Bakers Pride CH-4, CH-6, CH-10, CH-8, CH-16 Operation Manual

...

OPERATION MANUAL

DANTE SERIES GAS CHARBROILERS

SERIES: XX & CH

BUILT BY CRAFTSMEN. TESTED BY TIME®.

XX & CH CHARBROILER OPERATION MANUAL

CHARBROILER OPERATION MANUAL

Models:

Dante XX & CH

Bakers Pride Oven Company, LLC is a wholly owned

subsidiary of Standex International Corporation.

All gas operated Bakers Pride® charbroilers are intended

for use with the type of gas specified on the rating plate

and for installation will be in accordance with National

Fuel Gas Code ANSI Z223.1 (latest edition).

WARNING

FOR YOUR SAFETY: Do not store or use gasoline

or other flammable vapors or liquids in the vicinity

of this or any other appliance.

WARNING

After the gas supply has been connected to your

unit, it is extremely important to check piping

for possible leaks. To do this, use soap and water

solution or solutions which are expressly made

for this purpose. DO NOT USE matches, candles,

flames, or other sources of ignition since these

methods are extremely dangerous.

Post in a prominent location instructions to be

followed in the event you smell gas. Obtain these

instructions from your local gas supplier.

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

WARNING

Instructions must be posted in a prominent

location. All safety precautions must be taken in

the event the user smells gas. Safety information

can be obtained from your local gas supplier.

Please retain this manual for future references.

This equipment is design engineered for commercial

use only.

This equipment has been engineered to provide

you with year round dependable service when used

according to the instructions in this manual and

standard commercial kitchen practices.

Phone: 800.527.2100 | Fax: 914.576.0605 | www.bakerspride.com

BAKERS PRIDE OVEN COMPANY, LLC.

1307 N. Watters Rd., Suite 180

Allen, TX 75013

P/N U46023A 06/17

TABLE OF CONTENTS

DANGER

WARNING

CAUTION

NOTICE

XX & CH CHARBROILER OPERATION MANUAL

GENERAL DESCRIPTION 2

INSTALLATION 2

CLEARANCES 2

GAS CONNECTION 2

BURNERS 2

RADIANTS 3

TOP GRATES 3

LIGHTING 3

GRIDDLE PLATES 3

ADDITIONAL INSTALLATION REQUIREMENTS 4

INSTALLATION WITH CASTERS 4

OPTIONAL SMOKER BASE 4

OPERATING INSTRUCTIONS 5

LIGHTING PROCEDURE 5

BROILING PROCEDURE 5

SEASONING 5

STEAKS AND CHOPS 5

HAMBURGERS 5

THICKNESS 5

COOKING TOOLS 5

OPERATIONAL GUIDELINES FOR CHARBROILER 5

NATURAL SMOKE ESSENCE 5

HELPFUL HINTS 6

MAINTENANCE 6

SERVICE 6

CARE AND CLEANING OF TOP GRATES 6

GREASE COLLECTION 6

CLEANING TOOLS 6

AVERAGE PRODUCTION GUIDE 7

TROUBLESHOOTING GUIDE 7

BURNER FLAME ADJUSTMENT 7

PILOT FLAME ADJUSTMENT 7

LACK OF HEAT 7

ONE BURNER FAILS TO LIGHT 8

TROUBLESHOOTING CHART 8

VALVE ASSEMBLY VIEWS 9

PARTS LISTS & EXPLODED VIEWS 10

MODELS: XX-4, -6, -8, -10 & 12

PARTS LISTS & EXPLODED VIEWS 10

MODELS: CH-6, -8, -10, -12 & 14

PARTS LIST & EXPLODED VIEW 13

SAFETY PRECAUTIONS

This symbol warns of imminent hazard which will

result in serious injury or death.

This symbol refers to a potential hazard or unsafe

practice, which could result in serious injury or

death.

WARRANTY 15

This symbol refers to a potential hazard or unsafe

practice, which may result in or moderate injury or

product or property damage.

This symbol refers to information that needs

special attention or must be fully understood even

though not dangerous.

1

XX & CH CHARBROILER OPERATION MANUAL

CAUTION

NOTICE

INSTALLATION INSTRUCTIONS

General:

The instructions in this manual apply to all XX series and

CH series Broilers.

The XX series may include the following options:

Ceramic briquettes designated by a GS Suffix on the

model number.

Installation:

(a) In USA, INSTALLATION of this broiler must

conform with the latest edition of the National Fuel

Gas Code, ANSI Z223.1 and/or local codes.

(b) In CANADA, INSTALLATION must conform with

the latest edition of the National Gas Installation

Code, CAN/CGA-B149.1 or the Propane

Installation Code, CAN/CGA-B149.2, as applicable

and/or local codes.

(c) In MASSACHUSETTS, All gas products must be

installed by a “Massachusetts” licensed plumber

or gas fitter. Ventilation hoods must be installed in

accordance with NFPA-96, current edition, with

interlocks as described in that standard.

For units using propane gas, supply lines less than

1/2” inside diameter should not be used, even for a

small unit.

On the XX and CH series, the gas connection is located

on the right rear of the unit.

Be sure to cap whichever side is not connected.

A shut-off valve in a readily accessible location

must be mounted on the gas supply line before

the unit.

When making gas pipe connections, pipe joint

compound resistant to the action of liquefied petroleum

gases should be used.

The broiler and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.45 kPa).

Acceptable Clearances:

Due to intense heat generated by radiation, these

broilers should be installed in non-combustible locations

only including above the grate level.

Minimum Clearance From Non-Combustible

Construction.

Series Right Left Back

XX 0” 0” 0”

CH 0” 0” 0”

Gas Connection:

The gas pressure regulator supplied must be installed

at the gas inlet of each broiler. Each regulator is

adjusted to yield a manifold pressure of 5 in. water

column for natural gas or 10 in. water column for

propane gas. No pressure regulator is required for

propane gas in Canada.

Recommended minimum gas supply lines are listed below

All XX Models CH-4 thru CH-8 CH-10 thru CH-16

3/4” 1” 1 1/2”

The broiler must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.45 kPa).

Burners:

Check to see that AIR MIXER CAPS on the front of

all burners are tightened and adjusted, allowing half

the opening to show. Install the burners and deflector

shields first following the steps below.

(a) Install all burners with deflector shield assemblies

attached.

(B) Place the front of the burner into the valve

assembly by fitting the center hole of the mixer

cap over the brass orifice.

(c) Drop the rear end of the burner over the burner

support pin on the back of the unit.

2

XX & CH CHARBROILER OPERATION MANUAL

NOTICE

INSTALLATION INSTRUCTIONS

Radiants:

Mount the “V” shaped radiants over the burners with

each end mounted on special supports on the front and

rear of the chamber. A radiant should be mounted over

each burner assembly.

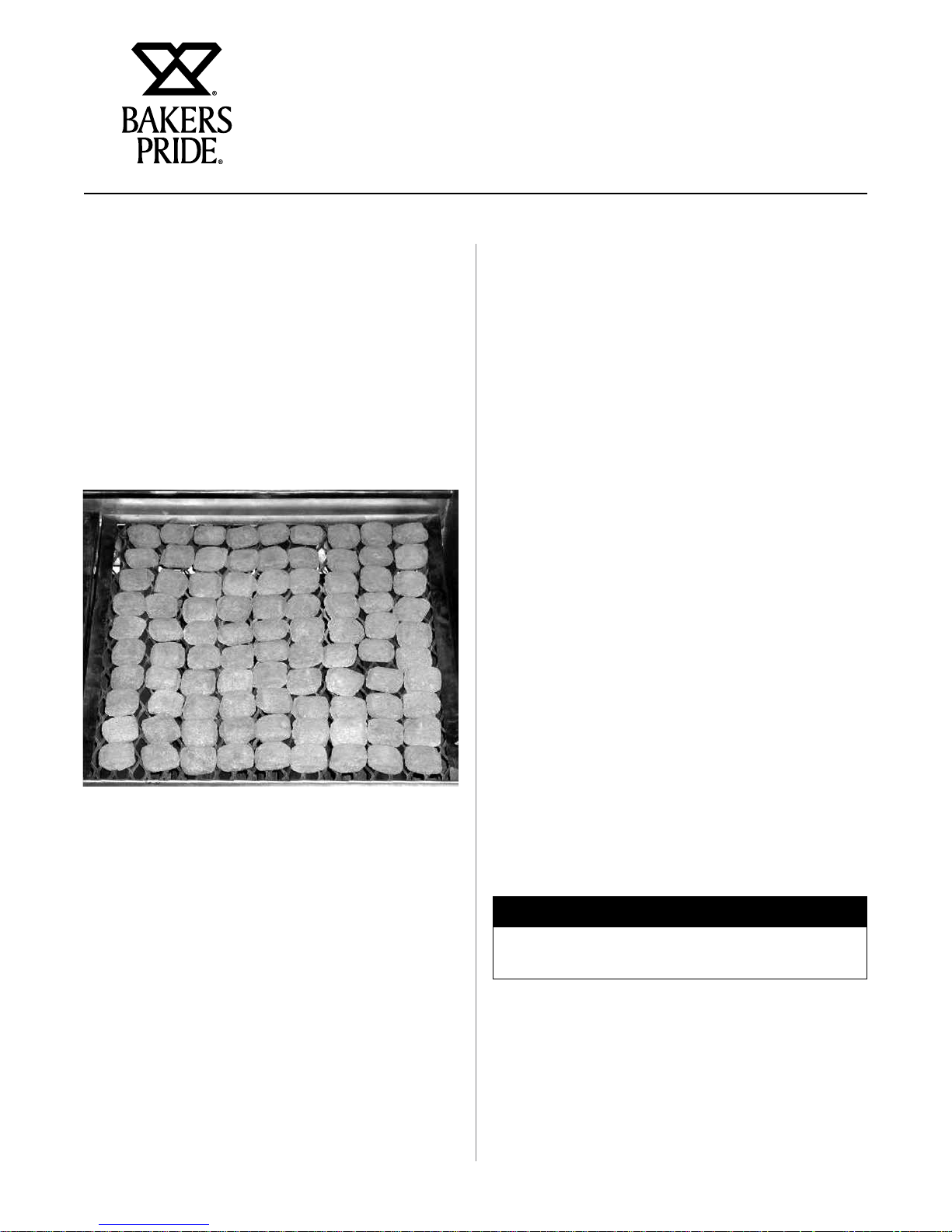

GS Ceramic Briquettes Option:

The radiants supplied for the GS option are flattened to

allow for the installation of an expanded metal grate. The

grate is installed directly on top of the flattened radiant

burner shield. Ceramic briquettes are installed on the

grate as shown:

Lighting:

Each burner on the base charbroiler has a standing pilot

burner that must be lit before the burners can be lit. To

light the pilot burners:

(a) Turn all broiler valves to the off position.

(b) Remove each top grate and radiant.

(c) Open main gas SHUT-OFF valve (supplied by

customer).

(d) Allow air to bleed from the gas line through the

pilot burners.

(e) Light the pilot burners using a lit taper.

(f) Turn the burner control valves “ON” to light the

burners.

(g) If any burner fails to light, turn the burner valves

to “OFF”, wait five minutes and repeat the above

procedure.

(h) After all burners have been ignited properly, turn

each burner valve “OFF” and allow the unit to cool.

NOTE: Make sure that the pilot burners stay lit.

Figure 1: Typical Ceramic Briquette Installation

Top Grates:

Place a grate over each of the radiants. For normal

operation, the pointed side of the grate is facing up. For

use with foods that require extra support, the flat side

may be used.

On XX Models, grates can be placed on three levels;

two positions are built into the rear of the unit; the third

position requires a special adapter. On CH models, three

positions are already built into the rear of the unit.

(i) Replace radiants and top grates.

(j) Each burner may now be adjusted to the desired

flame size by turning the individual burner valve

handle.

(k) To shut down the unit, turn all valves “OFF”

Wait five minutes before attempting to re-light.

The pilot burners will stay lit until the gas supply

to the unit is turned “OFF”.

Griddle Plate:

Griddle plates should not cover more than 50% of the

BROILING area. Each Griddle Plate fits on top of two

grates (one 4 1/2” and one 6”). It is not necessary to

remove the top grates and radiants before installing the

griddle plate.

3

XX & CH CHARBROILER OPERATION MANUAL

INSTALLATION INSTRUCTIONS

Additional Installation Instructions

(a) Keep the area around the broiler free and clear of

combustible materials.

(b) The provision of an adequate air supply to your

broiler is essential. Provide for sufficient outside

air to enter the broiling area and assure that this

airflow is not obstructed.

(c) Air enters the burner area from the front and

bottom of your broiler. Assure that these areas are

kept open and unobstructed.

(d) Servicing is accomplished through the front and

top of the broiler. Assure that these areas are kept

unobstructed for proper servicing and operation.

Installation With Casters

(a) Install the casters with the wheel brakes on the

front of the appliance.

(b) Installation should be made with a connector that

complies with the latest edition of the Standard

for Connectors for Movable Gas Appliances, ANSI

Z21.69 in the USA (CAN/CGA-6.16 in Canada),

and a quick disconnect device that complies

with the latest edition of the Standard for Quick

Disconnect Devices for use with gas fuel, ANSI

Z21.41 in USA (CAN 1-6.7 in Canada) and

adequate means must be provided to limit the

movement of the appliance without depending

upon the connector and any quick disconnect

device or its associated piping to limit the

appliance movement.

Optional Smoker Base

Installation

(a) Remove the grease pans from their rails completely

and set aside.

(b) Unscrew to remove the legs from the broiler.

Discard.

(c) Set the broiler into the base unit. The frame will

fit into the lip around the top of each side and the

back.

(d) Install the #10 self-threading sheet metal screws

around the base into the broiler frame to hold

in place. Each screw requires a 5/32 hole to be

drilled into the broiler frame.

(e) Get the grease pan(s) previously set aside. Insert

a log holder into each pan. Slide the pan into the

bottom of the base.

(c) The restraint should be attached to the legs on

which the casters are mounted.

(d) If disconnection of the restraint is necessary,

the restraint should be reconnected after the

appliance has been returned to its originally

installed position.

4

Loading...

Loading...