 Adc

Inductive Ratings

120 Vac, 125 Vdc, 250 Vdc: Break 0.3 A (L/R = 0.04)

1-4 BE1-50 General Information 9171000990 Rev F

Page 13

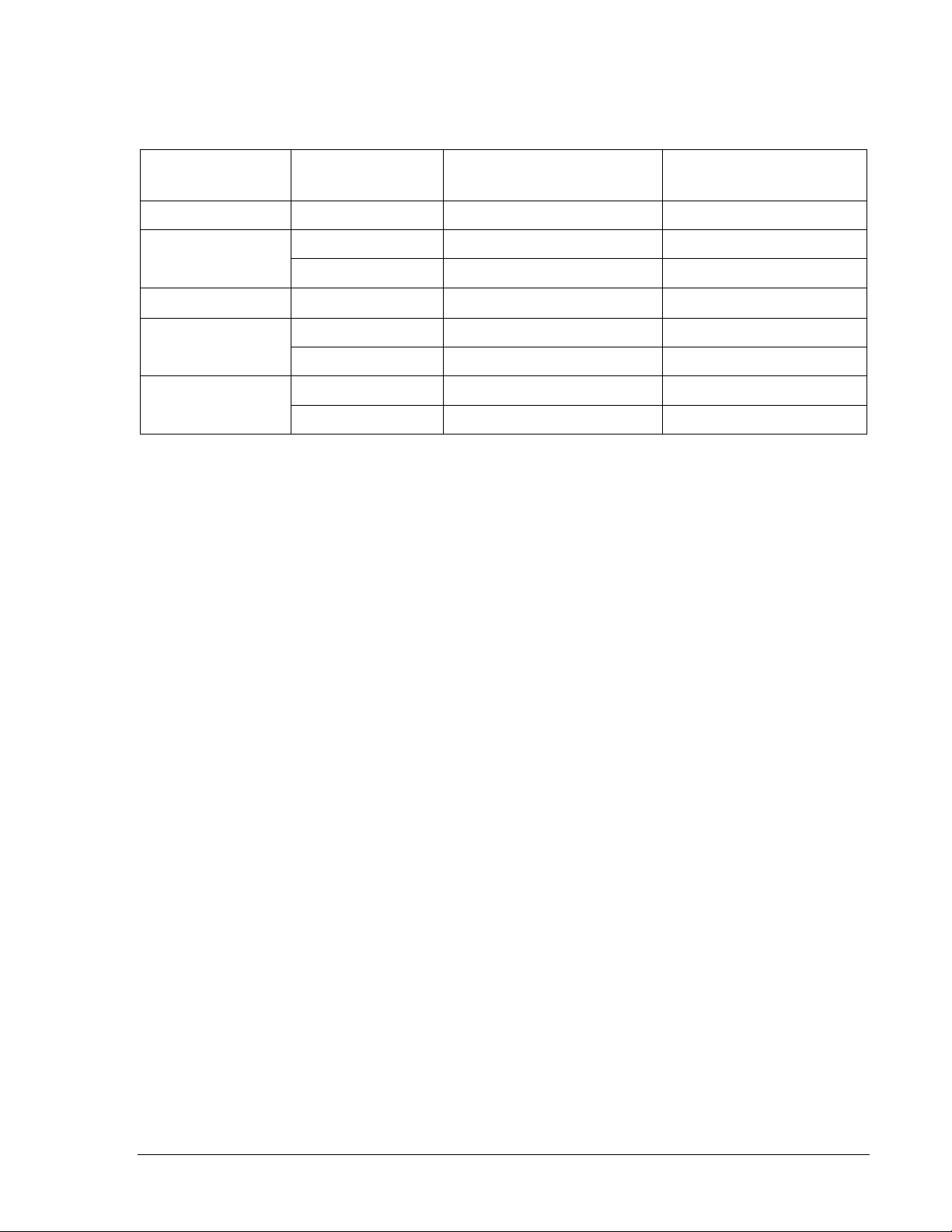

Power Supply

Input Voltage

O (midrange)

48 Vdc

24 to 150 Vdc

1.2 W

125 Vdc

24 to 150 Vdc

1.5 W

120 Vac

90 to 132 Vac

19.3 VA

R (low range)

24 Vdc

12 to 32 Vdc ∗

1.3 W

48 Vdc

24 to 150 Vdc

1.2 W

125 Vdc

24 to 150 Vdc

1.5 W

250 Vdc

68 to 280 Vdc

1.7 W

240 Vac

90 to 270 Vac

31.6 VA

Externally powered power supply types are listed in Table 1-2.

Table 1-2. Power Supply Ratings

Type

P (midrange)

S (midrange)

T (high range)

∗ Type R power supply initially requires 14 Vdc to begin operating. Once operating, the input voltage may

be reduced to 12 Vdc and operation will continue.

Target Indicators

Electronically latched, manually reset target indicators are optionally available to indicate closure of the

trip output contacts. Either internally operated or current operated targets may be specified. Internally

operated targets should be selected when normally closed (NC) output contacts are specified.

Current Operated Targets

Minimum Rating: 200 mA flowing through the trip circuit

Continuous Rating: 3 A

1 Second Rating: 30 A

2 Minute Rating: 7 A

Nominal

Input Voltage Range Burden at Nominal

Type Tests

Shock: Withstands 15 G in each of three mutually perpendicular planes

without structural damage or performance degradation.

Vibration: Withstands 2 G in each of three mutually perpendicular planes,

swept over the range of 10 to 500 Hz for a total of six sweeps, 15

minutes each sweep, without structural damage or degradation of

performance.

Dielectric Strength: Tested in accordance with IEC 255-5 and IEEE C37.90. All circuits to

ground: 2,121 Vdc. Input to Output circuits: 1,500 Vac/2,121 Vdc.

Radio Frequency Interference: Maintains proper operation when tested for interference in

accordance with IEEE C37.90.2-1987, Standard Withstand

Capability of Relay Systems to Radiated Electromagnetic

Interference from Transceivers.

Surge Withstand Capability: Qualified to IEEE C37.90.1-1989, Standard Surge Withstand

Capability (SWC) Tests for Protective Relays and Relay Systems.

Physical

Temperature

Operating Range: –40 to 70°C (–40 to 158°F)

Storage Range: –65 to 100°C (–85 to 212°F)

Weight: 17.5 lb (7.76 kg)

Case Size: S1 (Refer to Section 4 for case dimensions.)

9171000990 Rev F BE1-50 General Information 1-5

Page 14

Agency Recognition/Certification

UL Recognition: UL recognized per Standard 508, File E97033

NOTE: Output contacts are not UL recognized for voltages greater

than 250 volts.

GOST-R Certification: GOST-R certified per the relevant standards of Gosstandart of

Russia.

1-6 BE1-50 General Information 9171000990 Rev F

Page 15

SECTION 2 • CONTROLS AND INDICATORS

INTRODUCTION

All BE1-50 controls and indicators are located on the front panel. The controls and indicators are shown in

Figure 2-1 and described in Table 2-1. Figure 2-1 illustrates a relay with the maximum number of controls

and indicators. Your relay may not have all of the controls and indicators shown and described here.

Figure 2-1. BE1-50 Controls and Indicators

Table 2-1. Control and Indicator Descriptions

Locator Description

A

B

C Power Indicator. This red LED lights when operating power is applied to the relay.

D Target Reset Switch. This switch is operated to reset the target indicators.

9171000990 Rev F BE1-50 Controls and Indicators 2-1

Phase Current Adjust. This multi-turn potentiometer sets the pickup point for all phase

overcurrent elements within the relay. Continuously adjustable over the range defined by

the style number.

Neutral Current Adjust. This multi-turn potentiometer sets the pickup point for the neutral

overcurrent element within the relay. Continuously adjustable over the range defined by

the style number.

Page 16

Locator Description

E

F

Target Indicators. These electronically latched red target indicators illuminate when the

corresponding output relay energizes. To ensure proper operation of the current-operated

targets, the current flowing through the trip circuit must be 200 mA or higher. The target

indicators are reset by operating the target reset switch (locator D).

Output Test Pushbuttons. These pushbuttons allow manual actuation of the output relays.

Output relay actuation is achieved by inserting a nonconductive rod through the front

panel access hole.

2-2 BE1-50 Controls and Indicators 9171000990 Rev F

Page 17

SECTION 3 • FUNCTIONAL DESCRIPTION

INTRODUCTION

BE1-50 Instantaneous Overcurrent relays are static devices that respond to the current magnitude of the

monitored circuit. BE1-50 relay functions are illustrated in Figure 3-1 and described in the following

paragraphs.

Figure 3-1. Function Block Diagram

STEP-DOWN TRANSFORMER

Monitored system currents are applied to the primaries of internal current transformers and stepped down

to internal circuit levels. The internal current transformers provide 1,500 V of isolation for the twelve-volt

logic circuits of the relay.

FULL-WAVE RECTIFIERS

Outputs from each step-down transformer are full-wave rectified and applied to resistor networks to

develop voltages that represent the magnitude of the monitored system currents.

RESPONSE CHARACTERISTICS

Input current signals are rectified and passed through a low pass filter. Filtering smoothes out current

spikes and provides a degree of security against operation on short-term transients.

Filtering also smoothes out the harmonic component effects on current signals. Harmonic component

effects are reduced approximately by 1/n where n is the order of the harmonic. For example, the third

harmonic effect is reduced by filtering to 1/3 of what is would be without filtering. With filtering, the

response characteristics are similar to those of electromechanical relays.

9171000990 Rev F BE1-50 Functional Description 3-1

Page 18

PICKUP SETTINGS

A front panel multiple-turn potentiometer controls the pickup setting for all phases. The potentiometer

establishes the reference voltage representative of the system current, which will cause the relay to

respond. On relay styles monitoring neutral current, an independent potentiometer is provided to establish

the pickup level for neutral.

PICKUP COMPARATORS

The magnitude of each monitored current is compared with the appropriate pickup setting. When a pickup

setting is exceeded, a pulse stretcher for that phase (or neutral) is activated.

PULSE STRETCHERS

Because the sensed currents are full-wave rectified and minimally filtered to retain high-speed operation,

the pulse output from the comparators must be extended.

OUTPUTS

Defined by the style number, individual output relays may be provided for each monitored phase (and

neutral). One output relay may serve for all monitored phases (and neutral). In addition, one auxiliary

output relay may be provided that serves for all monitored phases (and neutral).

PUSH-TO-ENERGIZE OUTPUT PUSHBUTTONS

Small pushbutton switches may be provided as an option to allow testing the primary output contacts and

(if present) the auxiliary output contact. To prevent accidental operation, the pushbuttons are recessed

behind the front panel and are depressed by inserting a thin, non-conducting rod through an access hole

in the front panel.

POWER SUPPLY STATUS OUTPUT

The optional power supply status relay has a set of normally closed contacts and energizes when

operating power is applied to the BE1-50. If relay operating power is lost or one side of the power supply

output (+12 Vdc or –12 Vdc) fails, the power supply status relay de-energizes and closes the power

supply status output contacts. If the power supply status output is provided, then the auxiliary contact is

not available.

POWER SUPPLY

Operating power for the relay circuitry is supplied by a wide range, electrically isolated, low-burden power

supply. Power supply operating power is not polarity sensitive. The front panel power LED and power

supply status output indicate when the power supply is operating. Power supply specifications are listed in

Table 1-2.

TARGET INDICATORS

Target indicators are optional components selected when a relay is ordered. The electronically latched

and reset targets consist of red LED indicators located on the relay front panel. A latched target is reset

by operating the target reset switch on the front panel. If relay operating power is lost, illuminated

(latched) targets are extinguished. When relay operating power is restored, the previously latched targets

are restored to their latched state.

A relay can be equipped with either internally operated targets or current operated targets.

Internally Operated Targets

The relay trip outputs are directly applied to drive the target indicators. The indicators are illuminated

regardless of the current level in the trip circuit.

3-2 BE1-50 Functional Description 9171000990 Rev F

Page 19

Current Operated Targets

Current operated targets are triggered by closure of the output contacts and the presence of at least 200

milliamperes of current flowing in the trip circuit.

NOTE

Prior to September 2007, BE1-50 target indicators consisted of magnetically

latched, disc indicators. These mechanically latched target indicators have been

replaced by the electronically latched LED targets in use today.

9171000990 Rev F BE1-50 Functional Description 3-3

Page 20

This page intentionally left blank.

3-4 BE1-50 Functional Description 9171000990 Rev F

Page 21

SECTION 4 • INSTALLATION

INTRODUCTION

BE1-50 relays are shipped in sturdy cartons to prevent damage during transit. Upon receipt of a relay,

check the model and style number against the requisition and packing list to see that they agree. Inspect

the relay for shipping damage. If there is evidence of damage, file a claim with the carrier, and notify your

sales representative or Basler Electric.

If the relay will not be installed immediately, store it in its original shipping carton in a moisture- and dustfree environment. Before placing the relay in service, it is recommended that the test procedures of

Section 5, Testing be performed.

RELAY OPERATING GUIDELINES AND PRECAUTIONS

Before installing or operating the relay, not the following guidelines and precautions.

• For proper current operated target operation, a minimum current of 200 milliamperes must flow

through the output trip circuit.

• If a wiring insulation test is required, remove the connection plugs and withdraw the relay from its

case.

CAUTION

When the connection plugs are removed, the relay is disconnected from the

operating circuit and will not provide system protection. Always be sure that

external operating (monitored) conditions are stable before removing a relay for

inspection, test, or service.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12 AWG

copper wire attached to the ground terminal on the rear of the case. When the

relay is configured in a system with other devices, it is recommended to use a

separate lead to the ground bus from each device.

MOUNTING

Because the relay is of solid-state design, it does not have to be mounted vertically. Any convenient

mounting angle may be chosen. Relay outline dimensions and panel drilling diagrams are illustrated in

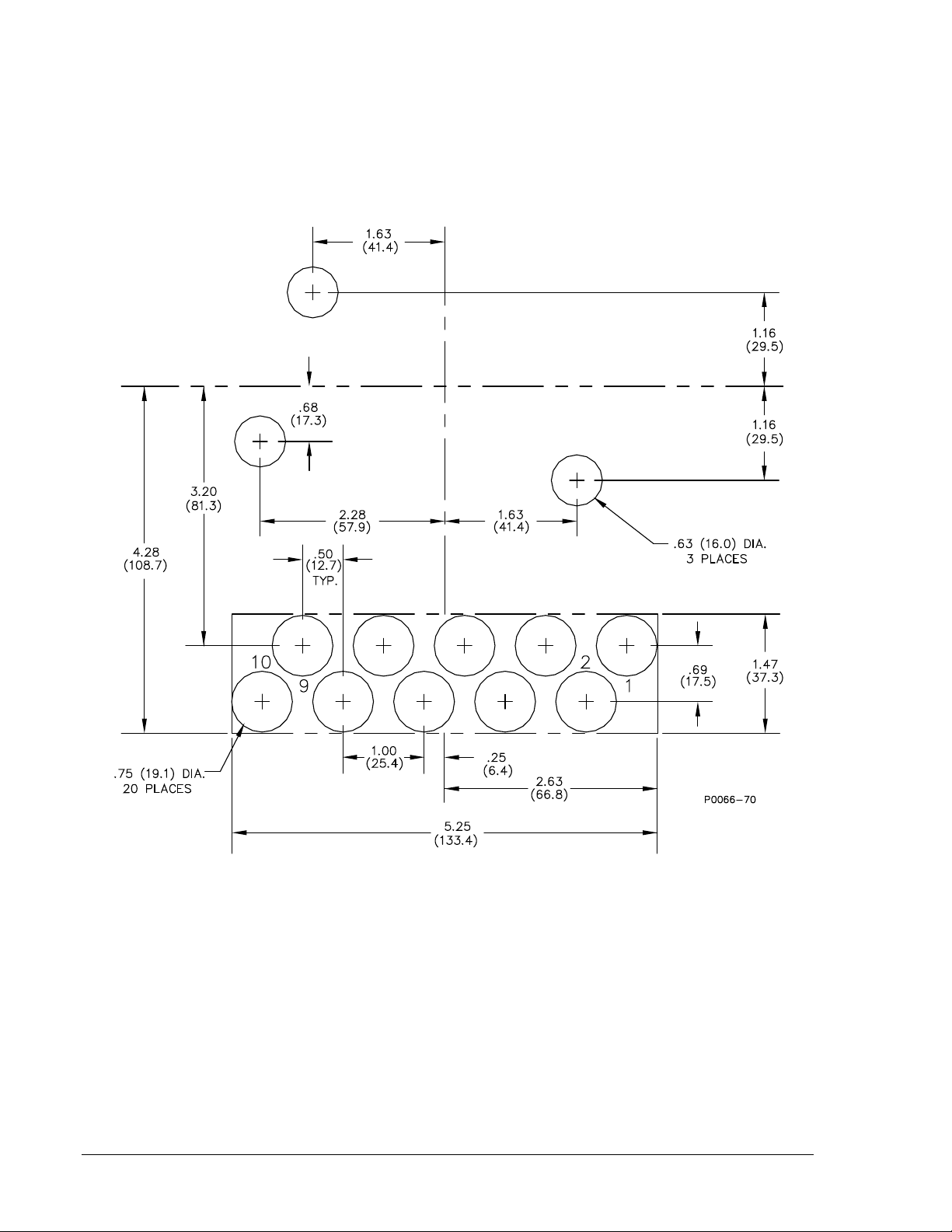

Figures 4-1 through 4-12.

9171000990 Rev F BE1-50 Installation 4-1

Page 22

3.03 (77)

6.06 (154)

0.25 (6) diameter, 4 places

C

L

Cut-Out

0.575

(15)

8.63

(219)

0.552

(14)

5.69 (144)

Outer Edge of Cover

0.480

(12)

8.25

(210)

4.13

(105)

0.480

(12)

P0072-12

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, S1 Case

4-2 BE1-50 Installation 9171000990 Rev F

Page 23

Figure 4-2. S1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

9171000990 Rev F BE1-50 Installation 4-3

Page 24

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

MOUNTING PANEL

(55.75)

2.195

P0066-64

Figure 4-3. S1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

4-4 BE1-50 Installation 9171000990 Rev F

Page 25

Figure 4-4. S1 Case Dimensions, Rear View, Single Ended, Semi-Flush Mount

9171000990 Rev F BE1-50 Installation 4-5

Page 26

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-69

8.06

(204.72)

(7.9)

.31

Figure 4-5. S1 Case Dimensions, Side View, Single Ended, Semi-Flush Mount

4-6 BE1-50 Installation 9171000990 Rev F

Page 27

Figure 4-6. Panel Cutting/Drilling, Double Ended, Projection Mount, S1 Case

9171000990 Rev F BE1-50 Installation 4-7

Page 28

Figure 4-7. S1 Case Dimensions, Rear View, Double Ended, Projection Mount

4-8 BE1-50 Installation 9171000990 Rev F

Page 29

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

(55.75)

2.195

P0066-67

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

Figure 4-8. S1 Case Dimensions, Side View, Double Ended, Projection Mount

9171000990 Rev F BE1-50 Installation 4-9

Page 30

Figure 4-9. Panel Cutting/Drilling, Single Ended, Projection Mount, S1 Case

4-10 BE1-50 Installation 9171000990 Rev F

Page 31

Figure 4-10. S1 Case Dimensions, Rear View, Single Ended, Projection Mount

9171000990 Rev F BE1-50 Installation 4-11

Page 32

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-71

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

8.06

(204.72)

(7.9)

.31

.75

(19.1)

Figure 4-11. S1 Case Dimensions, Side View, Single Ended, Projection Mount

4-12 BE1-50 Installation 9171000990 Rev F

Page 33

P

0066-

68

Figure 4-12. S1 Case Cover Dimensions, Front View

9171000990 Rev F BE1-50 Installation 4-13

Page 34

CONNECTIONS

Be sure to check the model and style number of a relay before connecting and energizing the relay.

Incorrect wiring may result in damage to the relay. Except where noted, connections should be made with

wire no smaller than 14 AWG.

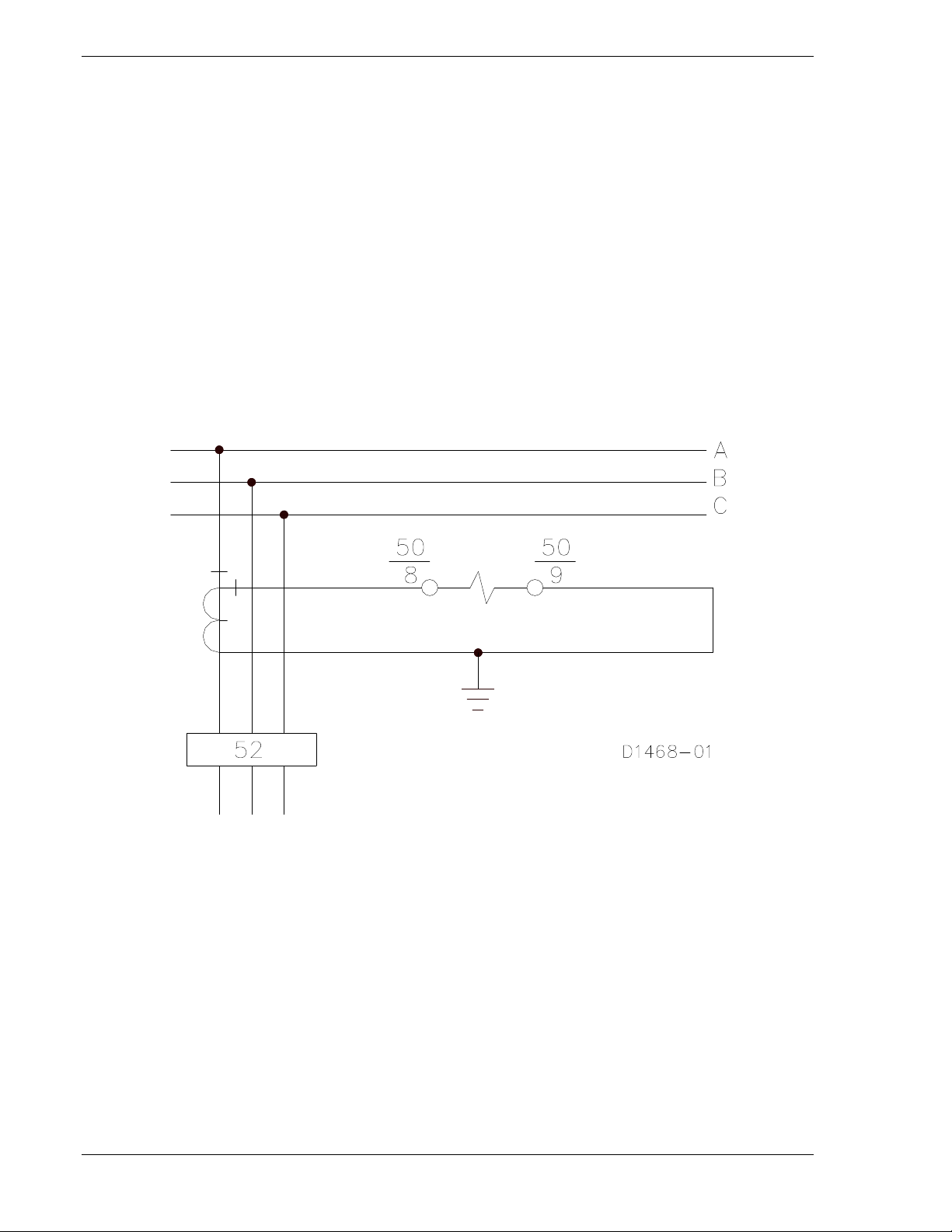

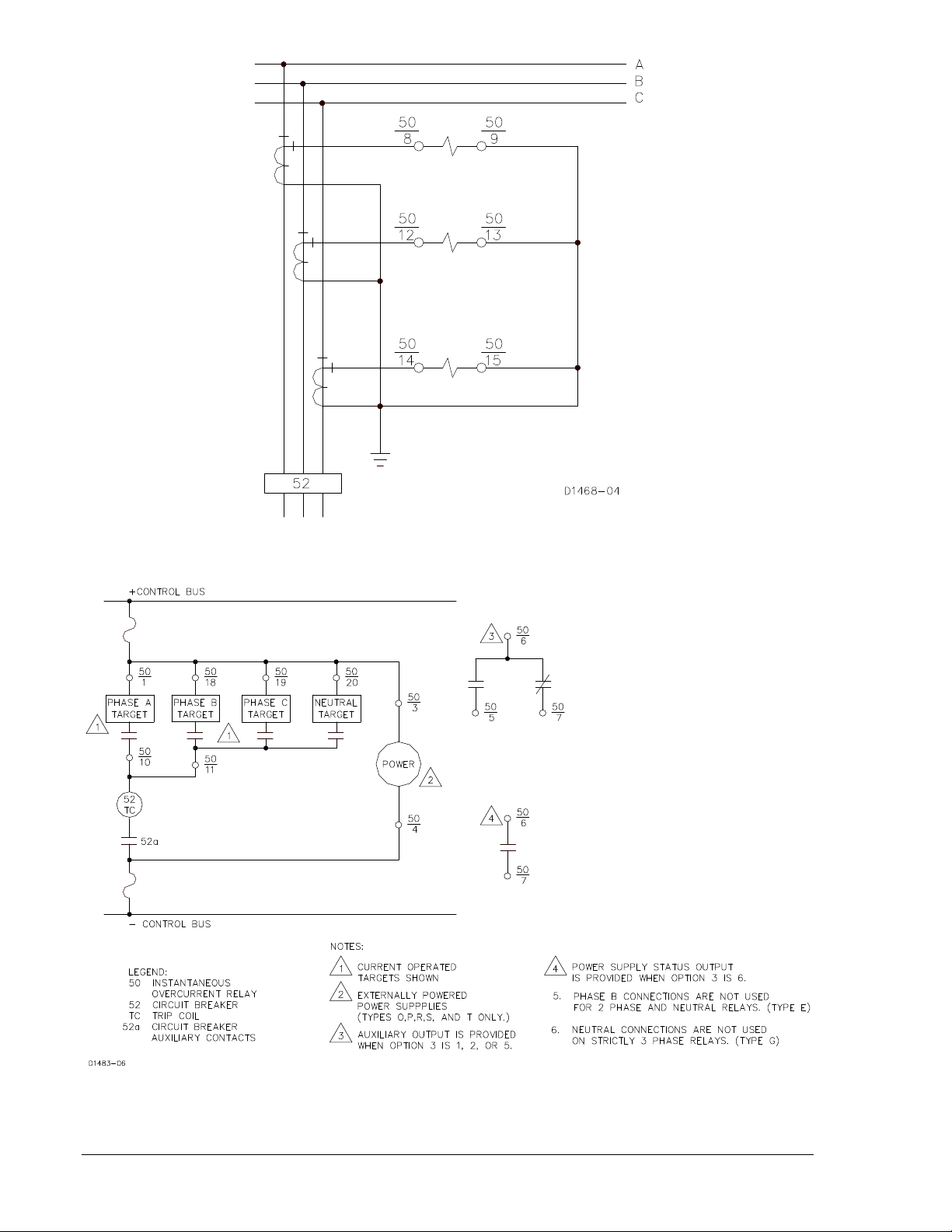

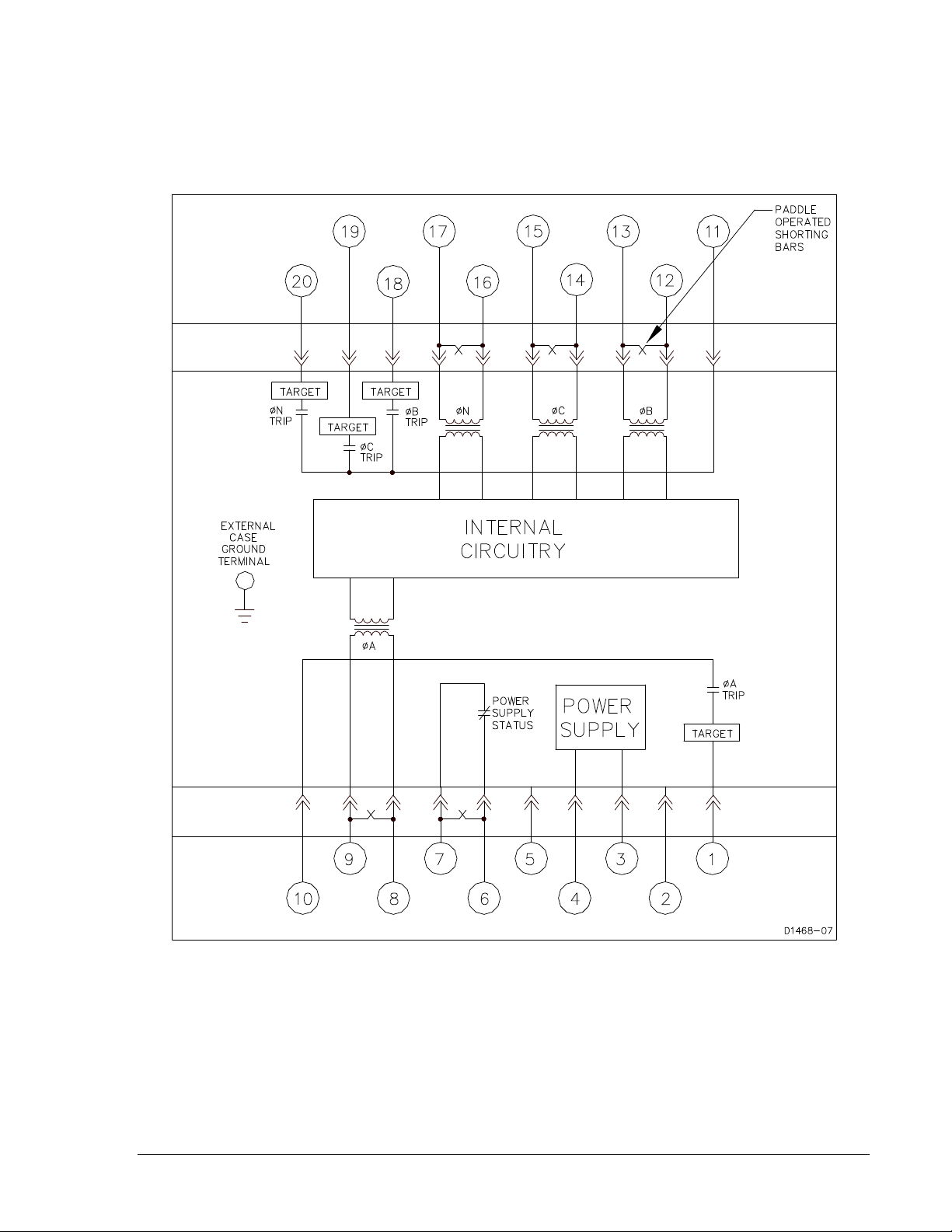

Typical sensing input connections are shown in Figures 4-13 through 4-16. Typical output connections

are shown in Figures 4-17 and 4-18. Internal wiring diagrams are shown in Figures 4-19 through 4-21.

Figure 4-13. Single-Phase Sensing Input Connections

4-14 BE1-50 Installation 9171000990 Rev F

Page 35

Figure 4-14. Three-Phase-and-Neutral Sensing Input Connections

Figure 4-15. Two-Phase-and-Neutral Sensing Input Connections

9171000990 Rev F BE1-50 Installation 4-15

Page 36

Figure 4-16. Three-Phase Sensing Input Connections

Figure 4-17. Typical Output Connections (Sensing Input Type E or G and Output F or H)

or (Sensing Input Type J and Output J or K)

4-16 BE1-50 Installation 9171000990 Rev F

Page 37

Figure 4-18. Typical Output Connections (Sensing Input Type F and Output E or G)

9171000990 Rev F BE1-50 Installation 4-17

Page 38

Figure 4-19. Typical Internal Connections, Three-Phase-and-Neutral Sensing, Output Type E

4-18 BE1-50 Installation 9171000990 Rev F

Page 39

Figure 4-20. Typical Internal Connections, Three-Phase-and-Neutral Sensing, Multiple Output Relays

9171000990 Rev F BE1-50 Installation 4-19

Page 40

Figure 4-21. Typical Internal Connections, Single-Phase, Output E

MAINTENANCE

BE1-50 relays require no preventative maintenance other than a periodic operational check. If the relay

fails to function properly, contact Technical Sales Support at Basler Electric to coordinate repairs.

STORAGE

This device contains long-life electrolytic capacitors. For devices that are not in service (spares in

storage), the life of these capacitors can be maximized by energizing the device for 30 minutes once per

year.

4-20 BE1-50 Installation 9171000990 Rev F

Page 41

SECTION 5 • TESTING

INTRODUCTION

The following procedures verify proper relay operation and calibration.

Results obtained from these procedures may no fall within specified tolerances. When evaluating results,

consider three prominent factors:

• Test equipment accuracy

• Testing method

• External test set components tolerance level

CAUTION

When adjusting for currents higher than 20 amperes AC, do NOT allow sustained

current flow longer than thirty seconds. Allow a minimum one minute cooling time

between applications.

OPERATIONAL TEST

Step 1. Connect the test circuit shown in Figure 5-1. For relay styles with power supply types O, P, R,

S, or T, apply appropriate operating power to terminals 3 and 4. If equipped with power supply

status contacts (option 3-6), verify that these contacts when external power is applied. Remove

input power and verify that the status contacts close. (For relay styles with power supply types

F, G, and H, the relay is powered from the current sensing inputs.)

Figure 5-1. Test Circuit Connection

9171000990 Rev F BE1-50 Testing 5-1

Page 42

Step 2. Turn the phase pickup adjustment fully CCW. For relay styles with target indicators, operate the

manual reset switch to ensure that the targets are reset.

Step 3. Apply sensing current (near zero) and slowly increase the sensed current until the test indicator

changes state.

Result: Current indicated by the ammeter is within two percent of the low end of the sensing

range. If present, the target indicator for the tested phase (or neutral) should be

actuated.

Step 4. Turn the pickup adjustment fully CW. Reset target indicators if present.

Step 5. Apply sensing current (near zero) and slowly increase the sensed current until the test indicator

changes state.

Result: Current indicated by the ammeter is within two percent of the high end of the sensing

range. If present, the target indicator for the tested phase (or neutral) should be

actuated.

Step 6. Repeat Steps 2 through 5 for each phase and neutral as necessary for your style relay. (Neutral

sensing ranges may be different from the phase sensing range.)

5-2 BE1-50 Testing 9171000990 Rev F

Page 43

Page 44

12570 State Route 143

P.A.E. Les Pins

No. 59 Heshun Road Loufeng District (N)

111 North Bridge Road

Highland IL 62249-1074 USA

Tel: +1 618.654.2341

Fax: +1.618.654.2351

email: info@basler.com

67319 Wasselonne Cedex

FRANCE

Tel: +33 3.88.87.1010

Fax: +33 3.88.87.0808

email: franceinfo@basler.com

Suzhou Industrial Park

215122 Suzhou

P.R. CHINA

Tel: +86 512.8227.2880

Fax: +86 512.8227.2887

email: chinainfo@basler.com

15-06 Peninsula Plaza

Singapore 179098

Tel: +65 68.44.6445

Fax: +65 68.44.8902

email: singaporeinfo@basler.com

Loading...

Loading...