Page 1

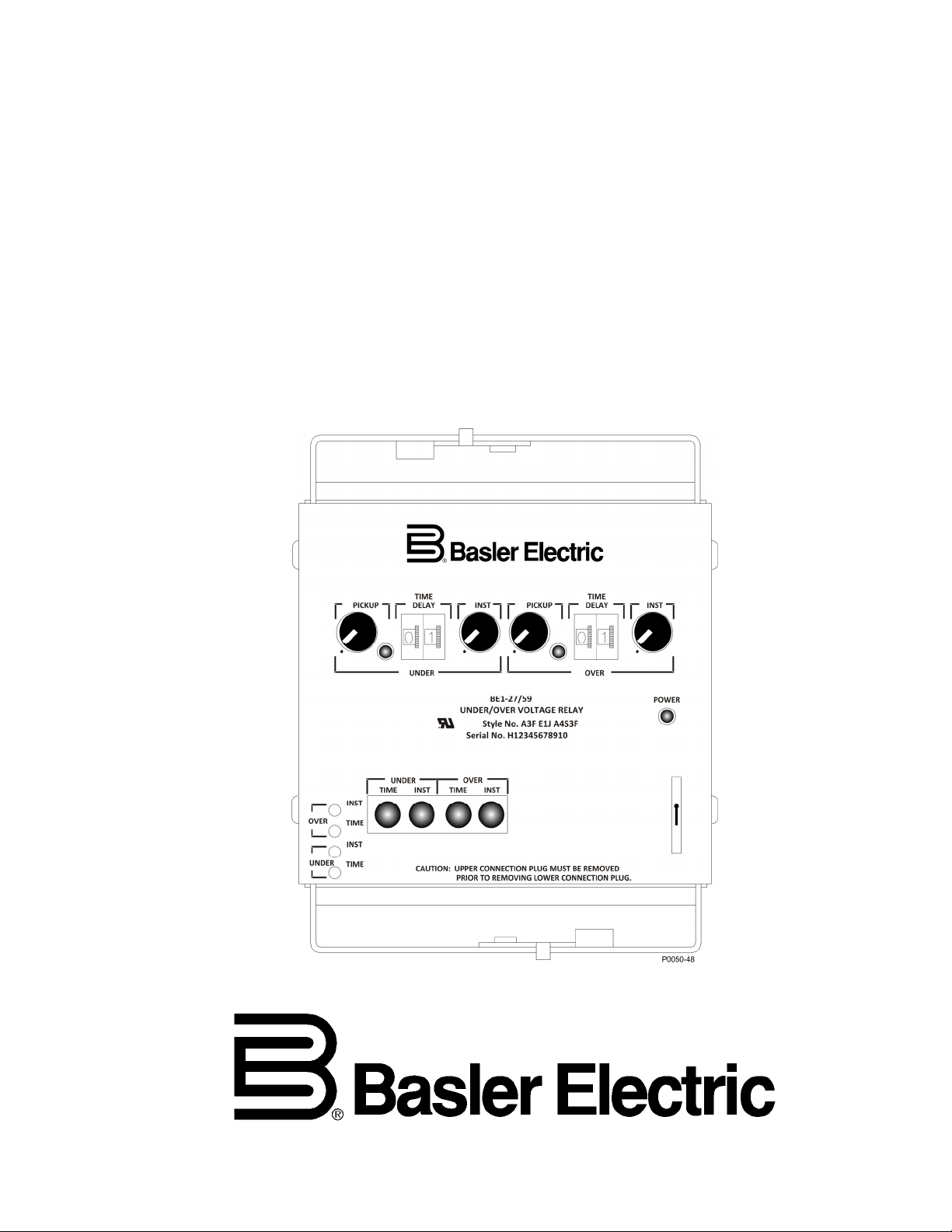

INSTRUCTION MANUAL

FOR

UNDERVOLTAGE, OVERVOLTAGE,

UNDER/OVERVOLTAGE RELAYS

BE1-27, BE1-59, BE1-27/59

Publication: 9170600990

Revision: L 12/12

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-27

Undervoltage Relay, the BE1-59 Overvoltage Relay, and the BE1-27/59 Under/Overvoltage Relay. To

accomplish this, the following information is provided:

General Information and Specifications

Controls and Indicators

Functional Description

Installation

Testing

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12

AWG copper wire attached to the ground terminal on the rear of the unit case.

When the relay is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9170600990 Rev L BE1-27/59 Introduction i

Page 4

First Printing: January 1986

Printed in USA

© 1986-2012 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

December 2012

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use,

subject to return on request, and with the mutual understanding that it will not

be used in any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-27/59 Introduction 9170600990 Rev L

Page 5

REVISION HISTORY

The following information provides a historical summary of the changes made to the BE1-27, BE1-59, and

BE1-27/59 instruction manual (9170600990). Revisions are listed in reverse chronological order.

Manual

Revision and Date

L, 12/12

K, 09/11

J, 07/08

H, 02/08

G, 09/07

F, 06/07

E, 07/04

D, 06/03

C, 11/99

—, 01/86

Change

Standardized case and cover drawings in Section 4.

Changed notes 3 and 4, and added note 5 in Style Chart in Section 1.

Updated GOST-R statement in Section 1.

Updated Storage statement in Section 4.

Modified style chart in Section 1 by adding note #4 to Timing options

C4 through D8.

Removed “Range 2” from Figures 3-3, 3-5, 3-6, and 3-7.

Consolidated sensing input range options in style chart of Figure 1-2

to cover all relay models.

Updated Output Contacts ratings in Section 1.

Moved content of Section 6, Maintenance to Section 4.

Updated front panel illustrations to show laser graphics.

Moved content of Section 7, Manual Change Information to manual

introduction.

Added manual part number and revision to all footers.

Updated cover drawings.

Updated power supply burden data in Section 1.

Updated target Indicator description in Section 3.

Updated specifications listed in Section 1.

Added missing square root symbol to equations of System Voltages

paragraph in Section 3, Functional Description.

Revised Resistive and Inductive Output Contact Ratings on page 1-4.

Updated the Definite Time Accuracy setting on page 1-5.

Deleted Range 2 row from Figures 3-2 through 3-4.

Added a new step (Step 3) under Timing for instantaneous to page 5-

4.

Changed the table that Note 2 referred to in Figure 5-2.

Page 5-5, Table 5-3, Timing Test Results, Definite Timing Type specs

were changed.

Revised the manual to the current standard format.

Changed characteristic curves figures in Section 3 to improve the

accuracy.

Added ground terminals to new Figures 1-1 and 4-16.

Added interconnection diagrams, Figures 4-13, 4-14, and 4-15.

Added Section 7, Manual Change Information.

Initial release

9170600990 Rev L BE1-27/59 Introduction iii

Page 6

iv BE1-27/59 Introduction 9170600990 Rev L

Page 7

CONTENTS

SECTION 1 GENERAL INFORMATION ................................................................................................ 1-1

PURPOSE ........................................................................................................................................... 1-1

APPLICATION .................................................................................................................................... 1-1

Motor Protection ........................................................................................................................... 1-1

Automatic Transfer Switching ....................................................................................................... 1-1

Cogeneration ................................................................................................................................ 1-1

Transformer Protection ................................................................................................................. 1-2

Ground Fault Detection ................................................................................................................ 1-2

MODEL AND STYLE NUMBER .......................................................................................................... 1-2

Style Number Example ................................................................................................................. 1-4

SPECIFICATIONS .............................................................................................................................. 1-4

Voltage Sensing Inputs ................................................................................................................. 1-4

Undervoltage and Overvoltage Pickup Range ............................................................................. 1-4

Timing Characteristics .................................................................................................................. 1-4

Output Contacts ............................................................................................................................ 1-5

Power Supply................................................................................................................................ 1-5

Target Indicators ........................................................................................................................... 1-5

Type Tests .................................................................................................................................... 1-5

Temperature ................................................................................................................................. 1-6

Physical ........................................................................................................................................ 1-6

Agency Recognition/Certification.................................................................................................. 1-6

SECTION 2 CONTROLS AND INDICATORS ....................................................................................... 2-1

INTRODUCTION ................................................................................................................................. 2-1

SECTION 3 FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

INTRODUCTION ................................................................................................................................. 3-1

SYSTEM VOLTAGES ......................................................................................................................... 3-1

STEP-DOWN TRANSFORMER ......................................................................................................... 3-2

LOW-PASS FILTER AND FULL WAVE RECTIFIER ......................................................................... 3-2

PICKUP SETTINGS ............................................................................................................................ 3-2

PICKUP COMPARATORS.................................................................................................................. 3-2

TIMER CIRCUIT ................................................................................................................................. 3-2

OUTPUTS ........................................................................................................................................... 3-6

PUSH-TO-ENERGIZE OUTPUT PUSHBUTTONS ............................................................................ 3-6

POWER SUPPLY STATUS OUTPUT ................................................................................................ 3-6

POWER SUPPLY ............................................................................................................................... 3-6

TARGET INDICATORS ...................................................................................................................... 3-6

Internally Operated Targets .......................................................................................................... 3-6

Current Operated Targets ............................................................................................................ 3-6

SECTION 4 INSTALLATION .................................................................................................................. 4-1

INTRODUCTION ................................................................................................................................. 4-1

RELAY OPERATING GUIDELINES AND PRECAUTIONS ............................................................... 4-1

MOUNTING ......................................................................................................................................... 4-1

CONNECTIONS ................................................................................................................................ 4-14

MAINTENANCE ................................................................................................................................ 4-19

STORAGE ......................................................................................................................................... 4-19

SECTION 5 TESTING ............................................................................................................................ 5-1

TRODUCTION ................................................................................................................................. 5-1

IN

REQUIRED TEST EQUIPMENT ........................................................................................................ 5-1

OPERATIONAL TEST ........................................................................................................................ 5-1

Power Supply Status Output ........................................................................................................ 5-1

Pickup ........................................................................................................................................... 5-1

Timing ........................................................................................................................................... 5-4

9170600990 Rev L BE1-27/59 Introduction v

Page 8

vi BE1-27/59 Introduction 9170600990 Rev L

Page 9

SECTION 1 • GENERAL INFORMATION

Purpose

The BE1-27 Undervoltage, BE1-59 Overvoltage and the BE1-27/59 Under/Overvoltage Relays are solidstate devices that provide reliable protection for generators, motors, and transformers against adverse

system voltage conditions.

Application

Electric power systems are designed for constant voltage operation. Loads utilizing commercial electric

power are designed to operate at a constant input voltage level with some tolerance. Radical voltage

variations on a power system are indicative of a system malfunction. Protective relays that monitor

system voltage and provide an output signal when the voltage goes outside predetermined limits, find a

variety of applications. Some of these applications include motor and transformer protection, interface

protection for cogeneration systems, and supervision of automatic transfer switching schemes.

Motor Protection

When selecting the type of protection for motor applications, the motor type, voltage rating, horsepower,

thermal capability during start-up, and exposure to automatic transfer restarting following a voltage

interruption need to be considered. During motor start-up, a low terminal voltage condition will inhibit the

motor from reaching rated speed. The BE1-27 Undervoltage Relay will detect this low voltage condition

and trip. Critical applications requiring continuous motor operation and applications where overloads

during start-up may be maintained for a given time period, usually have a definite time or inverse time

delay characteristic incorporated to avoid unnecessary tripping during low voltage dips. If the

undervoltage condition persists for the established time delay, the relay output contacts are connected to

the station alarm annunciator panel, allowing the station operator to take corrective action. The BE1-59

Overvoltage Relay is applied to insure the voltage does not exceed the limits established by the machine

manufacturer for proper operation. Overvoltage conditions stress the insulation level of the equipment and

may cause a dielectric breakdown resulting in a flash over to ground.

Automatic Transfer Switching

Distribution substations are sometimes designed with duplicate supply circuits and transformers to

eliminate service interruptions due to faults located on the primary feeder. In order to restore service

within a given acceptable time period, automatic transfer switching can be applied to initiate the throw

over from primary power to the alternate power source. The BE1-27 Undervoltage Relay can initiate

switching after a given time delay to void transfer switching during temporary low voltage conditions. To

return the substation to normal service upon the restoration of primary voltage, the BE1-59 Overvoltage

Relay supervises the transition to its normal operating condition.

Cogeneration

Utilities employ the use of a voltage check scheme to supervise reclosing at the substation when

cogenerators are connected to a radial distribution feeder and the cogenerator is capable of supplying the

entire load when the utility circuit breaker is open. During a faulted condition, the utility requires the

cogenerator to be disconnected from the system before reclosing the utility breaker. If the cogenerator is

connected to the system, the utility will reclose to an energized line.

This could result in reconnecting two systems out of synchronism with each other. A BE1-27

Undervoltage Relay monitoring the line voltage will inhibit reclosing of the utility circuit breaker if the

cogenerator energizes the line.

At the interface between the utility and the cogenerator, overvoltage and undervoltage relays are installed

as minimum protection to provide an operating voltage window for the cogenerator. During faulted

conditions, when the cogenerator may become overloaded, the BE1-27 Undervoltage Relay will detect

the decline in voltage and remove the cogenerator from the system. The BE1-59 Overvoltage Relay will

protect the system from overvoltage conditions that occur when power factor correction capacitors are

located on the feeder.

9170600990 Rev L BE1-27/59 General Information 1-1

Page 10

Transformer Protection

BE1-59

7

6

D2816-13

05-29-98

Voltage relays can be applied to protect large transformers from damage because of overexcitation. The

concern for transformer overvoltage may be minimized in many power system applications where proper

voltage control of the generating unit is provided. However, where a tap changing regulating transformer

is located between the generating source and the load, some form of voltage protection may be required

to supplement the tap changing control and to prevent equipment damage due to over, as well as

undervoltage resulting from a failure of the tap changing control. The BE1-27/59 Under/Overvoltage Relay

is well suited for these applications.

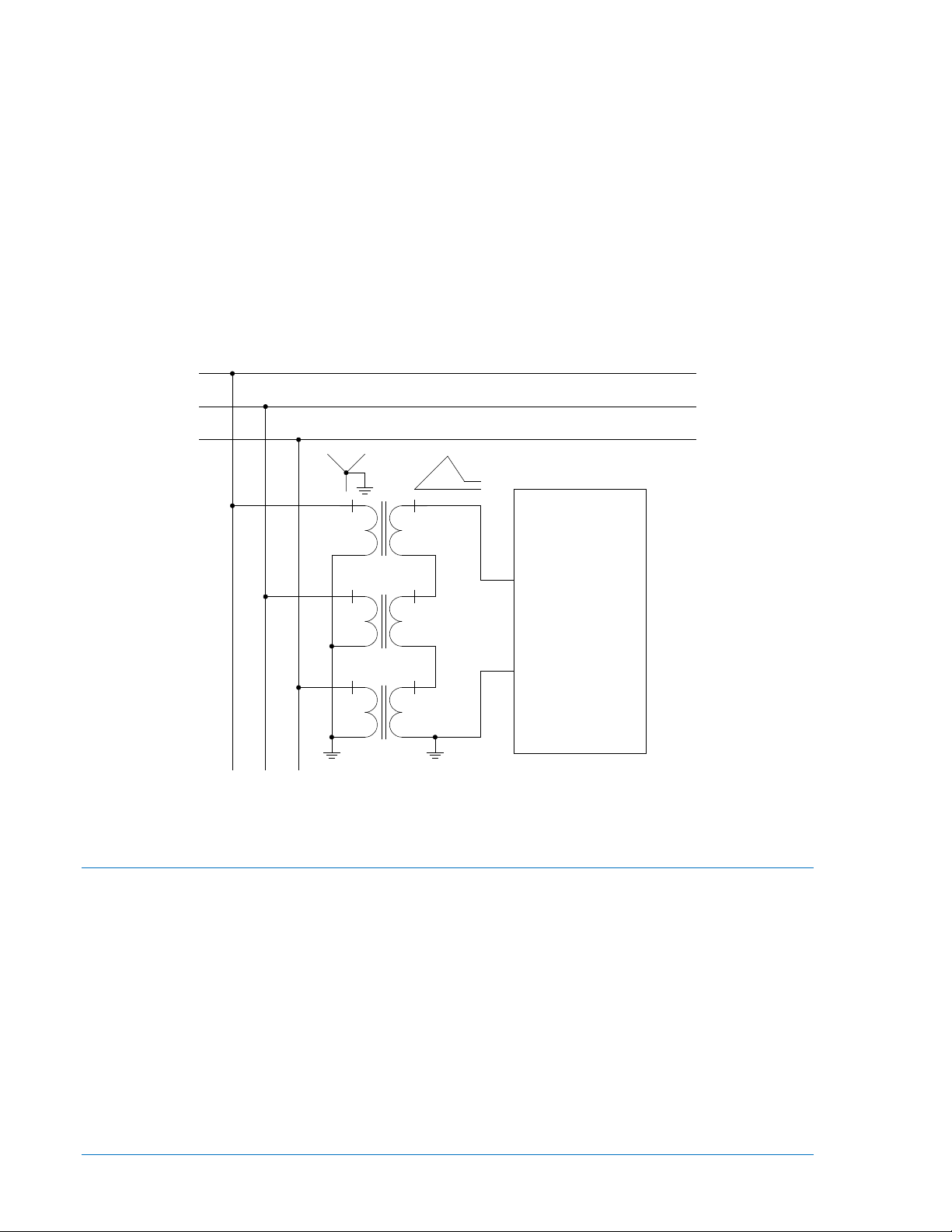

Ground Fault Detection

In a three-phase, three-wire system, a single conductor may break or the insulation may deteriorate

resulting in a high resistance ground fault that may not be detected by the overcurrent relays. This

condition, however, may be sensed by an overvoltage relay connected to a grounded wye, broken delta

set of potential transformers (PT's) as illustrated in Figure 1-1 with this connection, and a sensitive relay

setting, an unbalanced voltage condition such as described above, can be quickly detected and isolated.

Figure 1-1. Ground Fault Detection

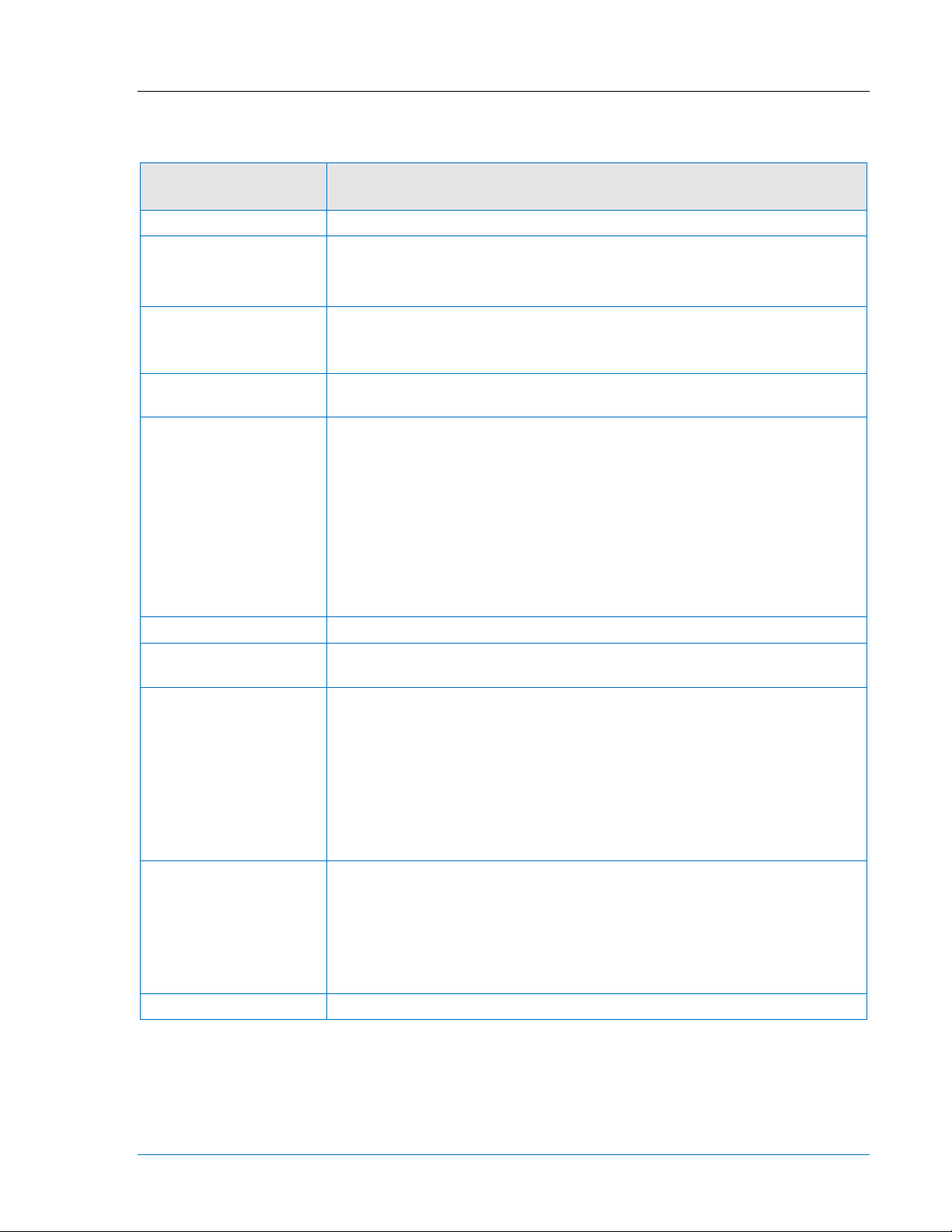

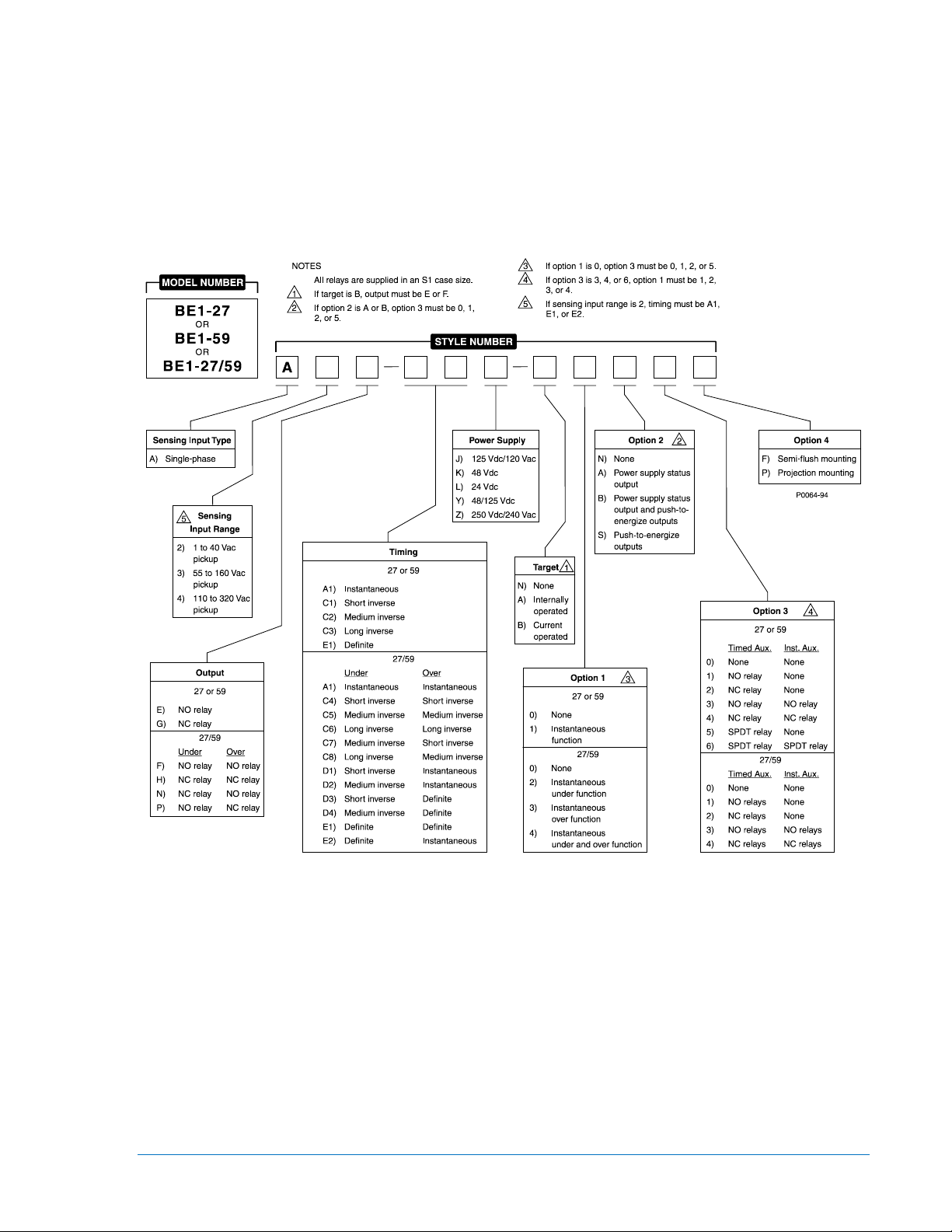

Model and Style Number

BE1-27, BE1-59, and BE1-27/59 electrical characteristics and operational features are defined by a

combination of letters and numbers that make up the style number. Model number BE1-27/59 designates

the relay as a Basler Electric Under/Overvoltage Protective Relay. The model number, together with the

style number, describes the options included in a specific device and appears on the front panel, draw-out

cradle, and inside the case assembly.

The style number identification chart for the BE1-27/59 relay is illustrated in Figure 1-2.

1-2 BE1-27/59 General Information 9170600990 Rev L

Page 11

Figure 1-2. Style Number Identification Chart

9170600990 Rev L BE1-27/59 General Information 1-3

Page 12

Style Number Example

If a BE1-27/59 relay has a style number of A3F–E1J–A0S1F, the relay has the following features:

A ------- Single-phase voltage sensing input

3 -------- Sensing input compatible with a pickup adjustment range of 55 to 160 Vac

F -------- 2 normally open output relays (one per function)

E1 ------ Definite timing for each function

J -------- Relay control power is 125 Vdc or 120 Vac, nominal

A ------- Two internally operated target indicators (one per function)

0 -------- No instantaneous functions

S ------- Push-to-energize outputs

1 -------- Two normally-open auxiliary output relays (one per function)

F -------- Semi-flush mounting case

Specifications

Electrical and physical specifications are listed in the following paragraphs.

Voltage Sensing Inputs

Nominally rated at 50/60 Hz, (120/240 V or 100/200 V) with a maximum continuous voltage rating of 360

V (120 V nominal) or 480 V (240 V nominal) at a burden less than 1 VA per phase. Frequency range is

from 40 to 70 Hz.

Undervoltage and Overvoltage Pickup Range

Pickup Range ................................... Continuously adjustable over the range of 1 to 40, 55 to 160, or 110

to 320 Vac as defined by the Style Chart. See Section 3, Functional

Description, System Voltages, for explanation of pickup ranges.

Pickup Accuracy ............................... ±2% or ±0.5 volts of the pickup setting, whichever is greater.

Dropout ............................................. ±2% of pickup.

Timing Characteristics

Instantaneous ................................... Less than 50 milliseconds for a voltage level that exceeds the pickup

setting by 5% or 1 volt, whichever is greater

Definite .............................................. Adjustable from 0.1 to 9.9 seconds, in steps of 0.1 seconds.

Accuracy is ±2% or ±50 milliseconds, whichever is greater. (A setting

of 0.0 provides instantaneous timing.)

Inverse .............................................. Inverse curve types are defined by the Style Chart and are

represented by the curves shown in Section 3, Functional

Description. Inverse time is adjustable from 01 to 99 in increments of

01. Incrementing the time dial varies the inverse curve along the Y

axis. A setting of 00 designates instantaneous timing.

Accuracy is within ±5% or 50 milliseconds (whichever is greater) of

the indicated time for any combination of the time dial setting and

pickup setting and is repeatable within ±2% or 50 ms (whichever is

greater) for any combination of time dial and tap setting. Curves

were generated with Prefault voltage at 10% greater than pickup for

the 27 curves and 10% less than pickup for the 59 curves. For

Prefault voltages that are greater in difference from the pickup

setting, the timing accuracy is ±10% or 100 ms (whichever is

greater).

1-4 BE1-27/59 General Information 9170600990 Rev L

Page 13

Output Contacts

Resistive Ratings

120 Vac ............................................. Make, break, and carry 7 Aac continuously

250 Vdc ............................................. Make and carry 30 Adc for 0.2 s, carry 7 Adc continuously,

break 0.3 Adc

500 Vdc ............................................. Make and carry 15 Adc for 0.2 s, carry 7 Adc continuously,

break 0.3 Adc

Inductive Ratings

120 Vac, 125 Vdc, 250 Vdc .............. Break 0.3 A (L/R = 0.04)

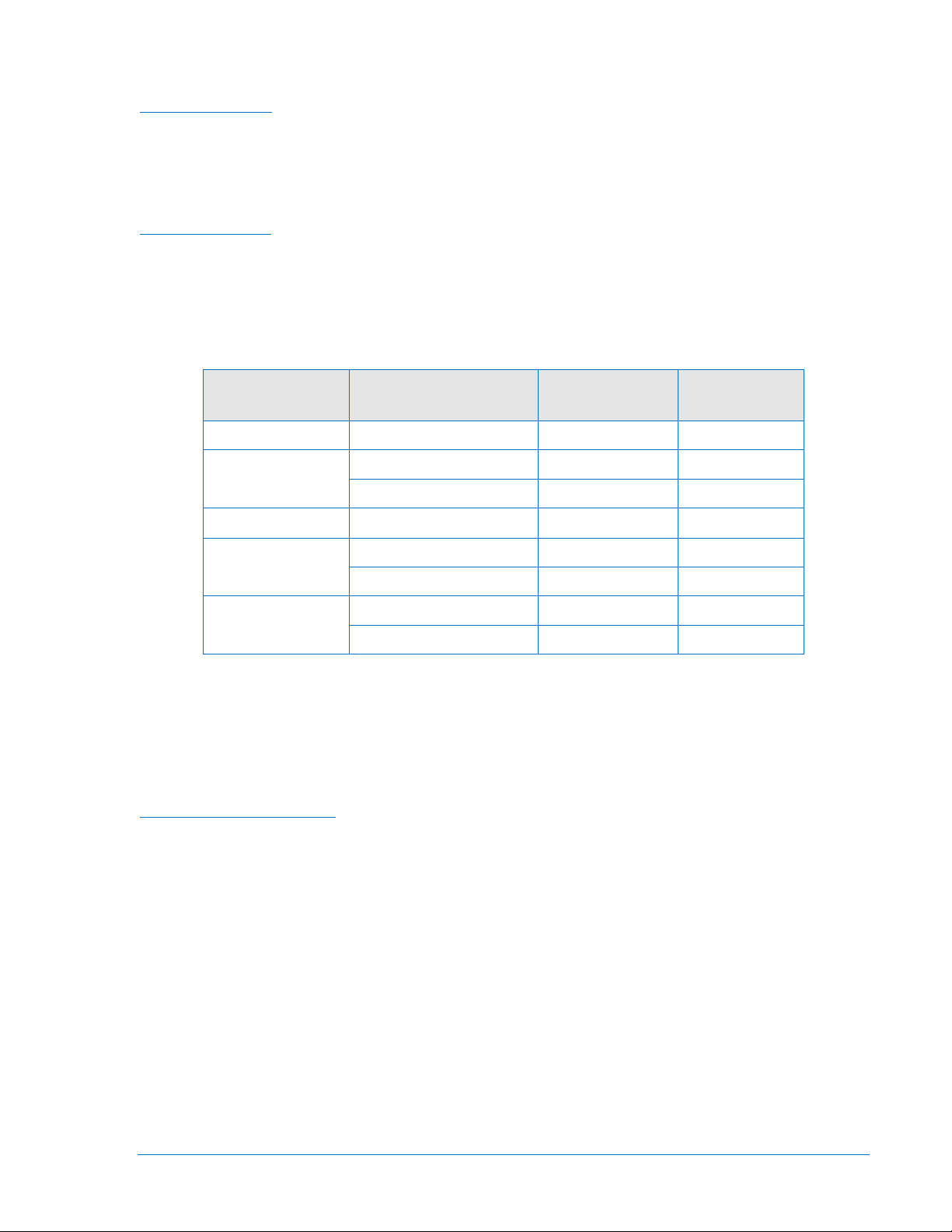

Power Supply

Power supply types and specifications are listed in Table 1-1.

Table 1-1. Power Supply Ratings

Type

K (midrange) 48 Vdc 24 to 150 Vdc 3.8 W

J (midrange)

L (low range) 24 Vdc

Y (midrange)

Z (high range)

* Type L power supply initially requires 14 Vdc to begin operating. Once operating, the input voltage may

be reduced to 12 Vdc and operation will continue.

Nominal

Input Voltage

125 Vdc 24 to 150 Vdc 4.0 W

120 Vac 90 to 132 Vac 17.1 VA

48 Vdc 24 to 150 Vdc 3.8 W

125 Vdc 24 to 150 Vdc 4.0 W

250 Vdc 68 to 280 Vdc 4.1 W

240 Vac 90 to 270 Vac 28.4 VA

Input Voltage

Range

12 to 32 Vdc *

Burden at

Nominal

3.9 W

Target Indicators

Electronically latched, manually reset target indicators are optionally available to indicate closure of the

trip output contacts. Either internally operated or current operated targets may be specified. Internally

operated targets should be selected when normally closed (NC) output contacts are specified.

Current Operated Targets

Minimum Rating ................................ 200 mA flowing through the trip circuit

Continuous Rating ............................ 3 A

1 Second Rating ............................... 30 A

2 Minute Rating................................. 7 A

Type Tests

Shock ................................................ Withstands 15 G in each of three mutually perpendicular planes

without structural damage or performance degradation.

Vibration ............................................ Withstands 2 G in each of three mutually perpendicular planes,

swept over the range of 10 to 500 Hz for a total of six sweeps, 15

minutes each sweep, without structural damage or degradation of

performance.

Dielectric Strength ............................ Tested in accordance with IEC 255-5 and IEEE C37.90: 2,000 Vac

applied for 1 min

Impulse Test ..................................... Qualified to IEC 255-5

9170600990 Rev L BE1-27/59 General Information 1-5

Page 14

Radio Frequency Interference .......... Qualified to IEEE C37.90.2-1995, Standard for Withstand Capability

of Relay Systems to Radiated Electromagnetic Interference from

Transceivers.

Surge Withstand Capability .............. Qualified to IEEE C37.90.1-1989, Standard Surge Withstand

Capability (SWC) Tests for Protective Relays and Relay Systems.

Temperature

Operating Range .............................. –40 to 70°C (–40 to 158°F)

Storage Range .................................. –65 to 100°C (–85 to 212°F)

Physical

Weight ............................................... 14 lbs (6.35 kg)

Case Size ......................................... S1 (See Section 4 for panel cutting/drilling dimensions.)

Agency Recognition/Certification

UL Recognition ................................. UL recognized per Standard 508, File E97033

NOTE: Output contacts are not UL recognized for voltages greater

than 250 volts.

GOST-R Certification ........................ GOST-R certified per the relevant standards of Gosstandart of

Russia.

1-6 BE1-27/59 General Information 9170600990 Rev L

Page 15

SECTION 2 • CONTROLS AND INDICATORS

Introduction

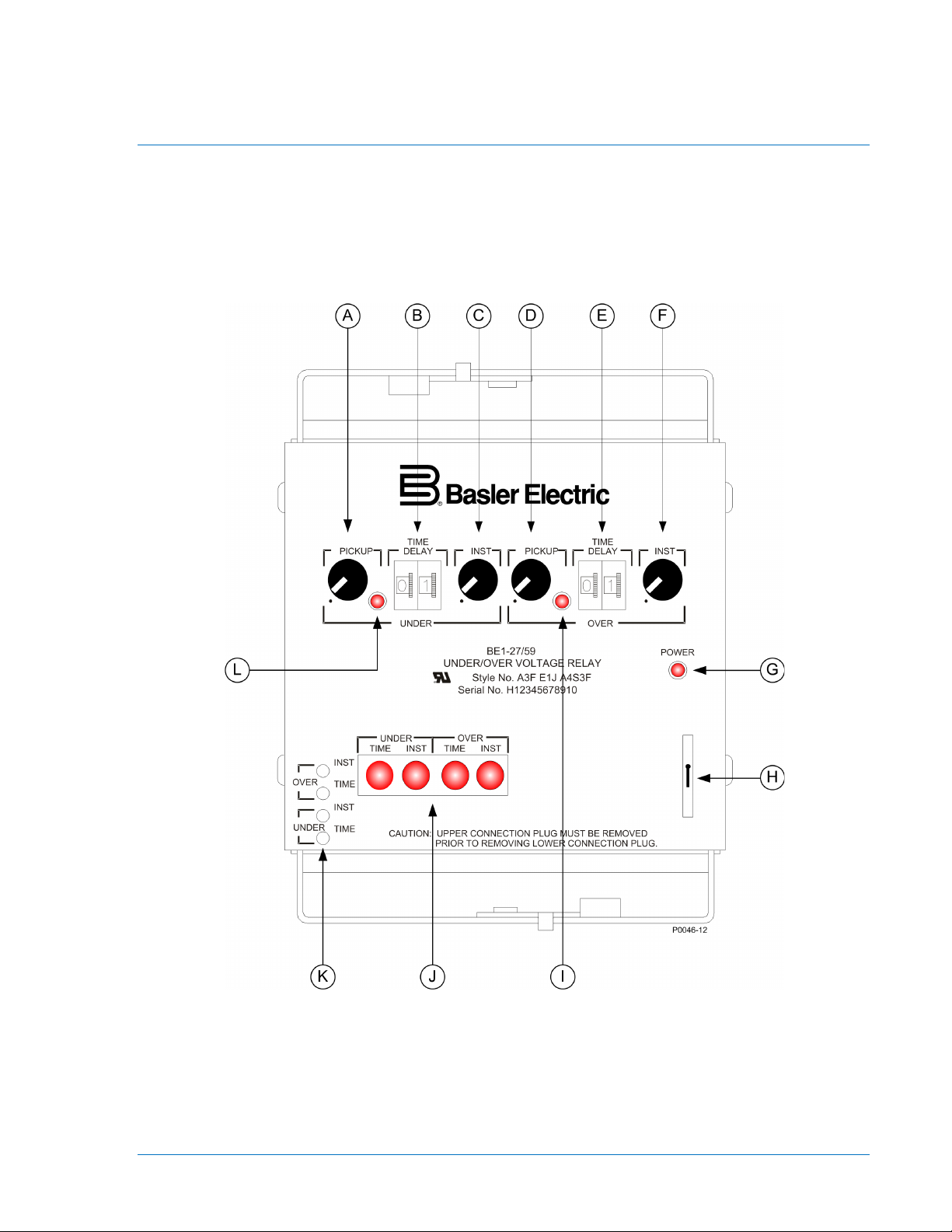

Controls and indicators are located on the front panel. The controls and indicators are shown in Figure

2-1 and described in Table 2-1. Figure 2-1 illustrates a relay with the maximum number of controls and

indicators. Your relay may not have all of the controls and indicators shown and described here.

Figure 2-1. Location of Controls and Indicators

9170600990 Rev L BE1-27/59 Controls and Indicators 2-1

Page 16

Establishes setpoint for the instantaneous

setpoint for the instantaneous

Table 2-1. Control and Indicator Descriptions

Locator Description

A

B

D

E

Undervoltage Pickup Control. Establishes setpoint for the timed undervoltage function.

Continuously adjustable over the range defined by the style number.

Undervoltage Time Delay Control. Establishes the interval between undervoltage pickup

and the time delayed output. Defined by the style number, this delay is either a useradjustable definite time or inversely proportional to the magnitude of the undervoltage

condition. A setting of 0.0 provides an instantaneous response.

Definite - adjustable from 0.0 to 9.9 seconds in 0.1 second increments.

InverseC - adjusts inverse timing characteristic curve relative to the time axis. (See the

characteristic curves in Section 3.)

Undervoltage Instantaneous Control.

undervoltage function. Continuously adjustable over the range defined by the style

number.

Overvoltage Pickup Control. Establishes setpoint for the timed overvoltage function.

Continuously adjustable over the range defined by the style number.

Overvoltage Time Delay Control. Establishes the interval between overvoltage pickup

and the time delayed output. Defined by the style number, this delay is either a useradjustable definite time or inversely proportional to the magnitude of the overvoltage

condition. A setting of 0.0 provides an instantaneous response.

Definite - adjustable from 0.0 to 9.9 seconds in 0.1 second increments.

InverseF - adjusts inverse timing characteristic curve relative to the time axis. (See the

characteristic curves in Section 3.)

Overvoltage Instantaneous Control. Establishes

overvoltage function. Continuously adjustable over the range defined by the style

number.

G Power Indicator. This red LED lights when operating power is applied to the relay.

H Target Reset Switch. This switch is operated to reset the target indicators.

I

J

K

L

Overvoltage Pickup LED. A red LED that illuminates when overvoltage exceeds the

pickup setting.

Target Indicators. The electronically latched red target indicators illuminate when the

corresponding output relay energizes. To ensure proper operation of current-operated

targets, the current flowing through the trip circuit must be 200 mA or higher. Target

indicators are reset by operating the target reset switch (locator H).

Output Test Pushbuttons. These pushbuttons allow manual actuation of the output relays.

Output relay actuation is achieved by inserting a nonconductive rod through the front

panel access holes.

Undervoltage Pickup LED. A red LED that illuminates when undervoltage exceeds the

pickup setting.

2-2 BE1-27/59 Controls and Indicators 9170600990 Rev L

Page 17

SECTION 3 • FUNCTIONAL DESCRIPTION

AUX.

TARGET

AUX.

AUX.

AUX.

POWER

SUPPLY

STATUS

OV TIME

DIAL

OV

TIMER

TIMED

OV

COMPARATOR

OV

PICKUP SETTINGS

INST. TIMED

UNDER OVER

UNDER

OVER

UV TIME

DIAL

UV

TIMER

TIMED

UV

COMPARATOR

UV

INST.

OV

COMPARATOR

INST.

UV

COMPARATOR

POWER

SUPPLY

SENSOR

UV

POWER

SUPPLY

SENSOR

TO INTERNAL

CIRCUITRY

FULL-WAVE

RECTIFIER

LOW-PASS

FILTER

MONITORED

VOLTAGE

OPERATING

POWER

D2354-03

03-11-96

TARGET

TARGET

TARGET

Introduction

BE1-27, BE1-59, and BE1-27/59 relay functions are illustrated in Figure 3-1 and described in the following

paragraphs.

Figure 3-1. Function Block Diagram

System Voltages

The BE1-27, BE1-59, and BE1-27/59 relays are available with three sensing input ranges. The 55 to

160V range is intended for use with nominal system voltages of 120V or 69V (120 ÷ √3). The 110 to 320V

range is intended for use with nominal system voltages of 240V, 208V (120 x √3) or 277V (480 ÷ √3). The

1 to 40V range is intended for use with a wye/broken delta PT configuration with 120V or 69V (120 ÷ √3)

line-to-ground secondary voltages. The wye/broken delta PT configuration is a zero sequence filter

capable of producing three times the line-to-ground voltage (3Vo).

9170600990 Rev L BE1-27/59 Functional Description 3-1

Page 18

Step-Down Transformer

The monitored system voltage is applied to the primary of an internal potential transformer and stepped

down to internal circuit levels. The transformer provides a high degree of isolation.

Low-Pass Filter and Full Wave Rectifier

The output of the step-down transformer is low-pass filtered to prevent undesired response to highfrequency noise. Frequencies above 226 Hz are attenuated. The ac signal is then full-wave rectified to

produce positive-going half-cycles that represent the magnitude of the monitored system voltage.

Pickup Settings

Controlled by front panel single-turn potentiometers, the pickup settings establish reference voltages

representative of the system voltage that will cause the relay to respond. Pickup settings are individually

adjustable for timed under/overvoltage functions and instantaneous under/overvoltage functions. On BE127/59, Under/Overvoltage Relays, the undervoltage function takes precedence over the overvoltage

function.

Pickup Comparators

The output of the rectifier circuit is compared to each pickup setting. When the monitored system voltage

is greater than any pickup setting, the effected comparator’s output goes high. When the monitored

system voltage is less than any pickup setting, the effected comparator’s output goes low. The effects of

these outputs are shown below.

Relevant Pickup Setting

Comparator

High

Low

Undervoltage Overvoltage Undervoltage Overvoltage

No effect Lights OV pickup

Lights UV pickup

indicator; initiates

timer

Timed Instantaneous

No effect Energizes output

indicator; initiates

timer

No effect Energizes output

relay

relay

No effect

Timer Circuit

Once initiated, the timer circuit measures the interval from pickup. If the adverse condition continues

through the programmed delay, the timer circuit energizes the appropriate output relay. In relay styles

with inverse timing, the extent to which the monitored system voltage exceeds the pickup setting

influences the actual time delay such that a greater voltage difference from pickup produces a more rapid

response. This response is illustrated in the characteristic curves as shown in Figures 3-2 through 3-7.

3-2 BE1-27/59 Functional Description 9170600990 Rev L

Page 19

Voltage Difference From Pickup

01

02

03

05

07

10

20

30

40

50

60

80

99

D2857-24

0.1

1.0

100

1000

Range 3

Range 4

0

48

121620

24

28

32

36404448

0

816

243240

48

56

64

72808896

Time in Seconds

10

Figure 3-2. Undervoltage, Short Inverse Timing Characteristic Curve

Figure 3-3. Undervoltage, Medium Inverse Timing Characteristic Curve

9170600990 Rev L BE1-27/59 Functional Description 3-3

Page 20

0.1

1.0

10

1000

Voltage Difference From Pickup

Time in Seconds

01

02

03

05

07

10

20

30

40

50

60

80

99

0

4

8

121620

24

28

32

36404448

0

8

16

243240

48

56

64

72808896

D2857-25

06-09-03

Range 3

Range 4

100

Figure 3-4. Undervoltage, Long Inverse Timing Characteristic Curve

Figure 3-5. Overvoltage, Short Inverse Timing Characteristic Curve

3-4 BE1-27/59 Functional Description 9170600990 Rev L

Page 21

Figure 3-6. Overvoltage, Medium Inverse Timing Characteristic Curve

Figure 3-7. Overvoltage, Long Inverse Timing Characteristic Curve

9170600990 Rev L BE1-27/59 Functional Description 3-5

Page 22

Outputs

27/59 target indicators consisted of

Defined by the style number, the output relays may be provided for each of the following functions: timed

undervoltage, timed overvoltage, instantaneous undervoltage, and instantaneous overvoltage. Auxiliary

output relays may be provided for each of these functions as well. Once energized, output relays will

remain energized until the adverse condition stops.

Push-To-Energize Output Pushbuttons

Small pushbutton switches may be provided as an option to allow testing the primary output contacts and

(if present) the auxiliary output contacts. To prevent accidental operation, the pushbuttons are recessed

behind the front panel and are depressed by inserting a thin, non-conducting rod through an access hole

in the front panel.

Power Supply Status Output

The power supply status relay has a set of normally closed contacts and energizes when operating power

is applied to the relay. If relay operating power is lost or either side of the power supply output (+12 Vdc

or –12 Vdc) fails, the power supply status relay de-energizes and closes the power supply status output

contacts.

Power Supply

Operating power for the relay circuitry is supplied by a wide range, electrically isolated, low-burden power

supply. Power supply operating power is not polarity sensitive. The front panel power LED and power

supply status output indicate when the power supply is operating. Power supply specifications are listed in

Table 1-1.

Target Indicators

Target indicators are optional components selected when a relay is ordered. The electronically latched

and reset targets consist of red LED indicators located on the relay front panel. A latched target is reset

by operating the target reset switch on the front panel. If relay operating power is lost, any illuminated

(latched) targets are extinguished. When relay operating power is restored, the previously latched targets

are restored to their latched state.

A relay can be equipped with either internally operated targets or current operated targets.

Internally Operated Targets

The relay trip outputs are directly applied to drive the appropriate target indicator. Each indicator is

illuminated regardless of the current level in the trip circuit.

Current Operated Targets

A current operated target is triggered by closure of the corresponding output contact and

at least 200 milliamperes of current flowing in the trip circuit.

NOTE

Prior to September 2007, BE1magnetically latched, disc indicators. These mechanically latched target

indicators have been replaced by the electronically latched LED targets in use

today.

the presence of

3-6 BE1-27/59 Functional Description 9170600990 Rev L

Page 23

SECTION 4 • INSTALLATION

When the relay is configured in a system with other devices, it is

Introduction

The relays are shipped in sturdy cartons to prevent damage during transit. Upon receipt of a relay, check

the model and style number against the requisition and packing list to see that they agree. Inspect the

relay for shipping damage. If there is evidence of damage, file a claim with the carrier, and notify your

sales representative or Basler Electric.

If the relay will not be installed immediately, store it in its original shipping carton in a moisture- and dustfree environment. Before placing the relay in service, it is recommended that the test procedures of

Section 5, Testing be performed.

Relay Operating Guidelines and Precautions

Before installing or operating the relay, note the following guidelines and precautions.

● For proper current operated target operation, a minimum current of 200 milliamperes must flow

through the output trip circuit.

● If a wiring insulation test is required, remove the connection plugs and withdraw the relay from its

case.

● An undervoltage target indication may occur when the lower connection paddle is removed if:

○ The instantaneous time function is selected, or

○ A time delay (definite or inverse) below 0.3 seconds is selected.

○ No actual trip output occurs if the upper paddle is removed first.

CAUTION

When the connection plugs are removed, the relay is disconnected from the

operating circuit and will not provide system protection. Always be sure that

external operating (monitored) conditions are stable before removing a relay

for inspection, test, or service.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12

AWG copper wire attached to the ground terminal on the rear of the case.

recommended to use a separate lead to the ground bus from each device.

Mounting

Because the relay is of solid-state design, it does not have to be mounted vertically. Any convenient

mounting angle may be chosen.

A panel cutting/drilling diagram for a semi-flush, S1 case is illustrated in Figure 4-1. An outline of the case

cover is shown around the cut-out. Relay outline dimensions and panel drilling diagrams are illustrated in

Figures 4-2 through 4-12.

9170600990 Rev L BE1-27/59 Installation 4-1

Page 24

0.552

(14)

8.63

(219)

0.480

(12)

Outer Edge of Cover

Cut-Out

5.69 (144)

0.480

(12)

8.25

(210)

C

L

0.575

(15)

0.25 (6) diameter, 4 places

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, S1 Case

6.06 (154)

3.03 (77)

4.13

(105)

P0072-12

4-2 BE1-27/59 Installation 9170600990 Rev L

Page 25

Figure 4-2. S1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

9170600990 Rev L BE1-27/59 Installation 4-3

Page 26

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

MOUNTING PANEL

(55.75)

2.195

P0066-64

Figure 4-3. S1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

4-4 BE1-27/59 Installation 9170600990 Rev L

Page 27

Figure 4-4. S1 Case Dimensions, Rear View, Single Ended, Semi-Flush Mount

9170600990 Rev L BE1-27/59 Installation 4-5

Page 28

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-69

8.06

(204.72)

(7.9)

.31

Figure 4-5. S1 Case Dimensions, Side View, Single Ended, Semi-Flush Mount

4-6 BE1-27/59 Installation 9170600990 Rev L

Page 29

Figure 4-6. Panel Cutting/Drilling, Double Ended, Projection Mount, S1 Case

9170600990 Rev L BE1-27/59 Installation 4-7

Page 30

Figure 4-7. S1 Case Dimensions, Rear View, Double Ended, Projection Mount

4-8 BE1-27/59 Installation 9170600990 Rev L

Page 31

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

(55.75)

2.195

P0066-67

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

Figure 4-8. S1 Case Dimensions, Side View, Double Ended, Projection Mount

9170600990 Rev L BE1-27/59 Installation 4-9

Page 32

Figure 4-9. Panel Cutting/Drilling, Single Ended, Projection Mount, S1 Case

4-10 BE1-27/59 Installation 9170600990 Rev L

Page 33

Figure 4-10. S1 Case Dimensions, Rear View, Single Ended, Projection Mount

9170600990 Rev L BE1-27/59 Installation 4-11

Page 34

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-71

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

8.06

(204.72)

(7.9)

.31

.75

(19.1)

Figure 4-11. S1 Case Dimensions, Side View, Single Ended, Projection Mount

4-12 BE1-27/59 Installation 9170600990 Rev L

Page 35

P0066-68

Figure 4-12. S1 Case Cover Dimensions, Front View

9170600990 Rev L BE1-27/59 Installation 4-13

Page 36

Connections

Be sure to check the model and style number of a relay before connecting and energizing the relay.

Incorrect wiring may result in damage to the relay. Except where noted, connections should be made with

wire no smaller than 14 AWG.

Typical internal connections are shown in Figures 4-13 through 4-15. Typical ac connections are shown in

Figure 4-16. Typical dc connections are shown in Figure 4-17.

Figure 4-13. BE1-27 Internal Connections

4-14 BE1-27/59 Installation 9170600990 Rev L

Page 37

Figure 4-14. BE1-59 Internal Connections

9170600990 Rev L BE1-27/59 Installation 4-15

Page 38

Figure 4-15. BE1-27/59 Internal Connections

4-16 BE1-27/59 Installation 9170600990 Rev L

Page 39

Figure 4-16. Typical AC Connections

9170600990 Rev L BE1-27/59 Installation 4-17

Page 40

Figure 4-17. Typical DC Connections

4-18 BE1-27/59 Installation 9170600990 Rev L

Page 41

Maintenance

BE1-27, BE1-59, and BE1-27/59 relays require no preventative maintenance other than a periodic

operational check. If the relay fails to function properly, contact Technical Sales Support at Basler Electric

to coordinate repairs.

Storage

This device contains long-life aluminum electrolytic capacitors. For devices that are not in service (spares

in storage), the life of these capacitors can be maximized by energizing the device for 30 minutes once

per year.

9170600990 Rev L BE1-27/59 Installation 4-19

Page 42

4-20 BE1-27/59 Installation 9170600990 Rev L

Page 43

SECTION 5 • TESTING

Introduction

The following procedures verify proper relay operation and calibration.

Results obtained from these procedures may no fall within specified tolerances. When evaluating results,

consider three prominent factors:

• Test equipment accuracy

• Testing method

• External test set components tolerance level

Required Test Equipment

Minimum test equipment required for relay testing and adjustment is listed below. Refer to Figure 5-1 for

the test setup.

NOTE

Commercially available frequency relay test sets with frequency and time

generating accuracies exceeding those of the relay and including electronic

switching, may be used.

• Appropriate ac or dc power source for relay operation.

• Appropriate ac source for frequency sensing. (A source with frequency stability of 0.00002 Hz

must exhibit phase noise of less than 90 db for accurate measurement. The accuracy and

stability of this source is necessary as the relay precisely measures the period between positive

going zero-crossings of the applied waveform and responds instantaneously to the sensed

condition.)

• Hardware (battery and lamp, multimeter, etc.) or method of determining that the output contacts

close.

Operational Test

Power Supply Status Output (Option 2-A or B)

Step 1. With the unit in a powered-up condition, verify that the power supply status output contacts

are energized open.

Step 2. Remove input power and verify that the status output contacts close.

Pickup

Step 1. Connect the test circuits shown in Figure 5-1 as necessary for the functions included in your

relay model. See Table 5-1. Turn all undervoltage pickup controls fully CCW and all

overvoltage pickup functions fully CW. Set all time delay controls to 00. Adjust T1 to nominal

voltage for your sensing input range as indicated below.

Table 5-1. Sensing Input Range

Sensing Input Range

2 3 4

120 Vac 120 Vac 240 Vac

9170600990 Rev L BE1-27/59 Testing 5-1

Page 44

NOTE

V

3

4

6

7

12

11

13

10

2

1

OPERATING

POWER

AC

SOURCE

BE1-27, 59,

27/59

+

D2816-15

Results assume normally open output contacts. Test indicator states will be

opposite for normally closed output contacts.

Figure 5-1. Pickup and Dropout Test Circuit Diagram

Figure 5-2. Timing Test Circuit Diagram

5-2 BE1-27/59 Testing 9170600990 Rev L

Page 45

RESULTS: In relays with Sensing Input Range 2, the OVER PICKUP indicator is illuminated as well as

the timed and instantaneous overvoltage test indicators. In units with Sensing Input Range 3 or 4, all

pickup and test indicators will be extinguished.

Table 5-2. Output Terminals

Pickup Function

Timed Undervoltage 1-10

Instantaneous Undervoltage 2-10

Timed Overvoltage

Instantaneous Overvoltage

NOTE

Steps 2 through 4 apply only to units with Sensing Input Range 2.

Step 2. Slowly decrease the T1 voltage until the OVER PICKUP indicator and the timed and

instantaneous overvoltage test indicators extinguish. Slowly increase the T1 voltage until the

OVERVOLTAGE PICKUP indicator and the timed and instantaneous overvoltage test

indicators illuminate. Record the voltage.

RESULT: This voltage is between 39.2 and 40.8 Vac.

Step 3. Turn the timed and instantaneous OVERVOLTAGE PICKUP controls fully CCW. Slowly

decrease the T1 voltage until the OVERVOLTAGE PICKUP indicator and the timed and

instantaneous test indicators extinguish.

Step 4. Slowly increase the voltage at T1 until the OVERVOLTAGE PICKUP indicator and the timed

and instantaneous overvoltage test indicators illuminate. Measure and record the voltage.

RESULT: This voltage is between 0.5 and 1.5 Vac.

This concludes the pickup test for units with Sensing Input Range 2.

Relay Model

27 59 27/59

2-10

12-13

—

—

—

—

1-10 1-10

2-10 11-13

NOTE

Steps 5 and 6 apply only to undervoltage functions.

Step 5. Slowly decrease the voltage at T1 until the UNDER PICKUP indicator and the timed and

instantaneous test indicators illuminate. Measure and record the voltage.

RESULT: The voltage is between 53.9 and 56.1 Vac for Sensing Input Range 3 or between 107.8 and

112.2 Vac for Sensing Input Range 4.

Step 6. Increase T1 voltage to 170 Vac for Sensing Input Range 3 or 330 Vac for Sensing Input

Range 4. Turn all undervoltage pickup controls fully CW. Slowly decrease T1 voltage until

the UNDER PICKUP indicator and timed and instantaneous undervoltage test indicators

illuminate. Measure and record the voltage.

RESULT: This voltage is between 156.8 and 163.2 Vac for Sensing Input Range 3 or between 313.6

and 326.4 for Sensing Input Range 4.

This concludes the pickup test for the undervoltage functions.

NOTE

Steps 7 and 8 apply only to overvoltage functions.

9170600990 Rev L BE1-27/59 Testing 5-3

Page 46

Step 7. Slowly increase the T1 voltage until the OVER PICKUP indicator and the timed and

instantaneous overvoltage test indicators illuminate. Measure and record the voltage.

RESULT: This voltage is between 156.8 and 163.2 Vac for Sensing Input Range 3 or between 313.6

and 326.4 for Sensing Input Range 4.

NOTE

Step 8 applies only to BE1-59 relays with Sensing Input Range 3 or 4.

Step 8. Decrease the T1 voltage to 50 Vac. Turn all overvoltage pickup controls fully CCW. Slowly

increase the T1 voltage until the OVER PICKUP indicator and the timed and instantaneous

overvoltage test indicators illuminate. Measure and record the voltage.

RESULT: The voltage is between 53.9 and 56.1 Vac for Sensing Input Range 3 or between 107.8 and

112.2 Vac for Sensing Input Range 4.

This concludes the pickup test.

Timing

The following procedure verifies timing characteristics.

Step 1. Connect the test circuit shown in Figure 5-2. Output terminal connections are dependent on

the function to be tested. See Table 5-1.

Step 2. Adjust the under or overvoltage pickup settings and the T1 and T2 tap voltage levels as

indicated in Table 5-3 below for the function being tested.

Table 5-3. T1 and T2 Tap Voltage Levels

Sensing

Range

2 30

Over

Pickup

Under

Pickup

—

T1

Voltage

20 40

T2

Over Under

—

3 120 100 110 152 68

4 240 200 220 304 136

Step 3. Set the time delay control for the function being tested to 00 (50 ms or less). Press and

release S2 to assure that K1 is de-energized. Reset the timer. Press and release S1.

RESULT: The timer displays a response time, dependent on timing type, as indicated in Column 1 of

Table 5-4.

Table 5-4. Timing Test Results

Timing Type Column 1 Column 2

Instantaneous 50 ms or less 50 ms or less

Definite 0.050 to 0.150 sec 9.702 to 10.098 sec

Short Inverse 0.087 to 0.187 sec 0.092 to 0.192 sec 6.231 to 6.687 sec 6.557 to 7.247 sec

Under Over Under Over

Medium Inverse 0.292 to 0.392 sec 0.307 to 0.407 sec 24.626 to 27.218 sec 25.991 to 28.727 sec

Long Inverse 0.553 to 0.653 sec 0.583 to 0.683 sec 49.185 to 54.363 sec 51.895 to 57.358 sec

5-4 BE1-27/59 Testing 9170600990 Rev L

Page 47

Step 4. Set the time delay control for the function being tested to 01 (0.1 seconds). Press and

release S2 to assure that K1 is de-energized. Reset the timer. Press and release S1.

RESULT: The timer displays a response time, dependent on timing type, as indicated in Column 1 of

Table 5-4.

Step 5. Press and release S2. Set the time delay control for the function being tested to 99 (9.9

seconds). Reset the timer. Press and release S1.

RESULT: The timer displays a response time, dependent on timing type, as indicated in Column 2 of

Table 5-4.

Step 6. Repeat Steps 1 through 5, as necessary, for each function’s time delay control.

This concludes the operational test procedure.

9170600990 Rev L BE1-27/59 Testing 5-5

Page 48

5-6 BE1-27/59 Testing 9170600990 Rev L

Page 49

Page 50

12570 State Route 143

P.A.E. Les Pins

No. 59 Heshun Road Loufeng District (N)

111 North Bridge Road

Highland IL 62249-1074 USA

Tel: +1 618.654.2341

Fax: +1.618.654.2351

email: info@basler.com

67319 Wasselonne Cedex

FRANCE

Tel: +33 3.88.87.1010

Fax: +33 3.88.87.0808

email: franceinfo@basler.com

Suzhou Industrial Park

215122 Suzhou

P.R. CHINA

Tel: +86 512.8227.2880

Fax: +86 512.8227.2887

email: chinainfo@basler.com

15-06 Peninsula Plaza

Singapore 179098

Tel: +65 68.44.6445

Fax: +65 68.44.8902

email: singaporeinfo@basler.com

Loading...

Loading...