Page 1

OMNI-BEAM™ Sensor Heads

The Sensing Component of OMNI-BEAM Modular Photoelectric Sensors

Printed in USA P/N 03522A9E

WARNING . . .

Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current

Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

OMNI-BEAM Features

• Sensor heads feature Banner’s D.A.T.A.™ (Display And Trouble Alert) indicator

system* which warns of an impending sensing problem before a failure occurs

• 10-element LED array displays sensing contrast and received signal strength and

warns of a sensing problem due to any of the following causes:

- Severe condensation or moisture

- High temperature

- Low supply voltage

- Output overload (dc operation)

- Too much sensing gain

- Not enough sensing gain

- Low optical contrast

• Separate indicators for target sensed and output energized

• Sensor heads are field-programmable for the following response parameters:

- Sensing hysteresis

- Signal strength indicator scale factor

- Light or dark operate of the load output

- Normally open or closed alarm output

• Choose power blocks for high-voltage ac or low-voltage (10 to 30V) dc operation

• Sensor head and power block plug (and bolt) together quickly and easily

• Optional plug-in output timing modules may be added at any time

OMNI-BEAM Overview

Modular Design

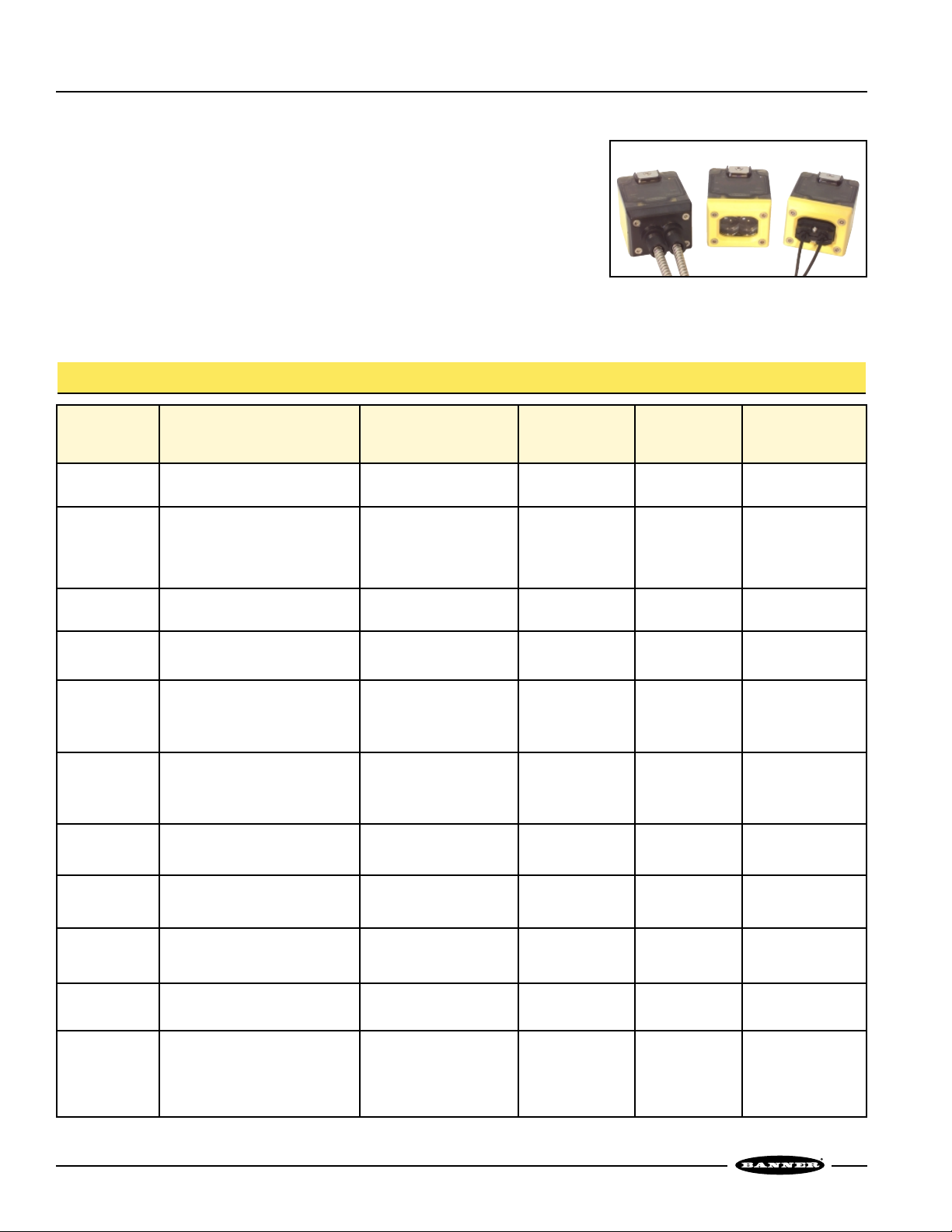

OMNI-BEAM is a modular self-contained sensor. It is made up of a sensor head and a

power block; an optional plug-in timing logic module may be added easily. The three

modular components, sold separately, simply plug and bolt together — without

interwiring — to create a complete self-contained photoelectric sensor tailored to a

particular application’s exact sensing requirements.

The sensor lenses and modular components are all field-replaceable. OMNI-BEAM’s

modular design makes change-out of any component quick and easy.

*U.S. Patent 4965548

Figure 1. OMNI-BEAM sensor head and

power block bolt and plug

together quickly and easily; an

optional timing logic module

may be added at any time.

!

Page 2

OMNI-BEAM Sensor Heads

page

2

Sensor Heads

A sensor head module is available for every sensing situation. Sensor heads bolt

directly onto the power block, and are fully gasketed for protection against

environmental elements. The D.A.T.A. self-diagnostic feature is standard on all OMNIBEAM sensor heads (except emitters and model OSBFAC). Select from most sensing

modes, with infrared or visible red, green or blue sensing beams available.

Figure 2. OMNI-BEAM sensor heads are

available for most sensing

modes, including fiber optic

models.

Model Sensing Mode Light Source Range Response Repeatability

OSBE

OSBR

Opposed emitter

Opposed receiver

Infrared,

880 nm

45 m (150') 2 ms 0.01 ms

OSBLV

OSBLVAG

Non-polarized retroreflective

Polarized retroreflective

Visible red

650 nm

0.15 to 9 m

(6' to 30')

0.3 to 4.5 m

(12" to 15')

4 ms 0.2 ms

OSBD

OSBDX

Short-range diffuse

Long-range diffuse

Infrared,

880 nm

300 mm (12")

2 m (6.5')

2 ms

15 ms

0.1 ms

1 ms

OSBCV

OSBCVG

OSBCVB

Convergent

Visible red, 650 nm

Visible green, 525 nm

Visible blue, 475 nm

38 mm (1.5")

Focus

4 ms 0.2 ms

OSBF

OSBFVG

OSBFVB

Glass fiber optic

–high speed

Infrared, 880 nm

Visible green, 525 nm

Visible blue, 475 nm

Range varies with

fiber optics used

2 ms 0.1 ms

OSBFX

Glass fiber optic

–high power

Infrared, 880 nm

Range varies with

fiber optics used

15 ms 1 ms

OSBFP

OSBFPG

OSBFPB

Plastic fiber optic

Visible red, 650 nm

Visible green, 525 nm

Visible blue, 475 nm

Range varies with

fiber optics used

2 ms 0.1 ms

OMNI-BEAM Sensor Head Models

OSBLVAGC

Polarized retroreflective, clear

object detection

Visible red

650 nm

4 m (12') 4 ms 0.2 ms

OSBFV

Glass fiber optic

–high speed

Visible red, 650 nm

Range varies with

fiber optics used

2 ms 0.1 ms

OSBEF

OSBRF

Glass fiber optic emitter

Glass fiber optic receiver

Infrared, 880 nm

Range varies with

fiber optics used

2 ms 0.01 ms

OSBFAC

Glass fiber optic

–ac-coupled

Infrared, 880 nm

Range varies with

fiber optics used

1 ms 0.01 ms

NOTE: See pages 9 and 10 for Excess Gain and Beam Pattern curves.

Page 3

OMNI-BEAM Sensor Heads

page

3

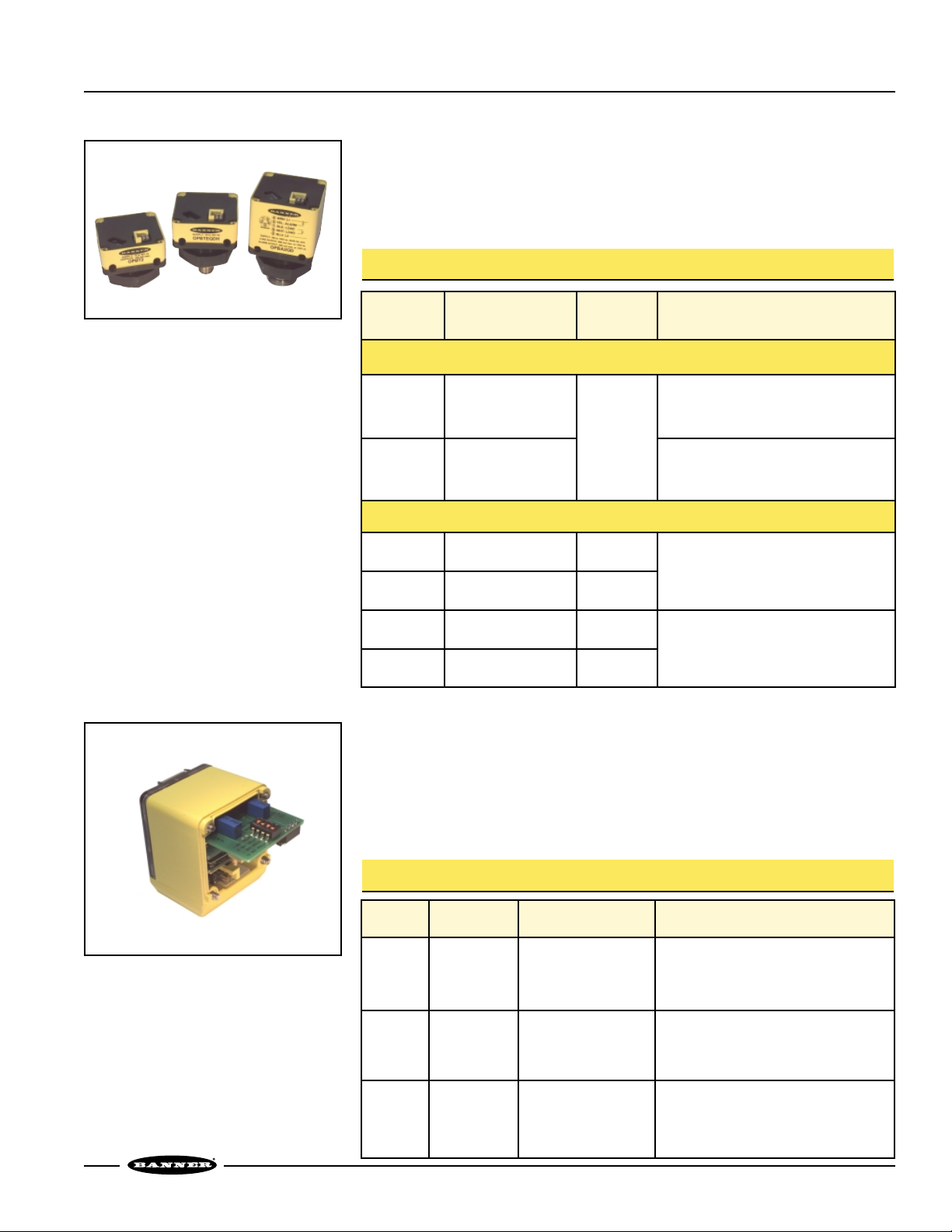

OMNI-BEAM Power Blocks

Power Blocks

The power block determines the sensor operating voltage and also the sensor output

switch configuration. Models are available with a built-in 2 m (6.5') or 9 m (30')

cable, or with either Mini-style or Euro-style quick-disconnect (“QD”) plug-in cable

fittings. Emitter power blocks have no output circuitry.

Figure 3. OMNI-BEAM power blocks

provide the input and output

circuitry for OMNI-BEAM sensor

heads. Select models for either

ac or dc power.

OPBA2

OPBA2QD

2 m (6.5')

5-Pin Mini QD

105-130V ac

SPST solid-state ac relay

Two outputs: Load and Alarm

OPBB2

OPBB2QD

2 m (6.5')

5-Pin Mini QD

Models

210-250V ac

Cable

0PBAE

OPBAEQD

Supply

Voltage

Output Type

2 m (6.5')

5-Pin Mini QD

AC Voltage

(see data sheet p/n 03531 packed with the power block)

105-130V ac

No output:

for powering emitter only sensor heads

OPBBE

OPBBEQD

2 m (6.5')

5-Pin Mini QD

210-250V ac

OPBTE

OPBTEQD

OPBTEQDH

2 m (6.5')

4-Pin Mini QD

4-Pin Euro QD

No output:

for powering emitter only sensor heads

OPBT2

OPBT2QD

OPBT2QDH

2 m (6.5')

4-Pin Mini QD

4-Pin Euro QD

10-30V dc

Bi-Modal

™

NPN/PNP

Two outputs: Load and Alarm

DC Voltage

(see data sheet p/n 03532 packed with the power block)

NOTE: 9 m (30') cables are availabe by adding the suffix “w/30” to the model number

of any cabled power block (for example, OPBT2 w/30).

Optional Timing Logic Modules

Timing logic may be added at any time, using one of three timing delay and pulse

logic modules. Installation is simple and quick; the logic modules simply slide into the

sensor head (see Figure 4). Program them for timing functions and ranges via four

DIP switches; each module includes easily accessible 15-turn clutched potentiometers

for accurate timing adjustments.

Figure 4. OMNI-BEAM optional timing

logic modules

Logic Function

ONE-SHOT pulse timer or

DELAYED ONE-SHOT

logic timer

OLM8

ON-DELAY or OFF-DELAY

or ON/OFF DELAY

Pulse Timer

Logic Module

Delay: 0.01 to 1 sec,

0.15 to 15 sec, or none

Pulse: 0.01 to 1 sec, 0.15 to 15 sec

Models Type Timing Ranges

ONE-SHOT pulse timer or

DELAYED ONE-SHOT

logic timer

OLM5

Delay Timer

Logic Module

OLM8M1

ON-Delay: 0.01 to 1 sec,

0.15 to 15 sec, or none

OFF-Delay: 0.01 to 1 sec,

0.15 to 15 sec, or none

Pulse Timer

Logic Module

Delay: 0.002 to 0.1 sec,

0.03 to 1.5 sec, or none

Pulse: 0.002 to 0.1 sec,

0.03 to 1.5 sec

OMNI-BEAM Timing Logic Modules

(see data sheet p/n 03533 packed with the module)

Page 4

OMNI-BEAM Sensor Heads

page

4

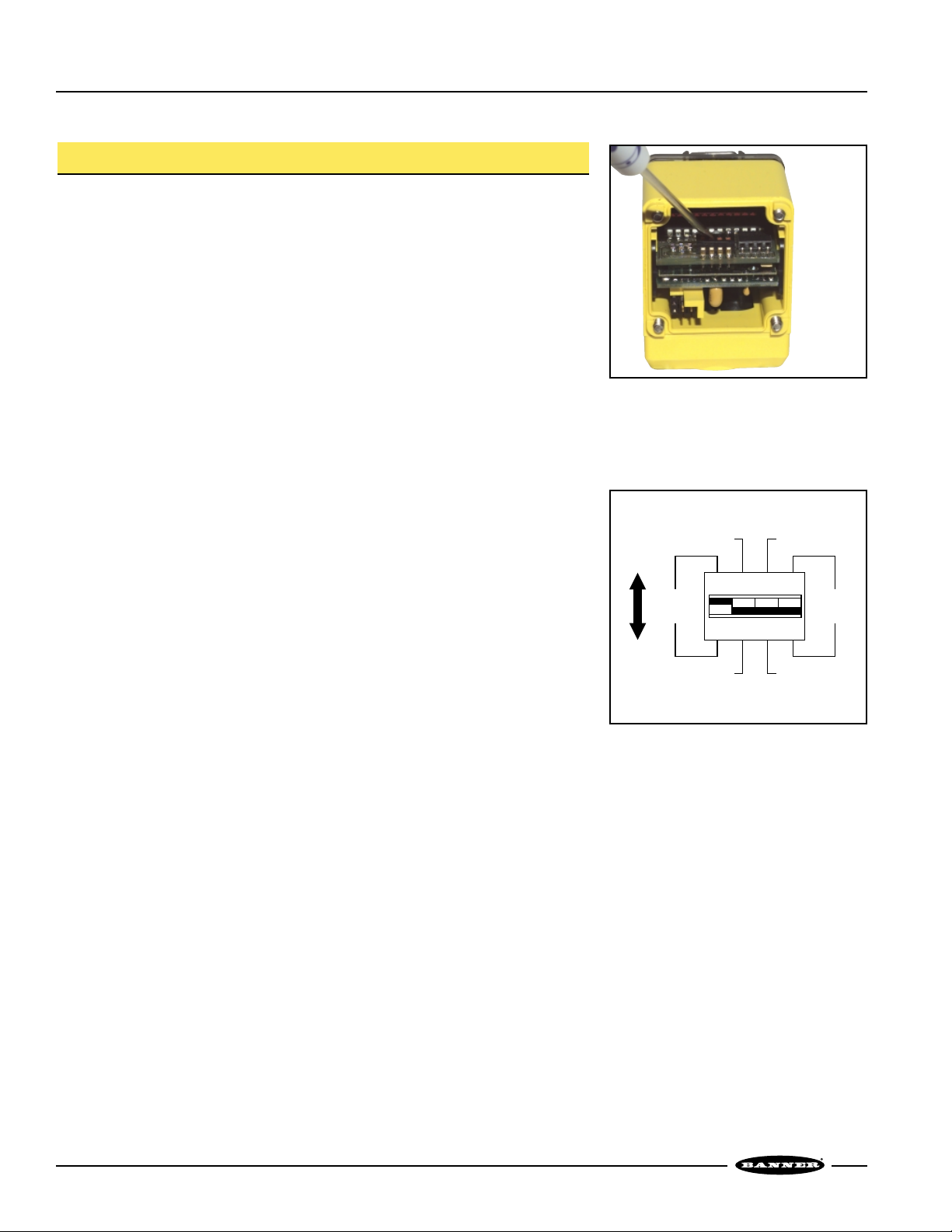

Figure 5. OMNI-BEAM program switches

Alarm N/O

ON

OFF

Standard

Hysteresis

Low

Fine

Scale

Standard

Dark Operate

Alarm N/C Light Operate

1

OFF

234

Figure 6. OMNI-BEAM program switch

configuration

Sensor Head Programming

DIP Switch Settings

OMNI-BEAM sensor heads are field-programmable for four operating parameters. To

access the four programming DIP switches (see figure 5), remove the sensor block

from the power block.

Switch #1, Sensing Hysteresis

ON: Standard hysteresis.

OFF: Low hysteresis; should be used only when all sensing conditions remain

completely stable.

Hysteresis is an electronic sensor requirement that the amount of received light

needed to energize the sensor’s output not be equal to the amount needed to release

the output. This differential prevents the sensing output from “buzzing” or

“chattering” when the received light signal is at or near the sensing threshold level.

The standard setting should be used always, except for low-contrast applications

such as the detection of subtle differences in reflectivity.

Switch #2, Alarm Output Configuration

ON: Alarm output is normally open (it conducts with an alarm).

OFF: Alarm output is normally closed (the output opens during an alarm).

Normally closed mode (OFF) is recommended; it allows a system controller to

recognize a sensor power loss or an open sensor output as an alarm condition.

Normally open alarm mode (ON) should be used when the alarm outputs of multiple

OMNI-BEAMs are wired in parallel to a common alarm or alarm input.

Switch #3, Light or Dark Operate

ON: Dark Operate mode; the output energizes (after a time delay, if applicable) when

the received light level is less than the sensing threshold (4 or fewer D.A.T.A.

lights ON).

OFF: Light Operate mode; the sensor’s load output energizes (after a time delay, if

applicable) when the received light level is greater than the sensing threshold (5

or more D.A.T.A. lights ON).

Switch #4, Scale Factor for the D.A.T.A. Signal Strength Indicator Display

ON: Fine scale.

OFF: Standard scale.

This switch should always be OFF, except for close differential sensing situations (for

example, some color registration applications, which also require the Low hysteresis

setting/switch #1 OFF).

Factory Settings

The following are the factory program settings for OMNI-BEAM sensor head DIP

switches.

Switch #1: ON (Standard hysteresis)

Switch #2: OFF (Normally Closed alarm output)

Switch #3: OFF (Light Operate load output)

Switch #4: OFF (Standard Scale Factor for signal strength display)

Page 5

OMNI-BEAM Sensor Heads

page

5

Figure 6. OMNI-BEAM D.A.T.A. LEDs

Using the D.A.T.A. Sensor Self-Diagnostic Feature

Banner’s exclusive D.A.T.A. feature warns of marginal sensing conditions, usually

before a sensing failure occurs, by flashing one or more lights in its multiple-LED

array, and by sending a warning signal to the system logic controller (or directly to an

audible or visual alarm). The chart below describes the meanings of the possible

signals.

Flashing LED Problem Description

#1 Moisture Alert

Severe moisture is inside the sensor head, caused by condensation or by entry of moisture when the

access cover is removed.

#2

High Temperature

Alert

The temperature inside the sensor head exceeds +70°C (+158°F).

#3

Low Voltage

or

Overload Alert

Sensor supply voltage is below the minimum specified for the power block in use. Power block outputs

also shut down to prevent damage to the load(s) from low voltage.

DC power blocks OPBT2, OPBT2QD, or OPBT2QDH: Either the load output or the alarm output is

shorted. Both outputs will be inhibited, and the circuit will “retry” the outputs every 1/10 second. The

outputs automatically reset and function normally when the short is corrected.

#9

High Gain

Warning

The “dark” signal never goes below #4 on the display; decrease the Gain setting. There are two possible

causes:

1) The “dark” signal slowly increases and remains at the #4 level for a predetermined delay time,

commonly caused by a gradual increase of unwanted background reflections in reflective sensing

modes (such as diffuse or convergent). The alarm will reset as soon as the cause of the unwanted

light signal is removed, or if the Gain control setting is reduced to bring the “dark” condition below

the #4 level.

2) The “dark” signal does not fall below the #4 level during a sensing event. The alarm automatically

resets when the “dark” sensing level falls below the #4 level (accomplished by reducing the Gain

control setting and/or by removing the cause of unwanted light return in the “dark” condition).

#10

Low Gain Warning

The “light” signal never goes above #5 on the display; increase the Gain setting. There are two possible

causes:

1) The “light” signal slowly decreases to the #5 level and remains at that level for a predetermined

delay. This most commonly occurs in opposed or retroreflective sensing systems, caused by a

gradual decrease in light in the unblocked condition, due to obscured lenses or sensor

misalignment. The alarm will reset when the light signal strength exceeds the #5 level.

2) The “light” signal does not exceed the #5 level during a sensing event. The alarm automatically

resets when the “light” signal exceeds the #5 level (accomplished by increasing the GAIN control

setting and/or cleaning the lens and realigning the sensor).

#9 and #10

Low Contrast

Warning

The lights flash simultaneously to indicate inadequate optical contrast for reliable sensing (the “light”

condition is at the #5 level and the “dark” condition is at the #4 level). If this occurs, re-evaluate the

application to find ways to increase the differential between the “light” and “dark” conditions. The alarm

automatically resets when the “light” signal exceeds the #5 level and the “dark” signal falls below the #4

level.

Page 6

OMNI-BEAM Sensor Heads

page

6

Sense and Load LED Indicators

The Sense LED indicates when a target has been sensed. When the sensor head is

programmed for Light Operate, it lights when the received light signal exceeds the #5

threshold. When programmed for Dark Operate, it lights when the received light

signal falls below the #5 threshold. See figure 7.

The Load indicator LED lights whenever the output is energized (after the timing

function, if applicable).

Measuring Excess Gain

OMNI-BEAM’s D.A.T.A. indicator display may be used to measure the excess gain and

contrast during sensing, installation, or maintenance.

Excess gain is a measurement of the amount of light energy falling on a photoelectric

sensor’s receiver, over and above the minimum amount needed to operate the

sensor’s amplifier. Excess gain is expressed as a ratio:

Excess gain (E.G.) = light energy falling on receiver

amplifier threshold

The amplifier threshold is the point at which the sensor’s output switches

(corresponding to the #5 level of the D.A.T.A. display). When LEDs #1 through #5 are

ON, the excess gain of the received light signal is equal to “1x.” The chart below

shows how excess gain relates to the D.A.T.A. light array indication.

Figure 7. Sense and Load indicators

Relationship Between Excess Gain and D.A.T.A System Lights

D.A.T.A. Light

LED Number

STANDARD

Scale Factor

FINE*

Scale Factor

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

0.25x Excess Gain

0.35x Excess Gain

0.5x Excess Gain

0.7x

Excess Gain

1.0x Excess Gain

1.3x Excess Gain

1.7x Excess Gain

2.2x Excess Gain

2.9x Excess Gain

3.7x Excess Gain (or more)

0.5x Excess Gain

0.7x Excess Gain

0.8x Excess Gain

0.9x

Excess Gain

1.0x Excess Gain

1.1x Excess Gain

1.2x Excess Gain

1.3x Excess Gain

1.7x Excess Gain

2.2x Excess Gain (or more)

Page 7

OMNI-BEAM Sensor Heads

page

7

Figure 8. Dark condition example:

D.A.T.A. system LEDs #1

and #2 lit.

Figure 9. Light condition example:

D.A.T.A. system LEDs

#1 through #8 lit.

Measuring Sensing Contrast

Contrast is the ratio of the amount of light falling on the receiver in the “light” state,

compared to the “dark” state (sometimes called “light-to-dark ratio”). Optimizing the

contrast in any sensing situation increases the sensing reliability. Contrast may be

calculated if excess gain values are known for both the light and dark conditions:

Contrast = Excess gain (light condition)

Excess gain (dark condition)

To determine the contrast for any sensing application, present both the Light and Dark

conditions to the OMNI-BEAM, and note how many LEDs in the D.A.T.A. display are

ON for each condition. Compute the ratio from the corresponding excess gain

numbers (from the chart on page 6) for the two conditions.

For example, if LEDs #1 through #8 come ON in the Light condition and LEDs #1 and

#2 come ON in the Dark condition (assuming Standard scale factor), contrast is

calculated as follows:

Light condition: 2.2x excess gain

Dark condition: 0.35x excess gain

Contrast = 2.2x = 6

0.35x

This value is expressed as 6:1 (“six-to-one”).

The best sensor adjustment will cause all ten D.A.T.A. LEDs to come ON for the Light

condition, and none in the Dark condition. In this situation (such as an application in

which a box breaks the beam of an opposed-mode emitter/receiver pair):

Contrast is greater than 3.7x = 15

0.25x

While it is not always possible to adjust a sensor to maintain this much contrast, it is

important to always adjust for the maximum possible contrast. The D.A.T.A. feature

makes this easy. The chart below gives general guidelines for contrast values.

Contrast Values and Corresponding Guidelines

Contrast Recommendation

1.2 or Less Unreliable. Evaluate alternative sensing schemes.

1.2 to 2

Poor Contrast. Use the LOW hysteresis setting and the FINE

scale factor.

2 to 3

Low Contrast. Sensing environment must remain per fectly clean and

all other sensing variables must remain stable.

3 to 10

Good Contrast. Minor sensing system variables will not affect

sensing reliabilty.

10 or Greater

Excellent Contrast. Sensing should remain reliable as long as the

sensing system has enough excess gain for operation.

Page 8

OMNI-BEAM Sensor Heads

page

8

Certifications

Supply Voltage and Current Supplied by OMNI-BEAM power block

Output Response Time See individual sensing heads for response times (page 2)

200 millisecond delay on power-up: outputs are non-conducting during this time.

Adjustments OMNI-BEAM sensor heads are field-programmable for four operating parameters. A set of four

programming DIP switches is located at the base of the sensor head and is accessible with the sensor

head removed from the power block (see page 4).

Switch #1 selects the amount of sensing hysteresis

Switch #2 selects the alarm output configuration

Switch #3 selects LIGHT operate (switch #3 OFF) or DARK operate (switch #3 ON)

Switch #4 selects the STANDARD (switch #4 OFF) or FINE (switch #4 ON) scale factor for the D.A.T.A.

light signal strength indicator array

15-turn slotted brass screw Gain (sensitivity) adjustment potentiometer (clutched at both ends of travel)

Indicators Sense and Load indicator LEDs are located on the top of the sensor head on either side of the D.A.T.A. array.

Sense LED indicates when a target has been sensed

Load LED lights whenever the load output is energized

Also, Banner’s exclusive D.A.T.A. sensor self-diagnostic system located on the top of the sensor head

warns of marginal sensing conditions usually before a sensing failure occurs (except on model OSBFAC).

Construction Sensor heads are molded of rugged reinforced thermoplastic polyester; top view window is LEXAN

®

polycarbonate; acrylic lenses; stainless steel hardware

Environmental Rating Meets NEMA standards 1, 2, 3, 3S, 4, 12, and 13; IEC IP66 when assembled to power block

Operating Temperature Temperature: -40° to +70°C (-40° to +158°F)

Maximum relative humidity: 90% at 50°C (non-condensing)

OMNI-BEAM Sensor Head Specifications

OMNI-BEAM Dimensions – Sensor Head Shown Assembled to Power Block

OMNI-BEAM Sensor with Attached Cable

Transparent Cover (Gasketed)

View: D.A.T.A. Lights

Sensing Status

Output Load

Remove to Access:

Sensitivity (Gain) Adjustment

Logic Timing Adjustments

44.5 mm (1.75")

57.4 mm w/DC

(2.26")

38.1 mm w/DC

(1.50")

60.5 mm w/AC

(2.38")

79.8 mm w/AC

(3.14")

7.1 mm

(0.28")

30.0 mm

(1.18")

30.0 mm

(1.18")

7.1 mm

(0.28")

Internal Thread

(1/2-14NPSM)

External Thread

M30 X 1.5

5.6 mm (0.22")

Lens

Centerline

2 m ( 6.5' Cable)

76.2 mm w/DC Power Block

(3.00")

98.6mm w/AC Power Block

(3.88")

#10 Screw

Clearance (4)

Cross-hole design for front,

back, or side mounting

54.6 mm*

(2.15")

Hex Nut

Supplied

*

61.7 mm (2.43") for OSBCV, CVG, CVB

60.5 mm (2.38") for OSBF, FV, FVG, FVB, FX, EF, RF, FAC

59.8 mm (2.35") for OSBFP, FPG, FPB

14 mm (0.6")

Mini-style QD Connector

15 mm (0.6")

Euro-style QD Connector

OMNI-BEAM Sensor with Quick Disconnect

Mini-Style Euro-Style

LEXAN®is a registered trademark of General Electric Company

Page 9

OMNI-BEAM Sensor Heads

page

9

Excess Gain Curves

OSBE & OSBR

(Opposed)

OSBLV

(Retroreflective)

OSBLVAG

(Polarized Retroreflective)

OSBD

(Diffuse)

1

10

100

1 m

3.3 ft

10 m

33 ft

100 m

330 ft

0.1 m

0.33 ft

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

OSBE & OSBR

Opposed Mode

1

10

100

.10 m

.33 ft

1.0 m

3.3 ft

10 m

33 ft

.01 m

.033 ft

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

OSBLV

Retroreflective Mode

With BRT-3 Reflector

1

10

100

.10 m

.33 ft

1.0 m

3.3 ft

10 m

33 ft

.01 m

.033 ft

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

OSBLVAG

Retroreflective Mode

W/BRT-3 Reflector

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

OSBD

Diffuse Mode

OSBDX

(Diffuse)

OSBCV

(Convergent)

OSBCVG

(Convergent)

OSBCVB

(Convergent)

OSBF

(Opposed)

OSBF

(Diffuse)

OSBFVG

(Diffuse)

OSBFVB

(Diffuse)

OSBFX

(Opposed)

OSBFX

(Diffuse)

OSBFP

(Opposed)

OSBFP

(Diffuse)

OSBFPG

(Diffuse)

OSBFPB

(Diffuse)

OSBLVAGC: Refer to data sheet p/n 34151

OSBFV: Refer to data sheet p/n 03543

OSBEF/OSBRF: Refer to data sheet p/n 03546

OSBFAC: Refer to data sheet p/n 03553

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

0.01 m

0.033 ft

1000

E

X

C

100

E

S

S

10

G

A

N

X

C

S

S

G

A

N

E

X

C

E

S

S

G

A

N

I

1

1 mm

.04 in

1000

E

100

E

10

I

1

0.01 m

0.03 ft

1000

100

10

I

1

.1 mm

.004 in

IT13S Fibers

IT13S fibers

0.1 m

0.33 ft

DISTANCE

10 mm

.4 in

DISTANCE

0.1 m

0.33 ft

DISTANCE

1 mm

.04 in

DISTANCE

OSBDX

Diffuse Mode

1.0 m

3.3 ft

OSBF

Opposed Mode

IT23S Fibers

100 mm

4 in

OSBFX

Opposed Mode

IT23S fibers

1.0 m

3.3 ft

OSBFPG

Diffuse Mode

Plastic Fiber

PBT46U Fiber

10 mm

.4 in

10 m

33 ft

1000 mm

40 in

10 m

33 ft

100 mm

4 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

1 mm

.04 in

1000

E

X

C

100

E

S

S

10

G

A

I

BT13S Fiber

N

1

1 mm

.04 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

1 mm

0.04 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

.1 mm

.004 in

10 mm

10 mm

BT13S Fiber

10 mm

0.4 in

1 mm

.04 in

.4 in

DISTANCE

BT23S Fiber

.4 in

DISTANCE

DISTANCE

DISTANCE

OSBCV

Convergent Mode

100 mm

4 in

OSBF

Diffuse Mode

100 mm

4 in

OSBFX

Diffuse Mode

BT23S Fiber

100 mm

4.0 in

OSBFPB

Diffuse Mode

Plastic Fiber

PBT46U Fiber

10 mm

.4 in

1000 mm

40 in

1000 mm

40 in

1000 mm

40 in

100 mm

4 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

1 mm

.04 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

0.1 mm

0.004 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

1 mm

.04 in

PIT26U Fibers

10 mm

.4 in

DISTANCE

1.0 mm

0.04 in

DISTANCE

10 mm

.40 in

DISTANCE

OSBFVG

BT23S Fiber

PIT46U Fibers

Convergent Mode

100 mm

4 in

Diffuse Mode

10 mm

0.4 in

OSBFP

Opposed Mode

Plastic Fibers

100 mm

4.0 in

OSBCVG

P

1000 mm

100 mm

1000 mm

40 in

4 in

40 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

1 mm

.04 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

0.1 mm

0.004 in

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

.1 mm

.004 in

10 mm

.4 in

DISTANCE

1.0 mm

0.04 in

DISTANCE

PBT26U Fiber

1 mm

.04 in

DISTANCE

BT23S Fiber

OSBCVB

Convergent Mode

100 mm

4 in

OSBFVB

Diffuse Mode

10 mm

0.4 in

OSBFP

Diffuse Mode

PBT46U Fiber

10 mm

.4 in

1000 mm

40 in

100 mm

4 in

100 mm

4 in

Page 10

OMNI-BEAM Sensor Heads

page

10

Beam Patterns

OSBE & OSBR

(Opposed)

OSBLV

(Retroreflective)

OSBLVAG

(Polarized Retroreflective)

OSBD

(Diffuse)

OSBDX

(Diffuse)

OSBCV

(Convergent)

OSBCVG

(Convergent)

OSBCVB

(Convergent)

OSBF

(Opposed)

OSBF

(Diffuse)

OSBFVG

(Diffuse)

OSBFVB

(Diffuse)

OSBFX

(Opposed)

OSBFX

(Diffuse)

OSBFP

(Opposed)

OSBFP

(Diffuse)

OSBFPG

(Diffuse)

OSBFPB

(Diffuse)

OSBLVAGC: Refer to data sheet p/n 34151

OSBFV: Refer to data sheet p/n 03543

OSBEF/OSBRF: Refer to data sheet p/n 03546

OSBFAC: Refer to data sheet p/n 03553

OSBE and OSBR

1500 mm

Opposed Mode

1000 mm

500 mm

0

500 mm

1000 mm

1500 mm

10 m

0

30 ft

OSBDX

75 mm

Diffuse Mode

50 mm

25 mm

0

25 mm

50 mm

75 mm

0.4 m

0

1.25 ft

OSBF

75 mm

Opposed Mode

50 mm

25 mm

0

IT13S IT23S

25 mm

50 mm

75 mm

100 mm

0

4 in

150 mm

100 mm

50 mm

0

IT13S Fibers

50 mm

100 mm

150 mm

0.4 m

0

15 in

20 m

60 ft

DISTANCE

0.8 m

2.5 ft

DISTANCE

200 mm

8 in

DISTANCE

IT23S Fibers

0.8 m

30 in

DISTANCE

30 m

90 ft

1.2 m

3.75 ft

300 mm

12 in

1.2 m

45 in

40 m

120 ft

1.6 m

5.0 ft

400 mm

16 in

OSBFX

Opposed Mode

1.6 m

60 in

50 m

150 ft

2.0 m

6.25 ft

500 mm

20 in

2.0 m

75 in

3.0 in

2.0 in

1.0 in

0

1.0 in

2.0 in

3.0 in

3 in

2 in

1 in

0

1 in

2 in

3 in

6.0 in

4.0 in

2.0 in

0

2.0 in

4.0 in

6.0 in

60 in

40 in

20 in

0

20 in

40 in

60 in

OSBLV

150 mm

Retroreflective Mode

100 mm

50 mm

0

50 mm

100 mm

150 mm

0

2.4 mm

1.6 mm

0.8 mm

0

0.8 mm

1.6 mm

2.4 mm

12.5 mm

0

0.50 in

1.9 mm

1.3 mm

0.65 mm

0

0.65 mm

1.3 mm

1.9 mm

7.5 mm

0

0.3 in

3.8 mm

2.5 mm

BT13S Fiber

1.3 mm

0

1.3 mm

2.5 mm

3.8 mm

25 mm

0

4 m

2 m

13 ft

6.6 ft

DISTANCE

OSBCV

Convergent Mode

25 mm

1.0 in

DISTANCE

OSBF

Diffuse Mode

15 mm

0.6 in

DISTANCE

50 mm

2 in

1 in

DISTANCE

With BRT-3 Reflector

8 m

6 m

26 ft

20 ft

50 mm

37.5 mm

2.0 in

1.5 in

BT23SBT13S

30 mm

22.5 mm

1.2 in

0.9 in

OSBFX

Diffuse Mode

BT23S Fiber

100 mm

75 mm

4 in

3 in

10 m

33 ft

62.5 mm

2.5 in

37.5 mm

1.5 in

125 mm

5 in

75 mm

50 mm

25 mm

0

25 mm

50 mm

75 mm

0

2.4 mm

1.6 mm

0.8 mm

0

0.8 mm

1.6 mm

2.4 mm

0

1.8 mm

1.2 mm

0.6 mm

0

0.6 mm

1.2 mm

1.8 mm

0

OSBFP

45 mm

Opposed Mode

30 mm

15 mm

0

15 mm

30 mm

45 mm

0

OSBLVAG

Retroreflective Mode

12.5 mm

0.50 in

OSBFVG

Diffuse Mode

PIT26U

25 mm

6.0 in

4.0 in

2.0 in

0

2.0 in

4.0 in

6.0 in

0.09 in

0.06 in

0.03 in

0

0.03 in

0.06 in

0.09 in

0.075 in

0.050 in

0.025 in

0

0.025 in

0.050 in

0.075 in

0.15 in

0.10 in

0.05 in

0

0.05 in

0.10 in

0.15 in

2 m

1 m

6.6 ft

3.3 ft

DISTANCE

OSBCVG

Convergent Mode

25 mm

1.0 in

10 mm

5 mm

0.4 in

0.2 in

50 mm

2 in

1 in

With BRT-3 Reflector

3 m

10 ft

37.5 mm

1.5 in

DISTANCE

BT23S Fiber

15 mm

0.6 in

DISTANCE

75 mm

3 in

DISTANCE

4 m

13 ft

50 mm

2.0 in

20 mm

0.8 in

PIT46U

100 mm

4 in

P

5 m

16 ft

62.5 mm

2.5 in

25 mm

1.0 in

125 mm

5 in

3.0 in

2.0 in

1.0 in

0

1.0 in

2.0 in

3.0 in

0.09 in

0.06 in

0.03 in

0

0.03 in

0.06 in

0.09 in

0.075 in

0.050 in

0.025 in

0

0.025 in

0.050 in

0.075 in

1.8 in

1.2 in

0.6 in

0

0.6 in

1.2 in

1.8 in

7.5 mm

5.0 mm

2.5 mm

0

2.5 mm

5.0 mm

7.5 mm

0

2.4 mm

1.6 mm

0.8 mm

0

0.8 mm

1.6 mm

2.4 mm

0

1.8 mm

1.2 mm

0.6 mm

0

0.6 mm

1.2 mm

1.8 mm

0

OSBFP

3.8 mm

Diffuse Mode

2.5 mm

1.2 mm

0

1.2 mm

2.5 mm

3.8 mm

0

OSBD

Diffuse Mode

75 mm

3 in

OSBCVB

Convergent Mode

12.5 mm

0.50 in

OSBFVB

Diffuse Mode

5 mm

0.2 in

PBT26U

7.5 mm

0.3 in

150 mm

6 in

DISTANCE

25 mm

1.0 in

DISTANCE

10 mm

0.4 in

DISTANCE

15 mm

0.6 in

DISTANCE

225 mm

9 in

37.5 mm

1.5 in

15 mm

0.6 in

PBT46U

22.5 mm

0.9 in

300 mm

50 mm

2.0 in

BT23S Fiber

20 mm

0.8 in

30 mm

1.2 in

12 in

375 mm

15 in

62.5 mm

2.5 in

25 mm

1.0 in

37.5 mm

1.5 in

0.3 in

0.2 in

0.1 in

0

0.1 in

0.2 in

0.3 in

0.09 in

0.06 in

0.03 in

0

0.03 in

0.06 in

0.09 in

0.075 in

0.050 in

0.025 in

0

0.025 in

0.050 in

0.075 in

0.15 in

0.10 in

0.05 in

0

0.05 in

0.10 in

0.15 in

3.0 mm

2.0 mm

1.0 mm

1.0 mm

2.0 mm

3.0 mm

0

0

OSBFPG

Diffuse Mode

4 mm

0.15 in

PBT46U

8 mm

0.30 in

DISTANCE

12 mm

0.45 in

16 mm

0.60 in

20 mm

0.75 in

0.12 in

0.08 in

0.04 in

0

0.04 in

0.08 in

0.12 in

3.0 mm

2.0 mm

1.0 mm

1.0 mm

2.0 mm

3.0 mm

0

0

OSBFPB

Diffuse Mode

4 mm

0.15 in

PBT46U

8 mm

0.30 in

DISTANCE

12 mm

0.45 in

16 mm

0.60 in

20 mm

0.75 in

0.12 in

0.08 in

0.04 in

0

0.04 in

0.08 in

0.12 in

Page 11

OMNI-BEAM Sensor Heads

page

11

Accessories

Mounting Brackets

SMB30C

SMB30SC

SMB30MM

• 30 mm split clamp, black reinforced thermoplastic

polyester

• Stainless steel hardware included

• Compact 30 mm swivel bracket

• Excellent range of articulation

• 30 mm, 11-gauge stainless steel

• Clearance for M6 (1/4") hardware

SMB30UR

• Rugged stainless steel construction

• Swivel mount

56.0 mm

63.0 mm

(2.48")

13.5 mm

(0.53")

(2.20")

45.0 mm

(1.77")

31.5 mm

(1.24")

2.5 mm

(0.10")

13 mm

(0.5")

Nut Plate

M5 x 0.8

x 80 mm

Screw (2)

50.8 mm

58.7 mm

(2.31")

(2.00")

66.5 mm

(2.62")

30.0 mm

(1.18")

12.7 mm

(0.50")

29.0 mm

(1.14")

ø30.5 mm

(1.20")

8X #10-32

38.1 mm

(1.50")

50.8 mm

(2.00")

70.0 mm

(2.75")

9.7 mm

(0.38")

59.9 mm

(2.36")

30.0 mm

(1.18")

23.1 mm

(0.91")

15.2 mm

(0.60")

31.8 mm

(1.75")

3.4 mm

(0.14")

89.8 mm

(3.54")

82.2 mm

(3.24")

50.8 mm

(2.00")

66.0 mm

(2.6")

76.2 mm

(3.00")

15.2 mm

(0.60")

5X 7.1 mm

(0.28")

ø57.2 (2.25")

25.4 mm

(1.0")

22.4 mm

(0.88")

9.7 mm

(0.38")

6X 1/4-28

3.4 mm

(0.14")

SMB30UR Top

60º

27.9 mm

(1.11")

31.8 mm

(1.25")

SMB30UR Bottom

31.8 mm

(1.25")

77.1 mm

(3.04")

90º

25.4 mm

1.00")

ø38.1 mm

(1.50")

57.1 mm

(2.25")

12.7 mm

(0.50")

2X ø7.1

(0.28")

172.0 mm

(6.77")

57.2 mm

(2.25")

ø 6.4 mm

(0.25")

25.4 mm

(1.00")

35.1 mm

(1.38")

69.9 mm

(2.75")

35.1 mm

(1.38")

7.1 mm x 90°

(0.28") (2 Slots)

R 25.4 mm

(1.00")

25.4 mm

(1.00")

57.2 mm

(2.25")

1/4 x 28 x 1/2"

Screw

2X 1/4"

Lock Washer

Flat Washer

2X

2X 1/4"

76.2 mm

(3.00")

Page 12

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 612.544.3164 • Fax: 612.544.3213 • E-mail: sensors@baneng.com

OMNI-BEAM Sensor Heads

Replacement Lenses

OMNI-BEAM lens assemblies are field-replaceable.

Model Description

OUC-C

OUC-D

OUC-F

OUC-FP

OUC-L

OUC-LAG

Replacement lens for convergent models (model suffix CV)

Replacement lens for short range diffuse models (model suffix D)

Replacement lens for glass fiber optic models (model suffix F, FAC, FV, FX, EF, and RF)

Replacement lens for plastic fiber optic models (model suffix FP)

Replacement lens for non-polarized retroreflective and opposed models (model suffix DX, LV, E and R)

Replacement lens for polarized retroreflective models (model suffix LVAG and LVAGC)

Retroreflective Targets

Banner offers a wide selection of high-quality retroreflective targets. See Banner Product Catalog for complete information.

Cable Protector

HF1-2NPS

• Flexible black nylon cable protector

• Includes a neoprene gland that compresses around the OMNI-BEAM cable to provide an

additional seal against moisture

• Resistant to gasoline, alcohol, oil, grease, solvents and weak acids

• Working temperature range of -30° to +100°C (-22° to +212°F)

Model Description

WARRANTY: Banner Engineering Corporation warrants its products to be free from defects for one year. Banner Engineering Corporation

will repair or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the

warranty period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu

of any other warranty either expressed or implied.

Loading...

Loading...