Page 1

EZ-SCREEN® Type 2 Light Screen Instruction Manual

122452 rev. B 3/2/2011

Original Instructions

Page 2

Contents

Contents

About This Document ............................................................................................................................4

Important . . . Read This Before Proceeding! ...................................................................................................................4

Introduction ............................................................................................................................................5

Features ..........................................................................................................................................................................5

System Description ..........................................................................................................................................................5

Appropriate Applications and Limitations ........................................................................................................................7

Control Reliability and Safety Categories .........................................................................................................................8

Operating Features ..........................................................................................................................................................9

Mechanical Installation ........................................................................................................................12

Pre-Installation Considerations ......................................................................................................................................12

Mounting System Components ......................................................................................................................................23

Electrical Installation and Testing ......................................................................................................26

Routing Cordsets ............................................................................................................................................................26

Initial Electrical Connections ..........................................................................................................................................27

Initial Checkout Procedure .............................................................................................................................................28

Electrical Connections to the Guarded Machine ...........................................................................................................34

Reference Wiring Diagrams ...........................................................................................................................................40

System Operation .................................................................................................................................43

Security Protocol ...........................................................................................................................................................43

Reset Procedures ..........................................................................................................................................................43

Status Indicators ............................................................................................................................................................44

Use of Warnings and Cautions ................................................................................................................................4

EC Declaration of Conformity (DOC) ......................................................................................................................4

Examples: Appropriate Applications .......................................................................................................................8

Examples: Inappropriate Applications ....................................................................................................................8

Trip/Latch Output ....................................................................................................................................................9

Wiring Options for Emitter/Receiver Swapability ..................................................................................................10

Manual Reset/Remote Test Input and EDM .........................................................................................................10

Status Indicators ...................................................................................................................................................11

Calculating the Safety Distance (Minimum Distance) ............................................................................................13

Reducing or Eliminating Pass-Through Hazards ..................................................................................................17

Supplemental Safeguarding .................................................................................................................................17

Other Considerations .............................................................................................................................................18

Overview of Emitter/Receiver Mounting Hardware ................................................................................................23

Mounting and Initial Alignment of Emitter/Receiver Pairs ......................................................................................24

Configuring the System for Initial Checkout ..........................................................................................................29

Initial Power-Up ....................................................................................................................................................29

Optical Alignment ..................................................................................................................................................31

Trip Test ................................................................................................................................................................32

OSSD Output Connections ...................................................................................................................................34

FSD Interfacing Connections ................................................................................................................................35

Machine Primary Control Elements ......................................................................................................................36

Manual Reset/Remote Test Input and EDM .........................................................................................................36

Preparing for System Operation ...........................................................................................................................38

Commissioning Checkout .....................................................................................................................................38

Generic Emitter Wiring Diagram ...........................................................................................................................40

Generic Wiring to FSDs (manual reset) ................................................................................................................41

Generic Wiring — Interface Module (2-Channel EDM, Manual Reset) ................................................................42

Receiver Resets ...................................................................................................................................................43

Emitter Resets ......................................................................................................................................................44

2 122452 rev. B

Page 3

Contents

Emitter ..................................................................................................................................................................44

Receiver ................................................................................................................................................................44

Normal Operation ..........................................................................................................................................................45

System Power-Up .................................................................................................................................................45

Run Mode .............................................................................................................................................................45

Manual Reset Procedure ......................................................................................................................................46

Periodic Checkout Requirements ..................................................................................................................................46

Troubleshooting and Maintenance .....................................................................................................47

Troubleshooting and Lockout Conditions ......................................................................................................................47

Recovery Procedures ....................................................................................................................................................47

Receiver (System Reset) ......................................................................................................................................47

Emitter Reset ........................................................................................................................................................47

Electrical and Optical Noise ...........................................................................................................................................49

Sources of Electrical Noise ...................................................................................................................................49

Sources of Optical Noise ......................................................................................................................................49

Servicing and Maintenance ............................................................................................................................................49

Cleaning ................................................................................................................................................................49

Warranty Service ..................................................................................................................................................50

Disposal .................................................................................................................................................................50

Checkout Procedure Schedule ...........................................................................................................51

Schedule of Checkouts ..................................................................................................................................................51

Specifications and Accessories .........................................................................................................52

Specifications .................................................................................................................................................................52

General Specifications ..........................................................................................................................................52

Emitter Specifications ...........................................................................................................................................53

Receiver Specifications ........................................................................................................................................53

Emitter and Receiver Dimensions .........................................................................................................................54

Bracket Dimensions ...............................................................................................................................................55

Accessories ...................................................................................................................................................................57

Cordsets ................................................................................................................................................................57

Interface Modules ..................................................................................................................................................60

Contactors ............................................................................................................................................................60

Lens Shield ............................................................................................................................................................60

EZ-LIGHT™ for EZ-SCREEN® ...........................................................................................................................61

MSA Series Stands (Base Included)* ...................................................................................................................62

MSM Series Corner Mirrors ..................................................................................................................................62

SSM Series Corner Mirrors ...................................................................................................................................63

Accessory Mounting Brackets ..............................................................................................................................64

Alignment Aids ......................................................................................................................................................65

Replacement Parts ...............................................................................................................................................65

Documentation ......................................................................................................................................................65

Standards and Regulations .................................................................................................................66

U.S. Application Standards ............................................................................................................................................66

OSHA Regulations .........................................................................................................................................................66

International/European Standards ..................................................................................................................................66

Sources of Standards and Regulations ..........................................................................................................................67

Contact Us .....................................................................................................................................................................67

Glossary ................................................................................................................................................68

3

Page 4

EZ-SCREEN® Type 2 Light Screen Instruction Manual

About This Document

Important . . . Read This Before Proceeding!

It is the responsibility of the machine designer, controls engineer, machine builder and/or maintenance electrician to apply and maintain

this product in full compliance with all applicable regulations and standards. The product can provide the required safeguarding function

only if it is properly installed, properly operated, and properly maintained. This manual attempts to provide complete installation, operational, and maintenance instruction. Reading the manual completely is highly recommended. Please direct any questions regarding the

application or use of the product to the Banner Engineering Applications at the locations listed here.

For more information regarding U.S. and international institutions that provide safeguarding application and safeguarding product performance standards, see the following sections.

WARNING: User Responsibility

The user is responsible to:

• Carefully read, understand and follow the information in all documentation for this product.

• Perform a risk assessment of the specific machine guarding application.

• Determine what safeguarding devices and methods are appropriate per the requirements defined in

EN ISO 13849-1 and other appropriate standards.

• Create and confirm each configuration and then verify that the entire safeguarding system (including

input devices and output devices) is operational and working as intended.

• Periodically re-verify as needed, that the entire safeguarding system is working as intended.

Failure to follow any of these recommendations can potentially create a dangerous condition that

may lead to serious injury or death.

Use of Warnings and Cautions

This manual contains numerous WARNING and CAUTION statements:

• Warnings refer to situations that could lead to significant or serious personal injury or death.

• Cautions refer to situations that could lead to slight personal injury or potential damage to equipment.

Warnings are intended to remind the machine designer, control engineer, machine builder, maintenance electrician, or end user how to

avoid misapplication of this product and effectively apply the EZ-SCREEN Type 2 to meet the various safeguarding application requirements. You must read and abide by the warnings.

EC Declaration of Conformity (DOC)

Banner Engineering Corp. herewith declares that the EZ-SCREEN Type 2 Light Screen is in conformity with the provisons of the Machinery Directive (Directive 2006/42/EC) and all essential health and safety requirements have been met. For more information, visit

www.bannerengineering.com/EZSCREEN.

4 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 5

Introduction

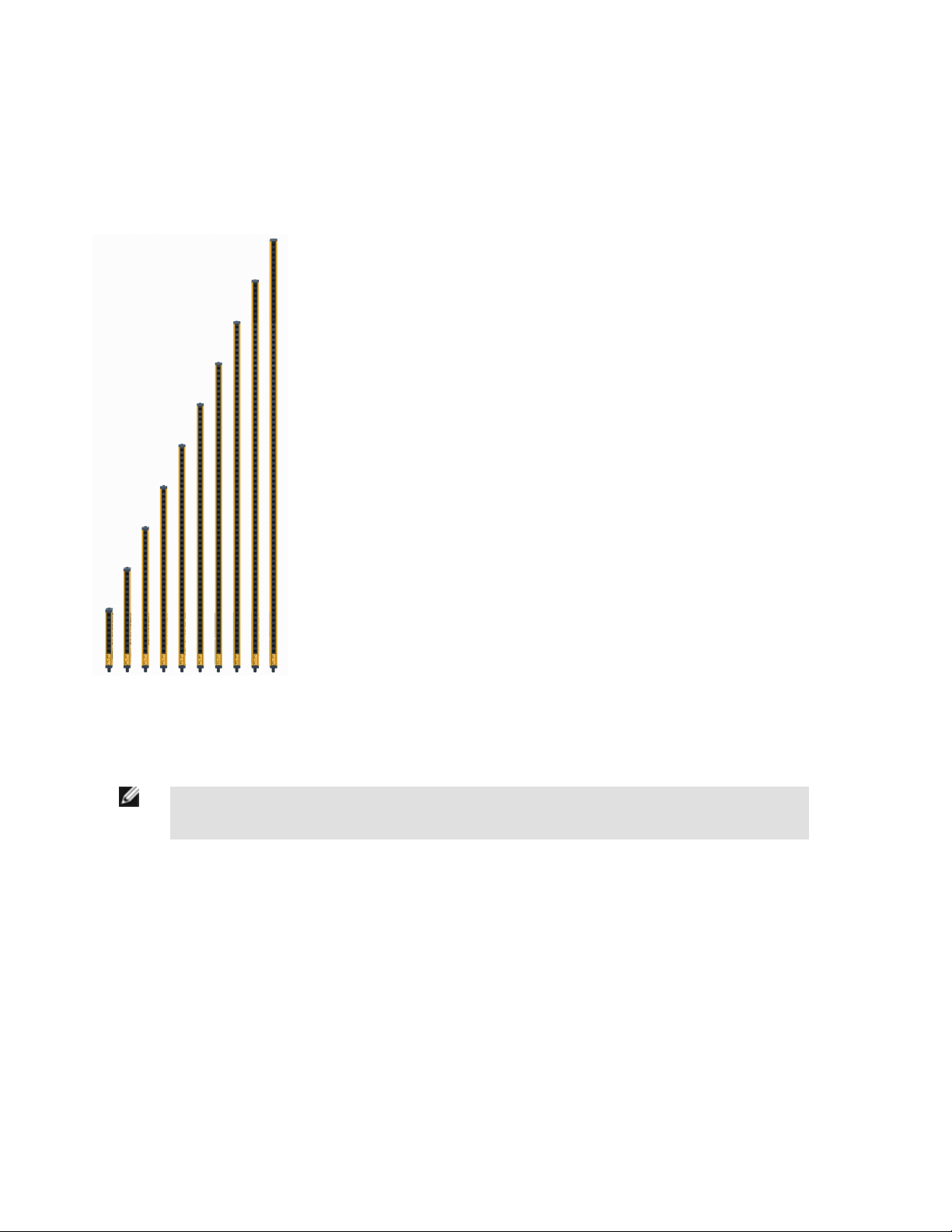

Features

• An optoelectronic safeguarding device

• Creates a screen of synchronized, modulated infrared sensing beams. Choose from 10

sizes, in 150 mm (6") increments: defined areas from 150 mm to 1.8 m (6" to 71")

• Compact package for smaller production machines

• Models available with Trip or Latch output operation (automatic or manual start/restart)

• 30 mm (1.18") resolution

• Remote Test input terminals for simulating a "blocked" condition

• Operating range up to 15 m (50')

• Type 2 per IEC 61496-1/-2; Category 2 PLd per EN ISO 13849-1

• FMEA tested according to IEC 61496-1, Type 2 requirements

• Receiver LEDs provide system status and emitter/receiver alignment indications

• Highly immune to EMI, RFI, ambient light, weld flash, and strobe light

• Two-piece design

• Vibration-tolerant, factory burned-in emitter and receiver circuitry for toughness and dependability

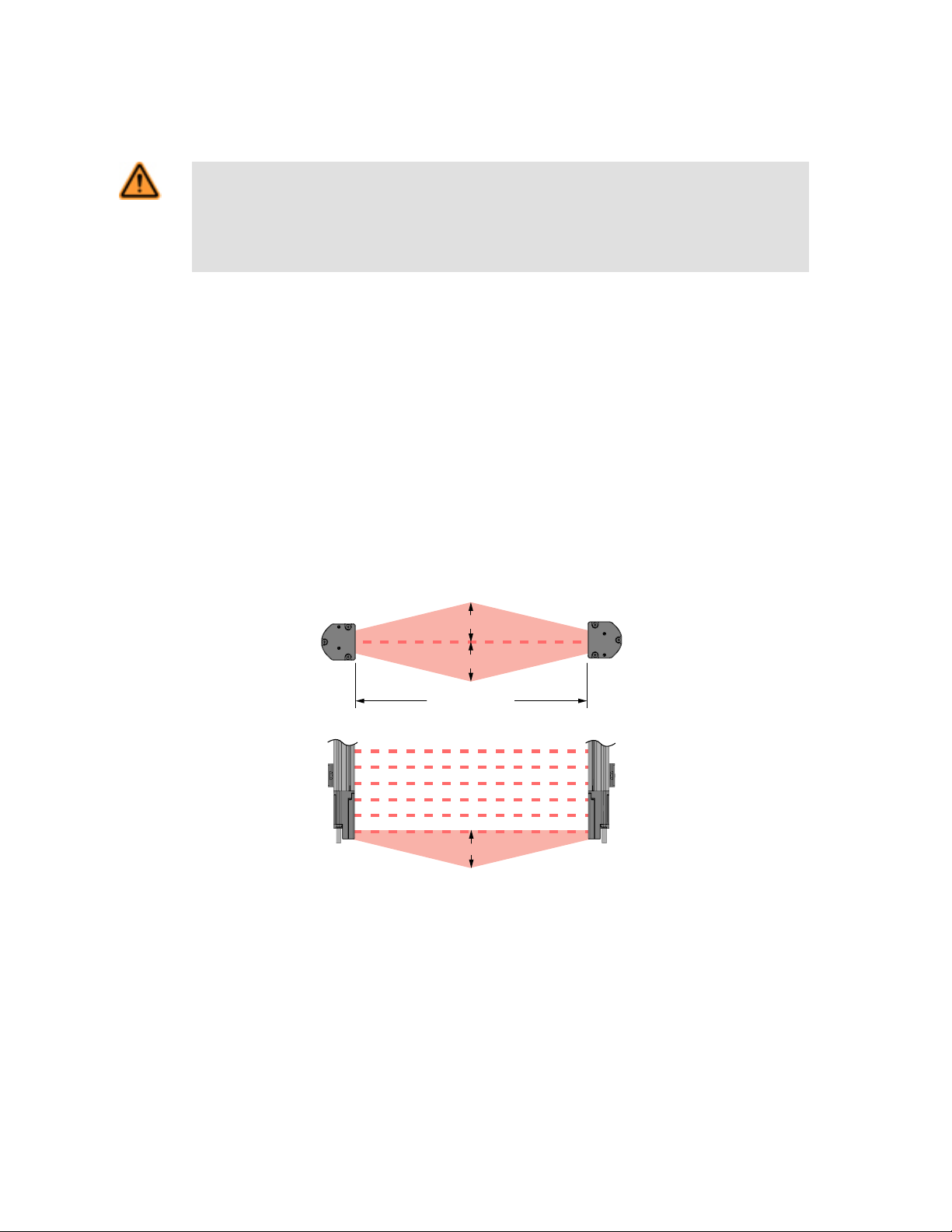

System Description

NOTE: A “System” as referred to in this manual may be defined as an emitter and its receiver, plus their ca-

bling.

Banner EZ-SCREEN Type 2 emitters and receivers provide a redundant, microprocessor-controlled, opposed-mode optoelectronic "curtain of light," or "light screen." EZ-SCREEN Type 2 typically is used for point-of-operation safeguarding, and is suited to safeguard a

variety of lower-risk machinery.

The EZ-SCREEN Type 2 is a two-piece (“two-box”) system – comprising an emitter and a receiver, but no external controller. The external device monitoring (EDM) function ensures the fault detection capability required by EN ISO 13849-1 Category 2.

The EZ-SCREEN Type 2 emitters have a row of synchronized modulated infrared (invisible) light-emitting diodes (LEDs) in a compact

metal housing. Receivers have a corresponding row of synchronized photodetectors. The light screen created by the emitter and receiver

is called the “defined area”; its width and height are determined by the length of the sensor pair and the distance between them. The lowprofile housing provides maximum sensing within minimum space; its defined area (sensing area) is equivalent to the height of the housing. The maximum range is 15 m (50'), which decreases if corner mirrors are used. Resolution is 30 mm (1.18")..

Both emitter and receiver feature LEDs to provide continuous indication of the System’s operating status, alignment and error conditions.

122452 rev. B

www.bannerengineering.com - tel: 763-544-3164 5

Page 6

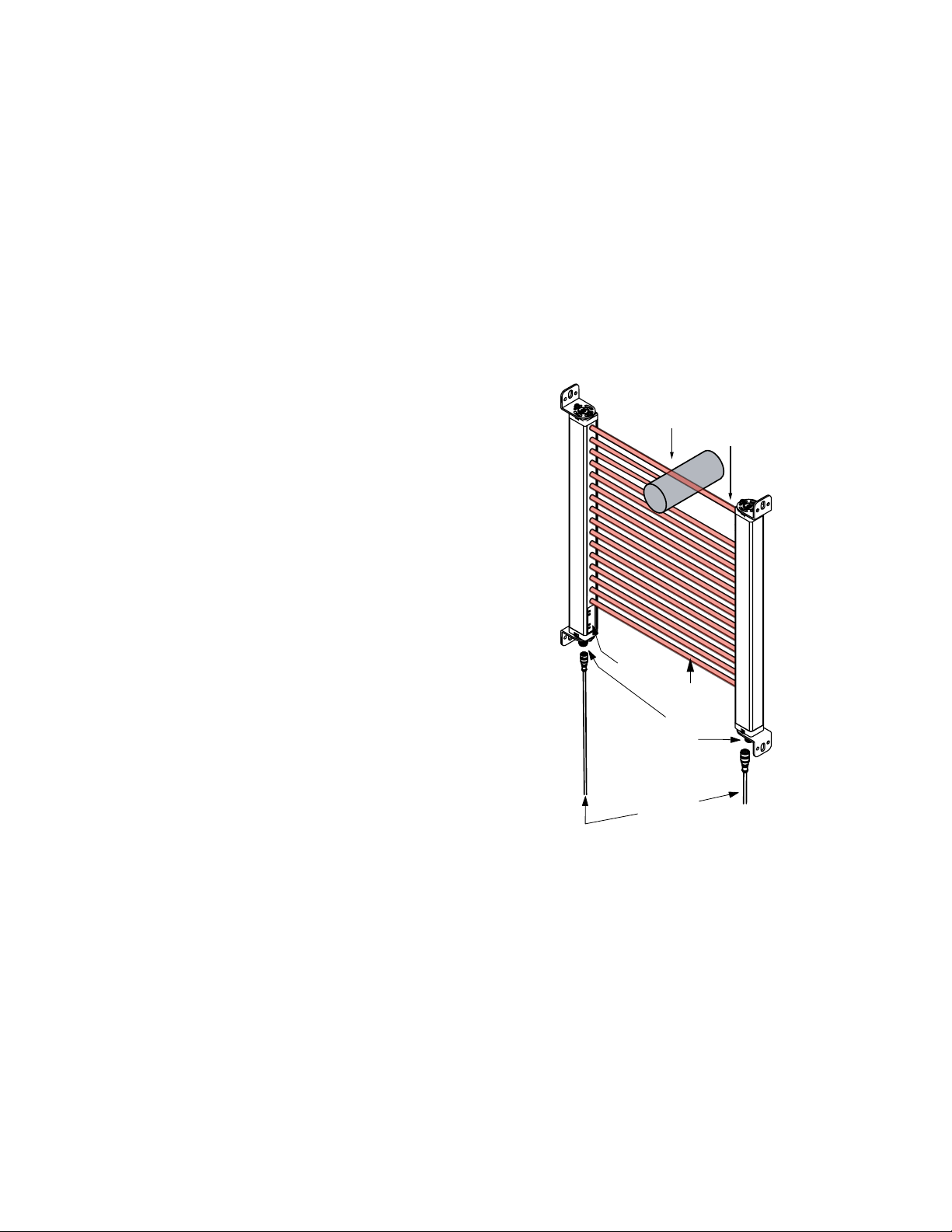

Quick-Disconnect

Cables

M12 QD

Fittings

Defined

Area

Emitter

Specified Test Piece

Synchronization

Beam

Receiver

Status

Indicators

EZ-SCREEN® Type 2 Light Screen Instruction Manual

In typical operation, if any part of an operator’s body (or any opaque object) of more than a pre-determined cross section is detected, the

solid-state Output Signal Switching Device (OSSD) safety outputs will turn OFF. These safety outputs are connected to the guarded

machine’s Final Switching Devices (FSDs) that control the machine primary control elements (MPCEs), which immediately stop the motion of the guarded machine.

Both OSSD outputs must be connected to the machine control so that the machine’s safety-related control system interrupts the circuit or

power to the MPCEs (Machine Primary Control Elements), resulting in a non-hazardous condition. Each OSSD is capable of sourcing

0.5A at +24V dc.

The OSSD safety outputs are not capable of performing a “handshake” communication with the Muteable Safety Stop Interface (MSSI) or

Universal Safety Stop Interface (USSI) found on other Banner Engineering safety products.

EZ-SCREEN Type 2 is extensively FMEA (Failure Mode and Effects Analysis) tested to IEC 61496-1/-2 requirements. The design of the

EZ-SCREEN Type 2 has considered all single faults such that a loss of a critical safety function will result in a stop command and a

lockout condition. In the event of an accumulation of undetected faults, a remote external test (or check) is required to maintain the safety

function.

Electrical connections are made through M12 (or Euro-style) quickdisconnects. An optional hookup that provides sensor interchangeability (or “swapability”) – the ability to install either sensor at either

QD connection – is possible. Using a parallel connection (color-forcolor), the emitter cable can be connected to the receiver cable,

providing the ability to swap the emitter and receiver position, similar to a popular feature of Banner MINI-SCREEN® safety light

screens. This hookup option provides advantages during installation, wiring, and troubleshooting.

All models require a supply voltage of +24V dc ±20%.

Figure 1. Banner EZ-SCREEN Type 2: emitter, receiver, and

two interconnecting cables

6 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 7

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Appropriate Applications and Limitations

WARNING: Read this Section Carefully Before Installing the System

If all mounting, installation, interfacing, and checkout procedures are not followed properly, the EZSCREEN Type 2 cannot provide the protection for which it was designed. The user has the responsibility

to ensure that all local, state, and national laws, rules, codes, or regulations relating to the installation and

use of this control system in any particular application are satisfied. Extreme care should be taken to ensure that all legal requirements have been met and that all technical installation and maintenance instructions contained in this manual are followed.

The user has the sole responsibility to ensure that this EZ-SCREEN Type 2 is installed and interfaced to

the guarded machine by Qualified Persons, in accordance with this manual and applicable safety regulations.

The Banner EZ-SCREEN Type 2 is intended for lower-risk machine guarding applications and other safeguarding applications, as determined by a risk assessment. It is the user’s responsibility to verify whether the safeguarding is appropriate for the application and is

installed, as instructed by this manual, by a Qualified Person (as defined in the Glossary).

CAUTION: Install System Only on Appropriate Applications

Banner EZ-SCREEN Type 2 are for use only on machinery that can be stopped immediately after a stop

signal is issued at any point in the machine's stroke or cycle, such as part-revolution clutched machines.

Under no circumstances may the EZ-SCREEN Type 2 be used on full-revolution clutched machinery or in

unsuitable applications as those listed. If there is any doubt about whether or not your machinery is

compatible with the EZ-SCREEN Type 2, contact Banner's Application Engineers at the factory.

CAUTION: Use of EZ-SCREEN Type 2

EZ-SCREEN Type 2 meets the Type 2 requirements of IEC 61496 and Category 2 PLd requirements of

EN ISO 13849-1. DO NOT use EZ-SCREEN Type 2 unless it is installed, tested, and inspected in accordance with this manual. DO NOT use EZ-SCREEN Type 2 where Control Reliability is required, or where

Category 3, Category 4, or Type 4 AOPD (active opto-electronic protective device) have been mandated,

or where a risk assessment has determined that frequent access by personnel to the hazard could result

in an irreversible or serious injury (for example, OSHA reportable injury).

Typical use is for safeguarding in situations where the consequence of an accident will result in only slight

(normally reversible) injuries that are typically treated by the normal healing processes and minor medical

treatment (that is, first aid, as defined by OSHA 29CFR1904.7).

Failure to follow these instructions could result in serious bodily injury or death.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 7

Page 8

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Examples: Appropriate Applications

EZ-SCREEN Type 2 are typically used, but is not limited to, the following applications (dependent on machine risk assessment):

• Small assembly equipment

• Automated production equipment

• "Table-top" robotic work cells

• Component insertion/"pick-and-place" machines

• Small packaging machines

• Equipment and process protection (non-personnel safety

• Applications that could result in only slight (normally reversible) injuries (such as bump, bruise, knock-down, trapping but not crushing, minor cuts and abrasions, etc.)

Examples: Inappropriate Applications

EZ-SCREEN Type 2 may NOT be used with the following machinery or inappropriate applications:

• As a primary safeguard in frequently accessed hazardous situations that could result in serious injuries (normally irreversible, including death).

• In any case where Control Reliability, Category 3, Category 4, or Type 4 AOPD (active opto-electronic protective device) have been

mandated. See EN ISO 13849-1, IEC 61496-1, or other appropriate standard.

• Any machine that cannot be stopped immediately after a stop signal is issued, such as single-stroke (or “full-revolution”) clutched

machinery.

• Any machine with inadequate or inconsistent machine response time and stopping performance.

• Any machine that ejects materials or component parts through the defined area.

• In any environment that is likely to adversely affect photoelectric sensing efficiency. For example, corrosive chemicals or fluids or

unusually severe levels of smoke or dust, if not controlled, may degrade sensing efficiency.

• As a tripping device to initiate or reinitiate machine motion (PSDI applications), unless the machine and its control system fully comply

with the relevant standard or regulation (see ISO 12100-2, IEC 60204-1, IEC 61496-1, or other appropriate standard).

If an EZ-SCREEN Type 2 is installed for use as a perimeter guard (that is, where a pass-through hazard may exist), the dangerous

machine motion can be initiated by normal means only after the safeguarded area is clear of individuals and the EZ-SCREEN Type 2 has

been manually reset.

Control Reliability and Safety Categories

To summarize the expected safety circuit performance in high-risk situations, requirements of Control Reliability (OSHA 29CFR1910.217,

ANSI B11.19, and ANSI/RIA R15.06) and Category 3 and Category 4 (EN ISO 13849-1) demand that a reasonably foreseeable, single

failure does not lead to the loss of the safety function, and does not prevent a normal or immediate stop from occurring. The failure or the

fault must be detected at or before the next demand of safety (e.g., at the beginning or end of a cycle, or when a safeguard is actuated).

The safety-related part of the control system then must issue an immediate stop command, or prevent the next machine cycle or hazardous situation until the failure or fault is corrected.

The effect of ANSI/RIA R15.06, ANSI B11.19, and EN ISO 13849-1 is to set a baseline for situations in which a minimum level of performance has been mandated or in cases where a risk assessment has determined a need for Control Reliability, Category 3 or Category

4 level of performance.

In lower-risk safety applications, safeguards and safety circuits do not require the level of performance and fault tolerance described by

Control Reliability, Category 3 or Category 4. Applications involving situations that could result in a slight or normally reversible injury

(e.g., only requiring first aid, as defined by OSHA 29CFR1904) can be solved by EN ISO 13849-1 Category 2.

EN ISO 13849-1 Category 2 does not require the same level of performance and fault tolerance as required by Control Reliability, Category 3 or Category 4. Safety-related parts of control systems designed to Category 2 “shall be designed so that their function(s) are

checked at suitable intervals by the machine control system.” This allows a single fault to lead to the loss of the safety function between

the check [test] of the system, but the loss of safety function is detected by the check. By comparison, in a system designed to EN ISO

13849-1 Category 4, a single fault or an accumulation of faults will not lead to a loss of the safety function.

While EN ISO 13849-1 generally applies to the machine level, IEC61496-1/-2 specifies requirements for the design, construction and

testing for two levels or “types” of active opto-electronic protective devices (AOPDs) or light curtains (light screens). “Type 2” and “Type

8 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 9

EZ-SCREEN® Type 2 Light Screen Instruction Manual

4” describe differing requirements to ensure that appropriate safety-related performance is achieved. The appropriate type is dependent

on the overall degree of risk reduction, as determined by the machine’s Risk Assessment (see ISO 14121, ANSI B11.19, ANSI/RIA

R15.06).

A Type 2 AOPD relies on periodic testing to detect a failure to danger. Between tests, a single fault can result in the loss of the safety

function. While this level of performance and fault tolerance is generally not allowed in Category 4 situations, it is acceptable in the lowerrisk situations described by Category 2.

While the EZ-SCREEN Type 2 conducts continual internal self-tests and all single faults have been considered, the installation should

provide an additional periodic test/check of the EZ-SCREEN Type 2 and its interface to ensure the integrity of the safety function (see

Manual Reset/Remote Test Input and EDM on page 36). A component failure detected by periodic test/check must cause a “stop”

signal to be sent to the guarded machine and put the System into a Lockout condition.

Recovery from this type of Lockout condition requires:

• Replacement of the failed component (to restore the safety function)

• The appropriate reset procedure.

Operating Features

The Banner EZ-SCREEN Type 2 Light Screen models described by this manual feature standard selectable functions:

• Trip or Latch Output (depending on model)

• External Device Monitoring (EDM) via the Test/Retest input

The System Response Time (Tr) can be determined by the model number on the emitter and receiver.

Trip/Latch Output

Whether a receiver features Trip or Latch Output determines whether the System will enter RUN mode automatically after power-up, or if

it will require a manual reset first. If the System has Trip Output, other measures must be taken to prevent a pass-through hazard.

For Latch Output models, the EZ-SCREENEZ-SCREENEZ-SCREEN Type 2 requires a manual reset for the OSSD outputs to turn ON,

after power is applied and all beams are clear.

• For Trip Output models, the OSSD outputs will turn ON after power is applied and the receiver passes its internal self-test/synchronization and recognizes that all beams are clear. Trip Output models will also automatically reset after all beams are cleared.

• For Latch Output models, the EZ-SCREEN Type 2 requires a manual reset for the OSSD outputs to turn ON, whenever power is

applied and all beams are clear.

WARNING: Use of Trip/Latch Output

Application of power to the EZ-SCREEN Type 2, the clearing of the defined area, or the reset of a Latch

condition MUST NOT initiate dangerous machine motion. Machine control circuitry must be designed so

that one or more initiation devices must be engaged (i.e., a conscious act) to start the machine – in addition to the EZ-SCREEN Type 2 going into RUN mode. Failure to follow these instructions could result in an

increased risk of harm.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 9

Page 10

D

C

A

B

EZ-SCREEN® Type 2 Light Screen Instruction Manual

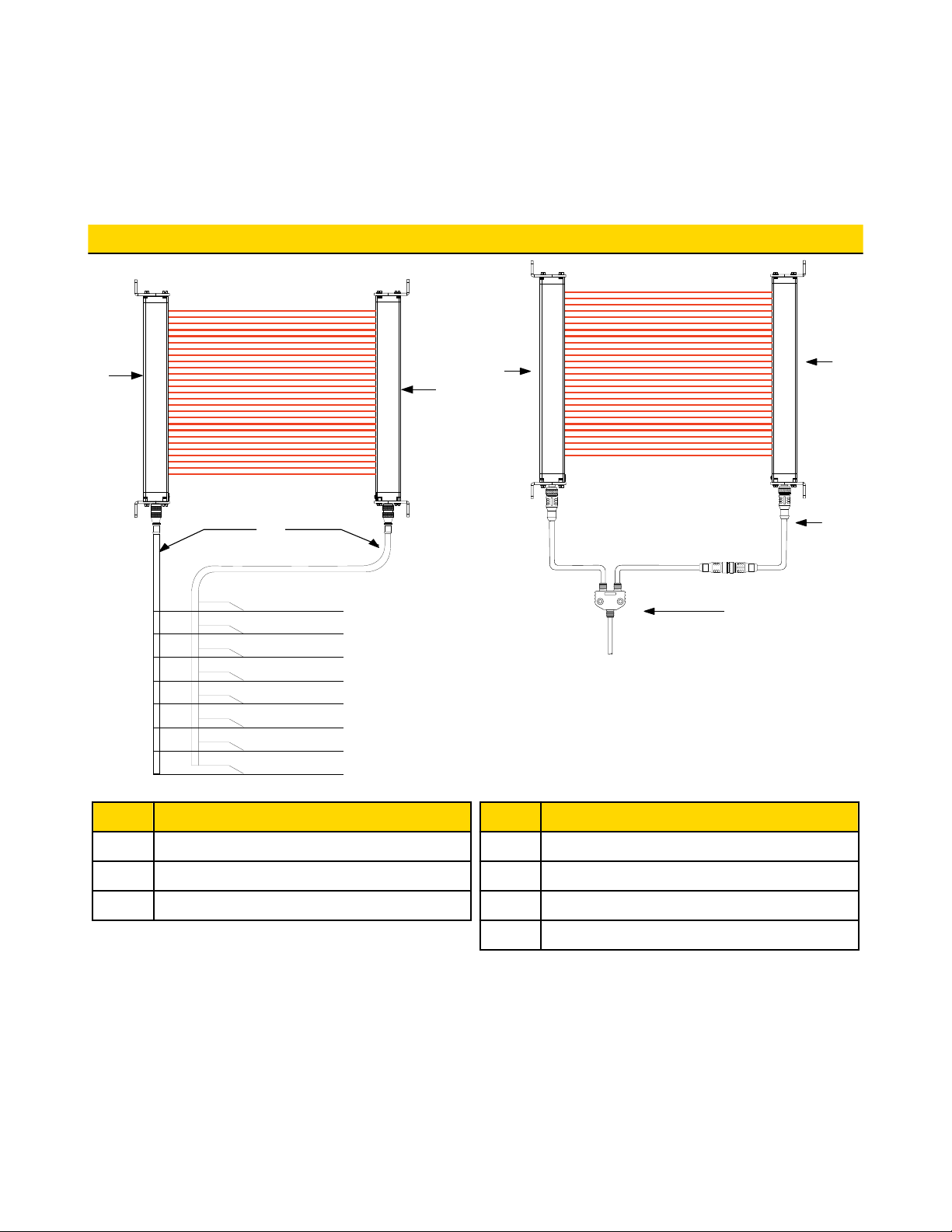

Wiring Options for Emitter/Receiver Swapability

Each EZ-SCREEN Type 2 sensor can be connected to its own power supply or, color-for-color to the other sensor’s cable. The color-forcolor hookup allows the emitter and receiver positions to be interchanged without rewiring (functionality known as sensor " swapability").

Model CSB.. splitter cordsets and DEE2R.. double-ended cables facilitate interconnection between an EZ-SCREEN Type 2 receiver and

emitter, providing a single "homerun" cable for optional swapable hookup.

Individual Cordsets Splitter Cordsets

EZ-SCREEN Type 2

A

Key Description

C

Bn

Or/Bk

Or

Wh

Bk

Bu

Gn/Ye

Vi

B

+24V dc

n.c.

n.c.

OSSD2

OSSD1

0V dc

Ground

Reset/Test & EDM

Key Description

A Emitter

B Receiver

C QDE-8..D Cordsets

A Emitter

B Receiver

C DEE2R.. Cordsets

D CSB.. Cordsets

Manual Reset/Remote Test Input and EDM

A single input provides the means to reset the system from a latch or lockout condition, to externally test the light screen and its interface,

and to monitor external devices (EDM) for proper operation. If the System is in Run condition with outputs ON, operating the switch

results in a test. If the System is Latched or Locked Out, operating the switch results in a reset.

10 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 11

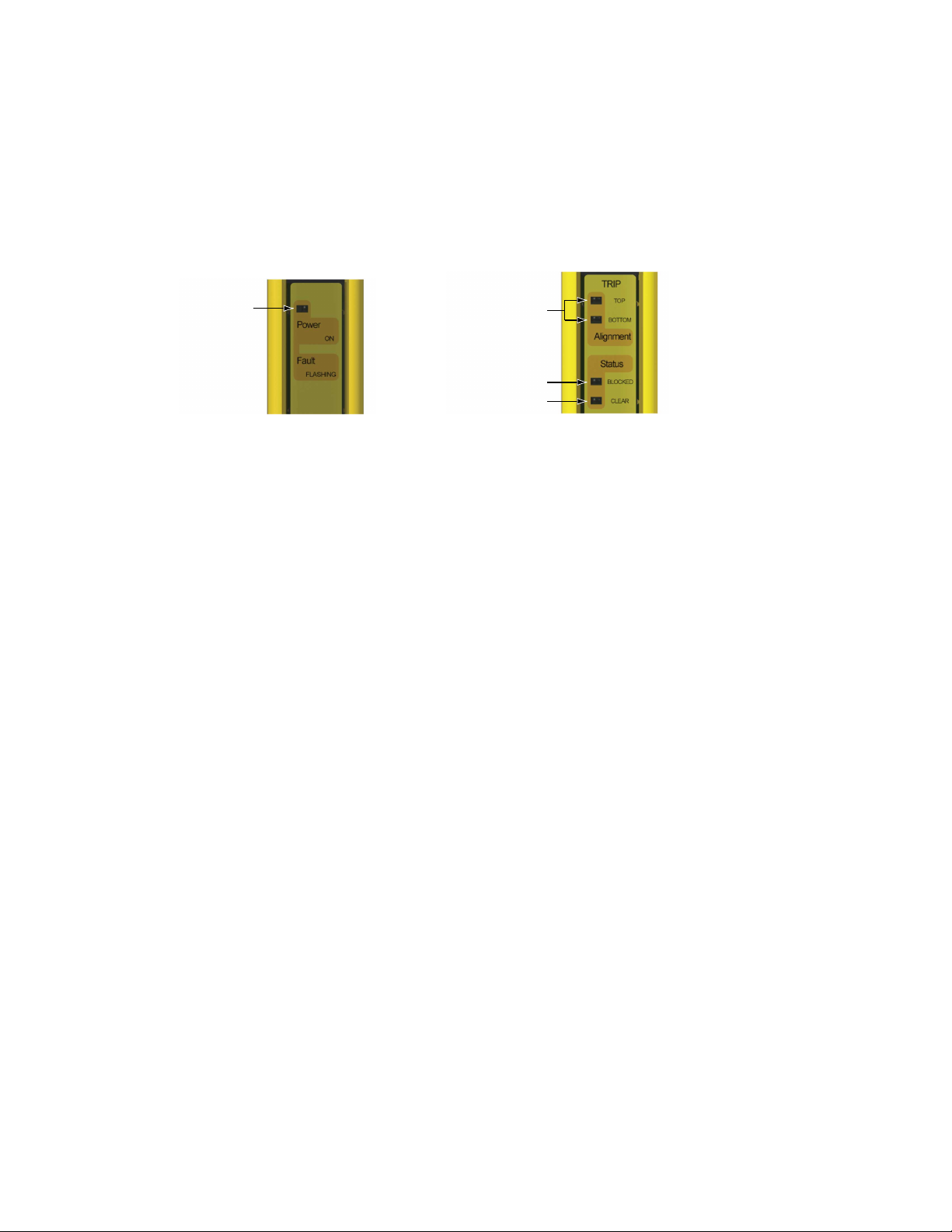

Power/Fault LED (Green)

Alignment LEDs

(Yellow)

Status Blocked LED (Red)

Status Clear LED (Green)

EZ-SCREEN® Type 2 Light Screen Instruction Manual

External Device Monitoring (EDM)

This feature allows the EZ-SCREEN Type 2 system to monitor the status of external devices such as MPCEs. The EDM used in this

system is similar to Power Monitoring employed by MINI-SCREEN safety light screens. A normally closed and a normally open contact

from each monitored device are wired in series-parallel to detect if one of the devices fails.

Status Indicators

Status indicators on both the emitter and receiver are clearly visible on each sensor’s front panel.

Figure 2. EZ-SCREEN Type 2 emitter and receiver status indicators

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 11

Page 12

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Mechanical Installation

The effective use of the EZ-SCREEN Type 2 as a safety guarding device depends on two things:

• the suitability of the application

• the proper mechanical and electrical installation and interfacing to the guarded machine.

WARNING: Read this Section Carefully Before Installing the System

If all mounting, installation, interfacing, and checkout procedures are not followed properly, the EZSCREEN Type 2 cannot provide the protection for which it was designed. The user has the responsibility

to ensure that all local, state, and national laws, rules, codes, or regulations relating to the installation and

use of this control system in any particular application are satisfied. Extreme care should be taken to ensure that all legal requirements have been met and that all technical installation and maintenance instructions contained in this manual are followed.

The user has the sole responsibility to ensure that this EZ-SCREEN Type 2 is installed and interfaced to

the guarded machine by Qualified Persons, in accordance with this manual and applicable safety regulations.

This section has two main subsections:

• Considerations in designing the layout of the application

• Mounting the hardware

Pre-Installation Considerations

This subsection describes important considerations before you begin installing the EZ-SCREEN Type 2. The two primary factors that

influence the layout of the EZ-SCREEN Type 2 System’s mechanical installation the most are the Safety Distance (See Calculating the

Safety Distance (Minimum Distance) on page 13) and eliminating pass-through hazards (see Reducing or Eliminating Pass-Through

Hazards on page 17). Additionally, you will find information on the following in this section:

• Emitter and receiver orientation (see Emitter and Receiver Orientation on page 21)

• Dealing with the affects of adjacent reflective surfaces (see Adjacent Reflective Surfaces on page 19)

• Using corner mirrors (see Use of Corner Mirrors on page 20)

• Installing multiple systems (see Installation of Multiple Systems on page 21)

12 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 13

D

EZ-SCREEN

® Type 2 Light Screen Instruction Manual

Calculating the Safety Distance (Minimum Distance)

Safety Distance (Ds), also called Minimum Distance (S), is the minimum distance required between the defined area and the closest

reachable hazard point. The distance is calculated so that when an object or a person is detected (by blocking a sensing beam), the EZSCREEN Type 2 will send a stop signal to the machine, causing it to stop by the time the person can reach any machine hazard point.

The distance is calculated differently for domestic U.S. and European installations. Both methods take into account several factors, including a calculated human speed, the total system stopping time (which itself has several components), and the depth penetration factor. After the distance has been determined, record the calculated distance on the Daily Checkout Card

WARNING: Proper Safety Distance

Banner EZ-SCREEN Type 2 emitters and receivers must be mounted at a distance from the nearest hazard such that an individual cannot reach the hazard before cessation of hazardous motion or situation.

Failure to establish and maintain the minimum distance could result in increased risk of harm.

Figure 3. Safety distance and hard guarding

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 13

Page 14

EZ-SCREEN® Type 2 Light Screen Instruction Manual

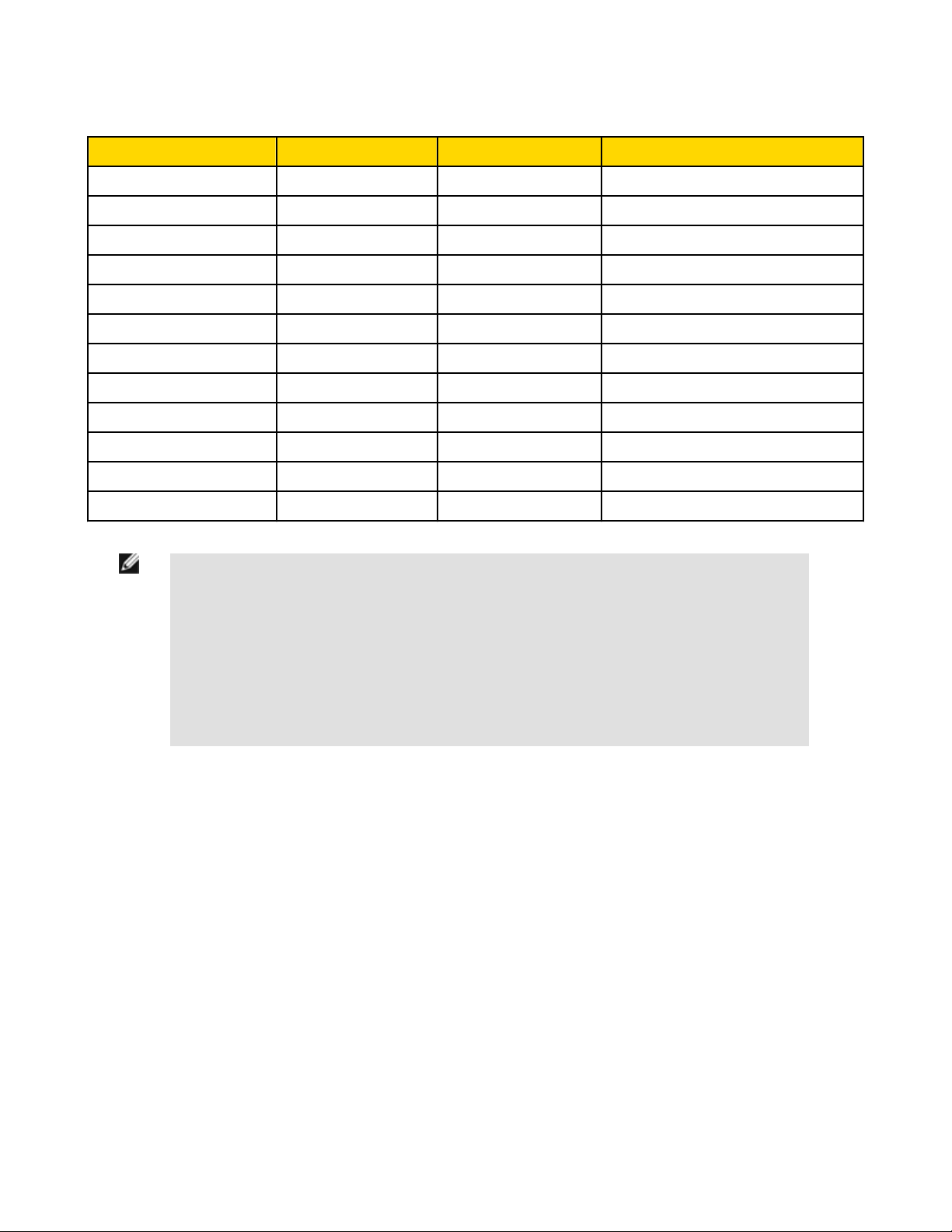

EZ-SCREEN Type 2 Models With Response Times

Models (see note below) Defined Area Height Number of Beams Response Time (Tr)

LS2..30-150Q8 150 mm (5.9") 8 11 ms

LS2..30-300Q8 300 mm (11.8") 16 13 ms

LS2..30-450Q8 450 mm (17.7") 24 14 ms

LS2..30-600Q8 600 mm (23.6") 32 16 ms

LS2..30-750Q8 750 mm (29.5") 40 17 ms

LS2..30-900Q8 900 mm (35.4") 48 19 ms

LS2..30-1050Q8 1050 mm (41.3") 56 21 ms

LS2..30-1200Q8 1200 mm (47.2") 64 22 ms

LS2..30-1350Q8 1350 mm (53.1") 72 24 ms

LS2..30-1500Q8 1500 mm (59") 80 25 ms

LS2..30-1650Q8 1650 mm (65") 88 27 ms

LS2..30-1800Q8 1800 mm (70.9") 96 29 ms

NOTE: The .. in the model numbers is one of the following:

• E = Emitter

• TR = Trip-Output Receiver

• LR = Latch-Output Receiver

• TP = Trip-Output Emitter/Receiver Pair

• LP = Latch-Output Emitter/Receiver Pair

Pair model numbers end in 88 (for example, LS2TP30-150Q88) to indicate that both the transmitter and receiver have an 8-pin connector.

14 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 15

EZ-SCREEN

® Type 2 Light Screen Instruction Manual

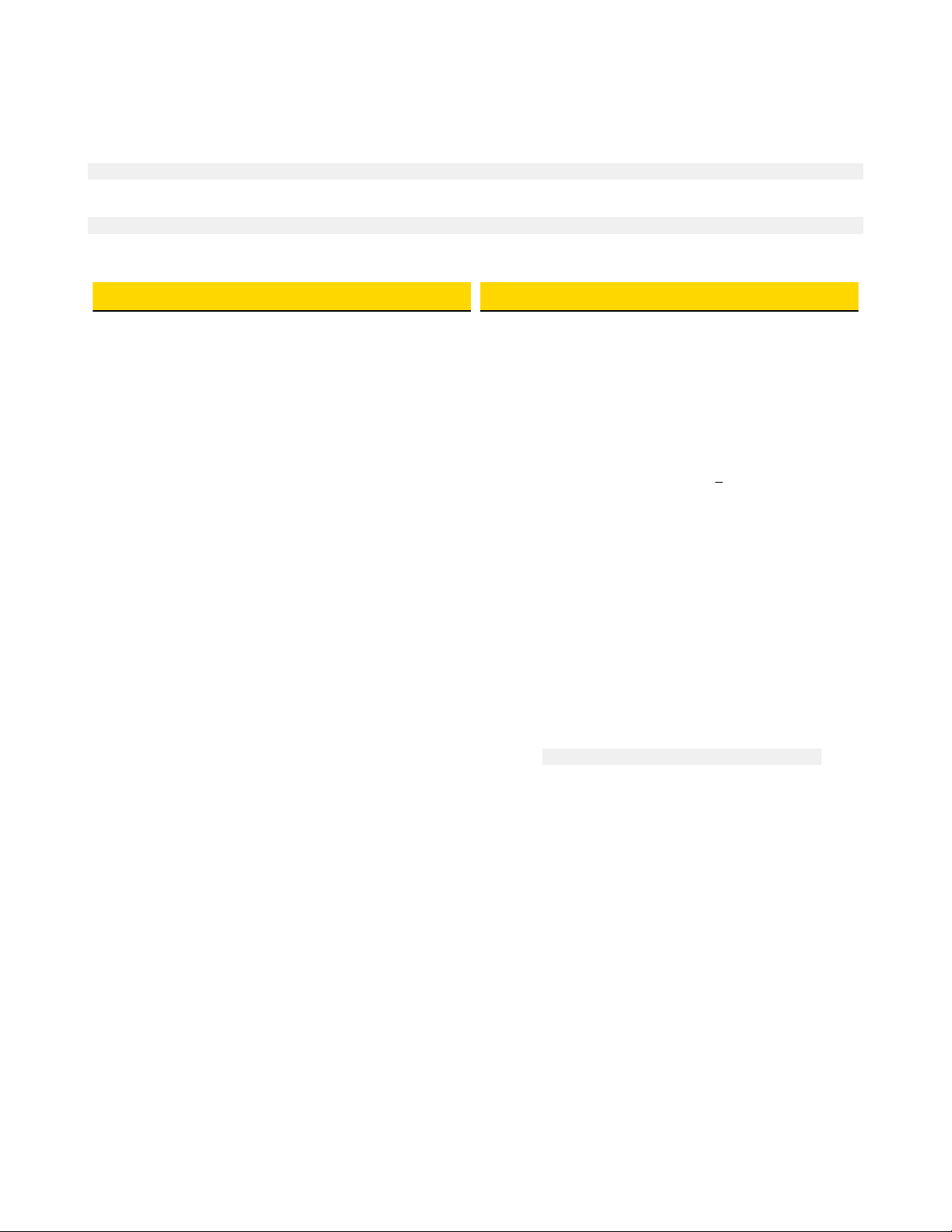

Formula and Examples

The Safety (separation) distance formula for U.S. applications:

Ds = K x (Ts + Tr) + Dpf

The minimum distance formula for European applications:

S = (K x T) + C

where:

U.S. Applications

Ds

the safety distance, in mm (inches).

K

1600 mm per second (or 63" per second), the

OSHA 29CFR1910.217, ANSI B11.19, ANSI/RIA

R15.06 recommended hand-speed constant

(See Note 1 below)

Ts

the overall stop time of the machine (in seconds)

from the initial “stop” signal to the final ceasing of

all motion, including stop times of all relevant

control elements (e.g., IM-T-.. Interface Modules)

and measured at maximum machine velocity

(See Note 3 below).

Tr

the maximum response time, in seconds, of the

EZ-SCREEN Type 2 emitter/receiver pair (depending on model).

Dpf

the added distance – in this case, 78 mm (3") –

due to depth penetration factor as prescribed in

OSHA 29CFR1910.217, ANSI B11.19, ANSI/RIA

R15.06 for U.S. applications .

European Applications

S

the minimum distance, in mm, from danger zone

to light screen center line; minimum allowable

distance is 100 mm ( 175 mm for non-industrial

applications), regardless of calculated value.

K

hand-speed constant (see Note 2); 2000 mm/s

(for minimum safety distances < 500 mm) 1600

mm/s (for minimum safety distances > 500 mm)

T

the overall machine stopping response time (in

seconds), from the physical initiation of the safety

device and the machine coming to a stop (or the

hazard removed). This can be broken down into

two parts: Ts and Tr where T = Ts + Tr

C

the additional distance, in mm, based on intrusion of hand or object towards danger zone prior

to actuation of a safety device.

Calculate using the formula:

C = 8 x (d - 14)

where d is the resolution of the light curtain (for d

< 40 mm). For EZ-SCREEN Type 2, d = 30 mm

and C = 128 mm (5").

Notes:

1. The OSHA-recommended hand speed constant K has been determined by various studies and, although these

studies indicate speeds of 1600 mm/sec. (63"/sec.) to more than 2500 mm/sec. (100"/sec.), they are not conclusive determinations. Consider all factors, including the physical ability of the operator, when determining the value

of K to be used.

2. The recommended hand speed constant K, derived from data on approach speeds of the body or parts of the

body as stated in ISO 13855.

3. Ts is usually measured by a stop-time measuring device. If the machine manufacturer's specified stop time is

used, at least 20% should be added to allow for possible clutch/ brake system deterioration. This measurement

must take into account the slower of the two MPCE channels, and the response time of all devices or controls

that react to stop the machine. See Notice Regarding MPCEs. If all devices are not included, the calculated separation distance (Ds) will be too short and serious injury could result.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 15

Page 16

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Examples

Example: U.S. Applications, Model LS2..30-600

K = 63" per second (the hand speed constant set by

OSHA)

Ts = 0.32 (0.250 second is specified by the machine

manufacturer; plus 20% safety factor; plus 20 ms

for interface module IM-T-9A response)

Tr = 0.016 second (the specified response time of an

LS2..30-600 EZ-SCREEN Type 2)

Dpf = 3"

Substitute the numbers into the formula as follows:

Ds = K x ( Ts + Tr ) + Dpf

Ds = 63 x (0.32 + 0.016) + 3 = 24.2"

Mount the EZ-SCREEN Type 2 emitter and receiver so that no

part of the defined area will be closer than 24.2" to the closest

reachable hazard point on the guarded machine.

WARNING: Determine Correct Stop Time

Example: European Applications, Model LS2..30-600

K = 1600 mm per second

T = 0.336 (0.250 second specified by machine manufac-

turer; plus 20% safety factor; plus 20 ms interface

module response), plus 0.016 second (the specified

LS2..30-600 response time)

C = 8 x (30-14) = 128 mm

Substitute the numbers into the formula as follows:

S = (K x T ) + C

S = (1600 x 0.336) + 128 = 665.6 mm

Mount the EZ-SCREEN Type 2 emitter and receiver so that no

part of the defined area will be closer than 665.6 mm to the closest reachable hazard point on the guarded machine.

Stop time (Ts) must include the response time of all devices or controls that react to stop the machine. If all devices are not included, the calculated safety distance (Ds) will be too short. This can lead to

an increased risk of harm. Be sure to include the stop time of all relevant devices and controls in your

calculations.

If required, each of the two Machine Primary Control Elements (MPCE1 and MPCE2) must be capable of

immediately stopping the dangerous machine motion, regardless of the state of the other. These two channels of machine control need not be identical, but the stop time performance of the machine (Ts, used to

calculate the safety distance) must take into account the slower of the two channels.

16 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 17

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Reducing or Eliminating Pass-Through Hazards

A pass-through hazard is associated with applications where personnel may pass through a safeguard (which issues a stop command to

remove the hazard), and then continues into the guarded area, such as in perimeter guarding. Subsequently, their presence is no longer

detected, and the related danger becomes the unexpected start or restart of the machine while personnel are within the guarded area.

In the use of light screens, a pass-through hazard typically results from large safety distances calculated from long stopping times, large

minimum object sensitivities, reach-over, reach-through, or other installation considerations. A pass-through hazard can be generated

with as little as 75 mm (3") between the defined area and the machine frame or hard guarding.

Eliminate or reduce pass-through hazards whenever possible. While it is recommended to eliminate the pass-through hazard altogether,

this may not be possible due to machine layout, machine capabilities, or other application considerations.

One solution is to ensure that personnel are continually sensed while within the hazardous area. This can be accomplished by using

supplemental safeguarding, such as described by the ANSI B11.19 of safety requirements or other appropriate standards.

An alternate method is to ensure that once the safeguarding device is tripped it will latch, and will require a deliberate manual action to

reset. This method of safeguarding relies upon the location of the reset switch as well as safe work practices and procedures to prevent

an unexpected start or restart of the guarded machine.

WARNING: Use of EZ-SCREEN Type 2 for Perimeter Guarding

If an EZ-SCREEN Type 2 is installed in an application that results in a pass-through hazard (e.g., perimeter guarding), either the EZ-SCREEN Type 2 System or the Machine Primary Control Elements (MPCEs)

of the guarded machine must cause a Latched response following an interruption of the defined area.

The reset of this Latched condition may only be achieved by actuating a reset switch that is separate from

the normal means of machine cycle initiation.

Lockout/Tagout procedures per ANSI Z244.1 may be required, or additional safeguarding, as described by

ANSI B11.19 safety requirements or other appropriate standards, must be used if a passthrough hazard

can not be eliminated or reduced to an acceptable level of risk. Failure to observe this warning could

result in an increased risk of harm.

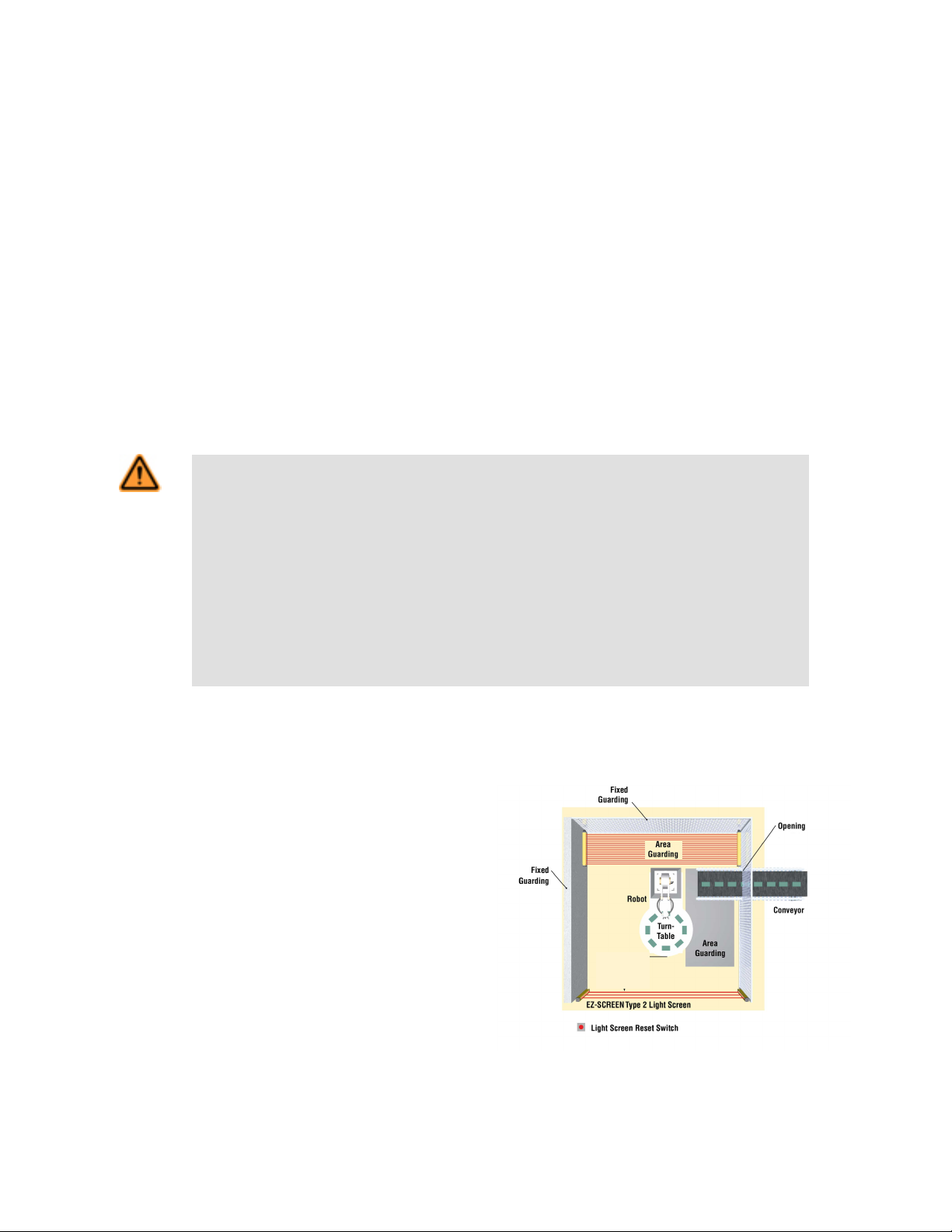

Supplemental Safeguarding

As described in Calculating the Safety Distance (Minimum Dis-

tance) on page 13, the EZ-SCREEN Type 2 must be properly posi-

tioned such that an individual can not reach through the defined

area and access the hazard point before the machine has stopped.

Additionally, the hazard can not be accessible by reaching around,

under, or over the defined area. To accomplish this, supplemental

guarding (mechanical barriers, such as screens or bars), as described by ANSI B11.19 safety requirements or other appropriate

standards, must be installed. Access will then be possible only

through the defined area of the EZ-SCREEN Type 2 System or

through other safeguarding that prevents access to the hazard

(see Figure 4. An example of supplemental safeguarding on page

17).

The mechanical barriers used for this purpose are typically called

"hard guarding'; there must be no gaps between the hard guarding

and the defined area. Any openings in the hard guarding must

comply with the safe opening requirements of ANSI B11.19 or other appropriate standard.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 17

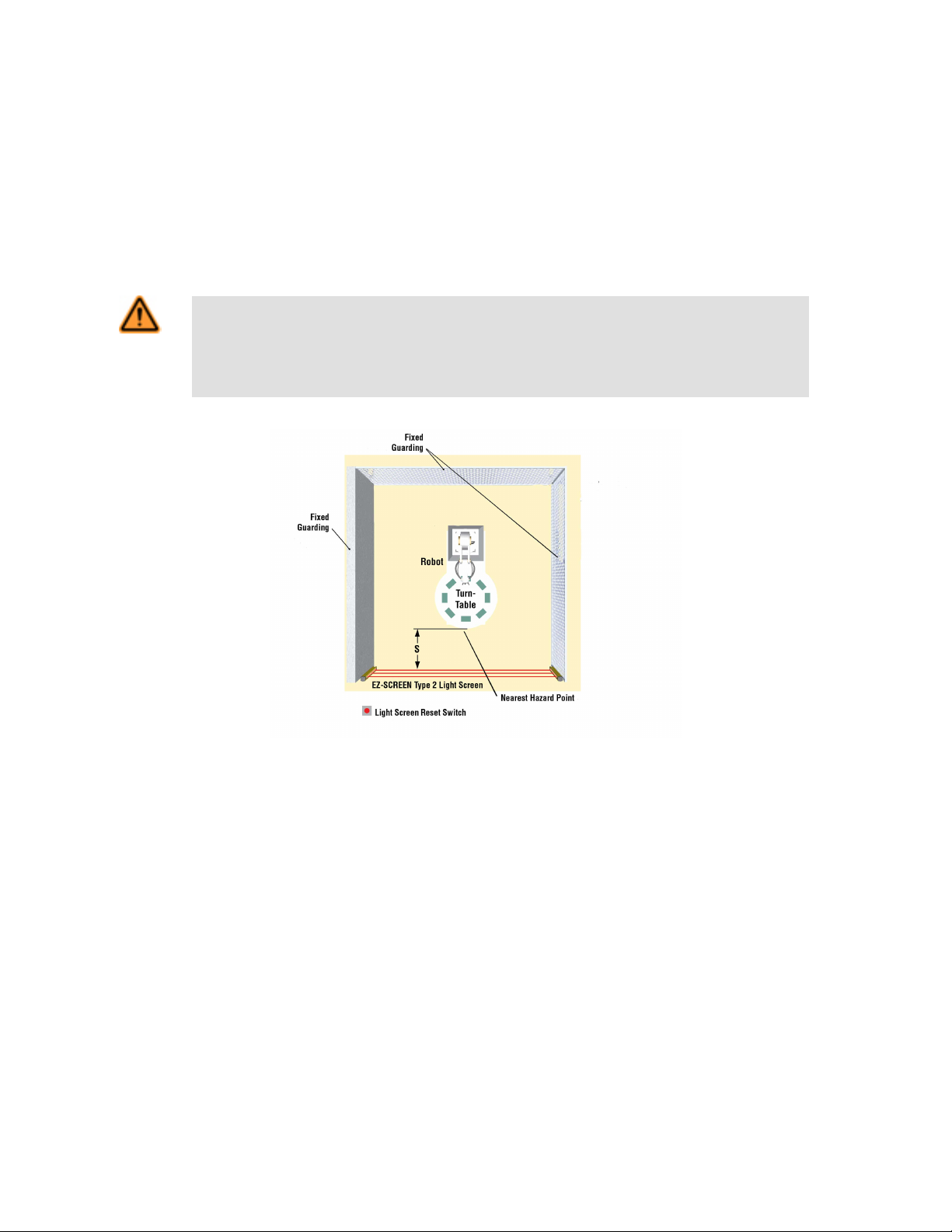

Figure 4. An example of supplemental safeguarding

Page 18

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Figure 4. An example of supplemental safeguarding on page 17 shows an example of supplemental safeguarding inside a robotic work

cell. The EZ-SCREEN Type 2, in conjunction with the hard guarding, is the primary safeguard. Supplemental safeguarding (such as a

horizontal-mounted safety light screen as an area guard) is required in areas that can not be viewed from the reset switch (i.e., behind

the robot and the conveyor). Additional supplemental safeguarding may be required to prevent clearance or trapping hazards (for example, the safety mat as an area guard between the robot, the turntable, and the conveyor).

WARNING: The Hazard Must Be Accessible Only through the Defined Area

The installation of the EZ-SCREEN Type 2 System must prevent any individual from reaching around, under, over or through the defined area and into the hazard without being detected. Mechanical barriers (for

example, hard guarding) or supplemental safeguarding may be required to comply with this requirement,

and is described by ANSI B11.19 safety requirements or other appropriate standards.

Other Considerations

Reset Switch Location

A key-actuated reset switch provides some operator or supervisory control, as the key can be removed from the switch and taken into the

guarded area. However, this does not prevent unauthorized or inadvertent resets due to spare keys in the possession of others, or additional personnel entering the guarded area unnoticed. When considering where to locate the reset switch, follow the guidelines in the

Warning below.

WARNING: Reset Switch Location

When considering where to locate the reset switch, you must follow the guidelines outlined in this section.

If any areas within the guarded area are not visible from the reset switch, additional safeguarding must be

provided, as described by the ANSI B11.19 series or other appropriate standards.

Failure to follow these instructions could result in an increased risk of harm

All reset switches must be:

• Outside the guarded area

• Located to allow the switch operator a full, unobstructed, view of the entire guarded area while the reset is performed

• Out of reach from within the guarded area

• Protected against unauthorized or inadvertent operation (such as through the use of rings or guards).

Important: Resetting a safeguard must not initiate hazardous motion. Safe work procedures require a startup procedure to be followed and the individual performing the reset to verify that the entire hazardous area is

clear of all personnel, before each reset of the safeguard is performed. If any area can not be observed from

the reset switch location, additional supplemental safeguarding must be used: at a minimum, visual and audible warnings of machine start-up.

18 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 19

d

d

d

Operating Range

(R)

Emitter Receiver

Do not position reflective surfaces

within the shaded area

top view

side view

EZ-SCREEN

® Type 2 Light Screen Instruction Manual

Adjacent Reflective Surfaces

WARNING: Avoid Installation Near Reflective Surfaces

Avoid locating the defined area near a reflective surface; it could reflect sensing beam(s) around an object

or person within the defined area, and prevent its detection by the EZ-SCREEN Type 2.

Reflections will result in incomplete guarding and could result in an increased risk of harm.

A reflective surface located adjacent to the defined area may deflect one or more beams around an object in the defined area. In the

worst case, an optical short circuit may occur, allowing an object to pass undetected through the defined area.

This reflective surface may result from shiny surfaces or glossy paint on the machine, the workpiece, the work surface, the floor or the

walls. Beams deflected by reflective surfaces are discovered by performing the trip test and the periodic checkout procedures. To eliminate problem reflections:

• If possible, relocate the sensors to move the beams away from the reflective surface(s), being careful to maintain adequate separation distance.

• Otherwise, if possible, paint, mask or roughen the shiny surface to reduce its reflectivity.

• Where these are not possible (as with a shiny workpiece), mount the sensors in such a way that the receiver's field of view and/or the

emitter's spread of light are restricted.

• Repeat the trip test (see Trip Test on page 32) to verify that these changes have eliminated the problem reflection(s). If the workpiece is especially reflective and comes close to the defined area, perform the trip test with the workpiece in place.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 19

For 0.2 to 3 m (8" to 10') Operating range: d = 0.26 m (10")

For Operating range > 3 m (> 10'): d = 0.0875 x R (m or ft)

Figure 5. Adjacent reflective surfaces

Page 20

Recommended sensor

configuration angle

Emitter

Emitter

Receiver

Receiver

Mirror Mirror

A

45° < A < 120°

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Use of Corner Mirrors

EZ-SCREEN Type 2 Systems may be used with one or more cor-

SSM and MSM Series Glass-Surface Mirrors

ner mirrors. The use of glass-surface corner mirrors reduces the

maximum specified emitter/receiver separation by approximately 8

percent per mirror, as follows:

Corner Mirrors Max. Emitter / Receiver

Range

1 13.8 m (45')

2 12.7 m (42')

3 11.7 m (38')

4 10.8 m (35')

Mirrors are not allowed for applications that would allow personnel undetected access into the safeguarded area.

If mirrors are used, the difference between the angle of incidence from the emitter to the mirror and from the mirror to the receiver must

be between 45° and 120°. If placed at a sharper angle, as shown in the example, an object in the light screen may deflect beam(s) to the

receiver, preventing the object from being detected (that is, "false proxing"). Angles greater than 120° result in difficult alignment and

possible optical short circuits.

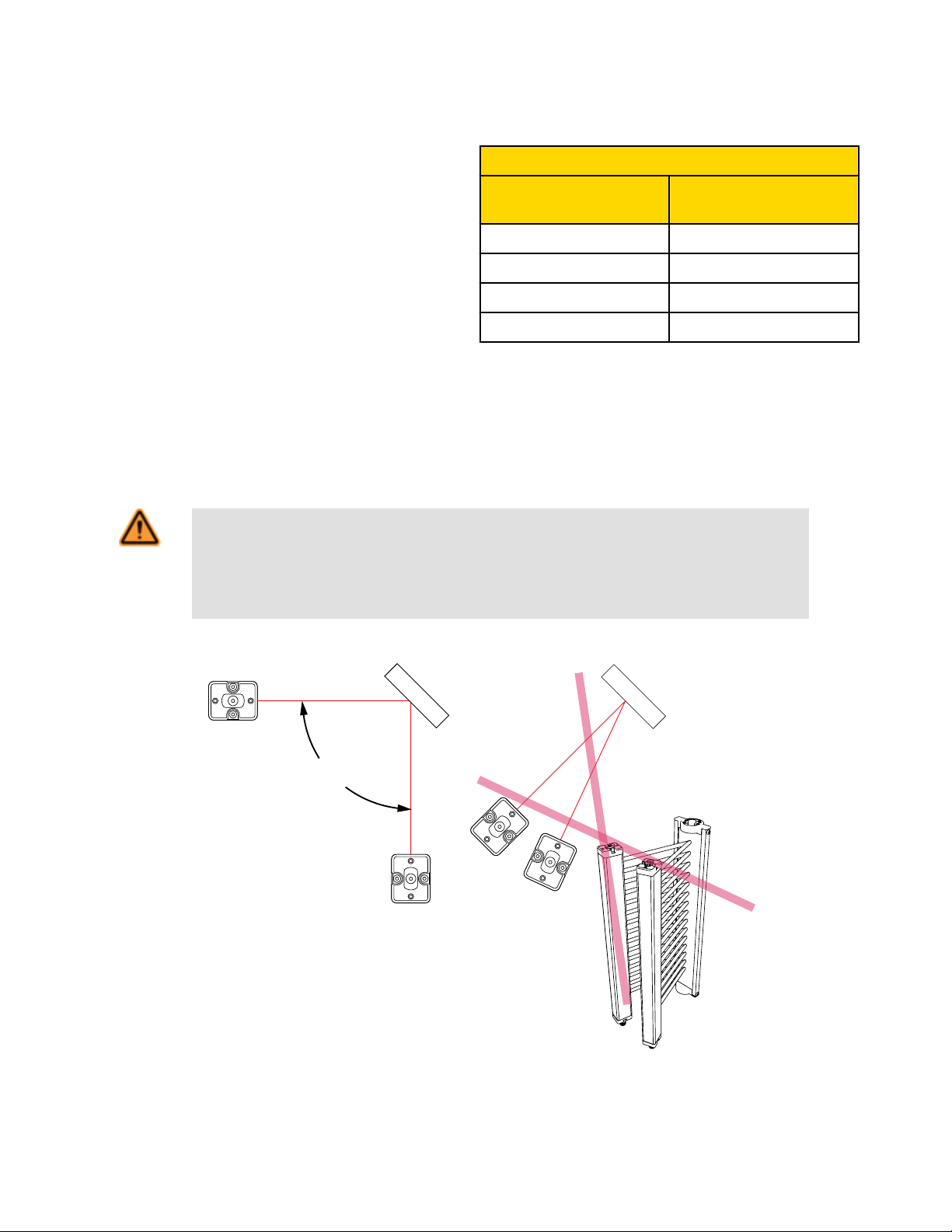

WARNING: Avoid Retroreflective Installation

Do not install emitters and receivers in "retroreflective" mode, with less than a 45° angle of incidence, as

shown.

Sensing could be unreliable in this configuration; an increased risk of harm could result.

20 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Figure 6. Never use EZ-SCREEN Type 2 sensors in a retroflective mode.

Page 21

Receiver

Emitter

Receiver

Emitter

Receiver

Emitter

Receiver

Emitter

Receiver

Emitter

EZ-SCREEN

® Type 2 Light Screen Instruction Manual

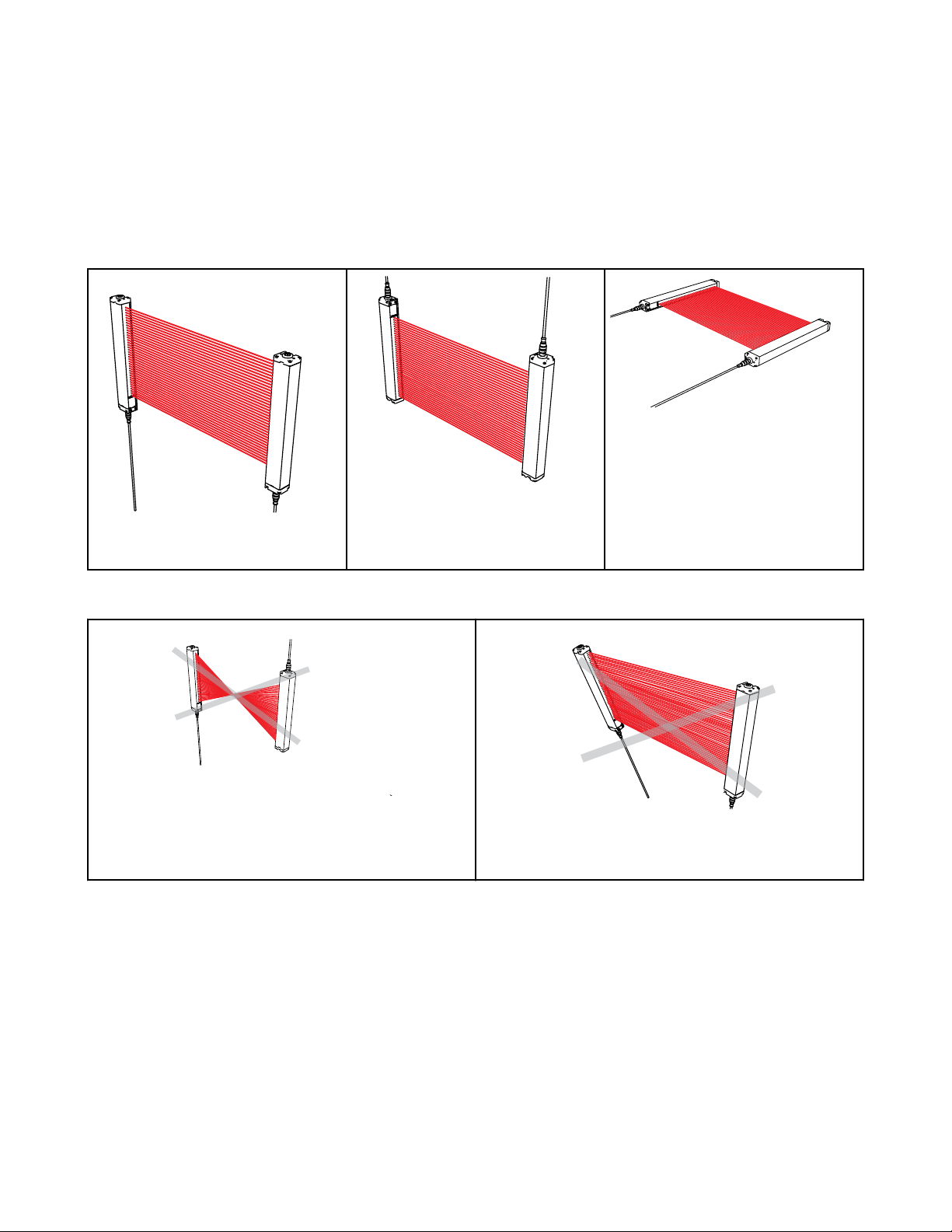

Emitter and Receiver Orientation

The emitter and receiver must be mounted parallel to each other and aligned in a common plane, with both cable ends pointing in the

same direction. Never mount the emitter with its cable end oriented opposite the cable end of the receiver. If this occurs, voids in the light

screen may allow objects or personnel to pass through the defined area undetected.

The emitter and receiver may be oriented in a vertical or horizontal plane, or at any angle between horizontal and vertical, as long as they

are parallel and their cable ends point in the same direction. Verify that the light screen completely covers all access to the hazard point

that is not already protected by hard guarding or other supplemental guarding.

a) Both cable ends down. b) Both cable ends up. c) Orientation parallel to floor with both ca-

ble ends pointing in the same direction.

Figure 7. Examples of Correct Emitter/Receiver Orientation

a) Cable ends point in opposite directions.

Problem: Voids in defined area

b) Emitter and receiver not parallel to each other.

Problem: Reduced excess gain

Figure 8. Examples of incorrect Emitter/Receiver Orientation

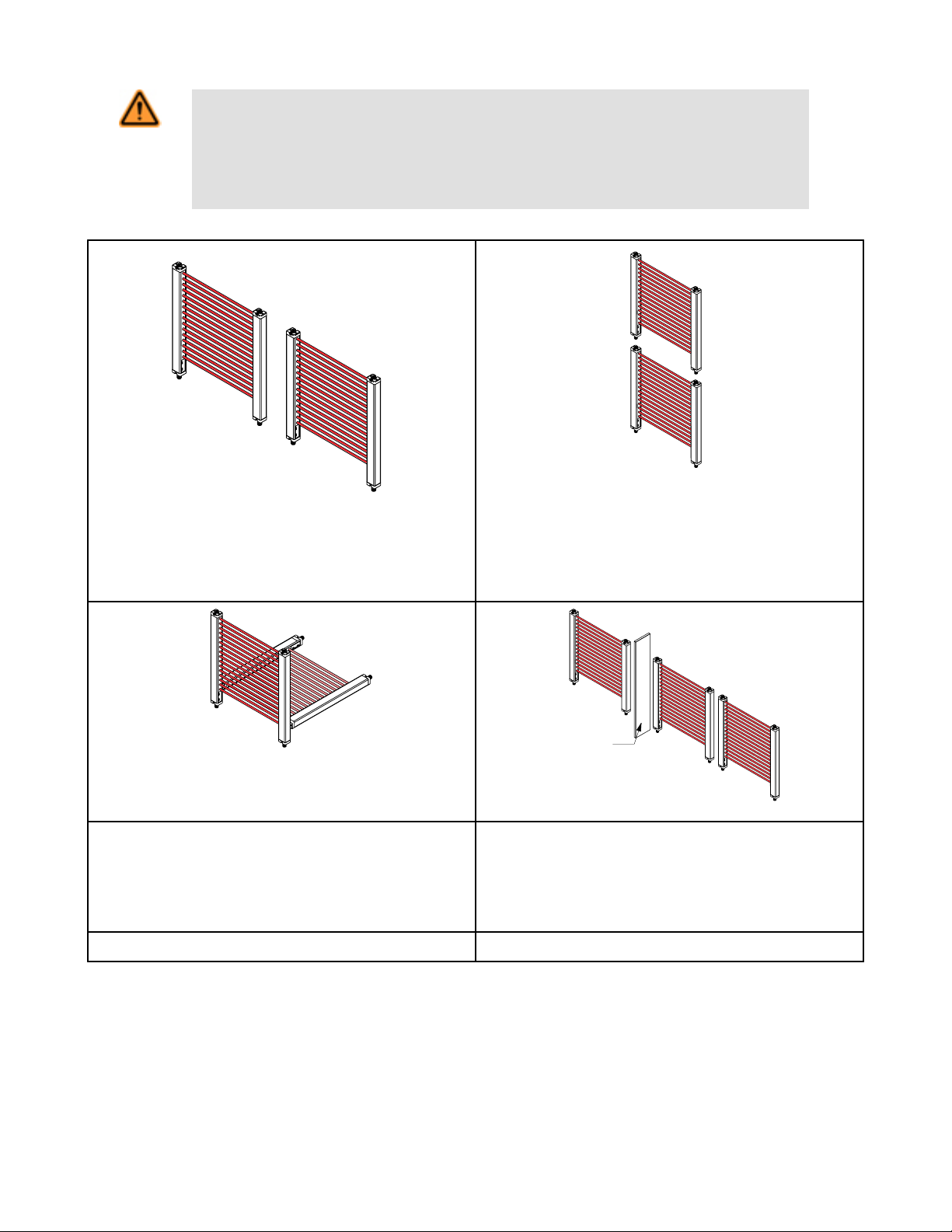

Installation of Multiple Systems

Whenever two or more EZ-SCREEN Type 2 emitter and receiver pairs are adjacent to one another, optical crosstalk may potentially take

place between systems. To minimize optical crosstalk, alternate the positions of emitters and receivers, (see Figure 9. Installation of

multiple systems on page 22).

When two or more systems are installed in the same plane (as shown in Figure 9. Installation of multiple systems on page 22), optical

crosstalk may occur between sensor pairs whose emitter and receiver lenses are oriented in the same direction. In this situation, eliminate optical crosstalk by mounting these sensor pairs exactly in line with each other within one plane, or by adding a mechanical barrier

between the pairs.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 21

Page 22

R

E

R

E

R2

E2

R1

E1

R 3

E 3

R 1

E1

R2

E 2

A

EZ-SCREEN® Type 2 Light Screen Instruction Manual

WARNING: Proper Orientation of System Emitters and Receivers

EZ-SCREEN Type 2 System emitters and receivers must be installed with their corresponding cabled

ends pointing in the same direction (for example, both cabled ends facing up). Failure to orient them properly will impair the performance of the EZ-SCREEN Type 2 System and will result in incomplete guarding,

and could result in an increased risk of harm.

E

R

R

E

E = Emitter R = Receiver E = Emitter R = Receiver

a. Two systems in a horizontal plane b. Two or three systems stacked (or alternate receiver/emitter po-

sitions)

E1 = Vertical Emitter E2 = Horizontal Emitter

R1 = Vertical Receiver R2 = Horizontal Receiver

A = Opaque Shield

E1 = Emitter #1 E2 = Emitter #2 E3 = Emitter #3

R1 = Receiver #1 R2 = Receiver #2 R3 = Receiver #3

c. Two systems at right angles d. Multiple systems

Figure 9. Installation of multiple systems

22 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 23

EZ-SCREEN

® Type 2 Light Screen Instruction Manual

WARNING: Synchronization

In situations where multiple systems are mounted closely together, or where a secondary emitter is in view

(within ±5°), within range of an adjacent receiver; a receiver may synchronize to the signal from the wrong

emitter, reducing the safety function of the light screen.

WARNING: Multiple Pairs of Sensors

Do not connect multiple pairs of sensors to one Interface Module (for example, IM-T-9A/-11A) or otherwise

parallel OSSD outputs.

Connection of multiple OSSD safety outputs to a single device can result in an increased risk of

harm, and is prohibited.

Mounting System Components

Overview of Emitter/Receiver Mounting Hardware

Mounting Hardware

The EZ-SCREEN standard end-cap mounting bracket hardware is

supplied with each emitter and receiver. Brackets are designed to

mount directly to MSA Series stands using the hardware with the

supplied stands.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 23

Page 24

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Using Center Mounting Brackets

Center mounting brackets are supplied with longer sensors and

must be used whenever the sensors are subject to shock or vibration. The sensors are designed to be mounted with up to 450 mm

(18") distance between brackets:

• Sensors 600 to 900 mm (24" to 36") long are supplied with one

center bracket, which should be centered on the sensor.

• Sensors 1050 to 1350 mm (42" to 54") long are supplied with

two center brackets, which should be positioned 1/3 of the sensor's length from each sensor end.

• Sensors 1500 to 1800 mm (59" to 71") long are supplied with

three center brackets

To install each bracket:

1. Spread the clamp and snap over the back of the sensor so

that the clamp is securely fastened to the sensor without

blocking any beams.

2. Compress the foam spacer and slide the clamp along the

length of the sensor housing to align the clamp with the center mounting bracket as shown in Figure 3-9. Three separate

mounting holes are provided on the clamp to allow for all

possible mounting configurations.

3. Connect the clamp to the center bracket using the M3 screw

supplied.

4. Loosen all the mounting screws to the sensor, align the sen-

sors and then tighten the end screws. Finally, tighten the M3

screw joining the clamp to the center mounting bracket.

Mounting and Initial Alignment of Emitter/Receiver Pairs

Emitter/receiver pairs may be spaced from 0.2 to 15 m (8" to 50') apart. The maximum distance between an emitter and its receiver is

reduced if corner mirrors are used. The supplied brackets (when mounted to the sensor end caps) allow ±30° rotation.

To mount each emitter/receiver pair:

1. From a common point of reference (ensuring the calculated safety distance), make measurements to locate the emitter and receiver in the same plane with their midpoints directly opposite each other.

Important: The connector ends of both sensors must point in the same direction (see Emitter and Re-

ceiver Orientation on page 21 ).

2. Mount the emitter and receiver mounting brackets using the supplied M6 bolts and Keps nuts, or user-supplied hardware.

3. Mount the emitter and receiver in their brackets; position their windows directly facing each other.

4. Measure from a reference plane (for example, a level building floor) to the same point(s) on the emitter and receiver to verify their

mechanical alignment.

5. Use a carpenter's level, a plumb bob, or the optional LAT-1 Laser Alignment Tool or check the diagonal distances between the

sensors, to achieve mechanical alignment.

24 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 25

Level Surface

X X

Emitter Receiver

level

level

Y Y

Z

Z

Level Surface

A B

level level

XX

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Verifying Initial Emitter/Receiver Alignment

As you mount the sensors, make sure that

• The emitter and receiver are directly opposite each other.

• Nothing is interrupting the defined area (marked on the sensors).

• The defined area is the same distance from a common reference plane for each sensor.

• The emitter and receiver are in the same plane and are level/plumb and square to each other (vertical, horizontal, or inclined at the

same angle).

Angled or Horizontal Installations Vertical Installations

Verify that the

• Distance X at the emitter and receiver are equal.

• Distance Y at the emitter and receiver are equal.

• Distance Z at the emitter and receiver are equal from parallel

surfaces.

• Vertical face (that is, the lens) is level/plumb.

• Defined area is square. Check diagonal measurements if

possible; see Vertical Installations, at right.

NOTE: Make sure that the emitter and

receiver are not tilted front-to-back or

side-to-side as shown.

Verify that the

• Distance X at the emitter and receiver are equal.

• Both sensors are level/plumb (check both the Distance Z at

the emitter and receiver are equal from side and face).

• Defined area is square. Check diagonal measurements if

possible (Diagonal A = Diagonal B).

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 25

Page 26

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Electrical Installation and Testing

As with the previous section, it is important that you read, understand and follow the electrical installation and testing procedure as described in the following subsections.

WARNING: Read this Section Carefully Before Installing the System

If all mounting, installation, interfacing, and checkout procedures are not followed properly, the EZSCREEN Type 2 cannot provide the protection for which it was designed. The user has the responsibility

to ensure that all local, state, and national laws, rules, codes, or regulations relating to the installation and

use of this control system in any particular application are satisfied. Extreme care should be taken to ensure that all legal requirements have been met and that all technical installation and maintenance instructions contained in this manual are followed.

The user has the sole responsibility to ensure that this EZ-SCREEN Type 2 is installed and interfaced to

the guarded machine by Qualified Persons, in accordance with this manual and applicable safety regulations.

There following are the main steps to electrically install the EZ-SCREEN Type 2 components and interface with the guarded machine:

1. Apply power to each emitter/receiver pair (see Initial Electrical Connections on page 27).

2. Perform and Initial Checkout Procedure (see Initial Checkout Procedure on page 28).

3. Make all electrical interface connections to the guarded machine (see Electrical Connections to the Guarded Machine on page

34).

4. Perform a commissioning checkout procedure (see Commissioning Checkout on page 38).

Routing Cordsets

Connect the QD connectors and route the sensor cables to the junction box, electrical panel, or other enclosure in which the Interface

Module, the redundant mechanically linked interposing relays, FSDs, or other safety-related parts of the control system are located. This

must be done per local wiring code for low-voltage dc control cables and may require installation of electrical conduit. See Cordsets on

page 57 for selection of Banner-supplied cordsets.

The EZ-SCREEN Type 2 is designed and manufactured to be highly resistant to electrical noise and to operate reliably in industrial

settings. However, extreme electrical noise may cause a random Trip or Latch condition; in extreme cases, a Lockout is possible. Emitter

and receiver wiring is low voltage; routing the sensor wires alongside power wires, motor/servo wires, or other high-voltage wiring may

inject noise into the EZ-SCREEN Type 2 System. It is good wiring practice (and may be required by code) to isolate emitter and receiver

cables from high-voltage wires, avoid routing cables close to “noisy” wiring, and provide a good connection to earth ground.

26 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 27

EZ-SCREEN® Type 2 Light Screen Instruction Manual

Sensor QD cabling and any interconnect wiring should meet the following specifications. The wires used should have an insulation temperature rating of at least 90°C (194°F).

Maximum Machine Interface cable length versus total current draw (including both OSSD loads)

Cable Size Current Draw

0.5A 0.75A 1.0A 1.25A

0.823 mm2 (18 AWG) 375' 250' 188' 148'

0.518 mm2 (20 AWG) 240' 160' 120' 95'

0.326 mm2 (22 AWG)* 150' 100' 75' 59'

NOTE: Cable length includes power (+24V dc) and return (0V dc) wires at +25˚C, and is intended to ensure

that adequate power is available to the EZ-SCREEN Type 2 System when the supply is operating at +24V dc 10%.

Initial Electrical Connections

WARNING: Proper Electrical Hookup

Electrical hookup must be made by Qualified Personnel and must comply with NEC (National Electrical

Code) and local standards.

Connection of other wiring or equipment to the EZ-SCREEN Type 2 System could result in an increased

risk of harm.

Lockout/tagout procedures may be required (refer to OSHA1910.147, ANSI Z244-1, or the appropriate standard for controlling hazardous

energy). Following relevant electrical standards and wiring codes, such as the NEC, NFPA79 or IEC60204-1, always connect earth

ground (green/yellow wire. Do not operate the EZ-SCREEN Type 2 System without an earth ground connection.

Make the electrical connections in the order described in this section. Do not remove end-caps; no internal connections are to be made.

All connections are made through the M12 Eurostyle quick-disconnects.

Emitter Cordset Receiver Cordset

EZ-SCREEN Type 2 emitters have an 8-pin cordset, but only three

conductors are required:

• Brown = +24V dc

• Blue = 0V dc

• Green/Yellow = GND

Do not connect any wires to the machine control circuits (that

is, OSSD outputs) at this time.

For the initial checkout, only the following EZ-SCREEN Type 2 receiver conductors should be connected:

• Brown = +24V dc

• Blue = 0V dc

• Green/Yellow = GND

Additionally, connect the external reset switch, if used, or test signal contact to the Reset/Test wire (violet) and to 24V dc.

NOTE: The reset switch must be a normally closed switch that is held open for approximately 1/4 second, then

closed to accomplish the reset. The switch must be capable of switching 10 to 30V dc at 30 mA.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 27

Page 28

D

C

A

B

EZ-SCREEN® Type 2 Light Screen Instruction Manual

The other wires are for an optional hookup that allows for parallel connection (color-for-color) to the receiver cable. This optional hookup

provides for sensor interchangeability (or swapability) that facilitates installing either sensor at either QD connection. Besides providing

similar cabling, this wiring scheme is advantageous during installation, wiring, and troubleshooting.

Individual Cordsets Splitter Cordsets

EZ-SCREEN Type 2

A

Key Description

C

Bn

Or/Bk

Or

Wh

Bk

Bu

Gn/Ye

Vi

B

+24V dc

n.c.

n.c.

OSSD2

OSSD1

0V dc

Ground

Reset/Test & EDM

Key Description

A Emitter

B Receiver

C QDE-8..D Cordsets

A Emitter

B Receiver

C DEE2R.. Cordsets

D CSB.. Cordsets

Initial Checkout Procedure

The initial checkout procedure must be performed by a Qualified Person. It must be performed only after configuring the system and after

connecting the emitter and receiver.

The procedure is performed on two occasions:

• To ensure proper installation when the System is first installed

• To ensure proper System function whenever any maintenance or modification is performed on the System or on the machinery being

guarded by the System.

28 www.bannerengineering.com - tel: 763-544-3164 122452 rev. B

Page 29

EZ-SCREEN

® Type 2 Light Screen Instruction Manual

Configuring the System for Initial Checkout

For the initial checkout, the EZ-SCREEN Type 2 System must be checked without power being available to the guarded machine. Final

interface connections to the guarded machine cannot take place until the light screen system has been checked out. This may require

lockout/tagout procedures (refer to OSHA1910.147, ANSI Z244-1, or the appropriate standard for controlling hazardous energy). These

connections will be made after the initial checkout procedure has been successfully completed.

Verify that:

• Power has been removed from (or is not available to) the guarded machine, its controls or actuators; and

• The machine control circuit or the Interface Module is not connected to the OSSD outputs at this time (permanent connections will be

made later).

Initial Power-Up

Inspect the area near the light screen for reflective surfaces, including work pieces and the guarded machine. Reflective surfaces may

cause light beams to reflect around a person in the light screen, preventing the person from being detected and not stopping the machine

motion.

Eliminate the reflective surfaces as possible by relocating them, painting, masking or roughening them. Remaining problem reflections

will become apparent during the trip test.

1. Verify that power is removed from the EZ-SCREEN Type 2 System and from the guarded machine and that the OSSD safety

outputs are not connected. Remove all obstructions from the light screen.

2. Leaving power to the guarded machine OFF, make power and earth ground connections on both the emitter and receiver cables

and then power up the EZ-SCREEN Type 2 System (only).

3. Verify that input power is present to both emitter and receiver. At least one indicator on both emitter and receiver should be ON and

the start-up sequence should cycle.

122452 rev. B www.bannerengineering.com - tel: 763-544-3164 29

Page 30

Power/Fault LED (Green)

Alignment LEDs

(Yellow)

Status Blocked LED (Red)

Status Clear LED (Green)

EZ-SCREEN® Type 2 Light Screen Instruction Manual

4. Watch both the emitter and the receiver LED indicators to determine light screen alignment status.

Figure 10. Emitter Status Indicators

Figure 11. Receiver Status Indicators

Lockout Condition

On the emitter, the green Power indicator is flashing or on the receiver, the red Status Blocked indicator is flashing. See

Troubleshooting and Lockout Conditions on page 47 for diagnostic information.

Normal Operating Mode

On the emitter, the green Power indicator is ON.

Test Mode

On the receiver, the red Status Blocked indicator is ON and the green Status Clear indicator is flashing. Test input

open.

Test Mode, input fault

On the receiver, the red Status Blocked indicator is ON and the green Status Clear indicator is ON. Test input open at

power-up.

Latch Condition, all optical beams clear

On the receiver, the red Status Blocked indicator is ON and both yellow Alignment indicators are flashing. For Latch

Output receivers, the outputs are ON only when all beams are clear and after a manual reset. If a reset routine can

cause a Clear (Run) condition, optimize the alignment as described in Optical Alignment on page 31. If a Clear (Run)

condition can not be achieved, see “Blocked condition” below.

Clear (Run) Condition