Page 1

INSTRUCTION MANUA L

FOR

BE1-11g

Generator Protection System

Publication: 9424200994

Revision: N Sep-14

Page 2

Page 3

9424200994 Rev N i

Caution

Note

Preface

This instruction manual provides information about the installation and operation of the BE1-11g

Generator Protection System. To accomplish this, the following information is provided:

• General information and a quick start guide

• Controls and indicators

• Inputs and outputs

• Protection and control functions

• Reporting and alarms information

• Mounting and connection diagrams

• BESTCOMSPlus® software

• Communication and security

• Testing and troubleshooting procedures

• Specifications

• Time curve characteristics

• RTD module (optional)

Optional instruction manuals for the BE1-11g include:

• Modbus™ communication protocol (Basler Electric part number 9424200774)

• Distributed Network Protocol (DNP) (Basler Electric part number 9424200773)

• IEC 61850 communicat ion pr otoc ol (Basler Electric part number 9424200892)

Conventions Used in this Ma nua l

Important safety and procedural information is emphasized and presented in this manual through

warning, caution, and note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to installation

or operation.

BE1-11g Preface

Page 4

ii 9424200994 Rev N

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

manual.

The English-language version of this manual serves as the only approved manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2014 by Basler Electric

All rights reserved

First printing: June 2009

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the BE1-11g. Note

all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with the

product for reference. Only qualified personnel should install, operate, or service this system. Failure to

follow warning and cautionary labels may result in personal injury or property damage. Exercise

caution at all times.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual und er st and ing that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface BE1-11g

Page 5

9424200994 Rev N iii

Contents

Introduction ................................................................................................................................................. 1

Applications ............................................................................................................................................... 1

Features .................................................................................................................................................... 2

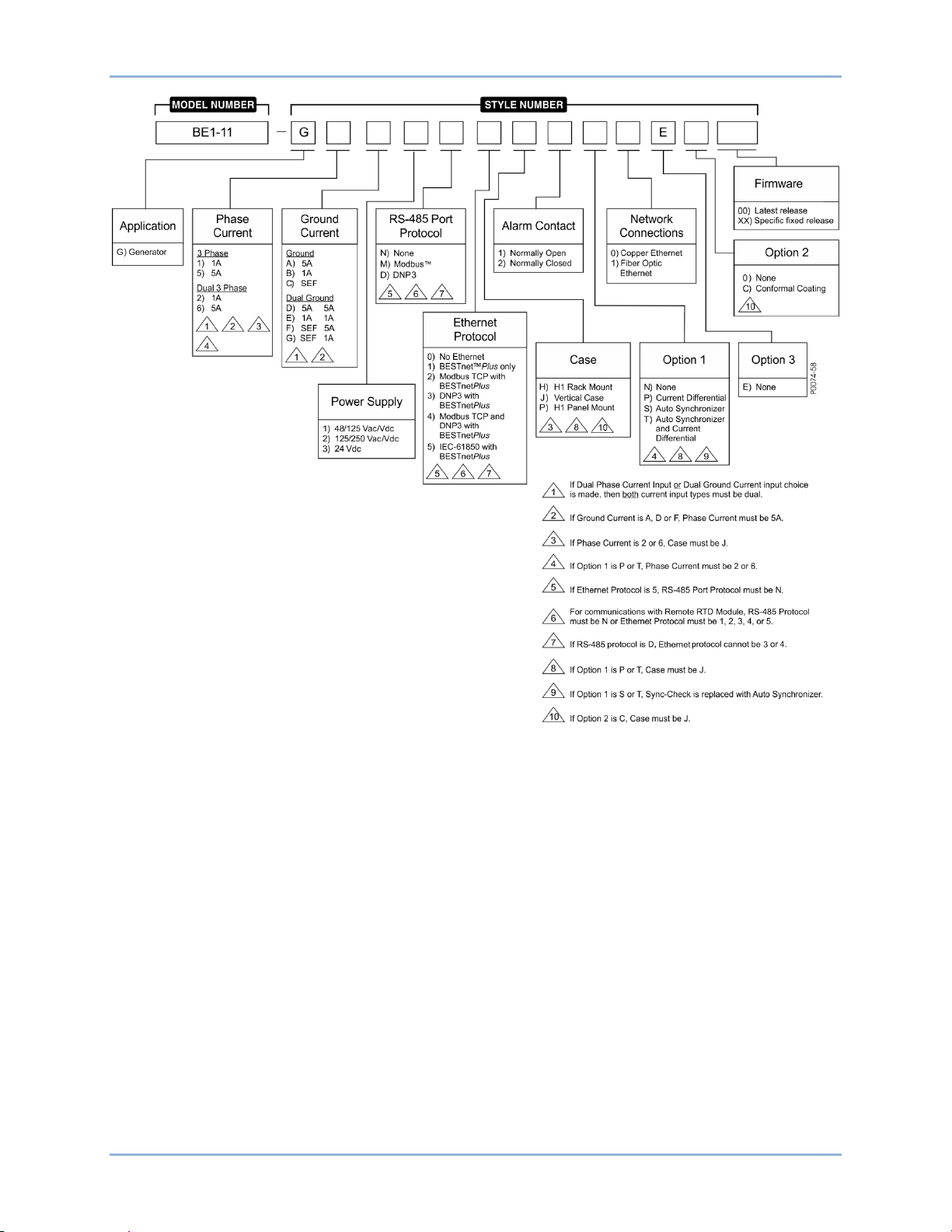

Model and Style Number Description ........................................................................................................ 8

Quick Start ................................................................................................................................................. 11

Maintenance ............................................................................................................................................ 11

Storage .................................................................................................................................................... 11

Install BESTCOMSPlus® Software .......................................................................................................... 11

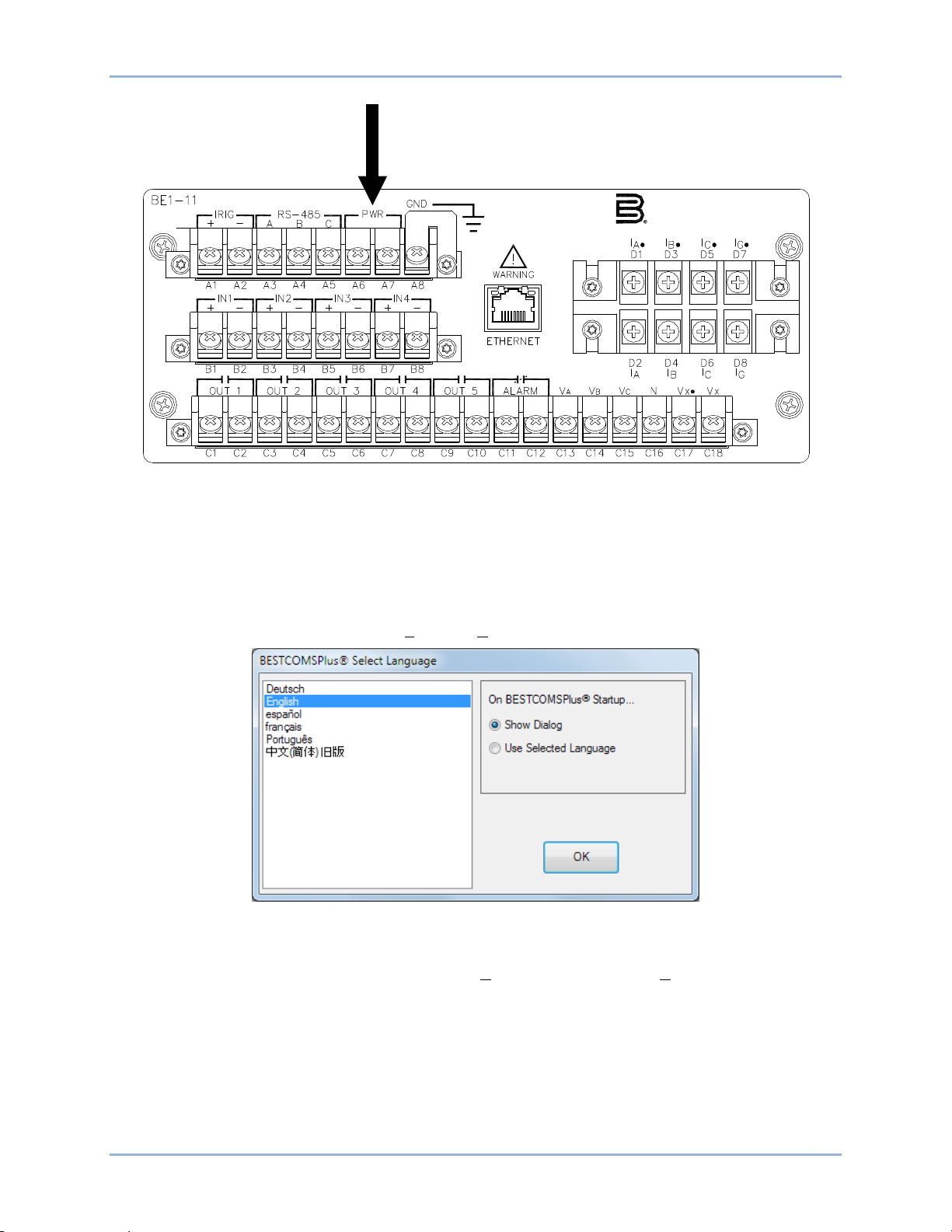

Power Up and Activate the BE1-11 Plug-In ............................................................................................ 12

Programming the BE1-11g ...................................................................................................................... 16

Controls and Indicators ............................................................................................................................ 25

Illustrations and Descriptions .................................................................................................................. 25

Menu Navigation ...................................................................................................................................... 28

Front Panel Operations ........................................................................................................................... 28

Display Setup .......................................................................................................................................... 30

Contact Inputs and Outputs ..................................................................................................................... 33

Contact-Sensing Inputs ........................................................................................................................... 33

Contact Outputs ....................................................................................................................................... 37

Overexcitation (24) Protection ................................................................................................................. 43

Element Operation ................................................................................................................................... 43

Logic Connections ................................................................................................................................... 45

Operational Settings ................................................................................................................................ 45

Settings Example ..................................................................................................................................... 46

Sync-Check (25) Protection ..................................................................................................................... 49

Element Operation ................................................................................................................................... 49

Logic Connections ................................................................................................................................... 52

Operational Settings ................................................................................................................................ 52

Phase Undervoltage (27P) Protection ..................................................................................................... 55

Element Operation ................................................................................................................................... 55

Logic Connections ................................................................................................................................... 56

Operational Settings ................................................................................................................................ 57

Auxiliary Undervoltage (27X) Protection ................................................................................................ 59

Element Operation ................................................................................................................................... 59

Logic Connections ................................................................................................................................... 61

Operational Settings ................................................................................................................................ 61

Negative-Sequence Voltage (47) Protection........................................................................................... 63

Phase Overvoltage (59P) Protec tion ....................................................................................................... 65

Element Operation ................................................................................................................................... 65

Logic Connections ................................................................................................................................... 66

Operational Settings ................................................................................................................................ 66

Auxiliary Overvoltage (59X) Protection .................................................................................................. 69

Element Operation ................................................................................................................................... 69

Logic Connections ................................................................................................................................... 71

Operational Settings ................................................................................................................................ 71

Stator Ground (64G) Protection ............................................................................................................... 73

Vector Jump (78V) Protection .................................................................................................................. 75

Element Operation ................................................................................................................................... 75

Logic Connections ................................................................................................................................... 76

Operational Settings ................................................................................................................................ 76

BE1-11g Contents

Page 6

iv 9424200994 Rev N

Frequency (81) Protection ........................................................................................................................ 79

Frequency Measurement......................................................................................................................... 79

Underfrequency and Overfrequency Protection ...................................................................................... 79

Frequency Rate-of-Change Protection .................................................................................................... 80

Logic Connections ................................................................................................................................... 82

Operational Settings ................................................................................................................................ 82

Negative-Sequence Overcurrent (46) Protection ................................................................................... 85

Pickup Settings ........................................................................................................................................ 85

Coordination Settings .............................................................................................................................. 86

Instantaneous Overcurrent (50) Protection ............................................................................................ 87

Element Operation ................................................................................................................................... 87

Logic Connections ................................................................................................................................... 88

Operational Settings ................................................................................................................................ 89

Breaker Failure (50BF) Protection ........................................................................................................... 91

Element Operation ................................................................................................................................... 91

Logic Connections ................................................................................................................................... 92

Operational Settings ................................................................................................................................ 93

Inverse Overcurrent (51) Protection ........................................................................................................ 95

Element Operation ................................................................................................................................... 95

Logic Connections ................................................................................................................................. 100

Operational Settings .............................................................................................................................. 100

Directional Overcurrent (67) Protection ................................................................................................ 103

Polarization Methods ............................................................................................................................. 103

Maximum Torque Angle and Directional Tests ..................................................................................... 105

Theory of Using Sequence Impedances for Fault Direction .................................................................. 106

Phase Current Differential (87) Prote ction ........................................................................................... 109

Element Operation ................................................................................................................................. 109

Logic Connections ................................................................................................................................. 112

Settings .................................................................................................................................................. 113

Neutral Current Differential (87N) Protection ....................................................................................... 117

Element Operation ................................................................................................................................. 117

Logic Connections ................................................................................................................................. 119

Operational Settings .............................................................................................................................. 120

Phase Differential Protection: Self-Balancing and Split-Phase Configurations (50/51) .................. 121

Power (32) Protection ............................................................................................................................. 123

Element Operation ................................................................................................................................. 123

Logic Connections ................................................................................................................................. 126

Operational Settings .............................................................................................................................. 126

Loss of Excitation - Reverse Var Based (40Q) Protection .................................................................. 127

Element Operation ................................................................................................................................. 127

Logic Connections ................................................................................................................................. 128

Operational Settings .............................................................................................................................. 129

Distance (21) Protection ......................................................................................................................... 131

Element Operation ................................................................................................................................. 131

Logic Connections ................................................................................................................................. 132

Operational Settings .............................................................................................................................. 132

Loss of Excitation - Impedance Based (40Z) Protection ..................................................................... 135

Element Operation ................................................................................................................................. 135

Logic Connections ................................................................................................................................. 136

Operational Settings .............................................................................................................................. 137

Typical Applic a tion ................................................................................................................................. 138

Contents BE1-11g

Page 7

9424200994 Rev N v

Out of Step (78OOS) Protection ............................................................................................................ 139

Element Operation ................................................................................................................................. 139

Logic Connections ................................................................................................................................. 140

Operational Settings .............................................................................................................................. 141

Resistance Temperature Detector (49RTD) Protection ....................................................................... 143

Element Operation ................................................................................................................................. 143

Logic Connections ................................................................................................................................. 144

Operational Settings .............................................................................................................................. 144

Remote RTD Metering........................................................................................................................... 145

Analog Input Protection ......................................................................................................................... 147

Element Operation ................................................................................................................................. 147

Logic Connections ................................................................................................................................. 148

Operational Settings .............................................................................................................................. 148

Remote Analog Input Metering .............................................................................................................. 149

Synchronizer (25A) ................................................................................................................................. 151

Element Operation ................................................................................................................................. 151

Logic Connections ................................................................................................................................. 155

Operational Settings .............................................................................................................................. 157

Virtual Control Switches (43) ................................................................................................................. 159

Element Operation ................................................................................................................................. 159

Logic Connections ................................................................................................................................. 161

Operational Settings .............................................................................................................................. 161

Logic Timers (62) .................................................................................................................................... 163

Element Operation ................................................................................................................................. 163

Logic Connections ................................................................................................................................. 166

Operational Settings .............................................................................................................................. 166

Lockout Functions (86) ........................................................................................................................... 169

Element Operation ................................................................................................................................. 169

Logic Connections ................................................................................................................................. 169

Operational Settings .............................................................................................................................. 169

Retrieving Lockout Status from the BE1-11g ........................................................................................ 170

Breaker Control Switch (101) ................................................................................................................. 171

Element Operation ................................................................................................................................. 171

Logic Connections ................................................................................................................................. 172

Operational Settings .............................................................................................................................. 173

Setting Groups ........................................................................................................................................ 175

Setting Group Functions ........................................................................................................................ 175

Logic Connections ................................................................................................................................. 178

Operational Settings .............................................................................................................................. 179

Logic Override of the Setting Group Selection Function ....................................................................... 181

Metering ................................................................................................................................................... 183

Metering Explorer .................................................................................................................................. 183

Analog Metering Functions .................................................................................................................... 184

Sequence of Events ................................................................................................................................ 191

Retrieving SER Information ................................................................................................................... 191

Fault Reporting ........................................................................................................................................ 193

Fault Reporting Trigger Logic ................................................................................................................ 193

Targets .................................................................................................................................................. 193

Fault Reports ......................................................................................................................................... 196

Oscillographic Records.......................................................................................................................... 199

Distance to Fault .................................................................................................................................... 200

Protective Fault Analysis ....................................................................................................................... 202

BE1-11g Contents

Page 8

vi 9424200994 Rev N

Alarms ...................................................................................................................................................... 205

Alarm Settings ....................................................................................................................................... 207

User Programmable Alarms .................................................................................................................. 207

Retrieving Alarm Information ................................................................................................................. 208

Resetting Alarms ................................................................................................................................... 208

Differential Reporting ............................................................................................................................. 211

Breaker Monitoring ................................................................................................................................. 213

Breaker Status Reporting ...................................................................................................................... 213

Breaker Duty Monitoring ........................................................................................................................ 214

Breaker Alarms ...................................................................................................................................... 218

Demands .................................................................................................................................................. 219

Current ................................................................................................................................................... 219

Power..................................................................................................................................................... 220

Retrieving Demand Reporting Information ............................................................................................ 220

Load Profile ............................................................................................................................................. 223

Setting the Load Profile Recording Function ......................................................................................... 223

Retrieving Load Profile Recorded Data ................................................................................................. 223

Power Quality .......................................................................................................................................... 225

Power Quality Settings .......................................................................................................................... 225

Retrieving Power Quality Data .............................................................................................................. 225

Trip Circuit Monitor (52TCM).................................................................................................................. 229

Element Operation ................................................................................................................................. 229

Logic Connections ................................................................................................................................. 234

Operational Settings .............................................................................................................................. 235

Fuse Loss (60FL) ..................................................................................................................................... 237

Element Operation ................................................................................................................................. 237

Logic Connections ................................................................................................................................. 239

Operational Settings .............................................................................................................................. 239

BESTnet™Plus ......................................................................................................................................... 241

Status Page ........................................................................................................................................... 241

Real Time Data ...................................................................................................................................... 241

Demand Data ........................................................................................................................................ 242

Faults ..................................................................................................................................................... 243

Sequence of Events .............................................................................................................................. 245

Power Quality ........................................................................................................................................ 245

Mounting .................................................................................................................................................. 247

J Type Case Cutouts and Dimensions .................................................................................................. 247

H or P Type Case Cutouts and Dimensions.......................................................................................... 255

Dovetailing Procedure ........................................................................................................................... 262

Terminals and Connectors ..................................................................................................................... 265

J Type Case .......................................................................................................................................... 265

H or P Type Case .................................................................................................................................. 266

CT Polarity ............................................................................................................................................. 267

Typical Connections ............................................................................................................................... 271

Power System Applications ................................................................................................................... 277

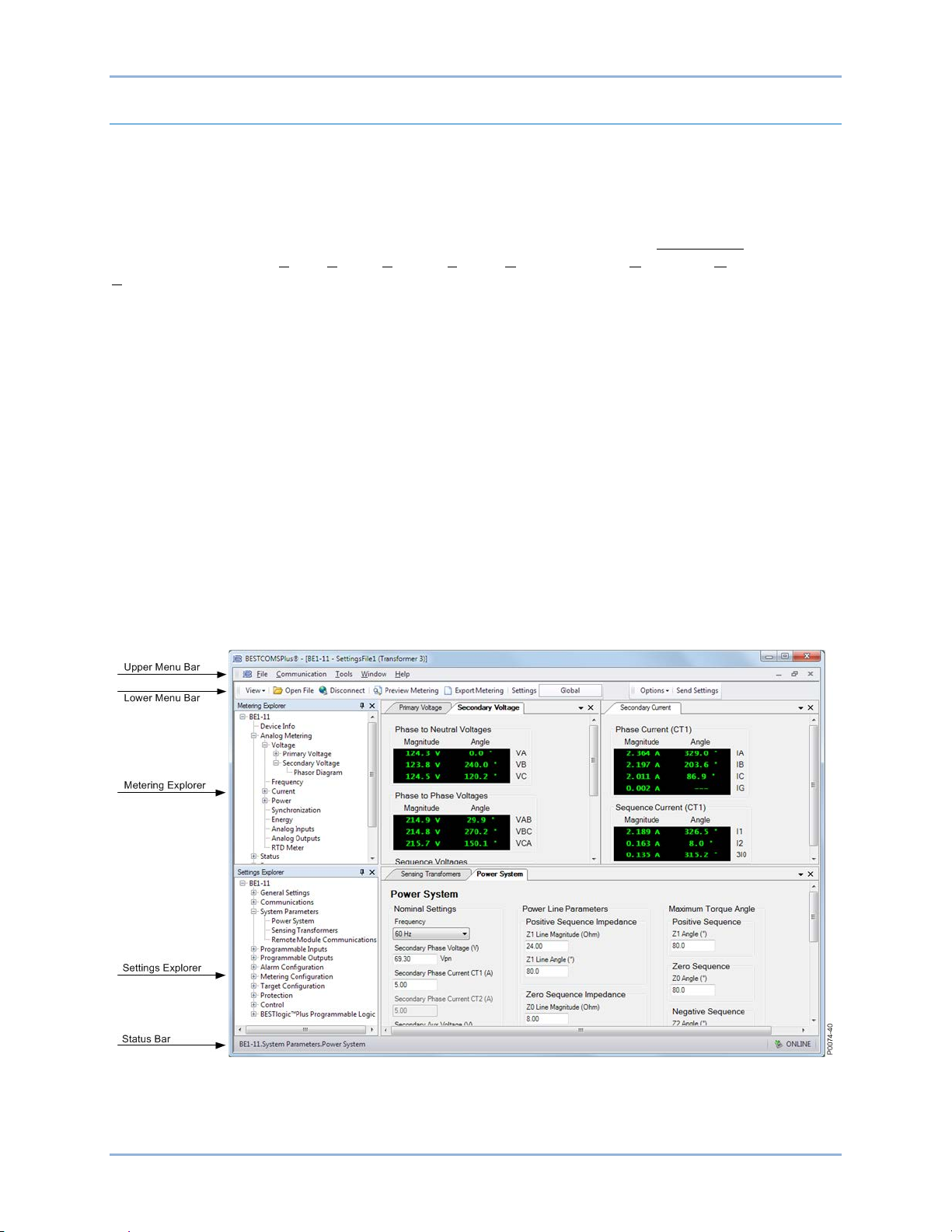

BESTCOMSPlus® Software .................................................................................................................... 283

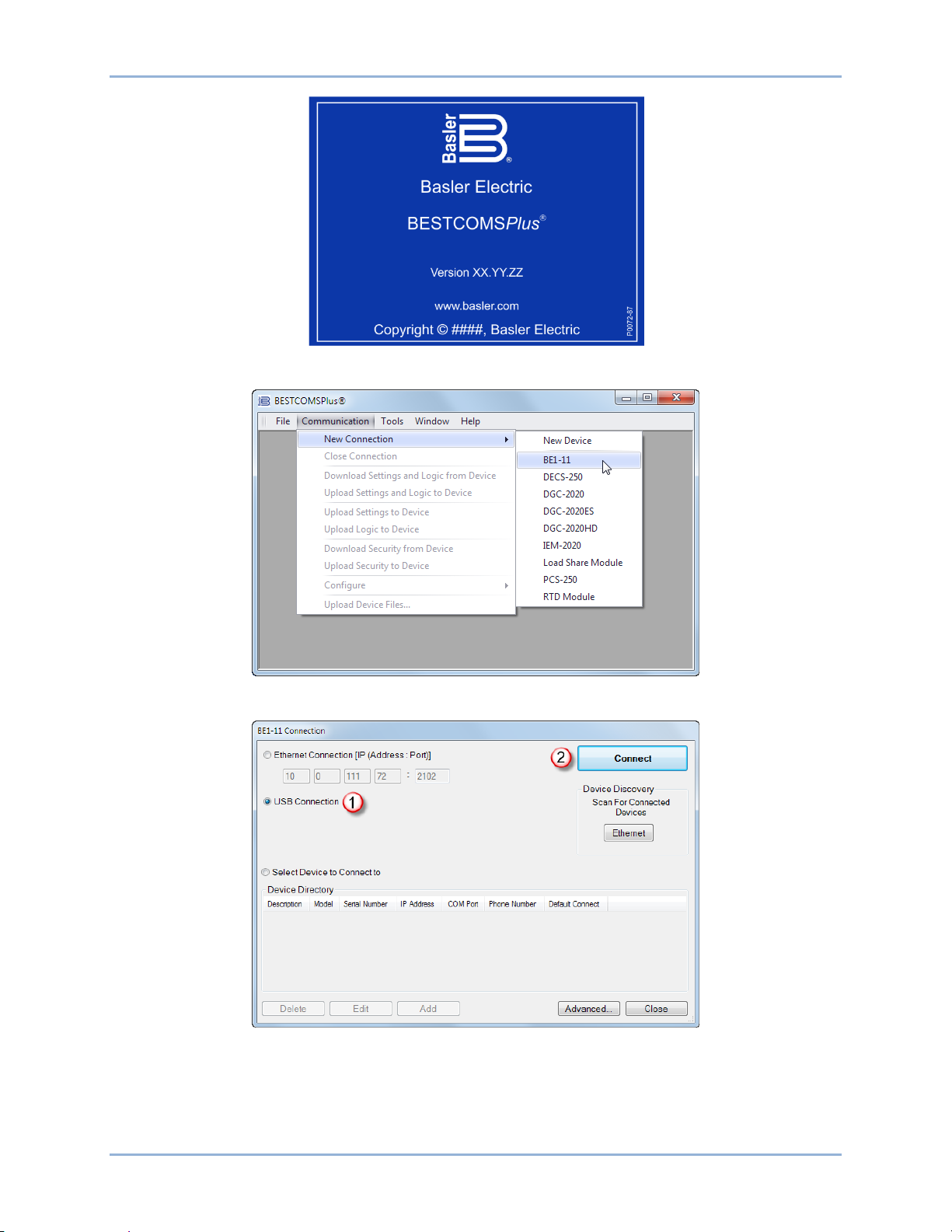

Installation ............................................................................................................................................. 284

Activate the BE1-11 Plugin for BESTCOMSPlus® ................................................................................ 284

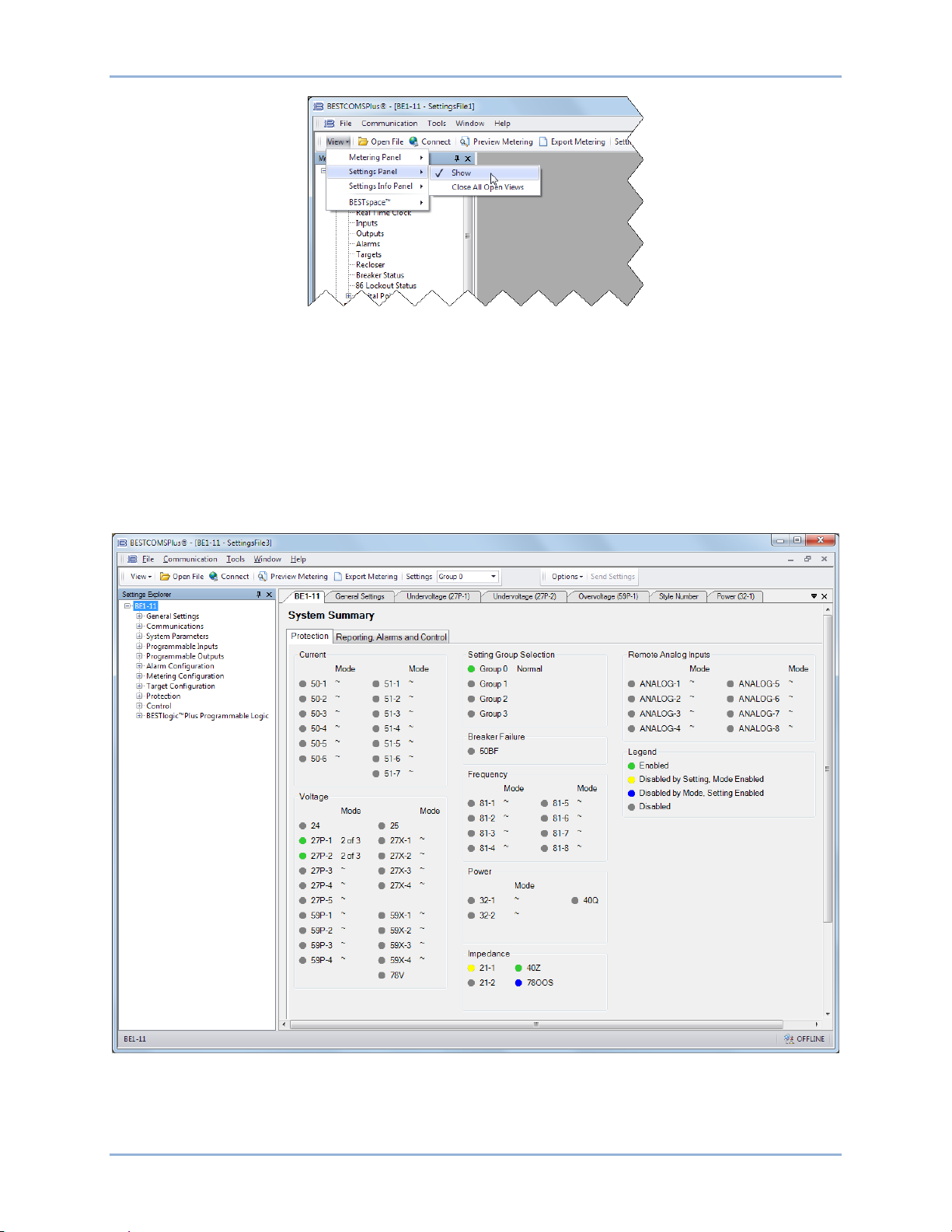

Menu Bars ............................................................................................................................................. 289

Settings Explorer ................................................................................................................................... 291

Metering Explorer .................................................................................................................................. 292

Contents BE1-11g

Page 9

9424200994 Rev N vii

Settings File Management ..................................................................................................................... 292

Auto Export Metering ............................................................................................................................. 294

BESTCOMSPlus® Updates ................................................................................................................... 295

Firmware Updates ................................................................................................................................. 295

BESTlogic™Plus ...................................................................................................................................... 297

Overview of BESTlogic™Plus ................................................................................................................ 297

Logic Schemes ...................................................................................................................................... 307

Programming BESTlogic ™Plus.............................................................................................................. 312

Offline Logic Simulator .......................................................................................................................... 313

BESTlogic™Plus File Management ....................................................................................................... 313

BESTlogic™Plus Ex amp les ................................................................................................................... 315

Communication ....................................................................................................................................... 317

Connections ........................................................................................................................................... 317

Ethernet Setup ....................................................................................................................................... 318

Email Setup ........................................................................................................................................... 320

RS-485 Setup ........................................................................................................................................ 321

DNP Setup ............................................................................................................................................. 321

Modbus™ Setup ..................................................................................................................................... 325

Security .................................................................................................................................................... 327

Access Levels ........................................................................................................................................ 327

Username Setup .................................................................................................................................... 327

Port Access Setup ................................................................................................................................. 328

Access Control ...................................................................................................................................... 329

Viewing the Security Log ....................................................................................................................... 330

Timekeeping ............................................................................................................................................ 331

Clock Setup ........................................................................................................................................... 331

Setting the Time and Date ..................................................................................................................... 332

IRIG Port ................................................................................................................................................ 333

Real-Time Clock Specificat ions ............................................................................................................. 333

Backup Battery for the Real-Time Clock ............................................................................................... 334

Device Information .................................................................................................................................. 339

Style Number ......................................................................................................................................... 339

Device Info ............................................................................................................................................. 340

Firmware Updates ................................................................................................................................. 340

Configuration ........................................................................................................................................... 343

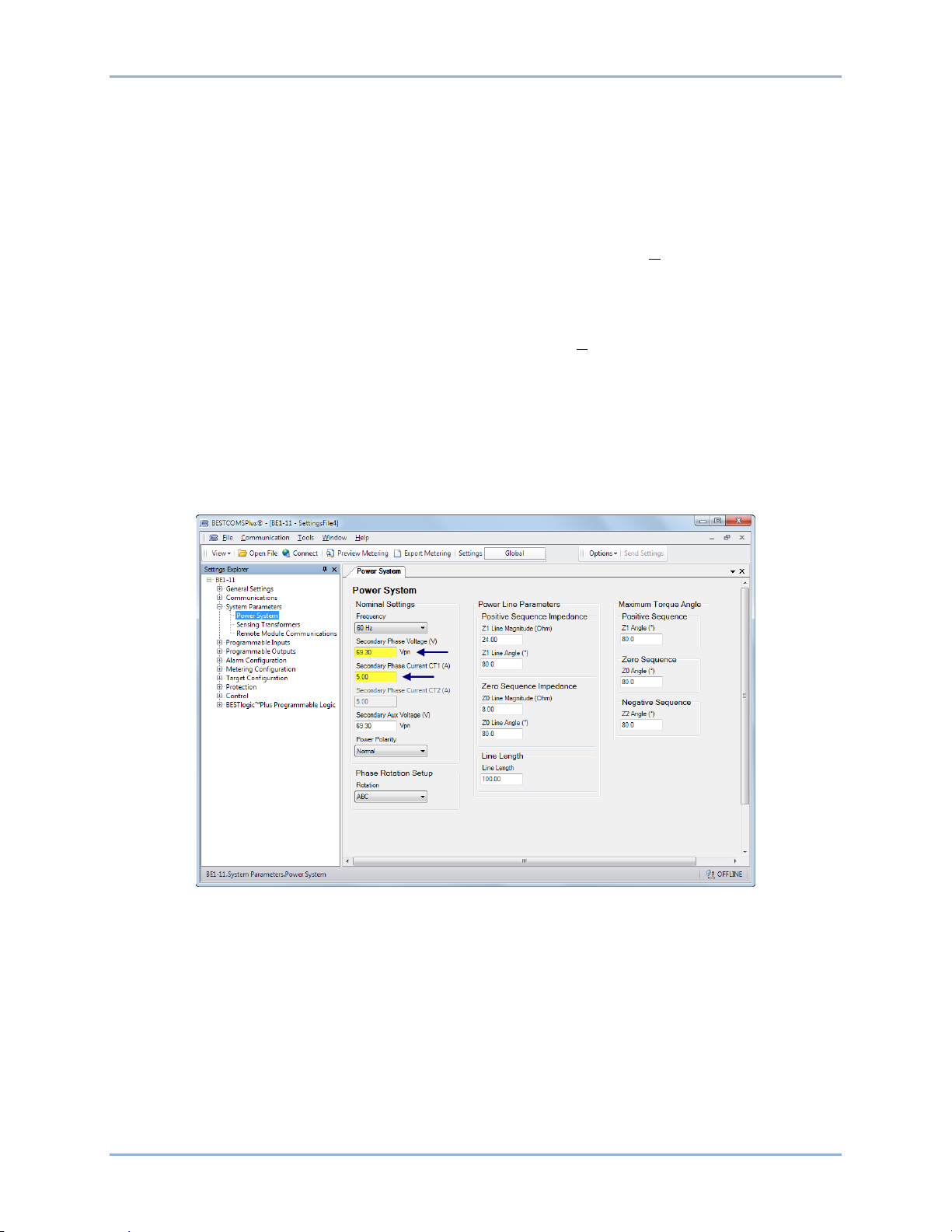

Power System Measurements .............................................................................................................. 343

Power System Settings ......................................................................................................................... 346

Sensing Transformers Settings ............................................................................................................. 347

Transformer Setup ................................................................................................................................. 349

Display Units .......................................................................................................................................... 359

Introduction to Testing ........................................................................................................................... 361

Testing Philosophies ............................................................................................................................. 361

Testing and Troubleshooting Aids ......................................................................................................... 362

Acceptance Testing ................................................................................................................................ 365

Test Equipment ..................................................................................................................................... 365

Power Up ............................................................................................................................................... 365

Communications .................................................................................................................................... 365

Style Number and Serial Number Verificat io n ....................................................................................... 365

IRIG Verification (if used) ...................................................................................................................... 366

Contact Sensing Inputs ......................................................................................................................... 366

Control Outputs ..................................................................................................................................... 366

Current Circuit Verification..................................................................................................................... 367

Three-Phase Voltage Circuit Verification .............................................................................................. 368

Power Reading Verification ................................................................................................................... 369

BE1-11g Contents

Page 10

viii 9424200994 Rev N

Auxiliary Voltage Input Verificati on - VX and VX 3

rd

(Fundamental and Third Harm onic ) ..................... 369

Frequency Verification ........................................................................................................................... 370

Commissioning Testing ......................................................................................................................... 371

Digital I/O Connection Verification ......................................................................................................... 371

Virtual Selector Switches ....................................................................................................................... 372

Virtual Contro l Sw i tc h ............................................................................................................................ 372

Protection and Control Function Verification ......................................................................................... 373

Verify Other Setpoints as Appropriate ................................................................................................... 373

Reporting and Alarm Functions ............................................................................................................. 373

Periodic Testing ...................................................................................................................................... 377

Settings Verification ............................................................................................................................... 377

Analog Circuit Verification ..................................................................................................................... 377

Overexcitation (24) Test ......................................................................................................................... 379

Functional Test Procedure .................................................................................................................... 379

Functional Test Report .......................................................................................................................... 383

Sync-Check (25) Test .............................................................................................................................. 385

Functional Test Procedure .................................................................................................................... 385

Functional Test Report .......................................................................................................................... 388

Phase Undervoltage (27P) Test ............................................................................................................. 391

Functional Test Procedure .................................................................................................................... 391

Functional Test Report .......................................................................................................................... 393

Auxiliary Undervoltage (27X) Test ......................................................................................................... 395

Functional Test Procedure .................................................................................................................... 395

Functional Test Report .......................................................................................................................... 404

Phase Overvoltage (59P) Test................................................................................................................ 407

Functional Test Procedure .................................................................................................................... 407

Functional Test Report .......................................................................................................................... 409

Auxiliary Overvoltage (59X) Test ........................................................................................................... 411

Functional Test Procedure .................................................................................................................... 411

Functional Test Report .......................................................................................................................... 419

Vector Jump (78V) Test .......................................................................................................................... 423

Functional Test Procedure .................................................................................................................... 423

Functional Test Report .......................................................................................................................... 424

Frequency (81) Test ................................................................................................................................ 427

Functional Test Procedure .................................................................................................................... 427

Functional Test Report .......................................................................................................................... 432

Instantaneous Overcurrent (50) Test .................................................................................................... 435

Functional Test Procedure .................................................................................................................... 435

Functional Test Report .......................................................................................................................... 442

Breaker Fail (50BF) Test ......................................................................................................................... 447

Functional Test Procedure .................................................................................................................... 447

Functional Test Report .......................................................................................................................... 450

Inverse Overcurrent (51) Test ................................................................................................................ 451

Functional Test Procedure .................................................................................................................... 451

Functional Test Report .......................................................................................................................... 461

Directional Overcurrent (67) Test .......................................................................................................... 467

Functional Test Procedure .................................................................................................................... 467

Functional Test Report .......................................................................................................................... 473

Phase Current Differential (87) Test ...................................................................................................... 475

Restrained Functional Test Procedure .................................................................................................. 475

Contents BE1-11g

Page 11

9424200994 Rev N ix

Unrestrained Functional Test Procedure ............................................................................................... 482

Harmonic Restraint Functional Test Procedure .................................................................................... 482

Functional Test Reports ........................................................................................................................ 484

Neutral Current Differential (87N) Test ................................................................................................. 487

Functional Test Procedure .................................................................................................................... 487

Functional Test Report .......................................................................................................................... 489

Power (32) Test ........................................................................................................................................ 491

Functional Test Procedure .................................................................................................................... 491

Functional Test Report .......................................................................................................................... 494

Loss of Excitation - Reverse Var Based (40Q) Test ............................................................................ 497

Functional Test Procedure .................................................................................................................... 497

Functional Test Report .......................................................................................................................... 499

Distance (21) Test ................................................................................................................................... 501

Pickup Verification ................................................................................................................................. 501

Timing Verification ................................................................................................................................. 502

Functional Test Report .......................................................................................................................... 503

Loss of Excitation – Impedance Based (40Z) Test .............................................................................. 505

Functional Test Procedure .................................................................................................................... 505

Functional Test Report .......................................................................................................................... 507

Out of Step (78OOS) Test ....................................................................................................................... 509

Functional Test Procedure .................................................................................................................... 509

Functional Test Report .......................................................................................................................... 512

Synchronizer (25A) Test ......................................................................................................................... 513

Phase-Lock-Loop (PLL) Functional Test Procedure ............................................................................. 513

Functional Test Report - PLL ................................................................................................................ 518

Anticipatory Functional Test Procedure ................................................................................................ 519

Functional Test Report - Anticipatory .................................................................................................... 523

Voltage Monitor Functional Test Procedure .......................................................................................... 523

Voltage Monitor Functional Test Report ................................................................................................ 526

Virtual Control Switches (43) Test ......................................................................................................... 527

Functional Test Procedure .................................................................................................................... 527

Functional Test Report .......................................................................................................................... 529

Logic Timers (62) Test ............................................................................................................................ 531

Functional Test Procedure .................................................................................................................... 531

Functional Test Report .......................................................................................................................... 539

Lockout Functions (86) Test .................................................................................................................. 541

Functional Test Procedure .................................................................................................................... 541

Functional Test Report .......................................................................................................................... 542

Breaker Control Switch (101) Test ........................................................................................................ 543

Functional Test Procedure .................................................................................................................... 543

Functional Test Report .......................................................................................................................... 544

Frequently Asked Questions (FAQ) ...................................................................................................... 545

Electrical/Connections ........................................................................................................................... 545

General Operation ................................................................................................................................. 545

Features ................................................................................................................................................ 546

Communications .................................................................................................................................... 546

Troubleshooting ...................................................................................................................................... 547

Communications .................................................................................................................................... 547

Inputs and Outputs ................................................................................................................................ 548

Metering/Display .................................................................................................................................... 548

General Operation ................................................................................................................................. 548

BE1-11g Contents

Page 12

x 9424200994 Rev N

Specifications .......................................................................................................................................... 551

Operational Specifications ..................................................................................................................... 551

General Specifications........................................................................................................................... 562

Specifications - 25 Hz Operation ........................................................................................................... 569

Operational Specifications ..................................................................................................................... 569

Time Curve Characteristics.................................................................................................................... 581

Inverse Overcurrent (51) ....................................................................................................................... 581

Under/Overvoltage (27/59) .................................................................................................................... 609

Overexcitation (24) ................................................................................................................................ 613

RTD Module ............................................................................................................................................. 617

Features ................................................................................................................................................ 617

Functional Description ........................................................................................................................... 617

Mounting ................................................................................................................................................ 618

Connections ........................................................................................................................................... 619

RTD Module Communications Setup Procedure .................................................................................. 622

RTD Module Plugin for BESTCOMSPlus® ............................................................................................ 625

Remote Analog Inputs Configuration .................................................................................................... 630

Remote Analog Outputs Configuration .................................................................................................. 631

Remote RTDs Configuration ................................................................................................................. 632

Specifications ........................................................................................................................................ 633

Repair .................................................................................................................................................... 636

Maintenance .......................................................................................................................................... 636

Storage .................................................................................................................................................. 636

Digital Points ........................................................................................................................................... 637

Revision History ...................................................................................................................................... 651

Contents BE1-11g

Page 13

9424200994 Rev N 1

Introduction

The BE1-11g Generator Protection System provides flexible, reliable, and economical protection, control,

monitoring, and measurement functions for small, medium, and large generators. The BE1-11g offers

vector jump, out of step, distance, phase and neutral current differential, overexcitation (V/Hz),

overcurrent, directional overcurrent, over/undervoltage, over/underfrequency, RTD (Resistance

Temperature Detector) with remote module, breaker failure, and fuse loss protection. It offers breakerand trip-circuit monitoring, and oscillography and sequential events recording. Control features include

virtual selector switches, circuit breaker control, virtual lockout, and variable-mode timer s. An auto

synchronizer is optional. System metering, status information, and fault locating are available at the

BE1-11g front panel and through the BE1-11g communication ports. The capabilities of the BE1-11g

make it suitable for detecting generator faults and abnormal operating conditions in an integrated system.

Suitable BE1-11g applications include large power generation, distributed generation, local backup

generation, and intertie protection applications.

A front-panel USB port or optional rear Ethernet port enables local communication between the BE1-11g

and a PC operating with BESTCOMSPlus® software. BESTCOMSPlus software simplifies the

commissioning process by providing a graphical interface for setting the BE1-11g and configuring a

protection and control scheme for your application. Through BESTCOMSPlus, all BE1-11g settings and

logic can be retained in a file for printing or uploading to other BE1-11g protection systems. Oscillography

and sequential events records can be retrieved from a BE1-11g, viewed, and printed.

Front-panel features include a large, backlit alphanumeric display and LED indicators that display system

parameters, BE1-11g settings, and BE1-11g status. Pushbuttons enable navigation through the display

menu, changes to settings, resetting of targets (with password access), and direct access to virtual

switches.

Applications

The capabilities of the BE1-11g make it ideally suited for applications with the following attributes:

• Generator specific protection and control elements including loss of field, out of step, stator

ground protection, and sync check or synchronizer

• Generator focused protection including reverse power, negative-sequence, overexcitation, and

differential

• Isolation between the RTDs and the BE1-11g due to distance between the BE1-11g package and

the RTD module

• Low burden to extend the linear range of CTs

• The flexibility provided by wide setting ranges, multiple setting groups, and multiple coordination

curves in one unit

• The economy and space savings provided by a multifunction, multiphase unit. This one unit can

provide all of the protection, control, metering, and local and remote indication functions required

for typical applications.

• Directional control and fault recording

• High-speed Ethernet communications and protocol support

• The capabilities of a numeric multifunction relay

• The small size and limited behind-panel projection facilitates modernizing protection and control

systems in existing equipment

• Detection of low ground current levels (SEF option)

• IEC 61850 functionality

• Logic library with logic schemes for basic low Z grounded generator protection, low Z grounded

generator with sequential trip, low Z grounded generator with sequential trip and sync check,

basic high Z grounded generator protection, high Z grounded generator protection

BE1-11g Introduction

Page 14

2 9424200994 Rev N

Features

The BE1-11g protection system includes many features for the protection, monitoring, and control of

power system equipment. These features include protection and control functions, metering functions,

and reporting and alarm functions. A highly flexible programmable logic system called BESTlogic™Plus

allows the user to apply the available functions with complete flexibility and customize the system to meet

the requirements of the protected power system. Programmable I/O, extensive communication features,

and an advanced user interface provide easy access to the features provided.

The following information summarizes the capabilities of this multifunction device. Each feature, along

with its setup and use, is described in greater detail in the later chapters of this manual.

General Features

HMI (Human-Machine Interface)

Each BE1-11g has a front-panel display and LED indicators. Protection systems in an H or P style case

have five LED indicators: Power Supply Status, Relay Trouble Alarm, Minor Alarm, Major Alarm, and Trip.

Protection systems in a J style case have 12 LED indicators: Power Supply Status, Relay Trouble Alarm,

Minor Alarm, Major Alarm, Trip, Select Control Switch, Operate Control Switch, and Indicator 1 through 7

(programmable in BESTlogicPlus). The backlit, liquid crystal display (LCD) allows the BE1-11g to replace

local indication and control functions such as panel metering, alarm annunciation, and control switches.

Four scrolling pushbuttons enable navigation through the LCD menu tree. Parameters are changed using

the Edit pushbutton. Targets, alarms, and other registers are cleared with the Reset pushbutton. In Edit

mode, the scrolling pushbuttons provide data entry selections. Edit mode is indicated by an LED on the

Edit pushbutton. Protection systems in a J-style case have pushbuttons for selecting and controlling the

virtual control switches.

The LCD has automatic priority logic to govern which metering values are displayed on the screen so that

when an operator approaches, the metering data of most interest is automatically displayed without

having to navigate the menu structure. Scrollable metering parameters are selected on the General

Settings, Front Panel HMI settings screen in BESTCOMSPlus.

Device Information

The version of the embedded software (firmware), serial number, and style number are available from the

front-panel display or the communication ports.

Three free-form fields (Device ID, Station ID, and User ID) can be used to enter information to identify the

BE1-11g. These fields are used by many of the reporting functions to identify the BE1-11g reporting the

information. Examples of BE1-11g identification field uses include station name, circuit number, relay

system, and purchase order, and others.

Device Security

Passwords provide access security for six distinct functional access areas: Read, Control, Operator,

Settings, Design, and Administrator. Each username/password is assigned an access area with access to

that area and each area below it. An administrator password provides access to all six of the functional

areas.

A second dimension of security is provided by the ability to restrict access for any of the access areas to

only specific communication ports. For example, you could set up security to deny access to control

commands through the Ethernet port.

Security settings affect read and write access. Refer to the Security chapter for more informat ion.

Setting Groups

Four setting groups allow adaptive relaying to be implemented to optimize BE1-11g settings for various

operating conditions. Auto matic and ex terna l log ic ca n be employ e d to select the active setting group.

Introduction BE1-11g

Page 15

9424200994 Rev N 3

Clock

The clock is used by the logging functions to timestamp events. BE1-11g timekeeping can be selfmanaged by the internal clock or coordinated with an external source through a network or IRIG device.

A backup capacitor and additional battery backup are provided for the clock. During a loss of operating

power, the backup capacitor maintains timekeeping for up to 24 hours depending on conditions. As the

capacitor nears depletion, the backup battery takes over and maintains timekeeping. The backup battery

has a life expectancy of greater than five years depending on conditions.

IRIG

A standard unmodulated IRIG-B input receives time synchronization signals from a master clock.

Automatic daylight saving time compensation can be enabled and set for floating or fixed dates.

NTP (Network Time Protocol)

NTP synchronizes the real-time clock to network time servers through the Ethernet port. BESTCOMSPlus

is used to establish the priority of time reference sources available to the BE1-11g, IRIG-B, NTP, DN P,

and RTC (real-time clock). The NTP address is set using BESTCOMSPlus.

Communications

Three independent communication ports provide access to all BE1-11g functions. A USB (universal serial

bus) port is located on the front panel, a two-wire RS-485 port is located on the rear panel, and an

optional Ethernet port is also located on the rear panel. The RS-485 and Ethernet ports are electrically

isolated.

Modbus™ and DNP3 protocols are optionally available for the RS-485 or Ethernet communication port.

The IEC 61850 protocol is optionally av ai lable for the Ether net port. Sep ar ate instruction manuals cover

each available protocol. Consult the product bulletin or Basler Electric for availability of these options and

instruction manuals. Modbus sessions can be operated simultaneously over the Ethernet and RS-485

ports.

System Parameters

Three-phase currents and voltages are digitally sampled and the fundamental is extracted using a

Discrete Fourier Transform (DFT) algorithm.

The voltage sensing circuits can be configured for single-phase, three-phase-three-wire, or four-wire

voltage transformer circuits. Voltage sensing circuitry provides voltage protection, frequency protection,

polarizing, and watt/var metering. Neutral-shift, positive-sequence, and negative-sequence voltage

magnitudes are derived from the three-phase voltages. Digital sampling of the measured frequency

provides high accuracy at off-nominal values.

An auxiliary voltage sensing input (Vx) provides protection capabilities for over/underv olta ge mon itor ing of

the fundamental and third harmonic voltage of the VT source connected to the Vx input. This capability is

useful for ground fault protection or sync-check functions.

Each current sensing circuit has low burden and is isolated. Neutral, positive-sequence, and negativesequence current magnitudes are derived from the three-phase curr ents . An ind e pend ent ground current

input is available for direct measurement of the current in a transformer neutral, tertiary winding or flux

balancing current transformer. Either one or two sets of CTs are provided in the BE1-11g depending on

the style number. Refer to the style chart for more information.

Programmable Inputs and Outputs

Programmable contact inputs and outputs are described in the following paragraphs.

Programmable Inputs

Programmable contact sensing inputs with programmable signal conditioning provide a binary logic

interface to the protection and control system. Each input function and label is programmable using

BE1-11g Introduction

Page 16

4 9424200994 Rev N

BESTlogicPlus. A user -meaningful label can be assigned to each input and to each state (energized and

de-energized) for use in reporting functions. Board mounted jumpers support dual voltage ratings.

Protection systems in a J style case are equipped with seven contact sensing inputs. Protection systems

in an H or P style case are equipped with five contact sensing inputs.

Programmable Outputs

Programmable general-purpose contact outputs provide a binary logic interface to the protection and

control system. One programmable, failsafe contact output serves as an alarm output. Each output

function and label is programmable using BESTlogicPlus. A user-meaningful name can be assigned to

each output and to each state (energized and de-energized) for use in reporting functions. Output logic

can be overridden to open, close, or pulse each output contact for testing or control purposes. All output

contacts are trip rated.

Protection systems in a J style case are equipped with eight general-purpose contact outputs. Protection

systems in an H or P style case are equipped with five general-purpose contact outputs.

Reporting and Alarms

Several reporting and alarm functions provide fault reporting, differential reporting, demand, breaker, and

trip circuit monitoring. Reporting of power quality, energy data, and general status is also provided.

Alarms

Extensive self diagnostics will trigger a fatal relay trouble alarm if any of the BE1-11g core functions are

compromised. Fatal relay trouble alarms are not programmable and are dedicated to the Alarm output

(OUTA) and the front panel Relay Trouble LED. Additional relay trouble alarms and all other alarm

functions are programmable for major or minor priority. Programmed alarms are indicated by major or

minor alarm LEDs on the front panel. Major and minor alarm points can also be programmed to any

output contact including OUTA. Over 50 alarm conditions are available to be monitored including userdefinable logic conditions u sing BE STlogicPlus.

Active alarms can be read and reset at the front panel or through the communication ports. A historical

sequence of events report with time stamps lists when each alarm occurred and cleared. These reports

are available through the communication ports.

Breaker Monitoring

Breaker statistics are recorded for a single breaker. They include the number of operations, fault current

interruption duty, and breaker time to trip. Each of these conditions can be set to trigger an alarm.

Trip Circuit Monitor (52TCM)

The trip circuit of a breaker or lockout relay can be monitored for loss of voltage (fuse blown) or loss of

continuity (trip coil open). Additional trip or close circuit monitors can be implemented in BESTlogicPlus

using additional inputs, logic timers, and programmable logic alarms.

Demands

Demand values are continuously calculated for phase currents, neutral current, negative-sequence

current, ground current, real power, reactive power, and apparent power. The demand interval and

demand calculation method are independently settable for phase, neutral, and negative-sequence

measurements. Demand reporting records peak and present demand with time stamps for each register.

Power Quality

The BE1-11g offers IEC 61000-4-30 Class B power quality measurement performance. Power quality

settings include a fixed or sliding reference mode, dip hysteresis, dip ratio, swell hysteresis, and swell

ratio.

Energy Data Reporting

Energy information in the form of watthours and varhours is measured and reported by the BE1-11g. Both

positive and negative values are reported in three-phase, primary units.

Introduction BE1-11g

Page 17

9424200994 Rev N 5

General Status Reporting

The BE1-11g provides extensive general status reporting for monitoring, commissioning, and

troubleshooting. Status reports are available from the front-panel display or communication ports.

Fault Reporting