Bake Max TCO6G, TCO6E, TCO7G, TCO7E Installation And Operation Manual

Combi Oven Touch

TCO6G

MODELS

TCO6E

TCO7G

TCO7E

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service, operation or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions thoroughly

before installing, operating or servicing this equipment.

NOTICE

Instructions must be posted in a prominent location that will provide the user of this equipment with

procedures, in the event he/she smells and/or detects gas. This information must be obtained by

consulting the local gas utility.

WARNING

Electrical Grounding Instructions

This appliance is equipped with a three-prong (grounding) plug for your protection

against shock hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove tie grounding prong from this plug.

WELCOME TO THE TOUCH WORLD

Congratulations on your new purchase! From now on you have in your kitchen a legitimate

Combination Oven with BAKEMAX touch screen technology, one of the icons of the

world-class food service industry. We brought together the best components with the highest

technology combined to the construction made by hand individually by our team. We make no effort

to present this equipment.

So that your device performs best, please read this manual carefully and follow the instructions

correctly. If you have any doubts and/or suggestions, call Venâncio, qualified professionals will be

at your disposal

RECEIPT

We recommend the care and inspection to detect any damage during transportation, such

as:

- Breaking or kneading of parts;

- Lack of parts;

- Penetration of water or other liquids.

In the event of any damage during transportation, it must be noted to the carrier's notice, notifying

the plant immediately.

Keep these instructions because it will be very helpful to answer questions and

ensure the proper operation and maintenance of the equipment.

IMPORTANT: READ THIS BEFORE INSTALLING THE EQUIPMENT!

BAKEMAX

cannot be held liable for any material or personal injury resulting

from failure to comply with any instructions presented in this manual.

The power and other data required for installation are available in the tables in the

"Technical Characteristics" section of this manual.

The equipment should only be installed in accordance with the standards set forth

in this manual.

Before installation, make sure that the voltage, frequency, and power are in

accordance with the points installed.

This equipment is a convertible voltage, DO NOT ATTEMPT TO CHANGE THE

VOLTAGE as it may be severely damaged and is not covered under warranty. If

necessary, contact the plant for advice to our nearest service station.

The equipment must be grounded electrically.

Do not install before solving any doubts regarding the correct construction of the

installation points detailed in this manual.

IDENTIFICATION OF EQUIPMENT

The equipment is identified by a nameplate on which the serial number is registered. This so

that records of possible modifications made to the components can be keps, this is located on the

left side of the equipment.

GENERAL TECHNICAL DATA OF THE EQUIPMENT

POWER GRID

VOLTAGE OF THE EQUIPMENT: check if the voltage of the equipment is the same as the

connection point.

The socket-outlet where the equipment is to be connected must be single-phase or three-phase,

rated for the rated current of the protection circuit (thermoelectric circuit breaker), allowing full

insertion of the plug pins, without any gaps, so that live parts are not accessible to touch.

Model

TCO6G/TCO7G TCO6E/ TCO7E TCO10G / TCO12G TCO10E / TCO12E

No. of Meals

Approx. 350 Approx. 350 Approx. 500/600 Approx. 500/600

Gas

0,8

1,2

-

Three-phase voltage (V)

- 220/380/440 - 220/380/440

Single Phase Voltage (V)

110/220

-

110/220

-

Installed power (Kw)

0,3 10,5 0,3 18

Gas power / heating

9000kal - 17200kal

-

Power consumption (kw / h)

0,1 5,3 0,1 6.5

Gas consumption (kg / h)

0,8

1,2

-

Water inlet (BSP)

3/4" 3/4" 3/4" 3/4"

Drain

Ø 1.1/2” Ø 1.1/2” Ø1.1/2” Ø 1.1/2”

Height (mm)

900 900

1200 1200

Width (mm)

1025 1025 1025 1025

Depth (mm)

830 830 830 830

Net weight (kg)

140

126 180 160

Capacity (Gns prof.65mm)

6/7 GNs 1x1 6/7 GNs 1x1 10/12 GNs 1x1 10/12 GNs 1x1

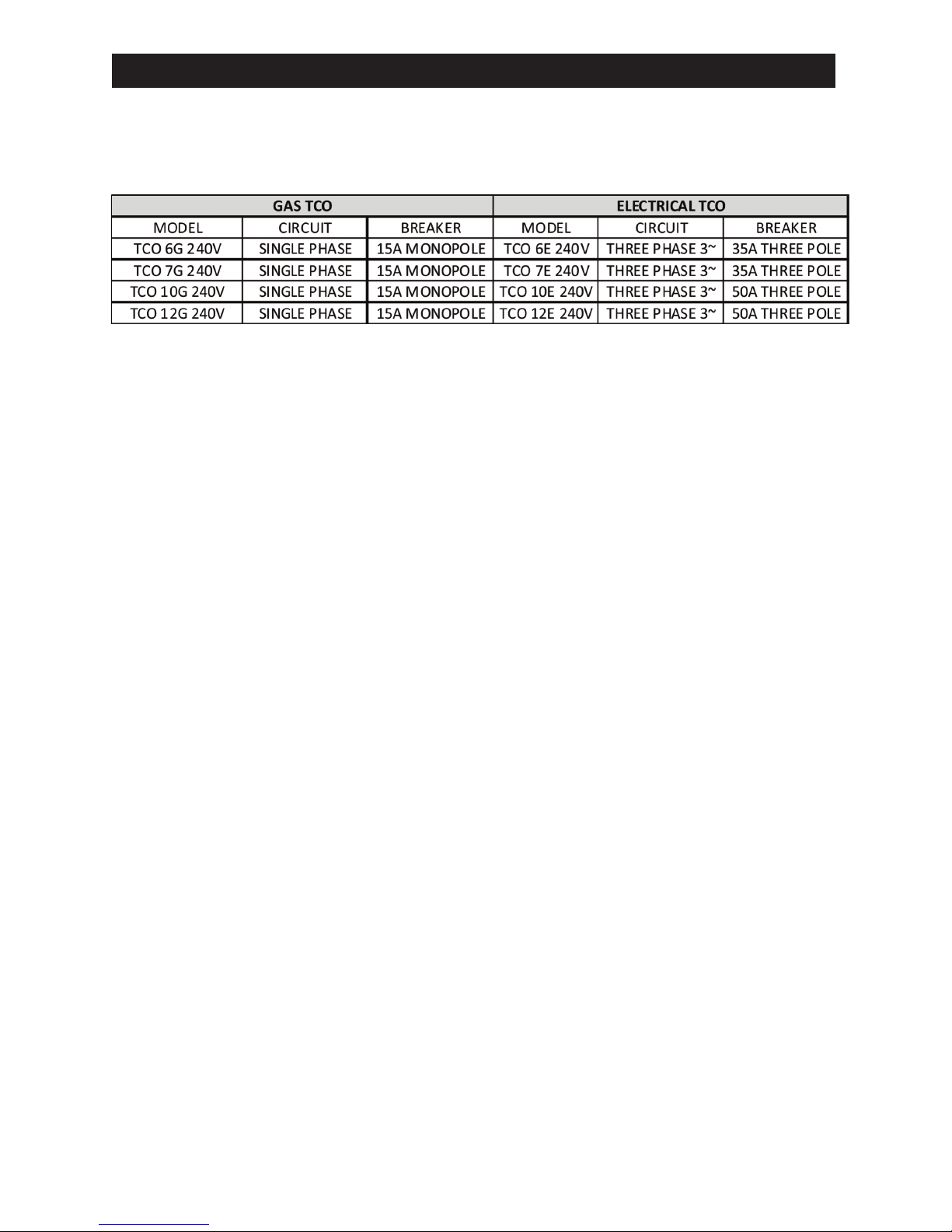

TABLE OF BREAKERS ACCORDING TO TYPE OF EQUIPMENT

Grounding or ground wire: The ground wire of your equipment must be connected to an

efficient ground cable, avoiding personal hazards. The connection of the ground wire is

necessary at any voltage, and should not be connected to the neutral wire of the taps,

hydraulic piping, electric, gas network, etc. For a correct grounding, observe the instructions

in accordance with local codes.

THE CONNECTION OF THE GROUND WIRE IS INDISPENSABLE

Electrical extensions, T-pins, adaptors or the liker: do not use in any case, to connect

other devices in the same socket-outlet. Doing so may cause overloading of the electrical

installation and/or poor contact. Overloads can cause harmful heating to the insulation,

connections, terminals or near the conductors, causing damages and even the burning of the

installations and the product.

Voltage fluctuations: if the voltage of your establishment displays fluctuations that are not

in accordance with the permitted fluctuations, ask the utility company for regularization, or in

cases of impossibility, install an automatic stabilizer according to the maximum rated power.

Circuit breaker: in the circuit in which the equipment will be connected, there must be a

thermoelectric protection circuit breaker (see following table).

technical pressure specifications which must be at least 0,8 kg/f maximum of 2 kg/f.

The hose connection that accompanies the Combi Oven TOUCH is a ¾" BSP threaded fitting.

Observe in the equipment installation if it has the water pressure specified in the technical

data sheet of the product. If this does not occur, add a pressure reducer, as shown below.

NOTE: The pressure reducer is supplied with the equipment.

OVEN INSTALLATION

Location:

1 - Provide on the installation site:

* Box with circuit breaker and fuse; (see table of circuit-breakers according to the type of equipment);

* Electric power socket-outlet (see power grid);

* Socket-outlet (see power grid);

* Point for drainage of water (drain or sewage); (Refer to GENERAL EQUIPMENT DATA)

Note. DRAIN OR FLOW POINT IS OF EXTREME IMPORTANCE. PIPING FOR HOT

OR METALLIC PIPING SHOULD BE PROVIDED WITH 1" ½" INPUT. We orientate

the use of metallic tubes or weldable CPVC of the best brands of the market.

* Water supply point with valve.

HYDRAULIC NETWORK

Water inlet: it is required a fixed water inlet point, preferably exclusive, which meets the

THE EQUIPMENT MUST BE INSTALLED WITH ADEQUATE BACKFLOW PROTECTION

TO COMPLY WITH APPLICABLE FEDERAL, STATE, AND LOCAL CODES.

UNPACKING

1. Remove all packaging and transit protection including all

protective plastic coating from the exterior stainless steel

panels.

2. Check the oven and supplied parts for damage. Report any

damage immediately to the carrier and distributor.

3. Check that the following parts have been supplied with your

oven:-

4. Report any deciencies to the distributor who supplied your

oven.

5. Check that the available electrical supply is correct to that

shown on the Technical Data Plate located on the front right hand

side panel.

LOCATION

1. Position the oven in its approximate working position.

2. The unit should be positioned so that the control panel

and oven shelves are easily reachable for loading and

unloading.

CLEARANCES

To ensure correct ventilation for the motor and controls, the following minimum installation clearances are to be adhered to:

Top 8”. 20/ 0 mm

Rear 300mm / 12”.

Left-hand side 450mm / 18”.

Right-hand side 900mm / 36”.

· Installation shall comply with local elec trical, health and safety requirements.

· It is most important that this oven is installed correctly and that oven operation is correct before use.

· If you have any questions regarding the proper installation and

/ or operation of this oven, please contact your local

distributor.

Qualied installation personnel are individuals, a rm or a company which either in person or through a representative are engaged

in and responsible for the installation of electrical wiring from the electric meter, main control box or service outlet to the electric

appliance.

Qualied installation personnel, licensed and bonded, must be experienced in such work, familiar with all precautions required and

have complied with all requirements of state or local authorities having jurisdiction.

U.S. and Canadian Installations - All ovens, when installed, must be electrically grounded in accordance with local codes, or in the

absence of codes, with the National Electrical Code ANSI/NFPA 70 - Latest Edition and/or Canadian National Electrical Code C22.2

as applicable.

The ventilation of these ovens should be in accordance with local codes. In absence of local codes, refer

to the national ventilation code titled, Standard for the Installation of Equipment for the Removal of

Smoke and Grease Laden Vapors from Commercial Cooking Equipment, NFPA-96-Latest Edition.

The appliance is to be installed with a check valve in accordance with applicable federal, province and local codes.

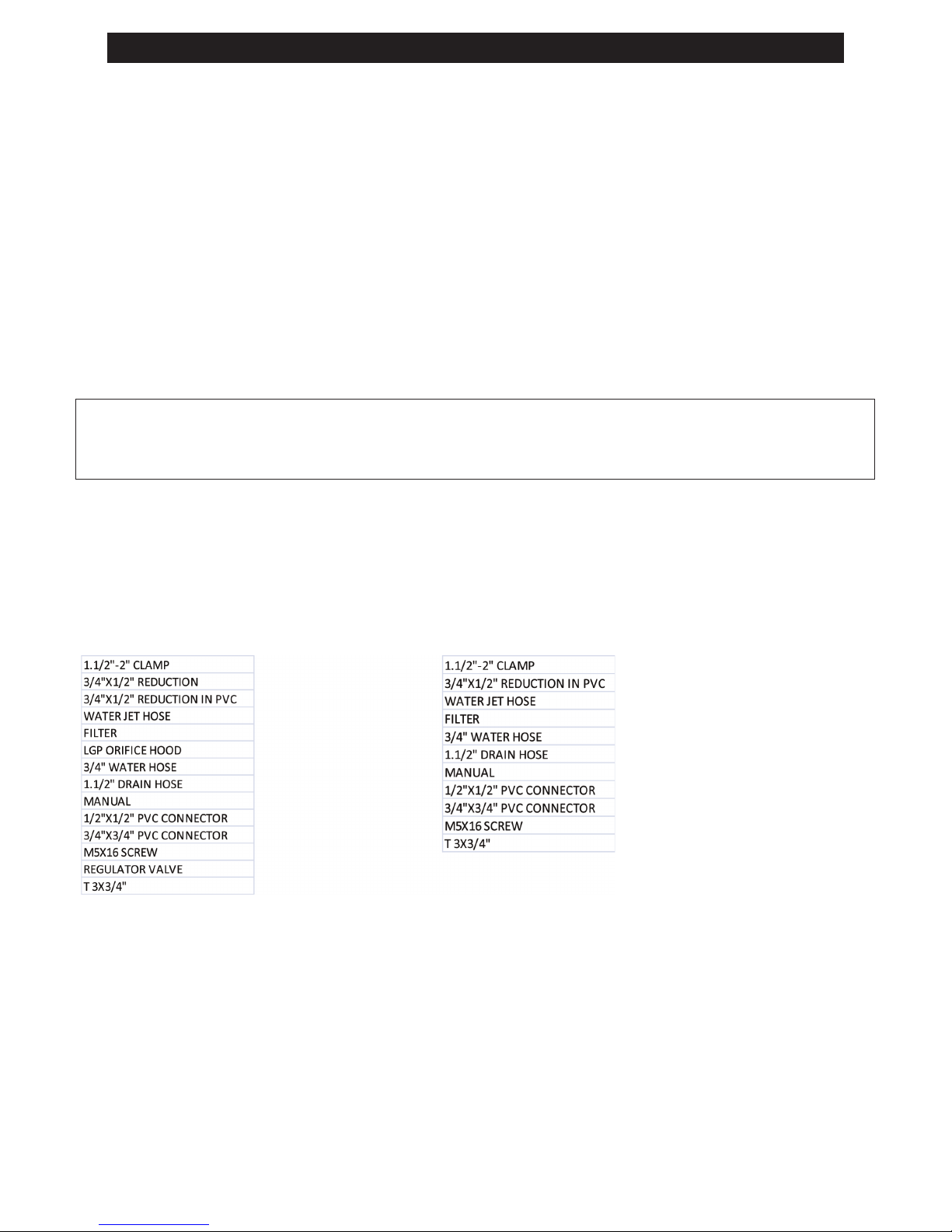

FCT6/7G FCT6/7E

IMPORTANT

INSTALLATION REQUIREMENTS

THIS APPLIANCE IS INTENDED FOR OTHER THAN HOUSE HOLD USE

All BAKEMAX commerical gas appliances are manufactured by skilled craftsman using the finest quality materials.

PROPER installation by qualified personnel is essential for safe, efficient, and trouble-free operation of the unit. Any alteration and/or

tampering, without proper knowledge, tools, and test equipment, is DANGEROUS and will void all warranties. The installation must

conform with local codes, or in the absence of locel codes, with the National Fuel Gas Code, ANSIZ223.1- latest edition.

PRESSURE TESTING: FAILURE TO INSTALL PRESSURE REGULATOR WILL VOID WARRANTY.

(Most units have a convertible regulator.) The appliance and its indivdual shut-off valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressure in excess of 1/2 psig (3.45 kPa). The appliance must be isolated

from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig (3.45 kPa).

NOTICE

The proper installation of this gas appliance is the total responsibility of the end user. It is the responsibility of the purchaser to

determine that the installer is qualified in installation procedures. Conversion, connecting gas lines, calibrating thermostats, burners,

lighters, setting gas pressure with manometer, and etc., is all part of normal installation and will not be paid for under warranty. If a

warranty technician is called out and finds the unit improperly installed, the end user may be subject to billing.

FOR MAINTENANCE, SERVICE, REPAIRS, OR INSTALLATION - Contact your dealer or the factory, for your local Factory Authorized

Service Agency.

The gas pressure regulator provided with the equipment must be installed when the appliance is connected to the gas supply.

The area around the appliance must be kept free and clear of combustibles such as solvents, cleaning liquids, brooms, rags, etc.

Proper clearances must be provided at the front of the appliances for servicing and proper operation.

Provisions shall be incorporated in the design of the kitchen, to ensure an adequate supply of fresh air and adequate clearance for

air operanings into the combustion chamber, for proper combustion and ventilation.

For proper operation of the appliance, do not obstruct the ow of combustion and ventilation air.

The installation must conform with local codes, or in the absence of local codes, with the national fuel gas code, ANSI Z223.1 - 1988

(or latest addenda).

The gas supply line must be at least 3/4" NPT.

INSTALLATION - GAS STANDARDS AND CODES

1. The appliance and its individual shut off valve must be disconnected from the gas supply piping system during any pressure testing

of that system at test pressure in excess of 1/2 psi (3.45 kPa).

2. The appliance must be isolated from the gas supply piping system by closing the individual manual shut-off valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 PSI.

IMPORTANT - The installation of this appliance must conform to local codes or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149-1, or the Propane Installation Code, CAN/CGA-B149-2 as

applicable, incluiding:

GAS INSTALLATION INSTRUCTIONS

GAS CONNECTION - The gas inlet line size of this appliance is 3/4" NPT. For proper operation, the gas supply service line must be

the same size or greater than the inlet line size of the appliance. The gas line size must not be reduced at any point along the

supply line.

MANUAL SHUT - OFF VALVE - A gas pressure regulator and a contractor-supplied shut-off valve must be plumbed in the gas ser vice

line ahead of the appliance – in a physical location where it can be reached quickly in the event of an emergency .

A. Gas pressure regulator

A

D C E

F

G

C

B

GAS

B. 90º Street elbow

C. Adapter (must be 3/4" male pipe thread)

D. Flexible connector

E. Manual gas shut-off valve

F. 3/4" gas supply

G. Use pipe-joint compound

NATURAL

Visually double check any installer-supplied intake pipes and/or blow them out using compressed air to clear any dirt or debris,

threading chips, or other foreign matter – before installing a service line. Those particles will clog gas orices when gas pressure is

applied. Compounds used on threaded joints of this appliance piping must be resistant to the action of NG and LP gas and provide

a gas tight seal to prevent leaks.

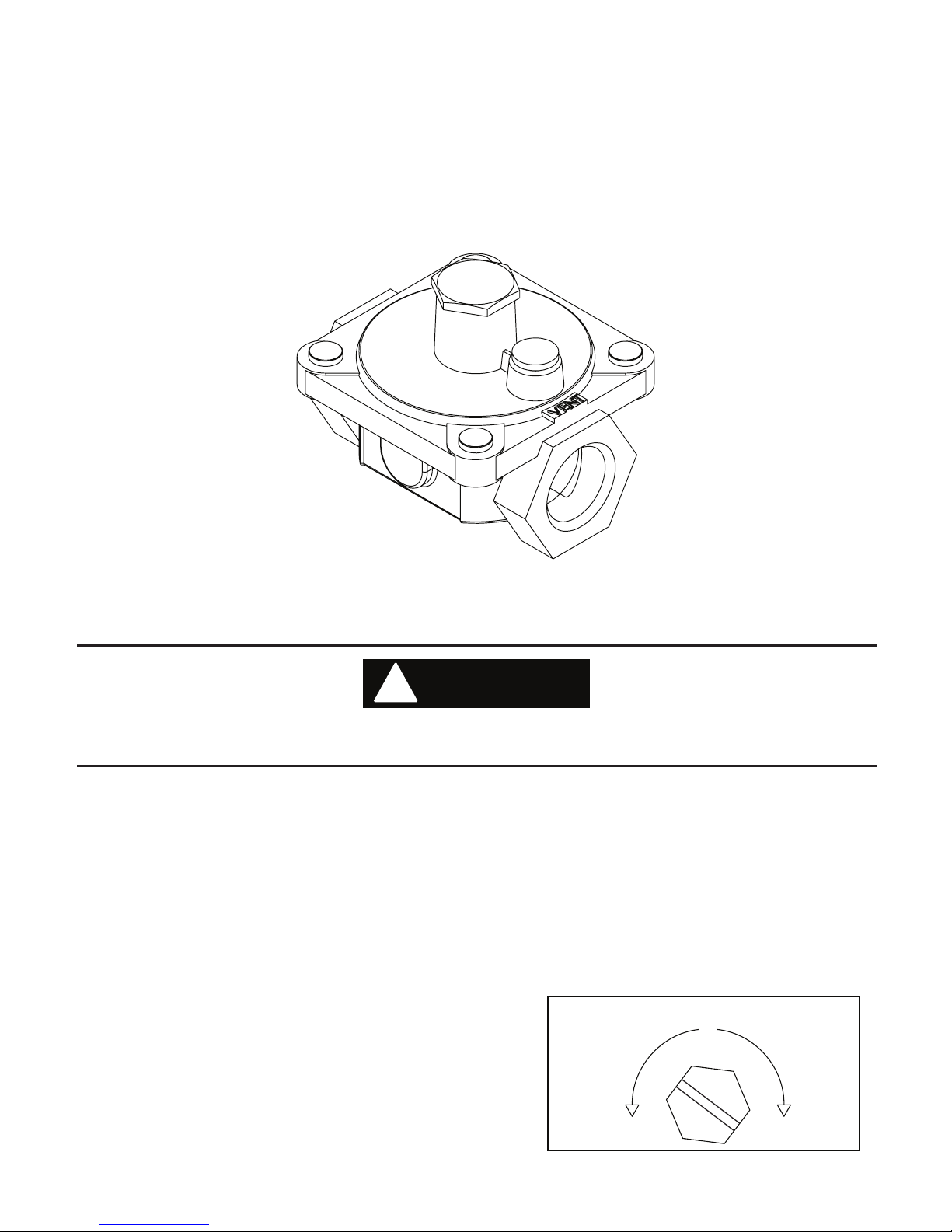

When installing the pressure regulator - remember it can only handle 1/2 PSI. In e very LPG installation, you have high source pressures,

ranging from 20 PSI to 100 PSI. If the high pressure gas line from the LPG tank is directly connected to the unit without the proper

step-down regulator, it will rupture the diaphragm in the valve, rendering it useless.

!

WARNING

The gas pressure regulator must be installed in the gas line – failure to install a pressure regulator will void the equipment warranty.

The regulators supplied with ranges have 3/4" NPT connections; the regulator is adjusted at the factory for 4" W.C. (water column)

manifold gas pressure (natural gas) or 10" W.C. manifold gas pressure for propane gas operation.

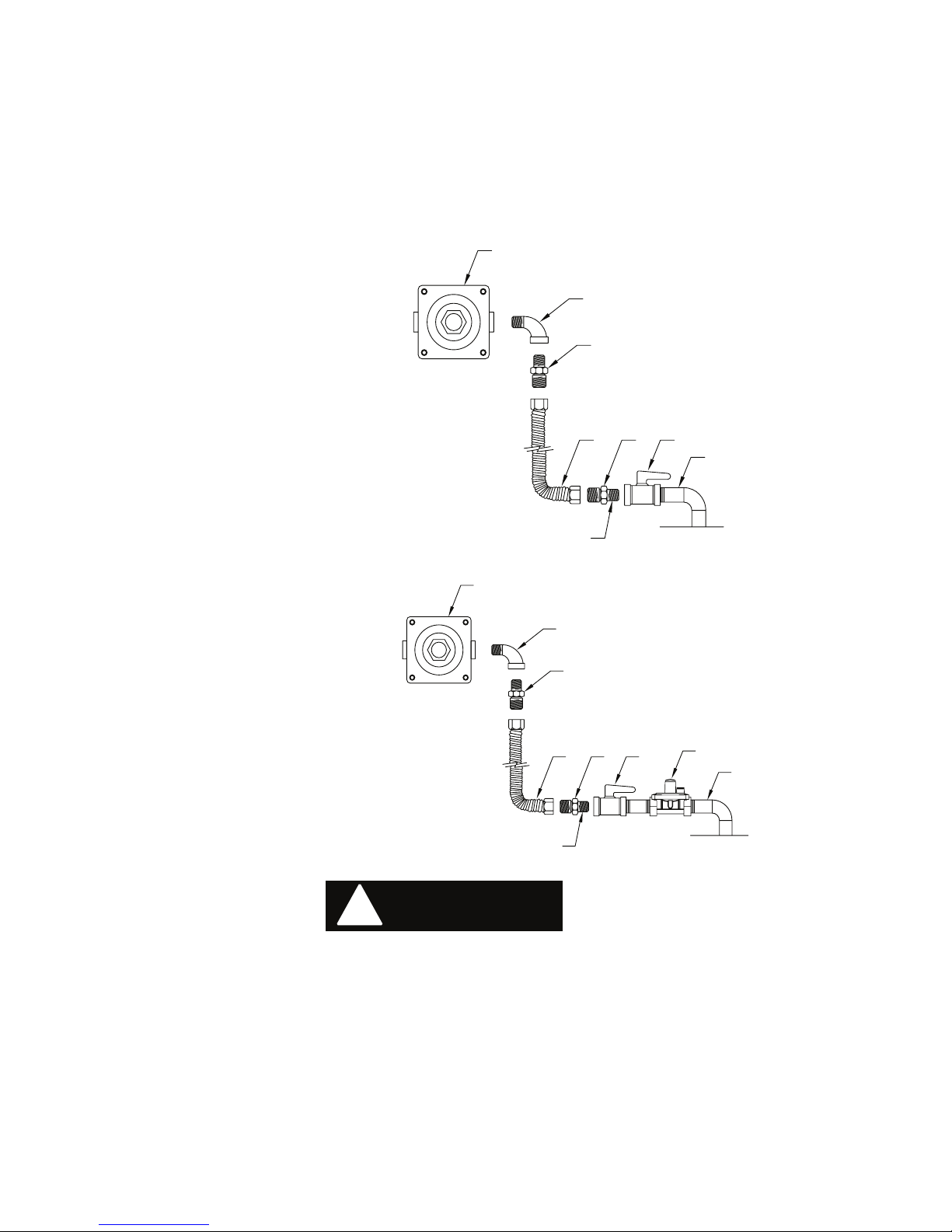

B

C

G

F

ECD

A

A. Gas pressure regulator

B. 90º Street elbow

C. Adapter (must be 3/4" male pipe thread)

D. Flexible connector

E. Manual gas shut-off valve

F. 3/4" gas supply

G. Use pipe-joint compound

H. Step down regulator

H

LP GAS

Before connecting the regulator, check the incoming line pressure – as these regulators can only withstand a maximum inlet pressure

of 14" W.C. (1/2 PSI); exceeding this pressure will damage them. If the gas supply line pressure is greater than this amount, a step-down

regulator will be required.

A gas ow direction arrow is cast into the body of the regulator to minimize installation error – it should point downstream to the

appliance. T he blue air vent cap on the top of the regulator is part of the regulator and should not be removed.

!

WARNING

Any adjustment to the regulator must be made only by qualified and licensed s e r v i c e personnel with the proper calibrated test

equipment. Gas connections should be performed by a qualified licensed contractor.

In the event of a power failure, no attempt should be made to operate the unit during power failure.

Before lighting, check all joints in the gas supply line for leaks. Do not use an open ame to check for leaks!

1. Turn pilot valves to OFF position by turning adjustment screws clockwise.

2. Turn ON the manual gas valve at the inlet side of the gas supply line.

3. Check for gas leaks at the exible coupling or gas connector tting using a solution of one part soap and three par ts water.

4. Sparingly spray or brush the soapy solution at the gas ttings; active bubbling indicates location of gas leak.

6. Turn pilot adjustment screw counter-clockwise, then light standing pilot and adjust ame 1/4" high.

7. Turn ON gas valve/thermostat to light main burners.

8. For complete shut down, shut off gas valves and turn pilot adjustment

screw clockwise to shut off gas to the pilots.

5 . If a gas leak is detected turn off the manual gas valve at the inlet side of the gas line. Call your certied and licensed

service technician.

OPERATING INSTRUCTIONS

PILOT ADJUSTMENT SCREW

MORE GAS LESS GAS

+ -

Use soap and water solution.

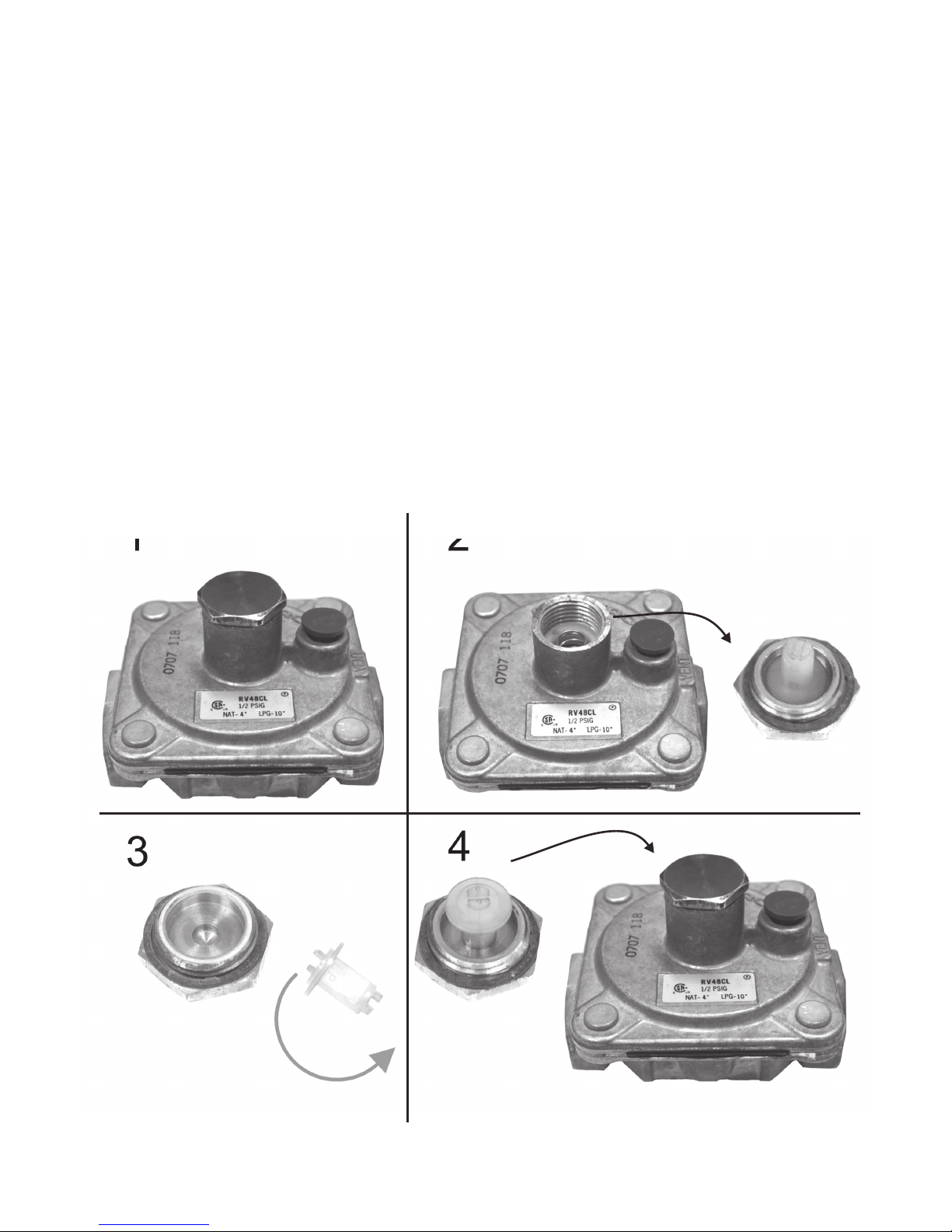

PROPANE GAS CONVERSION INSTRUCTIONS

A griddle is equipped with xed orice hoods and shipped from the factory for use on natural gas.

To convert to propane gas, install the propane burner orice hoods supplied as follows:

1 - Remove the griddle plate by lifting with two people and set a side.

2 - Slide the burners back off of the valve orice hoods a couple of inches and let it rest.

3 - Remove the natural gas orice hoods with a 1/2” wrench.

4 - Apply a very little bit of pipe dope on the threads of the valve.

DO NOT APPLY PIPE DOPE INTO ORIFICE HOOD.

5 - Attach the supplied propane burner orice hoods with a 1/2” wrench.

6 - Convert the pressure regulator from Natural to Propane gas by inverting the snap-in device beneath the

cap on the regulator. This will require a fair amount of pressure. Do not remove the spring. When replacing

the cap make sure the snap-in insert goes down on top of the middle of the spring.

7 - Test for proper pressure; 10” W.C. (water column) using a manometer.

8 - Slide burners back onto the orice hoods.

9 - Apply the Propane “Notice” stickert to the front of the unit for futer reference.

1 2

3

4

180º

PROPANE GAS

NATURAL GAS

Installation - Electric Utility Connections-Standards and Codes

Qualied installation personnel are individuals, a rm or a company which either in person or through a representative are engaged

in and responsible for the installation of electrical wiring from the electric meter, main control box or service outlet to the electric

appliance.

Qualied installation personnel, licensed and bonded, must be experienced in such work, familiar with all precautions required and

have complied with all requirements of state or local authorities having jurisdiction.

The installation instructions contained here are for the use of qualied installation and service personnel only. Installation or service

by other than certied / licensed personnel will void the warranty and will result in damage to the oven and/or injury to the operator.

!

To avoid burning, do not use any liquid or containers loaded with products to be cooked which

become fluid by heating at higher levels than those which can be easily observed. OBS .: Stick the

adhesive accompanying this manual to a minimum height of 5,24ft above the floor.

Be careful when in contact with the external parts of the oven, because its surface will become

hot during operation. Note the sticker that indicates caution when touching the hot parts of the

equipment.

U.S. and Canadian Installations - All ovens, when installed, must be electrically grounded in

accordance with local codes, or in the absence of codes, with the National Electrical Code

ANSI/NFPA 70 - Latest Edition and / or Canadian National Electrical Code C22.2 as applicable.

ELETRIC INSTALLATION INSTRUCTIONS

OVEN INSTALLATION

IMPORTANT

The rotation of the motor that drives the turbine is for both sides in order to guarantee the

best cooking (only in eletric model).

OVEN LEVELING

The oven has adjustable feet for easy leveling.

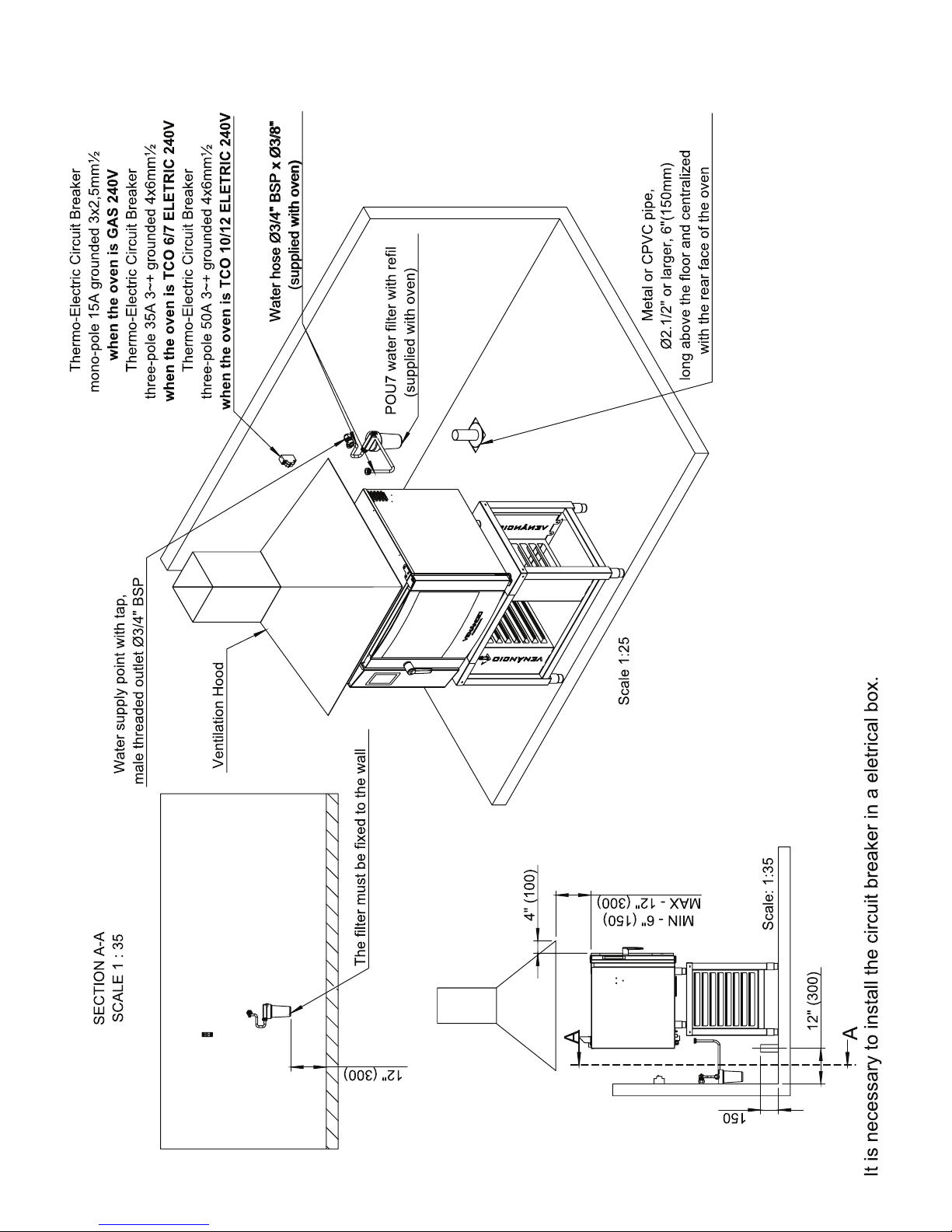

INSTALLATION EXAMPLE OF THE COMBI OVEN TOUCH AND THE MANDATORY

CONNECTION POINTS FOR GAS OR ELECTRIC OVENS, FOLLOWS:

You have more benefits regarding the energy consumption, because of the rapid heating of the

oven and the little loss of heat during the cooking process, you save more gas or electricity

compared to the traditional process.

TECHNICAL CHARACTERISTICS

1-Capacity

Note the maximum capacity in kg that can be used in your Combi oven. (Eg: meats, potatoes...)

Maximum capacity:

TCO6 = 30 kG

2-Pre-heating

It is extremely important that the oven is preheated, especially for foods where the cooking

time is less than 30 minutes. This function is implemented in the device controller for use in any

function.

TCO7 = 35 kG

TCO10 = 50 kG

TCO12 = 60 kG

COMBI OVEN TCO TOUCH

The Combi oven Touch ensures greater practicality, economy and quality in the

preparations. The various combinations of humidity and heat, allow a proper cooking to the food,

avoiding the loss of nutrients.

It is extremely important to leave an empty rail between one GN and another for best results.

Use the same procedure for frying and grilling by adding a low-height GN at least every 3

spacings.

5-Temperature

-

Roasted meats

For large parts that require very high cooking time, use low temperature

Example:

Eyeround, rib, hump, topside, knuckle, pork ham, etc = between 140º C to 150ºC. Loin,

poultry, etc. = Between 170 °C to 180 °C

6-Containers

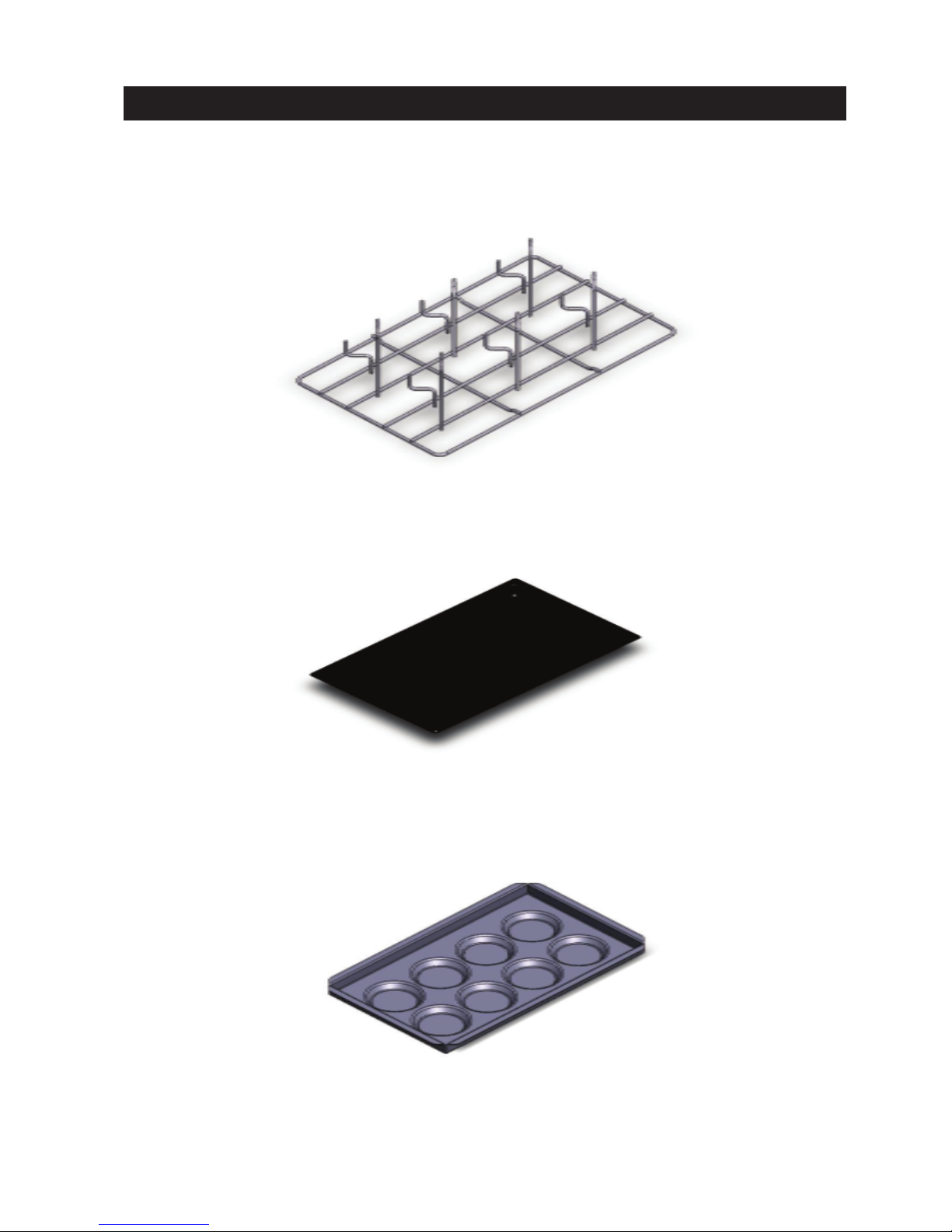

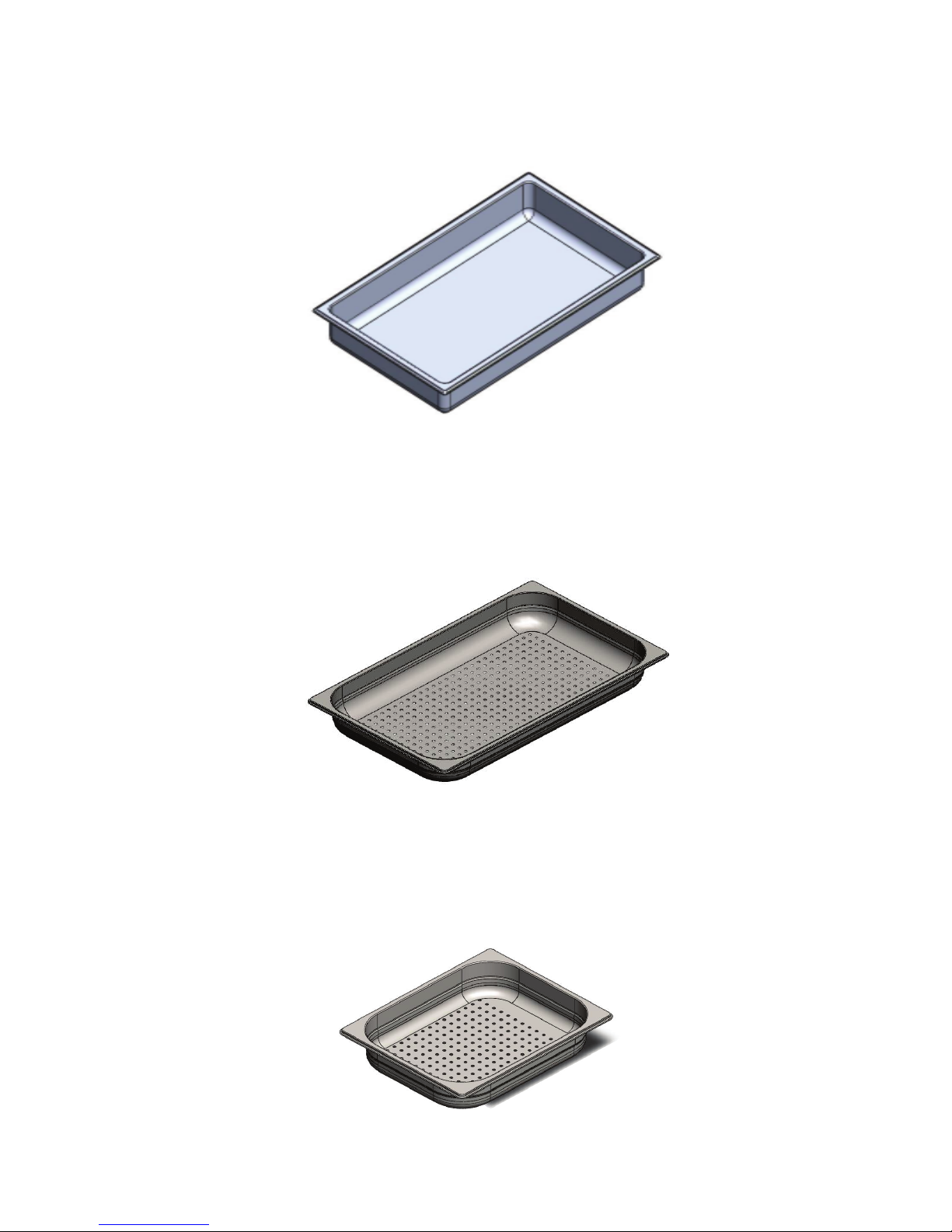

Grills - For whole chickens, grilled, fried, roasted and base for common baking trays.

Flat GNs - Use up to 65mm deep to cook rice and foods in which the liquid needs to be

retained.

Perforated GNs - Use a depth of up to 100mm for cooking vegetables, greens, seafood,

eggs, etc.

IMPORTANT

65 mm deep GNs bear a maximum of 5kg of food (solid foods).

3-Temperature

All temperatures are easily programmed through the touch screen controller in a very simple

view.

4 - Loading the oven (for baked, confectionery, fried and grilled products)

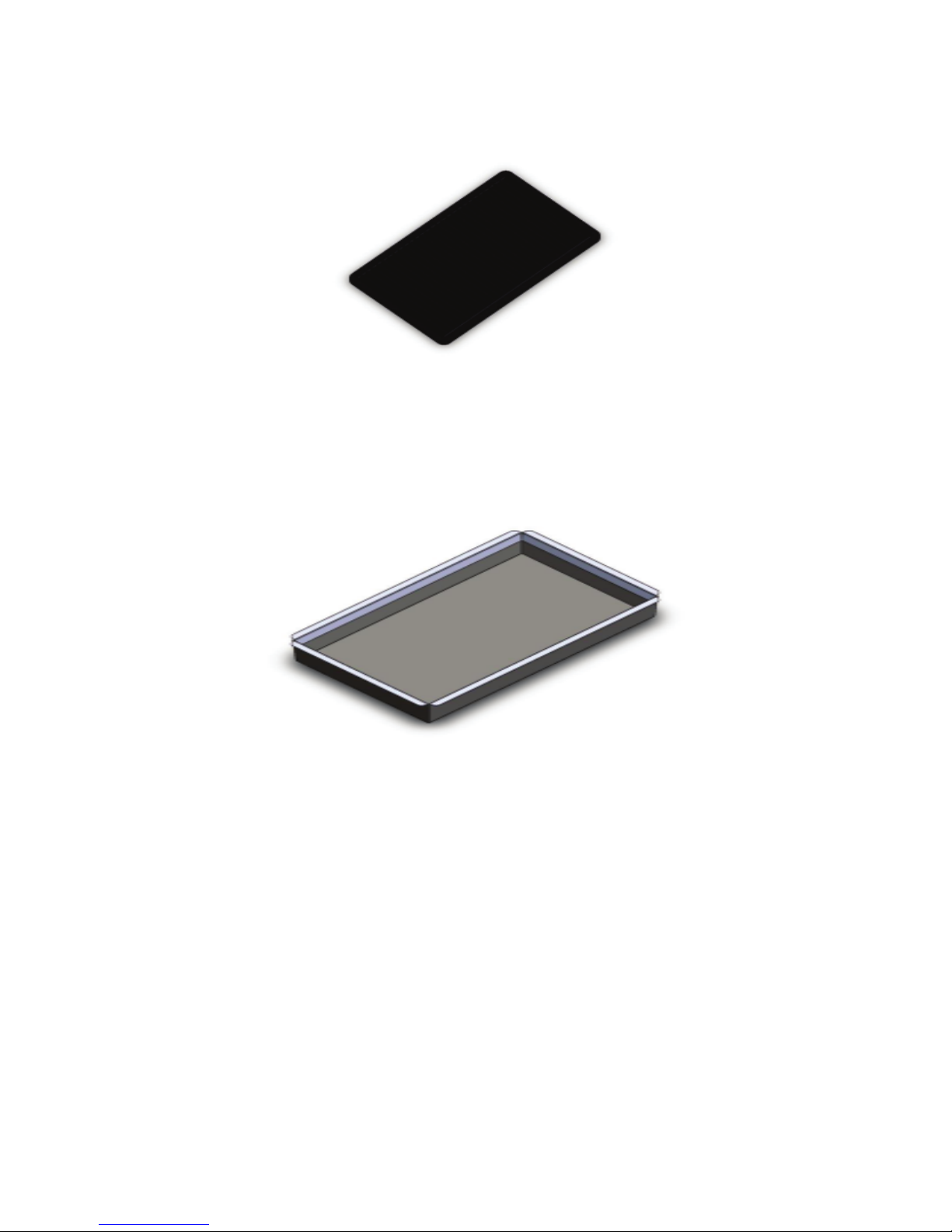

Enamel Coated Stainless Steel GN 20mm high

GN to fry eggs and hamburger

GASTRONORM LINE ACCESSORIES

GN for 06 Whole Chickens

Perforated GN 65 mm Deep

½ perforated GN 65 mm deep

Flat GN 65 mm Deep

GN to Fry French Fries

Metalúrgica Venâncio manufactures all the accessories used by the Combi oven.

Flat / Beaded Aluminum GN

OPERATING INSTRUCTIONS FOR THE COMBI OVEN TOUCH

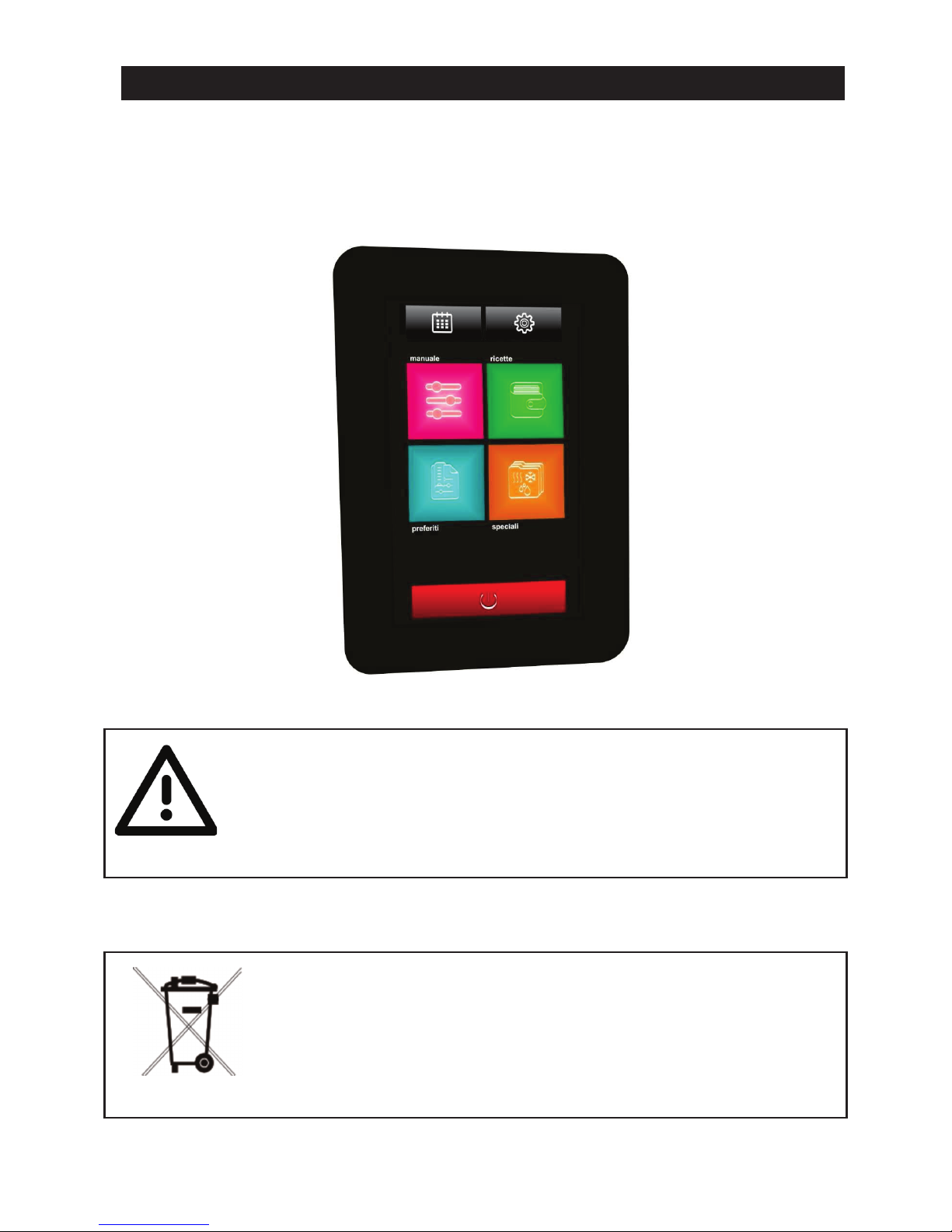

Vcolor 338 L

Combi top-class oven controller with 7-inch color touch-screen TFT graphic display.

Read this document carefully before installation and before using the device

and follow all warnings; Please keep this document with your device for future

reference.

Important

Use the device only in the ways described in this document.

The device must be discarded according to local regulations in accordance

with the collection of eletrical and eletronic equipment.

Disposal

INTRODUCTION

Vcolor 338 L is a stylish design controller for the management of top-class electric ovens for

gastronomy.

It is available in split version and is integrable either mechanically or aesthetically in the unit; the

user interface is comprised of a 7-inch color I-screen TFT graphic display and guarantees an IP65

degree of protection for agile cleaning.

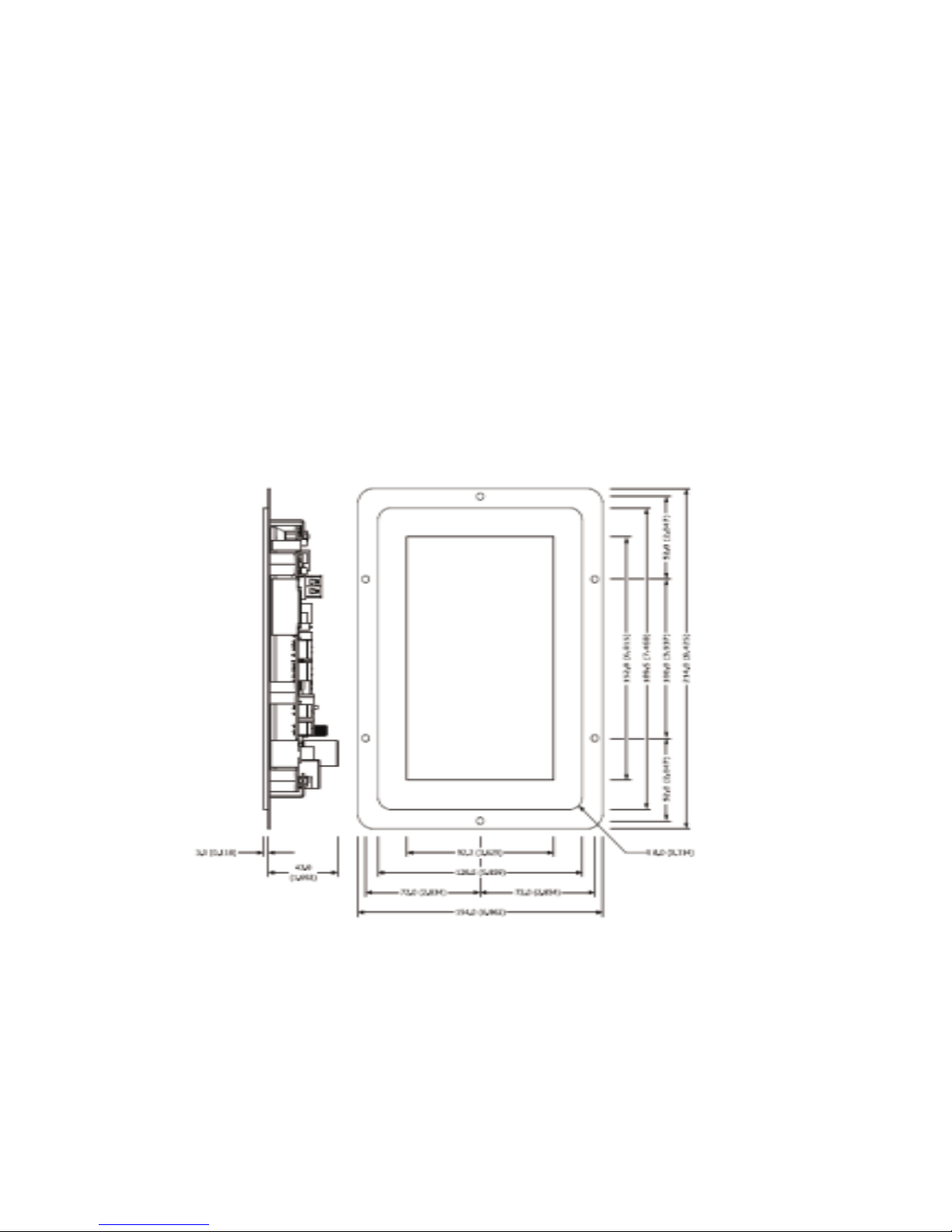

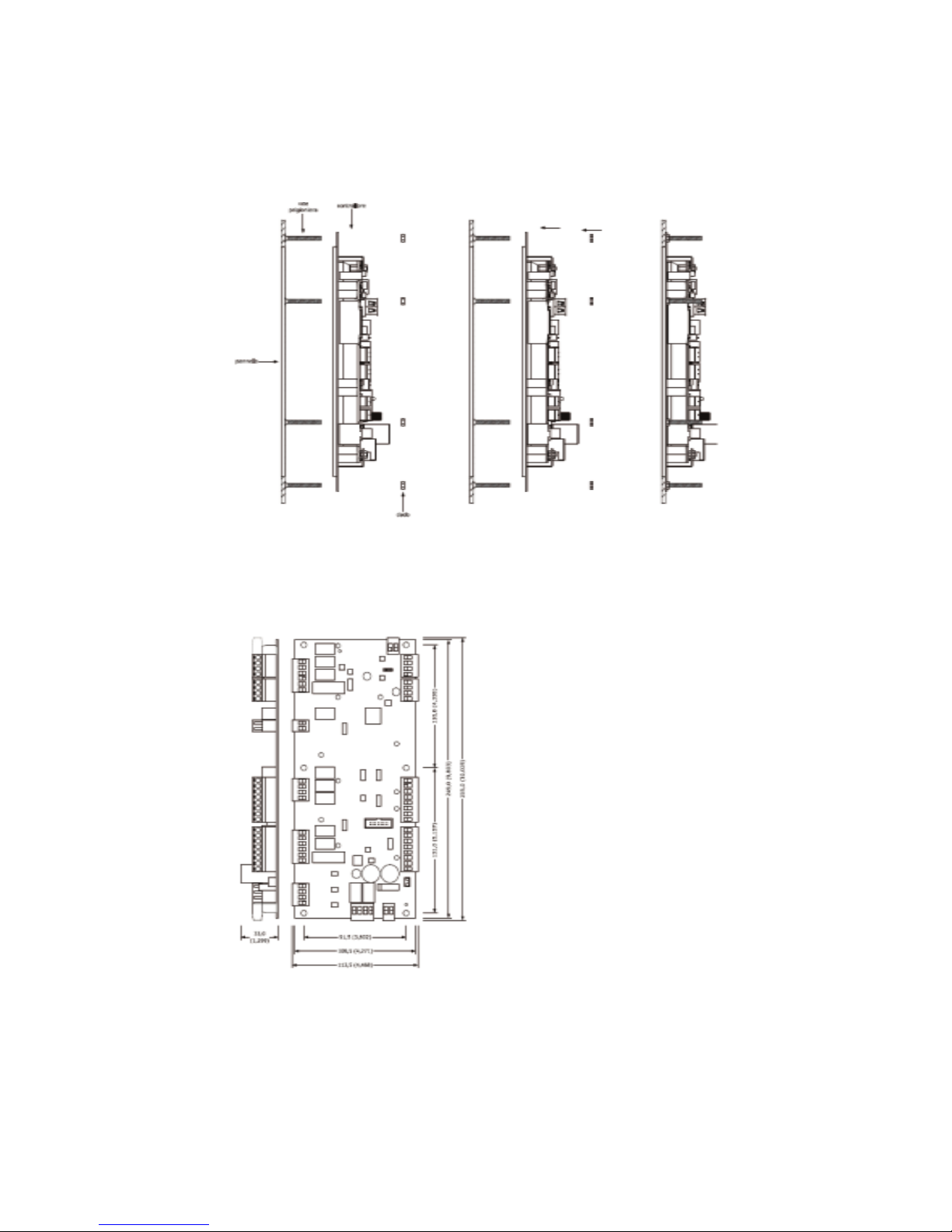

DIMENSIONS AND INSTALLATION

User Interface Dimensions

The following drawing illustrates the dimensions of the device´s user interface; the dimensions are expressed in mm

(in).

User Interface Installation

The following drawing illustrates the installation of the device´s user interface.

The installation is provided on the rear panel, with screws fastened and ensures the absence of

gaps.

Dimensions and installation of the control module.

The following drawing illustrates the dimensions of the device´s control module; the dimensions are

expressed in mm (in).

The installation is planned on a flat surface with spacers/separators.

MANAGEMENT OF THE TOUCH CONTROLLER UTILITIES

MANAGEMENT OF UTILITIES

Preliminary descriptions

This topic illustrates the activity of the independent utilities that the Combi oven has.

Temperature regulation

The output is activated when room temperature reaches the operating set point and is reactivated

when the temperature drops below the set temperature.

To set the operating set point, refer to "Setting the cooking cycle"; to set the configuration parameters

"Setting"

Room light;

The room light is switched on/off by touching the reference area:

Control panel fan;

The technical compartment fan is switched on until the operating temperature of the control module

reaches the set temperature with parameter F6 and is switched on again when the temperature rises

beyond that set with parameter F7 (i.e. "F6 + F7").

To set the configuration parameters, see "Setting the configuration parameters".

Turbine;

The type of ventilation management used is managed in "on/off" mode, double speed and with

reverse direction of the fan controlled by a frequency inverter programmed to 540 seconds to turn

right and left.

Steam Reduction;

Steam reduction is activated until the temperature reached by the steam reduction probe reaches

the set temperature of 90 °C.

Output management for special washing cycles;

The controller has an efficient water recirculation system with the appropriate type of detergent to

manage the washing typology:

- Washing with detergent tablet, with water recirculation system

At the beginning of each washing cycle, the camera automatically turns on, from the exclusive

option, you can turn it off or on again at any time.

The following is a detailed description of the washing typology:

There are 3 management relays dedicated to:

- Relay K10: solenoid valve for introducing water from condenser water network

- Relay K11: pump with recirculating water system

- Relay K12: Condenser water drain pump

This type of washing can also use a probe to control the drainage temperature of the water used for

washing, as the water temperature should not normally exceed 60-75 °C to be discharged in sewage

system (state regulation).

To enable temperature control of discharged water, the appropriate probe (alternating with the steam

reduction probe) with parameter P3 = 2 must be enabled.

The washing with tablet provides the selection of 4 different types:

- Rinsen

- SOFT Washing

- MEDIUM Washing

- HARD Washing

The "Rinsen" washing typology is a special sequence cycle, the other cycle typologies differ by the

number of repetitions of the washing phases performed.

The image that follows represents the selection screen "WASHING", from which it will be possible

to choose one of the four washing typologies.

Cycle selection and start

In case a RINSEN cycle is selected and started, the cycle will be immediately placed in the prewash phase.

If, on the other hand, one of the other 3 types of washing is selected, the controller will promptly

request the introduction of the number of doses of detergent in the camera:

- 2 doses = SOFT Washing

- 4 doses = MEDIUM Washing

- 6 doses = HARD Washing

After the detergent has been inserted (the machine does not perform controls on the effective

insertion of detergent) by pressing the START option again, the machine starts the prewashing

phase.

Stage 1 - Pre-wash:

The temperature of the oven is brought to the pre-wash temperature of 60 °C (parameter w0). In

case the camera temperature is lower, the heating output will be activated together with the

ventilation.

If the temperature is, on the contrary, higher than it was set, the controller will keep the ventilation

active only and a pop-up message will prompt the door to be opened to make the camera cool

faster.

When the temperature reaches its set value the door closes (if opened earlier) and the controller will

activate the relay k10 (water electro-valve) for 2 minutes during which the condenser will be filled

with water and filled allowing the pump in recirculation system to reach the water for the various

washing phases.

The ventilation remains active throughout the phase and the heating output keeps the set

temperature constant.

After the time has elapsed, the operation of the washing system will vary according to the type of

cycle defined: RINSEN, i.e., WASHING cycle.

Phase 2A - RINSEN

After the pre-wash phase is concluded, the selected cycle is performed.

A count of a 5-minute cycle is started during which the outputs of the "condenser´s water network

supply electro-valves", "direct steam injection" and "water recirculation system pump" are enabled,

with activated ventilation at maximum speed.

After the time has elapsed, the machine will return to HOME screen, keeping according to the time

of 15 seconds, the output of the water drain pump so that it empties the condenser.

If the door is opened or the STOP button is pressed, the cycle will stop immediately and return to

the HOME screen.

Stage 2B - Washing Preparation

The Combi oven TOUCH is brought to the washing preparation temperature of 70 °C with

humidification in 100% for 5 minutes, during which the relay k10 (condenser´s water network supply

electro-valve) will also be activated.

Stage 3B - Washing

After the Washing Preparation phase, the cycle will start the Washing phase.

The washing phase takes 10 minutes during which the Combi oven TOUCH is brought to the

washing temperature of 70 °C, the ventilation is always active at maximum speed, the recirculation

system pump that will supply hot water to the chamber from the condenser is activated, by passing

it to the detergent tablets.

No steam is to be introduced at this stage.

A 2-minute time is then loaded during which the Combi oven TOUCH disables all uses (except light)

to allow detergent action.

The Duty Cycle (detergent action time) will be repeated:

- 3 times in case you are running a SOFT washing cycle;

- 6 times in case you are running a MEDIUM washing cycle;

- 9 times in case you are running a HARD washing cycle;

During the entire washing phase, if enabled via parameter P3 and if the value of the Water Drain

probe is higher than the maximum water flow set point 70 °C, the controller will activate the Network

Water Supply output to reduce the temperature of the condenser.

The differential of this setting is fixed at -10 °C, i.e., the water supply is interrupted when the

temperature read by the probe Water Drain is below 10 °C in relation to the maximum set point of

water drain 70 °C.

At the end of the number of cycles foreseen for the current one, the next phase will be initiated.

Phase 4B - Rinse

This phase lasts 12 minutes during which, the water supply from the condenser´s water network,

the direct injection of steam and ventilation at full speed, will be activated.

No heating phase is foreseen and no recirculation system is provided. Once the rinsing time has

elapsed, the cycle will pass to the next stage.

Stage 5B - Drying

After the rinsing phase, the drying stage starts.

Loading...

Loading...