Page 1

Specifications

MULTI-BEAM® Sensors

Compact modular self-contained photoelectric sensing controls

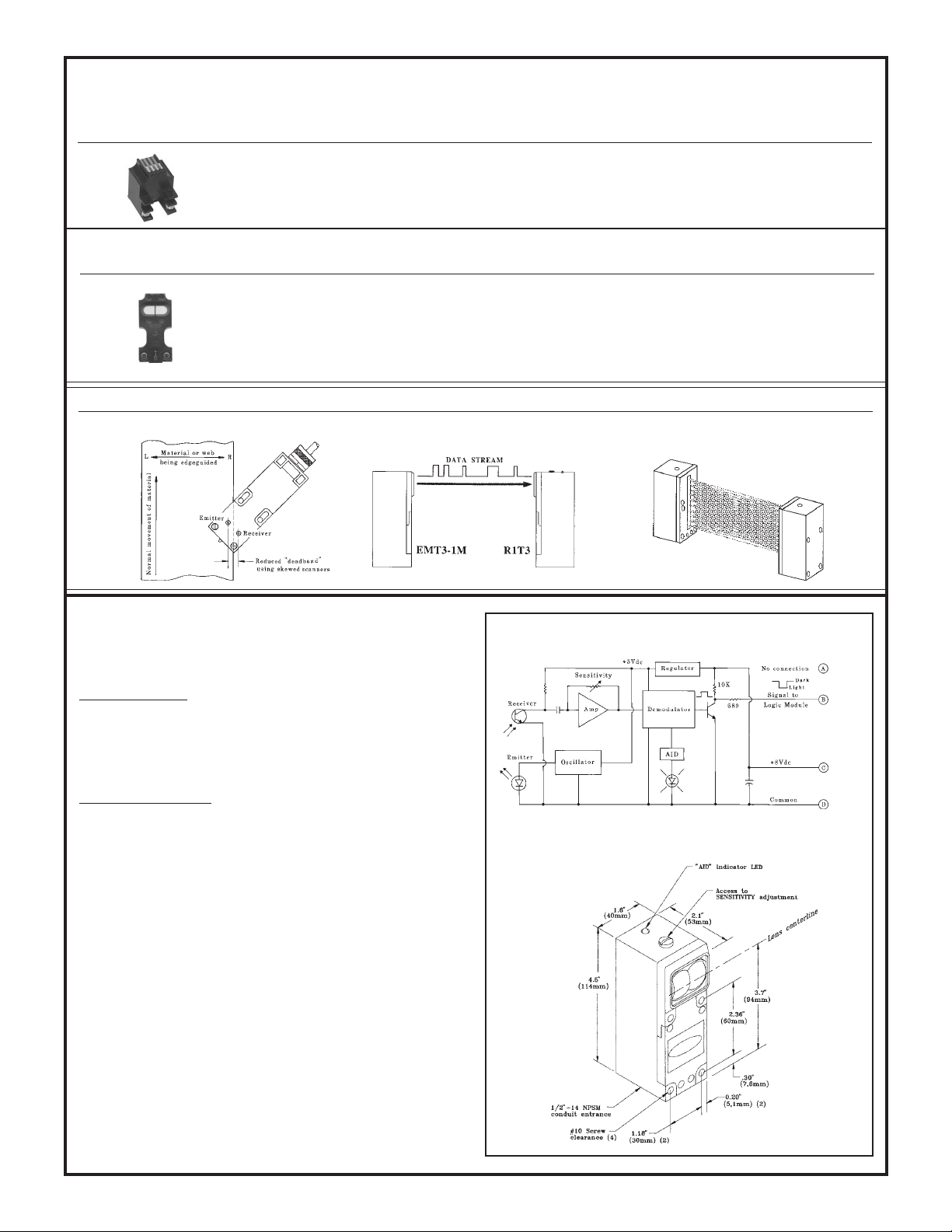

Status Indicator LED

(except emitters)

Access to

1.6"

(40 mm)

Sensitivity Adjustment

2.1" (53 mm)

Lens Centerline

Product

Line

4.5"

(114 mm)

1/2" – 14 NPSM

Conduit Entrance

5 mm (#10) Screw

Clearance (4)

1.18"

(30.0 mm)

3.7"

(94 mm)

2.36"

(60.0 mm)

0.30"

(7.6 mm)

0.20"

(5.1 mm)

Modular design with interchangeable components (scanner

•

blocks, power blocks, and logic timing modules);

over 5,000 sensor configurations possible

Scanner blocks for opposed, retro, diffuse, convergent, and

•

fiber optic sensing modes (including high-gain models)

Power blocks for ac or dc operation, including 2-wire ac

•

operation

Logic modules to support a wide variety of delay, pulse, limit,

•

and rate sensing logic functions

Most scanner blocks include Banner's exclusive, patented

•

AID™ (Alignment Indicating Device) system, which lights a

top-mounted indicator LED whenever the sensor sees its

own modulated light source, and pulses the LED at a rate

proportional to the strength of the received light signal.

Printed in USA P/N 32887

Page 2

Contents

Introduction to MULTI-BEAM® Modular Sensors ........................... page 3

Selection of components and summary of available models ............ pages 4-6

MULTI-BEAM® 3- and 4-wire Sensors............................................ pages 6-23

3- and 4-wire Scanner Blocks................................................. pages 6-14

3- and 4-wire Scanner Block modifications ........................... page 14

3- and 4-wire Power Blocks ................................................... pages 15-20

3- and 4-wire Logic Modules ................................................. pages 21-23

MULTI-BEAM® 2-wire Sensors....................................................... pages 24-29

2-wire Scanner Blocks............................................................ pages 24-26

2-wire Power Blocks .............................................................. pages 27-28

2-wire Logic Modules ............................................................ page 29

MULTI-BEAM® Accessories............................................................ pages 30-31

Upper Covers (lens assemblies).............................................. page 30

Lower Covers ......................................................................... page 30

Mounting Brackets ................................................................. page 31

Quick Disconnect ................................................................... page 31

WARNING MULTI-BEAM

checking redundant circuitry necessary to allow their use in personnel safety applications. A sensor failure or malfunction

!

Only MACHINE-GUARD and PERIMETER-GUARD Systems, and other systems so designated, are designed to meet OSHA and ANSI

machine safety standards for point-of-operation guarding devices. No other Banner sensors or controls are designed to meet these standards,

and they must NOT be used as sensing devices for personnel protection.

WARRANTY: Banner Engineering Corporation warrants its products to be free from defects for one year. Banner Engineering Corporation will

repair or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period.

This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either

expressed or implied.

Banner Engineering Corp. 9714 Tenth Ave. No. Minneapolis, MN 55441 Telephone: (612)544-3164 FAX (applications): (612)544-3573

can result in either an energized or a de-energized sensor output condition.

Never use these products as sensing devices for personnel protection. Their use as a safety device may create an unsafe

condition which could lead to serious injury or death.

®

photoelectric presence sensors described in this catalog do NOT include the self-

Page 3

MULTI-BEAM

®

Sensors

E71083

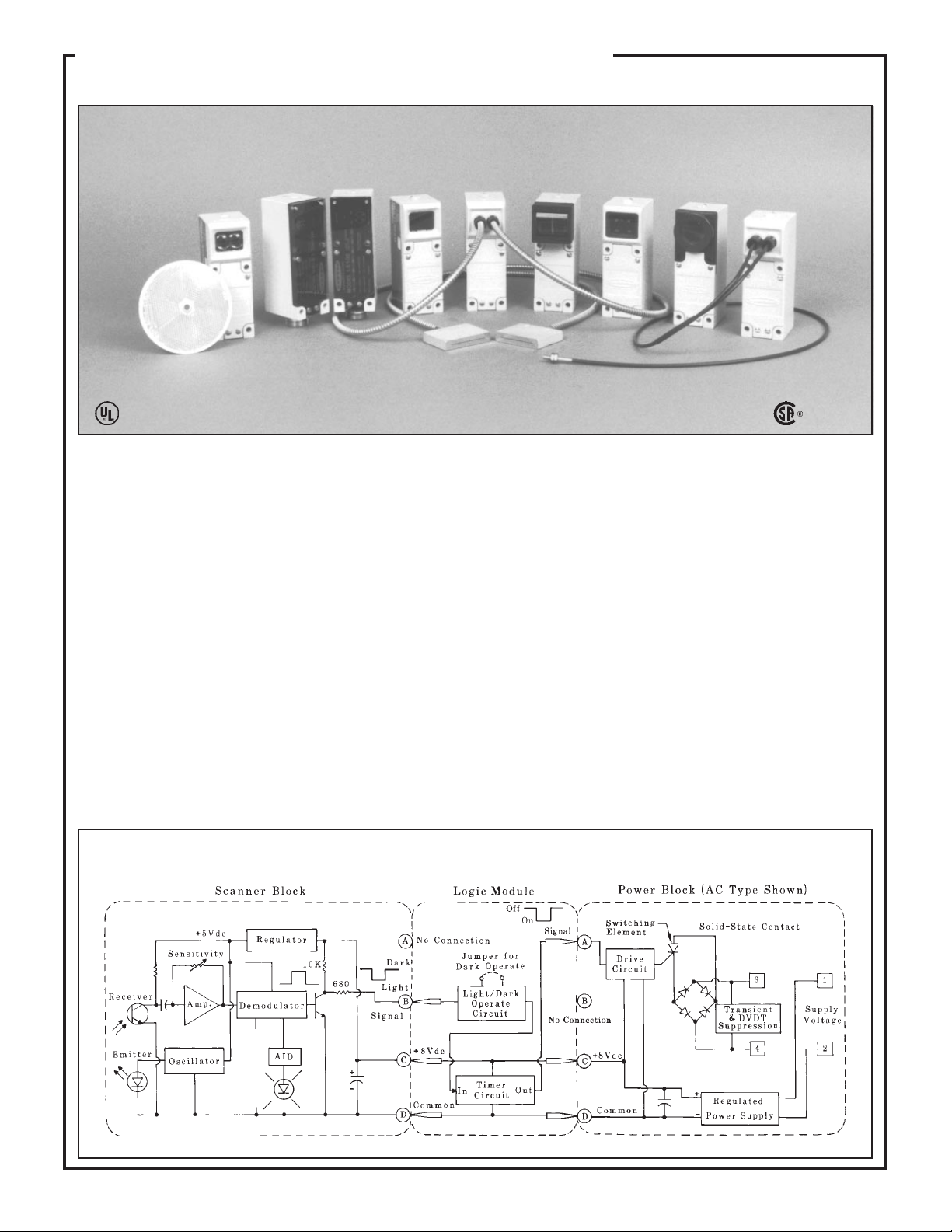

Banner MULTI-BEAM® sensors are compact modular self contained photoelectric switches. Each MULTI-BEAM consists of

three components: scanner block, power block, and logic module.

The scanner block contains the complete modulated photoelectric

amplifier as well as the emitter and receiver optoelements. It also

contains the sensing optics and the housing for the other two

modules. The power block provides the interface between the

scanner block and the external circuit. It contains a power supply

for the MULTI-BEAM plus a switching device to interface the

circuit to be controlled. The logic module interconnects the power

block and scanner block both electrically and mechanically. It

provides the desired timing logic function (if any), plus the ability

to program the output for either light- or dark-operate. The

emitters of MULTI-BEAM emitter-receiver pairs do not require

a logic module. Emitter scanner blocks are supplied with a bladepin to interconnect the scanner block and power block. This

modular design, with field-replaceable power block and logic

module, permits over 5,000 sensor configurations, resulting in

exactly the right sensor for any photoelectric application.

There are two families of MULTI-BEAM sensors: 3- and 4-wire,

and 2-wire. Three- and four-wire MULTI-BEAMs offer the

greatest selection of sensor configurations. They permit either ac

or dc operation and offer the fastest response times and the

greatest sensing ranges. Two-wire MULTI-BEAMs are used in

ac-powered applications where simplicity and convenience of

wiring are important. They are physically and electrically interchangeable with heavy-duty limit switches.

The circuitry of all MULTI-BEAM components is encapsulated

within rugged, corrosion-resistant VALOX

meet or exceed NEMA 1, 3, 12, and 13 ratings. Most MULTIBEAM scanner blocks include Banner's patented Alignment

Indicating Device (AID™) which lights a top-mounted LED

when the sensor sees its own modulated light source and pulses

the LED at a rate proportional to the received light signal. Most

MULTI-BEAM sensor assemblies are UL listed and certified by

CSA (see power block listings). All MULTI-BEAM components

(except power block models 2PBR and 2PBR2) are totally solidstate for unlimited life.

Composite Functional Schematic, 3- and 4-wire Sensors

LR41887

®

housings, which

3

Page 4

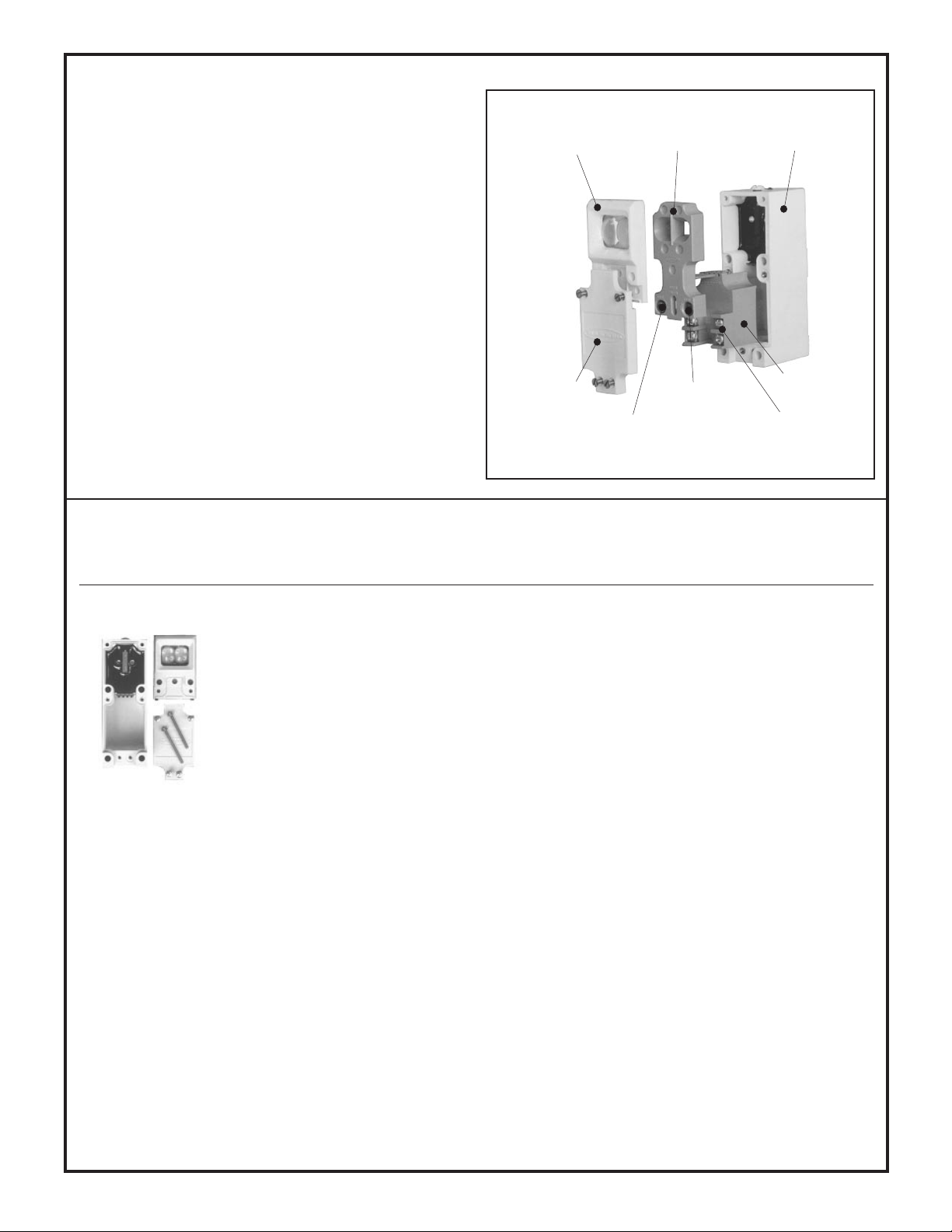

Selection of MULTI-BEAM Components

MULTI-BEAM sensors are made up of three components: scanner

block, power block, and logic module. This is true for all MULTIBEAMs with the exception of opposed mode emitter units which

require only a power block (no logic module).

The first decision in the component selection process is to determine

which family of MULTI-BEAM sensors is appropriate for the application: 3- and 4-wire, or 2-wire.

Next, decide which scanner block (within the selected family) is best for

the application. The guidelines in the catalog introduction will help you

to determine the best sensing mode. Then narrow the choice by

comparing the specifications listed in the following charts and on the

pages referenced in the charts.

Finally, choose a power block and logic module to complete the

MULTI-BEAM assembly. Components snap together without interwiring to form a complete photoelectric sensing system that meets your

exact requirements while maintaining the simplicity of a self-contained

sensor.

If you have any questions about selecting MULTI-BEAM components,

please contact your Banner sales engineer or call Banner's Applications

Department at (612) 544-3164 during normal business hours.

3- and 4-wire Systems (pages 6 through 23)

Upper Cover (lens)

(supplied with

Scanner Block)

Lower Cover

(supplied with

Scanner Block)

Logic Module

LIGHT/DARK

Logic

Operate Select

Timing

Adjustment

Scanner Block

Housing

Power

Block

Wiring

Terminals

Scanner Blocks Model Sensing Mode Range Response Page

SBE & SBR1 Opposed: high speed 150 feet 1 millisecond p. 7

SBED & SBRD1 Opposed: high speed, narrow beam 10 feet 1 millisecond p. 7

SBEX & SBRX1 Opposed: high power, long range 700 feet 10 milliseconds p. 7

SBEV & SBRX1 Opposed: visible beam 100 feet 10 milliseconds p. 7

SBEXD & SBRXD1 Opposed: high power, wide beam angle 30 feet 10 milliseconds p. 7

SBLV1 Retroreflective: high speed, visible beam 30 feet 1 millisecond p. 8

SBLVAG1 Retroreflective: polarized beam (anti-glare) 15 feet 1 millisecond p. 8

SBL1 Retroreflective: high speed, infrared beam 30 feet 1 millisecond p. 8

SBLX1 Retroreflective: high power, long range 100 feet 10 milliseconds p. 8

SBD1 Diffuse (proximity): high speed 12 inches 1 millisecond p. 9

SBDL1 Diffuse (proximity): medium range 24 inches 1 millisecond p. 9

SBDX1 Diffuse (proximity): high power, long range 6 feet 10 milliseconds p. 9

SBDX1MD Diffuse (proximity): wide beam angle 24 inches 10 milliseconds p. 9

SBCV1 Convergent beam: high speed, visible red 1.5-inch focus 1 millisecond p. 10

SBCVG1 Convergent beam: high speed, visible green 1.5-inch focus 1 millisecond p. 10

SBC1 Convergent beam: high speed, infrared 1.5-inch focus 1 millisecond p. 10

SBC1-4 Convergent beam: high speed, infrared 4-inch focus 1 millisecond p. 10

SBC1-6 Convergent beam: high speed, infrared 6-inch focus 1 millisecond p. 10

SBCX1 Convergent beam: high power, infrared 1.5-inch focus 10 milliseconds p. 10

SBCX1-4 Convergent beam: high power, infrared 4-inch focus 10 milliseconds p. 10

SBCX1-6 Convergent beam: high power, infrared 6-inch focus 10 milliseconds p. 10

SBEF & SBRF1 Opposed fiber optic (glass fibers): high speed see specs 1 millisecond p. 11

SBEXF & SBRXF1 Opposed fiber optic (glass fibers): high power see specs 10 milliseconds p. 11

SBFX1 Fiber optic (glass fibers): high power, infrared see specs 10 milliseconds p. 11

SBF1 Fiber optic (glass fibers): high speed, infrared see specs 1 millisecond p. 12

SBF1MHS Fiber optic (glass fibers): very high speed see specs 0.3 millisecond p. 12

SBFV1 Fiber optic (glass fibers): visible red see specs 1 millisecond p. 13

SBFVG1 Fiber optic (glass fibers): visible green see specs 1 millisecond p. 13

SBAR1 Ambient light receiver see specs 10 milliseconds p. 14

SBAR1GH Ambient light receiver: high gain see specs 10 milliseconds p. 14

SBAR1GHF Ambient light receiver: for glass fiber optics see specs 10 milliseconds p. 14

4

Page 5

3- and 4-wire Systems (pages 6 through 23)

Agency

Power Blocks Model Input Voltage Output Configuration Approvals Page

PBT 10 to 30V dc SPST NPN (sink), 250mA maximum UL & CSA p. 15

PBT2 10 to 30V dc SPDT NPN (sink), 250mA each output p. 15

PBP 10 to 30V dc SPST PNP (source), 250mA maximum UL & CSA p. 15

PBT-1 10 to 30V dc No output: for powering emitters UL & CSA p. 16

PBT48 44 to 52V dc SPST NPN (sink), 250mA maximum p. 15

PBP48 44 to 52V dc SPST PNP (source), 250mA maximum p. 15

PBT48-1 44 to 52V dc No output: for powering emitters p. 16

PBD-2 11 to 13V ac (50/60Hz) SPST SCR, 3/4 amp maximum p. 17

PBD 22 to 28V ac (50/60Hz) SPST SCR, 3/4 amp maximum UL & CSA p. 17

PBD-1 22 to 28V ac (50/60Hz) No output: for powering emitters p. 19

PBA 105 to 130V ac (50/60Hz) SPST SCR, 3/4 amp maximum UL & CSA p. 17

PBAQ 105 to 130V ac (50/60Hz) SPST SCR, normally closed, 3/4 amp max. UL & CSA p. 19

PBAT 105 to 130V ac (50/60Hz) SPST isolated transistor, 100mA max. (ac or dc) UL & CSA p. 18

PBO 105 to 130V ac (50/60Hz) SPST isolated transistor, 50mA max. (dc only) UL & CSA p. 18

PBAM 105 to 130V ac (50/60Hz) Voltage source: 8V dc at 8ma max. UL & CSA p. 18

PBA-1 105 to 130V ac (50/60Hz) No output: for powering emitters UL & CSA p. 19

PBB 210 to 250V ac (50/60Hz) SPST SCR, 3/4 amp maximum UL & CSA p. 17

PBBT 210 to 250V ac (50/60Hz) SPST isolated transistor, 100mA max. (ac or dc) UL & CSA p. 18

PBOB 210 to 250V ac (50/60Hz) SPST isolated transistor, 50mA max. (dc only) UL & CSA p. 18

PBB-1 210 to 250V ac (50/60Hz) No output: for powering emitters UL & CSA p. 19

Logic Modules Model Timing Logic Function Time Range(s) Page

LM1 ON/OFF (no timing function), light operate only NOTE for items below: other p. 21

LM3 ON/OFF (no timing function), light or dark operate time ranges available (p. 23) p. 21

LM5 ON-delay .15 to 15 seconds p. 22

LM5R OFF-delay .15 to 15 seconds p. 22

LM5-14 ON & OFF delay .15 to 15 seconds (both delays) p. 22

LM5T Limit timer (time-limited ON/OFF) .15 to 15 seconds p. 22

LM4-2 One-shot, retriggerable .01 to 1 second p. 21

LM4-2NR One-shot, non-retriggerable .01 to 1 second p. 22

LM8-1 Delayed one-shot .15 to 15 seconds (both times) p. 23

LM8A ON-delay one-shot .15 to 15 seconds (both times) p. 23

LM6-1 Rate sensor 60 to 1200 pulses per minute p. 22

LM8 Repeat cycle timer .15 to 15 seconds (both times) p. 23

LM2 Alternate action, divide by 2 p. 21

LM10 Alternate action, divide by 10 p. 23

LMT Test module p. 23

2-wire Systems (pages 24 through 29)

Scanner Blocks Model Sensing Mode Range Response Page

SBE & 2SBR Opposed 150 feet 10 milliseconds p. 25

2SBL1 Retroreflective 30 feet 10 milliseconds p. 25

2SBD1 Diffuse (proximity): short range 12 inches 10 milliseconds p. 26

2SBDX1 Diffuse (proximity): long range 30 inches 10 milliseconds p. 26

2SBC1 Convergent beam 1.5-inch focus 10 milliseconds p. 25

2SBC1-4 Convergent beam 4-inch focus 10 milliseconds p. 25

2SBF1 Fiberoptic see specs 10 milliseconds p. 26

5

Page 6

2-wire Systems (pages 24 through 29)

Power Blocks Model Input Voltage Output Configuration Agency Approvals Page

2PBD 22 to 28V ac (50/60Hz) 2-wire, SPST SCR, 3/4 amp max. UL & CSA p. 27

2PBA 105 to 130V ac (50/60 Hz) 2-wire, SPST SCR, 3/4 amp max. UL & CSA p. 27

2PBB 210 to 250V ac (50/60Hz) 2-wire, SPST SCR, 3/4 amp max. UL & CSA p. 27

2PBR 105 to 130V ac (50/60Hz) 4-wire, SPST E/M relay, 5 amps max. p. 27

2PBR2 105 to 130V ac (50/60Hz) 4-wire, SPDT E/M relay, 5 amps max. p. 27

Logic Modules Model Timing Logic Function Time Range(s) Page

2LM3 ON/OFF (no timing) p. 29

2LM5 ON-delay .15 to 15 seconds p. 29

2LM5R OFF-delay .15 to 15 seconds p. 29

2LM5-14 ON & OFF delay .15 to 15 seconds (both delays) p. 29

2LM5T Limit timer (time limited ON/OFF) .15 to 15 seconds (both delays p. 29

2LM4-2 One-shot, retriggerable .01 to 1 second p. 29

LMT Test module p. 23

Other MULTI-BEAM Systems (described in Banner product catalog or in the data sheets noted below)

Edgeguide Systems (data sheet 03506) Optical Data Transmitter (data sheet 03321) Light Screen System (data sheet 03557)

MULTI-BEAM 3- & 4-WIRE

SCANNER BLOCKS

DESCRIPTION

MULTI-BEAM 3- & 4-wire scanner blocks offer a complete complement of sensing modes. There are 3 or more models for each sensing

mode, resulting in a choice of exactly the right sensor for any application. The high power models (10 millisecond response time) offer

greater optical sensing power than any other industrial sensors.

SPECIFICATIONS

SUPPLY VOLTAGE: input power and output connections are made

via a 3- or 4-wire power block (see pages 15 to 20).

RESPONSE TIME: 1 millisecond ON and OFF, except high gain

models with "X" suffix and ambient light receivers which are 10

milliseconds ON and OFF.

REPEATABILITY OF RESPONSE: see individual sensor specs.

SENSITIVITY ADJUSTMENT: easily accessible, located on top of

scanner block beneath o-ring gasketed screw cover. 15-turn clutched

control (rotate clockwise to increase gain).

ALIGNMENT INDICATOR: red LED on top of scanner block.

Banner's exclusive, patented Alignment Indicating Device (AID™)

circuit lights the LED whenever the sensor detects its own modulated

light source, and pulses the LED at a rate proportional to the received

light level.

CONSTRUCTION: reinforced VALOX® housing with components

totally encapsulated. Stainless steel hardware. Meets NEMA standards

1, 3, 12, and 13.

OPERATING TEMPERATURE RANGE: -40 to +70 degrees C

(-40 to +158 degrees F).

VALOX® is a registered trademark of General Electric Company.

Functional Schematic, 3- and 4-wire Scanner Block

Dimensions, 3- and 4-wire Scanner Block

6

Page 7

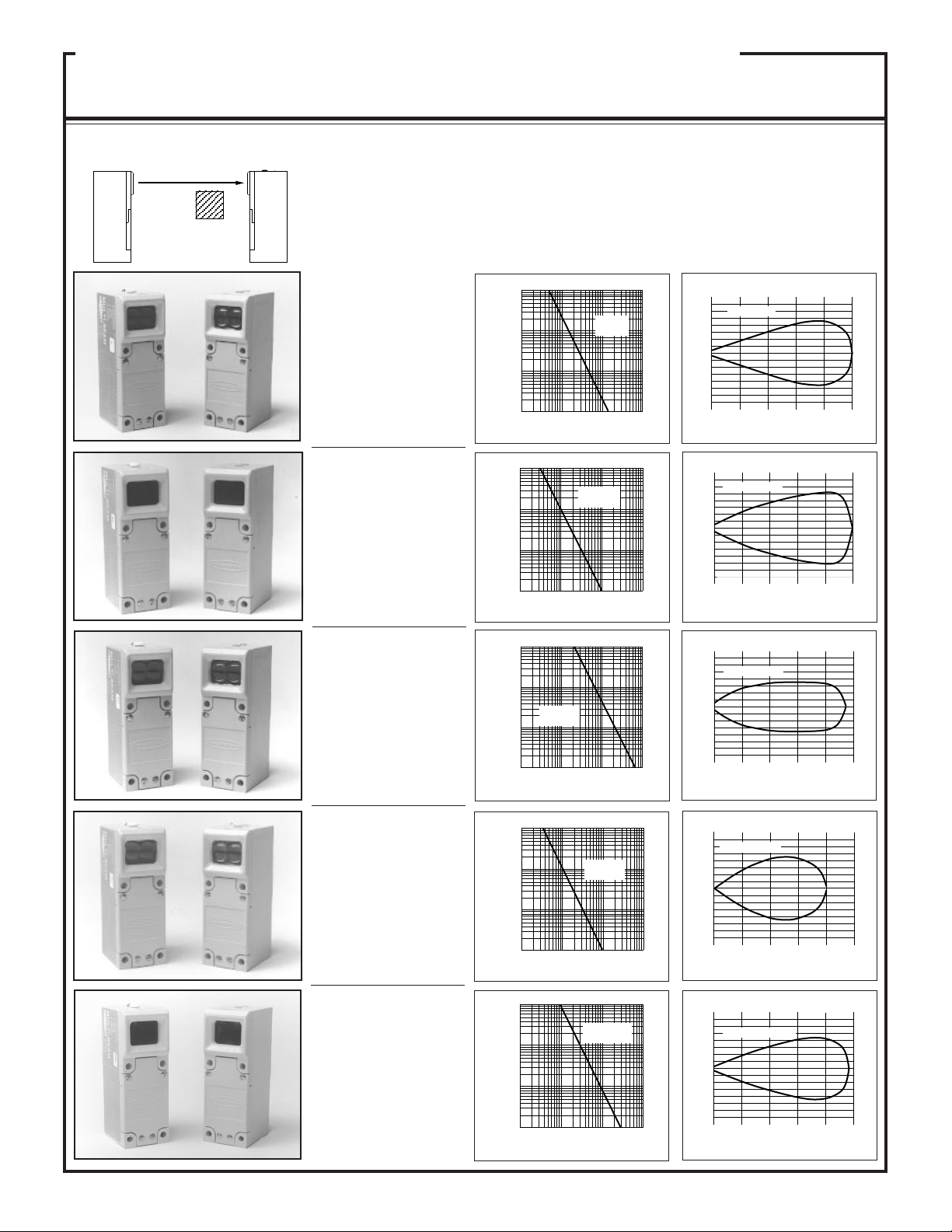

T

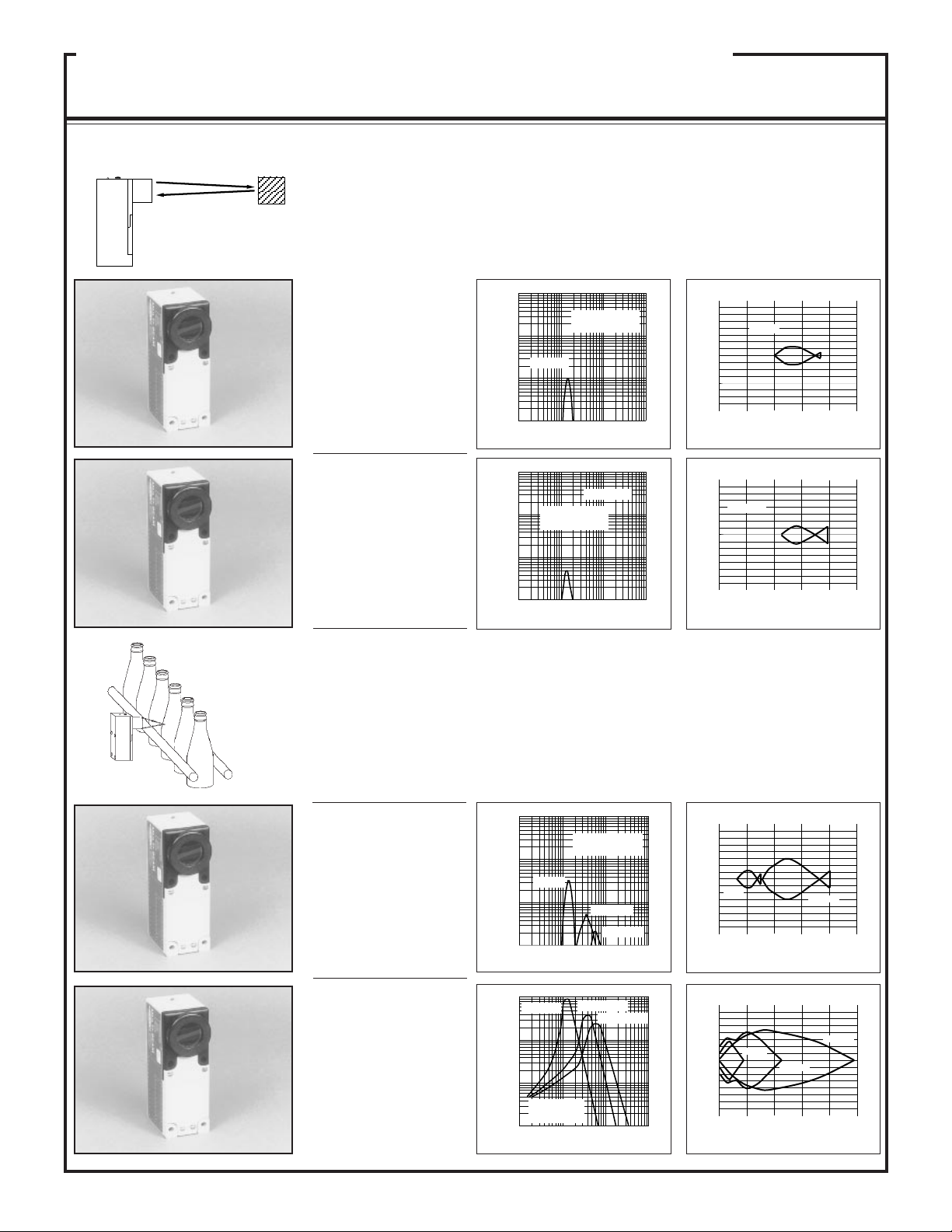

MULTI-BEAM 3- & 4-wire Scanner Blocks

Sensing Mode

OPPOSED Mode

OBJECT

Models Excess Gain

Beam Pattern

SBE/SBR1: this opposed pair has the highest gain available at 1 ms response.

SBED/SBRD1: fast response and small effective beam; will detect objects as small as .14 inch in crossection

moving at up to 10 feet per second. Best choice for repeatability of position sensing.

SBEX/SBRX1: best choice for opposed sensing in extremely dirty environments. Use for outdoor applications

and all applications requiring opposed range of 100 feet or more. Also useable side-by-side for long-distance

mechanical convergent sensing. Alignment difficult beyond 400 feet.

SBEV/SBRX1: SBEV has visible red beam for easiest alignment and system monitoring.

SBEXD/SBRXD1: wide beam angle and high gain for the most forgiving emitter-receiver alignment.

1000

60

SBE & SBR1

Range: 150 feet (45m)

Response: 1ms on/off

Repeatability: 0.03ms

Beam: infrared, 940nm

Effective beam: 1" dia.

SBED & SBRD1

Range: 10 feet (3m)

Response: 1ms on/off

Repeatability: 0.03ms

Beam: infrared, 880nm

Effective beam: .14" dia.

E

X

100

C

E

S

S

G

10

A

I

I

N

1

1 FT

1000

E

X

100

C

E

S

S

G

10

A

I

I

N

1

.1 FT 1 FT 10 FT 100 FT

SBE &

SBR1

10 FT 100 FT 1000FT

DISTANCE

SBED &

SBRD1

DISTANCE

40

I

20

N

C

0

H

E

20

S

40

60

12

8

I

4

N

C

0

H

E

4

S

8

12

SBE/SBR1

300

60 90 120 150

OPPOSED DISTANCE--FEET

SBED/SBRD1

20

4 6 8 10

OPPOSED DISTANCE--FEET

SBEX & SBRX1

Range: 700 feet (200m)

Response: 10ms on/off

Repeatability: 0.7ms

Beam: infrared, 940nm

Effective beam: 1" dia.

SBEV & SBRX1

Range: 100 feet (30m)

Response: 10ms on/off

Repeatability: 0.1ms

Beam: visible red, 650nm

Effective beam: 1" dia.

SBEXD &

SBRXD1

Range: 30 feet (9m)

Response: 10ms on/off

Repeatability: 0.7ms

Beam: infrared, 880nm

Effective beam: .14" dia.

1000

E

X

100

C

E

S

SBEX &

S

SBRX1

G

10

A

I

I

N

1

10 FT 100 FT 1000 F

1 FT

1000

E

X

C

100

E

S

S

G

A

10

I

I

N

1

1 FT

1000

E

X

C

100

E

S

S

G

10

A

I

I

N

1

.1 FT 1 FT 10 FT 100 FT

DISTANCE

SBEV &

SBRX1

10 FT 100 FT 1000FT

DISTANCE

SBEXD &

SBRXD1

DISTANCE

60

SBEX/SBRX1

40

I

20

N

C

0

H

E

20

S

40

60

150 450 600 750

0

OPPOSED DISTANCE--FEET

15

SBEV/SBRX1

10

I

5

N

C

0

H

E

5

S

10

15

250

OPPOSED DISTANCE--FEET

30

SBEXD/SBRXD1

20

I

10

N

C

0

H

E

10

S

20

30

6 12 18 24 32

0

OPPOSED DISTANCE--FEET

300

50 75 100 150

7

Page 8

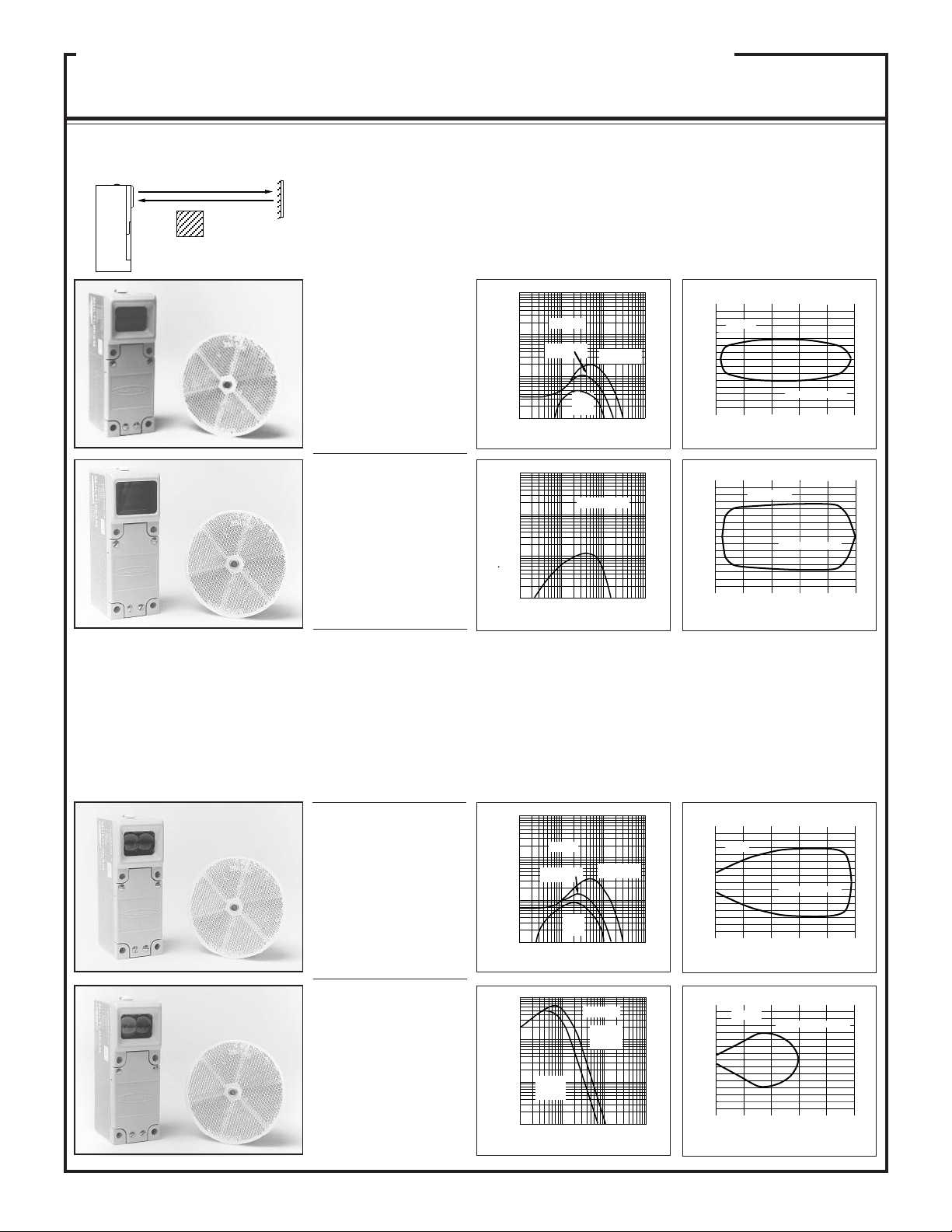

MULTI-BEAM 3- & 4-wire Scanner Blocks

Sensing Mode

RETROREFLECTIVE

Mode

RETRO

OBJECT

TARGET

Models Excess Gain

Beam Pattern

SBLV1: visible beam makes alignment very easy, and is the first choice for most retroreflective applications.

Not for use in dirty environments; rather use opposed mode or see SBL1 & SBLX1, below. Do not locate

retroreflector closer than 6 inches (15cm) from sensor.

SBLVAG1: uses anti-glare filter for immunity to direct reflections from shiny objects. Use only with models

BRT-3 or BRT-1.5 retroreflective targets. Use only in clean environments. Do not locate retroreflector closer

than 12 inches (30cm) from sensor.

1000

SBLV1

Range: 6 in. to 30 ft.

(0,15 to 9m)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: visible red, 650nm

SBLVAG1

Range: 12 in. to 15 ft.

(0,3 to 4.5m)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: visible red, 650nm

E

X

C

E

S

S

G

A

I

I

N

1000

E

X

C

E

S

S

G

A

I

I

N

SBLV1

100

with BRT-1 1"

reflector

10

1

.1 FT 1 FT 10 FT 100 FT

with

BRT-T

tape

DISTANCE

with BRT-3 3"

reflector

SBLVAG1

100

10

1

.1 FT 1 FT 10 FT 100 FT

DISTANCE

6

SBLV1

4

I

2

N

C

0

H

E

2

S

4

6

6 12 18 24 32

0

DISTANCE TO REFLECTOR--FEET

3

SBLVAG1

2

I

1

N

C

0

H

E

1

S

2

3

3 6 9 12 15

0

DISTANCE TO REFLECTOR--FEET

with BRT-3 reflector

with BRT-3 reflector

NOTE: for detailed information on

available retroreflective materials, see

the Banner product catalog.

SBL1: use where invisible beam is advantageous (e.g. security applications or film processing). First choice for

retroreflective sensing in slightly or moderately dirty environments. Do not use when the object to break the

beam has a shiny surface, unless the angle of light to the surface can be predicted.

SBLX1: highest gain available in a retroreflective sensor. Use for all applications requiring more than 30-foot

range where opposed mode sensors cannot be used. Objects must pass at a distance of at least 10 feet from the

sensor to be reliably sensed.

1000

SBL1

Range: 1 in. to 30 ft.

(2,5cm to 9m)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: infrared, 940nm

SBLX1

Range: 10 to 75 ft. (3 to

22m) with one BRT-3 target;

10 to 100 ft. (3 to 30m) with

three BRT-3 targets

Response: 10ms on/off

Repeatability: 1.5ms

Beam: infrared, 880nm

E

X

C

E

S

S

G

A

I

I

N

1000

SBL1

100

with BRT-1 1"

reflector

10

1

.1 FT 1 FT 10 FT 100 FT

with

BRT-T

tape

DISTANCE

with BRT-3 3"

reflector

SBLX1

E

X

100

C

E

S

S

G

with one

10

A

BRT-3 3"

I

I

reflector

N

1

1 FT

10 FT

DISTANCE

with three

BRT-3 3"

reflectors

100 FT 1000 FT

6

SBL1

4

I

2

N

C

0

H

E

2

S

4

6

6 12 18 24 32

0

DISTANCE TO REFLECTOR--FEET

SBLX1

30

20

I

10

N

C

0

H

E

10

S

20

30

25 50 75 100 125

0

DISTANCE TO REFLECTOR--FEET

with BRT-3 reflector

with one BRT-3 reflector

8

Page 9

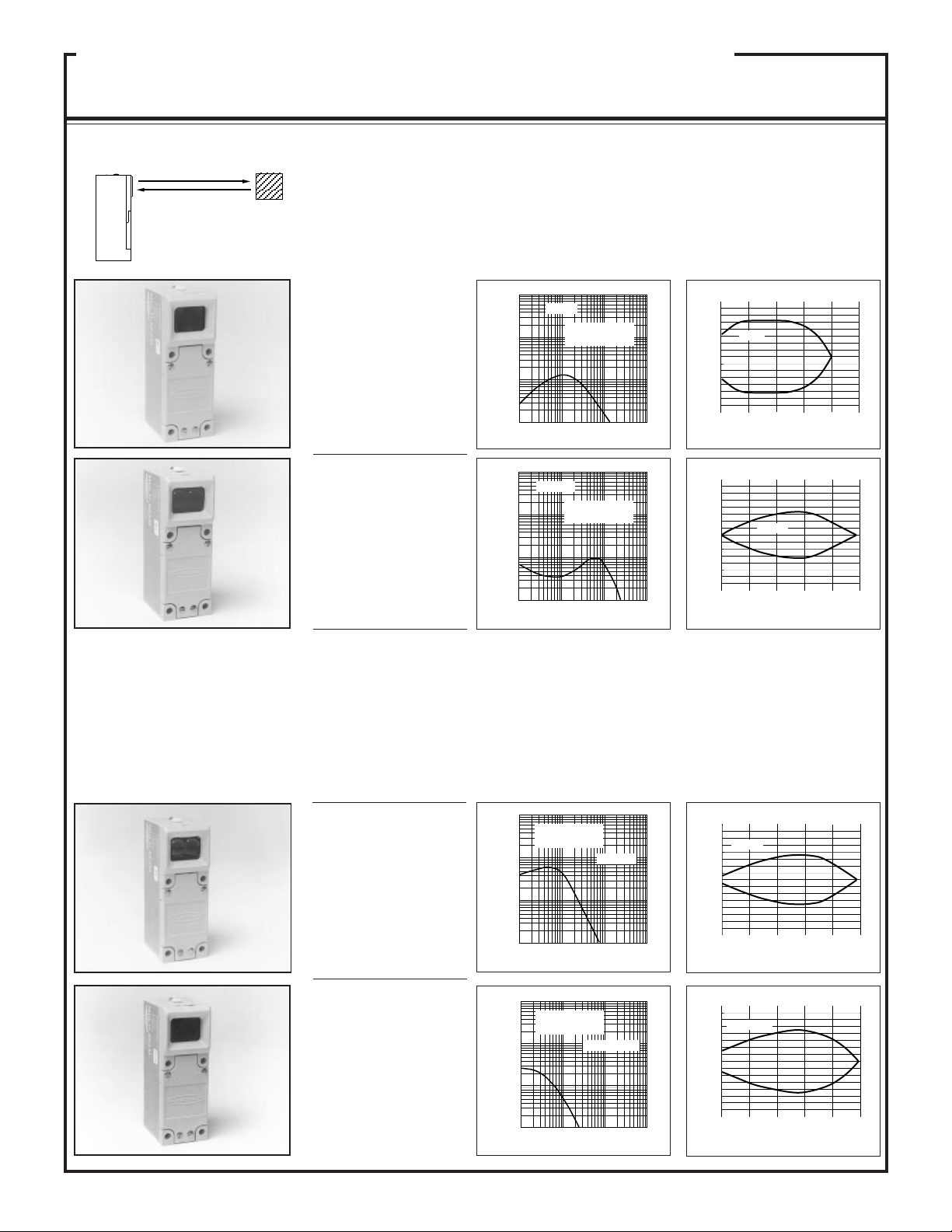

%

%

%

%

S

S

MULTI-BEAM 3- & 4-wire Scanner Blocks

Sensing Mode

DIFFUSE Mode

OBJECT

Models Excess Gain

Beam Pattern

SBD1: short range diffuse mode sensor with relatively wide field of view. Loses gain rapidly near the end of its

range. As a result, its response to background objects is suppressed. However, use caution when applying any

diffuse mode sensor if background reflectivity exceeds the reflectivity of the object to be sensed.

SBDL1: longer range than SBD1, but with less response to objects passing the sensor at close range, and greater

sensitivity to background objects. Models SBD1 and SBDL1 are identical except for their upper cover (lens)

assembly (SBD1 uses UC-D; SBDL1 uses UC-L; see Upper Cover Chart in the Banner product catalog).

1000

SBD1

Range: 12 inches (30cm)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: infrared, 940nm

SBDL1

Range: 24 inches (60cm)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: infrared, 940nm

E

X

C

E

S

S

G

A

I

N

SBD1

(Range based on 90

100

10

I

1

.1 IN 1 IN 10 IN

1000

reflectance white

test card)

DISTANCE

SBDL1

E

X

100

C

E

S

S

G

10

A

I

I

N

1

.1 IN 1 IN 10 IN

(Range based on 90

reflectance white

test card)

DISTANCE

100 IN

100 IN

.3

.2

SBD1

I

.1

N

C

0

H

E

.1

S

.2

.3

3 6 9 12 15

0

DISTANCE TO 90% WHITE TEST CARD--INCHES

.75

.5

I

.25

N

C

H

E

.25

S

.75

DISTANCE TO 90% WHITE TEST CARD--INCHE

SBDL1

0

.5

5 10 15 20 25

0

APPLICATION NOTE: as a general rule

regarding background objects in diffuse sensing, verify that the distance to the nearest

background object is at least three times the

distance from the sensor to the object to be

sensed. For example, if a product passes one

inch from an SBD1 sensor, the nearest background object should be at least three inches

further away.

SBDX1: first choice for diffuse (proximity) mode applications when there is no requirement for less than 10 ms

response and where there are no background objects to falsely return light. High excess gain for reliable detection

of most materials with low reflectivity which pass within 10 inches (25cm) of the sensor.

SBDX1MD: wide beam angle for forgiving alignment to reflective objects. First choice for detection of clear or

translucent glass or plastics. High excess gain at close range, with fast fall-off of gain near the maximum sensing

distance for optical suppression of reflective background. This model may be created from model SBDX1 by

substituting upper cover (lens) model UC-DMB.

1000

(Range based on 90

SBDX1

Range: 6 feet (2m)

Response: 10ms on/off

Repeatability: 1.5ms

Beam: infrared, 880nm

SBDX1MD

Range: 24 inches (60cm)

Response: 10ms on/off

Repeatability: 1.5ms

Beam: infrared, 880nm

reflectance white

test card)

E

X

C

100

E

S

S

G

10

A

I

I

N

1

1 IN

10 IN 100 IN 1000 IN

DISTANCE

1000

(Range based on 90

reflectance white

test card)

E

X

C

100

E

S

S

G

10

A

I

I

N

1

1 IN 10 IN 100 IN

DISTANCE

SBDX1

SBDX1MD

1000 IN

3

SBDX1

2

I

1

N

C

0

H

E

1

S

2

3

15 30 45 60 75

0

DISTANCE TO 90% WHITE TEST CARD--INCHES

1.5

SBDX1MD

1

I

.5

N

C

0

H

E

.5

S

1

1.5

5 10 15 20 25

0

DISTANCE TO 90% WHITE TEST CARD--INCHE

9

Page 10

%

%

%

S

S

S

MULTI-BEAM 3- & 4-wire Scanner Blocks

Sensing Mode

CONVERGENT Mode

OBJECT

Excess GainModels

Beam Pattern

SBCV1: .06-inch (1.5mm) dia. visible red spot, for precise positioning, edge-guiding, & small parts detection.

Sensor-to-product distance must be consistent. Some products ≥1" tall may be sensed against immediate

background like parts on a conveyor. Excellent for high-contrast registration-sensing applications (except red-onwhite). Use with LM6-1 logic module for speed detection sensing gear teeth, pulley hubs, or chain links.

SBCVG1: .12-inch (3mm) diameter visible green spot. Use to detect color differences (e.g. color registration

marks), including red-on-white combinations. For subtle shade variations, use model FO2BG (see Banner product

catalog).

SBCV1

Focus at: 1.5 inch (38mm)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: visible red, 650nm

SBCVG1

Focus at: 1.5 in. (38mm)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: visible green, 560nm

1000

E

X

C

100

E

S

S

SBCV1

G

A

10

I

I

N

1

.1 IN 1 IN 10 IN

1000

E

X

100

C

E

S

S

G

10

A

I

I

N

1

.1 IN 1 IN 10 IN

DISTANCE

(Range based on 90

reflectance white

test card)

DISTANCE

(Range based on 90

reflectance white

test card)

SBCVG1

100 IN

100 IN

.120

.080

I

N

C

H

E

S

I

N

C

H

E

S

SBCV1

.040

0

.040

.080

.120

.50 1.0 2.0 2.5

0

DISTANCE TO 90% WHITE TEST CARD--INCHE

.12

.08

SBCVG1

.04

0

.04

.08

.12

.5 1.0 1.5 2.0 2.5

0

DISTANCE TO 90% WHITE TEST CARD--INCHE

1.5

Counting radiused

products

SBC1, SBC1-4, SBC1-6: infrared LED light source provides higher gain for reliable sensing of products of low

reflectivity, while controlling sensing depth of field. Does not offer the same precision possible with visible light

models. Good for sensing clear materials within the sensor's depth of field. Good for reliably counting the flow

of radiused products which are kept at a fixed distance from the sensor (e.g. bottles against conveyor guide rail).

SBCX1, SBCX1-4, SBCX1-6: these models offer the greatest optical gain available in any reflective mode sensor.

They reliably detect most non-reflective black materials in applications where opposed mode sensing is not

possible (e.g. web break monitoring). Not meant for ignoring background objects (see excess gain charts).

SBC1

Focus at: 1.5 inch (38mm)

SBC1-4

Focus at: 4 inches (10cm)

SBC1-6

Focus at: 6 inches (15cm)

Response: 1ms on/off

Repeatability: 0.3ms

Beam: infrared, 940nm

SBCX1

Focus at: 1.5 inch (38mm)

SBCX1-4

Focus at: 4 inches (10cm)

SBCX1-6

Focus at: 6 inch (15cm)

Response: 10ms on/off

Repeatability: 1.5ms

Beam: infrared, 880nm

1000

E

X

100

C

E

S

SBC1

S

G

10

A

I

I

N

1

.1 IN 1 IN 10 IN

1000

E

X

C

100

E

S

S

G

A

10

I

I

N

1

.1 IN 1 IN 10 IN

SBCX1

(Range based on

90% reflectance

white test card)

DISTANCE

DISTANCE

(Range based on 90

reflectance white

test card)

SBC1-4

SBC1-6

SBCX1-4

SBCX1-6

100 IN

100 IN

.120

.080

I

.040

N

C

0

H

E

.040

SBC1

S

.080

.120

1.5 3.0 4.5 6.0 7.5

0

DISTANCE TO 90% WHITE TEST CARD--INCHES

.24

.16

I

.08

N

SBCX1

C

0

H

E

.08

S

.16

.24

8 16 24 30 36

0

DISTANCE TO 90% WHITE TEST CARD--INCHE

SBC1-4

SBCX1-6

SBCX1-4

10

Page 11

%

0

MULTI-BEAM 3- & 4-wire Scanner Blocks

OPPOSED FIBER OPTIC

Mode (glass fiber optics)

OBJECT

Models Excess Gain

SBEF & SBRF1

Range: see excess gain curve

Response: 1ms on/off

Repeatability: 0.03ms

Beam: infrared, 880nm

NOTE: fiber optic gain

curves apply to 3-foot fiber

lengths. Gain decreases by

approximately 10% for each

additional foot of fiberoptic

1000

E

X

100

C

E

S

S

G

A

I

N

with

L9

lenses

10

I

no

lenses

1

.1 FT 1 FT 10 FT 100 FT

DISTANCE

SBEF &

SBRF1

opposed mode,

IT23S fibers

with

L16F

lenses

Beam PatternSensing Mode

12

8

I

4

N

C

0

H

E

4

S

8

12

SBEF/SBRF1

IT23S, L9 lenses

with IT23S fibers

and L16F lenses

80

16 24 32 40

OPPOSED DISTANCE--FEET

cable.

SBEF & SBRF1: use with individual glass fiber optic assemblies in lieu of model SBF1 where it is inconvenient

to run fibers from a single scanner block.

SBEXF & SBRXF1: use in place of model SBFX1 (shown below) for long-range opposed fiber optic sensing.

Or use where high excess gain is required and it is difficult to run the fibers to both sides of the process from a single

scanner block. Lenses for fiber optics are shown in the Banner product catalog.

SBEXF & SBRXF1

Range: see excess gain

curve

Response: 10ms on/off

Repeatability: 0.7ms

Beam: infrared, 880nm

1000

E

X

100

C

E

S

S

G

10

A

no lens

I

I

N

1

.1 FT 1 FT 10 FT 100 FT

with

L9

lenses

DISTANCE

SBEXF &

SBRXF1

with

L16F

lenses

Opposed

mode,

IT23S

fibers

SBEXF & SBRXF1

24

16

I

8

N

C

0

H

E

8

S

16

24

with IT23S fibers

and L16F lenses

200

40 60 80 10

OPPOSED DISTANCE--FEET

FIBER OPTIC Mode

(glass fiber optics)

HIGH-POWER SCANNER

BLOCK

OPPOSED MODE

OBJECT

DIFFUSE MODE

OBJECT

For complete information on glass

fiber optic assemblies and

accessories, see product catalog.

SBFX1

Range: see excess gain

curves

Response: 10ms on/off

Repeatability: 1.5ms

Beam: infrared, 880nm

Fiber optic information:

IT13S: individual assembly

.06 in (1,5mm) dia. bundle

IT23S: individual assembly

1000

E

X

C

100

E

S

S

G

opposed mode,

A

10

IT13S fibers

I

I

N

1

.1 IN 1 IN 10 IN

DISTANCE

SBFX1

opposed mode,

IT23S fibers

100 IN

6

SBFX1

4

I

2

N

C

0

H

E

2

S

4

6

100

OPPOSED DISTANCE--INCHES

IT13S

IT23S

20 30 40 50

.12 in. (3mm) dia. bundle

BT13S: bifurcated assembly, .06 in. (1.5mm) dia.

bundle

BT23S: bifurcated assembly, .12 in. (3mm) dia.

bundle

L9: .5in. (12mm) dia. lens

L16F: 1.0 in. (25mm) dia.

lens

1000

E

Diffuse mode, glass fibers

X

100

C

E

S

S

G

10

A

I

I

N

1

.1 IN 1 IN 10 IN

BT13S

(Range based on 90

reflectance white test

card)

DISTANCE

BT23S

SBFX1

100 IN

.15

.1

I

.05

N

C

0

H

E

.05

S

.1

.15

DISTANCE TO 90% WHITE TEST CARD--INCHES

BT13S

1 2 3 4 5

0

SBFX1

BT23S

Model SBFX1 is the first choice for glass fiber optic applications, except in fiber optic retroreflective applications

or where faster response speed or visible light are a requirement. Model SBFX1 contains both emitter and receiver

and thus accepts either one bifurcated fiberoptic assembly or two individual fiber optic cables. The excess gain

of model SBFX1 is the highest available in the photoelectric industry. As a result, opposed individual fibers

operate reliably in many very hostile environments. Also, special miniature bifurcated fiber optic assemblies with

bundle sizes as small as .020 inch (.5mm) in diameter may be used successfully with model SBFX1 for diffuse

mode sensing. The excess gain curves and beam patterns illustrate response with standard .060 inch (1.5mm)

diameter and .12 inch (3mm) diameter bundles. Response for smaller or larger bundle sizes may be interpolated.

NOTE: opposed ranges shown are meant to illustrate excess gain only, and are limited by fiber length. Use scanner

block models SBEXF and SBRXF1 (above) for long range opposed fiber optic sensing.

11

Page 12

e

e

S

e

e

MULTI-BEAM 3- & 4-wire Scanner Blocks

FIBER OPTIC Mode

(glass fiber optics)

HIGH-SPEED SCANNER BLOCK

OPPOSED MODE

OBJECT

RETROREFLECTIVE MODE

RETRO TARGET

OBJECT

DIFFUSE MODE

OBJECT

Models Excess Gain

SBF1

Range: see excess gain

curves

Response: 1ms on/off

Repeatability: 0.3ms

Beam: infrared, 940nm

Fiber optic information:

IT13S: individual assembly

.06in (1,5mm) dia. bundle

IT23S: individual assembly

.12 in. (3mm) dia. bundle

BT13S: bifurcated assembly, .06 in. (1,5mm) dia.

bundle

BT23S: bifurcated assembly, .12 in. (3mm) dia.

bundle

L9: .5in. (12mm) dia. lens

L16F: 1.0 in. (25mm) dia.

lens

For information on the

complete line of glass fiber

optics, see Banner product

catalog.

1000

E

X

100

C

E

S

S

G

10

A

I

I

N

no lenses

1

.1 FT 1 FT 10 FT 100 FT

1000

E

SBF1

X

C

100

E

S

S

G

A

10

I

I

N

1

.1 FT 1 FT 10 FT 100 FT

1000

SBF1

E

X

C

100

E

(Range based on 90% reflectanc

S

white test card)

S

G

A

10

I

I

N

1

.1 IN 1 IN 10 IN 100 IN

with

BT13S

fibers

with

BT23S fibers

SBF1

Opposed mode,

with IT23S fibers

with

L9

lenses

DISTANCE

Retroreflective mode,

with BRT-3 reflector

and BT13S fibers

with

L9

lenses

DISTANCE

Diffuse mode

DISTANCE

with

L16F

lenses

with

L16F

lenses

Beam PatternSensing Mode

3

SBF1 opposed mod

NO LENSES

2

I

1

N

C

0

H

E

1

S

2

3

6

4

I

2

N

C

0

H

E

2

S

4

6

.075

.05

I

.025

N

C

0

H

E

.025

S

.05

.075

0

DISTANCE TO 90% WHITE TEST CARD--INCHE

IT13S fibers

IT23S fibers

40

8 12 16 20

OPPOSED DISTANCE--INCHES

SBF1

L9 LENS

0

DISTANCE TO REFLECTOR--FEET

with BT13S fibers

and BRT-3 reflector

L16F LENS

4 8 12 16 20

BT13S

BT23S

.5 1.0 1.5 2.0 2.5

SBF1

Fiber optics are often used to sense small parts. Small parts or narrow profiles which move at a high rate of speed can require sensors with fast response times for

reliable detection. High speed fiber optic sensors are ideal for sensing gear or sprocket teeth or other targets in applications involving counters or shift registers for

position control. Selection of the fiber optic sensing tip should involve matching the effective beam of the fiber to the profile of the part to be sensed to maximize

the time that the part is sensed and/or the time between adjacent parts. Combining the best selection of fiber tip geometry with a high speed sensor will result in

a highly repeatable position sensing system. The model BT13S fiber optic assembly used with a model L9 or L16F lens and a high speed scanner block is an excellent

system for retroreflective code reading or for almost any short range retroreflective sensing application. Response time of a MULTI-BEAM sensor is also a function

of the power block. For this reason, only power blocks which switch dc (e.g. PBT, PBP, PBO, PBAT, etc) should be used if the fast response time of the scanner

block is to be utilized.

E

X

C

E

S

S

G

A

I

N

E

X

C

E

S

S

G

A

I

I

N

I

1000

1000

100

10

100

10

1

1

.1 IN

with BT13S

fiber

.01 IN

with IT13S

fibers

SBF1MHS

with IT23S

fibers and

L9 lenses

1 IN 10 IN

DISTANCE

SBF1MHS

(Diffuse mode,

ranges based on

90% reflectance

white test card)

with BT23S

fiber

.1 IN 1 IN

DISTANCE

with IT23S

fibers

100 IN

10 IN

3

SBF1MHS opposed mod

2

I

1

N

C

0

H

E

1

S

2

3

0

.075

SBF1MHS diffuse mod

.05

I

.025

N

C

0

H

E

.025

S

.05

.075

0

DISTANCE TO 90% WHITE TEST CARD--INCHES

IT13S

IT23S

IT23S w/L9

8 16 24 32 40

OPPOSED DISTANCE--INCHES

BT13S fibers

BT23S fibers

.2 .4 .6 .8 1.0

FIBER OPTIC Mode (glass fiber optics)

VERY HIGH-SPEED SCANNER

BLOCK

OPPOSED MODE

OBJECT

DIFFUSE MODE

OBJECT

For complete information on glass

fiber optic assemblies and accessories,

see Banner product catalog.

SBF1MHS

Range: see excess gain

curves

Response: 300 microseconds on/off

Repeatability:

100 microseconds

Beam: infrared, 940nm

NOTE: gain curves illustrate that faster response

comes at the expense of

lower gain.

12

Page 13

n

s

n

0

e

4

e

S

e

S

MULTI-BEAM 3- & 4-wire Scanner Blocks

FIBER OPTIC Mode

(glass fiber optics)

VISIBLE RED LIGHT SOURCE

OPPOSED MODE

OBJECT

RETROREFLECTIVE MODE

RETRO TARGET

OBJECT

DIFFUSE MODE

OBJECT

Models Excess Gain

SBFV1

Range: see excess gain

curves

Response: 1ms on/off

Repeatability: 0.3ms

Beam: visible red, 650nm

Fiber optic information:

IT13S: individual assembly

.06in (1,5mm) dia. bundle

IT23S: individual assembly

.12 in. (3mm) dia. bundle

BT13S: bifurcated assembly, .06 in. (1,5mm) dia.

bundle

BT23S: bifurcated assembly, .12 in. (3mm) dia.

bundle

L9: .5in. (12mm) dia. lens

L16F: 1.0 in. (25mm) dia.

lens

For information on the

complete line of glass fiber

optics, see Banner product

catalog.

1000

E

X

C

100

E

S

S

with IT23S

G

fibers

A

10

I

I

N

E

X

C

E

S

S

G

A

I

I

N

E

X

C

E

S

S

G

A

I

I

N

with IT13S

fibers

1

..1 IN 1 IN 10 IN

1000

Retroreflective mode,

with BRT-3 reflector

100

10

with L9 lens,

BT13S fiber

1

..1 FT 1 FT

1000

Diffuse mode

100

10

BT13S fiber

1

.01 IN .1 IN 1 IN 10 IN

SBFV1

Opposed mode

DISTANCE

SBFV1

with L16F lens,

BT13S fiber

10 FT

DISTANCE

SBFV1

(Range based o

90% reflectance

white test card)

BT23S fibers

DISTANCE

with IT23S

fibers, L9

lenses

100 IN

100 FT

Beam PatternSensing Mode

1.5

SBFV1 opposed mod

1.

I

.5

N

C

IT13S fibers

0

H

E

.5

S

1.0

1.5

0

OPPOSED DISTANCE--INCHES

6

SBFV1 retroreflective mod

I

2

N

C

with

0

H

L9 lenses

E

2

S

4

6

0

DISTANCE TO REFLECTOR--FEET

.075

SBFV1 diffuse mod

.05

I

.025

N

C

0

H

E

BT13S fibers

.025

S

.05

.075

.3 .6 .9 1.2 1.5

0

DISTANCE TO 90% WHITE TEST CARD--INCHE

IT23S fibers

3 6 9 12 15

BT13S fibers

with

L16F lenses

with BRT-3 reflector

4 8 12 16 20

BT23S fibers

Scanner block model SBFV1 supplies visible red light to the emitter half of a glass fiber optic photoelectric system. Visible light sensors have less optical energy

as compared to infrared systems. There are, however, some sensing situations which require visible light wavelengths in order to realize adequate optical contrast.

Opposed fibers using visible red light are used to reliably sense translucent materials (e.g. plastic bottles) which appear transparent to infrared opposed sensors. Fiber

assembly model BT13S used with a the model L9 or L16F lens makes an excellent visible light sensing system for retroreflective code reading as well as many shortrange retroreflective applications (e.g. retro scanning across a narrow conveyor). When combined with a bifurcated fiber, model SBFV1 may be used for color

registration sensing for applications where there is a large difference between the two colors (e.g. black-on-white). For combinations of red-on-white, however,

the visible-green light source of model SBFVG1 (below) is needed. Visible light emitters are also helpful for visual system alignment and maintenance.

FIBER OPTIC Mode

(glass fiber optics)

VISIBLE GREEN LIGHT SOURCE

for COLOR SENSING

(REGISTRATION CONTROL)

SBFVG1

Range: see excess gain curve

Response: 1 ms on/off

Repeatability: 0.3ms

Beam: visible green,

560nm

1000

Diffuse mode

E

X

C

100

E

S

S

G

A

10

I

I

N

1

.01 IN .1 IN 1 IN 10 IN

SBFVG1

(Range based o

90% reflectance

white test card)

BT23S

fiber

DISTANCE

.075

SBFVG1

.05

I

.025

N

C

0

H

E

.025

S

.05

.075

DISTANCE TO 90% WHITE TEST CARD--INCHE

BT23S fiber

.1 .2 .3 .4 .5

0

Convergent beam sensors like model SBCVG1 are often used for color registration sensing. However, there are

some registration applications where the use of bifurcated fiber optics is beneficial. Fiber optics are able to fit

into tight locations which are too small for a convergent sensor. Fibers also allow a choice of image size. It is

important to create an image size which is smaller than the registration mark in order to maximize optical contrast

and to ease sensor response requirements. Fibers allow a match of the light image to the geometry of the

registration mark. Scanner block model SBFVG1 will sense most bold color differences, including red-on-white.

Use only power blocks which switch dc (e.g. PBT, PBP, PBO, PBAT, etc.) for fast response.

13

Page 14

MULTI-BEAM 3- & 4-wire Scanner Blocks

Sensing Mode

AMBIENT LIGHT

RECEIVER

NOTE: MULTI-BEAM ambient light receivers do not have the Alignment Indicating

Device (AID™) signal strength feature. The

alignment indicator is "ON" steadily when

enough light is sensed.

Models

SBAR1

Response: 10ms on/off

Amplifier: normal gain

Optical response: ultra-

violet through near infrared

(includes all visible

wavelengths)

SBAR1GH

Response: 10ms on/off

Amplifier: high gain

Optical response: ultra-

violet through near infrared

(includes all visible

wavelengths)

These scanner blocks are non-modulated receivers which are operated by sunlight or incandescent, fluorescent,

infrared, or laser sources. A typical application would involve mounting the scanner block underneath a roller

conveyor, "looking" up between the rollers at the overhead factory lighting. Any objects passing over the sensor

would then cast a shadow, resulting in an output (dark operate). Ambient receivers are used with LM5-14 delay

logic to sense daylight for outdoor lighting control. These sensors can also sense the large amounts of infrared light

(heat energy) which is emitted by hot or molten glass, metal, or plastic during processing of these materials.

Model SBAR1 is for general application. Model SBAR1GH is a high gain version. It is about twenty times more

sensitive to light as compared to the SBAR1. The range at which either model will sense a light source depends

upon both the intensity of the light source and the contrast in intensity between the source and the rest of the ambient

light in the viewing area.

NOTE: ambient receiver scanner blocks will also work with 2-wire power blocks and logic. However, the light/

dark operate functions will be reversed when using 2-wire components.

Functional Schematic

SBAR1GHF

Response: 10ms on/off

Amplifier: high gain

Optical response: wave-

lengths from visible blue

through near infrared

Direct Sensing of Radiant Infrared Energy

FIBER OPTIC AMBIENT

LIGHT RECEIVER

(glass fiber optics)

Model SBAR1GHF is identical to model SBAR1GH (above) except that it is equipped with an upper cover

assembly (model UC-RF) which allows an individual glass fiber optic assembly to be attached to the receiver

optoelement. This model is used for ambient light detection in locations which are either too confined or too hot

for mounting of the complete scanner block. A typical application involves sensing product presence or counting

during processing of red-hot or molten glass or metal. The addition of an L9, L16F, L16FAL, or L16FSS lens to

For information on the complete

selection of individual glass fiber

optics, see Banner product catalog.

a threaded fiber assembly (e.g. IT23S) can narrow the angle of light acceptance to less than the angle of the SBAR1

lens. The high gain amplifier of model SBAR1GHF helps to offset light losses which are experienced with

fiberoptic light pipes. NOTE: glass fibers will not efficiently pass ultraviolet wavelengths.

MULTI-BEAM 3- and 4-wire Scanner Block Modifications

The following are popular modifications to MULTI-BEAM 3- & 4-wire scanner blocks. They are not stocked, but are available on a quote basis.

HIGH SPEED MODIFICATION "MHS": scanner blocks with 1 millisecond response may be modified for 300 microsecond (0.3 millisecond) response.

This modification is designated by adding suffix "MHS" to the scanner block

model number (e.g.- SBF1MHS, etc.). High speed is most often required in

fiberoptic or opposed mode sensing. The MHS modification reduces the

available excess gain by about 50%, and also decreases the sensor's immunity

to some forms of electrical "noise".

14

ZERO HYSTERESIS MODIFICATION "MZ": amplifier hysteresis may

be removed from 3- and 4-wire scanner blocks when attempting to sense very

small signal changes (contrasts less than 3). This modification is designated by

adding suffix "MZ" (Modified Zero Hysteresis). Be sure that all variables

affecting the sensor's optical response remain constant before ordering the zero

hysteresis modification .

Page 15

MULTI-BEAM 3- & 4-wire DC Power Blocks

MULTI-BEAM 3- & 4-wire power blocks provide regulated low voltage DC power to

the scanner block and logic module, and a solid state infinite-life switch (except in

emitter-only scanner blocks). Connections are made to heavy-duty screw terminals

which accept up to #14 gauge wire (no lugs are necessary). All power blocks are epoxyencapsulated and rated for -40 to +70 degrees C. Response times are determined by

the scanner block used, except that power blocks switching ac require up to 8.3

milliseconds to turn OFF in addition to the response time of the scanner block (plus

logic module time delays, if any).

Photo shows DC power block (left) and AC power block (right).

DC power blocks have gray housings; AC models are red.

DC Models

PBT

Input: 10 to 30V dc at less than 60mA (current draw

depends on scanner block used). 10% max. ripple.

Output: one open-collector NPN transistor (sinks

current to negative side of power supply). 250mA

maximum.

On state voltage drop: less than 1V dc

Off state leakage current: less than 10 microamps

PBT48

Input: 44 to 52V dc at less than 60mA (current draw

depends on scanner block used). 10% max. ripple.

Output: one open-collector NPN transistor (sinks

current to negative side of power supply). 250mA

maximum.

On state voltage drop: less than 1V dc

Off state leakage current: less than 10 microamps

PBT2

Input: 10 to 30V dc at less than 60mA (current draw

depends on scanner block used). 10% max. ripple.

Output: two open-collector NPN transistors (one

normally open, one normally closed). 250mA

maximum, each output.

On state voltage drop: less than 1V dc

Off state leakage current: less than 10 microamps

Connections

+

PBT: the most commonly used dc power block. Its output is an NPN transistor, which sinks current to

the negative side of the power supply. The load is connected between the output and the positive side of

the power supply. Switching capacity is 250mA. There is no connection to terminal #4.

PBT48: exactly the same configuration as the PBT, but for 48V dc systems.

PBT2: provides two NPN outputs; one normally open, the other normally closed (equivalent to SPDT

relay). The normally closed output may be used when a load must de-energize when the MULTI-BEAM

operates (e.g. normally closed one-shot). NOTE: both outputs are open when dc power is removed.

+

V dc

(See Specifications)

LOAD

3 4

1 2

10 to 30V dc

LOAD

LOAD

3 4

1 2

-

-

Functional Schematics

PBP

Input: 10 to 30V dc at less than 60mA (current draw

depends on scanner block used). 10% max. ripple.

Output: one open-collector PNP transistor (sources

current from positive side of power supply). 250mA

maximum.

On state voltage drop: less than 1V dc

Off state leakage current: less than 10 microamps

PBP48

Input: 44 to 52V dc at less than 60mA (current draw

depends on scanner block used). 10% max. ripple.

Output: one open-collector PNP transistor (sources

current from positive side of power supply). 250mA

maximum.

On state voltage drop: less than 1V dc

Off state leakage current: less than 10 microamps

+

PBP: similar to model PBT, except that it provides a PNP sourcing type output transistor. Sourcing

outputs are frequently required when interfacing to logic systems and programmable logic controllers

(PLCs) which require a positive source of dc voltage to generate an input condition. This type of interface

may also be accomplished by using PBT with a "pullup" resistor installed between terminals #1 and #3.

PBP48: a 48V dc version of model PBP.

V dc

(See Specifications)

LOAD

3 4

1 2

-

15

Page 16

-

c

r

c

MULTI-BEAM 3- & 4-wire DC Power Blocks

DC Models

Connections

Functional Schematic

These are power blocks for emitter scanner blocks only (models SBE, SBED, SBEX, SBEV, SBEXD, SBEF, SBEXF). Emitter assemblies do

not require logic modules.

PBT-1

Input: 10 to 30V dc at less than 60mA (current draw

depends on scanner block used). 10% max. ripple.

PBT48-1

Input: 44 to 52V dc at less than 60mA (current draw

depends on scanner block used). 10% max. ripple.

Hookup Diagrams for DC Power Blocks

Hookup to DC Relay or Solenoid

(using sinking output)

When using power blocks with current sinking (NPN)

outputs, simple loads connect between the power block

output (terminal #3) and the positive supply (terminal

#1).

+

10 to 30V dc: PBT, PBT2

PBT

PBT2

PBT48

LOAD

44 to 52V dc: PBT48

3 4

1 2

-

+

V dc

(See Specifications)

1 2

-

Hookup to DC Relay or Solenoid

(using sourcing output)

When using power blocks with current sourcing (PNP)

outputs, simple loads connect between the power block

output (terminal #3) and dc common (terminal #2).

+ -

10 to 30V dc: PBP

44 to 52V dc: PBP48

PBP

PBP48

3 4

1 2

LOAD

Output capacity: 250mA

maximum, each output.

Hookup to Logic Gate

A logic zero (0 volts dc) is applied to the gate input

when the MULTI-BEAM output is energized. When

de-energized, a logic one is applied. The logic supply

must be common to the MULTI-BEAM supply negative.

*

Use pullup resisto

to logic supply

+5V to 30V d

logic supply

(-) dc

*

+

PBT

PBT2

3 4

1 2

10 to 30V d

-

Hookup to a Programmable Controller

requiring a current sink

Use power blocks with NPN

outputs to interface to PLCs and

other logic devices requiring a

current sink at the inputs. Connect the output of the power

block (terminal #3) to any input

of the PLC. Also connect the

negative of the MULTI-BEAM

power supply (terminal #2) to

the negative of the PLC power

supply.

+10

to

30V dc

PBT

PBT2

3 4

1 2

1

2

3

4

5

6

7

8

dc com

dc +

P

r

I

o

N

g.

P

U

C

T

t

S

r

l.

Hookup to a Programmable Controller

requiring a current source

Use power blocks with PNP outputs to interface to PLCs and

other logic devices requiring a

current source at the inputs. Connect the output of the power block

(terminal #3) to any input of the

PLC. Also connect the negative

of the MULTI-BEAM power

supply (terminal #2) to the negative of the PLC power supply.

Parallel Hookup to a Common Load

Any number of MULTI-BEAMs may be connected in parallel to one load to create "LIGHT-OR" (light operate

mode) or "DARK-OR" (dark operate mode) multiple sensor logic. In most situations, MULTI-BEAM dc power

blocks cannot wire in series. However, addition of an interposing relay with a normally closed contact or a Banner

logic module will permit "AND" logic with a parallel sensor array.

To load requiring current source:To load requiring current sink:

-

LOAD

LOAD

+10 to 30V dc

PBT

PBT2

3 4

1 2

PBT

PBT2

3 4

1 2

+

3 4

1 2

10 to 30V dc

PBP PBP

3 4

1 2

1

P

2

r

I

3

o

N

4

g.

P

5

U

6

7

8

dc com

dc+

C

T

t

S

r

l.

+10

to

30V dc

PBP

3 4

1 2

Hookup of DC Emitter

MULTI-BEAM emitter-only scanner blocks use dc power

block models PBT-1 or PBT48-1. These power blocks

connect directly across the dc supply, as shown.

Emitter models:

SBE

SBED

SBEX

SBEV

SBEXD

SBEF

SBEXF

PBT-1

1 2

10 to 30V dc

+

16

Page 17

-

t

-

MULTI-BEAM 3- & 4-wire DC Power Blocks

Hookup Diagrams for DC Power Blocks (continued)

Hookup to MAXI-AMP Logic Module

The current sinking output(s) of MULTI-BEAM power block

models PBT and PBT2 may be connected directly to the input

of CL Series MAXI-AMP modules. A MAXI-AMP which is

powered by ac voltage offers a dc supply with enough

capacity to power one MULTI-BEAM sensor, as is shown in

this hookup diagram. When emitter/receiver pairs are used,

the emitter should be powered from a separate power source

(e.g.- using PBA-1, etc.)

54

CL3RA

CL3RB

76

CL5RA

8

CL5RB

The current sinking output(s) of

MULTI-BEAM power block models PBT and PBT2 may be connected directly to the primary input

(terminal #7) or the other inputs of

MICRO-AMP logic modules. The

following logic modules may be

used:

MA4-2 One shot

MA5 On/off delay

MA4G 4-input "AND"

MA4L Latch

9 1011 1 2 3

7

8

1

2

MODEL MPS-15

120

VacNO

Micro-

Amp

Logic

6

5

4

3

Relay

N

C

C

Hookup to B Series Logic Module (MRB Chassis)

PBT

PBT2

3 4

1 2

The current sinking output(s)

of MULTI-BEAM power

block models PBT and PBT-2

may be connected directly to

the input (terminal #5) or the

auxiliary input (terminal #3) of

any Banner B Series logic module. The MULTI-BEAM is

powered by the MRB chassis

as shown. Additional logic

may be added on a longer chassis. Banner PLUG-LOGIC

modules may also be used.

7

8

1

23

+15V dc

7

8

1

23

B-series

Module

120 Vac

6

5

4

6

5

4

MRB

PBT

PBT2

34

12

Hookup to CounterHookup to MICRO-AMP Logic (MPS-15 Chassis)

Most counters, totalizers, rate meters,

NO

NC

PBT

PBT2

3 4

1 2

10 to 30V dc

+

etc., including the battery-powered

LCD types, accept the NPN current

sinking output of MULTIBEAM power block models PBT and PBT2 as an

input. Counters which are

powered by ac line voltage

usually offer a low voltage

dc supply with enough capacity to power one

MULTI-BEAM (≥10V dc

at ≥60mA).

Count or reset inpu

Common

3 4

1 2

10 to 30V dc

+

PBT

PBT2

NOTE: MULTI-BEAM dc power blocks cannot be wired in series.

MULTI-BEAM 3- & 4-wire AC Power Blocks

AC Models

PBA

Input: 105 to 130V ac, 50/60Hz.

PBB

Input: 210 to 250V ac, 50/60Hz.

PBD

Input: 22 to 28V ac, 50/60Hz.

PBD-2

Input: 11 to 13V ac, 50/60Hz.

Output: SPST solid-state switch for ac, 3/4 amp

maximum (derated to 1/2 amp at 70 degrees C).

Maximum inrush: 10 amps for one second or 30

amps for one ac cycle (non-repeating).

On-state voltage drop: less than 2.5V ac at full load.

Off-state leakage current: less than 100 microamps.

Response: add 8.3 milliseconds to the off-time re-

sponse of the scanner block.

L

These power blocks are the most commonly used for ac operation. As the typical hookup

shows, they are intended to switch the same ac voltage as is used to power the MULTI-BEAM.

However, the output of all four blocks is rated for 250V ac maximum, and all can switch a

voltage which is different than the supply as long as both ac circuits share a common neutral.

For example, a PBA could switch a 24V ac door chime, etc. Observe local codes when mixing

ac voltages in a wiring chamber. These blocks are designed to handle the inrush current of ac

inductive loads like motor starters and solenoids. The "holding current" specification of any

inductive load should not exceed the 750mA output rating. There is no minimum load

requirement. These power blocks will interface directly to all ac programmable controller

inputs. All contain built-in transient suppression to prevent false turn-on or damage from

inductive loads and line "spikes". Outputs of multiple power blocks may be wired in series or

parallel for "AND" and "OR" logic functions.

Connections Functional Schematic

L

1

(See Specifications)

3 4

1 2

V ac

2

LOAD

17

Page 18

MULTI-BEAM 3- & 4-wire AC Power Blocks

AC Models

PBAT

Input: 105 to 130V ac, 50/60Hz.

Output: SPST isolated solid-state switch;

100mA maximum (no inrush capacity),

200V dc max., 140V ac max.

On-state voltage drop: less than 3 volts at full

load.

Off-state leakage current: less than

100 microamps.

PBBT

Input: 210 to 250V ac, 50/60Hz.

Output: SPST isolated solid-state switch;

100mA maximum (no inrush capacity),

350V dc max., 250V ac max.

On-state voltage drop: less than 3 volts at full

load.

Off-state leakage current: less than

100 microamps.

PBO

Input: 105 to 130V ac, 50/60Hz.

PBOB

Input: 210 to 250V ac, 50/60Hz.

Connections

L

1

V ac

(See Specifications)

V ac/dc

3 4

1 2

LOAD

L

2

Functional Schematics

Power block models PBAT and PBBT have an isolated solid-state output switch which may be used

to switch either ac or dc. The switch is rated at 100mA maximum, and there is no capacity for inrush.

As a result, these power blocks usually should not be used to switch ac inductive loads. However,

100mA is enough capacity to switch many inductive dc loads like small relays and solenoids. Models

PBAT and PBBT interface directly to all ac programmable controller inputs.

Since the saturation voltage of these power blocks is typically greater than 1 volt, they should not be

used to interface 5V dc logic circuits like TTL. Instead, use special order model PBOL or PBOBL.

add 8.3 milliseconds to the off-time response of the scanner block.

NOTE:

L

1

+

LOAD

V ac

(See Specifications)

V dc

3 4

1 2

L

2

Output: SPST isolated optically coupled

transistor switch (will switch dc only); 50mA

maximum, 30V dc max.

On-state saturation voltage: less than 1 volt at

2mA, less than 1.3 volts at 50mA.

Off-state leakage current: less than 10

microamps.

PBAM

Input: 105 to 130V ac, 50/60Hz.

Output: 8Vdc at 8mA maximum (short

circuit proof).

If you are unable to find the power

block for your interface, contact

the Banner Application Engineering Department during normal

business hours at (612) 544-3164.

These power blocks are designed to interface an electronic circuit (or control) at a low dc voltage level, but

where there is no dc supply voltage available to power the MULTI-BEAM. Since the output is isolated

it may be wired to either source or sink current, and multiple units may be wired in either series or parallel.

The output of model PBO or PBOB will directly interface Banner component system logic modules. The

low on-state saturation voltage allows direct interfacing to most solid-state low voltage dc logic systems

or electronic totalizers.

Note: the 1-volt saturation prevents direct interfacing to 5-volt logic systems like TTL. For these lowvoltage interfaces, use instead special order power block model PBOL or PBOBL.

+

Low Voltage

Sonalert

-

L

2

L

1

V ac

3 4

1 2

Model PBAM is a special-purpose power block that is powered by 120V ac, and provides a low level source

of dc output voltage when the sensor's output is energized. It is used primarily to power low voltage audio

tone annunciators such as "SONALERTS". The PBAM may also provide a signal to many types of logic

devices. The output is approximately 8V dc when energized, and the output impedance is 1K ohm (short

circuit proof). The output is totally isolated from the ac supply voltage, and may be used to provide an input

signal to many line-powered or battery-powered electronic totalizers.

18

Page 19

MULTI-BEAM 3- & 4-wire AC Power Blocks

AC Models

PBAQ

Input: 105 to 130V ac, 50/60Hz.

Output: SPST isolated solid-state switch; nor-

mally closed, 3/4 amp maximum (derated to 1/2

amp at 70 degrees C).

Maximum inrush: 10 amps for one second or 30

amps for one ac cycle (non repeating).

On-state voltage drop: less than 2.5V ac at full

load.

Off-state leakage current: less than 100

microamps.

Response: add 8.3 milliseconds to the off-time

response of the scanner block.

NOTE: the output of the PBAQ will not conduct

when power is removed from terminal #1 or 2.

These are power blocks for emitter scanner

blocks only (models SBE, SBED, SBEX, SBEV,

SBEXD, SBEF, SBEXF). Emitter assemblies

do not require logic modules.

PBA-1

Input: 105 to 130V ac, 50/60Hz.

Connections Functional Schematics

LOAD

L

2

L

2

L

1

V ac

3 4

1 2

Model PBAQ is identical to model PBA (page 17) except that the solid-state output contact is

normally closed instead of normally open. It is used where it is necessary to have the load deenergize when something is sensed (e.g.- one shot pulse to de-energize load). When no timing

logic is involved, model LM3 can program any power block for normally open or normally

closed operation via the light/dark operate jumper. NOTE: model PBAQ is not comaptible

with logic module models LM5 and LM5-14. For normally closed on-delay logic, use PBA

with LM5R and reverse the light/dark function.

L

1

V ac

(See Specifications)

PBB-1

Input: 210 to 250V ac, 50/60Hz.

1 2

PBD-1

Input: 22 to 28V ac, 50/60Hz.

Hookup Diagrams for AC Power Blocks

NOTE: output switching capacity

is 3/4 amp maximum.

AC voltage is connected to terminals #1 and #2 to provide power to the MULTI-BEAM. The solid-state output

switch behaves as if there were a contact between terminals #3 and #4. L1 is most conveniently applied to

terminal #3 by jumpering terminals #1 and #3 inside the MULTI-BEAM.

The outputs of all five power block models are rated

for 250V ac maximum, and can switch an ac voltage

which is different from the supply as long as both ac

circuits share a common neutral. Observe local

wiring codes when mixing AC voltages in a common

wiring chamber.

Since the output switch is a solid-state device, contact continuity cannot be checked by means of an

ohmeter, continuity tester, etc. To check the functioning of the output switch, a load must be installed

and tested along with the MULTI-BEAM.

CAUTION: the output switch could be destroyed if

the load becomes a short circuit (i.e., if L1 and L2 are

connected directly across terminals #3 and #4).

NOTE: this hookup depicts the output switch as a

normally open contact. Model PBAQ actually has a

normally closed output switch.

L1 L2

PBA

PBB

PBD

PBD2

PBAQ

V ac

(See Specifications)

3 4

1 2

LOAD

Hookup of an AC EmitterHookup to a Simple AC Load

MULTI-BEAM emitter-only ac power blocks connect directly

across the ac line, as shown.

Emitter models: SBE, SBED, SBEX, SBEV, SBEXD, SBEF,

and SBEXF.

L1 L2

V ac

(See Specifications)

PBA-1

PBB-1

PBD-1

1 2

19

Page 20

MULTI-BEAM 3- & 4-wire AC Power Blocks

t

s

Hookup Diagrams for AC Power Blocks (continued)

Hookup in Parallel with other MULTI-BEAMs

Any number of 3- & 4-wire

MULTI-BEAM power block

outputs may be connected in

parallel to a load. Parallel sensor connection is usually used to

yield "OR" logic (i.e., if an event

occurs at any sensor, the load is

energized).The total off-state

leakage current through the load

is the sum of the leakage current

of the individual power blocks.

However, the maximum leakage current of MULTI-BEAM

3- & 4-wire ac power blocks is

only 100 microamps. As a result, installation of an artificial

load resistor in parallel with the

load is necessary only for large

numbers of sensors wired in parallel to a light load.

L1 L2

PBA

PBB

PBD

PBD2

PBAQ

PBA

PBB

PBD

PBD2

PBAQ

V ac

(See Specifications)

3 4

1 2

3 4

1 2

LOAD

Hookup in Parallel with Contacts or Switches

Any number of "hard" contacts

may be wired in parallel with

one or more MULTI-BEAM

3- & 4-wire power blocks. All

models have less than 100

microamps (0.1 milliamp) of

off-state leakage current. The

load operates when either the

contacts close or the MULTIBEAM output is energized.

L1 L2

PBA

PBB

PBD

PBD2

PBAQ

START

V ac

(See Specifications)

CR

3 4

1 2

STOP

CR

Hookup to a Programmable Logic Controller (PLC)

Interfacing to a PLC I/O is direct with MULTI-BEAM 3- & 4-wire ac power

blocks. All models have less than 100 microamps (0.1 milliamp) of off-state

leakage current. If you have a question on hookup to a particular brand of

PLC, contact the Banner Applications Department during normal business

hours.

Hookup in Series with other MULTI-BEAMs

MULTI-BEAM 3- & 4-wire ac power blocks may be wired in series with

each other for the "AND" logic function. The total voltage drop across the

series will be the sum of the individual voltage drops across each power

block (approximately 3 volts per block). With most loads, 10 or more

power blocks may be wired in series.

L1 L2

V ac

(See Specifications)

PBA

PBB

PBD

PBD2

PBAQ

3 4

1 2

3 4

1 2

LOAD

Hookup in Series with Contacts or Switches

Terminals #3 and #4 of

MULTI-BEAM 3- & 4-wire