Page 1

INSTRUCTION MANUA L

FOR

AUTO SYNCHRONIZER

BE1-25A

Publication: 9146600990

Revision: S 10/14

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-25A Auto

Synchronizer. To accomplish this, the following information is provided:

• General Information and Specifications

• Controls and Indicators

• Functional Description

• Installation

• Maintenance

WARNING!

To avoid personal inj ury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the BE1-25A is hard-wired to earth ground w ith no smaller tha n 12

AWG copper wire attache d to the ground terminal on the rear of the unit case.

When the BE1-25A is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9146600990 Rev S BE1-25A Introduction i

Page 4

First Printing: July 1985

WARNING

Basler Electric does not assume any responsibility to compliance or noncompliance with national code,

understood prior to installation, operation, or maintenance.

For terms of service relating to this product and software, see the Commercial Terms of Products and

Services document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It

procedures, contact Basler Electric for the latest revision of this manual.

The English-language version of this manual serves as the only approved manual version.

Printed in USA

© 2014 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

October 2014

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the BE1-25A.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

local code, or any other applicable code. This manual serves as reference material that must be well

is loaned for confidential use, subject to return on request, and with the mutual understanding that it will

not be used in any manner detrimental to the interests of Basler Electric Company and used strictly for

the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this

manual provide data for every possible contingency regarding installation or operation. The availability

and design of all features and options are subject to modification without notice. Over time,

improvements and revisions may be made to this publication. Before performing any of the following

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-25A Introduction 9146600990 Rev S

Page 5

REVISION HISTORY

Revision and Date

Change

The following informat ion provides a historical su mmary of the ch anges made t o the BE1-25A instruction

manual (9146600990). Revisions are listed in reverse chronological order.

Manual

S, 10/14

R, 03/11

Q

P, 05/10

O

N, 12/09

• Added note about sync output closure in Sections 1 and 5.

• Added note about Reset switch functionality in Sections 2 and 5.

• Updated the MCU Sync Module Readings label in Figures 2-1, 2-2,

5-2, and drawing on front cover.

• This revision letter not used.

• Corrected definition of 3. POWER under Locator B in Table 2-1.

• Improved definition of SYNC LED under Locator M in Table 2-1.

• Updated Storage stat em ent in Section 4.

• Improved Verification and Calibration procedure in Section 5.

• This revision letter not used.

Section 2

• Updated Additional Modules, Frequency Matching Module F5

description.

• Updated Additional Modules, Frequency Matching Module F5, F1

Function, Pulse Contact Closure description.

• Updated Additional Modules, Frequency Matching Module F5, F3

Function, Continuous Correction Pulse description.

• Under Additional Modules, Frequency Matching Module F5, F5

Proportional Frequency Correction, changed “+12 Vdc = raise pulse;

−12 Vdc = lower pulse” to “+5 Vdc = raise pulse; −5 Vdc = lower

pulse”.

• Under Additional Modules, Frequency Matching Module F5, F5 Phase

Correction, changed “+12 Vdc = raise pulse; −12 Vdc = lower pulse”

to “+5 Vdc = raise pulse; −5 Vdc = lower pulse” and removed

sentence “The frequency of the target pulses is approximately 1.5

percent of the correction pulse width setting loaded into the

microprocessor.”

Section 3

• Corrected numbering of Figures. Figure 3-6 was skipped.

• Under Frequency Matching Modules, Frequency Correction, changed

“+12 Vdc = raise pulse; −12 Vdc = lower pulse” to “+5 Vdc = raise

pulse; −5 Vdc = lower pulse”.

• Under Frequency Matching Modules, Phase Correction, changed

“+12 Vdc = raise pulse; −12 Vdc = lower pulse” to “+5 Vdc = raise

pulse; −5 Vdc = lower pulse” and removed sentence “The frequency

of the target pulses is approximately 1.5 percent of the correction

pulse width setting loaded into the microprocessor.”

Section 4

• Deleted Dielectric Test. This is in Section 5, Testing.

• Added Maintenance and Storage from original Section 6.

Section 6

• Moved Section 7, Relay Differences to Section 6, Relay Differences.

• Corrected references to several figures.

9146600990 Rev S BE1-25A Introduction iii

Page 6

Manual

Revision and Date

Change

M, 05/08

L, 06/06

K, 05/05

J, 11/99

I

H, 08/98

G, 10/97

F, 07/96

E, 03/94

D

C

B

A

—, 07/85

• Corrected Max Slip Control range in Sections 1 & 2.

• Corrected Breaker Operating Time range in Section 2.

• Added manual part number and revision to footers.

• Corrected wording in Section 2 paragraph describing F3 function.

• Added metric weights to the specifications of Section 1.

• Changed name of the glossary to Appendix A, Glossary.

• Moved contents of Section 8, Manual Change Information, to the

• Changed all front panel illustrations to reflect changes to the panel of

• Updated Figure 4-1 to show new front panel and dimensions.

• Updated Figure 4-2 to show height of panel cutout.

• Added UL and CSA data to the specifications.

• In the cutout dimensions illustration, added clearance holes for

• This revision letter not used.

• Added US patent declaration to the specifications.

• Updated the manual format.

• Made various, minor changes to text.

• Revisions made to accommodate changes to firmware (version 5.02)

• Revised manual in response to option F5 being made standard.

• Divided Installation and Testing section into two sections.

• Changed all front panel illustrations to reflect changes in the controls

• Changed all references to voltage difference adjustment (option A2)

• Corrected dead bus VOLTS control from dc to ac.

• Deleted note attached to the SLIP HIGH LED.

• Added manual change information sec t ion to the man u al.

• Specification for max slip adjustment was corrected.

• Specification for isolation added.

• UL and CSA approval cited.

• Test procedures simplified.

• Manual completely revised to reflect the incorporation of a

• Relay differences section added.

• General editorial revisions.

• Initial release

manual introduction and deleted Section 8.

the power supply module.

attaching the cover.

which improved the performance of F1 and F3 type frequency

correction.

and indicators.

from 1-50 Vac to 1-10 Vac .

microprocessor in the synchronizer module (renamed the MCU Sync

module), and related changes beginning with product serial number

300.

iv BE1-25A Introduction 9146600990 Rev S

Page 7

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • HUMAN-MACHINE INTERFACE ....................................................................................... 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

SECTION 5 • TESTING ............................................................................................................................ 5-1

SECTION 6 • RELAY DIFFERENCES...................................................................................................... 6-1

APPENDIX A • GLOSSARY ..................................................................................................................... A-1

9146600990 Rev S BE1-25A Introduction v

Page 8

This page intentionally left blank .

vi BE1-25A Introduction 9146600990 Rev S

Page 9

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

DESCRIPTION ...................................................................................................................................... 1-1

OPTIONS ............................................................................................................................................... 1-1

MULTI-GENERATOR OPERATION ...................................................................................................... 1-1

APPLICATION ....................................................................................................................................... 1-2

General ............................................................................................................................................... 1-2

Generator-to-Bus Applicat i on ............................................................................................................. 1-2

Bus-to-Bus Application ....................................................................................................................... 1-2

Application Checklist .......................................................................................................................... 1-3

Defining the Parameters..................................................................................................................... 1-4

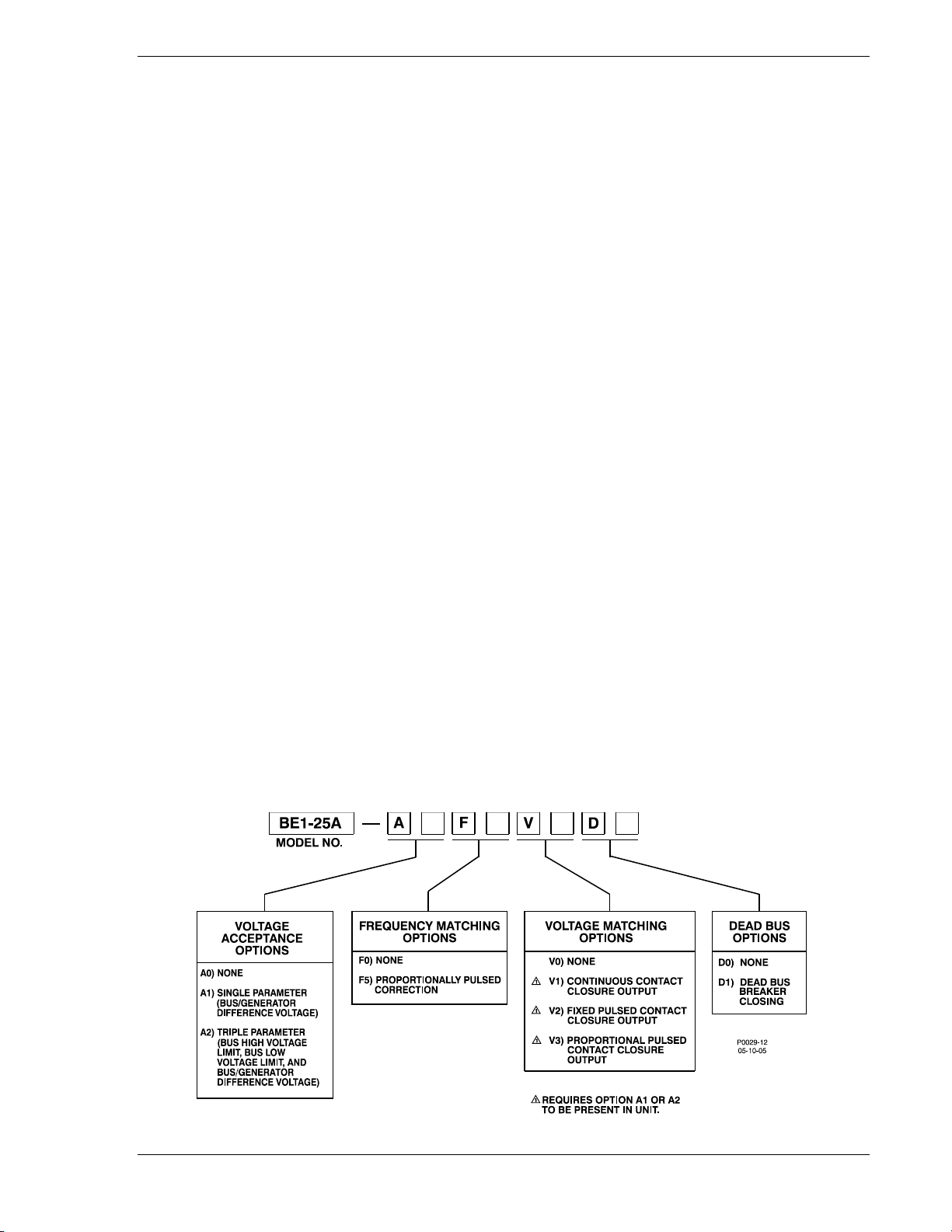

MODEL AND STYLE NUMBER............................................................................................................. 1-5

SPECIFICATIONS ................................................................................................................................. 1-6

SPECIFICATIONS OF OPTIONS .......................................................................................................... 1-8

Voltage Acceptance Option A1 .......................................................................................................... 1-8

Voltage Acceptance Option A2 .......................................................................................................... 1-8

Frequency Matching Option F5 .......................................................................................................... 1-8

Voltage Matching Option V1............................................................................................................... 1-8

Voltage Matching Option V2............................................................................................................... 1-8

Voltage Matching Option V3............................................................................................................... 1-8

Dead Bus Option D1 .......................................................................................................................... 1-8

Figures

Figure 1-1. Slip, Advance Angle, and Breaker Clos in g Time .................................................................... 1-4

Figure 1-2. Style Number Identification Chart ........................................................................................... 1-5

9146600990 Rev S BE1-25A General Information i

Page 10

This page intentionally left blank .

ii BE1-25A General Information 9146600990 Rev S

Page 11

SECTION 1 • GENERAL INFORMATION

DESCRIPTION

A basic BE1-25A Auto-Sy nchronizer consists of three rack -mounted modules that determine the proper

time to in itiate c los ing of a break er to paral lel a gen erator and a bus . The thr ee s tand ard m odules are t he

master control unit ( MCU) s ync modu le, the test module, and t he pow er s upply. Optio nal p lug-in mod ules

are available for installation (at initial purchase, or at any later time) to enhance this basic capability.

Among the options are the frequency matching and v oltage matching modules t hat direct the generator

control system to adjust vol tage or frequency ( or both) to meet sys tem requireme nts. The unit is not tru ly

an automatic synchronizer unless one or more of the matching options is incorporated.

An ideal closing is one that minimizes electrical and mechanical transients. Because the ideal closing

occurs when the voltages are in phase, the initiating signal must be delivered ahead of phase coincidence

by a factor equal to the operating speed of the breaker. This factor (termed the advance angle) is

calculated by the M CU sync module. This module is essentially a d edicated computer tha t monitors the

voltages on both sides of t he breaker to be closed, calculates th e slip frequency, and then (taking int o

consideration the operating speed of the breaker) calculates the required advance angle.

Closure will occur only if the slip frequency is less than the limit established by the slip setting. Once

breaker closure has been initiated, the BE1-25 A is inhibited from further operat ion for a minimum of 15

seconds. If the breaker reopens dur ing this 15-second inhibit period, the unit enter s a lockout condition

that prevents further operation until the unit is reset.

OPTIONS

Plug-in options can extend the capability of the basic unit. These are briefly summarized here as to

overall function. (They are explained in detail in the later sections of this manual.)

• A voltage acceptance module may be added to the basic synchronizer to assure that the

oncoming generator voltage is withi n a pre-selected magnitude with respect to the bus voltag e

before breaker closur e is allowed. Th is option is required if o ne of the vo ltage matc hing modules

is to be used.

• Voltage matching modules provide RAISE and LOWER signals to the voltage regulator of the

oncoming generator to bring the machine voltage within the limits defined by the voltage

acceptance module.

• Frequency matching (i.e., speed control) module provides RAISE and LOWER signals to the

governor to bring the oncoming generator s peed to within the slip frequency limit that is preset

into the Auto-Synchronizer. If the slip is very smal l and the p hase ang le is large, a target puls e is

initiated to change the generator speed in the direction of the closest phase coincidence.

• A dead bus module allows selection of various low bus voltage conditions to enable breaker

closing without synchronization. This provides a black start capability for the system.

MULTI-GENERATOR OPERATION

BE1-25A relays can contr ol more than one ge nerator by simultaneo usly switchin g all of the relay relevant

inputs and outputs fr om one generator to t he next. Those inputs a nd outputs are: the generator sensing

voltage, breaker 52b and closing coil circuits, and the leads associated with options (such as the

frequency and voltage matching lines to regulator or governor). All of these must be switched

simultaneously by a ganged switch called the synchronizing select switch. (This switch is installed

external to the BE1-25A un it, and is not supp lied with t he relay. Inst allation d etails are giv en in Section 4 ,

Installation.)

In addition to the re lay relevant inputs and output s, settings for the system oper ational parameters are

entered using the MCU fro nt panel LOAD/FUNCTION select switc h. Settings for six generator systems

can be entered and stored into MCU memory.

9146600990 Rev S BE1-25A General Information 1-1

Page 12

APPLICATION

General

From large, single or multip le generator s to sma ll, mult iple-unit a pplications , slip fr equenc y synchr onizers

such as the BE1-25A provide fas t, accurate, synchronization of g enerator-to-bus or bus-to-bus break er

closures if a slip rate exists between the two s ides of the open break er. For the BE1-25A to be capable of

closing the breaker, the ph as e ang le bet wee n the tw o v oltag e in put s must first pass through 180 elec tric a l

degrees and maintain a slip rate until the synchronizer issues a breaker close signal.

Excluded from this discussion are phase lock type synchronizers (such as the BE3-25A) that do not

require nor allow a slip to occur between the oncoming generator and the bus.

Generator-to-Bus Application

For a slip frequency sync hronizer to oper ate pr op er ly i n a gener at or -to-bus application, the followi ng list ed

operational parameters are entered into the memory of the synchronizer using the front panel

LOAD/FUNCTION select switch.

• Generator breaker closing time (calculates advance angle)

• Generator speed correction pulse width(maximum correction pulse width)

• Generator speed correction pulse interval (maximum correction pulse interval)

• Maximum slip frequency (maximum slip frequency and still allow breaker closing)

• Generator undervoltage (inhibits synchronization below this limit)

• Lockout ON/OFF (arms or disarms lockout feature)

Synchronization is enabled when the slip frequency is less than the maximum slip setting and the

generator voltage is greater than the generator undervoltage setting. Synchronization is NOT enabled

(inhibited) when th e slip fr equency is greater than the maxim um slip s etting, th e generat or voltage is less

than the generator u ndervoltage setting, or a lockout condition exists. If a voltage acceptance optio n is

included, synchronization is NOT enabled if the bus voltages are out of limits, the voltage difference

between generator and b us is greater than the setting, or the p hase angle difference is greater than the

calculated advance angle. If a dead bus option is included, immediate sync hronization is enabled if the

bus voltage is less than the setting and the dead bus enable input is closed.

When generator spee d correction pulses are required, pr oportional pulses are generated bas ed on the

slip frequency and the max imum slip freque ncy s etting. If the slip freq uency is gre ater than four times the

maximum slip frequenc y setting, proportional pulse are generat ed that are equal to 100 percent of the

correction pulse wi dth. Correction pulses proporti onally reduce in duty cycle (rati on of ON time to OFF

time) down to zero for s lip frequencies less than four times the max imum slip frequency setting. At onehalf the setting, correction pulses are disabled. If the slip frequency falls below one-sixteenth of the

maximum slip frequency s etting for ten sec onds, targe t pulses are gener ated to prev ent a hung-scope or

non-slip condition.

Bus-to-Bus Application

Some transmission c ircuits, when sp lit apart , ass ume a phas e ang le diff erence t hat s tabil izes as a s teady

offset. When this occurs , it is possible to reclose by supervisory means (usually supervised by a synccheck relay) if the angle is small eno ugh or the shoc k to the system c an be tolerated. In cases where a

slip exists, re-connection can be attained us ing a BE1-25A. In this case, one of the follo wing conditions

must be met for the BE1-25A to initiate closure.

• A slip frequency exists the prescribed limit (i.e., within the setting adjustment of the synchronizer).

• The phase angle difference is less than three degrees, with no system slip. In this case, the

phase angle between the two systems must have passed through 180 degrees to enable the

synchronizer.

If either of the two conditio ns is met, the BE1-25A will operate in a bus-to-bus environment as it would in

the case of an oncoming generator . It provides a closure comman d so that breaker closur e occurs when

the phase difference is near zero. To achieve this advance timing, the closing time of the controlled

breaker must be set into the synchronizer memory.

1-2 BE1-25A General Information 9146600990 Rev S

Page 13

Application Checklist

When developing the appropriate operating parameters and safeguards for synchronizing a generator

with a bus, the foll owing items should be considered.

1. Secondary potential transformer voltage waveforms should be carefully compared with the

primary voltages. Consider the following:

a. Are the secondary and primary voltages identical for both bus and generator?

b. Is there a power transformer involved? (Suppose, for example, that the generator is

operating at 2,400 volts, delta, and the bus at 34,500 volts, wye. Are the power

transformer secondary voltages the same when the bus and generator voltages are

proper?)

c. Is there a phase shift?

d. Is the phase rotation correct?

e. Do the potential transformers reflect the actual primary voltage changes without

significant delay?

2. When switching the auto-synchronizer from one generator to another, ALL of the autosynchronizer/generator cont rol inputs mus t be si multan eously trans ferred t o the co rrec t oncomin g

breaker and the associate d generator. During this trans fer, the 52b contact of the breaker m ust

be closed. Otherwise, an interlock (in the software) prevents the auto-synchronizer from

operating. The signals that must be switched include (but are not limited to):

a. Breaker status signal (i.e., 52b)

b. Generator voltage

c. Breaker close (contact input) circuit

d. Breaker closing time

3. Whenever frequency or voltage c ontrol options are used, their outp uts must also be switched to

the correct machine governor and voltage regulator.

4. The frequency correc tion pulse width (the amount of tim e a raise or lower signal rema ins ON)

should be coordinated with the speed of respons e of the governor, the fuel system, and the pr im e

mover to minimize the time required bringing the generator frequency into the required

relationship with the bus frequency without excessive overshoot or hunting.

5. The voltage correction puls e width and frequency should be c oordinated with the response tim e

of the voltage regulat or/exc iter/g enerator com bination t o mini mize the ti me require d to cor rect t he

voltage without overshooting or hunting.

6. If a dead bus closin g is des ired − i.e., if the m achin e can b e star ted without the b us (to w hich it is

to be synchronized) be ing energ ized tw o con ditions m us t be met:

a. Operating power for the s ynchronizer must come fro m a separate sourc e (like a bat tery)

or from the generator bus.

b. A dead bus option must be included in the uni t and be programmed to allow c losure to a

dead bus.

7. Some systems, where speed of synchronizing is a primary consideration, allow an oncoming

generator to be closed o nto the bus from ei ther the fast or s low side, and with t he voltage either

high or low.

a. Fast means that the machine is running with a positive slip (faster than the bus).

b. Slow indicates a negative slip (i.e., slower than the bus).

c. High is generator voltage greater that bus voltage.

d. Low is generator voltage less than bus voltage.

Most systems include a pr ovision to permit c losing only with th e speed fast and v oltage high. This allow s

the generator to pick up some watt and var load at once, thus stabilizing the system quickly.

By contrast, when the sp eed is slow and the voltage low, the sys tem must feed watts and reactive VA to

the machine (to add power to the pr ime mover and excitation to the exc iter field), thereby raising both

speed and voltage. S ince this ac tion is con trolled only by th e sub-s ynchr onous reac tance of the machi ne,

it can cause uncontrolle d swings of both vars and watts. The resulting tend ency toward destabilization

9146600990 Rev S BE1-25A General Information 1-3

Page 14

may cause winding, iro n, or shaft stress. Accordingly, the selection of closing direc tion and permissible

limits should consider these and other pertinent application data.

Defining the Parameters

These application notes are not intended to cover every possible set of circumstances, but rather to

provide a basic description of slip frequency synchronization. The relationship between slip, advance

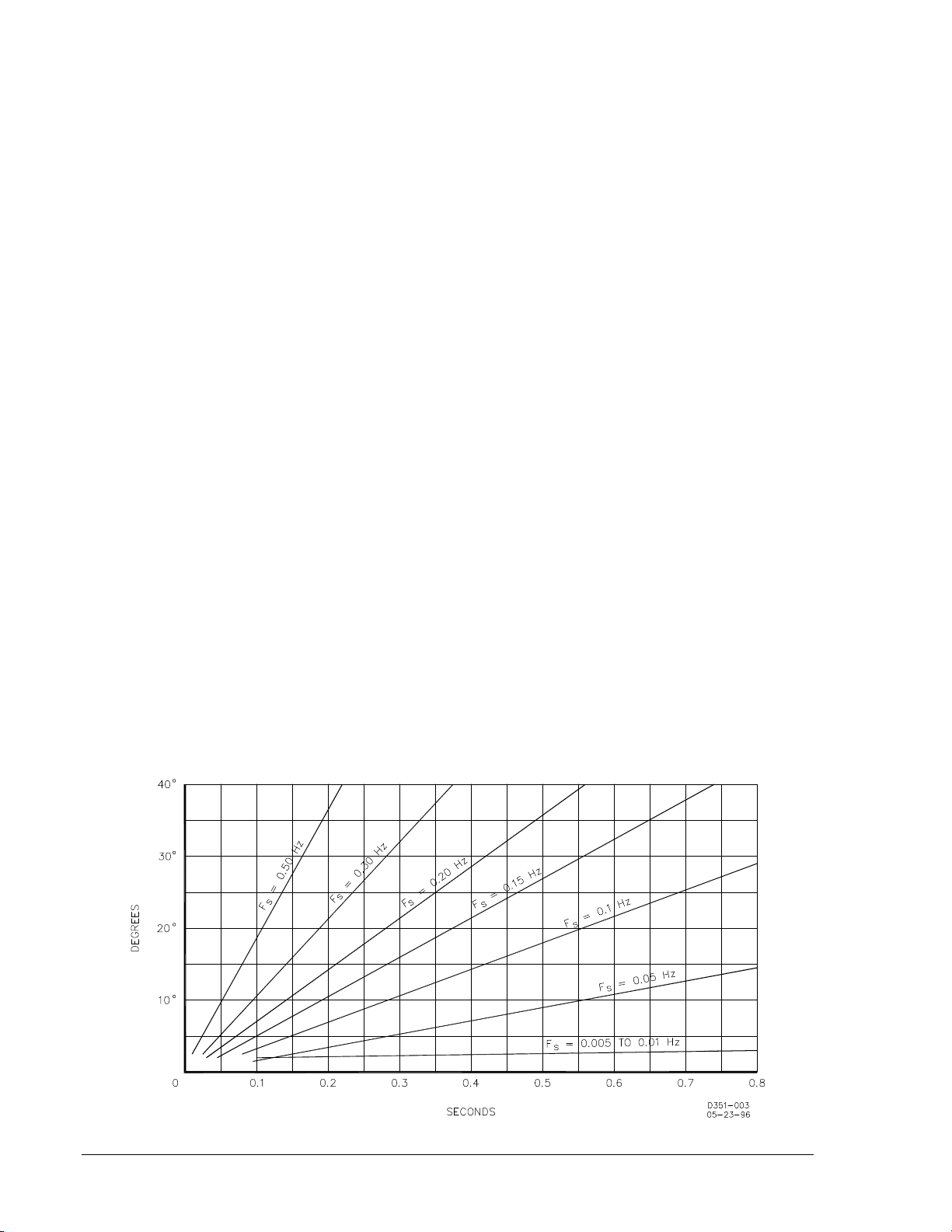

angle (or window), and breaker closing time is shown in Figure 1-1, and described by the formula:

= 360(+

)

where:

A

= advance angle in degrees. This is the time, measured in electrical degrees, between

A

initiation of breaker closure and the actual closure of the breaker contacts.

360 = degrees per slip cycle.

T

= the closing time of the circuit br eaker in secon ds. This is the t ime required fr om the c losure

CB

of the synchronizer output contact to the actual closing of t he circuit breaker contacts .

T

CB

is preset in synchronizer memory for each different break er controlled by the synchronizer .

EXCEPTION: In some applications ,

T

may re present the c haracteristic closing time of a

CB

group of breakers all having the same closing time.

T

= response time, in seconds, of the synchronizer breaker close output relay. (A non-

R

adjustable parameter approximately 0.008 second.)

F

= slip frequency in cy cles per second. This is the onc oming generator frequency minus the

S

bus frequency: positive for a generator speed higher than bus, negative for lower.

The relationships defined above should prove helpful in determining the settings for the autosynchronizer. Note that re ducing the advance angle (or window) also reduces the absolute v alue of the

slip frequency (which is the maximum permissible sp eed difference for which the mach ine is allowed to

close onto the bus). Lower slip frequenc ies are softer (i.e., les s liable to produce sy stem disturbance or

machine damage).

Higher frequencies, on the other hand, ar e quicker (i.e., allow sync hronizati on to be ac complis hed fas ter).

Again, these considerations should be balanced against others such as:

1. How fast do I need to be on line?

2. How critical is the machine?

3. How expensive is the machine as against possible outage (down) times?

A proper synchronizer application will take int o account the considerat ions mentioned above, as well as

others that may be unique to the system under consideration. See Figure 1-1.

Figure 1-1. Slip, Advance Angle, and Break er Closin g T ime

1-4 BE1-25A General Information 9146600990 Rev S

Page 15

MODEL AND STYLE NUMBER

BE1-25A Auto-Synchronizer style numbers define the features of a specific device. Each pair of

characters within the style number is associated with a specific feature or option that m ay be selected

from the style chart on the following page.

For example, if the f irst two digits of the style number are A2, t he unit has the capab ility of deferring it s

closure command to the br eaker for any of the fo llowi ng reasons: (1) the bus is under a specif ied voltag e;

(2) the bus is over a spec ified volt age; and ( 3) the bus -to-genera tor voltage is less than a selecte d value.

Another consideratio n: If a voltage matching opt ion is desired (let assume it is), including one of the A

options is essential.

The second pair of digits determines the manner in which the Auto-Synchronizer commands the

generator to change s peed. This relay uses option F5, whic h can initiate two different types of sp eedchange commands: (1) pr oportional cor rection pulse s, that are issued w hen the slip freq uency is abov e

the allowable limit; and (2) target correction pulses, that automatically f orces synchronization when ever

an out-of-phase condition coincides with a near-zero slip rate.

The third pair of digits s elects the voltage matching c apabilities that are required for an application. We

might look first at the voltag e matc h ing m odu le w ith th e mos t features, V3. Let examine these capabilities,

and how they might be useful to a specific application.

Option V3 (like Option V2) can automatically initiate c orrective pulses to bring the generator voltage to

within the limits estab lished by O ption A1 or A 2. However, w hen the voltage differenc e between bus and

generator is less th an 20.0 volts, V3 has the a dditional capability of r educing the width of t he corrective

pulses by an amount proportional to the correction required. This feature can significantly reduce

overshoot where inert ia is particularly high (as in th e control of sluice gates). If this is beneficial to our

hypothetical application (let assume it is) then the matter is decided: the third pair of digits is V3.

Finally, we choose D1 as the last pair of digits because we want the capability of obtaining a closure

when a dead bus is det ected. ( D1 a lso has t he me ans of sett ing a thresh old vo ltage to define a de ad bus

condition.)

When ordering, it is recom mended that the s tyle nu mber be prec eded by th e mo del nu mber. Accor dingly ,

the style number now looks like (Figure 1-2):

BE1-25A A2 F5 V3 D1

where:

BE1-25A = the model number

A2 = 3-parameter voltage restraint

F5 = both proportional correction pulse and target pulse capability

V3 = proportional correction pulse capability

D1 = automatic closure capability upon recognition of a dead bus

Figure 1-2. Style Number Identification Chart

9146600990 Rev S BE1-25A General Information 1-5

Page 16

SPECIFICATIONS

General specifications for the BE1-25A system are provided in the following paragraphs. For

specifications that apply only to particular options, see the ensuin g subsection entitled Specificat ions of

Options.

Voltage Sensing Inputs 70 to 150 Vac, 50/60 Hz. Burden: Les s than 6 VA for the generator

(Bus and Generator) input; less than 2 VA for the bus input.

Contact Sensing Inputs Requires a user-supplied contact with a minimum rati ng of 0.05 A at

250 Vdc.

Power Supply Power for the internal circuitry may b e derived from 90 to 132 Vac at

50/60 Hz (single phase), o r 70 to 150 Vdc. B urden: Less than 20.0

VA.

Outputs Output contacts are rated as follows:

Breaker Closing

Normally open. Make and carry 30 A at 250 Vdc for 1 second, 7 A

continuously, and break 0.3 A at 250 Vdc. (L/R = 0.04).

Voltage, Frequency (Speed) Correction, and Lockout

Form C (SPDT). Make and break 5 A at 250 Vac (80% PF), 5 A at 28

Vdc (resistive), and 0.5 A at 120 Vdc (resistive).

Tolerances

Advance Angle The command for breaker closure occurs within ±3.0° of phase

coincidence of bus and generator. (Closure will not occur if the

calculated advance angle exceeds 40°.)

Lockout Occurs when breaker reopens within 15 ±10% seconds after the

initiation of breaker closure.

F

Slip Frequency (

) ±0.001 Hz

S

Generator Undervoltage ±1.0 V

Inhibit

Control Ranges The following parameters are settable over the indicated ranges.

MAX SLIP Adjustable from 0.01 to 0.500 in steps of 0.001.

BRKR TIME The characteristic breaker time settings are adjustable from 0.02 to

0.8 seconds.

NOTE

When a sync output closure is initiated, the sync output contact will be held

closed for the duration of the Breaker Operating Time setting (or 250 ms

minimum).

Generator Undervoltage Adjustable from 40 to 110 Vac.

Inhibit

1-6 BE1-25A General Information 9146600990 Rev S

Page 17

Generator Speed Adjustable between 0 to 99.9 seconds in 0.1 second increments.

Correction Pulses

Shock In standard tests, the relay withstood 15 G in each of three mutually

perpendicular axes without structural damage or degradation of

performance.

Vibration In standard tests the relay withstood 2 G in each of three mutually

perpendicular axes swep t o ver the r ange of 10 to 50 0 Hz for a total of

six sweeps, 15 minutes each sweep, without structural damage or

performance degradation.

Isolation 1,500 Vac at 60 Hz for one minute in accor dance wit h IEC 2 55-5 and

ANSI/IEEE C37.90-1978 (Dielectric Test).

Surge Withstand Capability Qualified to ANSI/IEEE C37.90.1-1989, Standard Surge Withstand

Capability Tests, and to IEC 255-5, Impulse Test and Dielectric Test.

Radio Frequency Interference Field tested using a five-watt, hand-held transceiver operating at

random frequencies centered around 144 MHZ and 440 MHZ, with

the antenna located six inches from the relay in both horizonta l and

vertical planes.

Maintains proper operation when tested for interference in

accordance with IEC C37.90-1989, Trial-Use Standard Withstand

Capability of Relay Sys tem s to Radiated Electromagn etic Int er ferenc e

from Transceivers.

Patent Patented in U.S., 1998, Patent No. 5761073.

UL Listed UL listed per Standard 508, UL File Number E97033.

C.S.A. Certification CSA certified per Standard CAN/C.S. A.-C22.2 Number 14.

CE Qualification This product meets or exceeds th e standards r equired for distribution

in the European community.

GOST-R Certification GOST-R certified per the relevant standards of Gosstandart of

Russia.

Temperature

Operating –40 to 70°C (–40 to 158°F)

Storage –65 to 100°C (–85 to 212°F)

Weight 16.0 lb (7.26 kg) net for basic synchr onizer (Includes the rac k frame,

MCU module, and power supply module.)

9146600990 Rev S BE1-25A General Information 1-7

Page 18

SPECIFICATIONS OF OPTIONS

To eliminate repetiti on, only the spec ifications that un iquely apply to a par ticular option are g iven below.

Specifications that are applicable throughout the unit (including the options) are stated above.

Voltage Acceptance Option A1

VOLTAGE DIFFERENCE CONTROL Minimum threshold adjustable from 0.5 to 5% of

generator voltage. (Generator voltage minus bus

voltage)

Weight 6.6 oz (186.0 g)

Voltage Acceptance Option A2

BUS VOLTAGE UPPER LIMIT CONTROL Maximum threshold adjusta ble from 100 t o 150 Vac.

BUS VOLTAGE LOWER LIMIT CONTROL Minimum threshold adjustable from 80 to 120 Vac.

VOLTAGE DIFFERENCE CONTROL Minimum threshold adjustable from 1 to 10 Vac of

generator voltage. (Generator voltage minus bus

voltage)

Weight 8 oz (226.8 kg)

Frequency Matching Option F5

CORRECTION PULSE WIDTH CONTROL Adjustable from 0 to 99.9 seconds.

CORRECTION PULSE INTERVAL CONTROL Adjustable from 0 to 99.9 seconds.

Weight 6.6 oz (186.0 g)

Voltage Matching Option V1

Weight 5 oz (140.6)

Voltage Matching Option V2

CORRECTION PULSE WIDTH CONTROL Adjustable from 0.1 to 5.0 seconds.

CORRECTION PULSE INTERVAL CONTROL Adjustable from 0.2 to 10.0 seconds.

Weight 7.0 oz (200.0 g)

Voltage Matching Option V3

CORRECTION PULSE WIDTH CONTROL Adjustable from 0.1 to 5.0 seconds.

CORRECTION PULSE INTERVAL CONTROL Adjustable from 0.2 to 10.0 seconds.

Weight 8.5 oz (240.4 g)

Dead Bus Option D1

VOLTS CONTROL Adjustable from 10.0 to 40.0 Vac.

Weight 6.6 oz (186.0 g)

1-8 BE1-25A General Information 9146600990 Rev S

Page 19

SECTION 2 • HUMAN-MACHINE INTERFA CE

TABLE OF CONTENTS

SECTION 2 • HUMAN-M ACHINE INTERF ACE ....................................................................................... 2-1

INTRODUCTION ................................................................................................................................... 2-1

ADDITIONAL MODULES ....................................................................................................................... 2-5

Voltage Acceptance Module A1 ......................................................................................................... 2-5

Voltage Acceptance Module A2 ......................................................................................................... 2-6

Frequency Matching Module F5 ......................................................................................................... 2-6

Voltage Matching Module V1 ........................................................................................................... 2-10

Voltage Matching Module V2 ........................................................................................................... 2-10

Voltage Matching Module V3 ........................................................................................................... 2-11

Dead Bus Module D1 ....................................................................................................................... 2-12

Figures

Figure 2-1. Location of Controls and Indicators ........................................................................................ 2-1

Figure 2-2. Test Module in Test Position ................................................................................................... 2-2

Figure 2-3. Proportional Corr ec tion Pulses ............................................................................................... 2-4

Figure 2-4. Module A1 ............................................................................................................................... 2-5

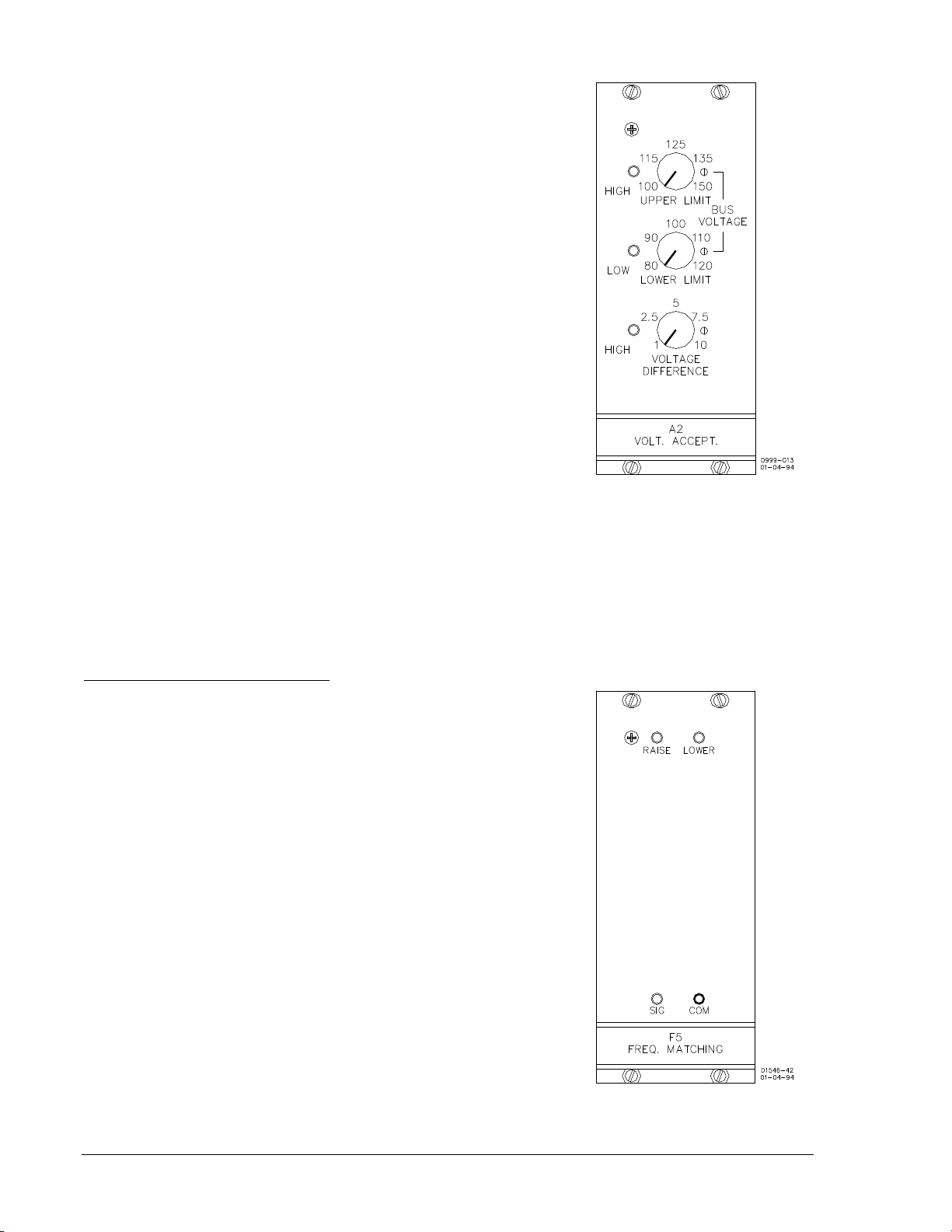

Figure 2-5. Module A2 ............................................................................................................................... 2-6

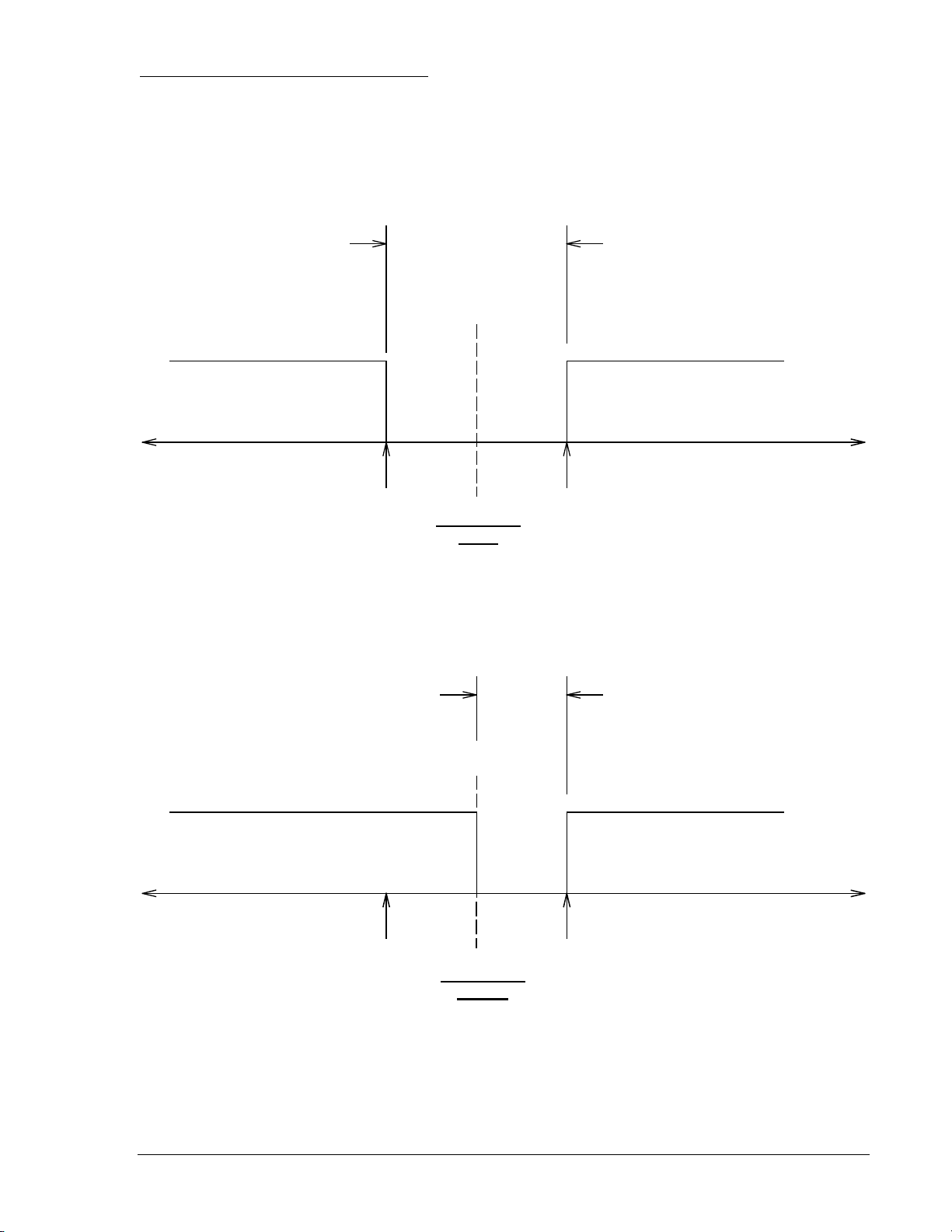

Figure 2-6. Module F5 ............................................................................................................................... 2-6

Figure 2-7. F3 Function Correction Pulse and Slip Frequency Relationship ............................................ 2-7

Figure 2-8. Proportional Relationship when GF>BF Switch is Open ........................................................ 2-8

Figure 2-9. Proportional Relationship when GF>BF Switch is Closed ...................................................... 2-9

Figure 2-10. Module V1 ........................................................................................................................... 2-10

Figure 2-11. Module V2 ........................................................................................................................... 2-10

Figure 2-12. Module V3 ........................................................................................................................... 2-11

Figure 2-13. Pulse Duration Timing for Option V3 .................................................................................. 2-11

Figure 2-14. Module D1 ........................................................................................................................... 2-12

9146600990 Rev S BE1-25A Human-Machine Interface i

Page 20

This page intentionally left blank .

ii BE1-25A Human-Machine Interface 9146600990 Rev S

Page 21

SECTION 2 • HUMAN-MACHINE INTERFACE

INTRODUCTION

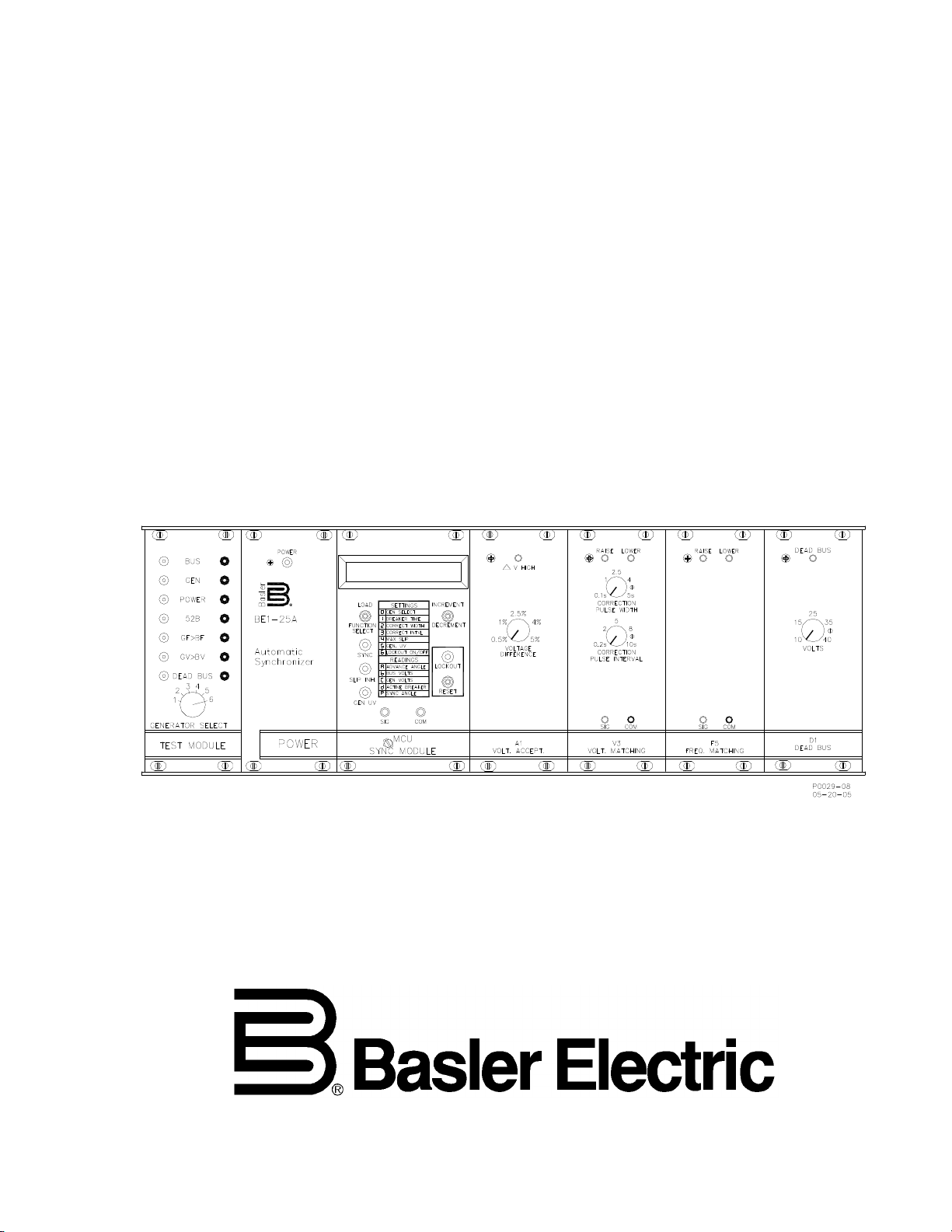

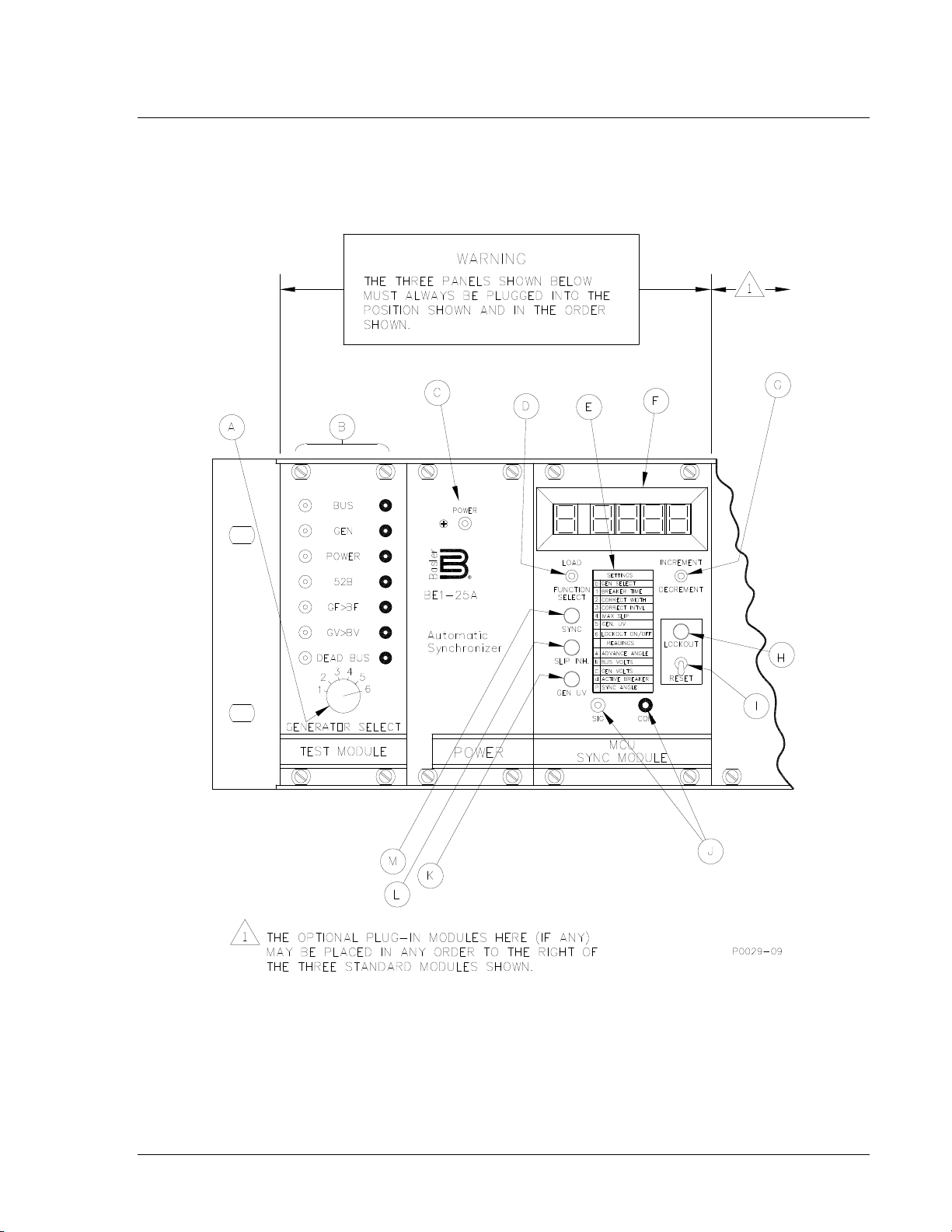

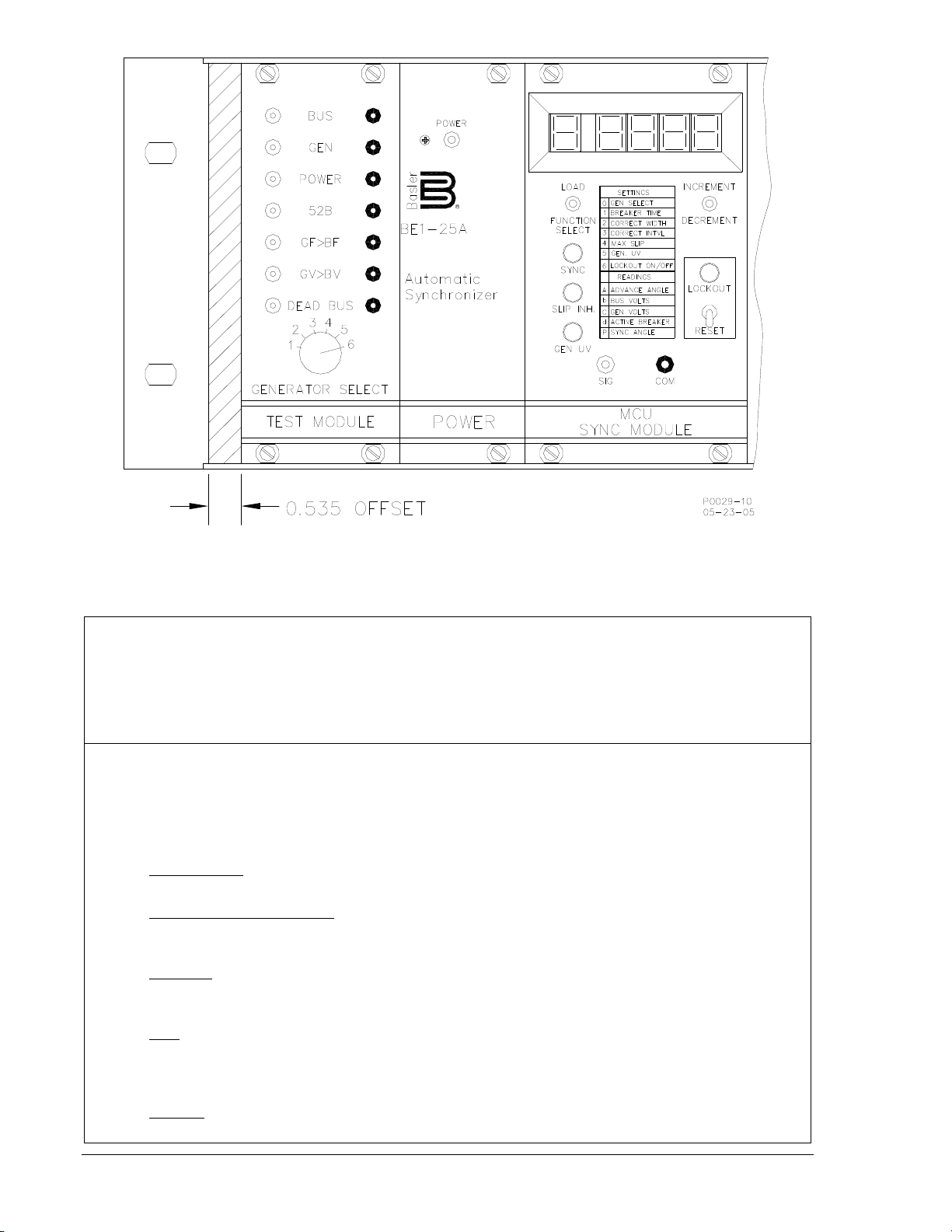

A basic BE1-25A Synchronizer (without options) is shown in Figure 2-1 and described in Table 2-1.

Figure 2-2 shows the Test Module in its offset position as required for testing. The remaining figures

describe the various options currently available.

Figure 2-1. Location of Controls and Indicators

9146600990 Rev S BE1-25A Human-Machine Interface 2-1

Page 22

Figure 2-2. Test Module in Test Position

Table 2-1. BE1-25A, Controls and Indicators (Refer to Figures 2-1 and 2-2)

Locator A - GENERATOR SEL ECT Control

When the Test Module is i n the tes t p os it ion (as s how n in Figure 2-2), this c ontro l s elect s one of t h e six

possible generator operation times that are stored in the memory of the MCU Sync module. This

selection process all ows the stored constant for a particular gen erator to be employ ed as a reference

for test purposes. This control has no function when the Test Module is in the operate position (as

shown in Figure 2-1.)

Locator B - Test Jacks

When the Test Module is in the test p osition (Figure 2-2), t he tip jac ks faci litate t esting in the follo wing

described manner. Wh en the Test Module is in the n ormal position (Figure 2-1), certain jacks s erve as

monitoring points as described in the following paragraphs.

Starting from the top, the seven pairs of jacks are:

1. BUS Voltage. When th e t est module is in t es t p os iti on , a simulated bus volta ge c an b e in jec ted

for test purposes. In normal position, monitors the bus voltage.

2. GEN (Generator) Voltage. When the test module is in the test position, allows a simulated

generator voltage to be injected for test purposes. In normal position, allows the generator

voltage to be monitored.

3. POWER. When th e test module is i n tes t position, allows the op er ati ng pow er t o be s u ppl ie d t o

the BE1-25A relay. In the normal p osition, allows the supp ly voltage from terminals 21 and 22

of TB1 to be monitored.

4. 52b. When the test module is in the test pos it ion, provides a means of simulatin g a 52b c ontac t

closure (by applyin g a jumper or closing a switch across thes e jacks). In the no rmal position,

allows the 52b contact input to be monitor ed. (Measur es approxi mately 10 0 Vdc when t he 52b

contact input is open, 0 Vdc otherwise.)

5. GF>BF. When the module is in the tes t position, provides the input term inals for a simulated

GF>BF contact closure. In the normal position, these jacks have no function.

2-2 BE1-25A Human-Machine Interface 9146600990 Rev S

Page 23

6. GV>BV. When the test module is in the test position, provides the input terminals for a

appears. The appropriate character appears until the INCREMENT/DECREMENT switch is

simulated GV>BV contact closure. In the normal position, these jacks have no function.

7. DEAD BUS. When the module is in the test position, provides the input terminals for a

simulated Dead Bus Enable signal. (This signal is useful only if the Dead Bus option is

present.) In the normal position, these jacks have no function.

Locator C - POWER LED

LED lights to indicate that the power supply is operating correctly.

Locator D - LOAD/FUNCTION SELECT Switch

A three-position switch with the following two active positions. (The switch is spring loaded to the

center position.)

FUNCTION SELECT. Each time the switc h is depres sed, it adv ances the displ ay (F) to s how the next

register (in the sequence listed in SETTINGS/READINGS chart (E)). The leftmost character of the

display may be found in the left c olumn of SETTINGS/READINGS chart wh ich describes the use o f

each register.

LOAD. Used to store data into memor y . To do s o, hold the s witc h in the raised position until the display

flashes (disappears and r eappears) (this takes approximately 1 second). The da ta showing in the four

rightmost digits of the display is now recorded in memory.

Locator E - SETTINGS/READINGS Chart

This chart lists various computer registers that control the sy nchronizer or monitor the system. Each

register is identified by the associated character in the left-hand column of the chart. This dig it also

appears as the left-m os t d i git of d is pl ay F w hen ev er th at register has been ac c ess ed by sw itc h D − i.e.,

the characters displayed in the righ tmos t d igi ts of the di splay repr es ent th e generator selected or status

of the particular register identified by the character in the left column of the chart.

The SETTINGS registers are:

0 (GEN SELECT). When f unction 0 is se lected, a — or a digit (1 through 6) appears as th e rightmost

character. After powering up or after reset, a — appears, but once a generator is selected, a digit

incremented. The I NCREMENT/DECR EMENT switch must be held for approximately one-half secon d

for the change to occur. The sequence is from — to 1 and incrementing to 6, and then wrapping

around to 1.

After a generator is sel ected an d t he FUN CTION SEL ECT sw itch is de press ed, t he dis play c hanges to

indicate the setting number (1 through 6) in the leftmost position and the constant (value) in the four

rightmost display characters. If a setting is changed, it must be loaded by operating the LOAD switch.

1 (BREAKER TIME). These registers ho ld the charac teristic op erating t imes of th e various bre akers in

the system. Numbers may be entered to represent break er operating time over the range of 0. 02 to

0.800 seconds.

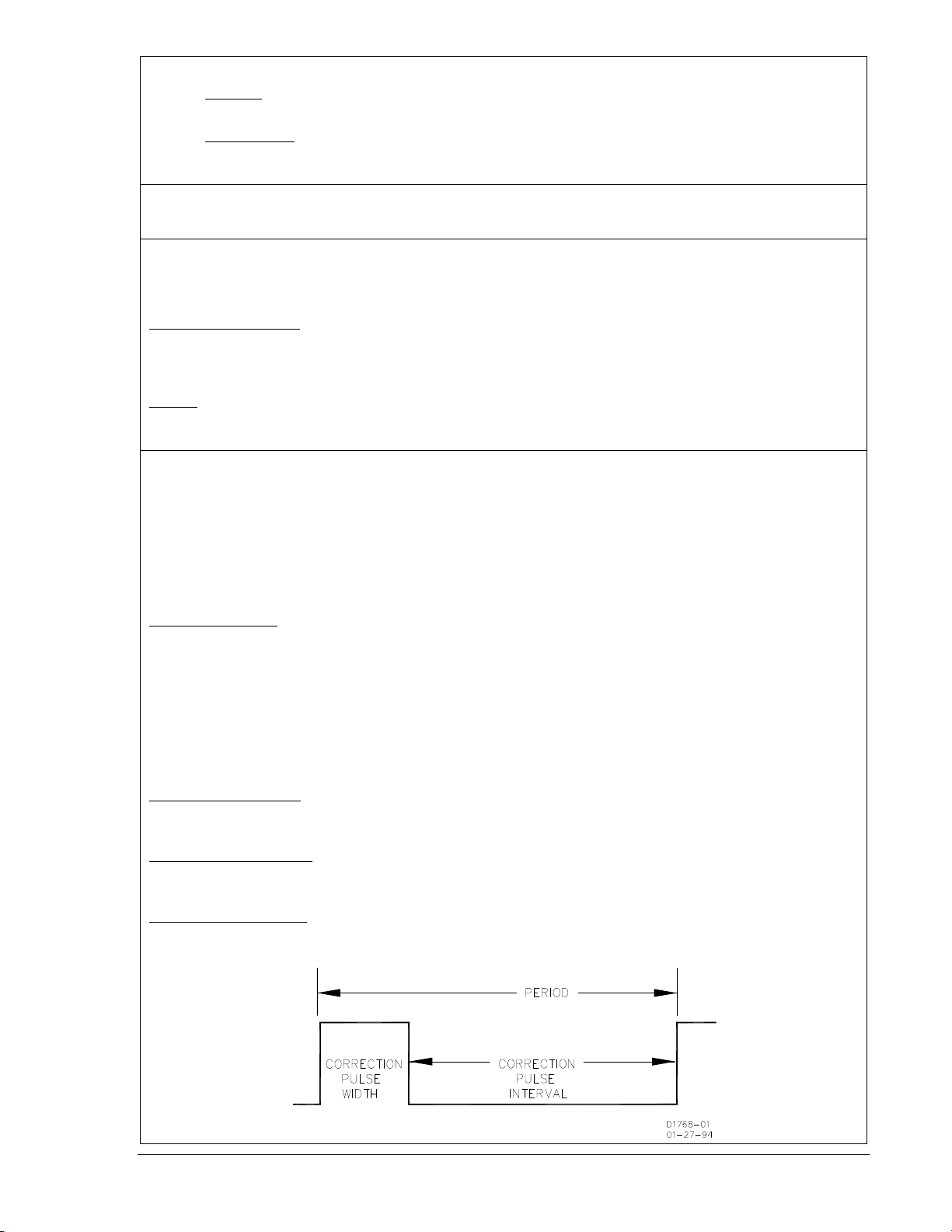

2 (CORRECT WIDTH). The number in this regist er represents the raise and lower speed cor rection

pulse width. The pulse w idth is settable from 0 to 99.9 sec onds in 0.1 second increments. (Refer to

Figure 2-3.)

3 (CORRECT INTVL). The number in this register represents the raise and lower speed correction

pulse interval. The pu lse int er v al is s e ttab le from 0 to 99.9 seco nds i n 0 .1 sec o nd i nc r ements. (Refer to

Figure 2-3.)

9146600990 Rev S BE1-25A Human-Machine Interface 2-3

Page 24

Figure 2-3. Proportional Co rr ection Pulses

4 (MAX SLIP). The number in this register represents the maximum slip rate that is acceptable for

closure of any breaker t hat is under the supervision of the Sy nc Acceptor Relay. When the slip r ate

exceeds this setting, t he sy nc acc eptor clos ure out put is inhibite d. Th e maximu m slip limit is adjusta ble

over the range of 0.01 to 0.500 Hz in 0.001 Hz increments.

5 (GEN. UV). The number in th is register represents the m inimum voltage output that the generator

must have before an operator breaker closure attempt is enabled. This value is adjustable over the

range of 40 to 110 Vac in 1.0 volt increments . If the generator voltage is below this setting, voltage

correction pulses are inhibited.

6 (LOCKOUT ON/OFF). This regist er indicates whether or not the lockout feature is enabled. When

enabled, the BE1-25A rel ay will automatically enter L OCKOUT whenever the break er re-opens within

15 seconds after closure by the synchronizer. This prevents another clos ure of the breaker from this

source until LOCKOUT is terminated by (1) manually resetting the unit, using either the front panel

RESET control or an external (remote) contact; or (2) by removing, then reapplying power.

The READINGS registers are:

A (ADVANCE ANGLE). This r epresents the number of degr ees that the breaker closur e signal must

precede actual closure so t hat the latter will occur at, or c lose to, a phase difference of zero degr ees.

This compensation takes into consideration the operating speed of the breaker, as well as the armature

operation time of the outpu t relay. (This register perfo rms a monitoring function only. N o provision for

adjusting the data.)

b (BUS VOLTS). A d igital voltmeter with a range of 0 to 135 Vac th at reads the bus voltage. (This

register performs a monitoring function only. No provision for adjusting the data.)

C (GEN VOLTS). A digita l voltmeter with a range of 0 to 135 Vac that r eads the output v oltage of the

generator being addressed. (This register performs a monitoring function only. No provision for

adjusting the data.)

d (ACTIVE BREAKER). Displays an identifying digit (1 through 6) that represents the particular

breaker whose operating time, b-contact, closing circuit, and associated generator voltage is being

addressed by the BE1-25 A relay. (In some situations, this number can represent a group of breakers

having an identical operating time.)

P (SYNC ANGLE). This variable i ndicates the instantaneo us phase angle differenc e across the open

breaker. (This register performs a monitoring function only.)

Locator F - Five-Digit , 7-Segment Display

The leftmost digit indicates the functio n selected, while the remaining four digits indicat e the present

value held in memory for that function.

Locator G - INCREMENT/DECREMENT Switch

The constants and gen erator (SETTINGS) that may b e viewed in Display E (but not the R EADINGS,

such as bus voltage, etc.) may be a ltered in value by means of th is switch. When th e switch is ra ised

for approximately one-ha lf second and released, the number on the display is incremented. But wh en

held raised, the number o n the display is incremented repeatedly − at first slowly, then much f aster.

Similarly, when the s witch is depr essed, a decreme nt oc curs , and then rep eats sl owly, t hen fas ter − as

long as the switch is held down.

The switch is spring loaded to return to the center position from both directions.

Locator H - LOCKOUT LED

This LED lights to indicate t he occ urrenc e of a lock out c onditio n. During l ockout , the out put of the r elay

is inhibited from signaling the breaker to close. Lockout may be cleared by the front panel RESET

switch, by a (continued) remotely located contact, or by powering down and then powering up.

Locator I - RESET Switch

When momentarily raised, this switch restores the relay to operation after a lockout has occurred.

This switch is also used to return to the READING registers after changing settings.

Locator J - SIG (Signal)/COM (Common) Test Points

2-4 BE1-25A Human-Machine Interface 9146600990 Rev S

Page 25

Used to monitor the output breaker closure signal during testing or calibration.

Locator K - GEN UV (Generator Undervoltage) LED

An LED that lights when the generator voltage is below an acceptable range of the synchronizer. Under

this circumstance, the synchronizer is not allowed to close the breaker. (The acceptable range is

defined by the GEN UV setting of register 5.)

Locator L - SLIP INH LED

An LED that lights when the s lip frequency exceeds the para lleling tolerance establis hed by the MAX

SLIP setting. The breaker close output is inhibited whenever this LED is ON.

Locator M - SYNC LED

This LED is in parallel with the coil of the sync output relay. This LED will light (turn ON) during the time

that the sync output is energiz ed – i.e. only once each time the s ync conditi ons are met an d the output

is energized.

ADDITIONAL MODULES

Controls and indicators of the additional plug-in modules for the BE1-25A relay are described in the

following paragraphs.

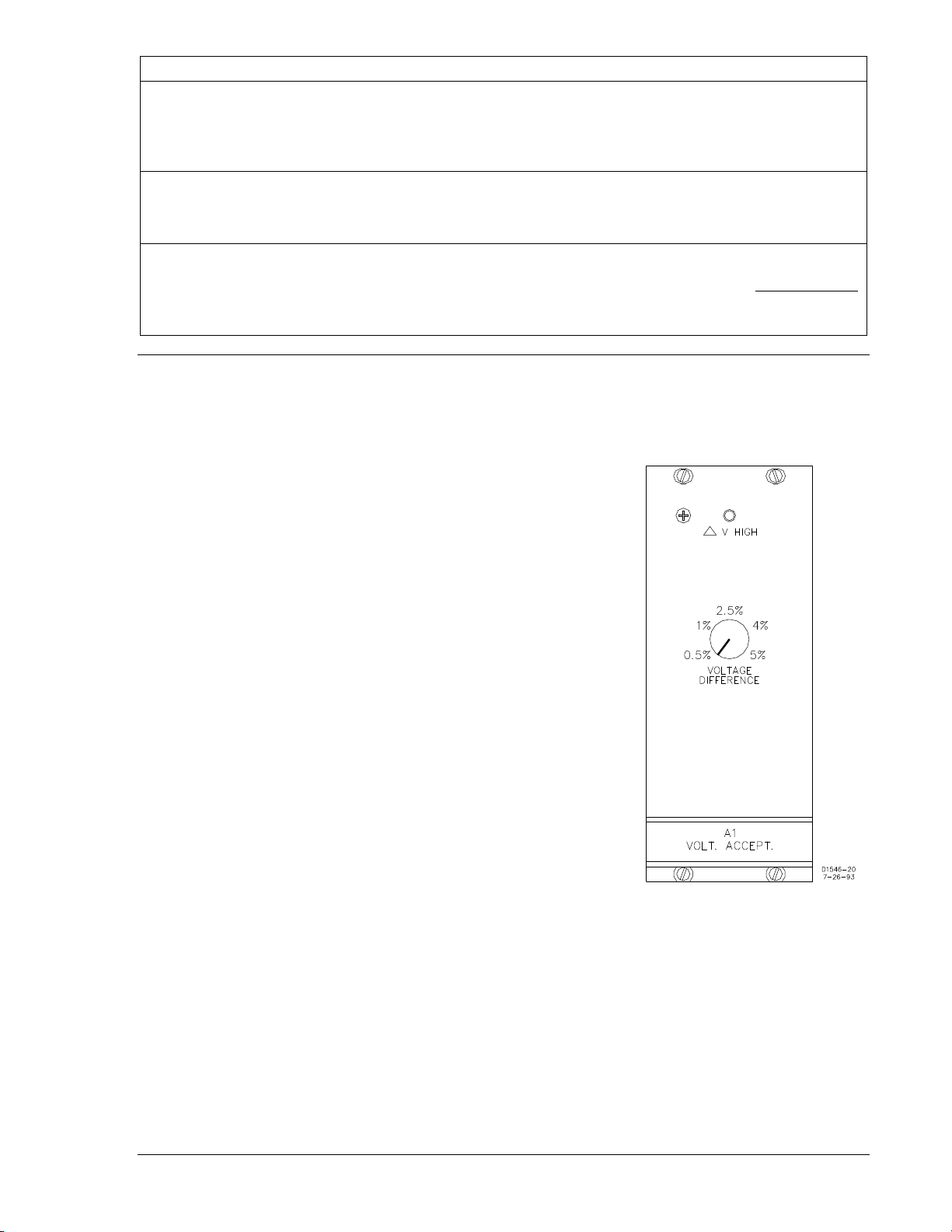

Voltage Acceptance Module A1

Option A1 introduces an a dditional enabling factor for the breaker

closing signal. This additional parameter, ∆V, represents the

difference in voltage o n the two sides of the circuit br eaker. I.e., if

∆V is greater than the setting established by the VOLTAGE

DIFFERENCE co nt ro l (Figure 2-4), the closure c o mm a nd out put o f

the BE1-25A unit is inhibited.

Note that the magnitude of the VOLT AGE DIFF EREN CE setti ng is

expressed as a percentage of the bus voltage: the voltage

difference (in %) = |∆V| * 100/V

An LED indicator, ∆V HIGH, illuminates when the voltage

difference exceeds the setting and the synchronizer is inhibited.

As will be seen later , this option or option A2 is a prerequisite of,

and a controller of, any Voltage Matching option that may be

present.

BUS

.

9146600990 Rev S BE1-25A Human-Machine Interface 2-5

Figure 2-4. Module A1

Page 26

Voltage Acceptance Module A2

Voltage acceptance mo dule A2 can use as many as three voltage

parameters to add constraints to the issuance of breaker

command signals. This option or option A1 is a prerequisite of,

and a controller of, any voltage matching option that may be

present. Figure 2-5 illustrates the following descriptions.

1. The UPPER LIMIT control establishes a maximum bus

voltage. No closure is to be attempted when the bus

voltage is above the upper limit.

2. The LOWER LIMIT control establishes a minimum bus

voltage. No closure is to be attempted when the bus

voltage is below the lower limit.

3. The VOLTAGE DIFFERENCE control establishes the

maximum acceptabl e voltage difference between t he two

sides of the circuit breaker (generator voltage minus bus

voltage). No closure is to be attempted continuously

variable over the range of 1 to 10 Vac.

An LED to the left of each c ontrol lights whenever the associated

parameter is beyond the ra nge set by the control. As a result, the

breaker closure is inhibited.

Figure 2-5. Module A2

Frequency Matching Module F5

The F5 frequency matching module (Figure 2-6) provides a frequency-corrective (speed) signal that is

compatible with motor-oper ated m achi ne speed c ontro ls. Begin ning on A pril 30, 1 996, (BE1-25A, revis ion

R), the optional F5 frequency matching module includes the functionality of F1, F3, and F5 modes of

operation. The F1 mode of operation pr ovides fixed width puls es, fired pro portional to the slip fre quency.

The F3 mode of operation prov ides a continu ous correc tion signal unt il the measur ed slip is les s than the

slip setting. The F5 mode of operation issues correction pulse width proportional to the slip frequency.

F1 Function, Pulse Contact Closure

The F1 function generates a fixed-width correction pulse s ettable

from 0.1 to 99.9 seconds in 0.1 secon d increments . These pu lses,

though fixed in pulse width, are sent more often at higher slip

frequencies and less often as the slip decreases. In this (F5)

implementation, the fixed width pulse is fired proportional to the

slip frequency. The F1 function is implemented by setting the

correction pulse width to any non-zero value and setting the

correction pulse interval to zero. The F1 function provides a

continuous correction signal at high slip frequencies.

Approximately when the inverse of the slip frequency is greater

than the pulse width setting, the c ontinuous correction signal will

become a fixed-width correction pulse with a pulse interval

approximately equal to the inverse of the slip frequency.

Correction pulses are issued until the slip frequency is within 0.5 of

the slip setting. Sync closure can occur any time below the slip

setting if no correction pulses are being issued.

Figure 2-6. Module F5

2-6 BE1-25A Human-Machine Interface 9146600990 Rev S

Page 27

F3 Function, Continuous Correction Pulse

Correction

area

Correction

area

Neg

Slip

Pos

Slip

Max

Slip

Max

Slip

Slip =

0

GF > BF Sw

Open

Correction

area

Correction

area

Neg

Slip

Pos

Slip

Max

Slip

Max

Slip

Slip =

0

Correction Dead Zone

And

Synchronization Zone

Correction Dead Zone

And

Synchronization Zone

GF > BF Sw

Closed

D

2610-07

10-03-97

The F3 function provides a continuous correction signal until the measured slip is less than the slip

setting. The F3 funct ion is implemented by setti ng the correction pulse w idth to zero and the correc tion

pulse interval to zero or an y non-zero number . The correc tion pulse is continuo us (full-on) as long as the

slip frequency is greater t han the slip setting. No cor rections are issued if the s lip frequency is less than

the slip s etting. One exception would be t o bump the target pulse if the slip fre quency is very close to

zero. Figure 2-7 shows the F3 function correction pulse and slip frequency relationship.

Figure 2-7. F3 Function Correction Pulse and Slip Frequency Relationship

9146600990 Rev S BE1-25A Human-Machine Interface 2-7

Page 28

F5 Function, Proportional Frequency Correction

Max Slip

4 *

Max Slip 4 *

Max Slip

12.5%

25%

50%

2 *

Max Slip

100

%

50

%

25%

12

.5

%

Max Slip

2 *

Max Slip

Pos Slip

(GF>BF)

100%

Target Slip

Band

Min Slip &

Sync Range

Zero Slip

Correction Width

Setting Value

Correction Width

Setting Value

Percentage Correction

Pulse Width

Neg Slip

(GF<

BF)

Slip Inhibit LED On

Slip Inhibit LED On

Proportional Correction

Proportional Correction

1/2 Max Slip

1

/2 Max Slip

Frequency Correction Dead Band

Proportional Correction

Range

Proportional Correction

Range

D2610-08

10-03-97

A proportional correc tion pulse train is issued when the slip frequency is greate r than 50 percent of the

maximum slip frequency setting. The pulses are steered (as appropriate) to operate one of the two speedadjust output relays . The contacts of one relay are used to signal the ge nerator to r aise speed, w hile the

contacts of the other relay are used to signal the generator to lower its speed. The period of the correction

pulses is determine d by the settings loaded into the microprocessor. That is, the period is equal to the

sum of the correctio n p uls e int erv al plus the correction pulse w idth . T he period remains cons tan t o nc e th e

correction pulse width and correction pulse interval are set. The proportional correction pulse is

determined by the percent of correction required. If the slip frequency is greater than four times the

maximum slip allowed, the proportional c orrection pulse train is a t 100 percent of the sett ing (correction

pulse interval settin g plus correction pulse width sett ing). If the slip frequency is equal to the maximum

slip setting, the proportio nal correction pulse width is at 25 percent of the origina l setting. The correction

pulse interval (wait time) will increase t o maintain a consisten t correction pulse period (total of the pulse

interval and pulse width). Figure 2-8 shows the proportional relationship when the GF>BF switch is open.

Proportional correction is linear between 100 percent (four times maximum slip frequency setting) and

12.5 percent (equal to one-half maximum slip frequency setting). Synchronization is enabled at slip

frequencies less than the maximum slip setting. Although sync hronization is enabled at slip frequenc ies

below 50 percent of the maximum slip allowed, n o cor r ection pu ls es are is sued . T he pu ls es is s ued by t his

option (to direct the output relays ) may be monitored at the SIG and COM jack s. (+5 Vdc = raise pulse;

−5 Vdc = lower pulse.) Figure 2-9 shows the proportional relationship when the GF>BF switch is closed.

Figure 2-8. Proportional Relationship when GF>BF Switch is Open

2-8 BE1-25A Human-Machine Interface 9146600990 Rev S

Page 29

Figure 2-9. Proportional Relationship when GF>BF Switch is Closed

1/2 Max Slip

1/2 Max Slip

Max Slip

4 * Max Slip

12.5%

25%

50%

2 * Max Slip

100%

50%

25%

12.5%

Max Slip

Pos Slip

(GF>BF)

100%

Target Slip

Band

Min Slip &

Sync Range

Percentage Correction

Pulse Width

Neg Slip

(GF<BF)

Slip Inhibit LED On

Slip Inhibit LED On

Zero Slip

Correction Width

Setting Value

Frequency Correction

Dead Band

Proportional

Correction

Correction Width

Setting Value

Proportional Correction

3-1/2 * Max Slip

1-1/2 * Max Slip

D2610-05

10-06-97

Phase Correction

A target pulse is issued to the cor rection pulse train when the bus and generator are freque ncy matched

(within approximately six percent of the maximum slip setti ng) but not phase matched. The pulses are

steered to induce a s lip fre quency that may be a djusted to fall wit hin the all owable limits of th e correcti on

pulse train. The contacts of one r elay are used to signal the generat or to raise speed, while the cont acts

of the other relay are used to signal the generat or to lower its speed. The tar get pulses issued may be

monitored at the SIG and CO M jacks and are additional pulses to the correc tion pulse train. (+5 Vdc =

raise pulse; −5 Vdc = lower pulse .)

NOTE

If the generator voltage is less than the generator undervoltage setting,

correction pulses are inhibited.

9146600990 Rev S BE1-25A Human-Machine Interface 2-9

Page 30

Voltage Matching Module V1

Option V1 (Figure 2-10) issues a correc tive signal whose pur pose

is to increase or decrease the generator termi nal voltage to within

the voltage difference limit determined by the setting of the

Voltage Acceptance Optio n A1 or A2 (whichever is present). The

signal is in the form of a continuous closed-contact output.

Control and indicators are limited to:

a. RAISE LED, that lights when a raise voltage signal is

being output (at which time the raise output contact is

closed).

b. LOWER LED, that lights when a lower voltage signal is

being output (at which time the lower output contact is

closed).

Figure 2-10. Module V1

Voltage Matching Module V2

Option V2 (Figure 2-11), like opti on V1, issues corrective signals

that increase or decrease the generator voltage to within the

voltage difference limit determined by the setting of whichever

Voltage Acceptance o ption is present (A1 or A2). In the case of

this option, however, the c orrective signal is not c ontinuous (as in

V1), but rather is in the form of a pulsing output contact.

Pulse duration and interval are independently controlled by the

CORRECTION PULSE WIDTH control, and by th e CORRECTION

PULSE INTERVAL control.

When correction pulses are issued, the direction of the c orrection

is indicated by either the RAISE or the LOWER LED. This also

indicates which of the two output relays (and w hich set of output

contacts) is delivering the pulses: the raise output relay or the

lower output relay.

The pulses issued by this option (to direc t the output relays) may

be monitored at the SIG and COM jacks. (+12 Vdc = relay deenergized; 0 Vdc = relay energized.)

Figure 2-11. Module V2

2-10 BE1-25A Human-Machine Interface 9146600990 Rev S

Page 31

Voltage Matching Module V3

Option V3 (Figure 2-12) is similar to O ption V2, in that it initiates

corrective pulses that are used to increase or decrease the

generator voltage to within the voltage difference limit as

determined by the Voltage Acceptance mod ule (either A1 or A2).

Both V2 and V3 are functionally identical when the voltage

difference between genera tor and bus is equal to or greater than

20.0 Vac.

But when the voltage differ ence is less than 20.0 Vac, Option V3

differs in this respect: the duration of the corrective pulses no

longer follows in lockstep with the setting of the CORRECTION

PULSE WIDTH control. Instead, the duration of the corrective

pulses is reduced by an amount proportional to the correction

required (Figure 2-13). Note that the minimum pulse duration is

0.1 seconds.

The CORRECTION PULSE INTERVAL control determines the

period of the pulse train. (Unlike the PULSE WIDTH control, the

INTERVAL control does NOT vary from the set ting as a function

of voltage difference.)

The pulses issued by this option (to direct either the raise or the

lower output relay) may be monitor ed at the SIG and COM jacks.

(+12 Vdc = relay de-energized; 0 Vdc = relay energized.)

Figure 2-12. Module V3

Figure 2-13. Pulse Duration Timing for Option V3

9146600990 Rev S BE1-25A Human-Machine Interface 2-11

Page 32

Dead Bus Module D1

When the external d ead bus c ontact is close d, module D1 ( Figure

2-14) determines when the bus is dead, and acts upon this

determination (if the br eaker is detected op en) by init iating a close

breaker signal. This signal is terminated as soon as the sync

acceptor recognizes the breaker as having closed, or when 100

milliseconds have passed (whichever occurs first).

The VOLTS control defi nes a dead b us condi tion by establ ishing a

voltage threshold between 10 and 40 Vac.

The DEAD BUS indicator i s an LED that lights whenever the bus

voltage is below the control setting.

Figure 2-14. Module D1

2-12 BE1-25A Human-Machine Interface 9146600990 Rev S

Page 33

SECTION 3 • FUNCTIONAL DES CRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SYSTEM OPERATION .......................................................................................................................... 3-1

INPUT CIRCUITS .................................................................................................................................. 3-3

Contact Inputs .................................................................................................................................... 3-3

Front Panel Inputs .............................................................................................................................. 3-3

Analog Inputs ..................................................................................................................................... 3-3

MICROPROCESSOR CIRCUITRY ....................................................................................................... 3-3

OUTPUTS .............................................................................................................................................. 3-4

OPTIONS ............................................................................................................................................... 3-4

VOLTAGE ACCEPTANCE MODULE A1 .............................................................................................. 3-6

VOLTAGE ACCEPTANCE MODULE A2 .............................................................................................. 3-7

FREQUENCY MATCHING MODULE F5 .............................................................................................. 3-8

Frequency Correction ......................................................................................................................... 3-8

Phase Correction ................................................................................................................................ 3-8

VOLTAGE MATCHIN G M ODULE V1 .................................................................................................... 3-9

VOLTAGE MATCHIN G M ODULE V2 .................................................................................................. 3-10

VOLTAGE MATCHIN G M ODULE V3 .................................................................................................. 3-11

DEAD BUS MODULE D1 ..................................................................................................................... 3-12

Figures

Figure 3-1. System Block Diagram ............................................................................................................ 3-1

Figure 3-2. Auto-Synchronizer Block Diagram .......................................................................................... 3-2

Figure 3-3. Synchronizer Flow Diagram .................................................................................................... 3-5

Figure 3-4. Voltage Acceptance Module A1 Block Diagram ..................................................................... 3-6

Figure 3-5. Voltage Acceptance Module A2 Block Diagram ..................................................................... 3-7

Figure 3-6. Frequency Matching Module F5 Block Diagram ..................................................................... 3-8

Figure 3-7. Voltage Matching Module V1 Bl ock Diagram.......................................................................... 3-9

Figure 3-8. Voltage Matching Module V2 Block Diagram........................................................................ 3-10

Figure 3-9. Voltage Matching Module V3 Block Diagram........................................................................ 3-11

Figure 3-10. Dead Bus Module D1 Block Diagram ................................................................................. 3-12

9146600990 Rev S BE1-25A Functional Description i

Page 34

This page intentionally left blank .

ii BE1-25A Functional Description 9146600990 Rev S

Page 35

SECTION 3 • FUNCTIONAL DESCRIPTION

SYSTEM OPERATION

As the prime mover brings the oncoming gener ator up to speed, t he BE1-25A Au to-Synchronizer (Figure

3-1) compares the generat or output with the bus. When the m onitored frequency and phase angle (and,

optionally, the voltage) are within preset limits as described below, the BE1-25A Auto-Synchronizer

signals the controlled breaker to close.

Figure 3-1. System Block Diagram

To accomplish closur e qu ic k ly and with the least stress on th e sy s tem, a m ic ropr o c ess or in the MCU s y nc

module calculates (and thu s anticipa tes) the adv ance angle neces sary to compen sate for br eaker c losure

time, as well as for operation time of the output relay. To do so, it utilizes data stored in memory

concerning the characteristic closing times of the generator breaker to which it is connected.

As detailed in Section 4, the BE1-25A Auto-Synchronizer can be set-up to co ntrol multiple generators.

Each generator may be associated with a breaker whose closing time may b e different from the others .

The various closing times are stored in the synchronizer memory and called up according to which

generator/breaker combination the BE1-25A Auto-Synchronizer is connected. (The connecting is

performed by user-installed switches.)

After breaker closur e has been initiated, the Auto-Synchronizer is inhibited from fur ther operation for 15

±1.5 seconds.

9146600990 Rev S BE1-25A Functional Description 3-1

Page 36

A functional block diagram of the Auto-Sync hronizer is given in Figure 3-2, and is ref erred to in the circui t

descriptions that foll ow. A black box approach is tak en, with the emphasis on t he inputs and outputs to

the external world. Omitted from the diagram are the internal signals that communicate between the

various modules of t he system. Note that t he output relays show n in the lower right corn er of the figure

are not present unless the controlling options are installed.

Later in this section, additional functional diagrams are provided that describe the options.

Figure 3-2. Auto-Synchronizer Block Diagram

3-2 BE1-25A Functional Description 9146600990 Rev S

Page 37

INPUT CIRCUITS

Contact Inputs

At the upper left corner of Figure 3-2 are the contact sensing inputs. N ote that opto-isolator s protect the

internal circuits from the unwanted noise that is present on unconditioned lines. The inputs are:

• 52b - An input th at monitor s the 5 2b aux iliary c ontac t of th e contr olled breaker . (The 52b contac t,

when closed, indicates that the breaker is open.)

• Reset - An input that may be used to monitor a remotely located reset switch. (Not to be

confused with the RESET switch on the front panel of the unit.)

• GF>BF - An input that may be used to monitor a remotely located switch, that when closed,

enables the closure output of the Auto-Synchronizer if (and only if) t he generator frequency is

greater than the bus frequency. When this contact is open, closure is allowed from both

directions.

• 2, 3, 4, 5, 6 - Thes e five input contacts, in conjuncti on with the c ommon c ontact, p rovide a mea ns

of informing the Auto-Synchronizer which generator (and which generator breaker) has been

connected to the Auto-Synchronizer. A sixth generator /break er com bi nat ion ( gen e r ator/br eak er 1)

may be recognized by opening all five inputs, 2 throu gh 6. This is a d efault input tha t addresses

the first generator/breaker combination.

The various contact input signals are directed to input-conditioning circuitry, where they are translated into

binary notation and strobed into the microprocessor. Notice that power for the contact inputs is isolated by

means of a transformer supplied by the generator voltage sensing input.

At the lower left corner of Figure 3-2 are tw o inputs that go directly to optiona l modules. They are als o

translated into binary notation and strobed into the microprocessor. They are:

• GV>BV - If one of the volt age ac ceptanc e op tions is present, this input may be us ed to m on itor a

remotely located switch, t hat when cl osed, enab les the closur e output of the A uto-Synchronizer if

(and only if) the generator voltage is greater than the bus voltage. When this contact is open,

closure is allowed from both directions.

• Dead Bus Enable - If the dead bus enable option is installed, the clos ure of this contact input

coupled with a dead bus condition will bring about an immediate breaker close output.

Front Panel Inputs

Front panel inputs (Figure 3-2, abo ut one-third down at the left), represent (1) the LOAD & FU NCTION

switch, (2) the INCREMENT-DECREMENT switch, and (3) the LOCKOUT RESET switch of the MCU

sync module. Switches (1) and (2) control the d isplay and the memory of the Auto-Synchronizer. Switch

(3), when momentarily raised, restores the operation of the Auto-Synchronizer to the initialized condition.

Analog Inputs

Generator and bus volta ge inputs together mon itor both sides of the break er, and have a nominal rat ing

of 150 Vac at 50/6 0 Hz. Internal tra nsformers provide isolation and s caling. After the transformers, the

analog inputs enter squaring circuits. These circuits allow the phase information to be represented by

precise square waves nee ded to accurately determ ine the zero crossings . Additional circuitry pr ovides a

dc-analog representation of voltage magnitude for evaluation by the microprocessor and associated

circuits.

To conclude the inp ut description, a source of pow er for the digital circuits is r equired. Internal diod es

steer these voltages so tha t no polarity needs to be obs erved in makin g connect ions . These terminals will

accept either ac or dc, provided that it is within the voltage range of 70-150 V (and 50/60 Hz if ac).

MICROPROCESSOR CIRCUITRY

The microprocessor, with the as soci ated me mory a nd dec odin g log ic, perf orms a ll calc u lations, makes all

decision, and controls t he display and out put circuitry. Thes e functions are f or the most part, d etermined

by the software in the manner illustrated by the flow diagram of Figure 3-3.

Returning to Figure 3-2, a crystal os cillator provides a precise tim e reference for determining frequ ency

and phase relationships.

The power up/down r eset logic (at th e lower left corner) moni tors the intern al logic v oltages. If any of the

voltages fall below a critical threshold, the microprocessor is placed in a park mode. All decision making is

9146600990 Rev S BE1-25A Functional Description 3-3

Page 38