Page 1

INSTRUCTION MANUAL

FOR

DIRECTIONAL POWER RELAYS

BE1-32R AND BE1-32O/U

Publication: 9171100990

Revision: T 01/13

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-32R and

BE1-32O/U Directional Power Relays. To accomplish this, the following information is provided:

General Information and Specifications

Controls and Indicators

Functional Description

Installation

Tests and Adjustments

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12 AWG

copper wire attached to the ground terminal on the rear of the unit case. When

the relay is configured in a system with other devices, it is recommended to use a

separate lead to the ground bus from each unit.

9171100990 Rev T BE1-32R, BE1-32O/U Introduction i

Page 4

First Printing: September 1986

Printed in USA

© 2013 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

January 2013

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use, subject

to return on request, and with the mutual understanding that it will not be used in

any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-32R, BE1-32O/U Introduction 9171100990 Rev T

Page 5

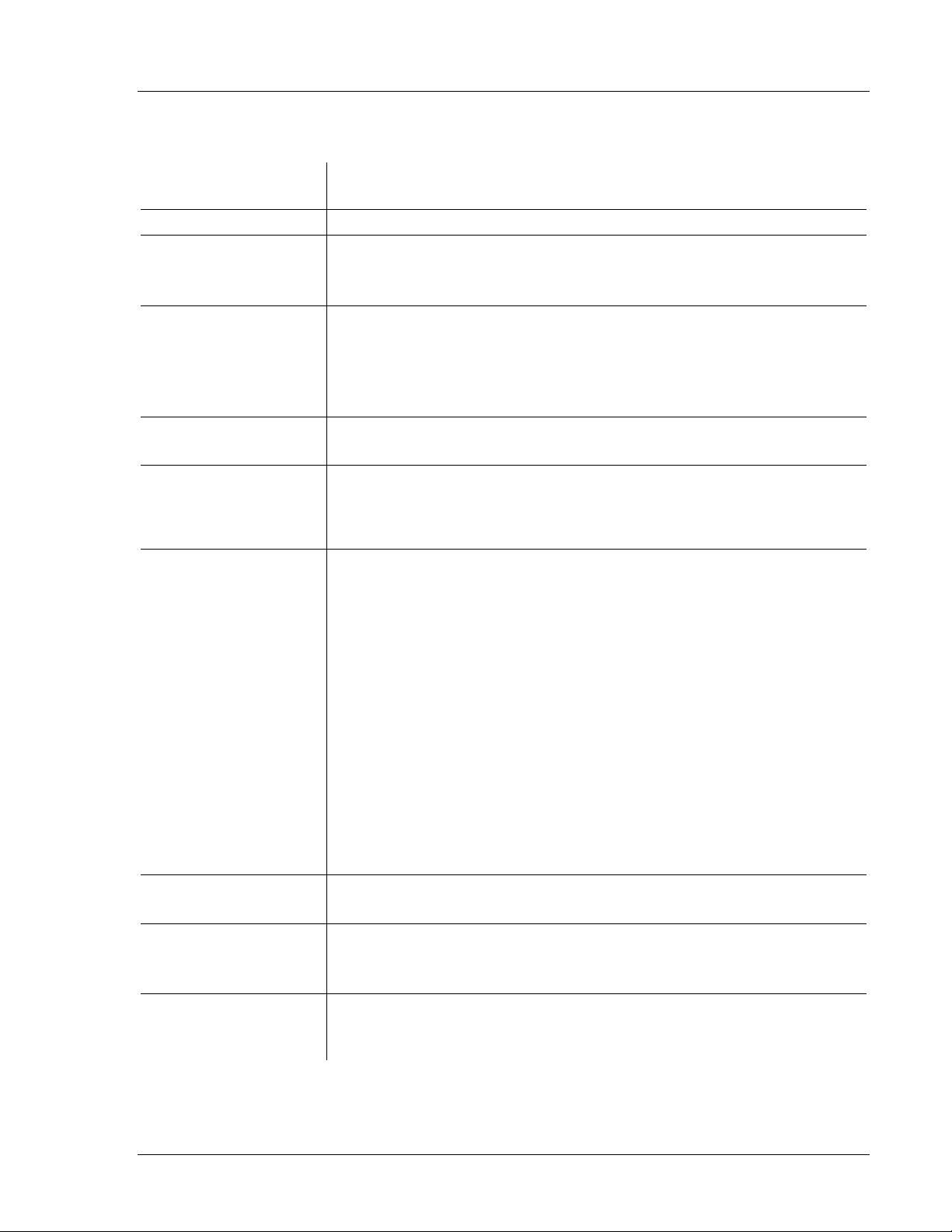

REVISION HISTORY

The following information provides a historical summary of the changes made to the BE1-32R and BE132O/U instruction manual (9171100990). Revisions are listed in reverse chronological order.

Manual

Revision and Date

T, 01/13

S, 05/10

R, 09/07

P, 11/06

N, 08/05

M, 10/03

L, 08/02

K, 08/01

J, 09/00

Updated case and cover drawings in Section 4.

Replaced Figure 4-4, Panel Drilling/Cutout for M1 Case.

Added Notes for Figure 4-16, Control Circuit Diagram.

Added Storage statement in Section 4.

Added manual part number and revision to all footers.

Updated Power Supply Burden data in Section 1.

Updated Target Indicator description in Section 3.

Moved content of Section 6, Maintenance to Section 4 and deleted

Section 6.

Updated Table 1-1 Steam Turbine Percent of Rated kW.

Added GOST-R to Specifications in Section 1.

In Section 1 and 3, where applicable, added recommendation against

using relay with power factors below 0.10.

Corrected the shorting bar illustration across terminals 8 and 9 in

Figures 4-17, 4-18, 4-19, and 4-20.

Replaced cover illustrations and Figure 2-1 with drawing showing

revised front panel layout.

Modified style chart (Figure 1-11) to clarify sensing input range

selection.

Modified the function block diagram of Figure 3-1.

Added information to Section 3 about sensing input range 1, 4, and 7

current ratings and burden.

Deleted Tables 3-1, 3-2, and 3-3. (These tables are duplicates of the

tables already provided in Section 1.) Modified the text references

accordingly.

Reorganized the Section 4 mounting drawings according to type:

drilling, outline-rear view, outline-side view, and outline-cover.

Deleted Section 4 dielectric test information (already provided in

Section 1).

Moved manual revision information from Section 7 to introduction

section of the manual.

Revised Figure 1-14 to illustrate the new 32R inverse time curves.

Corrected various minor errors throughout the manual.

Improved Pickup description in Section 3.

Revised Figures 4-2 and 4-12 to show slotted knob on the front panel.

Revised Figure 4-4.

Updated the outline drawings in Section 4 to show new case cover

design.

Removed the selectable power supply option from the style chart.

Change

9171100990 Rev T BE1-32R, BE1-32O/U Introduction iii

Page 6

Manual

Revision and Date

H, 06/98

G, 07/95

F, 06/94

E, 02/94

Change

Deleted references to Service Manual 9171100620.

Changed power supply voltage and burden data listed in Section 1.

Added information to instantaneous response time specification in

Section 1.

Added Figure 1-13 and associated paragraphs describing the

underpower element.

Corrected the power supply entries in the style chart.

Add information to the pickup accuracy specification in Section 1.

Added information to the Power Supply paragraph in Section 3.

Added outline drawings to cover all available case options.

Changed the case ground symbol shown in the Internal Connection

diagrams.

Revised the manual format.

Revised the pickup accuracy stated in Specifications of Section 1.

Corrected isolation specification in Section 1 and dielectric test values

in Section 4.

Added Note 3 to Figure 4-20.

Corrected CT sensing connections in Figure 4-21.

Moved polarity indications in Figure 4-25.

Deleted 30 label in Figure 5-5 and corrected equation.

Added 120 Vac label to Figure 1-11.

Changed reference for Figure 1-12 from Specifications, Timing

Accuracies to Timing Adjustment Range.

Added Figure 1-13.

Corrected input sensing terminal numbers in Figure 4-23.

Deleted reference to Figure 3-8 (Figure 3-8 was replaced by Figure 1-

13.)

Added internal connection and typical connection diagrams to Section

4.

Added Phase Rotation Sensitivity to Section 1.

Revised the format of the manual.

iv BE1-32R, BE1-32O/U Introduction 9171100990 Rev T

Page 7

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • CONTROLS AND INDICATORS ........................................................................................ 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

SECTION 5 • TESTING ............................................................................................................................ 5-1

9171100990 Rev T BE1-32R, BE1-32O/U Introduction v

Page 8

This page intentionally left blank.

vi BE1-32R, BE1-32O/U Introduction 9171100990 Rev T

Page 9

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

INTRODUCTION.................................................................................................................................... 1-1

APPLICATION ....................................................................................................................................... 1-1

Example 1: Anti-Motoring ................................................................................................................... 1-1

Example 2: Co-Generator Control ...................................................................................................... 1-2

Example 3: Generator Overload ........................................................................................................ 1-3

Example 4: Intertie ............................................................................................................................. 1-3

Example 5: Delayed Electrical Trip .................................................................................................... 1-4

Example 6: Breaker Opening Detection ............................................................................................. 1-4

Example 7: Reactive Power (Vars) Detection .................................................................................... 1-6

MODEL AND STYLE NUMBER ............................................................................................................. 1-7

Style Number Example ....................................................................................................................... 1-8

SPECIFICATIONS ................................................................................................................................. 1-9

Current Sensing ................................................................................................................................. 1-9

Voltage Sensing ................................................................................................................................. 1-9

Targets ............................................................................................................................................... 1-9

Output Circuits .................................................................................................................................. 1-10

Power Supply ................................................................................................................................... 1-10

Pickup ............................................................................................................................................... 1-10

Timing ............................................................................................................................................... 1-10

Timing—continued ........................................................................................................................... 1-13

Power Range (Pickup) ..................................................................................................................... 1-13

Type Tests ........................................................................................................................................ 1-13

UL Recognition ................................................................................................................................. 1-14

GOST-R ............................................................................................................................................ 1-14

Temperature ..................................................................................................................................... 1-14

Weight .............................................................................................................................................. 1-14

Figures

Figure 1-1. Single-Phase ........................................................................................................................... 1-1

Figure 1-2. Power Relay Start Control....................................................................................................... 1-2

Figure 1-3. Power Relay Start/Stop Control .............................................................................................. 1-3

Figure 1-4. Power Relay Distribution Protection ....................................................................................... 1-3

Figure 1-5. Single-Phase, Non-Electrical Trip Supervision ....................................................................... 1-4

Figure 1-6. Breaker Opening Detection ..................................................................................................... 1-4

Figure 1-7. Power Factor, First and Second Quadrants............................................................................ 1-5

Figure 1-8. Power Factor, Third and Fourth Quadrants ............................................................................ 1-5

Figure 1-9. Underpower Tripping ............................................................................................................... 1-5

Figure 1-11. Modified Type A Sensing ...................................................................................................... 1-7

Figure 1-12. Style Number Identification Chart ......................................................................................... 1-8

Figure 1-13. Overpower Instantaneous Response Time......................................................................... 1-11

Figure 1-14. Underpower Instantaneous Response Time....................................................................... 1-11

Figure 1-15. Overpower Inverse Time Characteristic Curves ................................................................. 1-12

Tables

Table 1-1. Motoring Reverse Power Requirements .................................................................................. 1-2

Table 1-2. Current Sensing Burden in Ohms ............................................................................................ 1-9

Table 1-3. Power Supply Specifications .................................................................................................. 1-10

Table 1-4. Power Pickup Ranges ............................................................................................................ 1-13

9171100990 Rev T BE1-32R, BE1-32O/U General Information i

Page 10

This page intentionally left blank.

ii BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 11

SECTION 1 • GENERAL INFORMATION

INTRODUCTION

BE1-32R, Directional Overpower and BE1-32O/U, Directional Over/Underpower Relays sense real power

(IE times the cosine of θ). These solid-state relays are designed for use in single- or three-phase systems

to protect equipment against overpower and/or underpower conditions. They may also be used in the

supervisory control of circuits.

APPLICATION

Directional Power Relays are typically used in applications where excessive power flow in the tripping

direction is bad. Over and/or underpower protection is desirable where:

• Power flows into a generator, indicating loss of prime mover torque (motoring).

• Power flows into the secondary of a station distribution transformer, indicating an industrial or private

customer is supplying power into the utility system.

• Excessive load has been connected to a system.

• Overload has been placed on a distribution system.

• Overspeeding is a prime concern.

• An open breaker creates an overload on a local generation facility.

• Loss of excitation can be determined by var sensing.

NOTE

This product is not recommended for power factors below 0.10. Contact Basler

Electric for recommended products.

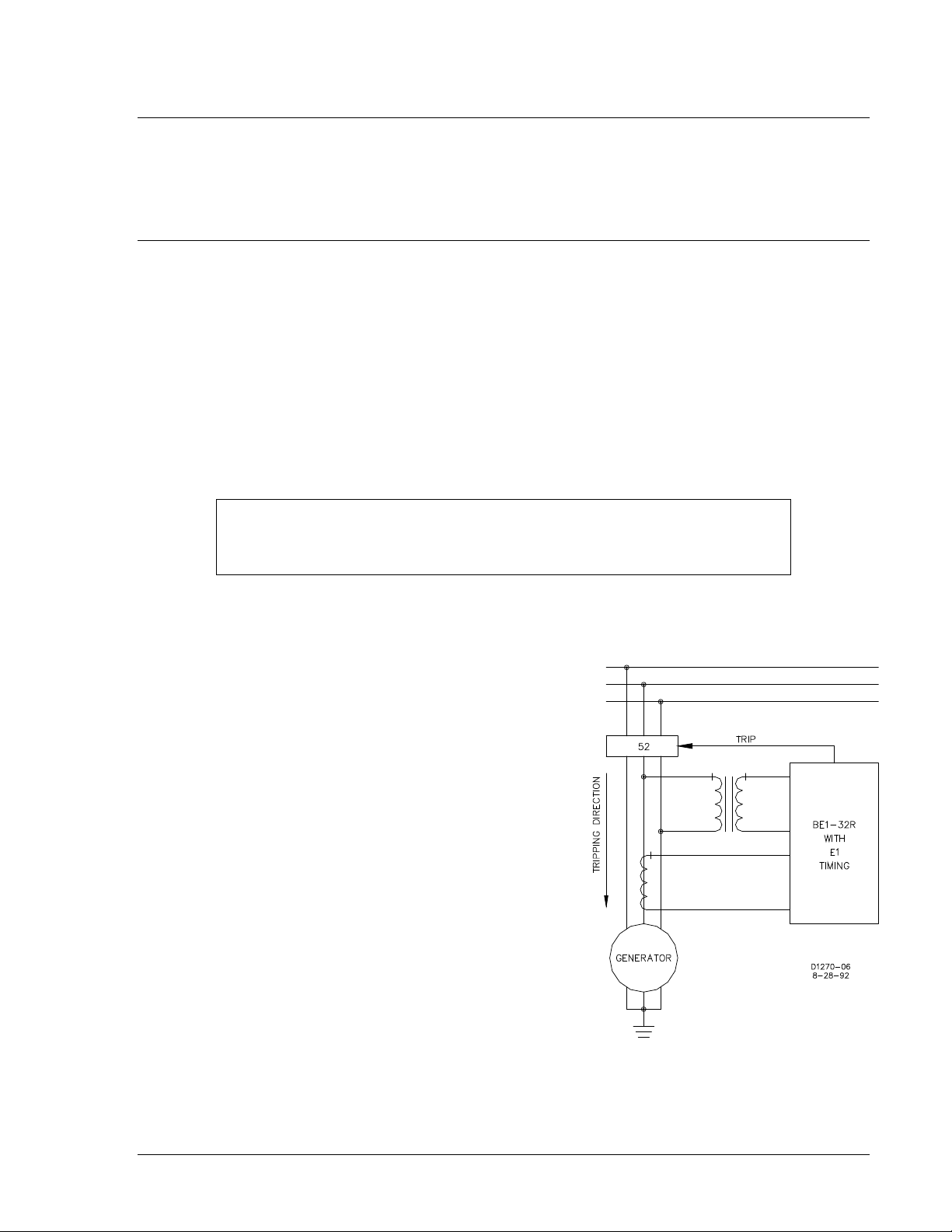

Example 1: Anti-Motoring

When a synchronous generator, operating in parallel

with a power system, loses prime mover torque, it

remains in synchronism with the system and continues

to run as a synchronous motor. Motoring draws power

from the system to drive the prime mover and can cause

severe damage to the prime mover. Steam turbines

require a constant flow of steam to remove the heat

caused by turbulence or cavitations on or about the

blades. Without this flow of steam, heat builds up and

may cause softening or distortion of the turbine blades.

Diesel engines and gas turbines are less susceptible to

immediate damage, but unburned fuel may present a fire

or explosion hazard.

BE1-32 Directional Power Relays can detect power flow

into the generator and disconnect the generator before

the prime mover sustains inevitable damage. Unlike the

conditions arising from faults, the electrical conditions

involved in anti-motoring protection are balanced.

Therefore, single-phase relay protection is adequate.

Figure 1-1 shows connections for single-phase relay

(type B or V sensing). This connection measures real

power if the system voltages are balanced.

The BE1-32R, Reverse Power Relay must be sensitive

enough to detect power levels lower than those required

to motor the generator. Sensitivity is much more

important on steam and hydro turbines than on

reciprocating engines and gas turbines.

Figure 1-1. Single-Phase

Motoring Protection

9171100990 Rev T BE1-32R, BE1-32O/U General Information 1-1

Page 12

Table 1-1 represents the reverse power requirements to motor a generator when the prime mover is

Prime Mover Type

Percent of Rated kW

rotating at synchronous speed with no input power supplied by the prime mover.

Table 1-1. Motoring Reverse Power Requirements

Hydro Turbine 0.2 to 2.0

Steam Turbine (condensing or non-condensing) 0.5 to 3.0

Diesel Engine (no cylinders firing) Up to 25

Gas Turbine Up to 50 (due to compressor load)

The Reverse Power Relay is generally set for levels as low as possible with steam turbines typically being

set not higher than three percent and diesels and gas turbines slightly below ten percent.

Time delays are usually employed to avoid nuisance tripping caused by reverse power transient surges

that may result from synchronizing or other system disturbances. These time delays are typically set from

2 to 10 seconds, but may be set as high as 30 seconds or more.

An operating condition with very low power levels at a low power factor may not be detected by this

product. For very low power levels at power factors of 0.10 or lower, contact Basler Electric for

recommended products.

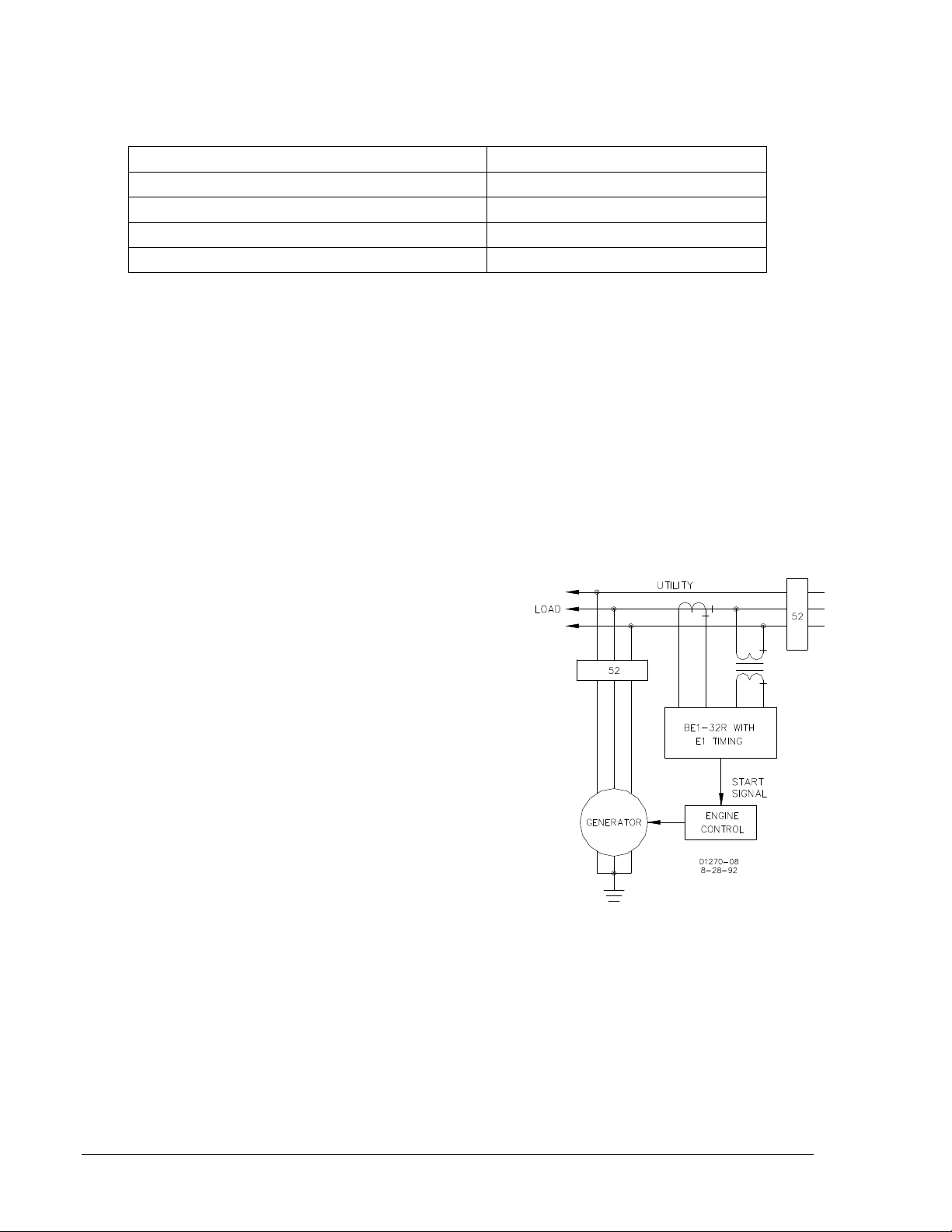

Example 2: Co-Generator Control

In this example, cogeneration concepts are addressed.

To illustrate, assume that the cogeneration system has

automatic engine controls, an auto-synchronizer,

automatic kW, and kvar controls. The system operates

virtually by itself. The only function lacking is the

start/stop signals to the generators. Two system

configurations may be implemented to generate contact

closures for start/stop signals.

The first configuration (Figure 1-2) shows a directional

power relay connected to the utility to sense kW. The

pickup point of the relay is set at the maximum desired

utility power level. When the utility power level exceeds

the relay pickup point, the output relay contact closes

and the generator is automatically started and paralleled

with the utility. A time delay is generally included in the

start circuit of about 15 or more seconds to ignore

transient overload conditions.

When the generator is paralleled and loaded, the kW

signal of the utility decreases by the amount of load the

generator has accepted. An underpower relay can

measure utility power and generate a stop signal when

the utility power decreases below a selected level. A

time delay is typically provided for the stop signal of one

minute or more (however, time delays are totally user

controlled). The Basler Electric Model BE1-32O/U Power

Relay incorporates both overpower and underpower

sensing in a single relay unit and is ideal for this type of

application.

Figure 1-2. Power Relay Start Control

1-2 BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 13

In the second configuration, the start signal is generated in the same manner as that of Figure 1-2. The

start signal setpoint may be set above the import power setting. The stop signal will require an

underpower relay on the generator output. This system is illustrated in Figure 1-3.

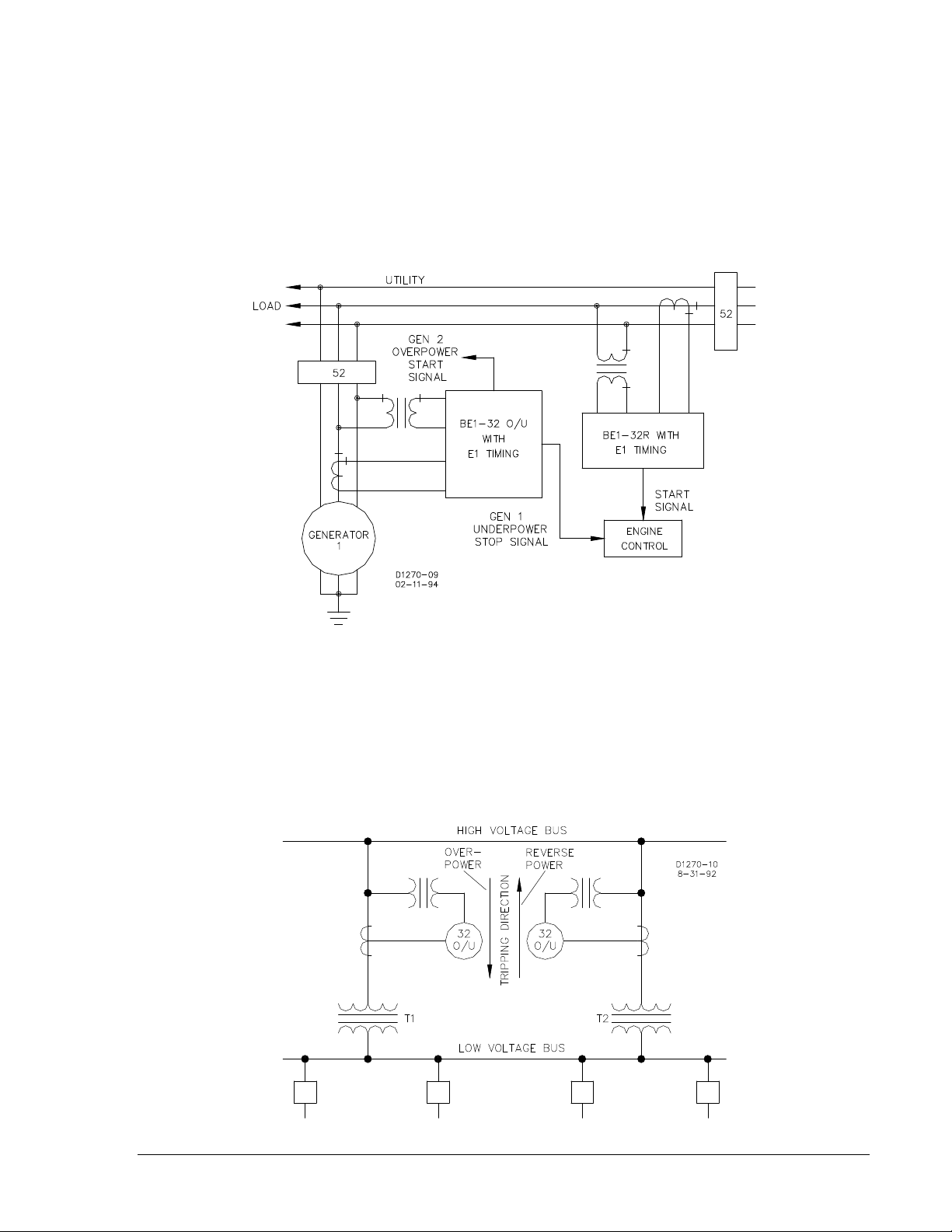

Example 3: Generator Overload

When excessive load has been connected to a generating system, the directional power relay can initiate

corrective action. Corrective action could be energizing an alarm to alert the station operator. For

automated systems, corrective action could be initiating the sequence to either shed non-critical load or to

start and parallel an in-house generator to assume the excess load.

Figure 1-3. Power Relay Start/Stop Control

Example 4: Intertie

Another typical use of the directional power relay, addresses excessive load and concerns distribution

protection (Figure 1-4). A high voltage bus supplies two transformers: T1 and T2. Both T1 and T2 can

supply all connected load. However, neither T1 nor T2 alone can supply the total load. A BE1-32O/U,

over/underpower directional relay can protect this distribution system by providing overload protection for

each transformer (overpower function) or by sensing power flow through the transformers (reverse power

function) in an undesired direction.

Figure 1-4. Power Relay Distribution Protection

9171100990 Rev R BE1-32R, BE1-32O/U General Information 1-3

Page 14

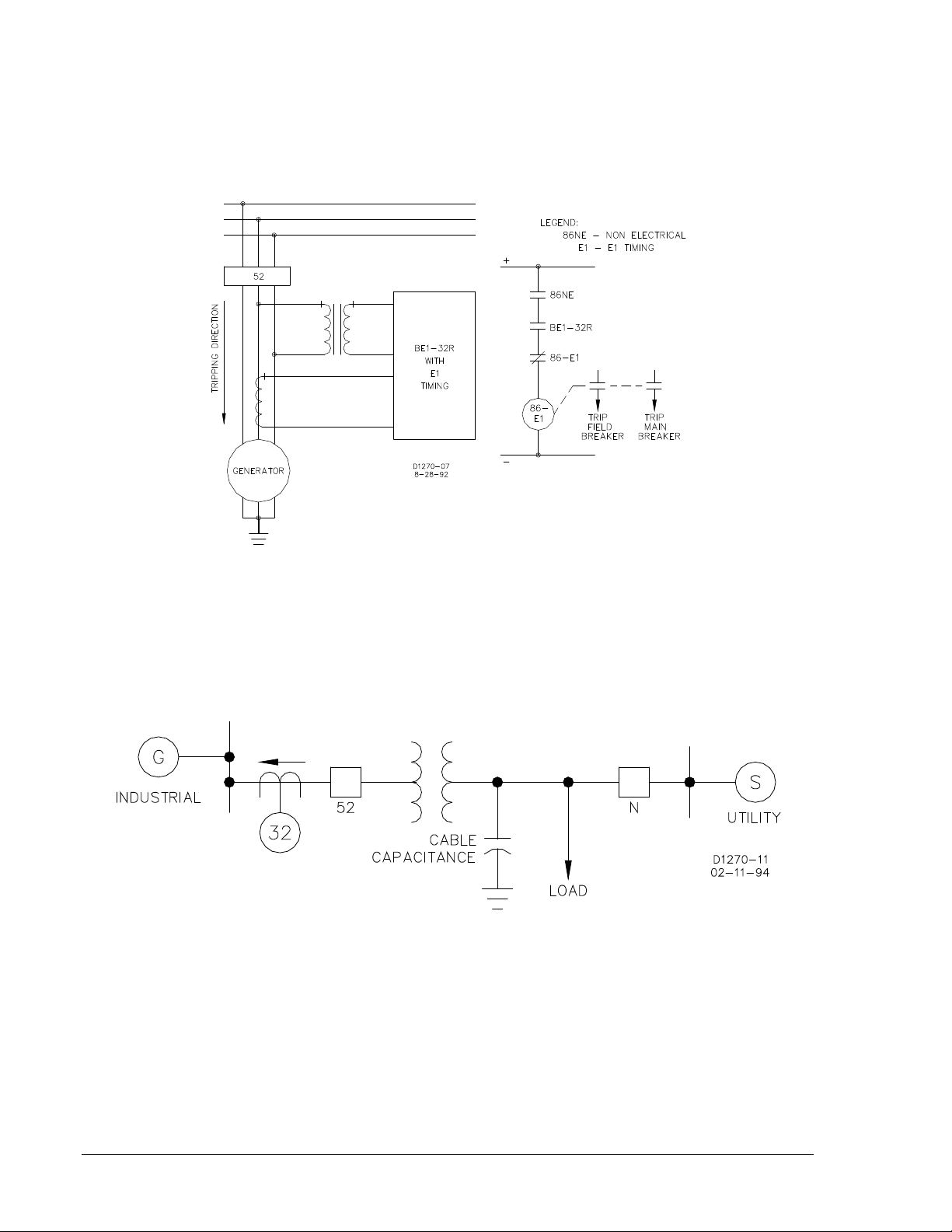

Example 5: Delayed Electrical Trip

On large steam units, where overspeeding is a prime concern, a reverse power relay can be used to

supervise electrical tripping (field and main ac breakers) for selected relay operations (e.g., non-electrical

trips, loss of field relay), as shown in Figure 1-5. The reverse power relay delays breaker tripping until

trapped steam has been removed from the piping. In this case, a separate direct-tripping anti-motoring

relay can be used to protect for situations not related to an automatic shutdown of the unit.

Figure 1-5. Single-Phase, Non-Electrical Trip Supervision

Example 6: Breaker Opening Detection

Figure 1-6 shows a reverse power relay used to detect the opening of a source at an industrial (or other

independent generation) location. A location with no generation but multiple ties from a common source is

a good candidate for this relay application. With local generation, the relay is applicable if the local

generation is not to deliver real power to the utility.

Figure 1-6. Breaker Opening Detection

Under near-floating conditions (minimal flow of real power from the utility), the relay can encounter a wide

range of power factor angles in the first and second quadrants (see Figure 1-7). If the local generation is

underexcited, reactive power is supplied by the utility and operation is in the first quadrant. Figure 1-7

shows the range of power factor angles (also in the first two quadrants) under heavy line loading.

Because of these power factors, the relay must not operate for any angle in the first and second

quadrants.

1-4 BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 15

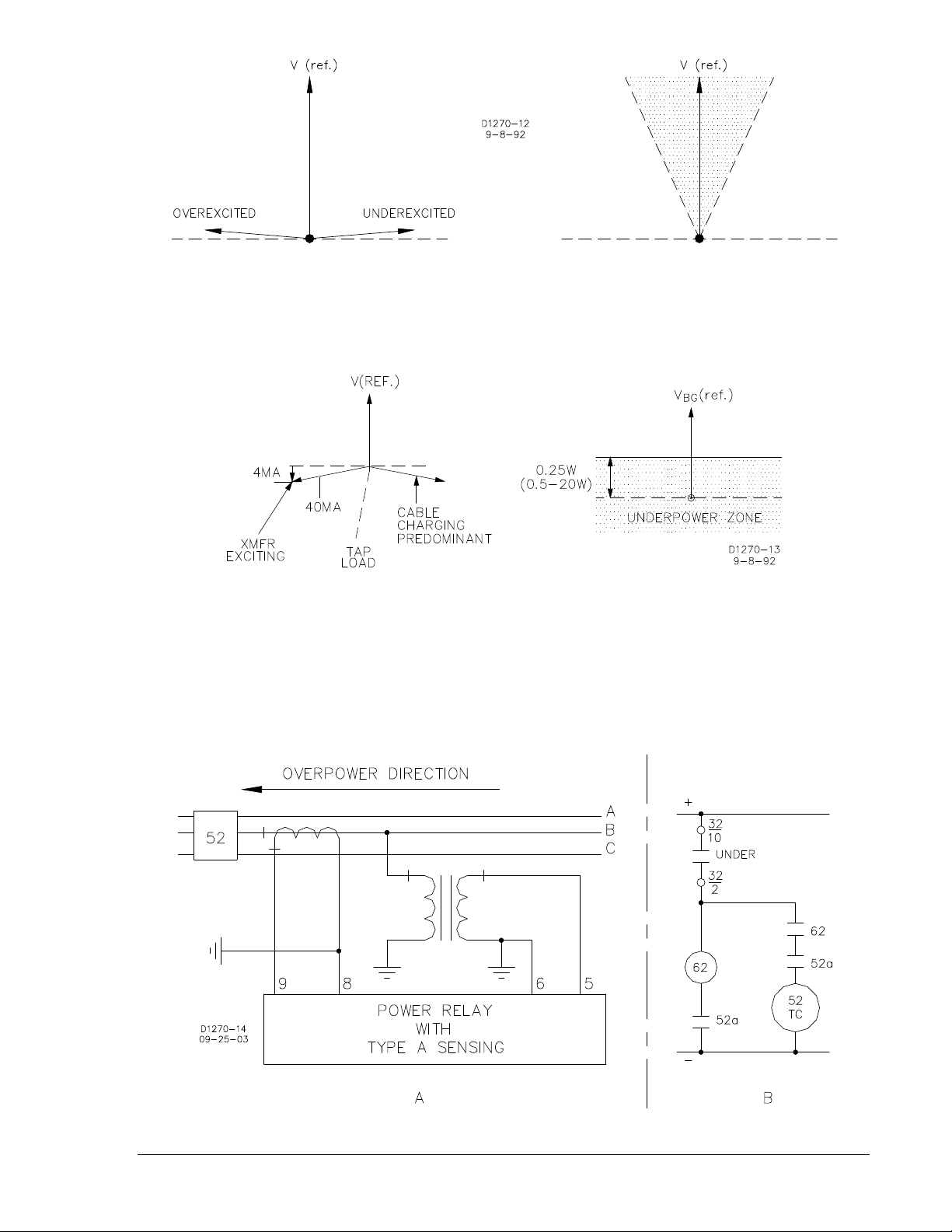

Figure 1-7. Power Factor, First and Second Quadrants

When breaker N opens, operation transfers to the third or fourth quadrants (see Figure 1-8). If transformer

exciting current predominates, operation falls in the third quadrant. If cable charging current predominates, operation falls in the fourth quadrant. In either case, the transformer losses must be supplied.

In Figure 1-8, a real current component of four milliamperes is shown and represents core losses of the

transformer (about 0.1% of rated).

Figure 1-8. Power Factor, Third and Fourth Quadrants

When breaker N opens, real power reverses from normal and flows toward the utility. This power may be

flowing to the tapped load. At this time, the relay operates and causes the 52 breaker to open.

Figure 1-9A shows an underpower tripping application based on the BE1-32O/U, model A1F with an

overpower setting of 0.5 watts and an underpower setting of 50%. The control circuit for this application is

shown in Figure 1-9B. Figure 1-10 shows the operating characteristic in the first and second quadrant.

The relay Under contact closes to trip the breaker when the real power flow from the utility drops below

0.25 watts. Because this contact is pre-closed at the instant of breaker closing, the trip circuit must be

disabled by a timing relay (62) until after the breaker has closed.

Figure 1-9. Underpower Tripping

9171100990 Rev R BE1-32R, BE1-32O/U General Information 1-5

Page 16

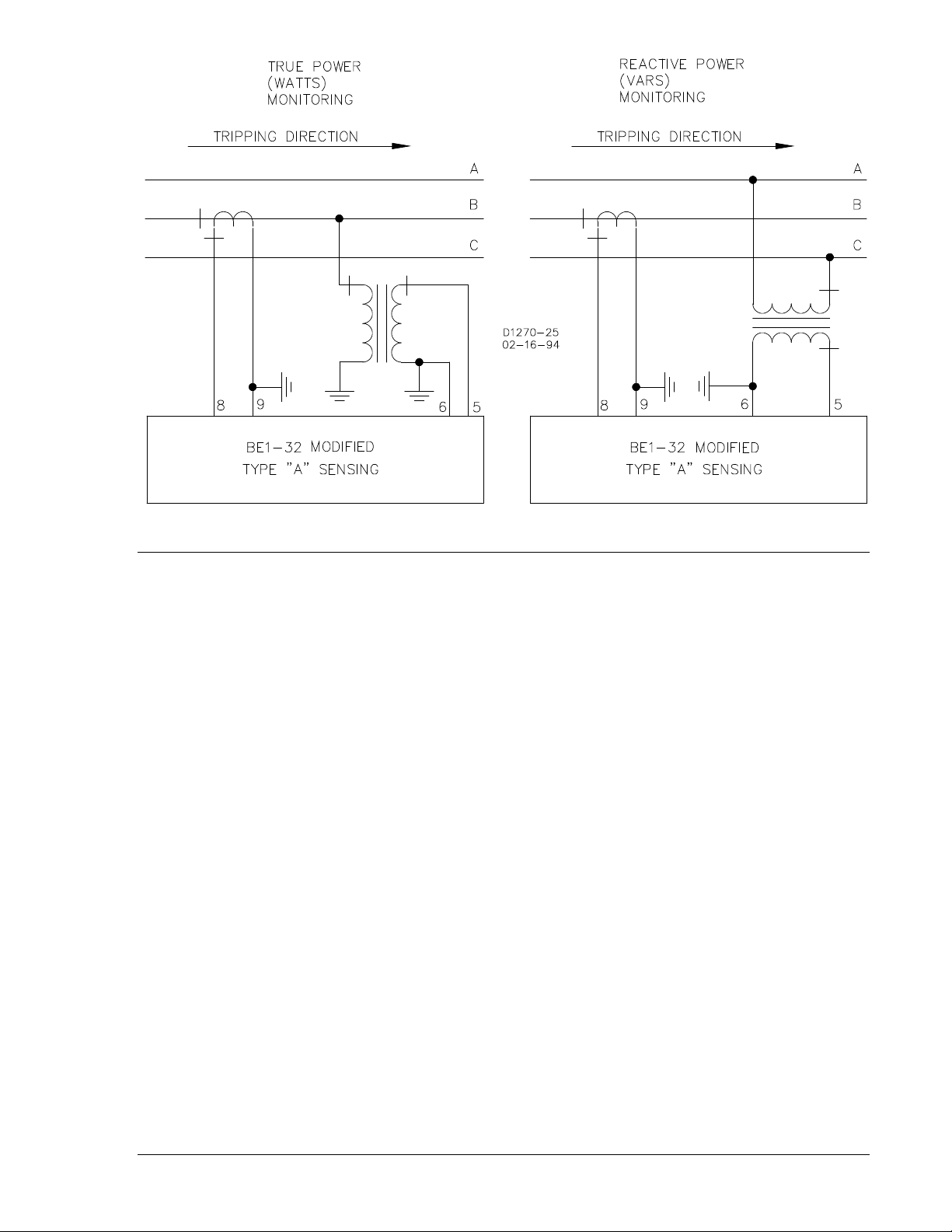

Example 7: Reactive Power (Vars) Detection

Figure 1-10. True

This example illustrates a directional power relay configured to distinguish between real and reactive

power. Real power (watts) is supplied to the synchronous generator by the prime mover, and reactive

power (vars) is supplied to the field by the exciter. When field excitation is significantly reduced and the

connected system can provide sufficient reactive power to maintain the generator terminal voltage,

reactive power flows into the machine and causes it to operate as an induction generator with essentially

the same kW output. This situation causes two major problems. First, the additional reactive loading of

the faulty generator must be redistributed to other synchronous generators on the system. Secondly, a

synchronous generator is not designed to operate as an induction generator. Excessive heating results in

the damper (amortisseur) windings, slot wedges, and in the surface iron of the rotor due to the slip

frequency current flow when a synchronous generator is operated as an induction generator.

BE1-32R and BE1-32O/U Directional Power Relays are designed to respond to true power (P) as defined

by the following equation and illustrated in Figure 1-10.

P = EI (cos θ)

where: P = real power (watts)

I = effective current

E = effective EMF or system voltage

θ = the power factor angle

However, reactive power (Q) is defined by the equation:

Q = EI (sin θ)

Using the trigonometric identity sine θ = cos(θ – 90 )

then: Q = EI (cos(θ – 90 ))

If the phase of the sensed voltage is shifted +90°, the true power relay can be used to monitor reactive

power. In practice, this can be accomplished by applying the appropriate line-to-line voltage to a true

power measuring relay designed for line-to-neutral sensing. Figure 1-11 illustrates how a single-phase

BE1-32R or BE1-32O/U can be connected to measure either real power (watts) or reactive power (vars)

flow in a three-phase system. Note the difference of phase relationship between the alternate connections

in Figure 1-11.

1-6 BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 17

Figure 1-11. Modified Type A Sensing

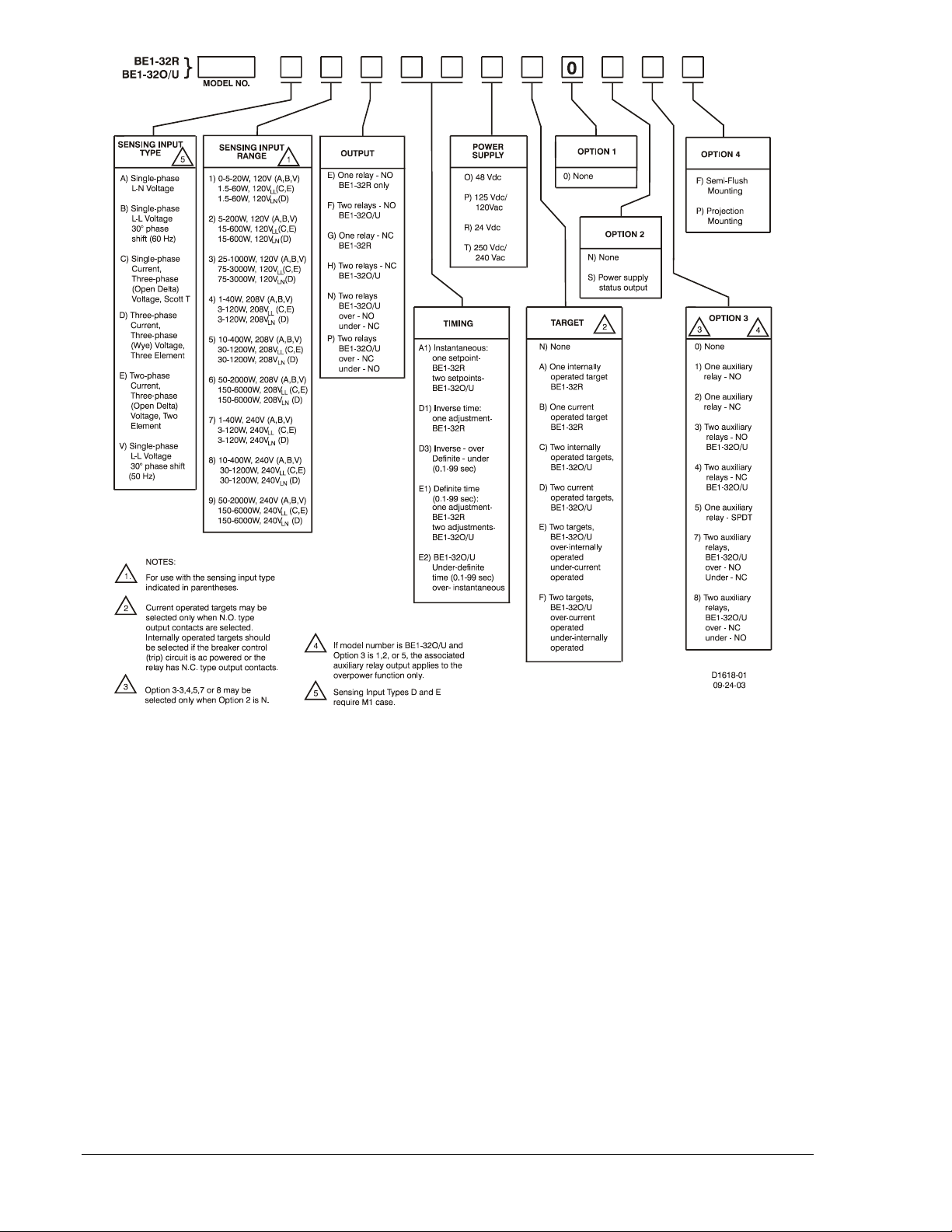

MODEL AND STYLE NUMBER

BE1-32R and -32 O/U Directional Power Relays electrical characteristics and operational features are

defined by a combination of letters and numbers that make up the style number. Model numbers BE132R or BE1-32O/U designate the relay as a Basler Electric, Class 100, Directional Power Relay. The

model number and style number describe the options included in a specific device, and appear on the

front panel, draw-out cradle, and inside the case assembly. Upon receipt of a relay, be sure to check the

style number against the requisition and the packing list to ensure that they agree.

The style number chart is shown in Figure 1-12.

9171100990 Rev R BE1-32R, BE1-32O/U General Information 1-7

Page 18

Figure 1-12. Style Number Identification Chart

Style Number Example

If a BE1-32R Directional Overpower Relay is ordered with a style number of A1GA1PA0N1F, the relay

would have the following features.

A ------- Single-phase current sensing and line-to-neutral voltage sensing

1 -------- 120 Vac, 0.5 to 20 W sensing input range

G ------- One output relay with normally closed (N.C.) contacts

A1 ------ Instantaneous timing characteristics with one setpoint

P ------- 125 Vdc/120 Vac power supply

A ------- One internally operated target

0 -------- No option 1

N ------- No power supply status output

1 -------- One normally-open, auxiliary output relay

F -------- Semi-flush mounting case

1-8 BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 19

SPECIFICATIONS

Range

Sensing Input Range

1, 4, 7 *

2, 5, 8

3, 6, 9

Low

High

Low

High

Low

High

Tap A

4.811

0.400

0.096

0.022

0.013

0.010

Tap B

2.466

0.240

0.058

0.019

0.012

0.010

Tap C

1.677

0.190

0.045

0.018

0.011

0.010

Tap D

1.277

0.165

0.039

0.018

0.011

0.010

Tap E

1.036

0.151

0.034

0.017

0.011

0.010

Tap F

0.874

0.142

0.032

0.017

0.011

0.010

Tap G

0.760

0.134

0.030

0.017

0.011

0.010

Tap H

0.674

0.129

0.0029

0.017

0.011

0.010

Tap J

0.611

0.126

0.028

0.017

0.011

0.010

Tap K

0.556

0.123

0.027

0.017

0.011

0.010

Current Sensing

BE1-32R and -32 O/U Directional Power Relays are designed for use with five amperes nominal (50/60

HZ) system current transformer secondaries. The input sensing current transformers within the relay are

rated as follows.

Sensing Input Ranges 1, 4, and 7 *

Continuous Rating: 7 A

1 Minute Rating: 10 A

1 Second Rating: 140 A

* Refer to Section 3, Functional Description, Current Sensing for sensing input range 1, 4, and 7 current

rating and burden considerations.

Sensing Input Ranges 2, 3, 5, 6, 8, and 9

Continuous Rating: 10 A

1 Minute Rating: 15 A

1 Second Rating: 200 A

Burden

Burden values (in ohms) are listed for each sensing input range in Table 1-2.

Table 1-2. Current Sensing Burden in Ohms

* See Section 3, Functional Description, Current Sensing for sensing input range

1, 4, and 7 burden considerations.

Voltage Sensing

Voltage signals are provided by the secondary windings of standard potential transformers (100/200, 50

Hz or 120/240, 60 Hz).

Continuous Voltage Rating: 150% of nominal

Burden: <1 VA

Targets

Electronically latched, manually reset target indicators are optionally available to indicate that a trip output

contact has been energized. Either internally operated or current operated targets may be selected.

Internally operated targets should be selected if the relay has normally closed output contacts.

Current Operated Targets

Minimum Required Current: 200 mA

Continuous Rating: 3 A

2 Minute Rating: 7 A

1 Second Rating: 30 A

9171100990 Rev R BE1-32R, BE1-32O/U General Information 1-9

Page 20

Output Circuits

Resistive Ratings

120 Vac: Make, break, and carry 7 Aac continuously

250 Vdc: Make and carry 30 Adc for 0.2 s, carry 7 Adc continuously, and break 0.3 Adc

500 Vdc: Make and carry 15 Adc for 0.2 s, carry 7 Adc continuously, and break 0.3 Adc

Inductive Ratings

120 Vac, 125 Vdc, 250 Vdc: Break 0.3 A (L/R = 0.04)

Power Supply

Power supply specifications are listed in Table 1-3. All ac references are at 50/60 Hz.

Table 1-3. Power Supply Specifications

Input Voltage

Type

Nominal Range

O (mid range) 48 Vdc 24 to 150 Vdc 3.6 W

Burden at Nominal

P (mid range)

R (low range) 24 Vdc

T (high range)

* Type R power supply may require 14 Vdc to begin operation. Once operating, the voltage may be

reduced to 12 Vdc.

Pickup

Single-Phase Accuracy

PF = 1: ±2 percent of front panel setting or 0.05 W, whichever is greater

0.5<PF<1: ±5 percent of front panel setting or 0.05 W, whichever is greater

Three-Phase Accuracy

PF =1 ±2 percent of front panel setting or 0.15 W, whichever is greater

0.5<PF<1 ±5 percent of front panel setting or 0.15 W, whichever is greater

This product is not recommended for power factors below 0.10. Contact Basler Electric for recommended

products.

Dropout Accuracy

95% of actual pickup.

125 Vdc

120 Vac

250 Vdc

240 Vac

24 to 150 Vdc

90 to 132 Vac

12 to 32 Vdc *

68 to 280 Vdc

90 to 270 Vac

3.7 W

17.3 VA

3.7 W

3.8 W

24.6 VA

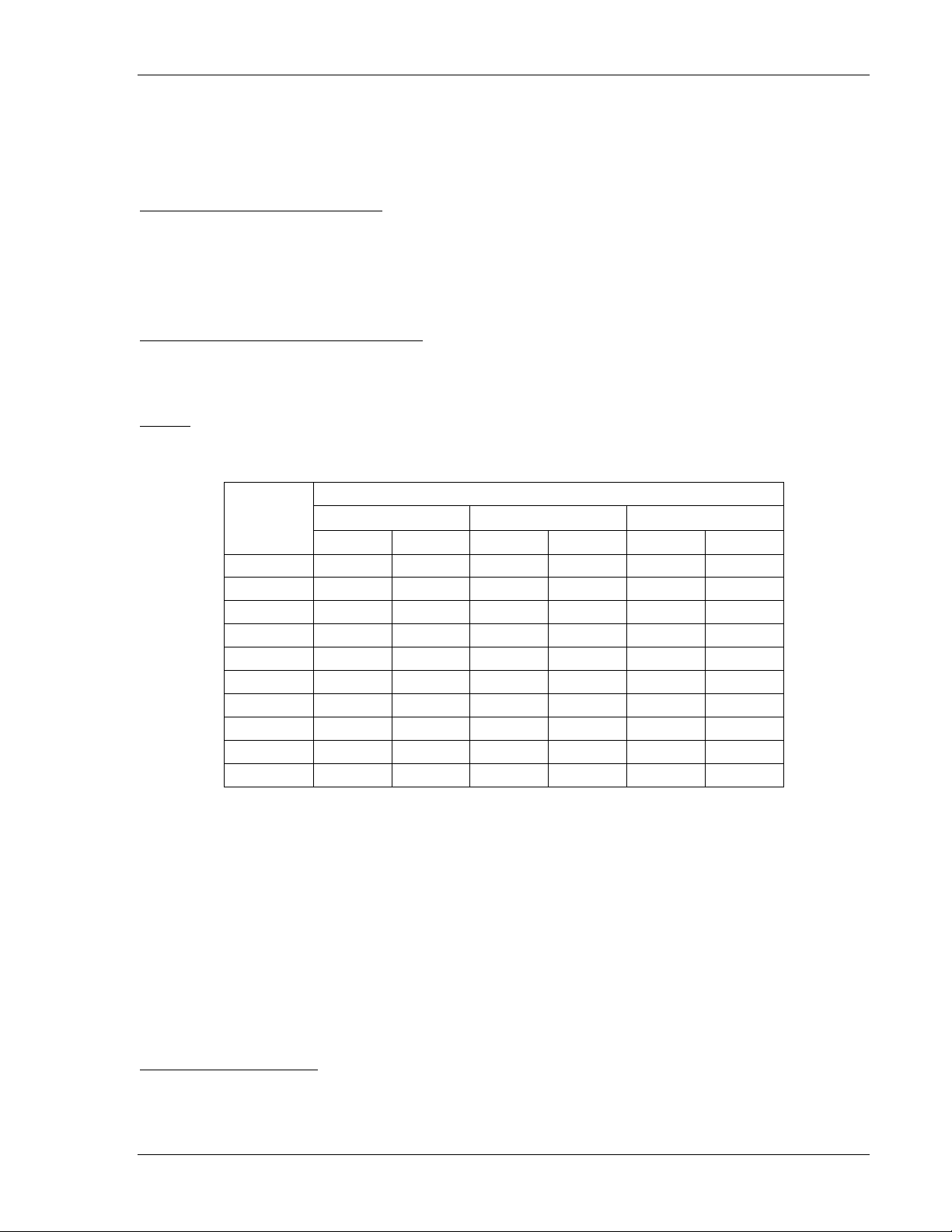

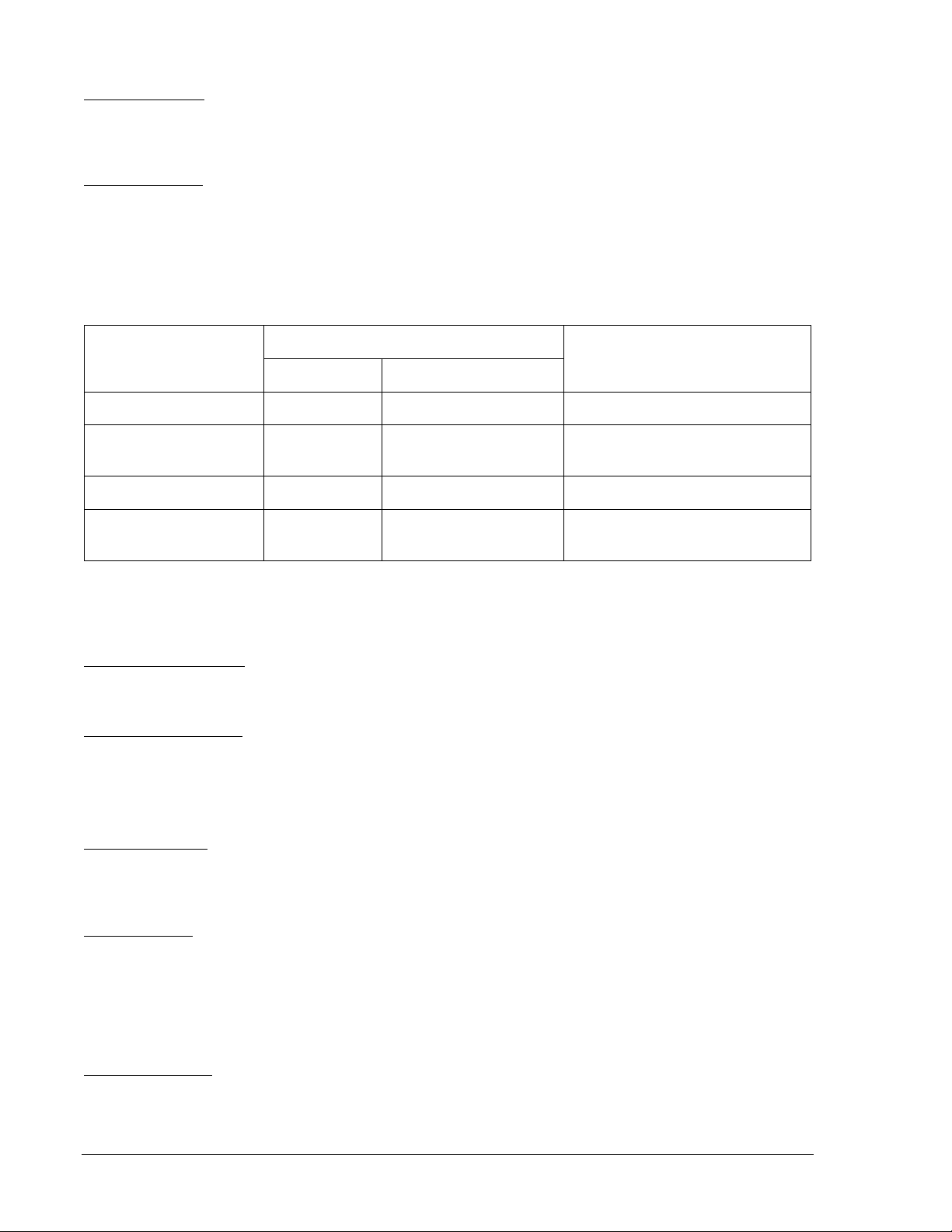

Timing

Response Time

Instantaneous Overpower: <80 ms (60 Hz) or <100 ms (50 Hz) for real power magnitude of

2 times the setting and greater. The response time is characterized by the graph in Figure 1-13.

Instantaneous Underpower: <50 ms (60 Hz) or <65 ms (50 Hz) for real power magnitude of

0.8 times the setting and less. The response time is characterized by the graph in Figure 1-14.

Adjustment Range

Definite Time: Thumbwheel adjustable over the range of 0.1 to 9.9 seconds in

increments of 0.1 seconds or by use of a multiplier switch, 1 to

99 seconds in increments of 01 seconds. A setting of 00 enables

instantaneous timing.

1-10 BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 21

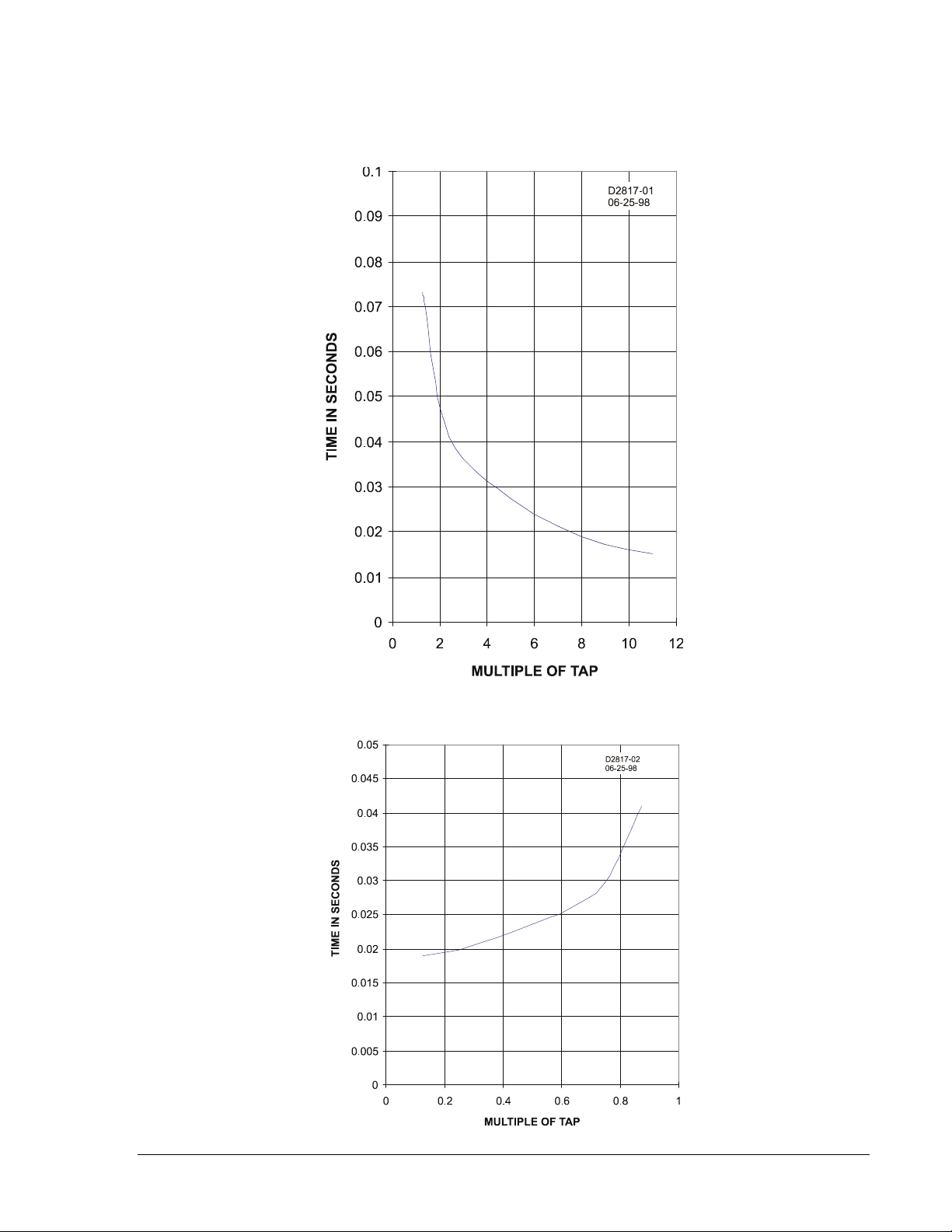

Inverse Time: Available for the overpower function only. Adjustment of the

Time Dial thumbwheel selects curves from 01 to 99 in

increments of 01. A setting of 00 enables instantaneous timing.

Refer to Figure 1-15 for examples of the overpower inverse time

characteristic curves.

Figure 1-13. Overpower Instantaneous Response Time

Figure 1-14. Underpower Instantaneous Response Time

9171100990 Rev R BE1-32R, BE1-32O/U General Information 1-11

Page 22

Figure 1-15. Overpower Inverse Time Characteristic Curves

1-12 BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 23

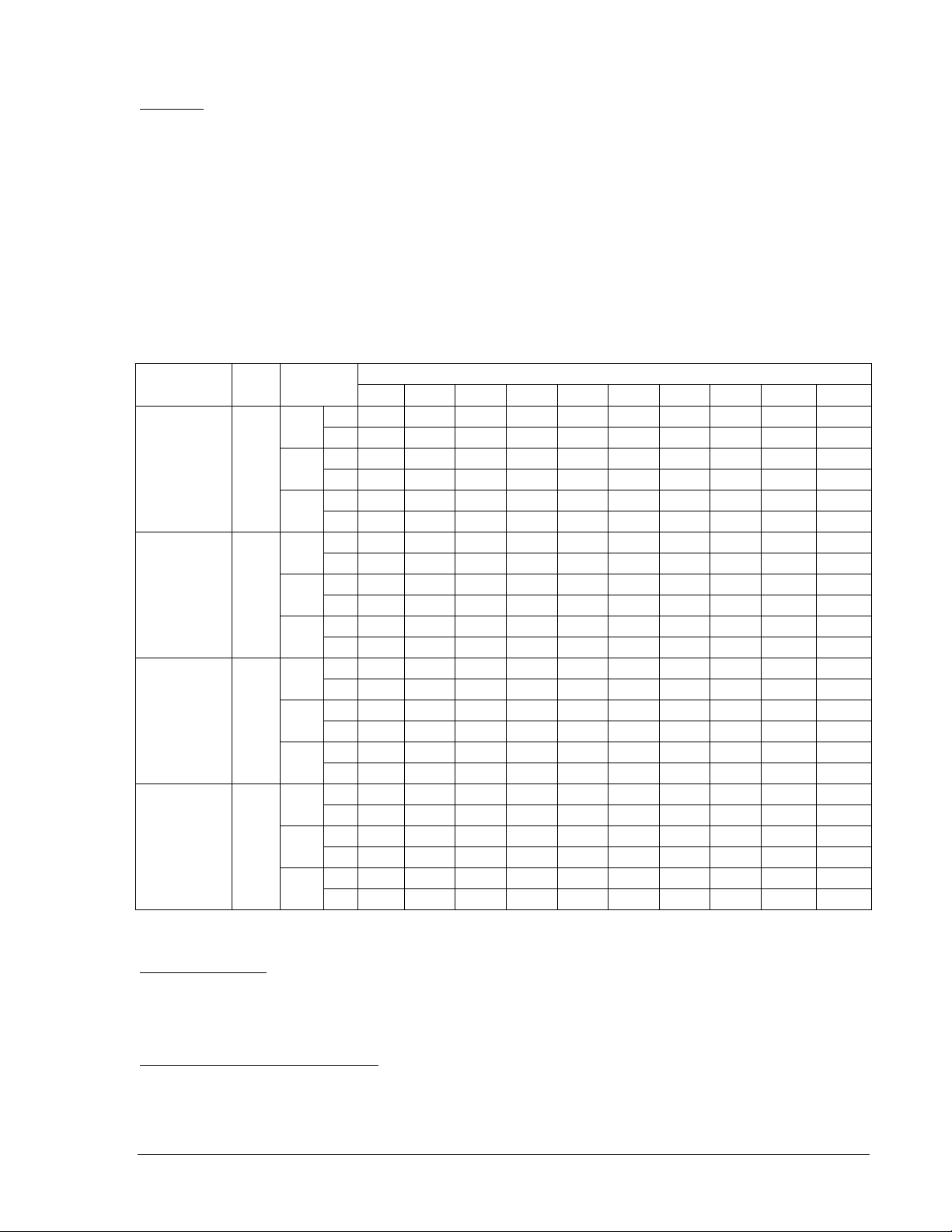

Timing—continued

Input Type

Nom.

Volts

Range

Switch Position (in watts)

A B C D E F G H J

K

A, B or V

120

1

Hi

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

Lo

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

2

Hi

20

40

60

80

100

120

140

160

180

200

Lo 5 10

15

20

25

30

35

40

45

50

3

Hi

100

200

300

400

500

600

700

800

900

1000

Lo

25

50

75

100

125

150

175

200

225

250

C, D, or E

120

1

Hi

6.0

12.0

18.0

24.0

30.0

36.0

42.0

48.0

54.0

60.0

Lo

1.5

3.0

4.5

6.0

7.5

9.0

10.5

12.0

13.5

15.0

2

Hi

60

120

180

240

300

360

420

480

540

600

Lo

15

30

45

60

75

90

105

120

135

150

3

Hi

300

600

900

1200

1500

1800

2100

2400

2700

3000

Lo

75

150

225

300

375

450

525

600

675

750

A, B, or V

208

4, 7

Hi

4.0

8.0

12.0

16.0

20.0

24.0

28.0

32.0

36.0

40.0

Lo

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

5, 8

Hi

40

80

120.

160

200

240

280

320

360

400

Lo

10

20

30

40

50

60

70

80

90

100

6, 9

Hi

200

400

600

800

1000

1200

1400

1600

1800

2000

Lo

50

100

150

200

250

300

350

400

450

500

C, D, or E

208

4, 7

Hi

12.0

24.0

36.0

48.0

60.0

72.0

84.0

96.0

108.0

120.0

Lo

3.0

6.0

9.0

12.0

15.0

18.0

21.0

24.0

27.0

30.0

5, 8

Hi

120

240

360

480

600

720

840

960

1080

1200

Lo

30

60

90

120

150

180

210

240

270

300

6, 9

Hi

600

1200

1800

2400

3000

3600

4200

4800

5400

6000

Lo

150

300

450

600

750

900

1050

1200

1350

1500

Accuracy

Instantaneous: <80 ms (60 Hz) or <100 ms, (50 Hz) up to a real power

magnitude of 2 times the setting

Definite: ±5 percent or 50 ms, whichever is greater

Inverse: +5 percent or 50 ms, whichever is greater

NOTE: Operating time is repeatable within 2% or 50 ms

(whichever is greater) for any combination of time dial and power

settings within the specified operating temperature range.

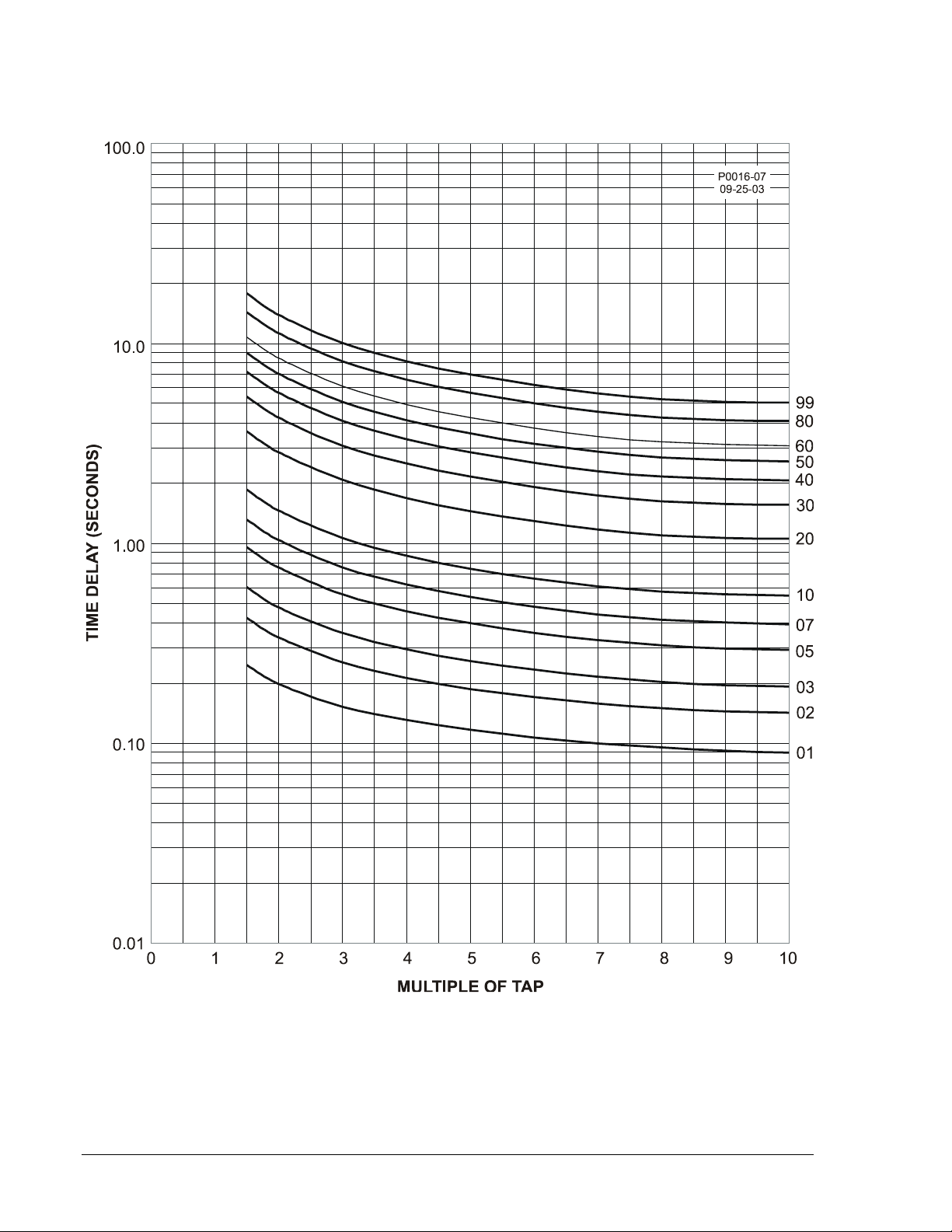

Power Range (Pickup)

The power pickup range is adjustable over the ranges listed in Table 1-4.

Table 1-4. Power Pickup Ranges

Sensing

1-phase

3-phase

1-phase

or

240

3-phase

or

240

Type Tests

Dielectric Strength

Tested in accordance with IEC 60255-5 and IEEE C37.90. Withstands the following tests.

All circuits to ground: 2,121 Vdc

Input to output circuits: 1,500 Vac or 2121 Vdc

Surge Withstand Capability (SWC)

Qualified to IEEE C37.90.1-1989, Standard Surge Withstand Capability (SWC) Tests for Protective

Relays and Relay Systems

9171100990 Rev R BE1-32R, BE1-32O/U General Information 1-13

Page 24

Radio Frequency Interference

Maintains proper operation when tested for interference in accordance with IEEE C37.90.2-1987,

Standard Withstand Capability of Relay Systems to Radiated Electromagnetic Interference from

Transceivers.

Shock

In standardized testing, the relay has withstood 15 G in each of three mutually perpendicular planes

without structural damage or degradation of performance.

Vibration

In standardized testing, the relay has withstood 2 G in each of three mutually perpendicular planes, swept

over the range of 10 to 500 Hz for a total of six sweeps, 15 minutes each sweep, without structural

damage or degradation of performance.

UL Recognition

Recognized per Standard 508, file number E97033. Note: Output contacts are not UL recognized for

voltages greater than 250 volts.

GOST-R

GOST-R certified per the relevant standards of Gosstandart of Russia.

Temperature

Operating: –40°C to 70°C (–40°F to 158°F)

Storage: –65°C to 100°C (–85°F to 212°F)

Weight

S1 Configuration: 13.5 lb (6.12 kg) maximum

M1 Configuration: 18.5 lb (8.39 kg) maximum

1-14 BE1-32R, BE1-32O/U General Information 9171100990 Rev T

Page 25

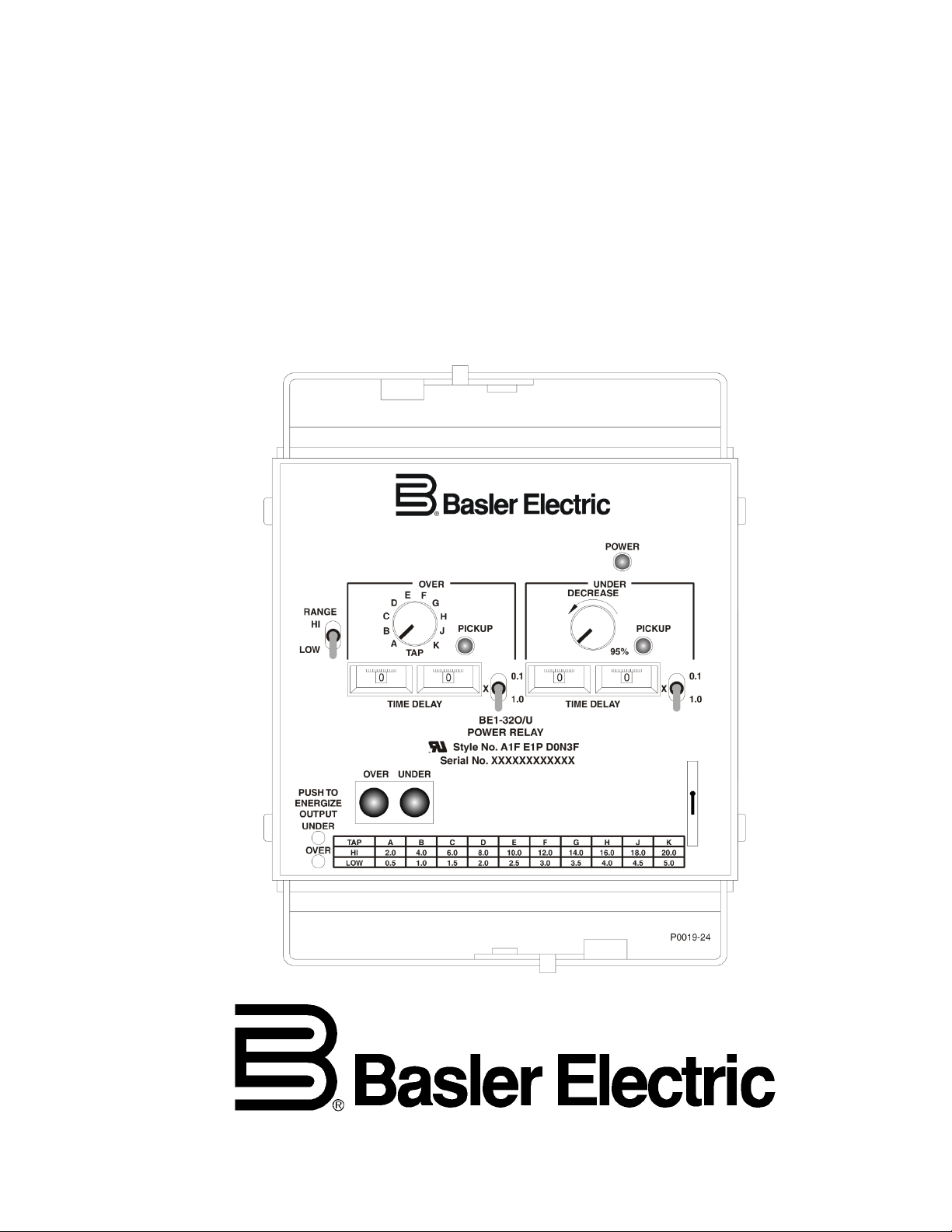

SECTION 2 • CONTROLS AND INDICATORS

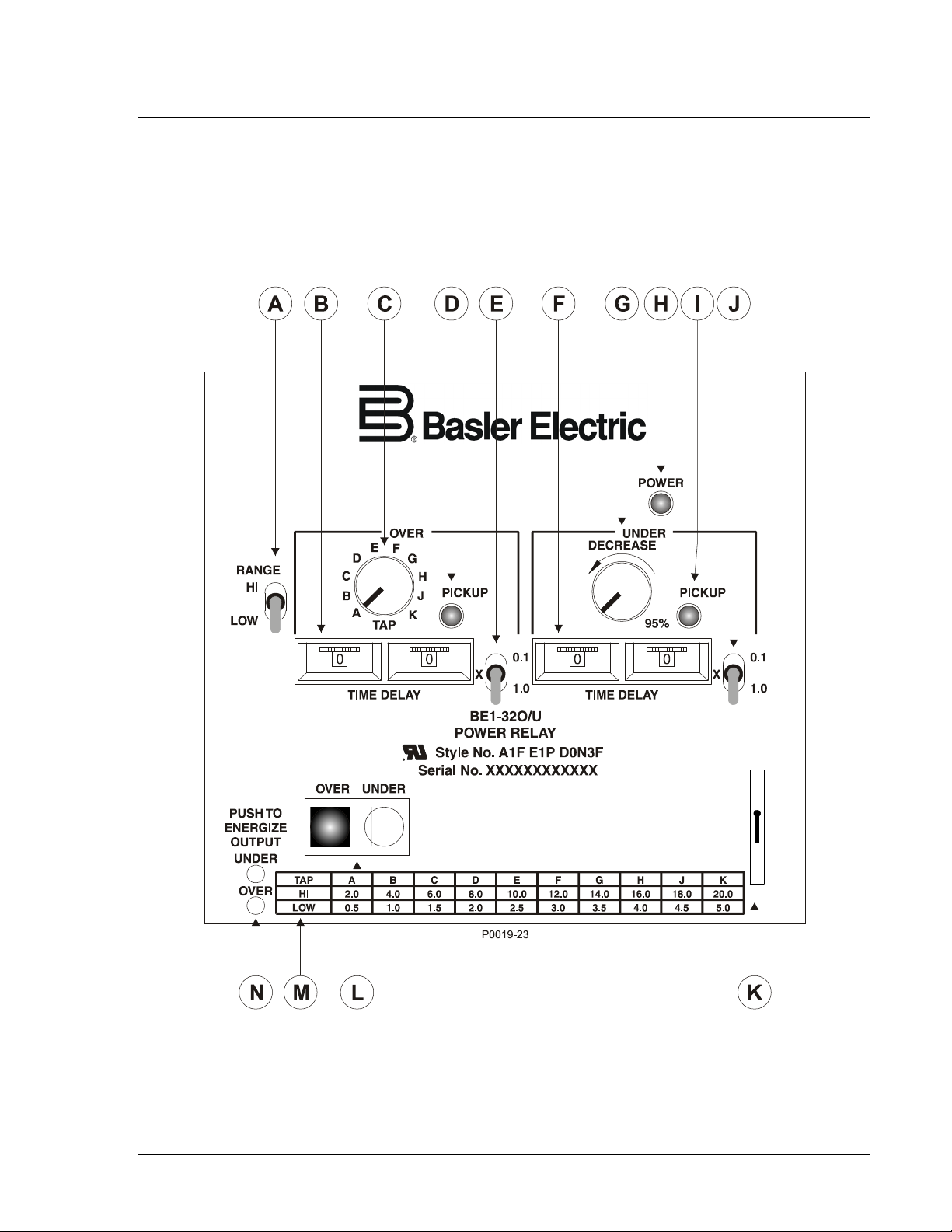

INTRODUCTION

All BE1-32R and BE1-32O/U controls and indicators are located on the front panel. The controls and

indicators are shown in Figure 2-1 and described in Table 2-1. Figure 2-1 illustrates a relay with the

maximum number of controls and indicators. Your relay may not have all of the controls and indicators

shown here.

Figure 2-1. Controls and Indicators

9171100990 Rev T BE1-32R, BE1-32O/U Controls and Indicators 2-1

Page 26

when the

Table 2-1. Control and Indicator Descriptions

Locator Description

A Range Select Switch. This two-position switch is used in conjunction with the Overpower

Tap Selector (locator C) and selects either the high or low overpower pickup range.

B Overpower Time Delay Control. These thumbwheel switches select the overpower trip time

delay. For relays with definite timing, these switches are used in conjunction with the

Overpower Time Delay Multiplier Switch (locator E) to select the overpower trip time delay.

C Overpower Tap Selector. This rotary switch is used in conjunction with the Range Select

Switch (locator A) and selects the overpower pickup point. The tap settings correspond to

the power levels listed in the Tap Select Range Chart (locator M).

D Overpower Pickup Indicator. This light emitting diode (LED) lights when the power level

exceeds the setting of the Overpower Tap Selector (locator C) and Range Select Switch

(locator A).

E Overpower Time Delay Multiplier Switch. This two-position switch selects the multiplier (0.1

or 1.0) applied to the definite time setting of the Overpower Time Delay Control (locator B).

F Underpower Time Delay Control. These thumbwheel switches select the underpower trip

time delay. For relays with definite timing, these switches are used in conjunction with the

Underpower Time Delay Multiplier Switch (locator J) to select the underpower trip time

delay.

G Underpower Pickup Selector. This potentiometer control adjusts the underpower pickup

level from 10 to 95 percent of the overpower pickup setting.

H Power Indicator. This LED lights when operating power is applied to the relay.

I Underpower Pickup Indicator. This LED lights when the power level decreases below the

setting of the Underpower Pickup Selector (locator G).

J Underpower Time Delay Multiplier Switch. This two-position switch selects the multiplier (0.1

or 1.0) applied to the definite time setting of the Underpower Time Delay Control (locator F).

K Target Reset Switch. Operating this switch resets the electronically latched target indicators.

L Target Indicators. The electronically latched red target indicators illuminate

corresponding output relay energizes. The targets are reset by operating the Target Reset

Switch (locator K).

M Tap Selection Chart. This chart indicates the Overpower Tap Selector and Range Select

Switch positions required to initiate an overpower trip at the listed power levels.

N Output Test Pushbuttons. These pushbuttons allow manual actuation of the output relays.

Output relay actuation is achieved by inserting a nonconductive rod through the front panel

access holes.

2-2 BE1-32R, BE1-32O/U Controls and Indicators 9171100990 Rev T

Page 27

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

INTRODUCTION.................................................................................................................................... 3-1

Current Sensing ................................................................................................................................. 3-1

Phase Rotation Sensitivity .................................................................................................................. 3-1

Sensing Input Types ........................................................................................................................... 3-3

kW Transducer ................................................................................................................................... 3-5

Comparator Circuits ........................................................................................................................... 3-5

Pickup ................................................................................................................................................. 3-5

Timing ................................................................................................................................................. 3-6

Outputs ............................................................................................................................................... 3-7

Output Test Pushbuttons .................................................................................................................... 3-7

Power Supply ..................................................................................................................................... 3-7

Target Indicators ................................................................................................................................ 3-7

Figures

Figure 3-1. Function Block Diagram .......................................................................................................... 3-1

Figure 3-2. Type E Sensing with ABC Rotation ........................................................................................ 3-2

Figure 3-3. Type E Sensing with ACB Rotation ........................................................................................ 3-2

Figure 3-4. Type B or V Sensing with ABC Rotation ................................................................................. 3-2

Figure 3-5. Type B or V Sensing with ACB Rotation ................................................................................. 3-3

Figure 3-6. Type A Sensing ....................................................................................................................... 3-3

Figure 3-7. Type B/Type V Sensing .......................................................................................................... 3-4

Figure 3-8. Type C Sensing ....................................................................................................................... 3-4

Figure 3-9. Type D Sensing ....................................................................................................................... 3-5

Figure 3-10. Type E Sensing ..................................................................................................................... 3-6

9171100990 Rev T BE1-32R, BE1-32O/U Functional Description i

Page 28

This page intentionally left blank.

ii BE1-32R, BE1-32O/U Functional Description 9171100990 Rev T

Page 29

SECTION 3 • FUNCTIONAL DESCRIPTION

INTRODUCTION

BE1-32R and BE1-32O/U relay functions are illustrated in Figure 3-1 and described in the following

paragraphs.

Figure 3-1. Function Block Diagram

Current Sensing

System current transformers (CTs), with 5 Aac (nominal) secondary windings, supply the relay current

sensing transformers with current. For current sensing input ratings, refer to Section 1, General

Information, Specifications.

Sensing Input Range 1, 4, and 7 Current Rating

In some applications, the 7 ampere current rating for sensing input ranges 1, 4, and 7 may be exceeded if

due care is not exercised. The most common CT has a thermal rating factor of 1.33, yielding a maximum

continuous current of 6.67 amperes, which is below the rating of the relay. However, many CTs have

thermal rating factors of 1.5 or 2. In many applications, current that exceeds the rating of the relay might

be applied. The designer/engineer needs to recognize this relay limitation when setting up the steadystate current that the relay is exposed to.

Sensing Input Range 1, 4, and 7 Burden

The burden for sensing input ranges 1, 4, and 7 can be high and have a substantial impact on the total

CT burden calculations and CT performance during fault conditions. The high burden can be easily

accounted for in normal operation and CT selection. However, the larger concern is what occurs during

fault conditions and how other relays on the CT string will be affected by the BE1-32 burden.

Phase Rotation Sensitivity

Relays that use phase current and phase-to-phase voltages to determine direction are sensitive to phase

rotation. BE1-32 Directional Power Relays with sensing type B, E, or V are phase rotation sensitive.

Unless otherwise noted, all connections shown in this manual assume ABC rotation.

9171100990 Rev T BE1-32R, BE1-32O/U Functional Description 3-1

Page 30

Type E Sensing

Relays with type E sensing (two elements) monitor two phase-to-phase voltages (the third phase is used

as a reference) and two phases of current to determine directional power flow. This is sometimes referred

to as the two-wattmeter method for power flow measurement. Figure 3-2 shows the phasor representation

for ABC rotation. Figure 3-3 shows the phasor representation for ACB rotation.

Figure 3-2. Type E Sensing with ABC Rotation

Figure 3-3. Type E Sensing with ACB Rotation

Type B and V Sensing

Relays with type B sensing (60 hertz) and type V sensing (50 hertz) monitor one phase-to-phase voltage

and one phase of current to determine directional power flow. An internal 30-degree phase delay network

(frequency dependent) aligns the voltage signal with the current signal. Figure 3-4 shows the phasor

representation for monitoring A-phase to B-phase voltage and A-phase current with ABC rotation. Figure

3-5 shows the phasor representation for monitoring A-phase to C-phase voltage with ACB rotation.

Figure 3-4. Type B or V Sensing with ABC Rotation

3-2 BE1-32R, BE1-32O/U Functional Description 9171100990 Rev T

Page 31

Figure 3-5. Type B or V Sensing with ACB Rotation

Sensing Input Types

The following paragraphs describe the current and voltage sensing types available in BE1-32R and BE132O/U relays.

Type A Sensing: Single-Phase Current and Single-Phase Voltage

In three-phase, four-wire circuits, relays with type A sensing calculate the power flowing in the tripping

direction by monitoring line-to-neutral voltage and a single phase of current. Relays with type A sensing

can also be applied in a three-phase, three-wire system using phase-to-ground voltages. Type A sensing

configurations are not phase rotation sensitive. The range switch for this sensing type is calibrated in

single-phase watts. Figure 3-6 illustrates the type A sensing configuration.

Figure 3-6. Type A Sensing

Type B and V Sensing: Single-Phase Current and Single-Phase Voltage

In three-phase, three-wire circuits, relays with type B or type V sensing calculate the power flowing in the

tripping direction by monitoring the line-to-line voltage and a single phase of current. The power equation

assumes balanced conditions. Because the input voltage leads the input current by 30 degrees

(assuming unity power factor), a 30 degree lagging phase shift network is designed into the voltage input

circuit. Type B or V sensing configurations are sensitive to phase rotation. The range switch of this

sensing type is calibrated in single-phase watts. Figure 3-7 illustrates the type B/V sensing configuration.

Type C Sensing: Single-Phase Current and Three-Phase Voltage

In three-phase, three-wire circuits, relays with type C sensing calculate the power flowing in the tripping

direction by monitoring three line-to-line voltages and a single phase of current. The relay measures

actual power even if the system voltages are not balanced. Therefore, the power equation using E

AVE

is

approximate. Type C sensing configurations are not sensitive to phase rotation. The range switch of this

sensing type is calibrated in three-phase watts. Figure 3-8 illustrates the type C sensing configuration.

9171100990 Rev T BE1-32R, BE1-32O/U Functional Description 3-3

Page 32

Figure 3-7. Type B/Type V Sensing

Figure 3-8. Type C Sensing

Type D Sensing: Three-Phase Current and Three-Phase Voltage

In three-phase, four-wire circuits, relays with type D sensing calculate the power flowing in the tripping

direction by monitoring three line-to-neutral voltages and three phases of current. This sensing type can

also be applied on a three-phase, three-wire system using phase-to-ground voltages. Type D sensing

configurations are not phase rotation sensitive. The range switch of this sensing type is calibrated in

three-phase watts. Figure 3-9 illustrates the type D sensing configuration.

3-4 BE1-32R, BE1-32O/U Functional Description 9171100990 Rev T

Page 33

10

volts nominal

(setting) watts

×

Figure 3-9. Type D Sensing

Type E Sensing: Two-Phase Current and Three-Phase Voltage

In three-phase, three-wire circuits, relays with type E sensing calculate the power flowing in the tripping

direction by monitoring the three line-to-line voltages and two phases of currents. The relay measures

actual power under balanced or unbalanced conditions. The power equation assumes that conditions are

balanced. Type E sensing configurations are sensitive to phase rotation. The range switch for this sensing

type is calibrated in three-phase watts. Figure 3-10 illustrates the type E sensing configuration.

kW Transducer

Single-phase or three-phase current and voltage signals (determined by the sensing input circuitry type)

are applied to the kW transducer. The signals are applied to a multiplexor that selectively combines the

input conditions and feeds them to a multiplier circuit. The output of the multiplier is true power (watts)

that is then integrated to produce a dc voltage proportional to the monitored power flow. The conditioned,

proportional signal is then applied to the comparator circuits.

Comparator Circuits

A dc signal that represents the monitored power level is applied to the comparator circuits for comparison

with the front panel underpower and overpower settings. When the reference level of the comparators is

surpassed, the appropriate output is energized (if instantaneous timing is selected) or timing is initiated.

Pickup

The overpower pickup point is selected by the front panel Overpower Tap Selector and Range Select

Switch. Table 1-3 lists the overpower pickup range for each sensing input type.

The underpower pickup point is selected by the Underpower Pickup Selector and has an adjustment

range of 10 to 95% of the overpower pickup setting.

Pickup accuracy is ±2% of the front panel setting at unity power factor and ±5% at a power factor above

0.5. The specified accuracy is for current below 10 times the current required to pick up at nominal volts

and unity power factor. The maximum current to maintain specified accuracy can be expressed by the

equation:

9171100990 Rev T BE1-32R, BE1-32O/U Functional Description 3-5

Page 34

This product is not recommended for power factors below 0.10. Contact Basler Electric for recommended

products.

Figure 3-10. Type E Sensing

Timing

BE1-32R and BE1-32O/U timing is defined by the style number and can be instantaneous, definite timedelayed, or inverse time-delayed.

A relay with instantaneous timing responds to a trip condition with no intentional time delay. For a realpower magnitude of two times the pickup setting, overall response time is less than 80 milliseconds at 60

hertz and less than 100 milliseconds at 50 hertz. The response time decreases as the magnitude of the

input signal increases. Typical response curves are illustrated in Figures 1-13 and 1-14.

A relay with definite timing begins timing toward a trip when the power level exceeds the relay overpower

setpoint or decreases below the underpower setpoint. Overpower and underpower definite time delays

are adjusted by the corresponding Time Delay Control thumbwheel switches and the Time Delay

Multiplier switch. The definite time delay can be adjusted from 0.1 to 9.9 seconds with the Time Delay

Multiplier switch in the times 0.1 position and from 1 to 99 seconds with the Time Delay Multiplier switch

in the times 1.0 position. A Time Delay Control setting of 00 enables instantaneous timing.

Inverse timing is available only for the overpower function. A relay with inverse timing begins timing

toward a trip when the power level exceeds the relay overpower setpoint. The desired inverse time curve

is selected by the Overpower Time Delay Control thumbwheel switches. The available inverse time

characteristic curves are illustrated in Figure 1-15.

3-6 BE1-32R, BE1-32O/U Functional Description 9171100990 Rev T

Page 35

Outputs

BE1-32R and BE1-32O/U relay outputs are divided into three categories: Overpower and Underpower,

Auxiliary, and Power Supply Status.

Overpower and Underpower Outputs

A dedicated output relay is provided for each overpower and underpower protection function. The BE132R is equipped with a set of overpower output contacts that are configured as normally-open (NO) or

normally-closed (NC). The BE1-32O/U is equipped with a set of overpower output contacts and a set of

underpower output contacts. The BE1-32O/U outputs may be any combination of NO or NC contact

configurations. Output contact configuration is determined by the output digit of the relay style number.

Auxiliary Outputs

Auxiliary output contacts are supplied when specified by the Option 3 digit of the relay style number.

Auxiliary outputs are provided for both overpower and underpower protection functions. The auxiliary

output contacts may be NO, NC, or single-pole, double-throw (SPDT).

Power Supply Status Output

The power supply status relay has a set of NC contacts and energizes when operating power is applied to

the BE1-32R or BE1-32O/U. If either side of the power supply output (+12 Vdc or –12 Vdc) fails, the

power supply status relay de-energizes and closes the power supply status output contacts. Shorting bars

within the relay case short-circuit the power supply status output when the upper connection plug is

withdrawn from the case.

Output Test Pushbuttons

The output test pushbuttons allow testing of the overpower and underpower outputs and optional auxiliary

outputs. To prevent accidental operation, the pushbuttons are recessed behind openings in the front

panel. An output is tested by inserting a nonconductive rod through the access holes.

Power Supply

Operating power for the relay circuitry is supplied by a wide-range, electrically isolated, low-burden power

supply. The power supply operating power input is not polarity sensitive. The front panel Power Indicator

and power supply status output indicate when the power supply is operating. Power supply specifications

are listed in Table 1-3.

Target Indicators

Target indicators are optional components selected when a relay is ordered. The electronically latched

and reset targets consist of red LED indicators located on the relay front panel. A latched target is reset

by operating the target reset switch on the front panel. If relay operating power is lost, any illuminated

(latched) targets are extinguished. When relay operating power is restored, the previously latched targets

are restored to their latched state.

A relay can be equipped with either internally operated targets or current operated targets.

Internally Operated Targets

The relay trip outputs are directly applied to drive the appropriate target indicator. Each indicator is

illuminated regardless of the current level in the trip circuit.

Current Operated Targets

A current operated target is triggered by closure of the corresponding output contact and the presence of

at least 200 milliamperes of current flowing in the trip circuit.

NOTE

Prior to September 2007, BE1-32 and BE1-32O/U target indicators consisted of

magnetically-latched, disc indicators. These mechanically latched target

indicators have been replaced by the electronically latched LED targets in use

today.

9171100990 Rev T BE1-32R, BE1-32O/U Functional Description 3-7

Page 36

This page intentionally left blank.

3-8 BE1-32R, BE1-32O/U Functional Description 9171100990 Rev T

Page 37

SECTION 4 • INSTALLATION

TABLE OF CONTENTS

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

INTRODUCTION.................................................................................................................................... 4-1

RELAY OPERATING GUIDELINES AND PRECAUTIONS .................................................................. 4-1

MOUNTING ............................................................................................................................................ 4-1

CONNECTIONS................................................................................................................................... 4-21

Notes for Figure 4-20 ....................................................................................................................... 4-21

Notes for Figures 4-25 and 4-26 ...................................................................................................... 4-26

MAINTENANCE ................................................................................................................................... 4-32

Repair ............................................................................................................................................... 4-32

Maintenance Accessories ................................................................................................................ 4-32

STORAGE ............................................................................................................................................ 4-32

Figures

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, S1 Case .......................................................................... 4-2

Figure 4-2. S1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount ................................... 4-3

Figure 4-3. S1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount .................................... 4-4

Figure 4-4. S1 Case Dimensions, Rear View, Single Ended, Semi-Flush Mount ..................................... 4-5

Figure 4-5. S1 Case Dimensions, Side View, Single Ended, Semi-Flush Mount ..................................... 4-6

Figure 4-6. Panel Cutting/Drilling, Double Ended, Projection Mount, S1 Case ........................................ 4-7

Figure 4-7. S1 Case Dimensions, Rear View, Double Ended, Projection Mount ...................................... 4-8

Figure 4-8. S1 Case Dimensions, Side View, Double Ended, Projection Mount ...................................... 4-9

Figure 4-9. Panel Cutting/Drilling, Single Ended, Projection Mount, S1 Case ........................................ 4-10

Figure 4-10. S1 Case Dimensions, Rear View, Single Ended, Projection Mount ................................... 4-11

Figure 4-11. S1 Case Dimensions, Side View, Single Ended, Projection Mount .................................... 4-12

Figure 4-12. S1 Case Cover Dimensions, Front View............................................................................. 4-13

Figure 4-13. Panel Cutting/Drilling, Semi-Flush, M1 Case ...................................................................... 4-14

Figure 4-14. M1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount ............................... 4-15

Figure 4-15. M1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount ............................... 4-16

Figure 4-16. Panel Cutting/Drilling, Double Ended, Projection Mount, M1 Case .................................... 4-17

Figure 4-17. M1 Case Dimensions, Rear View, Double Ended, Projection Mount ................................. 4-18

Figure 4-18. M1 Case Dimensions, Side View, Double Ended, Projection Mount .................................. 4-19

Figure 4-19. M1 Case Cover Dimensions, Front View ............................................................................ 4-20

Figure 4-20. Control Circuit Diagram ....................................................................................................... 4-21

Figure 4-21. Internal Connections, Sensing Type A, B, or V .................................................................. 4-22

Figure 4-22. Internal Connections, Sensing Type C ............................................................................... 4-23

Figure 4-23. Internal Connections, Sensing Type D ............................................................................... 4-24

Figure 4-24. Internal Connections, Sensing Type E ................................................................................ 4-25

Figure 4-25. BE1-32R Typical External Connections .............................................................................. 4-26

Figure 4-26. BE1-32O/U Typical External Connections .......................................................................... 4-26

Figure 4-27. Type A Sensing Connections .............................................................................................. 4-27

Figure 4-28. Type B or V Sensing Connections with ABC Rotation ........................................................ 4-27

Figure 4-29. Type B or V Sensing Connections with ACB Rotation ........................................................ 4-28

Figure 4-30. Type C Sensing Connections ............................................................................................. 4-28

Figure 4-31. Type D Sensing Connections ............................................................................................. 4-29

Figure 4-32. Type E Sensing Connections with ABC Rotation ............................................................... 4-30

Figure 4-33. Type E Sensing Connections with ACB Rotation ............................................................... 4-31

9171100990 Rev T BE1-32R, BE1-32O/U Installation i

Page 38

This page intentionally left blank.

ii BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 39

SECTION 4 • INSTALLATION

INTRODUCTION

BE1-32R and BE1-32O/U relays are shipped in sturdy cartons to prevent damage during transit. Upon

receipt of a relay, check the model and style number against the requisition and packing list to see that

they agree. Inspect the relay for shipping damage. If there is evidence of damage, file a claim with the

carrier and notify your sales representative or Basler Electric.

If the relay will not be installed immediately, store it in its original shipping carton in a moisture- and dustfree environment. Before placing the relay in service, it is recommended that the test procedures of

Section 5, Testing be performed.

RELAY OPERATING GUIDELINES AND PRECAUTIONS

Before installing or operating the relay, note the following guidelines and precautions.

• For proper current-operated target operation, a minimum current of 200 milliamperes must flow

through the output trip circuit.

• If a wiring insulation test is required, remove the connection plugs and withdraw the relay from its

case.

CAUTION

When the connection plugs are removed, the relay is disconnected from the

operating circuit and will not provide system protection. Always be sure that

external operating (monitored) conditions are stable before removing a relay for

inspection, test, or service.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12 AWG

copper wire attached to the ground terminal on the rear of the unit case. When

the relay is configured in a system with other devices, it is recommended to use a

separate lead to the ground bus from each device.

MOUNTING

Because the relay is of solid-state design, it does not have to be mounted vertically. Any convenient

mounting angle may be chosen. Relay outline dimensions and panel drilling diagrams are illustrated in

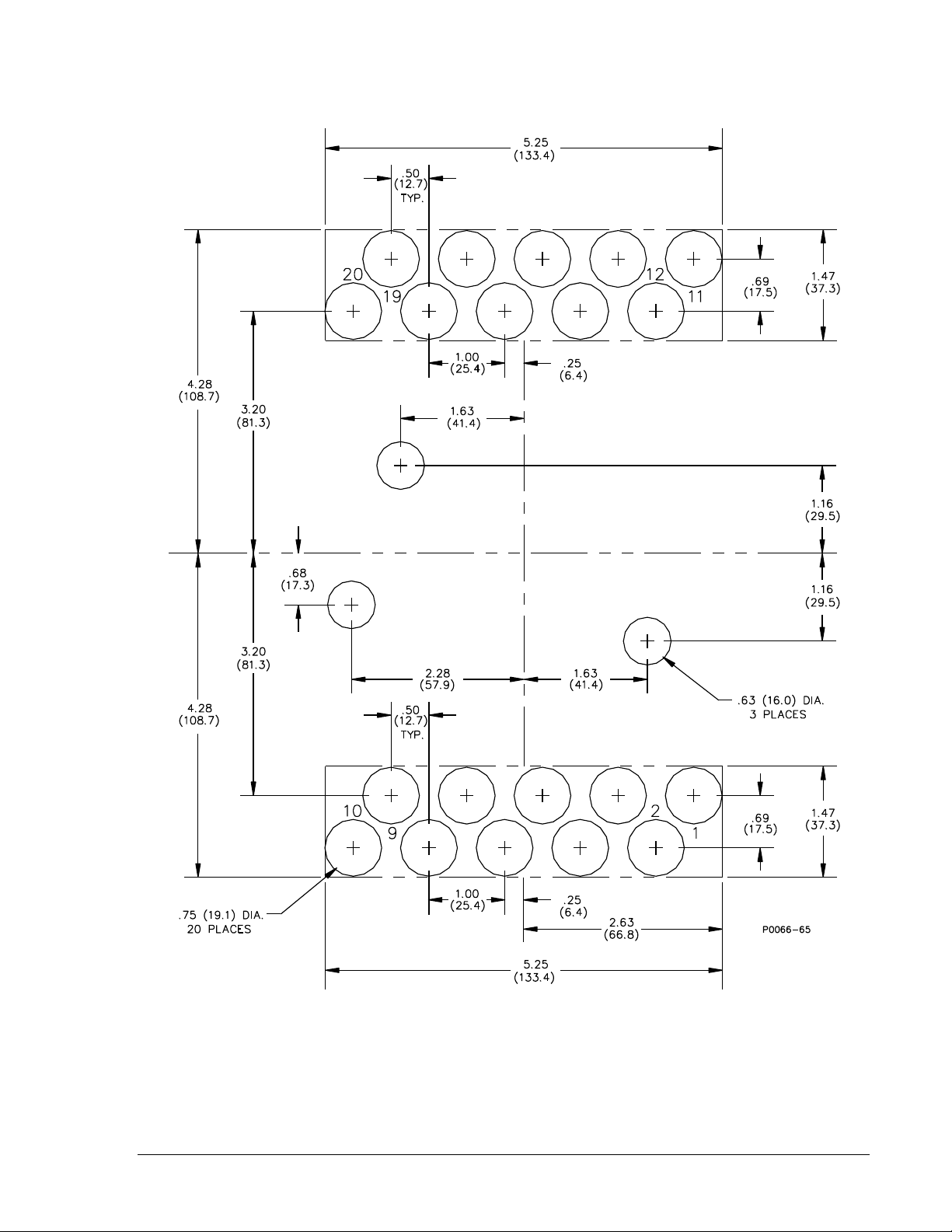

Figures 4-1 through 4-19.

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-1

Page 40

3.03 (77)

6.06 (154)

0.25 (6) diameter, 4 places

C

L

Cut-Out

0.575

(15)

8.63

(219)

0.552

(14)

5.69 (144)

Outer Edge of Cover

0.480

(12)

8.25

(210)

4.13

(105)

0.480

(12)

P0072-12

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, S1 Case

4-2 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 41

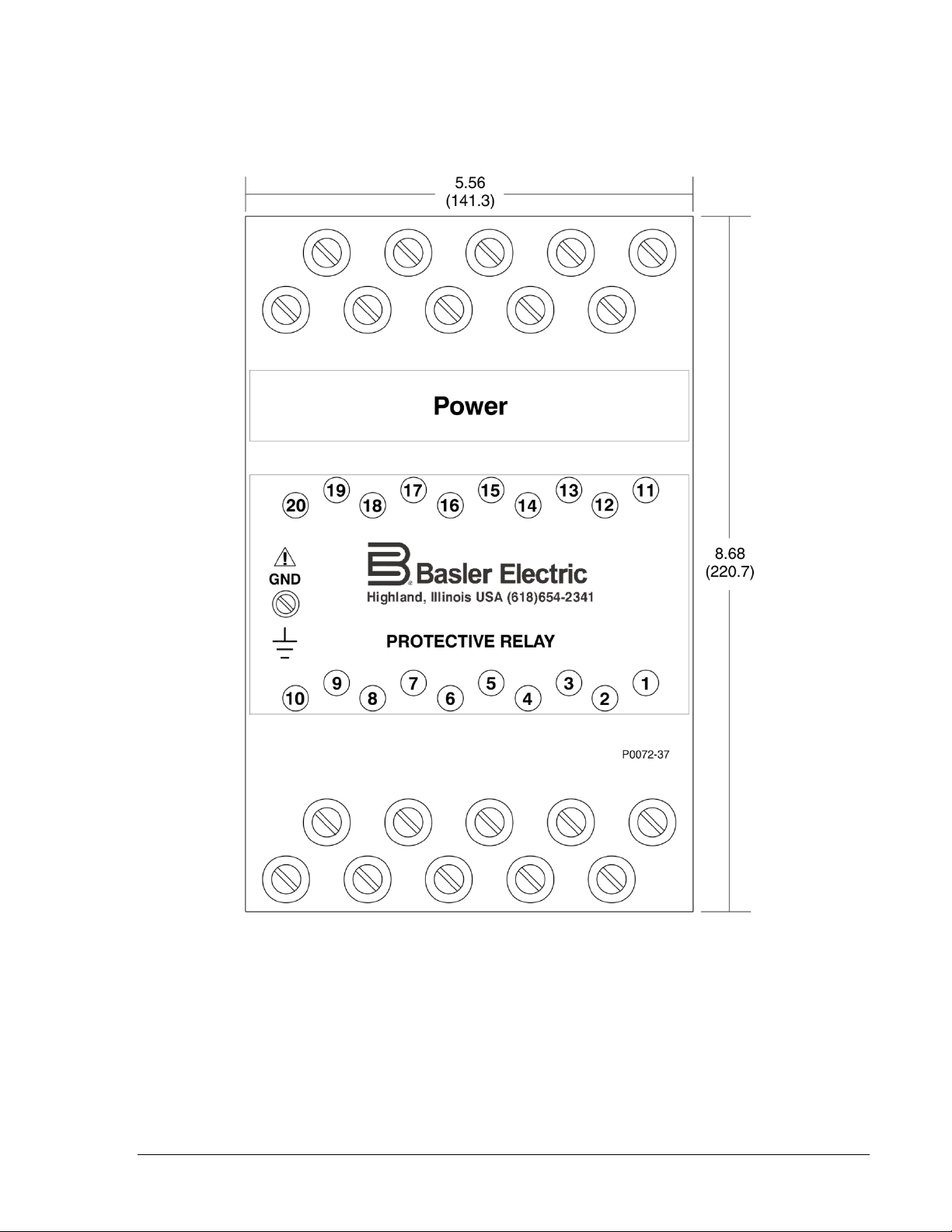

Figure 4-2. S1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-3

Page 42

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

MOUNTING PANEL

(55.75)

2.195

P0066-64

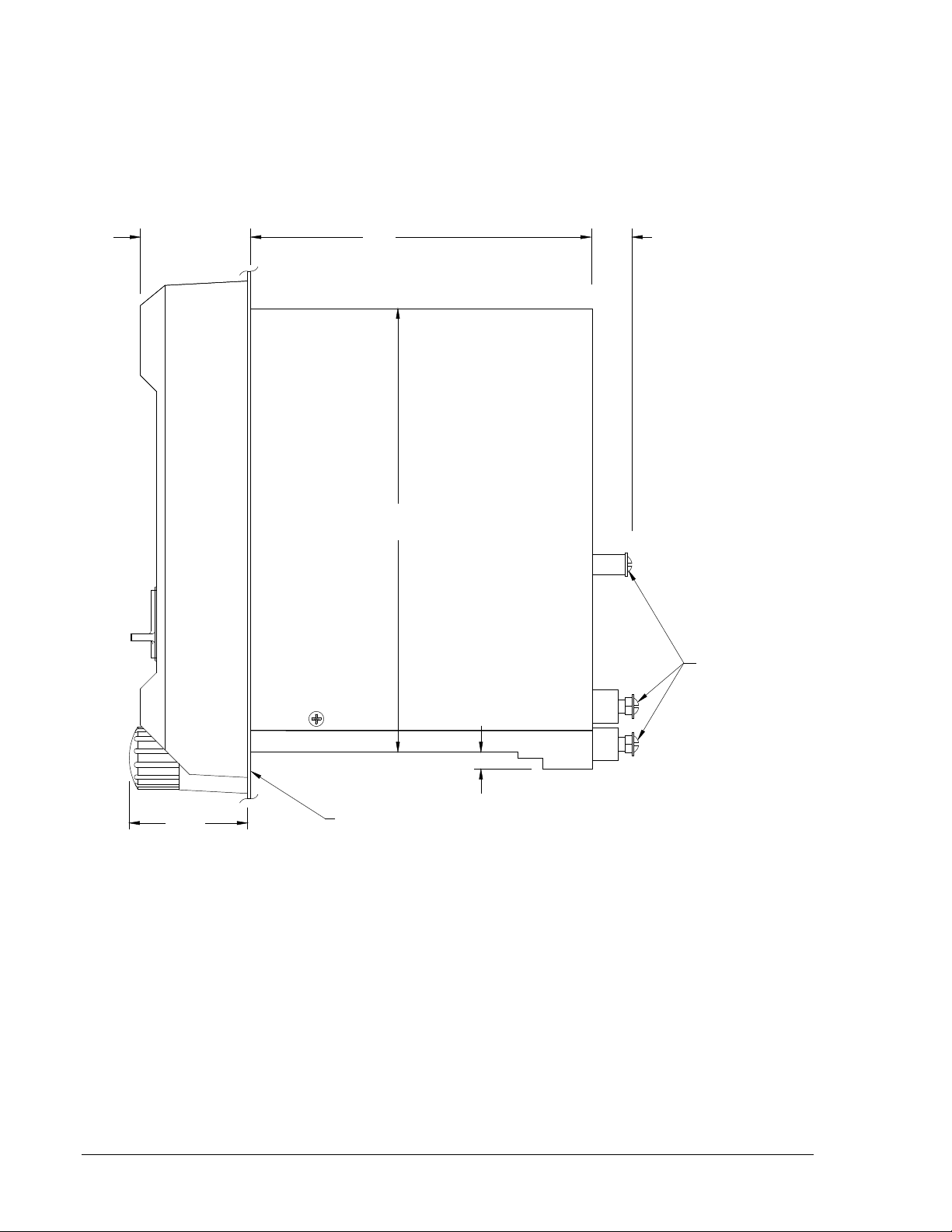

Figure 4-3. S1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

4-4 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 43

Figure 4-4. S1 Case Dimensions, Rear View, Single Ended, Semi-Flush Mount

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-5

Page 44

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-69

8.06

(204.72)

(7.9)

.31

Figure 4-5. S1 Case Dimensions, Side View, Single Ended, Semi-Flush Mount

4-6 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 45

Figure 4-6. Panel Cutting/Drilling, Double Ended, Projection Mount, S1 Case

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-7

Page 46

Figure 4-7. S1 Case Dimensions, Rear View, Double Ended, Projection Mount

4-8 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 47

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

(55.75)

2.195

P0066-67

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

Figure 4-8. S1 Case Dimensions, Side View, Double Ended, Projection Mount

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-9

Page 48

Figure 4-9. Panel Cutting/Drilling, Single Ended, Projection Mount, S1 Case

4-10 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 49

Figure 4-10. S1 Case Dimensions, Rear View, Single Ended, Projection Mount

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-11

Page 50

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-71

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

8.06

(204.72)

(7.9)

.31

.75

(19.1)

Figure 4-11. S1 Case Dimensions, Side View, Single Ended, Projection Mount

4-12 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 51

P

0066-

68

Figure 4-12. S1 Case Cover Dimensions, Front View

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-13

Page 52

3.03 (77)

6.06 (154)

0.25 (6) diameter, 4 places

C

L

Cut-Out

0.575

(15)

14.63

(371.5)

0.552

(14)

5.69 (144.5)

Outer Edge of Cover

0.480

(12)

14.25

(362.1)

7.13

(181.0)

0.480

(12)

P0072-21

7.31

(185.7)

2.84 (72.1)

Figure 4-13. Panel Cutting/Drilling, Semi-Flush, M1 Case

4-14 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 53

Figure 4-14. M1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-15

Page 54

P0066-76

10-32 SCREWS

10-32 SCREWS

MOUNTING PANEL

2.195

(55.75)

.31

(7.9)

.31

(7.9)

.75

(19.1)

6.19

(157.2)

1.95

(49.53)

7.03

(178.56)

7.03

(178.56)

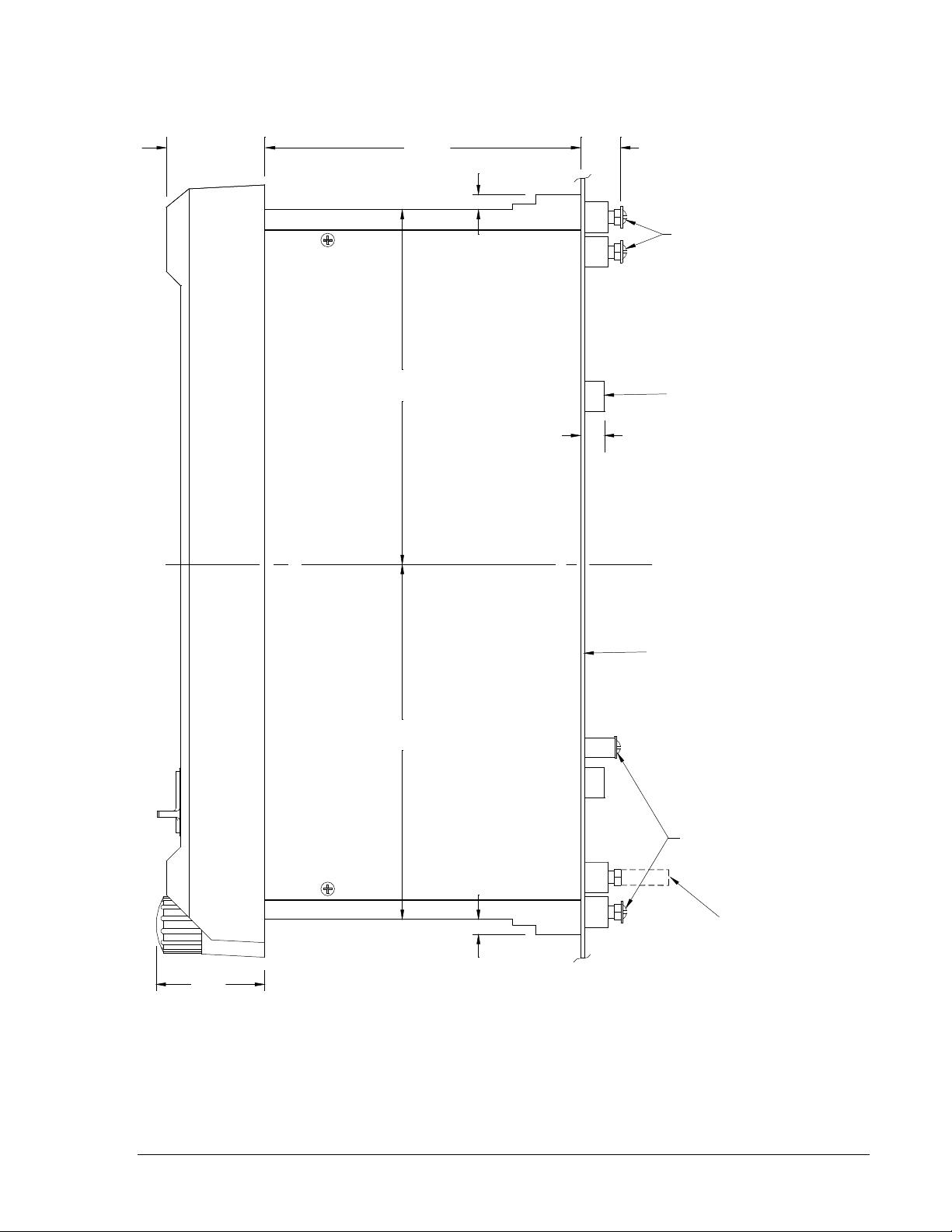

Figure 4-15. M1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

4-16 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 55

Figure 4-16. Panel Cutting/Drilling, Double Ended, Projection Mount, M1 Case

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-17

Page 56

Figure 4-17. M1 Case Dimensions, Rear View, Double Ended, Projection Mount

4-18 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 57

P0066-78

10-32 SCREWS

10-32 SCREWS

2.195

(55.75)

.31

(7.9)

.31

(7.9)

.75

(19.1)

6.19

(157.2)

1.95

(49.53)

7.03

(178.56)

7.03

(178.56)

TERMINAL EXTENTION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

Figure 4-18. M1 Case Dimensions, Side View, Double Ended, Projection Mount

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-19

Page 58

P0066

-79

Figure 4-19. M1 Case Cover Dimensions, Front View

4-20 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 59

CONNECTIONS

Be sure to check the model and style number of a relay before connecting and energizing the relay.

Incorrect wiring may result in damage to the relay.

Except where noted, connections should be made with wire no smaller than 14 AWG. Relay connections

are shown in the following illustrations.

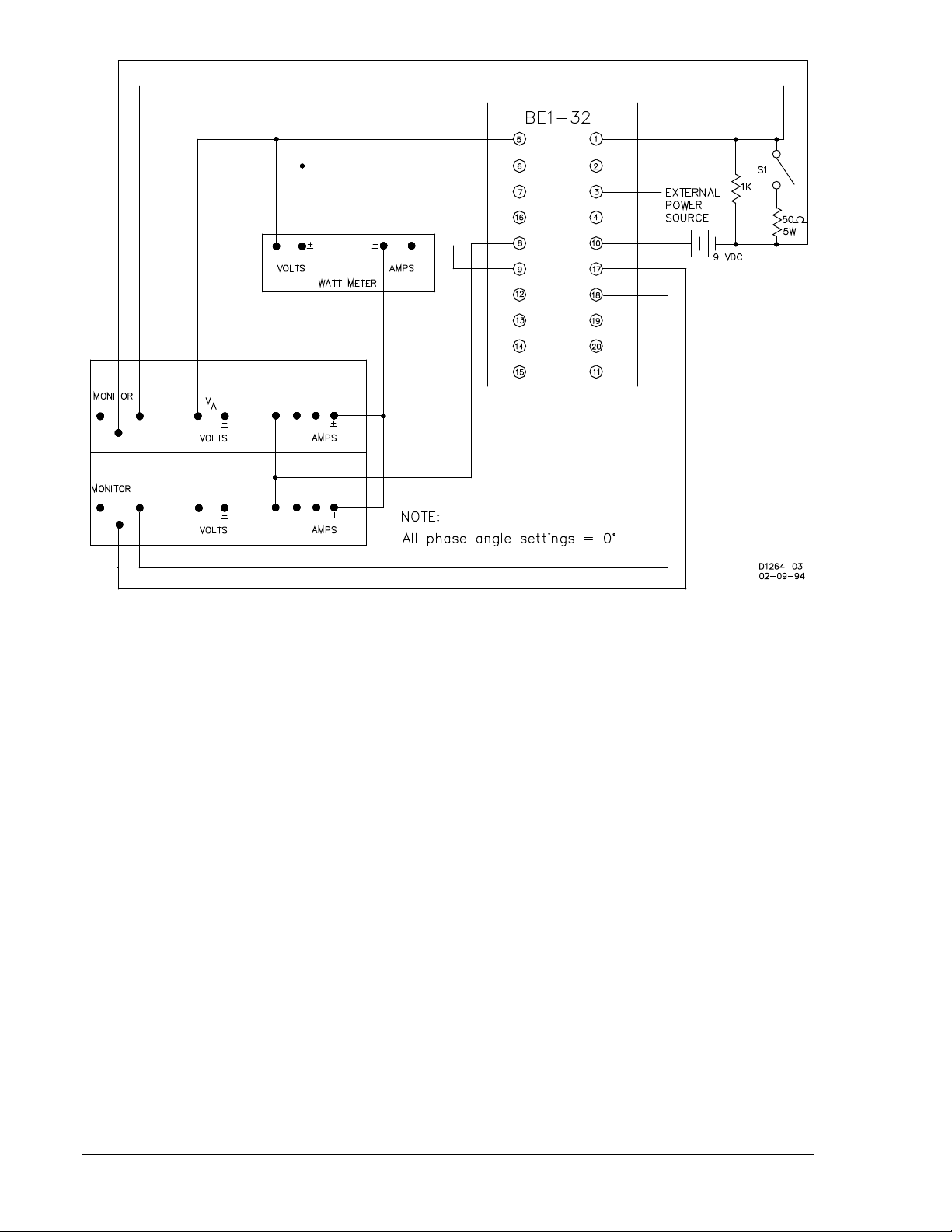

• Control circuit connections: Figure 4-20

• Internal connections: Figures 4-21 through 4-24

• Typical external connections: Figures 4-25 and 4-26

• Sensing input connections: Figures 4-27 through 4-33

Figure 4-20. Control Circuit Diagram

Notes for Figure 4-20

1. Overpower, underpower, and power supply status output contacts are optionally normally open or

normally closed.

2. Auxiliary output contacts are optionally normally open, normally closed, or SPDT. If SPDT, power

supply status is not available.

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-21

Page 60

See Figure

4-16

Figure 4-21. Internal Connections, Sensing Type A, B, or V

4-22 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 61

See Figure 4-16

Figure 4-22. Internal Connections, Sensing Type C

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-23

Page 62

See Figure 4-16

Figure 4-23. Internal Connections, Sensing Type D

4-24 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 63

See Figure 4-16

Figure 4-24. Internal Connections, Sensing Type E

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-25

Page 64

Figure 4-25. BE1-32R Typical External Connections

Figure 4-26. BE1-32O/U Typical External Connections

Notes for Figures 4-25 and 4-26

1. The overpower and underpower output contact configuration is determined by the relay style number

and may be NO or NC.

2. The auxiliary output contact configuration is determined by the relay style number and may be NO,

NC, or SPDT. If SPDT auxiliary output contacts are selected, the power supply status output is not

available.

3. The relay sensing input type determines the configuration of the sensing inputs.

4-26 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 65

Figure 4-27. Type A Sensing Connections

Figure 4-28. Type B or V Sensing Connections with ABC Rotation

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-27

Page 66

Figure 4-29. Type B or V Sensing Connections with ACB Rotation

Figure 4-30. Type C Sensing Connections

4-28 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 67

Figure 4-31. Type D Sensing Connections

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-29

Page 68

Figure 4-32. Type E Sensing Connections with ABC Rotation

4-30 BE1-32R, BE1-32O/U Installation 9171100990 Rev T

Page 69

Figure 4-33. Type E Sensing Connections with ACB Rotation

9171100990 Rev T BE1-32R, BE1-32O/U Installation 4-31

Page 70

MAINTENANCE

BE1-32R and BE1-32O/U relays require no preventative maintenance other than testing performed

according to scheduled practices.

Repair

Repair of the draw-out assembly by replacement of individual circuit boards is not recommended. The